Page 1

(CD11021C)

QUICK REFERENCE GUIDE

PI Catch sensor

Purpose

The

PI Catch

sensor detects when the

trawl has been filled with fish. The sensor

monitors the opening of the meshes in

the cod end, and will be activated once

the volume caught is enough to pull the

detector wires.

Catch sensor principle: Three sensors are mounted at the cod end of the trawl to detect

the amount of fish caught.

Daily operation

To monitor the filling rate, we

recommend that you use minimum two

sensors. The first sensor is located at the

far end of the cod-end indicating that the

trawl is fishing, while the second sensor

tells when to haul. Due to the fish moving

back and forth in the cod-end, the sensor

will normally change status (on/off)

several times until the volume caught

keeps the opening of the meshes stable.

Once installed and put to use, the

sensor will automatically be switched

on once the waterswitch is activated.

After an initial startup, the sensor starts

transmission of the detector wire (F)

status (in or out). When the sensor is not

in use, check that the sensor lamp (D)

is not flashing from time to time, as this

indicaties that the sensor is on and is

discharging its batteries.

If you operate with Fast update rate, the

sensor must be charged approximately

every 35 hours. Used with Normal

or Slow update rates, the operational

life is approximately 150 or 300 hours

respectively. The optimal sensor charging

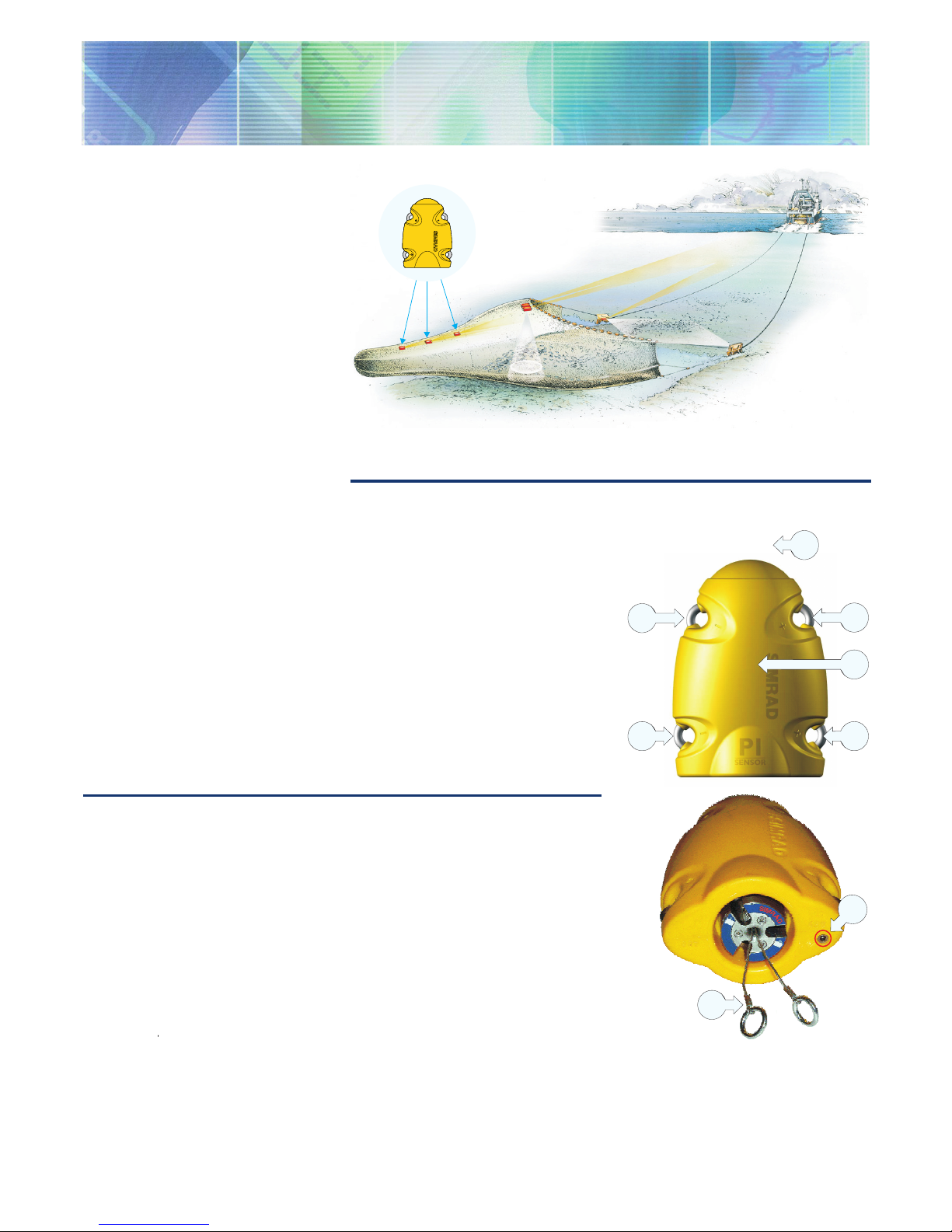

Main parts

(A) = Negative charging / fastening lug

(B) = Positive charging / fastening lug

(C) = Communication link

(D) = Location of sensor lamp

(E) = Water switch sensor

(F) = Detection wires

temperature is from +10 to +25° C.

Note that charging sensors at sub-zero

temperatures can create explosive gasses.

Simrad AS assumes no liability for the

improper charging of sensors or the use

of chargers not specified in Simrad sensor

charging documentation.

Sensor confi guration

On delivery, all Catch sensors are

configured in

Channel 4

and with

Normal

update rate. If you use more than one

Catch sensor, make sure that you set them

up to operate on different channels and

with different sensor numbers!

Note: The sensor and the PI system

setup must correspond, otherwise the

communication will not work.

To change the sensor setup (channel

selection, update rate etc), use the

PI

Configurator

utility.

The Catch sensor can be configured

(using the PI Configurator software)

to act as a

FA701

catch sensor. This

will allow the sensor to be used

with the Simrad

FS

trawl sonar. The

communication channel on the FS sonar

must be set up to correspond to the

equivalent sensor number (1, 2 3 or 4).

The sensor update rate controls how

often the amount of fish caught is

measured and transmitted to the vessel.

Three settings are available. Note that a

faster update rate will decrease the battery

life.

Fast

(~5,3 sec): Recommended for

trawling in areas where the rate of filling

is very high. Use this setting to avoid

damage to the trawl or excessive catches.

Normal

(~33 sec): Recommended for

normal fishing.

Slow

(~125 sec): Recommended if

maximum operational battery life before

charging is required. The system will be

more sensitive to bad communication

conditions due to the slow data update.

When the Catch sensor is configured as

an FA701, it will have a constant update

rate of approximately 64 seconds. This

rate must not be changed.

857-165109 / Rev.A / February 2005

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

A

A

B

C

B

D

F

(CD11021D)

E

Page 2

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

www.simrad.com

System confi guration

Sensor configuration:

The sensor

must be configured with a unique

sensor number. Select update rate

and channel number according to the

sensor’s configuration. Write down this

configuration for future reference.

Status & Receiver:

The Interference

filter must be switched on. Set it to level

9 if you have noise problems from other

hydroacoustic sources. Note that with

the filter on, it will influence the signal

spectrum shown in the Status display.

Catch/Bottom sensor filter:

Switch this

filter off. Set it to

Light

or

Heavy

only if

you experience excessive noise.

(CD11009B)

A

D

E

F

D

G

H

B

C

Catch presentation

On the PI display, the Catch

sensor status is displayed with

graphic symbols. The timers

count the total number of

minutes the sensor has been

activated (red rectangle). If

only predicted timer values

exist, the timer characters are

shown in grey. If the sensor

communication is lost, the

graphic symbol is replaced by

the characters ***.* (in grey).

(A) = Sensor set up as sensor no.2.

(B) = Sensor in standby. The timer has

stopped.

(C) = The timer counts how many minutes

the sensor has been activated during a

tow. It must be reset manually.

(D) = Indicator, lit for every sensor

interrogation.

(E) = Interference symbol

(F) = Sensor set up as sensor no.3.

(G) = The sensor has been activated. The

timer starts. An audible alarm may be

enabled.

(H) = The timer shows how many minutes

the sensor has been activated.

(CD11021B)

C

C

A

B

B

F

E

D

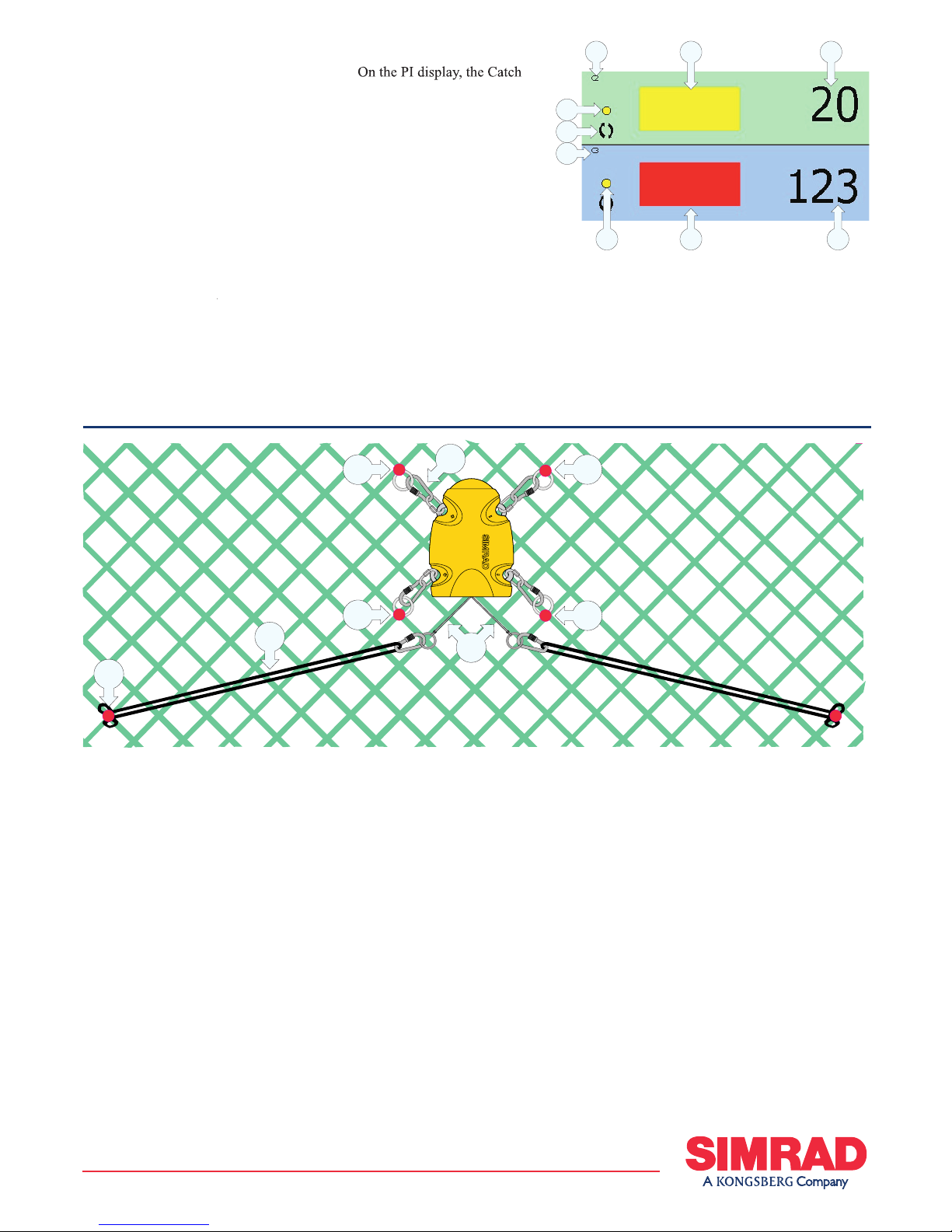

Mounting

Location:

Attach the sensor on top

of the cod-end where the catch is to be

monitored. As the cod-end fills, the net’s

meshes will open pulling the detector

wires activating the sensor.

Attachment:

The Catch sensor’s

orientation towards the vessel is

maintained by the steel and nylon

attachment rings. The number of meshes

the attachment rings are supported

between must be restricted to avoid

unnecessary stress on the sensors

fastening lugs when the cod-end is filled

to maximum. The use of both nylon

and steel attachment rings is required to

secure the sensor lugs if excessive forces

are applied on them. The nylon rings will

stretch or break down, but the steel ring

will prevent the sensor from being lost.

Sensor attachment to a net with an

approximate mesh size of 140 mm. The

distance between the anchor points for

the attachment rings and rubber straps

will vary according to mesh size and

sensitivity required.

(A) = Snap hook and screw link

(B) = Steel attachment rings bent to the

net

(C) = Nylon attachment rings bent to the

net

(D) = Detection wires

(E) = Rubber strap

(F) = Attachment point

Note that two steel rings must be mounted

on the same side.

Sensitivity:

The sensitivity of the Catch

sensor is determined by the number of

meshes separating the rubber straps. You

can simulate this by stretching the net’s

meshes to approximate the mesh opening

estimated to trigger the sensor. Mark the

location (with colored thread) for future

references.

Rubber straps:

Inspect the rubber straps

regularly and always before a new haul.

Replace them if you detect visible signs

of cracks or damage.

Loading...

Loading...