SIMATIC NET

SPC4 Siemens PROFIBUS Controller

User Description Date 08.05.96

Order No. 6GK1 971-5XA00-0BA0

SINEC

(Siemens PROFIBUS Controller)

SPC4

User Description

Release: V1.2

Date: 08.05.1996

WKF B1 T2 SPC4

Liability Exclusion

We have tested the contents of this document regarding agreement

with the hardware and software described. Nevertheless, deviations

can’t be excluded and we can’t guarantee complete agreement. The

data in the document is checked regularly, however. Required

corrections are included in subsequent versions. We gratefully accept

suggestions for improvement.

Copyright

Copyright © Siemens AG 1995 All Rights Reserved

Unless permission has been expressly granted, passing on this

document or copying it, or using and sharing its content is not allowed.

Offenders will be held liable. All rights reserved, in the event a patent

is granted, or a utility model or design is registered.

The trademarks SIMATIC, SINEC and SOFTNET, L2 are protected

by law through registration by Siemens.

All other product- and system names are (registered) trademarks of

their respective owner and are to be treated as such.

Subject to technical change.

Page 2 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

Table of Contens

1 INTRODUCTION 7

2 FUNCTION OVERVIEW 8

3 PIN ASSIGNMENT 9

4 MEMORY ASSIGNMENT 10

4.1 Addressing of the SPC4 10

4.2 Memory Area Distribution of the Internal RAM 11

4.2.1 Overview 11

4.2.2 RAM Parameter Block 12

4.2.3 SAP List 12

4.2.4 Data Areas in the Internal RAM 14

4.2.5 Addressing via the Memory Window 14

4.3 Assignment of the Parameter Latches 15

5 FLC INTERFACE 18

5.1 SAP List 18

5.1.1 Structure of the SAP List 18

5.1.2 Control Byte 18

5.1.3 Request SA 20

5.1.4 Request SSAP 20

5.1.5 Access Byte 20

5.1.6 Reply Update Ptr/ SDN-DDB-TIn-Tab-Ptr 21

5.1.7 Special Features for the DEFAULT SAP 22

5.2 SM-SAP List 22

5.3 Indication Queue 23

5.3.1 Description 23

5.3.2 Structure of the Indication Block 24

5.4 Reply on Indication Blocks 27

5.4.1 Function 27

5.4.2 Structure of the Reply-on-Indication Blocks 27

6 DP INTERFACE 29

6.1 Description 29

6.2 Productive Services 30

6.2.1 Data Exchange 30

6.2.2 Read Input Data 31

6.2.3 Read Output Data 32

6.2.4 Global Control (Sync, Freeze, Clear Data) 32

6.2.5 Leave Master 34

6.2.6 Baudrate Search 34

SPC4 User Description Release V1.2 Page 3

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

7 ASIC INTERFACE 36

7.1 Latch Parameters 36

7.1.1 Slot Time Register 36

7.1.2 Baudrate Register 36

7.1.3 BEGIN PTR Register 37

7.1.4 UMBR PTR Register 38

7.1.5 BASE PTR Register 38

7.1.6 TRDY Register 38

7.1.7 PREAMBLE Register 39

7.1.8 SYN Time Register 39

7.1.9 Delay Timer Register 39

7.1.10 Factor Delay Timer Clock Register 40

7.1.11 Mode Register 40

7.2 RAM Parameter Block 46

7.2.1 Indication Write Pointer 46

7.2.2 Indication Write PRE Pointer 46

7.2.3 Indication Read Pointer 46

7.3 Interrupt Controller 47

7.4 SPC4 Timer 52

7.4.1 Delay Timer 52

7.4.2 Idle Timer 53

7.4.3 Syni Timer 53

7.4.4 Slot Timer 53

7.4.5 Time Out Timer 54

8 ASYNCHRONOUS INTERFACE 55

8.1 Baudrate Generator 55

8.2 Transmitter 55

8.3 Receiver 55

8.4 Serial Bus Interface PROFIBUS Interface (asynchronous) 55

8.4.1 Interface Signals 55

8.4.2 Timing RS 485: 56

8.4.3 Example for the RS 232 Interface 57

9 SYNCHRONOUS INTERFACE 58

9.1 Overview 58

9.2 Baudrate Generator 58

9.3 Transmitter 58

9.4 Receiver 60

10 CLOCK SUPPLY 61

Page 4 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

11 PROCESSOR BUS INTERFACE 63

11.1 Universal Processor Interface 63

11.2 Bus Interface Unit (BIU) 65

11.3 Dual Port RAM Controller 65

11.3.1 Function 65

11.3.2 Access to the SPC4 under LOCK 65

11.4 Other Pins 66

11.4.1 Test Pins 66

11.4.2 XHOLDTOKEN 66

11.4.3 XINTCI 66

11.5 Interrupt Timing 67

11.6 Reset Timing 67

11.7 Intel / Siemens 8051 (synchronous) etc. 68

11.7.1 Diagram 68

11.7.2 Timing 80C32 69

11.8 Intel X86 (asynchronous) 70

11.8.1 Diagram 70

11.8.2 Timing X86 71

11.9 Siemens 80C165 (asynchronous) 73

11.9.1 Diagram 73

11.9.2 Timing 80C165 74

11.10 Motorola 68HC16 (asynchronous) 76

11.10.1 Diagram 76

11.10.2 Timing 68HC16 76

11.11 Motorola 68HC11 (synchronous) 78

11.11.1 Diagram 78

11.11.2 Timing 68HC11 78

12 TECHNCIAL SPECIFICATION 80

12.1 Maximum Limits 80

12.2 Permissible Operating Values 80

12.3 DC Specification of the Pad Cells 81

12.4 Identification Data for the Output Drivers 81

13 CASING 82

13.1 Notes on Processing 83

14 BIBLIOGRAPHY 84

SPC4 User Description Release V1.2 Page 5

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

15 ADDRESS LIST 84

15.1 PNO 84

15.2 Technical Contact Persons in the Interface Center 84

16 APPENDIX 85

16.1 Server Software for the SPC4 85

16.1.1 Application 85

16.1.2 Special features of the PROFIBUS -PA / -FMS / -DP server software: 85

16.1.3 Functions of the Server Software 86

16.2 SIM1 88

16.2.1 Area of Appliction 88

16.2.2 Special Functions 89

16.2.3 Fields of application 89

16.2.4 Function of the Application 90

16.2.5 Electrical Data 91

Page 6 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

1 Introduction

For simple and fast digital exchange between programmable logic controllers, Siemens offers its users

several ASICs. These ASICs are based on and are completely handled on the principles of the PROFIBUS

DIN 19245, Part 1 and the Draft, Part 3, of data traffic between individual programmable logic controller

stations.

The following ASICs are available to support intelligent slave solutions, that is, implementations with a

microprocessor.

The SPC (Siemens Profibus Controller) is built directly on Layer 1 of the OSI model and requires an

additional microprocessor for implementing Layers 2 and 7.

The ASPC2 already has integrated many parts of Layer 2, but the ASPC2 also requires a processor’s

support. This ASIC supports baud rates up to 12 Mbaud. In its complexity, this ASIC is conceived primarily

for master applications.

Due to the integration of the complete PROFIBUS-DP protocol, the SPC3 decisively relieves the processor

of an intelligent PROFIBUS slave. The SPC3 can be operated on the bus with a baud rate of up to 12

MBaud.

However, there are also simple devices in the automation engineering area, such as switches and

thermoelements, that do not require a microprocessor to record their states.

There are two additional ASICs available with the designations SPM2 (Siemens Profibus Multiplexer,

Version 2 ) and LSPM2 (Lean Siemens PROFIBUS Multiplexer) for an economical adaptation of these

devices. These blocks work as a DP slave in the bus system (according to DIN E 19245 T3, EN 50 170)

and work with baud rates up to 12 Mbaud. A master addresses these blocks by means of Layer 2 of the 7

layer model. After these blocks have received an error-free telegram, they independently generate the

required response telegrams.

The LSPM2 has the same functions as the SPM2, but the LSPM2 has a decreased number of I/O ports and

diagnostics ports.

In the SPC4, parts of Layer2 which handle the bus protocol, are already integrated. For the remaining

functions of Layer2 (interface service, management), an additional microprocessor is needed.

In addition to the Layer2 functionality, the following productive services are integrated: Data_Exchange,

Read_Input, Read_Output and the Global_Control command of DIN E 19245 Part 3(EN 50 170), as well as

the PROFIBUS PA functionality (Part 4).

The server software offered for the SPC4 provides support for simple access to the protocols

o FMS

o PA

o DP

The analog ASIC SIM1 facilitates the configuration of the PROFIBUS PA interface (synchronous)

considerably. Please have also a look to the short descriptions in the appendix, and the detailed

descriptions of the analog ASIC SIM1 and the Server Software.

The chip supports passive stations on the bus system and filters out all external messages as well as faulty

user messages.

SPC4 User Description Release V1.2 Page 7

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

2 Function Overview

Except for the bus drivers, the entire PROFIBUS periphery is contained in the SPC4. The additional

processor doesn’t have to make a hardware timer available( except the Server Software), in order to

process the bus protocol.

Baudrates starting with 9.6kBd to 12MBd are supported.

The SPC4 has a universal micro-controller interface with an 8bit data bus interface and a 10 bit address

bus. Depending on the configuration, the data-/address bus can be operated multiplexed or separate; thus,

processors with standard Intel timing, with Motorola timing, with SABC165 timing or with 80C32 timing can

be connected.

Since the interface supports INTEL- as well as MOTOROLA architectures, the Intel- or Motorola data format

is specified with two configuration pins, and synchronous (rigid timing) or asynchronous (with Ready

support) processor bus timing is supported.

The handshake between the processor and the SPC4 is executed by the FLC firmware (Fieldbus Link

Control) and carried out via the 1.5 kB Dual Port RAM integrated in the SPC4.

From the view of the user, the SPC4 occupies an address space of 1kByte.

The SPC 4 carries out all the checks when request messages are received.

Page 8 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

3 PIN Assignment

The SPC4 has a 44 pin EIAJQPF casing with the following signals:

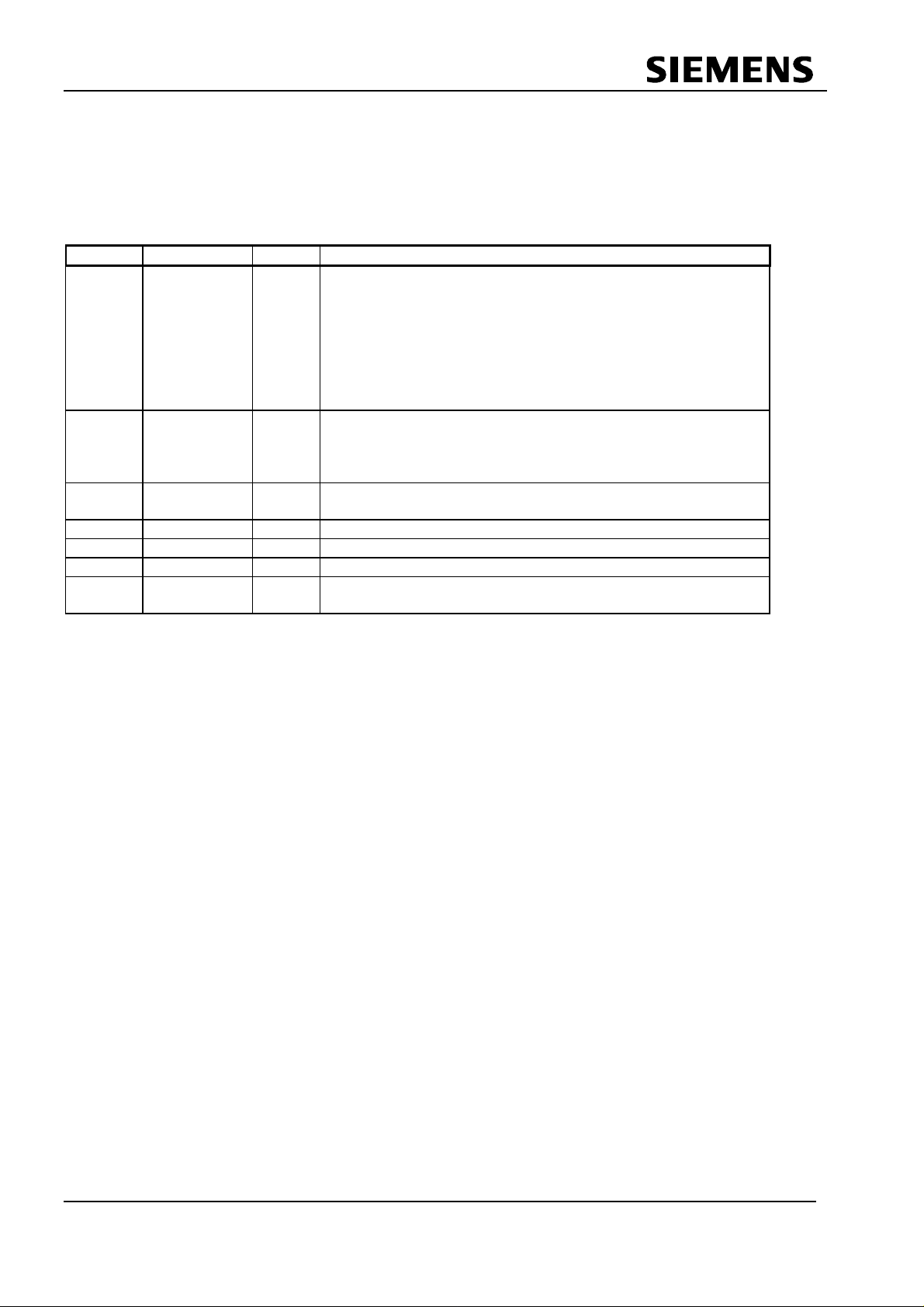

Pin Signal Name In/

1 XCS I Chip Select CPU C32 Mode: apply to

2 XWR / E I Write Signal

3 Divider I Divider for ISCLK-OUT (Pin 7)

4 XRD

R/W

5 CLK I Clock Input System

6 GND

7 ISCLK-Out O Clock divided by 2 or 4 System, CPU

8 TYP I see mode table

9 XINT O Interrupt Output CPU, Interrupt Contr.

10 XINTCI O not used

11 DB0 I/O Data Bus CPU, Memory C32 Mode: Data-

12 DB1 I/O Data Bus CPU, Memory alt.: Data-/Address Bus

13 XHOLDTOKEN O not used

14 XREADY

XDTACK

15 DB2 I/O Data Bus CPU, Memory

16 DB3 I/O Data Bus CPU, Memory

17 GND

18 VDD

19 DB4 I/O Data Bus CPU, Memory

20 DB5 I/O Data Bus CPU, Memory

21 DB6 I/O Data Bus CPU, Memory

22 DB7 I/O Data Bus CPU, Memory

23 MODE I see Mode Table System

24 ALE

AS

25 AB9 I Address Bus CPU C32 Mode: <log> 0

26 TXD-TXS O serial Send Channel RS 485 Sender

27 RTS-ADD O Request to Send RS 485 Sender

28 GND

29 AB8 I Address Bus System, CPU

30 RXD-RXS I serial Receive Channel RS 485 Receiver

31 AB7 I Address Bus System, CPU

32 AB6 I Address Bus System, CPU

33 XCTS I Clear to Send <log> 0 = send enable MODEM/FSK

34 XTEST0 I Pin has to be applied to VDD permanently

35 XTEST1 I Pin has to be applied to VDD permanently

36 RESET I Reset Input: connect with portpin of CPU

37 AB4 I Address Bus System, CPU

38 GND

39 VDD

40 AB3 I Address Bus System, CPU

41 AB2 I Address Bus System, CPU

42 AB5 I Address Bus System, CPU

43 AB1 I Address Bus System, CPU

44 AB0 I Address Bus System, CPU

Note: all signals which start with X.. are low-active

Description Source/Destination Processor Variant

Out

E-Clock for Motorola 1pulse=1memory cycle (for

asynchronous operation, apply to VDD)

0=:4, 1=:2

I Read Signal

Read/Write for Motorola (low=Write)

O Ready for external CPU

Data Transfer Acknowledge for Motorola

I Address Latch Enable

Address Strobe for Motorola (for synchronous

operation, apply to VDD)

CPU

System

CPU

System, CPU

CPU C32 Mode: ALE

VDD

alt.: CS-Signal

/Address Bus

multiplexed

separate

Motorola Mode AS

SPC4 User Description Release V1.2 Page 9

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

4 Memory Assignment

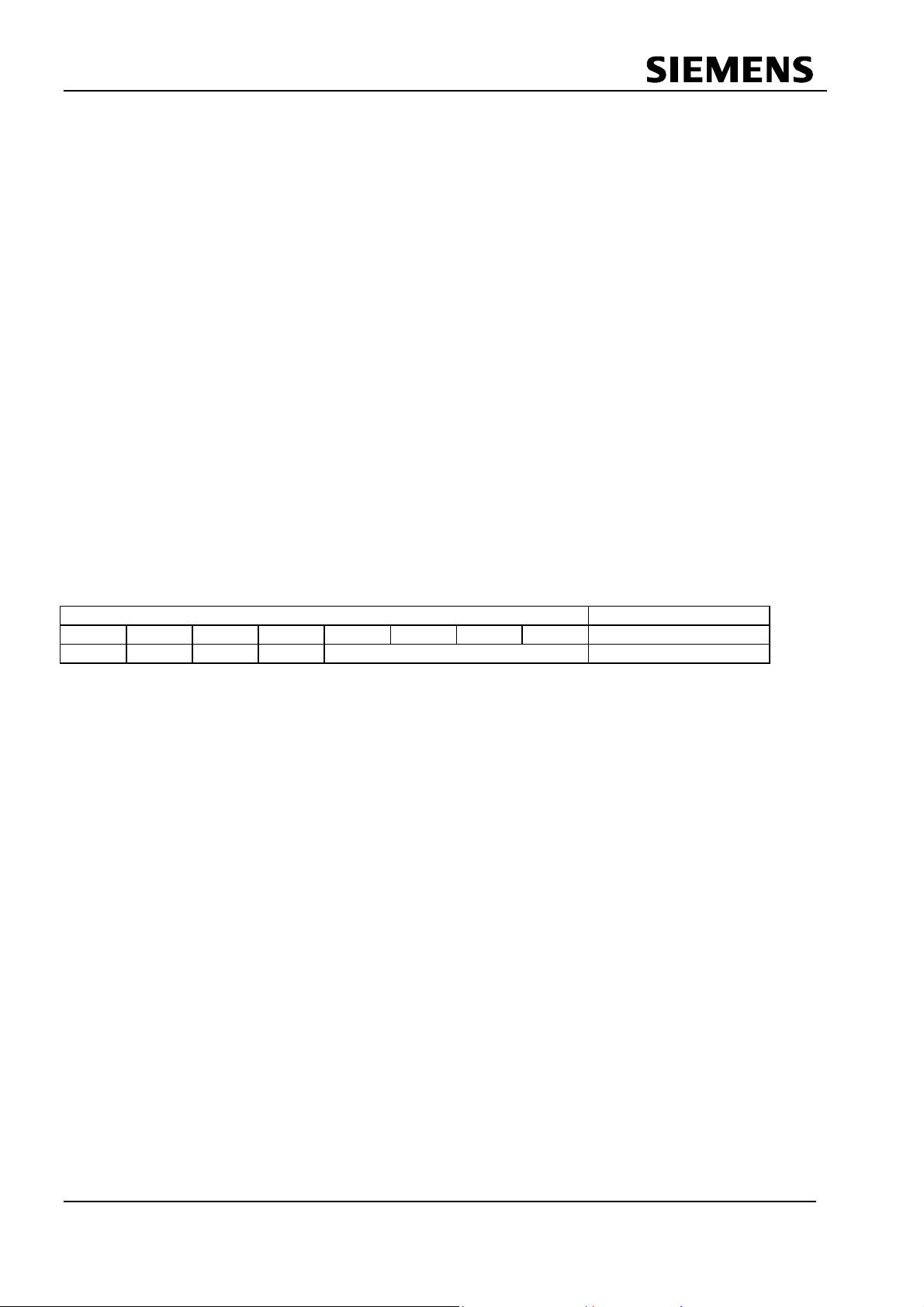

4.1 Addressing of the SPC4

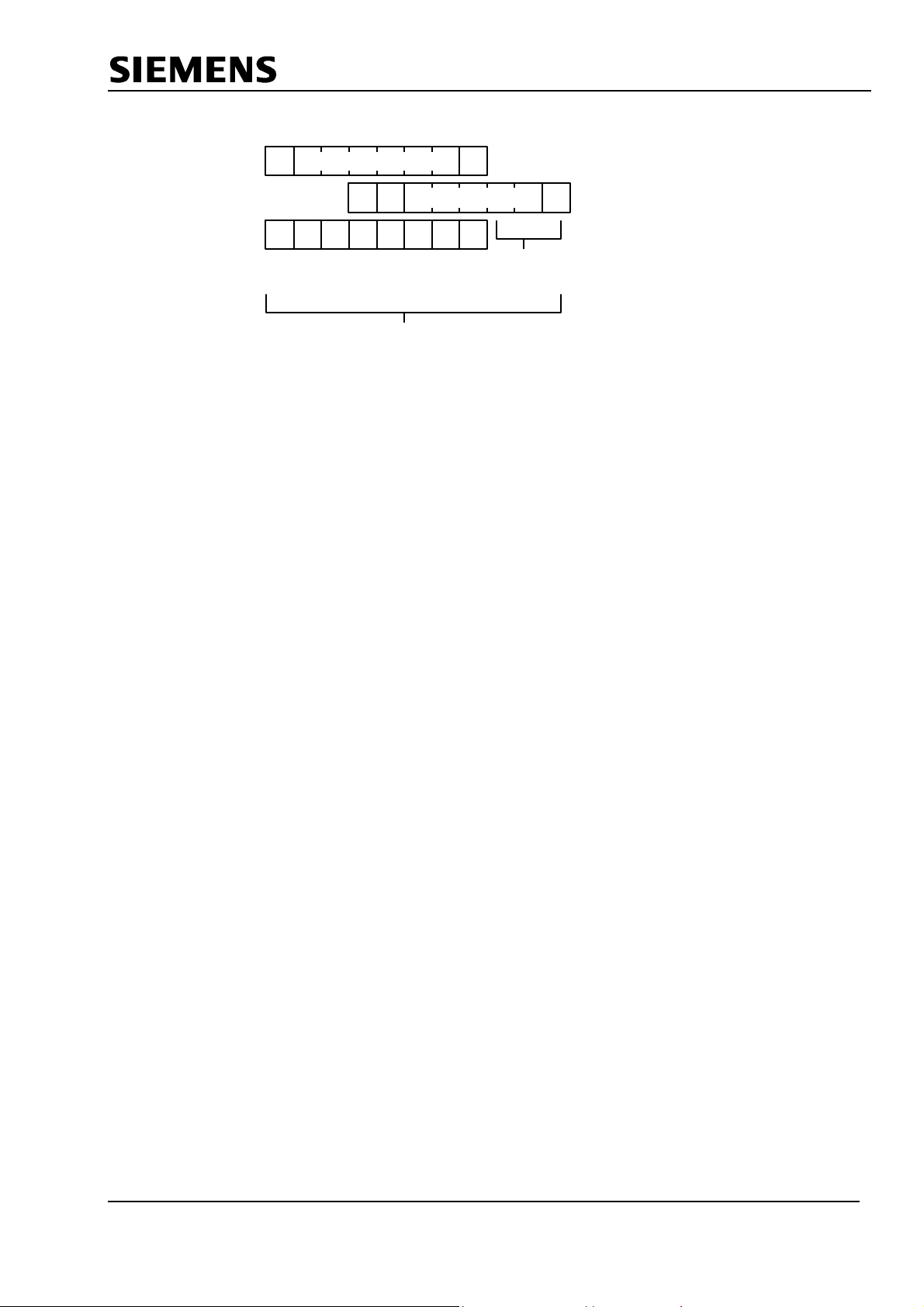

From the view of the user, the 1.5 kByte internal Dual Port RAM and the internal latches use a 1kByte

address space. Parts of the internal RAM are directly imaged into the address area of the microprocessor;

the other parts can be addressed via a window mechanism.

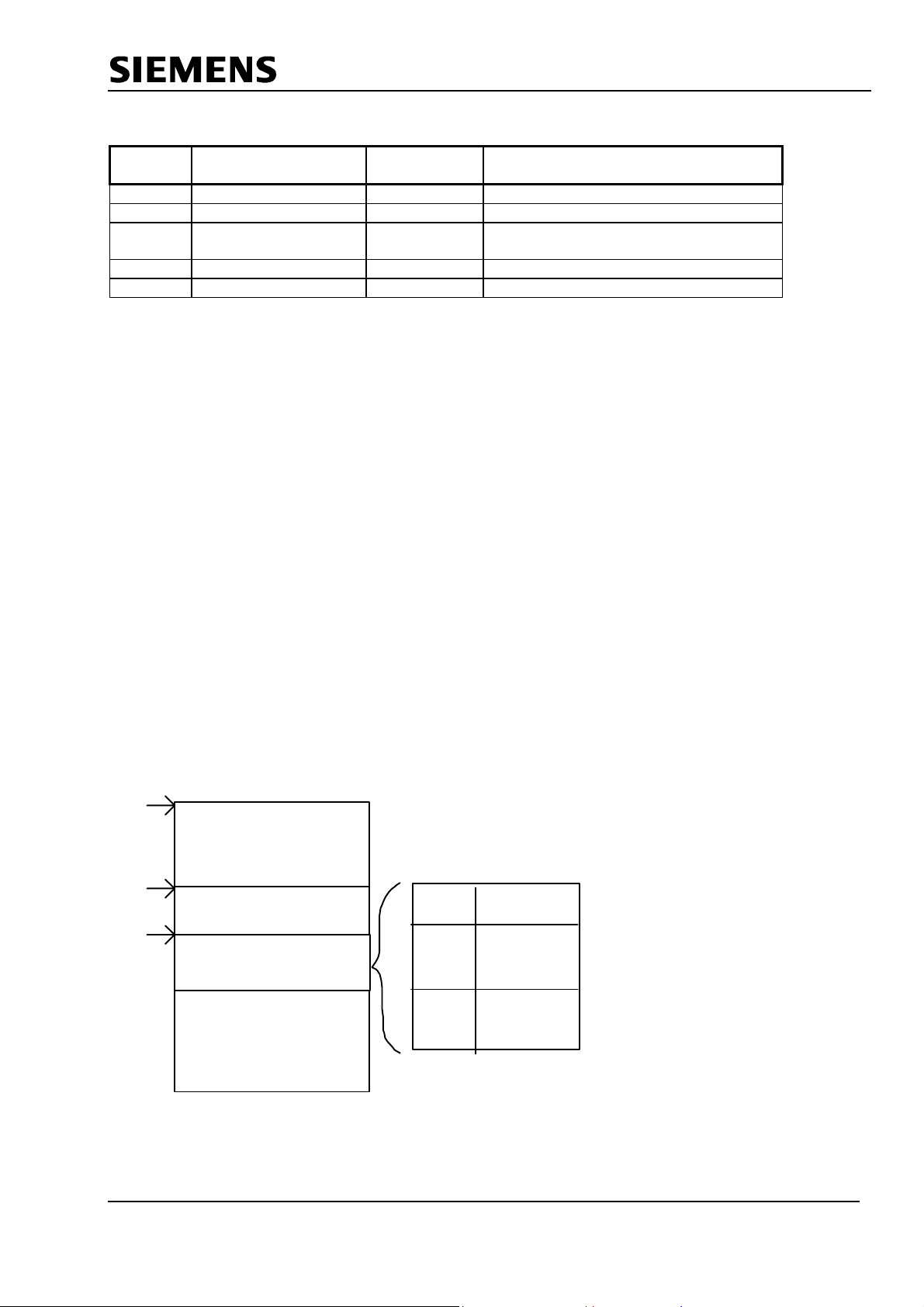

0H

1FFH

200H

MicroProcessor

512 Byte

General

Parameter

SAP-List

SPC4

0H

1.5 kB RAM

256 Byte

Memory Window

Base Pointer

2FFH

300H

256 Byte

Control Unit

Parameter

3FFH

Figure 4.1 Addressing the Internal 1.5k RAM

The 1k byte address range is divided into four 256 byte blocks with different functions.

Via the lower address window, the FLC can directly access the first 512 (2x256) bytes of the RAM physically

(without having to load the base pointer). This has the advantage that the FLC can access the general

parameters and the SAP list directly, without having to load the base pointer first.

Page 10 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

5FFH

Latches

SPC4 WKF B1 T2

Via the second 256 kByte address window (200h to 2FFh), the entire internal memory can be addressed

with an 8 bit base pointer. The FLC has to load this pointer; it always addresses the beginning of an 8 byte

segment. Thus, the FLC can address up to 256 bytes via the offset address applied to the address pins of

the SPC4.

The third segment which also consists of 256 bytes (300h to 3FFh), addresses the internal latches which are

stored for directly controlling the hardware. These latches are not integrated in the internal RAM area!

Address BitA9Address BitA8Window Select

0 0 Parameter Area (physically 00h-FFh)

0 1 Parameter Area (physically 100h-1FFh)

1 0 entire RAM via Base Pointer

1 1 Parameter Latches

Table 4.1 Window Select

Attention: The hardware won’t prevent overwriting the address area; that is, if the user writes beyond the

station table, the parameters in the lower memory area are overwritten through the wrap-around. In this

case, the SPC4 generates the Mem-Overflow interrupt. If the user writes on write-protected parameters, an

access violation interrupt will be generated.

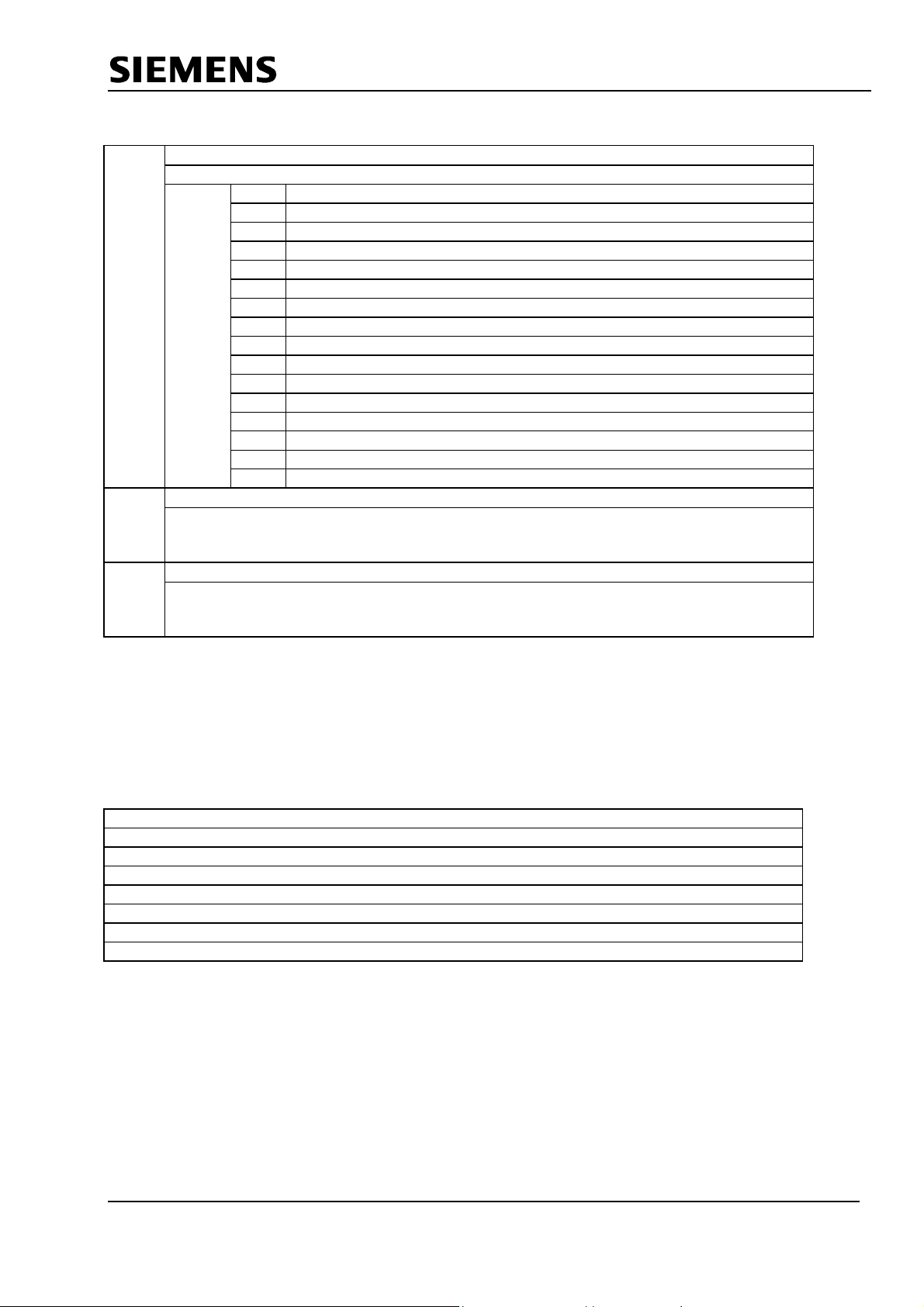

4.2 Memory Area Distribution of the Internal RAM

4.2.1 Overview

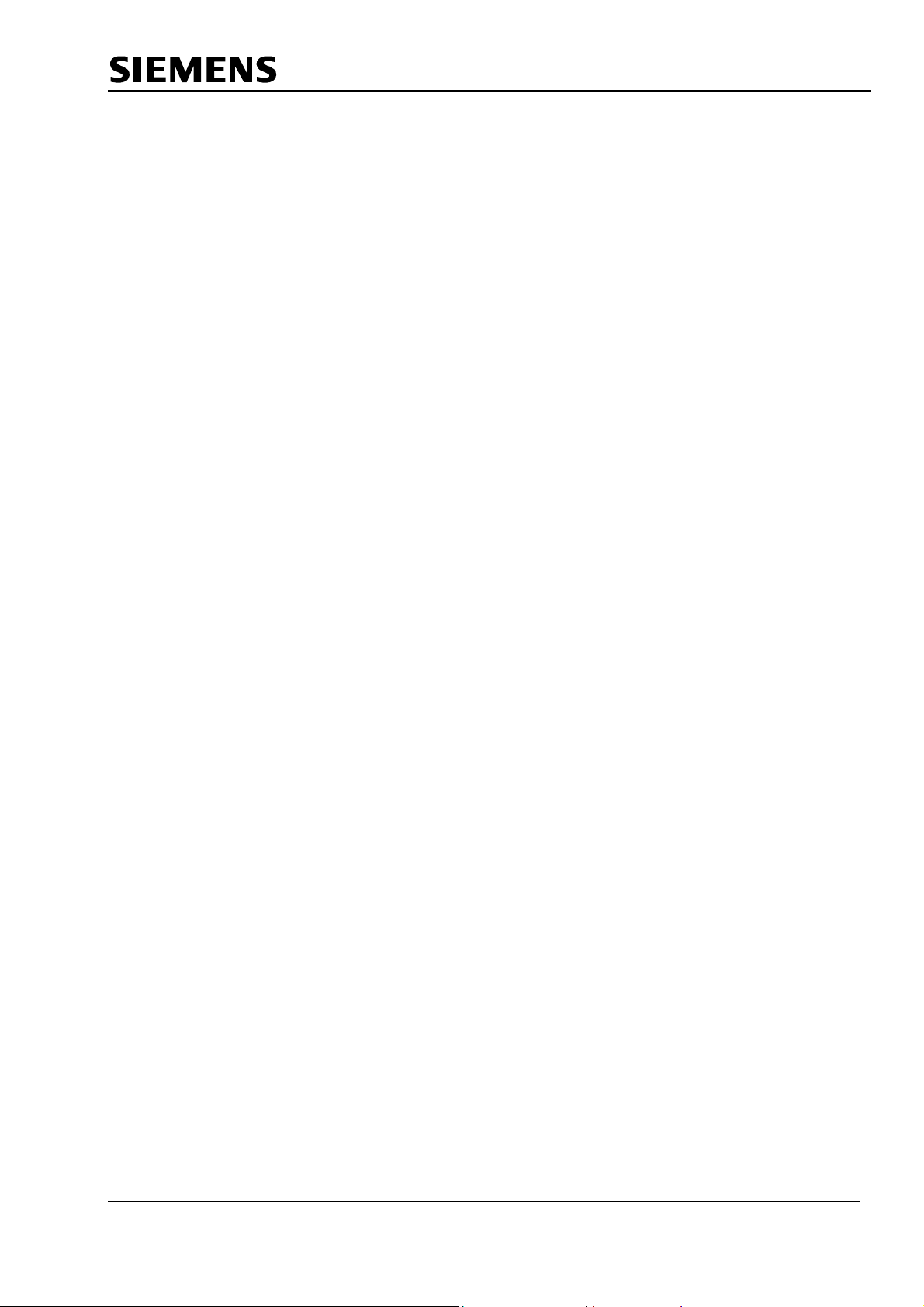

The figure shows the distribution of the internal 1.5k RAM of the SPC4. The entire memory, divided into

segments of 8 bytes each, is broken down into different areas.

Segment 0

BEGIN-PTR

UMBR_PTR

RAM Parameter

SAP-List

SM-SAPs (5x5 byte)

Default-SAP (16 byte)

SAP-0..SAP-63

(64 x 5 byte)

Indication Queue

Reply on IndicationBlocks

Exchange Buffer

Byte 0

Segment 0

Byte 7

Segment 1

Segment 2

Segment 3

Segment 4

Station Table

Ident Buffer

Segment 191

Figure 4.2 Memory Area Distribution

SPC4 User Description Release V1.2 Page 11

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

4.2.2 RAM Parameter Block

In the first 6 bytes of the integrated RAM, the general parameters, such as the read- and write pointers of

the indication queue, are filled which don’t directly engage the control. The FLC is only to write parameters

with the addresses 00H to 5H. The internal user cells are not allowed to be overwritten (the hardware will

generate a write violation interrupt and enter Offline).

Address Name Access Meaning

00H IND-WP-PRE RD/WR The write pointer for early indication processing points to the

next free segment which follows the request message received

last, even if no indication “IND” has been made. The pointer

IND-WP-PRE makes fast slave reaction possible (for example,

for PROFIBUS DP). Immediately after the correct receipt of a

request message (and before a response message is sent), the

pointer IND-WP-PRE is set to the next free segment boundery.

At the same time, the interrupt “IND-PRE” is generated.

01H IND-WP RD/WR The write pointer of the indication queue points to the next free

segment which follows the request message indicated last.

With each indication interrupt “IND”, the SPC4 will set IND-WP

to a new segment boundary.

02H IND-RD RD/WR The read pointer of the indication queue is also a segment

address and is managed by the FLC.

03H FDL-Ident-Ptr RD/WR Pointer to ident-buffer

04H TS-ADR-REG RD/WR Contains station address

05H SAP-MAX RD/WR The highest SAP list number is parameterized

06H..17H internal

working cells

The following cells must not be overwritten (write violation

interrupt)

Table 4.2 Assignment of the RAM Parameter Block

In addition to correctly setting up the corresponding address bits, access to the parmeter latches or the

internal RAM also requires applying an XCS signal to the SPC4. Moreover, the XREADY signal of the

SPC4 has to be noted, or corresponding wait states have to be inserted.

When writing the RAM parameters, the upper, unutilized bits have to be set to ‘0’, while for the

parameter latches, the unassigned bit positions are ‘don’t care’.

4.2.3 SAP List

The SAP list can be addressed directly; segmentation and using the base pointer are not required, but

addressing via the base pointer is also possible. To address the data to which an SAP points, the base

pointer must be used.

The area of the SAPs uses 361 bytes; that is, 46 segments (segment 5...50; of the last segment, only 1

byte is assigned). The SAP list consists of the following:

- 5 SM SAPs (System Management Service Access Point) of 5 bytes each

- DEFAULT SAP with 16 bytes

- 64 SAPs of 5 bytes each

The function of the individual registers and bits is explained in the following chapters.

Page 12 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

Address Name Register Meaning

18H SM1 Control Byte Bit Information

19H Request-SA Request-Source Address

1AH reserved

1BH reserved

1CH Reply-Update-Ptr/

SDN-DDB/-Tln-Tab-Ptr

1DH - 21H SM2 see above SM1 see above SM1

22H - 26H SM3 see above SM1 see above SM1

27H - 2BH SM4 see above SM1 see above SM1

2CH - 30H SM5 see above SM1 see above SM1

31H DEFAULT

SAP

32H Request SA Request-Source Address

33H Request SSAP Request-SourceServiceAccessPoint

34H Access Byte Access Protection

35H Reply-Update-Ptr/

36H Reply-Update-Ptr D

37H Reply-Update-Ptr N

38H Reply-Update-Ptr U

39H Response-Buffer-Length

3AH Response Status

3BH Indication-Buffer-Ptr D

3CH Indication-Buffer-Ptr N

3DH Indication-Buffer-Ptr U

3EH Indication-Buffer-Length

3FH Active-Group-Ident

40H Control Command

41H SAP[0] Control-Byte Bit Information

42H Request-SA Request-SourceAddress

43H Request SSAP

44H Access-Byte

45H Reply-Update-Ptr/SDN-DDB/-Tln-

46H - 4AH SAP[1] see above SAP (0) see above SAP(0)

4BH -

17BH

17CH SAP[63] Control-Byte Bit Information

17DH Request-SA Request-SourceAddress

17EH Request SSAP

17FH Access-Byte

180H Reply-Update-Ptr/SDN-DDB/-Tln-

181-187H not used The indication queue has to start at

188H IndicationQueue Start of Indication Queue

SAP[2]-

SAP[62]-

Control Byte Bit Information

SDN-DDB/-Tln-Tab-Ptr

Tab-Ptr

see above SAP (0) see above SAP(0)

Tab-Ptr

Pointer to Response Buffer

Pointer to Response Buffer

Pointer to response buffer

Pointer to Response buffer

the beginning of an 8 Byte segment

Table 4.3: SAP List

SPC4 User Description Release V1.2 Page 13

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

4.2.4 Data Areas in the Internal RAM

4.2.4.1 Indication Queue

The FLC can set the memory area of the indication queue at the segment boundaries.

The BEGIN-PTR is the address of the 1st segment of the indication queue. The end of the queue is marked

by the UMBR_PTR. The UMBR_PTR points to the address of the 1st segment which is not part of the

indication queue.

After initialization, both pointers have to be set to the desired area start in the offline state. THEY

CAN’T BE CHANGED DYNAMICALLY; that is, to modify memory distribution, the SPC4 has to be set

to the offline state. Exchanging the pointer sequence leads to faulty behavior of the SPC4 relative

to the individual memory areas.

If the SPC4 receives request messages, it will enter them in the indication queue. The indication queue is

organized as cyclic buffer (queue); that is, data to be processed is successively entered in the queue as

long as there is enough memory space, while blocks which have been processed are removed. The

indication queues are organized with write- and read pointers. The FLC has to set the indication read

pointer (IND-RP), while the hardware of the SPC4 is responsible for updating the indication write pointer

(IND-WP).

Since it is a cyclic buffer, the end of the queue is to be monitored when data is entered. If the end of the

queue is exceeded, the address has to be wrapped around. For this, the SPC4 offers hardware support

which does the wrap-around automatically.

4.2.4.2 Reply on Indication Blocks

In these buffers, the FLC has to make reply data available. The reply data is assigned to the calls via

pointers in the SAP lists.

4.2.4.3 Exchange Buffers

If PROFIBUS DP services are to be supported (DP mode = 1 in Mode Register 0), six exchange buffers

have to be made available.

4.2.4.4 Ident Buffer

The ident buffer contains the reply data for ident messages.

4.2.4.5 Station Table

The station table is needed for filtering SDN and DDB response messages.

4.2.5 Addressing via the Memory Window

The physical address of the integrated RAM is generated (when addressing the SPC4 via the address

window (200h to 2FFh)) from the base pointer, the segment address for the indication queue and the lower 8

bits of the address bus. For this, the address bus adds the base pointer to the address shifted by 3 bit

positions.

The address is calculated in an ALU which also automatically calculates the address wrap- around when the

queue boundary is exceeded. If the queue boundary is exceeded, the central processor calculates the wrap

around address according to the following pattern:

New segment address = base pointer + AB7..3 - end pointer + start pointer

Together with the 3 least significant address bits, the result is the physical 11bit RAM address for the

memory. After the FLC has loaded the base pointer, it can read up to 256 data bytes through the central

processor, without having to reload the base pointer, and without having to concern itself with the wrap

around at the queue boundary.

Page 14 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

Base Pointer Register

SPC4 WKF B1 T2

+

A10

11 Bit-RAM Address

Address Bus Bit 7..0

A3

Byte Address

within a Segment

Figure 4.3 Calculating the Physical RAM Address

4.3 Assignment of the Parameter Latches

Access to the internal parameter latches -that is, those memory cells which directly intervene in the controlis only possible at the SPC4 via the address window 300H to 3FFH.

These cells can either only be read or written, and in that case, have a different function. In the Motorola

mode, the SPC4 swaps addresses when accessing the address area of 300H (word register); that is, it

exchanges the address bit 0 (it generates from an even address an odd one, and vice versa).

The SPC4 has an 8 bit data interface. When accessing the byte register via this interface, it makes no

difference whether the SPC4 is operated in the Intel- or in the Motorola mode.

When a word register ( two byte register) is accessed, the SPC4 has to decide between Intel and Motorola:

Example: INT-MASK-REG

Intel Mode: write access with address 300

ð INT-MASK-REG (7..0) is written (little endian)

Motorola Mode: write access with address 300

ð INT-MASK-REG (15..8) is written (big endian)

The meaning of the individual bits in the registers is described in more detail in the following chapters.

Since the addresses of the parameters latches are not completely decoded, these registers will reappear at

every 32 bytes. This facilitates implementation since different addresses (names) can be assigned for the

read- and write accesses.

SPC4 User Description Release V1.2 Page 15

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

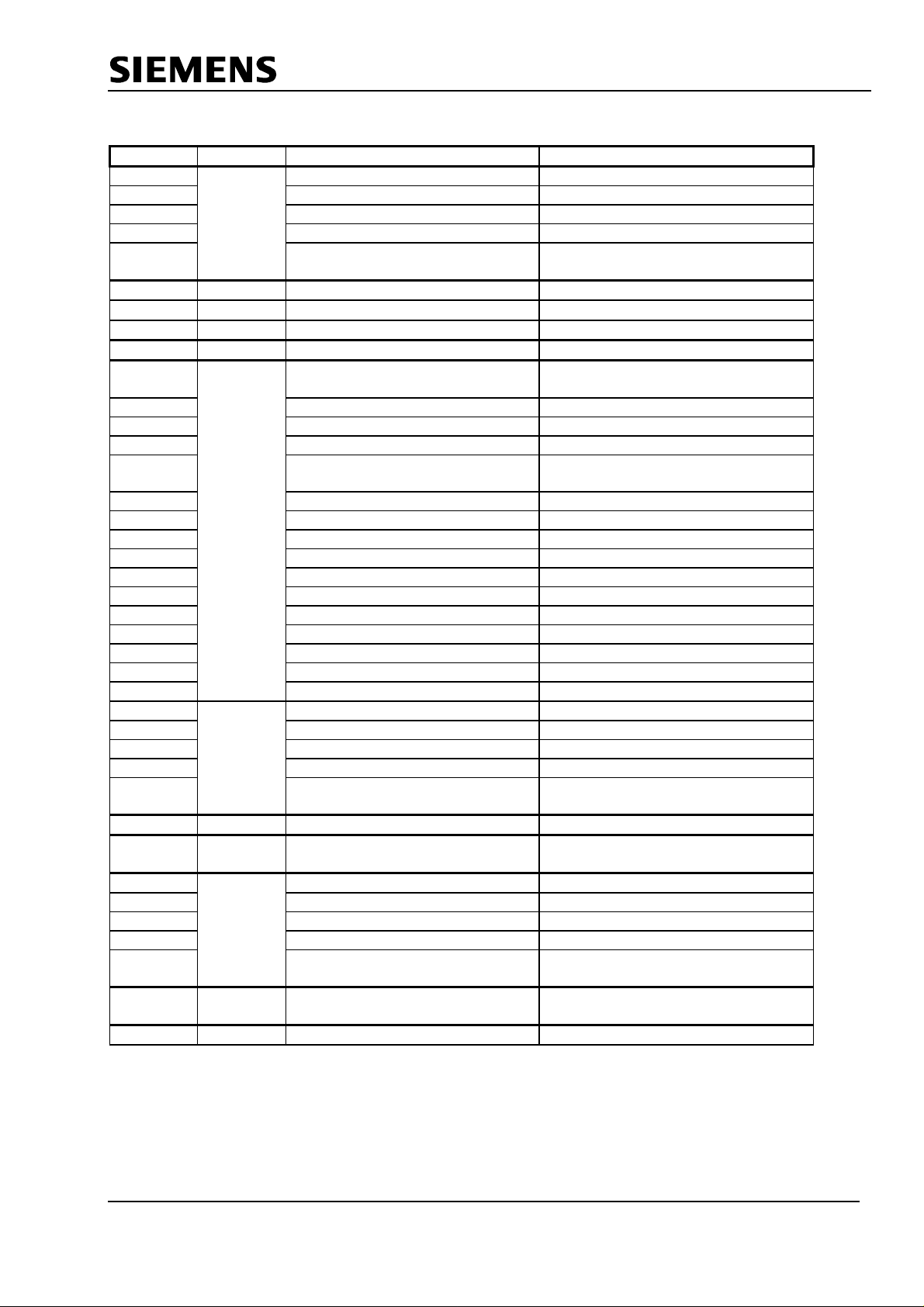

Addresse

Intel /Motorola

300H 301H Int--Req-Reg 7..0 Interrupt Controller Register

301H 300H Int--Req-Reg 15..8

302H 303H Int-Reg 7..0

303H 302H Int-Reg 15..8

304H 305H Status-Reg 7..0 Status Register

305H 304H Status-Reg 15..8

306H 307H Delay 7..0 Delay Timer Register (actual counter value)

307H 306H Delay 15..8

308H 309H reserved

309H 308H reserved

30AH 30BH reserved

30BH 30AH reserved

30CH- 30FH reserved

310H reserved

311H reserved

312H reserved

313H reserved

314H reserved

315H reserved

316H reserved

317H reserved

318H Mem-Lock 0 Memory Lock Cell

319H reserved

31AH reserved

Name

Meaning (READ Access !)

Figure 4.4 Assignment of the Internal Parameter Latches for READ

Page 16 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

Address

Intel /Motorola

300H 301H Int--Mask-Reg 7..0 Interrupt Controller Register

301H 300H Int--Mask-Reg 15..8

302H 303H Int-Ack-Reg 7..0

303H 302H Int-Ack-Reg 15..8

304H 305H TSLOT 7..0 Parameter assignment of Wait-to-Receive time

305H 304H TSLOT 13..8

306H 307H BR-REG 7..0 Parameter assignment of the division factor

307H 306H BR-REG 10..8 for generating the baudrate

308H 309H TID1 7..0

309H 308H TID1 10..8

30AH 30BH FACT-DEL-CLK 7..0 DelayTimer for SM time service

30BH 30AH FACT-DEL-CLK 10..8

30CH- 30F reserved

310H UMBR_PTR S 7..0 UMBR_PTR points to the address of the first

311H Mode-Reg 7..0 Parameter assignment of single bits

312H Mode-Reg1-Res 5..0

313H Mode-Reg1-Set 5..0

314H Base-PTR 7..0 Base address for accesses to the internal RAM

315H TRDY 7..0 Parameter assignment for TRDY (ready time valid

316H PREAMBLE Parameter assignment of number of bits

317H TSYN The following time is parameterized:

318H Mem-Lock 0 Memory Lock Cell

319H BEGIN-PTR 7..0 BEGIN-PTR points to the smallest segment

31AH Mode-Reg2 2..0 Parameter assignment of single bits

Name

Meaning (Write Access !)

segment which is no longer part of the indication

queue

before sending a response message)

(preamble) in the synchron-mode

TSYN (33Bit asynchronous mode)

TIFG (Interframe GAP-Time; synchronous mode)

address of the indication queue. The BEGIN-PTR

have to point at the beginning of an 8 byte

segment.

Figure 4.5: Assignment of the Internal Parameter Latches for WRITE

SPC4 User Description Release V1.2 Page 17

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

5 FLC Interface

5.1 SAP List

5.1.1 Structure of the SAP List

In the FLC, a data transmission service is processed via a Service Access Point (SAP). For each station,

up to 64 SAPs, that is SAP [0..63], are possible at the same time, and the default SAP.

Communication from DEFAULT SAP to a SAP and vice versa is possible. The SPC4 checks the Request

SSAP.

Each SAP (including the DEFAULT SAP) has special entries in the SAP list; via this SAP list, the FLC

makes receive resources available. If the SPC4 receives a message to a SAP which is not available, it will

respond with No Service Activated (SD1 response).

In the SAP list already described, individual registers are assigned to each SAP.

5.1.2 Control Byte

Bit Position Designation

7 6 5 4 3 2 1 0

SAPLocked

SDN/

DDBFilter

RS/RA

or UE

RR IN USE Buffer available Control Byte

Page 18 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

Bit 0-2 Buffer available

The three bits are counters for the resources made available externally. The FLC

increments the 3 bits, as soon as it loads a resource. The SPC4 decrements the 3 bits,

if a received block was indicated. At receipt, after it has received the entire message,

the SPC4 reads the 3 bits. If the status = zero, it will cancel the receipt, set the event

flag ‘No Ressource’ (RR, see below) and respond with No Ressource (SD1-Response)

Exception:

If DP Mode = 1 is set, the SPC4 will not change Buffer Available in the DEFAULT

SAP. Buffer Available has to be parameterized larger than zero, however; otherwise,

the response will be No Resource.

Bit 3 IN USE

The SPC4 will set this bit as soon as it has entered the complete message of a request

message in the indication buffer. It will only reset it if an indication was executed (valid

or invalid). If the FLC wants to assign a new reply block, it has to wait until the bit is

reset. Only then (under Mem-Lock) can it reload the Reply Update Pointer. This

prevents that the FLC can reload data for the SPC4 during transmission operation.

Exception:

If DP Mode = 1 is set, the SPC4 will not set the In Use Bit in the DEFAULT SAP. A

correctly received request message to the DEFAULT SAP will not be entered in the

Indication Queue and not be indicated.

Bit 4

RS/RA or UE

No Service Activated/ Service Access Point Blocked or User-Error: the SPC4 will

set this flag if the plausibilization of Request-SA was negative (Request SA differs from

the SA received ; that is, the call is from an unauthorized station). The SPC4 responds

with Service Access Point Blocked [RA] in the PA-Mode or No Service Activated

[RS] in the Profibus-Mode (SD1-Response). This flag will also be set if Request-SA =

7FH, that is, if the SAP is inactive. The SPC4 responds with No Service Activated

[RS] (SD1-Response). This bit is set as User Error [UE] if the SAP was locked. The

SPC4 responds with User Error [UE] (SD1-Response).

SPC4 WKF B1 T2

Bit 5

Bit 6

Bit 7

Figure 5.1: Control Byte

RR = No Resource

The SPC4 will set this bit if, after receipt of the message header, the content of the

Buffer Available bit = zero; that is, the FLC has made no resources available or the

queue is full. In both cases, the SPC4 will respond with No-Ressource[RR] (SD1-

Response).

SDN-/DDB-Filter

This bit makes it possible to activate the SDN-/DDB filter

0 = The “Reply-Update-Ptr/SDN-/DDB-Tln-Tab-Ptr“ pointer points to the Reply-

1 = The “Reply-Update-Ptr/SDN-/DDB-Tln-Tab-Ptr pointer points to the station

SAP locked

For the moment, the SAP is not accepting data. If the SPC4 receives data for this SAP,

it will set the event flag User Error (UE) and respond with User Error (SD1-Response).

on-Indication block and with that, to the response to be transmitted. If the

pointer = 00H, no response buffer is available, and the SPC4 responds to an

SRD request with a short acknowledgement (SC).

table, and the SPC4 is a “subscriber” for this SAP. The SDN-/DDB-Tln list

will be evaluated at the access “Subscriber for DDB-Response“ and SDNRequest.

SPC4 User Description Release V1.2 Page 19

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

5.1.3 Request SA

The SA received is compared with this entry. If it differs, the SPC4 will set the event flag No Service

Activated (RS) and respond with Service Access Point Blocked [RA] in the PA mode, and with No Service

Activated [RS] in the Profibus mode (SD1 Response). In the case of the default-SAP, the addresses 00H 7EH are possible; in the case of all other SAPs, 80H - FEH (expansion bit set); 7FH leads to “No Service

Activated” since 7FH is locking the SAP. If this entry = FFH (=all), the call won’t be checked. If an SRD is

received with DDB, the bit “SDN-/DDB Filter” will be tested in addition, and if needed, compared further in

the DDB-TIn list, before there is a response or the event flag is set.

5.1.4 Request SSAP

The SSAP received is compared with this entry. If it differs, the SPC4 will set the event flag No Service

Activated (RS) in the PA mode, and Service Access Point Blocked (RA) in the Profibus mode, and respond

with No Service Activated (SD1 Response). If Request SA is 00H-7EH, Request-SSAP = FFh will select

the DEFAULT SAP. If the expansion bit is set in Request SA, and the Request SSAP = FFH, SSAP will not

be checked.

5.1.5 Access Byte

The access byte controls access protection to the matching SAP at receipt. The entry 0H means “no access

protection”. If the SPC4 receives a message that doesn’t match the access byte, it will respond with “NO

SERVICE ACTIVATED”. The event bit RS will be set.

All access violations are filtered to the FLC, the response [RS] (No Service Activated) is transmitted to the

requester. The DDB response (subscriber) is an exception; it is not acknowledged negative.

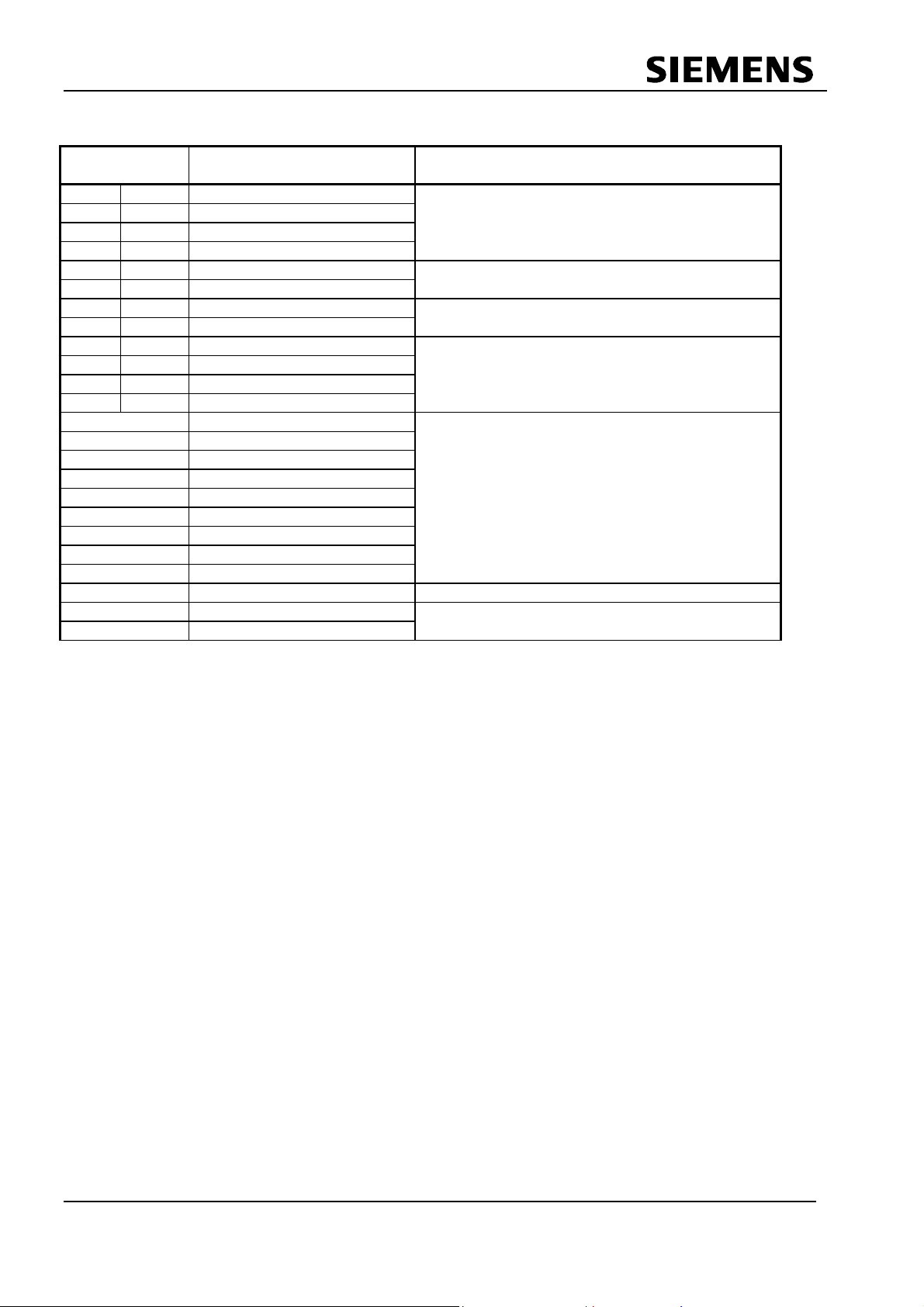

Bit Position Designation

7 6 5 4 3 2 1 0

IND-N RUP-N Access Value Access Byte

Page 20 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

Bit 0-3

Bit 4

Bit 5

Access Value

Access Protection

0H = All

1H = SDN-Low

2H = SDN-High

3H = SDN-Low/High

4H = 5H = SDA-Low

6H = SDA-High

7H = SDA-Low/High

8H = SRD-Low/High DDBREQ DDB-RES-Low/High

9H = SRD Low

AH = SRD-High

BH = SRD-Low/High

CH = DDB-REQ

DH = DDB-RES-low

EH = DDB-RES-high

FH = DDB RES low/high

RUP-N-Valid (Only for DEFAULT SAP)

This bit is set by the application, if in the DP-Mode, valid input data is entered in the

Reply-Update-Buffer N. The SPC4 will reset the RUP-N-Valid, after it has

exchanged the Reply Update Buffers D and N

IND-N-Valid (Only for DEFAULT SAP)

This bit will be set by the SPC4 if in the DP mode, valid output data is entered in

Indication Buffer N . The FLC will reset IND-N-Valid after the FLC has exchanged

the Indication Buffers N and U.

Figure 5.2 Access Byte

5.1.6 Reply Update Ptr/ SDN-DDB-TIn-Tab-Ptr

The Reply Update Ptr/ SDN-DDB-TIn-Tab-Ptr pointer points to the Indication Reply Buffer, or to the SDN/DDB-TIn list (see also SDN-/DDB filter). The data buffers have to be above the UMBR_ PTR in the SPC4.

The SDN-/DDB-TIn list has the following structure:

SDN-/DDB-Tln List (optional)

tab-data-length 8 Bit indicates the length of the SDN-/DDB-Tln list

don’t care 8 Bit

Request-SA 1 8 Bit 1st entry in the DDB-Tln list Meaning like Request-SA

Request-SSAP 1 8 Bit 1st entry in the DDB-Tln list Meaning like Request-SSAP.

........

Request-SA n 8 Bit n entry in the DDB-Tln list Meaning like Request-SA

Request-SSAP n 8 Bit n entry in the DDB-Tln list Meaning like Request-SSAP.

Figure 5.3: SDN-/DDB List

All SDN messages (except SM TIME; it is always indicated and DDB response messages can be filtered by

the SPC4 via the station table. In this station table, the “Request SA” and the “Request SSAP” are defined

per entry. Only if the received SDN-/DDB message with one of the entries is plausible, there will be an

indication.

The SDN-/DDB filter is active if the bit “SDN/DDB filter” is set in the receive-SAP. The station table is

addressed by the pointer “SDN-/DDB-TIn-Tab-Ptr”. If “tab-data-length” = 0, the SDN-/DDB-TIn list is not

plausibilized.

SPC4 User Description Release V1.2 Page 21

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

In order to make it possible for the sender to process via the DEFAULT-SAP, “req-ssap=0FFh” and the

expansion bit “req-sa” = 0 has to be entered in the station table on the receiver side. In all other cases, the

expansion bit “req-sa” = 1 is set.

5.1.7 Special Features for the DEFAULT SAP

When using the DP mode, the following entries are also to be processed in the SAP list.

• • Reply Update Ptr D,N,U:

These 8 bit pointers point to the 1st segment respectively of the Reply Update Buffers D, N and U. In

the Reply Update Buffer U, the FLC compiles the input data, and then exchanges the U-Buffer with the

Reply Update Buffer N. The SPC4 responds to a request message with the input data from the Reply

Update Buffer D. The SPC4 receives new input data by exchanging the D and N buffer. The Reply

Update Buffers D, N and U only contain net data.

• • Response Buffer Length:

This value specifies the length of the Reply Update Buffers D, N and U (0 to 246 bytes).

• • Response Status:

specifies the priority of the response messages to the DP master. 2 values are permitted:

- 08H: response low priority

- 0AH: response high priority

• • Indication Buffer Ptr D, N and U:

These 8 bit pointers point respectively to the 1st segment of the Indication Buffers D, N and U. In the

Indication Buffer D, the SPC4 enters output data received faultlessly from the master, and then

exchanges (possibly not until Sync, see Chapter 2.7) the D-Buffer with the Indication Buffer N. The

output data of the FLC is in the Indication Buffer U.The FLC receives new output data by exchanging

Indication Buffer U and N. The Indication Buffers D, N and U only contain net data.

• • Indication Buffer Length:

This value specifies the length of the Indication Buffers D, N and U (0 to 246 bytes).

• • Active Group Ident:

This byte encodes the association of the DP slave with 8 groups maximum. Active group ident is ANDoperated bit by bit with the group select byte of a received Global Control Message (GCM). The DP

slave is addressed if the bit by bit AND operation supplies a value unequal to zero at at least one

position. If the group select byte of the GCM = zero, all DP slaves are addressed.

• • Control Command of a Global Command Message

Here, the SPC4 enters the last received control command of a global control message.

5.2 SM-SAP List

The structure of the SM-SAP entries is analog to the normal SAPs.

Register Meaning

Control Byte Bit Information

Request SA Request SourceAddress

reserved

reserved

Reply-Update-Ptr/SDN-DDB/-Tln-

Tab-Ptr

Pointer to Reply Buffer

SAPs which are not needed are to be deactivated; for example, with Request SA=7FH.

Page 22 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

SAP Service Transmission

Description

Function Code

SM1 SM_SDN 2 SM-SDN messages

SM2 SM_SRD_SLOT_DEL 10 SM-SRD-Slot-Del messages

SM3 SM_SRD_SLOT_KEEP11 SM-SRD-Slot-Keep messages

SM4 SM_SRD 1 SM-SRD messages

SM5 SM_Time 0 SM-Time messages

Figure 5.4 SM SAP list

The use of the SM-SAPs depends on the control octet. No SAP expansions are used, analog to the use of

the DEFAULT-SAP.

The SPC4 recognizes from the message received (CO field) which SM service is to be executed, and

assigns it autonomously to the matching SAP (see table).

Like all other messages, the services SM_TIME and SM_SDN are transferred to the Indication Queue; no

resources are needed for transmission (slave).

5.3 Indication Queue

5.3.1 Description

If the SPC4 receives a message, it will enter the message header in the indication queue, and then check

the free length in the queue (this is possible, because one segment always has to remain free). If at least

one segment (8 bytes) is free (in addition to the spec. free segment), it will continue receiving and enter the

data in the queue as long as free memory is available. When receiving a request message (call), the SPC4

plausibilizes the corresponding message headers with the values specified for it from the SAP list.

The Indication Queue is managed as circular buffer with read- (IND-RD) and write pointers (IND-WR). The

SPC4 is responsible for the write pointer, and the FLC for the read pointer.

The pointer IND-WR-PRE makes fast slave reaction possible (for DP, for example). An indication interrupt

will be generated (if corresponding parameter was assigned) after the correct receipt of the request

message, and not at the end of the next message to another station.

BEGIN-PTR

IND-RD

IND-WR

Indication Queue

Indication Block n-1

Indication Block n

Indication-Block

Response

Header

(2 Byte)

Request

Header

(6 Byte)

Request

Buffer

(max. 246

Byte)

resp-buf-ptr (8 Bit)

indic-status

(00 valid, CFH invalid)

req-data-length

rem-adr

loc-adr

co-code

rem-sap

loc-sap

Figure 5.5: Structure of the Indication Queue

If a message is received without SAP expansion (rem SAP, loc SAP), the SPC4 will enter 0FFh in the

corresponding cell.

SPC4 User Description Release V1.2 Page 23

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

Page 24 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

5.3.2 Structure of the Indication Block

SPC4 WKF B1 T2

SPC4 User Description Release V1.2 Page 25

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

Response Header

Byte 0 resp-buf-ptr This pointer points to the relocated response buffer (in the area Reply-On-

Indication blocks, see Memory Area Distribution). It is recopied by the SPC4

from the SAP list

Byte 1 indic-status Here, the SPC4 enters the status 00 for a ‘valid indication’.

Request-Header (Message Header of the Requester)

Byte 2 req-data-

length

Byte 3 rem-adr Here, the SPC4 enters the SA received. The remote station, which is to

Byte 4 loc-adr Here, the SPC4 enters DA received.

Byte 5 co-code This value specifies the function code of the request message. Here, the

This value specifies the length of the entered net data in the request buffer (0

to 244 Bytes with SAP expansion, 0 to 246 bytes without SAP expansion).

maintain data traffic with the respective SAP of the local station {sentence

not quite clear in original}. It can be entered in the SAP lists under req-sa as

filter.

complete control octet, as received from the bus, is entered.

Function Code

Request FDL-Status with Reply x9H

Send Data with no Acknowledge low x4H

Send Data with no Acknowledge high x6H

Send Data with Acknowledge low x3H

Send Data with Acknowledge high x5H

Send and Request Data low xCH

Send and Request Data high xDH

SM_Time x0H

SM_SRD x1H

SM_SDN x2H

SM_SRD_SLOT_DEL xAH

SM_SRD_SLOT_KEEP xBH

Send and Request Data with DDB x7H

DDB-Response low y8H

DDB-Response high yAH

x:

Frame Type 1; that is, Bit 6=1 and FCB/FCV according to message entry

y:

Frame Type 0; that is, Bit 6=0 and station type1 according to message entry

Bit 7 (b8) of the control octet received is only evaluated for SM time

messages; for all other request messages, bit 7 (b8) of the control octet is

don´t care

Byte 6 rem-sap Here, the SPC4 enters the service access point (SSAP) of the remote

station. This field is only valid if the expansion bit in rem-adr is set (the two

upper bits of rem-sap have to be ‘0’ ). If a message is received without SAP

expansion (rem-SAP, loc-SAP), the SPC4 will enter 0FFh .

Byte 7 loc-sap Here, the SPC4 enters the service access point (DSAP) of the local station.

This field is only valid if the expansion bit in rem-adr is). If a message is

received without SAP expansion (rem-SAP, loc-SAP), the SPC4 will enter

0FFH .

Request Buffer contains the received message

Byte 8 data 0 Byte 0 of the net data

Byte

data 0+x Byte x of the net data

8+x

Figure 5.6: Indication Block

1

Note: For PROFIBUS, the station-type is bit 5 (b6) und bit 4 (b5), for PA bit 7 (b8) is relevant in addition.

Page 26 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

5.4 Reply on Indication Blocks

5.4.1 Function

The FLC has to load response data in the buffers of the Reply-on-Indication blocks.

If response data is requested, the SPC4 will fetch the reply update pointer from the corresponding SAP lists,

and transmit the loaded data from the reply buffer. If the request is processed, the SPC4 will indicate {index}

the request by entering the status (valid indication) in the response buffer, setting the write pointer to the

next free segment and generate the interrupt IND.

A request is processed and will be indicated if:

• an SM message, an SDN- or a DDB response message was received faultlessly.

• an SDA- or SRD message was received faultlessly, the response has been transmitted and the next

request message to another station or (with toggeled FCB/FCV bits) to its own station address was

received correctly.

If the SPC4 receives an SRD- or a DDB request message with net data length = 0, and if the response data

length also = 0, the SPC4 will not enter this message in the indication queue(empty polling).

With a bit in the responder status (byte 2), the FLC can control how often the loaded data is transmitted

from the indication reply buffer. If Bit (4):single update reply is set in “resp-status” of the indication reply

buffer, a loaded response in the indication reply buffer is transmitted only once. If this bit = log. “0”, the

SPC4 will again transmit the buffer to this SAP with each call message (multiple update reply).

The less significant nibble (lower 4 bits) indicates whether the request is transmitted high priority or low

priority.

5.4.2 Structure of the Reply-on-Indication Blocks

Area of Reply-on-Indication Blocks

WRAP AROUND

-PTR1

Indication Reply Buffer

Indication Block

Byte 1

Byte 2

Net Data

Buffer of Responder

resp-buf-ptr

Reply-Update-PTR

(SAP List)

resp-buf/data-length

resp-status

(08h,18h: low priority

0Ah,1Ah high priority)

Figure 5.7: Structure of Reply-on-Indication Block

The response buffer is attached to the area ‘Reply on Indication Blocks’ and contains the response buffer

length, the response status and the pure net data of the response message.

SPC4 User Description Release V1.2 Page 27

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

Reply Header

Byte 0 resp-data-

length

Byte 1 resp-status In this field, the responder status is stored. The FLC has to load the

Reply Buffer contains the response data

Byte 3 data 0 Byte 0 of the net data

Byte

8+x

Figure 5.8: Reply-on-Indication Block

data 0+x Byte x of the net data

Here, the FLC enters the length of the response buffer.

status. The following codes are permitted:

Function Code

Response FDL/FMA1/2-data low

(& Send Data OK)

Response FDL/FMA1/2-data high

(& Send Data OK)

Bit (4) = x :Single Update Reply

If this bit is set in addition, a reply loaded in the indication buffer is

transmitted only once. Otherwise, the SPC4 will retransmit this buffer

for each reply message

000x1000b

000x1010b

Page 28 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

6 DP Interface

6.1 Description

In the PROFIBUS DP mode (DIN 19245 Part 3), the SPC4 supports the following productive services:

• • Data Exchange

• • Read Input Data

• • Read Output Data

• • Global Control (Sync, Freeze, Clear Data)

Other PROFIBUS DP services (diagnosis, parameterisation and configuration) have to be realized by the

FLC; that is, the software has to operate the corresponding SAPs according to the PROFIBUS DP state

machine.

For the above named services to be supported by the SPC4, DP Mode = 1 is to be set in Mode Register 0.

In the DP mode, data between the DEFAULT SAP of the DP master and the DEFAULT SAP of the DP

slave is exchanged with exchange buffers:

For received data (output data), the Indication Buffers D, N and U are available. For the response data

(input data), the Reply Update Buffers D, N and U are used.

No indication interrupts will be generated. If new output data is made available to the FLC, the interrupt

“Output Data Exchange” will be generated. The interrupt “Watchdog Reset” indicates that valid output data

from the DP master to the DEFAULT SAP was received. The interrupt “Watchdog Reset” causes the FLC

to reset the “Software Watchdog” which monitors the activity of the DP master.

Request messages to an SAP other than the DEFAULT SAP are only accepted if SSAP differs from

DEFAULT SAP. Request SSAP has to be parameterized by the FLC correspondingly. The received data is

entered in the indication queue. The reply is made with the data of the Reply Update Buffer to which the

Reply Update Pointer of the addressed SAP points. If the received request data is entered in the indication

queue, the pointer “IND-WP-PRE” is set to the next free segment, and the interrupt “IND-PRE” is generated.

If the request is processed, the pointer IND-WP is also set to the next free segment and the interrupt “IND”

is generated (indication).

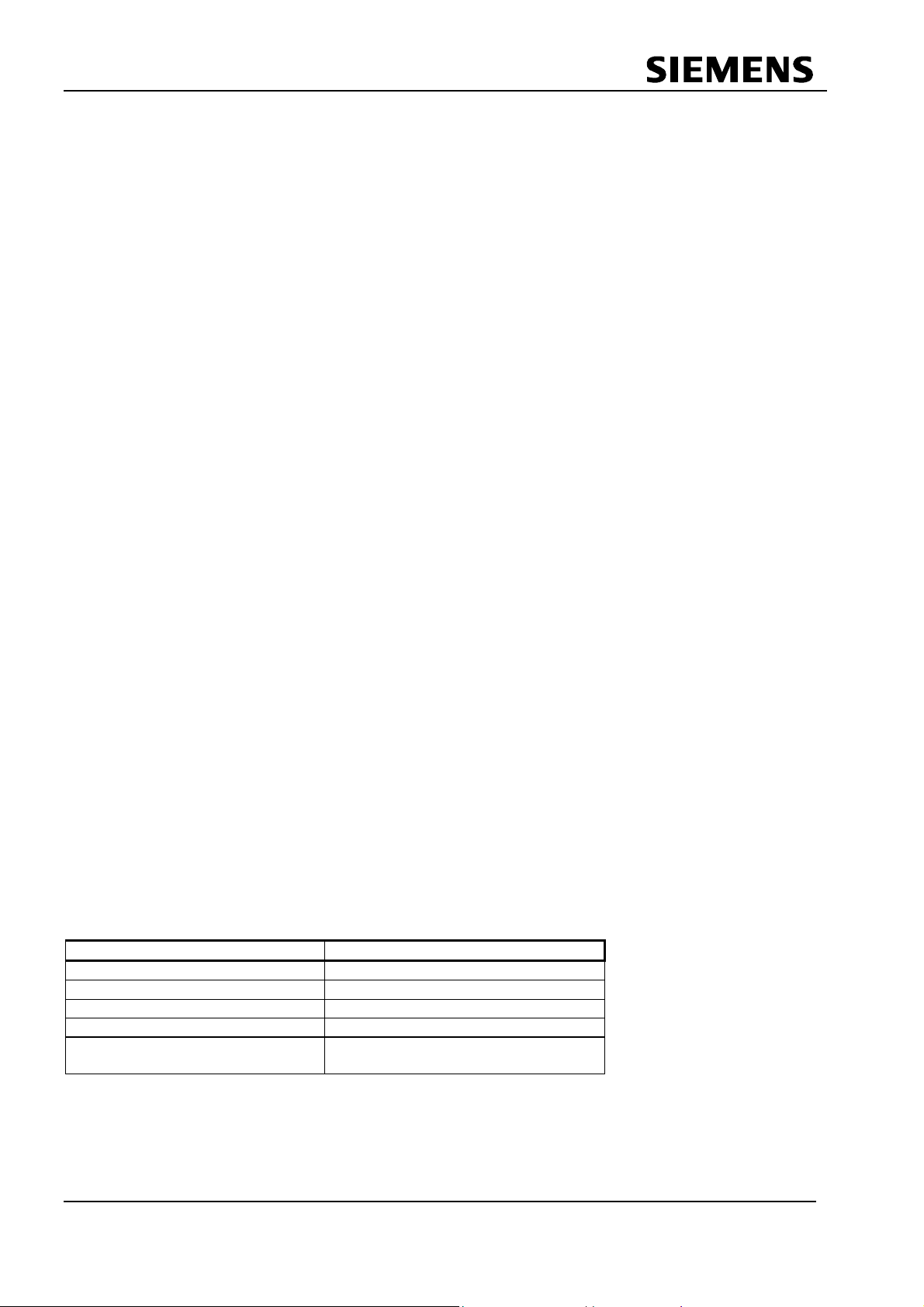

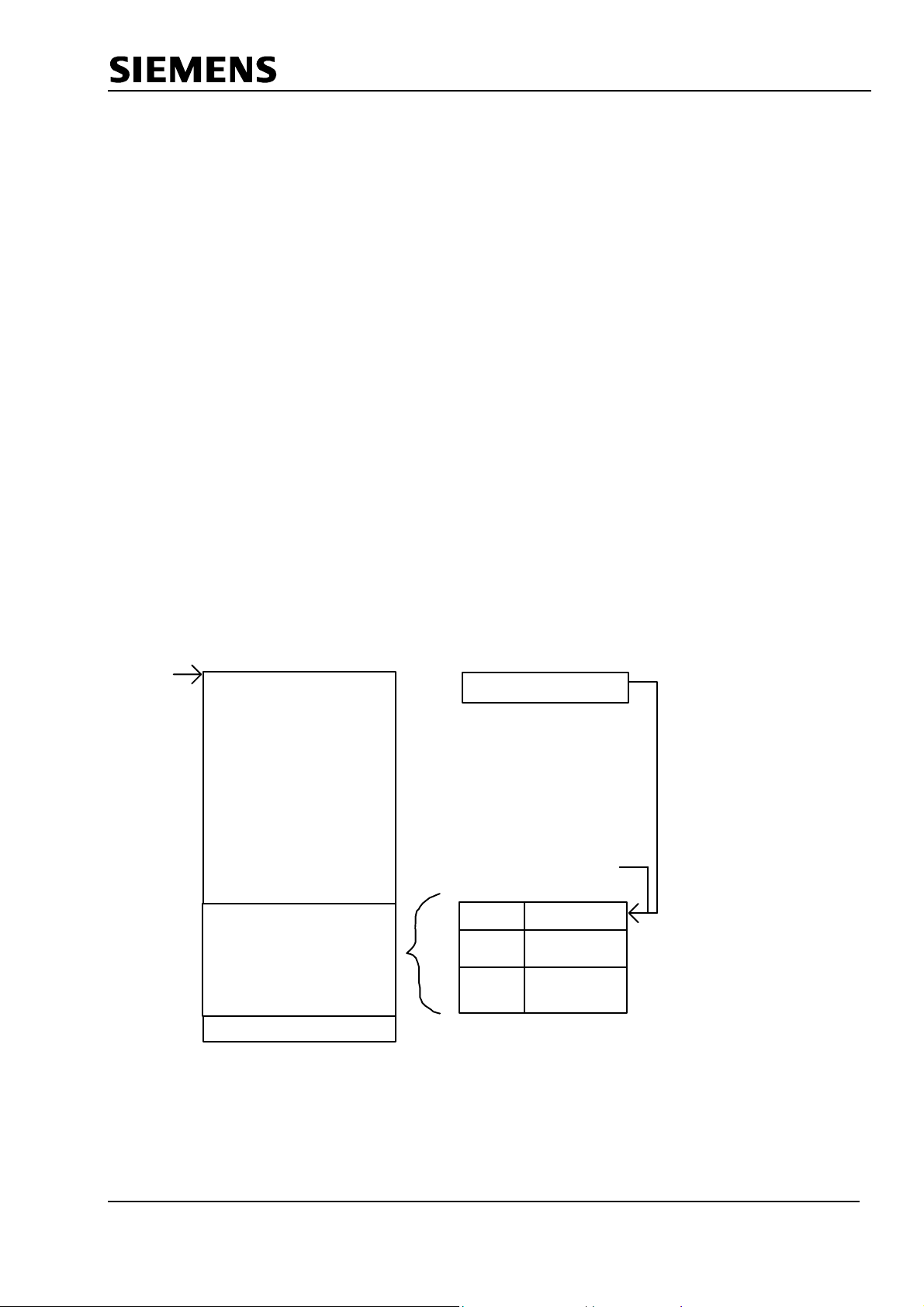

The figure below shows the principle of the exchange buffer:

Exchange Exchange

through FLC

Buffer

U

Buffer

D

through SPC 4

Buffer

N

Figure 6.1: Exchange Buffer Principle

In the Indication Buffer D, the SPC4 enters output data to the local DEFAULT SAP, received faultlessly

from the DEFAULT SAP of the DP master. The SPC4 generates the interrupt “Watchdog Reset”. Then, the

SPC4 exchanges the Indication Buffers D and N either immediately (DIAG.SYNC Mode = 0), or with the

next “Sync” command (DIAG.SYNC Mode = 1). After exchanging the Indication Buffer Pointers D and N,

the SPC4 will set the flag IND-N-Valid = 1 in the DEFAULT SAP, and generate the interrupt “Output Data

Exchange”.

SPC4 User Description Release V1.2 Page 29

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

These indications are carried out under Lock to guarantee data consistency. If the FLC wants to update its

output data in the Indication Buffer U, it has to check first whether IND-N-Valid = 1 (that is, whether valid

output data is entered in the Indication Buffer N). If this is the case, the FLC can update its output data by

exchanging the Indication Buffers N and U. In addition, the FLC has to reset the flag IND-N-Valid = 0 in the

DEFAULT SAP. The FLC has to carry out these actions under Lock.

In the Reply Update Buffer U, the FLC combines the input data, and then exchanges the U buffer with the

Reply Update Buffer N. In addition, the FLC has to set the flag RUP-N-Valid = 1 in the DEFAULT SAP

when the Reply Update Pointers U and N are exchanged. The FLC has to carry out these actions under

Lock. If the DP master requests input data with a request message, the SPC4 will respond

• either with the “old” input data of Reply Update Buffer D (that is, Reply Update Buffer D and N are not

exchanged before the response is transmitted). This is the case if no valid input data is entered in the

Reply Update Buffer N (that is, RUP-N-Valid = 0 in the DEFAULT SAP) or the input data in the Reply

Update Buffer D is frozen (DIAG.FREEZE Mode = 1, see Chapter 2.7.4);

• or with the “new” input data, if before transmitting the response, the Reply Update Buffers D and N are

exchanged. The buffers are exchanged if RUP-N-Valid = 1 and DIAG.FREEZE Mode = 0. Then, the

SPC4 will set the flag RUP-N-Valid = 0 in the DEFAULT SAP. The buffers are exchanged and the flag

RUP-N-Valid is reset under Lock.

6.2 Productive Services

6.2.1 Data Exchange

The control unit for the PROFIBUS DP protocol is to be realized by the FLC. As DP slave, the SPC4 is

permitted to receive request message from the DEFAULT SAP of the DP master to its own DEFAULT SAP

only if the DP control unit is in the mode “data exchange” . Therefore, the FLC has to parameterize

Request SA - Station Address of the DP Master

in the DEFAULT SAP. In all other DP modes (for example Wait-PRM, Wait-Config), the FLC has to

deactivate the DEFAULT SAP with

Request SA = 7FH

A request message by the DP master to the DEFAULT SAP would in this case be rejected with “No Service

Activared” (RS).

In the DEFAULT SAP of the SPC4,

Request SSAP = FFH (for DEFAULT SAP)

Access Value = 08H

is to be parameterized in the DP mode.

Access Value = 08 filters all request messages except

• Send and Request Data low (SRD low)

• Send and Request Data high (SRD high)

• Send and Request Data with DDB (DDB Request)

• DDB Response low

• DDB Response high

The transpparence for DDB response low/high messages makes it possible for the SPC4 to listen in on the

bus as slave also via the DEFAULT SAP, and to evaluate the received data. Since, as a rule, the publisher

is not going to be the DP master, the SDN-/DDB filter is to be activated. If the SDN-/DDB filter bit is set in

the control byte of the DEFAULT-SAP, the source address (SA) and SSAP are plausibilized exclusively in

Page 30 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

the SDN-/DDB station list. Received DDB response messages are entered in the indication queue. Then

the pointers “IND-WP-PRE” and “IND-WP” are set to the next free segment, and the interrupts “IND-PRE”

and “IND” are generated.

If an SRD low/high message is received from the DP master, and no input data is available (that is,

response buffer length = 0), the SPC4 will reply

• either with SC, if 08H (that is, low priority) is entered in the response status of the DEFAULT SAP

• or with an SD2 message with the length LE = 4 and FFH as dummy byte (that is, net data length = 1), if

0AH (that is high priority) is entered in the response status of the DEFAULT SAP.

If a DDB request is received from the DP master and no input data is available (that is, response buffer

length = 0), the SPC4 replies with “No Service Activated (RS)” and sets the RS flag in the control byte of the

DEFAULT SAP.

6.2.2 Read Input Data

Read Input Data is an SRD message without request data, by any bus master, with SSAP different from

DEFAULT SAP, to the SAP 56 of the DP slave. As DP slave, the SPC4 is permitted to evaluate this

message only if the DP control unit is in the mode “data exchange”. In all other modes (for example, Wait

PRM, Wait Config), SAP 56 is to be deactivated by the FLC with Request SA = 7FH. A Read Input Data

message would in this case be rejected with “No Service Activated (RS)”.

In the SAP 56 of the SPC4, the following is to be parameterized in the DP mode “Data Exchange”:

Buffer Available > 0

Request-SA = FFH (all)

Request-SSAP = SSAP (different than DEFAULT-SAP)

Access Value = {09H, 0AH, 0BH}

Reply Update Ptr / SDN-/DDB-TIn-Tab-Ptr = don´t care

Read Input Data messages are not indicated by the SPC4 and are not entered in the indication queue. In

the control byte of SAP 56, Buffer Available is not decremented.

If input data is requested with Read Input Data, the SPC4 will respond

• either with the “old” input data of Reply Update Buffer D (that is, Reply Update Buffer D and N are not

exchanged before the response is transmitted). This is the case if no valid input data is entered in the

Reply Update Buffer N (that is, RUP-N-Valid = 0 in the DEFAULT SAP), or the input data in the Reply

Update Buffer D is frozen (DIAG, FREEZE Mode = 1, see Chapter 2.7.4);

• or with the “new” input data, if before transmitting the response, the Reply Update Buffers D and N are

exchanged. The buffers are exchanged if RUP-N-Valid = 1 and DIAG, FREEZE Mode = 0 in the

DEFAULT SAP. Then, the SPC4 will set the flag RUP-N-Valid = 0 in the DEFAULT SAP. The buffers

are exchanged and the flag RUP-N-Valid is reset under Lock.

If the response buffer length = 0 is parameterized in the DEFAULT-SAP, the SPC4 will respond with SC.

An SRD message with request data to the SAP 56 of the DP slave is rejected by the SPC4 with “No

Resource (RR)”.

SPC4 User Description Release V1.2 Page 31

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

6.2.3 Read Output Data

Read Output Data is an SRD message without request data by any bus master, with SSAP different from

DEFAULT SAP, to the SAP 57 of the DP slave. As DP slave, the SPC4 is permitted to evaluate this

message only if the DP control unit is in the mode “data exchange”. In all other modes (for example, Wait

PRM, Wait Config), SAP 57 is to be deactivated by the FLC with Request SA = 7FH. In this case a Read

Output Data message would be rejected with “No Service Activated (RS)”.

In the SAP 57 of the SPC4, the following is to be parameterized in the DP mode “Data Exchange”:

Buffer Available > 0

Request-SA = 0FFH (all)

Request-SSAP = SSAP (different than DEFAULT-SAP)

Access Value = {09H, 0AH, 0BH}

Reply Update Ptr / SDN-/DDB-Tln-Tab-Ptr = don´t care

Read Output Data messages are not indicated by the SPC4 and are not entered in the indication queue. In

the control byte of SAP 57, Buffer Available is not decremented.

Read Output Data causes the SPC4 to respond with the output data of the Indication Buffer U.

If the indication buffer length = 0 is parameterized in the DEFAULT SAP, the SPC4 responds with SC.

An SRD message with request data for the SAP 57 of the DP lave is rejected by the SPC4 with “No

Resource(RR)”.

6.2.4 Global Control (Sync, Freeze, Clear Data)

The global control message is an SDN message with 2 bytes net data from the DP master with SSAP =

DEFAULT SAP, to the SAP 58 of the DP slave. As DP slave, the SPC4 is permitted to evaluate this

message only if the DP control unit is in the mode “data exchange”. In all other modes (for example, Wait

PRM, Wait Config), SAP 58 is to be deactivated by the FLC with Request SA = 7FH. In this case a global

control message would be rejected with “No Service Activated (RS)”.

In the SAP 58 of the SPC4, the following is to be parameterized in the DP mode “Data

Exchange”:

Buffer Available > 0

Request-SA = station address of the DP master

Request-SSAP = SSAP (different than DEFAULT-SAP)

Access Value = {01H, 02H, 03H}

Reply Update Ptr / SDN-/DDB-Tln-Tab-Ptr = don´t care

In the control byte of SAP 58, Buffer Available is not decremented. A global control message with a net

data length unequal to 2 is not evaluated by the SPC4 if “Check GCM-Length-Off = 0” is parameterized in

Mode Register 2.

With Check GCM-Length-Off = 1, monitoring of the net data length of GCMs is switched off.

The function Global Control makes it possible to transmit a special control command to one (single), several

(multi) or all (broadcast) DP slaves. The figure below shows the data format of the 2 user bytes.

Address Bit Position Designation

7 6 5 4 3 2 1 0

Byte 0 Res Res Sync Unsync Freeze Unfreeze Clear_

Data

Byte 1 Select7Select6Select5Select4 Select3 Select2 Select1 Select0 Group Select

Res Control

Command

Page 32 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

Byte 0: Control Command

Bit Designation Meaning

0 Reserved The designation “Reserved” indicates that these bits are reserved

for future function expansions, and are to be preassigned with “logic

0”.

If the bit “Check-GCM-Resbits-Off = 0 in Mode Register 2, the

reserved bits will be checked for zero. If at least one of these

reserved bits is “logic 1”, the SPC4 will execute “Leave Master”.

If Check-GCM-Resbits-Off = 1, the reserved bits are don’t care for

the SPC4.

1 Clear_Data Output data in the indication buffer is deleted, and the interrupt

Output_Data_Exchange is generated

2 Unfreeze If Unfreeze is set, the SPC4 deactivates the Freeze Mode

(DIAG.FREEZE Mode = 0) and exchanges the Reply Update

Buffers D and N if the flag RUP-N-Valid = 1 in the DEFAULT SAP.

Then, the SPC4 will set RUP-N-Valid = 0. These actions are carried

out under Lock.

If DIAG.FREEZE Mode = 0, the SPC4 will respond to a request

message which is requesting input data with the “new” input data;

that is, before transmitting the response, the SPC4 exchanges the

Reply Update Buffers D and N if the flag RUP-N-Valid = 1 in the

DEFAULT SAP.

3 Freeze If Freeze is set, the SPC4 will activate the Freeze Mode

(DIAG,FREEZE Mode = 1) and exchange the Reply Update Buffers

D and N if the flag RUP-N-Valid = 1 in the DEFAULT SAP. Then,

the SPC4 will set RUP-N-Valid = 0. The SPC4 executes these

actions under Lock. If, in the Freeze Mode, input data is requested

from the SPC4 with a request message, the SPC4 will respond with

the “old” input data of Reply Update Buffer D; that is, the Reply

Update Buffers D and N will not be exchanged prior to transmitting

the response.

4 Unsync If Unsync is set, the SPC4 deactivates the Sync Mode (DIAG.SYNC

Mode = 0), and exchanges the Indication Buffer D and N if valid

data is {entered} in the D buffer. In addition, it will set the flag INDN-Valid = 1 in the DEFAULT SAP and generate the interrupt

“Output Data Exchange”.

If DIAG.SYNC Mode = 0 when a global control message with

Unsync = 1 is received, Unsync will have no effect.

If DIAG.SYNC Mode = 0, the SPC4 exchanges the Indication

Buffers D and N immediately if it has received new valid output

data.

5 Sync If Sync is set, the SPC4 will activate the Sync Mode (DIAG.SYNC

Mode = 1) without exchanging the Indication Buffers D and N. If

DIAG.SYNC Mode = 1 when a global control message is received

with Sync = 1, the SPC4 exchanges the Indication Buffers D and N

if valid output data is {entered} in the D-buffer. In addition, it will set

the flag IND-N-Valid = 1 in the DEFAULT SAP, and generate the

interrupt “Output Data Exchange”. The SPC4 executes these

actions under Lock.

If DIAG.Sync Mode = 1, the SPC4 enters new output data from the

DP master in the Indication Buffer D and generates the interrupt

“Watchdog Reset”. The SPC4 waits with the exchange of the

Indication Buffers D and N, however, until the next “Sync”

command.

6,7 Reserved

Figure 6.2 Global Control

SPC4 User Description Release V1.2 Page 33

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

Byte 1: Group Select

Group Select specifies which groups are to be addressed by the DP slaves.

The SPC4 AND-operates the Group Select byte of a received global control message bit by bit with the byte

“Active Group Ident” of the DEFAULT SAP. The DP slave is addressed if the bit by bit AND operation

supplies a value unequal to zero on at least one position {location}.

If the Group Select byte = 00H, all DP slaves are addressed.

If the control command of a global control message (GCM) is different than the control command in the

DEFAULT SAP, the SPC4 will enter the GCM in the indication queue and generate the indication interrupt.

In addition, the received control command is stored in the DEFAULT SAP.

6.2.5 Leave Master

In the case of Leave Master, the SPC4 will carry out the following actions:

• output data in the indication buffer is deleted; that is 00H is entered {?}

• then, the Indication Buffers D and N are exchanged (under Lock)

• the interrupt “Output Data Exchange” is not generated

• DEFAULT SAP, SAP 56, SAP 57, SAP 58 are deactivated; that is, under Lock,

Request SA = 7FH is entered in all 4 SAPs

• generate interrupt “leave master”

The SPC4 will execute “Leave Master” if

• the bit Cmd-Leave-Master = 1 is set in Mode Register 1:

at the end of “Leave Master”, the SPC4 will reset Cmd-Leave-Master

to “logic 0” in Mode Register 1

• in the control command of a GCM, at least 1 reserved bit is “logic 1”,

and in Mode Register 2 Check-GCM-Resbits-Off = 0 is parameterized

• the received net data length of a DP data message is less than the

indication buffer length in the DEFAULT SAP:

The SPC4 responds with input data from the Reply Update Buffer D; if

DIAG.FREEZE mode = 0 and RUP-N-Valid = 1, the Reply Update Buffers

D and N will be exchanged first

• the received net data length of a DP data message is larger than the

indication buffer length in the DEFAULT-SAP:

The SPC4 responds with “No Resource (RR)”, and sets the RR flag in the

control byte of the DEFAULT SAP to “logic 1”.

The execution time tLM which the SPC4 needs for “Leave Master”, is dependent on the indication buffer

length n and the baudrate

12 MBaud: (25 + n) bit pulses <= t

To baudrates less than 3 M Baud, the following applies:

(30 + 1.5 n) bit pulses

LM <=

tLM ≈ (20 + n/2) bit pulses

Attention:

In the case of "Leave-Master", the danger exists that request messages to the SPC4, which were received

during the execution time tLM will be lost. Since, during this time t

receive but can’t be flushed, the interrupt "FIFO-Overflow" is possible.

Page 34 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

the receiver of the SPC4 is ready to

LM ,

SPC4 WKF B1 T2

6.2.6 Baudrate Search

If the bit “Baudrate Search” is set in Mode Register 1, the automatic baudrate search is switched on. In this

mode, the SPC4 doesn’t evaluate messages; it only checks whether a message was received faultless

physically. In order to be able to also receive reply messages, the T

regardless of the value which was parameterized in the SYN time register. If the receipt is faulty, the

interrupt “wrong SD” will be generated. If SD4 or a complete SD1/SD2/SD3 message is received faultlessly,

the interrupt “correct SD” is generated. A faultlessly received SC is ignored.

The baudrate which is to be checked respectively has to be parameterized by the FLC.

is reduced to 10 bit pulses,

SYN

SPC4 User Description Release V1.2 Page 35

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

7 ASIC Interface

Below, the registers will be described which specify the hardware function of the ASIC as well as message

processing.

Parameters which intervene directly in the control, or sephamores which are directly set by the control, are

stored in the SPC4 in a parameter latch array. All other parameters are in the lower area of the RAM. In

the parameter cells, the FLC transfers operating data to the FLC. Parameters are assigned only in the

offline state (for example, after switch on). The SPC4 must leave the offline state only after all parameters

have been loaded (START SPC4 = 1, Mode Register 1). Some control bits, however, have to be changed

continuously during operation. These are combined in a special register (Mode Register 1) and can be set

or deleted independent of one another.

7.1 Latch Parameters

7.1.1 Slot Time Register

(writable; can only be changed offline)

Address Bit Position Designation

Control

Register

304H

(Intel)

7 6 5 4 3 2 1 0

TSL7 TSL6 TSL5 TSL4 TSL3 TSL2 TSL1 TSL0 TSLOT

7..0

Address Bit Position Designation

Control

Register

305H

(Intel)

Figure 7.1: Slot Time Register

The Wait-to-Receive time TSL is 14 bits wide maximum, and to be entered in transmission bit steps. It is

needed to calculate timeout.

7.1.2 Baudrate Register

(writable; can only be changed offline)

Address Bit Position Designation

Control

Register

306H

(Intel)

Address Bit Position Designation

Control

Register

307H

(Intel)

15 14 13 12 11 10 7 8

TSL13 TSL 12 TSL 11 TSL 10 TSL 9 TSL8 TSLOT

13..8

7 6 5 4 3 2 1 0

BR7 BR6 BR5 BR4 BR3 BR2 BR1 BR0 BR-Reg

7..0

15 14 13 12 11 10 7 8

BR 10 BR 9 BR8 BR-REG

10..8

Figure 7.2: Baudrate Register

Page 36 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

In the baudrate register, the division factor for the baudrate generator is parameterized. The division factor

G is calculated according to the following formula:

CLK

G =

BR * SCAN RATE

CLK = clock supply in MHz

BR = baudrate

G = division factor

SCAN RATE is the result of the bits FILTER ON/OFF and SYN/ASYN of Mode Register 0:

- 1

SYN/ASYNFILTER

ON/OFF

0 0 16

0 1 16

1 0 4

1 1 16

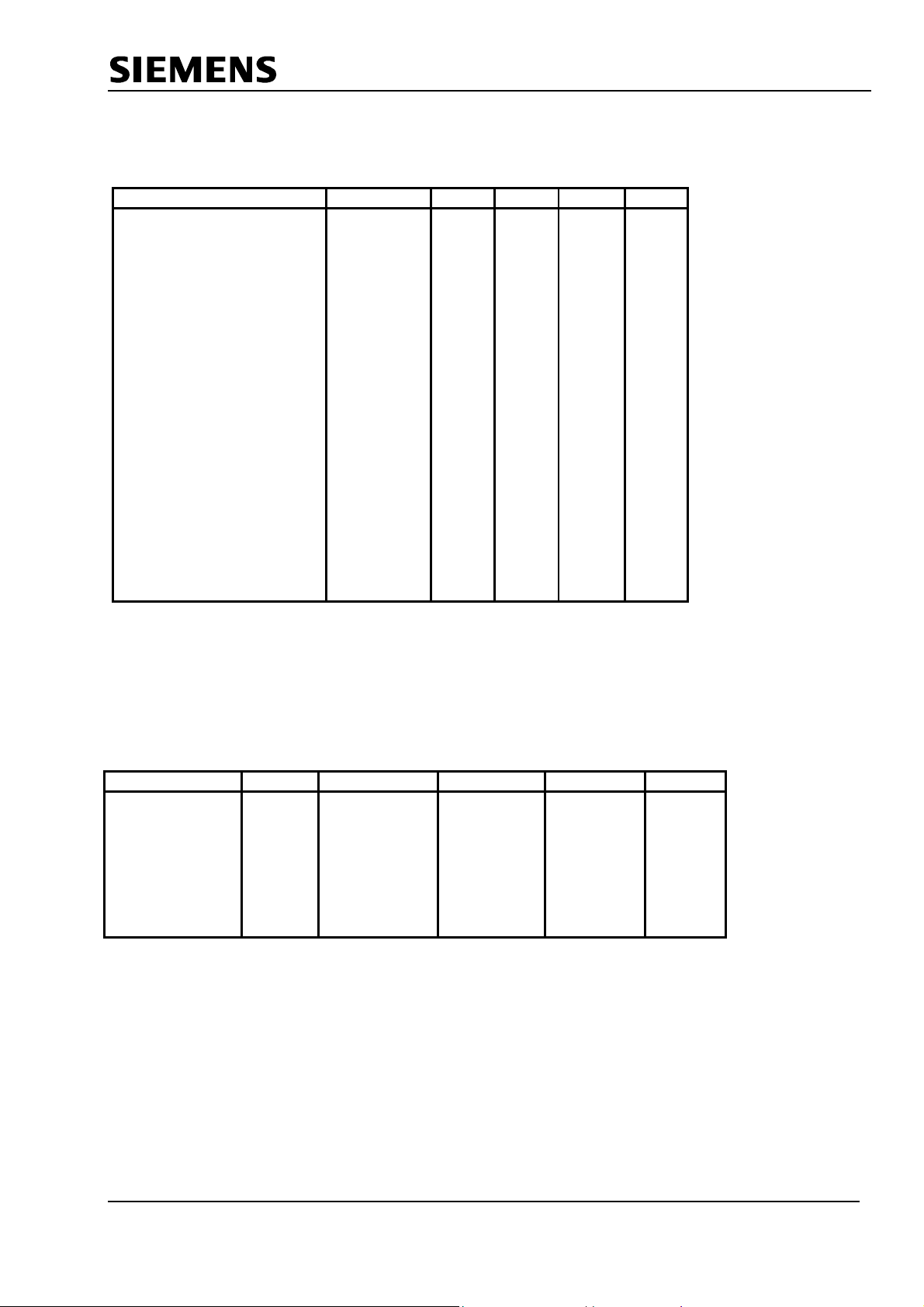

In the table below, the division factors for the individual baudrates for both operating modes are listed.

CLK Baudrate (BR) Division Factor (G)

48 MHz 12.0 MBd 0 48 MHz 6.0 MBd 1 48 MHz 3.0 MBd 3 0

48 MHz 1.5 MBd 7 1

48 MHz 500.00 kBd 23 5

48 MHz 187.50 kBd 63 15

48 MHz 93.75 kBd 127 31

48 MHz 31.25 kBd 383 95

48 MHz 19.2 kBd 624 48 MHz 9.6 kBd 1249 -

SCAN

RATE

for ABTAST = 4

Division Factor (G)

for ABTAST = 16

7.1.3 BEGIN PTR Register

(writable; can only be changed offline)

Address Bit Position Designation

Control

Register

319H BPTR7 BPTR6 BPTR5 BPTR4 BPTR3 BPTR2 BPTR1 BPTR0 BEGIN-PTR

Figure 7.3: BEGIN PTR Register

The BEGIN PTR is the address of the 1st segment of the indication queue.

SPC4 User Description Release V1.2 Page 37

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

7 6 5 4 3 2 1 0

7..0

WKF B1 T2 SPC4

7.1.4 UMBR PTR Register

(writable; can only be changed offline):

Adress Bit Position Designation

Control

Register

310H

Figure 7.4: UMBR PTR Register

The UMBR PTR (WRAP AROUND PTR) points to the address of the 1st segment which does not belong to

the indication queue.

7.1.5 BASE PTR Register

(writable)

Address Bit Position Designation

Control

Register

314H BASE-

Figure 7.5: BASE PTR Register

7 6 5 4 3 2 1 0

UPTR7 UPTR6 UPTR5 UPTR4 UPTR3 UPTR2 UPTR1 UPTR0

7 6 5 4 3 2 1 0

PTR7

BASEPTR6

BASEPTR5

BASEPTR4

BASEPTR3

BASEPTR2

BASEPTR1

BASEPTR0

UMBR-PTRReg 7..0

BASE-PTRReg 7..0

The base pointer addresses the start of the 256 byte memory window.

7.1.6 TRDY Register

(writable)

Address Bit Position Designation

Control

Register

315H

(Intel) TRDY7 TRDY6 TRDY5 TRDY4 TRDY3 TRDY2 TRDY1 TRDY0

Figure 7.6: TRDY Register

The time TRDY has to pass as quiet time on the bus before a reply message is transmitted. It is 8 bits

maximum and is indicated in transmission bit steps.

The FLC may change TRDY even if the MAC state machine is not in the offline state.

In the DP mode, TRDY can be changed dynamically. For this, the DP master transmits a parameter

assignment message to the DP slave with the new value for TRDY. Since the SPC4 doesn’t evaluate

parameter assignment messages, the FLC has to do it. The value for TRDY which the FLC has to

parameterize is the result of

TRDY for SPC4 = T

7 6 5 4 3 2 1 0

of parameter assignment message + 2.

RDY

TRDY-Reg

7..0

Page 38 Release V1.2 SPC4 User Description

Order Nr. 6GK1 971-5XA00-0BA0 Copyright (C) Siemens AG 1997. All rights reserved.

SPC4 WKF B1 T2

7.1.7 PREAMBLE Register

(writable; can only be changed offline):

Address Bit Position Designation

Control

Register

316H

(Intel)

Figure 7.7: PREAMBLE Register

PREAMB: quantity of preamble bits

00 = 1

01 = 2

10 = 4

11 = 8

In the synchronous mode of the serial interface, the quantity of preamble bytes can be set here.

7.1.8 SYN Time Register

(writable; can only be changed offline)

7 6 5 4 3 2 1 0

PREAB1 PREA0 PREAMBLE

7..0

Address Bit Position Designation

Control

Register

317H

(Intel)

Figure 7.8: SYN Time Register

In the asynchronous mode (RS485), 33 bits are always to be parameterized.

In the synchronous mode, the T

7.1.9 Delay Timer Register

(readable)

Address Bit Position Designation

Control

Register

306H

(Intel)

Address Bit Position Designation

Control

Register

307H

(Intel) TDEL1

7 6 5 4 3 2 1 0

TSYN5 TSYN4 TSYN3 TSYN2 TSYN1 TSYN0 TSYN-Reg

7..0

(Interframe GAP Time) is to be parameterized here (4...32 bit).

IFG

7 6 5 4 3 2 1 0

TDEL7 TDEL6 TDEL5 TDEL4 TDEL3 TDEL2 TDEL1 TDEL0 DELAY

7..0

15 14 13 12 11 10 7 8

TDEL

14 TDEL1

5

3

TDEL12 TDEL11 TDEL10 TDEL9 TDEL8 DELAY

15..8

Figure 7.9: Delay Timer Register

The delay timer register contains the current counter state of the delay timer.

SPC4 User Description Release V1.2 Page 39

Copyright (C) Siemens AG 1997. All rights reserved. Order Nr. 6GK1 971-5XA00-0BA0

WKF B1 T2 SPC4

7.1.10 Factor Delay Timer Clock Register

(writable)

Address Bit Position Designation

Control

Register

30AH

(Intel)