Page 1

Print Instructions for Print Vendors (Paper Manuals)

PAR

TS MANUAL

TOTAL PAGE COUNT: Less than 80

Paper Size: • 11 x 17

• Body - 50 lbs brilliant white offset or equivalent.

• Cover - on 80 lbs coated, pre-printed “grid” cover stock

(NOTE: If total order quantity is less than 100 pieces, use uncoated cover stock)

Press: • Body - 1-color, 2-sided

• Cover imprint - 1-color, 2-sided

Bindery: • Fold & Staple (2X), Face Trim, 3-Hole Drill

TOTAL PAGE COUNT: 80 or greater

Paper Size: • 8-1/2 x 11

• Body - 50 lbs brilliant white offset or equivalent.

• Cover - on 80 lbs coated, pre-printed “grid” cover stock

(NOTE: If total order quantity is less than 100 pieces, use uncoated cover stock)

Press: • Body - 1-color, 2-sided

• Cover imprint - 1-color, 2-sided

Bindery: • Perfect Bind, Face Trim (3 knife), 3-Hole Drill

GENERAL

COVERS: • Covers are located at the beginning of this package.

• Back cover is the page IMMEDIATELY AFTER the front cover.

• If supplied, the “Hardware Identification & Torque Specifications” is located IMMEDIATELY AFTER

the back cover. This page MUST be printed on the INSIDE of the BACK cover.

• Check the front cover for the individual part number (typically a 2xxxx or 182xxxx number).

• Check the front cover for the document number (TP 4xx - xxxx - xx - xx - xx)

BODY: •ODD number pages are ALWAYS right hand pages, and EVEN number are ALWAYS left hand

pages.

General: • This instruction page is NOT part of the manual and must NOT be printed.

• Pages labeled with the text “THIS PAGE INTENTIONALLY BLANK” are placement pages ONLY,

and should NOT be printed.

If you have any further questions regarding this manual, please contact Ken Cehonski in

Ferris Industries Engineering Department at (315) 495-0100 ext. 249.

Page 2

THIS PAGE INTENTIONALLY BLANK

Page 3

TM

Parts Manual

1822418

Revision 01

Rev. Date: 1/2004

D-PAC-PAR-01

The Pacer

Walk Behind Mower

Model:

HW1436

mowers are built by

Ferris Industries, a

Simplicity company.

Ferris Industries

5375 North Main Street

Munnsville, NY 13409

800-933-6175

TM

Page 4

Ferris Industries

5375 North Main Street

Munnsville, NY 13409

800-933-6175

www.ferrisindustries.com

© Copyright 2004 Ferris Industries

All Rights Reserved. Printed in USA.

Page 5

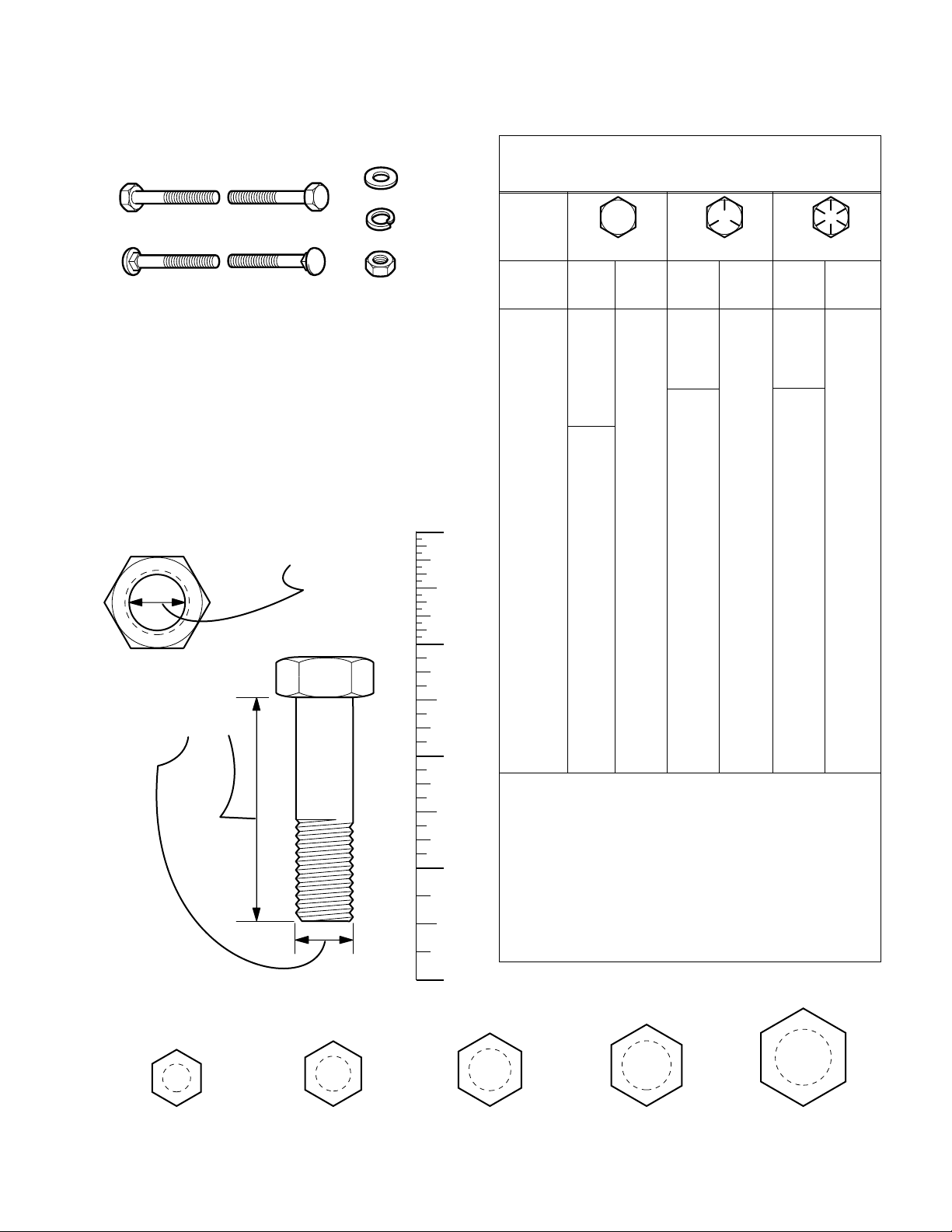

Hardware Identification & Torque Specifications

Common Hardware Types

Hex Head Capscrew

Carriage Bolt

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

nominal size

second number is present it represents the

When a bolt or capscrew is identified as 1/2 - 16 x 2” , this

means the

second number represents the

example), and the final number is the

bolt or screw (2 inches long in this example).

, meaning the

nominal size

inside diameter

, or

body diameter

threads per inch

body length

Washer

Lockwasher

Hex Nut

is 1/2 inch; if a

threads per inch.

is 1/2 inch; the

(16 in this

of the

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

0

Nut, 1/2”

Inside

1/4 3/4

1/2

Diameter

1

1/4 3/4

1/2

Screw, 1/2 x 2

Body

Diameter

Body

Length

2

1/4 3/4

1/2

3

1/4 3/4

1/2

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

Size Of

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0 420 571.2

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. For prevailing torque locknuts:

use 65% of Grade 5 torque.

b. For flange whizlock nuts and screws:

use 135% of Grade 5 torque.

3. Unless otherwise noted on assembly drawings,

all torque values must meet this specification.

No

Marks

SAE Grade 2 SAE Grade 5 SAE Grade 8

3.4

3.5

4.9

5.5

in/lbs

41

43

60

68

in/lbs in/lbs

19

20

27

31

66

76

2.1

2.3

3.1

3.5

7.6 8 10.9 12 16.3

8.6 10 13.6 14 19.0

30

31

43

49

NOTES

4.6

4.9

6.8

7.7

Wrench & Fastener Size Guide

1/4

1/4” Bolt or Nut

Wrench—7/16”

5/16

5/16” Bolt or Nut

Wrench—1/2”

4

3/8

3/8” Bolt or Nut

Wrench—9/16”

7/16

7/16” Bolt or Nut

Wrench (Bolt)—5/8”

Wrench (Nut)—11/16”

1/2

1/2” Bolt or Nut

Wrench—3/4”

Page 6

THIS PAGE INTENTIONALLY BLANK

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

REF NO. PART NO. QTY. DESCRIPTION

Handle Bar Group

9

D-PAC-PAR-01

The above parts group applies to the following Model Nos.:

HW1436 Pacer 14 HP Walker w/ 36” Mower

1 1845480 1 HANDLE BAR ASSEMBLY

2 20837 2 GRIP, Foam

3 1844625 1 BRAKE HANDLE, Complete (Includes Ref 4)

4 25510 5 GRIP, Foam

5 45477 1 BRAKE SHAFT COVER

6 1845575 1 BRAKE HANDLE MOUNT

7 22095 1 SWITCH, Brake

8 1845584 1 BRAKE HANDLE SHAFT

9 25139 2 NUT, Hex, Serrated Flange, 5/16-18

10 21242 1 SPRING, Extension

11 25155 1 WASHER, 5/16

12 25011-12 1 CAPSCREW, Hex Hd, 5/16-18 x 1-1/2

13 50832-3 1 BRAKE CABLE

14 1843424 1 SWITCH ROD

15 43417 2 HEX ADJUSTER

16 25034 2 NUT, Hex, 5/16-18

17 1845485 1 HANDLE, Operator Presence, RH, Complete (Includes Ref 18)

18 21490 2 GRIP, Vinyl

19 1845484 1 HANDLE, Operator Presence, LH, Complete (Includes Ref 18)

20 20637 1 SPRING, Compression

21 25010-24 1 CAPSCREW, Hex Hd, 1/4-20 x 3

22 25095 1 NUT, Hex, Nylon Lock, 1/4-20

23 1841982 2 BRAKE HANDLE, Complete (Includes Ref 4)

24 42547 2 BRAKE HANDLE ROD

25 25220 2 SHOULDER BOLT, 1/2 x 1-1/2

26 20047 2 COLLAR, 5/16 Set

27 25033 6 NUT, Hex, 5/16-24

28 20979 6 CLEVIS, Plastic, 5/16

29 42554 2 THUMB CONTROL ROD

30 1845483 1 CONTROL PIVOT, RH

31 1845482 1 CONTROL PIVOT, LH (not shown)

32 25223 4 SHOULDER BOLT, 1/2 x 1

33 1842614 2 THUMB CONTROL LEVER, Complete (Includes Ref 4)

34 1842648 2 BRAKE PIVOT

35 42624 2 CABLE CLAMP

36 1842623 1 SUPPORT, Handle Bar

37 1842682 1 SUPPORT, Engine Deck

38 21769 1 SWITCH, Operator Presence

39 22180 1 SWITCH, PTO

40 20927 1 SWITCH, Ignition

41 20811 1 CABLE, Throttle

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Loading...

Loading...