Page 1

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

maneuverability. Expertly engineered by Trevor Ashline with Safety Solutions technology,

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

INSTALLATION MANUAL

INSTALLATION MANUAL

INSTALLATION MANUAL

DRIVEN BY

SAFETY

Page 2

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

INSTALLATION MANUAL

OF COURSE, IT’S THE SAFEST.

OVERVIEW

SIMPSON HEAD RESTRAINT

TIE PLATES

You’re ready to use the technology that protects the

world’s top drivers. Here are the steps to get started.

Overview 3

Anchor Installation 4

Fitting the Restraint 7

Seat Positions 7

In Car Adjustments

Tether Adjustment 8

Side Stabilizing Gusset Adjustment 10

Seat Belt Positioning

Restraint System Mounting Zones 11

Optional Accessories

Seat belt Anchor Systems (SAS) 12

Hybrid Molded Pad 13

Helmet Tethers and Clips 14

Helmet Anchors 15

Frequently Asked Questions 16

Certifi cations 19

Questions? Call us at 800.654.7223

11

IT’S A SIMPSON.

Simpson Hybrid Head Restraints are the best

choice for racing protection.

HYBRID, HYBRID PRO and HYBRID SPORT

Head Restraints are SFI 38.1 Certifi ed

and FIA 8858-2010 Certifi ed. Designed

for easily exiting the car without

the danger of getting hung up

on other gear, our Head

Restraints also offer the

lowest profi le and highest

level of multiple angle

impact protection of

any competing device.

Plus, they provide you

with maximum comfort

and maneuverability. Expertly

engineered by Trevor Ashline

with Safety Solutions technology,

Simpson Head Restraints give you every

advantage on the track.

DUAL END FITTINGS

RUBBER SHOULDERS

SHOULDER STRAP

BACK STRAP

BUCKLE

The Simpson Hybrid head restraints series carries SFI 38.1 certifi cation; the Hybrid

and Hybrid Pro are NASCAR certifi ed, the Hybrid, Hybrid Pro, and Hybrid Sport are FIA

Approved. Our head restraints are recognized by most major sanctioning bodies across the

world. If you are unsure, check with your local sanctioning.

3-BAR

SLIDING TETHER

DEVICE PAD

QUICK RELEASE

(STANDARD on

SFI CERTIFIED

RESTRAINTS)

Figure 1

Hybrid Pro pictured with optional M6 upgrade

DRIVEN BY SAFETY TEAMSIMPSON.COM 3

Page 3

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

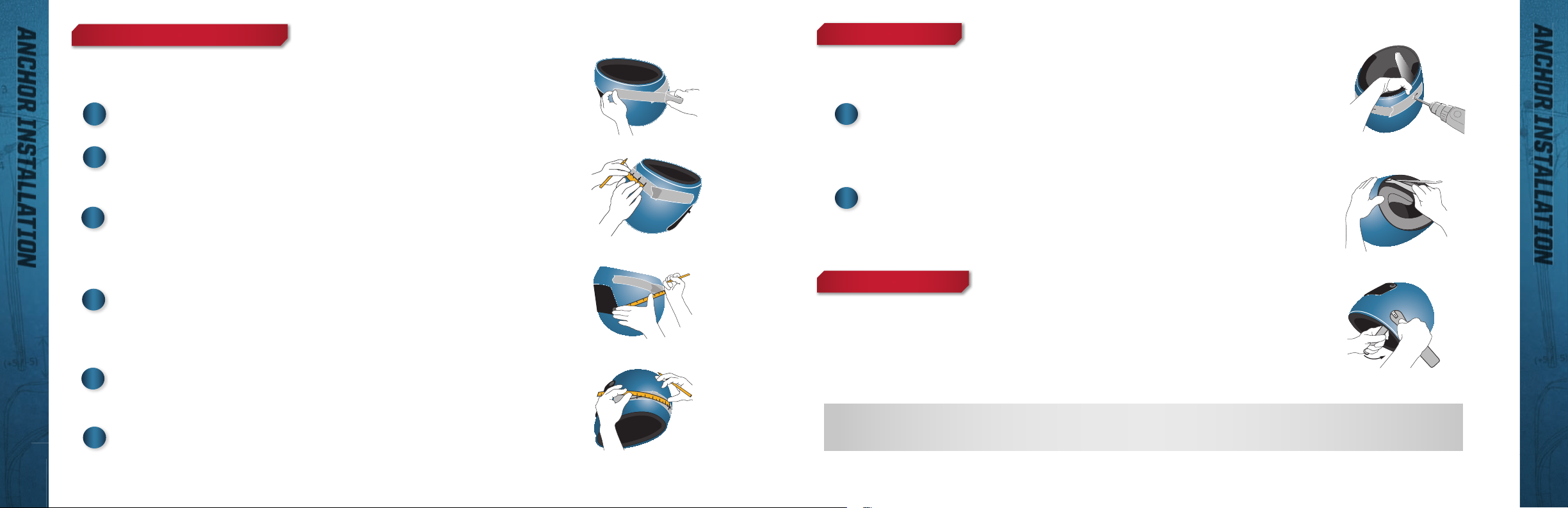

ANCHOR INSTALLATION

ANCHOR INSTALLATION INSTRUCTIONS

ANCHOR INSTALLATION

M6 AND POST ANCHORS

Initial Steps for Helmets without holes for tether anchors.

Apply masking tape around the bottom of your helmet approximately 1”

1

(26mm) up from the top edge of the rubber molding.

On the masking tape at the back of the helmet, mark three points 1.5” (43mm)

2

above the rubber molding and spaced about a half inch apart. Connect the

dots to create a horizontal line.

Using a fl exible ruler, measure the same distance from a fi xed point (for

3

example - the visor mounting hole) on each side of the helmet back to the

horizontal line. The center line of the helmet is midway between where the two

lines intersect the horizontal line at the back of the helmet.

4

Measure 6” (150mm) forward from the rear center line on each side of the

helmet to a point 1.5” (43mm) above the rubber molding.

Make sure you have two marks, each 6” forward from the rear center line a 1.5”

above the top edge of the rubber edge molding.

Slowly drill a 1/4” (6mm) hole at the two hole centers marked above. Drill

5

through the helmet shell but not through the soft padding. A thin piece of sheet

metal can be slipped between the shell and padding to help this.

De-burr and clean holes.

6

See Figure 3

See Figure 2

See Figure 4

See Figure 5

See Figure 6

Figure 2

Figure 3

Figure 4

Figure 5

Final Steps - Helmets without holes and pre-drilled helmets.

1

Gently pry helmet liner away from shell using a blunt instrument. See Figure 7

Insert the nutwasher inside the helmet against the shell using a wrench. Align

with hole. Insert post through the cap, spring and base and screw into nutwasher.

Tighten until the point of the post faces rearward.

Use a 7/16” (11mm) wrench to hold the post anchor outside of the helmet in

2

position and tighten from inside.

Tighten 1/4 turn beyond snug. The fl ats and slot of the post anchor should be

parallel with the ground and the point of the post should face the rear of the helmet.

QUICK RELEASE ANCHORS

Gently pry helmet away from shell using blunt instrument.

Insert the nutwasher inside the helmet against the shell using a wrench.

Align the hole. Screw anchor into nutwasher. Hand tighten until the tether or hasp

faces rearward. Use a 7/16” (11mm) wrench to hold the nutwasher inside the helmet

and tighten exterior screw 1/4 turn beyond snug.

SAFETY NOTE Simpson recommends using thread locking fl uid when assembling the M6 and helmet post anchors.

*REFER TO YOUR SANCTIONING RULES FOR HELMET INSTALLATION.

See Figure 8

Figure 6

Figure 7

See Figure 7

Figure 8

4 TEAMSIMPSON.COM TOLL FREE 800.654.7223

DRIVEN BY SAFETY TEAMSIMPSON.COM 5

Page 4

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

ANCHOR INSTALLATION

ANCHOR INSTALLATION INSTRUCTIONS

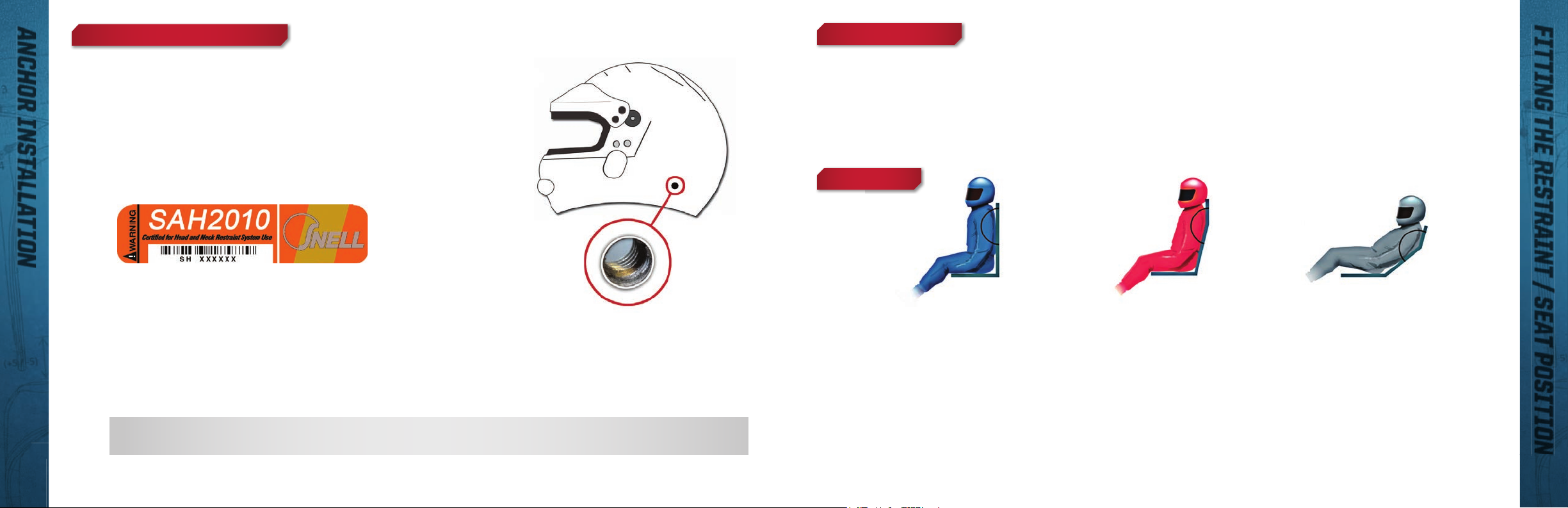

FITTING THE RESTRAINT / SEAT POSITION

FITTING THE RESTRAINT

SAH2010 Helmets with Bonded-in Threaded Anchor Terminals

You may have purchased one of the newest helmets marked Snell

SAH2010. These helmets are certifi ed for head restraint system use.

Snell SAH2010 decal located inside the helmet

Helmets marked Snell SAH2010 have a bonded-in and threaded

terminal (nutwasher) making Simpson anchor installation easy. Screw

the anchor into the nutwasher. Hand tighten until the point on the collar

(if post anchor) or bail (if quick release) faces rearward. Tighten the

mounting screw 1/4 turn beyond snug.

SAFETY NOTE Simpson recommends using thread locking fl uid when assembling the M6 and helmet post anchors.

6 TEAMSIMPSON.COM TOLL FREE 800.654.7223

Figure 9

Bonded-in terminal

on sides of helmet

The Hybrid Head Restraint has an adjustable chest strap to fi t a variety of body types. Custom made restraints are also available. Call Team Simpson at 800-654-7223 for more information.

To adjust the chest strap: loosen the chest strap at the buckle and slide the buckle to fi t

the occupant’s chest size. Chest strap should fi t snug, but comfortable.

SEAT POSITIONS

0°-10° 10°- 30° 30°+

Figure 10 Figure 11 Figure 12

STRAIGHT

A completely smooth or fl at

back to the seat.

Typical applications are:

Sprint Cars, Pro Mods, Pro Stock,

Top Sportsman, Monster Truck

NOTE: Changing seat confi gurations may require tether adjustments.

CONTOURED

A 10-30 degree of change in the

seat at the shoulder blade area.

Typical applications are:

Late Models, GT-1, Pro Trucks,

Hydroplanes

LAYBACK

A 30 degree of more change in the

seat at the shoulder blade area.

Typical applications are:

Indy Cars, Nostalgia Dragsters

DRIVEN BY SAFETY TEAMSIMPSON.COM 7

Page 5

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

IN CAR ADJUSTMENTS

IN CAR HELMET TETHER ADJUSTMENT

RESTRAINT TETHERS

1

2

3

Helmet Tethers MUST be adjusted for proper fi t before use.

Helmet tether adjustment needs to be made with the driver seated and buckled into the vehicle with full gear

including, suit, helmet, and seatbelt harnesses.

Get into car and buckle fully into the seat with seat belts. The head restraint

should fi t comfortably under the shoulder harnesses.

Seat the restraint against the shoulder belts by pulling up on the helmet

tethers, before they are hooked to the helmet. The device will rest against the

shoulder belts on the top, the seat in back and the driver’s shoulders.

The helmet tethers should be adjusted or changed to allow for no more than

2.25” of straight forward head movement. Measure from a resting position

(See Figure 13 dotted line) moving your entire head forward (not your chin to

your chest). You should still be able to rotate your chin to your chest.

no more than 2.25” of straight

forward movement

ADJUSTABLE (SFI) TETHRS

Adjust the rear helmet tether fi rst; they are the PRIMARY RESTRAINT The tethers are easily

4

adjusted by unlacing the tether webbing through the 3-bar adjuster and lengthening or shortening

the tethers through the 3-bar adjustments.

The forward helmet movement can be checked by measuring the amount of forward movement as

5

the driver moves their head straight forward, with the chin up.

The tether adjustment is the measurement when the tethers fi rst have tension.

6

When the rear tether adjustments are complete make sure to lock down the tether by weaving

7

the webbing back through the adjuster one last time. Use the rubber O-ring to hold the excess

webbing in place.

IN CAR ADJUSTMENTS

8 TEAMSIMPSON.COM TOLL FREE 800.654.7223

Figure 13

DRIVEN BY SAFETY TEAMSIMPSON.COM 9

Page 6

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

o o

o o

IN CAR ADJUSTMENTS

SIDE STABILIZING GUSSET (SSG) ADJUSTMENT

RESTRAINT SYSTEM MOUNTING ZONES

RESTRAINT SYSTEM MOUNTING ZONES

9

Unhook the tether from the helmet.

Hold the SSG up to the Helmet Anchor.

10

Adjust the length of the tether to the bottom of the Helmet Anchor

11

with the driver in their normal position looking straight forward.

NOTE: Some drivers may want this tether shortened for

more side to side restriction. The tether may be adjusted

shorter by as much as 1” depending on driver comfort.

With this adjustment too short, the helmet will be pulled

downward on the driver’s head and may be

uncomfortable.

12

Tethers adjusted properly should create a “Triangle” in the tether

adjustment.

10 TEAMSIMPSON.COM TOLL FREE 800.654.7223

See Figure 14

Figure 14

The shoulder belts should be mounted as close to the occupant as possible,

separated by 2-3 inches between the inside edges of the belts.

CRISSCROSS

BELT POSITION

Figure 15

Figure 16

SEPARATED

BELT POSITION

Recommended distance between the

inside edges of the belts is 2” - 3”.

DRIVEN BY SAFETY TEAMSIMPSON.COM 11

Figure 17

Page 7

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

OPTIONAL SEAT BELT ANCHOR SYSTEM

OPTIONAL HYBRID MOLDED PAD

OPTIONAL HYBRID MOLDED PAD

OPTIONAL HYBRID MOLDED PADOPTIONAL SEAT BELT ANCHOR SYSTEM (SAS)

The SAS straps need to attach to the seat belt buckle; the

SAS is an additional load path for the restraint allowing for

stabilization of the driver.

Camlock Attachment Slide each SAS O-ring onto two of

the camlock buckle tongues.

Latch-in-Link Attachment Pair the SAS O-rings and slide

them into the latch link shoulder belts or the fi ve point

depending on your set-up.

The SAS straps should be adjusted to be snug when the

buckle is latched with no more than 2 fi ngers of room.

Adjustment is made by sliding the 1” webbing attached to

the loops through the 3-bar adjuster.

OPTIONAL SAS LOOPS AVAILABLE

Figure 20 Figure 21

12 TEAMSIMPSON.COM TOLL FREE 800.654.7223

See Figure 18

See Figure 19

Figure 18

Figure 19

The Hybrid Optional Molded Pad is placed

behind the driver between the seat and the

driver’s back and shoulders.

The U-Shaped Molded Pad can be cut, and/or

trimmed to fi t driver’s seat. Tape, glue, or Velcro

the molded pad in place depending on type of

seat. If the seat has a cover, the pad can be

installed under the cover.

The Pad is inserted into the seat back. When

the driver sits back, the device nests into the

voided area creating one smooth surface behind

the driver’s back. The wings of the restraint

should extend under the shoulder belts between

the seat back and the driver.

Figure 22

DRIVEN BY SAFETY TEAMSIMPSON.COM 13

Page 8

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

OPTIONAL TETHERS, ANCHORS & CLIPS

OPTIONAL HELMET TETHERS

OPTIONAL TETHERS, ANCHORS & CLIPS

OPTIONAL HELMET ANCHORS

QUICK RELEASE TETHERS

USED WITH D-RING (STANDARD)

M61 DUAL END FITTING TETHER

USED WITH M6 ANCHOR SYSTEM

14 TEAMSIMPSON.COM TOLL FREE 800.654.7223

HYBRID QUICK CLICK TETHERS

EZ SLIDE DUAL END FITTING TETHER

AVAILABLE WITH QUICK RELEASE OPTION

EZ SLIDE LOOPS

USED WITH SIMPSON QUICK CLICKS

HYBRID POST CLIPS

USED WITH SIMPSON POST ANCHORS

M6 ANCHOR

WITH DUAL END FITTING

SIMPSON QUICK CLICK SYSTEM

DRIVEN BY SAFETY TEAMSIMPSON.COM 15

SIMPSON POST ANCHORS

QUICK RELEASE ANCHORS

Page 9

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

FREQUENTLY ASKED QUESTIONS

FAQS

FREQUENTLY ASKED QUESTIONS

FAQS

Q: My Helmet came pre-drilled, can I use the pre-drilled hole?

A: Simpson helmets will be the correct location. If your helmet is not a Simpson check with your helmet

manufacturer to confi rm the location.

Q: Do I need special seat belts to work with your devices?

A: No, our devices work with 2 or 3 inch seat belts, Latch and Link or Cam Lock.

Q: Do I need to replace my head restraint if I am involved in a wreck?

A: Your Simpson Head Restraint device is built to sustain the most violent of wrecks. However, in the event

of a hard wreck, you should send your restraint to us for proper inspection by a Simpson Safety Specialist.

We may recommend replacing the helmet tethers. While the chances of the device being unharmed are great,

it is not worth taking a chance.

Q: Can two people of different sizes share the same device?

A: Yes, we have a chest extender that will plug into the chest strap to give more length in the chest.

Q: Is my device adjusted wrong if I can touch my chin to my chest?

A: No, with your device adjusted correctly you should be able to rotate you head enough for your chin to

touch your chest.

Q: I am having trouble turning my head even after adjustments, what should I do?

A: Call you Simpson Safety Specialist; your setup may require an EZ Slide System.

Q: When I measure my helmet for the anchors hard foam in the way on the inside, what should I do?

A: Very gently use a large fl at screw driver or small pry bar to wedge between the liner and the shell.

This liner is not glued into the helmet, but use caution not to compromise the shell or the liner. Then

simply slide the nut washer into place. DO NOT DRILL THROUGH OR COMPROMISE THIS FOAM LINER.

Q: I have a Hybrid and it feels like it pushes me forward out of the seat. What can I do?

A: You can order the optional molded seat pad that can be cut, trimmed, shaved or ground to be

whatever shape you need to be comfortable.

Q: My child is just getting started racing, will I have to purchase another device as they grow?

A: Probably not. This will depend on how big they are and how fast they grow. Once the child is at a 28

inch chest, the device that they wear will be able to be re-sized to whatever size they need.

Q: How often should I replace my head restraint?

A: Each Sanctioning body is different. As of 2012 SFI required all SFI 38.1 certifi ed devices to be

inspected every 5 years. For additional information on recertifi cation please check out our web site at

www.teamsimpson.com

16 TEAMSIMPSON.COM TOLL FREE 800.654.7223

DRIVEN BY SAFETY TEAMSIMPSON.COM 17

Page 10

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

TAKING IMPACTS

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

prove that it is the safest option on the market. As part of Simpson’s SFI 38.1 certifi ed line of

Head and Neck Restraints, it was designed with the lowest profi le for maximum comfort and

With the 2012 mandates in effect, the Simpson Hybrid Pro has endured stringent testing to

AND

MULTIPLE ANGLE IMPACTS ACTUALLY, AND A LOT OF THEM.

DISCLAIMER

DISCLAIMER

Vehicle racing is inherently a dangerous sport with signifi cant risk of person injury or even death. When a user participates in vehicle racing, he accepts the risk inherent therein.

Simpson Performance, Inc. makes no warranty that the use of its products or parts guarantees personal safety or freedom from physical injury or operates as a life saving device.

SIMPSON PERFORMANCE, INC.’S PRODUCTS AND PARTS ARE SOLD “AS IS” WITHOUT ANY WARRANTY WHATSOEVER. EXPRESS WARRANTIES, IMPLIED WARRANTIES,

WARRANTIES OF MERCHANTABILITY AND WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. THE ENTIRE RISK OF QUALITY AND PERFORMANCE OF

SUCH PRODUCTS AND PARTS IS WITH THE BUYER, USER SUBSEQUENT USER, OR AGENT THEREOF (HEREIN “USER”). SHOULD SUCH PRODUCTS OR PARTS PROVE DEFECTIVE

FOLLOWING THEIR PURCHASE, THE BUYER AND NOT THE MANUFACTURE(S), DISTRIBUTOR(S), OR RETAILER(S), ASSUME THE ENTIRE COST OF ALL NECESSARY SERVICES OR

REPAIR.

Simpson Performance, Inc. disclaims all liability for any special, direct, incidental or consequential damages, or any damages whatsoever, including, without limitation, the loss of

life or limb, or damages due to bodily or personal injury, which may arise or result from the sale, installation, or use of any of its products and parts.

It is the user’s responsibility to inspect and verify the dimensions, specifi cations, and performance of all products and parts as being appropriate for the use to which the user will

put them prior to any actual installation and/or use of said products and parts.

Simpson Performance, Inc.’s products and parts are to be inspected by the user before each use for evidence of damage, defect, or wear. Any deviation by the user from the

manufacturer’s specifi cations concerning use, maintenance, repair, alterations and modifi cations constitutes willful negligence.

The installation of Simpson Performance, Inc.’s products or parts may adversely affect other vehicle components, safety equipment or manufactured goods (collectively “goods”).

Simpson Performance, Inc. assumes no responsibility for any damage to other goods, or bodily injury that may arise due to failure of other goods, due to installation and/or use,

either proper or improper, of its products or parts.

The liability of Simpson Performance, Inc. is limited to the replacement of defective products or parts found under examination by manufacturer to be defective in material or

workmanship within 60 days after purchase, and which has not been caused by an accident, improper use, alteration, tampering, excessive use, misuse, modifi cation or abuse.

The damage of the user shall be deemed liquidated in the costs of replacement of the product or part.

Simpson Performance, Inc. assumes no responsibility for errors, omissions, diagrams, pictures, illustrations or text in these instructions or the documents contained herewith.

By purchasing or using this product, the user agrees that if any provision of this Disclaimer is held to be illegal, invalid or unenforceable under present or future law, such provision

shall be fully severed from the Disclaimer and this Disclaimer shall be construed and enforced as if such illegal, invalid or unenforceable provision never comprised a part

hereof, and the remaining provisions hereof shall remain in full force and effect and shall not be affected by the illegal, invalid, or unenforceable provision, there shall be added

automatically as part of this Disclaimer a provision as similar in its terms to such illegal, invalid or unenforceable provision as may be possible and be legal, valid and enforceable.

CERTIFICATIONS

CERTIFICATIONS

SINCE 1959, SIMPSON PERFORMANCE PRODUCTS has been the leading manufacturer of safety equipment for the

Motorsports Industry. We believe in putting safety fi rst and are dedicated to elevating the standards of racing safety

through continuous development, refi nement and testing as well as a strong partnership with racing sanctioning

bodies worldwide. The Hybrid Head Restraints are certifi ed by SFI and FIA.

SFI: THE SFI FOUNDATION, INC is a non-profi t organization established to issue and administrate safety standards

for specialty and performance of automotive and racing equipment. SFI Oversees testing and standards for fi re suits,

restraints and many other high performance safety products in the United States. NASCAR and NHRA are among the

sanctioning bodies who abide by SFO standards.

MORE INFORMATION CAN BE FOUND AT WWW.SFIFOUNDATION.COM

FIA: THE FEDERATION INTERNATIONALE DE L’AUTOMOBILE is a non-profi t organization that brings together

227 national motoring and sporting organizations from 132 countries on fi ve continents. FIA Formula One World

Championship, FIA World Rally Championship and FIA World Touring Car Championship are among the sanctioning

bodies who abide by FIA standards.

MORE INFORMATION CAN BE FOUND AT WWW.FIA.COM

MODEL # SERIAL #

18 TEAMSIMPSON.COM TOLL FREE 800.654.7223

The products and parts shown herein are to be installed and used adjusted in accordance with these instructions. Any deviation by the buyer,

installer, or user from these instructions constitutes willful negligence. Products and parts are not to be used if defective, damaged or worn.

Products and parts are not to be used after a severe use, in any event.

DRIVEN BY SAFETY TEAMSIMPSON.COM 19

Page 11

DRIVEN BY

SAFETY

CALL CUSTOMER SERVICE TOLL FREE 800.654.7223

OR E-MAIL SALES SALES@TEAMSIMPSON.COM

VISIT TEAMSIMPSON.COM

DRIVEN BY SAFETY TEAMSIMPSON.COM 20

Loading...

Loading...