Page 1

M5000 Series Monitors

User Guide

ENGLISH

www.navico.com/commercial

Page 2

Page 3

Preface

As Navico is continuously improving this product, we retain the right to make changes to the

product at any time which may not be reected in this version of the manual. Please contact

your nearest distributor if you require any further assistance.

It is the owner’s sole responsibility to install and use the equipment in a manner that will

not cause accidents, personal injury or property damage. The user of this product is solely

responsible for observing safe boating practices.

NAVICO HOLDING AS AND ITS SUBSIDIARIES, BRANCHES AND AFFILIATES DISCLAIM ALL

LIABILITY FOR ANY USE OF THIS PRODUCT IN A WAY THAT MAY CAUSE ACCIDENTS, DAMAGE

OR THAT MAY VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user guides and other

information relating to the product (Documentation) may be translated to, or has been

translated from, another language (Translation). In the event of any conict between any

Translation of the Documentation, the English language version of the Documentation will be

the ocial version of the Documentation.

This manual represents the product as at the time of printing. Navico Holding AS and its

subsidiaries, branches and aliates reserve the right to make changes to specications

without notice.

Copyright

Copyright © 2016 Navico Holding AS.

Warranty

The warranty card is supplied as a separate document.

In case of any queries, refer to the brand web site of your display or system:

www.navico.com/commercial

xxx/xx

Compliance Statements

The M5000 series monitors complies with:

• IEC 60945 (2002)

• IEC 62288 edition 1 (2008)

• IEC 62288 edition 2 (2014)

• IEC 60174

The relevant Declaration of Conformity is available in the following website under model

documentation section: www.navico.com/commercial

The Wheelmark

The Marine Equipment Directive 96/98/EC (MED), applies to all new ships, to existing ships not

previously carrying such equipment, and to ships having their equipment replaced for ships

ying EU or EFTA ags.

This means that all system components covered by annex A1 must be type-approved

accordingly and must carry the Wheelmark, which is a symbol of conformity with the Marine

Equipment Directive.

The M5000 Series (M5016, M5019, M5024 and M5027) monitors comply with IEC62388 Ed.2

for Radars. The monitors can be used as part of a radar system applying for type approval.

The M5024 and M5027 monitors are color calibrated according to ECDIS requirements (IHO

S-52). Only the M5024 and M5027 monitors can therefore be used as part of an ECDIS system

applying for type approval.

¼ Note: The monitors only comply with the Marine Equipment Directive as part of a type

approved system, not as stand-alone units.

Navico has no responsibility for incorrect installation or use of the monitor, so it is essential for

the installer to be familiar with the relevant requirements as well as with the contents of the

manuals, which covers correct installation and use.

Preface | M5000 Series User Manual

|

3

Page 4

Trademarks

• NMEA 2000 is a registered trademark of the National Marine Electronics Association

• B&G, Simrad, StructureScan, Navico, SonicHub, SimNet, Skimmer, InsightHD, Broadband Radar

and Broadband Sonar are trademarks of Navico, registered in the US and other countries

• The terms HDMI and HDMI High-Denition Multimedia Interface, and the HDMI Logo are

trademarks or registered trademarks of HDMI Licensing LLC in the United States and other

countries

About this manual

This manual is a reference guide for installing and operating the Simrad M5000 Series

monitors.

Important text that requires special attention from the reader is emphasized as follows:

¼ Note: Used to draw the reader’s attention to a comment or some important information.

Warning: Used when it is necessary to warn personnel that they

should proceed carefully to prevent risk of injury and/or damage to

equipment/personnel.

4 |

Preface | M5000 Series User Manual

Page 5

Contents

6 Introduction

6 Items included

7 Installation

7 Cutout template

8 Fixing options

8 Flush-mounting the display

11 VESA mounting the display

12 Connecting the display

12 Rear connections

12 Cable retention

13 Connecting power

14 Color calibration connection for MARIS ECDIS900 MK5 PC

14 Serial connection using the CT&A cable

15 Operating the display

15 First time operation

16 OSD menu

18 Cleaning and maintenance

18 Display removal

18 Replacing the gasket

19 Replacing the lters

19 Other maintenance

19 Checking current rmware version

19 Installing an update

20 Troubleshooting

21 Accessories

22 Specications

23 Dimensional drawings

Contents | M5000 Series User Manual

|

5

Page 6

1

Introduction

The Simrad M5000 series monitors oer a low prole solution for displaying video from a

variety of sources. This includes 4 models; M5016, M5019, M5024 and M5027.

• The whole M5000 series range complies with IEC62388 for Radars.

• The M5024 and M5027 monitors are color calibrated according to ECDIS requirements. The

monitors can be used as part of a type approved ECDIS system.

¼ Note: A color calibrated monitor used in an ECDIS system should be regularly tested to detect

the stage at which the display can no longer be used to discriminate important features by

color. Refer to the color verication process in your ECDIS documentation.

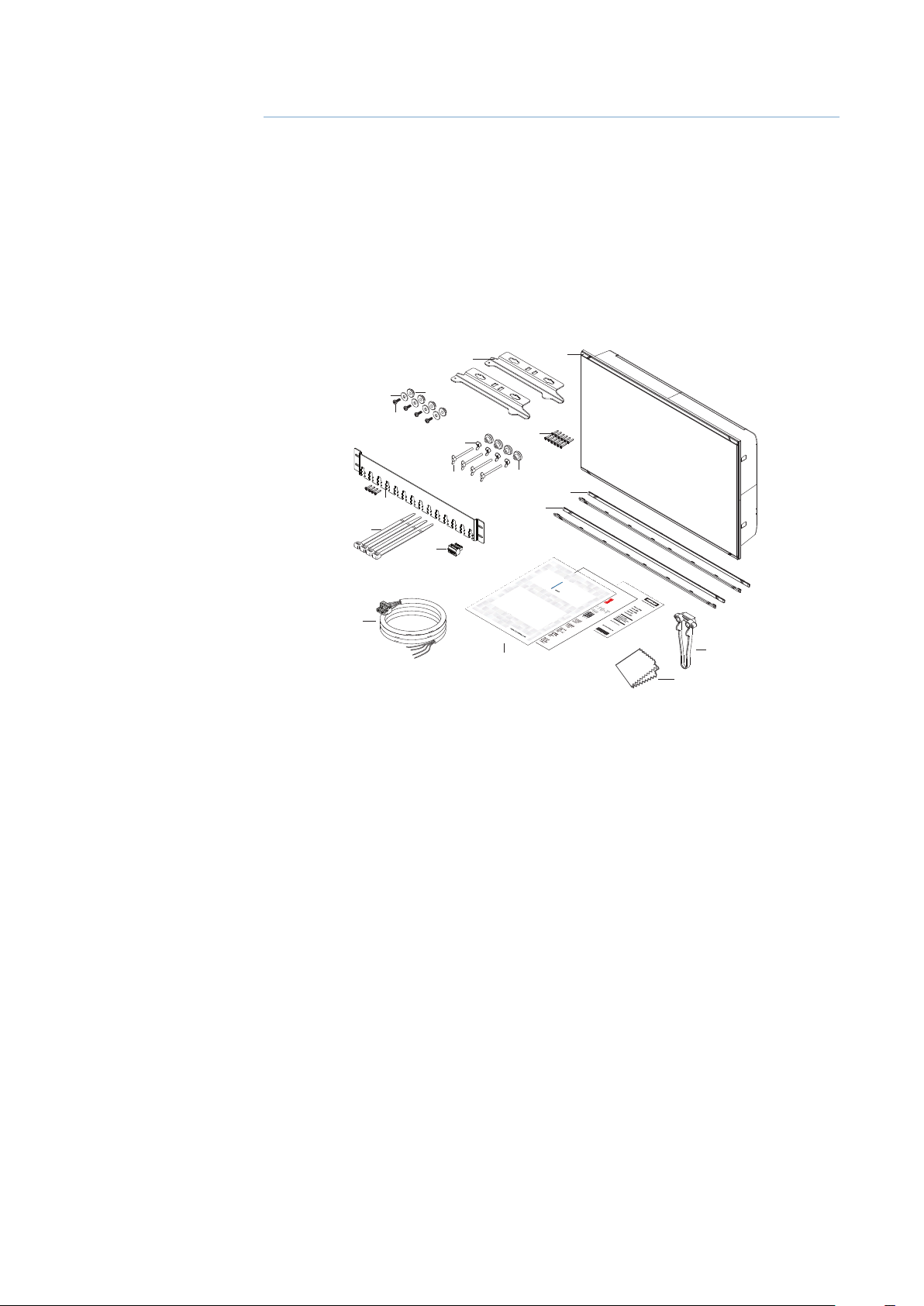

Items included

2

5

3

4

6

1

9

7

10

11

12

13

1 Monitor

2 Dash mount brackets (x2)

3 Washer, M4, 12 mm, SS (x4)

4 Phillips pan head machine screw, M4 x 12 mm, SS (x4)

5 Plastic spacer (x4)

6 Wing nut M5 (x4)

7 Wing head machine screw (x4)

8 Plastic stopper - dash mount (x4)

8

15

14

16

17

18

6 |

9 Phillips pan head self-tapping screws 4G x 1/2”

10 Cable retention bracket with screws 4G x 1/2” (x4)

11 Cable ties (x4)

12 Connector block (serial data)

13 Power cable with connector

14 Bezel trim, black (x2)

15 Bezel trim, silver (x2)

16 User manual , Cut-out template and Warranty card

17 Drill and screw guide tool

18 Microber cleaning cloth

Introduction | M5000 Series User Manual

Page 7

2

Installation

It is recommended that the unit be powered and connected to a video source to assist in

selecting a suitable mounting location, prior to irreversible modication of the vessel’s helm

station. When planning the monitor location, the following points should be considered to

ensure safe, comfortable and reliable operation:

• Convenience - the mounting location should be easily accessible to allow operation of the

controls and should enable easy viewing of the monitor.

• Viewing distance - the monitor is designed with a nominal viewing distance of 1 meter

(3 ft).

• Access - there must be sucient space behind the monitor to allow cable connections to the

rear connectors, avoiding tight bends in the cable. Also ensure there is sucient access for

tightening wing nuts/screws on the mounting brackets, where used.

• Interference - the selected location should be far enough away from devices that may

cause interference, such as motors, generators and radio transmitters/receivers.

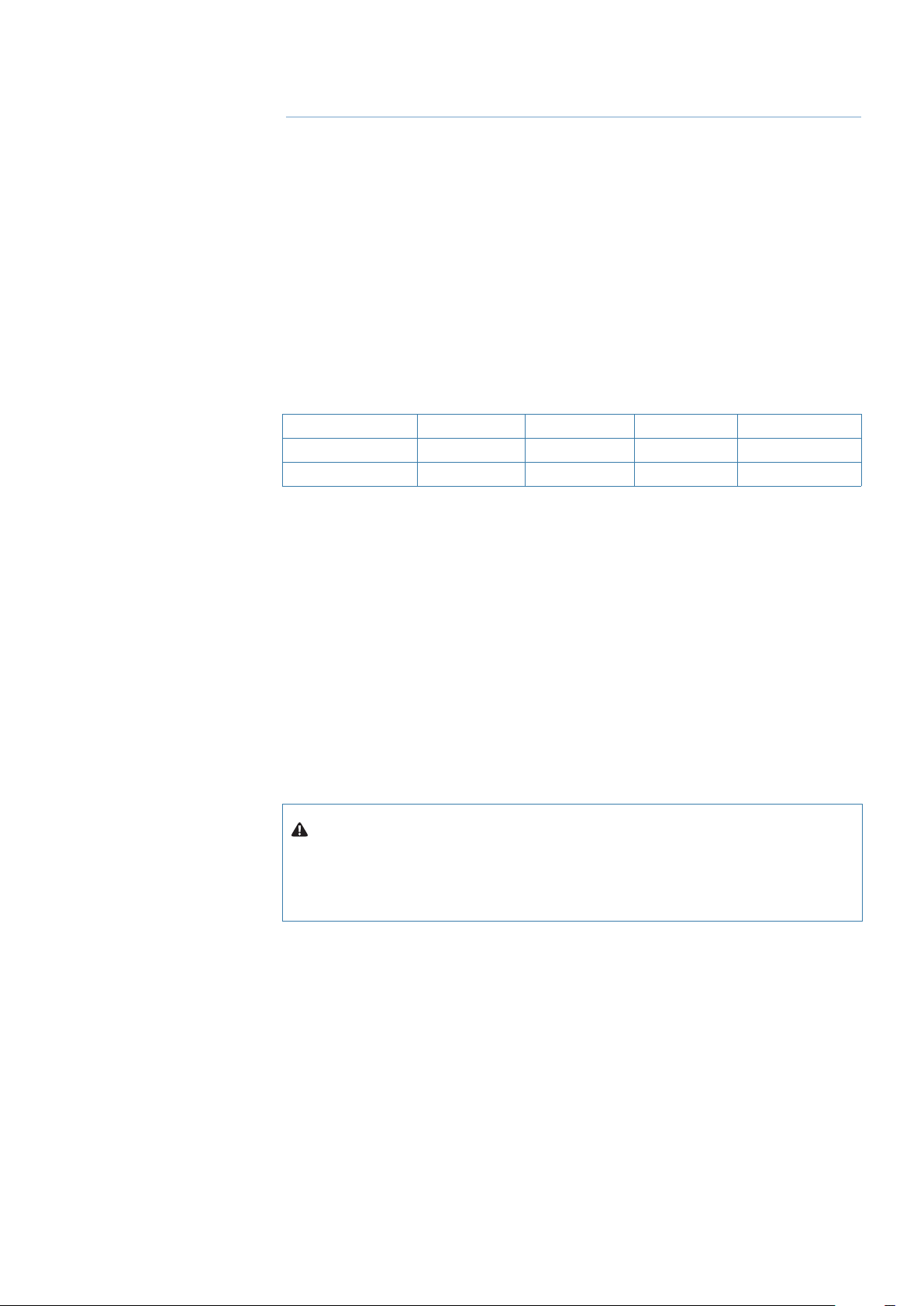

• Compass safe distance -

16” monitors 19” monitors 24” monitors 27” monitors

Standard compass 1.90 m (6.3 ft) 2.00 m (6.6 ft) 2.30 m (7.6 ft) 1.4 m (4.6 ft)

Steering compass 1.10 m (3.7 ft) 1.10 m (3.7 ft) 1.20 m (4.0 ft) 0.75 m (2.4 ft)

• Environment - to prevent overheating, do not restrict airow at the rear of the monitor;

ensure that there is adequate ventilation, particularly if the monitor is pod-mounted. If the

space behind the monitor is air conditioned or cooled by a fan, it will help in keeping the

unit’s temperature down. The monitors are designed to operate in protected environments,

however, we recommend the units not be mounted in a location where they will be exposed

to direct sunlight for prolonged periods.

The monitor should be protected from physical damage and excessive vibration. Although

the monitor is waterproof from the front when installed correctly, it is good practice to mount

it in a protected area away from prolonged and direct exposure to rain and salt spray.

¼ Note: Where ush mounted, the enclosure should be dry and well ventilated. The ventilation

of the space behind the unit should be enough to prevent excessive heat build up as a combined result of radiated heat o the monitor, and sunlight heating of the enclosure. In very

small enclosures, it may be required to t forced cooling.

Warning: Inadequate ventilation and subsequent overheating of

display may cause unreliable operation and reduced service life. Ensure

enclosure does not con sistently exceed +55° C (+131° F) during normal

daytime operation (in direct sunlight, and at full screen brightness).

Cutout template

Use the supplied scale template to help mark up the cutout area.

¼ Note: Always check the template dimensions against the physical monitor to ensure

dimensions are correct, prior to making the cutout.

Installation | M5000 Series User Manual

|

7

Page 8

Fixing options

REMOVE SHADED AREA

*988-10455-001*

NOTE:

DO NOT SCALE

PRINT 1:1

IMPORTANT. Do not use this template if it has been rescaled

by copying or prin

ng. If this is not the original, or is a print

from a le, please check the dimension lines below are to

scale before use.

IMPORTANT. Ne pas u

liser ce gabarit s’il a été photocopié ou

imprimé en format réduit ou agrandi. Si ce gabarit n’est ni un

original ni une version imprimée d’un

chier PDF, veuillez

véri er qu’il est à l’échelle avant de l’u

liser.

IMPORTANTE. no usar la plan

lla si hay peligro que la escala

original exacta se ha alterado por copias o procesos de

impresión imprecisos. Si esto no es el original, o un PDF, veri

car que las líneas abajo están a la escala antes de usar.

WICHTIG. Diesen Vordruck nicht verwenden, wenn er durch

Kopieren oder Drucken im Maßstab verändert wurde. Sollte

es nicht das Original oder ein PDF-Ausdruck sein, müssen

untenstehende Zeilen vor erwendung an den rich

gen

Maßstab angepasst werden.

BELANGRIJK. Gebruik deze mal niet indien de schaal is veranderd doordat het is gecopieerd of gedrukt. Indien deze mal

niet het origineel of een print van PDF is, controleer dan of de

onderstaande lijnen de juiste schaal zijn voordat u ze gebruikt.

IMPORTANTE. Não u

lize este gabarito se a escala do mesmo

ver sido alterada por cópia ou impressão. Se não for o

original ou uma cópia impressa de um arquivo PDF, veri que

as linhas abaixo, para acertar a escala antes da u

lização.

VIKTIGT. Använd inte denna mall om den skalats om genom

utskri

eller kopiering. Om de

a inte är originalet eller en

utskri

från en PDF, kontrollera a

linjerna nedan stämmer

med skalan innan det används.

IMPORTANTE. Non u

lizzare questo modello se è stato

ridimensionato copiandolo o stampandolo. Se questo non è

l’originale o la stampa di un le PDF, veri care se le linee che

seguono devono essere dimensionate prima di essere u

lizza-

te.

TÄRKEÄÄ. Älä käytä tätä kaaviota, jos sen mi

akaava on

muu

unut kopio-idessa tai tulostaessa. Jos tämä ei ole alku-

peräinen tai PDF tuloste tarkista rajat mi

akaavasta alla

ennen käy

öä.

注意:请尽量不要使用本安装挖孔尺寸模版图的复印件。

如果使用复印件,则在使用之前请确认其比例一定要与原

件大小必须一致。

중요: 복사나 출력으로 크기가 조정 된 경우 이 템플릿을

사용하지 마십시오. 원본이 아니거나 인쇄물이면,

사용하기 전 아래 치수선의 눈금을 확인 해 주십시오.

注:このテンプレートは印刷やコピーによって縮尺が変

わっていることがありますので使用しないで下さい。テ

ンプレートがオリジナルのものでない場合には、下の寸

法線を使って縮尺を確認してください。

ВНИМАНИЕ: Не используйте эту инструкцию, ес

ли она была изменена в размерах при копирова

нии или распечатке. Если вы используете не ор

игинал, а распечатку из файла, убедитесь в соо

тветствии размеров линейки в нижней части и

нструкции с действительными размерами.

Check dimensions before cutting

12"

300 mm

L

C

L

C

192.5 mm (7.58")

186.0 mm (7.32")

192.5 mm (7.58")

186.0 mm (7.32")

200.0 mm (7.87")

117.5 mm (4.63")

111.0 mm (4.37")

130.0 mm (5.12")130.0 mm (5.12")

117.5 mm (4.63")

111.0 mm (4.37")

200.0 mm (7.87")

385.0 mm (15.16")

372.0 mm (14.65")

400.0 mm (15.75")

235.0 mm (9.25")

222.0 mm (8.74")

260.0 mm (10.24")

ZM-16

Marine Monitor

B&G

X4

1

3

x4

x2

4

CLICK

5

6

7

2

The M5000 series monitors can be dash or bracket mounted (using optional VESA adaptor).

When dash mounting, unit should be tted using the rear mounted dash mount brackets,

and bezel screws from the front. Exclusion of the dash mount bracket will increase strain on

bezel screws and adjacent bezel plastics, and is not recommended.

¼ Note: The VESA adaptor xing option is NOT tested against IEC 60945. Monitors that are part

of a type approved system can therefore NOT use the VESA bracket mounting option.

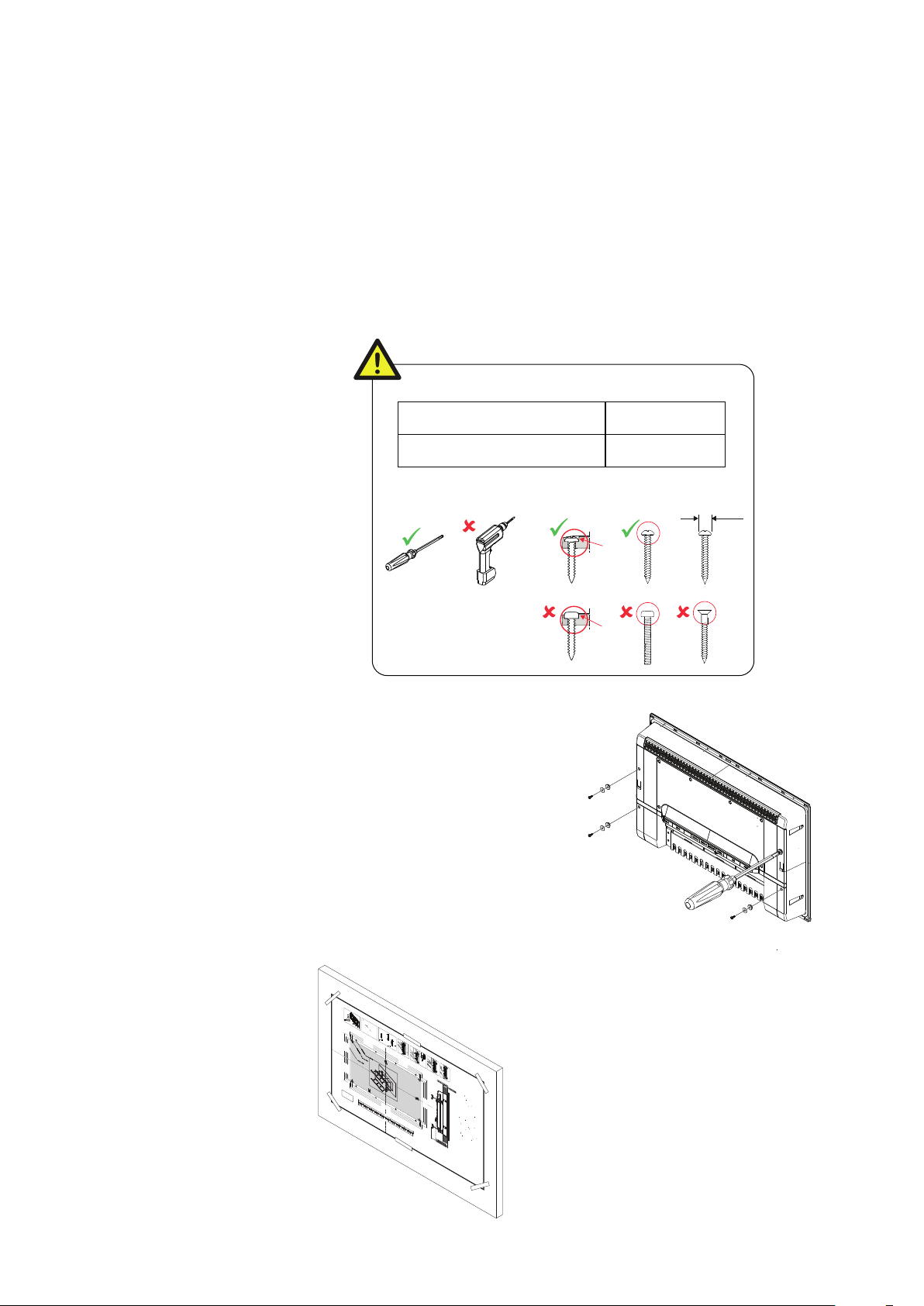

Flush-mounting the display

¼ Note: The following guidelines and warnings apply:

Important drill bit size selection information

Soft materials e.g. Plywood

Hard materials e.g. GRP, Acrylic, hardwoods

Front mount screw recommendations

1. Fit the supplied M4 machine screws,

washers, and plastic spacers to each of

the four threaded ttings on the back

case of screen. Hand tighten only.

1.9 - 2.3 mm (5/64")

2.3 - 2.5 mm (3/32")

Max 5.5 mm

(0.22”)

2. Tape appropriate mounting

template in place on dash, and

ensure cutout lines are level relative

to a reference point on dash.

3. Drill cutout corners with a small

pilot drill bit followed with 13 mm

drill bit. Complete cutout with

jigsaw or similar tool.

8 |

Installation | M5000 Series User Manual

¼ Note: It is recommended to drill the

screw pilot holes using the drill and

screw guide tool included in the

box.

Page 9

4. Place the display in the dash hole.

5. Place the guide tool on the glass of the display.

6. Slide the tool across so the drill bit hole guide lines up with the center of a screw

location hole on the case of the display.

7. Drill the pilot hole.

¼ Note: Before drilling the rest of the pilot holes it is recommended to secure the

display with at least one screw to allow for movement in the dash cutout.

8. Insert one of the supplied screws in to the screw guide and tighten using a hand

screw driver.

9. Repeat for the rest of the mounting screws.

Installation | M5000 Series User Manual

10. Wind wing nut on to wing screw,

then wind the wing screw assembly

in to bracket till approximately 5

mm of threaded rod protrudes

through other side of bracket.

11. Fit stopper foot on to end of wing

screw.

12. Complete for both threaded holes

on each bracket.

|

9

Page 10

13. Fit brackets to rear of display, aligning

‘key holes’ on bracket with screws on

back of display case.

14. With bracket making contact with

back of monitor, slide bracket down

till it engages with a click and is

held in place.

CLICK

15. Wind in the wing screw, until stoppers

make rm contact with rear of

dashboard material.

16. Check front of unit, ensuring that unit’s

bezel is making even contact with the

dash surface.

¼ Note: Not applicable for M5027

monitor.

17. Hand tighten wing nuts against the

back of the mounting brackets to

lock the wing screw in place. Hold

wing screw stationary if it turns

while adjusting the wingnut.

10 |

18. When tting bezels, ensure hook tabs

on back of each bezel recess into

opposing slots on screen frame. Once

ush with front surface of screen, slide

top bezel to the left, and bottom bezel

to the right to lock in to place.

Installation | M5000 Series User Manual

Page 11

VESA mounting the display

¼ Note: The VESA adaptor xing option is NOT tested against IEC 60945. Monitors that are part

of a type approved system can therefore NOT use the VESA bracket mounting option.

VESA bracket adaptor is available as an optional part for all display sizes, allowing a variety of

wall and free standing bracket mounting options. The fasteners for attachment to the display

are included with the bracket.

Monitors mounted using a Vesa bracket should be mounted in an area sheltered from rain and

sea spray.

¼ Note: For IPX rating refer to “Specications” on page 22.

¼ Note: Tilting the monitor forward by more than 15 degrees compromises the IPX2 rating. In

fully enclosed helm stations, this limitation may be disregarded.

¼ Note: The bracket mounting points on the monitor are only intended to carry the weight of

the monitor - do not install monitor in such a place where it may be used as a handhold, or

have additional equipment attached to it.

Installation | M5000 Series User Manual

|

11

Page 12

3

Connecting the display

The M5000 series monitors largely use industry standard cables, which can be purchased

pre-terminated in a variety of lengths. The following chapter provides additional detail where

cables require eld termination by the installer.

Rear connections

1 2

Key Connection Function

1 HDMI-1 Video input (digital)

2 DVI-2 Video input (digital)

3 VIDEO-3 Video input for camera (composite - analogue)

4 VIDEO-4 Video input for camera (composite - analogue)

5 NMEA2K Control input/output, software upgrade

6 SERIAL Color calibration (used by some systems only)

7 USB NOT USED

8 POWER 12/24 V DC power supply input

¼ Note: HDMI-1, and DVI-2 inputs do not support HDCP (High bandwidth Digital Content

Protection). Sources such as protected DVDs may not display correctly/at all on this monitor.

Warning: Make sure power is switched o before commencing with

installation.

3

4

6

5

7

8

Cable retention

12 |

Cables tted to the display should utilize

some form of strain relief. All displays are

supplied with a retention bracket, which

should be attached to the rear case.

Connecting the display | M5000 Series User Manual

Page 13

Connecting power

1

2

With the cable and plug tted in place, secure

the cable to the retention bracket using a cable

tie. Do not secure in such a way that applies

strain to the cable, or causes the plug or socket

to be bent out of alignment.

3 421

3

5

+

Key Color Function

1 Yellow Power control

2 Green Chassis ground

3 Red Positive DC supply (12 V or 24 V system)

4 Black Negative DC supply (12 V or 24 V system)

5 Fuse - see table at end of section

6 DC supply

¼ Note: This display is not intended for use vessels tted with a positive ground electrical

system. The power input cable screen drain wire should be connected to a negative ground.

¼ Note: Chassis ground will typically not be required. In certain problematic installations it may

help stabilize touch screen sensitivity, i.e. prevent ‘false’ touches, or non-registered touches.

¼ Note: In an ECDIS conguration connect the red and yellow wires in parallel.

4

-

6

Recommended fuse rating

Model M5016 M5019 M5024 M5027

Fuse 3 amp 4 amp 4 amp 4 amps

Connecting the display | M5000 Series User Manual

|

13

Page 14

Color calibration connection for MARIS ECDIS900 MK5 PC

The M5000 series monitors support color calibration and brilliance control from the MARIS

ECDIS900 MK5 PC system. The connection must be made using the CT&A cable.

Serial connection using the CT&A cable

The M5000 series monitors must always be connected to the MARIS ECDIS900 MK5 PC via

serial. Make all connections with power turned o.

3

4521

Key Function CT&A serial cable colors

1 RX+ yellow

2 RX- red

3 TX+ green

4 TX- blue

5 CT&A cable

14 |

Connecting the display | M5000 Series User Manual

Page 15

1 2 3 4 5

4

Operating the display

The display is congured and controlled using the row of touch sensitive buttons along

the lower edge of the monitor frame. All buttons are backlit - only the power button is

illuminated when the monitor is turned o.

Key Description

1 ON/OFF key

- Press to return to previous menu level when the OSD menu is active

- Press and hold (2 seconds) to turn the unit ON/OFF

2 BRILLIANCE adjustment keys

- Press minus key to decrease brightness and plus key to increase it (no

on-screen display of brightness level)

- Press minus key to move cursor down and plus key to move it up

when OSD menu is activate

- Simultaneously press and hold (2 seconds) both keys to reset the

brightness level to default value. The default value is set in the OSD

menu *

3 ENTER key

- Press to conrm a selection when operating the OSD menu

4 Red LED

- Solid red = ‘active o ’ (no video source)

- Flashing = booting or upgrading

5 Menu key

- Press and hold (2 seconds) to activate the OSD menu

¼ * Not applicable for ECDIS where the default values for brilliance, contrast and colour

temperature are set according to the calibrated values for current active palette.

First time operation

The display has the capability to automatically adjust itself to the resolution of the source to

which it is attached. This auto adjustment will take place when the unit is rst installed and

connected to a source and there after, if the video input changes, or is user initiated.

Operating the display | M5000 Series User Manual

|

15

Page 16

OSD menu

This menu accesses controls for all aspects of picture setup, and is accessed by pressing and

holding the Menu key for 2 seconds when the monitor is on. The main menu options are

explained in the following:

Option Sub option Range Function

Brightness

Default Brightness

Display

Option Sub option Setting Function

Scaling

Contrast

Hue

(analogue video only)

Saturation

(analogue video only)

HDMI-1

DVI-2

VID-3

VID-4

1:1, FILL, ASPECT

0-100

Adjusts backlighting level

Sets the default brightness, activated

by pressing the Minus/Plus keys

simultaneously when the OSD is not

displayed

Adjusts image contrast (range

between darkest and lightest )

Shifts colors represented by screen

Varies colour intensity, from dull to

full and rich

Sets input image to true size, ll available

screen area, or to ll screen vertically or

horizontally but maintain correct aspect

ratio

Option Sub option Setting/

Range

PIP Mode

PIP Swap Swaps main source with PIP source

PIP Control

(Picture-inPicture)

Option Sub option Setting/Range Description

Source

PIP Size

PIP Horizontal 0-100

PIP Vertical 0-100

Main Source

PIP Source

OFF, PIP,

Split

Small,

Medium,

Large

HDMI-1, DVI-2,

VID-3, VID-4

Description

Sets to either no PIP, regular PIP as dictated by

following settings, or 50:50 split pane (image

scaled to t)

Controls PIP window size. Sets screen area to:

small: 409 x 240 pixels

medium: 555 x 312 pixels

large: 683 x 384 pixels

Adjusts horizontal position, where 0 = left, and

100 = right

Adjusts vertical position, where 0 = bottom,

and 100 = top

Select which physical input should be

displayed

Note: PIP source can only be set to VID-3

or VID-4 when HDMI or DVI are the main

source. The reverse applies when either of

the analogue sources is set as main source

16 |

Option Sub option Range Description

OSD

Position

Operating the display | M5000 Series User Manual

Horizontal

0-100

Vertical

Adjusts horizontal position, where 0 = left,

and 100 = right

Adjusts vertical position, where 0 = left, and

100 = right

Page 17

Option Sub option Description

English

French

Language

Option Sub option Range Description

Conguration

German

Spanish

Italian

Portuguese

Power

Control

Key Beeps O, On Turns on or o the OSD key beeps

Factory Reset Yes, No Restore all settings to default

Select language for OSD text

In slave mode monitor will turn on if 12/24

V is detected on the yellow wire. In master

Slave, Master

mode monitor will turn on slave devices

by switching 12 V to yellow wire when

monitor is on

Operating the display | M5000 Series User Manual

|

17

Page 18

5

Cleaning and maintenance

If the display requires cleaning, use a damp soft cloth (e.g. microber) with a mild, nonabrasive glass cleaner. Ensure cloth is regularly washed or replaced.

¼ Note: Do not use paper products as they may scratch the surface. To minimize the risk of

abrasion, allow the screen to air dry.

¼ Note: Never use acidic, ammonia based, or abrasive cleaning products to clean the display.

These products will damage special coatings on the glass.

¼ Note: To prevent damage caused by lightning strikes, it is recommended to disconnect the

display from the power source during intense storms, or when the product is not in use for

extended periods.

Display removal

The display’s top and bottom bezel trim

must be removed in order to undo the

fasteners holding unit in place by the

mounting ange. The bezel trim have

been designed to be very low prole, and

therefore fully conceal the locking tabs

that keep them from being accidentally

disengaged from the mounting ange. To

release the locking tab, it is necessary to

gently lever the centre of the bezel trim

away from the mounting ange. To remove

the cover, simultaneously slide it sideways;

to the right for the top cover, and to the left

for the bottom cover.

The mounting brackets should be loosened

in reverse order to tting. To remove the

brackets, depress the locking tab before

sliding brackets upwards.

Replacing the gasket

The foam gasket on the rear of the display bezel is available as an optional accessory, should

the factory installed item be damaged.

Fit the two lengths of foam gasket in to the

rebated channel on the back of the displays

mounting ange. Only remove backing

paper from the side to be stuck to monitor,

and only remove a small amount at a time.

Ensure the gasket ends of the two halves

overlap and make contact.

18 |

¼ Note: Take care not to stretch gasket when applying. Only pull gasket minimum amount

required to lay it on straight. The backing paper on outside of gasket will help prevent stretch,

and should only be removed when display is ready to install in to dashboard.

Cleaning and maintenance | M5000 Series User Manual

Page 19

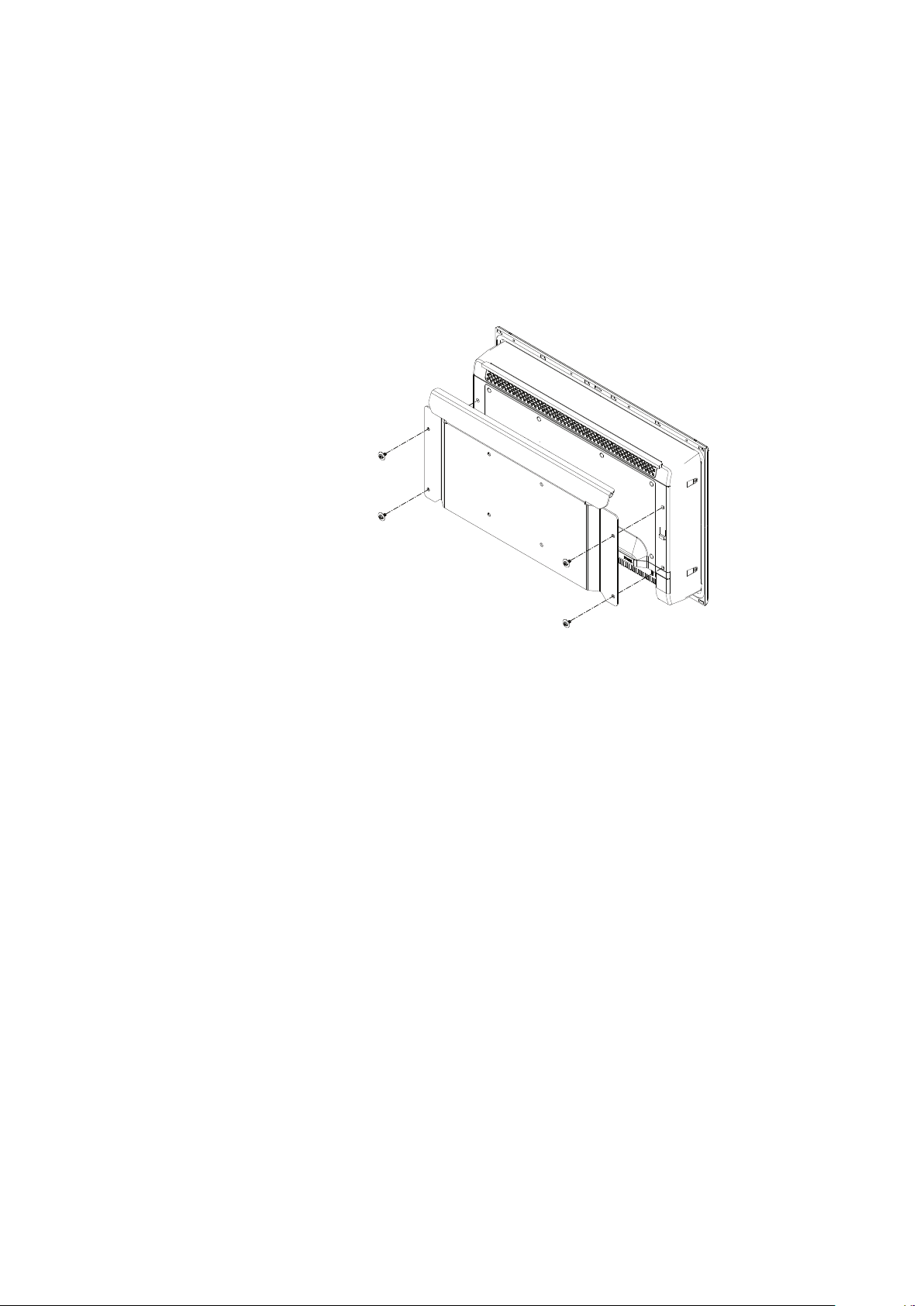

Replacing the lters

Where displays are installed in an unsealed enclosure, air intake lters should be inspected

yearly, and replaced if noticeably fouled. If vessel is subject to major works involving spray

painting or sanding, it is recommended that the monitor either be removed, or completely

covered in a clean fabric drop cloth.

¼ Note: M5016 and M5019 models require three lter elements. The lter accessory kit includes

ve elements.

Other maintenance

Only qualied service personnel should perform any repairs that require opening of the case.

Warning: Some components in the display unit operate on high

voltages. Repairs require specialized service procedures and tools only

available to service technicians - there are no user serviceable parts or

adjustments. The operator should never remove the display unit cover

or attempt to service the equipment. Any attempt to do so may make

the warranty invalid.

Updating the rmware

Updates to the M5000 series monitor rmware may occasionally become available. The

updates will typically include improvements to existing functionality or new features, and will

be made available via the Simrad PRO website: www.navico.com/commercial

Checking current rmware version

On the Conguration page it is possible to see the name of the monitor, resolution (native),

OSD version, BIOS version, and the serial number.

Installing an update

Updates should be loaded via a compatible Simrad device such as the NSO evo2. Refer to the

applicable product manual on how to upgrade a device over NMEA 2000.

Alternatively, return the device to a Navico dealer to arrange updating.

¼ Note: We do not recommend updating more than two displays at the same time. Do not

update the display being used to monitor the update status. In the rare occurrence the

update fails, the LED indicator will ash and nothing will be visible on the screen.

Cleaning and maintenance | M5000 Series User Manual

|

19

Page 20

Troubleshooting

Issue Possible Cause

6

No picture - red LED ON

No picture - red LED

ashing

No picture - red LED OFF

Image persistence

LED on continuously indicates no (compatible) video is available

on currently selected source;

Conrm that the correct video input is selected

Check that the video signal cable is properly connected to the

display. Test cable with ‘known good‘ equipment

Check display settings of the video source - ensure the

resolution is supported by the display

Ensure brightness is turned up to a suitable level

Flashing LED indicates there is no ground connection detected.

Make sure power is connected to an appropriate DC voltage

source, and that the fuse is tted or breaker is switched on. After

pressing power button, the red LED should blink as monitor

starts up, followed by momentary display of the logo on the

screen. Make sure brightness level is set to a suitable level.

Image persistence occurs when a ghost of an image remains

on the screen after the screen image has been changed. Unlike

a CRT monitor, an LCD monitor’s image persistence is not

permanent. To erase an image ghost, turn the monitor o for

several hours. To avoid this condition, do not leave the monitor

displaying the same image unnecessarily, for an extended

period of time

Check for video cable condition; is shield intact, and does cable

not exceed maximum distance for video standard

20 |

Check the signal source is outputting a compatible resolution at

Picture quality & image

stability

Low level backlight

Slight distortion in text

or graphics

Display is present but

“bars” appear or roll

across screen

Vertical shaded bars on

screen image

Troubleshooting | M5000 Series User Manual

a supported frequency

Monitor may be receiving incorrect/bad sync signals from

source

Video compromised by interference from other equipment

Supply voltage has dropped below 10 V. Will restore at >11 V

Unit has been subject to excessively hot direct sunlight for an

extended period and/or unit enclosure is too hot. Automatic

thermal protection has been enabled

Not working in native resolution, where possible adjust the

video source to output correct resolution

Ground loop problem between video source and monitor

Video compromised by interference from other equipment

Incoming video may be in 4:3 ratio, either leave in ‘aspect’ mode,

or set to ‘ll’ to use full screen space.

Page 21

7

Accessories

Part description Part number

M5016 bezel trim, silver and black (4 pieces) 000-11620-001

M5019 bezel trim, silver and black (4 pieces) 000-11621-001

M5024 bezel trim, silver and black (4 pieces) 000-11622-001

M5027 bezel trim, silver and black (4 pieces) 000-13550-001

M5016 Vesa bracket 000-11615-001

M5019 Vesa bracket 000-11616-001

M5024 Vesa bracket 000-11617-001

M5027 Vesa bracket 000-13548-001

M5027 Gimbal bracket kit 000-13547-001

Cable retention bracket (all models), includes 4 cable ties, screws 000-11614-001

M5016/19/24/27 rear mounting kit 000-11618-001

M5016/19/24 dash seal kit (6 pieces) 000-11619-001

M5027 dash seal kit 000-13549-001

M5016/19/24/27 inlet lters (5 pack) 000-11623-001

M5016/19/24/27 inlet lter cover 000-11624-001

HDMI cable (3 m) 000-11248-001

HDMI cable (10 m) 000-11249-001

Connector kit (power and serial plugs) 000-11625-001

¼ Note: Available accessories may change - refer to the website:

www.navico.com/commercial

Accessories | M5000 Series User Manual

|

21

Page 22

Specications

¼ Note: The most up-to-date specications list is available at: www.navico.com/commercial

8

15.6” TFT Active Matrix Panel

LCD display

Brightness 300 nit Screen glass

Native

resolution

Contrast ratio

Viewing angles

Power

consumption

Display colors 16.7 million Video inputs

Temperature

Operable

humidity

Bezel & rear

case

Water ingress

resistance

(M5016/19/24)

18.5” TFT Active Matrix Panel

24.0” TFT Active Matrix Panel

27.0” TFT Active Matrix Panel

M5016: 1366 x 768

M5019: 1366 x 768

M5024: 1920 x 1080

M5027: 1920 x 1080

M5016: 500 :1

M5019: 1000 :1

M5024: 5000 :1

M5027: 3000 : 1

M5016: 80°

M5019: 160°

M5024: 89°

M5027: 178°

M5016: 12 W

M5019: 13 W

M5024: 30 W

M5027: 30 W

Operating: -15°C to +55°C

Non-operating: -20°C to 60°C

95%

PC/ABS

IPX6 (dash mount - front only

exposed)

Weight (monitor

only):

Protection

Power and setup

keys

Comms / Control RS422, USB, NMEA 2000

Picture in Picture

Auto video

detection

Auto video

scaling

Supply voltage 12 V / 24 V DC (9-31.2 V)

M5016 = 3.60 Kg

M5019 = 4.60 Kg

M5024 = 6.60 Kg

M5027 = 9.00 Kg

Anti-Reective (AR) and

Anti-Fingerprint (AF)

Thermal: auto screen

dimming, overvoltage,

reverse polarity, low

voltage

Capacitive touch

1x HDMI, 1x DVI-I, 2x

composite (NTSC &

PAL)

YES; variable position

& size

YES

YES

22 |

Compass safe distance

16” monitors 19” monitors 24 “ monitors 27 “ monitors

- Standard compass 1.90 m (6.3 ft) 2.00 m (6.6 ft) 2.30 m (7.6 ft) 1.4 m (4.6 ft)

- Steering compass 1.10 m (3.7 ft) 1.10 m (3.7 ft) 1.20 m (4.0 ft) 0.75 m (2.4 ft)

Supported Resolutions

640 x 480

(8-32 bit colour, 59, 60 Hz)

720 x 480

(8-32 bit colour, 59, 60 Hz)

720 x 576

(16-32 bit colour, 50-60 Hz)

Specications | M5000 Series User Manual

800 x 480

(8-32 bit colour, 60 Hz)

800 x 600

(8-32 bit colour, 60 Hz)

1024 x 600

(8-32 bit colour, 60 Hz)

1024 x 768

(8-32 bit colour, 60 Hz)

1280 x 768

(8-32 bit colour, 60 Hz)

1280 x 720

(8-32 bit colour, 50-60 Hz)

1360 x 768

(8-32 bit colour, 60 Hz)

1366 x 768

(8-32 bit colour, 60 Hz)

1920 x 1080

(8-32 bit colour, 50-60 Hz)

1920 x 1080

(8-32 bit colour, 25, 29, 30,

60 Hz)

Page 23

Dimensional drawings

9

M5027: 420 mm

M5019: 305 mm M5024: 386 mm

M5016: 260 mm

M5016: 383 mm M5019: 461 mm M5024: 598 mm

M5016: 400 mm M5019: 478 mm M5024: 625 mm M5027: 675 mm

M5027: 646.5 mm

MAX 25.4 mm (1.00")

M5027: 380 mm

M5016: 233 mm M5019: 278 mm M5024: 349 mm

8 mm (0.31")

66.0 mm (2.60")

MAX 88.0 mm (3.46")

Dimensional drawings | M5000 Series User Manual

|

23

Page 24

*988-10795-005*

www.navico.com/commercial

Loading...

Loading...