Page 1

Installation manual

TECHNOLOGY FOR SUSTAINABLE FISHERIES

www.simrad.com

Simrad ES38-12

38 kHz split-beam transducer

Page 2

Page 3

SimradES38-12

Installationmanual

Thisdocumentprovidesageneraldescriptionofhowto

installtheSimradES38-12Splitbeamtransducer.The

informationmustberegardedasgeneralguidelinesand

recommendationsonly.Theinstallationshipyardmust

designandmanufactureinstallationhardwaretotthe

ES38-12transduceroneachindividualvessel.

344276/A

17.02.2010

©

KongsbergMaritimeAS

Page 4

Documenthistory

Simraddocumentnumber:344276/ISBN-13:978-82-8066-119-7/Currentrevision:A

Rev.A15.022010

Copyright

©2010KongsbergMaritimeAS

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.Nopart

ofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformationcontained

withinitisnottobecommunicatedtoathirdparty,withoutthepriorwrittenconsentofKongsberg

MaritimeAS.Thedocument,oranypartofit,maynotbetranslatedtoanyotherlanguagewithoutthe

writtenapprovalfromKongsbergMaritimeAS.

Firstversion.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichit

wasdesigned.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjury

topersonnel.Theusermustbefamiliarwiththecontentsoftheappropriatemanualsbefore

attemptingtoinstall,operateorworkontheequipment.

KongsbergMaritimeASdisclaimsanyresponsibilityfordamageorinjurycausedbyimproper

installation,useormaintenanceoftheequipment.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Youcanalsocontactususingthefollowing

address:contact@simrad.com.Ifyouneedinformationaboutourotherproducts,visitourwebsite.On

thewebsiteyouwillalsondalistofourdealersanddistributors.

KongsbergMaritimeAS

www.kongsberg.com

Page 5

Installationmanual

Tableofcontents

ABOUTTHISMANUAL.......................................................5

SIMRADES38-12..............................................................6

WHERETOMOUNTTHETRANSDUCER...............................7

HOWTOINSTALLTHETRANSDUCER..............................11

Transducerinstallationinblister............................................................................11

Useamountingplatewheneverprovided.....................................................11

Smoothsurfaceisimportant........................................................................11

Example:Largecirculartransducer..............................................................12

Example:Mediumandlargetransducers,principle.......................................13

Example:Mediumandlargetransducers,detail............................................13

Commonguidelines....................................................................................14

Toe-in........................................................................................................14

Physicallocation.........................................................................................14

Transducerinstallationinboxkeel.........................................................................15

Usemountingplatewheneverprovided........................................................15

Smoothsurfaceisimportant........................................................................15

Example:Boxkeelinstallation....................................................................16

Transducerushmountedinasteeltank...............................................................16

Usemountingplatewheneverprovided........................................................16

Smoothsurfaceisimportant........................................................................16

Waterlled.................................................................................................16

Example:Flushmountinginasteeltank......................................................17

Transducerwithacousticwindow..........................................................................17

Usemountingplatewheneverprovided........................................................17

Smoothsurfaceisimportant........................................................................17

Example:Acousticwindow.........................................................................18

Transducermountedinsidethehull.......................................................................18

Usemountingplatewheneverprovided........................................................18

Smoothsurfaceisimportant........................................................................18

Example:Mountinginsidethehull..............................................................19

Transducermountedonadropkeel.......................................................................19

Retractabletransducer............................................................................................20

TOWEDBODYINSTALLATION.........................................21

Generalrequirements.............................................................................................21

Smoothsurfaceisimportant........................................................................21

Usemountingandclampingringswheneverprovided...................................21

Useamountingplatewheneverprovided.....................................................21

Installationinatowedbody...................................................................................22

344276/A

3

Page 6

SimradES38-12

Example:Smalltransducer..........................................................................23

Example:Mediumandlargetransducers......................................................23

Example:Dualtransducerarrangement........................................................24

STEELCONDUIT..............................................................25

TRANSDUCERHANDLINGANDMAINTENANCE................26

Rulesfortransducerhandling.................................................................................26

Rulesfortransducermaintenance..........................................................................27

Approvedanti-foulingpaintsfortransducers.........................................................28

Usingself-lockingtaps...........................................................................................28

IntroductiontoEmugeself-lockingthreads...................................................29

Drawingstandard........................................................................................30

Tapsandgauges..........................................................................................30

Self-locktapsprovidedbySimrad...............................................................31

Supplierandmanufacturer...........................................................................31

TRANSDUCERCABLESPLICING.......................................32

DRAWINGFILE...............................................................33

Echosounderconnections......................................................................................33

Splicingthetransducercable.......................................................................33

GeneralPurposeTransceiver(GPT)wiring...................................................34

GeneralPurposeTransceiver(GPT)transducerplugassembly.......................35

ES38-12Outlinedimensionsandinstallationdrawings.........................................36

Outlinedimensions[111337].......................................................................37

Mountingplate[111492].............................................................................38

Installationprinciples[111495]....................................................................39

4

344276/A

Page 7

Aboutthismanual

Aboutthismanual

Purpose

Thepurposeofthisinstallationmanualistoprovidethegenericdescriptionsand

illustrationsthatallowsyoutounderstandthebasicprinciplesforechosounder

transducerinstallation.

Abouttheinformationprovidedinthisdocument

Theinformationinthisdocumentmustberegardedasgeneralguidelinesand

recommendationsonly.Theinstallationshipyardmustdesignandmanufacture

installationhardwaretoteachindividualtransducerandvessel.

Approvalbymaritimeauthorities

Wheneverrequired,theinstallationshipyardmustalsohavetheinstallationapprovedby

theapplicablemaritimeauthorities.

Additionalinformation

Foradditionaldetailedinformationaboutthetransducertobeinstalled,refertothe

documentationprovidedwiththetransducer.Drawingsanddescriptionscanalsobe

obtainedfromh

t t p : / / w w w . s i m r a d . c o m .

344276/A

5

Page 8

SimradES38-12

SimradES38-12

Thepurposeofthismanualistheprovidethebasicinformationrequiredtoinstallthe

SimradES38-12Splitbeamtransducer.

Transduceranddocuments

•SimradES38-12:KSV-111497

•Datasheet:164276

•Drawings:

–Outlinedimensions:111337

–Mountingplate:111492

–Installationprinciples:111495

Note

Althoughdrawingsareprovidedtoexplaintheinstallationprinciples,theinstallation

shipyardmustprovidethenaldrawingsrequiredtotthetransducertoeach

individualvessel.Also,whenapplicable,theinstallationshipyardmusthavethe

drawingsandinstallationapprovedbythepropermaritimeauthorities.

ThedrawingsspecicfortheES38-12transducerarelocatedintheDrawingleon

page33.

Technicalspecications

RefertotheSimradES38-12datasheet.Youcanreadand/ordownloadthedatasheeton

t t p : / / w w w . s i m r a d . c o m .

h

Additionalpartsprovidedforinstallation

ThefollowingitemscanbesuppliedbySimradtofacilitateinstallation.Theitems

mustbeorderedseparately.

•Mountingplate:499–111492

6

344276/A

Page 9

Wheretomountthetransducer

Wheretomountthe

transducer

Asingleanswertothequestionwheretolocatethetransducercannotbegiven.It

dependsverymuchonthevessel’sconstruction,howthehullisshapedandhowthe

waterrunsalongthehull.Therearehoweveranumberofimportantguidelines,and

someoftheseareevenconicting.

Mountthetransducerdeep

Mountthetransduceratadeeppositiononthehull.Considerthesituationswhenthe

vesselisunloaded,andwhenitispitchinginheavyseas.

Thereareseveralreasonsforthis.

1Theupperwaterlayersoftheseacontainamyriadofsmallairbubblescreatedbythe

breakingwaves.Inheavyseastheupper5to10metresmaybelledwithair,and

thehighestconcentrationswillbenearthesurface.Airbubblesabsorbandreectthe

soundenergy,andtheymayinworstcasesblockthesoundtransmissionaltogether.

2Anotherreasontogodeepisthecavitationinfrontofhighpowertransducers.

Cavitationistheformationofsmallbubblesinthewaterduetotheresultinglocal

pressurebecomingnegativeduringpartsoftheacousticpressurecycles.The

cavitationthresholdincreaseswiththehydrostaticpressure.

3Thetransducermustneverbeliftedfreeofthewatersurface.Transmittinginto

openairmaydamagethetransducerbeyondrepair.Mountingthetransducerata

deeppositiononthehullpreventsthis.

4Ifthetransducerisliftedupfromthewaterduringheavyseas,itmaybedamaged

whenthehullstrikesbackattheseasurface.Thisisespeciallyimportantforlow

frequencytransducerswithlargefaces.

Mountthetransducerawayfromprotrudingobjectsonthehull

Objectsprotrudingfromthehull,suchaszincanodes,sonartransducersoreventhe

vessel’skeel,generateturbulenceandownoise.Holesandpipeoutletsarealso

importantnoisesources.Theymayactasresonantcavitiesamplifyingtheownoise

atcertainfrequencies.Donotplaceanechosoundertransducerinthevicinityofsuch

objects,andespeciallynotclosebehindthem.Forthesamereason,itisveryimportant

344276/A

7

Page 10

SimradES38-12

thatthehullareaaroundthetransducerfaceisassmoothandlevelaspossible.Even

tracesofsealingcompound,sharpedges,protrudingboltsorboltholeswithoutlling

compoundwillcreatenoise.

Mountthetransducerattheforwardpartofthehulltominimisetheeffectsfrom

theboundarywaterlayer

Whenthevesselforcesitswaythroughthesea,thefrictionbetweenthehullandthe

watercreatesaboundarylayer.Thethicknessoftheboundarylayerdependsuponvessel

speedandtheroughnessofthehull.Objectsprotrudingfromthehull,anddentsinthe

hull,disturbtheowandincreasethethicknessoftheboundarylayer.Theowinthis

boundarylayermaybelaminarorturbulent.Alaminarowisanicelyordered,parallel

movementofthewater.Aturbulentowhasadisorderlypattern,fullofeddies.The

boundarylayerincreasesinthicknesswhentheowgoesfromlaminartoturbulent.The

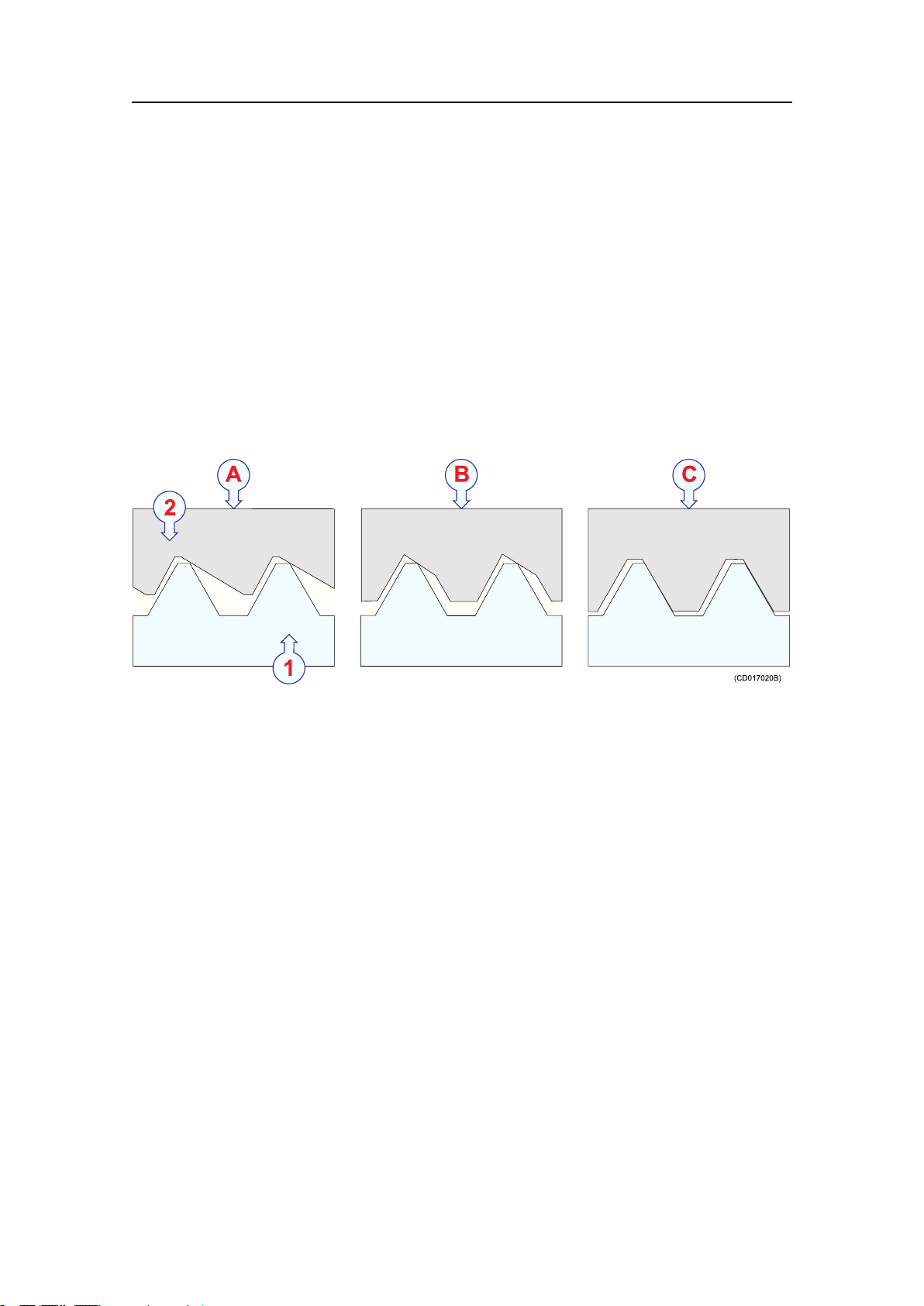

gurebelowillustratestheboundarylayerofavesselmovingthroughthewater.

Furthermore,airbubblesintheseawaterarepresseddownbelowthehullandmixed

intotheboundarylayer.Theboundarylayeristhinunderneaththeforwardpartofthe

vessel,andincreasesinthicknessasitmovestowardsaft.Ifthesidesofthehullare

steep,someoftheairbubblesintheboundarylayermayescapetotheseasurfacealong

thevesselsides.Itisourexperiencethatawideandatbottom,witharisingangleless

thanaround13degrees,ispronetogivingairproblemsforthetransducer.Inanycasea

transducerlocationintheforwardpartofthehullispreferredinordertominimisethe

inuenceoftheboundarylayer.

Figure1Boundarywaterlayer

ATurbulentow

BLaminarow

CAirbubblesinthewater

8

344276/A

Page 11

Wheretomountthetransducer

Mountthetransducerfarawayfromthepropellers

Thepropulsionpropelleristhedominantnoisesourceonmostshingvessels,research

vessels,merchantvesselsandpleasurecrafts.Thenoiseistransmittedthroughthesea

water.Forthisreason,thetransducershouldbeplacedfarawayfromthepropeller,

whichmeansontheforepartofthehull.Positionsoutsidethedirectlineofsightfrom

thepropellerarefavourable.Onsmallvesselswithshortdistancesitisadvisedtomount

thetransduceronthatsideofthekeelwherethepropellerbladesmoveupwards,because

thepropellercavitationisstrongestontheotherside.Thecavitationstartsmosteasily

whenthewaterowsinthesamedirectionasthepropellerblade,andthatistosome

degreethecaseatthatsideofthekeelwherethepropellerbladesmovedownwards.

Mountthetransducerfarawayfromthebowthrusters

Bowthrusterpropellersareextremelynoisy.Wheninoperation,thenoiseandcavitation

bubblescreatedbythethrustermaketheechosounderuseless,almostnomatterwhere

thetransducerisinstalled.Andwhennotinoperation,thetunnelcreatesturbulence,

andifthevesselispitching,thetunnelmaybelledwithairoraeratedwaterinthe

upperpositionandreleasethisinthelowerposition.Ingeneral,alltransducersmust

bethereforeplacedwellawayfromthebowthruster.However,thisisnotaninvariable

rule.Certainthrusterdesignscombinedwithitsphysicallocationonthehullmaystill

offersuitabletransducerlocationsnearthethruster.Ifyouareindoubt,consultanaval

architect.

Mountthetransducerwithaslightlyinclinedtransducerface

Ideally,thetransducerfaceshouldbemountedinparallelwiththeseasurfacewhen

thevesselisinnormaltrim,asthiswillprovidethemostaccurateechoinformation.

However,itisalsoveryimportantthatthew

a t e r o w overthetransducerfaceislaminar.

Inordertoensurelaminarow ,thetransducerfacemaybetiltedslightlyupwardsin

relationtothewaterow.Thisallowstheowingwatertomeetthefacedirectly,and

assureslaminarow.Theinclinationanglemusthoweverbedeterminedcarefully.The

anglemustbesmallontransducerswithnarrowbeamangles.Asaruleofthumb,mount

transducerswithbeamanglessmallerthansevendegreeswithminimuminclination

angle.Thesmallerbeamangleyourtransducerhas,thesmallertheinclinationanglecan

be.Ensurethatyoudonotmountthetransducerwithanegativeinclinationangle.This

maycauseturbulenceunderthetransducerface,andreducedechosounderperformance.

Summaryandgeneralrecommendations

Someoftheaboveguidelinesareconicting,andeachcasehastobetreatedindividually

inordertondthebestcompromise.Generallythepropellernoiseisthedominantfactor,

andarecommendedtransducerlocationisintheforepartofthehull,withmaximum

distancefromthebowequaltoonethirdofthetotallengthofthehullatthewaterline.

344276/A

9

Page 12

SimradES38-12

Figure2Generalrecommendationfortransducerlocation

ATransducer

BInclinationangle

CHulllengthat

waterline

DMaximum1/3of

thehulllengthat

waterline(C)

Ifthevesselhullhasabulbousbow,thismaywellbeagoodtransducerlocation,but

alsoheremustbetakenintoconsiderationtheowpatternoftheaeratedwater.Often

theforemostpartofthebulbispreferable.

Figure3Recommendedlocationofthetransducer

onabulboushull

AThruster

BTransducerlocation

10

344276/A

Page 13

Howtoinstallthetransducer

Howtoinstallthetransducer

Therearemanydifferentwaystomountthetransducer.Thesearetherecommended

methodstomountalargeandmediumsizedtransducerusingamountingplate.

Topics

•Transducerinstallationinblisteronpage11

•Transducerinstallationinboxkeelonpage15

•Transducerushmountedinasteeltankonpage16

•Transducerwithacousticwindowonpage17

•Transducermountedinsidethehullonpage18

•Transducermountedonadropkeelonpage19

•Retractabletransduceronpage20

Transducerinstallationinblister

Onerecommendedtransducerinstallationmethodisbymeansofablister.Theblister

mustbedesignedandmanufacturedbytheinstallationshipyardtotboththetransducer

body,andthevessel’ssizeandhullshape.

Useamountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

344276/A

11

Page 14

SimradES38-12

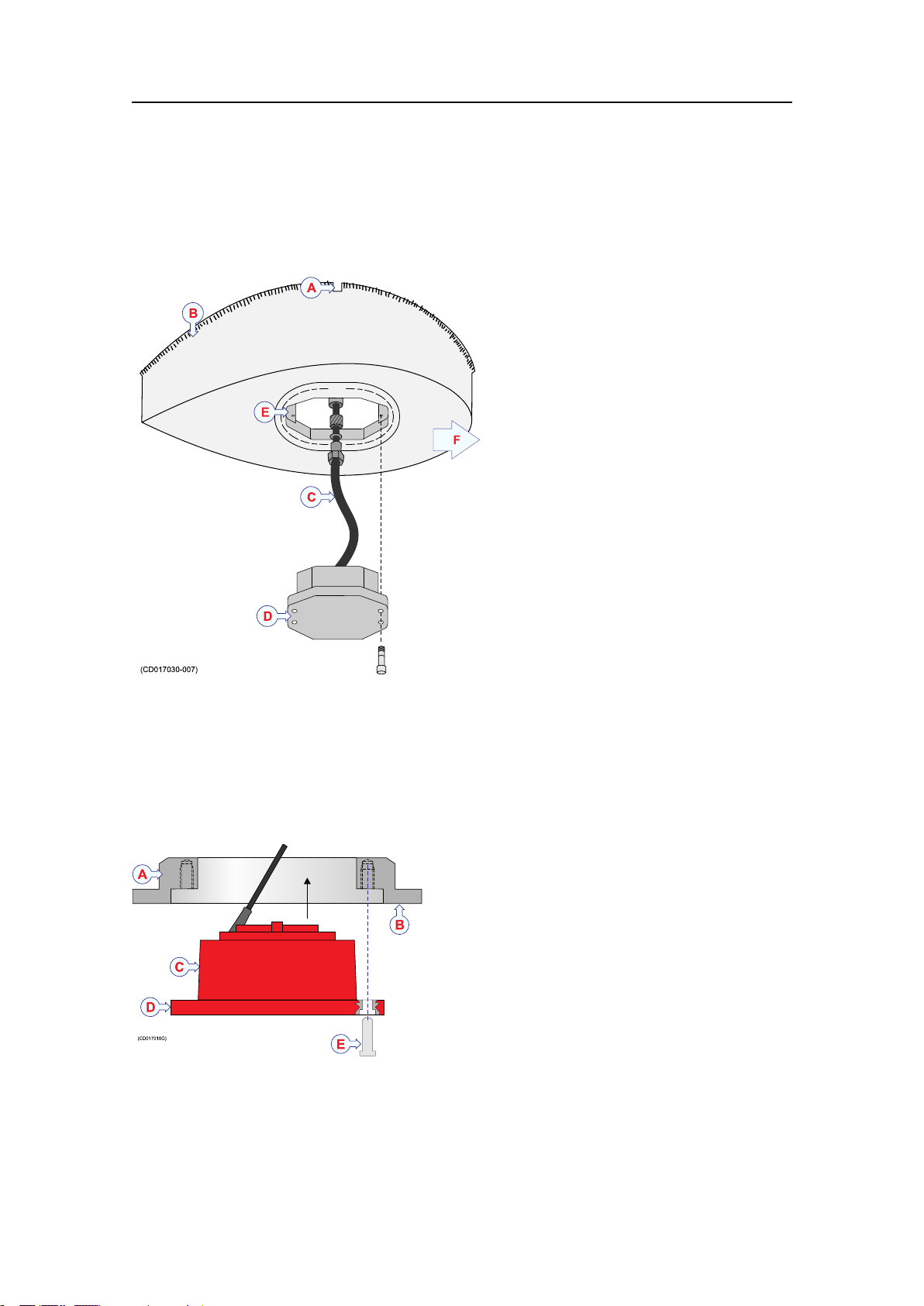

Example:Largecirculartransducer

Theillustrationbelowshowsatypicaltransducerblisterdesignedforalargetransducer.

Notethatduetothephysicalsizeofthetransducer,aU-shapedsupportbar(E)isused

tosupportthetransducer.Thepurposeofthissupportistopreventthetransducerfrom

beingpushedupintotheblisterinheavyseas.

Figure4Largecirculartransducer

AStreamlinedblister

BStiffeningrib

CDrainageholes

DInclinationangle

EU-shapedsupportbar(recommended

onlargetransducers)

FForward

GCableserviceloop

HStufngtube

IMinimum400mm

JRoundedcorners

KAiroutlet

12

344276/A

Page 15

Example:Mediumandlargetransducers,principle

Howtoinstallthetransducer

Figure5Mediumandlargetransducers

usingmountingplate

Thisillustrationshowsthe

installationprincipleofamedium

orlargetransducerusingamounting

plate.

AAiroutlet

BStreamlinedblister

CTransducercable

DTransducer

EMountingplate

FForward

Example:Mediumandlargetransducers,detail

Figure6Installationprinciple,

mediumandlargetransducers

AMountingring/plate

BHullplatingontowedbody

CTransducer

D“Clampingring”functionality

facilitatedbytransducerbody

EBolt

Thisillustrationshowstheinstallation

principleofamediumorlargetransducers

usingamountingringor-plate.Note

thataclampingringisnotrequired,asthe

transducerbodyisshapedtofacilitatethis

function.

344276/A

13

Page 16

SimradES38-12

Commonguidelines

Thebestperformanceisobtainedwithablisterheightof40cmormore.Astreamlined

shapeandroundededgesreducetheownoise.Averticalleadingedgeorfrontwill

guidetheaeratedwatertothesidesoftheblister.Theorientationoftheblistershould

followthewaterow.

Theinterioroftheblistermustbelledwithseawater.Usedrainageholesinthe

bottomandanairoutletonthetop.Thewaterpressurebehindthetransducerwillthen

compensatefortheoutsidepressureduringvesselmovementsinroughsea.

WerecommendthatlargediametertransducersarettedwithahorizontalU-shaped

supportbar.Thisbarcanthenbesecuredtothemountingringusingthreadedrods.

Thetransducercablepenetratesthehullinastufngtube.Leaveanadequateloopofthe

cablebehindthetransducerforeasymountingorremovalofthetransducer.

Toe-in

Figure7T oe-inprinciple

towardsthebow.

Theanglemustbechosentoallowformostefcientwaterow.Itwillvarywiththe

locationofthetransducer;thedepthbelowthehull,thedistancefromthebow,andthe

distancetothekeel.Typicalanglesarefrom0to3°ondeplacementhulls.Onplaning

hulls,theangleisnormallycloseto0°.

AKeel

BBlister

CT oe-inangle

Theprimaryconsiderationmustbetoallow

laminarwaterow.Inmostcasesthisis

achievedbydesigningtheblisterinparallel

withthekeel.However,iftheblisteris

locatedclosetothebow,thefrontofthe

blistermayhaveafewdegreestoe-in

Physicallocation

Theblisterisplacedononeofthesidesofthehull,andthedistancefromthekeelisa

tradeoffbetweenaclosedistancegivingaturbulentowofwaterinanarrowpassage,

andalargedistancebringingthetransducerhigherupandalsomoreaffectedbyvessel

roll.Normallyadistanceofapproximately1misagoodcompromise.

14

344276/A

Page 17

Howtoinstallthetransducer

Figure8Physicallocationofblister AKeel

BTransducerblister

CHorizontaldistancebetweenkeeland

blister

DV erticaldistancebetweentheblister

surfaceandthekeel

Observethehorizontalandvertical

distances(CandD)betweenthekeeland

thetransducerblister.Onamediumsized

vessel,thehorizontaldistance(C)should

beapproximately1meter.Theverticaldistance(D)mustingeneralbeassmallas

possible.Thisisimportanttopreventthekeelfromshadowingthetransducerbeam

inshallowwaters.

Transducerinstallationinboxkeel

Vesselswithaboxkeelmayusethisfortransducerinstallation.

Theboxkeelisalreadythedeepestpartofthevessel.Iftheboxkeelistoonarrowto

accommodatethetransducer,itcanbewidened,eithersymmetricallyortoonesideonly.

Inthelastcasetheinstallationcouldalsobedescribedasablistermergedintothekeel.

Usemountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

344276/A

15

Page 18

SimradES38-12

Example:Boxkeelinstallation

Figure9Boxkeelinstallation

Thegureillustratesa

symmetricalboxkeelinstallation.

ABoxkeel

BU-shapedsupportbar

(onlyrecommendedonlarge

transducers)

CStufngtube

DCableinsteelconduit

ECableserviceloop

Transducerushmountedinasteeltank

Flushmountingisusedonverylargevesselswithahullsodeepthatnoairbubblesare

foundbelowthehull,andonvesselsoperatinginshallowharboursorwaters,where

aprotrudingblistercannotbeaccepted.

Thestandardprocedureforushmountingonasteelvesselistoweldasteeltankinside

thehull,andmountthetransducerintothistank.

Usemountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

Waterlled

Asforablister,theinteriorofthetankmustbelledwithwater.

16

344276/A

Page 19

Howtoinstallthetransducer

Thiscanbeaccomplishedbyairreleasethroughasteeltube,whichisextendedeither

toopenair1.5mabovethewaterlineortothewateroutsidethehullatapointhigher

thanthetankinterior.

Ifthetubeisextendedtoopenair,drainagemustbeprovidedwithleakageatthe

transducerangeoraseparateholeinthetankbottom.

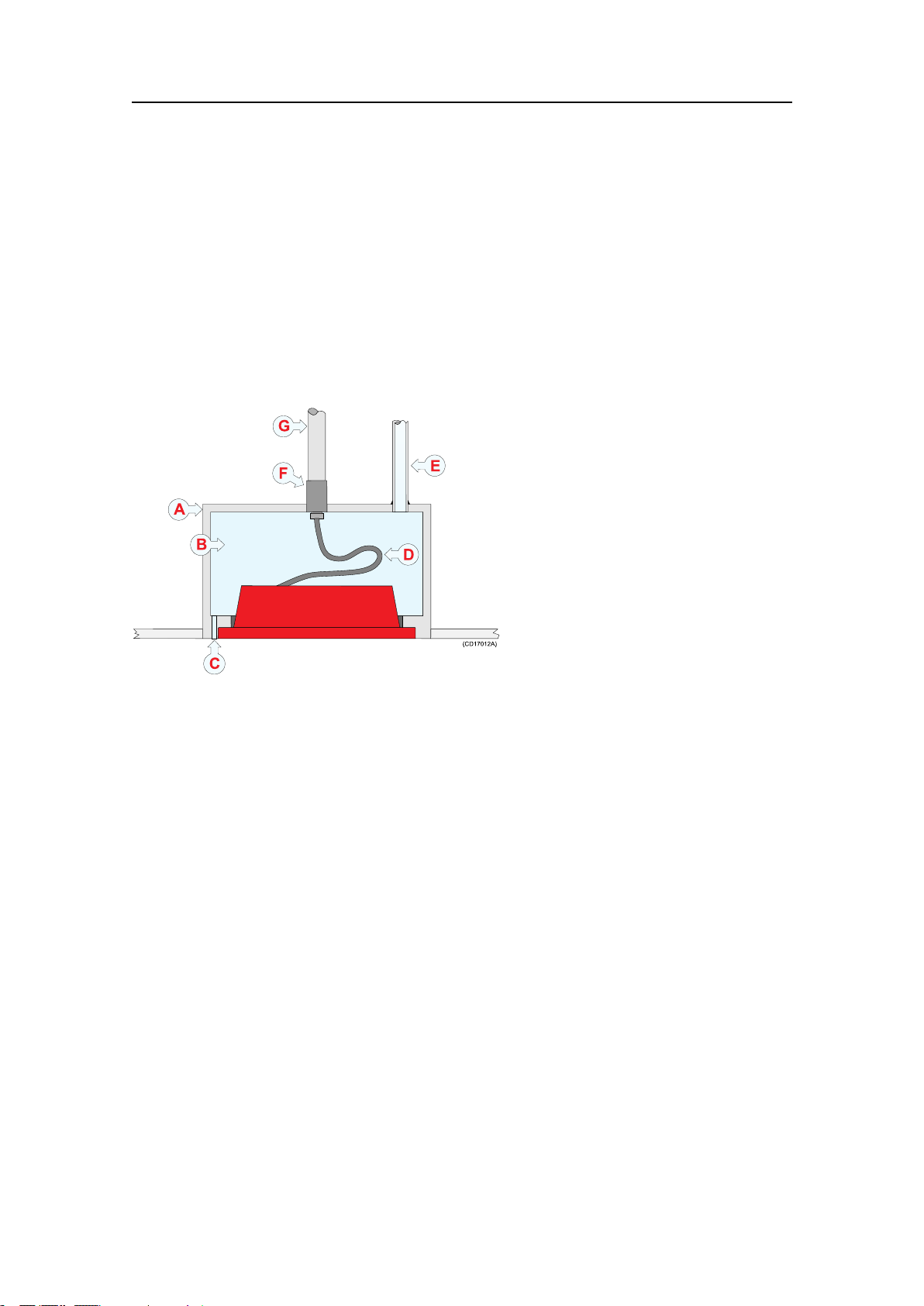

Example:Flushmountinginasteeltank

Figure10Flushmountinginasteeltank

ASteeltank

BWater

CDrainagehole

DCableserviceloop

ESteeltubeforairoutlet

FStufngtube

GCableinsteelconduit

Thegureillustratesthe

installationprincipleswhenthe

transducerismountedinasteel

tank.

Transducerwithacousticwindow

Vesselsoperatinginarcticwatersneedspecialattentionontransducerinstallation.

Floatingblocksoficemaydamageevenaushmountedtransducerface.Forthis

situationSimradoffersarctictanksindifferentsizes.

Usemountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

344276/A

17

Page 20

SimradES38-12

Example:Acousticwindow

Figure11Acousticwindow

polycarbonate.Thetankislledwithoil.

ASteeltank

BOil

CAcousticwindow

DCableserviceloop

EStufngtube

FCableinsteelconduit

GOilinlet

Thetransducershowninthegureis

mountedinsidethetankbehindastrong

acousticwindow.

Thewindowistypicallymadeof

Transducermountedinsidethehull

Thetransducercanalsobemountedinsidethehull.

Aninstallationofthetransducerinsidethehull,andsoundingthroughthehull,requiresa

goodacousticcontactbetweenthetransducerfaceandthehull.Buildatankaroundthe

transducerandllitwithaliquid.Oilusedinhydraulicsystemsisawellsuitedliquid

forthispurpose.Itcontainsnogasbubblesandisnon-corrosive.

Typicalvaluesofthetwowaylossare3dBforpolyester,6dBforaluminiumand10dB

forsteel.Hullsmadeofwoodorasandwichtypewithfoaminthemiddle,attenuate

thesoundsomuchthatthroughhullsoundingmustberegardedasimpossible.Theloss

varieswiththedistancebetweentransducerfaceandthehull.Thebestresultisobtained

whenthedistanceishalfawavelength.ConsultSimradforadvice.Inadditiontothe

loss,thebeampatternisdegraded,becausealargerareaofthehullissetintovibrations.

Usemountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

18

344276/A

Page 21

Howtoinstallthetransducer

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

Example:Mountinginsidethehull

Figure12Mountinginsidethehull

Thetransducershowninthegureismountedinsidethehull.Thetankislledwithoil.

ASteeltank

BOil

CHullplating

DCableserviceloop

EStufngtube

FCableinsteelconduit

GHoleforoillling

HAiroutlet

Transducermountedonadropkeel

Theuseofadropkeelwiththepurposeofstabilisingthevesseliswellknown.

Figure13Dropkeelinstallation

AInstrumentkeel

shaft

BLoweredposition

CBottomview

Adropkeelisalso

asuperiorplatform

forechosounder

transducers.Such

instrumentkeelshave

beenbuilt,mainlyon

researchvessels,often

protrudingasfaras

threemetersbelowthe

hull.Atthatdepth,the

waterisfreeofairbubblesuptoveryhighseastates.Thevesselisthenabletoperform

reliableacousticmeasurementsinopenseaalargerpartoftheyear.

344276/A

19

Page 22

SimradES38-12

Retractabletransducer

Hullunitsallowingthetransducertobeloweredandhoistedarecommonlyusedfor

horizontallookingsonars.Whennotinuse,thetransducerisretractedintoatrunk.

Figure14Retractable

transducer

ATransducer

BTrunk

CTransducershaft

DTransducershaftsleeve

EKeel

Theretractablehullunitismoreexpensivethan

ablister,butonvesselswithahullwhereitis

difcultorimpossibletoinstallablister,itmay

stillbeworthwhile.Theprinciplesofahullunit

witharetractabletransducerisshownbelow.

Vesselswithoutakeelandwithawide,atbottom

isanexamplewherearetractablehullunitcanbe

theonlyacceptablemethodforbringingtheecho

soundertransducerbelowtheboundarylayer.

20

344276/A

Page 23

Towedbodyinstallation

Towedbodyinstallation

Thesearetherecommendedmethodstomounttransducersinatowedbody.

Topics

•Generalrequirementsonpage21

•Installationinatowedbodyonpage22

Generalrequirements

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthetransducerorthearea

immediatelyaroundit.

Makesurethatthesurfaceofthetransducerface,theinstallationhardwareusedtomount

it,thehullplatingandtheputtyaroundthetransducerisasevenandsmoothaspossible.

Obstructionsonthesesurfaceswillcreateproblemswithturbulentow.

Usemountingandclampingringswheneverprovided

Circulartransducersmaybeprovidedwithmountingandclampingrings,orwith

drawingstoallowforlocalproductionofthese.

Themountingringisweldedtotheholepreparedforthetransducer,whiletheclamping

ringtsaroundtheedgeofthetransducerbody.Boltsthroughtheclampingringintothe

mountingringwillsecurethetransducerbetweenthem.

Notethatseveraltransducersusedirectionguidestoallowcorrectmounting.

Useamountingplatewheneverprovided

Certaintransducersmaybeprovidedwithamountingplate,orwithdrawingstoallow

forlocalproductionofthis.

Themountingplateisweldedtotheholepreparedforthetransducer.Boltsthroughthe

transducerbodyintothemountingplatewillsecurethetransducer.

344276/A

21

Page 24

SimradES38-12

Installationinatowedbody

Transducersdesignedtowithstandlargewaterpressureareprovidedforuseintowed

bodies.

Therecommendedinstallationmethodisthroughthehullplatinghullusingamounting

plate,orwithmountingandclampingrings.Theinstallationarrangementonthetowed

bodymustbedesignedbythemanufacturerofthetowedbodytotitsshapeand

characteristics.

22

344276/A

Page 25

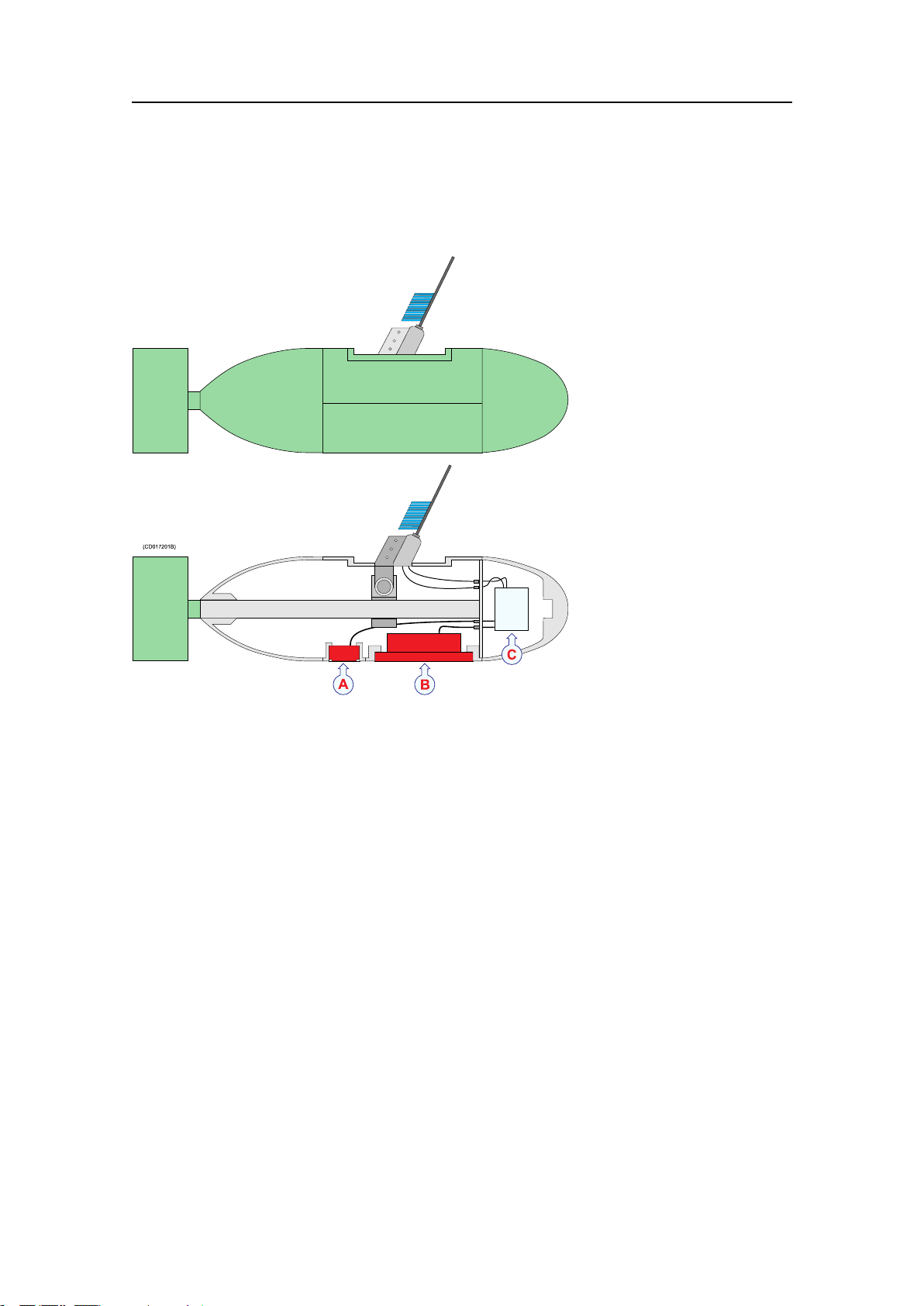

Example:Smalltransducer

Towedbodyinstallation

Figure15Smalltransducerwith

mountingandclampingrings

AMountingring

BHullplatingontowedbody

CTransducer

DClampingring

EBolt

Thisillustrationshowstheinstallation

principleofasmallcirculartransducerusing

clampingandmountingrings.

Example:Mediumandlargetransducers

Figure16Installationprinciple,

mediumandlargetransducers

AMountingring/plate

BHullplatingontowedbody

CTransducer

D“Clampingring”functionality

facilitatedbytransducerbody

EBolt

Thisillustrationshowstheinstallation

principleofamediumorlargetransducers

usingamountingringor-plate.Note

thataclampingringisnotrequired,asthe

transducerbodyisshapedtofacilitatethis

function.

344276/A

23

Page 26

SimradES38-12

Example:Dualtransducerarrangement

Figure17Dualtransducerarrangement

Thisillustrationshows

atypicalthroughthehull

installationofsmalland

largecirculartransducers

onatowedbody.

ASmalltransducer

BMediumorlarger

transducer

CElectronic

equipmentin

watertight

compartment

24

344276/A

Page 27

Steelconduit

Whyusesteelconduits?

Itisstronglyrecommendedtolayasteelconduitfromthetransducer’scablegland

totheechosoundertransceiver,andtopullthetransducercablethroughthisconduit.

Thereareseveralreasonsforthis.

•Itwillmakeiteasieratalaterstagetoreplacethetransducer.

Steelconduit

•Noiseandinterferencefromotherelectricalequipmentisgreatlyreduced.

•Theriskofoodingisgreatlyreducedifthepipeisterminateabovethewaterline.

WithasteelconduittheinstallationwillsatisfytheEUregulationsforEMCinterference.

Withoutasteelconduit,thereisariskofreducedechosounderperformance.

Steelconduitsqualitiesandshielding

Thesteelconduitmustbeunbrokenandwatertightfromthetransducertoabovethe

waterline.Fromthere,thecablecanbepulledfurther,orajunctionboxcanbeinstalled

tofacilitatefurtherconnections.Notethatthesteelconduitmustactasacontinuous

electricalscreenalltheway.

Steelconduitdimensions:

•minimum35mminnerdiameter

•minimum6mmwallthickness(4.5mmifgalvanised)

Morethatonetransducercable?

Iftwoormoretransducersareinstalledclosetoeachotheritispossibletopulltheir

cablesinthesamesteelconduit,providedtheconduitdiameterisincreasedaccordingly.

However,foreasyreplacementitisrecommendedthateachtransducerhasitsown

steelconduit.

344276/A

25

Page 28

SimradES38-12

Transducerhandlingand

maintenance

YouMUSTobservethefollowingrulesforhandling,maintenanceandpainting.

Topics

•Rulesfortransducerhandlingonpage26

•Rulesfortransducermaintenanceonpage27

•Approvedanti-foulingpaintsfortransducersonpage28

•Usingself-lockingtapsonpage28

Rulesfortransducerhandling

Note

Donotliftthetransducerbythecable.

Donotexposethetransducertodirectsunlight.

Donotexposethetransducertoexcessiveheat.

Transportprotection

Sometransducersaredeliveredwithacoverplateonthefaceforprotectionduring

transport.Letthisplatestayonaslongaspossible,butdonotforgettoremoveitbefore

thevesselgoesintothesea.

Paintingthetransducerface

Ananti-foulingpaintmaybeappliedtothetransducerface.Becausesomepainttypes

maybeaggressivetothepolyurethaneinthetransducerface,pleaseconsultSimrad’slist

ofapprovedpaints.SeeApprovedanti-foulingpaintsfortransducersonpage28.

26

344276/A

Page 29

Transducerhandlingandmaintenance

Cleaningthetransducerface

Wheneveropportunityarise,forexamplewhenthevesselisdrydocked,thetransducer

facemaybecleanedforshellsandothermarinefouling.B e c a r e f u l n o t t o m a k e c u t s i n

t h e t r a n s d u c e r f a c e . Useapieceofsoftwoodoraverynegradeemerypaper.

Specialrulesforacousticwindows

Arctictankshaveacousticwindowsmadeofpolycarbonate.T

p a i n t e d n o r c l e a n e d w i t h c h e m i c a l s . Acousticwindowsmustnotbeexposedtodirect

sunlight.

h e s e m u s t n e i t h e r b e

Rulesfortransducermaintenance

Onceinstalled,thetransducerismaintenancefree.However,whenthevesselisdocked,

itishighlyrecommendedtocleanthetransducerfacetoremovemarinegrowth.

1Performathoroughvisualcheckofthetransducer.

2Ifnecessary,cleanthetransducer

•Tocleanthetransducer,usenormalsyntheticsoapandwater.

•Toremovemarinegrowth,usene-gradesandpaperoremerypaper.

Note

D o n o t usestrongsolvents.

o n o t attempttoscrapeofmarinegrowthwithsheetsofmetal,screwdriversor

D

othermetallictools.

o n o t usehighpressurewatertocleanthetransducer .

D

3Ifnecessary,applyanewlayerofanti-foulingpainttothetransducerface.

Becausesomepainttypesmaybeaggressivetothepolyurethaneinthetransducer

face,pleaseconsultSimrad’slistofapprovedpaints.

→Approvedanti-foulingpaintsfortransducersonpage28

344276/A

27

Page 30

SimradES38-12

Approvedanti-foulingpaintsfortransducers

ThisisSimrad’slistofapprovedantifoulingpaintsonpolyurethanetransducerhousing.

Jotun

Headofceaddress:P .O.Box2021,N-3248Sandefjord,Norway

Website:w

1Racing

2Non-stop

3SafeguardUniversalprimer(125micron)withAntifoulingSeaQuantumUltra(125

micron)

4AntifoulingSeaguardian

InternationalMarineCoatings

Address:World-wideofces

Website:w

1Intersleektiecoat+425FCS

•BXA386/BXA390/BXA391Grey

•HKA563/HKA570/HKA571Y ellow

•MixBXA386,BXA390andBXA391rst,thenapply.Whendry,mixHKA563,

2Intersmooth360EcoloexSPC

3MicronExtra

w w . j o t u n . c o m .

w w . i n t e r n a t i o n a l - m a r i n e . c o m .

HKA570andHKA571,apply .

HempelIFACoatings

Headofceaddress:HempelA/S,Lundtoftevej150,Kgs.Lyngby ,DK-2800

Copenhagen,Denmark

Website:w

1HempelA/FClassic76550

Note

Refertothemanufacturer’sdocumentationanddatasheetsforacompleteprocedure.

w w . h e m p e l . c o m .

Usingself-lockingtaps

Screwconnectionsaregenerallymadesothattheycanbeloosenedagain.However,

accidentalloosening,especiallyunderdynamicstress,mustbeavoided.Forthisreason

itisoftennecessarytouseadditionallockingdevices.Theseareoftenexpensive,they

canbeusedonceonly,orreactcriticallytotemperaturechanges.

28

344276/A

Page 31

Transducerhandlingandmaintenance

IntroductiontoEmugeself-lockingthreads

Emugeself-lockisatapdesignwithanintegratedlockingfeature.Standardmetricbolts

areused.Theinternalthreadprovidesaself-lockingconnection,whichcanbeused

repeatedly.Itisnotnecessarytoinvolveasecondarylockingdevice(e.g.chemical,

nylonormechanical).TheEmugeself-lockboltswithstandvibrationsbetterthanstandard

(metric)threads,becausethethreadcontactstopsthesidewaysmovement.Thespecial

designoftheinternalthreadprolealsoprovidesamoreevendistributionofthe

tighteningstressoverthewholethreadlength.Theassemblyisjustaseasyaswitha

normal(metric)thread.Thereisnogeneralapplicablestandard(e.g.DINstandard)

fortheEmugeself-lockthread.

Figure18Example,internalandexternalthreads

AEmuge’ ssaw-toothproleuptopitchP≤0.7mm

BEmuge’ssaw-toothproleuptopitchP≥0.7mm

CStandardthread

1Externalthread

2Internalthread

Advantages

•Thethreadlockingfeatureisintegratedintheinternalthread

•Modiedprolewithrampsurfaceinthedirectionofstress

•30degreerampsurfaceprovidesself-lockingeffect

•Easyassembly

•Noassemblyerrors(forgettingthelockingdevice)possible

•Useofstandardexternalthreads(screws)withtoleranceclass“medium”

•Evendistributionofstressoverthewholethreadlength

•Nostrippingofthreads

•Economicallyefcientlockingsystem,noadditionalcomponentsarenecessary

•Undiminishedholdingpowerevenunderdynamicstress

•Repeatedlooseningandre-tighteningwithoutlossoffunction

344276/A

29

Page 32

SimradES38-12

•InternalthreadscanbeproducedwithEmugetaps,coldformingtapsorthreadmills

•Largerthreadholediameters,i.e.increasedtoollifeforthreadingtools

•Largertolerancesforthreadholediameters

Drawingstandard

Wheneverself-lockingthreadsarerequired,thisisshownonthetechnicaldrawing.

Inthecaseoftappingthroughholes,thearrowattheendofthecenterlineillustrates

thescrew-indirectionofthebolt.

Figure19Drawingexamples,self-lockingthread

Thedrawingisnormallyprovidedwiththefollowingtext(orsimilar):

Note:Theself-lockthreadsmarkedwithSL*mustbemadeinaccordancewith

procedure842–202125.Drilldiametersforthreadsdifferfromstandard.Self-lock

tapscanbesuppliedbySimrad.

Tapsandgauges

Thepretensionlockingthreadself–lock(taps)frommanufacturerEmugemustbeused.

30

344276/A

Page 33

Transducerhandlingandmaintenance

Figure20Exampleofuse

Note

InthecaseoftappingthroughholesitisimportantthattheproleoftheEmugeself-lock

threadsisinthecorrectdirectioncomparedwiththeenteringdirectionofthebolt.

UseEmugeself-lockgauges.Notethatthegaugemustbeusedinthecorrectdirection.

Self-locktapsprovidedbySimrad

Thefollowingself-locktapsareonstockatSimrad,andcanbeorderedfromus.

Threads

M6ø5.2700-078838

M8ø7.0700-078531

M10ø8.8700-078408

M12ø10.7700-078409

M16ø14.5700-078410

Drilldiameterforthreads

Part.no

Supplierandmanufacturer

Norwegiansupplieris:

TingstadAS,P .O.Box83,Kalbakken,0902Oslo,Norway

h

t t p : / / w w w . t i n g s t a d . n o

Manufactureris:

EMUGE-WerkRichardGlimpel,NurnbergerStrasse96-100,D-90607Lauf,Germany

h

t t p : / / w w w . e m u g e . d e

344276/A

31

Page 34

SimradES38-12

Transducercablesplicing

Ifyouneedtocutorlengthenthetransducercable,youmustspliceitcorrectly.The

cablebetweenthejunctionboxandthetransceivermustthenbesuppliedbySimrad,

andthismustbethesametypeasusedonthetransducer(s).Tosplicethecable,usea

metaljunctionboxwithEMCcableglandsandaterminalblock.Theterminalblock

mustprovidesolidfasteningofthecableendsaswellassufcientinsulationbetween

thewires.Werecommendthatthecablescreenisconnectedtothejunctionboxchassis

usingtheEMCcableglands,butifyoudothis,thejunctionboxchassism

connectedtovessel’sground.

u s t n o t be

Note

D o n o t solderthewirestogetherwithonlyelectricaltapeforinsulation.Thiswillresult

inelectricalnoiseandreducedoperationalperformance.

o n o t connectthecablescreentothevessel’ sground.

D

32

344276/A

Page 35

Drawingle

Thischaptercontainsrelevantdrawingsrelatedtotheelectricalandphysicalinstallation

oftheSimradES38-12Splitbeamtransducer.

Note

Themechanicaldrawingsareforinformationandguidanceonly.Theyarenotinscale,

andmaydifferslightlyfromtheoriginaldrawings.Alldimensionsareinmmunless

otherwiseisnoted.

Drawingle

TheoriginalinstallationdrawingsareavailableonPDFand/orDWG(AutoCad)format.

Visitw

Topics

•Echosounderconnectionsonpage33

•ES38-12Outlinedimensionsandinstallationdrawingsonpage36

w w . s i m r a d . c o m todownload.

Echosounderconnections

ObservethefollowinginformationrelatedtoelectricalconnectionoftheES38-12Split

beamtransducer.

Splicingthetransducercable

Ifyouneedtosplicethetransducercable,itisveryimportanttousethecorrectcable,

andtoavoidgroundloops.Westronglyrecommendtheuseofajunctionbox.Wealso

recommendthatyouinstallthetransducercableinasteelconduit.

Formoreinformation,see:

•Transducercablesplicingonpage32

•Steelconduitonpage25

•GeneralPurposeTransceiver(GPT)transducerplugassemblyonpage35

344276/A

33

Page 36

SimradES38-12

GeneralPurposeT ransceiver(GPT)wiring

ObservethedrawingbelowtoconnecttheSimradES38-12Splitbeamtransducertothe

GeneralPurposeTransceiver(GPT).Formoreinformationabouttheseconnections,

refertotheapplicableechosounderinstallationmanual.

34

344276/A

Page 37

GeneralPurposeT ransceiver(GPT)transducerplugassembly

Drawingle

344276/A

35

Page 38

SimradES38-12

ES38-12Outlinedimensionsandinstallation drawings

Note

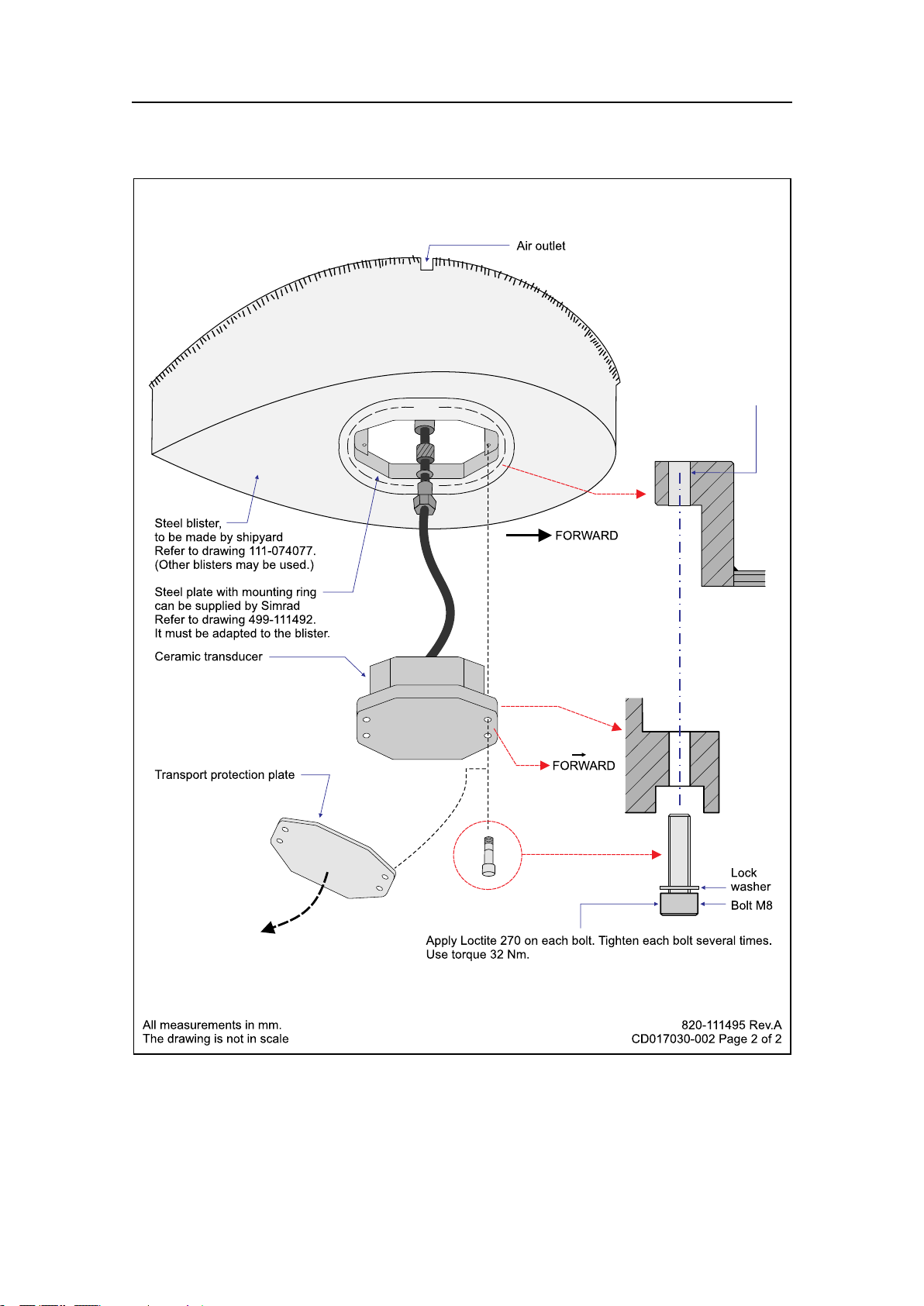

Whenyoufastenthetransducertothemountingplate,applyLoctite270oneachbolt,

andtightentheboltsseveraltimes.Usemaximumtorque32Nm.

Topics

•Outlinedimensions[1 11337]onpage37

•Mountingplate[1 11492]onpage38

•Installationprinciples[1 11495]onpage39

36

344276/A

Page 39

Outlinedimensions[111337]

Drawingle

344276/A

37

Page 40

SimradES38-12

Mountingplate[111492]

38

344276/A

Page 41

Installationprinciples[111495]

Drawingle

344276/A

39

Page 42

SimradES38-12

40

344276/A

Page 43

Index

Index

A

About,5

informationinthis

manual,5

Acousticwindow,27

example,18

installation,17

Additionalinformation,5

Airoutlet

example,12

Anti-fouling

paint,28

Approval

maritimeauthorities,5

B

Blister

Commonguidelines,14

installation,11

physicallocation,14

Boundarywaterlayer,8

Bowthrusters

noise,9

Boxkeel

example,16

installation,15

C

Cable

transducer,splicing,32

Clampingring

example,12,23

Clampingrings,21

Cleaning

transducerface,27

Commonguidelines

blister,14

Conduit

steel,25

D

Diameter

steelconduit,25

Dimensions

drawing,37

Drawing

GPTTransducerplug,35

Mountingring,38–39

outlinedimensions,37

Drawingle,33

E

EMCinterference,25

Emuge,29

Example

Acousticwindow,18

Airoutlet,12

boxkeel,16

Clampingring,12,23

ushmounting,17

Insidethehull,19

Mountingplate,13,23

Mountingring,12–13,23

Streamlinedblister,12

F

Flushmounting

example,17

steeltanl,16

G

GeneralPurpose

Transceiver

transducerplug,35

wiring,34

GPT

wiring,34

GPTTransducerplug

drawing,35

Groundloops

avoiding,33

H

Handling,26

Handlingrules

transducer,26

Heat,excessive

doNOTexpose

transducer,26

HempelIFACoatings,28

I

Important

smoothsurface,11,

15–18,21

Inclination

angle,9

Insidethehull

example,19

installation,18

Installation

drawings,6,33

hardware,6

responsibility,6

Installationmethod

Acousticwindow,17

Blister,11

Boxkeel,15

Flushmounting,16

Insidethehull,18

Steeltank,16

InternationalMarine

Coatings,28

Introduction,6

J

Jotun,28

Junctionbox

cablesplicing,33

L

Lifting

transducer,26

Location

recommendation,9

M

Maintenance,26

Maintenancerules

transducer,27

Maritimeauthorities

approval,5

Mountingplate,11,15–18,21

example,13,23

Mountingring

drawing,38–39

example,12–13,23

Mountingrings,21

N

Noise

boundarywaterlayers,8

bowthrusters,9

propeller,9

protrudingobjects,7

O

Ordernumber

transducer,6

Outlinedimensions

drawing,37

344276/A

41

Page 44

SimradES38-12

P

Paint

anti-fouling,28

Painting

transducerface,26

Physicaldimensions

drawing,37

Physicallocation

blister,14

Propeller

noise,9

Protrudingobjects,7

Purpose

thismanual,5

S

Self-lockingtaps,29

Shielding

steelconduit,25

Simradwebsite,5

Smoothsurface,11,15–18,21

Splicing

transducercable,32–33

Steelconduit

diameter,25

qualities,25

shielding,25

why,25

Steeltank

ushmounting,16

waterlled,16

Streamlinedblister

example,12

Sunlight

doNOTexpose

transducer,26

Surface

smooth,11,15–18,21

splicing,32–33

termination,34

Transducerface

cleaning,27

painting,26

Transducerplug

drawing,35

Transportprotection,26

W

Waterlled

steeltank,16

Wiring

GeneralPurpose

Transceiver,34

T

Taps,self-locking,29

Termination

GPT,34

Toe-in,14

Towedbody

dualtransducer

arrangement,24

Transducer

handling,26

lifting,26

maintenance,27

ordernumber,6

recommendedlocation,9

Transducerarrangement

towedbody,24

Transducercable

42

344276/A

Page 45

Index

344276/A

43

Page 46

Simraddocumentnumber:344276/V ersionA

ISBN-13:978-82-8066-119-7

©

2010KongsbergMaritimeAS

Loading...

Loading...