Page 1

Regent Series Riding Mower

1737264

Revision D

Operator’s Manual

Mfg. No. Description

2690810 Regent, 19.5HP Hydro Tractor and 38” Mower Deck

Not for

Reproduction

Page 2

2

General Information

Thank you for purchasing this quality-built SIMPLICITY riding mower. We’re pleased that you’ve placed your confidence in

the SIMPLICITY brand. When operated and maintained according to the instructions in this manual, your SIMPLICITY

product will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with riding mowers and

how to avoid them. This product and its approved attachments/accessories are designed and intended only for lawn work

or snow removal and are not intended for any other purpose. It is important that you read and understand these

instructions thoroughly before attempting to start or operate this equipment. Save these original instructions for future

reference.

The Illustrated Parts List for this machine can be downloaded from www.simplicitymfg.com. Please provide model and

serial number when ordering replacement parts.

Copyright © 2010 Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, All rights reserved.

SIMPLICITY is a trademark of Simplicity Manufacturing, Inc.

Milwaukee, WI USA

ENGINE REFERENCE DATA

Model Description Name/Number

Unit MFG

Number

PRODUCT REFERENCE DATA

Unit SERIAL Number

Dealer Name

Date Purchased

Engine Make

Engine Type/Spec

Engine Model

Engine Code/Serial Number

Mower Deck MFG Number

Mower Deck SERIAL

Number

When contacting your authorized dealer for replacment

parts, service, or information you MUST have these

numbers.

Record your model name/number, manufacturer’s identification numbers, and engine serial numbers in the space provided for easy access. These numbers can be found in the

locations shown.

Tractor ID Tag

Product Identification Tag

Product Reference Data

Not for

Reproduction

Product Identification Tag

Model / Modéle / Model xxxxxxxx

Serial / Sèrie / Serie xxxxxxxxxx

Briggs & Stratton Power Products Group, L.L.C.

Milwaukee, WI 53201 USA

Page 3

3

Operator Safety........................................................................................4

Decal Locations......................................................................................9

Features and Controls...........................................................................10

Tractor Controls ....................................................................................10

Parking Brake Function.........................................................................12

Cruise Control ......................................................................................12

Operation ................................................................................................13

Safety Interlock System Tests ...............................................................13

Adding Fuel ..........................................................................................13

Starting the Engine ...............................................................................13

Driving the Tractor.................................................................................14

Mowing.................................................................................................14

Mowing in Reverse (RMO) ...................................................................14

Pushing the Tractor by Hand.................................................................15

Adjusting Mower Cutting Height ...........................................................15

Attaching a Trailer.................................................................................15

Stopping the Tractor and Engine...........................................................15

Maintenance ...........................................................................................16

Maintenance Chart...............................................................................16

Check Tire Pressure .............................................................................16

Check Mower Blade Stopping Time .....................................................16

Battery Maintenance ............................................................................17

Cleaning the Battery and Cables..........................................................17

Battery Charging ..................................................................................17

Seat Adjustment...................................................................................17

Storage.................................................................................................18

Troubleshooting.....................................................................................19

Warranties...............................................................................................21

Specifications.........................................................................................23

Parts and Accessories ..........................................................................23

TABLE OF CONTENTS

Not for

Reproduction

Page 4

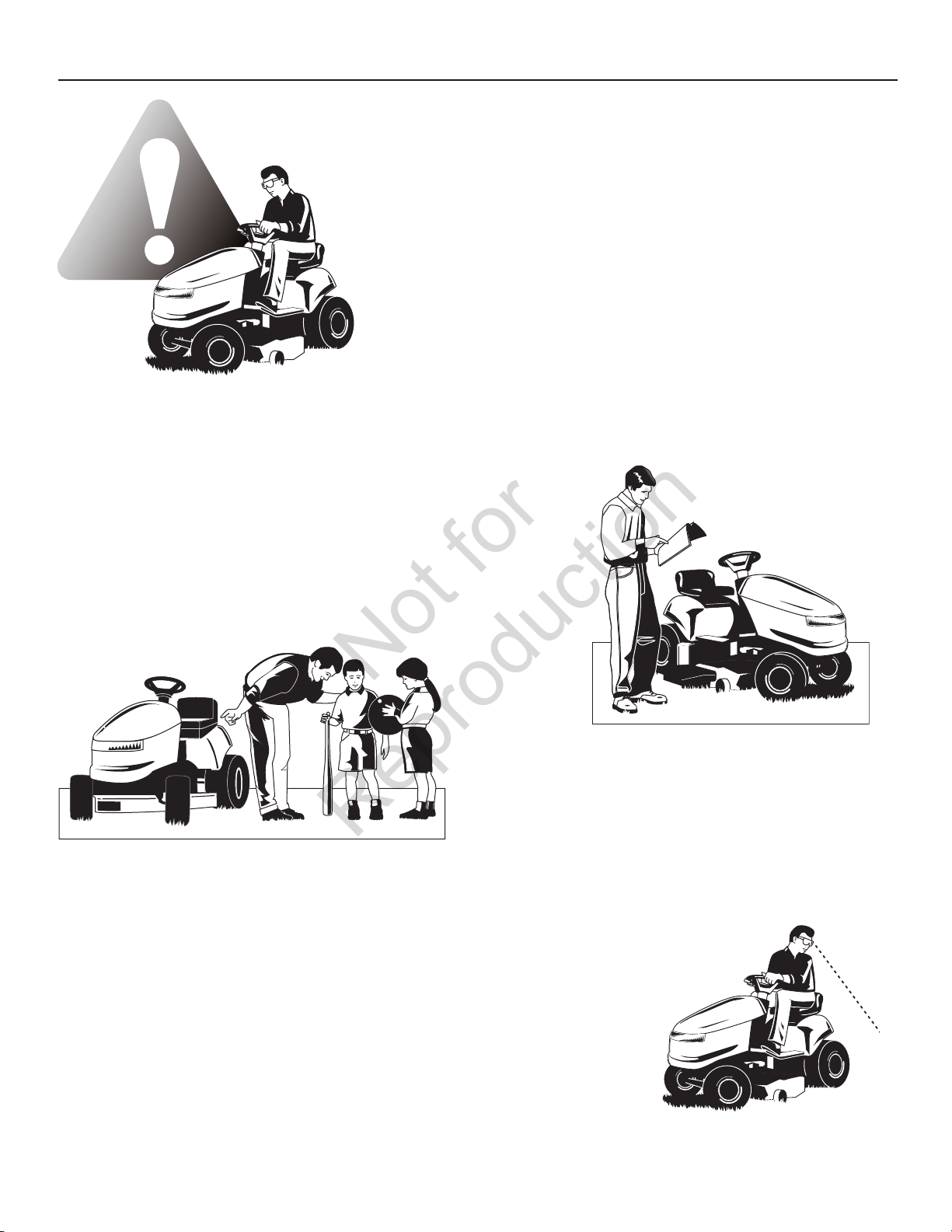

Operating Safety

Congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or

exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is misused, or not

properly maintained, it can be dangerous! Remember, you are responsible for your safety and that of those around you.

Use common sense, and think through what you are doing. If you are not

sure that the task you are about to perform can be safely done with the

equipment you have chosen, ask a professional: contact your local authorized dealer.

Read the Manual

The operator’s manual contains important safety information you need to be

aware of BEFORE you operate your unit as well as DURING operation.

Safe operating techniques, an explanation of the product’s features and

controls, and maintenance information is included to help you get the

most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on

the following pages. Also completely read the Operation section.

Children

Tragic accidents can occur with children. Do not allow them

anywhere near the area of operation. Children are often attracted to the unit and mowing activity. Never assume that

children will remain where you last saw them. If there is a

risk that children may enter the area where you are mowing, have another responsible adult watch them.

DO NOT GIVE CHILDREN RIDES ON THIS UNIT! This

encourages them to come near the unit in the future while it

is running, and they could be seriously hurt. They may then

approach the unit for a ride when you are not expecting it,

and you may run over them.

Reverse

Do not mow in reverse unless absolutely necessary. Always look

down and behind before and

while traveling in reverse

even with the mower

blades disengaged.

OPERATOR SAFETY

4 www.simplicitymfg.com

Not for

Reproduction

Page 5

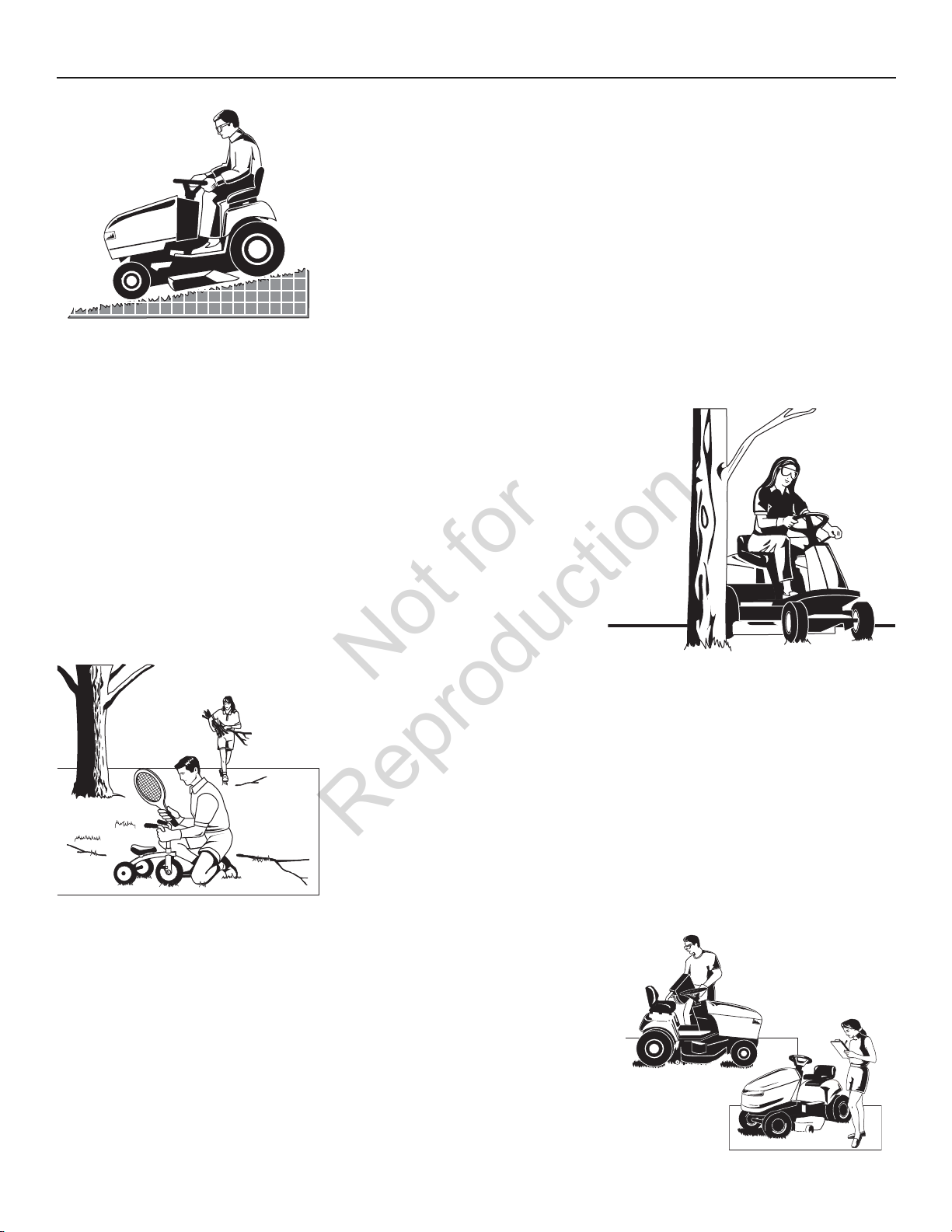

OPERATOR SAFETY

5

3.5 ft

(1,5 m)

20.0 ft (6,0 m)

Slope Operation

You could be seriously injured or even killed if you use this unit on too

steep an incline. Using the unit on a slope that is too steep or where you

don’t have adequate traction can cause you to lose control or roll over.

A good rule of thumb is to not operate on any slope you cannot back up

(in 2-wheel drive mode). You should not operate on inclines with a slope

greater than a 3.5 ft (1,5 m) rise over a 20.0 ft (6,0 m) length. Always

drive up and down slopes: never cross the face.

Also note that the surface you are driving on can greatly impact stability

and control. Wet grass or icy pavement can seriously affect your ability

to control the unit.

If you feel unsure about operating the unit on an incline, don’t do it. It’s

not worth the risk.

Moving Parts

This equipment has many moving parts that can injure you or someone else. However, if you are seated in the seat properly, and follow all the rules in this book, the

unit is safe to operate.

The mower deck has spinning mower blades that can amputate hands and feet.

Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an operatorpresent safety system. Do NOT attempt to alter or bypass the system. See your

dealer immediately if the system does not pass all the safety interlock system

tests found in this manual.

Thrown Objects

This unit has spinning mower blades. These blades can pick up and throw debris

that could seriously injure a bystander. Be sure to clean up the area to be

mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard (deflector) in place.

Also, do not allow anyone in the area while the unit is running! If someone does

enter the area, shut the unit off immediately until they leave.

Fuel and Maintenance

Gasoline is extremely flammable. Its vapors are also extremely flammable and

can travel to distant ignition sources. Gasoline must only be used as a fuel, not

as a solvent or cleaner. It should never be stored any place where its vapors

can build up or travel to an ignition source like a pilot light. Fuel belongs in an

approved, plastic, sealed gas can, or in the tractor fuel tank with the cap securely closed. Spilled fuel needs to be cleaned up immediately.

Proper maintenance is critical to the safety and performance of your unit. Be

sure to perform the maintenance procedures listed in this manual, especially periodically testing the safety system.

Not for

Reproduction

Page 6

GENERAL OPERATION

1. Read, understand, and follow all instructions in the

manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at all

times.

3. Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

4. Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blade(s).

5. Be sure the area is clear of other people before mowing. Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary. Always look down and behind before and while travelling

in reverse.

8. Never direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction. Material may ricochet back toward the operator. Stop the

blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety devices in place.

10. Slow down before turning.

11. Never leave a running unit unattended. Always disengage the PTO, set parking brake, stop engine, and remove keys before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete stop

before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of alcohol or drugs.

15 Watch for traffic when operating near or crossing road-

ways.

16. Use extra care when loading or unloading the unit into a

trailer or truck.

17. Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and above,

are involved in a large percentage of power equipmentrelated injuries. These operators should evaluate their

ability to operate the equipment safely enough to protect themselves and others from injury.

19. Follow the manufacturer’s recommendations for wheel

weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers. Never

operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades and

blade hardware are present, intact, and secure. Replace worn or damaged parts.

24. Disengage attachments before: refueling, removing an

attachment, making adjustments (unless the adjustment

can be made from the operator’s position).

25. When the machine is parked, stored, or left unattended,

lower the cutting means unless a positive mechanical

lock is used.

26. Before leaving the operator’s position for any reason,

engage the parking brake (if equipped), disengage the

PTO, stop the engine, and remove the key.

27. To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

28. It is a violation of California Public Resource Code Section 4442 to use or operate the engine on or near any

forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark arrester meeting any applicable local or state laws. Other

states or federal areas may have similar laws.

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of unit,

severe personal injury or death to you, or bystanders, or damage to property or equipment. This mowing deck

is capable of amputating hands and feet and throwing objects. The triangle in text signifies important cautions or warnings which must be followed.

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If the

unit is facing backwards, wind lift could damage the unit.

2. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an ignition source (such as a furnace, water heater, etc.) and

cause an explosion. Fuel vapor is also toxic to humans

and animals.

4. Always follow the engine manual instructions for storage preparations before storing the unit for both short

and long term periods.

5. Always follow the engine manual instructions for proper

start-up procedures when returning the unit to service.

6. Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a water

heater. Allow unit to cool before storing.

OPERATOR SAFETY

6 www.simplicitymfg.com

Not for

Reproduction

Page 7

OPERATOR SAFETY

7

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the mowing activity. Never assume that children will remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind and

down for small children.

4. Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with

safe unit operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over by

the machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tipover accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not operate

on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake.

The main reasons for loss of control are: insufficient tire grip

on the ground, speed too fast, inadequate braking, the type

of machine is unsuitable for its task, lack of awareness of the

ground conditions, incorrect hitching and load distribution.

1. Mow up and down slopes, not across.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to stop

or change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Always keep unit in gear especially when traveling

down slopes. Do not shift to neutral and coast downhill.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengage the blade(s) and proceed

slowly straight down the slope.

7. Keep all movement on slopes slow and gradual. Do not

make sudden changes in speed or direction, which

could cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the stability of the unit. Do not use on steep slopes.

9. Do not try to stabilize the machine by putting your foot

on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes you cannot back up them.

13. See your authorized dealer/retailer for recommendations of wheel weights or counterweights to improve

stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes even

through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

TOWED EQUIPMENT (RIDE-ON UNITS)

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturer’s recommendations for weight

limit for towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel weights

or counterweights. See your dealer/retailer to

determine which weights are available and appropriate

for your unit.

Select slow ground speed before driving onto slope. In

addition to front weights, use extra caution when

operating on slopes with rear-mounted grass catchers.

Mow UP and DOWN the slope, never across the face,

use caution when changing directions and DO NOT

START OR STOP ON SLOPE.

Not for

Reproduction

Page 8

8

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as near a

water heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing immediately.

10. Never over-fill the fuel tank. Replace gas cap and

tighten securely.

11. Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment bolts,

tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if they

are not functioning properly.

4. Keep unit free of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage. and remove any fuelsoaked debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer’s recommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service

as required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot as

spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline additives, or white gas because engine/fuel system damage

could result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replace faulty silencers/mufflers.

15. Use only factory authorized replacement parts when

making repairs.

16. Always comply with factory specifications on all settings

and adjustments.

17. Only authorized service locations should be utilized for

major service and repair requirements.

18. Never attempt to make major repairs on this unit unless

you have been properly trained. Improper service procedures can result in hazardous operation, equipment

damage and voiding of manufacturer’s warranty.

19. On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

20. Do not change engine governor settings or over-speed

the engine. Operating the engine at excessive speed

can increase the hazard of personal injury.

21. Disengage drive attachments, stop the engine, remove

the key, and disconnect the spark plug wire(s) before:

clearing attachment blockages and chutes, performing

service work, striking an object, or if the unit vibrates

abnormally. After striking an object, inspect the machine for damage and make repairs before restarting

and operating the equipment.

22. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top of

the transaxle).

23. Units with hydraulic pumps, hoses, or motors: WARNING: Hydraulic fluid escaping under pressure may have

sufficient force to penetrate skin and cause serious injury. If foreign fluid is injected into the skin it must be

surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result. Keep

body and hands away from pin holes or nozzles that

eject hydraulic fluid under high pressure. Use paper or

cardboard, and not hands, to search for leaks. Make

sure all hydraulic fluid connections are tight and all hydraulic hoses and lines are in good condition before applying pressure to the system. If leaks occur, have the

unit serviced immediately by your authorized dealer.

24. WARNING: Stored energy device. Improper release of

springs can result in serious personal injury. Springs

should be removed by an authorized technician.

25. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, never attempt to remove the radiator cap while the engine is running. Stop

the engine and wait until it is cool. Even then, use extreme care when removing the cap.

OPERATOR SAFETY

www.simplicitymfg.com

Not for

Reproduction

Page 9

OPERATOR SAFETY

9

Danger, Side-Discharge Models

Part No. 1704276

Danger, Side Discharge Models

Part No. 1704277

Transmission

Release

Part No. 1730202

Danger, Main Panel

Part No. 1734879

Attachment Lift

Part No. 1730263

Ignition Switch

Positions

Part No. 1722806

Height of Cut

Part No. 1721197

Decal Locations

Not for

Reproduction

To avoid injury from rotating blades and

thrown debris, stay clear of deck edge

and discharge. Do not mow without

deflector or entire grass catcher in place.

DANGER

Amputation and

Thrown Objects Hazard

1704277

DANGER

Amputation Hazard

To avoid injury from rotating

blades, stay clear of deck edge.

1

2

3

1704276

4

5

6

+

1730263

173xxxx

TransportFree Float

Page 10

Tractor Controls Figure 1

10

FEATURES AND CONTROLS

Tractor Controls

Throttle Control

The throttle controls engine speed. Move the throttle forward to increase engine speed and back to decrease engine speed. Always operate at FULL throttle.

Choke

Close the choke for cold starting. Open the choke once

the engine starts. A warm engine may not require choking. Move the lever forward to close the choke.

Headlights

The light switch turns the tractor headlights on and off.

Hour Meter

The hour meter measures the number of hours the key has

been in the RUN position.

www.simplicitymfg.com

Not for

Reproduction

Page 11

FEATURES AND CONTROLS

11

Reverse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or use of

other PTO driven attachments) while traveling in reverse.

If you choose to mow in reverse, turn the RMO key after

the PTO is engaged. The L.E.D. light will illuminate, and

the operator can then mow in reverse. Each time the PTO

is engaged the RMO needs to be reactivated if desired.

PTO Switch

The PTO (Power Take-Off) switch engages and disengages attachments that use the PTO. To engage the PTO,

pull UP on the switch. Push DOWN to disengage.

Note that

the operator must be seated firmly in the tractor seat for

the PTO to function.

Ignition Switch

The ignition switch starts and stops the engine, it has three

positions:

OFF Stops the engine and shuts off the

electrical system.

RUN Allows the engine to run and powers the

electrical system.

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN position

with the engine stopped–this drains the battery.

Ground Speed Pedals

The tractor’s forward ground speed is controlled by the forward ground speed control pedal. The tractor’s reverse

ground speed is controlled by the reverse ground speed

control pedal.

Depressing either pedal will increase ground speed. Note

that the further down the pedal is depressed, the faster the

tractor will travel.

Cruise Control

The cruise control is used to lock the ground speed control

in forward. The cruise control has five lock positions.

Mower Height of Cut Adjustment

The cutting height adjustment knob controls the mower

cutting height. The cutting height is infinitely adjustable

between 1.0” and 4.0” (2,5 - 10,2 cm).

Attachment Lift Control Lever

The mower deck lift lever raises and lowers the mower

deck and has two positions: Transport and free-float. Set

the lever to free-float for mowing. Set the lever to transport when using the tractor for non-mowing applications

or when transporting the tractor. DO NOT engage the

PTO with the mower in the raised transport position or

you may damage the belt.

Seat Adjustment Lever

The seat can be adjusted forward and back. Move the

lever, position the seat as desired, and release the lever

to lock the seat into position.

Transmission Release Valve Lever

The transmission release valve lever deactivates the

transmission so that the tractor can be pushed by hand.

See

Pushing the Tractor by Hand

section.

Fuel Tank

To remove the cap, turn counterclockwise.

Fuel Level Gauge

Displays the fuel level in the tank.

Parking Brake

The parking brake knob is used to lock the parking brake

when the tractor is stopped. Fully depressing the brake

pedal and pulling up on the knob engages the parking

brake.

Brake Pedal

Depressing the brake pedal applies the tractor brake.

Not for

Reproduction

Page 12

FEATURES AND CONTROLS

12

Parking Brake Function

Applying the Parking Brake - See Figure 2. To lock the

parking brake, release the ground speed pedals (A), fully

depress the brake pedal (B), pull UP on the parking brake

knob (C), and then release brake pedal.

Releasing the Parking Brake - See Figure 2. To release

the parking brake, fully depress the brake pedal (B) and

push the parking brake knob (C) DOWN.

Figure 2. Parking Brake and Cruise Control

B

C

D

Cruise Control

TO ENGAGE:

1. Pull up on the cruise control knob (D, Figure 2).

2. Depress the forward ground speed pedal (A).

3. Lift up the cruise control knob (D) when desired

speed is reached. The Cruise will lock in one of its

five locking positions.

TO DISENGAGE:

1. Depress the brake pedal (B).

OR

2. Depress the forward ground speed pedal (A).

A

www.simplicitymfg.com

Not for

Reproduction

Page 13

OPERATION

13

Safety Interlock System Tests

This unit is equipped with safety interlock

switches and other safety devices. These

safety systems are present for your safety:

do not attempt to bypass safety switches, and never

tamper with safety devices. Check their operation regularly.

Test 1 — Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

• The cruise control lever is NOT in NEUTRAL.

Test 2 — Engine SHOULD crank and start if:

• Operator is sitting in seat, AND.

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

• The cruise control lever is in NEUTRAL.

Test 3 — Engine should SHUT OFF if:

• Operator rises off seat with PTO engaged, OR

• Operator rises off seat with brake pedal NOT fully

depressed (parking brake OFF).

Test 4 — Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO switch

is turned OFF (or operator rises off seat). If mower drive

belt does not stop within five seconds, see an authorized

dealer.

Test 5 — Reverse Mow Option (RMO) Check

• Engine should shut off if reverse travel is attempted if

the PTO has been switched on and RMO has not been

activated.

• RMO light should illuminate when RMO has been activated.

WARNING

If the unit does not pass a safety test, do not

operate it. See an authorized Briggs & Stratton

Dealer.

Adding Fuel

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Adding Fuel

• Turn engine off and let engine cool at least 2

minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of

the fuel, do not fill above the bottom of the fuel tank

neck.

• Keep fuel away from sparks, open flames, pilot

lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently

for cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting

engine.

1. Clean the fuel cap area of dirt and debris. Remove

the fuel cap (A, Figure 3).

2. Fill the fuel tank with fuel. To allow for expansion of the

fuel, do not fill above the bottom of the fuel tank neck.

3. Reinstall the fuel cap.

Starting the Engine

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air

cleaner (if equipped) are in place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/RUN

position, move throttle (if equipped) to FAST position

and crank until engine starts.

Not for

Reproduction

Page 14

OPERATION

14 www.simplicitymfg.com

WARNING

Mowing in reverse can be hazardous to bystanders.

Tragic accidents can occur if the operator is not

alert to the presence of children. Never activate

RMO if children are present. Children are often

attracted to the unit and the mowing activity.

1. Check the oil level. See the HOW TO CHECK/ADD

OIL section in the Engine Manual.

2. Make sure equipment drive controls, if equipped, are

disengaged.

3. Turn the fuel shut-off valve, if equipped, to the ON

position.

4. Move the throttle control to the FAST position.

Operate the engine in the FAST position.

5. Move the choke control, or the combination

choke/throttle lever, to the choke position.

NOTE: Choke is usually unnecessary when restarting a

warm engine.

6. Turn the electric start switch to the on/start position.

NOTE: If the engine does not start after repeated attempts, go to

BRIGGSandSTRATTON.COM

or call

1-800-233-3723

(in USA).

NOTICE: To extend the life of the starter, use short starting

cycles (five seconds maximum). Wait one minute between

starting cycles.

7. As the engine warms up, move the choke control to the

run position.

WARNING

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if

doors or windows are open.

Mowing

1. Set the mower cutting height to the desired level using

the mower lift lever.

2. Engage the parking brake. Make sure the PTO switch is

disengaged.

3. Start the engine (see Starting the Engine).

4. Set the throttle to FULL.

5. Engage the PTO to activate the mower blades.

6. Begin mowing.

7. When finished, shut off the PTO and raise the deck

using the mower lift lever.

8. Stop the engine (see Stopping the Tractor and

Engine).

WARNING

The engine will shut off if the reverse ground speed

pedal is depressed while the PTO is on and the

RMO has not been activated. The operator should

always turn the PTO off prior to driving across on

roads, paths or any area that maybe used by other

vehicles. Sudden loss of drive could create a

hazard.

Driving the Tractor

1. Sit in the seat and adjust the seat so that you can comfortably reach all the controls and see the dashboard

display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see Starting the Engine).

5. Disengage the parking brake and release the brake

pedal.

6. Depress the forward ground speed control pedal to

travel forward. Release the pedal to stop. Note that the

further down the pedal is depressed the faster the tractor will travel.

7. Stop the tractor by releasing the ground speed control

pedals, setting the parking brake, and stopping the engine (see Stopping the Tractor and Engine).

Mowing in Reverse (RMO)

If an operator chooses to mow in reverse, the RMO system can be used. To use the Reverse Mowing Option

(RMO) turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then mow

in reverse. Each time the PTO is engaged the RMO needs

to be reactivated if desired. The key should be removed to

restrict access to the RMO feature.

Not for

Reproduction

Page 15

OPERATION

15

Pushing the Tractor by Hand

1. Disengage the PTO and turn the engine off.

2. Push the lever approximately 2.3/8” (6 cm) to release

the transmission (B, Figure 3).

3. The tractor can now be pushed by hand.

DO NOT TOW TRACTOR

Towing the unit will cause transmission damage.

• Do not use another vehicle to push or pull

this unit.

• Do not actuate the transmission release

valve lever while the engine is running.

Figure 3. Transmission Release Lever & Fuel Tank

B

A

Figure 5. Trailer Weight Recommendations

A

B

Attaching a Trailer

The maximum horizontal drawbar force allowed is 280

Newton. The maximum vertical drawbar force is 160

Newton. This equates to a 250 lbs (113 kg) trailer on a

10 degree hill. Secure the trailer with an appropriately

sized clevis pin (A, Figure 5) and clip (B).

Figure 4. Raising & Lowering Mower Deck

B

Adjusting Mower Cutting Height

The mower lift lever (A, Figure 4) is used to lower the

deck to cutting position or raise the deck to transport position.

To lower the deck, pull back slightly on the mower lift

lever, push it to the left and slide it down. To raise the

deck to transport pull up on the mower lift lever and lock

in notch to the right. Do not cut in transport.

The cutting height adjustment knob (B) controls the

mower cutting height. The cutting height is infinitely adjustable between approximately 1.0” and 4.0” (2,5 - 10,2

cm). Turn the knob clockwise to raise the deck and counterclockwise to lower it.

A

Stopping the Tractor and Engine

1. Move the throttle control to the SLOW position. Turn

the key switch to the OFF position. Remove the key

and keep in a safe place out of the reach of children.

2. After the engine stops, turn the fuel shut-off valve, if

equipped, to the closed position.

WARNING

Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

• Do not choke the carburetor to stop engine.

Not for

Reproduction

Page 16

MAINTENANCE

16

Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a complete stop within five seconds after the electric PTO switch

is turned off.

1. With tractor in neutral, PTO disengaged and operator in

seat, start the engine.

2. Look over the left-hand footrest at the mower drive belt.

Engage the PTO and wait several seconds. Disengage

the PTO and check the amount of time it takes for the

mower drive belt to stop.

3. If mower drive belt does not stop within five seconds,

see an authorized dealer.

Check Tire Pressure

Tire pressure should be checked periodically, and maintained

at the levels shown in the chart. Note that these pressures may

differ slightly from the “Max Inflation” stamped on the side-wall

of the tires. The pressures shown provide proper traction, improve cut quality, and extend tire life.

Size PSI bar

15 x 6.0-6 12-14 0,82-0,96 bar

20 x 8.0-8 10 0,68 bar

Maintenance Chart

TRACTOR AND MOWER

Every 8 Hours or Daily

Check safety interlock system

Clean debris off tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check mower blade stopping time

Check tractor and mower for loose hardware

Check tire pressure

Every 50 Hours or Annually *

Check tractor brakes

Clean battery and cables

See Dealer Annually to

Lubricate tractor and mower

Check mower blades **

* Whichever comes first

** Check blades more often in regions with sandy soils or

high dust conditions.

ENGINE

First 5 Hours

Change engine oil - see engine manual

Every 8 Hours or Daily

Check engine oil level - see engine manual

Every 25 Hours or Annually *

Clean engine air filter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil filter

Annually

Replace air filter

Replace pre-cleaner

See Dealer Annually to

Inspect muffler and spark arrester

Replace spark plug

Replace fuel filter

Clean engine air cooling system

* Whichever comes first

** Clean more often in dusty conditions or when airborne

debris is present.

www.simplicitymfg.com

Not for

Reproduction

Page 17

MAINTENANCE

17

Cleaning the Battery and Cables

1. Disconnect the cables from the battery, negative cables

first (A, Figure 6) then the cover and positive cables

(B).

2. Loosen the wingnut and washer (D).

3. Pivot the hold-down rod (C) up and away from battery.

Secure to steering tower.

4. Remove the battery (E).

5. Clean the battery compartment with a solution of baking soda and water.

6. Clean the battery terminals and cable ends with a wire

brush and battery terminal cleaner until shiny.

7. Reinstall the battery (E) in the battery compartment.

Secure with the battery hold-down rod (C) and wingnut

and washer (D).

8. Re-attach the battery cables, positive cables and cover

first (B) then the negative cables (A).

9. Coat the cable ends and battery terminals with petroleum jelly or non-conducting grease.

WARNING

When removing or installing battery cables,

disconnect the negative cable FIRST and

reconnect it LAST. If not done in this order,

the positive terminal can be shorted to the

frame by a tool.

Battery Maintenance

Battery Charging

WARNING

Keep open flames and sparks away from

the battery; the gasses coming from it are

highly explosive. Ventilate the battery well

during charging.

A dead battery or one too weak to start the engine may be

the result of a defect in the charging system or other electrical component. If there is any doubt about the cause of

the problem, see your dealer. If you need to replace the

battery, see the

Cleaning the Battery and Cables

sec-

tion.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the

Operator Safety

section of this manual.

Charge the battery until fully charged. Do not charge at a

rate higher than 10 amps.

Figure 6. Battery Maintenance

D

E

C

A

B

Seat Adjustment

The seat can also be adjusted forward and back. Move the

lever (A, Figure 7), position the seat as desired, and release

the lever to lock the seat into position.

A

Figure 7. Seat Adjustment

Not for

Reproduction

Page 18

MAINTENANCE

18

Storage

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can travel to

an ignition source (such as a furnace, water

heater, etc.) and cause an explosion. Fuel

vapor is also toxic to humans and animals.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or

other appliances that have pilot lights or other ignition

sources because they can ignite fuel vapors.

Equipment

Disengage the PTO, set the parking brake, and remove

the key.

Battery life will be increased if it is removed. Put in a cool,

dry place and fully charged about once a month. If the

battery is left in the unit, disconnect the negative cable.

Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel system or on essential carburetor parts. To keep fuel fresh,

use Briggs & Stratton FRESH START® fuel stabilizer,

available as a liquid additive or a drip concentrate cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system. The engine and fuel can then be stored

up to 24 months.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container.

Run the engine until it stops from lack of fuel. The use of a

fuel stabilizer in the storage container is recommended to

maintain freshness.

www.simplicitymfg.com

Engine Oil

While the engine is still warm, change the engine oil. See

Engine Manual.

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended checks and procedures

found in this manual.

• Allow the engine to warm up for several minutes before use.

Not for

Reproduction

Page 19

TROUBLESHOOTING

19

PROBLEM LOOK FOR REMEDY

Engine will not turnover

or start.

Brake pedal not depressed. Fully depress brake pedal.

PTO (electric clutch) switch is in

ON position.

Place in OFF position.

Cruise control engaged. Move knob to NEUTRAL/OFF position.

Out of fuel. If engine is hot, allow it to cool, then refill the fuel tank.

Engine flooded. Disengage the choke.

Fuse is blown. See authorized dealer.

Battery terminals require

cleaning.

See Cleaning the Battery and Cables section.

Battery discharged or dead. Recharge or replace battery.

Wiring loose or broken. Visually check wiring. If wires are frayed or broken, see authorized dealer.

Solenoid or starter motor faulty. See authorized dealer.

Safety interlock switch faulty. See authorized dealer.

Water in fuel. See authorized dealer.

Gas is old or stale. See authorized dealer.

Engine starts hard or runs

poorly.

Fuel mixture too rich. Clean air filter.

Engine has other problem. See authorized dealer.

Engine knocks.

Low oil level. Check/add oil as required.

Using wrong grade oil. See Engine Manual.

Excessive oil consumption.

Engine running too hot. See authorized dealer.

Using wrong grade oil. See Engine Manual.

Too much oil in crankcase. Drain excess oil.

Engine exhaust is black.

Dirty air filter. See Engine Manual.

Choke closed. Open choke.

Engine runs, but tractor

will not drive.

Ground speed control pedals

not depressed.

Depress pedals.

Transmission release lever in

PUSH position.

Move into DRIVE position.

Parking brake is engaged. Disengage parking brake.

Traction drive belt is broken or

slipping.

See authorized dealer.

Troubleshooting the Tractor

Not for

Reproduction

Page 20

20

TROUBLESHOOTING

PROBLEM LOOK FOR REMEDY

Brake will not hold.

Internal brake worn. See authorized dealer.

Tractor steers hard or

handles poorly.

Steering linkage is loose. See authorized dealer.

Improper tire inflation. See Check Tire Pressure section.

Front wheel spindle bearings

dry.

See authorized dealer.

Troubleshooting the Tractor (Continued)

PROBLEM LOOK FOR REMEDY

Mower will not raise.

Lift linkage not properly

attached or damaged.

See authorized dealer.

Mower cut is uneven.

Mower not leveled properly. See authorized dealer.

Tractor tires not properly

inflated.

See Check Tire Pressure section.

Mower cut is rough

looking.

Engine speed too slow. Set to full throttle.

Ground speed too fast. Slow down.

Mower has other problem. See authorized dealer.

Engine stalls easily with

mower engaged.

Engine speed too slow. Set to full throttle.

Ground speed to fast. Slow down.

Dirty or clogged air filter. See Engine Manual.

Cutting height set too low. Cut tall grass at maximum cutting height during first pass.

Engine not up to operating

temperature.

Run engine for several minutes to warm-up.

Starting mower in tall grass. Start the mower in a cleared area.

Excessive mower vibration.

Mower has other problem. See authorized dealer.

Engine runs and tractor

drives, but mower will not

drive.

PTO not engaged. Engage the PTO.

Mower has other problem. See authorized dealer.

Troubleshooting the Mower

www.simplicitymfg.com

Not for

Reproduction

Page 21

21

Not for

Reproduction

Page 22

CALIFORNIA, U.S. EPA, AND BRIGGS & STRATTON CORPORATION EMISSIONS CONTROL WARRANTY STATEMENT

Not for

Reproduction

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Effective November 2008

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S)

are pleased to explain the emissions control system warranty on your Model

Year 2008 and later engine/equipment. In California, new small off-road engines

must be designed, built, and equipped to meet the State’s stringent anti-smog

standards. B&S must warrant the emissions control system on your engine/

equipment for the periods of time listed below provided there has been no abuse,

neglect, or improper maintenance of your small off-road engine.

Yo ur emissions control system may include parts such as the carburetor or

fuel injection system, fuel tank, ignition system, and catalytic converter. Also

included may be hoses, belts, connectors, sensors, and other emissions-related

assemblies. Where a warrantable condition exists, B&S will repair your engine/

equipment at no cost to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines are warranted for two years. If any emissions-related part

on your engine/equipment is def

B&S.

ective, the part will be repaired or replaced by

Owner’s Warranty Responsibilities:

• As the small engine/equipment owner, you are responsible for the performance

of the required maintenance listed in your owner’s manual. B&S recommends that

you retain all receipts covering maintenance on your engine/equipment, but B&S

cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance.

• As the engine/equipment owner, you should however be aware that B&S may

deny you warranty coverage if your engine/equipment or a part has failed due to

abuse, neglect, improper maintenance, or unapproved modifications.

• You are responsible for presenting your engine/equipment to a B&S distribution

, servicing dealer, or other equivalent entity, as applicable, as soon as a

center

problem exists. The warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days. If you have any questions regarding your warranty

rights and responsibilities, you should contact B&S at (414) 259-5262.

BRIGGS & STRATTON EMISSIONS CONTROL WARRANTY PROVISIONS

The following are specific provisions relative to your Emissions Control Warranty

Coverage. It is in addition to the B&S engine warranty for non-regulated engines

found in the Operator’s Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the

emissions control systems parts) to the extent these parts were present on

the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Connectors and assemblies

2. Length of Coverage

For a period of two years from date of original purchase, B&S warrants to

• Vacuum, temperature, position, time sensitive valves and

switches

the original purchaser and each subsequent purchaser that the engine is

designed, built, and equipped so as to conform with all applicable regulations

adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and

that it is identical in all material respects to the engine described in the

manufacturer’s application for certification. The warranty period begins on the

date the engine is originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

• Any warranted part that is scheduled for replacement as required

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine

maintenance in the owner’s manual supplied, is warranted for the

warranty period stated above. If any such part fails during the period

of warranty coverage, the part will be repaired or replaced by B&S at

no charge to the owner. Any such part repaired or replaced under the

warranty will be warranted for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the

owner’s manual supplied, is warranted for the warranty period stated

above. Any such part repaired or replaced under warranty will be

warranted for the remaining warranty period.

maintenance in the owner’s manual supplied, is warranted for the

period of time prior to the first scheduled replacement point for that

part. If the part fails prior to the first scheduled replacement, the part

will be repaired or replaced by B&S at no charge to the owner. Any

such part repaired or replaced under warranty will be warranted for the

remainder of the period prior to the first scheduled replacement point

for the part.

• Add on or modified parts that are not exempted by the Air Resources

Board may not be used. The use of any non exempted add on or

modified parts by the owner will be grounds for disallowing a warranty

claim. The manufacturer will not be liable to warrant failures of

warranted parts caused by the use of a non exempted add on or

modified part.

the failure of any warranted emissions parts.

warranty policy. Warranty coverage does not apply to failures of emissions

parts that are not original equipment B&S parts or to parts that fail due to

abuse, neglect, or improper maintenance as set forth in the B&S engine

warranty policy. B&S is not liable for warranty coverage of failures of

emissions parts caused by the use of add-on or modified parts.

LOOK FOR RELEVANT EMISSIONS DURABILITY PERIOD AND AIR INDEX INFORMATION ON YOUR ENGINE

EMISSIONS LABEL

Engines that are certified to meet the California Air Resources Board (CARB)

Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to

the consumer on our emissions labels. The engine emissions label will indicate

certification information.

The Emissions Durability Period describes the number of hours of actual

running time for which the engine is certified to be emissions compliant, assuming

proper maintenance in accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate:

Engine is cer

for 125 hours of actual engine running time.

Intermediate:

Engine is certified to be emissions compliant

for 250 hours of actual engine running time.

Extended:

Engine is certified to be emissions compliant

for 500 hours of actual engine running time.

tified to be emissions compliant

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with an intermediate

rating would equate to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental

Protection Agency (USEPA) Phase 2 emissions standards. For Phase 2 certified

engines, the Emissions Compliance Period referred to on the Emissions

Compliance label indicates the number of operating hours for which the engine

has been shown to meet Federal emissions requirements.

For engines less than 225 cc displacement:

Category C = 125 hours

Category B = 250 hours

Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours

Category B = 500 hours

Category A = 1000 hours

Page 23

23

ENGINE

19.5 HP* Briggs & Stratton

Model 310000, Extended Life Series™

Horsepower 19.5 HP @ 3500 +/- 100 rpm

Displacement 30.42 cu in. (500cc)

Electrical System 12V-15A Reg.

Battery: 12 Volt, 195 CCA

Oil Capacity 46-48 oz (1,36 -1,4 L)

Spark Plug Gap 0.030 in. (0,76 mm)

Spark Plug Torque 180 in-lbs (20 Nm)

CHASSIS

Fuel Tank Capacity Capacity: 3.5 gal (13,2 L)

Front Wheels Tire Size: 15 x 6,0-6

Inflation Pressure: 12-14 psi (0,82-0,96 bar)

Rear Wheels Tire Size: 20 x 8,0-8

Inflation Pressure: 10 psi (0,68 bar)

TRANSMISSION

K46Z

Type Hydrostatic Tuff Torq K46Z

Engine Oil 10w 30 Premium Engine Oil

Speeds Forward: 0-5.5 MPH (0-9,0 km/h)

@ 3400 rpm Reverse: 0-3.0 MPH (0-4,6 km/h)

Continuous Torque 170 ft-lbs (230,5 Nm)

Output

Drawbar Rating 227 lbs (103 kg)

Maximum Weight 675 lbs (306 kg)

on Axle

MOWER

Width of Cut 38” (96,5 cm)

Number of Blades 2

Base Deck Platform Side Discharge

Cutting Height 1.0-4.0 in. (2,5-10,2 cm)

Cutting Positions Infinite

DIMENSIONS

Overall Length 71” (180,3 cm)

Overall Width 62” (116,8 cm)

Height 45” (114,3 cm)

Weight:

19.5 hp Tractor

w/ 38” Mower Deck 502 lbs (227 kg)

*The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values are

derived at 3600 RPM. Actual gross engine power will be lower and is affected by, among other things, ambient operating

conditions and engine-to-engine variability. Given both the wide array of products on which engines are placed and the variety of environmental issues applicable to operating the equipment, the gas engine will not develop the rated gross power

when used in a given piece of power equipment (actual "on-site" or net horsepower). This difference is due to a variety of

factors including, but not limited to, accessories (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to

manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this Series engine.

SPECIFICATIONS

Replacement Parts

We recommend that you see any authorized dealer for all

maintenance and service of the tractor/engine and parts.

PARTS AND ACCESSORIES

Accessories

For a list of the available accessories, see an authorized

dealer.

Engine Power Rating Information

Not for

Reproduction

Page 24

Simplicity Manufacturing, Inc.

P.O. 702

Milwaukee, WI 53201-0702

1-800-837-6836

simplicitymfg.com

Not for

Reproduction

Loading...

Loading...