Page 1

Installation manual

Simrad PI44

Catch monitoring system

www.simrad.com

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

Page 2

Page 3

851-165101 / Rev.A

Simrad PI44

Catch monitoring system

Installation manual

NOTICE

Operation of the PI44 system assumes that the

communication between the Operator Unit and the

sensors is fully functional. Ensure that the

communication channels defined on the Operator Unit

matches those of the sensors.

Page 4

About this document

Rev Date Written by Checked by Approved by

Rev.A

03.06.05 RBr KR KR

Original issue.

© 2005 Simrad AS

ISBN 82-8066-048-8

All rights reserved. No part of this work covered by the copyright hereon may be

reproduced or otherwise copied without prior permission from Simrad AS.

The information contained in this document is subject to change without prior notice.

Simrad AS shall not be liable for errors contained herein,or for incidental or consequential

damages in connection with the furnishing, performance, or use of this document.

The equipment to which this manual applies must only be used for the purpose for which

itwasdesigned.Improperuseormaintenancemay causedamagetotheequipment or injury

topersonnel. The usermustbefamiliar with the contentsof the appropriate manuals before

attempting to operate or work on the equipment. Simrad AS disclaims any responsibility

fordamageorinjurycausedbyimproperinstallation,useormaintenanceoftheequipment.

If you require maintenance on your Simrad equipment, contact your local dealer. You can

also contact Simrad using the following e-mail address: fish-support@simrad.com

Page 5

Sections

1Introduction

This section provides a general introduction to the PI44 installation. Refer

to page 1.

2 Echo sounder transducer installation

This section provides general guidelines for the installation of the optional

echo sounder transducer. Refer to page 18.

3 Purse hydrophone installation

This section provides general guidelines for the installation of the PI44

purse seine hydrophone. Refer to page 42.

4 Trawl hydrophone installation

This section provides general guidelines for the installation of the PI44

trawl hydrophone. Refer to page 79.

Installation manual

5 Portable hydrophone

This section provides general guidelines for the use of the PI44 portable

hydrophone. Refer to page 120.

6OperatorUnit

This section explains how to install the PI44 Operator Unit cabinet. Refer to

page 127.

7Sensors

This section provides an introduction to PI44 sensors and the configuration

of these. Refer to page 133.

8 Cable layout

This section details all cabling. Refer to page 142.

9Interfacesetup

This section explains how to connect external equipment, such as navigation

and positioning sensors. Refer to page 165.

10 Installing sensor adapters

This section explains how to install the PI Spread and PI Remote sensors on

the trawl doors. Refer to page 179.

11 Software updates

If you need to upgrade the software in your PI44 Operator Unit, the necessary

procedures can be found here. Refer to page 194.

851-165101 / Rev.A

I

Page 6

Simrad PI44

1 INTRODUCTION 1.........................................

System diagram 2..........................................

Scope of supply 3..........................................

Supply conditions 5........................................

General installation requirements 6............................

Equipment handling 7......................................

11 TRANSDUCER INSTALLATION 18..........................

Purpose 18................................................

Transducer location 19.......................................

External mounting 23........................................

Transducer blister 28........................................

Box keel 33...............................................

Cable glands 35............................................

Cable in steel conduit 39.....................................

Handling and maintenance 40.................................

Approved anti-fouling paints 41...............................

12 PURSE SEINE HYDROPHONE 42...........................

Purpose 42................................................

Installation precautions 43....................................

Considerations 44...........................................

Pre-installation check-list 48..................................

Optimal location of purse seine hydrophones 50...................

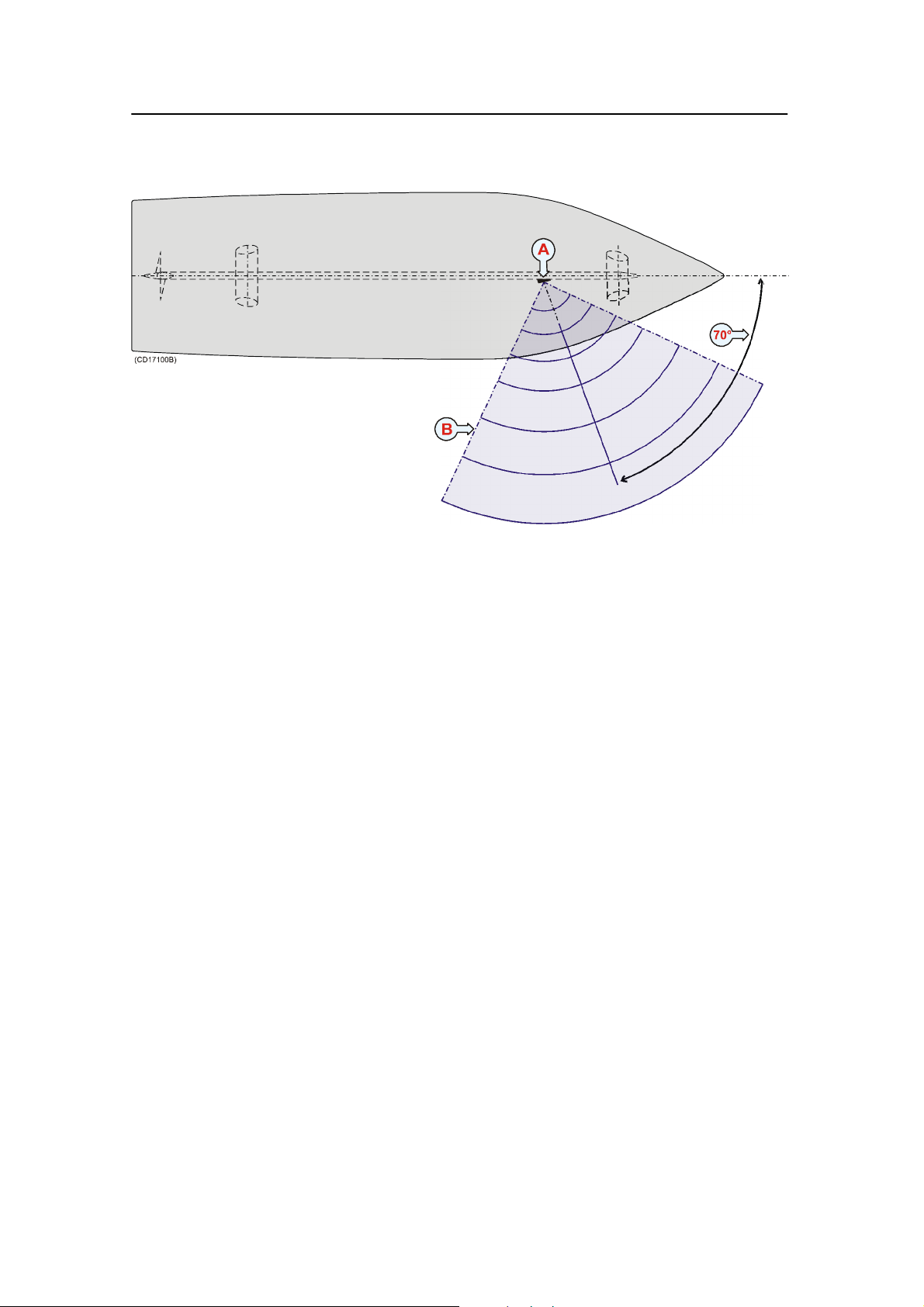

Coverage area, orientation and tilt 51...........................

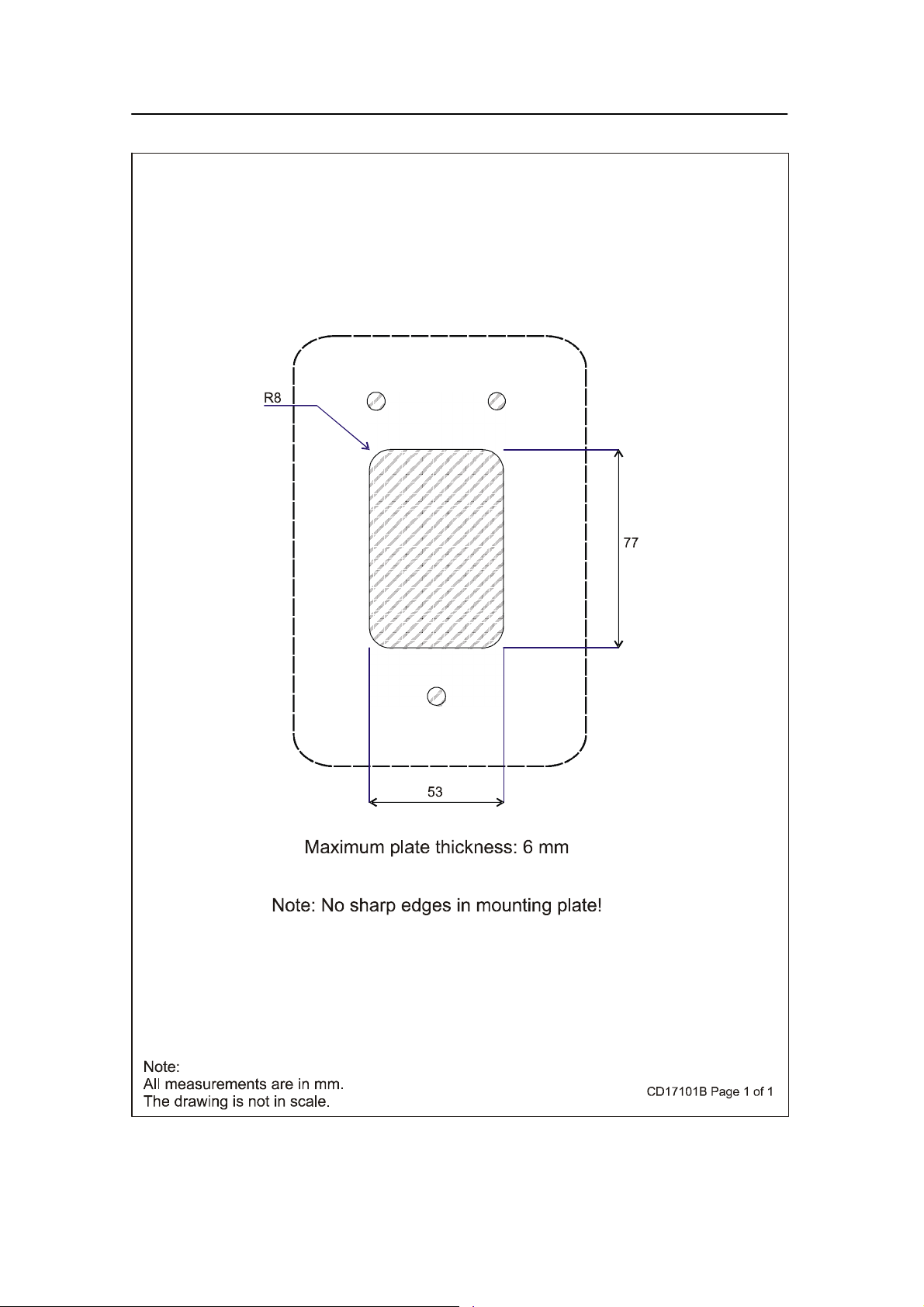

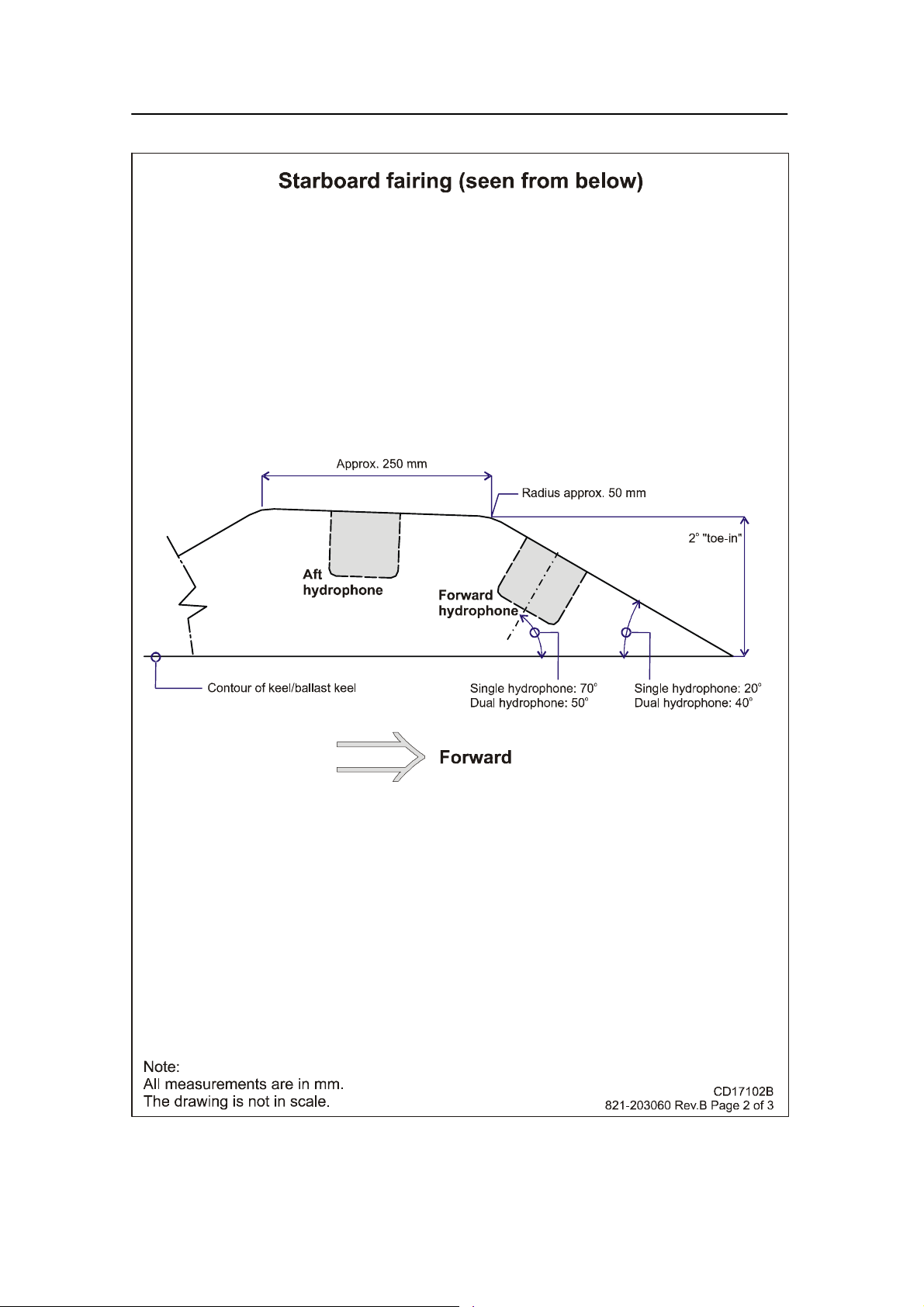

Mounting arrangement 54....................................

Dual hydrophone installation 57...............................

Hydrophone protection 59....................................

Hydrophone cable 62........................................

Installation drawings 67......................................

13 TRAWL HYDROPHONE 79...................................

Purpose 79................................................

Installation precautions 80....................................

Considerations 81...........................................

Pre-installation check-list 86..................................

Optimal location of trawl hydrophones 88.......................

Coverage area, orientation and tilt 91...........................

Mounting arrangement 95....................................

Dual hydrophone installation 101...............................

Hydrophone protection 102....................................

Hydrophone cable 105........................................

II

851-165101 / Rev.A

Page 7

Installation manual

Installation drawings 110......................................

14 PORTABLE HYDROPHONE 120...............................

Purpose 120................................................

General guidelines 121........................................

Deployment over the side 122..................................

Paravane arrangement 123.....................................

Portable hydrophone storage 126................................

15 OPERATOR UNIT 127.........................................

Purpose 127................................................

Installation choices 128.......................................

16 SENSORS 133.................................................

Introducing the sensors 134....................................

Sensor configuration 139......................................

8 CABLE LAYOUT 142..........................................

System cabling 143..........................................

Cable plan 144..............................................

Cable specifications 146......................................

Basic cabling requirements 162.................................

19 INTERFACE SETUP 165.......................................

Hydrophones 166............................................

Echo sounder transducers 167..................................

Positioning and navigation data 170.............................

Water depth, speed and temperature 173..........................

Data output on NMEA format 177..............................

NMEA Interface verification 178................................

20 INSTALLING SENSOR ADAPTORS 179......................

Introduction 179.............................................

Installation keypoints 180.....................................

Before work begins 183.......................................

Procedure 183...............................................

21 SOFTWARE UPDATES 194....................................

Overview 194...............................................

DSP Software upgrade 195....................................

MMI Software upgrade 199....................................

PI DSP Upload 202..........................................

851-165101 / Rev.A

III

Page 8

Simrad PI44

IV

851-165101 / Rev.A

Page 9

Introduction

1INTRODUCTION

The purpose of this manual is to provide the information and

basic drawings required for installation of the Simrad PI44 catch

monitoring system. These instructions must be followed

carefully to ensure optimal system performance. As a guide,

installation procedures are presented in the order they are to be

performed. After installation, this document must be stored on

board the vessel for later reference when updating or servicing

the equipment.

Note: The installer is responsible for the equipment during the

installation. The guarantee is only valid when the installation is

made in accordance with this manual.

Topics

→ System diagram, page 2

→ Scope of supply, page 3

→ Supply conditions, page 5

→ General installation requirements, page 6

→ Equipment handling, page 7

851-165101 / Rev.A

1

Page 10

Simrad PI44

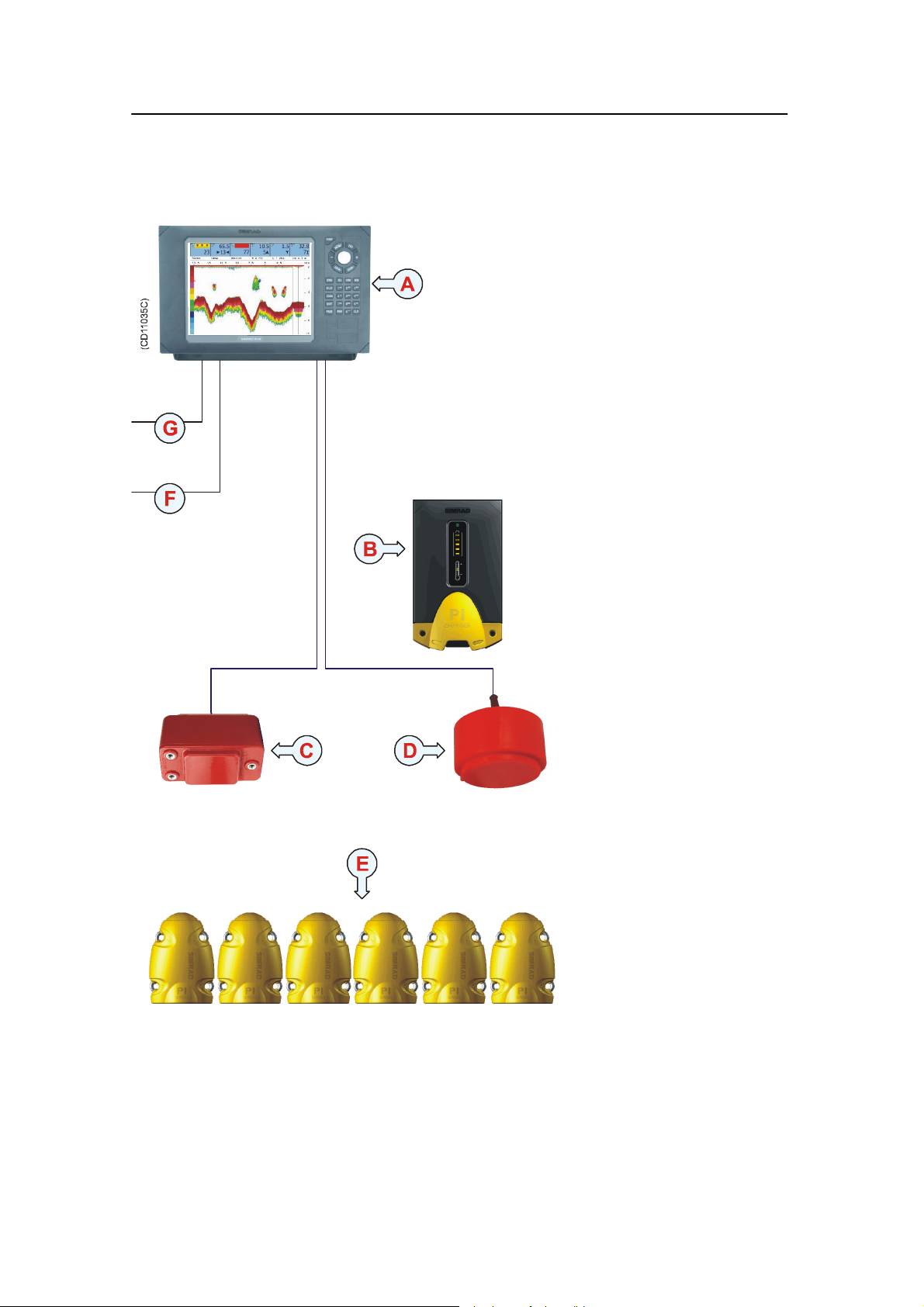

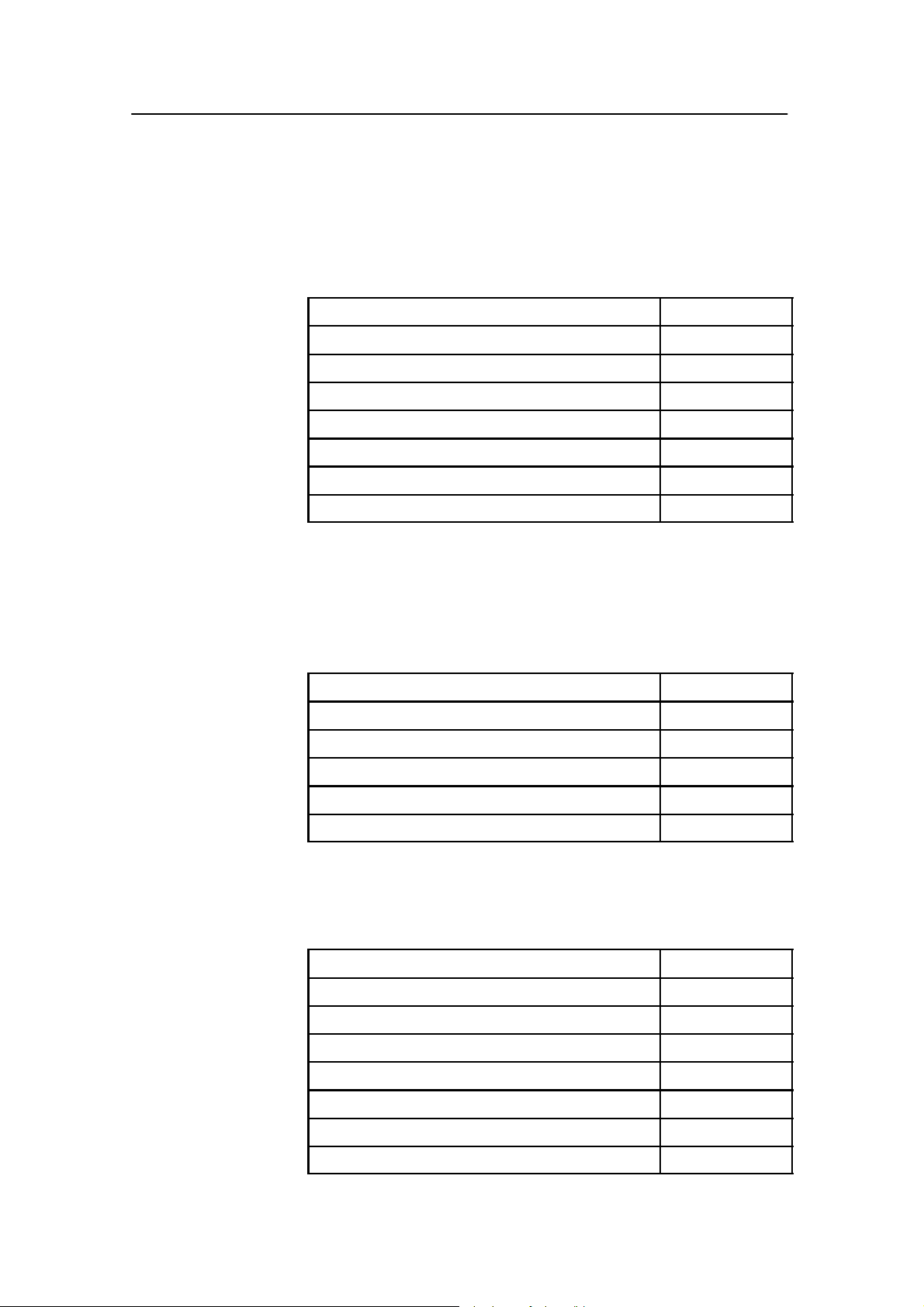

System diagram

(A) = Operator Unit

(B) = PI charger

(C) = Hydrophone

(provides communication

with the sensors)

(D) = Optional echo

sounder transducer.

Several types are

available.

(E) = Sensors mounted on

the net. Maximum six

sensors may be used

simultanously, and several

types are available.

(F) = Interfaces to

external sensors (serial

lines, NMEA format)

(G) = DC power input

2

851-165101 / Rev.A

Page 11

Introduction

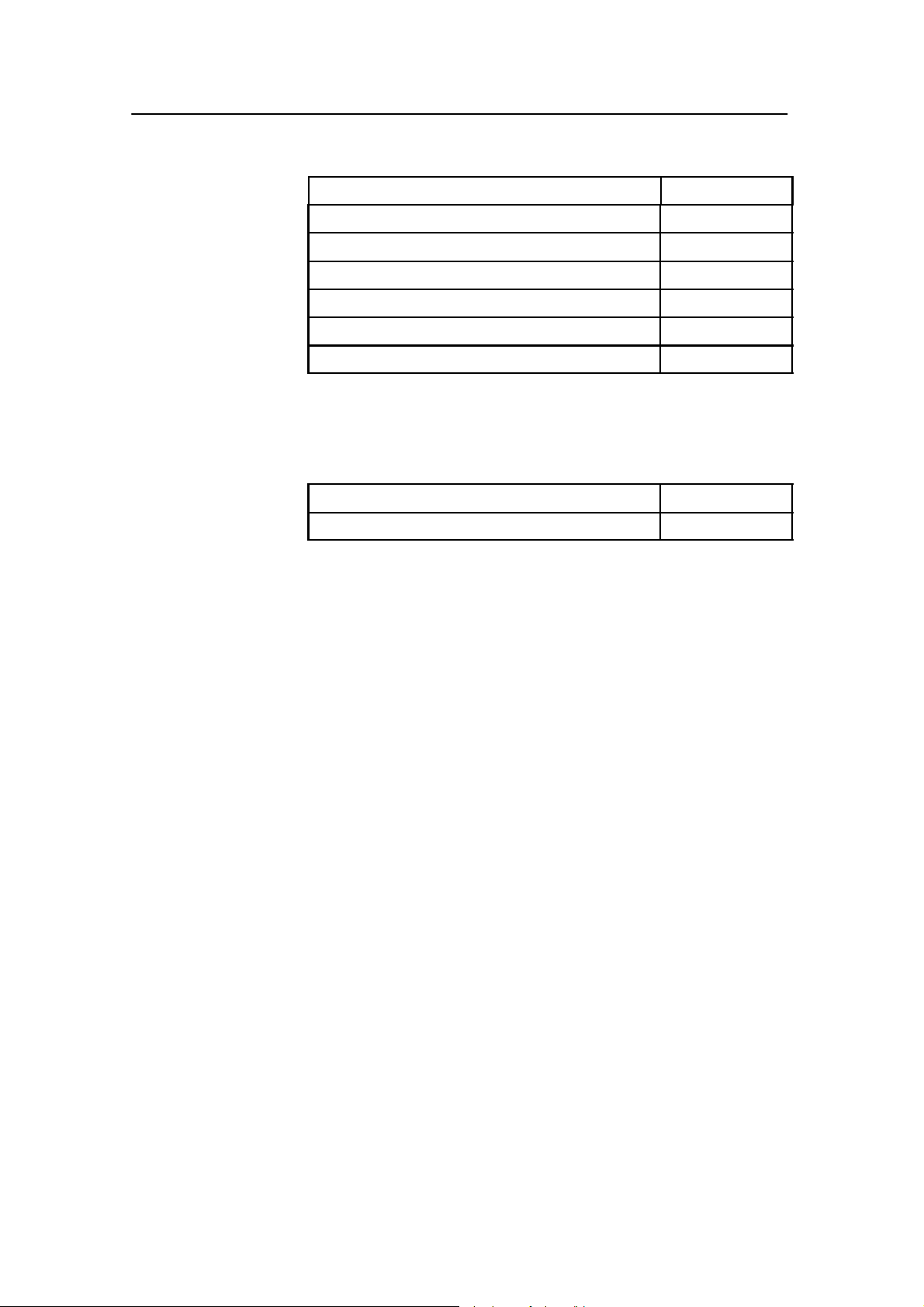

Scope of supply

Main units

The standard Simrad PI44 catch monitoring system is comprised

of the following main units. All must be ordered separately.

Unit Order number

Operator Unit PI3--208872

Hydrophone, purse seine HYD--202711

Hydrophone, trawl HYD--205254

Hydrophone, portable HYD--202713

Paravane kit for portable hydrophone KIT--207284

+24 Vdc 5 A Power supply (230 vac) 290--076359

+13,2 Vdc 10 A Power supply (230 vac) 290--087521

Echo sounder transducers

The echo sounder transducers are optional. Note that only one

of the echo sounder transducers is required. Only the

transducers recommended by Simrad for use with the PI44

system are listed.

Transducer Order number

38/200 Combi C KSV--202192

38/200 Combi D KSV--203004

38/200 Combi W KSV--208845

50/200 Combi C KSV--202193

50/200 Combi D KSV--203005

Sensors

The Simrad PI44 catch monitoring system can operate with six

sensors simultanously. Several sensor types are available.

Sensor Order number

PI Bottom Contact sensor PI3--207642

851-165101 / Rev.A

PI Catch sensor PI3--207641

PI Depth sensor, 300 m PI3--207637

PI Depth sensor, 600 m PI3--207638

PI Depth sensor, 1000 m PI3--207639

PI Height sensor PI3--280002

PI Spread sensor PI3--206869

3

Page 12

Simrad PI44

Sensor Order number

PI Twin Spread sensor PI3--206896

PI Remote 1 sensor PI3--206870

PI Remote 2 sensor PI3--206871

PI Remote 3 sensor PI3--206872

PI Remote 4 sensor PI3--206885

PI Temperature sensor PI3--207640

Sensor chargers

In order to charge the PI44 sensor batteries, the following

charger is available.

Sensor Order number

PI Sensor charger LAD--207624

4

851-165101 / Rev.A

Page 13

Introduction

Supply conditions

The following supply conditions are applicable to standard

Simrad PI44 deliveries and associated optional equipment.

Equipment responsibility

The shipyard performing the installation and/or dealer becomes

fully responsible for the equipment upon receipt unless

otherwise stated in the contract. The duration of responsibility

includes:

• The period of time the equipment is stored locally before

installation.

• During the entire installation process.

• While commissioning the equipment.

• The period of time between commissioning and the final

acceptance of the equipment by the end user (normally the

owner of the vessel which the equipment has been installed).

The Simrad PI44 system guarantee period (as specified in the

contract) begins when the acceptance documents have been

signed unless other arrangements have been made in the

contract.

Receipt, unpacking and storage

Upon accepting shipment of the equipment, the shipyard and/or

the dealer should ensure that the delivery is complete and

inspect each shipping container for evidence of physical

damage. If this inspection reveals any indication of crushing,

dropping, immersion in water or any other form of damage, the

recipient should request that a representative from the company

used to transport the equipment be present during unpacking.

All equipment should be inspected for physical damage, i.e.

broken controls and indicators, dents, scratches etc. during

unpacking. If any damage to the equipment is discovered, the

recipient should notify both the transportation company and

Simrad so that Simrad can arrange for replacement or repair of

the damaged equipment.

Once unpacked, the equipment must be stored in a controlled

environment with an atmosphere free of corrosive agents,

excessive humidity or temperature extremes. The equipment

must be covered to protect it from dust and other forms of

contamination when stored.

851-165101 / Rev.A

5

Page 14

Simrad PI44

General installation requirements

Responsibility and approval

The Simrad PI44’s hydrophone and echo sounder i nstallation

must be approved on a case-by-case basis with regard to the

vessel’s national registry and corresponding maritime authority.

The shipowner and shipyard performing the installation are

responsible for obtaining installation approval.

Environmental requirements

All equipment, unless otherwise specified, must be protected

from temperature extremes and excessive humidity.

Compass deviation

Once the installation is complete, the vessel must be swung with

the PI44 system in both the operative and inoperative modes.

The shipowner and captain are responsible for updating the

deviation table accordingly with regard to the vessel’s national

registry and corresponding maritime authority.

Noise sources

The vessel’s hull, rudder(s) and propeller(s) should be

thoroughly inspected in dry dock prior to installation.

Roughness below the water-line deformities in the shell plating

and protruding obstacles can create underwater noise. These

sources of turbulence must be smoothed or removed as best as

possible. It is especially important that the propeller(s) is not

pitted or damaged.

Dry docking

Make sure that ample clearance under the hydrophone and e cho

sounder transducer is provided when dry docking the vessel.

Avoid locating supporting blocks or structures in the vicinity of

this equipment.

Note: The location of the hydrophone and echo sounder transducer

must be noted on the vessel’s docking plan for future reference.

Wiring

The cables from the wheelhouse to the hydrophone and echo

sounder transducer must be supported and protected along its

entire length using conduits and/or cable trays. Note that the

cables must not be installed in the vicinity of high-power

supplies and cables, antenna cables or other possible sources of

interferences.

6

851-165101 / Rev.A

Page 15

Introduction

Equipment handling

The units may be supplied as spare parts, or as parts of a

delivery.

Transportation

Unless otherwise stated in the accompanying documentation,

electronic, electro-mechanical and mechanical units supplied by

Simrad can be transported using all methods approved for

delicate equipment; (by road, rail, air or sea). The units are to be

transported in accordance with general or specific i nstructions

for the appropriate unit(s), using pallets, transport cases, or

carton boxes as appropriate.

Note: Special local restrictions concerning air transportation may be

applied to units containing certain types of batteries. The units

should be checked and the regulations investigated by the

packer/shipper before the unit is dispatched.

All local transportation must be carried out according to the

same specifications as for the initial delivery. In general, all

units must be handled with care. The carton or case containing

the equipment must be kept dry at all times, and must be

sheltered from the weather. It must not be subjected to shocks,

excessive vibration or other rough handling.

The carton or case will normally be marked with text or symbols

indicating which way up it is to be placed. Follow any

instructions given and ensure the case is always placed with its

“top” uppermost.

The carton or case must not be used for any purpose for which it

was not intended (step, table, etc.), and in the absence of other

information, no other cartons or cases must be stacked on top of

it.

Lifting

A heavy crate will normally be marked with its weight, and the

weights of other cartons or crates will normally be entered on

the packing list.

851-165101 / Rev.A

• Always check the weight of a crate before attempting to lift

it.

• Always use lifting apparatus that is certified for the load.

7

Page 16

Simrad PI44

Heavy units may be equipped with lifting lugs for transportation

by crane within the workshop or installation area. Before a crane

is used, check:

• The applicable weight certificate for the crane.

• The security of the lifting lugs.

Ensure that all available lifting lugs are used. Ensure the unit

remains under control during the operation to avoid damage to

the unit, equipment or personnel.

Heavy units may be transported using a fork-lift truck. Special

attention must then be paid to the position of the unit’s centre of

gravity. The units must be properly secured to the truck.

Initial preservation

When a system, a unit or a spare part has been delivered to the

customer, it may be subject to long-time storage prior to

installation and use. During this storage period, certain

specifications must be met.

The equipment must be preserved and stored in such a way that

it does not constitute any danger to health, environment or

personal injury.

Specific specifications are presented below.

→ For further information about storage, refer to page 12.

→ For further information about re-packing, refer to page 15.

→ For further information about temperature protection, refer to

page 17.

Preserving the original packing crate

1 The equipment must be stored in its original transportation

crate.

2 Ensure that the units are clearly separated in the shelves

and that each unit is easily identifiable.

3 The crate must not be used for any purpose for which it

was not intended (eg. work platform etc.).

4 The crates must not be placed on top of each other, unless

specific markings permit this.

5 The crates must not be placed directly on a dirt-floor.

6 Do not open the crate for inspection unless special

circumstances permit so.

- “Special circumstances” may be suspected damage to

the crate and its content, or inspections by civil

authorities.

8

851-165101 / Rev.A

Page 17

Introduction

- If any units are damaged, prepare an inspection report

stating the condition of the unit and actions taken.

Describe the damage and collect photographic evidence

if possible. Re-preserve the equipment.

- If the units are not damaged, check the humidity

absorbing material. If required, dry or replace the bags,

then repack the unit(s) according to the packing

instructions.

7 If the crate has been opened, make sure that is it closed

and sealed after the inspection.

- Use the original packing material as far as possible.

→ Refer to information on page 15.

Ambient temperature and humidity during

storage

1 The storage room/area must be dry, with a non-condensing

atmosphere. It must be free from corrosive agents.

2 The storage area’s mean temperature must not be lower

than -30°C, and not warmer than +70° C.

- If other limitations apply, the crates will be marked

accordingly.

Note: Transducers must not be stored in temperatures below -20°C, or

higher than +60°C.

3 The crate must not be exposed to moisture from fluid

leakages.

4 The crate must not be exposed to direct sunlight or

excessive warmth from heaters.

Shock and vibration during storage

1 The crate must not be subjected to excessive shock and

vibration.

851-165101 / Rev.A

ESD precautions during storage

→ Refer to the information on page 16.

If the unit contains normal batteries, these may have been

disconnected/isolated before the unit was packed. These must

only be reconnected before the installation starts. Units

containing batteries are marked.

9

Page 18

Simrad PI44

Caution: Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

Inspection and unpacking

An inspection must be carried out immediately after the unit(s)

have arrived at their destination.

• Check all wooden or cardboard boxes, plastic bags and

pallets for physical damage. Look for signs of dropping,

immersion in water or other mishandling.

• If damage is detected externally, you will have to open the

packaging to check the contents.

- Request a representative of the carrier to be present while

the carton is opened, so any transportation damage can be

identified.

• If any units are damaged, prepare an inspection report stating

the condition of the unit and actions taken. Describe the

damage and collect photographic evidence if possible. Send

the inspection report to Simrad as soon as possible.

• If the units are not damaged, check the humidity absorbing

material. If required, dry or replace the bags, then repack the

unit(s) according to the packing instructions.

Inspection and unpacking: General procedure

Normal precautions for the handling, transportation and storage

of fragile electronic equipment must be undertaken.

Note: If the unit is not to be prepared for immediate use, you may

consider storing it unopened in its original packing material.

However, it may be useful to open the case to check its contents

for damage and retrieve any accompanying documentation.

10

• Check the carton before opening it to ensure it shows no

signs of dropping, immersion in water or other mishandling.

- If the carton shows signs of such damage, refer to the

paragraph covering Inspection on receipt.

851-165101 / Rev.A

Page 19

Introduction

• Place the carton on a stable work bench or on the floor with

the top of the carton uppermost.

• In the absence of other instructions, always open the top of

the carton first. The contents will normally have been

lowered into the carton from above, so this will usually be

the easiest route to follow.

- Care must be used when opening the carton to ensure the

contents are not damaged.

Caution: Do not use a knife to open cardboard cartons - the

contents may lie close to the surface, and may be

damaged by the blade.

• If the carton has been closed using staples, remove the staples

from the carton as you open it. This will reduce the

possibilities of scratch injury to yourself and damage to the

contents.

• If a wooden crate has been closed using screws, always

remove them using a screw-driver. Do not attempt to prise

the lid off with a crow-bar or similar.

• Once the carton is open, carefully remove all loose packing

and insulation material. Check for manuals and other

documents that may have been added to the carton during

packing, and put these to one side. Check also for special

tools, door keys etc.

Unpacking electronic and electro-mechanical

units

Caution: Beware of the dangers of Electro-Static Discharge

(ESD) both to yourself and to the equipment, when

handling electronic units and components. Refer to the

precautions starting on page 16.

Electronic and electro-mechanical units will normally be

wrapped in a clear plastic bag. Lift the unit, in its bag, out of the

carton and place it in a stable position on the floor/work bench.

Inspect the unit for damage before opening the plastic bag.

Note: Cables must never be used as carrying handles or lifting points.

851-165101 / Rev.A

11

Page 20

Simrad PI44

Note: Do not break the seal to open a circuit board package before the

board is to be used. If the board package is returned to the

manufacturers with the seal broken, the contents will be

assumed to have been used and the customer will be billed

accordingly.

Assuming all is well, open the bag and remove the unit.

Open the unit and check inside. Remove any packing and

desiccant material that may be inside.

Unpacking mechanical units

Mechanical units may be heavy. Using a suitably certified lifting

apparatus, lift the unit out of the crate and place it in a stable

position on the floor/work bench.

Inspect the unit for damage and remove any packing material

that may be inside the unit.

Unpacking transducers

Transducers may be supplied mounted to a hull unit (if any), or

packed separately. Crates are normally identified by the order

number and the serial number.

The transducer face must be protected by a rigid, padded cover

(e.g. a wooden box lined with foam rubber) all the time it is

exposed to the risk of physical damage.

Note: Once the units are unpacked, great care must be taken to ensure

that transducers and cabling are not exposed to any mechanical

stress.

Re-packaging

If the unit is not to be installed immediately, re-pack it in its

original packing material to prevent damage in the intervening

period.

12

→ Refer to the information on page 15.

Pre-installation storage

The equipment should be stored in its original transportation

crate until ready for installation. The crate must not be used for

any purpose for which it was not intended (eg. work platform

etc.).

851-165101 / Rev.A

Page 21

Introduction

Once unpacked, the equipment must be kept in a dry, non

condensing atmosphere, free from corrosive agents and isolated

from sources of vibration.

Note: Do not break the seal to open a circuit board package before the

board is to be used. If the board package is returned to the

manufacturers with the seal broken, the contents will be

assumed to have been used and the customer will be billed

accordingly.

The unit must be installed in its intended operating position as

soon as possible after unpacking.

If the unit contains normal batteries, these may have been

disconnected/isolated before the unit was packed. These must

then be reconnected during the installation procedure. Units

containing batteries are marked.

Caution: Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

After use storage

If a unit is removed from its operating location and placed into

storage, it must be properly cleaned and prepared before

packing.

Cleaning cabinets

If a cabinet has been exposed to salt atmosphere while it was in

use, it must be thoroughly cleaned both i nternally and externally

to prevent corrosion.

• Wipe the cabinet externally using a damp cloth and a little

detergent. Do not use excessive amounts of water as the unit

may not be water tight. On completion, dry the unit

thoroughly.

851-165101 / Rev.A

• All surfaces must be inspected for signs of corrosion, eg.

flaking/bubbling paint, stains etc. Damaged or suspect areas

must be cleaned, prepared and preserved using the correct

preservation mediums for the unit. The mediums to be used

will usually be defined in the units’ maintenance manual.

13

Page 22

Simrad PI44

• Open the unit, and using a vacuum cleaner, remove all dust

etc. from the unit. Great care must be taken to ensure the

circuit boards and modules are not damaged in the process.

Mechanical units

If a mechanical unit may have been exposed to a salt

atmosphere while it was in use, it must be thoroughly cleaned

both internally and externally to prevent corrosion.

• If the construction materials and type of unit permits, wash

the unit using a high-pressure hose and copious amounts of

fresh water.

Examples:

- The lower parts of hull units (outside the hull)

- Subsea units

• Ensure that all traces of mud and marine growth are removed.

Use a wooden or plastic scraper to remove persistent growth,

barnacles etc. On completion, dry the unit thoroughly.

Caution: Do not use a high pressure hose in the vicinity of cables

or transducers. Do not use sharp or metal tools on a

transducer face.

• If the materials or type of unit prevents the use of a

high-pressure hose, wipe the unit using a cloth dampened

with water containing a little detergent.

Examples:

- The upper parts of hull units (inside the hull)

- Hydraulic systems

• Do not use excessive amounts of water as some components

on the unit may not be water tight. Wipe off the detergent

with a damp cloth, then dry the unit thoroughly.

• All surfaces must be inspected for signs of corrosion, eg.

flaking/bubbling paint, stains etc. Damaged or suspect areas

must be cleaned, prepared and preserved using the correct

preservation mediums. The mediums to be used will

normally be defined in the unit’s maintenance manual.

14

Cables

Wipe clean all exposed cables, and check for damage. If a cable

shows signs of wear or ageing, contact Simrad for advice.

851-165101 / Rev.A

Page 23

Introduction

Internal batteries

If the unit contains batteries, these may discharge slowly during

storage. If the unit is to be stored for an extended period,

disconnect or remove all internal batteries.

A suitable piece of insulating material can be placed between

the battery and the electrical contacts to prevent electrical

discharge. The battery can then remain in the unit, reducing the

risk of it being misplaced during the storage period.

Caution: Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

Dehumidifier

Place a suitably sized bag of desiccant material (silica gel or

similar) into the unit to keep the electronic components as dry as

possible.

Coatings

Spray the unit externally with a corrosion inhibitor (e.g. a light

oil) before packing.

Re-packing

The unit should be stored and transported in its original packing

material and/or crate. In the event that this material is not

available, proceed as follows:

• Small units must be protected from damp by being placed

within a plastic bag at least 0.15 mm thick. An appropriate

quantity of desiccant material should be placed inside this

bag, and the bag sealed. The sealed unit must then be placed

in an appropriate carton or crate, and supported in the

container by appropriate shock-absorbing insulation

(polystyrene foam chips etc.).

851-165101 / Rev.A

• Large units must be placed in a suitable cardboard box or

wooden crate. The unit must be protected against physical

damage by means of shock-absorbing insulation mats. The

box must be clearly marked with its contents, and must be

stored in a dry and dust-free area.

15

Page 24

Simrad PI44

ESD precautions

Electro-Static Discharge (ESD) is the transfer of an electrostatic

charge between two bodies at different electrostatic potentials,

caused either by direct contact or induction by an electrostatic

field.

The passing of a charge through an electronic device can cause

localised overheating, and it can also “puncture” insulating

layers within the structure of the device. This may deposit a

conductive residue of the vaporised metal on the device, and

thus create a short circuit. This may result in a catastrophic

failure, or degraded performance of the device.

Sensitive electronic equipment must be transported and stored in

protective packing bags, boxes and cabinets. The equipment

must NOT be transported or stored close to strong electrostatic,

electro-magnetic or radioactive fields.

If it is necessary to open and touch the electronics inside the

boxes/cabinets, then the following precautions MUST be taken:

• The working area must be covered by an approved

conductive service mat that has a resistance of between 50kΩ

and2MΩ, and is connected directly to a reliable earth point

via its earthing cord.

• The service personnel involved must wear a wrist-band in

direct contact with the skin, connected to the service mat.

• Printed circuit boards and other components should be placed

on the conductive service mat during installation,

maintenance etc.

Caution: If, for any reason, it is necessary to move the circuit

board or components from the conductive service mat,

they must be placed in an approved anti-static

transportation container (e.g. static shielding bag)

before transportation.

• During installation and servicing, all electrical equipment

(soldering irons, test equipment etc.) must be earthed.

16

851-165101 / Rev.A

Page 25

Temperature protection

If the unit must be protected against extremes of temperature,

the carton/crate must be lined on all walls, base and lid with

5 cm thick polyurethane or polystyrene foam.

These units will be identified as delicate i n the applicable

documentation.

The package must then be clearly marked:

Note: Must not be transported or stored in temperatures

below -5 degrees Celsius.

Other units can normally be stored in temperatures

between -30° C and +70° C, refer t o the system’s technical

specifications for details.

Introduction

Transducers must not be stored in temperatures below -20°C

and above +60°C.

851-165101 / Rev.A

17

Page 26

Simrad PI44

2 TRANSDUCER INSTALLATION

Purpose

Due to the fact that several transducer types may be used with

the PI44 system, you will need to read the installation manual

for the chosen transducer. The information provided in this

chapter will only provide general information. Refer to the

installation manuals provided with the transducers for more

specific information.

The PI44 can be used with maximum two transducers

simultanously, one low frequency (38 or 50 kHz) and one high

frequency (200 kHz). We recommend that any one of the

following transducers are used:

• Simrad 38-200 Combi C (dual frequency)

• Simrad 38-200 Combi D (dual frequency)

• Simrad 38-200 Combi W (dual frequency, wide beam)

Other transducers may also be used. Budget transducers

designed for leasure crafts are however not recommended for

professional fishery applications.

Topics

→ Transducer location, page 19

→ External mounting (Combi C and D), page 23

→ Blister mounting (Combi W), page 28

→ Cable glands, page 35

→ Cable in steel conduit, page 39

→ Handling and maintenance, page 40

→ Approved anti-fouling paints, page 41

Related topics

→ Purse seine hydrophone installation, page 42

→ Trawl hydrophone installation, page 79

→ Portable hydrophone, page 120

18

851-165101 / Rev.A

Page 27

Transducer installation

Transducer location

General

A single answer to the question where to locate the transducer

cannot be given. It depends very much on the vessel’s

construction. However, there are some important guide lines.

Go deep

The upper water layers of the sea contain a myriad of small air

bubbles created by the breaking waves. In heavy seas the

uppermost 5 to 10 metres may be air-filled, with the highest

concentrations near the surface. Air bubbles absorb and reflect

the sound energy, and may in worst cases block the sound

transmission totally. Therefore, mount the transducer at a deep

position on the hull.

Consider the situation when the vessel is unloaded, and when it

is pitching in heavy seas. The transducer must never be lifted

free of the water surface. Not only will the sound transmission

be blocked, but the transducer may be damaged by slamming

against the sea surface.

Another reason to go deep is cavitation in front of high power

transducers. Cavitation is the formation of small bubbles in the

water due to the resulting local pressure becoming negative

during parts of the acoustic pressure cycles. The cavitation

threshold increases with the hydrostatic pressure.

Vessel heave

Heave is the up and down movement of the vessel. It disturbs

the echo traces in the echogram, so that a flat bottom is

displayed as a wave. A transducer location in the middle of the

vessel minimises the influence of vessel roll and pitch.

Noises from protruding objects on the hull

Objects protruding from the hull, such as zinc anodes, sonar

transducers or even the vessel’s keel, generate turbulence and

flow noise. Also holes and pipe outlets are noise sources. They

may act as resonant cavities amplifying the f low noise at certain

frequencies. Do not place an echo sounder transducer in the

vicinity of such objects, and especially not close behind them.

For the same reason, it is very important that the hull area

around the transducer face is as smooth and level as possible.

Even traces of sealing compound, sharp edges, protruding bolts

or bolt holes without filling compound will create noise.

851-165101 / Rev.A

19

Page 28

Simrad PI44

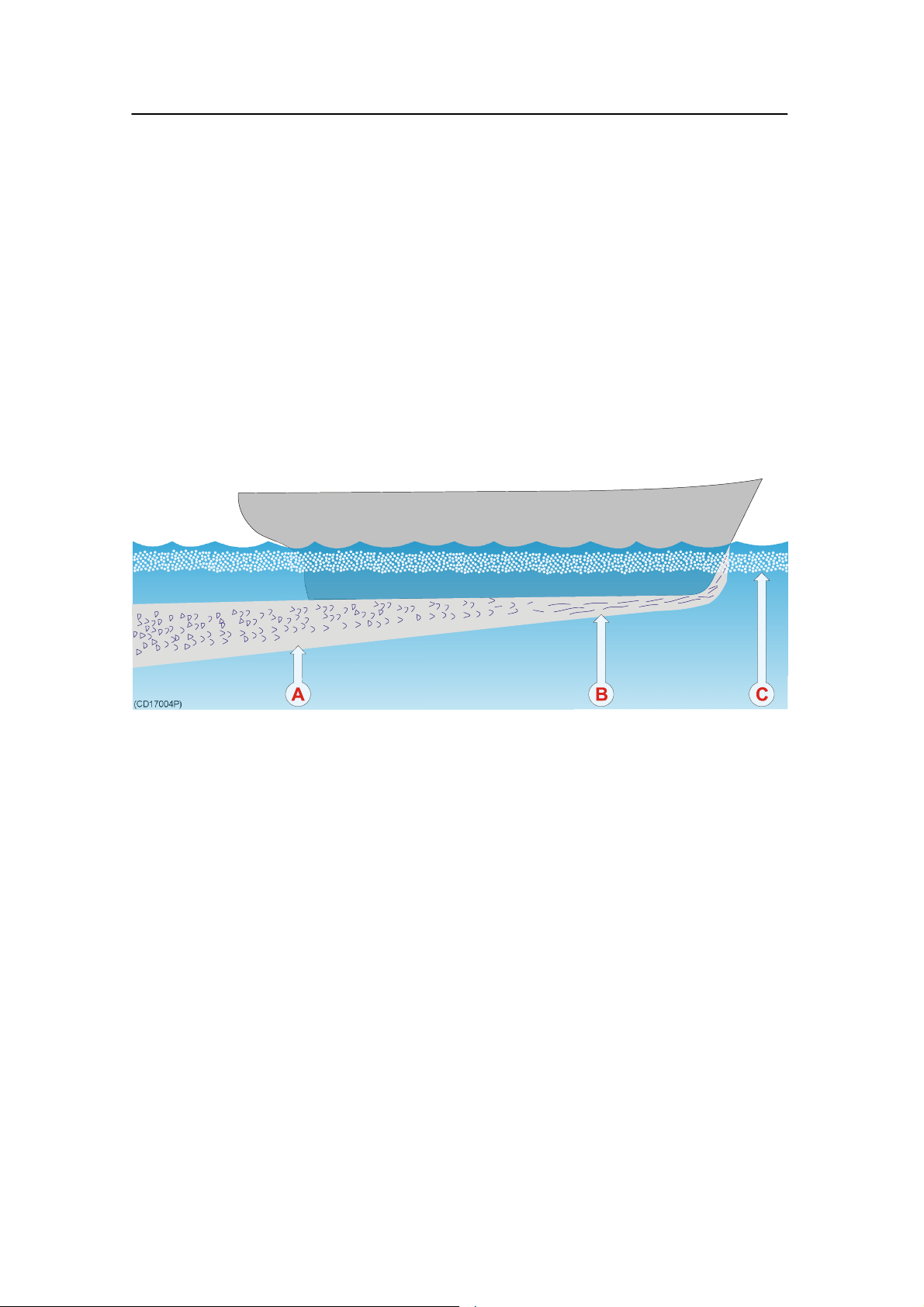

Boundary water layer

When the vessel forces its way through the sea, the friction

between the hull and the water creates a boundary layer. The

thickness of the boundary layer depends upon vessel speed and

the roughness of the hull. Objects protruding from the hull, and

dents in the hull, disturb the flow and increase the thickness of

the boundary layer. The flow in this boundary layer may be

laminar or turbulent. A laminar flow is a nicely ordered, parallel

movement of the water. A turbulent flow has a disorderly

pattern, full of eddies. The boundary layer increases in thickness

when the flow goes from laminar to turbulent. The figure below

illustrates the boundary layer of a vessel moving through the

water.

Boundary water layers:

(A) = Turbulent flow

(B) = Laminar flow

(C) = Air bubbles in the water

Furthermore, air bubbles in the sea water are pressed down

below the hull and mixed into the boundary layer. The boundary

layer is thin underneath the forward part of the vessel, and

increases in thickness as it moves towards aft. If the sides of the

hull are steep, some of the air bubbles in the boundary layer may

escape to the sea surface along the vessel sides. It is our

experience that a wide and flat bottom, with a rising angle less

than around 13 degrees, is prone to giving air problems for the

transducer. In any case a transducer location in the forward part

of the hull is preferred in order to minimise the influence of the

boundary layer.

20

851-165101 / Rev.A

Page 29

Transducer installation

Propeller noise

The propulsion propeller is the dominant noise source on most

fishing vessels, research vessels, merchant vessels and pleasure

crafts. The noise is transmitted through the sea water. For this

reason, the transducer should be placed far away from the

propeller, which means on the fore part of the hull. Positions

outside the direct line of sight from the propeller are favourable.

On small vessels with short distances it is advised to mount the

transducer on that side of the keel where the propeller blades

move upwards, because the propeller cavitation is strongest on

the other side. The cavitation starts most easily when the water

flows in the same direction as the propeller blade, and that is to

some degree the case at that side of the keel where the propeller

blades move downwards.

Bow thruster propellers are extremely noisy. When in operation,

the noise and cavitation bubbles make the echo sounder useless,

almost no matter where the transducer is installed. And when

not in operation, the tunnel creates turbulence, and if the vessel

is pitching, the tunnel may be filled with air or aerated water in

the upper position and release this in the lower position.

Therefore, an echo sounder transducer should be placed well

away from the bow thruster.

851-165101 / Rev.A

21

Page 30

Simrad PI44

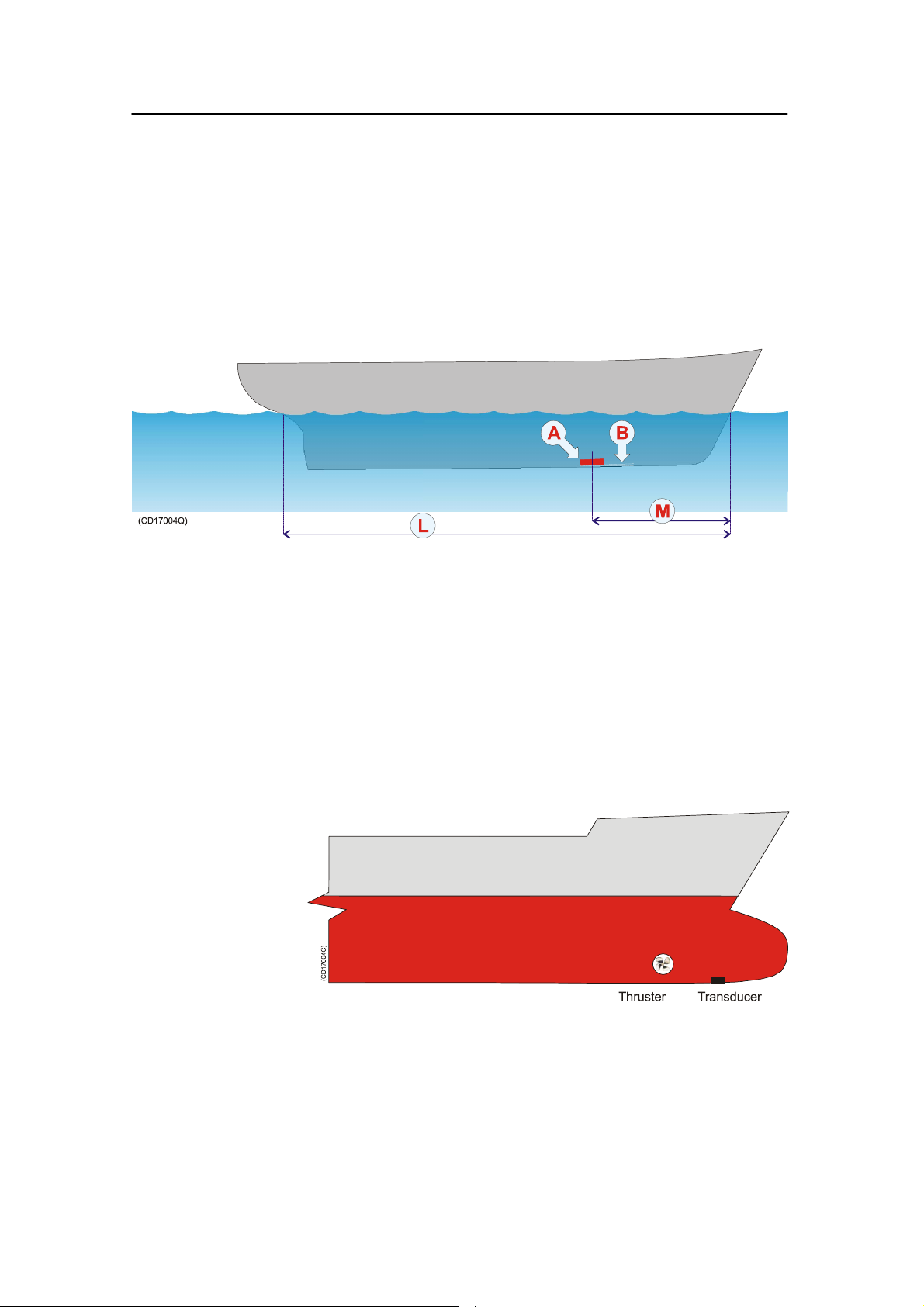

Summary and general recommendation

Some of the above guide lines are conflicting, and each case has

to be treated individually in order to find the best compromise.

Generally the propeller noise is the dominant factor, and a

recommended transducer location is in the fore part of the hull,

with maximum distance from the bow equal to one third of the

total length of the hull at the water line.

General recommendation for transducer location:

(A) = Transducer

(B) = Angle 1 - 2 degrees

(L) = Hull length at water line

(M) = Maximum 1/3 of the hull length at water line (L)

If the vessel hull has a bulbous bow, this may well be a good

transducer location, but also here must be taken into

consideration the flow pattern of the aerated water. Often the

foremost part of the bulb is preferable.

22

851-165101 / Rev.A

Page 31

Transducer installation

External mounting

This transducer has a streamlined housing, and it is designed for

installation outside the hull.

This transducer is mainly used on smaller vessels. A location

approximately 0.5 m aside from the keel may be adequate for

the passage of water between the keel and the transducer. The

figures illustrate external mounting of transducers on steel hulls

and on wood or polyester hulls respectively.

Inclination of the transducer face

Incline the transducer face approximately 1-2 degrees (D), so

that the flowing water meets it directly. This assures laminar

water flow. Mounting screws must not be extruding from the

transducer, and the space around the screws must be filled with

a compound (C) and/or a locking ring.

Smooth surface

Ensure that the surface of the transducer face, the hull plating

and putty around the transducer is as even and smooth as

possible. Obstructions on these surfaces will create problems

with turbulant flow.

851-165101 / Rev.A

23

Page 32

Simrad PI44

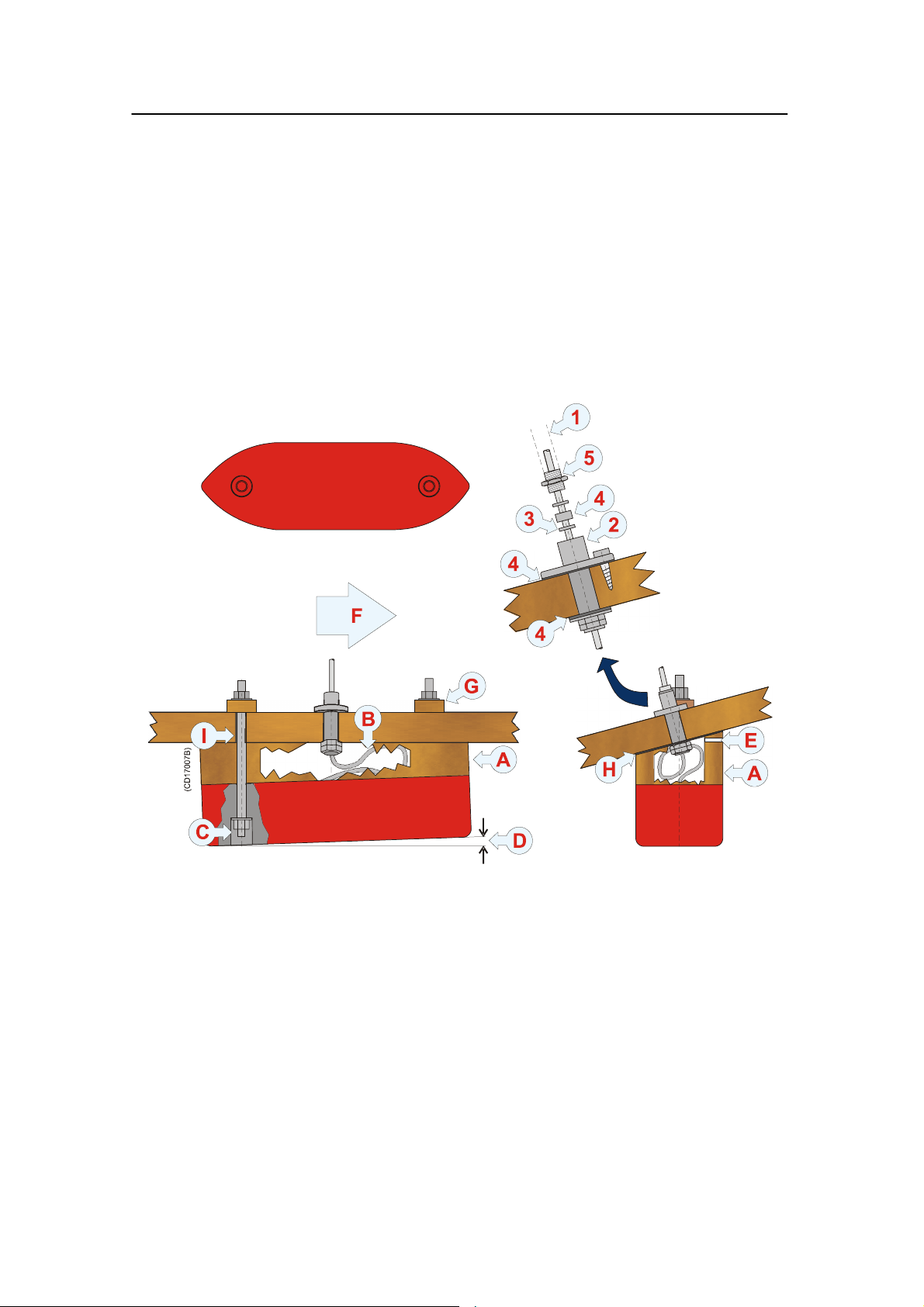

Steel hull

A fairing (A), made by the shipyard, is placed between the

transducer and the hull. It is required in order to adapt for the

deadrise angle of the hull, and it will also house a cable service

loop (B). The fairing can be made of wood or steel, and should

have the same outline dimensions as the transducer. Remember

to create an air outlet (E) on the fairing, and to fill the bolt holes

with a filling compound to ensure a smooth transducer surface.

24

(A) = Fairing (1) = Steel conduit

(B) = Cable service loop (2) = Stuffing tube

(C) = Filling compound (3) = Washer

(D) = 1-2 degrees inclination (4) = Rubber gasket

(E) = Air outlet (5) = Packing nipple

(F) = Forward

(I) = Threaded rod with nuts and washers, or bolt

851-165101 / Rev.A

Page 33

Transducer installation

Wood or polyester hull

A fairing (A), made by the shipyard, is placed between the

transducer and the hull. It is required in order to adapt for the

deadrise angle of the hull, and will also house a cable service

loop (B). The fairing is made from wood, polyester or steel, and

should have the same outline dimensions as the transducer. Use

tarred felt (H) between th fairing and the hull. Remember to

create an air outlet (E) on the fairing, and to fill the bolt holes

with a filling compound to ensure a smooth transducer surface.

851-165101 / Rev.A

(A) = Fairing (1) = Steel conduit

(B) = Cable service loop (2) = Stuffing tube

(C) = Filling compound (3) = Washer

(D) = 1-2 degrees inclination (4) = Rubber gasket

(E) = Air outlet (5) = Packing nipple

(F) = Forward

(G) = Shim (wood)

(H) = Tarred felt

(I) = Threaded rod with nuts and washers

25

Page 34

Simrad PI44

Flat hull

If the vessel’s hull is flat you do not need a fairing. The

transducer is then be bolted directly to the hull using two bronze

or stainless steel bolts (I) and a cable bushing. Note that the

cable bushing must be mounted with proper gaskets (4) under

and over the hull, as well as sealing compound (J) around the its

body. Also, fill the bolt holes with a filling compound to ensure

a smooth transducer surface.

(C) = Filling compound (3) = Washer

(F) = Forward (4) = Rubber gaskets

(I) = Threaded rod with nuts and washers

(J) = Sealing compound

26

851-165101 / Rev.A

Page 35

Transducer installation

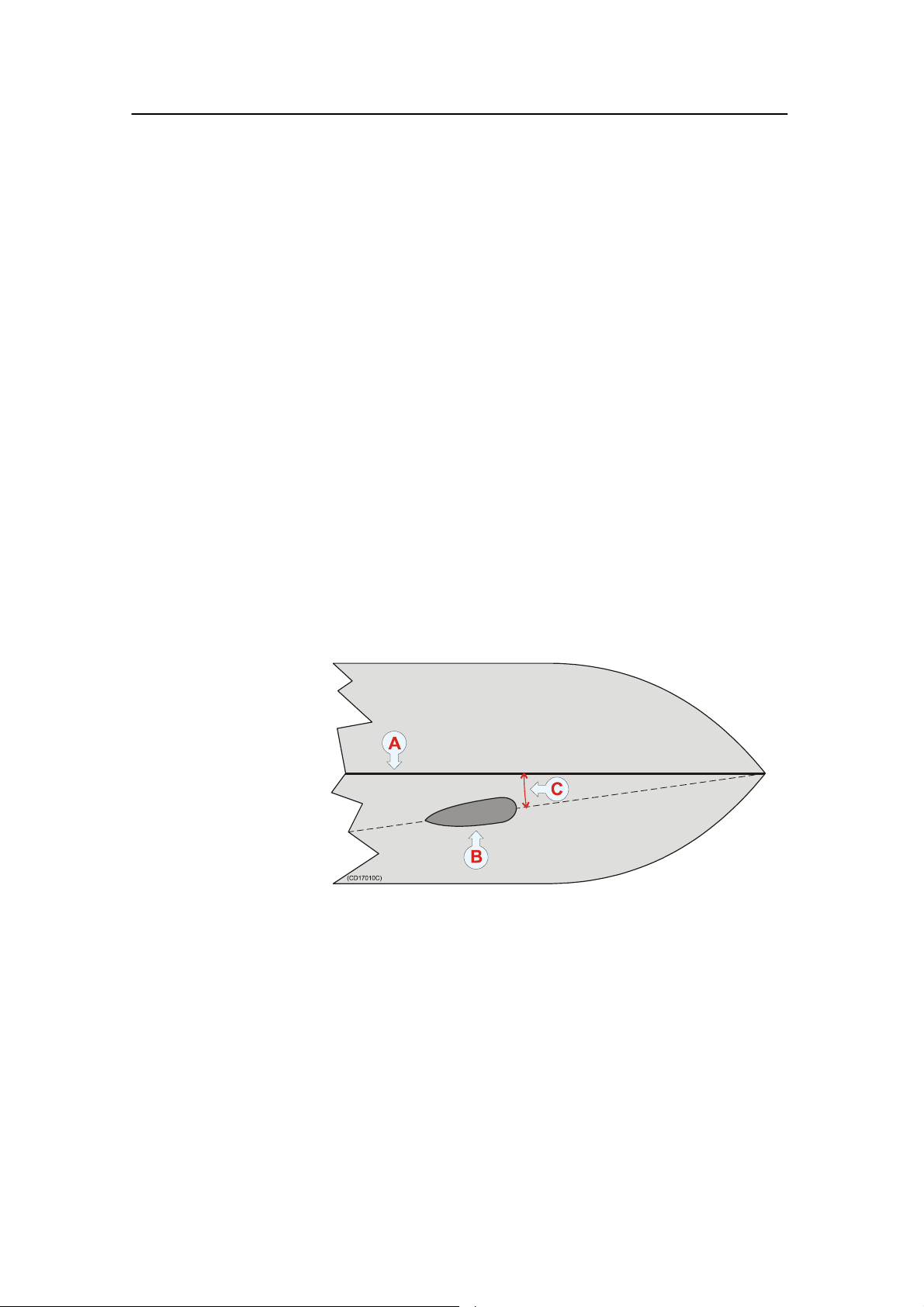

Longitudinal angle

On deplacement hulls, the transducer (A) must be mounted in an

angle of 5 to 8 degrees (B) in relation to the keel (C).

With a planing hull, this angle must be 0 degrees.

(A) = Transducer

(B)=5to8°ondeplacementhulls,0°onplaninghulls

(C) = Keel

(F) = Forward

851-165101 / Rev.A

27

Page 36

Simrad PI44

Transducer blister

With a transducer with circular housing, one recommended

installation method is by using a blister.

The transducer blister must be designed and manufactured by

the installation shipyard to fit the vessel’s sixe and hull shape.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production

of these. The mounting ring is welded to the hole in the

transducer blister, while the clamping ring fits around the edge

of the transducer body. Bolts through the clamping ring into the

mounting ring will then secure the transducer between them.

Note that several transducers use direction guides to allow

correct mounting.

Inclination of the transducer face

Incline the transducer face approximately 1-2 degrees, so that

the flowing water meets it directly. This assures laminar water

flow.

Smooth surface

Mounting screws or bolts must not be extruding from the

transducer blister. Ensure that the surface of the transducer face,

the blister, the hull plating and putty around the transducer is as

even and smooth as possible. Obstructions on these surfaces will

create problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

28

851-165101 / Rev.A

Page 37

Transducer installation

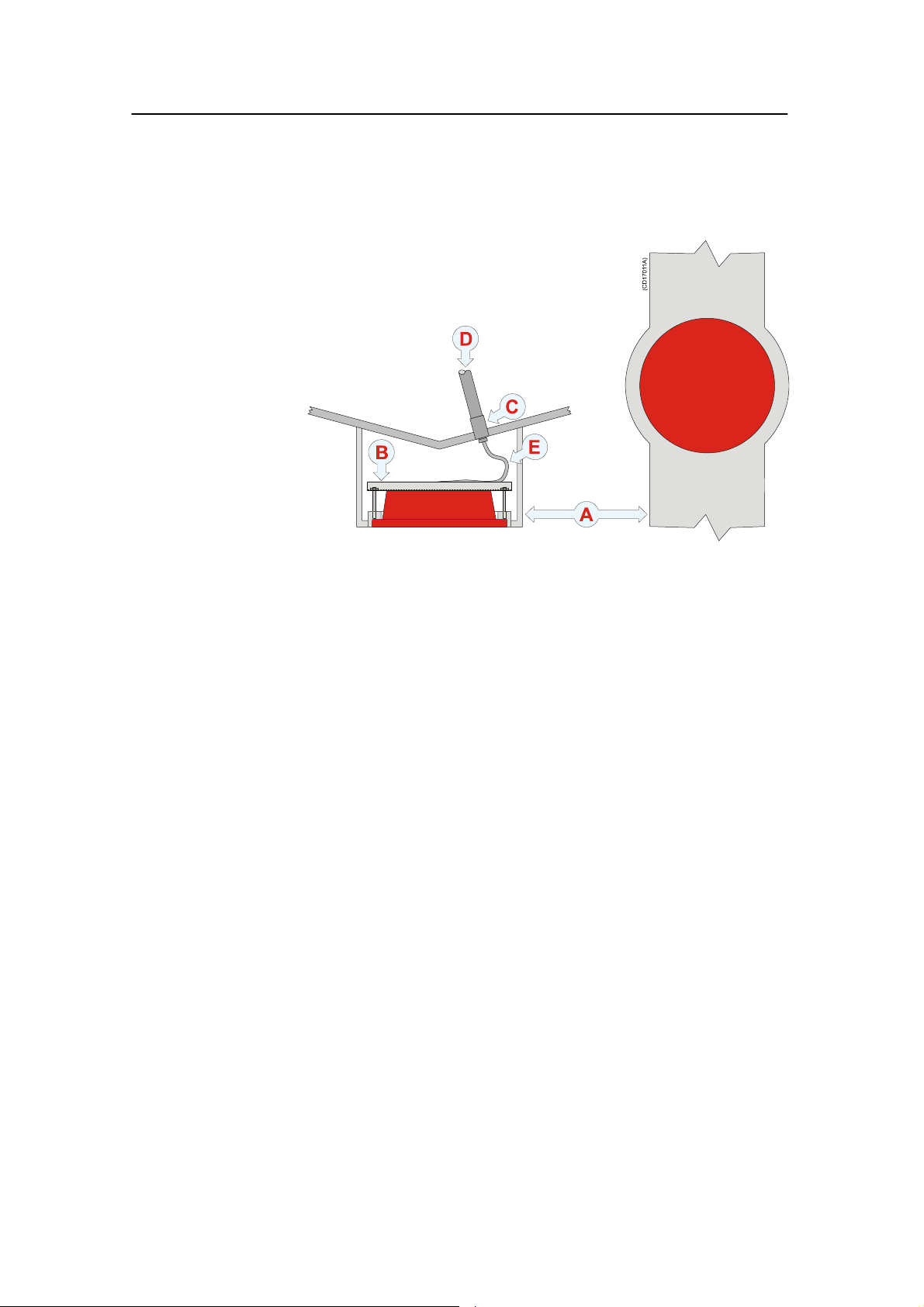

Example: Large transducer

The illustration below shows a typical transducer blister

designed for a large transducer. Note that due to the physical

size of the transducer, a U-shaped support bar (E) is used to

support the transducer.

(A) = Streamlined blister (F) = Forward

(B) = Stiffening rib (G) = Cable service loop

(C) = Drainage holes (H) = Stuffing tube

(D) = 1-2 degrees angle (I) = Minimum 400 mm

(E) = U-shaped support bar (J) = Rounded corners

(K) = Air outlet

851-165101 / Rev.A

29

Page 38

Simrad PI44

Example: Small transducer

The illustration below shows a typical transducer blister

designed for a small transducer. The same blister design

principles as for a large transducer apply.

30

(A) = Streamlined blister (E) = Air outlet

(B) = Mounting ring (F) = Forward

(C) = Clamping ring (G) = Transducer cable

(D) = Guide

Note that the transducer cable must be provided with a cable

loop inside the blister. Observe the vertical forward edge of the

blister. This will guide the water to each side of the blister.

851-165101 / Rev.A

Page 39

Transducer installation

Common guidelines

The best performance is obtained with a blister height of 40 cm

or more. A streamlined shape and rounded edges reduce the

flow noise. A vertical leading edge or front will guide the

aerated water to the sides of the blister. The orientation of the

blister should follow the water flow.

The interior of the blister must be filled with sea water. Use

drainage holes in the bottom and an air outlet on the top. The

water pressure behind the transducer will then compensate for

the outside pressure during vessel movements in rough sea.

Large diameter transducers must be fitted with a horizontal

U-shaped support bar. This bar can then be secured to the

mounting ring using threaded rods.

The transducer cable penetrates the hull in a stuffing tube. Leave

an adequate loop of the cable behind the transducer for easy

mounting or removal of the transducer.

Toe-in

On a conventional hull shape, without a bulb, the front of the

blister should have a few degrees toe-in towards the bow.

(A) = Keel

(B) = Blister

(C) = Toe-in angle 5 to 8 degrees

851-165101 / Rev.A

31

Page 40

Simrad PI44

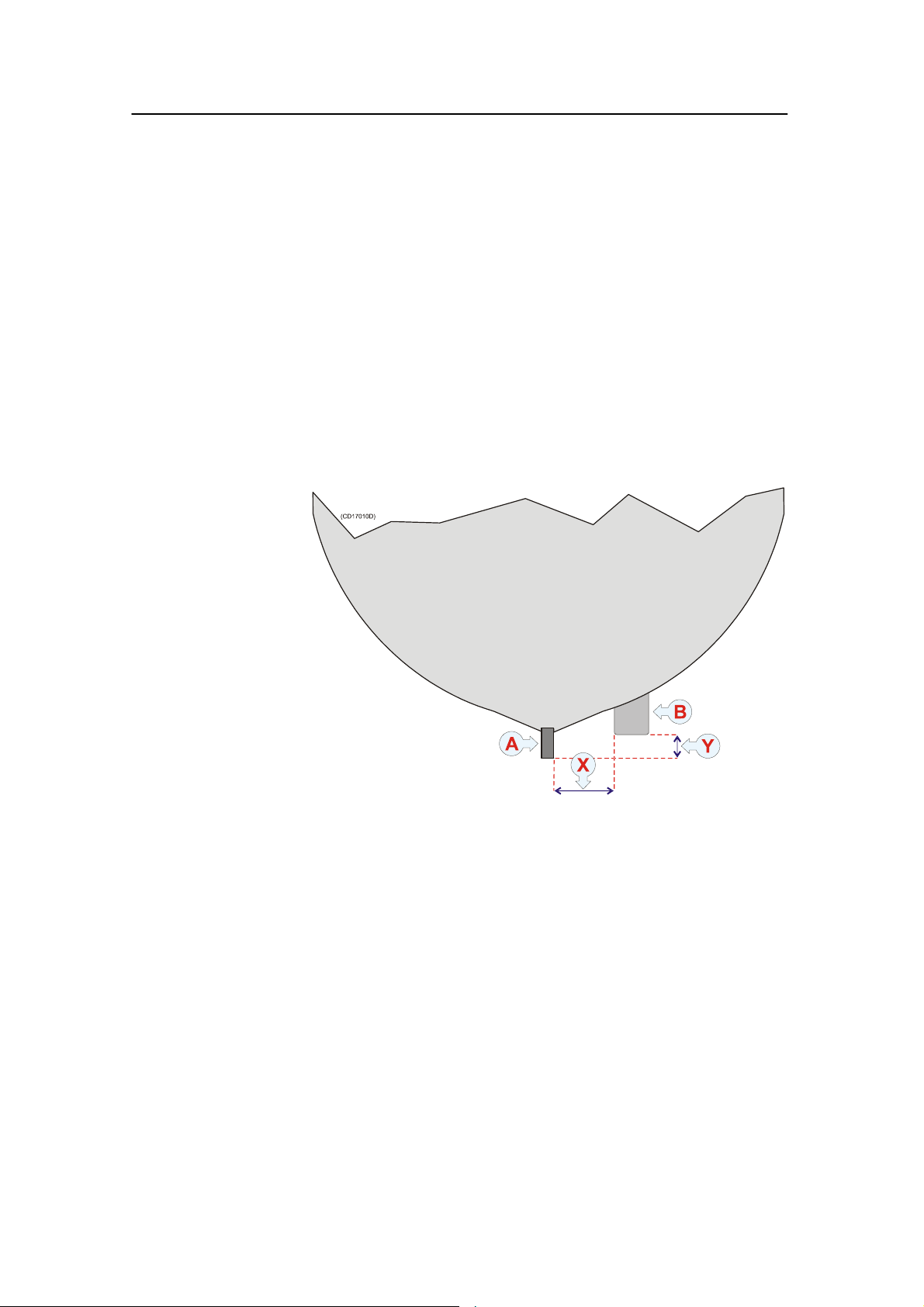

Physical location

The blister is placed on one of the sides of the hull, and the

distance from the keel is a trade off between a close distance

giving a turbulent flow of water in a narrow passage, and a large

distance bringing the transducer higher up and also more

affected by vessel roll. Normally a distance of approximately

1 m is a good compromise.

Observe the horizontal and vertical distances (X and Y) between

the keel and the transducer blister. On a medium sized vessel,

the horizontal distance (X) should be approximately 1 meter.

The vertical distance (Y) must in general be as small as possible.

This is important to prevent the keel from shadowing the

transducer beam in shallow waters.

32

(A) = Keel

(B) = Transducer blister

(X) = Horizontal distance between keel and blister

(Y) = Vertical distance between the blister surface and the keel

851-165101 / Rev.A

Page 41

Transducer installation

Box keel

Vessels with a box keel may use this for transducer installation.

The box keel is already the deepest part of the vessel. If the box

keel is too narrow to accommodate the transducer, it can be

widened, either symmetrically or to one side only. In the last

case the installation could also be described as a blister merged

into the keel.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production

of these. The mounting ring is welded to the hole in the box

keel, while the clamping ring fits around the edge of the

transducer body. Bolts through the clamping ring into the

mounting ring will then secure the transducer between them.

Note that several transducers use direction guides to allow

correct mounting.

Inclination of the transducer face

If possible, incline the transducer face approximately 1-2

degrees, so that the flowing water meets it directly. This assures

laminar water flow.

Smooth surface

Mounting screws or bolts must not be extruding from the box

keel. Ensure that the surface of the transducer face, the box, the

hull plating and putty around the transducer is as even and

smooth as possible. Obstructions on these surfaces will create

problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

851-165101 / Rev.A

33

Page 42

Simrad PI44

Example

The figure below illustrates a symmetrical box keel installation.

(A) = Box keel (D) = Cable in steel conduit

(B) = U-shaped support bar (E) = Cable service loop

(C) = Stuffing tube

34

851-165101 / Rev.A

Page 43

Transducer installation

Cable glands

The transducer cable must pass through the hull using approved

cable glands for the type of vessel in question.

A steel cable gland is normally used on professional vessels

with steel hulls. A bronze cable gland can be delivered as an

option for vessels with wood or fibreglass construction. Vessel

not to be classified can as an option use a cable gland made of

plastic.

Note: Simrad strongly recommends that a length of conduit is fitted

around transducer cable glands made of steel or bronze and

extended over the water-line inside the vessel. This precaution

reduces the danger of flooding in the event of gland failure and

transducers installed in this manner are also easier to replace.

Some vessels may experience difficulties finding suitable areas

of the hull for mounting transducer cable glands due to existing

water tanks, concrete ballast or other obstacles. A possible

solution in such cases is to run the transducer cables in a steel

conduit aft along the hull until a suitable cable gland location is

available. The respective cable gland can then be installed as

described in the following instructions.

Note: Simrad takes no responsibility for the correct installation of

cable glands, associated hull modifications and/or structural

support of transducer cable penetration. These activities are

subject to individual approval by the respective classification

society for the vessel in question.

Order numbers

Steel hull cable gland kit: 599-202216

Wood/GRP hull cable gland kit: 119-038200

Small vessel cable gland kit: 599-202182

851-165101 / Rev.A

35

Page 44

Simrad PI44

Cable gland installation for steel hulls

This cable gland kit is designed for steel vessels. It must be

welded to the hull plates.

(A) = Steel conduit

(B) = Stuffing tube, DNV

approved carbon steel st52.3

(C) = Washers, 24 x 8 x 2 mm

(D) = Rubber gasket

(E) = Packing nipple. Make

sure that you do not damage the

transducer cable by tightening

the packing nipple too hard!

(F) = Cable to the echo

sounder (or a junction box)

The gland gland kit includes all

of the necessary parts needed to

install the unit excluding

screws.

Simrad recommends that a one

inch steel conduit (that the

transducer cable will be run

through) with an inside

threaded diameter of

three-quarter inches is welded

to the gland’s stuffing tube. The

conduit must extend to above

the vessel’s water line.

36

851-165101 / Rev.A

Page 45

Transducer installation

Gland installation for wood or GRP hulled vessels

A bronze cable gland kit is available for wood and GRP vessels.

(A) = Packing nipple. Make

sure that you do not damage the

transducer cable by tightening

the packing nipple too hard!

(B) = Washers

(C) = Rubber gaskets

(D) = Hole diameter 28 mm

(E) = Steel conduit

(F) = Cable to the echo

sounder (or a junction box)

The gland gland kit includes all

of the necessary parts needed to

install the unit excluding

screws.

Simrad recommends that a one

inch steel conduit (that the

transducer cable will be run

through) with an inside

threaded diameter of

three-quarter inches is attached

to the gland’s packing nipple.

This connection must be

watertight, and the conduit must

extend to above the vessel’s

water line.

851-165101 / Rev.A

37

Page 46

Simrad PI44

Cable gland installation for smaller vessels

This cable glands made of plastic is designed for those smaller

vessels that do not need to be classified.

(A) = Packing nut (bronze).

Ensure that you do not to

damage the transducer cable by

tightening the packing nut too

hard!

(B) = Rubber gasket

(C) = Plastic disk

(D) = Rubber gasket

(E) = Stuffing tube

(F) = Backing nut (bronze)

(G) = Backing washer (plastic)

(H) = O-ring 42.5 x 3.0 N

(I) = O-ring 39.5 x 3.0 N

(J) = Cable to the echo sounder

(or a junction box)

Stuffing tube hole diameter: 36 mm ±1.5 mm.

Apply ample amount of sealant between the backing washer (H)

and the hull plate.

The cable gland kit contains all the listed parts, except the

sealant.

Note: The two O-rings must be clean, in good condition and free of cuts

or other defects which could affect their water-tight integrity.

Splicing

If you need to cut the transducer cable, you must splice it

correctly.

Note: DO NOT solder the wires together with only electrical tape for

insulation, as this will result in electrical noise and reduced

operational performance.

To splice the cable, use a metal junction box. The chassis of the

junction box must be grounded, but the cable shielding must

NOT be connected to the junction box ground.

38

851-165101 / Rev.A

Page 47

Transducer installation

Cable in steel conduit

It is strongly recommended to lay a steel conduit from the

transducer’s cable gland to the echo sounder transceiver, and to

pull the transducer cable through this conduit. There are two

reasons for this.

• First, it will make it easier at a later stage to replace the

transducer.

• Second, noise and i nterference from other electrical

equipment is greatly reduced.

With a steel conduit the installation will satisfy the EU

regulations for EMC interference. Without a steel conduit, there

is a risk of reduced echo sounder performance.

The steel conduit must be unbroken and watertight from the

transducer to above the water line. From there, the cable can be

pulled further, or a junction box can be installed to facilitate

further connections. Note that the steel conduit must act as a

continuous electrical screen all the way. To ensure proper

shieklding, the conduit must be electrically connected to the

echo sounder transceiver chassis.

Steel conduit dimensions:

• minimum 35 mm inner diameter

• minimum 6 mm wall thickness (4.5 mm if galvanised).

If two or more transducers are installed close to each other it is

possible to pull their cables in the same steel conduit, provided

the conduit diameter is increased accordingly. However, for easy

replacement it is recommended that each transducer has its own

steel conduit.

851-165101 / Rev.A

39

Page 48

Simrad PI44

Handling and maintenance

Do not lift the transducer by the cable.

Some transducers are delivered with a cover plate on the face

for protection during transport. Let this plate stay on as long as

possible, but do not forget to remove it before the vessel goes

into the sea.

An anti-fouling paint may be applied to the transducer face.

Because some paint types may be aggressive to the polyurethane

in the transducer face, please consult Simrad’s list of approved

paints on the next page.

Note: Arctic tanks have acoustic windows made of polycarbonate.

These must neither be painted nor cleaned with chemicals.

During dry docking of the vessel, the transducer face may be

cleaned for shells and other marine fouling. Be careful not to

make cuts in the transducer face. Use a piece of wood or a very

fine grade emery paper.

40

851-165101 / Rev.A

Page 49

Transducer installation

Approved anti-fouling paints

This is Simrad’s list of approved antifouling paints on

polyurethane transducer housing.

From Jotun Paints, Sandefjord Norway:

• Antifouling Seamate HB 33

• Antifouling Seamate HB 66

• Antifouling Seamate HB 99

• Racing

• Non-stop

From International Paints:

• Intersleek tie coat + 425 FCS

- BXA386/BXA390/BXA391 Grey

- HKA563/HKA570/HKA571 Yellow

Mix BXA386, BXA390 and BXA391 first, then apply. When

dry, mix HKA563, HKA570 and HKA571, apply.

From Hempel IFA Coatings AS:

• Hempel A/F Classic 76550

From Jotun-Henry Clark Ltd:

• Anti-fouling Seaguardian

From International Marine Coatings:

• Intersmooth 360 Ecoloflex SPC

• Micron Ekstra

Note: Refer to the manufacturer’s documentation and data sheets for a

complete procedure.

851-165101 / Rev.A

41

Page 50

Simrad PI44

3 PURSE SEINE HYDROPHONE

Purpose

The purpose of this chapter is to provide general guidelines for

the installation of the PI44 hydrophone for purse seining.

Note: If your vessel shall be fitted for trawl operations, DO NOT

install the hydrophone(s) as explained in this chapter!

Order numbers

Purse hydrophone, complete: HYD-202711

Purse hydrophone, without cable gland: HYD-205075

Topics

→ Precautions, page 43

→ Considerations, page 44

→ Pre-installation checklist, page 48

→ Location, page 50

→ Coverage area, orientation and tilt, page 51

→ Mounting arrangement, page 54

→ Dual hydrophones, page 57

→ Hydrophone protection, page 59

→ Hydrophone cable, page 62

→ Installation drawings, page 67

42

851-165101 / Rev.A

Page 51

Purse seine hydrophone installation

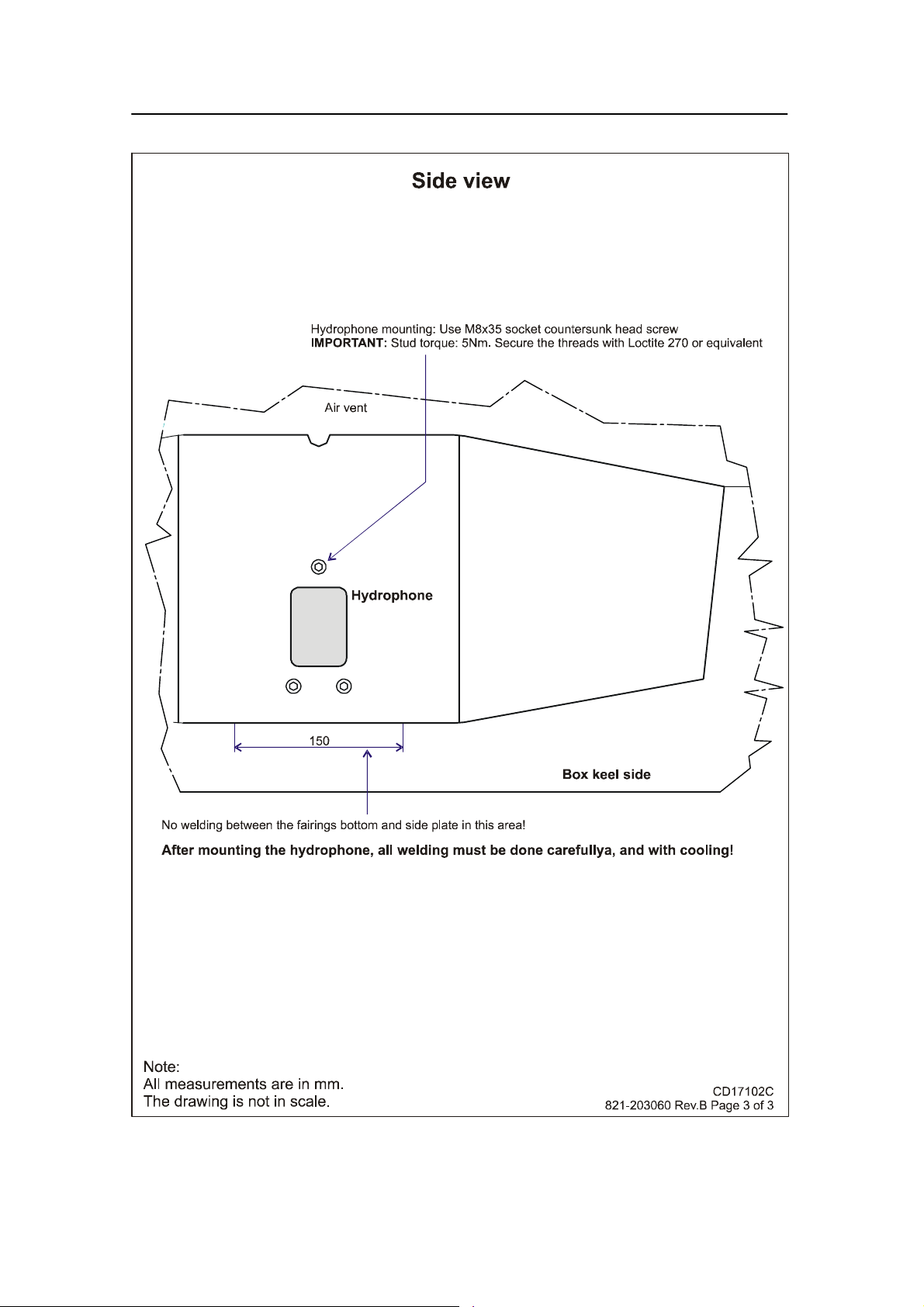

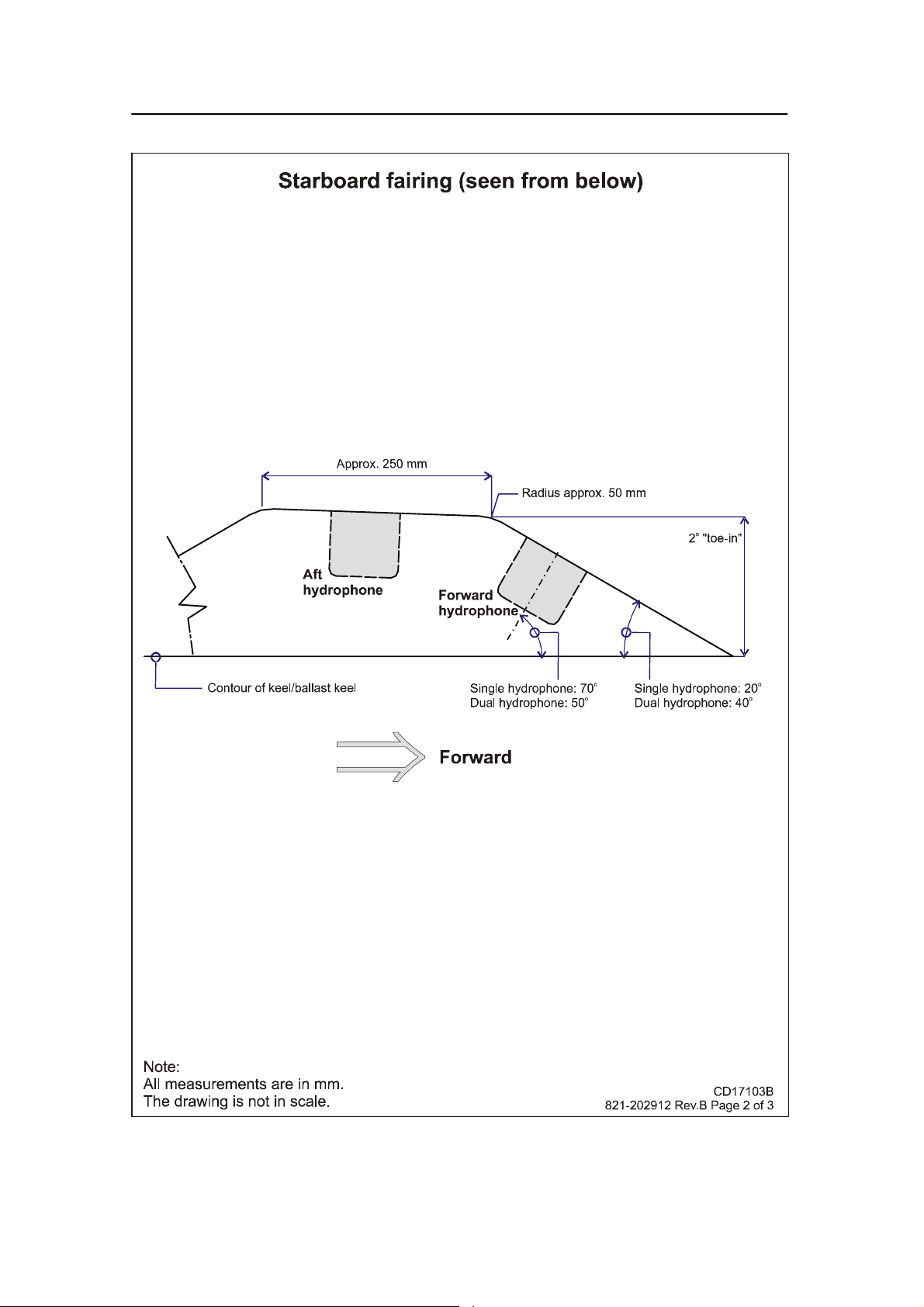

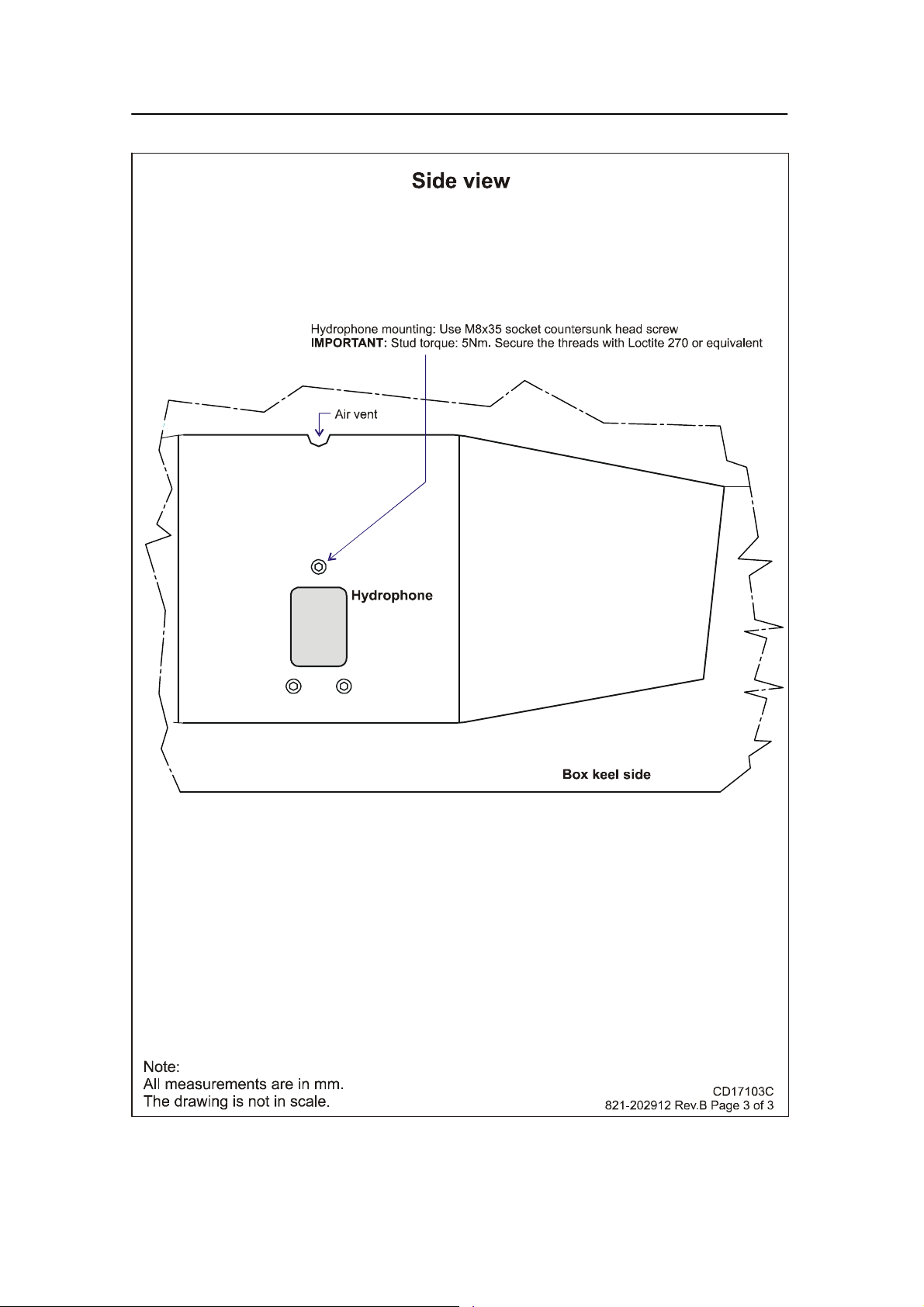

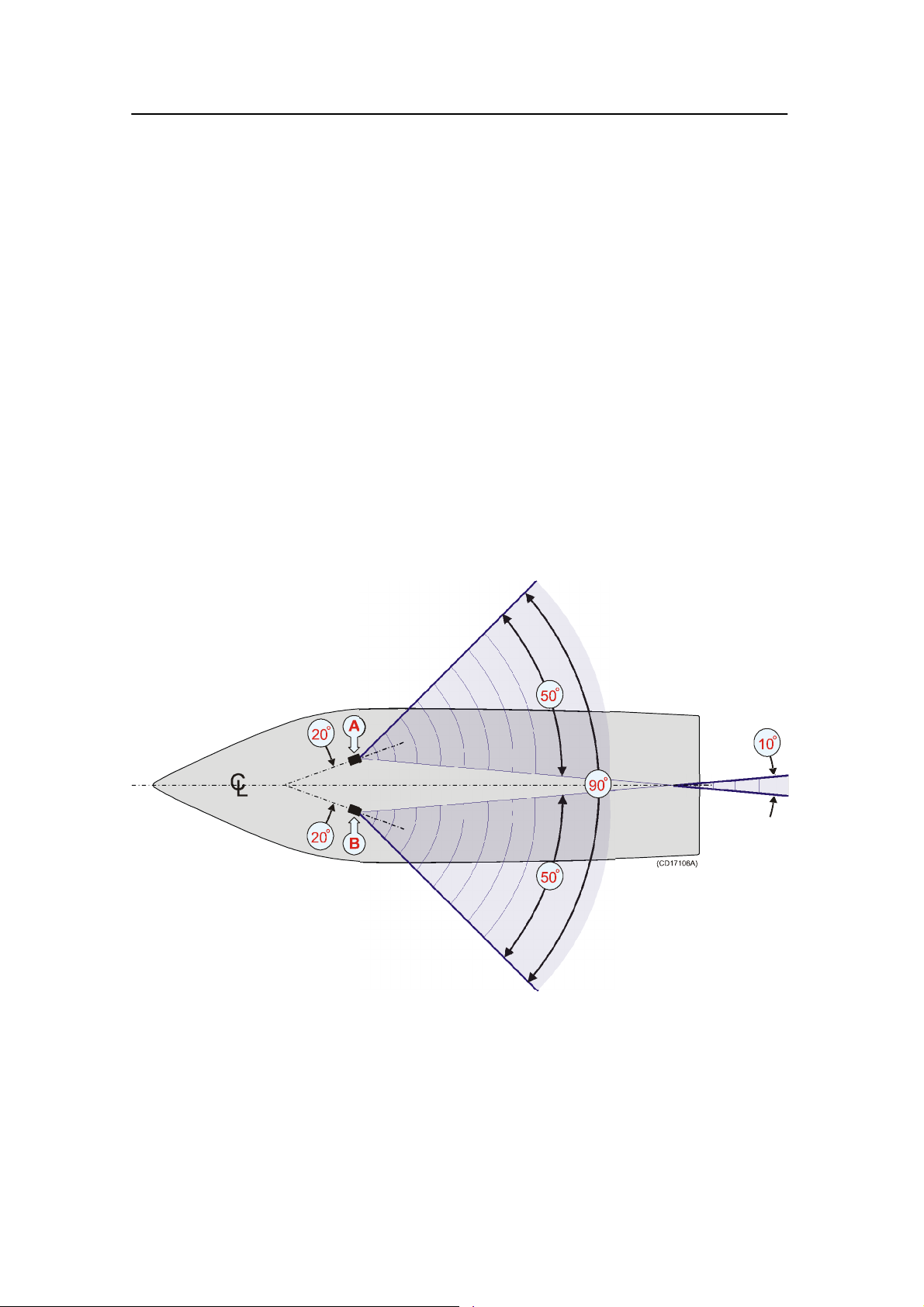

Installation precautions

Caution: The following precautions must be observed. Failure to

do so can result in damage to the hydrophone which

may render the PI44 catch monitoring system

inoperative.

1 Observe the maximum allowable torque warning of 5 Nm

when tightening the hydrophone studs.

2 Use only M8x30 socket countersunk head screws for

mounting the hydrophone.

3 Secure threaded hydrophone hardware with Loctitet 270

or the equivalent.

4 Do not paint the hydrophone.

5 Do not sand-blast, power or steam wash the hydrophone.

6 Do not scrape the hydrophone with metal or other hard

objects that may damage the polyurethane sheathing.

7 Do not strike the hydrophone.

8 Do not expose the hydrophone to harsh chemicals.

9 Do not perform hot work in the vicinity of the

hydrophone.

10 Do not lift the hydrophone by its cable.

851-165101 / Rev.A

43

Page 52

Simrad PI44

Considerations

Correct installation of the PI44 hydrophone is vital to the

system’s performance. Several variables must be taken into

consideration, the most important of which is the vessel’s

construction. This guide is for use in selecting the best location

for the hydrophone and includes a brief description of areas to

be avoided.

Note: Simrad strongly suggests that this information is read

thoroughly, and that the instructions are understood and

followed. Proper hydrophone placement is difficult to achieve,

but essential for correct system operation.

Depth

Water just below the sea surface contains a myriad of small air

bubbles created by the turbulence of breaking waves. The first

five to ten metres may be heavily saturated in moderate seas

with the greatest concentration and largest bubbles closest the

surface. Air bubbles disrupt sound waves in water. The degree

to which they absorb and reflect such energy vary, but in some

cases they can block hydrophone reception. It is therefore

recommended to mount the unit as deep as possible.

Pounding danger

When a vessel is in ballast and pitching in heavy seas, it is

important that the hydrophone is not lifted out of the water.

Should a vessel pound so heavily that the hydrophone be

exposed, sound reception will be interrupted and the unit may

be damaged on impact.

The boundary layer

The flow of water in the immediate vicinity of the hull of a

moving vessel is known as a boundary layer. This flow is

responsible for underwater noise that can disturb hydrophone

reception and its thickness is contingent on a vessel’s:

• Hull form

• Size and number of underwater protrusions

• Velocity

• Hull roughness

The boundary layer is thin (laminar flow) near the vessel’s bow

and becomes thicker (turbulent flow) as it moves aft. Laminar

flow is smooth with streamlines approximately parallel to the

hull and contributes relatively little to noise created by flow.

Conversely, turbulent flow is more disorderly and in turn

contributes to a greater extent.

44

851-165101 / Rev.A

Page 53

Purse seine hydrophone installation

Boundary water layers:

(A) = Turbulent flow

(B) = Laminar flow

(C) = Air bubbles in the water

Air bubbles may also be introduced into the boundary layer. If

the vessel’s hull has little flare and is relatively narrow, bubbles

may escape to the sea surface without incident. On the other

hand a wide, flat hull with minimal deadrise is prone to trapping

air bubbles no matter how little flare it has. Regardless of a

vessel’s hull form, hydrophones are generally recommended to

be installed on the forward part of the hull to minimising the

influence of both turbulence and air bubbles.

Bulbous bow

The bulbous bow may be an acceptable hydrophone location.

Should this position be chosen, the foremost part of the bulb is

often best, but also the m ost susceptible to pounding.

851-165101 / Rev.A

Recommended location of the transducer on a bulbous hull:

(A) = Thruster

(B) = Hydrophone location

45

Page 54

Simrad PI44

Propeller noise

A vessel’s main propeller is the dominant source of underwater

acoustic noise. When ever possible, hydrophone(s) should be

located as far a way as possible from the main propeller and

never closer than ten meters. Hydrophone(s) should not be

mounted in the direct acoustic path (line-of-sight) of the main

propeller unless absolutely necessary.

The primary cause of propeller noise is cavitation (small

bubbles generated by the partial vacuum created by the blades as

they pass through the water). The resulting underwater acoustic

noise from cavitation is normally weakest on the side of the

vessel were the propeller blades rotate toward the surface and

most pronounced on the side were they rotate toward the

bottom. Most vessels have clock-wise rotating propellers

resulting in their port sides being less effected by cavitation

induced noise than their starboard.

To minimise the negative effect of cavitation noise on

hydrophone performance, installation is generally recommended

as follows:

• Single hydrophone - if only one hydrophone is to be

installed on a vessel with a clock-wise rotating propeller, it

should be located on the port side of the hull.

• Dual hydrophones - if two hydrophones are to be installed,

they should be placed on either side of the vessel’s keel.

When in doubt about the best fore-and-aft location for

hydrophones, they can be placed at different distances from

the bow (for example the port hydrophone can be a little

further aft than the starboard, approximately three to five

meters for a thirty-five meter vessel). When trawling in both

deep and shallow water the hydrophones should also be tilted

differently with respect to each other. The hydrophone that is

closest to the propeller should have the greatest tilt and be

located on the port side of the hull for a vessels with

clock-wise rotating propellers.

Bow/sternthruster noise

46

Bow and sternthruster operation may severely effect

hydrophone reception. Hydrophone installation closer than four

meters to either is strongly discouraged.

851-165101 / Rev.A

Page 55

Purse seine hydrophone installation

When not in operation, bow/sternthruster tunnels create

turbulence and hence underwater noise when a vessel is under

way. Also, as a vessel pitches in heavy weather, thruster tunnels

may fill with air or aerated water which can disturb hydrophone

reception when released. Hydrophone installation should take

into regard the noise and down stream disturbances found

around and aft of thrusters.

Note: Hydrophone installation must take into regard the noise and

down stream disturbances found around and aft of thrusters.

Noise from protruding objects and other sources

The primary sources of underwater disturbance (other than a

vessel’s main propeller and bow/sternthruster) that affect

hydrophone reception are:

• Main or bilge keels

• Zinc anodes

• Cooling elements protruding from the hull

• Equipment such as sonar hydrophones and pitot tubes

• Sea chests

• Overboard discharges

• Dents in the hull

All appendages to the hull, indentations and pipe outlets are

potential sources of underwater noise. They may act as resonant

cavities amplifying noise at certain frequencies, create cavitation

or turbulence. Hydrophones should not be located in the vicinity

of such objects and especially not immediately aft of them.

Minimum distance to sonar and echo sounder

transducers

To avoid interference, PI44 hydrophone(s) must be installed as

far away as possible from other sources of underwater acoustical

energy such as active sonars and echo sounder transducers.

Hydrophones should be placed at least two meters from such

equipment when ever possible and distances of less than one

meter avoided. Hydrophones installed in close proximity to

underwater acoustical sources should be located as far aft as

possible from them, and most importantly, not be subjected to

direct (frontal) transmission from such equipment.

Drop keel

In the event the vessel is equipped with a drop keel, the

hydrophones should be mounted aft of it. The choice between

installing a one, or two hydrophone system should be based on

the same horizontal and vertical coverage requirements for

vessels operating under similar conditions with fixed keels.

851-165101 / Rev.A

47

Page 56

Simrad PI44

Pre-installation check-list

Choosing the optimal locations for hydrophones is not always

easy, but decisions made at this phase of the installation process

are critical to future system performance. Determining the best

configuration for a given vessel often involves a compromise

between contradicting requirements.

To aid in this evaluation process Simrad recommends that this

installation manual be read thoroughly and the following check

list completed before deciding on a final installation strategy for

the PI44 system.

1 Hydrophones do not have a direct line-of-sight to the main

propeller and are placed where the vessel’s hull protects

them from underwater acoustic noise as well as possible.

2 Hydrophones must always have an unobstructed

line-of-sight to the sensors attached to the gear for the

system to operate properly.

3 The distance from the main propeller to the hydrophones

should be greater than ten meters. A separation of less

than ten meters can reduce system range significantly.

4 If thrusters are installed, hydrophones should be located at

least four meters from them.

5 Avoid locating hydrophones behind thrusters where air

bubbles from their tunnels generated when the vessel

pounds can block sensor signals.

6 Hydrophone should not be placed forward of other

underwater acoustic equipment and preferably behind it as

far away as possible, distances of less than one meter

should be avoided.

7 There should never be possible sources of underwater

acoustic noise placed in front of hydrophones.

8 Remember that hydrophones are to be mounted with their

long axis up (in the vertical plane).

9 Hydrophones installed in blisters should be located away

from the vessel’s keel and as deep as possible on the hull.

10 Hydrophones installed in shoes along the vessel’s keel

should be mounted as deeply as possible.

48

11 Hydrophone cables that are run in conduit along the

outside of the vessels hull should be arranged as to

produce the least amount of underwater acoustic noise as

possible.

12 Blisters and shoes should be as streamlined as possible and

have all of their corners rounded to minimize the

generation of underwater acoustic noise.

851-165101 / Rev.A

Page 57

Purse seine hydrophone installation

13 Conduit used to run hydrophone cables in the interior of a

vessel’s hull should extend well over its water line.

14 If you install both trawl and purse seine hydrophones, do

not confuse the two types. The Trawl hydrophones are

marked with order number 314-205250, while the Purse

seine hydrophones are marked with order number

314-202275.

15 Other well-founded information or experience regarding

hydrophone installation be available should also be

evaluated even though not directly mentioned in these

instructions.

851-165101 / Rev.A

49

Page 58

Simrad PI44

Optimal location of purse seine

hydrophones

The most influential factors effecting hydrophone reception

common to most vessels are:

• Noise from cavitation generated by the main propeller.

• Air bubbles in the water around the hydrophone which

impede acoustic signals.

• Noise from other acoustic equipment mounted in close

proximity.

Taking these main sources of disturbance into consideration, the

generally recommended location for mounting a single