Page 1

OWNER’S MANUAL

Submersible Sump Pumps

NOTICE D’UTILISATION

Pompes submersibles

pour puisard

MANUAL DEL USUARIO

Bombas sumergibles

para sumideros y efluentes

Installation/Operation

For further operating,

installation, or maintenance

assistance:

Call 1-800-468-7867 /

1-800-546-7867

English ...................... Pages 2-6

Installation/Fonctionnement

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867 /

1 (800) 546-7867

Français ................. Pages 7-11

Instalación/Operación

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867 /

1-800-546-7867

Español ...............Paginas 12-16

SIM852 (Rev. 5/28/09)

MODELS 12356, 12558

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

Web Site:

http://www.simerpump.com

5870 0808 B&W

Page 2

For assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Specifications and Safety 2

DESCRIPTION

This Submersible Sump Pump is designed for home

sumps. Unit is equipped with a 3-prong grounding-type

power cord. Motor is sealed for cooler running. Bearings

on motor shaft never need lubrication. Automatic reset

thermal protection. Not designed for use as a swimming

pool drainer.

SPECIFICATIONS

Power supply required ...........................115V, 60 HZ.

Liquid Temp. Range ................32°F to 95°F(0°-35°C)

Minimum Water Level when pump is operating ...5.5"

Max. Submergence Level.......................................23'

Individual Branch Circuit Required (min.) ....15 Amps

Discharge.................................................1-1/2" FNPT

NOTICE: Do not reduce size of discharge pipe or

hose below 1-1/4" diameter. If discharge is too small,

pump will overheat and fail prematurely.

This pump is designed for use in a residential sump

only. Pump water only with this pump.

NOTICE: This unit is not designed as a waterfall or fountain pump, or for applications involving salt water or

brine! Use with waterfalls, fountains, salt water or brine

will void warranty.

NOTICE: Pump can pump down to about 1/4" (6 mm),

but should not be allowed to run for a period of time

unless it is in at least 5-1/2" of water.

Do not use where water recirculates.

Not designed for use as a swimming pool drainer.

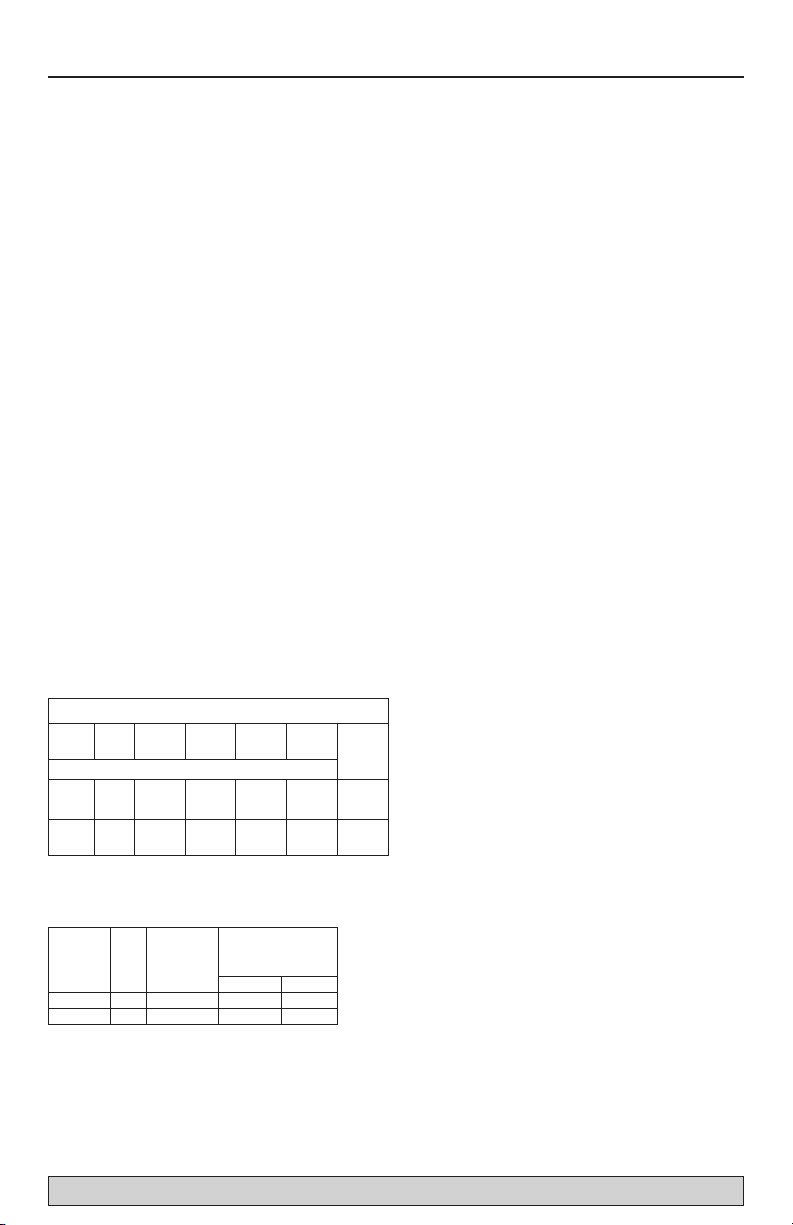

PERFORMANCE

ELECTRICAL & SWITCH SPECIFICATIONS

GENERAL SAFETY INFORMATION

Electrically powered sump pumps normally give

many years of trouble-free service when correctly

installed, maintained, and used. However, unusual

circumstances (interruption of power to the pump,

dirt/debris in the sump, flooding that exceeds the

pump’s capacity, electrical or mechanical failure in

the pump, etc.) may prevent your pump from functioning normally. To prevent possible water damage

due to flooding, consult your retailer about a secondary AC sump pump, a DC backup sump pump,

and/or a high water alarm. See the “Troubleshooting

Chart” in this manual for information about common

sump pump problems and remedies. For more information, see your retailer, call Simer customer

service at 1-800-468-7867 / 1-800-546-7867.

1. Know the pump application, limitations, and

potential hazards.

2. Do not use in water with fish present. If any oil

leaks out of the motor it can kill fish.

3. Disconnect power before servicing.

4. Release all pressure within system before servicing any component.

5. Drain all water from system before servicing.

6. Secure discharge line before starting pump. An

unsecured discharge line will whip, possibly

causing personal injury and/or property damage.

7. Check hoses for weak or worn condition before

each use, making certain that all connections are

secure.

8. Periodically inspect sump, pump and system

components. Keep free of debris and foreign

objects. Perform routine maintenance as

required.

9. Provide means of pressure relief for pumps whose

discharge line can be shut-off or obstructed.

10. Personal Safety:

a. Wear safety glasses at all times when working

with pumps.

b. Keep work area clean, uncluttered and prop-

erly lighted – replace all unused tools and

equipment.

c. Keep visitors at a safe distance from work

area.

d. Make workshop child-proof – with padlocks,

master switches, and by removing starter

keys.

11. When wiring an electrically driven pump, follow

all electrical and safety codes that apply.

12. This equipment is only for use on 115 volt

(single phase) and is equipped with an

approved 3-conductor cord and 3-prong,

grounding-type plug.

GPH (LPH) AT TOTAL FEET (M) OF LIFT

0102025

Model HP (0m) (3m) (6m) (7.6m)

CAPACITY GALLONS(L)/HOUR

12558

1/3

2880 2460 1800 1200 28'

(10,902) (9,312) (6,814) (4,542) (8.5m)

12356

1/2

3180 2700 2040 1500 30'

(12,037) (10,220) (7,722) (5,678) (9.1m)

Individual

Branch Switch Setting

Circuit in inches (mm)

Model HP Req.(Amps) On Off

12558 1/3 15 13.5"(330) 5.5"(140)

12356 1/2 15 14.0"(356) 6.0"(152)

No flow

at height

shown

below

Page 3

For assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Installation 3

To reduce risk of electric shock,

pull plug before servicing. This pump has not

been investigated for use in swimming pool

areas. Pump is supplied with a grounding conductor and grounding-type attachment plug. Be

sure it is connected only to a properly grounded

grounding-type receptacle.

Where a 2-prong wall receptacle is encountered, it must be replaced with properly

grounded 3-prong receptacle installed in accordance with codes and ordinances that apply.

13. All wiring should be performed by a qualified

electrician.

14. Make certain power source conforms to requirements of your equipment.

15. Protect electrical cord from sharp objects, hot

surfaces, oil, and chemicals. Avoid kinking cord.

Replace or repair damaged or worn cords

immediately.

16. Do not touch an operating motor. Modern motors

can operate at high temperatures.

17. Do not handle pump or pump motor with wet

hands or when standing on wet or damp surface,

or in water.

Hazardous voltage can shock, burn or

kill. If your basement has water or moisture on

floor, do not walk on wet area until all power has

been turned off. If shut-off box is in basement, call

electric company or hydro authority to shut-off service to house, or call your local fire department for

instructions. Remove pump and repair or replace.

Failure to follow this warning can result in fatal

electrical shock.

Do not lift pump by power cord.

INSTALLATION

1. Install pump in sump pit with minimum diameter

of 14" (356mm). Sump depth should be 22"

(559mm). Construct sump pit of tile, concrete,

steel or plastic. Check local codes for approved

materials and for proper installation.

2. Install pump in pit so that switch has maximum

possible clearance.

3. Pump should not be installed on clay, earth or

sand surfaces. Clean sump pit of small stones

and gravel which could clog pump. Keep pump

inlet screen clear.

NOTICE: Do not use ordinary pipe joint compound on plastic pipe. Pipe joint compound can

attack plastics.

4. Wrap elbow with TeflonTMtape and thread it into

the pump discharge.

5. Install discharge plumbing in the elbow. Use rigid

plastic pipe and wrap threads with TeflonTMtape.

Screw pipe into pump hand tight plus 1-1/2 turns.

Risk of flooding. If a flexible discharge hose is used, make sure pump is

secured in sump to prevent movement. Failure

to secure pump may allow pump movement,

switch interference and prevent pump from

starting or stopping.

6. To reduce motor noise and vibrations, a short

length of rubber hose (1-7/8" (47.6mm) I.D., e.g.

radiator hose) can be connected into discharge

line near pump using suitable clamps.

7. Install an in-line check valve to prevent flow

backwards through pump when pump shuts off.

NOTICE: If your check valve is not equipped with

an air bleed hole to prevent airlocking pump, drill

a 1/8" (3.2 mm) hole in discharge pipe just above

where the discharge pipe screws into the pump

discharge. Be sure the hole is below the waterline

and the check valve to prevent air locks.

8. Power Supply: Pump is designed for 115 V., 60

Hz., operation and requires a minimum 15 amp

individual branch circuit. Both pump and switch

are supplied with 3-wire cord sets with grounding-type plugs. Switch plug is inserted directly

into outlet and pump plug inserts into opposite

end of switch plug.

Pump should always be electrically

grounded to a suitable electrical ground such

as a grounded water pipe or a properly grounded

metallic raceway, or ground wire system. Do

not cut off round ground pin.

9. If pump discharge line is exposed to outside subfreezing atmosphere, portion of line exposed

must be installed so any water remaining in pipe

will drain to the outfall by gravity. Failure to do

this can cause water trapped in discharge to

freeze which could result in damage to pump.

10. After piping, check valve and float switch have

been installed, the unit is ready for operation.

11. Check the pump operation by filling sump with

water and observing pump operation through one

complete cycle. For switch settings see the Electrical

and Switch Specifications chart on Page 2.

Failure to make this operational

check may lead to improper operation, premature failure, and flooding.

TM

E.I. DuPont De Nemours and Company Corporation, Delaware.

Page 4

For assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

OPERATION

Risk of electric shock. Do not handle

a pump or pump motor with wet hands or when

standing on wet or damp surface, or in water.

1. Shaft seal depends on water for lubrication. Do

not operate pump unless it is submerged in

water as seal may be damaged if allowed to run

dry.

2. Motor is equipped with automatic reset thermal

protector. If temperature in motor should rise

unduly, switch will cut off all power before damage can be done to motor. When motor has

cooled sufficiently, switch will reset automatically

and restart motor. If protector trips repeatedly,

pump should be removed and checked as to

cause of difficulty. Low voltage, long extension

cords, clogged impeller, very low head or lift, or

a plugged or frozen discharge pipe, etc., could

cause cycling.

3. Pump will not remove all water. If the pump is

operating and suddenly no water comes out of

the discharge hose, shut off the unit immediately.

The water level is probably very low and the unit

has broken prime.

Risk of electric shock. Before

attempting to check why unit has stopped operating, disconnect power from unit.

NOTE: This pump has no serviceable parts.

Operation 4

Page 5

Troubleshooting 5

For assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

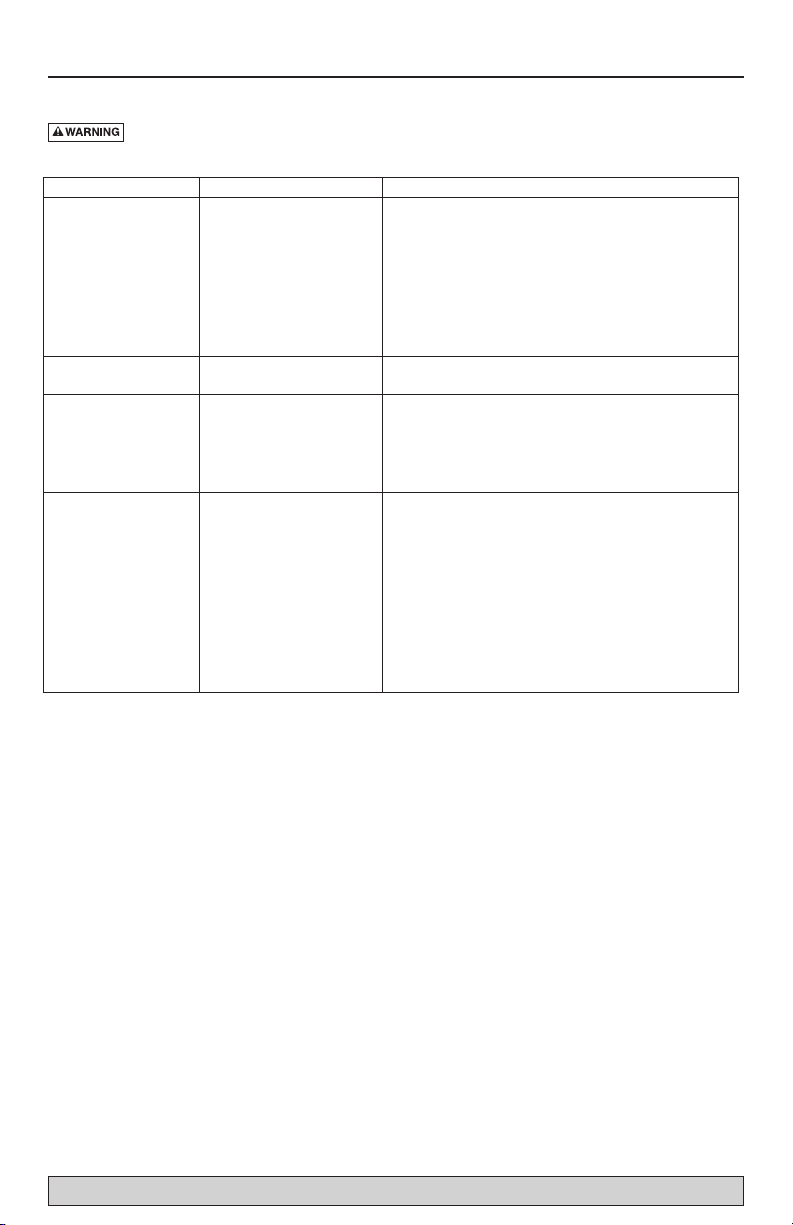

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

Pump won’t start or run. Pump is not plugged in. Check and see if pump is plugged in to a proper outlet.

Blown fuse. If blown, replace with fuse of proper size.

Low line voltage. If voltage under recommended minimum, check size of wiring

from main switch on property. If OK, contact power company

or hydro authority.

Defective motor. Replace pump.

Defective float switch. Replace pump.

Impeller. If impeller won’t turn, remove lower pump body and locate

source of binding.

Float obstructed. Remove obstruction.

Pump starts and stops Backflow of water from piping. Install or replace check-valve.

too often.

Faulty float switch. Replace pump.

Pump won’t shut off. Defective float switch. Replace pump.

Restricted discharge Remove pump and clean pump and piping.

(obstacle or ice in piping).

Float obstructed. Remove obstruction.

Restricted intake screen. Remove the pump and clean the intake screen and the

impeller.

Pump operates but Low line voltage. If voltage under recommended minimum, check size of wiring

delivers little or no water. from main switch on property. If OK, contact power company

or hydro authority.

Something caught in impeller. Remove the pump and clean out the impeller.

Worn or defective parts or Clean impeller if plugged; otherwise replace pump.

plugged impeller.

Check valve installed without Drill a 1/16" - 1/8" (1.6mm - 3.2mm) dia. hole between pump

vent hole. discharge & check valve (1-2” above where the discharge

pipe screws into the pump discharge and below the

waterline).

Restricted intake screen. Remove the pump and clean out the intake screen.

Check valve is installed either Be sure check valve is installed correctly.

backward or upside down.

TROUBLESHOOTING CHART

Hazardous voltage and risk of electric shock. Can shock, burn, or kill. Unplug pump before

servicing or cleaning pump.

Page 6

Warranty 6

RETAIN ORIGINAL RECEIPT FOR YOUR RECORDS.

LIMITED WARRANTY

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from

defects in material and workmanship for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall

be repaired or replaced at SIMER’s option, subject to the terms and conditions set forth below. The original purchase

receipt and product warranty information label are required to determine warranty eligibility. Eligibility is based on

purchase date of original product – not the date of replacement under warranty. The warranty is limited to repair or

replacement of product only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service

at 1-800-468-7867 / 1-800-546-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the

retail outlet where it was purchased immediately after the discovery of any alleged defect. SIMER will subsequently

take corrective action as promptly as reasonably possible. No requests for service will be accepted if received more

than 30 days after the warranty expires.

SEWAGE PUMPS

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage

pumps that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, CM10, CMK, M40, M40P 90 days

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 Years

4” Submersible Well Pumps, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 Years

Pre-Charge Water System Tank, 3985, 3986 5 Years

3963, 3988, 3995, 3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty

does not apply to the following: (1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to

negligence, abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation,

maintenance or storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or

other foreign materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long

an implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific

legal rights and You may also have other rights which vary from state to state.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

Web Site: http://www.simerpumps.com

Page 7

DESCRIPTION

Cette pompe de puisard submersible est conçue pour les

puisards domestiques. Elle est munie d’une fiche à trois

broches dont une de mise à la terre. Le moteur est étanche

afin qu’il chauffe moins pendant son fonctionnement.

Les paliers de l’arbre du moteur ne nécessitent aucune

lubrification. La pompe comporte également une protection

contre les surcharges thermiques. Elle n’est pas conçue

pour vider les piscines.

CARACTÉRISTIQUES

Courant d'alimentation requis ......................115 V, 60 Hz

Gammes de températures

du liquide............................de 0 à -35 °C (32 °F à 95 °F)

Niveau d’eau minimum lorsque

la pompe fonctionne ...............................................5,5 po

Niveau d’immersion maximal....................................23 pi

Circuit de dérivation individuel requis

(minimum) 15 ampères

Refoulement..............................................1-1/2 po FNPT

REMARQUE : S’assurer que le diamètre du tuyau de

refoulement est d’au moins 3,2 cm. Si le refoulement est

trop petit, il y aura surchauffement et panne prématurée

de la pompe.

Cette pompe est conçue pour être utilisée dans un puisard

résidentiel. Ne pomper que de l’eau avec cette pompe.

REMARQUE : Cette pompe n’est pas conçue pour être

utilisée en tant que pompe de fontaine ou de chute d’eau

ni dans des eaux salées ou de saumure! Son utilisation

avec une chute d’eau, une fontaine, de l’eau salée ou de

saumure annulera la garantie.

REMARQUE : La pompe peut pomper l’eau jusqu’à environ 1/4 po (6mm), mais ne devrait pas fonctionner pendent aucune durée si elle n’est pas immergée dans au

moins 5 1/2 po d’eau.

Ne pas utiliser où de l’eau recircule.

Cette pompe n’est pas conçue pour vider les piscines.

RENDEMENT

CARACTÉRISTIQUES ÉLECTRIQUES

ET DE COMMUTATION

RENSEIGNEMENTS CONCERNANT LES

CONSIGNES DE SÉCURITÉ GÉNÉRALES

Si elle est bien installée, bien entretenue et bien utilisée,

une électropompe assure de nombreuses années de ser-

vice sans entretien. Toutefois, toutes circonstances inhab-

ituelles (interruption du courant alimentant la pompe,

saletés ou débris dans le puisard, débits de crue dépas-

sant la capacité de la pompe, pannes électriques ou

mécaniques de la pompe, etc.) peuvent empêcher la

pompe de fonctionner normalement. Pour empêcher les

dégâts causés par l’eau suite à une inondation, s’adresser

au détaillant sur la possibilité de poser une deuxième

pompe de puisard fonctionnant sur le courant alternatif ou

une pompe de puisard de secours fonctionnant sur le

courant continu et/ou une alarme de niveau élevé d’eau.

Se reporter au «Tableau de recherche des pannes» de ce

Manuel pour plus de renseignements concernant les

problèmes courants des pompes de puisard et leurs

remèdes. Pour de plus amples renseignements,

s'adresser au détaillant, appeler le service à la clientèle

Simer en composant le 1 800 468-7867 /

1 800 546-7867.

1. Avant tout, il faut connaître les applications de la

pompe, ces limites et les dangers potentiels que

présente son utilisation.

2. Ne pas utiliser pour pomper de l'eau dans laquelle

se trouvent des poissons. Une fuite d’huile

provenant du moteur pourrait tuer les poissons.

3. Avant d'intervenir sur la pompe, couper le courant.

4. Dissiper toute la pression du circuit d'eau avant

d'intervenir sur un des éléments de la pompe.

5. Vidanger l'eau du circuit avant d'intervenir sur la

pompe.

6.

Bien immobiliser la canalisation de refoulement avant

de faire fonctionner la pompe. Une canalisation de

refoulement non immobilisée risque de se déplacer

comme un fouet et de causer des blessures corporelles

et/ou des dommages matériels.

7. Avant chaque utilisation, s'assurer que les tuyaux

souples ne comportent pas de points faibles ni de

parties usées et que tous les raccords sont bien

serrés.

8. Périodiquement, inspecter la pompe et tous les

éléments de l'ensemble. Procéder à un entretien

périodique selon le besoin.

9. Prévoir un moyen de dissiper la pression des

pompes dont la canalisation de refoulement peut

être fermée ou obstruée.

10. Sécurité personnelle :

a. Lorsque l'on intervient sur une pompe, toujours

porter des lunettes de sécurité.

b. Toujours garder la zone de travail propre,

dégagée et bien éclairée – Enlever tous les outils

et tout l'équipement inutiles.

c. Les visiteurs doivent se tenir à une distance sécu-

ritaire de la zone de travail.

d. Poser des cadenas pour s'assurer que les enfants

ne pourront pas pénétrer dans l'atelier de travail.

Poser aussi un interrupteur général et enlever les

clés des démarreurs.

11. Lorsque l'on câble une pompe électrique, observer

tous les codes de sécurité et de l'électricité

applicables.

12. Cet équipement ne fonctionne que sur le courant

115 volts (monophasé) et est muni d'un cordon

d'alimentation approuvé à 3 conducteurs et d'une

fiche à 3 broches dont une de mise à la terre.

Caractéristiques et Sécurité 7

LITRES PAR HEURE A LA HAUTEUR TOTALE DE REFOULEMENT EN METRES

0 m 3 m 6 m 7,6 m

Modèle Puiss. (0 pi) (10 pi) (20 pi) (25 pi)

VOLUME LITRES (GL)/HEURE

12558

1/3

10 902 9 312 6 814 4 542 8,5 m

(2 880) (2 460) (1 800) (1 200) (28 pi)

12356

1/2

12 037 10 220 7 722 5 678 9,1 m

(3 180) (2 700) (2 040) (1 500) (30 pi)

Aucun

débit à la

hauteur

suivante

Circuit de

dérivation Réglage de

individuel l’interrupteur

requis en en mm (po)

Modèle Puiss. ampères

Marche Arrêt

12558 1/3 15 330 (13,5) 140 (5,5)

12356 1/2 15 356 (14,0) 152 (6,0)

Pour l'assistance, appeler le service à la clientèle Simer en composant le

1 (800) 468-7867 / 1(800) 546-7867

Page 8

Installation 8

Avant d'intervenir sur la pompe et

pour minimiser les risques de chocs électriques,

débrancher la pompe de la prise de courant. Aucune

étude n'a été faite pour savoir si cette pompe pouvait

être utilisée aux alentours des piscines. Cette pompe

est livrée avec un conducteur et une fiche comportant

une broche de mise à la terre. Ne brancher cette fiche

que dans une prise de courant adéquatement mise à

la terre.

Au cas où l'installation ne comporterait que des prises

de courant à 2 trous, remplacer la prise dans laquelle

la fiche sera branchée par une prise de courant à 3

trous adéquatement mise à la terre et posée conformément aux Codes et aux décrets applicables.

13. Tout le câblage doit être exécuté par un électricien

qualifié.

14. S'assurer que la source du courant est conforme

aux caractéristiques de l'équipement.

15. Protéger le cordon électrique contre les objets tran-

chants, les surfaces chaudes, l'huile et les produits

chimiques. Éviter de nouer le cordon. Remplacer

immédiatement le cordon s'il est endommagé ou usé.

16. Ne pas toucher le moteur de la pompe pendant qu'il

fonctionne. Les moteurs peuvent fonctionner par les

températures élevées.

17. Ne pas manipuler la pompe ni le moteur de la pompe

lorsqu'on a les mains humides ou lorsqu'on se tient

debout sur une surface mouillée, humide ou dans l'eau.

Tension dangereuse. Risque de secousses, de brûleres, voire de mort. Si le sol du sous-sol

est humide ou couvert d'eau, ne pas marcher sur cette

surface humide tant que toute l'alimentation en courant

électrique n'a pas été interrompue. Si le sectionneur principal se trouve au sous-sol, appeler la compagnie qui

fournit l'électricité pour lui demander d'interrompre le

service parvenant à la maison ou appeler le service

d'incendie local pour plus de renseignements. Déposer la

pompe, la réparer ou la remplacer. On risque d'être

mortellement électrocuté si l'on n'observe pas cet

avertissement.

Ne pas lever la pompe par son cordon électrique.

INSTALLATION

1. Installer la pompe dans un puisard ayant un diamètre

minimum de 35,6 cm (14 pouces). Le puisard doit

avoir une profondeur minimum de 55,9 cm (22 po).

Le puisard peut être construit avec un tuyau en

ciment, du béton, en acier ou du plastique. Consulter

les codes municipaux pour connaître le matériau

approuvé et pour procéder adéquatement à

l'installation.

2. Installer la pompe dans le puisard de façon que

l'interrupteur puisse avant le plus grand dégagement

possible.

3. Il ne faut pas poser la pompe sur une surface en

argile, en terre ou sablonneuse. Enlever les petites

pierres et le gravier du puisard qui risqueraient de

boucher la pompe. La crépine d'admission d'eau de

la pompe doit toujours être dégagée.

NOTA : Ne pas utiliser de pâte à joint ordinaire pour

tuyaux filetés sur les tuyaux en plastique car cette

pâte attaque les plastiques.

4. Envelopper du ruban en Teflon

™

autour du coude et

visser celui-ci dans le refoulement de la pompe.

5. Brancher le tuyau de refoulement au coude. Utiliser

des tuyaux en plastique rigide et envelopper les filets

de ruban d’étanchéité en Teflon

™

. Visser bien serré

le tuyau à la main dans la pompe, puis le visser de

1-1/2 tour supplémentaire.

Risque d'inondation. Si l'on utilise un

tuyau de refoulement souple, s'assurer que la pompe

est bien immobilisée dans le puisard pour empêcher

qu'elle se déplace. Si la pompe n'est pas bien immobilisée, elle risque de se déplacer, l'interrupteur

risque de se coincer et d'empêcher la pompe de

démarrer ou de s'arrêter.

6. Pour minimiser le bruit du moteur et les vibrations,

un petit morceau de tuyau en caoutchouc (de 4,76

cm [1-7/8 po] de dia. int., une durite de radiateur,

par exemple) peut être posé sur la conduite de

refoulement à l'aide de colliers, près de la pompe.

7. Poser le clapet antiretour en ligne pour empêcher

l'eau de retomber dans la pompe lorsqu'elle est

arrêtée.

NOTA : Si le clapet antiretour ne comporte pas un

trou de purge d’air pour empêcher les bouchons

d’air dans la pompe, percer un trou de 3,2 mm

(1/8 de po) dans le tuyau de refoulement, juste audessus où le tuyau de refoulement se visse dans le

refoulement de la pompe. S’assurer que le trou est

sous le niveau de l’eau et le clapet antiretour pour

empêcher la formation de bouchons d’air.

8. Courant électrique : La pompe est conçue pour fonc-

tionner sur le courant électrique de 115 V, 60 Hz, et

elle doit être branchée sur un circuit de dérivation individuel d'au moins 15 ampères. La pompe et l'interrupteur sont livrés avec des cordons électriques à 3 conducteurs et des fiches avec broches de terre. La fiche

de l'interrupteur se branche directement dans la prise

de courant et la fiche du cordon de la pompe se

branche à l'arrière de la fiche de l'interrupteur.

La pompe doit toujours être raccordée

à la terre, sur un tuyau d'eau mis à la terre, une

canalisation métallique adéquatement mise à la terre

ou un circuit électrique adéquatement mis à la terre,

par exemple. Ne jamais couper la broche ronde de

mise à la terre de la fiche.

9. Si la conduite de refoulement de la pompe est

exposée aux températures de congélation

extérieures, la partie exposée doit être installée de

façon que l'eau restant dans le tuyau puisse se

vidanger en retombant par gravité. Si l'on ne

respecte pas cette recommandation, l'eau emprisonnée dans la conduite de refoulement risque de geler

et la pompe risque d'être endommagée.

10. Après avoir installé la tuyauterie, le clapet antiretour

et l'interrupteur à flotteur, la pompe est prête à

fonctionner.

11. Vérifier le fonctionnement de la pompe en remplissant le puisard d’eau, puis observer le fonctionnement de la pompe sur un cycle complet. Pour

connaître les réglages de l’interrupteur, se reporter

au tableau de la page 8 intitulé « Caractéristiques

électriques et de l’interrupteur ».

Ne pas procéder à cette vérification

de fonctionnement risque de causer un mauvais

fonctionnement, une panne prématurée, voire une

inondation.

TM

E.I. DuPont De Nemours and Company Corporation, Delaware.

Pour l'assistance, appeler le service à la clientèle Simer en composant le

1 (800) 468-7867 / 1(800) 546-7867

Page 9

Fonctionnement 9

Pour l'assistance, appeler le service à la clientèle Simer en composant le

1 (800) 468-7867 / 1(800) 546-7867

FONCTIONNEMENT

Risque de secousses électriques. Ne

pas toucher à la pompe ni au moteur de la pompe

lorsqu'on a les mains humides ou lorsqu'on se tient

debout sur une surface mouillée, humide ou dans

l'eau.

1. Le joint de l'arbre dépend de l'eau pour son grais-

sage. Ne pas utiliser la pompe si elle n'est pas

immergée dans l'eau, sinon son joint sera endommagé si la pompe fonctionne à sec.

2. Le moteur est équipé d'un protecteur thermique à

réarmement automatique. Si la température devait

s'élever anormalement, le disjoncteur interrompra

automatiquement l'arrivée de courant avant que le

moteur soit endommagé. Lorsque le moteur aura

suffisamment refroidi, le disjoncteur se réarmera

automatiquement et le moteur redémarrera. Si le

protecteur se déclenche constamment, sortir la

pompe du puisard et en déterminer la cause. Une

basse tension, des cordons prolongateurs trop

longs, un impulseur bouché, une hauteur de refoulement très basse ou un tuyau de refoulement bouché

ou gelé, etc. risquent de causer un fonctionnement

intermittent.

3. La pompe n'aspirera pas toute l'eau. Si la pompe

fonctionne et que brusquement l’eau ne sort plus du

tuyau de refoulement, fermer l’unité immédiatement.

Le niveau de l'eau est probablement très bas et la

pompe s'est désamorcée.

Risque de chocs électriques. Avant de

vérifier pourquoi cette pompe a cessé de fonctionner,

interrompre le courant parvenant à la pompe.

NOTA : Aucune pièce de cette pompe n’est réparable.

Page 10

Diagnostic des pannes 10

LOCALISATION DES PANNES

Tension dangereuse et risques de secousses électriques, de brûlures, voire de mort.

Débrancher la pompe avant de procéder à son entretien ou nettoyage.

Symptôme Cause(s) probable(s) Mesure corrective

La pompe ne démarre La pompe n'est pas branchée. S'assurer que la pompe est branchée dans une prise de

pas ou ne tourne pas. courant adéquate.

Niveau d’eau trop bas. L’interrupteur de la pompe ne se déclenche pas si l’eau ne

recouvre pas la partie supérieure de la pompe.

Fusible fondu. Si le fusible est fondu, remplacer par le calibre qui convient.

Basse tension de la ligne. Si la tension est au-dessous du minimum recommandé,

vérifier la force du câblage provenant de l’interrupteur général

de l’habitation. S’il n’y a pas de problème, contacter la

Compagnie d’électricité ou les services hydro-électriques.

Moteur défectueux. Remplacer la pompe.

Interrupteur du moteur Remplacer la pompe.

défectueux.

Roue motrice. Si la roue refuse de tourner, déposer la partie inférieure de

la pompe et cherche la cause du blocage.

Entrave trop longue. Raccourcir l’entrave.

Obstruction du flotteur. Dégager le mouvement du flotteur.

La pompe démarre et Reflux du liquide dans Installer un clapet antiretour.

s’arrête trop souvent. la pompe.

Interrupteur du flotteur Remplacer la pompe.

défectueux.

La pompe refuse de Interrupteur du flotteur Remplacer la pompe.

s’arrêter. défectueux.

Diminution du refoulement Déposer la pompe et nettoyer la pompe et la canalisation.

(obstruction ou glace dans

la tuyauterie)

Entrave trop longue. Raccourcir l’entrave.

Obstruction du flotteur. Dégager le mouvement du flotteur.

La crépine d'aspiration Déposer la pompe et nettoyer la crépine d'aspiration ainsi

est obstruée. que l'impulseur.

La pompe fonctionne Basse tension de la ligne. Si la tension est au-dessous du minimum recommandé,

mais elle ne délivre vérifier la force du câblage provenant de l’interrupteur

pas ou peu d’eau. général de l’habitation. S’il n’y a pas de problème, contacter

la Compagnie d’électricité.

Quelque chose bloque la Démonter la pompe et nettoyer l'impulseur.

rouemotrice.

Pièces usées ou défectueuses, Nettoyer la roue motrice si elle est obstruée ; autrement,

ou roue motrice obstruée. remplacer la pompe.

Clapet antiretour installé Percer un trou de 1,6 à 3,2 mm (de 1/16 à 1/8 po) de

sans orifice de ventilation. diamètre entre le refoulement de la pompe et le clapet

antiretour (Entre 2,5 et 5 cm (1 à 2 po) au-dessus des filets

du tuyau de refoulement qui se visse dans le refoulement de

la pompe, et sous le niveau de l’eau.

La crépine d'aspiration Déposer la pompe et nettoyer la crépine d'aspiration ainsi

est obstruée. que l'impulseur.

Le clapet antiretour est S'assurer que le clapet antiretour est installé correctement.

installé à l'envers.

Pour l'assistance, appeler le service à la clientèle Simer en composant le

1 (800) 468-7867 / 1(800) 546-7867

Page 11

Garantie 11

CONSERVER L’ORIGINAL DU REÇU POUR TOUTE RÉFÉRENCE ULTÉRIEURE.

GARANTIE LIMITÉE

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de

matériau et de fabrication. Cette garantie est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou

remplacé, à la discrétion de SIMER, conformément aux modalités et conditions exposées ci-dessous. Le reçu de

l’achat d’origine et l’étiquette d’information sur la garantie sont requis pour déterminer la recevabilité de la réclamation

au titre de la garantie. La recevabilité de la réclamation se base sur la date de l’achat d’origine du produit, et non sur la

date d’un éventuel remplacement sous garantie. La garantie est limitée à la réparation ou au remplacement du produit

uniquement. L’Acheteur assume les frais de retrait, d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la

clientèle de SIMER au 1-800-468-7867 / 1-800-546-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes

d’eaux d’égout, voir ci-dessous) au détaillant où il a été acheté, et ce, immédiatement après la découverte de la

défaillance supposée. SIMER prendra les mesures correctives nécessaires dans un délai rapide et raisonnable. Aucune

demande de réparation ne sera acceptée plus de 30 jours après l’expiration de la garantie.

POMPES D’EAUX D’ÉGOUT

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle

de SIMER. Les pompes d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porter des gants en caoutchouc pour manipuler la pompe.

• À des fins de garantie, retourner l’étiquette figurant sur le cordon de la pompe et l’original du reçu au détaillant.

• Mettre la pompe au rebut conformément à la réglementation locale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P, CM10, CMK, M40, M40P 90 jours

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 ans

Réservoir préchargé de système d’eau, 3985, 3986, 5 ans

3963, 3988, 3995, 3997 À vie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti

couvert par cette garantie. Cette garantie ne s’applique pas à ce qui suit : (1) Les catastrophes naturelles; (2) Les

produits qui, selon SIMER, ont fait l’objet d’une négligence, d’une utilisation abusive, d’un accident, d’une

mauvaise application ou d’une altération; (3) Les défaillances dues à une installation, une utilisation, un entretien ou

un entreposage inappropriés; (4) Une application, une utilisation ou une réparation atypique ou non approuvée;

(5) Les défaillances causées par la corrosion, la rouille ou d’autres matériaux étrangers au système, ou par une

utilisation à une pression supérieure au maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit

défectueux.

SIMER NE POURRA ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU

IMPLICITE, Y COMPRIS, MAIS SANS S’Y LIMITER, CELLE DE QUALITÉ MARCHANDE OU D’APTITUDE DU PRODUIT À

UN EMPLOI PARTICULIER. LES PRÉSENTES GARANTIES NE PEUVENT SE PROLONGER AU-DELÀ DE LA PÉRIODE DE

GARANTIE INDIQUÉE ICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations

relatives à la durée des garanties implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus

ne s’appliquent pas. Cette garantie procure des droits juridiques précis à l’Acheteur. Cependant, il est possible de

bénéficier d’autres droits, qui varient selon l’État.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 / 1 800 546-7867 • Télécopieur : 1 800 390-5351

Courriel : info@simerpumps.com • Site Web : http://www.simerpumps.com

Page 12

Especificaciones y Seguridad 12

Para asistencia, llame a Simer Servicios al Cliente al:

1 800 468-7867 / 1 800 546-7867

DESCRIPCION

Esta Bomba Sumergible de Sumidero ha sido diseñada para

sumideros domésticos. La unidad viene equipada con un

cordón eléctrico de tipo puesta a tierra, con tres puntas. El

motor viene cerrado herméticamente para un menor

calentamiento durante su funcionamiento. Los cojinetes

de manguito en el eje del motor nunca necesitan lubricación. Protección de reposición térmica automática. No se

ha diseñado para usar como bomba de desagüe para piscinas de natación.

ESPECIFICACIONES

Fuente de alimentación ...............................115 V, 60 Hz

Gama de la Temperatura

del Líquido.......................................0˚-35˚C (32˚F a 95F˚)

Nivel mínimo de agua durante el funcionamiento

de la bomba................................................................5.5"

Nivel máximo de inmersión ..................................23 pies

Requiere un ramal individual (mínimo)..............15 Amps

Tubería de Descarga......................................1-1/2" FNPT

AVISO: No reduzca el tamaño de la tubería o de la

manguera de descarga a un diámetro menor de 1-1/4".

Si la descarga es demasiado pequeña, la bomba se recalentará y fallara prematuramente.

Esta bomba ha sido diseñada sólo para uso en sumideros

domésticos. Bombee solamente agua con esta bomba.

AVISO: Este aparato no está diseñado como bomba de

cascada o fuente, ni para aplicaciones con agua salada o de

mar. El uso con cascadas, fuentes, agua salada o de mar

anulará la garantía.

AVISO: La bomba puede bombear agua hasta aproximadamente 1/4", pero no se debe hacerla funcionar por

un período de tiempo al menos que esté sumergida en

por lo menos 5-1/2" de agua.

No usar en donde hay recirculación de agua.

No ha sido diseñado para usar como desaguador de pisci-

nas de natación.

RENDIMIENTO

ESPECIFICACIONES ELECTRICAS

Y DEL INTERRUPTOR

INFORMACION GENERAL

SOBRE SEGURIDAD

Las bombas de sumidero eléctricas por lo regular duran

muchos años sin sufrir problemas de servicio, cuando

son instaladas, mantenidas y usadas correctamente. Sin

embargo, las situaciones inusuales (interrupción del

suministro eléctrico que va a la bomba, tierra o suciedad

en el sumidero, inundación superior a la capacidad de la

bomba, fallas eléctricas y mecánicas, etc.), pueden evitar

que su bomba funcione como acostumbra. Para evitar

posibles daños ocasionados por inundación de agua,

consulte a su representante de ventas sobre la instalación de una bomba de sumidero con CA secundaria,

una bomba de sumidero de respaldo con CD, y/o una

alarma de alto nivel de agua. Consulte la “Tabla de solución de problemas” contenida en este manual para información sobre problemas comunes de la bomba de sumidero y soluciones. Para mayor información, visite a su

representante de ventas, llame al Departamento de

Servicio al Cliente de Simer 1 800 468-7867 /

1 800 546-7867.

1. Infórmese sobre la aplicación, limitaciones y posibles riesgos de la bomba.

2. No usar en agua en donde haya peces. Si hay una

fuga de aceite del motor puede matar a los peces.

3. Desconecte la energía eléctrica antes de efectuar

reparaciones.

4. Alivie toda la presión dentro del sistema antes de

reparar cualquier componente.

5. Drene toda el agua del sistema antes de efectuar

reparaciones.

6. Asegure bien la tubería de descarga antes de poner en

marcha la bomba. Una tubería de descarga que no

esté bien segura puede moverse y causar lesiones

personales y/o daños materiales.

7. Antes de cada uso, verifique si las mangueras están

débiles o gastadas, asegurándose de que todas las

conexiones estén firmes.

8. Inspeccione periódicamente el sumidero, la bomba y

los componentes del sistema. Manténgala limpia de

basuras y objetos extraños. Realice el mantenimiento de rutina como sea necesario.

9. Provea un medio de alivio de la presión para aquellas bombas cuya tubería de descarga puede bloquearse u obstruirse.

10. Seguridad Personal:

a. Use lentes protectores en todo momento cuando

trabaje en la bomba.

b. Mantenga el lugar de trabajo limpio, despejado y

debidamente iluminado - guarde todas herramientas y el equipo que no se use.

c. Mantenga a los visitantes a una distancia segura

del lugar de trabajo.

d. Asegúrese de que su taller sea a prueba de niños

- con candados, interruptores maestros y sacando

las llaves del arrancador.

11. Cuando instale el cableado de una bomba accionada

eléctricamente, siga todos los códigos eléctricos y

de seguridad que correspondan.

12. Esta bomba solamente se puede usar con corri-

ente de 115 voltios (monofásica) y está equipado

con un cordón aprobado de 3 conductores y 3 clavijas, del tipo de puesta a tierra.

GPH (LPH) A ALTURA TOTAL EN M (PIES)

0 m 3 m 6 m 7,6 m

Modelo

HP

(0 pi) (10 pi) (20 pi) (25 pi)

CAPACIDAD EN LITROS (GALONES) POR HORA

12558

1/3

10 902 9 312 6 814 4 542 8,5 m

(2 880) (2 460) (1 800) (1 200) (28 pi)

12356

1/2

12 037 10 220 7 722 5 678 9,1 m

(3 180) (2 700) (2 040) (1 500) (30 pi)

Sin caudal

en al altura

indicada

abajo

Require un

Ajuste del

ramal

interruptor en mm

individual

(pulgadas)

Modelo

HP

(amperios)

Encendido Apagado

12558 1/3 15 330 (13,5) 140 (5,5)

12356 1/2 15 356 (14,0) 152 (6,0)

Page 13

Para asistencia, llame a Simer Servicios al Cliente al:

1 800 468-7867 / 1 800 546-7867

Para reducir el riegso de choque eléctrico, desenchufe la bomba antes de repararla. No se ha

comprobado aún si esta bomba pueda ser usada en

albercas. La bomba es suministrada con un conductor

de puesta a tierra y un enchufe del tipo de puesta a

tierra. Asegúrese de que sea conectado solamente a un

tomacorriente puesto a tierra, del tipo de puesta a tierra.

Si el tomacorriente mural es del tipo para 2 clavijas,

éste debe ser reemplazado por un tomacorriente de 3

clavijas e instalado de acuerdo con los códigos y

reglamentos que correspondan.

13. Todo el cableado debe ser efectuado por un elec-

tricista calificado.

14. Asegúrese de que la fuente de alimentación cumple

con los requisitos de su equipo.

15. Proteja el cordón eléctrico contra objetos afilados,

superficies calientes, aceite y productos químicos.

Evite que se enrede. Reemplace o repare inmediatamente un cordón que esté dañado o gastado.

16. No toque un motor cuando esté funcionando. Los

motores pueden funcionar a temperaturas altas.

17. No manipule la bomba o el motor de la bomba con

las manos mojadas o cuando esté parado en suelo

húmedo o mojado o en el agua.

Tensión peligrosa. Puede causar choques

eléctricos, quemaduras o muerte. Si su sótano tiene agua

o humedad en el piso, no camine en el lugar mojado

hasta que no haya cortado toda la energía eléctrica. Si la

llave de paso está en el sótano, llame a la compañía

eléctrica o a la compañía de electricidad para cortar el

servicio a su casa o llame al departamento de bomberos

de su localidad para solicitar instrucciones. Saque la

bomba y repárela o reemplácela. El incumplimiento de

esta advertencia puede resultar en un choque eléctrico

mortal.

No levante la bomba por medio del cordón de corriente.

INSTALACION

1. Instale la bomba en un foso de recogida con un

diámetro mínimo de 14" (356 mm.). La profundidad

del sumidero debe ser de 22" (559 mm.). Construya

el foso de recogida de losetas, hormigón, acero o

plástico. Confirme los materiales aprobados y la instalación adecuada requeridos por las normas locales.

2. Instale la bomba en el pozo de manera que el interruptor tenga el mayor juego posible.

3. La bomba no debe ser instalada en arcilla, tierra o

superficies arenosas. Saque las piedritas y arenillas

que puedan haber en el pozo del sumidero pues

pueden obstruir la bomba. Mantenga limpio el filtro

de admisión de la bomba.

AVISO: No use obturador de juntas de tubería en las

tuberías de plástico. El obturador de juntas de

tubería puede dañar el plástico.

4. Envuelva el codo con cinta de Teflon™ y enrósquelo

en la descarga de la bomba.

5. Conecte la tubería de descarga al codo. Use tuberías

de plástico rígido y envuelva las roscas con cinta de

Teflon™. Enrosque la tubería en la bomba a mano, y

después apriétela 1-1/2 vueltas.

Riesgo de inundación. Si se usa una

manguera de descarga flexible, asegúrese de que la

bomba esté bien inmobilizada para que no pueda

moverse dentro del sumidero. Si la bomba no está

bien firme puede moverse y causar interferencia con

el interruptor e impedir que la bomba se ponga en

marcha o se detenga.

6. Para reducir el ruido y las vibraciones del motor, se

puede conectar un pedazo corto de manguera de goma

de un diámetro exterior de 47,6 mm (1 7/8"), (por ej.

manguera de radiador) a la tubería de descarga cerca

de la bomba, utilizando abrazaderas convenientes.

7. Instale una válvula de retención en la línea para evitar que el flujo retroceda a través de la bomba cuando la bomba está apagada.

AVISO: Si su válvula de retención no viene equipada

con un orificio de purga de aire para impedir la

creación de bolsas de aire en la bomba, perfore un

orificio de 1/8" (3.2 mm) en la tubería de descarga,

justo por encima del punto en que la tubería de

descarga se atornilla a la descarga de la bomba.

Verifique que el orificio quede debajo de la línea de

agua y de la válvula de retención para impedir la

creación de bolsas de aire.

8. Fuente de Alimentación: La bomba está diseñada

para funcionar con corriente de 115 V., 60 Hz. y

requiere un ramal individual mínimo de 15 amps.

Tanto la bomba como el interruptor vienen con juegos de cordones de 3 conductores con enchufes del

tipo de puesta a tierra. El enchufe del interruptor se

enchufa directamente en el tomacorriente y el

enchufe de la bomba se enchufa en el extremo

opuesto del enchufe del interruptor.

La bomba siempre debe ser puesta a

tierra en una tierra eléctrica adecuada tales como una

tubería en el agua que esté puesta a tierra o un conducto metálico debidamente puesto a tierra o un sistema de alambre de puesta a tierra. No corte la clavija redonda de puesta a tierra.

9. Si la tubería de descarga de la bomba está expuesta

a temperaturas exteriores inferiores al punto de congelación, la porción expuesta de la tubería debe ser

instalada de manera que toda agua que quede en la

tubería se drene por gravedad hacia la descarga. El

incumplimiento de ésto puede causar que el agua

atrapada en la tubería de descarga se congele, lo

cual podría resultar en daño para la bomba.

10. Después de haber instalado la tubería, la válvula de

retención y el conmutador a flotador, la unidad está

lista para funcionar.

11. Verifique el funcionamiento de la bomba llenando el

sumidero con agua y observando el funcionamiento

de la bomba por un ciclo completo. Para las graduaciones del interruptor, consulte el gráfico de

“Especificaciones Eléctricas y del Interruptor” que

aparece en la página 14.

El incumplimiento de esta verificación

del funcionamiento puede resultar en funcionamiento

impropio, falla prematura e inundación.

TM

E.I. DuPont De Nemours and Company Corporation, Delaware.

Instalación 13

Page 14

Funcionamiento 14

FUNCIONAMIENTO

Riesgo de choque eléctrico. No manipule la bomba o el motor de la bomba con las manos

mojadas o cuando esté parado en suelo húmedo,

mojado o en el agua.

1. La junta del eje depende del agua para su lubricación. No haga funcionar la bomba a menos que

esté sumergida en agua ya que la junta puede

dañarse si se hace trabajar en seco.

2. El motor está equipado con un protector contra

sobrecargas térmicas de reposición automática. Si la

temperatura en el motor se elevara indebidamente,

el interruptor puede cortar toda la energía antes de

que se produzca daño al motor. Cuando el motor se

ha enfriado suficientemente, el interruptor se reposicionará automáticamente y el motor volverá a ponerse en marcha. Si el protector se desengancha en

forma continua, la bomba debe ser sacada y revisada para verificar cual es el problema. Baja tensión,

cables de alargue largos, impulsor atascado, muy

baja altura de aspiración o elevación o una tubería

de descarga tapada o congelada, etc. pueden hacer

que se pase por el ciclo.

3. La bomba no saca toda el agua. La bomba no aspirará toda el agua. Si la bomba está funcionando y

de repente el algua ya no sale de la manguera de

descarga, apague la unidad inmediatamente.

Probablemente el nivel del agua es muy bajo y la

unidad ha dejado de cebar.

Riesgo de choque eléctrico. Antes de

intentar revisar porque la bomba ha dejado de funcionar, desconecte la energía eléctrica.

AVISO: Esta bomba no contiene piezas reparables.

Para asistencia, llame a Simer Servicios al Cliente al:

1 800 468-7867 / 1 800 546-7867

Page 15

Solución de problemas 15

SÍNTOMA CAUSA PROBABLE MEDIDA CORRECTIVA

La bomba no arranca La bomba no está enchufada. Verifique que la bomba esté enchufada en un tomacorriente

ni funciona. adecuado.

El nivel de agua está El interruptor de la bomba no se conecta a menos que el agua

demasiado bajo. cubra la parte superior de la bomba.

Un fusible se ha quemado. Si el fusible está quemado, sustitúyalo con un fusible de la

capacidad correcta.

El voltaje de línea es Si el voltaje está por debajo del mínimo recomendado verifique

demasiado bajo. en el edificio el diámetro del alambre desde el interruptor

principal. Si es el correcto, comuníquese con la empresa de

electricidad o la autoridad hidroeléctrica.

El motor está defectuoso. Reemplace la bomba.

El interruptor del flotante Reemplace la bomba.

está defectuoso.

El rodete no gira. Si el rodete no gira, saque el cuerpo inferior de la bomba y

ubique el lugar donde el rodete se traba.

El brazo del flotador es Acorte el brazo del flotante.

demasiado largo.

El movimiento del flotante Retire las obstrucciones.

está obstruido.

La bomba se pone en Hay retroceso de agua de Instale una válvula de retención.

marcha y se detiene con la tubería.

demasiada frecuencia.

El interruptor del flotante Reemplace la bomba.

está fallado.

La bomba no se Interruptor defectuoso Reemplace la bomba.

desconecta. del flotante.

Descarga obstruida Retire la bomba y limpie la bomba y la tubería.

(obstáculos o hielo en las

tuberías).

El brazo del flotante es Acorte el brazo del flotante.

demasiado largo.

El movimiento del flotante Retire las obstrucciones.

está obstruido.

Tamiz de admisión restringido. Saque la bomba y limpie el tamiz de admisión y el impulsor.

La bomba funciona pero el El voltaje de línea es baja. Si el voltaje es inferior al mínimo recomendado, verifique el

caudal es reducido o nulo. diámetro del alambre que va desde el interruptor principal en

el edificio. Si es el correcto comuníquese con la empresa de

electricidad.

Algo se ha quedado trabado Saque la bomba y limpie el impulsor.

en el rodete.

El rodete tiene piezas Limpie el rodete si está taponado, en caso contrario reemplace

desgastadas o defectuosas. la bomba.

Válvula de retención instalada Perfore un agujero de 1/16 a 1/8 pulg. (1,6 a 2 mm) de diámetro

sin el orificio de purga. entre la descarga de la bomba y la válvula de retención

(1-2” por encima del punto en que la tubería de descarga se

atornilla a la descarga de la bomba y por debajo de la línea

de agua).

Tamiz de admisión restringido. Saque la bomba y limpie el tamiz de admisión.

Verifique que la válvula no esté Asegúrese de que la válvula de retención esté debidamente

instalada hacia atrás o invertida. instalada.

GUÍA PARA LA RESOLUCIÓN DE PROBLEMAS

Tensión peligrosa y riesgo de choque eléctrico. Puede provocar choque eléctrico,

quemaduras o muerte. Desenchufe la bomba antes de realizar trabajos de reparación o de limpieza.

Para asistencia, llame a Simer Servicios al Cliente al:

1 800 468-7867 / 1 800 546-7867

Page 16

Garantia 16

GUARDE EL RECIBO ORIGINAL PARA CULAQUIER REFERENCIA POSTERIOR.

GARANTÍA LIMITADA

SIMER le garantiza al comprador consumidor original (el “Comprador” o “Usted”) de sus productos, que éstos

estarán libres de defectos en materiales y en mano de obra por un período de doce (12) meses, a partir de la fecha de

la compra original del consumidor.

Si dentro de los doce (12) meses a partir de la fecha de la compra inicial del consumidor, se comprueba que

cualquiera de esos productos es defectuoso, éste será reparado o reemplazado, a la discreción de SIMER, sujeto a los

términos y a las condiciones indicadas a continuación. Se necesitará su recibo de compra original y la etiqueta de

información sobre la garantía del producto, para determinar la admisibilidad de la garantía. La admisibilidad se basa

en la fecha de compra del producto original - no en la fecha de reemplazo bajo la garantía. La garantía está limitada a la

reparación o el reemplazo del producto solamente - El comprador pagará todos los costos de remoción, instalación,

mano de obra y envío necesarios, así como todo costo adicional asociado.

Si necesita piezas o resolución de problemas, NO regrese el producto a la tienda minorista. Llame el Servicio a la

Clientela de SIMER al 1-800-468-7867 / 1-800-546-7867.

Las reclamaciones bajo esta garantía se deberán realizar mediante la devolución del producto (excepto en el caso de

las bombas cloacales, ver a continuación) a la tienda minorista en donde se haya adquirido, inmediatamente después

de haber descubierto un supuesto defecto. SIMER entonces tomará la medida correctiva tan pronto como sea

razonablemente posible. No se aceptarán solicitudes de servicio, si se reciben más de 30 días después del vencimiento

de esta garantía.

BOMBAS CLOACALES

NO devuelva una bomba cloacal (que se haya instalado) a su tienda minorista. Comuníquese con el Departamento

de Atención al Cliente de SIMER. Las bombas cloacales que hayan estado en servicio y se hayan removido pueden

representar un peligro de contaminación.

Si su bomba cloacal ha fallado:

• Use guantes de caucho cuando manipule la bomba;

• Para los fines de la garantía, devuelva la etiqueta del cordón de la bomba y el recibo de compra original a la tienda

minorista;

• Descarte la bomba cumpliendo con todas las normas locales que correspondan para su eliminación.

Excepciones para la Garantía Limitada de Doce (12) Meses

Producto Período de garantía

BW85P, CM10, CMK, M40, M40P 90 días

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 años

Bombas de pozo sumergibles de 4”, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 años

Tanque precargado del sistema de agua, 3985, 3986 5 años

3963, 3988, 3995, 3997 De por vida

Términos y condiciones generales

Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto

por esta garantía. Esta garantía no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos

que, a sólo juicio de SIMER hayan sido sometidos a negligencia, abuso, accidente, mala aplicación, manejo

indebido o alteraciones; (3) fallas debido a instalación, operación, mantenimiento o almacenamiento inadecuados;

(4) aplicaciones, usos o servicios que no sean normales o aprobados; (5) fallas provocadas por corrosión, herrumbre

u otros materiales extraños en el sistema, o una operación a presiones que excedan los máximos recomendados.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del Comprador con respecto a los

productos defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA EXPLÍCITA O

IMPLÍCITA, INCLUYENDO PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E

IDONEIDAD PARA UN FIN ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO SE EXTENDERÁN MÁS ALLÁ DE LA

DURACIÓN PROVISTA EN LA PRESENTE.

Algunos Estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de

tiempo sobre garantías implícitas, de modo que es posible que las limitaciones o exclusiones que preceden no

correspondan en su caso. Esta garantía le otorga derechos legales específicos y es posible que Usted también tenga

otros derechos que pueden variar de un Estado al otro.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Sitio Web: http://www.simerpumps.com

Loading...

Loading...