Page 1

SERVICE MANUAL

SVD800 HD

SVD800 HD Millennium

SVD800 Teatro

CRT VIDEO PROJECTOR

1° Edition April 2001

Page 2

SVD800HD SERVICE GUIDE

page - 2 -

WHITE PAGE

Page 3

SVD800HD SERVICE GUIDE

page - 3 -

1. SAFETY AND REGULATIONS ............................................................................................................................................4

INTRODUCTION...................................................................................................................................................................................4

IMPORTANT NOTES..............................................................................................................................................................................4

ABOUT THIS MANUAL........................................................................................................................................................................4

SAFETY INFORMATION .......................................................................................................................................................................4

2. GENERAL INFORMATION ..................................................................................................................................................5

3. SERVICE ADJUSTMEN T .......................................................................................................................................................6

PC028 MODULE: HORIZONTAL DEFLECTION..............................................................................................................................6

PC132 MODULE: EHT AND DYNAMIC FOCUS.............................................................................................................................7

PC121 SHIFT BOARD.....................................................................................................................................................................9

PC226 MODULE: SYNC PROCESSOR ............................................................................................................................................10

PC131 MODULE: VIDEO PROCESSOR..........................................................................................................................................11

M459X POWER SUPPLY.............................................................................................................................................................12

PC097 MICRO BOARD .................................................................................................................................................................13

4. WAVEFORM PC339.0...........................................................................................................................................................14

5. PROTECTION CIRCUITERY............................................................................................................................................19

EHT PROTECTION CIRCUIT ( PC132 BOARD):.............................................................................................................................19

FLY-BACK V OLTAGE PROTECTION CIRCUIT ( PC132 BOARD ):................................................................................................19

AUTOMATIC BEAM CURRENT LIMIT PROTECTION CIRCUIT ( PC132 BOARD ):......................................................................19

6. SERVICE ADJUSTMEN TS..................................................................................................................................................21

2/4 POLE ADJUSTMENT.............................................................................................................................................................21

SERVICE SETTING.......................................................................................................................................................................23

WHITE MENU .................................................................................................................................................................................24

SERVICE MENU.............................................................................................................................................................................29

7. SDG UPC2000 INSTALLATION PROCEDURE...........................................................................................................32

8. SPARE PARTS LIST..............................................................................................................................................................33

9. SVD800HD SPARE PART LIST .........................................................................................................................................34

Page 4

SVD800HD SERVICE GUIDE

page - 4 -

1. Safety and regulations

Introduction

• The instruction given in this manual are meant for service engineers only. A good knowledge of electronics and

mechanical engineering is absolutely necessary to repair and maintain the SVD800HD projector.

Important notes

• Should any question after reading this manual arise, please contact your local SIM2 distributor, who will be glad to

help you.

• In the interest of our customers we keep on improving the product. Therefore SIM2 reserves the right to change all

technical specifications and further information provided in this manual at any time without prior notice.

About this manual

• This manual is intended for those who are doing repairing work and maintenance on the SVD800HD.

• This manual has the following goals: to enable technicians to perform the necessary maintenance and repair work to

keep the unit in good operating condition.

• In case of relevant changes, the information provided in this manual could be updated with the issue of technical

notes.

Safety information

• This projector has been made in compliance with EN 60950 standard relative to the safety of information technology

equipment.

• This projector has been made in compliance with EN 50082-1 (Generic immunity law), EN61000-3-2 (Limits for

Harmonic current emission), EN55022 (Limits and measuring methods of radio disturbance produced by information

technology equipment), EN6100-3-3 (Limits- section 3 Limitation of Voltage Fluctuation and Flicker in low voltage

supply system for equipment with rated current SYMBOL 163\f “Symbol” 16A).

• The accessible metal parts are connected to the power socket round terminal. When installing make sure the ground

cable is properly connected and use only the power cable and extension leads supplied with the unit. The unit must

be grounded. Interruption of the protective conductors inside or outside the unit, or disconnecting protective earthing

may cause possible danger and malfunction of the unit.

• SVD800HD may only be maintained and serviced by qualified persons who are familiar with the machine.

• Always disconnect the cable plug from the mains socket for those service operations that need complete cut off of the

machine.

• To avoid damage, fire or electrical shock, do not expose the unit to rain or damp.

• Do not lead any kind of liquid spill inside the unit.

Page 5

SVD800HD SERVICE GUIDE

page - 5 -

• Do not let any kind of objects through the ventilation slits in the cabinet of the projector as they could touch the high

voltage components and cause a short circuit that could, in turn, cause fire or electrical shock hazards.

• If any object or liquid does get inside the projector take the power cable out of the socket immediately.

• Observe instruction, regulation and notes provided in this service instruction.

• It is distributor’s responsibility to ensure proper qualification of personnel working with the machine.

• Observe all CAUTION notes applied out or inside the unit. Keep them clean and in readable condition.

• Observe all local safety regulation regarding the handling of electric/electronic equipment.

2. General information

• For all information/instruction concerning the installation and the adjustment of the unit, please refer to the “User’s

and installation manual”, provided with each unit.

• Model and Serial number indications are located on the projector rear side label. Record the Serial Number in the

space below and refer to it for future Information/Service request to SIM2 customer service.

• Any part should be replaced using only original SIM2 spare parts. Failure to follows this advice can lead to a

deterioration of the unit’s performances, electrical damage, fire and electrical shock hazards and will also invalidate

the guarantee.

Page 6

SVD800HD SERVICE GUIDE

page - 6 -

3. SERVICE ADJUSTMENT

Factory conditions:

- ceiling-front installation

- screen 90"

- Signal: unless otherwise specified use internal HATCH COARSE FINE (without any signal applied to the

inputs slots)

PC028 MODULE: horizontal deflection

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. Switch-off the EHT pulling out the CN12 connector, placed on the mother board under the Red CRT.

2. Adjust P1 fully clockwise and P2 fully anticlockwise.

3. Connect a digital voltmeter on TP9 and adjust P2 for a voltage of 1050 Vd.c., than disconnect the voltmeter.

4. Adjust slowly P1 till to alight DL1 (the horizontal deflections will be switched-off: no signal at the anode of D2,

D3 and D4).

5. Adjust P2 fully anticlockwise.

6. Switch-off and switch- on the projector

7. Adjust P2 and P3 as described on B section.

B section (service adjustments)

1. Project the Pattern signal test on the screen

2. Adjust by the full function remote control the horizontal SIZE for: H 80

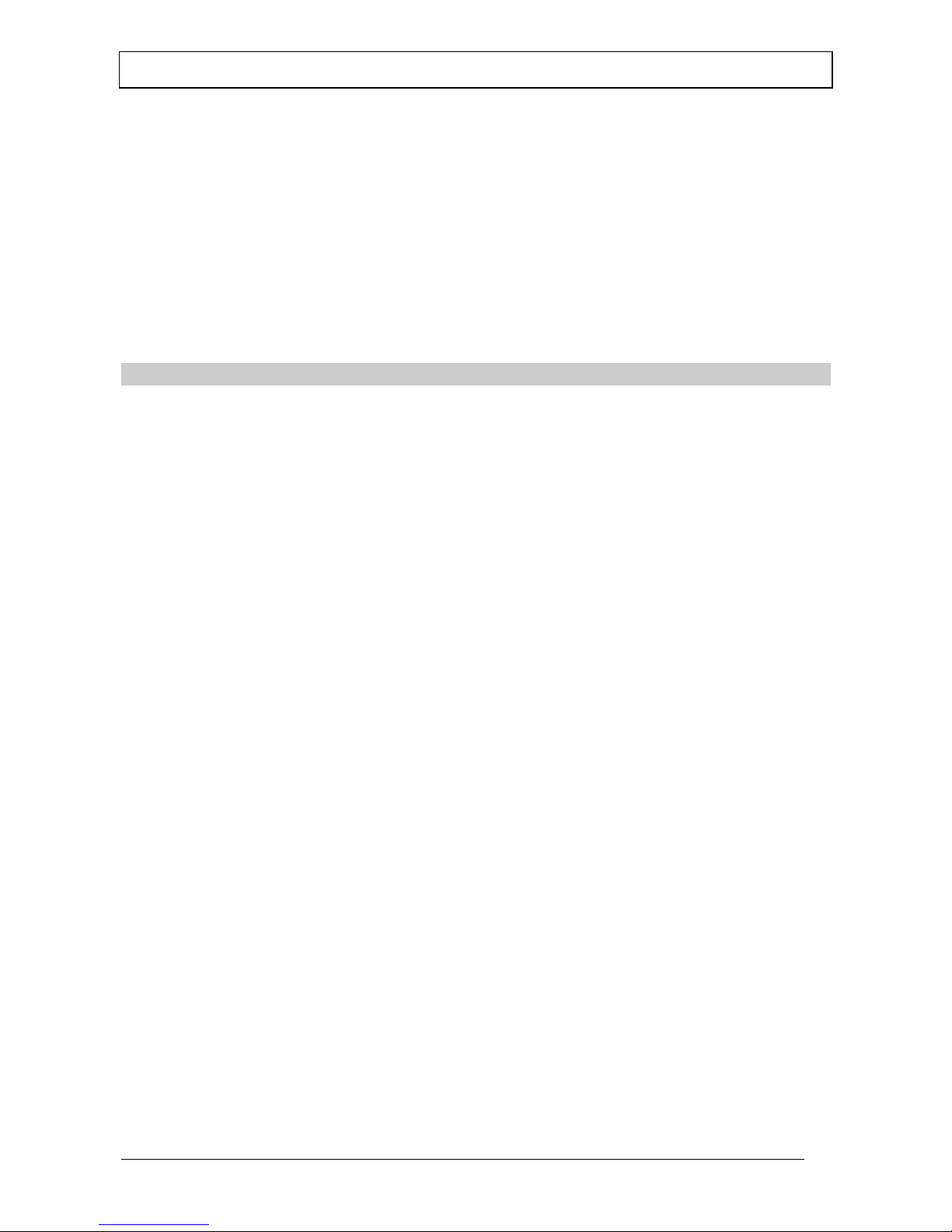

3. Adjust P2 for a correct horizontal amplitude: looking throw the lenses the top part of the raster must come out a

little the screen (see following picture).

view through the lenses

4. Adjust P3 for a correct keystone.

Page 7

SVD800HD SERVICE GUIDE

page - 7 -

PC132 MODULE: EHT and dynamic focus

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. The adjustments have to be executed, step by step, in the same sequence described below:

2. Adjusting and Testing of the EHT Generator Circuit:

3. Connect a Digital Multimeter with High Voltage Probe to the EHT splitter (removing one EHT cable)

4. Rotate the trimmers:

5. P1 fully clockwise (average beam current protection on the three tubes)

6. P4 fully counter clockwise (EHT protection n.1 – fly-back)

7. P5 fully clockwise (EHT protection n.2)

8. Switch the mains ON.

9. Select a black-page pattern 0,7 Vpp RGB signal.

10. Adjust Contrast to 100 and Brightness to 50 and memorise these values.

11. Select a white-page pattern 0,7 Vpp RGB signal.

12. Select the 6500 °K colour temperature.

13. Wait 20’ (warm-up time).

14. Switch the three CRTs OFF using the key “MUTE” on the remote control.

15. Adjust P3 for 33,5 ± 0,1 kV

16. Seal P3 with LOCTITE 454 adhesive.

17. Switch the three CRTs ON.

18. Verify that the EHT voltage is 33,5 ± 0,1 kV.

19. Switch the mains OFF.

20. Remove the High Voltage Probe from the EHT splitter and insert the EHT cable.

Adjusting and Testing of the EHT Protection Circuit:

1. Rotate P4 slowly clockwise until the protection circuit will be activated (EHT OFF and DL1 ON, after 10 seconds

the projector goes to stand-by mode).

2. Rotate P4 fully counter clockwise.

3. Connect the Digital Multimeter between GND2 and TP12.

4. Switch the projector ON by remote control.

5. Measure the voltage and write the value down.

6. Connect the Digital Multimeter between GND2 and TP5.

7. Adjust P4 for a voltage 0,1 ± 0,01 V less than the value reed on step 2.5 (this operation is equivalent to set the EHT

protection N.2 threshold to 37,5 ± 0,5 kV).

8. Seal P4 with LOCTITE 454 adhesive.

9. Check that the voltage on TP5 is not changed after P4 sealing.

10. Rotate P1 slowly counter clockwise until the protection circuit will be activated (EHT OFF and DL1 ON, after 10

seconds the projector goes to stand-by mode).

11. Rotate P1 fully clockwise.

12. Connect the Digital Multimeter between GND2 and TP4.

13. Switch the projector ON by remote control.

14. Adjust P1 for a voltage of 4,5 ± 0,1 V (this operation is equivalent to set the EHT protection N.1 threshold to 37,5 ±

0,5 kV).

15. Seal P1 with LOCTITE 454 adhesive.

16. Check that the voltage on TP4 is not changed after P1 sealing.

17. Connect the Digital Multimeter between GND1 and TP7.

18. Adjust P5 for a voltage of 0,9 ± 0,01 V (this operation is equivalent to set the Average Beam Current Protection to

4,0 ± 0,2 mA).

19. Connect the Digital Multimeter between GND1 and TP8.

20. Set contrast to 0 by remote control.

21. Connect R64 (reference side) to ground with a wire.

22. Increase the contrast value slowly and check that the protection circuit is activated when the voltage reaches the

value of -17,0 ± 0,5 V (EHT OFF and DL1 ON, after 10 seconds the projector goes to stand-by mode).

23. Remove the ground-wiring from R64.

24. Seal P5 with LOCTITE 454 adhesive.

Page 8

SVD800HD SERVICE GUIDE

page - 8 -

25. Connect the Digital Multimeter between GND1 and TP7.

26. Switch the projector ON by remote control.

27. Check that the voltage on TP7 ( 0,9 ± 0,01 V ) is not changed after P5 sealing.

B section (service adjustments)

1. Use white signal 100% of the screen area

2. Connect a high voltmeter to the EHT splitter (disconnecting one EHT cable)

3. Switch-off the RGB (black screen)

4. Adjust P3 for 33.5±0.1 KV

5. Inject silicon rubber into P3, sealing it.

6. Switch-on the three CRT's.

7. Adjust P5 for 0.9 Vd.c. on TP7.

8. Inject silicon rubber into P5, sealing it.

Page 9

SVD800HD SERVICE GUIDE

page - 9 -

PC121 SHIFT BOARD

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. Turn anticlockwise the cores of L1 and L5 till come out for about 1.5 cm.

2. Turn anticlockwise the core of L3 till come out for about 1 cm.

3. Select CROSS pattern.

4. Reset convergence values, using RESET ZONE (see user manual)

5. Select ZONE

6. Centre the Green raster looking through the lenses, using SHIFT control.

7. Centre the Red raster looking through the lenses, using SHIFT control.

8. Centre the Blue raster looking through the lenses, using SHIFT control.

9. Select HATCH COARSE pattern.

10. Move horizontally the Blue and Red tubes to superimpose the vertical central lines.

11. Select HATCH FINE pattern.

12. Switch-off B tube.

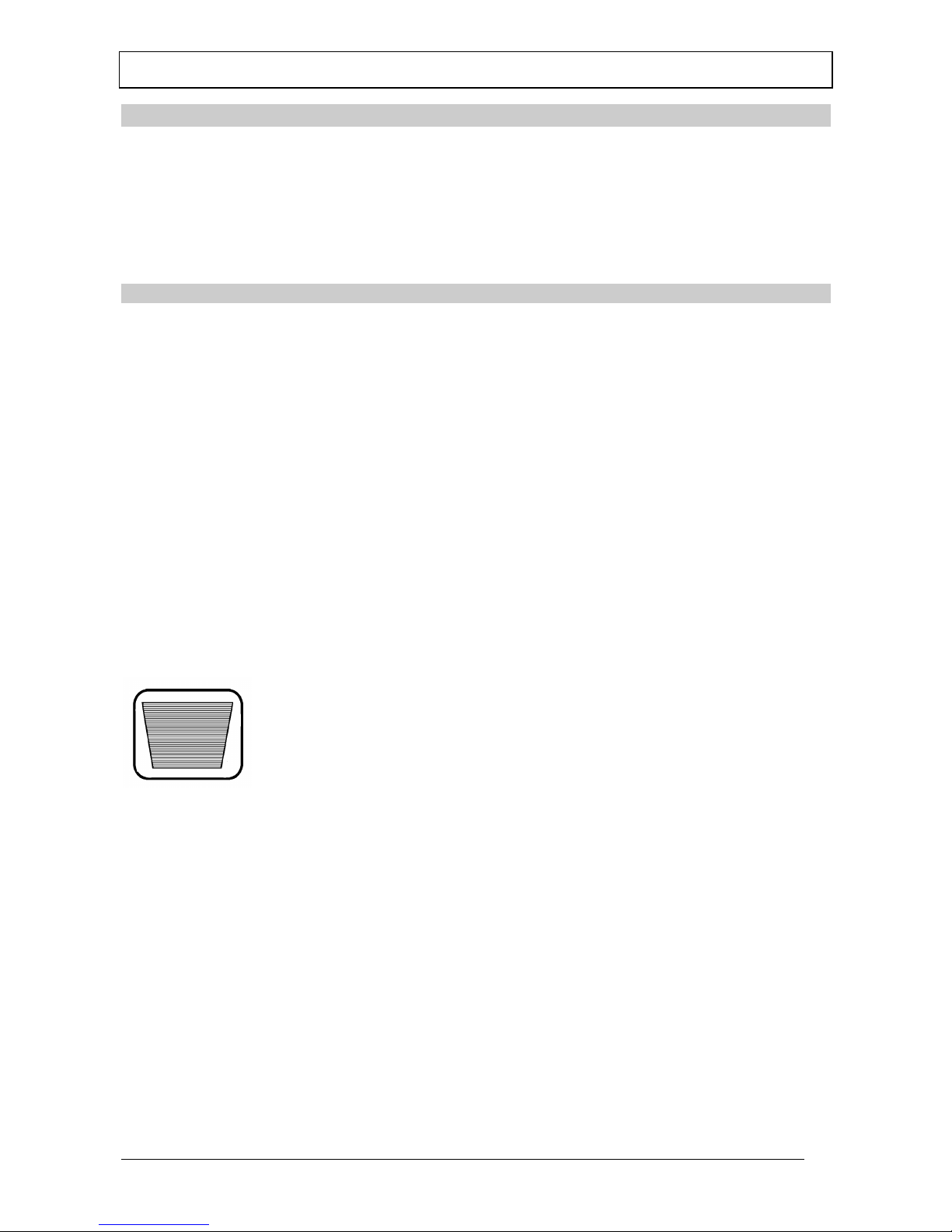

13. Adjust L1 to have a symmetrical convergence error of the RED at the sides (see following figure)

14. Switch-off R tube and switch-on the B tube.

15. Adjust L5 to have a symmetrical convergence error of the BLUE at the sides (see following figure)

RGB B G R

B section: service adjustments are not requested.

Page 10

SVD800HD SERVICE GUIDE

page - 10 -

PC226 MODULE: sync processor

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. Short circuit jumper J3.

2. Connect a frequency counter to TP8 HDRIVE.

3. Switch-on the video projector.

4. Select RGB slot without any signal applied to it.

5. Adjust P2 for the horizontal frequency into 14.8 KHz and 14.9 KHz range.

6. Connect a frequency counter to pin 37 of C.I.21.

7. Adjust P1 for the vertical frequency into 36 Hz and 37 Hz range.

8. Switch-off the projector

9. Remove jumper J3.

10. Short circuit jumper J4.

11. Connect a frequency counter to TP8 HDRIVE.

12. Switch-on the projector.

13. Select RGB slot without any signal applied to it.

14. Adjust P3 for the horizontal frequency into 105.7 KHz and 106.5 KHz range.

15. Remove jumper J4.

Check the correct PATTERN PHASE (see service menu)

B section: service adjustments are not requested.

Page 11

SVD800HD SERVICE GUIDE

page - 11 -

PC131 MODULE: video processor

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. Adjusting and Testing of the total (three CRTs active) Average Beam Current Limitation Circuit

1.1 Switch the mains ON.

1.2 Adjust P1 and P2 fully anticlockwise.

1.3 Select a white-page pattern 0,7Vpp RGB signal.

1.4 Adjust Contrast to 100 and Brightness to 50 and memorise these values.

1.5 Connect a Digital Multimeter between GND1 and TP8 (PC132 board).

1.6 Adjust P1 (PC131) for – 13,0 ± 0,1 V (this operation is equivalent to set the average beam current limitation

circuit of three tubes to 3,0 ± 0,1 mA).

1.7 Switch the projector OFF by remote control.

1.8 Seal P1 with LOCTITE 454 adhesive.

1.9 Switch the projector ON by remote control.

1.10 Check that the voltage on TP8 is not changed after P1 sealing.

2. Adjusting and Testing of the single CRT Average Beam Current Limitation Circuit

2.1 Connect the Digital Multimeter between GND1 and TP8 (PC132).

2.2 Switch the Red and the Blu CRTs OFF using the keys R and B of the remote control.

2.3 Adjust P2 (PC131) for – 8,0 ± 0,1 V (this operation is equivalent to set the average beam current limitation

circuit of a single tube to 2,1 ± 0,1 mA).

2.4 Switch the projector OFF by remote control.

2.5 Seal P2 with LOCTITE 45 4 adhesive.

2.6 Switch the projector ON by remote control.

2.7 Check that the voltage on TP8 is not changed after P2 sealing.

2.8 Remove the Digital Multimeter probes.

A section (service adjustments)

1. Adjusting and Testing of the total (three CRTs active) Average Beam Current Limitation Circuit

1.1 Switch the mains ON.

1.2 Adjust P1 and P2 fully anticlockwise.

1.3 Select a white-page pattern 0,7Vpp RGB signal.

1.4 Adjust Contrast to 100 and Brightness to 50 and memorise these values.

1.5 Connect a Digital Multimeter between GND1 and TP8 (PC132 board).

1.6 Adjust P1 (PC131) for – 13,0 ± 0,1 V (this operation is equivalent to set the average beam current limitation

circuit of three tubes to 3,0 ± 0,1 mA).

1.7 Switch the projector OFF by remote control.

1.8 Seal P1 with LOCTITE 454 adhesive.

1.9 Switch the projector ON by remote control.

1.10 Check that the voltage on TP8 is not changed after P1 sealing.

2. Adjusting and Testing of the single CRT Average Beam Current Limitation Circuit

2.1 Connect the Digital Multimeter between GND1 and TP8 (PC132).

2.2 Switch the Red and the Blu CRTs OFF using the keys R and B of the remote control.

2.3 Adjust P2 (PC131) for – 8,0 ± 0,1 V (this operation is equivalent to set the average beam current limitation

circuit of a single tube to 2,1 ± 0,1 mA).

2.4 Switch the projector OFF by remote control.

2.5 Seal P2 with LOCTITE 454 adhesive.

2.6 Switch the projector ON by remote control.

2.7 Check that the voltage on TP8 is not changed after P2 sealing.

2.8 Remove the Digital Multimeter probes.

Page 12

SVD800HD SERVICE GUIDE

page - 12 -

M459X POWER SUPPLY

A section includes the adjustments pre-set in the Factory.

B section includes the adjustments to be performed in service when the unit is replaced.

A section (Factory adjustments)

1. Switch-on the projector.

2. Switch-off the RGB tubes.

3. (*) Adjust RV1 on main power supply board for +6.25 Vd.c.±50mV between pins 6-7 of a CRT socket (PC029)

4. Adjust RV2 on B410.4 module, positioned vertically on main power supply board for +15.5 Vd.c.± 200mV on

pin 1 of the CN20 connector placed on the mother board.

5. Adjust RV1 on B410.4 module, positioned vertically on main power supply board for + 70 ±1Vd.c. to the anode

of D3, placed on PC132 (EHT & dynamic focus module).

(*) Note. The heater lines have a voltage of about 100 V higher than the ground.

B section (service adjustments)

1. Switch-on the projector.

2. Switch-off the RGB tubes.

3. (*) Adjust RV1 on main power supply board for +6.25 Vd.c.±50mV between pins 6-7 of a CRT socket (PC029)

4. Adjust RV2 on B410.4 module, positioned vertically on main power supply board for +15.5 Vd.c.± 200mV on

pin 1 of the CN20 connector placed on the mother board.

5. Adjust RV1 on B410.4 module, positioned vertically on main power supply board for + 70 ±1Vd.c. to the anode

of D3, placed on PC132 (EHT & dynamic focus module).

6. Check the following line:

• + 210 ± 5Vd.c.at the pin 3 of CN17 mother board connector.

(*) Note. The heater lines have a voltage of about 100 V higher than the ground.

Page 13

SVD800HD SERVICE GUIDE

page - 13 -

PC097 MICRO BOARD

1. When replace the micro board pay attention to use the EEPROM C.I.20 of the old board into the new one,

otherwise it's necessary to do again all type of adjustments, such as white & black, convergence and so on.

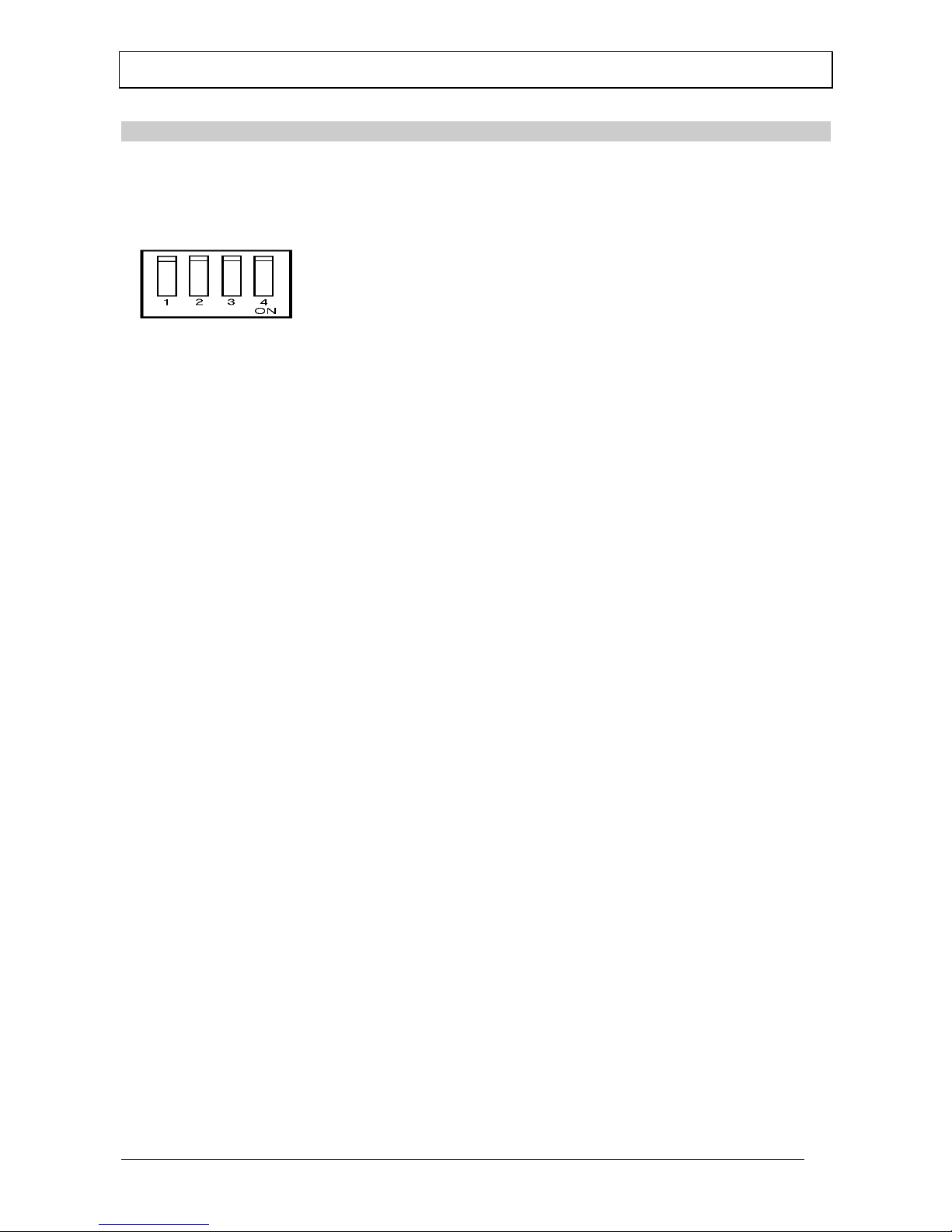

2. Positions of the DIP switch SW02:

Original setting

With Eprom (C.I.29) version <1.31

1-OFF = user mode.

1-ON = factory service mode

2-OFF = fan protection enabled

2-ON = fan protection disabled

3-not used in service (it must be set in OFF position)

4-not used in service (it must be set in OFF position)

3. Adjust the potentiometer placed on R126 position to centre the OSD: use MEMORY MANAGER the largest

menu and horizontal frequency towards the maximum of range.

Note. Usually in service no adjustments are requested. If introducing a new microprocessor board the OSD will appear

not correctly centred carry out the adjustment as at the step 3.

Page 14

SVD800HD SERVICE GUIDE

page - 14 -

4. Waveform PC339.0

VGA input signal 32K 50Hz

Install the board on t the extension card and power on the unit.

If DL1 on Convergence amplifier board PC324 lights, power off the unit, remove CN102 and CN103 on convergence

board and power on the unit.

Adjust H size and V size to maximum value.

Using a scope with 1/10 probe verify the following wave forms.

NOTE: All wave forms H have a time base of 32 us

All wave forms V have a time base of 20 ms

TP110 N1 from 2.2 to 2.5 Vpp Ramp HS+

TP110 N2 from 5.5 to 6.2 Vpp Ramp H-saw

TP103 N3 from 2.2 to 2.5 Vpp Ramp HS-

TP103 N4 from 2.2 to 2.5 Vpp Ramp VS+

Page 15

SVD800HD SERVICE GUIDE

page - 15 -

TP112 N2 from 5.5 to 6. 3 Vpp Ramp V-saw

TP103 N1 from 2.5 to 2.7 Vpp Parabola H-par

TP103 N2 from 2.3 to 2.8 Vpp Parabola V-par

TP104 N1 from 5. 5 to 7 Vpp V pin

TP104 N2 from 5.5 to 6.5 Vpp V key

TP104 N2 from 5. 5 to 6.7 Vpp H-pin

Page 16

SVD800HD SERVICE GUIDE

page - 16 -

TP111 N1 from +4Vpp to -0.7Vpp H/2

TP111 N2 from +4Vpp to -0.7Vpp V/2

TP106 N1 Ramp H+ H-saw L

Width from 2. 5 to 3.2 Vpp

From 0 to peak max 200mv

TP106 N2 Ramp H- H-saw R

Width from 2.5 to 3.2 Vpp

From 0 to peak max 200mv

TP107 N1 Ramp V+ V-saw L

Width from 2.5 to 3.2 Vpp

From 0 to peak max 100mv

TP107 N2 Ramp V- VsawR

Width from 2.5 to 3.2 Vpp

From 0 to peak max 100mv

Page 17

SVD800HD SERVICE GUIDE

page - 17 -

TP105 N1 from 2 to 2.5 Vpp Parabola H+

TP105 N2 from 2 to 2.5 Vpp Parabola V+

TP108 N1 from 2 to 2.5 Vpp Corners

From 0 to peak Max 200 mv

TP108 N2 from 2 to 2.5 Vpp Corners

From 0 to peak

Max 200 mv

TP108 N3 From 2 a 2.5 Vpp Corners

From 0 to peak

Max 200 mv

TP108 N4 from 2 to 2.5 Vpp Corners

From 0 to peak

Max 200 mv

Page 18

SVD800HD SERVICE GUIDE

page - 18 -

TP109 N1 from 2 a 2.5 Vpp H pc L

TP109 N2 from 2 to 2.5 Vpp H pc R

TP109 N3 from 2 to 2.5 Vpp V pc L

TP109 N4 from 2 to 2.5 Vpp V pc R

Page 19

SVD800HD SERVICE GUIDE

page - 19 -

5. PROTECTION CIRCUITERY

EHT Protection Circuit ( PC132 board):

This protection circuit is designed against the increasing of EHT caused by electronic components faults.

The EHT Splitter in conjunction to the resistor R37 divide the EHT and the resulting voltage is buffered by IC5B,

divided by R58, P4, R66 and it is applied to the positive input of the IC6A-pin7 Integrated Circuit (Test Point TP5),

which works as voltage comparator.

On the negative input of IC6A-pin6 (TP12), it’s applied a voltage of 0,89 V, available from the resistive divider R55

and R56.

If the EHT value increases and the voltage on IC6A-pin7 comparator exceeds the voltage on pin6, the output of IC6Apin1 is commuted to +12 V, the voltage on IC6B-pin5 increases over the reference voltage threshold of 5,1 V applied

on IC6B-pin4 from DZ1, the output of IC6B-pin2 goes to +12V and the protection circuit is activated, the protection

circuit sequence of operations is described here below:

When the voltage on IC6B-pin5 exceeds the voltage on it’s negative input, the IC6B-pin2 output goes to +12 V, the

protection is activated and the voltage comparator latches itself through D20.

The output voltage of IC6B-pin2 is applied to the transistor T7-base by D15, and T7 goes to ON state and DL1 is

switched ON.

The T7-emitter voltage is applied to the T2-base and it goes to ON state therefore the EHT driver signal is switched

OFF and the EHT is latched to zero.

The voltage on IC6B-pin2 through the R83-R84 divider is reduced to +5V and applied to the Microprocessor, and, after

about 10 seconds, it switches the projector to Stand-By mode.

Fly-back Voltage Protection Circuit ( PC132 board ):

This circuit is designed to protect the EHT circuitry against excessive fly-back voltage, it is a second protection circuit

in case of faults on the precedent circuit.

The fly-back voltage of the EHT circuit is rectified by D7, filtered by C17,R17, C16 and divided by R42, R43 and P1,

then it’a applied to the positive input of IC 6C-pin9, which is operating as voltage comparator.

On the negative input of the same IC6C-pin8, it’s applied a reference voltage of +5,1 V by DZ1.

If the fly-back voltage increases and the voltage on pin9 exceeds the voltage on pin8, the voltage output of IC6C-pin14

goes to +12 V and the protection circuit is activated:

Through R46 and D18 the voltage output on IC6C-pin14 is OR connected to IC6B-pin5 input which is operating as a

voltage comparator.

Automatic Beam Current Limit Protection Circuit ( PC132 board ):

This protection circuit is designed against the CRTs excessive beam currents that may happen in case of

faults on the video amplifiers or in the beam current sensing / limitation circuits of the video board PC131.

The resistors R63 and R100 are operating as current to voltage converters on the secondary circuits of the

fly-back transformers, if the converted voltage, available on TP8, exceeds the threshold voltage value of 17,0 V, the protection is activated:

The voltage detected on TP8 is divided by R62 – P5 and then it’s applied to the transistor T9-base, this

transistor is ON on the normal operating state.

Page 20

SVD800HD SERVICE GUIDE

page - 20 -

An increasing of the beam current is converted in an increasing of the negative voltage, which drives T9 to

the OFF state, and it collector goes to the level of +12 V. This voltage, through R59 and D22 is OR

connected to IC6B-pin5 input, activating this voltage comparator.

The protection circuit sequence of operation is the same as reported on points 1.1 – 1.4.

Page 21

SVD800HD SERVICE GUIDE

page - 21 -

6. SERVICE ADJUSTMENTS

These adjustments are performed when particular components (CRT, yoke, etc.) have been replaced.

2/4 POLE ADJUSTMENT

Non-pole

50 mm

1. Select VGA or RGB slot, without any signal applied.

2. Select the HATCH COARSE test pattern, using the TEST button on the full function remote control.

3. Project the pattern on the replaced CRT, using R, G and B buttons.

4. Align the centre of the CRT raster with the centre of the screen by SHIFT control (see User Manual).

5. Adjust the focus potentiometer of the corresponding CRT completely in anti-clockwise.

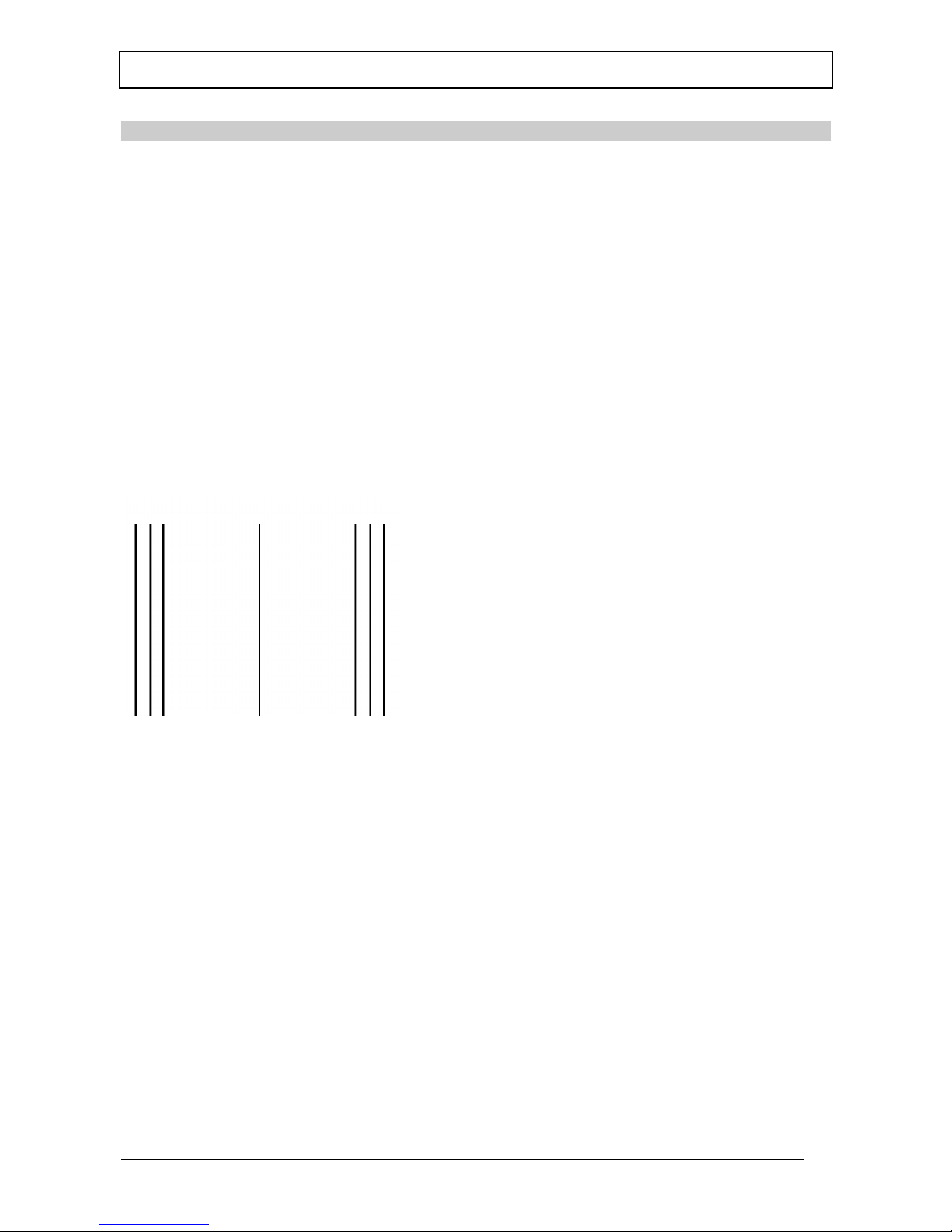

6. Adjust the 2 pole magnet till the flare is equal on both sides of the vertical and horizontal lines (see following

figure).

not correct correct

7. Select the DOT COARSE test pattern, using the TEST button on the full function remote control.

8. Adjust the focus potenti ometer of the replaced CRT slightly clockwise.

9. Adjust the 4-pole magnet till the dots have the best circular shape in the centre of the screen (see following

figure).

not correct correct

Note. Repeat the 2-pole and 4-pole magnets alignments if necessary, because they influence each other.

10. Select the HATCH COARSE test pattern, using the TEST button on the full function remote control.

Page 22

SVD800HD SERVICE GUIDE

page - 22 -

11. Adjust the focus till the flare disappear from the lines.

How to adjust the 2/4 pole

X

Y

X: adjusts the power of magnetic force

Y: adjusts the direction of the magnetic force

Page 23

SVD800HD SERVICE GUIDE

page - 23 -

SERVICE SETTING

Conditions:

Signal generator at 32 KHz horizontal frequency.

White window 50% of the screen.

Set the DIP switch SW02 on the micro board (with projector switched-off): switch no. 1 in ON position. The projector

will work in SERVICE MODE., .

To exit from SERVICE MODE: switch-off the projector and restore the DIP switch SW02 on the micro board:

1: OFF

2: OFF

3: OFF

4: OFF

Note: for a complete description of SW02 see paragraph regarding the PC097 micro board.

Use a signal window WHITE TEST PATTERN 100% modulated.

Press VID.S button, the following MENU will appear:

- VIDEO MENU -

- QSD MANAGER

- UPC MANAGER

- INPUT SETINGS

- BLANKINGS

- EHT NOISE RED.

- WHITE MENU

1 To exit from this MENU, press the EXIT button, or press the ESC button. The projector will return to the

external video signal.

Use the ↑ or ↓ cursor button to select WHITE MENU.

Page 24

SVD800HD SERVICE GUIDE

page - 24 -

WHITE MENU

This menu permits to change the three color temperature sets, presetted in Factory, at 3200°K, 6500°K and 9300°K.

- WHITE MENU -

- SET TO 3200° K

- SET TO 6500° K

- SET TO 9300° K

- SET TO USER° K

- SET TO BANK

- EDIT PRESET

- RESTORE PRESET

- CUT-OFF TIMING

1. Use the ↑↑ or ↓↓ cursor button to select 6500 °K of colour temperature and then press ENTER.

2. Use the ↑↑ or ↓↓ cursor button to select EDIT PRESET, pressing ENTER will be displayed

- G1 G2 PRESET 6500° K

R G B

TARGET 23 23 23

DAC 77 77 77

ADC 23 23 23

3. Connect an oscilloscope probe to G1 of the green tube, TPG1 test point (use 100:1 probe).

4. Select green tube pressing Gsel button.

5. Using ↑↑ or ↓↓ cursor button adjust the cut-off level to 25 V.

↓↓ cut-off: 25 V.

Page 25

SVD800HD SERVICE GUIDE

page - 25 -

0 Vd.c. →

6. Repeat the previous operations 3, 4 and 5 for the Red and for the Blue.

7. Adjust sequentially the three G2 potentiometers to obtain 23 ±5 value for each ADC relative to the R, G and B.

8. Press ENTER, will be displayed

- WHITE BALANCE 6500° K

R G B

BLACK 53 30 56

WHITE 67 76 61

9. Use a signal WINDOW WHITE TEST PATTERN 100% modulated (50% of the screen area).

10. Adjust the contrast to 100 and brightness to 0.

11. Connect an oscilloscope probe to the cathode of the GREEN tube, TPK test point (use 100:1 probe): adjust the

WHITE of the green for 150Vpp.

12. Disconnect the oscilloscope probe from the cathode of the green CRT.

13. Use a signal WINDOW WHITE TEST PATTERN 20% modulated (50% of the screen area).

14. Adjust contrast to 80 and brightness to 50.

15. Select colour temperature 6500° K on the COLOR ANALYSER

16. Press B button and with ↑↑ or ↓↓ cursor button adjust for the correct BLACK value (looking on the COLOR

ANALYZER).

17. Press R button and with ↑↑ or ↓↓ cursor button adjust for the correct R BLACK value (looking on the COLOR

ANALYZER).

Note. Don't adjust G value.

18. Use a signal window WHITE TEST PATTERN 60% modulated (50% of the screen area).

19. Press Bsel button and with ↑↑ or ↓↓ cursor button adjust for the correct B WHITE value (looking on the COLOR

ANALYZER).

20. Press Rsel button and with ↑↑ or ↓↓ cursor button adjust for the correct R WHITE value (looking on the COLOR

ANALYZER).

Note. Don't adjust G value.

Page 26

SVD800HD SERVICE GUIDE

page - 26 -

21. Repeat the operations from 16 to 20 till the BLA CK and WHITE values don't change.

Note. Adjusting the WHITE values could change the BLACK values and vice versa..

22. Select a signal window WHITE TEST PATTERN 20% modulated.

23. Adjust the brightness to 80, then press EXIT.

5. Press INFO and successively RGB buttons to display the gains of the RGB channels, that will appear to left

side of the black and white values.

- WHITE BALANCE 6500° K

92

100

84

R G B

BLACK 53 50 53

WHITE 65 90 65

25. Press B button to select B channel and with ↑↑ or ↓↓ cursor buttons adjust the gain for the correct BLACK value

(looking on the COLOR ANALYZER).

6. Press R button to select R channel and with ↑↑ or ↓↓ cursor button adjust the gain for the correct B BLACK

value (looking on the COLOR ANALYZER).

Note. Don't adjust G value.

27. Press EXIT. To memorise immediately press MEMO, will appear:

COLOR TEMPERATURE MEMORIZED!

or pressing EXIT will appear:

INIT ALL BANKS TO6500?

press ENTER to memorise or EXIT to return to WHITE BALANCE menu without to store.

Note: pressing ENTER will be stored 6500°K into all banks from 00 till 29.

30. For 3200°K (select like items 1 and 2) repeat the same operations from 8 to 29, taking the Red CRT as

reference: 150 Vpp on Red cathode and adjust only Green and Blue values to obtain the correct Black and White levels.

31. For 9300°K (select like items 1 and 2) repeat the same operations from 8 to 29, taking the Green CRT as

reference: 150 Vpp on Green cathode and adjust only Blue and Red values to obtain the correct Black and White levels.

Note. The bank SET TO USER °K is charged in Factory at 6500°K.

Page 27

SVD800HD SERVICE GUIDE

page - 27 -

RESTORE PRESET

This function is useful to restore the colour temperature of the three sets adjusted in Factory at 3200°K, 6500°K and

9300°K when have been changed in User mode.

Note. When change the colour temperature set into WHITE MENU will change the Factory setting.

From the WHITE BALANCE menu select RESTORE PRESET, using the ↑↑ or ↓↓ cursor button, and press the ENTER

button. The following indication will appear.

WARNING !

RESTORE OLD XXXX°K TEMP ?

Press ENTER to confirm, will appear:

OLD DATA RESTORED !

CUT-OFF TIMING

This menu permits to determine the condition of the automatic cut-off.

From the WHITE BALANCE menu select CUT-OFF TIMING using the ↑↑ or ↓↓ cursor button and press the ENTER

button. The following menu will appear.

- CUT-OFF TIMING

FIRST CUT-OFF AFTER 20

SECOND CUT-OFF AFTER 40

CUT-OFF EVERY 10

NUM CYCLES 100

CUT-OFF ENABLE NO

CUT-OFF WINDOW OFF

Use the ↑↑ or ↓↓ cursor button to select the item

and ← or →→ button to change the value of the selected item.

• FIRST CUT-OFF AFTER: may be changed from 02 to 30 min.

• SECOND CUT-OFF AFTER: may be changed from 02 to 30 min.

• CUT-OFF EVERY: may be changed from 02 to 30 min.

• NUM CYCLES: may be changed from 050 (~2 sec.) - 100 -150 - 200 till 250 (~ 10 sec.).

• CUT-OFF ENABLE: ON or OFF (when ON permits all cycles)

• CUT-OFF WINDOW: ON or OFF

Page 28

SVD800HD SERVICE GUIDE

page - 28 -

Note. When the CUT-OFF WINDOW is selected ON permits, pressing RESET button, to see if all "cut-off circuits" are

working correctly (with video projector out any menu), looking at the following window that will appear on the screen:

DAC ADC

97 23

78 23

69 23

Page 29

SVD800HD SERVICE GUIDE

page - 29 -

SERVICE MENU

Press the button for a long time to enter into MAIN MENU, the following menu will appear.

- MAIN MENU

- VIDEO MENU

- OPTIONS

- INSTALL MENU

- SERVICE MENU

Use the ↑↑ or ↓↓ cursor to select SERVICE MENU then press ENTER, the following menu will appear.

- SERVICE MENU

- PATTERN PHASE

- WAVEFORM TEST

This menu permits to adjust the horizontal phase of the internal Pattern Signal and to check the automatic waveform

test.

PATTERN PHASE

Select the RGB input without any signal applied to it.

Use the ←← or →→ cursor button to adjust the horizontal phase from 00 till 99.

The pattern have to be centred on the tubes, looking through the lenses.

PATTERN

CRT: RGB

PHASE

H. VALUE: XX

Escaping from this menu, if any changes are made on settings, the projector will ask if the changes have to be

memorised, with the following message:

MEMORIZE PATTERN PHASE?

Press ENTER to memorize the new adjustment or EXIT to maintain the previous value.

Page 30

SVD800HD SERVICE GUIDE

page - 30 -

WAVEFORM TEST

This menu is used as test only; it shows automatically all adjustments that can be performed by the full remote control.

From the SERVICE MENU select the WAVE FORM BOARD item using the ↑↑ or ↓↓ cursor button and then press the

ENTER button. The following menu will appear:

- WAVE FORM BOARD -

-ZONE WAVETEST

- REGISTRATIONS WT

- FOCUS WAVETEST

- PICTURE WAVETEST

ZONE WAVETEST

It shows the convergence adjustments (see ZONE in the User manual): after three adjustments it stops, press →→ cursor

button to continue or ←← cursor button to repeat the last three adjustments.

REGISTRATIONS WT

It shows the Registrations relative to geometry adjustments (see ZONE in the User manual); after three adjustments it

stops, press →→ cursor button to continue or ←← cursor button to repeat the last three adjustments.

FOCUS WAVETEST

It shows the adjustments relative to dynamic focus and focus phase); press →→ cursor button to continue or ←← cursor

button to repeat the last three adjustments.

PICTURE WAVETEST

It shows the black/white adjustments for the three CRT's and contrast, brightness, saturation and hue adjustments; after

three adjustments it stops, press →→ cursor button to continue or ←← cursor button to repeat the last three adjustments.

Page 31

SVD800HD SERVICE GUIDE

page - 31 -

PICTURE WAVETEST

To reach this menu select OPTION, pressing OPT button, then MISCELLANEUS, at the end WORKING TIME.

This menu permits to know how long the projector and each CRT worked. In Service when replace one CRT reset the

relative time, as follow:

- with ↑↑ or ↓↓ button select the CRT replaced

- press RESET button, will appear

WARNING!

RESET XXX WORKING TIME?

Pressing ENTER the selected CRT will be reset to 0000.

Page 32

SVD800HD SERVICE GUIDE

page - 32 -

7. SDG UPC2000 INSTALLATION PROCEDURE

• Check the projector EEprom release : press the INFO key on the remote control and read the “SOFTWARE REL.”

on page 2/2. If SOFTWARE REL. is 6.04 or lower, replace the EEprom using the one supplied in the kit,

otherwise nothing has to be done.

• Switch off the projector and remove the power cable

• Remove the top plastic cover (see: par. 4.2.1 page 16 of the Instruction Manual).

• Remove the top aluminum cover (A) by unscrewing 8 screws (B).

• Remove the bottom aluminum cover (C) by unscrewing 6 screws (D).

• Unscrew the 2 screws (E) at the side of the convergence heat sink and lift it.

• Unscrew the screws (F) on the top of the UPC holder.

• Insert UPC in the channels (G) and press it down.

• Replace EEprom if necessary : unscrew the screws and remove the aluminum cover of microprocessor board

PC328 (the board is vertically mounted near the UPC board), extract the board, find out the integrated circuit

labeled IC29, replace IC29 with the other one provided in the up-converter kit.

• Remount the microprocessor board

• Reposition all the aluminum cover and the screws.

• NOTE: When repositioning the bottom aluminum cover be careful to insert correctly the two LED 21 e 22 in the

holes (see page 6 pict. 3 of the Instruction Manual).

• Close the top plastic cover and the two screws.

• In order to use the UPC converter with the RC3100 remote see par. 3 page 8 and par. 3.14 page 11 of the

Instruction Manual, and with the RC3000 remote, see par.5 page 25 of the Instruct. Manual.

Page 33

SVD800HD SERVICE GUIDE

page - 33 -

8. SPARE PARTS LIST

How to find the correct part number

Choice the desired

ITEM number and

matches it with the

Technical Code

column; the technical

code is printed on to

the back panel label.

Example 1

ITEM 1with

TC850136003

Part number

800186000

Example 2

ITEM 1 with

TC850136019

Part number

800186200

SPARE PART LIST table 3/3 "CRT tubes"

ITEM DESCRIPTION TC

850136000TC850136003TC850136005TC850136007TC850136009TC850136011TC850136013

1 CRT video board 800186000 800186000 800186000 800186000 800186000 800186100 800186100

2 Astig. magnet assembly

722044000

722044000

722044000

722044000

722044000

722044000

722044000

3 Yokes assembly

702024000

702024000

702024000

702024000

702024000

702024000

702024000

4 RED Red CRT tube

710111000

710111000

710111000

710111000

710111000

710111000

710111000

4 GREEN

Green CRT tube

710112000

710112000

710112000

710112000

710112000

710112000

710112000

4 BLUE Blue CRT tube 710113000 710113000 710113000 710113000 710113000 710113000 710113000

5 Proj. lens (front cover incl.)

782089000

782089000

782089000

782089000

782089000

782089000

782089000

ITEM DESCRIPTION TC

850136014TC850136015TC850136017TC850136019TC850136021TC850123023TC850123025

1 CRT video board 800186200 800186200 800186200 800186200 800186200 800186200 800186200

2 Astigmatism magnet

assembly

722044000

722044000

722044000

722044000

722044000

722044000

722044000

3 Yokes assembly 702024000 702024000 702024000 702024000 702024000 702024000 702024000

4 RED Red CRT tube

710111000

710111000

710111000

710111000

710111000

710111000

710111000

4 GREEN

Green CRT tube

710112000

710112000

710112000

710112000

710112000

710112000

710112000

4 BLUE Blue CRT tube

710113000

710113000

710113000

710113000

710113000

710113000

710113000

5 Projection lens (front cover

included)

782089000

782089000

782089000

782089000

782089000

782089000

782089000

Page 34

1

2

3

5

6

9

8

7

4

Page 35

1

2

3

4

5

Page 36

9

8

7

6

5

4

3

10

11

12

14

13

2

1

16

15

Page 37

SVD800HD SERVICE GUIDE

page - 34 -

9. SVD800HD SPARE PART LIST

SVD800HD spare part list table 1/3 "Estetics"

ITEM DESCRIPTION

TC

850136000TC850136003TC850136005TC850136007TC850136009TC850136011TC850136013

1

Top cover 412663100 412663100 412663100 412663100 412663100 412663100 412663100

2

Back cover

480137000

480137000

480137000

480137000

480137000

480137000

480137000

3

Cooling fan

840179000

840179100

840179100

840179100

840179100

840179100

840179100

4

Right top cover

412669000

412669000

412669000

412669000

412669000

412669000

412669000

5

Right bottom cover

410113000

410113000

410113000

410113000

410113000

410113000

410113000

6

Back methallic panel

490228000

490228100

490228100

490228100

490228100

490228100

490228100

7

Left bottom cover

410112000

410112000

410112000

410112000

410112000

410112000

410112000

8

Left top cover 412672000 412672000 412672000 412672000 412672000 412672000 412672000

9

Front cover

423899000

423899000

423899001

423899001

423899001

423899001

423899001

10

Front bottom cover 420111000 420111000 420111000 420111000 420111000 420111000 420111000

ITEM DESCRIPTION

TC

850136014TC850136015TC850136017TC850136019TC850136021TC850123023TC850123025

1

Top cover 412663100 412663100 412663100 412663100 412663100 412663100 412663100

2

Back cover

480137000

480137000

480137000

480137000

480137000

480137000

480137000

3

Cooling fan

840179100

840179100

840179100

840179100

840179100

840179100

840179100

4

Right top cover

412669000

412669000

412669000

412669000

412669000

412669000

412669000

5

Right bottom cover

410113000

410113000

410113000

410113000

410113000

410113000

410113000

6

Back methallic panel

490228100

490228100

490228100

490228100

490228100

490228100

490228100

7

Left bottom cover

410112000

410112000

410112000

410112000

410112000

410112000

410112000

8

Left top cover

412672000

412672000

412672000

412672000

412672000

412672000

412672000

9

Front cover 423899001 423899001 423899001 423899001 423899001 423899001 423899001

10

Front bottom cover

420111000

420111000

420111000

420111000

420111000

420111000

420111000

Page 38

SVD800HD SERVICE GUIDE

page - 35 -

SVD800HD spare part list table 2/3 "Electronic boards"

ITEM DESCRIPTION

TC

850136000TC850136003TC850136005TC850136007TC850136009TC850136011TC850136013

1 Power supply

790117000 790117100 790117100 790117100 790119200 790119200 790119200

2 EHT & Dyn Focus PC132

800187000 800187100 800187100 800187100 800187100 800187100 800187100

3 Power convergence PC324

800182000

800182000

800182000

800182000

800182000

800182000

800182000

4 UPC PC122

5 Microprocessor PC328

800189100

800189100

800189100

800189100

800189100

800189100

800189100

5a EPROM with software

931590524

(vers. 603)

931590524

(vers. 603)

931590524

(vers. 603)

931590524

(vers. 603)

931590530

(vers. 6.04)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

5b EEPROM with factory datas

931590525 931590525 931590525 931590525 931590525 931590525 931590525

6 Waveform PC116

805073102

805073102

800195000

800195000

800195000

------------- -------------

6 Waveform PC339

------------- ------------- ------------- ------------- ------------- 800004000 800004010

7 Video processor PC131

805157203

800196000

800196000

800196000

800196000

800196000

800196000

8 Sync processor PC226

800190000 800190100 800190100 800190100 800190100 800190200 800190200

9 Input PC322

800169000

800169100

800169100

800169100

800169100

800169100

800169200

10 Vertical deflection PC098

805063100

800193000

800193000

800193000

800193000

800193100

800193110

11 Horizontal deflection PC028

805064101

800194000

800194000

800194000

800194000

800194000

800194000

12 Mther board PC323

800181000

800181100

800181100

800181100

800181100

800181100

800181100

13 Hor. Shift & Prot PC121

805083100

805083100

805083100

805083100

805083200

805083200

805083200

14 EHT distributor

540161000

540161000

540161000

540161000

540161000

540161000

540161000

15 Potentiometer block

550107000

550107000

550107000

550107000

550107000

550107000

550107000

16 FBT PC326

800185000

800185000

800185000

800185000

800185000

800185100

800185100

ITEM DESCRIPTION

TC

850136014TC850136015TC850136017TC850136019TC850136021TC850123023TC850123025

1 Power supply

790119200 790119200 790119200 790119200 790119200 790119200 790119200

2 EHT & Dyn Focus PC132

800187100

800187100

800187100

800187100

800187100

800187100

800187100

3 Power convergence PC324

800182000

800182000

800182000

800182000

800182000

800182000

800182000

4 UPC PC122

5 Microprocessor PC328

800189100

800189100

800189100

800189100

800189100

800189100

800189100

5a EPROM with software

931590531

(vers. 6.05)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

931590531

(vers. 6.05)

5b EEPROM with factory datas

931590525

931590525

931590525

931590525

931590525

931590525

931590525

6 Waveform PC116

------------- ------------- ------------- ------------- ------------- ------------- -------------

6 Waveform PC339

800004010

800004010

800004010

800004010

800004010

800004010

800004010

7 Video processor PC131

800196200

800196200

800196200

800196200

800196200

800196210

800196210

8 Sync processor PC226

800190200 800190200 800190300 800190300 800190300 800190300 800190300

9 Input PC322

800169200

800169210

800169210

800169210

800169210

800169210

800169210

10 Vertical deflection PC098

800193110 800193110 800193110 800193110 800193110 800193110 800193110

11 Horizontal deflection PC028

800194000

800194000

800194000

800194000

800194000

800194000

800194000

12 Mther board PC323

800181100 800181100 800181200 800181200 800181200 800181200 800181200

13 Hor. Shift & Prot PC121

805083200

805083200

805083200

805083200

805083200

800037000

800037000

14 EHT distributor

540161000 540161000 540161000 540161000 540161000 540161000 540161000

15 Potentiometer block

550107000

550107000

550107000

550107000

550107000

550107000

550107000

16 FBT PC326

800185200

800185200

800185200

800185200

800185200

800185200

800185200

Page 39

SVD800HD SERVICE GUIDE

page - 36 -

SVD800HD spare part list table 3/3 "CRT tubes"

ITEM DESCRIPTION

TC

850136000TC850136003TC850136005TC850136007TC850136009TC850136011TC850136013

1 CRT video board

800186000 800186000 800186000 800186000 800186000 800186100 800186100

2 Astigmatism magnet assy

722044000

722044000

722044000

722044000

722044000

722044000

722044000

3 Yokes assembly

702024000

702024000

702024000

702024000

702024000

702024000

702024000

4 R Red CRT tube

710111000

710111000

710111000

710111000

710111000

710111000

710111000

4 G Green CRT tube

710112000

710112000

710112000

710112000

710112000

710112000

710112000

4 B Blue CRT tube

710113000 710113000 710113000 710113000 710113000 710113000 710113000

5 Projection lens

(front cover included)

782089000

782089000

782089000

782089000

782089000

782089000

782089000

ITEM DESCRIPTION

TC

850136014TC850136015TC850136017TC850136019TC850136021TC850123023TC850123025

1 CRT video board

800186200 800186200 800186200 800186200 800186200 800186200 800186200

2 Astigmatism magnet assy

722044000

722044000

722044000

722044000

722044000

722044000

722044000

3 Yokes assembly

702024000

702024000

702024000

702024000

702024000

702024000

702024000

4 R Red CRT tube

710111000

710111000

710111000

710111000

710111000

710111000

710111000

4 G Green CRT tube

710112000

710112000

710112000

710112000

710112000

710112000

710112000

4 B Blue CRT tube

710113000

710113000

710113000

710113000

710113000

710113000

710113000

5 Projection lens

(front cover included)

782089000

782089000

782089000

782089000

782089000

782089000

782089000

Page 40

SVD800HD SERVICE GUIDE

page - 37 -

SVD800 Millennium spare part list table 1/3 "Estetics"

ITEM

DESCRIPTION

TC

850009000TC850009002TC850009004TC850009006TC850009008TC850009010TC850009012TC850009014

1 Top cover

410007000 410007000 410007000 410007000 410007000 410007000 410007000 410007000

2 Back cover

480013000 480013000 480013000 480013000 480013000 480013000 480013000 480013000

3 Cooling fan

840179100

840179100

840179100

840179100

840179100

840179100

840179100

840179100

4 Right top cover

410002000 410002000 410002000 410002000 410002000 410002000 410002000 410002000

5 Right bottom cover

150003000

150003000

150003000

150003000

150003000

150003000

150003000

150003000

6 Back methallic panel

490228100 490228100 490228100 490228100 490228100 490228100 490228100 490228100

7 Left bottom cover

150002000

150002000

150002000

150002000

150002000

150002000

150002000

150002000

8 Left top cover

410003000

410003000

410003000

410003000

410003000

410003000

410003000

410003000

9 Front cover

420001000

420001000

420001000

420001000

420001000

420001000

420001000

420001000

10 Front bottom cover

150001000

150001000

150001000

150001000

150001000

150001000

150001000

150001000

SVD800HD spare part list table 2/3 "Electronic boards"

ITEM

DESCRIPTION

TC

850009000TC850009002TC850009004TC850009006TC850009008TC850009010TC850009012TC850009014

1 Power supply

790117200 790117200 790117200 790117200 790117200 790117200 790117200 790117200

2 EHT/Dyn Focus PC132

800187100

800187100

800187100

800187100

800187100

800187100

800187100

800187100

3 Power conv. PC324

800182000 800182000 800182000 800182000 800182000 800182000 800182000 800182000

4 UPC PC122

5 Microprocessor PC328

800189100

800189100

800189100

800189100

800189100

800189100

800189100

800189100

5a EPROM with software

6.05

931590531

931590531

931590531

931590531

931590531

931590531

931590531

931590531

5b EEPROM with factory

datas

931590525

931590525

931590525

931590525

931590525

931590525

931590525

931590525

6 Waveform PC116

------------- ------------- ------------- ------------- ------------- ------------- ------------- -------------

6 Waveform PC339

800004010

800004010

800004010

800004010

800004010

800004010

800004010

800004010

7 Video proc. PC131

800196200 800196200 800196200 800196200 800196200 800196200 800196210 800196210

8 Sync proc. PC226

800190200

800190200

800190300

800190300

800190300

800190300

800190300

800190300

9 Input PC322

800014000 800014010 800014010 800014010 800014010 800014010 800014010 800014010

10 Vert. deflection PC098

800193110

800193110

800193110

800193110

800193110

800193110

800193110

800193110

11 Hor. deflection PC028

800194000 800194000 800194000 800194000 800194000 800194000 800194000 800194000

12 Mother board PC323

800181100

800181100

800181200

800181200

800181200

800181200

800181200

800181200

13 Hor.Shift/Prot PC121

805083200 805083200 805083100 805083100 805083200 805083200 800037000 800037000

14 EHT distributor

540161000

540161000

540161000

540161000

540161000

540161000

540161000

540161000

15 Potentiometer block

550107000

550107000

550107000

550107000

550107000

550107000

550107000

550107000

16 FBT PC326

800185000

800185000

800185000

800185000

800185000

800185000

800185000

800185000

Page 41

SVD800HD SERVICE GUIDE

page - 38 -

SVD800 Millennium spare part list table 3/3 "CRT tubes"

ITEM

DESCRIPTION

TC

850009000TC850009002TC850009004TC850009006TC850009008TC850009010TC850009012TC850009014

1 CRT video board

800186200 800186200 800186200 800186200 800186200 800186200 800186200 800186200

2 Astig. magnet assy

722044000

722044000

722044000

722044000

722044000

722044000

722044000

722044000

3 Yokes assembly

702024000

702024000

702024000

702024000

702024000

702024000

702024000

702024000

4 R Red CRT tube

710111000

710111000

710111000

710111000

710111000

710111000

710111000

710111000

4 G Green CRT tube

710112000

710112000

710112000

710112000

710112000

710112000

710112000

710112000

4 B Blue CRT tube

710113000 710113000 710113000 710113000 710113000 710113000 710113000 710113000

5 Projection lens

782089000

782089000

782089000

782089000

782089000

782089000

782089000

782089000

Page 42

SVD800HD SERVICE GUIDE

page - 39 -

SVD800HD Teatro spare part list table 1/3 "Estetics"

ITEM DESCRIPTION

TC 850063000 TC 850063002

1

Top cover 412663200 412663200

2

Back cover 480137000 480137000

3

Cooling fan 840179100 840179100

4

Right top cover 412669000 412669000

5

Right bottom cover 410113000 410113000

6

Back methallic panel 490228100 490228100

7

Left bottom cover 410112000 410112000

8

Left top cover 412672000 412672000

9

Front cover 423899001 423899001

10

Front bottom cover 420111000 420111000

SVD800HD Teatro spare part list table 2/3 "Electronic boards"

ITEM DESCRIPTION

TC 850062000 TC 850062000

1 Power supply

790117200 790117200

2 EHT & Dyn Focus PC132

800187100 800187100

3 Power convergence

PC324

800182000 800182000

4 UPC PC122

5 Microprocessor PC328

800189100 800189100

5a EPROM with software 6.03

931590524 931590524

5b EEPROM with factory

datas

931590525 931590525

6 Waveform PC339

800004010 800004010

7 Video processor PC131

800196210 800196210

8 Sync processor PC226

800190300 800190300

9 Input PC322

800014010 800014010

10 Vertical deflection PC098

800193110 800193110

11 Horizontal deflection

PC028

800194000 800194000

12 Mother board PC323

800182000 800182000

13 Hor. Shift & Prot PC121

800037000 800037000

14 EHT distributor

540161000 540161000

15 Potentiometer block

550107000 550107000

16 FBT PC326

800185000 800185000

SVD800HD Teatro spare part list table 3/3 "CRT tubes"

ITEM DESCRIPTION

TC 850062000 TC 850062002

1 CRT video board

800186200 800186200

2 Astigmatism magnet assy

722044000 722044000

3 Yokes assembly

702024000 702024000

4 R Red CRT tube

710111000 710111000

4 G Green CRT tube

710112000 710112000

4 B Blue CRT tube

710113000 710113000

5 Projection lens

782089000 782089000

Page 43

SVD800HD SERVICE GUIDE

page - 40 -

SVD800HDB Teatro spare part list table 1/3 “estetics"

ITEM DESCRIPTION

TC 850064000 TC 850064002

1

Top cover 41001000 41001000

2

Back cover 480009100 480009100

3

Cooling fan 840179100 840179100

4

Right top cover 410002000 410002000

5

Right bottom cover 410005000 410005000

6

Back methallic panel 490228100 490228100

7

Left bottom cover 410003000 410003000

8

Left top cover 410002000 410002000

9

Front cover 420002000 420002000

10

Front bottom cover 420001000 420001000

SVD800HDB Teatro spare part list table 2/3 "Electronic boards"

ITEM DESCRIPTION

TC 850064000 TC 850064002

1 Power supply

790117200 790117200

2 EHT & Dyn Focus PC132

800187100 800187100

3 Power convergence

PC324

800182000 800182000

4 UPC PC122

5 Microprocessor PC328

800189100 800189100

5a EPROM with software 6.03

931590524 931590524

5b EEPROM with factory

datas

931590525 931590525

6 Waveform PC339

800004010 800004010

7 Video processor PC131

800196210 800196210

8 Sync processor PC226

800190300 800190300

9 Input PC322

800169210 800169210

10 Vertical deflection PC098

800193110 800193110

11 Horizontal deflection

PC028

800194000 800194000

12 Mother board PC323

800182000 800182000

13 Hor. Shift & Prot PC121

800037000 800037000

14 EHT distributor

540161000 540161000

15 Potentiometer block

550107000 550107000

16 FBT PC326

800185000 800185000

SVD800HDB Teatro spare part list table 3/3 "CRT tubes"

ITEM DESCRIPTION

TC 850064000 TC 850064002

1 CRT video board

800186200 800186200

2 Astigmatism magnet assy

722044000 722044000

3 Yokes assembly

702024000 702024000

4 R Red CRT tube

710111000 710111000

4 G Green CRT tube

710112000 710112000

4 B Blue CRT tube

710113000 710113000

5 Projection lens

782089000 782089000

Loading...

Loading...