Page 1

Model 229 Series 2

Leakage Current Tester

OPERATOR’S MANUAL

Page 2

About this Manual

To the best of our knowledge and at the time written, the information contained in this document is technically correct and the procedures accurate

and adequate to operate this instrument in compliance with its original advertised specifications.

Notes and Safety Information

This Operator’s Manual contains warning symbols which alert the user to

check for hazardous conditions. These appear throughout this manual where

applicable, and are defined below. To ensure the safety of operating performance of this instrument, these instructions must be adhered to.

Warning, refer to accompanying documents.

!

Caution, risk of electric shock.

!

This instrument is designed to prevent accidental shock to the operator when

properly used. However, no engineering design can render safe an instrument which is used carelessly. Therefore, this manual must be read carefully

and completely before making any measurements. Failure to follow directions can result in a serious or fatal accident.

Any discussion in this manual regarding UL, ANSI, or IEC specifications is for

Reference purposes only. The input network utilized in the M229 2 is detailed

in Figure 1 on page 3. The customer is advised to obtain the latest specification from the rating agency.

NOTE: For specification information call:

ANSI at (212) 642-4900 or UL in Northbrook, IL at (847) 272-8800.

Technical Assistance

SIMPSON ELECTRIC COMPANY offers assistance Monday through Friday

8:00 am to 4:30 pm Central Time. To receive assistance contact Technical

Support or Customer Service at (715) 588-3311.

Internet: http://www.simpsonelectric.com

Warranty and Returns

SIMPSON ELECTRIC COMPANY warrants each instrument and other articles manufactured by it to be free from defects in material and workmanship

under normal use and service, its obligation under this warranty being limited

to making good at its factory or other article of equipment which shall within

one (1) year after delivery of such instrument or other article of equipment to

the original purchaser be returned intact to it, or to one of its authorized

service centers, with transportation charges prepaid, and which its examination shall disclose to its satisfaction to have been thus defective; this warranty

2

Page 3

being expressly in lieu of all other warranties expressed or implied and of all

other obligations or liabilities on its part, and SIMPSON ELECTRIC COMPANY neither assumes nor authorizes any other persons to assume for it any

other liability in connection with the sales of its products.

This warranty shall not apply to any instrument or other article of equipment

which shall have been repaired or altered outside the SIMPSON ELECTRIC

COMPANY factory or authorized service centers, nor which has been subject

to misuse, negligence or accident, incorrect wiring by others, or installation or

use not in accord with instructions furnished by the manufacturer.

This manual represents your meter as manufactured at the time of publication.

We reserve the right to make changes and improvements to the product

without obligation to incorporate these changes and improvements into units

previously shipped.

SHOCK HAZARD: As defined in American National Standard, C39.5, Safety

Requirements for Electrical & Electronic Measuring & Controlling Instrumentation, a shock hazard shall be considered to exist at any part involving a

potential in excess of 30 volts RMS (sine wave) or 42.4 volts DC or peak and

where a leakage

current from that part to ground exceeds 0.5 milliampere,

when measured with an appropriate measuring instrument defined in Section 11.6.1 of ANSI C39.5.

NOTE: The proper measuring instrument for the measurement of leakage

current consists essentially of a network of a 1500 ohm non-inductive resistor

shunted by a 0.15 microfarad capacitor connected between the terminals of

the measuring instrument. The leakage current is that portion of the current

that flows through the resistor. The Simpson Model 229-Series 2 AC Leakage Current Tester is designed around the ANSI C39.5 requirement for the

measurement of AC leakage current. See Figure 1 below.

R3

+

INPUT

500

C1

0.15UF

R1

1000

Leakage Current Input Network

Figure 1

3

Page 4

Contents

1. INTRODUCTION .................................................................................. 5

1.1 Why Measure Leakage Current? ....................................................... 6

1.2 Threshold Of Perception .................................................................... 6

1.3 Technical Data ................................................................................... 6

1.4 Items And Accessories .......................................................................7

2. OPERATION ..................................................................................... 8

2.1 Safety Precautions ............................................................................. 8

2.3 Operating Instructions ........................................................................9

3. MAINTENANCE .............................................................................. 10

3.1 Warranty ...........................................................................................10

3.2 Shipping ...........................................................................................10

3.3 Battery Replacement ........................................................................ 10

3.4 Calibration ........................................................................................11

3.5 Care ..................................................................................................11

4

Page 5

1. INTRODUCTION

5

6

4

3

2

1

.5

00

1

0

5

50

25

B

Y

R

E

T

T

A

0

B

E

0

C

A

L

P

E

R

VAC

DESIGNED TO MEET USA STANDARD C101.1 FOR LEAKAGE CURRENT TESTERS

A.C. LEAKAGE CURRENT TESTER

150 VAC

SHORT TEST

300 VAC

OFF

MODEL 229-2

0

mA

GROUND

1

0

mA

BATT TEST

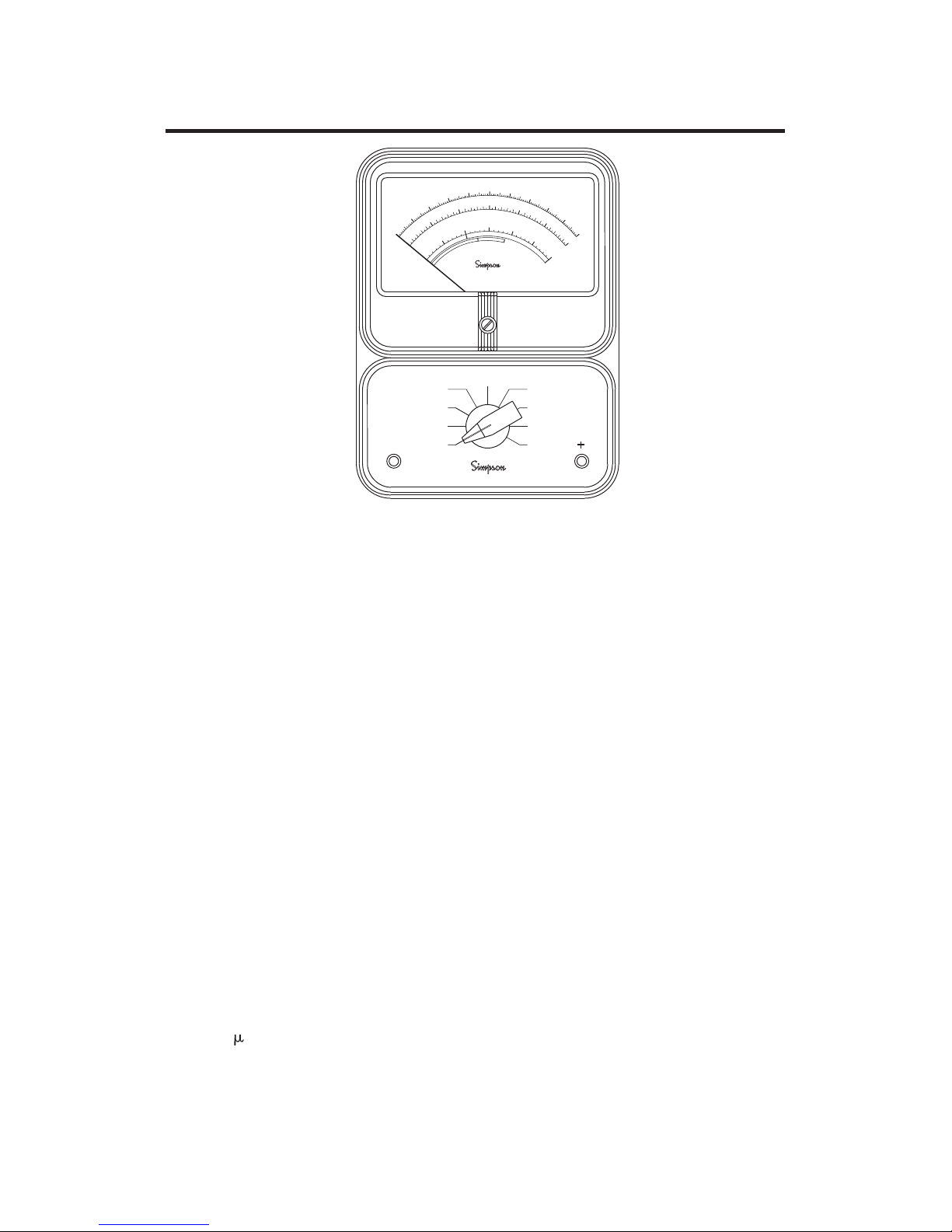

The Simpson Model 229-2 is a special purpose AC milliammeter designed to

measure hazardous leakage current from electrical appliances and other

power line operated equipment. A three-wire grounding power cord prevents

shock hazard by grounding the metal parts of the appliance; the grounding

connection, however, is subject to abuse and not always reliable or, sometimes, nonexistent or even defeated by the user (a two-wire extension cord,

for example). Leakage current is therefore measured with the grounding

connection open-circuited and is required to be within a specified limit for

shock prevention.

Leakage current (as it relates to a shock hazard), is the result of resistance

and capacitance between internal supply circuits and external parts accessible to an operator, which may flow through the operator’s body to an earth

ground and cause electric shock. Although the appliances are energized by

a 60 Hz power line circuit, some may have solid-state control circuits which

generate higher frequency currents and may contribute to the leakage current. The human body, however, has a decreasing sensitivity to the sensation

of electric shock as the frequency increases. The current ranges of the 2292 are compensated to indicate a decreasing value of current with an increase

in frequency in accordance with the perceptibility of the human body to shock.

The meter will have a constant indication for leakage current of 60 Hz and 20

kHz for the same degree of shock.

The 229-2 is designed only for measuring leakage current of appliances operating from 120 or 240 power line circuits. The current ranges of the 229-2 have

an insertion impedance of 1500 ohms, resistive with a parallel capacitance of

0.15

F. The meter indicates 1.1 times the average of the full-wave rectified

composite waveform of voltage across the 1500 ohm resistor. The 1500 resistance simulates the resistance of the human body and the capacitance compensates the meter indication to correspond with the decreasing sensitivity of

the body to shock at increasing frequency. See Figure 1 on page 3.

5

7

1.5

150

7

5

T

E

T

A

R

Y

OK

8

2

9

2.5

20

0

100

S

H

O

R

T

10mA

3mA

1mA

250

125

.3mA

10

mA

3

m

300

A

150

VAC

Page 6

The 229-2 is battery operated and completely insulated for user protection.

Solid-state circuitry permits a current sensitivity to be as high as 300

scale (minor divisions of 5

300V AC provide a convenient means of measuring the open circuit voltage

(between the accessible parts and ground) to determine whether leakage

current need be measured.

A). Two voltage ranges of 0-150V AC and 0-

1.1 Why Measure Leakage Current?

The primary purpose of measuring leakage current of electrically operated

equipment is to determine whether usage in a normal manner can present an

electrical safety hazard to the user. Leakage current may increase with use

and aging of the appliance and should be checked periodically to assure

continued safety to the user. Equipment with protective grounding through

the power cord is assumed to have faulty grounding connection at the outlet

when measuring leakage current. While the shock (see definition of shock

hazard on page 3 ) in itself might be slight from the standpoint of bodily harm,

the person, nevertheless might react violently out of surprise or fear, and may

cause injury to himself or someone else.

For a broad scope of leakage current measurements, the Simpson 229-2

covers the current measurement span from 5 microamperes to 10 milliamperes. The leakage current measurements can be made simply and dependably. The user can keep a record of potentially hazardous leakage

situations, and from data trends, be alerted to likely future failures. To evaluate the protection most meaningfully, one must test an electrical device or

appliance in accordance with the latest applicable national standards.

A full

1.2 Threshold Of Perception

Leakage current limits are based on the threshold of perception. The threshold of perception is the current level at which a particular person just perceives the flow of electrical current. A mean value of perception current equal

to 1.067 mA at 60 Hz was determined by tests performed on 28 men by

Charles F. Dalziel (see AIEE proceedings, Volume 69, 1950, Section 0184,

“Effect of Frequency on Perception Currents”). The threshold of perception of

some individuals tested was considerably less than 1.067 mA at 60 Hz.

1.3 Technical Data

Table 1. Technical Data

1. Function/Range: a) BATT. TEST

b) AC voltage (300V AC, and 150V AC)

c) SHORT TEST

d) AC current 10mA, 3mA, 1mA, and 0.3mA

2. Input Impedance On

Current Ranges: 1500

Figure 1

resistance shunted by 0.15 F. See

6

Page 7

3. Input Resistance On

Voltage Ranges 500K

1MEG

4. Accuracy @ 60 Hz,

Sine Wave: 3% on voltage and current ranges.

5. Frequency Response: Approximates Dalziel’s Percentile 50

(Current Ranges) Threshold of Perception Curve.

on the 150V VAC range

on the 300V VAC range

6. Reference Conditions: 23°C

7. Power Requirements: One 9-volt battery NEDA type 1604A

(Burgess Type PM-6 or equivalent).

8. Battery Life: Approximately 200 Hrs.

9. Rated Circuit-To- 300 Vrms

Ground Voltage:

10. Instrument Protection: The amplifier circuit and the meter are protected by signal clipping diodes at the amplifier input.

11. Overload Protection: The Instrument is capable of withstanding

momentary overloads up to 500 volts peak

(50/60 Hz) on all current and voltage ranges.

(See Section 2.3 Operating Instructions, #6.)

1°C, 30% to 60% relative humidity.

1.4 Items And Accessories

Table 2. Items Furnished With Instrument

Quantity .oN traPnoitpircseD

1 Test Lead Set — One red and one black, 00125

each 4 ft. long with combination probe tips

and removable insulated alligator clips at

one end and banana plugs on opposite end.

*1 9-volts batty, NEDA Type 1604A Alkaline Battery.

1O 511-5launaM s’rotarep705

*Batteries are standard item replaceable from local retail stores.

7

Page 8

2. OPERATION

!

The Model 229-2 is designed to prevent accidental shock when properly

used. However, no engineering design can make an Instrument safe when

used carelessly. Therefore, this manual must be read completely before

making any measurements. Failure to do so can result in a serious or fatal

accident.

This section of the manual contains information required to use and operate

the Model 229-2 in a safe and proper manner.

2.1 Safety Precautions

The Model 229-2 is designed to be used only by personnel qualified to recognize shock hazards and trained in the safety precautions required to avoid

possible injury. Refer to SHOCK HAZARD definition which is located on

page 3 of this manual.

1. Do not work alone when making measurements where a shock hazard

can exist. Notify a nearby person that you are intending to make such

measurements.

2. Remember, voltages might appear unexpectedly in defective equipment.

An open bleeder resistor can result in a capacitor’s retaining a dangerous charge. Remove all power and discharge all capacitors in the circuit

being measured before making connections or disconnections.

3. Locate all voltage sources and accessibility paths prior to making any

measurements or connections.

4. For your own safety, before each use, inspect the test leads, and connectors for cracks, breaks or crazes in the insulation. If defective, destroy and

replace immediately.

5. Hands, shoes, floor and workbench must be dry. Avoid measuring under

humid, damp or other environmental conditions that could affect the dielectric withstanding voltage of the test leads or the Instrument.

6. For maximum safety, do not

power is applied to the circuit being measured.

7. Do not use test leads which differ from those originally furnished with the

Instrument.

8. Do not float any measuring terminal more than the rated circuit to ground

voltage as specified in the Table 1, item 9.

touch test leads, circuit, or Instrument while

8

Page 9

2.3 Operating Instructions

!

Do not touch the device or appliance under test with power applied until

voltage and leakage current measurements have been made and found to be

within applicable requirements. Obviously, during the test the requisite electrical safety has not yet been established. Therefore when going through the

measurement procedure, do not touch test leads or device under test while

power is applied.

NOTE: Leakage current alone is not conclusive evidence of a shock hazard.

For safe operation, the open circuit voltage between the same two points

must not exceed 30V rms.

1. Turn the function selector switch to the BATT. TEST position. The pointer

will deflect to the right-hand side of the dial if the battery is OK, as indicated on the lower most arc.

2. With the appropriate voltage range of the Instrument, test for proper line

voltage being applied to the device under test.

3. De-energize the equipment to be tested.

4. Turn the function selector switch to the SHORT TEST position.

5. Connect Model 229-2 Leakage Current Tester, as shown in the figure 2.

Disconnect protective grounding

connection (3rd wire)

Power line

X

Polarity of input leads on

model 229-2 is not important

Figure 2. Model 229-2, Leakage Current Testing Diagram

6. Energize the equipment to be tested. If the pointer is deflected to the red

area (or above) on the second arc from the bottom, immediately turn off

power. The leakage current is greater than 10 mA and a “short” in the

device is probable.

Device under

test

!

Earth Ground

(Water pipe or

power line ground)

Connection to accessible part

being tested

Model 229-2

Model 229-2

Current Leakage

Leakage Current

Te st er

Te st er

9

Page 10

The Model 229-2 will withstand 300V AC (50/60 Hz) on short test for approximately 10 seconds.

7. If the pointer is deflected into the green area, the leakage current may be

measured more accurately by turning the selector switch clockwise until

best reading is obtained.

8. Observe the meter reading. If the device under test has an unpolarized

power plug (2 prong), reverse the plug in the socket and again note the

meter reading. The highest reading obtained is the leakage current. Refer

to the appropriate standard for the limitations of leakage current. As of

1976, the limit is 0.5 milliamperes (subject to change).

NOTE: Leakage current alone is not conclusive evidence of a hazard. The

open circuit voltage between the same two points must be less than 30V rms

for a hazardous condition to exist.

3. MAINTENANCE

The Simpson 229-2 is designed and constructed with high quality components. By providing reasonable care and following the instructions in this

manual the user can expect a long, useful service life from this Instrument.

3.1 Warranty

The Simpson Electric Company warranty policy is printed on the inside front

cover of this manual. Read it carefully before requesting a warranty repair.

NOTE: For assistance of any kind, including help with the Instrument under

warranty, contact the nearest Authorized Service Center for instructions. If

necessary, contact the factory directly, give full details of the difficulty, including the Instrument model number, serial number, and date of purchase. Service data or shipping instructions will be mailed promptly. If nonwarranty or

other service work is required, an estimate of the maximum charge will be

quoted. This charge will not be exceeded without prior approval.

3.2 Shipping

Pack the Instrument carefully and insure and ship it prepaid to the destination

indicated.

3.3 Battery Replacement

This Instrument is powered by one 9V alkaline battery (NEDA 1604A).

NOTE: Battery replacement is indicated whenever insufficient meter deflection occurs in the BATT TEST position.

Turn off all power and remove test leads from the Instrument before removing

its case.

10

Page 11

!

When battery replacement is required, the Instrument must be removed from

its case. To remove the case, proceed as follows:

1. Place Instrument face down on a soft padded surface.

2. Unscrew the four recessed screws located in each corner of the case.

3. Lift the case off the Instrument and set it aside.

4. Remove battery with mating connector from the holder.

5. Remove the old battery from the connector and insert the new battery into

the holder

3.4 Calibration

The Simpson 229-2 is a FACTORY SERVICE ONLY Instrument. If it is suspected that the Instrument is not performing within rated accuracy specifications send Instrument to Simpson Electric Co. for service. Contact Simpson

Technical Support if you are uncertain about performance specifications or

operation of this Instrument.

3.5 Care

Daily

1. If something is spilled on the Instrument, immediately shut off the power

from the test setup, disconnect the test leads, and wipe the Instrument

clean and allow to dry. If the spillage is corrosive, use a suitable cleaner

to neutralize the corrosive action, and remove the spillage.

2. When Instrument is not in use, rotate the function/range selector switch to

the OFF position.

3. Whenever possible, avoid prolonged exposure or usage in areas subject to temperature and humidity extremes, vibration or mechanical shock,

dust or corrosive fumes, or strong electrical or electromagnetic interferences.

Quarterly:

1. Verify Instrument accuracy by performing operational checks using known

accurate, stable sources. If the need for recalibration is indicated, contact your nearest Simpson Authorized Service Center.

2. If the Instrument has not been used for 90 days, check the batteries for

chemical leakage and replace if necessary.

Annually:

It is recommended that the Instrument be returned annually to your nearest

Simpson Authorized Service Center for a complete overall check, adjustment

and calibration.

Storage:

When not in use, store Instrument in a location free from temperature extremes, dust, corrosive fumes, and mechanical vibration or shock. If storage

time exceeds 90 days, remove the battery.

11

Page 12

SIMPSON ELECTRIC COMPANY 520 Simpson Avenue

Lac du Flambeau, WI 54538-0099 (715) 588-3311 FAX (715) 588-3326

Printed in U.S.A. Part No. 05-115705 Edition 12 07/17

Visit us on the web at: www.simpsonelectric.com

Loading...

Loading...