Page 1

INSTRUCTION MANUA

L

Simrad HS50

Heading Sensor

Page 2

Note!

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning!

The equipment to which this manual applies must only be used for the purpose for which

it was designed. Improper use or maintenance may cause damage to the equipment or

injury to personnel. The user must be familiar with the contents of the appropriate

manuals before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

© 2002 Simrad AS

The information contained within this document remains the sole property of Simrad AS.

No part of this document may be copied or reproduced in any form or by any means, and

the information contained within is not to be communicated to a third party, without the

prior written consent of Simrad AS.

Page 3

INSTRUCTION MANUAL

Instruction Manual

HS50 Heading Sensor

This manual is intended as a reference guide for installing,

operating and maintaining Simrad HS50 Heading Sensor.

20221081 / F i

Page 4

Simrad HS50 Heading Sensor

Document revisions

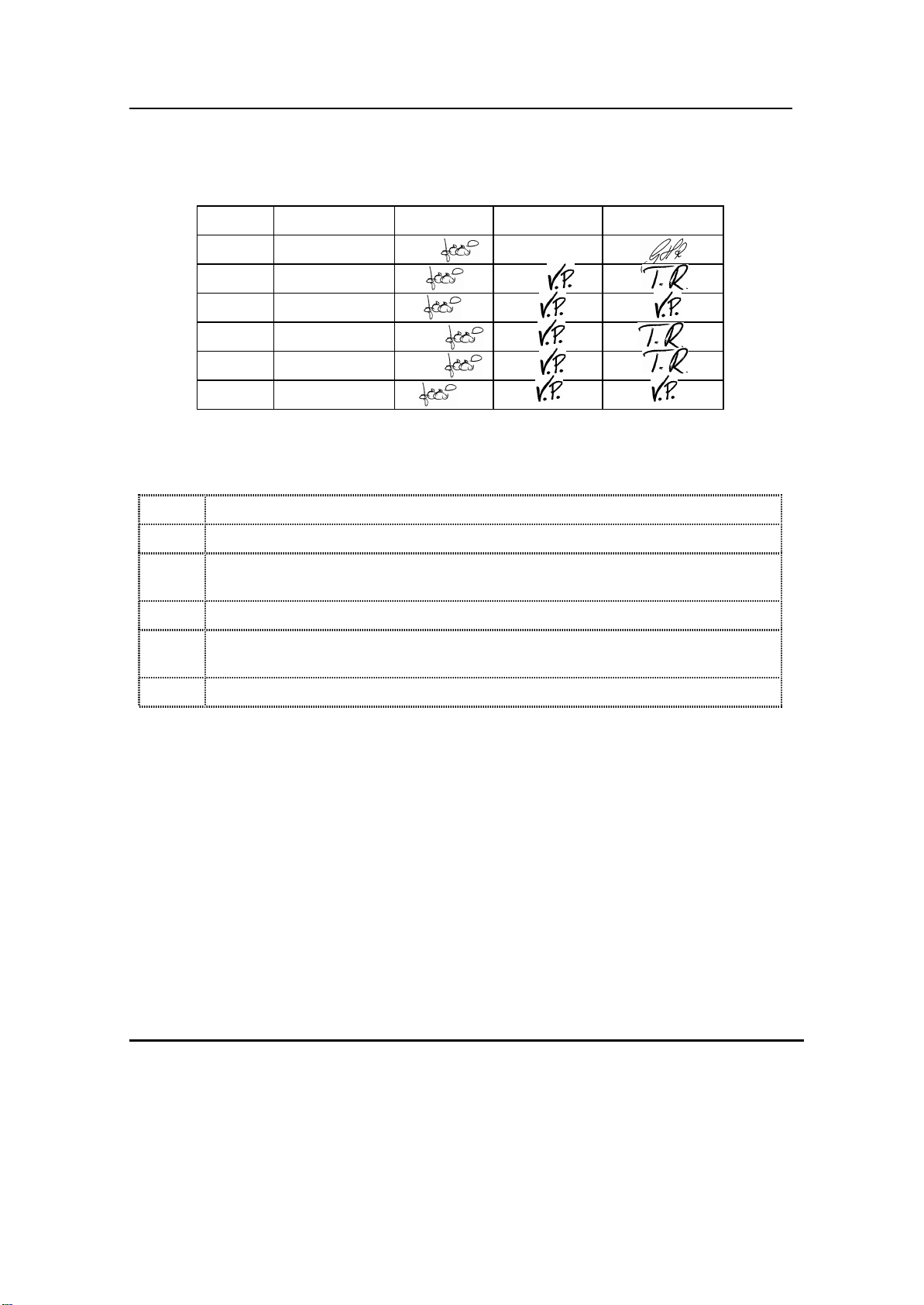

Rev Date Written by Checked by Approved by

A 12.06.02

B 26.09.02

C 06.11.02

D 02.04.03

FOS/

FOS/

E 06.11.03

F 07.01.04

FOS/

Document history

Rev. A Original issue.

Rev. B The manual updated and rewritten.

Rev. C Cable pair numbers for Sensor unit corrected (page 13). Optional documentation for

additional languages added.

Rev. D Updated to correspond with PU sw version 2.02.03 and DU sw version 1.02.

Rev. E Updated to correspond with PU sw version 2.02.04, DU sw version 1.03. and SU sw version

1.02 . Dim . drawing for Sensor unit updated to show mounting direction.

Rev.F Corrected part number for HS50 Display unit mounting bracket (page 16).

To assist us in making improvements to this manual, we would welcome comments and

constructive criticism. Please send all such - in writing to:

Simrad Egersund AS

Nyåskaien

P.O. Box 55

N-4379 Egersund, Norway

or by e-mail to:

simrad.documentation@simrad.com

ii 20221081 / F

Page 5

INSTRUCTION MANUAL

Contents

1. INTRODUCTION ................................................................1

1.1 HS50 System components............................................. 1

1.2 About this manual ........................................................ 3

1.3 Definitions, abbreviations and acronyms.......................... 3

Definitions ....................................................................... 3

Abbreviations and acronyms...............................................4

2. TECHNICAL SPECIFICATIONS ...........................................5

2.1 Health, environment and safety ..................................... 5

2.2 Restrictions in guarantee............................................... 5

2.3 Restrictions in use ........................................................ 5

2.4 Performance data......................................................... 6

2.5 Physical dimensions...................................................... 6

Sensor unit ......................................................................6

Display unit .....................................................................6

Processing unit .................................................................7

2.6 Power......................................................................... 7

Processing unit .................................................................7

2.7 Environmental specification ........................................... 7

Sensor unit ......................................................................7

Display unit .....................................................................7

Processing unit .................................................................8

2.8 Cable ......................................................................... 8

Processing unit to sensor unit cable .....................................8

2.9 Interface..................................................................... 8

3. INSTALLATION..................................................................9

3.1 General ...................................................................... 9

3.2 Cable connection.......................................................... 9

3.3 Grounding................................................................... 9

3.4 Sensor unit ................................................................10

Location of the unit ......................................................... 10

Mechanical installation..................................................... 11

20221081 / F iii

Page 6

Simrad HS50 Heading Sensor

Cable wiring................................................................... 13

Waterproofing the connectors ........................................... 14

3.5 Display unit ................................................................14

Location of the unit ......................................................... 14

Panel mounting .............................................................. 15

Bracket mounting (option) ............................................... 16

Display unit cable ........................................................... 17

3.6 Processing unit ...........................................................18

Cable connections ........................................................... 19

Connecting to Simrad equipment ...................................... 21

3.7 Software setup procedure.............................................24

Display Adjustments........................................................ 25

Differential corrections..................................................... 26

Data output ................................................................... 27

Ethernet ........................................................................ 28

General ......................................................................... 28

Expert setup .................................................................. 30

4. OPERATING INSTRUCTIONS ...........................................33

4.1 Overview ...................................................................33

4.2 Turning the system ON/OFF..........................................34

4.3 Performance monitoring ...............................................34

Navigation/HDT display ................................................... 36

Navigation/POS display.................................................... 36

Info displays .................................................................. 37

4.4 Alarms.......................................................................39

Invalid Position alarm ...................................................... 40

Invalid Heading alarm ..................................................... 40

Invalid Position and Heading alarm.................................... 40

4.5 Operation...................................................................41

Height aided GPS position ................................................ 41

5. MAINTENANCE ................................................................43

5.1 General .....................................................................43

5.2 Periodic maintenance...................................................43

Sensor unit .................................................................... 43

iv 20221081 / F

Page 7

INSTRUCTION MANUAL

Processing unit ............................................................... 44

Display unit ................................................................... 44

Software upgrades.......................................................... 44

5.3 Repairs and modifications.............................................45

Replacing damaged cables ............................................... 45

Replacing damaged units ................................................. 45

5.4 Troubleshooting ..........................................................45

No response................................................................... 46

No valid data.................................................................. 46

No Differential corrections ................................................ 47

Invalid Heading .............................................................. 47

Reduced heading indication .............................................. 48

Simulated data ............................................................... 48

6. FIGURES AND DRAWINGS...............................................49

6.1 Sensor unit, dimensions ...............................................50

6.2 Sensor unit bracket, dimensions....................................51

6.3 Sensor unit pedestal, dimensions ..................................52

6.4 Processing unit, dimensions..........................................53

6.5 Display unit, dimensions ..............................................54

7. PARTS LIST .....................................................................55

7.1 Standard delivery........................................................55

7.2 Optional equipment .....................................................55

7.3 Documentation ...........................................................55

20221081 / F v

Page 8

Simrad HS50 Heading Sensor

THIS PAGE INTENTIALLY LEFT

BLANK

vi 20221081 / F

Page 9

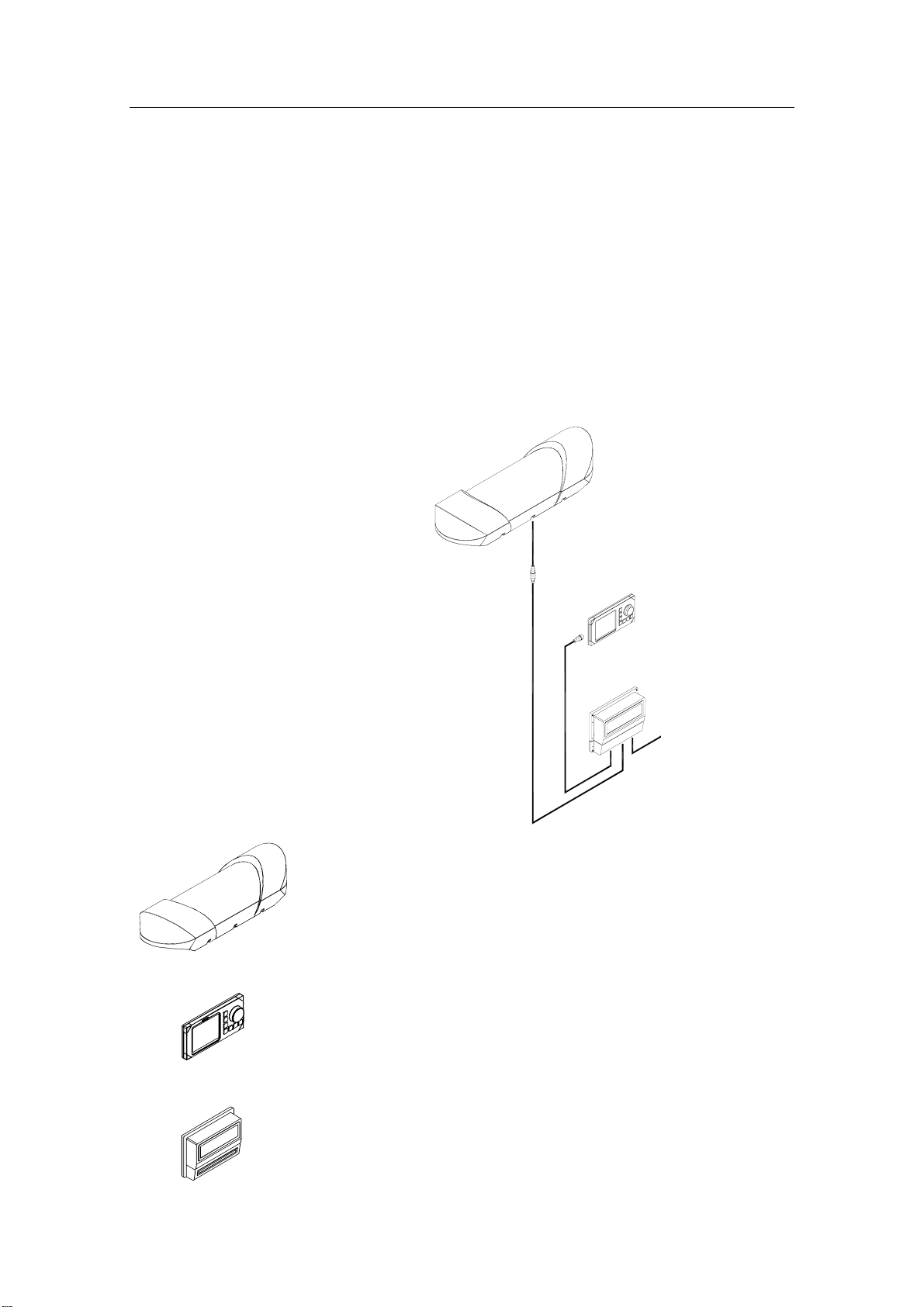

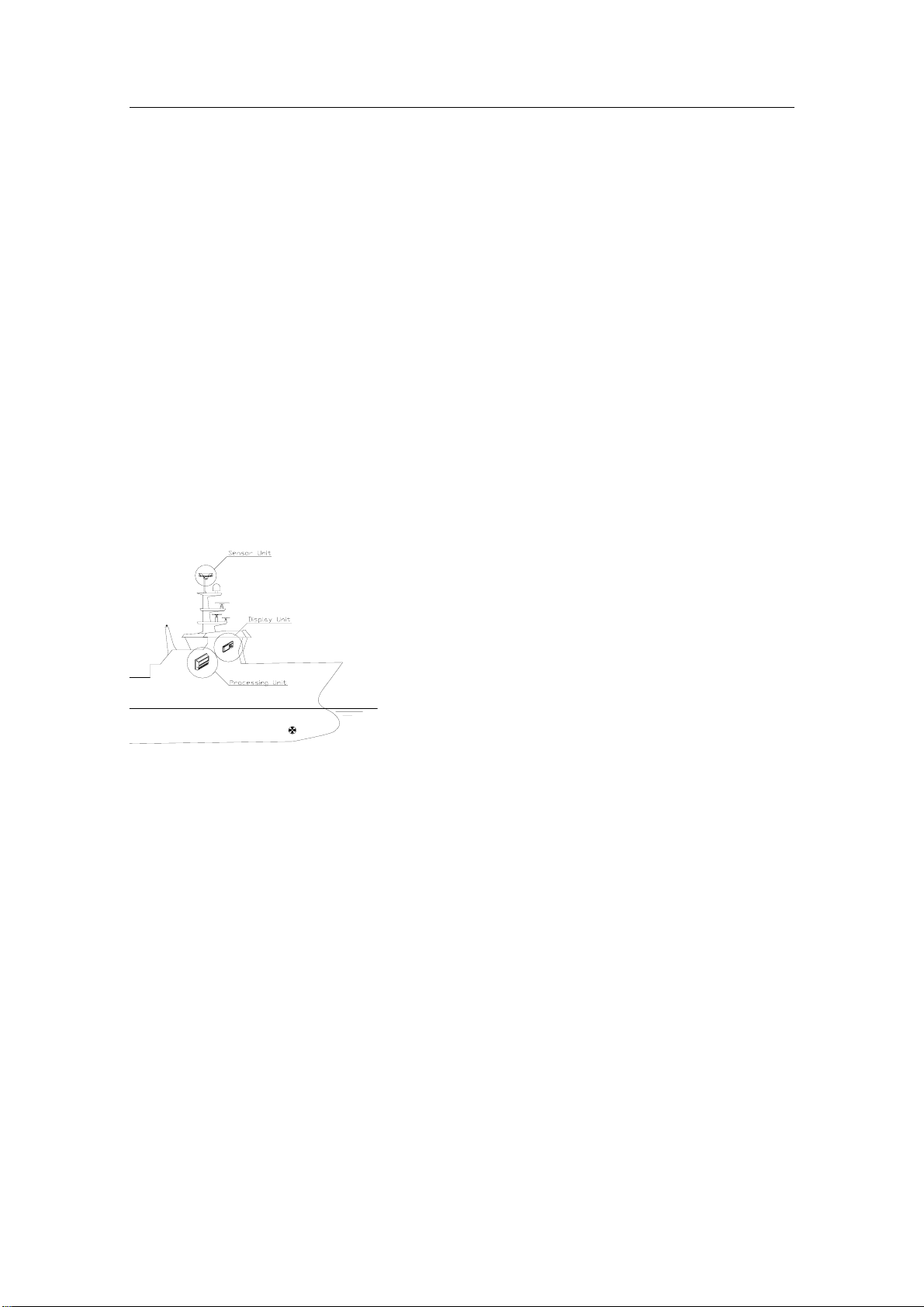

1. INTRODUCTION

1.1 HS50 System components

Simrad HS50 is a GPS compass that provides true heading

output with position, velocity and rate of turn information in

addition. This product replaces several vessel instruments with

one compact navigation package: gyrocompass, GPS system,

speed log and Rate Of Turn (ROT) indicator.

The HS50 comprises the following units:

1m

INTRODUCTION

SENSOR UNIT

DISPLAY UNIT

30m

15m

PROCESSING

UNIT

POWER INPUT

The Sensor unit contains two GPS sensors, electronic board

with I/O and an inertial rate element.

The Sensor unit is to be mounted in the vessel’s mast or flat on

a roof or deck.

The Display unit contains an LCD for navigation information,

mainboard with CPU, flash, power and I/O, and buttons for

setup and operation of the HS50 system.

The Processing unit contains the mainboard with CPU, flash,

power, I/O and a terminal list.

20221081 / F 1

Page 10

Simrad HS50 Heading Sensor

High-precision heading is derived from the fixed-distance dual

GPS antenna arrangement in the Sensor unit, using carrier phase

data to generate heading information independent of latitude and

vessel dynamics. GPS position and speed are calculated from

both antennas, which give redundant position and velocity

sources in this product. DGPS signals may be input to the HS50

to improve position and velocity accuracy, but has no impact on

the heading accuracy. Refer Performance data, page 6.

The inertial rate element provides yaw/ROT information. In case

of short GPS outages, the inertial sensor automatically takes

over as the prime source for heading determination until the

GPS comes back on line. Working together seamlessly, the

inertial and GPS elements of the system insure accurate,

continuous and robust heading information.

The Processing unit includes configurable output serial lines

(three RS-232 and three RS-422) and Ethernet connections

making it easy to distribute HS50 data to multiple users on

board the vessel.

The HS50 requires no scheduled maintenance or re-calibration.

The system offers flexible configuration of the output variables

and interface setup, depending on the vessel and application. It

is easy to operate, install and align.

The HS50 system has the following features:

• True heading anywhere on earth

• Replaces several instruments with one robust, integrated

product

• Heading available in periods of GPS drop-outs

• 20 Hz update rate on heading and rate of turn measurements

• 80°/sec follow-up rate

• Three RS-232 and three RS-422 configurable output serial

lines

• Output data on Ethernet

• Only one cable (no coax) between the mast unit and the

Processing unit on the bridge

2 20221081 / F

Page 11

INTRODUCTION

1.2 About this manual

This manual is intended as a reference guide for operating,

installing and maintaining the HS50 Heading Sensor. Please

take time to read this manual to get thorough understanding of

the operation and system components.

In this manual the following notations are used:

Caution! Used to make the user aware of procedures and operational

practice which, if not followed, may result in degraded

performance or damage to the equipment.

Note! Used to draw the user's attention to special features or behavior

of the equipment.

1.3 Definitions, abbreviations and acronyms

Alignment

Heading

Yaw

Definitions

The process of adjusting the current internal navigation frame

(sensor-frame) in the instrument to the true vessel body frame.

The direction of the main axis (bow direction) of the vessel.

This is opposed to course, which is the direction of the vessel

motion.

A rotation about the vertical axis and is positive when turning

eastward when the vehicle cruises in north direction. Normally

yaw means the dynamic yaw motion.

20221081 / F 3

Page 12

Simrad HS50 Heading Sensor

Abbreviations and acronyms

CEP

COG

DGPS

DU

EPE

GPS

GSA

HDOP

HGT

IEC

IMO

I/O

NMEA

PDOP

Circular Error Probability

Course Over Ground

Differential GPS

HS50 Display Unit

Estimated Position Error

Global Positioning System

A standard NMEA message including GPS satellite ID

numbers, PDOP, HDOP and VDOP

Horizontal Dilution Of Precision

GPS Antenna Height above the WGS-84 ellipsoid

International Electrotechnical Commission

International Maritime Organization

Input/Output

National Marine Electronics Association. NMEA 0183 is a

standard for interchange of information between navigation

equipment

Positional Dilution Of Precision. This is the sum of the VDOP

and HDOP figure

PSXN20

PU

RFI

RF

RMS

ROT

RRE

RTCM

SOG

SSB

UTC

VDOP

VHF

WGS-84

A proprietary NMEA message including position, height and

heading quality information

HS50 Processing Unit

Radio Frequency Interference

Radio Frequency

Root Mean Square

Rate of Turn

Range Residual Error, a proprietary format

Radio Technical Commission of Maritime Services

Speed over Ground

Single Side Band

Universal Time Co-ordinate. This is the official time in the

world and has replaced GMT (Greenwich Mean Time) as the

official time

Vertical Dilution Of Precision

Very High Frequency

World Geodetic System of 1984

4 20221081 / F

Page 13

TECHNICAL SPECIFICATIONS

2. TECHNICAL SPECIFICATIONS

2.1 Health, environment and safety

Operation or troubleshooting of HS50 equipment will not imply

any risk for high voltages, explosions or exposure to gas. The

HS50 is type-approved according to IEC 950/EN60950

standards regarding product safety (low voltage), and IEC

945/EN60945 standards on electromagnetic compatibility

(immunity/radiation) and vibration.

2.2 Restrictions in guarantee

The liability of the manufacturer is limited to repair of the HS50

only, and excludes consequential damages such as customer's

loss of profit or damage to other systems traceable back to HS50

malfunction. The warranty does not cover malfunctions of the

HS50 resulting from the following conditions:

a) The customer has opened the Sensor unit

b) Over-voltage or incorrect power connection

c) The equipment has been exposed to extreme chock and

vibrations

2.3 Restrictions in use

Simrad HS50 is designed for use on board marine surface

operated vessels with roll and pitch motions up to ±30°.

The HS50 function is based on GPS signals and requires free

sight to the sky, minimum 4 visible satellites, PDOP value less

than 6 and otherwise normal conditions to operate.

20221081 / F 5

Page 14

Simrad HS50 Heading Sensor

2.4 Performance data

Heading accuracy, static:...............................................0.3° RMS

Heading accuracy, dynamic:..........................................0.5° RMS

Heading resolution:............................................................... 0.01°

Heading operational measurement range: .Roll/pitch within ±30°

Rate of turn accuracy:................................................. 0.5º/s + 5%

Position accuracy:................................................... 5 m 95% CEP

Velocity accuracy: ............................................ 0.1 m/s 95% CEP

Follow-up rate:...................................................................80°/sec

The performance figures are valid with a minimum of 4 visible

satellites, HDOP less than 4, PDOP value less than 6, high

quality DGPS corrections * and otherwise normal conditions.

Excessive multipath, GPS signal obstructions or interference

may reduce the performance.

The HS50 Sensor unit includes two 12 channels GPS receivers.

* Has no impact on heading accuracy.

2.5 Physical dimensions

Sensor unit

Width ................................................................850 mm (33.5 in.)

Height: ................................................................205 mm (8.1 in.)

Depth: ...............................................................262 mm (10.3 in.)

Weight: ................................................................. 8 kg (17.6 lbs.)

Color: ...................................................................................White

Dimensional drawing........................................................Page 50

Display unit

Width: .................................................................220 mm (8.7 in.)

Height: ................................................................110 mm (4.3 in.)

Depth: ...................................................................39 mm (1.5 in.)

Weight: ................................................................ 0.5 kg (1.1 lbs.)

Color: ................................................................................... Black

Dimensional drawing........................................................Page 54

6 20221081 / F

Page 15

2.6 Power

TECHNICAL SPECIFICATIONS

Processing unit

Width: ...............................................................287 mm (11.3 in.)

Height: ...................................................................203 mm (8 in.)

Depth: ...................................................................60 mm (2.4 in.)

Weight: ................................................................ 1.3 kg (2.9 lbs.)

Color: ................................................................................... Black

Dimensional drawing........................................................Page 53

Processing unit

Voltage:.................................................................. 10 to 36 V DC

Power consumption: .............................................................15 W

2.7 Environmental specification

Sensor unit

Enclosure material, sensor housing: .........................Polyethylene

Enclosure material bracket: .......................... Anodized aluminum

Enclosure protection:............................................................. IP65

Operating temperature range: ........... -30 to +55ºC (-22 to 131°F)

Operating humidity (max.): ................................................. 100%

Storage temperature range:............... -30 to +70ºC (-22 to 158°F)

Storage humidity (max.):..................................................... 100%

Safe distance to compass: ........................................ 0.2 m (0.7 ft)

Display unit

Enclosure protection:.............. IP-56 from front, IP-43 from back

Operating temperature range: ................0 to +55ºC (32 to 131°F)

Storage temperature range:............... -30 to +80ºC (-22 to 176°F)

Safe distance to compass: ..................................... 0.35 m (1.1 ft.)

20221081 / F 7

Page 16

Simrad HS50 Heading Sensor

Processing unit

Enclosure material: .......................................Anodized aluminum

Enclosure protection:............................................................. IP44

Operating temperature range: ................0 to +55ºC (32 to 131°F)

Storage temperature range:................. -20 to +60ºC (-4 to 140°F)

Safe distance to compass: ........................................ 0.2 m (0.7 ft)

2.8 Cable

Processing unit to sensor unit cable

Type: ......................................................2x2x0.5 mm2 with shield

Maximum length:................................................... 100 m (328 ft)

Diameter: ..............................................................10 mm (0.4 in.)

Flame retardation:.....................................................IEC 332-3/A

2.9 Interface

Configuration:....... Display unit connected to the Processing unit

Data outputs:........................................Three RS-232 serial lines,

Data inputs:.................... One RS-232 and one RS-422 serial line

DGPS corrections: ..... RTCM 104 version 2.2 and SAPOS® EPS

Baud rate:...........................................................Max. 38.4 kBaud

HDT, ROT, GGA and GLL data update rates:.......... Up to 20 Hz

HDT, ROT, GGA and GLL data delay:...............Less than 50 ms

ZDA and VTG data update rate:....................................Max 1 Hz

VTG data delay:......................................................... Max 1.5 sec

ZDA data delay:..................................................................... 1 ms

Three RS-422 serial lines,

Ethernet UDP/IP

Data output formats:

• NMEA 0183 ZDA, GGA, GLL, VTG, HDT, ROT, GSA,

GRS and proprietary messages PSXN,20. The PSXN,20

message include position, height and heading quality

information

• RD Instrument ADCP proprietary NMEA format, "PRDID".

• Radar clock data

8 20221081 / F

Page 17

3. INSTALLATION

3.1 General

The following parts are supplied with a standard HS50 system:

− Sensor unit with 1 meter cable w/connector and 4

fastening bolts

− Display unit with 15 meters cable to the Processing

unit and flush mounting kit

− Processing unit including 4 fastening screws

− 30 meters cable to be used between Sensor unit and

Processing unit

− Documentation

INSTALLATION

Caution!

The Sensor unit has to be mounted in a way that

avoids blocking of the GPS signal.

The Processing and Display Unit can be

mounted on the bridge or in the instrument

room.

No units should be exposed to heavy vibration,

transformers or similar.

3.2 Cable connection

Use only shielded cables for the installation. This includes

power input and signal cables. The cables should be of 0.5 mm2

(AWG20) twisted pairs.

The cable to the Display unit and other cables (NMEA

input/output, Ethernet) should not be run in parallel with other

cables carrying RF or high current, such as VHF and SSB

transmitters, battery charges/generators and winches.

3.3 Grounding

All units in the HS50 system use the Processing unit as a

common ground/shield connection. The Processing unit should

therefore have a proper ground connection to the hull/bonding

system.

20221081 / F 9

Page 18

Simrad HS50 Heading Sensor

3.4 Sensor unit

Location of the unit

The Sensor unit is the most important part of the HS50 system,

and great care should be taken when deciding the mounting

location.

The space above the Sensor unit has to be free of obstructions of

any kind. A GPS compass is more sensitive for blocking and

reflections (multipath) of GPS signals than GPS sensors that are

only used for calculating position. This since HS50 also utilizes

carrier phase measurements for heading determination, and both

GPS antennas need to see at least two common satellites at the

same time.

The unit should be protected from direct illumination of radar

beams and other transmitting antennas such as Inmarsat

antennas.

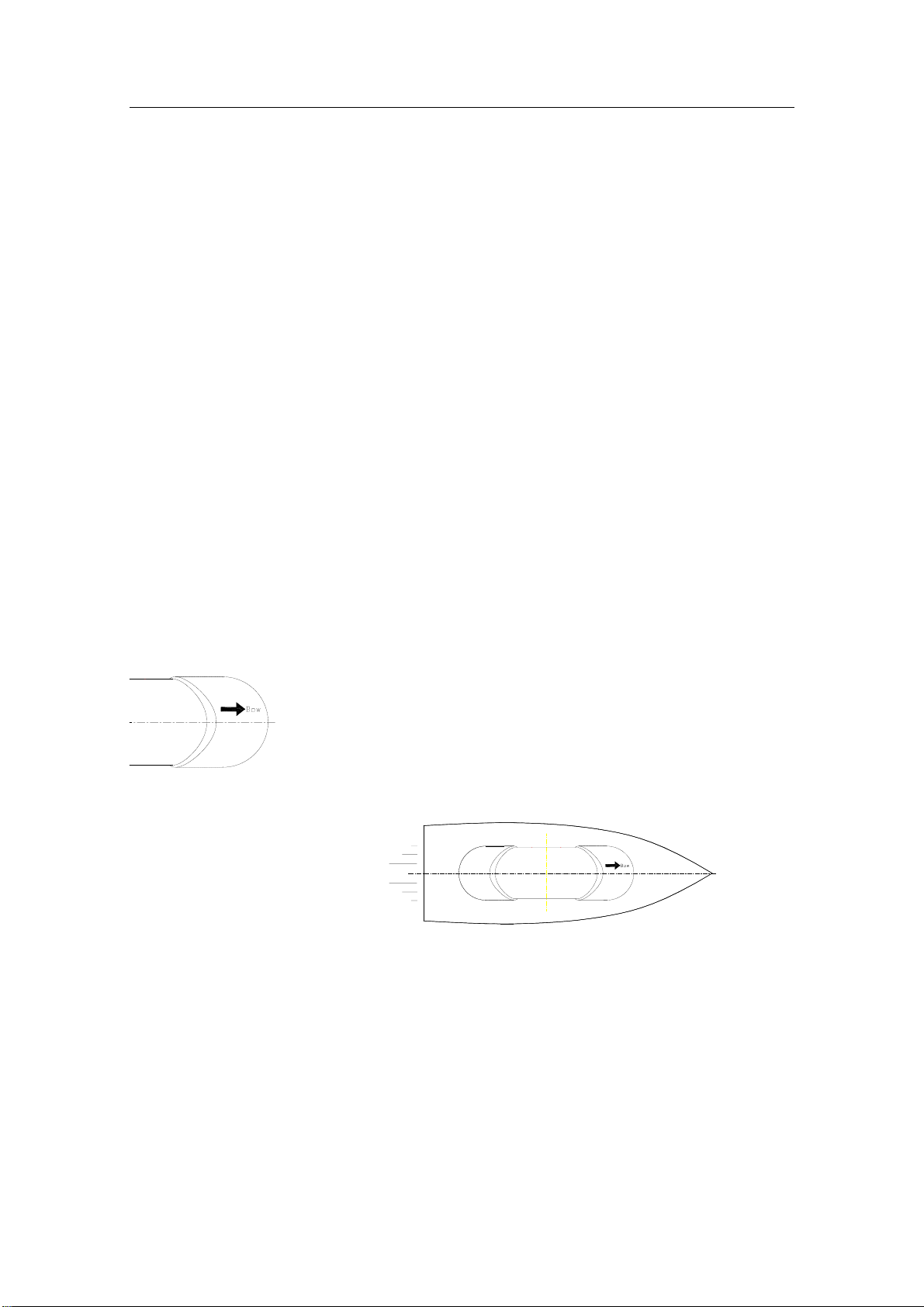

The Sensor unit has to be mounted horizontally in the mast or

directly on deck, with 5° maximum allowed deviation angle

from the horizontal plane. If mounted in the mast, the distance

from the unit to the nearest deck should be as large as possible

to reduce problem due to the multipath effect.

The unit should also be mounted parallel to the vessel’s

centerline with the bow arrow pointing forward. The heading

offset feature will however compensate for a heading offset

caused by the orientation of the Sensor unit. An eventual offset

correction is performed after the calibration as described in

Software setup procedure, Heading offset, page 31.

10 20221081 / F

Page 19

Holder

INSTALLATION

Mechanical installation

The Sensor unit may be mounted in the mast or directly on the

deck.

The dimensional drawing for the Sensor unit on page 50 shows

dimensions and internal distance for the mounting holes and the

cable outlet.

If necessary, a user-made holder may be used as

shown on the figure when installing the unit.

Bracket

A mounting bracket (part no. 20213039) or a

mounting pedestal (part no 20213021) can be

delivered from Simrad by request. Dimensions for

these optional mounting devices are shown on page

51 and page 52.

Refer Bracket mounting (option), page 12, and

Pedestal mounting (option), page 13.

Pedestal

Caution! Independent on which fastening method that is used, the

Sensor unit should not differ more than ±5° from the vessel’s

horizontal plane and the alongships axis. If the mounting is

not within this tolerance, the heading accuracy will be

degraded.

Connect the cable from the Processing unit to

the cable from the Sensor unit.

Caution!

The connector junction must be sealed with

self-bonding tape for waterproofing. After

Cable ties

Connectors with

self-bonding tape

coiling, make bonding by hard pressure.

Use the required number of cable ties to fasten

the cable to the mast.

Cable duct

20221081 / F 11

Page 20

Simrad HS50 Heading Sensor

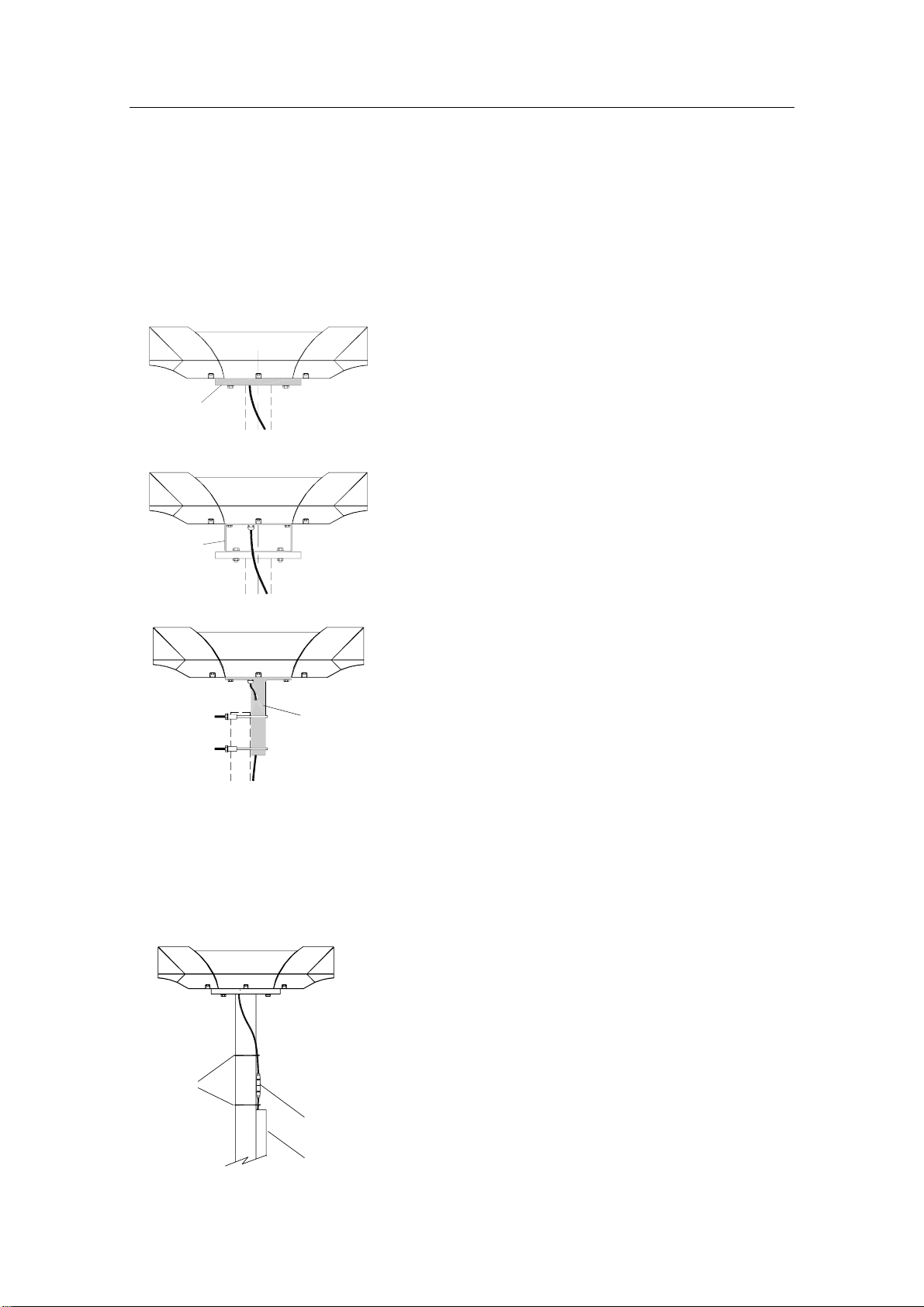

Bracket mounting (option)

An optional mounting bracket (part no. 20213039) can be

delivered from Simrad by request.

Assemble the mounting bracket to the Sensor unit with the four

screws with washers as shown in the figure below.

4

11

12

Holder

Cable ties

Connector with

self-bonding tape

Cable duct

10

Connect the cable from the Processing unit to

the cable as described in page 11.

12 20221081 / F

Page 21

Pipe clamps

Cable ties

INSTALLATION

Pedestal mounting (option)

An optional mounting pedestal (part no. 20213021) can be

delivered from Simrad by request. This pedestal is designed for

2-inch mast mounting.

Attach the pedestal to the Sensor unit with the four screws and

washers similar to the bracket mounting option described on

page 12.

1 Lift the Sensor unit in the preferred direction

on the mast. Use two pipe clamps with

preferred size for mounting the Sensor unit

pedestal to the mast top.

2 Ensure that the Sensor unit is mounted in

such a way that torsion movement relative to

the mast is kept at an absolute minimum.

All nuts should be secured with washers or by

Connector with

self-bonding tape

self-locking nuts.

Cable duct

Connect the cable from the Processing unit to the cable as

described in page 11.

Cable wiring

The wiring for the Sensor unit cable in the Processing unit

terminals is as follows:

Cable Wire No. Signal Description

Label

Screen Cable shield GND

4 Transmit COMM+

3 Receive COMM-

2 +24 VDC PWR+

1 Power ground PWR-

Processing Unit

Connector P201

20221081 / F 13

Page 22

Simrad HS50 Heading Sensor

If the Sensor unit connector needs to be reconnected to the

cable, the wiring for the cable within the Sensor unit connector

is as follows:

Sensor Unit

1

2

FRONT VIEW

Connector

Pin no.

4

3

Connector housing Screen Shield

2 4 Transmit

4 3 Receive

3 2 +24 VDC

1 1 Power ground

Cable Wire No. Signal Description

Waterproofing the connectors

The Sensor unit connector junction has to be sealed with selfbonding tape and PVC/Vinyl tape for waterproofing.

1 Coil the self-bounding tape from one cable end to the

other. Use at least two layers with tape. After coiling,

make a bonding by pressure of fingers.

2 Coil at least two layers of PVC/Vinyl tape without

stretching as shown in the figure below. After coiling,

make a bonding by pressure of fingers.

3.5 Display unit

Location of the unit

Avoid mounting the Display unit where it is easily exposed to

sunlight, as this will shorten the lifetime of the display. If this is

not possible, make sure the unit is always covered with the

white protection cover when not used.

The unit is designed for installation in an indoor environment

and for operation within the temperature range. The best

location is typically in the instrument room or on the bridge

mounted close to the Processing unit.

14 20221081 / F

Page 23

INSTALLATION

Panel mounting

Two mounting methods may be used when panel mounting the

HS50 Display unit.

A drilling template, part no. 22084883, is supplied with the

HS50 documentation. Use this template when making panel cutout and drilling holes.

Gasket

1 Remove the front panel corners.

2 Drill the mounting holes and make panel cut-out according

to supplied template.

3 Use the supplied gasket (part no. 22084693) between the

panel and the unit.

4 Fasten the Display unit to the panel with the supplied 19

mm screws.

5 Apply the front panel corners.

6 Connect the Processing unit cable to the Display unit

connector.

Caution! Do not over-tighten the mounting screws.

Alternative panel mounting

This way of mounting is simpler, but will lift the unit from the

panel surface. When installed adjacent to Simrad MarineLine

equipment there will be a 5.5 mm (0,22") difference in height

between the Display unit and other equipment.

Gasket

1 Remove the front panel corners.

2 Use the template and drill hole(s) only for the connectors.

3 Place the 7.5 mm gasket (part no. 22086029) between

panel and unit, correctly oriented (see marking on gasket).

4 Fasten the Display unit to the panel with the supplied 19

mm screws.

5 Apply the front panel corners.

6 Connect the Processing unit cable to the Display unit

connector.

20221081 / F 15

Page 24

Simrad HS50 Heading Sensor

Bracket mounting (option)

An optional bracket, part no. 22084941, may be ordered from

Simrad.

Note! When the Display unit is bracket-mounted, it is not

weatherproof from the back due to a breathing hole in the back

cabinet. When bracket-mounted, the exposed parts of the plugs

should be protected against salt corrosion.

1 Locate the cradle on the mounting site and mark the 4

holes for the screws on the mounting surface.

2 Drill the 4 holes and screw the cradle to the mounting

surface.

3 Remove the front panel corners, and use the supplied

screws to fasten the Display unit to the left and right

brackets.

4 Apply the front panel corners.

5 Use the two locking knobs to assemble the cradle with the

left and right brackets and adjust the Display unit for the

best viewing angle.

6 Connect the cable from the Processing unit to the Display

unit connector.

16 20221081 / F

Page 25

INSTALLATION

Display unit cable

The 15 m cable to the Processing unit has connector only at the

Display unit end. Optional extensions cable (10 m) is available

and has a male and a female connector.

The connector is of crimp type. It can be easily disassembled, if

desired for ease of installation. The extracting tool (p.no.

44161792) may be ordered from Simrad.

HOW TO REMOVE PINS:

Extraction tool

Pull the wire

Insert tool in slot

See the table below for pin configuration and color code for this

cable. DO NOT MIX THE PINS AND THE CABLE COLORS!

Note! Apply a thin layer of pure Vaseline on the connector threads

and make sure the connectors are properly secured to the

receptacle by the coupling ring. The connectors are weather

proof according to IP56, when properly installed. The plug must

be fitted with the plastic cap to keep the connector free of dirt

and moisture. A separate screw cap for the Display unit comes

as part of the installation kit.

Display Unit Cable

Cable

pairs

1st pair Pink 5 PWR

Grey 4 GND

2nd pair Brown 1 Bus–

White 2 Bus+

3rd pair Yellow 3 POWC

Color

code

Connect

or pin

Processing

Unit

Terminal

pin

6

1

3

FRONT VIEW

5

42

Green 6 ALARM

Note! For installations that require special cable length, contact your

Simrad distributor for information.

20221081 / F 17

Page 26

Simrad HS50 Heading Sensor

3.6 Processing unit

The Processing unit is not waterproof and should be mounted

vertically in a dry place. Reserve sufficient space below the unit

to allow insertion for cable connections.

It is recommended that ventilation or air conditioning is

provided in order to keep the ambient operating temperature

below +55ºC (+130ºF). The best location is typically in the

instrument room or on the bridge.

Dimensions for the Processing unit are shown on page 53.

Use the supplied mounting screws for fastening the Processing

unit as shown on the figure below.

18 20221081 / F

Page 27

INSTALLATION

Cable connections

Proceed as follows to connect the cables to the Processing unit:

1 Remove the bottom cover (terminal cover) to get access to

the plug-in terminals.

2 Strip 1 cm (0.4") of the cable's insulation and pull the

screen backward to cover the insulation. Position the

straps as shown in the figure below and tighten well to

make sure the screen has good contact.

3 Provide sufficient wire length so that the plug-in terminals

can be easily connected/disconnected.

4 Pull out each terminal before connecting the wires.

Remove all stands before putting on the terminal cover.

20221081 / F 19

Page 28

Simrad HS50 Heading Sensor

The pinout for each terminal is as follows:

P200 DISPLAY

P201 SENSOR

UNIT

UNIT

ALARM GREEN

POWC YELLOW

GND GREY

PWR PINK

BUS+ WHITE

BUS- BROWN

GND SHIELD

COMM + 4

COMM - 3

PWR+ 2

PWR- 1

J60 Ethernet

P80

P202 DATA

OUT 1

P203 DATA

OUT 1

P204 DATA

OUT 2

P205 DIFF

INPUT

RJ45

NOT USED

232 OUT

422- OUT

422+ OUT

GND_A

232 OUT

422- OUT

422+ OUT

GND_B

232 OUT

422- OUT

422+ OUT

GND_C

422+ IN

422- IN

P206 DIFF INPUT

P207

P208 RADAR

P300 POWER

232 IN

GND_D

NOT

USED

AD10_C

AD10_D

AD10_GND

SHIELD

PWR_+

PWR_GND

20 20221081 / F

Page 29

INSTALLATION

Connecting to Simrad equipment

The figures on the following pages show how HS50 is

connected to Simrad equipment.

All equipment using NMEA signal is connected to 232 OUT

and GND, alternatively to 422– OUT and 422+ OUT on P202,

P203 or P204. After the equipment is connected to HS50, the

data output line has to be configured as described in Data

output, page 27.

Connection to Simrad Radar is done from P208.

AP9MK3 Autopilot

HS50

PROCESSING UNIT

P202,

P203

or

P204

232 OUT

422- OUT

422+ OUT

GND

RGC Signal Interface unit

HS50

PROCESSING UNIT

P202,

P203

or

P204

232 OUT

422- OUT

422+ OUT

GND

AP9 MK3

CONTROL UNIT

J3

1

2

RGC

SIGN. INTERFACE

UNIT

TB3

NMEA IN

1

NMEA IN +

2

NMEA IN -

Note! DIP Switch SW1-2 on the Signal

4

3

12

Interface PCB has to be set to NMEA

according to the figure.

RGC SIGNAL INTER

ROBERTSON TRITE

20221081 / F 21

VR4

SW1

+

Page 30

Simrad HS50 Heading Sensor

J50/J300X Junction unit

HS50

PROCESSING UNIT

P202,

P203

or

P204

NI300X

HS50

PROCESSING UNIT

P202,

P203

or

P204

232 OUT

422- OUT

422+ OUT

GND

232 OUT

422- OUT

422+ OUT

GND

J50 / J300X

JUNCTION

UNIT

TB8

RX2+

RX2-

NI300

JUNCTION

UNIT

A RX+

B RX-

IS15 Instruments

HS50

PROCESSING UNIT

P202,

P203

or

P204

232 OUT

422- OUT

422+ OUT

GND

IS15

J4

1

NMEA

2

22 20221081 / F

Page 31

RGC12 Gyro Compass

INSTALLATION

HS50

PROCESSING UNIT

P202,

P203

or

P204

232 OUT

422- OUT

422+ OUT

GND

Simrad RA40/RA50 Radar

HS50

PROCESSING UNIT

P208

AD10_C

AD10_D

AD10_GND

RGC12

TERMINAL BOARD

TB7

GRXL

GRXH

RADAR

26

GYRCK+

GYRCK+

27

GYRCK-

9

GYRCK-

10

Note! Requires the optional 36-pins connector 72099 for the Radar.

Software set-up in Radar

1 Go to menu:

MENU → SETUP → CUSTOM → PRESET1

2 Change Input from NMEA to 10 BIT

3 Change Head from TRUE to MAGNETIC

20221081 / F 23

Page 32

Simrad HS50 Heading Sensor

3.7 Software setup procedure

This chapter describes a number of installation settings that

must be performed as part of the installation of the HS50.

Failure to correctly set the values in the installation settings may

prohibit the product from functioning properly.

Before attempting to turn on the HS50 and perform an

installation setup, the hardware and electrical installation must

be completed in accordance with the installation instructions.

The SETUP menu is entered on the Display unit by pressing and

holding the SETUP button for 5 seconds.

The settings are grouped into the following functional

categories:

• Display adjustments

• Diff. corrections

• Data output 1

• Data output 2

• Ethernet

• General

• (Expert Setup, refer page 30)

Use the arrow buttons to select category, and the

rotary knob to enter a category’s submenu.

The arrow buttons are also used to return from a submenu to the

SETUP menu.

Note! Activate and Discard selection together with the rotary knob is

used to exit the SETUP menu: changes are accepted by using

Activate, and all changes are erased when selecting Discard.

24 20221081 / F

Page 33

INSTALLATION

Example:

The following example shows how to change the ROT Max

value in the Display adjustment submenu using the keys and

the rotary knob:

1 Press the SETUP key for 5 seconds until the Setup menu

appear on the screen.

2 Select Display adjustment by turning the knob clockwise

3 Press the arrow down key until the cursor is at the ROT

Max position

4 Turn the knob to left or right until wanted value appear on

the screen

5 Press the SETUP key to get back to the main menu

Press the arrow down key until the cursor is at the Activate

position and then turn the knob clockwise. Then the new setup is

activated.

Display Adjustments

In the Display adjustments submenu the backlighting and

contrast of the display are adjusted. The format for velocity

(knots or m/s) and resolution on position displayed may be

specified, together with the maximum rate of turn (ROT) value

to be shown on the display. Default value for ROT is 20°/s.

When navigation information (NAV1 or NAV2 menu, refer

page 36) are selected, the display backlighting may be increased

or decreased by using the rotary knob.

20221081 / F 25

Page 34

Simrad HS50 Heading Sensor

Differential corrections

The signal cable with the differential corrections is connected to

the terminal block P205 on the Processing unit for RS-422 input

signal, and P206 for RS-232 input signal.

In the Diff. corrections submenu the correct baud rate and

format for the signal must be set. If RTCM format is selected,

the correct RTCM Options must be selected to enable

differential corrections to be used in the position solution.

If data from more than one reference station are available on the

link, HS50 automatically uses the nearest reference station to

obtain the best solution. The default RTCM Option is MSB 1st

and 6 of 8.

26 20221081 / F

Page 35

Data output

The Processing unit has two individually configurable output

serial lines.

On output line Data output 1 two RS-232 and two 422 serial

lines are available. The signal cables can be connected to both

terminal block P202 and P203.

On Data output 2 one RS-232 and one 422 serial lines are

available. The signal cables are to be connected to terminal

block P204.

Note! All six serial lines may be used simultaneously!

The setup of baud rate, interval between NMEA sentences and

output formats for each port are performed in the Data output 1

and Data output 2 submenu.

INSTALLATION

Baudrate: The rate at which bits are transmitted. 4800 is

standard NMEA rate.

Interval: Interval in seconds between each NMEA

sentence.

Example:

Interval setting Hz

1 sec 1 Hz

0.5 sec 2 Hz

0.2 sec 5 Hz

0.1 sec 10 Hz

0.05 sec 20 Hz

Format: Format on data output line. The following

selections are available: NMEA and none.

NMEA Format: NMEA sentences to be sent to output line.

WARNING! If “none” is selected as output format, no data will be

sent to output line.

20221081 / F 27

Page 36

Simrad HS50 Heading Sensor

Ethernet

The Processing unit can output data on Ethernet from terminal

J60. In the Ethernet submenu the IP address, netmask, IP port

number and output format have to be specified. For the NMEA

format the messages GGA, GLL, VTG, HDT, ROT and RRE are

included.

IP Address: Default setting: 010 000 021 030.

IP Netmast: Default setting: 255 255 255 000.

Format: Format on Ethernet line. The following

selections are available: NMEA and None.

WARNING! If “None” is selected as output format, no data will be

sent to Ethernet line.

Caution! A change in IP Address and IP Netmask parameter will not

take effect before the HS50 is restarted!

Note! The cable to be used has to be a crossed Ethernet cable.

General

The General submenu includes selection of height aiding,

velocity filtering, Clock data, NMEA id and Datum.

28 20221081 / F

Page 37

INSTALLATION

Height aiding

For operations with weak satellite geometry the position output

can be made more accurate by using height aiding. For normal

operation height aiding should be set to Filter or Off. When

Filter or Fixed is selected, an initial height has to be entered.

The value to be entered in Init. height is the GPS height value

HGT shown in the position display window no. 1, refer page 36,

average over some minutes.

Note! Height aiding is active only with input of differential GPS.

Velocity filtering

The HS50 output raw data for SOG and COG with the default

velocity filter value set to 3 sec. When smoothing of the SOG

and COG measurements are required the filter period could be

selected in the range 1 to 99 seconds in steps of one second.

With a high filter period more smoothing of the SOG and COG

measurements will be achieved and the response to speed and

course changes gets slow.

Radar format

On the Processing unit terminal P208 output to radar is available

(AD-10 format. The default setting is OFF.

NMEA ID

The NMEA ID for the HS50 output lines can be selected

between the following IN, HE, HC, GP and TI. The default

setting is IN (Inertial Navigation).

Datum

For the position Datum, only the WGS-84 is available.

20221081 / F 29

Page 38

Simrad HS50 Heading Sensor

Expert setup

By pressing the SETUP button twice and then holding this button

for 5 seconds, an Expert Setup category will be available in the

SETUP menu.

Use the rotary knob to enter the SETUP Expert submenu.

The following settings are available:

Head offset: Used for correcting a constant heading offset.

Refer Heading offset, page 31.

Alarm sound: Used for turning alarm text and alarm sound

on and off. Refer Alarms, page 39.

The following selections are available:

POS-Q

Only invalid position will activate alarm.

HDT-Q

Only invalid heading will activate alarm.

HDT-Q is the default setting.

All

Both invalid position and invalid heading will

give alarm.

Off

Used for tuning off all alarm text or alarm

sound.

30 20221081 / F

Page 39

INSTALLATION

Run mode: Used for switching the HS50 between

NORMAL and DEMO mode.

DEMO mode is used for simulating input data

to the system.

WARNING! The HS50 must not be switched to DEMO mode when

the system is in operation!

Log data, Server address, User name and Password:

Used for service purpose.

Caution! A change in Expert setup parameters (except Head offset and

Alarm sound) will not take effect before the HS50 is restarted.

Heading offset

The Head offset feature allows you to correct for a constant

compass heading offset that may be present as a result of an off

axis misalignment between the Sensor unit and the vessel

alongships axis.

Note! It is important that the Sensor unit is mounted accurately in the

alongships direction so the Head offset value does not exceed

±5°. If the mounting orientation is not within these tolerances

the heading accuracy will be degraded. Instead of exceeding a

Head offset value of ±5° the Sensor unit orientation should be

adjusted mechanically.

The system has to be calibrated on board the vessel after

installation. A typical calibration consists of calibrating the

direction of GPS antennas within the Sensor unit against an

external reference. Type of reference must be decided according

to the required accuracy. Alternative references for calibrating

the heading offset of the Sensor unit could be:

• The heading of the pier or quay the vessel is moored to.

• An external compass reading like from a gyro compass.

• Two fixed points on the chart that the vessel is sailing

between.

The observation period for the heading difference should

continue for an as long as possible period in order to eliminate

errors in the HS50 measurements caused by multipath effects.

These may be particularly pronounced in the static conditions of

a harbor area.

20221081 / F 31

Page 40

Simrad HS50 Heading Sensor

The average value for observations from each of the two

different systems should then be used, and the offset between

the two systems (reference value minus HS50 reading) input as

the Head offset value.

The offset value can be either positive or negative.

Example:

If the heading measured by the reference system is 32.1° and the

HS50 heading 28.5° during the calibration period, 3.6 (32.1 -

28.5) should be entered in the General submenu as the Head

offset value.

32 20221081 / F

Page 41

OPERATING INSTRUCTIONS

4. OPERATING INSTRUCTIONS

4.1 Overview

The Display unit is used for setup and operation of the HS50.

Each of the push buttons is clearly identified with the primary

function in large text, and a secondary function listed in smaller

text. Each button provides you with the ability to access a

primary display, a secondary display and/or multiple function

displays.

Adjustable settings are provided in the SETUP mode. The

settings allow adjustment of mounting orientation, selection of

differential correction, setup of output serial line formats,

Ethernet and the display. Refer Software setup procedure, page

21.

HDT

POS

HDT

POS

pfjo^a=epRM

The Display unit consists of the main elements as listed below.

FUNCTION

Power on/off. 34

Displays Navigation/HDT display with compass rose or

details.

Displays Navigation/POS with position and accuracy ellipse. 36

Displays SETUP menu. 21

REF.

PAGE

36

Used for displaying additional system information. 37

20221081 / F 33

Used for maneuvering in the SETUP submenus. 21

Page 42

Simrad HS50 Heading Sensor

The rotary knob is used for entering values in SETUP

submenus, and for adjusting the display brightness.

FUNCTION

4.2 Turning the system ON/OFF

A single press on the POWER button switches the system ON,

and the following start up information is shown on the display:

REF.

PAGE

21

Once installed, calibrated and started, the HS50 needs no

manual intervention during operation.

After power on, up to 15 minutes is needed to obtain full

accuracy on all data. Since there normally is no reason for

turning the unit off, it should be left running continuously.

The HS50 will be shut down in a controlled way when the

POWER button is pressed for 1-2 seconds. Then the message

Shutdown in process will appear on the screen. If the

button is pressed and held for 5 seconds or more, the system is

shut down immediately. Typically used if the system has a hangup and does not respond on any commands. The configuration

of HS50 is however stored on the internal flash disk independent

on how the unit is powered off.

4.3 Performance monitoring

The navigation display NAV1 and NAV2 includes on the left

side of the screen data quality and status information. The

indicators are as follows:

• HDT-Q. The quality of the heading measurements. Two

black bar graphs indicate normal accuracy, one black and one

white bar graph indicate reduced accuracy and two white

invalid heading.

POWER

34 20221081 / F

Page 43

OPERATING INSTRUCTIONS

• POS-Q. The quality of the position measurements. Two

black bar graphs indicate normal accuracy, one black and one

white bar graph indicate reduced accuracy and two white

invalid position.

• DIF. Indicated whether differential corrections are input and

used in the position determination or not. A black box

indicates that differential corrections are used. A white box

indicates no use of differential corrections.

• COG. A black box indicates valid COG calculation, a white

an invalid calculation.

• SOG. A black box indicates valid SOG calculation, a white

an invalid calculation.

• ROT. A black box indicates valid ROT calculation, a white

an invalid calculation.

• WGS84. Shows the Datum used for the position and velocity

determination. If the text DEMO appears in this field the

system is operating in demonstration mode with simulated

output data.

Bargraph

showing

quality

Bargraph

showing

quality

Datum or

operation

mode

HDT-Q

POS-Q

DIF

COG

SOG

ROT

WGS84

COG

270

P

000

336

348

ROT 0.6 º/s

True

heading

090

S

An invalid HDT-Q status indication will be shown after 300

seconds of loss of GPS heading in the system, and the output of

heading data will terminate. In the first 300 seconds after loss of

20221081 / F 35

Page 44

Simrad HS50 Heading Sensor

GPS heading, the heading output is determined from the inertial

element.

The data quality status information indicated on the Display unit

is also included in some of the NMEA messages that can be

output on the serial lines.

Navigation/HDT display

When pressing the NAV1/HDT button, the HS50 will toggle

HDT

between two different displays for heading information.

Primary NAV1/HDT display, shown after the start-up screen

when the HS50 is turned ON.

True heading is shown as a big number in the center of the

compass with the COG value above it.

Secondary NAV1/HDT display.

This display shows heading, course over ground and speed over

ground values in big characters.

Navigation/POS display

The HS50 will toggle between three different displays for

POS

position information when the NAV2/POS button is pressed.

Primary display shown when the NAV2/POS button is pressed

once. The display shows main navigation information.

Secondary NAV2/POS display.

The display presents position information in large numbers.

36 20221081 / F

Page 45

OPERATING INSTRUCTIONS

Third NAV2/POS display: the Satellite skyplot.

This display shows satellites in sight by the Sensor unit, and

which satellites the HS50 is tracking. The satellites are presented

according to satellite geometry. The bars on the left side of this

display indicate the signal-to-noise level for each satellite.

Info displays

When pressing the INFO button, the system will page through a

number of displays for information about system configuration

and performance. The information on some of these displays is

mainly used for troubleshooting the system.

In the GPS information display details for the position solution

is presented. This information is mainly for trouble shooting of

the system.

An explanation of the information shown is as follows:

HDOP

PDOP Quality indicators for the GPS solution.

Pos. accuracy Estimated accuracy on the position solution (RMS).

Vel. Accuracy Estimated RMS accuracy on the velocity solution (RMS).

Average sn gps1

Average sn gps2 Average signal-to-noise ratio on the GPS receiver 1 and 2.

Correction age Age of differential corrections. If HS50 receives no differential

correction, the displayed correction age will be high. See No

Differential corrections, page 47 for trouble shooting loss of

differential signal.

Diff. Station id Actual reference station utilized in the position solution.

UTC time World time referred to UTC.

20221081 / F 37

Page 46

Simrad HS50 Heading Sensor

In this display, a number of additional information on the

heading solution is presented. This information is mainly used

for troubleshooting the system.

An explanation of the information shown is as follows:

Gps hdt The heading determined from GPS alone.

Deviation The difference in heading determined from GPS and the internal

gyro element.

Accuracy The instantaneous heading accuracy determined from GPS

alone. The instantaneous accuracy might differ from the

specified accuracy which is a figure determined for the

combination of GPS heading and heading from the internal data

element. The specified accuracy figure for the product is also

calculated as a standard deviation over a number of samples.

The figure shown as Accuracy might occasionally be higher

than the specified heading accuracy. If the Accuracy figure

shown is much higher (3 times or more) than the specified

accuracy, then the performance of the system is poor. Check

Reduced heading indication, page 48 in this manual for

troubleshooting the system.

Last heading This is the time since the system calculated the GPS heading. If

GPS signals drops out this figure will increase. In the first 300

seconds after loss of GPS heading, the heading output is

determined from the inertial element. After 300 seconds of loss

of GPS heading in the system the output of heading data will

terminate. If so, see Invalid Heading, page 47 for trouble

shooting the system.

Common sat. Shows the number of common satellites seen by the two GPS

antennas. The number of common satellites have to be two or

higher to determine heading. If the number is less than two, see

Invalid Heading, page 47 for trouble shooting the system.

The other information in this display is only of interest to

service personnel.

Number of satellites used in the GPS position fix with indication

of increasing or decreasing azimuth (Az) and elevation (El).

This display is mainly used by service personnel.

38 20221081 / F

Page 47

OPERATING INSTRUCTIONS

Number of satellites used in the GPS position solution and the

number of satellites tracked by GPS antenna no. 1 (Tr1) and 2

(Tr2).

This display is mainly used by service personnel.

4.4 Alarms

Software version for each unit (Distribution Unit =

DU, Sensor

Unit = SU and Processing Unit = PU), together with internal

serial number for Sensor and Processing unit. The date behind

each unit’s software version refers to manufacture date for the

unit.

System load as percentage of used CPU capacity.

The HS50 will generate an acoustic alarm and an alarm text if

heading or position information is invalid or missing.

The acoustic alarm will sound for 5 seconds, and the alarm text

will remain in the display until the

NAV1 or NAV2 button is

pressed. No data will be output from HS50 as long as the alarm

situation is present.

If the SETUP menu is active when the alarm condition arises,

the alarm text will be displayed when the SETUP menu is left.

Note! No alarm will be activated if the system is setup to not respond

to alarm situations. Refer Expert setup, page 30.

20221081 / F 39

Page 48

Simrad HS50 Heading Sensor

Invalid Position alarm

Activated if the system has been unable to determine position

the last two seconds, or if the HDOP value is greater than 4.

See No valid data, page 46 for troubleshooting.

The following alarm text will be displayed:

Invalid Heading alarm

Activated 300 seconds after the system is unable to determine

GPS heading and the HDT-Q indication has become invalid.

Invalid Heading, page 47 for troubleshooting.

The following alarm text will be displayed:

Invalid Position and Heading alarm

If both heading and position data is invalid, the display will

show:

40 20221081 / F

Page 49

4.5 Operation

The HS50 will normally output signals on the serial lines

without any involvement from the user. However, the following

should be taken into consideration during operation:

Height aided GPS position

In periods with weak satellite geometry, the position can be

made more accurate by using height aiding function in the

General submenu. Refer General, page 28.

The height aiding improves the solution by using the knowledge

that a vessel at sea has only small short-term variations in height

caused by heave. The long-term variations caused by tide are

taken care of in the system. The height value used, as input to

the GPS solution is a low-pass filtered value of the measured

height.

OPERATING INSTRUCTIONS

A start value for the low-pass filter should be specified for use at

system start-up. The value to use is the height of the Sensor unit

above the WGS-84 ellipsoid when the sea level is at its mean

value. This height can be found in the primary Navigation/POS

display, where the HGT value is the GPS height. Refer

Navigation/POS display, page 36. The value should be

monitored for some minutes, and the average value should be

used.

Note! The height difference between mean sea level and the WGS-84

ellipsoid can be significant. Values between +/- 100 meters can

be encountered.

For normal operation, height aiding should be set to FILTER or

OFF. When FILTER or FIXED is selected, an initial height

has to be entered.

Height aiding is active only with input of differential GPS.

20221081 / F 41

Page 50

Simrad HS50 Heading Sensor

THIS PAGE INTENTIALLY LEFT

BLANK

42 20221081 / F

Page 51

5. MAINTENANCE

5.1 General

Service on the HS50 hardware in the field can consist of:

• Replacing damaged cables

• Replacing failed Sensor unit

• Replacing failed Processing unit

• Replacing failed Display unit

The Sensor unit is not designed for service in the field and

opening the housing will result in damage or degradation of the

unit and void the warranty. A failed Sensor unit has to be

shipped back to Simrad in the original transportation box or

another appropriate box for service. The return address is

provided in the last pages of this manual.

MAINTENANCE

The software in HS50 can be upgraded to latest version in the

field by connecting an external PC to the Processing unit. A

software upgrade has to be performed by Simrad service people

or representatives.

5.2 Periodic maintenance

The user should execute all necessary maintenance. This

includes normal cleaning of all units and inspection of cables

and connectors at intervals. Components which malfunction

should either be replaced or sent back to Simrad for service.

The periodic maintenance of the HS50 components is as

follows:

Sensor unit

Make a visual inspection at 2-3 months intervals, and at the start

of each season.

20221081 / F 43

Page 52

Simrad HS50 Heading Sensor

Re-calibration of the Sensor unit

The direction of the Sensor unit relative to the vessel's heading

has to be recalculated only if the Sensor unit has been moved or

dismounted from its holder. Then the calibration procedure

described in General section, page 28 has to be followed for re-

calibration of the heading.

Processing unit

No special maintenance is required. It is advisable, however, at

the start of each season to make a visual inspection of the

terminals below the bottom cover (terminal cover) and check all

connections.

Display unit

The Display unit will under normal use require little

maintenance.

If the unit requires any form of cleaning, use fresh water and a

mild soap solution (not a detergent). It is important to avoid

using chemical cleaners and hydrocarbons such as diesel, petrol

etc.

Make sure that all open connectors on the Display unit are fitted

with a protection cap.

It is advisable at the start of each season to check all connections

to the unit and cover with Vaseline or WD40. If the Display unit

is not removed from the vessel, it should be covered with the

white protection cover.

Software upgrades

Software upgrades with improvements and new functionality

will regularly be offered. Download of new software version is

performed from an external PC by utilizing the Ethernet port on

the PC and the HS50 Processing unit. Some new software

releases will also require a new PROMM installed in the

Display unit.

44 20221081 / F

Page 53

5.3 Repairs and modifications

Repair of the HS50 units is limited to replacement of damaged

cables, Sensor unit, Processing unit, or Display unit.

Replacing damaged cables

Power off the Processing unit and dismount the damaged cable.

If the connector is not damaged it may be re-used, else a new

connector has to be made available.

Assemble the connector to the new cable as described in the

wiring information for the damaged cable. Refer the

INSTALLATION section, page 9 onwards.

Terminate the cable to the Processing unit as described in Cable

connections, page 19.

Replacing damaged units

MAINTENANCE

No HS50 units are designed for service in the field, and a

damaged unit has to be shipped back to Simrad for repair.

Caution! Opening the Sensor unit housing may result in permanent

damage to the unit!

Install the new unit according to procedures described in the

INSTALLATION section, page 9 onwards.

5.4 Troubleshooting

A GPS compass is a complex system and performance is

dependent of a proper installation and a successful sea trial.

In case of a failure, the user will be helped by the Display unit,

which contains several test features that will assist you in

isolating a probable fault.

Pressing any button resets the audible alarm. The visual alarm

will remain and alternate with the operating display until the

fault has been rectified. Refer to the table below for hints and try

to solve the problem yourself, or consult your nearest Simrad

dealer for assistance.

The next sections contain some hints for troubleshooting.

20221081 / F 45

Page 54

Simrad HS50 Heading Sensor

No response

In normal operation it takes about one minute from the Display

unit is powered on until information appears in the display. If

the display screen is still black after three minutes from power

on, do as follows:

• Check the power connection to the Processing unit, and

check that the Processing unit is supplied with correct

voltage. Refer specification in Power section, page 7.

• Press the

times in case of poor connection.

If there are still no information on the display, consult your

nearest Simrad dealer for assistance.

POWER button on the Display unit two or three

No valid data

In normal operation it can take up to 15 minutes from the

Display unit is powered on to full accuracy on all data is

obtained, and the indicators showing valid data. If all the

indicator boxes are still white after 15 minutes from power on,

then do as follows:

• Check that connectors are properly connected to Display unit

and Sensor unit.

• Check that cables from Sensor unit and Display unit are

correctly terminated to the Processing unit according to the

pin-out shown on page 20.

• Check that the cables are correctly terminated in the

connectors. Refer Cable wiring, page 13 for the Sensor unit,

and Display unit cable page 17 for the Display unit. If not,

switch off the power, re-connect the cable to the connectors

properly, and power on the unit again.

• If all connections are correct and still no valid data, the

mounting location of the Sensor unit may not be suitable, less

than four satellites are in view, or there may be an

obstruction between the Sensor unit and the GPS satellites.

Check the mounting location and consider relocation

according to Location of the unit, page 10.

If there are still no valid data, consult your nearest Simrad dealer

for assistance.

46 20221081 / F

Page 55

MAINTENANCE

No Differential corrections

The possible reason for a white box for differential correction

indication (DIF) could be one of the following:

• No differential corrections are input through terminal port

P205 or P206 on the Processing unit. If differential

corrections are input through one of these terminal ports,

check that the parameters are properly set up in the Display

unit setup menu Diff. input, see Differential corrections,

page 26.

• You can be out of range to a radio reference station and the

differential corrections are therefore missing. If the reference

station is too far away or it is in the shadow of geographical

obstructions or other equipment on board, reception may be

unreliable or missing. Pressing the INFO button and the

display GPS Information shows the identification number of

the reference stations connected to the HS50.

• The reference station can be out of function. Check the status

of the reference station with the authorities responsible for it,

or consult your nearest Simrad dealer for assistance.

Invalid Heading

The possible problem can be one of the following:

• The number of GPS satellites the Sensor unit is able to see is

too few. Press the NAV2/POS button until the Skyplot view

appears. Check that at least four satellites are available and

that the PDOP value is less than 6. Refer Satellite Skyplot

display, page 37. Check also the number of common

satellites seen by the two GPS antennas by pressing the INFO

button and looking at the value for Common sat. in the

advanced heading information display as shown in page 38.

The number of common satellites have to be two or higher to

determine a heading.

If one of the criteria's above is not fulfilled, the mounting

location of the Sensor unit may not be suitable or there may be

an obstruction between the Sensor unit and the GPS satellites.

Check the mounting location and consider relocation according

to Location of the unit, page 10.

If it is still not working after checking the above items, consult

your nearest Simrad dealer for assistance.

20221081 / F 47

Page 56

Simrad HS50 Heading Sensor

Reduced heading indication

The reason for reduced heading performance could be one of the

following:

• The number of GPS satellites the Sensor unit is able to see is

too few. Press the NAV2/POS button until the Skyplot view

appears. Check that at least four satellites are available and

that the PDOP value is less than 6. Refer Satellite Skyplot

display, page 37.

• Check also the number of common satellites seen by the two

GPS antennas by pressing the INFO button and looking at the

value for Common sat. in the advanced heading information

display as shown in page 38. The number of common

satellites have to be two or higher to determine a heading.

If one of the criteria's above not is fulfilled, it may be an

obstruction between the Sensor unit and the GPS satellites.

Consider moving the vessel to another location to see whether

that helps.

If it is still reduced after checking the above items, consult your

nearest Simrad dealer for assistance.

Simulated data

If the HS50 system is not sending out real data, check whether

the system is operation in demonstration mode with only

simulated output data. If the system operates in demonstration

mode the text DEMO appear at the bottom of the status field as

shown in the figure.

Refer Expert setup, page 30.

48 20221081 / F

Page 57

FIGURES AND DRAWINGS

6. FIGURES AND DRAWINGS

This section contains outline drawings showing the mechanical

dimensions of the different HS50 parts. To scale drawings are

available upon request.

The following drawings are enclosed:

Name Drw. no Rev.

Sensor Unit, dimensions 3822-MA-015 1

Sensor Unit Bracket, dimensions 3822-MD-027 2

Sensor Unit Pedestal, dimensions 3822-MD-034 0

The following figures are enclosed:

Name Page

Processing Unit, dimensions 53

Display Unit, dimensions 54

20221081 / F 49

Page 58

Simrad HS50 Heading Sensor

6.1 Sensor unit, dimensions

Date, Sign.

KONGSBERG

SEATEX

Scale :

1:5 A3

Design by :

Usage:

KL

Assey

1

Rev. no:

Approved :

Checked :

03.08.28

Date:

262

BOW

Description

Ship Heading and Navigation Sensor

1

Rev.

Material in Housing: Polyethylene

Material in Nut`s and Screw`s : Stainless steel DIN 316

Weight : 8 Kg

Title :

3822-MA-015

02.05.08

Dimensions Sensor Unit

Issued :

Drawing no:

Subtitle:

proj3munin/3822/technical

notes/mechanicaldesign/

sensorunit/ma015_00

Projection:

Xref file :

27

225

77,5

850

27

25

140

M10 (4x)

205

BOW

50 20221081 / F

Page 59

FIGURES AND DRAWINGS

6.2 Sensor unit bracket, dimensions

030170200

Weight

Date, Sign.

KONGSBERG

SEATEX

Material

KL/HW

Design by :

Detail

Scale :

Usage:

2

Rev. no:

Approved :

Checked :

02.02.22 1:2

Date:

Description

Subtitle:

Sensor Unit Bracket Symmetrical Style

3822-MD-027

01.04.30

Issued :

Drawing no:

proj3munin/3822/technical

notes/wp7mechanical design/

sensorunit/md027_02

Projection:

Xref file :

Pos.

Tolerance: ISO 2768-M if not specified on drawing

Wall tickness: 4,0 mm

Material : Aluminium AISI 5052

0 7070

8

R

Colour : Grey RAL 7032

No.

Description

Ship Heading and Navigation Sensor

Rev.

Title :

110

262

0

0

1

R

0

1

R

1

0

3

0

1

R

2

1

0 35 112,5112,5

0 30 55 170 200

0

0

8

1

R

8

110

20221081 / F 51

200

Page 60

Simrad HS50 Heading Sensor

6.3 Sensor unit pedestal, dimensions

5

5

170

Weight

Date, Sign.

KONGSBERG

SEATEX

Material

1:2 (A3)

Scale :

Design by :

Usage:

KL

Detail

0

)

x

4

(

2

1

0

3

Rev. no:

Approved :

Checked :

02.05.06