Page 1

OFF RUN HOLD

LOCK

SIMPSON ELECTRIC CO. ELGIN , IL 60120

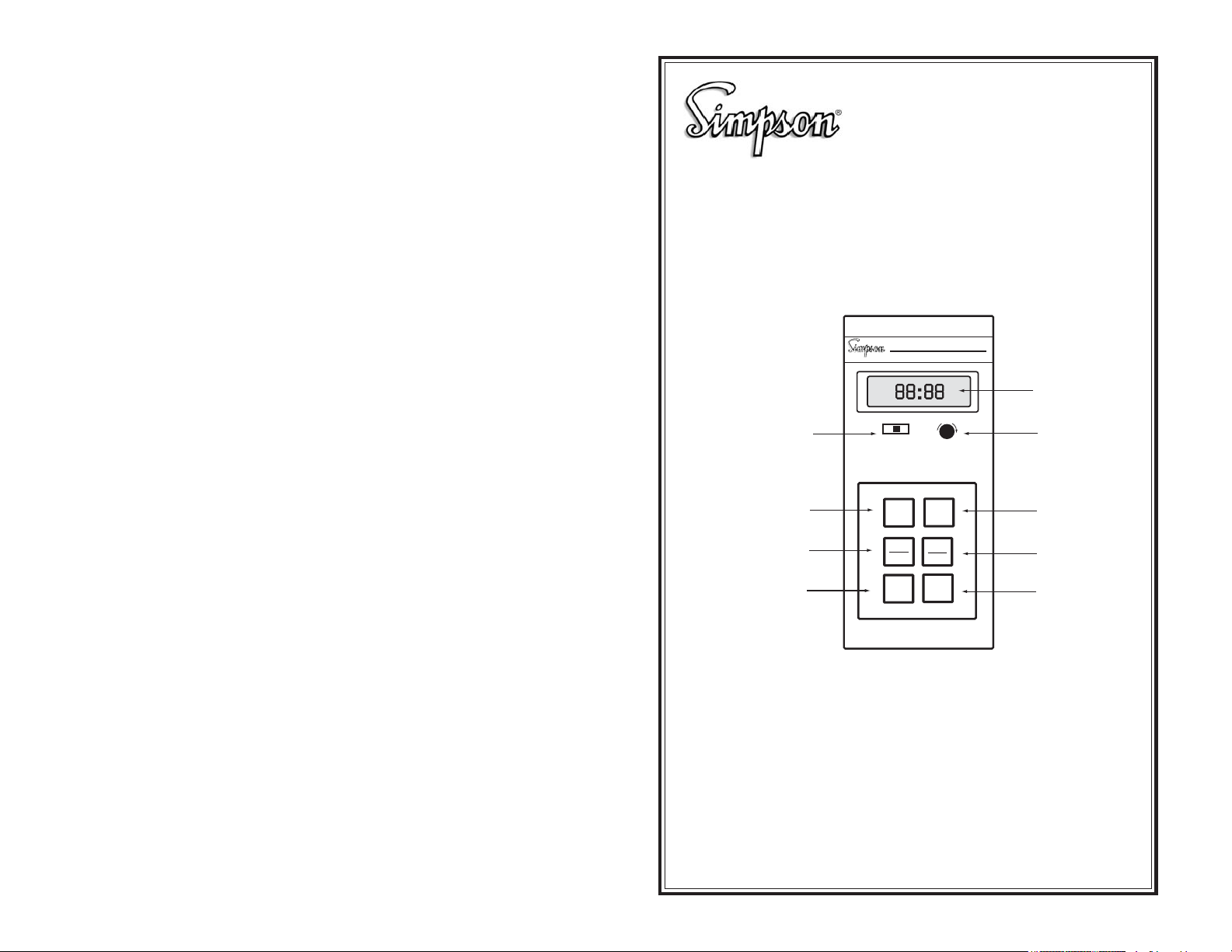

897 DOSIMETER

SOUND MEASURING SYSTEM

SPL

"CAL"

INT

(60 sec)

DOSE

PEAK

Leq

MAX

TIME

PRINT

TEST SETUP

1

2

3

4

5

6

7

8

9

LO BATT

SPL MAX

INT 60s

% DOSE

dBA

Model 897

Dosimeter Sound Measuring System

OPERATOR’S MANUAL

SIMPSON ELECTRIC COMPANY 520 Simpson Avenue

Lac du Flambeau, WI 54538-0099 (715) 588-3311 FAX (715) 588-3326

Printed in U.S.A. Part No. 06-115891 Edition 6, 05/07

Visit us on the web at: www.simpsonelectric.com

32

Page 2

About this Manual

To the best of our knowledge and at the time written, the information contained in

this document is technically correct and the procedures accurate and adequate

to operate this instrument in compliance with its original advertised specifications.

Notes and Safety Information

This Operator’s Manual contains warning symbols which alert the user to check

for hazardous conditions. These appear throughout this manual where applicable, and are defined below. To ensure the safety of operating performance of

this instrument, these instructions must be adhered to.

Warning, refer to accompanying documents.

!

NOTES

Caution, risk of electric shock.

This instrument is designed to prevent accidental shock to the operator when

properly used. However, no engineering design can render safe an instrument

which is used carelessly. Therefore, this manual must be read carefully and completely before making any measurements. Failure to follow directions can result

in a serious or fatal accident.

Technical Assistance

SIMPSON ELECTRIC COMPANY offers assistance Monday through Friday

8:00 am to 4:30 pm Central Time. To receive assistance contact Technical Support or Customer Service at (715) 588-3311.

Internet: http://www.simpsonelectric.com

Warranty and Returns

SIMPSON ELECTRIC COMPANY warrants each instrument and other articles

manufactured by it to be free from defects in material and workmanship under

normal use and service, its obligation under this warranty being limited to making

good at its factory or other article of equipment which shall within one (1) year

after delivery of such instrument or other article of equipment to the original

purchaser be returned intact to it, or to one of its authorized service centers, with

transportation charges prepaid, and which its examination shall disclose to its

satisfaction to have been thus defective; this warranty being expressly in lieu of

all other warranties expressed or implied and of all other obligations or liabilities

on its part, and SIMPSON ELECTRIC COMPANY neither assumes nor authorizes any other persons to assume for it any other liability in connection with the

sales of its products.

This warranty shall not apply to any instrument or other article of equipment

which shall have been repaired or altered outside the SIMPSON ELECTRIC

COMPANY factory or authorized service centers, nor which has been subject to

misuse, negligence or accident, incorrect wiring by others, or installation or use

not in accord with instructions furnished by the manufacturer.

!

2

31

Page 3

NOTES

NOTES

30

3

Page 4

Contents

1. INTRODUCTION ............................................................................... 7

1.1 General Description ........................................................................... 7

1.2 Items Furnished With Instrument ........................................................ 7

1.3 Technical Data .................................................................................... 8

2. PREPARATION FOR USE ............................................................... 11

2.1 Unpacking And Inspection ...............................................................11

2.2 Preparation For Use .........................................................................11

2.3 Warranty ........................................................................................... 12

2.4 Shipping ...........................................................................................12

3. APPLICATION ................................................................................. 12

3.1 Decibel Scale ...................................................................................12

3.2 Sound Level Meter ...........................................................................12

3.3 Measurement And Exposure Standards ..........................................13

3.3.1 Steady Level or Slowly Varying Noise ............................................. 13

3.3.2 Impact Noise .................................................................................... 15

3.4 Dosimeter .........................................................................................15

3.5 Dosimeter Equation ..........................................................................15

3.6 Sound Fields ....................................................................................1 6

3.6.1 Free Field .......................................................................................... 16

3.6.2 Reverberant Field ............................................................................. 16

3.7 Microphone Orientation ....................................................................16

3.7.1 Area Monitor in a Free Field ............................................................. 16

3.7.2 Fixed Position Monitor in a Reverberant Field ................................. 16

3.7.3 Use of Dosimeter as a Personal Monitor ........................................ 16

3.8 Windscreen.......................................................................................17

4. OPERATION .................................................................................... 17

4.1 Safety Precautions ...........................................................................17

4.2 Operating Items And Features ......................................................... 17

4.3 Top Panel Operating Features ........................................................ 19

4.4 Battery Charging ..............................................................................19

4.5 Preliminary Checks .......................................................................... 20

4.5.1 Underrange Display ......................................................................... 20

4.5.2 Overrange Display ........................................................................... 20

4.5.3 Diagnostic Memory Test .................................................................. 20

4.6 Setting The Dosimeter Parameters .................................................. 21

4.6.1 The Dosimeter Parameters ............................................................. 21

4.6.2 To Program the Dosimeter ............................................................... 21

4.7 Security Controls ..............................................................................23

4.8 Selection Of Parallel Or Serial Output Format .................................2 3

4.9 Automatic Data Logger .....................................................................23

4.10 Data Output Formats ........................................................................ 24

4.11 Parallel Output And Serial Format 2 “Prn 2” .................................... 24

4.12 Spreadsheet Output Format “Prn 1” .................................................2 6

4.13 Calibration ........................................................................................27

4.14 Dosimeter Application ......................................................................28

4.14.1 Using Microsoft Works 4.0 .............................................................. 28

4.14.2 Using Microsoft Works 3.0 For Dos ................................................ 29

4.15 Error Message .................................................................................. 30

4

12. Save data or copy to another program to print.

Data will remain stored in the dosimeter while the dosimeter is still on; once the

dosimeter is turned off, the data will be erased.

4.14.2 Using Microsoft Works 3.0 For Dos

Access the WORKS program, and follow the prompts. Data is first received by the

Communications portion of WORKS, then moved to the word processor portion,

and finally into the spreadsheet.

From the Quick Start Options Menu, select “Create a New File” and then continue

below:

4.15 Error Message

If the display indicates “ERRO3”, turn off the dosimeter and wait 10 seconds. Then

turn the dosimeter on. This resets the 897 and the calibration is unaffected.

Communications <OK>

Options

Communication

Baud Rate [match the 897--try 9600]

Data Bits [8]

Stop Bits [1]

Handshake [Hardware]

Parity [None]

Port [COM1 or COM2], as required

<OK>

File Save [this will save the setup]

Transfer

Capture Text

Save file as [897.DAT] <OK>

Connect

Connect

>> On the 897, slide the “OFF-ON-HOLD” SWITCH TO “HOLD” AND PRESS

“PRINT”. You will see the data appear on the computer screen. When the data

stops appearing...

Connect

Connect

OK to disconnect? <OK>

File

Close

File

Open Existing File

897.DAT <OK>

Open File As <Word Processor>

<OK>

Select

Replace

Search for [*...........]

<Replace All> <OK>

29

Page 5

FULLY INSERT

MICROPHONE

NOTES

SET TO "RUN"

PRESS

"CAL"

897 DOSIMETER

SOUND MEASURING SYSTEM

LO BATT

SPL MAX

INT 60s

SPL

INT

"CAL"

(60 sec)

TEST SETUP

DOSE

Leq

PEAK

MAX

TIME

PRINT

LOCK

OFF RUN HOLD

SIMPSON ELECTRIC CO. ELGIN , IL 60120

% DOSE

dBA

SOUND LEVEL CALIBRATOR

OUTPUT FREQUENCY: 1000 HERTZ

ON

OFF

ON

LOW BATTERY

CAUTION

NEVER PLACE CALIBRATOR AGAINS EAR.

READ OPERATOR'S MANUAL.

SIMPSON ELECTRIC CO., ELGIN IL 61020

MADE IN USA

114dB

94 dB

887-2

SET TO "114dB"

POSITION

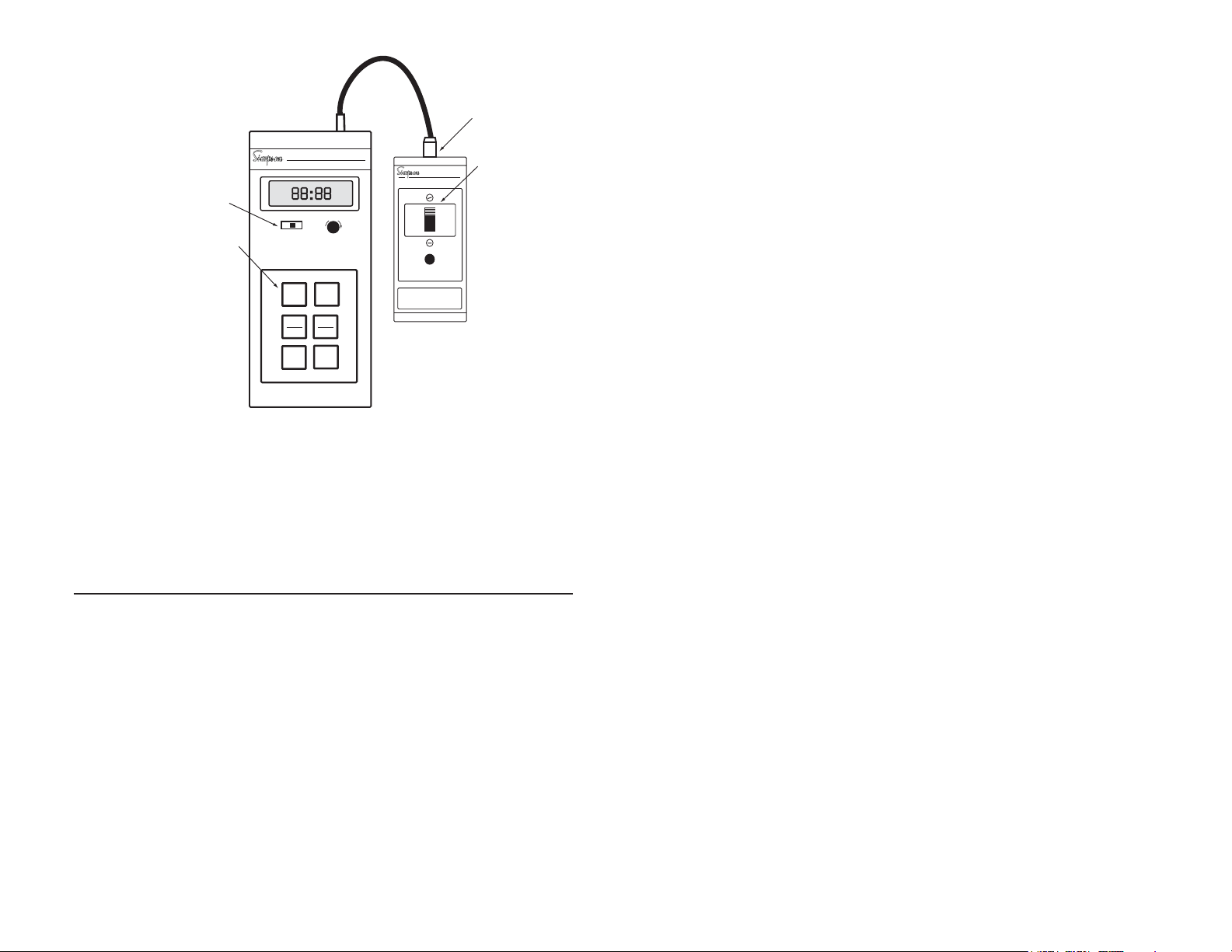

Figure 4-5. Calibration Hookup

f. (Optional) The time and date of this calibration may be recorded in the

Instrument’s memory by pressing and holding the “SPL (CAL)” switch until

the display flashes “CAL.” The Instrument will retain the two most recent such

occurrences, which may be observed only via the DATA OUTPUT. Due to

changes in atmospheric conditions, it is recommended that Instrument calibrations be conducted and recorded at the beginning and end of the day.

g. Turn off the calibrator, remove the microphone and replace the windscreen.

4.14 Dosimeter Application

The following text describes how to transfer data from the Simpson 897 Dosimeter into an IBM-compatible computer using Microsoft Works.

Using the optional RS-232-C serial cable, catalog #02233, connect the 897 to

your computer’s serial port, either COM1 or COM2.

4.14.1 Using Microsoft Works 4.0

1. Start Works 4.0

2. In Works Task Launcher, go to Works Tools.

3. Click on Communications.

4. Close the Easy Connect window if necessary.

5. Click on Settings and then Communications.

6. Choose the COM Port that the Dosimeter is connected to, then click on

Properties.

7. Set Port Settings to match the Dosimeter (Flow control=Xon/Xoff), click OK.

8. Click OK again.

9. Click on the Dial/Hang-up button on the toolbar.

10. Press PRINT on the Dosimeter.

11. Data should now be displayed.

28

5

Page 6

NOTES

START: 25/JAN/02 08:23

CAL: 114.0 dBA 08:09 25/JAN/02 RANGE: 80/130 dB

CAL: 114.0 dBa 08:40 25/JAN/02 RANGE: 80/130 dB

DOSE: 108.0%

LEQ 115.5

SPL-Max *130.0

Lc 90

th 80

rt 5

id 01

Pk 0

ET 17

HT 2

ET L

1 91.1 91.4 0 1 0

2 99.1 105.6 0 1 0

3 129.7 *130.0 0 1 0

4 130.0 *130.0 0 1 0

5 106.2 *130.0 0 1 0

6 *00.0 *00.0 0 1 0

7 *00.0 *00.0 0 0 0

8 95.9 96.7 0 1 0

9 89.9 96.7 0 1 0

10 80.1 80.3 0 1 0

11 80.5 94.6 0 -1 0

12 53.9 54.6 0 0 0

13 53.6 54.7 0 0 0

14 53.0 54.4 0 0 0

15 52.1 53.5 0 0 0

16 52.1 52.3 0 0 1

17 *00.0 *00.0 0 0 1

NOTES: 1 . When read by a spreadsheet program such as Microsoft Works™, the L

LMAX PEAKS RANGE HOLD

AVG

RANGE AND HOLD columns will be aligned.

2. *00.0 indicates an underrange reading

*100.0 or *130.0 indicates an overrange reading

Figure 4-5. Sample Printout - Spreadsheet Serial Format 1 (Prn 1)

, L-MAX, PEAKS,

AVG

4.13 Calibration

Always check the calibration before making any measurement. Use the Simpson

Sound Level Calibrator, Model 887, Series 2.

a. Remove the windscreen (if used) and carefully insert the microphone fully

into the acoustic cavity of the Calibrator.

b. Set the calibrator power switch to the “ON” position and check that the cali-

brator battery is okay.

!

Never place the operating calibrator tightly against the ear. The high sound level

could be harmful, especially to someone with a hearing deficiency.

c. Set the “OFF-RUN-HOLD” slide switch in the 897 to the “RUN” position. Wait

until the Display Test sequence is completed, then depress the SPL (CAL)

switch.

d. Select the desired range: For checking at 94 dB use the 50/100 range; for

checking at 114 dB use the 80/130 range.

e. If calibration is required, using the screwdriver supplied with the calibrator,

turn the adjustment control until a reading of either 94.0 dB or 114.0 dB is

indicated on the display.

6

27

Page 7

A sample of the Spreadsheet output format is illustrated in Figure 4-5. It is very

similar to the summary report, except it does not include a histograph and the

minute-by-minute data is not in real-time but in elapsed time. The Spread-Sheet

output is once for each minute of data saved by the data logger; that is once for

each minute of Elapsed Run Time (ET).

L

is the integrated (60 sec) reading.

AVG

L

is the maximum sound pressure level for this minute.

-MAX

PEAKS is the number of 140 dB peaks detected this minute.

RANGE can be 0 for the 50/100 range, 1 for 80/130 or -1 if the range

switch changed during this minute.

HOLD is a number “flag” with a 1 signifying that the dosimeter was

in “RUN”.

The Spreadsheet Output format is diagramed in Table 4-4. Note that each data

item is separated by two spaces.

Table 4-4. Spreadsheet Output Format

Actual Output Description

Start:<sp><sp>25/JAN/02<sp><sp>00:00<CR><LF> Starting date and time for this period

CAL:<sp><sp>0.0<sp>dBA<sp><sp>00:00<sp><sp>25/J The dBA reading, time, date and range

AN/100<sp><sp>RANGE:<sp><sp>80/130<sp><sp>

dB<CR><LF>

DOSE:<sp><sp>0.0<CR>LF> The calculated dose in percentage

Leq:<sp><sp>000.0<CR><LF> The calculated 8-hour Time Weighted

SPL-Max<sp><sp>000.0<CR><LF> The detected maximum SPL for this data

Lc<sp><sp>nn<CR><LF> Criterion Level in dB

Th<sp><sp>nn<CR><LF> Threshold in dB

rt<sp><sp>n<CR><LF> Exchange Rate in dB

ID<sp><sp>nn<CR><LF> Unit I.D. Number

Pk<sp><sp>nnn<CR><LF> Number of 140 dB peaks

ET<sp><sp>nnnn<CR><LF> Elapsed Run Time in minutes

HT<sp><sp>nnn<CR><LF><CR><LF> Elapsed Hold Time in minutes

ET<sp>L

RANGE<sp><sp>HOLD<CR>LF>

<sp><sp>MAX<sp><sp>PEAKS<sp><sp>

AVG

switch setting for each of two possible

calibration readings. If the output data is

only CAL:<sp><sp>?<CR><LF> then there

is no calibration reading stored. Also,

“RANGE:” may be 50/100.

Average (TWA) in dBA

period

1.INTRODUCTION

1.1 General Description

The Simpson Model 897 is a combination dosimeter and Class S2A sound level

meter. It is a portable, easy-to-operate, accurate digital sound measurement instrument designed to meet the requirements of OSHA and international noise

exposure regulations.

The 897 has a built-in data logger with a 31 hour storage capability. There are two

standard output formats available with the data logger, a Centronics compatible

parallel printer and an RS-232C serial printer or computer. The 897 also meets

the requirements for the American National Standard Institute (ANSI) Specification S1.4-1983 and IEC651 for class S2A sound level meters and American

National Standard Institute (ANSI) Specification S1.25-1978 for Personal Noise

Dosimeters.

Measuring continuous, intermittent and impulsive noise in the standard range

from 80 dBA to 130 dBA, the 897 also offers a 50 to 100 dB range where lower

sound level analysis is desired. When used as a personal noise dosimeter, the

897 may be worn in a shirt pocket or on a belt. The microphone is provided with a

clip which can be attached to the operator’s shirt close to the ear.

When used as a sound level meter, the Instrument is hand-held. A front end

attachment, properly contoured to avoid interference with incoming sound waves,

holds the microphone. The advanced microcomputer, large digital display and

special electret-condenser microphone offers easy operation and readability,

and excellent performance and reliability.

1.2 Items Furnished With Instrument

All items furnished with the 897 are listed in Table 1-1.

Table 1-1. Items Furnished with the Instrument

Qty Description Part No.

1 Windscreen Dust Cover 5-119753

1 Microphone Clip 5-119752

1 Splined Wrench 6-113274

1 Screwdriver, adjusting 5-116470

1 Microphone Adapter 10-865235

1 Operator’s Manual 6-115891

1 Parallel Cable 02234

1 AC Charger 6-115095

1 Carrying Case 10-865926

26

Optional Items

Description Part No.

887-2 Sound Level Calibrator 12648

RS-232 Serial Cable 02233

7

Page 8

1.3 Technical Data

The 897 conforms to ANSI S1.4-1983, ANSI S1.25-1978, and IEC651 (1979)

standards for type S2A sound level meters and noise dosimeters.

Table 1-2 lists the technical specifications for the 897 Noise Dosimeter/Sound

Level Meter.

Table 1-2. Instrument Specifications

Dosimeter Specifications

1. Microphone:

Type: 0.52 inch (13.2 mm) diameter electret con-

denser.

Maximum Pressure: 148 dBA sound pressure level.

Impedance: 1 K⍀

Directional Characteristics: Omnidirectional. The free field angle of inci-

dence which closely approximates the ran-

dom response is 70°.

2. Threshold Level: The threshold level is selectable over the

range of 50 to 99 dB, in 1 dB increments,

from the front panel. The dosimeter function

of the 897 is nonresponsive to noise levels

below the threshold setting.

3. Dose:

Resolution: 0.1% dose to 999.9%; above 1000%, dis-

play will automatically convert to a higher

range.

Maximum Indication: Dual automatic ranging: either 999.9% or

9999%. 100% corresponds to a criterion

level noise exposure for eight hours; 50%

corresponds to an eight hour noise exposure equal to the criterion level minus the

exchange rate.

4. Leq Display: Displays with 0.1 dB resolution. Selectable

upper limit of 115 or 130 dB.

5. Criterion Level: Selectable at 70, 80, 84, 85 or 90 dB from

the front panel.

6. Exchange Rates: 3, 4 or 5 dB, selectable from the front panel.

7. Elapsed Time: Displays either hours:minutes or

minutes:seconds, up to 99 hours, 59 minutes, 59 seconds. Timing accuracy: 6 0.05%.

8. Dynamic Range: Two switch selectable ranges, 50 to 100 dB

and 80 to 130 dB.

9. Accuracy: True RMS, per ANSI S1.4-1983, type S2 requirements.

10. Frequency Response

Weighting: “A” weighting.

11. Response Time: Slow (1 second).

12. Crest Factor: 10:1 at maximum indication.

13. Frequency Range: 31.5 Hz to 8 KHz.

14. Sound Pressure Reference: 0 dB = 20 µ Pascals.

15. Linearity: 60.5 dB @ 1 KHz: 50/100 Range: >60dB; 80/130 Range: >90dB

16. Criterion Duration (Tc): 8 hours.

8

Hrs:Min is the real-time that the data was logged.

L

is the integrated (60 sec) reading.

AVG

L-MAX is the maximum sound pressure level for that minute.

PEAKS is the number of 140 dB peaks detected in that minute.

RANGE is the range setting selected during that minute.

Readings preceded by an asterisk indicate they were either overrange or

underrange:

* 00.0 indicates an underrange reading (under 50 on the 50 to 100 dB range or

under 80 on the 80 to 130 dB range).

* 100.0 indicates an overrange reading on the 50 to 100 dB range.

* 130.0 indicates an overrange reading on the 80 to 130 dB range.

4.12 Spreadsheet Output Format “Prn 1”

SIMPSON 897 Dosimeter Sound Analysis Report Type S2A

CRITERION = 90 dB

THRESHOLD = 80 dB

EXCHANGE RATE = 5 dB

UNIT IDENTIFICATION # 01

JOB ______________________________________________________

NAME _____________________________________________________

LOCATION _________________________________________________

START DATE: 25/JAN/02

START TIME: 08:23

CALIBRATION: 114.0 dBA 08.09 25/JAN/02 RANGE: 80/130 dB

CALIBRATION: 114.0 dBA 08.40 25/JAN/02 RANGE: 80/130 dB

MEASUREMENT SUMMARY:

RUN TIME = 00:17

HOLD TIME = 00:02

L EQ = 115.5 dBA

SPL MAX = *130.0 dBA

DOSE = 108.0%

140 dB PEAKS = 0

HRS:MIN + --------- + ------------ + ------- + ---------- + ------------ + ---------------+ --------------- + ---------- +

08.24 = = = = = = = = = = = = = = = = = = = = = = = = 91

08:25 = = = = = = = = = = = = = = = = = = = = = = = 93

08:30 = = = = = = = = = = 69

08.35 == 52 HOLD

08:40 < HOLD

HRS:MIN + --------- + ------------ + ------- + ---------- + ------------ + ---------------+ --------------- + ---------- +

HRS:MIN L

08:24 91.1 91.4 0 80/130

08:25 99.1 105.6 0 80/130

08:26 129.7 *130.0 0 80/130

08:27 130.0 *130.0 0 80/130

08:28 106.2 *130.0 0 80/130

08:29 *00.0 *00.0 0 80/130

08:30 *00.0 *00.0 0 80/130

08:31 95.9 96.7 0 80/130

08:32 89.9 96.7 0 80/130

08:33 80.1 80.3 0 80/130

08:34 80.5 94.6 0 CHANGED

08:35 53.9 54.6 0 50/100

08:36 53.6 54.7 0 50/100

08:37 53.0 54.4 0 50/100

08:38 52.1 53.5 0 50/100

08:39 52.1 52.3 0 50/100 HOLD

08:40 *00.0 *00.0 0 50/100 HOLD

NOTE: *00.0 Indicates an underrange reading. *100.0 or *130.00 indicates an overrange reading

50 60 70 80 90 100 110 120 130

AVG

Figure 4-4. Sample Printout - Parallel Output and Serial Format 2 (Prn 2)

HISTOGRAPH

5-MIN AVERAGE LEVELS IN dBA

LMAX PEAKS RANGE

END OF REPORT

25

Page 9

observed during the preceding minute (not the same as the MAX function switch),

the number of 140 dB peaks during the preceding minute, the RANGE switch

setting, and the occurrence of the dosimeter entering the “HOLD” mode. This data

is available only via the “Data Output” connector.

4.10 Data Output Formats

Two standard output formats are available from the data logger of the dosimeter:

a summary report that can be printed on either a parallel printer, or an RS-232C

serial printer, and an output that is ideally formatted as input into a multi-column

spreadsheet type program such as Microsoft Works™. Each output format includes information of total “HOLD” time, dose, Leq, SPL MAX, total number of 140

dB peaks, and a minute-by-minute output of the data logger. Following are sample

printouts of the same data recorded by the 897 in each of the output formats. To

obtain a printout in either one of the formats: first set the dosimeter to “HOLD”,

then press the “PRINT” button to print the data.

4.11 Parallel Output And Serial Format 2 “Prn 2”

A sample of the summary report is illustrated in Figure 4-3. The report is divided

into four parts for explanatory reasons: Heading, Measurement Summary,

Histograph, and the Minute-by-Minute Data Logger Output.

Heading includes:

Type of report, measurement parameters set by the operator, location and job

identification as assigned by the operator

Date and time the Instrument was first set in “RUN” mode of operation. Also

included are calibration data and time if recorded by the operator. (See paragraph 4.13 for calibration instructions.)

Measurement Summary includes the following:

Run Time: Total time Instrument was in “RUN” mode.

Hold Time: Total time Instrument was in “HOLD” mode of operation.

Leq: The eight hour TWA (time weighted average) expressed in dBA.

This measurement can be from the threshold level, set by the

operator, up to 130 dB.

SPL Max: The maximum sound pressure level recorded by the data log-

ger.

DOSE: The calculated dose (in percent). A 100% equates to a criterion

noise level exposure for an eight hour time period.

140 dB Peaks: Total number of 140 dB peaks recorded.

Histograph presents five minute averages of the minute-by-minute L

ings. The histograph is independent of the range setting, however, when the L

readings are either underrange as indicated by * 00.0; or overrange as

indicated by * 100.0 or * 130.0, then these readings are averaged into the 5

minute summary. For example; if L

is averaged in the five minute histograph.

Note that the five minute averages start on the minute ending in either a 0 or a 5,

therefore, the initial and final averages may be less than 5 minute interval averages, as noted in Figure 4-3. The Instrument was in either the “HOLD” or “SPL”

mode of operation at anytime during the five minute interval, if the reading is

followed by the word “HOLD”.

Minute-by-Minute Data Logger Output includes the following:

= * 00.0, as noted in Figure 4-3, then 0.0 dB

AVG

24

AVG

read-

AVG

17. Calibration: Instantaneous with 100 Hz, 94 dB or 114 dB

SPL calibrator and adjustment on the top of

the 897. However, an annual factory

recalibration is recommended.

18. 140 dB Peaks: Front panel selectable display indicates

number of 140 dB peaks that have been detected.

19. Warm-up Time: One minute.

20: Data Logger

Recording Time: 31 hours maximum. Any data beyond this

time is not stored; only the first 31 hours

are retained.

Stored Information: a. The integrated 60 second average

(L

).

AVG

b. The highest SPL (Lmax).

c: The number of detected 140 dB peak

occurrences.

d: “HOLD” switch status.

e: “RANGE” switch status.

Storage Rate: Data is stored at 00:01:00 (hrs:min:sec) and

once per minute thereafter.

Data Retention: Data is retained for as long as the unit re-

mains powered in the “RUN” or “HOLD”

modes; all data is lost in the “OFFf” mode.

However, to minimize the chance that data

may be lost inadvertently, the data is retained

for 3 seconds after the power is turned off.

Data Output Port:

Parallel: With supplied cable, communicates with any

Centronics compatible, 80 column printer.

RS-232C Serial: With accessory cable, catalog #02233, com-

municates with any serial computer port at

baud rates of 300, 600, 1200, 2400, 4800 or

9600. (Serial port set for 8 bit words, no parity, 1 stop bit). It will also function with many

RS-232C serial printers.

Data Output Format:

Parallel: Includes criterion level, threshold level,

elapsed run time, elapsed hold time, Leq,

SPL MAX, dose, and number of 140 dB

peaks. A five minute average level

histograph is then output, which additionally gives indications of the RANGE switch

setting and activation of “HOLD” mode. This

is then followed by a complete listing of all

stored information on a minute-by-minute

basis. See para. 4:10 for further details.

Serial: Includes criterion level, threshold level, ex-

change rate, unit identification number,

elapsed hold time. Leq, SPL MAX, dose, and

number of 140 dB peaks. This is then followed by a complete listing of all stored in-

9

Page 10

formation on a minute-by-minute basis. All

of this data is formatted either for convenient

input to a spreadsheet program, such as

Microsoft Works 3.0 for DOS, or in the same

format as the parallel printer.

Real-Time Clock: A real-time clock provides time and date in-

formation on the printout. The clock continues running even with power “OFF”.

21. Power Requirements: The 897 is designed to be used with the

Simpson battery charger, part number 6115095, which is adequately insulated to

permit use of the 897 while being charged.

This charger has a rated input of 108 V AC to

264 V AC at 50/60 Hz. Use of any other

charger may be hazardous to the operator

or to the 897.

Internal Rechargeable

Nickel-cadmium Battery Pack: Rechargeable with supplied recharger.

Battery Life: Approximately 40 hours between charges in

“RUN”. Approximately 60 hours between

charges in “HOLD”.

NOTE: When the Instrument is switched to “RUN” and the display shows “ERR3”

and “LO BATT”, the battery must be charged at least 8 hours.

Clock, are saved in nonvolatile memory; the settings are retained even if the

battery becomes fully discharged.

4.7 Security Controls

The 897 has been designed with two special security provisions to prevent unauthorized personnel from tampering with the control settings.

A function lockout feature prevents selected functions from being changed. This

is accomplished by selecting the desired function, and while pressing this button,

moving the “OFF-RUN-HOLD” control switch from “RUN” to the “HOLD” position

and then back to the “RUN” position. The function touch pad is now disabled and

no further function selections will be acknowledged. To regain control of the function selections, simply move the “OFF-RUN-HOLD” switch from “RUN” to “HOLD”

and back to the “RUN” position.

The “OFF-RUN-HOLD” control switch can be locked in any one of the three

positions by inserting the #4 spline wrench into the Bristol Screw located next to

the switch and turning the screw clockwise.

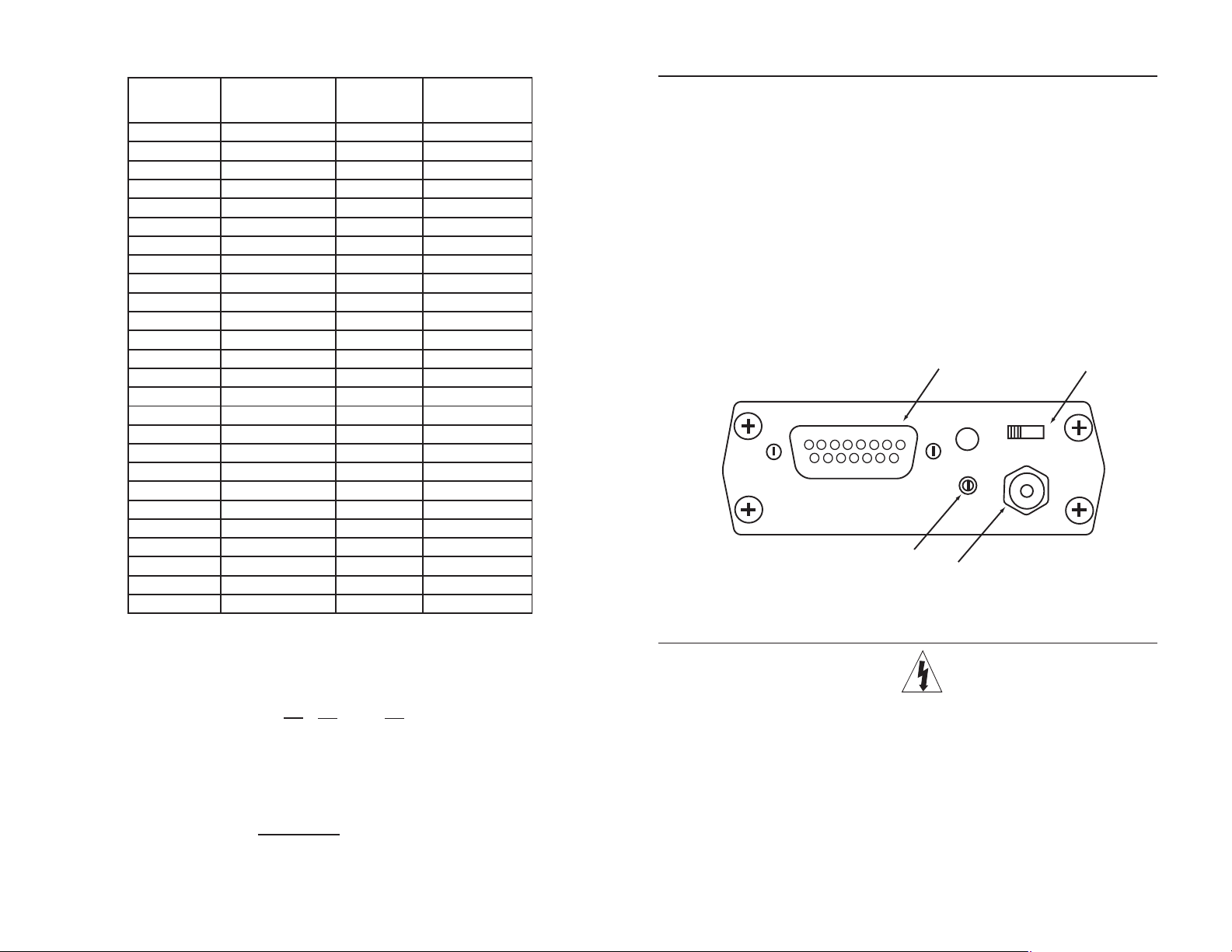

4.8 Selection Of Parallel Or Serial Output Format

The selection of either the parallel or serial output is performed by the available

accessory cables. No other user action is required, other than setting the RS-232

Baud Rate. The accessory RS-232 cable comes with a female dB-9 connector,

which is standard on IBM PC/AT™ and compatible personal computers. The

accessory parallel cable comes with a 36-pin connector that is compatible with

most parallel-input printers. In the event that another custom cable configuration

is required, the pinout of the “DATA OUTPUT” connector is shown below.

Low Battery Indicator: Automatically displays “LO BATT” to indicate

at least eight hours of time remaining.

22. Display 4-digit liquid crystal display with six additional

characters: SPL, SPL MAX, INT 60, LO BATT,

% DOSE, dBA, plus a colon and decimal

point.

23. Keyboard Selected Functions:

SPL(CAL): Sound Pressure Level

INT (60 Sec): Continuous 60 second integrated SPL (also

referred to as L

DOSE: In percent.

PEAK: The number of detected 140 dB peaks, up to

a maximum of 250.

Leq: The eight-hour Time Weighted Average.

MAX: The maximum detected SPL.

TIME: Displays elapsed HRS:MIN or MIN:SEC.

PRINT: Activates the Data Output.

24. Mechanical Construction

Security Provisions: “Special” (#4 spline) wrench provided to lock

“OFF-RUN-HOLD” slide switch into any po-

AVG.

).

10

DATA OUTPUT PINOUT

PIN USE PIN USE

1. Must not be connected for parallel.

Must be connected to pin 4 for serial

2. Parallel bit 6 output

3. Parallel bit 5 output

4. Ground

5. Parallel bit 2 output

6. Parallel bit 1 output

7. Serial cts input

8. Parallel data strobe output

The requirements for the RS-232C output are: 8 bit words, no parity, 1 stop bit.

Data is transmitted only; there is no “data receive” function. Handshaking is via

one signal line, “CTS.”

9. Parallel bit 7 output

10. Serial data output

11. Parallel bit 4 output

12. Parallel bit 3 output

13. Ground

14. Parallel bit 0 output

15. Parallel data ready input

4.9 Automatic Data Logger

The dosimeter has a self-contained data logger with a 31 hour storage capability,

and will store up to to 31 hours of data, as long as the “OFF-RUN-HOLD” switch

is never switched to “OFF” and/or the self-contained batteries do not become fully

discharged. On a once-per-minute basis, the following information is logged: the

present value of the INT (60 sec) function, the maximum sound pressure level

23

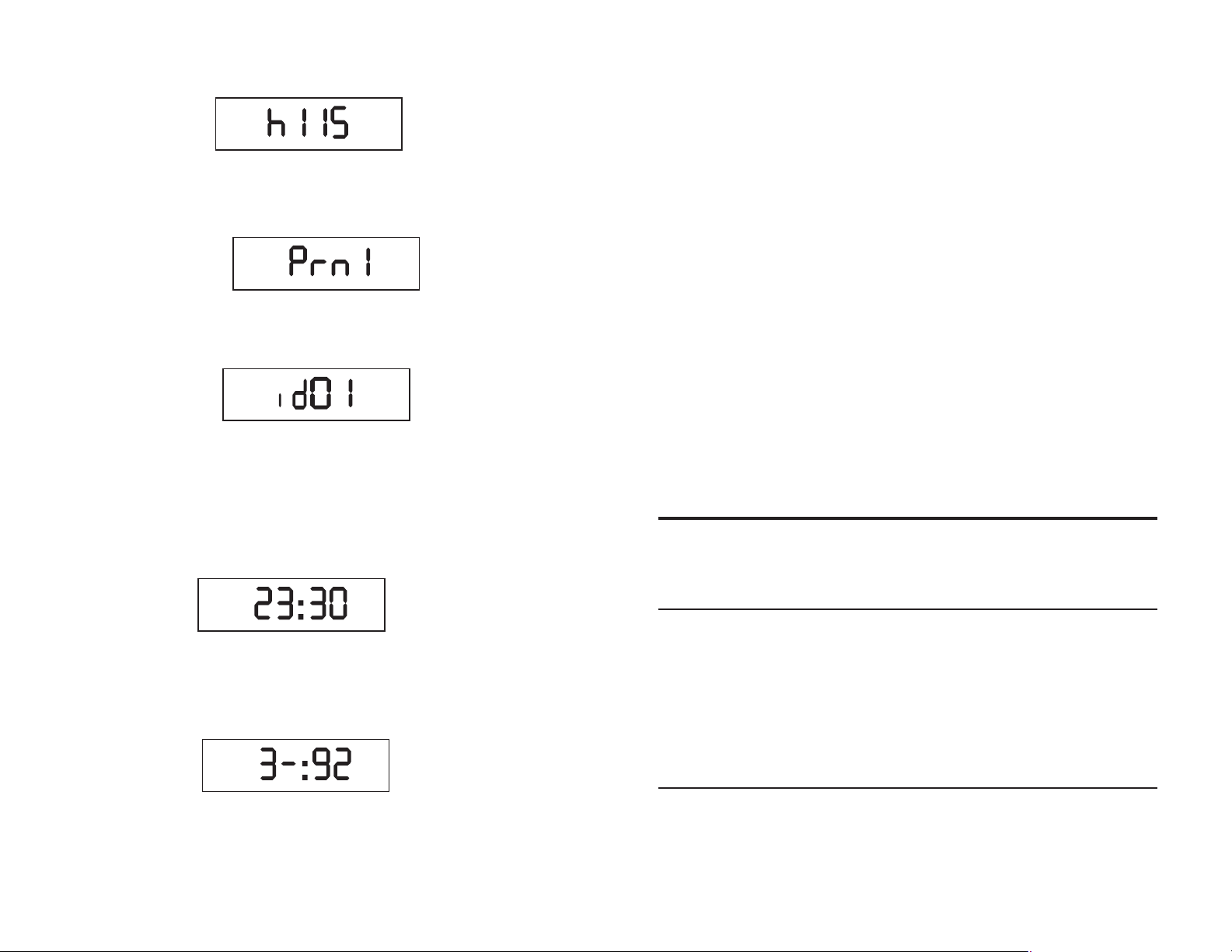

Page 11

NOTE: In order to determine how much the Leq exceeds the OSHA upper limit of

115 dB, set the Leq to 130 dB.

Example:

5. Serial Output, Option 1 or 2 (Prn): Option 1 formats the data in spreadsheet format for a computer; option 2 outputs the data formatted for a

serial printer. This setting has no effect on the parallel output data format.

This is factory set to option 1.

Example:

6. Unit Identification Number (id), if multiple units are in service, units or

tens digit: 0 through 9; thus the unit identification number may range

from 00 to 99. This is factory set to unit #01.

Example:

7. RS-232 Baud Rate (0000): 300, 600, 1200, 2400, 4800, or 9600 baud.

This has no effect on the parallel output. It is factory set at 9600.

8. Real-Time Clock - Set Time:

Set Minutes: Unit Digit (00:0

Set Minutes: Tens digit (00:

Set Hours: (

NOTE: Based on 24 hour clock

Example:

00:00) Select 00 through 23.

0) 9 through 9.

00) 0 through 5.

sition. A keyboard switch “lockout” feature

allows the 897 to be locked into any desired

function.

Case Construction: Anodized aluminum extrusion.

Physical Dimensions:

Length: 6.8 inches (172 mm)

Width: 3.1 inches (80 mm)

Thickness: 1.1 inches (28 mm), excluding microphone

and clip.

Weight: 18 oz. (500 gm)

25. Environmental Specifications

Temperature:

Influence: 60.03 dB/°C, -10 to +25°C, 60.05 dB, +25 to

50°C (Reference 1000 Hz and 105 dB).

Operating Range: -10 to 50°C.

Storage Range: -30 to 45°C (limitation of batteries).

Humidity:

Influence: Less than 0.5 dB over measurement range.

Range: 0 to 95% RH.

Magnetic Field: No effect when placed in a field of 1 oersted

(80 A/m) with Model 897 oriented for maxi-

mum sensitivity to the field.

Atmospheric Pressure: Correction data is provided in the calibrator’s

operator’s manual.

2. PREPARATION FOR USE

This section contains instructions for preparing the new Instrument for use. Also

included are unpacking and inspection procedures, warranty and shipping instructions.

9. Real-Time Clock - Set Date:

Set Day: (1-:

Set Month: (2-:

Set Year: Unit Digit: (3-:

Set Year: Decade Digit: (3-:

Example:

d. Once all the parameter choices are made, switch the “OFF-RUN-HOLD”

switch (see figure 4-1) to “OFF” for three seconds and all changes will be

saved in the internal memory. It is unnecessary to go through the entire

sequence; you may stop and switch the power “OFF” once all needed changes

are made. All of the above parameters, with the exception of the Real-Time

N) N = number 01 through 31.

N) N = number 01 through 12.

N) N = number 0 through 9.

N) N = number 0 through 9.

22

2.1 Unpacking And Inspection

Examine the shipping carton and Instrument for damage. If undamaged, check

for internal damage . (Preliminary checks of the operating condition of the Instrument can be made after carefully reading Section 4). If there is external or internal

damage, immediately file a complaint with the carrier. Make certain all items in

Table 1-1 are included in shipment. Save the shipping carton for possible future

shipping of the Instrument.

NOTE: The 897 is powered by a self-contained rechargeable nickel cadmium

battery pack. Charge Instrument for 16 hours before use.

2.2 Preparation For Use

Accuracy of measurements can be affected by several factors, including the position of the microphone with respect to the sound source and the positioning of

the microphone on the user. Read Section 3 carefully for general background

information.

In operation, the Instrument can be attached to the belt with the clip provided, or

can be placed in the shirt pocket. Ideally the microphone should be clipped

11

Page 12

upright to the shirt on the center of the shoulder. If this is impractical, clip the

microphone facing upward on the shirt collar. To protect the microphone in dusty

or windy environments, place the windscreen over the microphone before attaching it to the shirt.

2.3 Warranty

The Simpson Electric Company warranty policy is printed on the inside front

cover of this manual. Read it carefully before requesting warranty repairs. For all

assistance, including help with the Instrument under warranty, contact the factory.

Give full details of any difficulty and include the Instrument model number and

date of purchase. Shipping instructions will be mailed promptly. If an estimate of

charges for nonwarranty or other service work is required, a maximum charge

estimate will be quoted. This charge will not be exceeded without prior approval.

2.4 Shipping

Pack the Instrument carefully and ship it prepaid and insured to the proper destination.

3. APPLICATION

This section contains the basic information required for effective application of

the 897. To understand the operation of the Instrument, the following paragraphs

discuss its function in relation to some of the subtleties of sound.

3.1 Decibel Scale

The human ear has a sound sensitivity range of greater than one million to one,

from the lowest level that can be detected to the highest level that can be tolerated without pain. Because of the large ratio involved, a linear meter scale marked

in sound pressure units becomes impractical. A scale based on logarithms, called

a decibel (dB) scale, is used. This scale expresses the ratio between the sound

pressure level being measured, with respect to a reference level and converts

large ratios into smaller convenient numbers. For example, a million-to-one pressure ratio can be compressed on a 0 to 120 dB scale. The zero dB is the low limit

reference which the human ear can barely perceive.

3.2 Sound Level Meter

number 1, 2 or 3, and should then freeze on this display. If this occurs, the

Instrument must be returned for repair.

If these tests pass, the Instrument will proceed to a “rotating digits” test. This will

cycle the display through all digits and all special annunciators. This test will

continue until either the “TIME” switch is pressed or the “OFF-RUN-HOLD” switch

is switched to “OFF.”

If the “TIME” switch was pressed, then the Instrument will continuously display

the real-time clock until the “OFF-RUN-HOLD” switch is switched to “OFF.”

4.6 Setting The Dosimeter Parameters

4.6.1 The Dosimeter Parameters

Criterion Level (Lc), Threshold Level (Th), Exchange Rate (rt), Leq Upper Limit

(H), Unit ID Number, Baud Rate and Time are easily programmable using the

buttons located on the front panel.

4.6.2 To Program the Dosimeter

a. Press and hold the “Setup” button (see Figure 4-1) while switching the “OFF-

RUN-HOLD” switch (see Figure 4-1) from “OFF” to “RUN.”

b. Select the parameter to be programmed by sequentially pressing the “Setup”

button. The order of the sequence is given in Table 4-3, Setup Mode Sequence.

c. Once the desired parameter is displayed, press the “Test” button (see Figure

4-1) to select the available choices of that parameter. The digit or digits which

will change as a result of pressing the “Test” button will flash. The display

prompt for each function is given within the parenthesis.

Table 4-3. Setup Mode Sequence

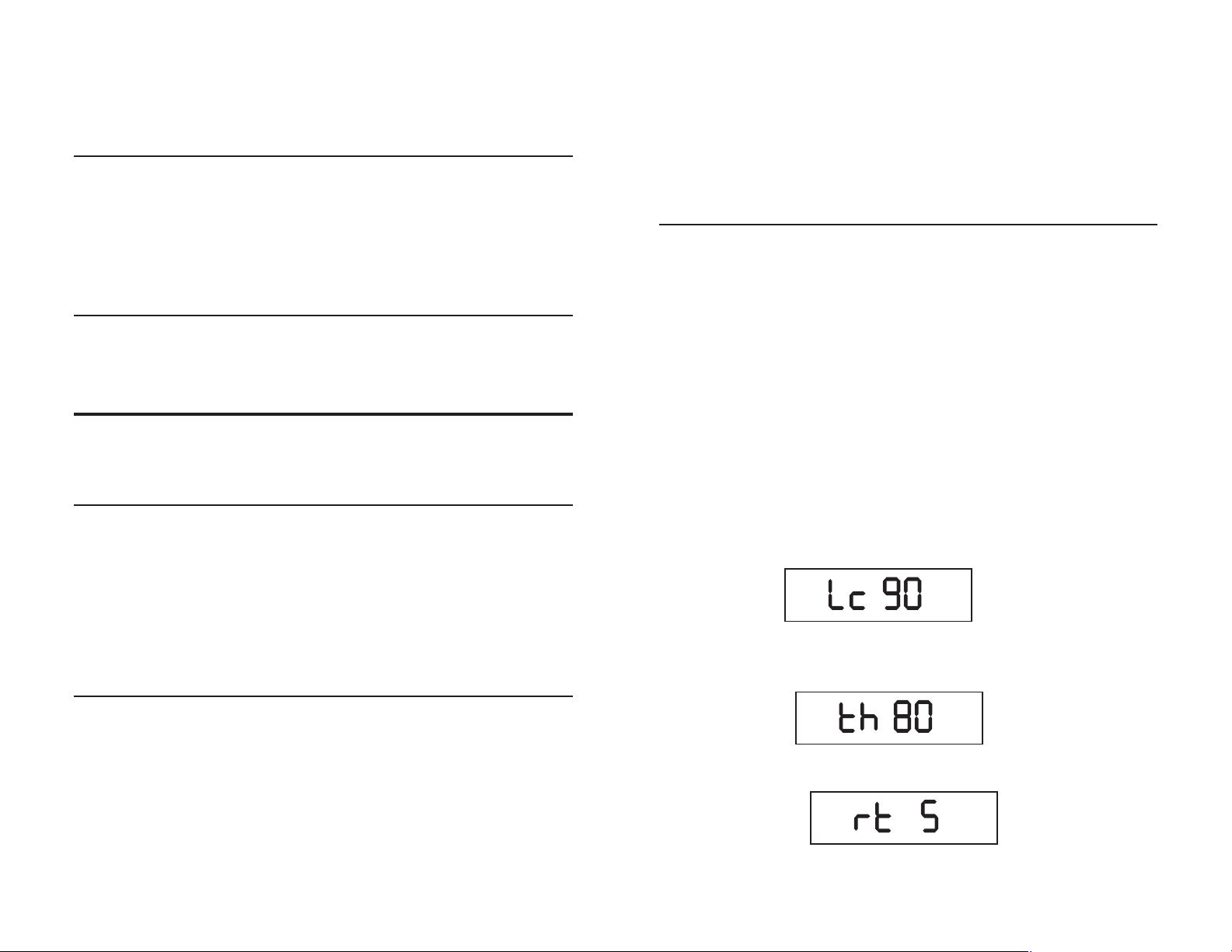

1. Criterion Level (Lc): 70, 80, 84, 85, or 90 dB. Factory set at 90 dB as

recommended by OSHA.

Example:

2. Threshold Level, units digit (th): 0 through 9.

Threshold Level, tens digit (th): 5 through 9; thus the threshold may be

set to any value from 50 through 99 dB. Factory set at 80 dB.

Example:

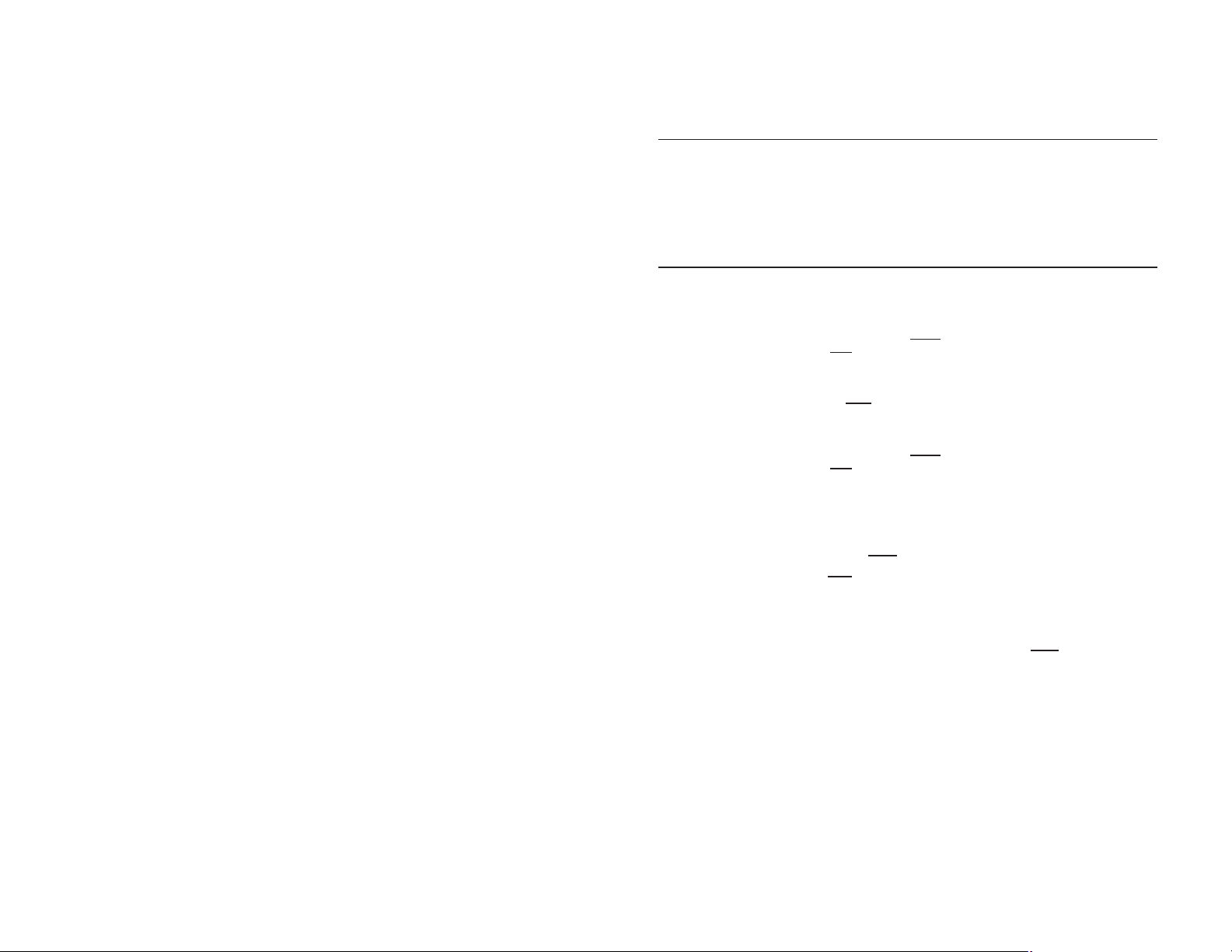

A sound level meter is a measuring device used to determine the existing sound

pressure level in a particular area. A choice of frequency responses called A, B

and C “weightings” is typically provided which relate to the human ear response

at low, middle and high sound pressure levels. The sound pressure level is expressed in dB A, dB B or dB C where 0 dB = 20 µ Pascals; the threshold of hearing

and the A, B and C define the “weighting” selected. (See Figure 3-1).

NOTE: All OSHA type sound level meters must be A-weighted. B and C weightings

are not required for compliance measurements.

The sound level meter function of the 897 meets the requirements of the American National Standards Institute (ANSI) Standard Specification S1.4 1983 for

type S2A (“A” weighted) general purpose sound level meter.

12

3. Exchange Rate (rt): 3, 4, or 5 dB. Factory set at 5 dB as recommended by

OSHA.

Example:

4. Leq Upper Limit (H): 115 or 130 dB. Factory set at 115 dB as recommended

by OSHA.

21

Page 13

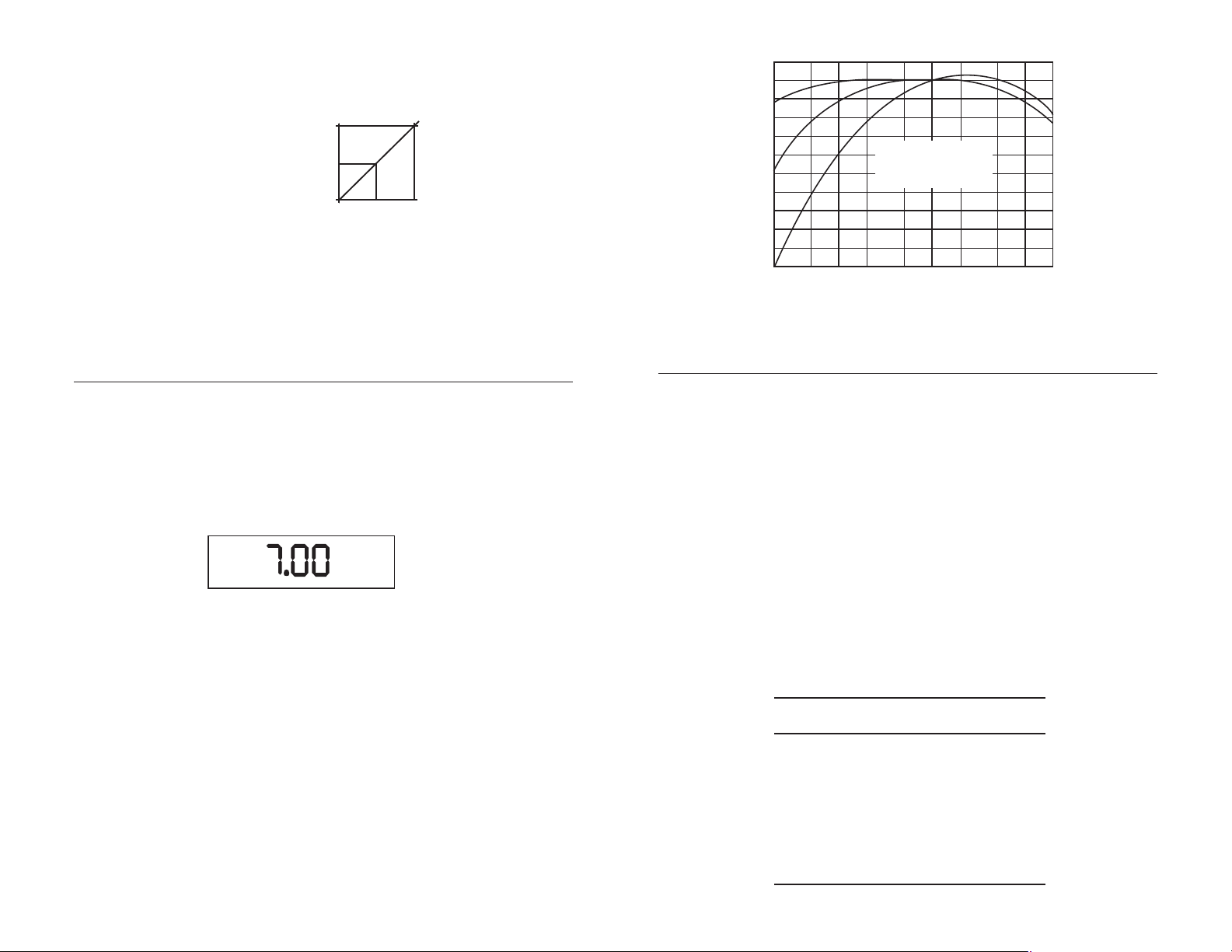

The approximate required time to fully charge the battery pack, in hours, is linearly proportional to the operating time of the dosimeter. See graph (Figure 4-3)

below.

TIME

16

10

2

0

15

OPERATING TIME

(HOURS)

40

CHARGE

(HOURS)

Figure 4-3

The Instrument will operate from the battery for approximately 40 hours between

charges in the “RUN” position or approximately 60 hours between charges in the

“HOLD” position, however, this time will vary according to use.

+5

0

–5

–10

–15

–20

–25

–30

–35

RELATIVE RESPONSE DECIBELS

–40

–45

–50

20 50 100

C

B

A

FREQUENCY RESPONSES

FOR SLM WEIGHTING

CHARACTERISTICS

1000 2000

500

200

FREQUENCY (Hz)

A

B AND C

5000

10,000

Figure 3-1. A, B & C Weighted Electrical Responses

20,000

4.5 Preliminary Checks

Set the “OFF-RUN-HOLD” switch to the “RUN” position. When the unit is first

turned on, a display segment test is performed. Next, the 897 will display in

sequence given:

Lc nn (Criterion Level)

th nn (Threshold Level)

rt n (Exchange Rate)

SPL Display

Example:

4.5.1 Underrange Display

The display will indicate “ur” if the SPL is underrange; i.e., under 50 on the 50 to

100 dB range or under 80 on the 80 to 130 dB range.

4.5.2 Overrange Display

The display will indicate “- - - -” if the SPL is overrange, i.e., over 100 on the 50 to

100 dB range, or over 130 on the 80 to 130 dB range.

4.5.3 Diagnostic Memory Test

The Instrument automatically performs a self diagnostic-memory test when turned

on. However, the operator may access and display this self-test routine via the

“TEST” switch. The self-test contains a complete memory diagnostic, a display

test routine, and a continuous real-time clock display. These three tests are enabled by pressing the “TEST” switch down and sliding the “OFF-RUN-HOLD”

switch to “RUN”. The display will first show “t 1.” If that passes, it will automatically

proceed to “t 2” and “t 3.” Each of these tests (t) are verifying different portions of

the internal memories. If any of these fail, the display will change to “Err” with the

20

3.3 Measurement And Exposure Standards

Sound level meter measurement standards are defined in American National

Standards Institute (ANSI) Specification S1.4-1983. Federal, State and local governments also have defined allowable noise (undesirable sound energy) level

exposure limits for persons in industrial environments. Selected and applicable

parts of those currently in force are cited in this manual.

NOTE: Standards and government regulatory laws are subject to modification or

expansion. Always check for latest available documents and information.

The Occupational Safety and Health Act of 1970 (OSHA), The Walsh-Healy Act

(Federal Register, Vol. 34, No. 96) and paragraph 1910.95 of the Occupational

Safety and Health Standards (Federal Register, Vol. 46, No. 162), set the present

legal standards of allowable employee noise exposure limits and are shown in

Tables 3-1 and 3-2.

3.3.1 Steady Level or Slowly Varying Noise

Table 3-1. Permissible Noise Exposure Limits

(Based on 90 dB criterion level and 5 dB exchange rate)

Duration Per Day Sound Level, dB A

in Hours SLOW Response

8 90

6 92

4 95

3 97

2 100

1 - 1/2 102

1 105

1/2 110

1/4 or less 115

13

Page 14

Table 3-2. Permissable Noise Exposure Limits for Continuous Noise

noitaruD

yaDreP

sruoHni

23

9.72

3.42

2.12

4.81

00.61

39.31

21.21

65.01

91.9

00.8

69.6

60.6

72.5

95.4

00.4

84.3

30.3

46.2

03.2

00.2

47.1

25.1

23.1

51.1

00.1

leveldnuoS

ABd

esnopserwolS

0878.0601

1867.0701

2866.0801

3875.0901

4805.0011

5844.0111

6883.0211

7833.0311

8892.0411

9852.05

0922.0611

1991.0711

2961.0811

3941.0911

49521.0021

5911.0121

69590.0221

79280.0321

89270

99360.0521

001450.0621

101740.0721

201140.0821

301630.0921

401130.0031

501

noitaruD

yadrep

sruohni

.0421

leveldnuoS

ABd

11

4.3 Top Panel Operating Features

Table 4-2. Top Panel Operating Features

esnopserwolS

1. RANGE switch: A 2-position switch that selects the operating range for

sound level measurements. The available ranges are 50

to 100 dB and 80 to 130 dB. The data logger records the

position of the switch and the time of any changes in the

position.

2. SPL (CAL)

adjust: Used with a calibrator to set the correct level.

3. EXT DC: Used with the supplied battery charger to recharge the

internal nickel-cadmium batteries. The Dosimeter may be

operated while connected to the charger.

4. DATA OUTPUT

CONNECTOR: Use with either parallel or RS-232 Serial accessory cable

to obtain data.

DATA OUTPUT

4

RANGE

50/100 80/130

SPL

CAL

EXT DC

1

2

3

Figure 4-2. Top Panel

Varying Level Noise

When daily noise exposure is composed of two or more periods of noise exposure at different levels, consider their combined effect rather than the individual

effect of each. The total dose is computed by the expression:

C1 + C2 + — + Cn

D +

T1 T2 Tn

Where: D is the noise dose; C1, C2 … Cn are the actual segments of exposure

time at different noise levels; and T1, T2 … Tn are the allowed time intervals (see

Table 4-1) for the mentioned segments of exposure. Unlike a sound level meter,

a dosimeter computes automatically the exposure, D, and displays the accumulated percentage of the allowed exposure.

B

Duration computed from where L = dB level, and rt = exchange

2 exp (L-90) rt

rate = 5 dB, in this example table.

*From the Federal Register, Vol. 46, No. 162, August 21, 1981.

14

4.4 Battery Charging

The 897 is designed to be used with the Simpson Battery Charger(part no. 6-

115095) which is insulated well enough to permit use of the 897 while being

charged. This charger has a rated input of 108V AC to 264V AC at 50/60 Hz. Use

of any other charger may be hazardous to the operator or the 897.

The self-contained, rechargeable nickel cadmium battery pack should be charged

before operating the Instrument for the first time, or when the Low Battery Indicator “LO BATT” is displayed, or before extended use where a power source is not

available.

The Instrument may be operated with the battery charger connected and thereby

maintaining its charge, however, cycling of the charge is “healthy” for Ni-Cad

batteries and extends their life. Do not attempt to keep them fully charged all the

time.

19

Page 15

D = 100

Tc

L - Lc

rt

兺

2

are suspended and printouts will indicate “HOLD” during the time SPL is

selected.

“HOLD”: In “HOLD” mode all data is retained without any modification except

that the elapsed time clock is kept running. The display will alternately flash

between “HOLD” and the presently selected function.

2. Control Switch “LOCK”:

A spline head screw is used to “lock” the control switch. Locking the control

switch, together with the keyboard switch lockout feature, provides protection against unauthorized tampering with control settings. To activate the

keyboard lockout, slide the “OFF-RUN-HOLD” switch to “HOLD”, then select

the desired function and while still holding that function button down, slide

the “OFF-RUN-HOLD” switch to “RUN”.

NOTE: The display will indicate four dashes (- - - -) for approximately five

seconds. At this point, none of the touch switches will respond. The keyboard may

be reactivated by again sliding the “OFF-RUN-HOLD” switch to “HOLD”.

3. Readout Display:

Four-digit LCD display plus eight special functions/units.

4. SPL (CAL):

When selected, the Instrument functions as a sound level meter. It reads the

incoming sound pressure level on a real time basis, and displays the Aweight dB reading.

NOTE: All dosimeter functions are suspended, and the printouts will indicate

“HOLD” during the time SPL is selected. The “SPL” mode is also used to calibrate

the Instrument when its microphone is inserted into the Model 887 Calibrator.

When the “SPL (CAL)” button is held down for three seconds until “CAL” is displayed, the reading will be retained in memory along with the time, date, and

position of the “RANGE” switch. The latest two such readings are always stored.

These saved readings are only viewable with the data output printout.

5. DOSE/PEAK:

Alternately displays the DOSE in percent or the number of 140 dB (or greater)

peaks that have been detected since entering “RUN”.

6. TIME:

Alternately selects an elapsed time display of “minutes:seconds” or

“hours:minutes” since the Dosimeter was first switched into “RUN” mode.

“Hours:minutes” is displayed with a flashing color indicator.

7. INT (60 sec):

Displays the sound pressure level integrated average over a 60 second time

period. The 60 second time period begins whenever the Dosimeter is switched

into “RUN” from either “OFF” or “HOLD”. It then updates continuously using

the latest 60 seconds of accumulated sound pressure levels. Additional depressions of this button will sequentially display the latest settings of the

programmable options, namely: cirterion level, threshold level, exchange

rate, time weighted average upper limit, serial output format, unit ID, baud

rate and time clock. Notice that it is not possible to change the settings here,

only to observe them. Refer to paragraph 4.6 for programming procedures.

8. Leq/Max:

Alternately displays Leq, based on eight hours, in dB or the maximum sound

pressure level in dB since entering “RUN”.

9. Print:

Instrument prints out one of the two output formats available from the data

logger depending on which accessory cable is presently connected. This

switch only functions while the Dosimeter is in the “HOLD” mode. (See paragraph 4.9 for further information.)

18

3.3.2 Impact Noise

For compliance, exposure to impulsive or impact noise must not exceed 140 dB

A peak sound level.

3.4 Dosimeter

To accurately determine a dosage level using a sound level meter is a tedious

procedure, as the total length of exposure at each dB level must be weighted and

summed (accumulated). The dosimeter function of the 897 automatically and

continuously performs these mathematical manipulations while it is operating

and provides the dosage readout directly in percent of allowable exposure.

3.5 Dosimeter Equation

The dosimeter function is defined by ANSI S1.25 as:

L - Lc

Dose (D) = 100

Tc

Where

q = rt

log 2

Thus:

D = 100

Tc

Since the A/D converter is performing continuous integration, the computer must

only resolve:

Note that the result is expressed as a percentage.

The equivalent sound level during the sample time, T, over which a percentage

criterion exposure (dose) is measured, is:

D = percentage criterion exposure;

Tc = criterion sound duration, defined as 8 hours;

T = actual exposure duration in hours;

L = slow, A-weighted sound level;

Lc = criterion sound level;

Lt = threshold level

rt = exchange rate: the change in sound level corresponding to a doubling or

halving of the exposure duration.

User selectable items:

Lt = 50 to 99 db;

Lc = 70, 80, 84, 85 or 90 dB;

rt = 3, 4 or 5 dB.

Upper level of allowable equivalent (Leq) sound level exposure: 115 or 130 dB.

T

q

10

冕

dt (when L > Lt)

0

L - Lc

rt

dt

T

2

冕

0

Leq = Lc + q log D Tc

100 T

15

Page 16

3.6 Sound Fields

3.8 Windscreen

3.6.1 Free Field

This field contains no reflecting objects. Ideally it is a point sound source located

in free space; however, it can be considered to exist whenever the sound level

being measured is caused mainly by the sound waves coming directly from the

sound source. This can occur even if there are reflecting objects.

3.6.2 Reverberant Field

This field is more common and exists whenever the sound level being measured

contains a significant amount of direct sound waves and a relatively small amount

of reflected sound waves.

3.7 Microphone Orientation

3.7.1 Area Monitor in a Free Field

When the Instrument is used as a fixed monitor in a free field or in a semireverberant field, the axis of the microphone should be oriented at approximately

70° with incident sound waves. Furthermore, the microphone should ideally be

placed as far from reflecting sound surfaces as possible. (See below.)

AXIS OF

SOUND

SOURCE

Figure 3-2. Microphone Orientation

3.7.2 Fixed Position Monitor in a Reverberant Field

When monitoring in a reverberant field, orientation of the microphone is not critical.

3.7.3 Use of Dosimeter as a Personal Monitor

For a practical and efficient application, clip the microphone to the shirt, on the

shoulder just below the ear, with the microphone diaphragm facing upward.

NOTE: The user of the Instrument disturbs the sound field near the microphone at

the upper limit of frequencies. For many practical situations, the measurement

error is relatively small, typically 1 to 3 dB higher than would occur with a fixed

monitor position. Since the fixed monitor cannot easily follow the motion of a

mobile individual, the personal dosimeter is the most accurate, practical means

of measuring individual noise dosage.

16

SOUND

WAVE

70˚

MICROPHONE

AXIS OF INCOMING

SOUND WAVE

MICROPHONE

NOTE: When the 897 is exposed to a dusty or windy environment, the windscreen

should be used to protect the microphone diaphragm from damage, and to assure a correct reading.

The windscreen will reduce the effects of wind noise by approximately 20 dB

without seriously affecting the frequency response of the microphone.

Grease and dirt on the windscreen may affect the accuracy of sound measurements. Under severe conditions the windscreen should be cleaned often. To

clean, wash with a mild detergent, thoroughly rinse and dry before placing over

the microphone.

4. OPERATION

This section provides the instructions required for the operation of the 897.

4.1 Safety Precautions

Read Section 3 before performing dosage measurements. Section 3 contains

important information pertaining to sound and noise measurement terminology,

standards, operating techniques and precautions.

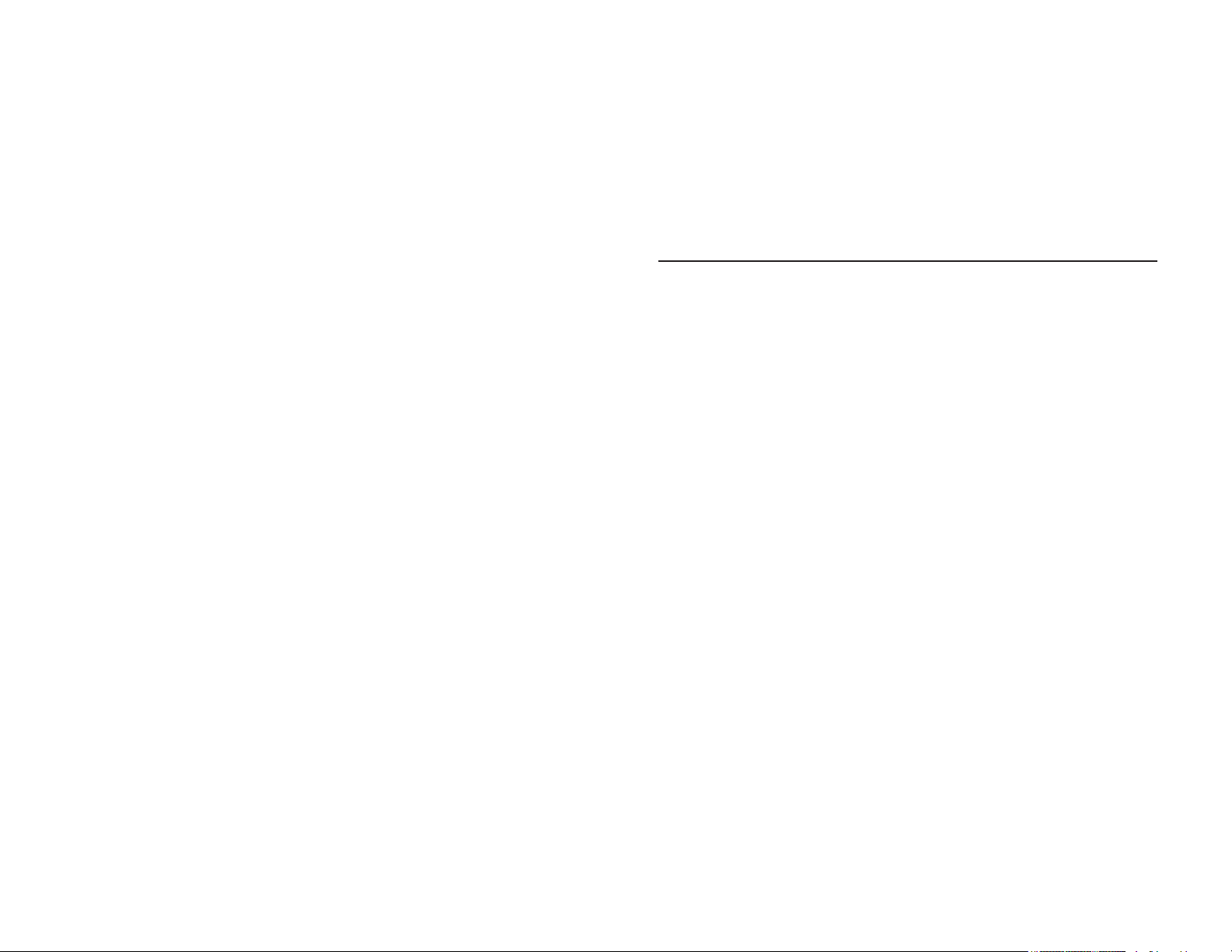

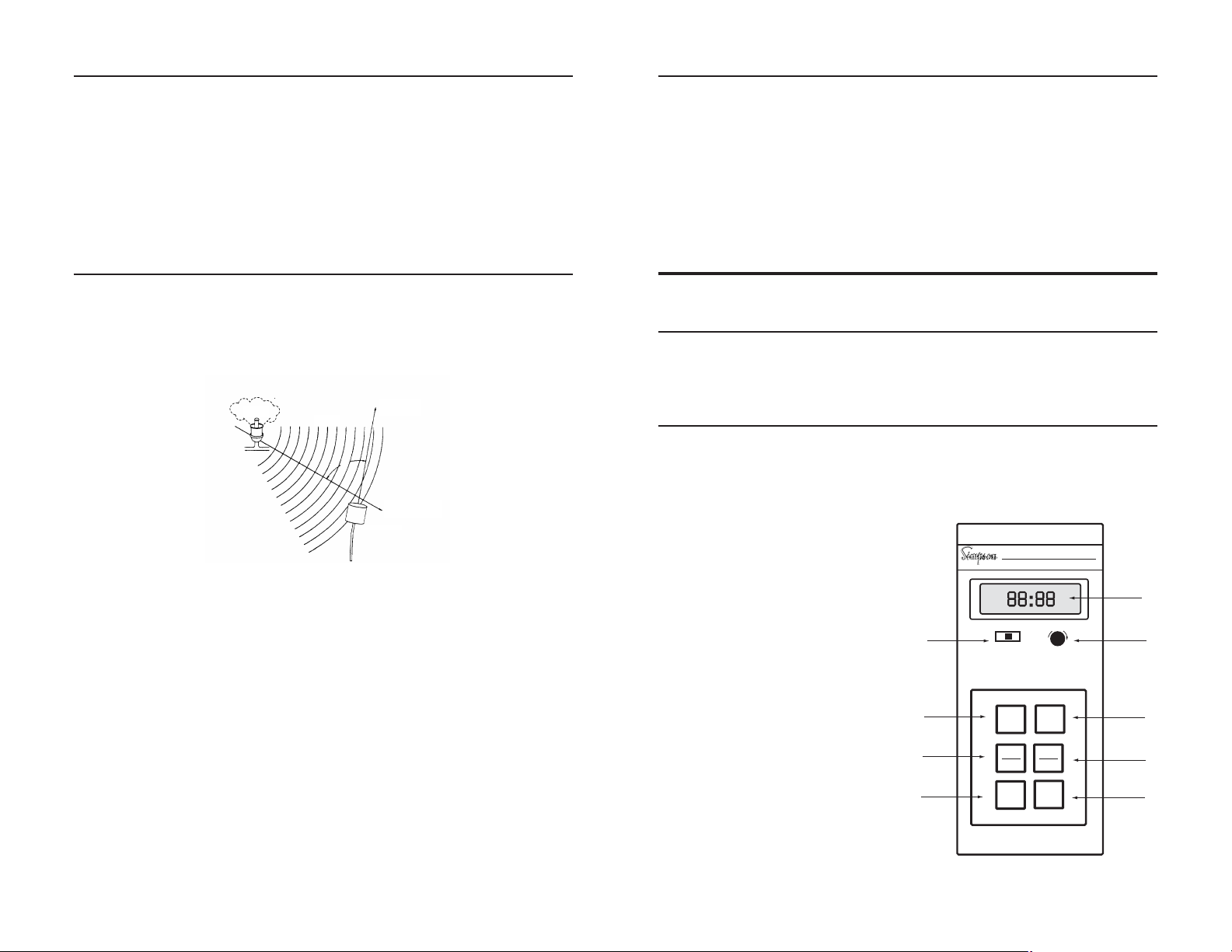

4.2 Operating Items And Features

All front panel operating controls are described in Table 4-1 and shown in Figure

4-1. Top panel adjustments, controls and connectors are described in Table 4-2

and shown in Figure 4-2.

Table 4-1. Front Panel Operating Features

1. “OFF-RUN-HOLD” Control

Switch:

A 3-position slide switch used to

activate the Instrument and

“hold” accumulated data.

“OFF”: Power is removed from

the Instrument and all accumulated data is erased. When

switching from “RUN” to “OFF”,

there is a minimum three second delay before the 897 actually goes off. This will aid in preventing accidental loss of accumulated data. During this three

second period, the display may

appear dim; this is normal operation.

“RUN”: In “RUN” mode all data

relating to DOSE, Leq, INT (60

sec), MAX and PEAK is continuously monitored, updated and

stored, except when in SPL

mode of operation. In the SPL

mode, all dosimeter functions

17

1

4

5

6

897 DOSIMETER

SOUND MEASURING SYSTEM

LOCK

INT

(60 sec)

Leq

MAX

PRINT

% DOSE

dBA

LO BATT

SPL MAX

INT 60s

OFF RUN HOLD

SPL

"CAL"

TEST SETUP

DOSE

PEAK

TIME

SIMPSON ELECTRIC CO. ELGIN , IL 60120

Figure 4-1. Front Panel

3

2

7

8

9

Loading...

Loading...