Simrad ES60 - INSTALLATION REV A Installation Manual

Installation manual

Simrad ES60

Fish nding

echo sounder

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

www.SIMRAD.com

Simrad ES60

Installation manual

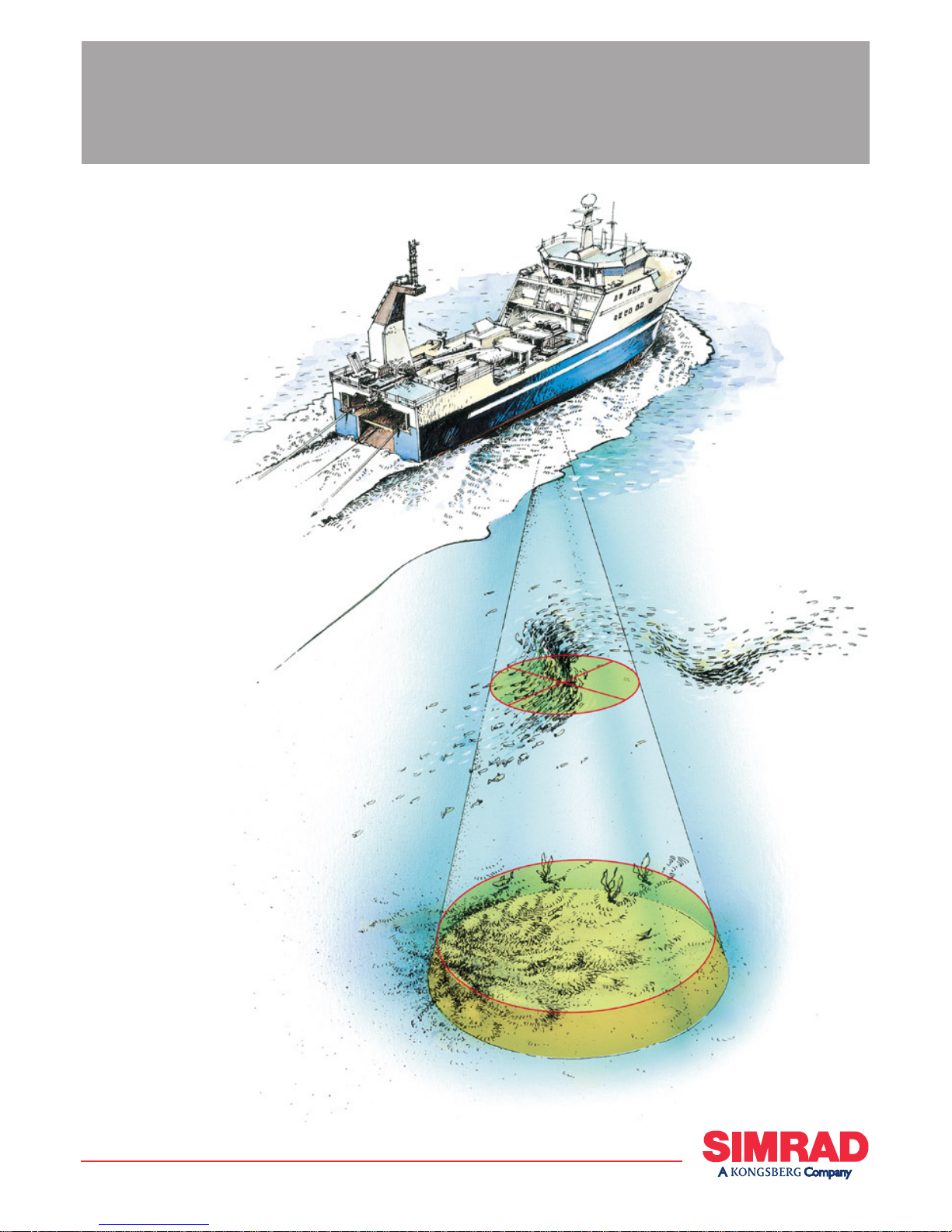

This manual provides you with the basic information

required to install the Simrad ES60 Fish finding ec ho

sounder. For more detailed information about the pract

ical

use of the product, refer to the Operator manual.

304699/A

September 2006

Document history

Document number: 304699 / ISBN-10: 82-8066-072-0 / ISBN-13: 978-82-8066-072-5

Rev. A

September 2006

First version. Information is extracted from the former Instruction

manual, and several details have been changed.

Copyright

©2006SimradHortenAS

The information contained in this document remains the sole property of Simrad Horten AS. No part of this

document may be copied or reproduced in any form or by any means, and the information contained

within

it is not to be communicated to a third party, without the prior written consent of Simrad

Horten AS. The document, or any part of it, may not be translated to any other language

without the written approval from Simrad Horten AS.

Disclaimer

Simrad Horten AS endeavours to ensure that all information in this document is correct and f

airly stated,

but does not accept liability for any errors or omissions.

Warning

The equipment to which this manual appliesmustonlybeusedforthepurposefor

which it was designed. Improper u se or maintenance may cause damage to the

equipment and/or injury to personnel. The user m ust be familiar with the cont

ents of

the appropriate manuals before attempting to install, operate or work on the equipment.

Simrad Horten AS disclaims any responsibility for damage or i njury caused by improper installation,

use or maintenance of the equipment.

Support

If you require maintenance on your Simrad equipment, contact you

r local dealer. You can also contact

Simrad using the following address: contact@simrad.com. If you need other information about this

product, or any o ther Simrad products, visit w

ww.simrad.com. On our web site yo u will also find a list of

our dealers and distributors.

Strandpromenaden 50

P. O. Bo x 1 11

N-3191 Horten,

Norway

Simrad Horten AS

Telephone:+4733034000

Telefax:+4733042987

simrad.sales@simrad.com

www.simrad.com

Installation manual

Table of contents

INTRODUCTION ................................................................ 9

Simplified system diagram ..................................................................................... 10

General safety rules ................................................................................................ 11

General supply conditions ...................................................................................... 12

Equipment responsibility............................................................................. 12

Receipt, unpacking and storage .................................................................... 12

General installation requirements........................................................................... 13

Approval by classification society ................................................................ 13

Supply power ............................................................................................. 13

Compass deviation ...................................................................................... 13

Noise sources ............................................................................................. 13

Dry docking ............................................................................................... 13

Wiring........................................................................................................ 14

Equipment handling ............................................................................................... 15

Transportation ............................................................................................ 15

Lifting ........................................................................................................ 15

Storage prior to installation or use................................................................ 16

Inspection................................................................................................... 17

Unpacking.................................................................................................. 18

General unpacking procedure.................................................................. 18

Unpacking electronic and electromechanical units.................................... 19

Unpacking mechanical units ................................................................... 19

Unpacking transducers ........................................................................... 19

Storage after unpacking............................................................................... 20

Storage after use ......................................................................................... 20

Cleaning cabinets................................................................................... 20

Mechanical units.................................................................................... 21

Cables ................................................................................................... 21

Internal batteries .................................................................................... 21

Dehumidifier ......................................................................................... 22

Coatings................................................................................................ 22

Re-packaging ............................................................................................. 22

Circuit board packaging .............................................................................. 22

Beware of ESD! ..................................................................................... 23

Unpacking and handling circuit boards .................................................... 23

Unpacking on board ............................................................................... 23

Returning a circuit board ........................................................................ 23

Temperature protection................................................................................ 24

What is ESD? ............................................................................................. 24

304699/A 3

Simrad ES60

INSTALLATION PROCEDURES ......................................... 26

Basic procedure ...................................................................................................... 26

Configuration..........................................................................................................27

Transducer ................................................................................................. 27

General Purpose Transceiver (GPT) ............................................................. 28

Computer ................................................................................................... 29

Display ...................................................................................................... 29

Software..................................................................................................... 30

Printer........................................................................................................ 30

General Purpose Transceiver installation ...............................................................31

ES60 Marine Computer installation .......................................................................33

CABLE LAYOUT................................................................ 34

Cabling principles................................................................................................... 35

Cable identifications.................................................................................... 35

Cable information ....................................................................................... 35

System and shipyard cables ......................................................................... 35

ES60 Cable plans....................................................................................................36

Cable plan with one transceiver ................................................................... 37

Cable plan with two transceivers.................................................................. 38

List of cables .............................................................................................. 39

Cable details ...........................................................................................................45

Generic RS-232 Serial line cable.................................................................. 47

Commercial power supply ........................................................................... 48

External power supply for transceiver .......................................................... 49

230 Vac power cable ................................................................................... 50

Ship’s ground ............................................................................................. 51

Ethernet cable with RJ45, “straight”............................................................. 52

Ethernet cable with RJ45, “crossover”.......................................................... 53

VGA/SVGA Display cable.......................................................................... 54

USB cable.................................................................................................. 55

PS/2 Adapter for mouse and keyboard.......................................................... 56

Serial line adapter ....................................................................................... 57

GPT remote on/off ...................................................................................... 58

GPT trigger / synchronisation...................................................................... 59

GPT external sensors .................................................................................. 60

GPT Event and New line ............................................................................. 61

GPT Alarm output ...................................................................................... 62

GPT battery ................................................................................................ 63

Cable between ITI and echo sounder ............................................................ 64

Cable between PI44/54 and echo sounder ..................................................... 65

Cable between PI30/32 and echo sounder ..................................................... 66

Cable between SH/SP sonar and echo sounder.............................................. 67

4

304699/A

Installation manual

Single beam, normal power transducer ......................................................... 68

Single beam, high power transducer............................................................. 69

Dual beam (wide or narrow) transducer ........................................................ 70

Split beam transducer.................................................................................. 71

Split beam transducer to single beam transceiver........................................... 72

Single beam transducer to split beam transceiver........................................... 73

Dual frequency, single beam transducer........................................................ 74

Deep water, split beam transducer ................................................................ 75

ES38–10 transducer .................................................................................... 76

12-16/60 transducer .................................................................................... 77

50/200 Combi C transducer ......................................................................... 78

38/200 Combi C transducer ......................................................................... 79

Basic cable requirements ........................................................................................80

Cable trays ................................................................................................. 80

Radio Frequency interference ...................................................................... 81

Physical protection...................................................................................... 81

Grounding.................................................................................................. 81

Cable connections....................................................................................... 82

Cable terminations...................................................................................... 82

Cable identification..................................................................................... 82

INTERFACES AND INTEGRATION .................................... 83

About NMEA interfaces and telegrams .................................................................83

NMEA....................................................................................................... 84

Telegrams................................................................................................... 84

Standard NMEA 0183 communication parameters........................................ 84

Ethernet interfaces ..................................................................................................84

BI500 interface........................................................................................... 85

Transceiver interface................................................................................... 85

Duplex interfaces....................................................................................................87

Trawl system interface ................................................................................ 87

Catch monitoring system interface ............................................................... 88

Input interfaces .......................................................................................................89

Navigation system interface......................................................................... 90

Heave sensor interface ................................................................................ 90

Temperature sensor interface ....................................................................... 92

Output interfaces ....................................................................................................92

Sonar system interface ................................................................................ 92

Depth interface ........................................................................................... 94

External triggering..................................................................................................95

Master system............................................................................................. 95

Slave system............................................................................................... 96

GPT Auxiliary connector ....................................................................................... 96

304699/A 5

Simrad ES60

DRAWING FILE ............................................................... 99

GPT Outline dimensions ......................................................................................100

GPT Power supply outline dimensions ................................................................ 102

Marine computer outline dimensions ................................................................... 104

GPT Transducer plug connection .........................................................................105

TECHNICAL SPECIFICATIONS ....................................... 106

Echo sounder specifications ................................................................................. 106

Interface specifications .........................................................................................106

General Purpose Transceiver specifications .........................................................107

Colour display specifications................................................................................108

ES60 Marine Computer specifications ................................................................. 108

TRANSDUCER I NSTA LLATION ....................................... 110

Transducer location .............................................................................................. 110

Go deep ....................................................................................................110

Vessel heave .............................................................................................. 111

Noise from protruding objects on the hull ....................................................111

Boundary water layer .................................................................................111

Propeller noise...........................................................................................112

Inclination of the transducer face ................................................................113

Summary and general recommendation .......................................................113

Ways of mounting t he transducer ......................................................................... 114

External mounting .....................................................................................115

Transducer blister ..................................................................................... 120

Box keel................................................................................................... 126

Flush mounting in a steel tank ................................................................... 128

Acoustic window...................................................................................... 130

Inside the hull........................................................................................... 132

Drop keel ................................................................................................. 134

Retractable transducer ............................................................................... 135

Cable glands .........................................................................................................136

Order numbers .......................................................................................... 136

Cable gland for steel hulls ......................................................................... 137

Cable gland for wood or GRP hulls............................................................ 138

Cable glands for small hulls....................................................................... 139

Cable splicing ........................................................................................... 140

Steel conduit .........................................................................................................140

Handling and maintenance ...................................................................................141

Approved anti-fouling paints ..................................................................... 142

SIMRAD TRANSDUCERS ................................................ 143

All 12 kHz transducers .........................................................................................144

All 18 kHz transducers .........................................................................................144

6

304699/A

Installation manual

All 27 kHz transducers .........................................................................................144

All 38 kHz transducers .........................................................................................145

All 50 kHz transducers .........................................................................................147

All 70 khz transducers.......................................................................................... 148

All 120 khz transducers........................................................................................ 149

All 200 kHz transducers .......................................................................................150

All 710 kHz transducers .......................................................................................152

304699/A 7

Simrad ES60

8 304699/A

Introduction

INTRODUCTION

The purpose of this installation manual is to present the

descriptions and drawings required to install the Simrad ES60

Fish finding echo sounder system. The equipment described

in this manual includes the complete system with associated

cabinets, but not those system units provided locally by the

customer, installation shipyard or local dealer.

The manual also defines the equipment responsibility, and

provides instructions for unpacking and storage.

Note

Detailed vessel specific mechanical drawings for the installation

must be provided by the customer, or any shipyard contracted to

perform the installation. Simrad may, on special order, provide

assistance to these drawings. D rawings must be approved by the

appropriate vessel certification authority prior to installation

of the system.

The installation instructions given in this document must be

adhered to. Failure to do so may render the guarantee void.

Topics

Simplified system diagram on page 10

General safety rules on page 11

General supply conditions on page 12

General installation requirements on page 13

Equipment handling on page 15

304699/A 9

Simrad ES60

Simplified system diagram

Asimplified system diagram is shown below.

System diagram with one transceiver

SIMR

AD

G

PT

(CD010200D)

B

C

D

A

(A) = Colour monitor

(B) = Processor Unit (computer)

(C) = General Purpose Transceiver (GPT)

(D) = Transducer

10

304699/A

Introduction

General safety rules

TheSimradES60Fishfinding echo sounder system operates on

230 Vac 50/60 Hz.

WARNING

This voltage may be lethal!

The following safety precautions must be followed at all times

during installation and maintenance work:

• Always switch off all power before installation or

maintenance. Use the main circuit breaker, and label

the breaker with a warning sign that informs others that

maintenance or installation work is being carried out on the

system.

• Do not open the rack or cabinet doors while in rough seas. It

may swing open suddenly and cause damage or injury.

• For safety reasons during troubleshooting on the equipment

with power ON, two persons must always be present.

• Read and understand the first aid instructions for electric

shock.

• Whenever maintenance is carried out, it is essential that a fi

rst

aid kit is available, and that the maintenance personnel ar

e

familiar with the first aid instructions for electrical s

hock.

• The various parts of the system are heavy. Make sure

that

the appropriate tools and certified lifting equi

pment are

available, and that the personnel are trained i

n installation

and maintenance work.

304699/A

11

Simrad ES60

General supply conditions

The following supply conditions are applicable to this Simrad

ES60 Fish finding echo sounder delivery.

Equipment responsibility

The shipyard performing the installation and/or equipment dealer

becomes fully responsible for the equipment upon receipt unless

otherwise stated in the contract. The duration of responsibility

includes:

• The period of time the equipment is stored locally before

installation.

• During the entire installation process.

• While commissioning the equipment.

• The period of time between commissioning and the final

acceptance of the equipment by the end user (normally the

owner of the vessel which the equipment has been installed).

Unless other arrangements have been made in the contract, the

ES60 Fish finding echo sounder system guarantee period (as

specified in the contract) begins when the acceptance documents

have been signed

Receipt, unpacking and storage

Upon accepting shipment of the equipment, the shipyard and/or

the dealer should ensure that the delivery is complete and inspect

each shipping container for evidence of physical damage. If

this inspection reveals any indication of crushing, dropping,

immersion in water or any other form of damage, the recipient

should request that a representative from the company used to

transport the equipment be present during unpacking.

All equipment should be inspected for physical damage, i.e.

broken controls and indicators, dents, scratches etc. during

unpacking. If any damage to the equipment is discovered,

the recipient should notify both the transportation company

andSimrad so that Simrad can arrange for replacement or repair

of the damaged equipment.

Once unpacked, the equipment must be stored in a controlled

environment with an atmosphere free of corrosive agents,

excessive humidity or temperature extremes. The equipment

must be covered to protect it from dust and other forms of

contamination when stored.

For more information, refer to Equipment handling on page 15

12

304699/A

Introduction

General installation r equirements

The following installation requirements are applicable to this

Simrad ES60 Fish finding echo sounder delivery.

Approval by classification society

The ES60 Fish finding echo sounder transducer installation

must be approved by Det Norske Veritas (DNV) or another

classification society. The shipowner and shipyard performing

the installation are responsible for obtaining installation approval.

Supply power

The supply voltage to the equipment is to be kept within ±10% of

the installation’s nominal voltage. Maximum transient voltage

variations on the main switchboard’s bus-bars are not to exceed

-15% to +20% of the nominal voltage (except under fault

conditions).

Simrad recommends that the ES60 Fish finding echo sounder is

powered using an Uninterruptable Power Supply (UPS). The

UPS should have the capacity to independently maintain power

to the system for a minimum of 10 minutes. This ensures that the

system can be switched off in a controlled manner in t he event

of a power failure.

Compass deviation

Once the installation is complete, the vessel must be swung with

the system in both the operative and inoperative modes. The

shipowner and captain are responsible for updating the deviation

table accordingly with regard to the vessel’s national registry and

corresponding maritime authority.

Noise sources

The vessel’s hull, rudder(s) and propeller(s) s hould be thoroughly

inspected in dry dock prior to installation. Roughness below

the water-line deformities in the shell plating and protruding

obstacles can create underwater noise. These sources of

turbulence must be smoothed or removed as best as possible. It is

especially important that the propeller(s) is not pitted or damaged.

Dry docking

Make sure that ample clearance under the sonar trunk and/or

protection blister is provided when dry docking the vessel. Avoid

locating supporting blocks or structures in the vicinity of this

equipment.

304699/A 13

Simrad ES60

Note

The location of the transducer and/or protection blister must be

noted on the vessel’s docking plan for future reference.

Wiring

All cables running between system cabinets located in different

rooms and/or on different decks must be supported and protected

along their entire lengths using conduits and/or cable trays. Note

that the cables must not be installed in the vicinity of high-power

supplies and cables, antenna cables or other possible sources

of interference.

Whenever possible, transducer cables must be run in steel

conduits.

For more detailed information about cables and wiring, refer to

Basic cable requirements on page 80

14

304699/A

Introduction

Equipment handling

This section provides the basic rules for transportation, storage

and handling of units. In this c ontext, a unit may be any large or

small part of the system. It can be supplied as part of the initial

delivery, or as a spare part.

Transportation

Unless otherwise stated in the accompanying documentation,

electronic, electro-mechanical and mechanical units supplied

by Simrad can be transported using all methods approved for

delicate equipment; (by road, rail, air or sea). The units are to be

transported in accordance with general or specific instructions for

the appropriate unit(s), using pallets, transport cases, or carton

boxes as appropriate.

Note

Special local restrictions concerning air transportation may be

applied to units containing certain types of batteries. These

units must be checked properly, and the regulations must be

investigated by the packer/shipper before the unit is dispatched.

All local transportation must be carried out according to the same

specifications as for the initial delivery. In general, all units must

be handled with care.

The carton or case containing the unit must be kept dry at all

times, and must be sheltered from the weather. It must not

be subjected to shocks, excessive vibration or other rough

handling. The carton or case will normally be marked with text

or symbols indicating which way it is to be placed. Follow any

instructions given, and ensure the case is always placed with its

“top” uppermost.

The carton or case must not be used for any purpose for which it

was not intended (step, table, etc.), and in the absence of other

information, no other cartons or cases must be stacked on top

of it.

Lifting

A heavy crate will normally be marked with its weight, and the

weights of other cartons or crates will normally be entered on

the packing list.

• You must always check the weight of a crate before you

attempt to lift it.

• You must always use lifting apparatus that is approved and

certified for the load.

304699/A 15

Simrad ES60

Heavy units may be equipped with lifting lugs for transportation

by crane within the workshop or installation area. Before you

use a crane:

• You must check the applicable weight certificateforthecrane.

• You must check the security of the lifting lugs.

Ensure that all available lifting lugs are used. Ensure the unit

remains under control during the operation to avoid damage to

the unit, equipment or personnel.

Heavy units may be transported using a forklift truck. Special

attention must t hen be paid to the position of the unit’s centre of

gravity. The units must be properly secured to the truck.

Storage prior to installation or use

When a system, a unit or a spare part has been delivered to

the customer, it may be subject to long time storage prior

to installation and use. During this storage period, certain

specifications must be met. The equipment m ust be preserved

and stored in such a way that it does not constitute any danger

to health, environment or personal injury.

1 The equipment must be stored in its original transportation

crate.

2 Ensure that the units are clearly separated in the shelves and

that each unit is easily identifiable.

3 The crate must not be used for any purpose for which it was

not intended (eg. work platform etc.).

4 The crates must not be placed on top of each other, unless

specific markings permit this.

5 The crates must not be placed directly on a dirt-floor.

6 Do not open the crate for inspection unless special

circumstances permit so.

• “Special circumstances” may be suspected damage to the

crate and its content, or inspections by civil authorities.

• If any units are damaged, prepare an inspection report

stating the condition of the unit and actions taken.

Describe the damage and collect photographic evidence

if possible. Re-preserve the equipment.

• If the units are not damaged, check the humidity

absorbing material. If required, dry or replace the

bags, then re-pack the unit(s) according to the packing

instructions.

7 If the crate has been opened, make sure that is it clos

ed

and sealed after the inspection. Use the original p

acking

material as far as possible.

16

304699/A

Introduction

8 The storage room/area must be dry, with a non-condensing

atmosphere. It must be free from corrosive agents.

9 The storage area’s mean temperature must not be lower than

-30° C, and not warmer than +70° C. If other limitations

apply, the crates will be marked accordingly.

Note

Transducers must not be stored in temperatures below -20°

C, or higher than +60° C.

10 The crate must not be exposed to moisture from fluid

leakages.

11 The crate must not be exposed to direct sunlight or excessive

warmth from heaters.

12 The crate must not be subjected to excessive shock and

vibration.

13 If the unit contains normal batteries, these may have been

disconnected/isolated before the unit was packed. These

must only be reconnected before the installation starts. Units

containing batteries are marked.

Caution

Units containing lithium or alkaline batteries must

be handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge

such batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

Inspection

An inspection must be carried out immediately after the unit(s)

have arrived at their destination.

1 Check all wooden or cardboard boxes, plastic bags and

pallets for physical damage. Look for signs of dropping,

immersion in water or other mishandling.

2 If damage is detected externally, you will have to open the

packaging to check the contents. Request a representative of

the carrier to be present while the carton is opened, so any

transportation damage can be identified.

3 If any units are damaged, prepare an inspection report

stating the condition of the unit and actions taken. Describe

the damage and collect photographic evidence if possible.

Send the inspection report to Simrad as soon as possible.

304699/A 17

Simrad ES60

4 If the units are not damaged, check the humidity absorbing

material. If required, dry or replace the bags, then re-pack

the unit(s) according to the packing instructions.

Unpacking

General unpacking procedure

Normal precautions for the handling, transportation and storage

of fragile electronic equipment must be undertaken.

Note

If the unit is not to be prepared for immediate use, you may

consider storing it unopened in its original packing material.

However, it may be useful to open the case to check its contents

for damage and retrieve any accompanying documentation.

Do not use a knife to open cardboard cartons - the contents may

lie close to the surface, and may be damaged by the blade.

1 Check the carton before opening it to ensure it shows no

signs of dropping, immersion in water or other mishandling.

If the carton shows signs of such damage, refer to the

paragraph covering Inspection on receipt.

2 Place the carton on a stable work bench or on the floor with

the top of the carton uppermost.

3 In the absence of other instructions, always open the top

of the carton first. The contents will normally have been

lowered into the carton from above, so this will usually be

the easiest route to follow. Care must be used when opening

the carton to ensure the contents are not damaged. D

o not

use a knife to open cardboard cartons

4 If the carton has been closed using staples, remove the

staples from the carton as you open it. This will reduce the

possibilities of scratch injury to yourself and damage to the

contents.

5 If a wooden crate has been closed using screws, always

remove them using a screwdriver. Do not attempt to prise

the lid off with a crowbar or similar.

6 Once the carton is open, carefully remove all loose packing

and insulation material. Check for manuals and other

documents that may have been added to the carton during

packing, and put these to one side. Check also for special

tools, door keys etc.

18

304699/A

Introduction

Unpacking electronic an d electromechanical units

Electronic and electromechanical units will normally be wrapped

in a clear plastic bag. Lift the unit, in its bag, out of the carton

and place it in a stable position on the floor/work bench.

Inspect the unit for damage before opening the plastic bag.

Note

Beware of the dangers of Electro-Static Discharge (ESD) both

to yourself and to the equipment, when handling electronic units

and components.

Cables must never be used as carrying handles or lifting points.

Do not break the seal to open a circuit board package before

the board is to be used. If the board package is returned to the

manufacturer with the seal broken, the contents will be assumed

to have been used and the customer will be billed accordingly.

Assuming all is well, open the bag and remove the unit.

Open the unit and check inside. Remove any packing and

desiccant material that may be inside.

Unpacking m echanical units

Mechanical units may be heavy. Using a suitably certified lifting

apparatus, lift the unit out of the crate and place it in a stable

position on the floor/work bench.

Inspect the unit for damage and remove any packing material that

may be inside the unit.

Unpacking transducers

Transducers may be supplied mounted to a hull unit (if any), or

packed separately. Crates are normally identified by the order

number and the serial number.

The transducer face must be protected by a rigid, padded cover

(e.g. a wooden box lined with foam rubber) all the time it is

exposed to the risk of physical damage.

Caution

Once transducer is unpacked, great care must be taken

to ensure that transducer body and cabling is not

exposed to any mechanical stress.

304699/A 19

Simrad ES60

Storage after unpacking

The unit must whenever possible be stored in its original

transportation crate until ready for installation. The crate must

not be used for any purpose for which it was not intended (eg.

work platform etc.).

Once unpacked, the equipment must be kept in a dry, non

condensing atmosphere, free from corrosive agents and isolated

from sources of vibration.

Note

Do not break the seal to open a circuit board package before

the board is to be used. If the board package is returned to the

manufacturers with the seal broken, the contents will be assumed

to have been used and the customer will be billed accordingly.

The unit must be installed in its intended operating position as

soon as possible after unpacking. If the unit contains normal

batteries, these may have been disconnected/isolated before the

unit was packed. These must then be reconnected during the

installation procedure. Units containing batteries are marked.

Note

Units containing lithium or alkaline batteries must be handled

separately and with care. Such units are marked accordingly. Do

not attempt to recharge such batteries, open them or dispose of

them by incineration. Refer to the applicable product data sheets.

Storage after use

If a unit is removed from its operating location and placed into

storage, it must be properly cleaned and prepared before packing.

Cleaning cabinets

If a cabinet has been exposed to salt atmosphere while it was in

use, it must be thoroughly cleaned both internally and externally

to prevent corrosion.

1 Wipe the cabinet externally using a damp cloth and a little

detergent. Do not use excessive amounts of water as the

unit may not be water tight. On completion, dry the unit

thoroughly.

2 All surfaces must be inspected for signs of corrosion,

flaking/bubbling paint, stains etc. Damaged or suspect areas

must be cleaned, prepared and preserved using the correct

preservation mediums for the unit. The mediums to be used

will usually be defined in the units’ maintenance manual.

20

304699/A

Introduction

3 Open the unit, and using a vacuum cleaner, remove all dust

etc. from the unit. Great care must be taken to ensure the

circuit boards and modules are not damaged in the process.

Mechanical units

If a mechanical unit may has been exposed to a salt atmosphere

while it was in use, it must be thoroughly cleaned both internally

and externally to prevent corrosion.

1 If the construction materials and type of unit permits, wash

the unit using a high-pressure hose and copious amounts

of fresh water. Examples are the lower parts of hull units

(outside the hull) or subsea units

2 Ensure that all traces of mud and marine growth are

removed. Use a wooden or plastic scraper to remove

persistent growth, barnacles etc. On completion, dry the

unit thoroughly.

Caution

Do not use a high pressure hose in the vicinity of

cables or transducers. Do not use sharp or metal

tools on a transducer face.

3 If the materials or type of unit prevents the use of a

high-pressure hose, wipe the unit using a cloth dampened

with water containing a little detergent. Examples are the

upper parts of hull units (inside the hull) and hydraulic

systems

4 Do not use excessive amounts of water as some components

on the unit may not be water tight. Wipe off the detergent

with a damp cloth, then dry the unit thoroughly.

5 All surfaces must be inspected for signs of corrosion,

flaking/bubbling paint, stains etc. Damaged or suspect

areas must be cleaned, prepared and preserved using the

correct preservation mediums. The mediums t o be used will

normally be defined in the unit’s maintenance manual.

Cables

Wipe clean all exposed cables, and check for damage. If a cable

shows signs of wear or ageing, contact Simrad for advice.

Internal batteries

If the unit contains batteries, these may discharge slowly during

storage. If the unit is to be stored f or an extended period,

disconnect or remove all internal batteries.

304699/A

21

Simrad ES60

A suitable piece of insulating material can be placed between the

battery and the electrical contacts to prevent electrical discharge.

The battery can then remain in the unit, reducing the risk of it

being misplaced during the storage period.

Caution

Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by incineration.

Refer to the applicable product data sheets.

Dehumidifier

Place a suitably sized bag of desiccant material (silica gel or

similar) into the unit to keep the electronic components as dry

as possible.

Coatings

Spray the unit externally with a corrosion inhibitor (e.g. a light

oil) before packing.

Re-packaging

Whenever possible, the unit m ust be stored and transported in

its original packing material and/or crate. In the event that this

material is not available, proceed as follows:

• Small units must be protected from damp by being placed

within a plastic bag at least 0.15 mm thick. An appropriate

quantity of desiccant material should be placed inside this bag,

and the bag sealed. The sealed unit must then be placed in an

appropriate carton or crate, and supported in the container

by appropriate shock-absorbing insulation (polystyrene foam

chips etc.).

• Large units must be placed in a suitable cardboard box or

wooden crate. The unit must be protected against physical

damage by means of shock-absorbing insulation mats. The

box must be clearly marked with its contents, and must be

stored in a dry and dust-free area.

Circuit board packaging

Circuit boards are delicate items. They may work year after year

in an advanced product, but then fail due to a small spark of

static electricity. For this reason, it is very important that they are

properly handled and protected during shipping.

22

304699/A

Introduction

Beware of ESD!

When you handle electronic circuit boards, you must beware of

the dangers of electrostatic discharge (ESD), both to yourself and

to the equipment. In order to ensure safe transport and storage,

circuit boards and other electronic units will always be wrapped

in a clear plastic protective bag, and the bag will be sealed.

See also: What is ESD? on page 24.

Unpacking and handling circuit boards

To unpack a circuit board:

• Wherever possible, prepare a suitable workbench. It must

have an approved conductive service mat, and i t must be

connected directly to a reliable earth point via its earthing

cord. You must wear a wristband in direct contact with the

skin, and the wristband must be connected to the service mat.

• Lift the circuit board, in its protective bag, out of the carton

and place it in a stable position on the a floor/work bench.

• Inspect the unit for damage before you open the plastic bag.

• Do not break the seal to open a circuit board package before

the board shall to be used. If the board package is returned

with the seal broken, we will assume that the content has been

used, and we will bill you accordingly.

• Assuming all is well, open the bag and remove the unit.

• Take out and keep the documentation. You will need it if

the circuit board shall be returned to us. Also, remove any

packing and desiccant material that may be inside.

• Keep the protective plastic bag for future use.

Unpacking on board

When you are working on board a vessel, an “approved

conductive service mat” is often far away. As you still need to

unpack circuit boards, make sure that you do it in the instrument

room, or at another location where you have a steel deck. Keep

far away from the bridge or any other rooms w ith wall-to-wall

carpets! If possible, bring a wristband and ground yourself.

Returning a circuit board

If you wish to return a circuit board to us, observe the following

rules.

• Place the circuit board to be returned in the same protective

plastic bag as you originally received it in - or a protective bag

of similar ESD protection quality.

•D

O NOT use standard plastic bags, such as commercial

bubble wrap.

304699/A 23

Simrad ES60

• Fill in all the necessary information on the applicable

documentation and place it inside the bag.

• Seal the bag.

• Place the circuit board in a suitable carton, and secure it for

shipping.

Note

Failure to follow these rules may result in unserviceable circuit

boards.

Temperature protection

If the unit must be protected against extremes of temperature,

the carton/crate must be lined on all walls, base and lid with 5

cm thick polyurethane or polystyrene foam. These units will be

identified as delicate in the applicable documentation.

The package must then be clearly marked:

Must not be transported or stored in temperatures below -5

degrees Celsius.

Other units can normally be stored in temperatures between -30°

C and +70° C, refer to the system’s technical specifications for

details.

Transducers must not be stored in temperatures below -20° C

and above +60° C.

What is ESD?

Electro-Static Discharge (ESD) is the transfer of a n electrostatic

charge between two bodies at different electrostatic levels,

caused either by direct contact or induction by an electrostatic

field. The passing of a charge through an electronic device can

cause localised overheating, and it can also “puncture” insulating

layers within the structure of the device. This may deposit a

conductive residue of the vaporised metal on the device, and thus

create a short circuit. This may result in a catastrophic failure, or

degraded performance of the device.

ESD protection

Sensitive electronic circuit boards must be transported and

stored in protective packing bags. The circuit boards must

not be transported or stored close to strong electrostatic,

electro-magnetic or radioactive fields. If it is necessary to open

and touch the circuit board inside the protective bag, then the

following precautions must be taken:

24

304699/A

Introduction

• The working area must be covered by an approved conductive

service m at that has a resistance of between 50 kΩ and 2

MΩ, and is connected directly to a reliable e arth point via

its earthing cord.

• The service personnel involved must wear a wristband in

direct contact with the skin, connected to the service mat.

• Printed circuit boards must be placed on the c onductive

service mat during installation, maintenance etc.

• If, for any reason, it is necessary to move the circuit board

from the conductive service mat, it must be placed in an

approved antistatic transportation container (e.g. static

shielding bag) before transportation.

• During installation and servicing, all electrical equipment

(soldering irons, test equipment etc.) must be earthed.

304699/A 25

Simrad ES60

INSTALLATION PROCEDURES

This chapter provides the basic information required to install

the physical units.

Note

Physical installation of commercial units (computers, printers,

displays) is n

ot described in this manual. Refer to the applicable

user manual(s) provided with the product.

Topics

Basic procedure on page 26

Configuration on page 27

General Purpose Transceiver installation on page 31

ES60 Marine Computer installation on page 33

Basic procedure

This is the basic installation procedure.

1 Check that you have received all parts required for the

installation; cables, connectors, brackets etc.

2 Install the transducer(s) and the transducer cables according

to the guidelines in this manual and the drawings provided

with the transducer.

3 If applicable, install the two-wire cable for the temperature

sensing thermistor.

4 Mount the Processor Unit (computer) and the display using

the appropriate brackets.

5 Connect the computer and display cables:

• Power cable to display monitor.

• Power cable to computer.

• Video cable from computer to display monitor.

• Connect the pointing device (mouse or trackball)

6 Mount the General Purpose Transceiver using the

appropriate brackets.

7 Connect the cables:

• Transducer cable(s)

• Power cable(s)

• If applicable, connect the cable from the temperature

sensor.

• If available, install a two-wire cable for remote on/off of

the General Purpose Transceiver(s).

26

304699/A

Installation procedures

8 Prepare and install the ethernet cable(s) between the

General Purpose Transceiver(s) and the computer:

• An Ethernet cable must be used between the General

Purpose Transceiver and the computer.

• If only one General Purpose Transceiver is used, you

need a t wisted pair cable with swapped receive and

transmit wires. The cable is connected between the

transceiver and the computer.

• An Ethernet switch is required if your system includes

more than one General Purpose Transceiver. If a hub

is used, all ethernet cables must be of the “straight

through” type.

9 Prepare and install the required serial line interfaces.

• Connect navigation receiver, trawl system and heave

sensor with serial line output to the rear of the echo

sounder computer using RS-232 cables. Heave sensors

with an analog output are connected directly to the

Auxiliary connector of the nearest transceiver.

10 If required, prepare and install the synchronization cable(s).

• Synchronous transmission is desirable if there are

several echo sounders on-board the vessel. For every

echo sounder and every transceiver on-board the ship,

connect the appropriate pins at the

Auxiliary connectors

together using a two-wire cable.

Configuration

TheSimradES60Fishfinding echo sounder is designed as a

modular system. It supports a variety of configurations and

frequency options. The delivery may consist of:

• Transducer(s)

• General Purpose Transceiver(s) (GPT)

• Ethernet switch (if the system comprises more than one GPT)

• Processing Unit (computer)

• Display monitor

• Pointing device (mouse or trackball)

The computer, display monitor and pointing device may be

provided locally using standard commercial components.

Transducer

One or more transducers are included. A single frequency

General Purpose Transceiver will accept one transducer, while a

dual frequency transceiver will accept two transducers.

304699/A 27

Simrad ES60

A large number of transducers are available. There are several

transducer alternatives for each operating frequency with

different beam widths, power rating and mounting arrangements.

All transducers are rated 60 or 75 ohms. Each has an efficiency

of approximately 50%.

Related topics

Simrad transducers on page 143

Transducer Installation on page 110

General Purpose Transceiver (GPT)

One or more General Purpose Transceivers (GPT) are included.

A single frequency General Purpose Transceiver accepts one

transducer, while a dual frequency transceiver accepts two

transducers.

The General Purpose Tra

nsceiver is a small self-contained unit

containing its own po

wer s upply. It operates on +12 Vdc or

115-230 Vac. The uni

t can be mounted anywhere on board

the ship, provi

ded that the location is dry and ventilated We

recommend th

at it is mounted as close to the transducer(s) as

possible. P

ower cable and mounting brackets are enclosed.

An Ethernet link connects the General Purpose Transceiver

to the Processor Unit (computer). This link may comprise a

standard Ethernet cable and - if necessary - an Ethernet switch.

The transceiver includes its own Ethernet interface. A network

interface board must be fitted to the computer.

The General Purpose Transceiver is available in single beam

and split beam configurations. A dual frequency single

beam configuration is also provided. The possible operating

frequencies are listed in the technical specifications. Typical

configurations include:

• GPT-S38(4)-F (single beam 38 kHz, 4 kW)

• GPT-S50(4)-F (single beam 50 kHz, 4 kW)

• GPT-S70(1)-F (single beam 70 kHz, 1 kW)

• GPT-S120(1)-F (single beam 120 kHz, 1 kW)

• GPT-S200(1)-F (single beam 200 kHz, 1 kW)

• GPT-Q38(4)-F (quad (split) beam 38 kHz, 4 kW)

• GPT-Q120(4)-F (quad (split) beam 120 kHz, 4 kW)

• GPT-S38(1)/S50(1)-F (single beam 38 and 50 kHz, 1+1 kW)

Two or more General Purpose Transceivers can exist on the same

Ethernet cable. A multi-frequency sounder e merges simply by

using several transceivers on the Ethernet cable.

28

304699/A

Loading...

Loading...