Page 1

Sewing Machine Model SA2200

INSTRUCTION MANUAL

& REFERENCE GUIDE

Simplicity S e

wing Machine Education Helpline: 636-651-0030

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using the sewing machine, basic safety precautions should always be followed, including

the following:

READ ALL INSTRUCTIONS BEFORE USING MACHINE

DANGER - To reduce risk of electric shock:

1. The sewing machine should never be left unattended w

2. Always unplug this sewing machine from the electrical outlet immediately after using and

before cleaning.

3. Always unplug before changing the light bulb. Replace bulb with same type rated 15 watts.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow this machine to be used as a toy. Close attention is necessary when the

sewing machine is used by or near children.

2. Use this sewing machine only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the sewing

machine to the nearest authorized dealer or service center for examination, repair, and

electrical or mechanical adjustment.

4. Never operate the sewing machine with any air openings blocked. Keep the ventilation

openings of the sewing machine and foot controller free from the accumulation of lint, dust

and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use this machine outdoors.

7. Do not operate this machine where aerosol spray products are being used or where oxygen

is being administered.

To disconnect, turn all controls to the off position then remove the plug from the outlet.

8.

Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

9.

Keep fingers away from all moving parts. Special care is required around the sewing

10.

hine needle.

mac

Always use the proper needle plate. The wrong plate can cause the needle to break.

11.

Do not use a bent needle.

12.

Do not pull or push the fabric while stitching. It may deflect the needle causing it to break.

13.

Unplug the sewing machine when making any adjustments in the needle area, such as

14.

threading the needle, c

Always unplug the sewing machine from the electrical outlet when removing covers,

15.

lubricating, or w

instruction manual.

hanging the needle, threading the bobbin, or changing the presser foot.

hen making any other user servicing adjustments mentioned in this

hen plugged in.

VE THESE INSTRUCTIONS

SA

his sewing machine is intended for household use.

T

1

Page 3

FORWARD

WELCOME TO THE CREATIVE WORLD OF SEWING WITH SIMPLICITY!

Congr

new to sewing, a lifelong sewer, or returning to sewing, we at Simplicity Sewing

Machines are dedicated to providing y

tomer service to ensure you many pleasurable hours of sewing satisfaction and success.

Before starting a sewing project, here are a few recommendations to help you become

acquainted with your new machine:

atulations on being the owner of a new Simplicity sewing machine. Whether you’re

ou with simply the BEST features, quality, and cus-

• Read through the instruction book and become familiar with the sewing

terms.

• Review the machine, using the instruction book as a guide, to identify each

part and function of the machine.

• Practice sewing on a variety of fabric scraps using various stitches and stitch

settings.

• Make a stitch sampler of your favorite techniques in the instruction book,

marking your machine setting preferences for future reference.

• • •

Thank you for choosing a Simplicity sewing machine.

If you have any questions or comments, give us a call – we’ll be glad to help you!

• • •

Simplicity Sewing Machine Education Department

636-651-0030

2

Page 4

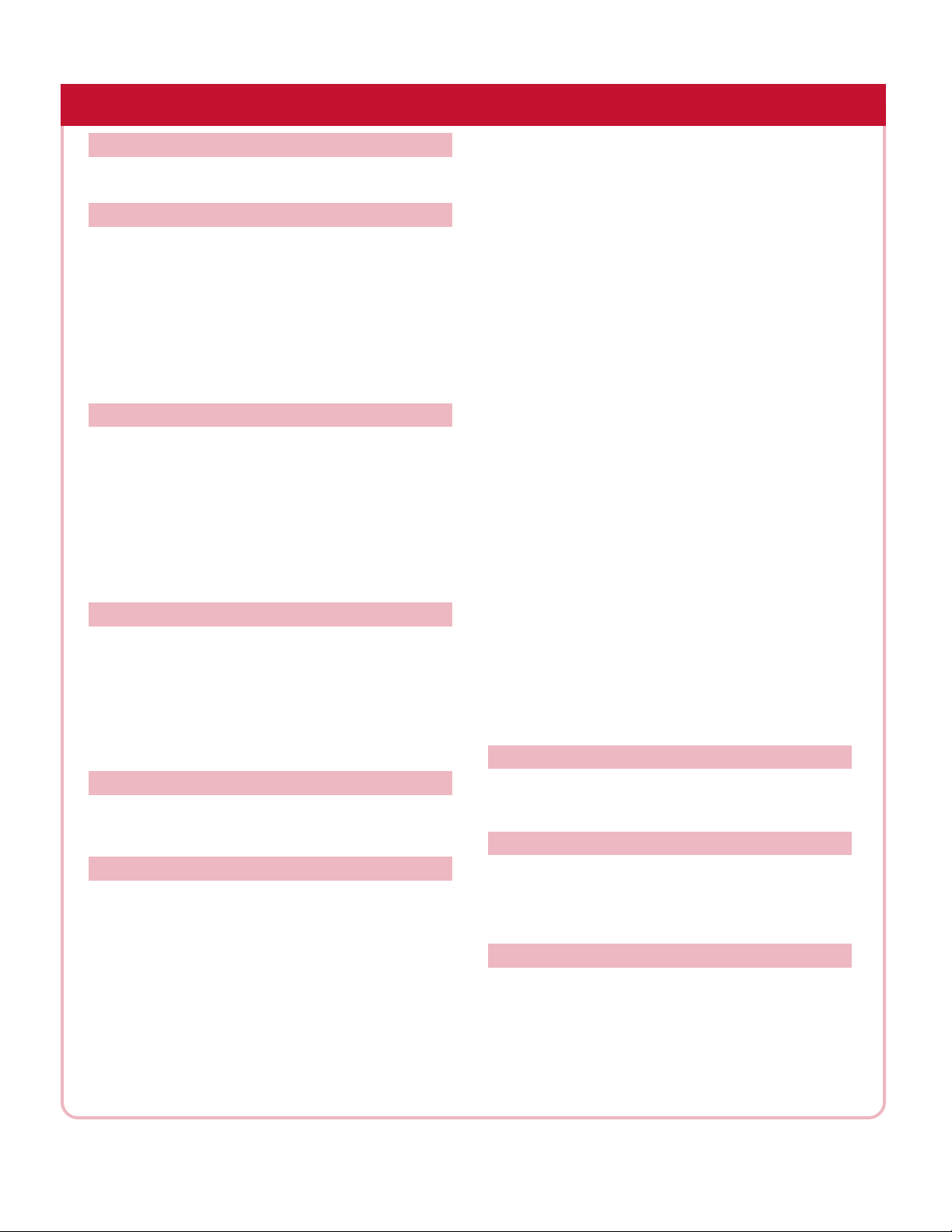

TABLE OF CONTENTS

KNOW YOUR SIMPLICITY SEWING MACHINE

PRINCIPAL PARTS........................................................................4-5

ACCESSORIES .................................................................................6

SIMPLICITY SEWING MACHINE SET-UP

PREPARATION FOR SEWING .........................................................7

ACCESSORY STORAGE ...................................................................7

CHANGING PRESSER FEET.............................................................7

Snap-on feet ...........................................................................7

Screw-on feet..........................................................................7

FREE-ARM SEWING ........................................................................8

PRESSER FOOT PRESSURE REGULATOR........................................8

DROP FEED ....................................................................................8

LEVELING BAR................................................................................8

STRETCH STITCH ADJUSTMENT. ...................................................8

CUSTOM STITCH SELECTION

STITCH SELECTION ........................................................................9

Stitch selector dial ..................................................................9

Stitch width dial......................................................................9

Stitch length dial .....................................................................9

Needle plate seam guides .......................................................9

Reverse sewing lever ..............................................................9

STITCH SELECTION TABLE ...........................................................10

TENSION ADJUSTMENTS.............................................................10

Upper thread tension ...........................................................10

Lower thread tension ............................................................10

THREADING YOUR MACHINE

WINDING THE BOBBIN...............................................................11

LOWER THREADING....................................................................12

Removing the bobbin ...........................................................12

Inserting new bobbin ............................................................12

Placing bobbin case in shuttle ..............................................12

UPPER THREADING .....................................................................13

Using the needle threader .....................................................13

Raising the bobbin thread .....................................................13

SEWING

SEWING TIPS................................................................................14

BEGINNING TO SEW....................................................................14

NEEDLE, THREAD & FABRIC GUIDE............................................15

BUILT-IN STITCHES

STITCH “A” STRAIGHT STITCH ....................................................16

Seaming................................................................................16

Basting..................................................................................16

Topstitching and edgestitching ..............................................16

Gathering..............................................................................16

Zipper insertion ....................................................................17

Piping insertion.....................................................................17

Narrow hemming..................................................................17

STITCH “A” ZIGZAG .....................................................................18

Overedging light to medium fabrics......................................18

Bartacking.............................................................................18

Satin stitch appliqué .............................................................18

Attaching buttons..................................................................19

Seaming knits .......................................................................19

STITCH “B, D, E” DECORATIVE SATIN STITCH............................20

STITCH “C” SCALLOP HEM..........................................................20

STITCH “F” BLINDHEM ................................................................20

STITCH “G” SHELL STITCH ..........................................................21

Seaming nylon tricot .............................................................21

Decorative picot hem ...........................................................21

Folk art appliqué...................................................................21

Decorative

STITCH “H” DOUBLE ACTION

Encasing elastic ....................................................................22

STITCH “I” THREE-STEP ZIGZAG

Attaching flat elastic .............................................................22

Overcasting ..........................................................................22

Mending ...............................................................................22

STITCH “J” MULTI-CORD SEWING ..............................................23

STITCH “K” FEATHER STITCH ......................................................23

STITCH “L” HONEYCOMB ...........................................................24

Decorative ribbon attaching..................................................24

Mock smocking ....................................................................24

STITCH “M” OVERLOCK ..............................................................24

Attaching rib knit trim ...........................................................24

STITCH “N” SLANT O

Seaming and ove

STITCH “O” ARRO

Decor

STITCH “P

STITCH “R” DECORA

STITCH “S”

Seaming bias curv

Seaming double knits

riple topstitching .................................................................27

T

STITCH “S” RICK RA

Overcasting heavy fabrics .....................................................27

Decorative rick rack..............................................................27

BUTTONHOLES............................................................................28

Classic buttonholes ...............................................................28

Corded buttonholes ..............................................................28

MONOGRAMMING .....................................................................29

OUTLINE QUILTING ....................................................................29

DARNING.....................................................................................29

SPECIAL

SEWING WITH TWO THREADS ...................................................30

TWIN NEEDLE SEWING ...............................................................30

Double stitched hem ............................................................30

SEWING OVER DENSE SEAMS .....................................................30

NEEDLES.......................................................................................31

CLEANING FEED TEETH AND SHUTTLE AREA ............................31

CHANGING

OILING

TROUBLESHOOTING .............................................................32-33

braid application.................................................21

....................................................22

..................................................22

VERCAST....................................................25

rcasting heavyweight fabrics ......................25

WHEAD ..........................................................25

ative flat fell seams ......................................................25

, Q” DECORATIVE EDGING.........................................25

TIVE TRIM ...................................................26

TRIPLE STRETCH STRAIGHT STITCH ........................27

es .............................................................27

............................................................27

CK ................................................................27

FREE-MO

TION SEWING

TY SEWING TECHNIQUES

ARE AND MAINTENANCE

C

THE LIGHT BULB.....................................................31

.........................................................................................31

3

Page 5

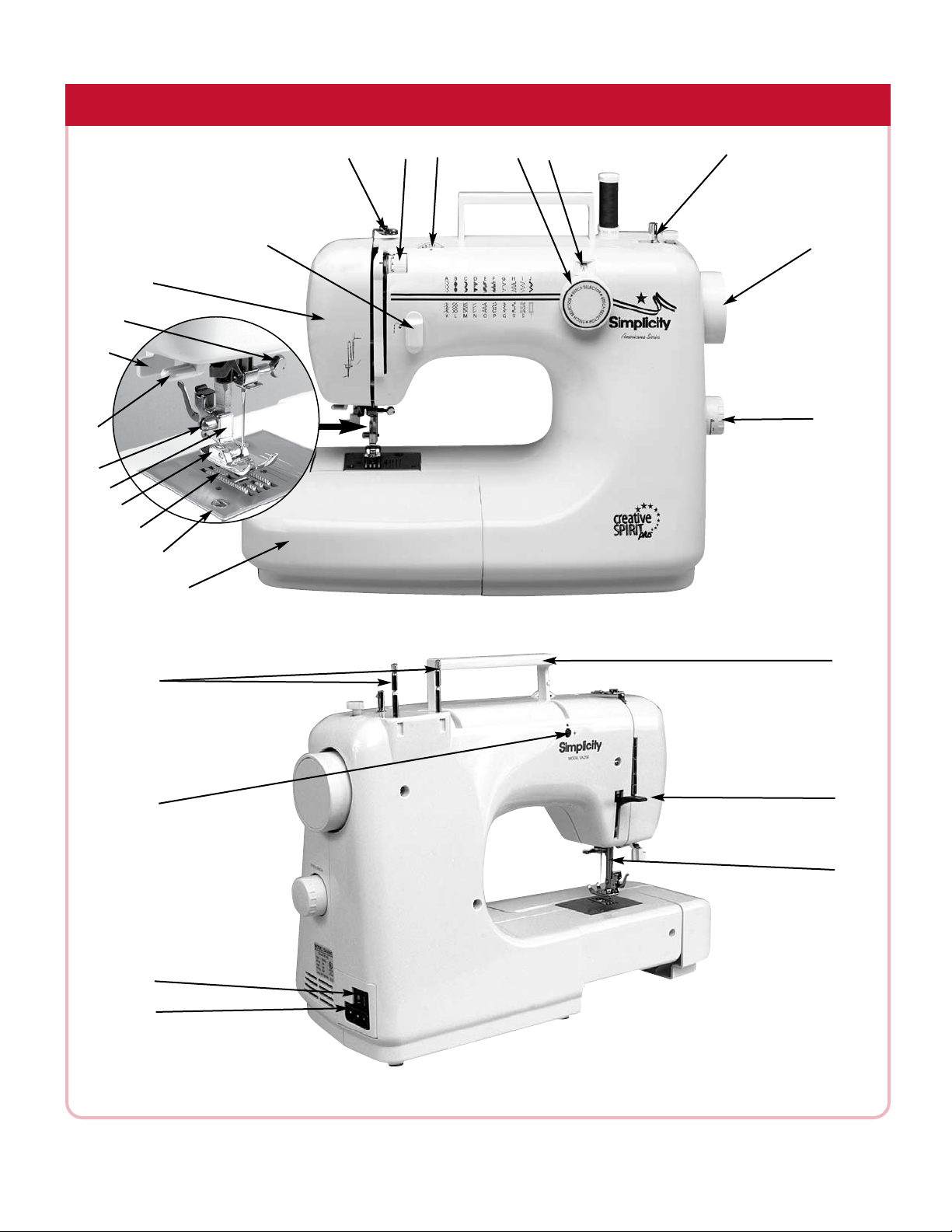

KNOW YOUR SIMPLICITY SEWING MACHINE

O

17

O

16

O

O

18

15

19

O

14

O

O

13

O

1

12

O

FRONT VIEW

O

11

O

5

3

O

2

4

O

O

6

O

7

O

8

O

9

O

10

O

26

O

25

O

24

O

23

O

CK VIEW

BA

20

O

21

O

22

O

4

Page 6

KNOW YOUR SIMPLICITY SEWING MACHINE

FRONT VIEW

1 FACE COVER

O

Opens to provide access to the light bulb and the

presser foot pressure regulator.

2 REVERSE LEVER

O

Press this lever down and hold in place to sew in

reverse.

3 BOBBIN WINDING TENSION DISC

O

Used to wind a bobbin when threading the

machine.

4 THREAD TENSION DIAL

O

Controls the upper thread for proper stitch formation.

5 STITCH WIDTH DIAL

O

Sets the width of a stitch.

6 STITCH SELECTOR DIAL

O

Turn the dial in either direction to select a stitch.

7 STITCH SELECTOR WINDOW

O

The letter of the selected stitch appears in this

window.

8 BOBBIN WINDER SPINDLE

O

Winds thread on a bobbin for lower threading.

9 HAND WHEEL

O

Turn the hand wheel toward you to raise the

needle up and down.

15 PRESSER FOOT HOLDER

O

Holds the snap-on presser foot in sewing position.

The presser foot holder is removed when using

screw-on feet.

16 PRESSER FOOT THUMB SCREW

O

Secures the presser foot or presser foot holder to

the presser foot bar.

17 BUILT-IN NEEDLE THREADER

O

Threads the eye of the needle, front to back.

18 BUTTONHOLE LEVER

O

Pull this lever down when using the one-step

buttonhole foot.

19 NEEDLE CLAMP SCREW

O

Loosen to remove a needle; tighten to secure a

needle in position.

BACK VIEW

20 CARRY HANDLE

O

Simply lift to carry the Simplicity sewing

machine from one place to another.

21 PRESSER FOOT LEVER

O

aise the presser foot and release the thread

Lift to r

tension; lower to lower the presser foot and engage

the thread tension.

10 STITCH LENGTH DIAL

O

Sets the length of the stitch.

11 FREE-ARM COVER

O

Provides a flat surface for most sewing. Remove

it to convert to free-arm sewing.

12 NEEDLE PLATE

O

Supports the fabric while sewing. Has seam guide

markings on right side.

13 FEED TEETH

O

The metal teeth under the needle plate that push

or feed the fabric through the machine.

14 PRESSER FOOT

O

Holds the fabric firmly against the feed teeth for

proper stitch formation.

22

THREAD CUTTER ON NEEDLE BAR

O

Use to cut threads after completing a seam.

23 POWER CORD RECEPTACLE

O

Connect the three-prong power plug here.

24 MAIN SWITCH

O

Turns the main power and built-in sewing light

on or off.

25 STRETCH STITCH ADJUSTMENT SCREW

O

Adjust this screw if stretch stitches (color-coded

red) are not forming properly.

26 RETRACTABLE SPOOL PINS

O

Raise the spool pin to hold the spools of thread.

5

Page 7

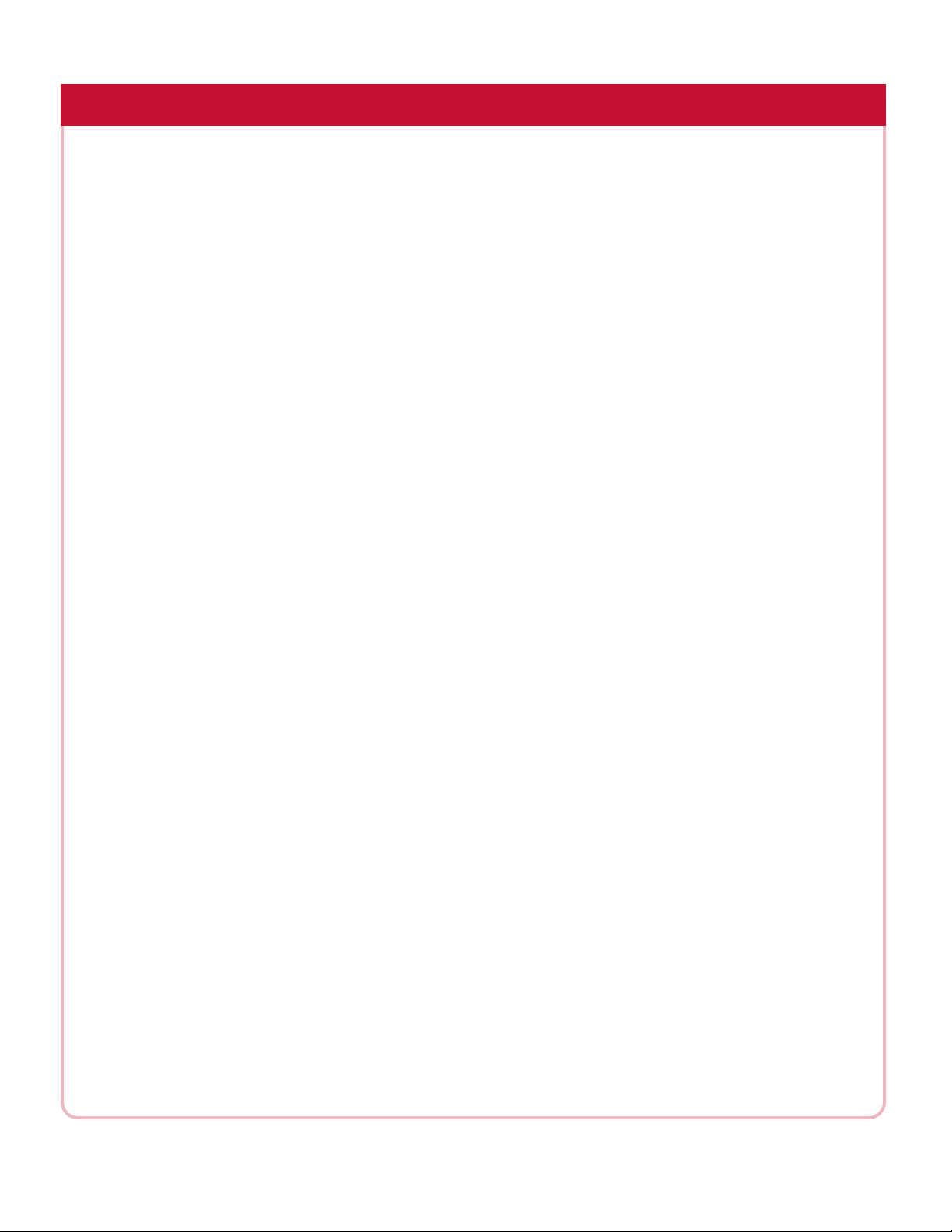

KNOW YOUR SIMPLICITY SEWING MACHINE

ACCESSORIES

The SIMPLICITY sewing machine comes

with the presser feet and accessories you

will need, conveniently stored in the free

arm cover. This low shank machine uses

snap-on or screw-on presser feet.

2

1

O

O

O

4

5

O

O

3

O

6

1

ALL-PURPOSE FOOT - snap-on

O

Use for most straight and zigzag seams. The needle opening

is rectangular to accommodate the swing of the needle in a

zigzag stitch. (The machine comes with this foot already

attached.)

2

BUTTONHOLE FOOT - snap-on

O

Use for sewing made-to-measure buttonholes in one step.

3

BUTTON ATTACHING FOOT - snap-on

O

Holds flat buttons secure for machine stitching in place.

4

ZIPPER FOOT - screw-on

O

Adjusts to stitch close to either side of the zipper without

catching the zipper coil.

5

BLIND HEM FOOT - snap-on

O

Features an adjustable guide for positioning and evenly

stitching blind hems, topstitching, or edgestitching.

6

OPEN TOE SATIN STITCH FOOT - snap-on

O

Satin stitching glides comfortably under the sole of this

foot and the open toe provides clear visibility of stitches.

12

O

7

O

10

O

14

O

8

O

9

O

O

13

O

11

O

15

7

OVERCASTING FOOT - snap-on

O

A pin on the foot holds fabric flat when ove

ric edges. The guide ensures perfect sewing alignment.

8

HEMMER FOOT - snap-on

O

Rolls fabric edge for narrow hemming.

9

EMBROIDERY FOOT - screw-on

O

Prevents fabric from “flagging” or popping when sewing

free-motion techniques.

10

CORDING FOOT - snap-on

O

Grooves on the foot guide lightweight cords under the

stitches for decorative applications.

11

PLASTIC BOBBINS (10)

O

Holds lower thread. These are “Class 15” bobbins.

12

SEAM RIPPER

O

Use to remove stitching and to open buttonholes.

13

SCREWDRIVER

O

Use to loosen and tighten the presser foot thumb screw,

needle clamp screw, and needleplate screw.

14

FELT CUSHIONS (2)

O

Fits on the spool pin beneath the thread spool, stabilizing

the spool and preventing the thread from wrapping

around the spool pin.

15

NEEDLES

O

The most commonly used “universal” needles, size #11 and

#14, are included. This machine uses 15x1 household

sewing machine needles.

rcasting fab-

6

Page 8

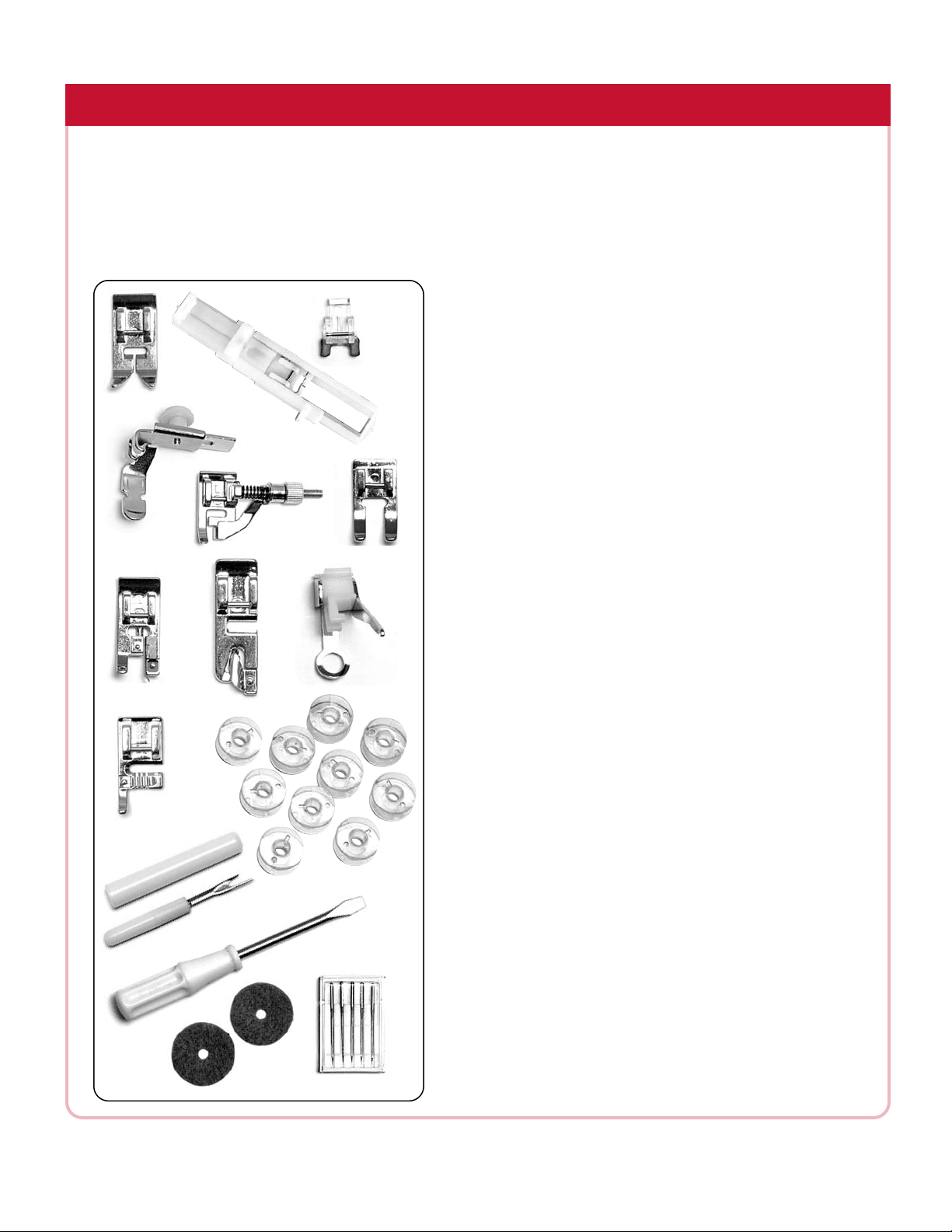

SIMPLICITY SEWING MACHINE SET-UP

The Simplicity sewing machine has many conversion options for a multitude of sewing

applications.

Fig. 1

Fig. 3

Fig. 5

Fig. 7

on/off

Fig. 2

g. 4

Fi

Fig. 6

Fig. 8

PREPARATION FOR SEWING

wer cord and foot control are one unit.

The po

Insert the three-prong plug into the machine [Fig. 1].

Insert the power supply plug into a wall outlet. Turn the

power switch to “on” [Fig.1].

Raise the left retractable thread spool pin for most sewing

[Fig. 2]. Raise both the left and right retractable thread

spool pins for twin needle or dual thread sewing.

ACCESSORY STORAGE

Accessories and presser feet are conveniently stored in

the free-arm cover.

Grasp the free-arm cover with your left hand and gently

pull up and toward you to open the storage tray [Fig.3].

CHANGING PRESSER FEET

Your Simplicity sewing machine comes with both snapon and screw-on presser feet. They're easy to change

and each foot helps make a specific se

Removing and Attaching Snap-on Presser Feet

1. Turn the handwheel toward you [Fig. 4] to bring the

needle to its highest position.

2. Raise the presser foot lever [Fig. 5].

3. Release the foot by pushing the presser foot release

lever located behind the presser foot holder [Fig. 6].

Place the desired foot on the needle plate, aligning

4.

the metal bar on the presser foot with the groo

the presser foot holder [Fig. 7].

5.

Lower the presser foot lever to snap the foot in place.

ving and Attaching Screw-on Presser Feet

Remo

1. Loosen the thumb screw located on the left side of the

presser foot on the presser foot bar [Fig. 8]. You may

need to use the screwdri

remove the screw completely.

2. Remove the presser foot holder and foot [Fig. 9].

3. Attach the desired screw-on presser foot onto the

presser bar.

4. Tighten the thumb screw with the screwdriver to hold

the presser foot securely in place [Fig. 10].

ver. It is not necessary to

wing task easier.

ve of

Fig. 9

Fig. 10

Note: After attaching a presser foot, select the desired

stitch and turn the hand-wheel toward you several times to

make sure the needle clears the opening in the foot. Some

presser feet require a straight or narrow width stitch only.

7

Page 9

SIMPLICITY SEWING MACHINE SET-UP OPTIONS

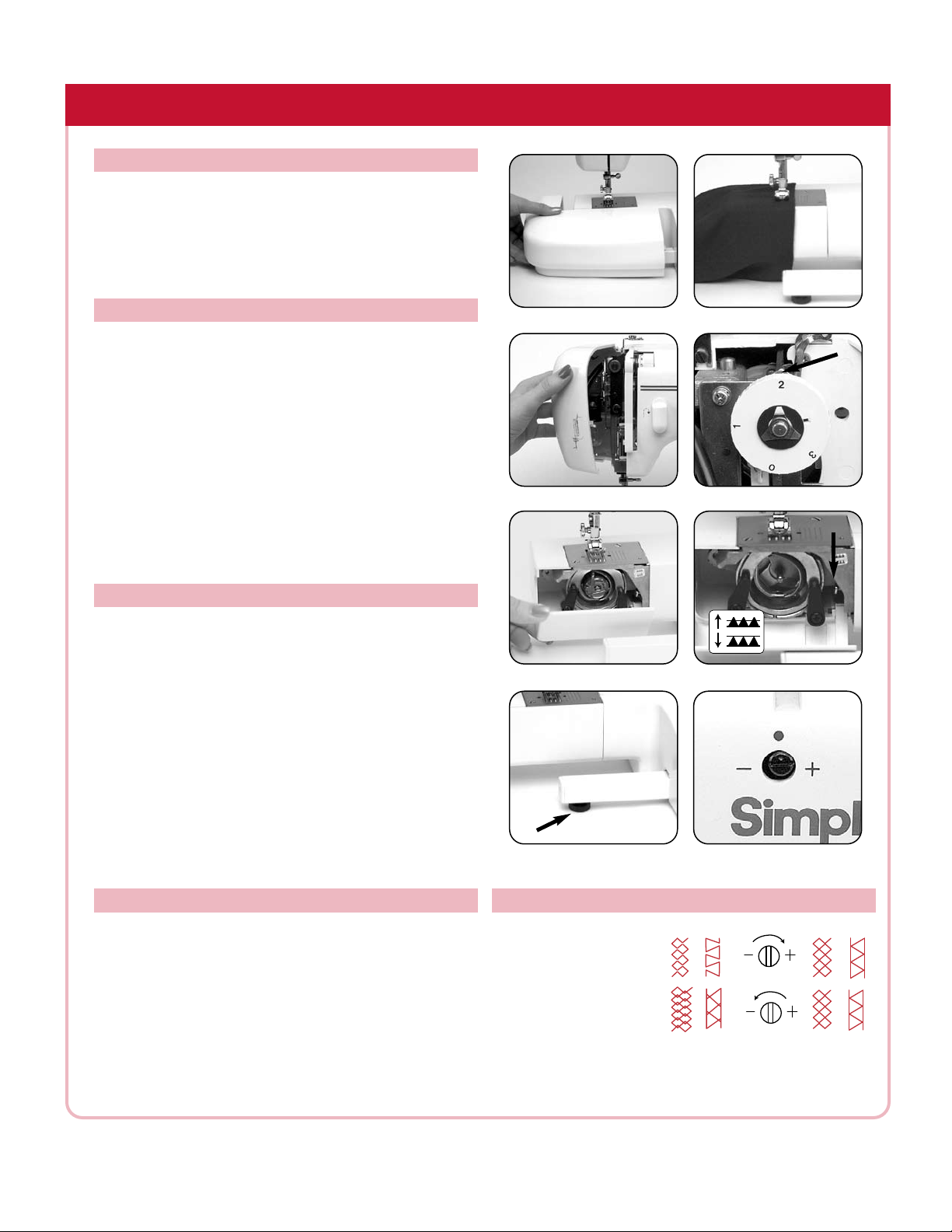

CONVERTING TO FREE-ARM SEWING

Free arm sewing makes it easy to sew hard to reach

areas such as sleeves, pant legs, and necklines.

To convert to free arm sewing, grasp the left end of the freearm cover and pull it out to the left to remove

sleeve or pant leg on the free arm as sho

[Fig. 1]. Slip the

wn and sew [Fig. 2].

PRESSER FOOT PRESSURE REGULATO

The pressure on the presser foot can be adjusted to accommodate sewing on various weights of fabric to ensure

proper fabric feeding and to eliminate skipped stitches.

1. Open the face cover [Fig. 3].

2. Rotate the dial until the desired pressure number is

aligned with the indicator [Fig. 4]. Standard setting is 2.

To increase pressure move to a higher number. To

decrease pressure move to a lower number.

Set lever at 1 for heavyweight fabrics

Set lever at 2 for mediumweight fabrics

Set lever at 3 for lightweight fabrics

Set the lever at 0 for darning and free-motion sewing.

R

DROP FEED

The drop feed mechanism lowers the feed teeth below the

needle plate, eliminating the need to make stitch length adjustments. When the feed teeth are lowered, the fabric is guided

by hand,

1. Turn the handwheel toward you to raise the needle to

2. Open the face cover and set the presser foot pressure

3.

4. Push down on the drop feed lever and the feed teeth

5. Push the lever up to return to normal sewing.

allowing free movement of the fabric in any direction.

its highest position.

regulator to 0.

Remove the free arm cover and open the front bobbin

cover [Fig. 5].

will drop belo

w the needle plate [Fig. 6].

Fig. 1

Fig. 3

Fig. 5

Fig. 7

Fig. 2

Fig. 4

Fig. 6

Fig. 8

LEVELING BAR

If the machine is not sitting on a level surface turn the

leveling screw to stabilize the machine.

1. Remove the free arm cover to access the screw under

eling bar [Fig. 7].

the lev

2. Turn the screw to the right to lower the machine.

Turn the screw to the left to elevate the machine.

8

STRETCH STITCH

When stretch stitches

(color-coded red) are

not forming properly,

turn the adjustment

screw with a flat blade

screwdriver [Fig. 8].

ADJUSTMENT

Page 10

9

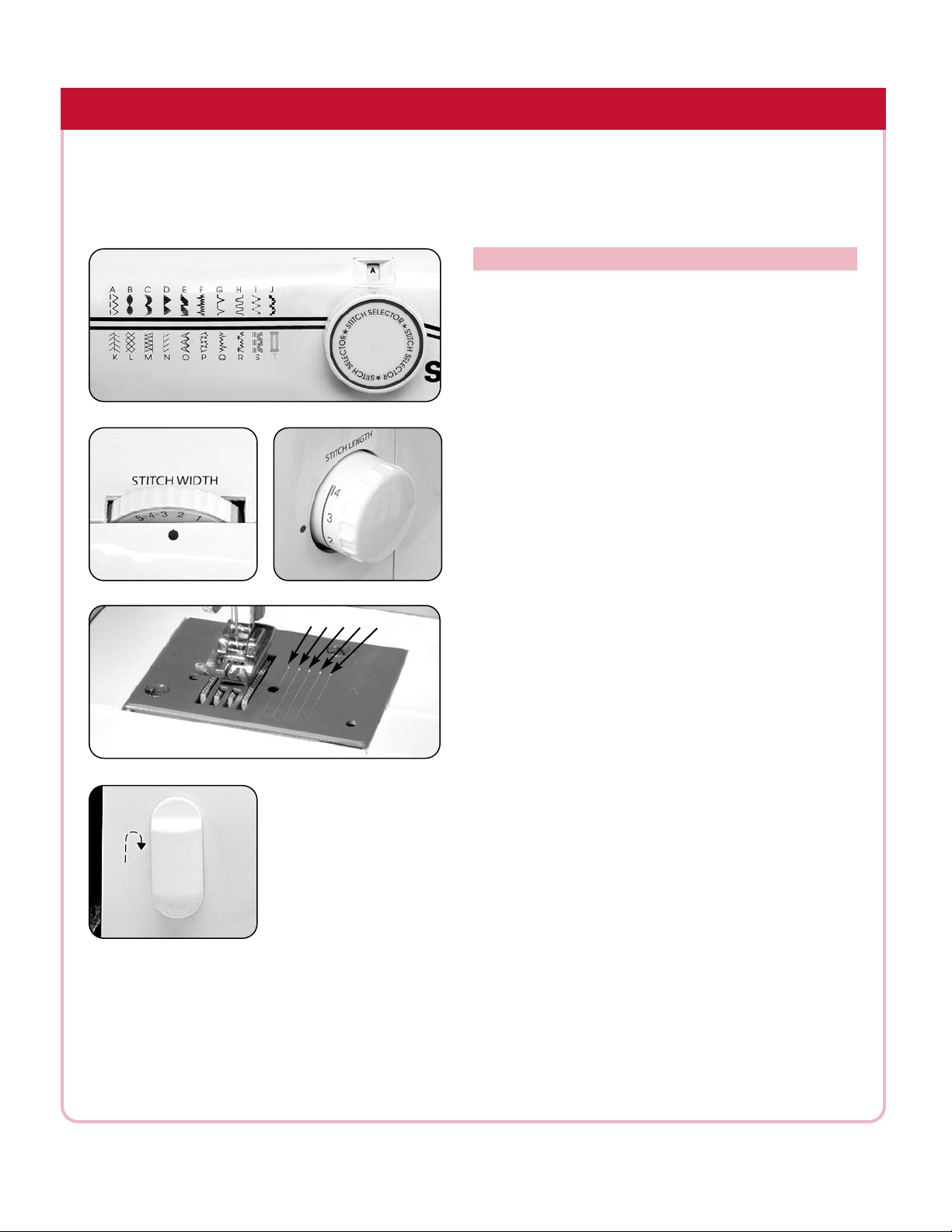

STITCH SELECTOR DIAL [Fig. 1]

To select a stitch, turn the stitch selector dial until the

letter that corresponds with the desired stitch shows in

the window.

STITCH WIDTH DIAL [Fig. 2]

The stitch width dial is numbered 0 - 5, representing

the various stitch widths in millimeters. The higher the

number, the wider the stitch. The yellow color-coding

between 3 and 5 represent the width range for making

buttonholes.

To select a stitch width, turn the dial until the desired

width setting is aligned with the indicator dot.

STITCH LENGTH DIAL [Fig. 3]

The stitch length dial is numbered 0 - 4 representing the

various stitch lengths in millimeters. The higher the

number, the longer the stitch.

To select a stitc

h length turn the dial until the desired

length setting is aligned with the indicator dot.

When set at 0 the fabric will not feed under the presser foot.

NEEDLE PLATE SEAM GUIDES [Fig. 4]

The five seam guide markings on the right side of the

needle plate are set at 1/8” intervals. The first mark is

1/2" from the needle; the second, 5/8” and so on. Align

the fabric edge at a seam guide marking for a consistent

seam width. The standard seam allowance width is 5/8”.

REVERSE SEWING LEVER [Fig. 5]

Use the reverse sewing lever to secure the beginning

and ends of seams.

With the foot control depressed, push and hold the

reverse lever down to sew in reverse. Release the lever

to return to forward sewing.

STITCH SELECTION

Each built-in stitch can be customized by making stitch length and stitch width adjustments.

T

he stitches are color-coded to correspond with the stitch length and width settings. Select a

stitch, then set the stitch length and width dials within the color range. These color ranges are

guidelines and may vary for some sewing techniques.

SIMPLICITY CUSTOM STITCH SELECTION

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fi

g. 5

1

⁄

2

”

5

⁄

8

”

3

⁄

4

”

7

⁄

8

”

1

”

Page 11

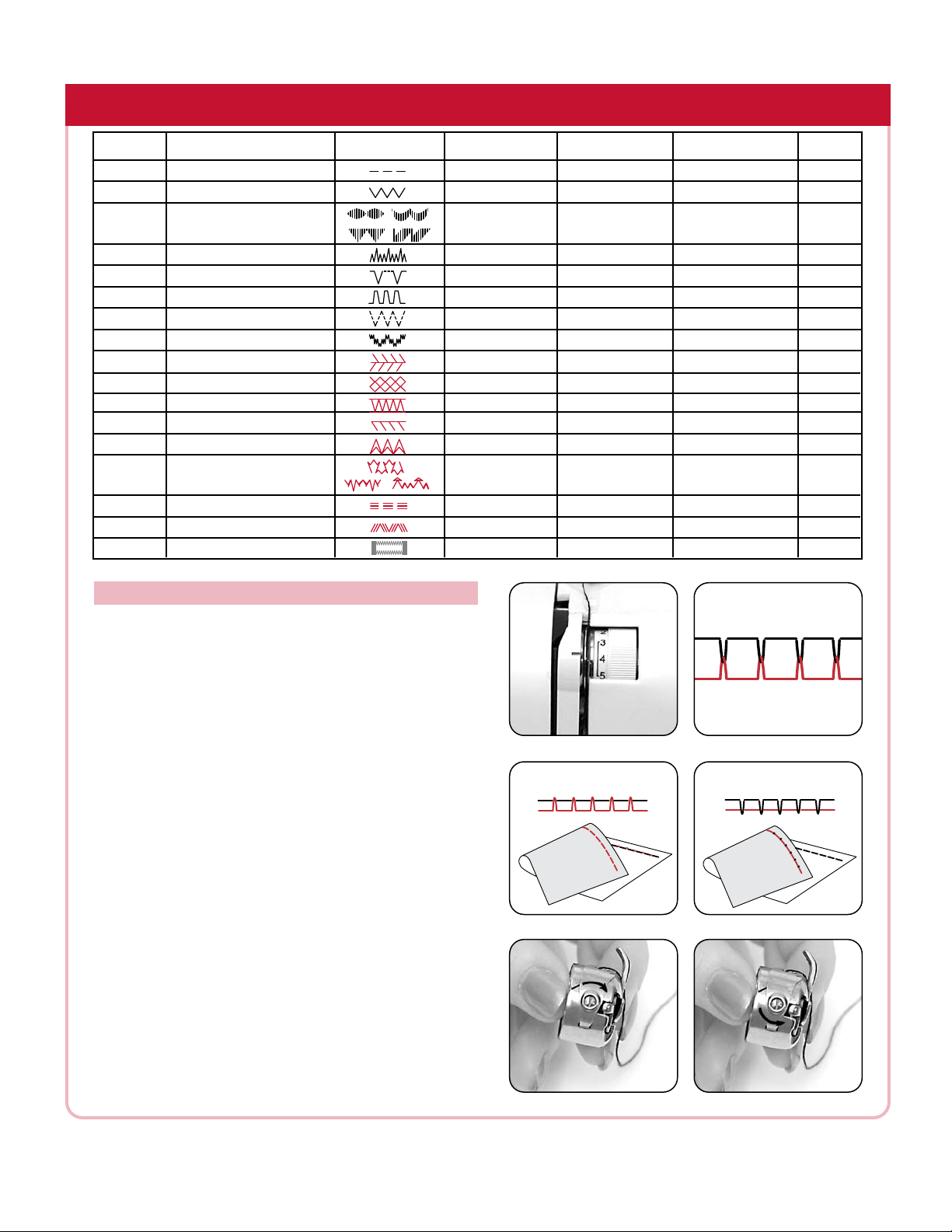

SIMPLICITY CUSTOM STITCH SELECTION

STITCH PATTERN

TITCH

S

WIDTH LENGTH FOOT FEED

TITCH

S

RESSER

P

ROP

D

A Straight 0 1-4 All feet Up

A Zigzag 1-5 1-4 All-purpose Up

B C D E Decorative satin 3-5 .5-1 Open toe Up

F Blindhem 3-5 4 Blind hem Up

G Shell stitch 3-5 1-4 All-purpose Up

H Double Action 5 4 All-purpose Up

I 3-step zigzag 3-5 2-4 Overcast Up

J Multi-cord 5 .5-2 Overcast Up

K Feather 3-5 4 Open toe Up

L Honeycomb 3-5 4 Open toe Up

M Overlock 3-5 4 Overcast Up

N Slant overcast 3-5 4 Open toe Up

O Arrowhead 3-5 4 Open toe Up

P Q R Decorative 3-5 4 Open toe Up

S Triple stretch straight 0 4 All-purpose Up

S Rick rack 1-5 4 All-purpose Up

T Buttonhole 3-5 .5-1 Buttonhole Up

TENSION ADJUSTMENTS

The upper thread

thread delivered to the bobbin case. Most thread tension

adjustments should be made using the upper thread

dial. In some cases, the lower thread tension on the bobbin

case may need to be adjusted for specialty sewing techniques.

UPPER THREAD TENSION

The numbers 0-9 on the dial represent upper thread

tension settings. The higher the number, the stronger the

upper tension. Tension settings between 3-5 are most

commonly used [Fig. 1]. In a balanced stitch, needle

thread and bobbin thread interlock in the center of the

two fabric layers [Fig. 2]. If needed, adjust an unbalanced

stitch by turning the dial until the new setting is aligned

with the indicator line on the machine [Fig. 1].

If the fabric gathers or the threads break, the upper thread

tension is too tight [Fig. 3]. Loosen the tension by moving

the dial to a lo

If loops form on the under side of the seam then the

upper tension is too loose [F

tension by turning the dial to a higher number.

LOWER THREAD TENSION

The lower thread tension can be adjusted by turning the

screw on the bobbin case slightly to the right (clockwise)

to increase the tension [Fig. 5]. Turn the tension slightly to

the left (counterclockwise) to decrease the tension [Fig. 6].

tension dial controls the amount of needle

tension

wer number.

ig. 4]. Tighten the upper

Fig. 1

Upper thread too tight

Fig. 3

Increase tension

Fig. 5

Fig. 2

Upper thread too loose

Fig. 4

Decrease tension

Fig. 6

10

Page 12

THREADING YOUR SIMPLICITY SEWING MACHINE

For best sewing results, use a top quality, long staple, polyester or poly/cotton thread for all-purpose

sewing. Skipped stitc

thread. Use the same type of thread for both upper and lower threading for a consistent stitch quality.

Fig. 2

hes, broken threads, and poor stitch quality are often a result of using old or inferior

WINDING THE BOBBIN

To release the clutch for bobbin winding, pull out the

1.

handwheel until it clicks [Fig. 1].

2. Place a spool of thread on the spool pin and bring

the thread around the bobbin winding tension disc as

shown [Fig. 2].

3. Place the thread end through a small hole in the bobbin

Fig. 1

from the inside to the outside [Fig. 3].

4. Place the bobbin on the bobbinwinder spindle

matching the small groove on the bobbin with the

spring on the spindle [Fig. 4]. Push the spindle to

the right [Fig. 5].

5. Hold the end of the thread [Fig. 6] and depress the

foot control [Fig. 7]. When the thread has wound on

the bobbin several times, stop the machine and clip

the thread end close to the hole in the bobbin [Fig. 8].

Depress the foot control again to continue winding the

bobbin.

6. When the bobbin is fully wound, stop the machine.

Push the bobbinwinder spindle to the left, clip the

thread and remove

Reengage the clutch by pushing the handwheel until

7.

it clicks into place [Fig. 10].

the bobbin [Fig. 9].

Fig. 3

Fig. 5

Fig. 7

Fig. 4

Fig. 6

g. 8

Fi

Fig. 9

Fig. 10

11

Page 13

THREADING YOUR SIMPLICITY SEWING MACHINE

LOWER THREADING

Removing the bobbin from the bobbin case:

1. Turn the handwheel toward you to raise the needle to

its highest position.

2. Remove the free-arm cov

er [Fig. 1].

cov

3. Open the hinged latch of the bobbin case and pull

the bobbin case out of the machine [Fig. 2].

4. Release the latch to remove the bobbin [Fig. 3].

Inserting a new bobbin:

1. Hold the bobbin case in your left hand. Hold the filled

bobbin in your right hand [Fig. 4]. Unwind about six

inches of thread, making certain the thread unwinds

over the top of the bobbin as illustrated. Place the

bobbin in the bobbin case.

2. With the bobbin in the bobbin case, pull the thread

into the slot on the edge of the bobbin case [Fig. 5].

3. Pull the thread under the tension spring and into the

thread outlet [Fig. 6]. Leave about six inches of

thread extending from the bobbin case.

Note: It’s important to be sure the bobbin is turning

CLOCKWISE [Fig. 7] as you pull thread from the bobbin

case. If it is turning counterclockwise, remove the bobbin

from the case, turn the bobbin over, place it back into the

case, and rethread the bobbin case.

er and open the bobbin

Fig. 1

Fig. 3

Fig. 2

Fig. 4

Placing the bobbin case into the shuttle:

1. Open the latch of the bobbin case and hold it with the

long finger pointing upward [Fig. 8]. Place the bobbin

case over the pin of the shuttle aligning the long finger

with the notch at the top of the shuttle [Fig. 9].

2. Release the latch and push the bobbin case firmly

into place [Fig. 10]. Close the bobbin cover.

Note: Be sure the bobbin thread (about six inches) falls

loose from the bobbin case and is not caught or tangled

in any way.

Fig. 5

Fig. 7

Fig. 9

Fig. 6

C L O C K W I S E

Fig. 8

Fig. 10

12

Page 14

THREADING YOUR SIMPLICITY SEWING MACHINE

UPPER THREADING

1. Turn the handwheel toward you to raise the take-up

lever to its highest position [Fig. 1].

2. Raise the presser foot to release the thread tension [Fig. 2].

3. Place felt cushion on spool pin. Place spool of thread on the

spool pin with thread coming from the back of the spool.

4. Snap the thread into the first thread guide at the top of

the machine and bring the thread down between the

tension discs [Fig. 3], down the right slot of the threading path, then across to and up the left slot [Fig. 4].

5. Bring the thread through the take-up lever from right

to left [Fig. 5], making sure the thread falls into the

take-up lever slot [Fig. 6].

6. Bring the thread back down the left slot of the threading path

[Fig. 7] and into the thread guide above the needle [Fig. 8].

Using the needle threader

wer the presser foot.

1. Lo

Lower the needle threader lever with your left index finger

2.

and pull the thread to the left, catching it on the large hook.

Hold the needle threader lever in its lowest position and

pull the thread to the right, between the prongs that are

around the needle. A mini hook that passes through the

needle’s eye will catch the thread [Fig. 9]. Gently hold the

thread and raise the needle threader lever [Fig. 10].

3. Pull the loop of thread through the eye of the needle

[Fig. 11].

hreading Diagram

T

Fig. 1

Fig. 3

Fig. 2

Fig. 4

Fig. 7

Fig. 10

Fig. 8

Fig. 5

Fig. 9

Fig. 11

Fig. 6

Raising the bobbin thread

1. Raise the presser foot lever.

2. Hold the end of the needle thread with your left hand.

Turn the hand wheel toward you with your right hand

until the needle goes down once and comes back up,

stopping when the needle is at its highest position.

3. Gently pull up on the needle thread [Fig. 12]. The

bobbin thread, looped around the needle thread, will

be drawn up through the needle hole.

4. Pull about six inches of both the upper and lower

threads toward the back of the machine, placing

them under the presser foot [Fig. 13].

Fig. 12

ig. 13

F

13

Page 15

SEWING

Several synchronized parts of the sewing machine interact to form a stitch. The needle moves up

and do

thread through the layers of fabric. To maintain this perfectly tuned timing, here are a few sewing

tips you'll want to follow:

• Always begin sewing with the needle in the highest

position. Always place the needle in the highest position

at the end of a seam before removing the fabric from the

machine.

• Always turn the handwheel toward you, not away

from you. Never “rock” the handwheel.

• Be sure to lower the presser foot before sewing to

engage the tension discs for perfect stitch balance. This

is an easy step to miss when sewing extr

• Gently guide the fabric as you sew; never push or

pull the fabric under the needle.

• Don't sew over pins. Simply remove the pins as they

approach the needle. Sewing over pins can damage

your machine, nick the needle or cause personal injury.

• Use the proper needle/thread/fabric combination.

See chart on page 15.

wn as the shuttle spins in perfect time so that the bobbin thread interlocks with the needle

SEWING TIPS

Fig. 1

a thick fabrics.

Fig. 2

BEGINNING TO SEW

1. Select a stitch. Make the appropriate stitch width

and length adjustments.

2. Turn the hand wheel toward you to raise the needle

to its highest position.

3. Raise the presser foot and pull about six inches of

thread to the back of the machine and under the

presser foot.

4. Place the fabric under the presser foot aligning the

cut edge of the fabric with the seam guide marking

on the needle plate. Position the fabric so the needle

is about 3/8” from the beginning fabric edge [Fig. 1].

5. Lower the presser foot and depress the foot controller to

begin sewing. The sewing speed is determined by the

amount of pressure you apply to the foot controller.

6. To secure the beginning of a seam, take 3-4 stitches

forward, then push down and hold the reverse lever

to take 3-4 stitches in reverse.

7. Release the lever and continue sewing forward at a

consistent speed while guiding the fabric along the

seam guide marking.

8. At the end of the seam, press and hold the reverse

lever to take 3-4 backstitches to secure the seam end.

9. Before removing the fabric raise the needle to the

highest position [Fig. 2].

Fig. 3

Fig. 4

Raise the presser foot and gently pull the fabric to

10.

the left, releasing at least six inches of thread

from needle and bobbin [Fig. 3].

Use the thread cutter on the back of the presser

11.

foot bar to cut both threads close to the fabric

[Fig. 4].

14

Page 16

SEWING

NEEDLE, THREAD & FABRIC GUIDE

Knit Fabrics NEEDLE STYLE NEEDLE SIZE

Lightweight: Tricot Universal or Ballpoint 9/65, 10/70

Medium: Interlock, Lycra Universal or Ballpoint 11/75, 12/80, 14/90

Heavyweight: Double Knit, Velour Universal or Ballpoint 12/80, 14/90

Fake Furs, Napped Fabrics Universal or Ballpoint 14/90, 16/100

Woven Fabrics NEEDLE STYLE NEEDLE SIZE

Sheer: Chiffon, Fine Lace, Tulle,

Georgette, Net, Organdy, Organza Universal 8/60, 9/65

Lightweight: Batiste, Chambray,

Voile, Crepe de Chine, Silk Jersey,

Handkerchief Linen, Sheer Crepe Universal 9/65, 10/70

Medium Lightweight: Challis,

Gingham, Taffeta, Percale,

Wool Crepe, Wool Jersey Universal 11/75

Medium Weight: Broadcloth, Chintz,

Velour, Corduroy, Crepe Backed

Satin, Faille, Flannel, Linen, Velvet,

Pique, Poplin, Satin, Shantung,

Velveteen Universal 12/80

Medium Heavyweight: Brocade,

Denim, Felt, Flannel, Fleece,

Gabardine, Quilted Fabrics,

Textured Linen, Tweed, Twill Universal 14/90

Heavyweight: Double-faced Wool,

Fake Fur, Heavy Coating,

Sail Cloth, Ticking Universal 16/100

Leather NEEDLE STYLE NEEDLE SIZE

Ultrasuede, Ultra Leather Stretch 11/75

Vinyl Leather Point 14/90

Vinyl with Knit Backing Leather Point 14/90

Light to Medium Weight Leather Leather Point 12/80

Heavy Leather Leather Point 16/100, 18/110

15

Page 17

BUILT-IN STITCHES

STITCH “A” - STRAIGHT STITCH

SEAMING

Use for seaming two or more layers of fabric together.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 0 3 All-purpose

Align the fabric edge with the seam guide marking on the

needle plate and begin sewing [Fig. 1]. Take a few stitches in

reverse (backstitch) to secure the seam. Continue stitching

forward at a consistent speed, while guiding the fabric along

the seam guide marking. Backstitch at the end of the seam

[Fig. 2]. Use a shorter stitch length (2-3) when patchwork

piecing [Fig. 3] or sewing sheer fabrics. Use a longer stitch

(3.5-4) when sewing hea

denim, polar fleece, or velvet [Fig. 4].

BASTING

Use a basting stitch to sew temporary seams, such as when you

need to test fit a garment before sewing the seams permanently.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 0 4 All-purpose

vy, thick, or napped fabrics such as

Fig. 1

Fig. 3

Fig. 2

Fig. 4

Align the fabric edge with the seam guide markings and sew

at an even speed. Do not backstitch at the beginning or end of

the seam. After sewing the permanent seam, pull the basting

stitch bobbin thread to remove the basting stitches [Fig. 5].

TOPSTITCHING and EDGESTITCHING

Embellish a garment or special project with topstitching.

Use a contrasting thread color for extra dimension.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 0 3 Blind hem

To topstitch, place fabric so the needle is 3/8” from the

finished edge of the fabric. Adjust the guide to butt up

against the fabric edge [Fig. 6]. Lower the foot and sew,

guiding the fabric edge along the foot guide [Fig. 7]. To

edgestitch, place the fabric so the needle is 1/8” from

the finished fabric edge. Adjust the guide, lower the

foot, and sew [Fig. 8].

GATHERING

Create beautiful ruffles and flounces with the gathering

technique.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 0 4 All-purpose

Sew a row of basting stitches 1/4” from the fabric edge.

Sew a second row of basting

stitches 1/2” from the fabric

edge [Fig. 9]. Do not backstitch. Gently pull the bobbin

thread from the underside of the fabric [

Fig. 10].Adjust

gathers evenly by pushing the fabric along the stitching.

Fig. 5

g. 7

Fi

Fig. 9

Fig. 6

Fig. 8

Fig. 10

16

Page 18

Fig. 1

Fig. 3

Fig. 2

g. 4

Fi

BUILT-IN STITCHES

STITCH “A” - STRAIGHT STITCH

ZIPPER INSERTION

The zipper foot is designed to allow you to sew close to

raised edges. Easily and accurately insert zippers and

covered cording or piping in seams using the zipper foot.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 0 3 Zipper

Remove the presser foot holder. Attach the zipper foot to

the presser foot bar. Raise the needle to the highest position. The foot can be adjusted to the left or right side of

the needle by loosening the screw on the foot, sliding

the foot and re-tightening the screw [Fig. 1].

To sew the right side of the zipper, adjust the zipper foot so

it is on the right side of the needle and the needle clears

the notch on the left side of the zipper foot [Fig. 2].

To sew the left side of the zipper, adjust the zipper foot so

it is on the left side of the needle and the needle clears

the notch on the right side of the zipper foot [Fig. 3].

Use ONLY the straight stitch with this foot.

PIPING INSERTION

Add decorativ

create designer fashion looks by inserting covered cord

or purchased piping within seams.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

e detail to home decorating projects and

A 0 3 Zipper

Fig. 5

Fig. 7

Narrow hem

Fig. 6

Fig. 8

Attach the zipper foot and adjust the sliding foot to the

right side of the needle. Baste the cord or piping to the

right side of one fabric piece along the seamline, using

the longest stitch length setting of 4 [Fig. 4].

Place the second layer of fabric with the first layer, right

sides together. Shorten the stitch length to 3 and stitch

the seam close to the piping [Fig. 5].

NARROW HEMMING

The narrow hem foot actually rolls the fabric edge to create

a narrow hem for napkins, ruffles, scarves, and dainty hem

finishes on clothing.

STITCH

A 0

STITCH WIDTH STITCH LENGTH PRESSER FOOT

3 Hemmer

Fold a 1/8” double hem to the wrong side of fabric, for

about 2” along the beginning of the hem [Fig. 6]. Place

the rolled edge of the hem under the presser foot. Lower

the foot and take several stitches. Stop with the needle

in the fabric [Fig. 7]. Raise the foot. Pick up the fabric

edge and roll it into the scroll of the foot. Lower the foot

and begin stitching slowly. Hold the fabric up and

slightly to the left as you sew [Fig. 8]. Practice makes

perfect with this technique!

17

Page 19

BUILT-IN STITCHES

STITCH “A” - ZIGZAG

OVEREDGING LIGHT TO MEDIUM WEIGHT FABRICS

The zigzag stitch is handy for overedging facings, hems,

and seam allowances to minimize raveling.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 3-5 2 Overcast

Position the fabric under the presser foot so the right

swing of the stitch forms just inside the edge of the fabric

[Fig. 1]. Test the position by turning the handwheel

toward you and manually "walking" the needle before

you begin sewing. Sew, guiding the fabric evenly.

BARTACKING

This stitch is excellent for reinforcing pocket corners and

belt loops. Because the feed teeth are lowered, there is

no need to make stitch length adjustments.

STITCH STITCH WIDTH DROP FEED PRESSER FOOT

A 4-5 Lowered All-purpose

Determine the location for the bar tack and position the

fabric under the needle.

Sew 4-6 stitches [F

Raise the needle to its highest position. T

width dial to 0 and sew 3-4 stitches to secure the stitch.

ig. 2].

urn the stitch

Fig. 1

Fig. 2

Overedging

Bartack

SATIN STITCH APPLIQUÉ

Use this popular, zigzag stitch creatively to sew appliqués.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 3-5 0.5-1 Open toe

Fuse a fabric appliqué shape to a base fabric. Place a

stabilizer beneath the base fabric [Fig. 3].

Satin stitch around the cut edges of the appliqué shape

guiding the fabric so the right s

wing of the stitch falls just

over the appliqué edge and into the base fabric [Fig. 4].

Fig. 3

Appliqué

Fig. 4

18

Page 20

Fig. 1

Fig. 3

Fig. 2

Fig. 4

BUILT-IN STITCHES

STITCH “A” - ZIGZAG

ATTACHING BUTTONS

Use this foot to quickly and securely attach flat buttons.

STITCH STITCH WIDTH DROP FEED PRESSER FOOT

A 5

Attach the button sewing foot. Set the stitch width to 0.

Position the button and fabric under the foot. Position the

needle over the left hole [Fig. 1]. Turn the handwheel to

make sure the needle clears the hole, and sew several

stitches to secure threads.

Turn the stitch width dial to 5 and reposition the fabric and

button to the left slightly so the needle is again aligned with

the left hole. Turn the handwheel to make sure the zigzag

stitch clears the holes of the button [Fig. 2]. Adjust the

stitch width, if needed. Sew 8-10 stitches [Fig. 3].

To secure the stitches, set the stitch width to 0, reposition

the needle over the button hole and sew a few stitches.

Remove the fabric and button from the machine and clip

the threads [Fig. 4].

Lowered Button attaching

Fig. 5

Seaming knits

SEAMING KNITS

A narro

it suitable

w zigzag stitch is very flexible and durable making

for medium to lightweight knit fabrics.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

A 2 2-3 All-purpose

Align the edge of the fabric with the seam guide markings

on the needle plate and sew the seam being careful not

to stretch the fabric as you sew [Fig. 5].

19

Page 21

BUILT-IN STITCHES

STITCH “B, D, E” - DECORATIVE SATIN STITCH

Using decorative stitches is one of the easiest and most

attractive ways to topstitch. Experiment with metallic,

rayon, or variegated threads for additional detail.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

B, D, E 3-5 .5-1 Open toe

Determine the placement of the stitching line. Place the

fabric under the presser foot and sew [Fig. 1]. Using a

stabilizer under the fabric will provide extra firmness.

STITCH “C” - SATIN SCALLOP HEM

Simply stitch and trim to create this lovely scallop finish.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

C 3-5 .5-1 Open toe

Mark the hem finish line on the fabric with a washout

fabric marker and stitch along the line [Fig. 2]. Place a

bead of seam sealant along the stitches and let dry. Trim

the fabric close to the stitching [Fig. 3].

Fig. 1

Fig. 2

Decorative satin stitches

Fig. 3

STITCH “F” - BLINDHEM

Eliminate time consuming hand sewing with the use of

the blindhem stitch. Use a thread color that matches the

fabric color for the best results.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

F 3-5 4 Blindhem

Turn up the finished edge of the fabric to the desired hem

depth [Fig. 4]. Fold back, leaving a 1/4” edge [Fig. 5].

Place garment under the foot with the folded edge along

the hem guide [Fig. 6]. Adjust the guide by turning the

screw so that the fabric fold is against the guide and the

needle just barely catches the fold as you sew. You may

need to sew a few test samples on scrap fabric to make

the correct guide adjustment on the presser foot.

Stitch slowly.

Satin scallop hem

Fig. 4

Fig 5

20

ig. 6

F

Blindhem (underside view)

Page 22

Fig. 1

g. 3

Fi

Fig. 2

Fig. 4

BUILT-IN STITCHES

STITCH “G” - SHELL STITCH

SEAMING NYLON TRICOT

Use the shell stitch for quick and easy, one-step seaming

and finishing on tricot and other soft fabrics.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

G 3-5 1-3 All-purpose

For 1/4” seam allowances, guide the fabric so the right

swing of the stitch forms just inside the edge of the fabric

[Fig. 1]. For 1/2” to 5/8” seam allowances, sew [Fig. 2],

then trim the excess fabric close to the stitching [Fig. 3].

DECORATIVE PICOT HEM

The shell stitch creates a lovely picot or scallop edge.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

G 5 4 All-purpose

Increase upper thread tension slightly by turning the dial

to a higher number.

Fold under the fabric edge. Place the fabric to the left of

the foot, with the fabric edge to the right of the foot. Sew

along the folded edge of the fabric so the right needle

swing drops just ov

the stitch puc

tension to its normal setting when sewing is complete.

er the fabric edge [Fig. 4].

kers the edge to create a dainty scallop. Return

The zigzag of

Picot hem

Fig. 6

Fig. 7

Fig. 5

Folk art appliqué

Decorative braid

FOLK ART APPLIQUÉ

Create the charming look of hand appliqué using the

blindhem stitch set at a short stitch length.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

G 4-5 1 Open toe

Fuse a fabric appliqué shape to a base fabric. Place a

stabilizer beneath the base fabric to support the stitches

[Fig. 5]. Stitch around the cut edge of the appliqué shape,

guiding the fabric so the left of the stitc

h sews just over

the appliqué edge into the base fabric and the right swing

takes one stitc

DECORA

h on the fabric shape [Fig. 6].

TIVE BRAID APPLICATION

Add glitzy detail to home decorating projects by attaching

purchased braid to the fabric surface.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

G 5 2-3 Open toe

Thread the machine in a color to match the braid.

Mark the braid placement on the fabric. Place the fabric

and braid under the foot and sew so the straight stitching

sews to the left of the braid and the right swing falls over

and to the right of the braid [Fig. 7].

21

Page 23

BUILT-IN STITCHES

STITCH “H” - DOUBLE ACTION

ENCASING ELASTIC

Create casings for 1/8” narrow elastic in minutes for

waistbands, cuffs, and craft items.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

H 5 4 All-purpose

Place the fabric wrong side up under the presser foot.

Insert the elastic through the front opening of the presser

foot, over the front and under the back. Leave a 1/2” tail

of elastic behind the foot. Begin sewing being careful not

to stitch the elastic [Fig. 1]. When sewing is complete,

pull the ends of the elastic until the desired amount of

fullness is obtained [Fig. 2]. Secure the ends of the elastic

with a straight stitch before sewing them into a seam.

STITCH “I” - THREE-STEP ZIGZAG

CHING FLAT ELASTIC

ATTA

STITCH STITCH WIDTH

I 3-5 2-4 All-purpose

STITCH LENGTH PRESSER FOOT

Fig. 1

Elastic casing

Fig. 2

Fig. 3

Place elastic and fabric under the presser foot.

Take a few stitches to anchor the elastic. Adjust the

width of the stitch to the width of the elastic.

Zigzag over the elastic, stretching the elastic in front of

the presser foot as you sew [Fig. 3].

OVERCASTING

The three-step zigzag is a strong stitch. It takes three

small stitches to the right and three

small stitches to the

left. Use the three-step zigzag stitch to overcast or clean

finish seam allowances. It is easier to overcast the raw

edges first before

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

I

seaming.

3-5 2-4 All-purpose

Position and guide the fabric under the presser foot so

the right swing of the stitch forms just inside the edge of

the fabric [Fig. 4].

MENDING

Use the three-step zigzag to repair small rips and tears.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

I 3-5 2-4 All-purpose

Place a stabilizer under the tear in the fabric. Sew

along the line of the tear [Fig. 5]. The stitch joins both

sides of the tear.

Fig. 4

Fig. 5

Overcasting

Mending

22

Page 24

BUILT-IN STITCHES

STITCH “J” - MULTI-CORD STITCHING

The cording foot evenly guides decorative threads as

you sew them in place.

Fig. 1

Multi-cord stitching

Fig. 4

Fig. 2

Fig. 3

Crazy quilt

STITCH

STITCH WIDTH STITCH LENGTH PRESSER FOOT

J 5 .5-2 Cording

Cut three strands of decorative cords (pearl cotton, baby

yarn, etc.) several inches longer than the finished length.

Use matching or contrasting thread in the needle. Before

attaching the foot to the machine, place the cords under

the spring plate and into the slots on the front of the foot

[Fig. 1]. Attach the foot to the machine. Place the fabric

and cords under the foot and sew [Fig. 2].

STITCH “K” - FEATHER STITCH

Crazy quilt patchwork is a wonderful way to use random-shaped fabrics and an excellent project for using

sewing machine stitches creatively.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

K 3-5 4 Open toe

Begin with a base fabric, suc

fabric with quilt batting (optional). Pin a fabric piece,

right side up, in the center of the base fabric. Place a

second piece of fabric on top of the first piece, right

sides together, aligning fabric edges. Sew a straight stitch

along the fabric edge [Fig. 3]. Flip the second piece over

and press the seam. Select stitch “K” and topstitch along

the finished seam [Fig. 4]. Continue to add, sew, and

topstitch fabric pieces, cove

fabric is cov

ered.

h as muslin. Top the base

ring raw edges until the base

23

Page 25

BUILT-IN STITCHES

STITCH “L” - HONEYCOMB

DECORATIVE RIBBON ATTACHING

This stitch is ideal for decorative topstitching. Use alone

or topstitch over ribbon or cording. Use a variegated

thread for extra pizzazz.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

L 5 4 All-purpose

Place the ribbon along the stitching line [Fig. 1].

When stitching over ribbon, it’s easiest to secure the

ribbon in place with fabric adhesive. Select a stitch

width to match the ribbon width and sew.

MOCK SMOCKING

Recreate elegant smocking in a fraction of the time it

takes to hand smock.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

L 4-5 4 All-purpose

Sew sev

the bobbin thread to gather fabric to the desired fullness.

Select the honeycomb stitc

Sew between the basting stitches [Fig. 2]. Remove the

basting stitches when complete.

eral rows of basting stitches on the fabric. Pull

h L.

Fig. 1

Fig. 2

Decorative honeycomb stitch

k smocking

Moc

STITCH

“M” - OVERLOCK

ATTACHING RIB KNIT TRIM

The overlock stitch is ideal for sewing knits and attaching

rib trim because it seams and overcasts at the same time.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

M 5 4 Overcast

For 1/4” seam allowances, guide the matched edges of

the seam allowances along the right edge of the

foot [Fig. 3].

For 1/2” to 5/8” seam allowances, guide the matched

edges of the seam allowances along the seam guide

marking on the needle plate [Fig. 4].

Sew, then trim the excess fabric close to the stitching

[Fig. 5].

Fig. 3

Fig. 5

Fig. 4

Rib knit trim

24

Page 26

BUILT-IN STITCHES

STITCH “N” - SLANT OVERCAST

SEAMING/OVERCASTING HEAVY WEIGHT FABRICS

Seam and overcast medium to heavyweight fabrics in

one step.

Fig. 1

Fig. 4

Fig. 2

ig. 3

F

Fig. 5

STITCH

N 5 4 Over

or 1/4” seam allowances, guide the matched edges of the

F

STITCH WIDTH STITCH LENGTH PRESSER FOOT

cast

seam allowances along the right edge of the foot [Fig. 1].

For 1/2” to 5/8” seam allowances, guide the matched

edges of the seam allowances along the seam guide

marking on the needle plate [Fig. 2].

Sew, then trim the excess fabric close to the stitching [Fig. 3].

STITCH “O” - ARROWHEAD

DECORATIVE FLAT FELL SEAMS

Use to creatively topstitch flat fell seams in knits and wovens.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

O 5 4 All-purpose

First, straight stitch a seam and press seam allowances to

one side [Fig. 4]. Select the stretch stitch B. Position the

fabric right side up under the presser foot, with the

pressed seam allowance to the left. Sew through all

three layers [Fig. 5].

Topstitch flat fell seam

25

Page 27

BUILT-IN STITCHES

STITCH “P or Q” - DECORATIVE EDGING

Add a touch of color to linens with this enticing decorative

stitch. A variegated thread used in the needle will add

dimension.

STITCH

P or Q 4-5 4 Open toe

STITCH WIDTH STITCH LENGTH PRESSER FOOT

Determine the stitching placement line. Place the finished

edge under the foot at the placement line and sew [Fig. 1].

It may be necessary to use a tear-away stabilizer under the

fabric for extra stability.

STITCH “R” - DECORATIVE TRIM

Stitch up matching trims for clothing or home decorating

projects by sewing a decorative stitch on purchased ribbon

1/2” wide or wider.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

R 3-5 4 All-purpose

Position the ribbon under the center of the presser foot and

sew [Fig. 3]. You may need to use a tear-away stabilizer

under the ribbon for extra stability.

Fig. 1

Fig. 3

Decorative edging

ative trim

Decor

26

Page 28

Fig. 1

Fig. 2

BUILT-IN STITCHES

Seaming stress areas

Seaming knits

STITCH “S” - TRIPLE STRETCH STRAIGHT

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

S 0 4 All-purpose

SEAMING BIAS CURVES

The triple stitch action of the stretch straight stitch offers

flexible and durable seams. Use it to sew stress areas such

as the crotch seams in pants or the sleeve underarm area.

Align the fabric edge with the seam guide marking on the

needle plate. Stitch the seam, guiding the fabric along the

seam guide [Fig. 1]. The machine takes two stitches forward

and one stitch back to create this durable seam.

SEAMING DOUBLE KNITS

The flexibility of the straight stretch stitch makes it ideal

for seaming heavy or double knits.

Align the fabric edge with a seam guide marking on the

needle plate [Fig. 2]. Stitch the seam, carefully guiding

the fabric edge along the seam guide.

TRIPLE TOPSTITCHING

Use this stitch for a bold, contrasting topstitch.

Stitch 1/4” away from the finished edge of the fabric. Use

the outer edge of the all-purpose presser foot as a guide

[Fig. 3] or use the adjustable blindhem foot as described

on page 16 under Topstitching and Edgestitching.

Fig. 3

Fig. 4

Fig. 5

Triple topstitch

Overcasting heavy fabrics

Decorative rick rack

STITCH “S” - RICK RACK

OVERCASTING HEAVY FABRICS

Sew on heavier weight stretch fabrics in any area you

would use a zigzag stitch.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

S

Position the fabric under the presser foot and guide the

fabric so the right swing of the stitch forms just inside

the edge of the fabric [Fig. 4].

Test the position by turning the handwheel toward you and

manually “walking” the needle before you begin sewing.

DECORATIVE RICK RACK

An ideal decorative edge finish for neckbands, armholes,

sleeves, and hems.

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

S 3-5 4 All-purpose

h along the finished edge of a project using a con-

Stitc

asting thread for added dimension [Fig. 5].

tr

3-5 4 Overcast

27

Page 29

BUILT-IN STITCHES

STITCH “T” - ONE-STEP BUTTONHOLE

CLASSIC BUTTONHOLES

The buttonhole foot makes made-to-measure buttonholes in

one easy step. The size of the buttonhole is automatically set

by placing the button in the back of the buttonhole foot. It

will hold a button up to 1˝ (2.5cm) in diameter

STITCH STITCH WIDTH STITCH LENGTH PRESSER FOOT

T .5 or Yellow range 5 or Yellow range Buttonhole

Place your button on the back of the buttonhole foot

and slide the gauge toward the button to hold it securely

in place [Fig. 1]. Mark the buttonhole on your fabric

with a washable marker [Fig. 2]. Attach the foot to the

presser foot holder with the button in the back. Pull the

buttonhole lever down as far as it will go and pull it forward [Fig. 3]. Place fabric underneath foot, aligning the

needle with the front bartack [Fig. 4]. Sew slowly, stopping

the machine when buttonhole is completed. The front

bartack and left side will sew first, then the back bartack

and right side.

Raise the needle and presser foot. Remove the fabric [Fig. 5]

and trim the thread near the stitching. Using the seam ripper,

carefully cut an opening in the middle of the buttonhole

[Fig. 6]. Be careful not to cut any stitches. You may want to

put a straight pin across both ends of the buttonhole to help

prevent cutting the buttonhole bartacks.

.

Fig. 1

Fig. 2

Fig. 3

CORDED BUTTONHOLES

Create a bolder buttonhole by stitching over a heavier

thread or cord such as buttonhole twist.

Begin with a 10” strand of heavy thread or cord and loop its

midpoint over the spur at the back of the buttonhole foot

[Fig. 7]. Slip the ends into the slot at the front of the foot

[Fig. 8]. Sew the buttonhole as usual and the stitches will

form over the cord. Remove the fabric from the machine

and pull the ends of the cord to hide the loop under the

k [Fig. 9]. Snip the excess cord length [Fig. 10].

bartac

Fig. 7

Fig. 8

28

Fig. 4

Fig. 6

g. 9

Fi

Fig. 5

Fig. 10

Page 30

FREE-MOTION SEWING

Free-motion sewing is easily accomplished. Lower the feed teeth, remove the presser foot and presser foot holder,

and attach the embroidery foot [Fig. 1]. This allows “free” movement of the fabric in any direction. Use stitch “A”

and a stitch width setting from 0-5. There is no need to adjust the stitch length because you will actually be guiding

the fabric movement. Use free-motion sewing to monogram, embroider, quilt, or darn.

MONOGRAMMING

STITCH STITCH WIDTH DROP FEED PRESSER FOOT

A 4-5 Lowered Embroidery

Mark the letter or letters to be monogrammed on the fabric with a wash-out marker. Place the fabric and stabilizer

Fig. 1

Fig. 3

Fig. 2

Fig. 4

into a machine embroidery hoop. Raise the needle to its

highest position and slide the hoop under the needle.

Lower the presser foot lever.

To lock the stitching, set the width at 0, hold the needle

thread in the left hand and turn the hand wheel toward

you to draw up the bobbin thread [Fig. 2].

threads firmly, take three to

five stitches in one spot. Set the

Holding

stitch width to 5. Begin sewing at a medium speed. Move

the hoop left to right, forw

marked letter [F

OUTLINE Q

ig. 3].

UILTING

ard and backward, following the

g. 5

Fi

Note: Relax your shoulders and breathe while

you work. Place hands firmly around the hoop,

using your index and middle fingers to guide the

fabric. Be sure to lower the presser foot lever

before sewing!

STITCH STITCH WIDTH DROP FEED PRESSER FOOT

A 0 Lowered Embroidery

Baste or pin-baste the fabric, batting, and backing

together. It is not necessary to place this in a hoop.

Select a design already in the fabric or transfer your own

design using a template. Continue with the directions

above following the design line [Fig. 4].

DARNING

STITCH STITCH WIDTH DROP FEED PRESSER FOOT

A 3-5 Lowered Embroidery

Place a stabilizer under the hole or tear.

Place the fabric under the foot. Lower the foot and sew,

moving the fabric from left to right and up and down

until the hole is completely covered [Fig. 5].

Use a thread to match the fabric color for a nearly

invisible mend.

29

Page 31

SPECIALTY SEWING TECHNIQUES

SEWING WITH TWO THREADS

Create a bold look or add extra color to a stitch by sewing

with two threads through the upper threading path. Use a

size 16 needle or topstitching needle (not included) which

has a larger eye to accommodate two threads.

STITCH STITCH WIDTH LENGTH PRESSER FOOT

Any 0-5 1.5-4 Any

Place a spool of thread on the left spool pin with the thread

coming off the back. Thread the machine as usual. Place a

second spool of thread on the right spool pin with the thread

coming off the front [Fig. 1]. Thread the machine along the

same path and through the needle eye as for the first thread.

Select a stitch and sew.

TWIN NEEDLE SEWING

Your sewing machine is designed for twin needle

sewing, which allows you to sew with two top threads

forming parallel stitching lines simultaneously. The twin

needle [Fig. 2, not included] has two needles mounted

to a single shank. Any stitch pattern, except for the buttonhole, can be sewn with the twin needle. Do not use a

stitch width greater than 3. Before stitching, manually turn

the handwheel to make sure the needles clear the presser

foot and needle plate.

DOUBLE STITCHED HEM

STITCH STITCH WIDTH LENGTH PRESSER FOOT

Any 0-3 1.5-4 Open toe

Press up a 1-1/2˝ hem. Stitch on the top side of the fabric,

one inch from the fold of the hem [Fig. 2]. Trim the excess

hem allowance on wrong side of fabric close to the stitching.

Fig. 1

Fig. 2 Twin needle

Fig. 4

Fig. 3

Double stitched hem

SEWING OVER DENSE SEAMS

Use a size 14 or 16 needle when sewing through multiple

layers of heavy fabric. The needle will penetrate the fabric

more easily.

STITCH STITCH WIDTH LENGTH PRESSER FOOT

A 0 3-4 All-purpose

When you come to the side seam of the pant hem, place a

shim (such as a piece of cardboard the same thickness as the

seam) under the foot and against the seam [Fig. 5]. This levels

the foot so the machine can sew through the extra thickness.

Use a roller foot (not included) with this technique when

hemming jeans to aid in sewing over the dense side seams.

The textured rollers on the foot will help feed the fabric.

30

Fig. 5 Cardboard shim

Page 32

CARE AND MAINTENANCE

To ensure the best possible operation of your machine, it is necessary to keep the essential parts clean

at all times. Disconnect the machine from the power source before performing any maintenance.

NEEDLES

The Simplicity sewing machine uses standard sewing

machine needles (15x1). The size and type of your needle should be compatible with the fabric (see page 15).

Change the needle often – after every other project is a

good habit. Bent or dull needles will cause skipped

stitches and thread breakage.

Fig. 1

Fig. 2

R ace

Shuttle

keepers

To change the needle, loosen the needle clamp screw

[Fig. 1]. Remove the needle by pulling it downward [Fig.

2]. Insert the new needle by pushing it up into the shaft

as far as it will go with the flat side toward the back of

the machine. Tighten the needle clamp screw.

Shuttle

Shuttle area

g. 3

Fi

Fig. 5

Shuttle ra ce cover

Bo bbin case

Fig. 4

Fig. 6

CLEANING FEED TEETH and SHUTTLE AREA

Raise the needle to its highest position. Remove both the

needle plate screws and the needle plate [Fig. 3].

Remove the bobbin case from the shuttle. Push aside the

two shuttle keepers and remove the shuttle race cover

and shuttle. Clean the feed teeth and shuttle area with a

lint brush [Fig. 4]. Turn the hand wheel until you see the

race forming a half moon as pictured [Fig. 5]. Holding

the shuttle by its center pin, place it on top of the race so

that it forms a half moon on the top side [Fig. 6]. Place

the shuttle race cover over the shuttle and race. Snap the

shuttle keepers back into position. Replace bobbin case.

Replace the needle plate and screws.

CHANGING the LIGHT BULB

Open the left side face cover. Turn the light bulb clockwise

to unscrew and remove the bulb. Install a new bulb by

turning it counter clockwise to screw it in place [Fig. 7].

Use a 15W (max.) screw-in type bulb.

OILING

Put 2-3 drops of sewing machine oil at each of the

points indicated [F

Run the machine unthreaded for 30-60 seconds. Wipe

off any excess oil. Oil every 7-10 hours of use. Use

sewing mac

ig. 8].

hine oil ONLY.

Fig. 7

Fig. 8

31

Page 33

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

TOP THREAD BREAKS Machine is threaded incorrectly . . . . . Rethread machine and needle

Tension is too tight . . . . . . . . . . . . . . . Reduce tension on top to a smaller number

Thread is too heavy for needle size . . . Use

Needle is inserted incorrectly

Needle is damaged . . . . . . . . . . . . . . . Insert new needle

hread is caught on spool pin . . . . . . . Remove spool, unwind excess thread, clip, turn spool

T

LOWER THREAD BREAKS Bobbin case is not inserted correctly . . Reposition bobbin. If thread pulls smoothly, it is correct

Bobbin case is improperly threaded . . . . Refer to instructions for correct threading

Bobbin tension is too tight. . . . . . . . . . Change bobbin tension according to instructions

SKIPPED STITCHES Needle is not inserted correctly. . . . . . Reinsert needle with flat side toward back

Needle is damaged . . . . . . . . . . . . . . . Insert new needle

Wrong type of needle is used . . . . . . . Match needle size to fabric and thread weight

Wrong presser foot is used . . . . . . . . . Check the proper presser foot needed for specific task

Foot pressure is wrong. . . . . . . . . . . . . Check foot pressure regulation for proper setting

. . . . . . . Reinsert needle with flat side toward back

a larger needle

over, and use felt disc on spool pin

NEEDLE BREAKS

STITCHING FORMS LOOPS Needle is not threaded correctly . . . . . Thread needle from front to back

SEAMS SHRINK OR PUCKER Presser foot pressure is too heavy . . . . Reduce presser foot pressure to a lower number

THREAD BUNCHING OR Top tension is too loose. . . . . . . . . . . . Increase top tension to a higher number. Normal

“NESTING” ON UNDERSIDE settings are between 3-5.

OF FABRIC Machine is not threaded correctly . . . . Rethread machine making sure presser foot is raised

Needle is damaged . . . . . . . . . . . . . . . Insert new needle

Needle is not inserted correctly. . . . . . Reinsert needle with flat side toward back

Fabric is too heavy/wrong needle size

abric is being pulled during sewing . . Chec

F

Bobbin is not threaded correctly . . . . . Check instructions for proper bobbin threading

Improper needle and/or thread used . . Match needle size to fabric and thread weight

Bobbin case is improperly threaded. . . . Refer to instructions for correct threading

Thread is of poor quality . . . . . . . . . . . Use quality thread

Needle is too large for fabric . . . . . . . . Use a smaller size needle

Wrong stitch length is used . . . . . . . . . Adjust length for proper stitches

Top and bottom threads are not. . . . . . Draw both threads back under the presser foot and

drawn back under the presser hold until a few stitches have formed

foot before sewing

. . Match needle size to fabric and thread weight

k for proper foot pressure; make sure feed teeth

are raised and operating correctly; lengthen stitch

length. Fabric should feed automatically. Pulling the

fabric will thro

and the take-up lever eye is threaded. Raising the

presser foot will help seat the thread between the

tension discs.

w the machine out of time.

32

Page 34

TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

IRREGULAR STITCHING Thread is of poor quality . . . . . . . . . . . Use quality thread

AND FEEDING Presser foot pressure is too light . . . . . Increase presser foot pressure to a higher number

Bobbin is not threaded correctly . . . . . Thread bobbin again and c

abric is being pulled during sewing . . Check for proper foot pressure; make sure feed teeth

F

are raised and operating correctly; lengthen stitch

length. F

fabric will throw the machine out of time.

MACHINE IS NOISY AND Machine needs oil. . . . . . . . . . . . . . . . Refer to cleaning and maintenance instructions

ROUGH WHEN SEWING Lint and oil residue have collected . . . Clean race and hook according to instructions

in hook or on needle bar

Inferior oil has been used . . . . . . . . . . Clean and oil again. Use only fine sewing machine

oil. Do not use WD40.

Needle is damaged . . . . . . . . . . . . . . . Insert new needle

Stitch length and/or width dials are set . Refer to instructions for proper machine settings

incorrectly for the type of stitch used

abric should feed automatically. Pulling the

heck for proper insertion

33

Page 35

1760 Gilsinn Lane

Fenton, MO 63026

For Sewing Machine assistance call:

Simplicity Education Department

636-651-0030

Monday-Friday 9:00 a.m. - 5:00 p.m. CT

IBSA2200©2002 Tacony Corporation

Loading...

Loading...