Page 1

User and Installation Manual

The home theater projector

HT300 LINK

cod.46.0327.100

Page 2

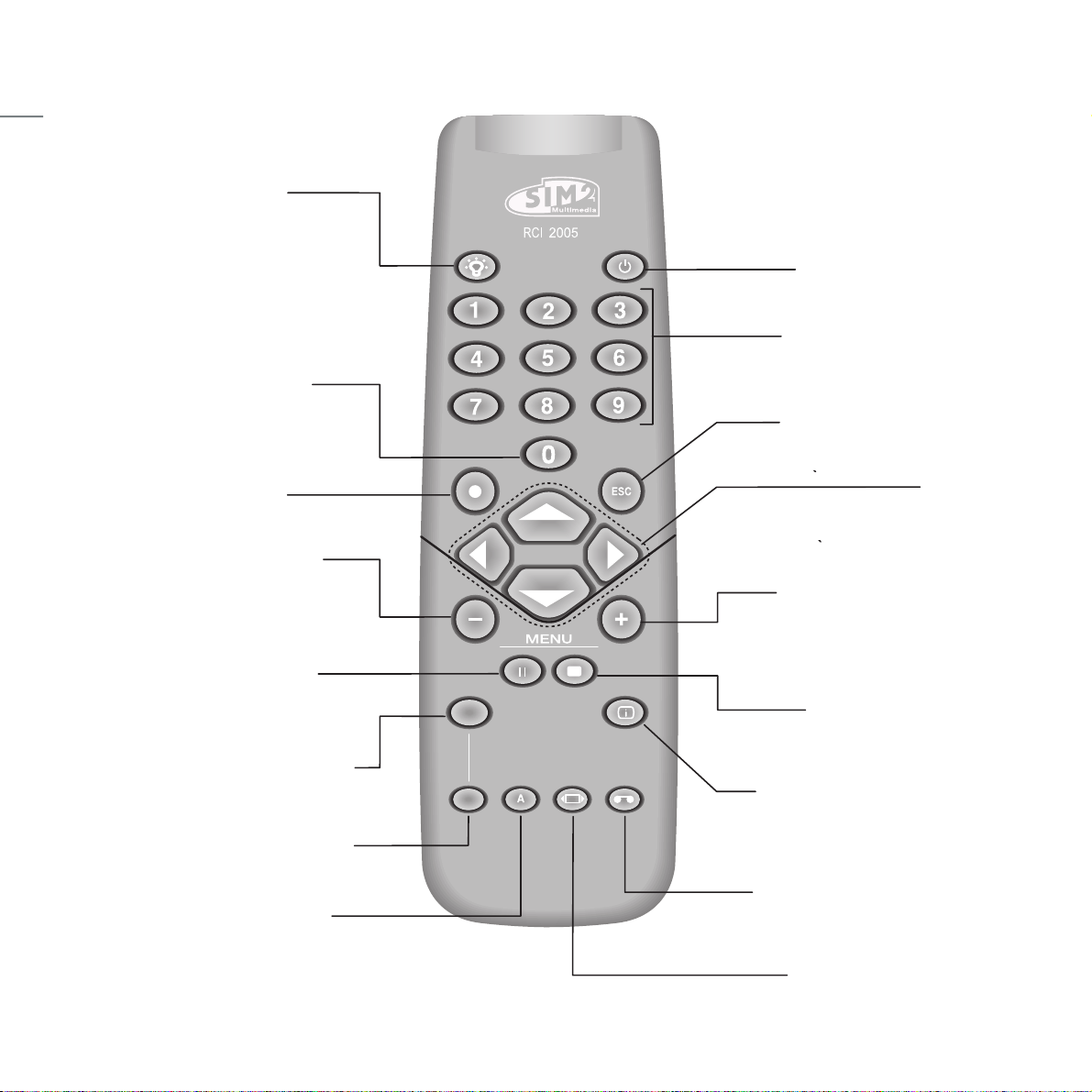

BACK LIGHT

Turn on the back light

SOURCE

Displays the Source

Selection menu.

Not active

in this model.

MENU -

Activates the On Screen

Display menus.

Navigates menu pages.

FREEZE

Freezes a moving

picture.

F1

function key

programmable via OSD

F2

function key

programmable via OSD

AUTO

Selects Auto Adjust

(automatic optimisation

of the displayed image).

ZOOM

F1

F2

FOCUS

LIGHT

STAND-BY

Switches off to stand-by.

0-9 Keys

Switch on from stand-by

and allow direct source

selection.

ESCAPE

Deactivates the On Screen Display.

Up/Down/Left/Right Arrow keys

Navigate through and make adjustments

to the On Screen menus.

Arrow Up/Down activate Quick

menus.

MENU +

Activates the On Screen Display menus.

Navigates menu pages.

Not active

in this model.

INFO

Displays the selected source information

and the projector status.

VCR

Improves the video recorder

signals quality.

ASPECT

Selects image Aspect ratio.

Page 3

1 INTRODUCTION

Congratulations on your choice of the SIM2 Grand Cinema

HT300 LINK system!

D

IG

IO

P

T

IC

™

I

M

A

G

E

P

R

O

C

E

S

S

O

R

O

N

O

FF

1

™

C

I

T

2

P

O

I

G

K

I

N

D

I

L

3

-

T

C

U

D

O

R

P

R

E

S

A

L

1

S

S

A

L

C

1

Page 4

The HT300 LINK system combines the signal processing

capabilities of the DigiOptic™ Image Processor with the high

fidelity reproduction of the DLP™ technology Projector by linking

the two units via a fibre optic cable.

The DigiOptic™ Image Processor, which should be ideally

located close to the signal sources, supports and processes a

wide range of video signals, transmitting them to the Projector

by means of a fibre optic link cable.

The large number of inputs available (2 Composite Video inputs,

2 S-Video inputs, up to 4 Component or RGB inputs, 2 graphic

RGB inputs, 1 DVI-D input, 1 Digital Input) ensures the system

supports a wide variety of analogue and digital sources: DVD

players, VCRs, satellite and terrestrial receivers, computers,

game consoles, video cameras, etc.

The signal processing capabilities of the Image Processor

ensure optimum reproduction of a broad range of input signals,

from interlaced video to high definition and graphics.

Conversion of interlaced video signals to progressive signals

by means of prestigious DCDi™ technology produces fluid,

natural, images free of flicker and stairstepping artefacts.

Faithful reproduction of signals at higher resolutions (such as

high definition video and graphics) occurs without loss of

information or reduction of image sharpness thanks to the

processor’s high pixel rate signal acquisition capabilities.

Adaptation of the input signal resolution to the Projector

resolution occurs without alterations of image quality, in

accordance with an ample choice of aspect ratios, including

several definable by the user.

All image adjustments can be performed with the remote control

with the aid of the On Screen Display; alternatively, the unit can

be controlled by from a home automation system through the

serial port.

The Projector produces an image using the very latest Texas

Instruments DLP™ technology (1280x720 pixel DMD™HD2+

panel with 12° technology), a proprietary dust-sealed optical

system, a new six-segment colour wheel.

The two units are connected via a three-core fibre optic cable

for transmission of the digital signal from the DigiOptic™ Image

Processor to the Projector and control signals in both directions.

Transmission occurs without interference or attenuation over

distances of up to 500 m.

Moreover, the flexibility and small size of the cable allow the

maximum freedom when installing the system in your home.

SIM2 carries out comprehensive functional testing

in order to guarantee the maximum product quality.

For this reason, when you start using the product

lamp operating hours may already be at between

30 and 60.

In addition to the regular tests, the Quality Control

department performs additional statistical tests at

the time of shipment.

In this case the packing may show signs of having

been opened, and the accumulated lamp operating

hours may be slightly higher than the hours associated with the standard tests.

DLP and DMD are registered trademarks of Texas

Instruments.

DCDi is a registered trademark of Faroudja, a division of

Genesis Microchip, Inc.

DigiOptic is a registered trademark of SIM 2

2

Page 5

2 IMPORTANT SAFETY INSTRUCTIONS

ATTENTION:

To reduce the risk of electric shock, disconnect

the power supply cable on the rear panel before

removing the top cover of the projector.

Refer to trained, authorised personnel for

technical assistance.

This symbol indicates the possible electric shock

hazard associated with uninsulated live components

in the interior of the unit.

This symbol indicates the presence of important

instructions regarding use and maintenance of the

product.

The HT300 LINK system consists of two parts connected by a fibre optic cable: the DigiOptic™ Image Processor and the Projector.

In this manual references to the “unit” refer to one of the two units that make up the system.

Prior to switching on the projector please read each chapter of

this manual carefully as this manual provides basic instructions

for using the projector.

The installation of the lamp assembly, preliminary adjustments

and procedures that necessitate the removal of the top cover,

must be carried out by authorised, trained technicians. There

are no user serviceable parts inside. To ensure safe and long

term reliability please use power cables supplied with the

projector. Observe all warnings and cautions.

• Federal Communication Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is used in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determinated by turning the equipment off and on,

the user is encuraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

• For customers in Canada

This Class B digital apparatus complies with Canadian ICES-003.

CLASS 1 LASER PRODUCT

This product complies with fda radiation performance standards, 21 cfr chapter

1 subchapter j.

This product complies with european standard en 60825.

This product is classified as a class 1 laser product and there is no hazardous

radiation with the safety protection.

Danger! Invisible laser radiation when open. avoid direct exposure to beam.

Do not open the covers of the product and never touch the internal parts in order

to avoid exposure to visible or invisible laser radiation.

• For customers in the United Kingdom

ATTENTION: This apparatus must be earthed

The wires in this mains lead are coloured in accordance with the following code:

Green-and-Yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying the terminals in your plug

proceed as follows:

The wire which is coloured green-and-yellow must be connected to the terminal in the plug which is marked by the letter E or by the safety earth

symbol or coloured green or green-and-yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the letter N or coloured black.

The wire which is coloured brown must be connected to the terminal which is marked with the letter L or coloured red.

3

Page 6

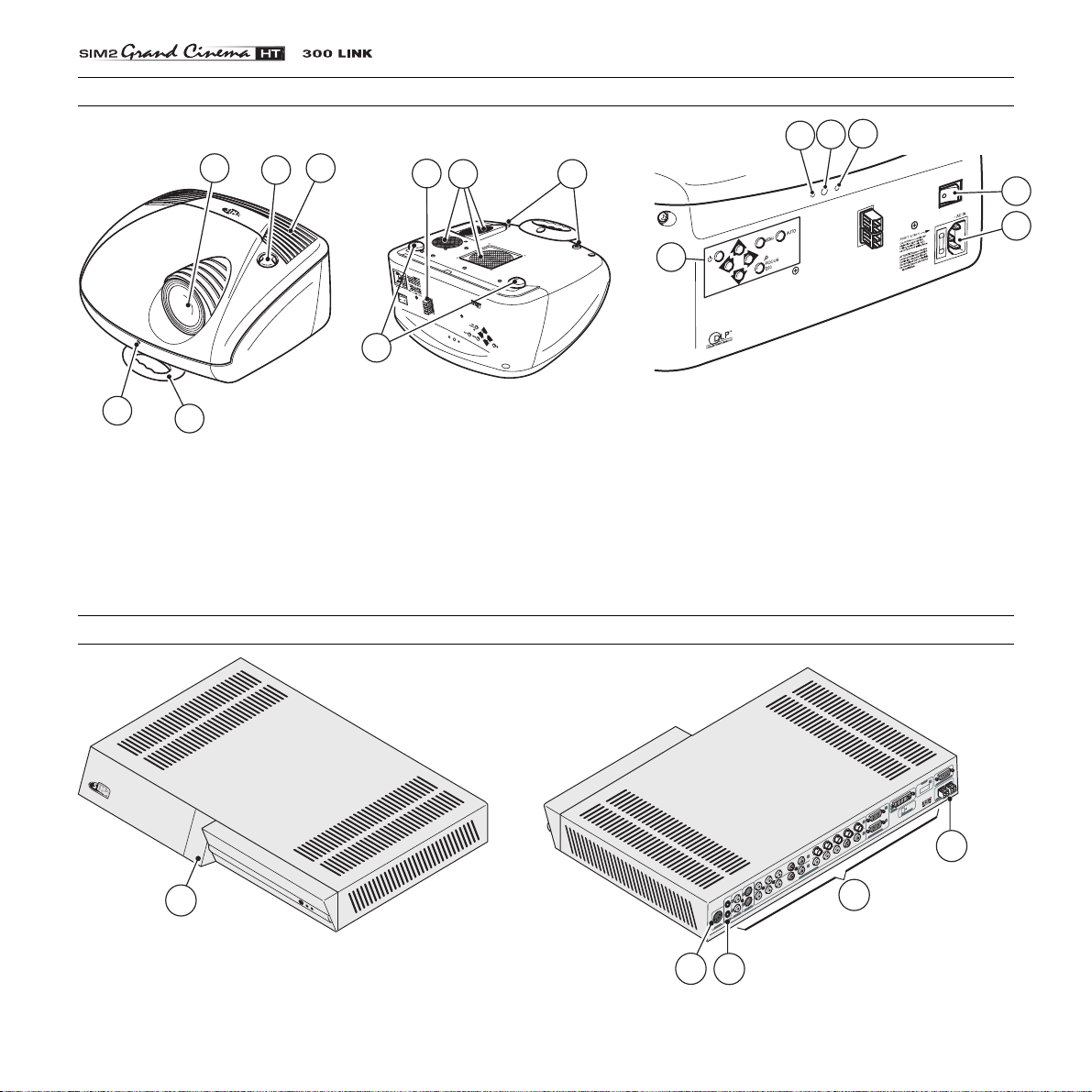

PROJECTOR

12

11

13

1

4

6

3

2

1 Projection lens

2 Lens shift knob

3 Cooling air inlet vents

4 Remote control IR sensor

5 Cooling air outlet vents

6 Adjustable carry-handle

7 Adjustable levelling feet

8 Ceiling/wall bracket fixing holes

DIGIOPTIC™ IMAGE PROCESSOR

5 8

9

10

1

2

3

-

15

14

T

C

U

D

O

PR

ER

S

A

L

1

S

S

A

L

C

-

3

2

K

1

IN

L

“

IC

T

P

IO

G

I

D

A

L

C

T

C

U

D

O

R

P

R

E

S

A

L

1

S

S

7

9 Fiber Optic cable connections

10 Main power switch

11 Remote control rear IR sensor

12 Green LED

13 Red LED

14 Rear keyboard pad

15 Fused power socket

DIGIOPTIC

“

IMAGE PROCESSOR

ON

OFF

1

1 ON/OFF switch

2 Power connection

3 Outputs for motorized screens

4 Inputs

5 Fiber Optic cable connections

4

2

1

0

1

1

1

9

8

7

6

5

4

2

3

IN

C

D

1

2

3

4

5

Page 7

• Read this manual carefully and keep it in a safe

place for future consultation.

This manual contains important information on how to install

and use this equipment correctly. Before using the

equipment, read the safety prescriptions and instructions

carefully. Keep the manual for future consultation.

• Do not touch internal parts of the units.

The units contain electrical parts carrying high voltages and

operating at high temperatures. Do not remove the cover

from the units, refer to qualified service personnel for all repair

and maintenance requirements.

The warranty will be automatically invalidated if the cover is

removed from the units.

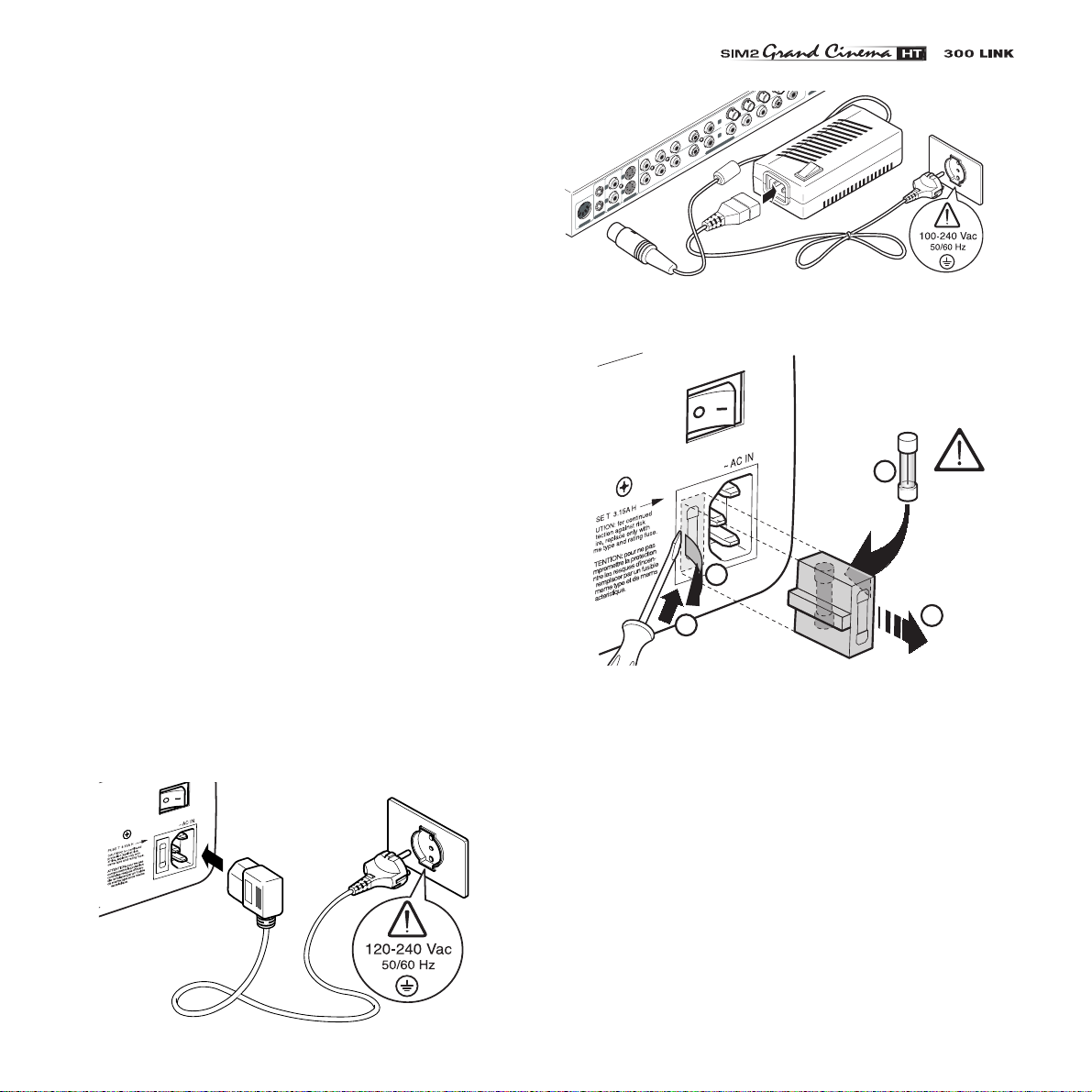

• Power supply disconnect device.

The device for disconnecting the units from the mains power

supply is constituted by the power cable plug. Ensure that

the power cable plugs and the electrical mains socket outlets

are easily accessible during installation operations. To

disconnect the units from the electric power supply, pull the

plug to remove it from the socket outlet. Do not pull the power

cable.

• Use only the specified type of mains power

supply.

Connect the units to a mains electrical supply with rated

voltage of between 120-240 VAC, 50/60 Hz and equipped

with a protective earth connection. If you are unsure of the

type of mains power supply in your home, consult a qualified

electrician.

Ensure that the power draw of the units is commensurate

with the rating of the electrical socket outlets and any

extension cables that are used.

For the DigiOptic™ Image Processor use exclusively the

power supply unit provided or an alternative power supply

unit expressly approved by SIM2.

6

5

I

4

2

3

N

C I

D

1

O

• Replace the safety fuse

4

250 V

T 3.15A H

2

1

3

• Beware of power supply cables.

Position the power supply cables so that they do not

constitute an obstruction.

Position the power supply cables where they cannot be

reached by children.

Install the units as close as possible to the wall electrical

socket outlet. Do not tread on the power cables, make sure

that they are not tangled or pulled; do not expose the power

cables to heat sources; make sure that the power cables do

not become knotted or kinked. If the power cables become

damaged, stop using the system and request the assistance

of an authorised technician.

Fig.2

Fig.3

Fig.1

5

Page 8

• Disconnect the apparatus from the mains power

supply in the event of electrical storms and when

not in use.

To avoid damage that could be caused by lightning striking

in the vicinity of your home, disconnect the units in the event

of electrical storms or when the system will remain unused

for prolonged periods.

• Avoid contact with liquids and exposure to

humidity.

Do not use the units near water (sinks, tanks, etc.); do not

place objects containing liquids on top of or near the units

and do not expose them to rain, humidity, dripping water or

spray; do not use water or liquid detergents to clean the

units.

• Prevent the units from overheating.

Do not obstruct ventilation openings. Do not place the units

near heat sources such as heaters, radiators or other devices

that generate heat (including amplifiers). Do not position the

units in confined, poorly ventilated places (bookcase, shelves,

etc.).

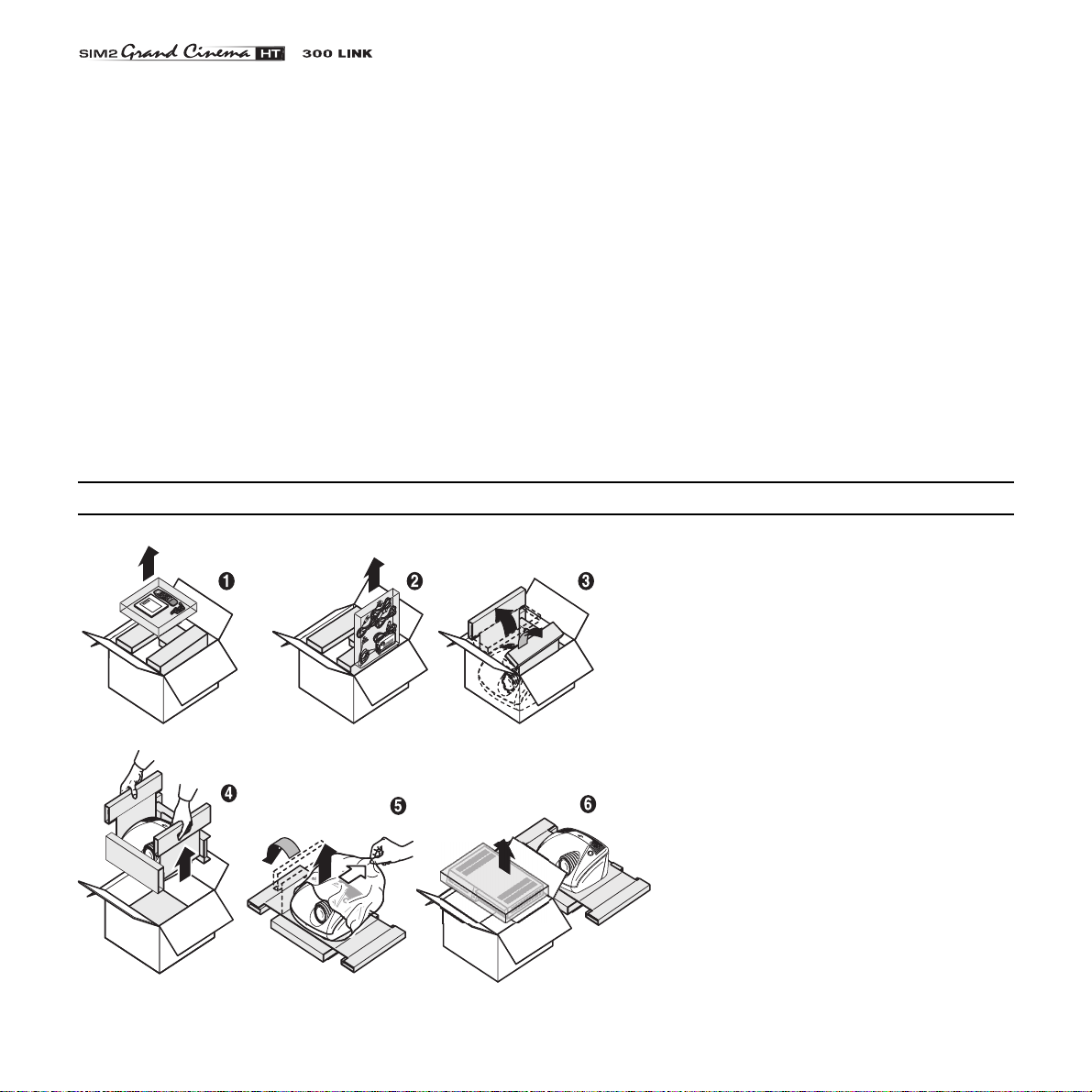

3 UNPACKING

• Do not expose the eyes to the intense light

emitted by the lamp.

Never look directly at the lamp through the ventilation

opening when the unit is switched on.

Risk of eyesight impairment. Ensure also that children do

not look directly at the lamp.

• Position the unit on a stable surface.

To avoid serious injury to persons and damage to property,

make sure the units are placed on a level, flat and stable

surface from which they cannot fall, tip over or slide. Pay

special attention if the units are placed on a trolley so that

they can be moved around. Ensure that the units are not

subjected to impact.

• Do not insert objects through the units’ openings.

Make sure that no objects are inserted inside the units. If

this should occur, disconnect the unit from the power supply

immediately and call an authorised technician.

To unpack the projector safely and easily

please follow steps 1 to 6, as per drawing

(Fig. 4).

It is recommended that the carton and

packaging is retained for future use and in

the unlikely event that your projector needs

to be returned for repair.

Fig.4

6

Page 9

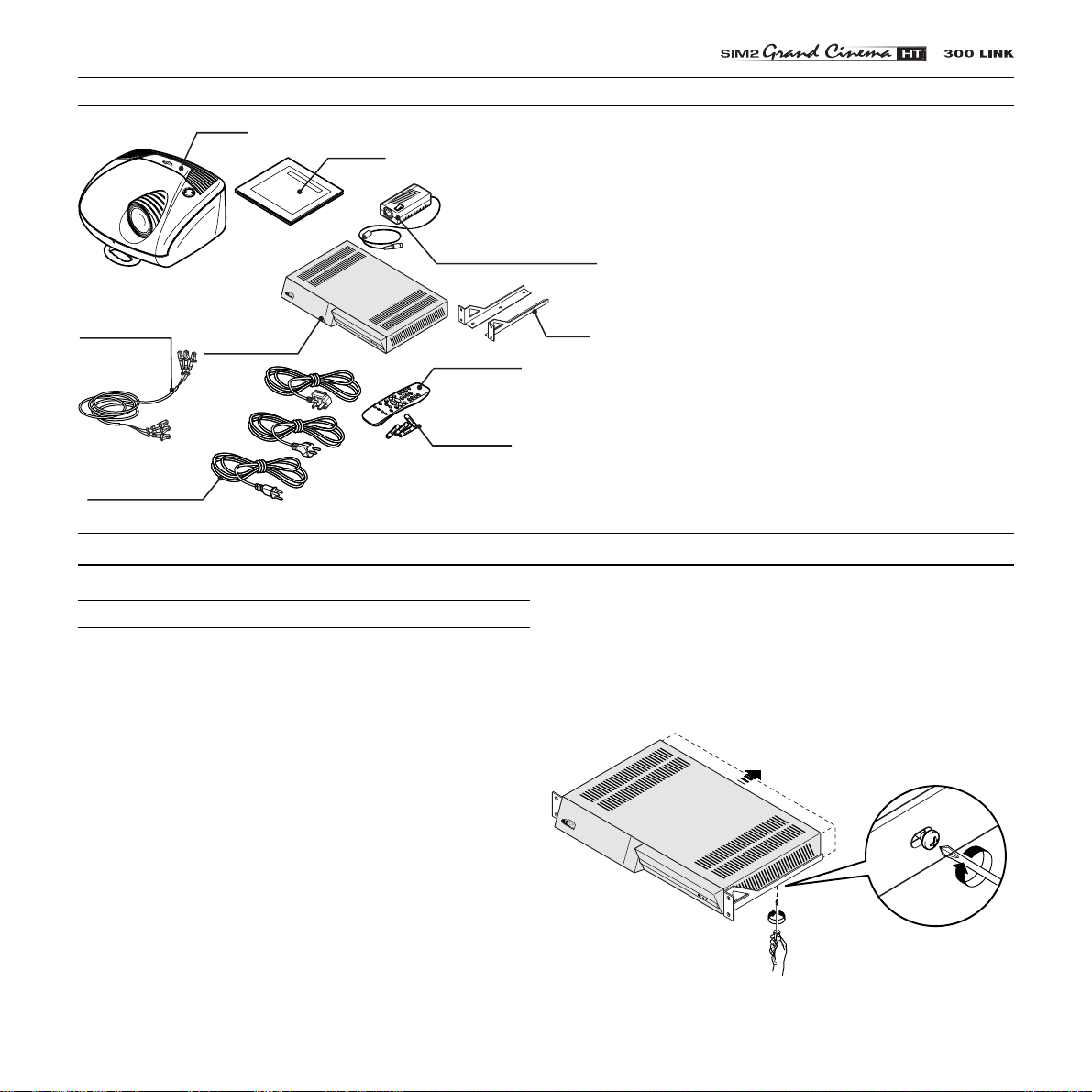

PACKAGE CONTENTS

Projector

Three-core

fibre optic cable

DigiOptic“

Image Processor

Power cables

Europe, UK, US (x2)

4 INSTALLATION

DIGIOPT

IC “ IMAG

E PR

OCESSO

Instruction

Manual

R

ON

OFF

I

O

DigiOptic“ Image

Processor power supply unit

Remote Control

1.5 V AAAtype batteries

Fig.5

Support

The carton should contain the following:

- the projector

- the DigiOptic™ Image Processor

- the remote control

- four 1.5V AAA batteries (for remote control)

- DigiOptic™ Image Processor power supply unit

- three power cables for the projector (EU, UK, USA)

- three power cables for the DigiOptic™ Image Processor

(EU, UK, USA)

- triple fiber optic cable for linking DigiOptic™ Image

Processor and the projector

- two brackets for mounting the DigiOptic™ Image

Processor to the rack.

- the user and installation manual.

If any accessories are missing, contact your Dealer as

soon as possible.

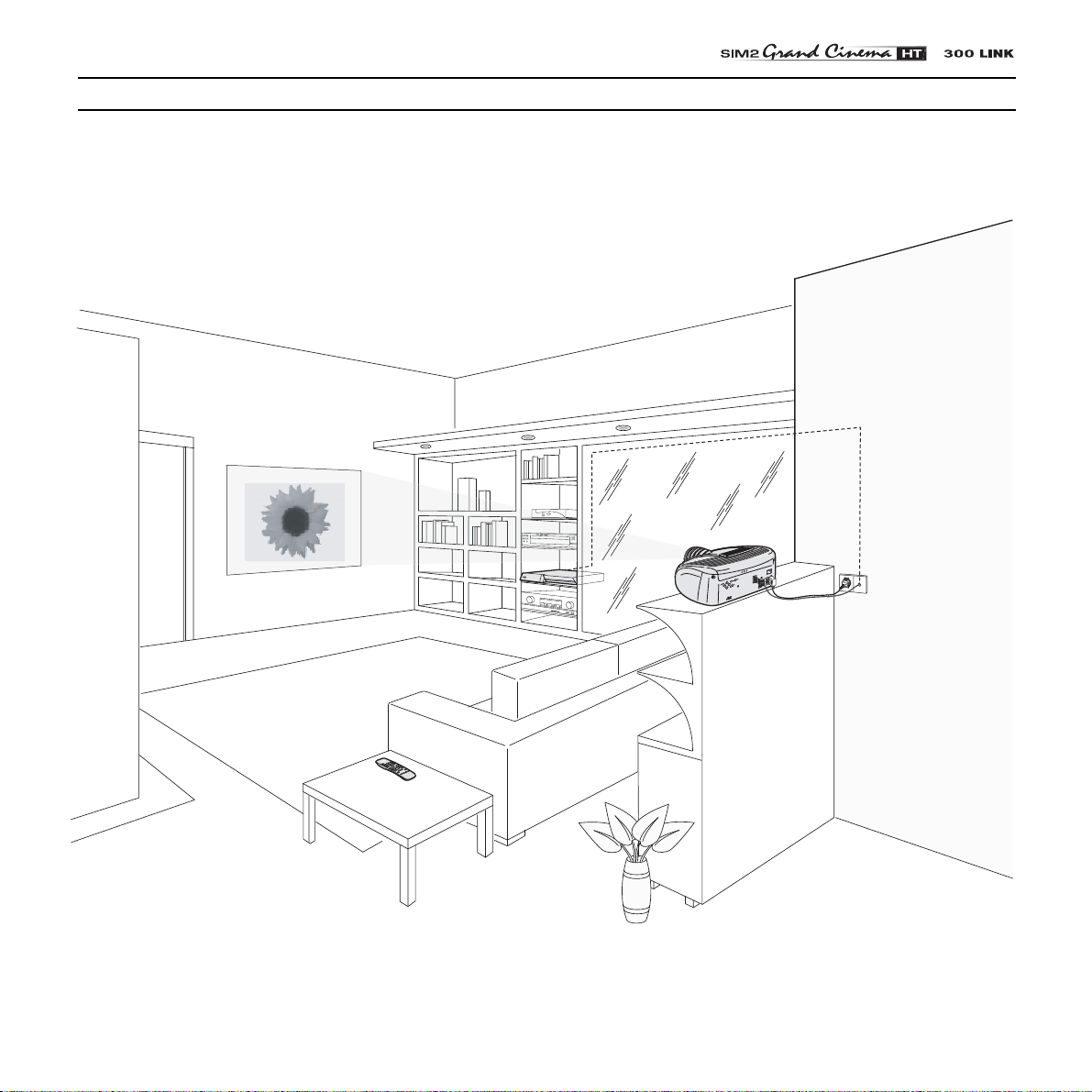

POSITIONING THE TWO UNITS

The HT300 LINK system consists of two separate units (the

DigiOptic™ Image Processor and the Projector), each of which

is equipped with a power cable; the two units are interconnected

by a 20 m fibre optic cable.

The ideal location for the DigiOptic™ Image Processor is on a

cabinet shelf or on a rack (dimensions compatible with a standard 19" rack). Make sure that the support surface is stable

and that the unit has sufficient space around it for ventilation

purposes (at least 3 cm).

The unit is connected to the mains via an external power supply

unit with an output of +7 Vdc; the unit’s main power switch is

on the power supply unit.

POWER

Connect the power supply unit output cable to the

located on the rear panel

(Fig. 2)

.

socket

Use exclusively the power supply unit provided with the system

or an alternative power supply unit expressly approved by SIM2.

To mount the DigiOptic Image Processor on an equipment rack

use the screws and RH / LH supports supplied with the

appliance. Unscrew the screws that secure the cover to the

DigiOptic unit base, position the RH and LH supports and fix

into place with the supplied screws. To secure the unit to the

(Fig.6)

rack use the supplied screws

D

IG

IOP

TIC

“ IM

A

G

E PRO

C

ES

SO

R

O

N

O

F

F

.

Fig.6

Position the projector on a stable, suitable platform or utilise

the optional bracket for a fixed ceiling or wall installation.

7

Page 10

CAUTION: In the case of ceiling or wall mounting using a

suspension bracket, follow the instructions carefully and comply

with the safety standards you will find in the box together with

the bracket. If you use a bracket different to the one supplied

by SIM2 Multimedia, you must make sure that the projector is

at least 65 mm (2-9/16 inch) from the ceiling and that the bracket

is not obstructing the air vents on the lid and on the bottom of

the projector.

Position the projector the desired distance from the screen:

the size of the projected image is determined by the distance

from the lens of the projector to the screen and the zoom setting.

See “Appendix C”: Projection distances” for more information.

CONNECTING THE TWO UNITS

The system can be fully controlled using the supplied IR

(infrared) remote control handset. There is a single remote

control for both the DigiOptic™ Image Processor and the

Projector; the remote control can be directed towards either

unit since they are both equipped with an IR sensor.

The connection between the two units is made with a single

cable containing three fibre optic cables each terminating in

an LC connector. The standard cable length of 20m will be

sufficient for most installation requirements.

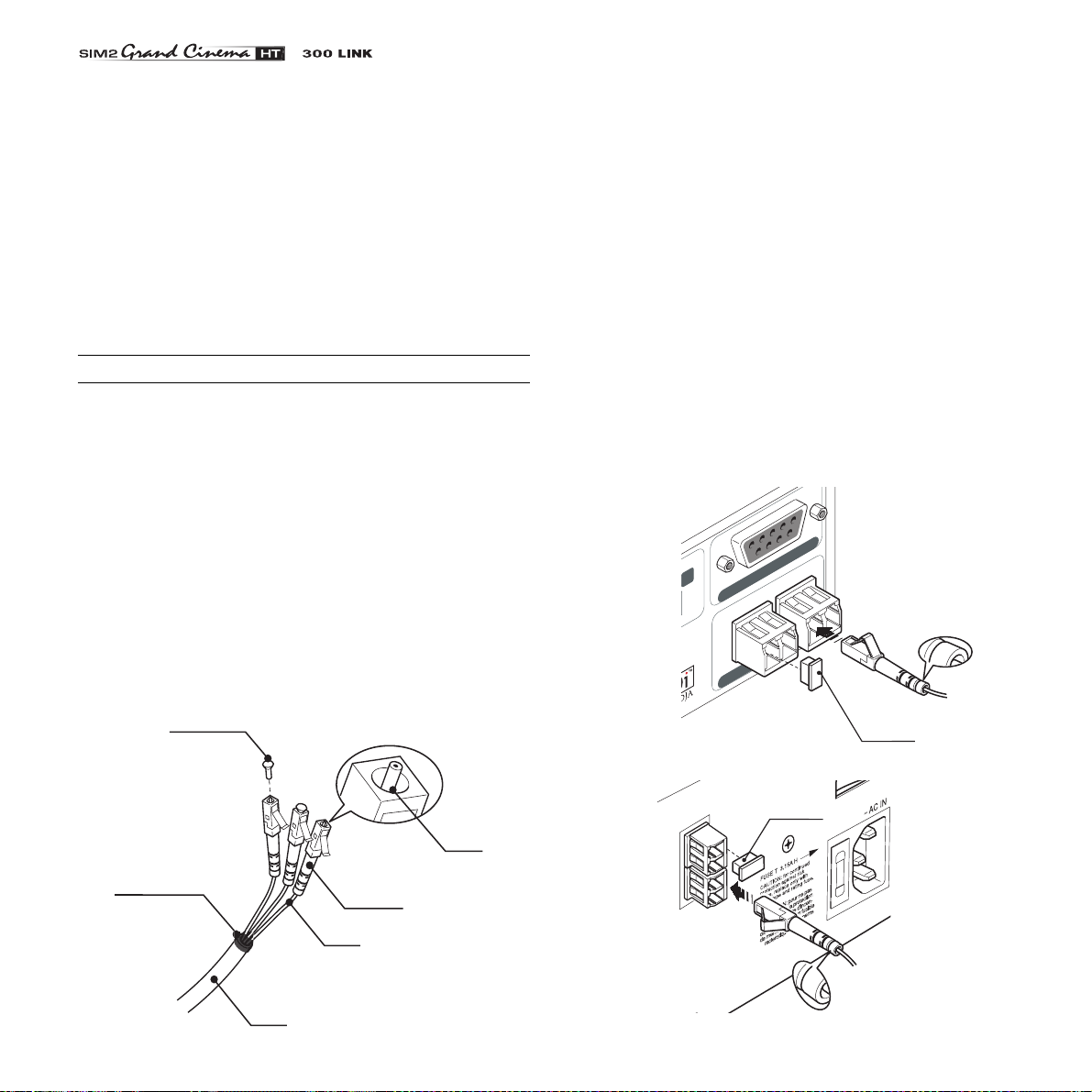

During installation of the fibre optic cable:

• The individual optical cables are delicate: always handle

the main cable without touching the individual optical cables

(Fig. 7)

.

Never pull the individual optical cables or connectors; if

necessary, you may pull the main three-core cable.

• Only remove the cap protecting the connector ferrule

immediately before inserting the connector; if the ferrule is

allowed to come into contact with foreign material it may be

damaged, making the connector unusable.

• Take particular care when inserting fibre optic connectors

in their respective sockets on the rear panel of the

DigiOptic™ Image Processor and the rear panel of the

Projector.

• Make sure that the single optical cables are not switched:

the numbers on the cables must match the numbers on the

connectors

(Fig.8-9)

.

• Check that the connectors are correctly inserted.

• Make sure that the cable does not constitute an obstacle for

persons moving around the room.

• Take care not to create knots in the cable; the minimum radius

of bends in the cable is 2 cm.

• Prevent the cable from pulling and mechanical stress: this

could cause the connectors to be pulled out and damaged.

12

3

3

Separation point

8

Protective cap

Cable

Connector

Fibre

Ferrule

Fig.7

Protective

cap

Protective

cap

1

2

3

-

3

DUCT

O

3

Fig.8

Fig.9

Page 11

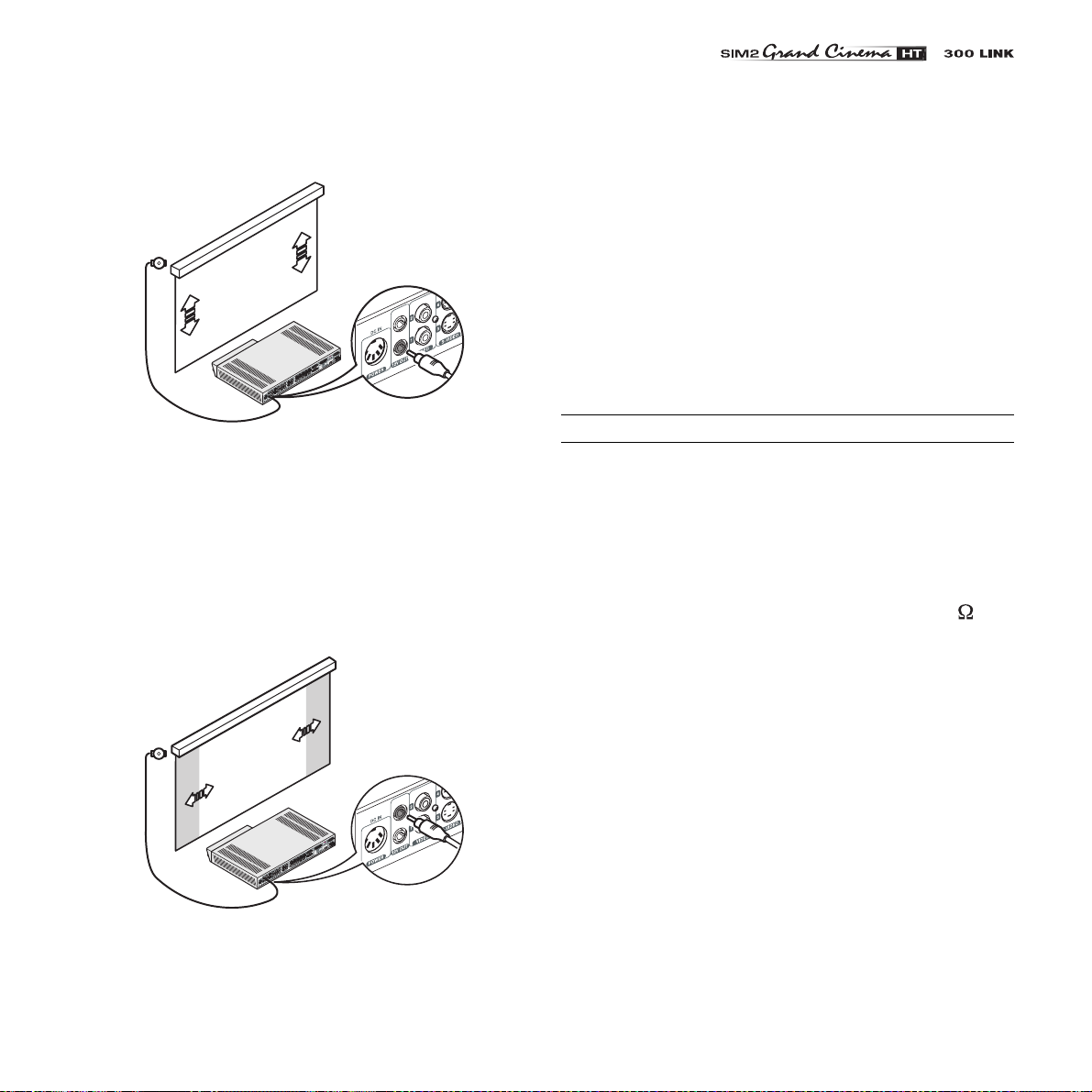

To activate an electric motorised screen a 12 Volt output is

provided at the rear of the DigiOptic™ Image Processor. This

can be connected to a screen interface unit, which can be

supplied by screen manufacturers

(Fig. 10)

.

Fig. 10

The output is activated (Voltage: 12 Vdc) when the Projector is

switched on and is de-activated (no Voltage output) when the

projector is in stand-by mode.

Some manufacturers offer screen-masking systems to help frame the projected image and improve picture contrast. These

systems can be connected to output, at the rear of the

DigiOptic™ Image Processor

(Fig. 11)

.

PFor rear projection the screen must be translucent.

For front projection, we recommend the use of screens with

low gain specifications (i.e. 1.3 to 2). The use of high gain

screens should be avoided due to their limited viewing angle,

which is undesirable for a large audience.

Preferably, use a screen with black, non-reflecting borders,

which will perfectly frame the projected image.

Avoid light shining directly on the screen during projection as

this will reduce contrast and black level detail on the projected

image. For the true cinema experience best results are

achieved with little or no ambient light.

Furniture and other objects with reflecting surfaces, as well as

light coloured walls should be avoided, as they are likely to

interfere with the screen’s characteristics.

CONNECTING THE VIDEO SOURCES

Connect the cables from the video sources, the serial cable

from the external control unit and the optical fibre cables for

connection to the Projector, to the rear panel of the DigiOptic™

Image Processor.

To obtain the best performance from the HT300 LINK system,

connect the various signal sources using good quality cables

designed for video applications (rated impedance 75

).

Ensure that:

• the cables are routed in such a way that they do not present

an obstruction to people moving around the room;

• the connectors are inserted carefully to avoid damaging the

pins;

• the cables are not twisted or crushed;

• when disconnecting the cables the connectors are not

violently pulled out of the sockets on the various units.

Video sources (television receivers, VCRs, DVD players, etc.)

often feature several outputs. To obtain the best performance

from your system, carefully choose which output to use.

Generally, the type of signal offering the best picture quality is

DVI-D, followed by RGB, Components, S-Video and Composite

Video, in that order.

However, the HT300 LINK system is equipped with an excellent

Fig. 11

Video Decoder and Deinterlacer and therefore even inferior

quality signals will produce high quality results.

9

Page 12

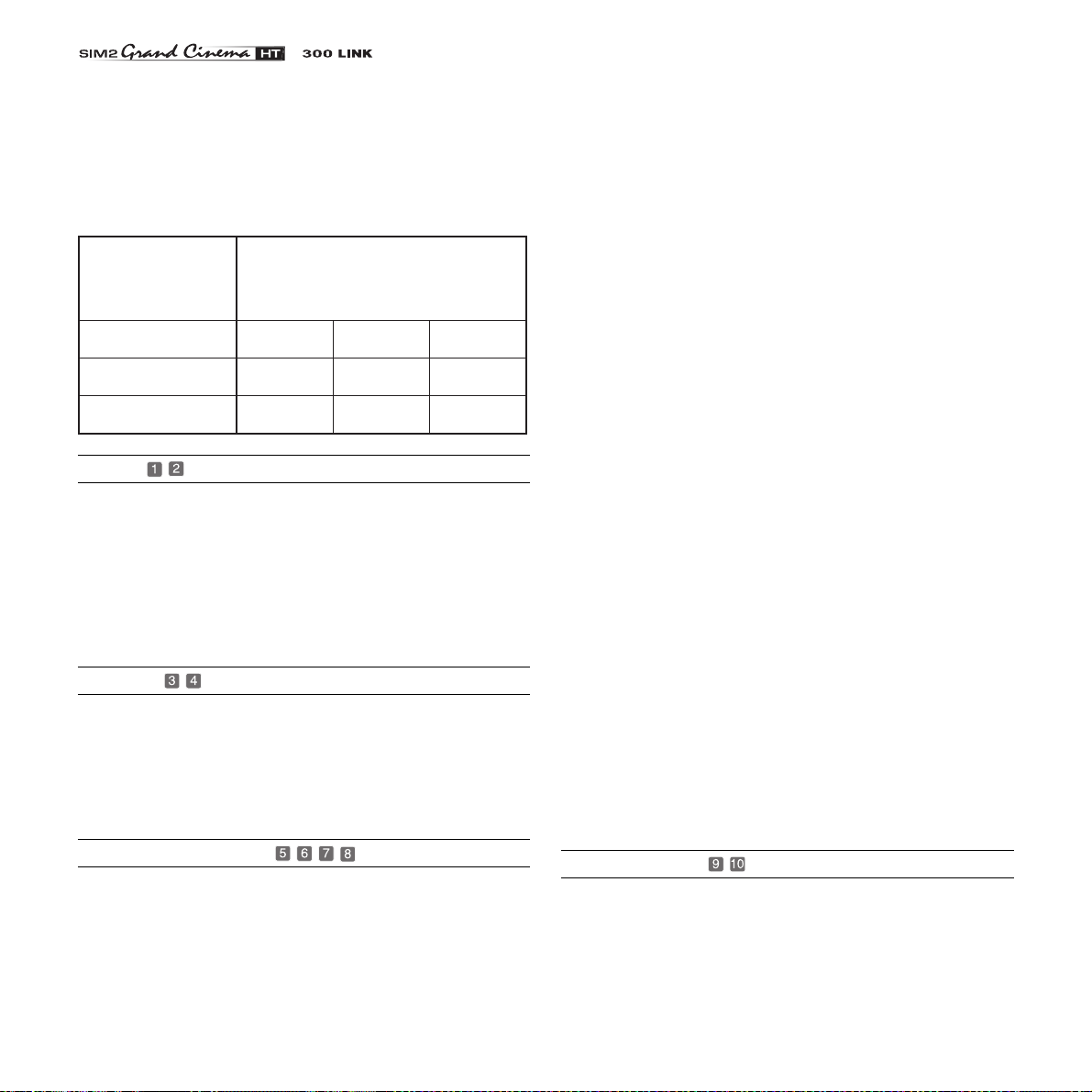

Table 1

shows the types of signals usually available for the

most common types of video sources and the corresponding

input connectors to use on the DigiOptic™ Image Processor).

Table 1

DigiOptical

Image Processor

Connector

Y (green) Y

Cr (red) P

Cb (blue)

Video signal

source connector

R

P

B

Y

R-Y

B-Y U

Y

V

VIDEO

These inputs should be connected to a Composite Video signal

(CVBS) by means of a cable with an RCA connector.

The connector on the source is usually yellow and is frequently

labelled VIDEO.

Although other types of signals are preferable (since they allow

better picture quality), this is still the most common type of

output, and nearly all television receivers, video-recorders, DVD

players, video cameras, etc., are equipped with CVBS outputs.

S-VIDEO

These inputs should be connected to an S-Video signal by

means of a cable with a 4-pin mini-DIN type connector.

The corresponding output on the source can be identified by

the wording S-VIDEO or Y/C.

Almost as widespread as Composite Video, S-VIDEO is

preferable because it offers a clearer and sharper picture.

Connect the R, G, B outputs of the source to the respective R,

G, B inputs of the DigiOptic™ Image Processor (paying attention

not to invert the positions) and any synchronisation signals to

the HV input or the H and V inputs. When connecting the three

sets of RCA connectors use the colours as a guide: connector

R is red, G is green, B is blue, H/HV is white and V is black.

By using a suitable SCART to RCA (or BNC) connector adapter

cable, an RGB video signal from a source equipped with an

SCART connector can be connected to this input.

Component signals are connected to inputs Y, Cr and Cb, taking

care to observe the correspondence with the outputs on the

source.

Since the latter can be labelled in various ways, refer to

Table 1

to establish the correspondence between the various signals.

The connector colours can also be of help, as shown in the

table.

Input 5 is dedicated for RGB and YCrCb signals up to 32 KHz

only. In fact, in order to guarantee a high image quality, even

with not so accurate sources, the input signal is elaborated by

specific circuit boards in the DigiOptic™ Image Processor.

The video signal suitable for inputs 6-7-8 can have a scan

frequency of 15KHz (standard video resolution) or 32KHz or

more (progressive scan video, high definition video).

Some sources provide the facility to choose between a

progressive signal or an interlaced signal. Although in general

a progressive signal is higher quality than an interlaced signal,

it is often preferable to perform the deinterlacing operation on

the HT300 LINK system rather than on the source because the

HT300 LINK system is equipped with Faroudja’s sophisticated

directional correlation deinterlacing technology (DCDi™).

Progressive signals usually provide better quality than interlaced

signals, but if the source features both progressive and

deinterlaced signal outputs it is good practice to compare the

quality of the pictures reproduced by the HT300 LINK system

in the two cases: deinterlacing performed by the HT300 LINK

system (thanks to Faroudja DCDi™ technology) is often more

effective than that performed at the source (typically a DVD

player).

COMPONENT / RGBS

These inputs are composed of three sets of 5 RCA connectors

(5,6,7) and a set of 5 BNC connectors (8).

Each set of connectors is suitable for RGB and Component

signals.

RGB signals can have the following synchronisations:

composite sync on the green signal (RGsB), H+V Composite

Sync, or separate H/V Sync.

10

RGB GRAPHICS

This input should be connected to an RGB-type video or graphic

signal using a cable with a DB15HD type connector.

The signal source device (typically a personal computer or

game console) must be able to provide separate H/V

synchronisation or composite H+V synchronisation or

composite synchronisation on the green signal (RGsB).

Page 13

The video or graphic signals that can be connected to this

input can have horizontal scan frequencies (H-sync) of between

15 and 110 kHz and a vertical frequency (V-sync) of between

40 and 100 Hz. Image resolution can vary between 640x480

and 1600x1200 pixels (VGA, SVGA, XGA, SXGA, UXGA).

DVI-D

This input allows you to advantage from the quality of the digital

images .

If your source is equipped with a DVI-D output, YCrCb or RGB

connect it to this input to exploit the quality of the HT300 LINK

system.

CONTROL (RS232)

The system can be controlled via a personal computer or home

automation systems by means of the serial port: simply connect

this input via a serial cable from an RS232 serial port. On

request, SIM2 will send you a document containing the serial

port settings and the list of main commands.

DIGITAL INPUT

12

The Digital Input allows to extend the signal quality to audio

signal as well.

Through this input it is possible to connect to source capable

of delivering excellent digital images supported by multichannel digital audio and by control data.

The internal data elaboration by the DigiOptic™ Image

Processor divides the video data from audio data.

The audio data is available through a TOSLINK connector for

fiber optic output.

11

Page 14

3 4

1 2

VIDEO

USCIT A +12V

POWER

DC IN

PO W

Source

R

E

5 6 7 8

S-VIDEO

2

1

UT

O

12V

CONTROL (RS 232)

OPTICAL FIBER LINK

12

DIGITAL INPUT

11

DVI-D

AUDIO OUTPUT

9

10

GRAPHICS RGB

10

11

-D

I

/OUT

DV

O

I

PRODUC T

D

U

A

SER

A

SS 1 L

A

L

C

8

H/HV

/Cb

COMPONENT / RGBS

R/C r

V

6

H/HV

Cb

B/

/Y

G

r

C

R/

4

3

O

E

ID

V

S-

O

IDE

V

G/Y B/

/C r V

R

Cb H

V

O

/H

C

Motorized

screen

R

5

GB S

/ R

T

NEN

O

P

M

Cr V

/

B

V

G/Y

B/C b H

/Y

G

Television receiver from

Aerial, Satellite or

Cable (Analogue or Digital)

DVD player

Video camera

Video camera

Game console

Television receiver from

Aerial, Satellite or

Cable (Analogue or Digital)

DVD player

Video recorder

Video camera

Game console

7

V

H

/

9

B

G

R

S

IC

PH

A

GR

Television receiver from

Aerial, Satellite or

Cable (Analogue or Digital)

HDTV receiver

DVD player

Video camera

Game console

12

2)

3

2

NTROL (RS

3-

O

C

2

1

K

N

I

L

BER

I

PTICAL F

O

HDTV receiver

Game console

Computer

Computer

Television receiver from

Aerial, Satellite or

Cable (Analogue or Digital)

HDTV receiver

DVD player

Video camera

Game console

Computer

Home

automation

system

3

2

1

Projector

Fig.12

12

Page 15

5 SWITCHING ON AND OFF

O

I

IM

AGE

P

ROCE

SS

OR

O

FF

ON

The HT300 LINK system consists of the Projector and the

DigiOptic™ Image Processor (which is also the system control

centre). The DigiOptic™ Image Processor sends commands

to the Projector and receives operating status information from

the Projector and function commands from the user. The system

can be controlled from either the remote control (via the infrared

sensors on the DigiOptic™ Image Processor and on the

Projector) or the keypad located on the rear of the Projector.

The two units have separate power supplies however: after

connecting the unit to the electrical mains supply:

1) Set the two power switches to “I”; the DigiOptic™ Image

Processor power switch is located on the external power supply

unit

(Fig. 13c)

(Fig. 13a)

, while the Projector switch is on the rear panel

.

2) Turn on the DigiOptic™ Image Processor by pressing the

button on the front panel

Fig.13c

Fig.13c

(Fig. 13b)

I

O

.

1

2

3

-

T

UC

D

O

R

P

R

E

S

A

L

1

S

S

A

L

C

D

IGI

O

P

T

I

C

™

Fig.13a

Fig.13a

IM

A

G

E P

R

O

C

E

S

S

O

R

O

N

OF

F

Significant status signals are given in

Table 3

.

Table 3

Status

Off

Initialisation

Stand-by

On

Cooling

Optical link not active

Caution

Error

: Off

: On

DigiOptic Image

Processor

Green LED Blue LED Green LED Blue LED

: Flashing

Projector

-

-

--

: Insignificant

-

If the “No optical link” or “Error” signals are active the system

cannot be operated; if the “Warning” signal is active the system

will operate but it may be unable to read certain input signals

correctly.

SWITCHING ON/OFF

Switching on the system

(Fig.14)

:

• from the remote control (keys 0-9)

• from the Projector keypad (keys and ).

Fig.13b

After a few seconds (system initialisation interval), the

DigiOptic™ Image Processor and the Projector assume standby mode.

System status information is provided by two LEDs (green and

0

RC

LI

I 2005

G

H

T

blue) on the front panel of the DigiOptic™ Image Processor, a

blue and green LEDS on the rear of the Projector.

Fig.14

13

Page 16

Typically, the picture will appear after 15-20 seconds. Pressing

a key from 1-9 on the remote control selects the corresponding

input; pressing 0 selects the input active at the time the system

was last switched off.

If the system is switched on very soon after it was last switched

off, the lamp may fail to come on because it is too hot. In this

case just wait a few minutes to allow the lamp to cool.

Switching the system off

• from the remote control (

• from the Projector keypad (

(Fig.15)

key)

:

key).

If you wish to power off the system completely, wait at least one

minute in stand-by before setting the mains power switches on

the units to the “O” position or disconnecting the power supply

cables. This is to allow the fans in the Projector unit sufficient

time to cool the lamp.

0

R

C

LI

I 2

GH

00

T

5

In case the Projector unit is shut down (for example due to a

shut down of the projector unit by putting the switch in the “O”

position or by accidentally unplugging the power cord cable)

to re-boost the HT300LINK system it is necessary to shut down

the DigiOptic™ Image Processor and repeat the power-on procedure described in point 1 and 2.

In case the connection with the fiber optics between the two

unit is interrupted (for example by unplagging one or more

cable), to restore the system, it is necessary to turn off the two

units through the main switches and once the connecectin is

restored, repeat steps 1 and 2 of the power-on procedure.

14

Fig.15

Page 17

6 KEYBOARD PAD

Eight push buttons, at the rear of the projector, will allow complete operation without the use of the remote control.

Menu

Activates the On Screen

Display menus. Navigates

Menu pages.

Switches off to stand-by.

Up/Down/Left/Right arrow keys

Navigate through and make adjustments to the On

Screen menus.

Arrow Up/Down switch on from stand-by and recall

Source Selection menu.

7 REMOTE CONTROL

The remote control transmits commands to the system by

infrared signals.

There are three infrared sensors, one at the front of the Projector,

one at the rear of the Projector and one on the front panel of the

DigiOptic™ Image Processor.

It is possible to control the projector by pointing the remote

control at the screen; the sensor at the front of the projector will

pick up the reflected infrared commands.

(Fig. 16)

.

Auto

Selects Auto Adjust

(automatic optimisation of

the displayed image).

-Focus-Esc

De-activates the On Screen Display and gives access to

the lens Zoom/Focus adjustment functions.

Avoid placing obstructions between the remote control and the

infrared sensor at the front of the projector; this will impair the

remote control performance.

Insert the batteries, taking care to match the polarity, as

indicated in the battery recess of the remote

(Fig. 17)

.

Change the batteries in the remote control if experiencing

difficulty in sending commands to the projector.

If the remote control is not to be used for a long period of time

remove the batteries. Replace all batteries at the same time;

do not replace one new battery with a used battery. If the

batteries have leaked, carefully wipe the case clean and replace

with new batteries.

-

+

+

-

-

VI

D

C

N

Y

S

C

+

+

-

Fig. 16

Four 1.5V

AAA type

batteries

Fig. 17

15

Page 18

8 ON SCREEN MENU

All system functions can be activated from the keypad or remote control with the aid of a practical and comprehensive system of

on screen menus.

INPUTS

The input selection menu (Inputs) is called by pressing 0 on

the remote control and, when no other menu is displayed, using

the and keys on the keypad. To select an input, scroll the

list with the and keys until the desired input is highlighted,

then press .

Display of the input selection menu is terminated

by pressing the ESC key, or when the time allowed for displaying

the on-screen menu has lapsed (set in the Set-up Menu).

Input 5 can accept RGB and YCrCb signals with a scan

frequency up to 32Khz.

Inputs 6, 7 and 8 can receive RGB and YCrCb signals, at 15

kHz, 32 kHz or higher. The association between the input and

the type of signal is made from the pull-down menu that appears

on the right of the < symbol after pressing the key

Inputs

1 VIDEO 1

2 VIDEO 2

3 S-VIDEO 3

4 S-VIDEO 4

5 COMP/RGB 5

6 COMP/RGB 6

7 COMP/RGB 7

8 COMP/RGB 8

9 GRAPH RGB 9

10 GRAPH RGB 10

11 DVI-D 11

12 DIGITAL INPUT 12

1

2

3

4

5 YCrCb 32kHz

6 RGBS 15kHz

7 YCrCb

8 YCrCb 15kHz

9

10

11 YCrCb

12

(Fig. 18b)

Fig. 18a

Input 11 is capable of receiving YCrCb or RGB signals coming

from DVI-D sources.

The selection should be made from the drop menu following

the indications described above.

After selecting the source signal (by means of the and

keys), press MENU+/MENU - to confirm and close the pulldown menu; the value you have just set will be displayed on

the right of the < symbol.

As with the other inputs, you can now select the input just set

by pressing the key.

During the short time it takes to find the signal, a box appears

showing the signal requested. As soon as the signal is shown

in the box additional information is displayed concerning the

.

video standard (for video signals) or resolution (for graphic

signals), and format.

Fom the

SETUP

menu it is possible to choose to visualize or not

this information, for more details check the “

INFORMATION

” in “

MENU

” section.

SOURCE

16

Inputs

1 VIDEO 1

2 VIDEO 2

3 S-VIDEO 3

4 S-VIDEO 4

5 COMP/RGB 5

6 COMP/RGB 6

7 COMP/RGB 7

8 COMP/RGB 8

9 GRAPH RGB 9

10 GRAPH RGB 10

11 DVI-D 11

12 DIGITAL INPUT 12

1

2

3

4

5 YCrCb 32kHz

6 RGBS 15kHz

RGBS 15kHz

7 YCrCb

RGBS

8 YCrCb 15kHz

YCrCb 15kHz

9

YCrCb

10

11 YCrCb

12

Fig. 18b

Page 19

MAIN MENU

To access the main menu of the On Screen Display press the

MENU

key on the keypad or the

MENU+ or MENU-

key on the remote control.

The main menu is divided into four windows,

IMAGE, SETUP

and

MENU

, in which the various adjustments are

PICTURE,

grouped according to the frequency of use. Use and

to select the line corresponding to the adjustment you wish to

make

(Fig. 19)

.

Picture

Brightness

Contrast

Colour

Tint

Sharpness

Filter

Cinema Mode

Video Type

Noise Reduction

60

50

50

50

Auto

3

2

Off

Normal

Auto

VCR1 VCR2

Fig. 19

The various menus only offer the relevant adjustments in

accordance with the type of input signal displayed (e.g. certain

typical adjustments for video signals, not necessary for graphic

signals, do not appear on the menus, and vice versa).

Some adjustments (e.g.

BRIGHTNESS

and

CONTRAST

) are

associated with a numerical value that can be varied within the

set limits using the keys / . For others (e.g.

VIDEO TYPE

) you

can choose among three options presented on the same

/ ).

Other adjustments (marked by the < symbol) provide submenus,

which appear as a superimposed window in which the selection

is made with the / keys

Image

Aspect

Colour Temperature

Gamma Correction

Overscan

Position

Y/C Delay

(Fig. 20)

1

1

. .

Image

Aspect

Colour Temperature

Gamma Correction

Overscan

Position

Y/C Delay

1

Normal

Anamorphic

Letterbox

Panoramic

Pixel to pixel

User 1

User 2

User 3

Fig. 20b

These submenus are accessed by pressing the key, while

MENU+/-

exit and return to the upper level occurs by pressing

Press

ESC

on the remote control or keypad to interrupt the

.

menu display or wait for it to disappear automatically after the

number of seconds set on the

SETUP

page.

PICTURE

This menu features the adjustments related to picture quality.

Adjustments that are not available for a given input do not

appear on the menu.

available for each input. For a complete overview of the onscreen menus, consult the ‘On screen menu layout’ in the

“Additional Information” section.

BRIGHTNESS

Use this control to adjust the image’s black level without

affecting white areas. Increasing the value will give more detail

in darker parts of the picture. For correct adjustment it may

prove useful to display the signal relative to the grey scale within

which the black level and the level immediately above it must

be separately identifiable. Alternatively use a scene composed

of black objects alongside other dark coloured objects.

CONTRAST

Use this control to adjust the image’s black level without

affecting white areas.

To ensure correct adjustment, it may prove useful to display

the signal relative to the grey scale, within which the white level

and the level immediately below it must be separately

identifiable. Alternatively use a scene composed of well-lit white

objects surrounded by light coloured objects with lower level

lighting.

Table 4

summarises the adjustments

Fig. 20a

COLOR

This control (also called Saturation) increases or decreases

17

Page 20

the picture colour intensity. When set to zero, colour images

will be shown in black and white. Increasing the value, try to

find the point at which the colours look natural: suitable

references include skin tones and grass in landscape shots.

TINT

Controls the purity of the colours. Basically determines the

red-green ratio of the picture.

Reducing the value will boost the red contents of the picture,

increasing the value will boost the green tones. For this

adjustment use skin tones or a test pattern image with colour

bars as a reference.

SHARPNESS

Use this adjustment to increase and decrease the level of

picture detail.

When the sharpness value is reduced the image details

appear less pronounced, while increasing the value raises

image definition, making the outline of objects sharper.

Note that an excessively high value may result in a ‘noisy’ picture

and the edges of objects may be unnaturally defined.

SHARPNESS MODE

This allows you to select the type of processing associated

with sharpness adjustment. In the case of a progressive or

interlaced video signal

signals use

GRAPHIC MODE

VIDEO

mode is advisable; with PC graphic

.

FILTER

This allows you to select the mode in which the input signal

is processed. Selecting the most appropriate value for a given

input signal ensures the best horizontal and vertical definition

and makes the picture sharper.

CINEMA MODE

In

AUTO

the deinterlacer recognises if the video signal source

is a movie film (obtained from a Telecine device with 3:2 or 2:2

pull-down) and applies a deinterlace algorithm optimised for this

type of signal.

If the video signal source is not identified as a film, or if you

select NO the deinterlacer applies a Motion compensated

algorithm optimised for video camera signals.

NOISE REDUCTION

This adjustments allows to choose the filter value for noise

reduction purposes.

As soon as this option is selected on the menu, the image is

divided in two parts.

In the left side the image is not altered by the filter, in the right

part the filter is activated.

This allows you to compare the effect of the filter.

It is possible to deactivated the filter (

AUTO

automatic adjustments (

) or to manually select (

the value suitable for the image with the

In case of using the

VALUE

adjustement, it is enoght to select to

NOT ACTIVE

VALUE

), to use the

adjustment.

MANUAL

cursor below and set the value with the / keys of the remote

control.

Associated to the

specific function

NOISE REDUCTION

(FLESH TONE CORRECTION)

there is the possibility to use the

to make skin tone more

natural. Often the use of noise reduction filter slightly degrades

the image in those areas where skin tones are visible. With the

use of this function it is possible to maintain an excellent image

quality throughout the entire projected image.

Table 4

Inputs

Adjustments

Brightness

Contrast

Colour - -

Tint

Sharpness

Sharpness Mode

Filter

Cinema Mode

Video Type

Noise reduction

Flesh tone correction

Present only if the Video Standard is NTSC

Video

RGBS 15kHz

S-Video

--

YCrCb 15kHz

RGBS

-

-

-

-

-

-

YCrCb

-

-

-

-

-

DVI-D

RGB Grafico

-

-

-

-

-

-

-

-

-

-

-

-

-

)

DIGITAL INPUT

VIDEO TYPE

Activates a filter to improve stability of pictures from video

recorders. To toggle between

NORMAL, VCR1

mode and

VCR2

mode press on the remote control.

18

Page 21

IMAGE

This menu features adjustments relating to picture position,

aspect ratio, etc.

ASPECT

This adjustment allows you to change the dimensions and

aspect ratio (relationship between width and height) of the

displayed image. There are five preset aspects available and

three personalised aspects (with user-settable parameters). You

can select a different aspect for each source: the selected

aspect ratio will be automatically called the next time the relative source is called.

You can also select the required aspect ratio by repeatedly

pressing the key, or by pressing and a numerical key

(1...8).

The following aspects are available.

NORMAL

: projects the image occupying the full height of the

screen while maintaining the aspect ratio of the input signal.

When the input signal aspect ratio is 4:3 black vertical bands

are displayed on the right and left of the picture.

ANAMORPHIC

: allows a 16:9 picture to be displayed correctly.

SCREEN CONTROL

If an appropriate screen-masking interface is connected to the

12V output socket it is possible to re-frame the screen to a

variety of aspect ratios and screen sizes (please refer to the

screen manufacturer’s manual).

COLOR TEMPERATURE

Changes the colour balance of the image.

Colours can be adjusted towards the red end of the spectrum

(low colour temperature values - expressed in degrees Kelvin)

or the blue end (high values).

Colour temperature can be selected with three preset values:

HIGH

(corresponding to approx. 9000 degrees Kelvin),

(approx. 8000 degrees Kelvin),

Kelvin) and one

separate adjustments for

In the personale color adjustment for all three colors it is possible

to set an Offset value and Gain.

The Offset adjustments have an impact of the low IRE values,

while the Gain adjustments impact of the higher IRE values.

Generally, the

images,

These adjustments are reserved for expert users since there is

a risk of obtaining results that impair projected image quality.

MEDIUM

PERSONAL

HIGH

value is more suitable for displaying graphic

and

LOW

for video images.

LOW

(approx. 6500 degrees

setting controlled by the user with

RED, GREEN

and

BLUE

.

MEDIUM

LETTERBOX

signal having black bands above and below the picture) so

that it fills the 16:9 screen and maintains the correct aspect

ratio.

PANORAMIC

cropping the upper and lower parts.

Panoramic is ideal for displaying a 4:3 image on the 16:9 screen

of the Display.

PIXEL TO PIXEL

adapting it to the screen.

The image is projected in the centre of the screen and if its

horizontal and/or vertical dimensions are smaller than the

display, it is bounded by vertical and/or horizontal black bands.

USER 1, 2, 3:

User formulas are available, with the facility for continuous

horizontal and vertical adjustment of picture size.

: serves to display 4:3 letterbox image (with source

: this aspect stretches the 4:3 image, slightly

: this aspect displays the image as it is input without

When none of the preset formulas are suitable, the

GAMMA CORRECTION

Determines the system’s response to the grey scale,

emphasising or attenuating the different grades of brightness

(blacks, dark, medium, light grey, whites) in the projected

image.

The

GRAPHICS

while the

images.

OVERSCAN

Remove noise around image. Some sources can produce a

picture with noise along edges, thanks to the overscan function

it is possible to drop such imperfections outside the projected

area. The overscan value can be included between 0 (no

overscan) and 32 (maximum value). The image maintains in

any case the aspect.

POSITION

Use this adjustment to position the image vertically and

horizontally. Determines the aspect ratio of the projected image.

These parameters do not normally require adjustment because

the system checks the input signal and automatically sets the

setting is more suitable for computer images,

FILM

and

VIDEO

settings are more suitable for video

19

Page 22

most suitable values.

However, if the image is not perfectly centralised it may prove

useful to request the system to repeat the input signal analysis

and image positioning, calling the automatic control procedure from the AUTO button on the remote control or keypad. When

this procedure is called it is helpful to have a white or light

coloured background on the screen in the current picture.

FREQUENCY/PHASE

These adjustments, available for progressive signals and for

signals from PC, ensure correspondence between the number

of pixels making up the signal and the number of pixels making

up the projected image.

These parameters do not normally require adjustment because

the system checks the input signal and automatically sets the

most suitable values.

However, if the image appears disturbed (loss of position within

the equidistant vertical bands or instability and lack of

sharpness on the narrow vertical lines) it may help to prompt

the system to repeat the input signal analysis and determination

of the best parameters by calling the automatic adjustment

procedure with the

AUTO

key on the remote control or on the

keypad.

If the automatic procedure fails to have the required effect, enter

the frequency and phase values manually and approach the

screen sufficiently to observe the effects of the adjustments.

Y / C DELAY

In the case of Video and S-Video signals, it may be necessary

to correct horizontal colour misalignment within the projected

image. For a given video standard (e.g. PAL or NTSC) the stored

value does not normally require further fine-tuning, unless the

source or connection cable has changed.

Table 5

Inputs

Adjustments

Position

Video

S-Video

RGBS 15kHz

YCrCb 15kHz

RGBS

YCrCb

RGB Grafico

DVI-D

DIGITAL INPUT

-

Aspect

Frequency

Phase

-

-

-

-

-

-

Colour Temperature

Gamma Correction

Overscan

-

-

Y/C Delay

-

-

SETUP

The setup menu contains less frequently used adjustments that

may be required during installation (e.g. On Screen Display

language selection or the display of Test Patterns).

ORIENTATION

Select the option that best describes the installation i.e. desktop

front, ceiling front, desktop rear and ceiling rear.

20

1

2

3

-

T

C

U

D

O

R

P

R

E

S

A

L

1

S

S

A

L

C

Fig. 21

HORIZONTAL/VERTICAL KEYSTONE

To obtain maximum quality of the projected image, we

recommend the installation of the projector on a level platform

parallel and central to the screen.

Page 23

Adjust the feet underneath to obtain a level position, lining up

the base of the projected image to the base of the projection

screen

(Fig. 22)

.

1

2

3

-

T

C

U

D

O

PR

R

E

AS

L

1

S

S

LA

C

Fig. 22

If the projected images needs to be centred horizontally, the

manual lens shift adjustment allows the projected image to be

moved vertically, up or down, in relation to the centre of the

screen; the maximum adjustment being equal to half the height

of the image in either direction

(Fig. 23)

.

LENS

The Zoom adjustment impacts on the motorized zoom lens

allowing to increase or decrease the dimension of the projected

image. The Focus adjustment impacts on the motorized lens

focus, allowing to obtain the highest definition on the projected

image, an accurate focus setting should allow the viewer to

distinguish each pixel that create the image one from another.

M

O

O

Z

Z

O

O

M

FOCUS

FOCUS

FOCUS

M

O

O

Z

ZOOM

FOCUS

Z

O

O

M

1

2

3

-

T

C

U

D

O

R

P

R

E

S

A

L

1

S

S

A

L

C

Fig. 24

In the initial phase of installation the configurable keys (F1, F2)

serve as optical zoom and optical focus

(Fig.24).

POWER ON

If active (

AUTO

) allows to power up the system directly from the

power feeder, once the initializing phase is completed.

If not active

(STAND-BY

) once the initializing phase is completed

the system remains in a stand-by mode waiting to receive the

power on command from the remote control or the key pad.

1

2

3

-

T

C

U

D

O

R

P

R

E

S

A

L

1

S

S

A

L

C

In the event you are unable to centre the image within the screen

area, tilt the projector until the image is correctly positioned.

Any keystone error can be removed by the Keystone adjustment

in the Set up menu.

The keystone adjustement helps to compensate possible

horizontal tilts of the projector.

TEST PATTERNS

Displays a series of five test patterns, useful for the installation

of the projector.

Press and keys to browse pattern.

Fig. 23

FACTORY DEFAULTS

Reconfigures the projector to original factory settings except

Position, Orientation, Y/C Delay, Zoom and Focus.

21

Page 24

MENU

No

Confirm?

Yes

This will make it easier to remember the source connected to a

specific input. You can use up to 12 alphanumeric letters to

name the source (for more details check the “Insert text” section)

Insert text

You will be able to insert text easily and rapidly by accessing

the text insertion menu

(fig. 26)

LANGUAGE

Lists the languages available for the On Screen Display menus.

SOURCE LIST

In order for the HT300 LINK system to be more flexible, the

following described functions allow to modify the input selection

menu making it more user friendly.

The main window shows all the inputs available on the

DigiOptic™ Image Processor.

If one or more inputs are not utilized, it is often helpful to blank

them from the input list (accessed with the 0 key).

Fig.25

Once the input has been chosen, in the drop menu that appears

by pressing the key, it is possible to activate the source

25)

.

(Fig.

The exclusion or activation of the source will automatically

renumber the remaining active inputs.

Source list

1 VIDEO

2 VIDEO

3 S-VIDEO

4 S-VIDEO

5 COMPONENT / RGBS

6 COMPONENT / RGBS COMPONENT / RGBS

7 COMPONENT / RGBS

8 COMPONENT / RGBS

9 GRAPHICS RGB

10

11

12

1

2

3

4

GRAPHICS RGB

11

DVI-D

DIGITAL INPUT

VIDEO 1

VIDEO 2

S-VIDEO 3

ACTIVE

S-VIDEO 4

NAME

5

COMP RGB 5

6

COMP RGB 6COMP RGB 6

7

COMP RGB 7

COMP RGB 8

8

9

10

12

GRAPH RGB 9

GRAPH RGB 10

DVI-D 11

DIGITAL INPUT 12

Yes No

The inputs with an active video signal (visible in the input

selection menu) are marked with a check symbol.

It can be also helpful to identify the input with a name chosen

by the user (for example with the name of the connected source)

rather than with the signal type.

Once chosen to have the input visible, in the drop menu, by

selecting the Name option it is possible to rename the source

in use.

Edit source name

_ _ _ _ _ _ _ _ _ _ _

Cancel

Confirm

()?@

1

GHI

4

PQRS

-

7

+

ABC

2

JKL

5

TUV

8

0

DEF

3

MNO

6

WXYZ

9

Fig.26

The text insertion mode remains the same if text is being inserted

for the first time or if a previously inserted name is being edited.

The letter insertion can be done in any available position

(represented by horizontal lines).

Use the and keys to move between letters either left or

right respectively.

Press the numeric key matching the letter (fig. 26), the first

click of the key selects the first letter, the second click the

second letter and so on.

The available letters are shown in the text insertion menu.

Once one letter has been inserted, to insert the following one it

is necessary to move with the cursor in the next right position

with the key of the remote control, repeat this procedure to

insert other letters.

Use the key to switch from small case to capital letters and

vic versa.

Any mistake can be deleted with the key once it has been

positioned on the wrong letter.

Once the text insertion process is finished, it can be confirmed

and saved by clicking the

If you want to delete the modifications use the

MENU+

key.

MENU-

key of the

remote control.

F1/F2 KEYS

This allows to assign different functions to the remote control

keys, named F1 and F2.

The window is made of 6 options, once for each line and by

22

Page 25

two columns showing the F1-F2 keys. The choice between F1

and F2 is made by the and keys of the remote control; the

function given to F1 and F2 is chosen with the and keys.

The function delivered by the key is memorized by the

intersection on the line and column.

In the following window are described the 6 options

Color temperature

The following click of the key (F1 or F2) allows to choose between

the different color temperatures available. High, Mid, Low, User.

Gamma correction

The following click of the key (F1 or F2) allows to choose

between the different gamma curves available.

Menu

Language

Source list

F1/F2 keys

Source info

OSD Backgroung

OSD Position

OSD Timeout

English

Zoom

Focus

Magnification

Blank

Colour temperature

Gamma correction

F1 F2

Fig.2

Zoom

Allows to access the optic zoom, where the and keys

allow to increase or decrease the size of the projected image.

Focus

Once selected, the and keys allow to focus the image.

Magnification

Allows you to select the area to be viewed and then magnify

the projected image. The degree of enlargement is selected in

Zoom mode (identified by a magnifying glass in the centre of

the image) using the and keys. The area of the picture to

be enlarged is selected in Pan mode (symbol in the centre of

the picture) using the and , arrow keys. You can

toggle between Zoom and Pan mode by pressing the F1/F2

key on the remote control.

Blank

Blanks the active video signal producing a completely black

screen. Once pressed the key an indication of a few seconds

on the OSD will confirm its activation. A click of any other key

of the remote control allows to restore the previous settings.

SOURCE INFORMATION

When active

related to the signal. If not active

(YES)

each source change will show the information

(NO)

there will be no information

on the selected source.

OSD BACKGROUND

Determines the type of background for the On Screen Display.

OSD TIMEOUT

Use this adjustment to set the display time after which the On

Screen Display will disappear.

7

OSD POSITION

Allows the On Screen Display to be positioned in a particular

area of the projected image. The OSD can be positioned using

the arrow keys for fine adjustments or keys 1...9 on the remote

control to select one of 9 preset positions.

INFO

Displays the current status of the projector and information

concerning the projected video/graphic signal.

This function is displayed on pressing

on the remote control

(or, in the absence of the On Screen Display, the key on the

remote control).

QUICK MENUS

The quick menus provide access to the main adjustments that

affect image quality, without calling the main On Screen menus.

BRIGHTNESS, CONTRAST, COLOUR, TINT, SHARPNESS

adjustments appear at the bottom of the screen one after the

other when the and keys are pressed .

and

FILTER

23

Page 26

MESSAGES

The following messages may appear during operation of the

system:

No signal

The system does not recognise any signal applied to the

selected input. In this case:

• Make sure the selected input is connected to a video or

graphic signal and that that source is functioning correctly.

• Check the condition of the cables used to connect the

system to the various sources.

9 CLEANING AND MAINTENANCE

• Make sure the video or graphic signals supplied by the

source are compatible with the system’s technical

specifications and, in particular, with those of the selected

input.

Out of Range

This message appears when either the resolution or the vertical/

horizontal frequency of the input signal exceeds system

specifications (e.g. a QXGA graphic signal) or when an input

is supplied with an incompatible signal (after setting the

components input to YCrCb 15kHz a progressive signal is

connected).

The Projector and DigiOptic™ Image Processor do not require

internal cleaning. There are no user serviceable parts inside

the projector. Please refer all service requirements to qualified

personnel.

Cleaning the projector’s cover:

Use a soft slightly damp cloth. Do not use abrasive cleaners,

solvents or other harsh chemicals, as this will damage the finish

of the cover. Avoid direct cleaning of the rear panel’s screenprinting.

24

Cleaning the lens:

The lens may be cleaned with a very soft, non-abrasive small

brush, in order to remove dust particles. Alternatively, use a

soft dry cleaning cloth (of the type used for camera lens

cleaning) to remove fingerprints and grease marks.

Page 27

10 TROUBLESHOOTING GUIDE

No power (Green and red LED are OFF)

- Check the power switch at the rear: it must be in position I.

- Check if the power cable has been connected correctly to a

working socket.

- Check the power socket fuse, at the rear of the projector.

- Replace the fuse on the mains socket with an identical type

(T 3.15A H)

- Should the problem persist, seek authorised technical

assistance.

The lamp is not coming on

- Allow a few minutes pause between switching off and turning

on again (from stand-by). This will allow the lamp to cool down

sufficiently.

- If the lamp doesn’t come on – even though the projector has

had sufficient time to cool down – seek technical assistance

from your nearest Dealer.

No image

- Check that the selected input is actually connected to a active

video or graphic signal.

- Check that the above source actually works.

- Verify compatibility of video/graphic signals with the technical

specifications of the projector.

- Check the integrity of cables used to connect various sources.

- Check the cooling air inlets or air outlets on the units are not

obstructed and the room temperature is below 35°C (95°F).

(Fig. 2)

.

- Should the problem be present with a signal coming from a

video-recorder, ensure that the videotape is an Original “first

generation” copy and in good condition.

- Adjust the VCR’s tracking control for optimum picture performance. Ensure the VCR mode is active in the Picture menu.

Incomplete image along borders (vertical and horizontal)

- Compare compatibility of video/graphic signals and technical specifications of your projector.

A

- Press

- Adjust the horizontal and vertical position of projected image

- Adjust the width and height of image, selecting

- Adjust the Overscan value in the

Image too dark, too pale or unnaturally coloured

- Verify compatibility of video/graphic signals with technical

- Go to

- If necessary, reset the

Graphic image with poor quality vertical detail

on your remote control or

automatic

by selecting

IMAGE ADJUSTMENTS

specifications of your projector.

accordingly:

CORRECTION

SETTINGS

adjustments.

POSITION

PICTURE

menu, select and regulate any of the following,

CONTRAST, BRIGHTNESS, COLOR,

(found on the

menu).

on the

menu.

AUTO

on keypad to execute

IMAGE ADJUSTMENTS

IMAGE/OVERSCAN

and

COLOR TEMPERATURE

IMAGE ADJUSTMENTS / ADVANCED

TINT

menu.

ASPECT

menu.

.

and

in the

GAMMA

Image is disturbed, unstable or noisy

- Verify compatibility of video/graphic signals with the technical

specifications of the projector.

- Check the integrity of cables connecting projector to various

sources.

- If the signal source is a terrestrial broadcast (via a VCR) check

that the receiving channel has been correctly tuned in and

that the aerial system is in good working order.

- Verify compatibility of video/graphic signals with technical

specifications of your projector.

- Press A on your remote control or AUTO on keypad to

execute automatic adjustments.

- Adjust

FREQUENCY

IMAGE ADJUSTMENTS

projected image.

and

menu, to optimise vertical detail of the

PHASE

parameters, found in the

25

Page 28

Video Image showing colour misalignment on vertical

details

- Verify compatibility of video/graphic signals with technical

specifications of your projector.

- Adjust Y/C DELAY settings in the IMAGE ADJUSTMENTS /

ADVANCED SETTINGS to reduce colour misalignment. For

best results use an external colour bar test pattern source.

11 OPTIONAL ACCESSORIES

Remote control does not work

- Check the batteries and for correct polarity.

- Ensure that the area between the infrared sensor (front of

projector) and the remote control is free of obstruction.

- Ensure that infrared sensors (front and rear of projector) are

not exposed to intense light levels.

You can purchase the following optional accessories at your

Dealer:

- Wall/Ceiling Bracket Kit.

Use only original, or SIM2 Multimedia approved,

accessories.

CAUTION: for ceiling/wall installation, by means of

suspension bracket, carefully follow the

instructions and safety instructions recommended

by the Manufacturer in the bracket’s literature.

26

Page 29

12 ADDITIONAL INFORMATION

A TECHNICAL SPECIFICATION

PROJECTOR

OPTICAL

Projection system: optical engine based on 1 DMD™

HD2+ chip, sealed housing, dusty

proof

DMD™ panel: resolution 1280x720 pixel

Brightness uniformity: 10% above or below the average

Contrast ratio: > 2800:1 (full On / full Off)

Projection lens: zoom, 12 elements AR multilayer

coating, motorized focus and zoom,

manual elevation

Aperture f#: 2.7 (zoom max) - 3.3 (zoom min)

Picture size: 50-250 inches (diagonal measure)

Aspect ratio: 4/3 and 16/9

Throw ratio: 1.8:1 - 2.5:1

(throw distance: picture width)

Focus range: 2.2 - 13.0 m (7’ 3” - 42’ 8”)

Throw Distance: 60”: 2.4m - 3.3m (7’ 11” - 10’ 10”)

80”: 3.2m - 4.4m (10’ 6” - 14’ 5”)

100”: 4.0m - 5.5m (13’ 2” - 18’ 1”)

Keystone adjustement: up to 26° (optical: ± 8° digital: ±18°)

Lamp: 120 W UHP

Lamp life time: 8000 hours (average value measured

in the laboratory under optimal conditions; it can be sensibly reduced by

the unit misusing)

GENERAL

Supply: from 120 to 240 Vac, -10% +6%

tolerance

Frequency: from 48 to 62 Hz

Consumption: 180 W max

Fuse: T 3.15A H, 5 x 20 mm

Dimensions of projector: 352 mm x 174 mm x 318 mm

(LxHxD)

13”-7/8 x 6”-7/8 x 12”-1/2 (LxHxD)

Weight of projector: 5.0 kg (11 lbs)

Packaging and 510 mm x 440 mm x 450 mm

(LxHxD)

ENVIROMENTAL

Operation temperature: 0 to 35°C (32° to 95°F)

Transportation temp.: -10 to 55°C (14° to 131°F)

Storage temperature: -10 to 55°C (14° to 131°F)

Humidity: 10% to 90% relative humidity non-

condensing

Safety: EN 60950, UL 60950

Transportability: desktop equipment

Electromagnetic EN 55022 Class B

compatibility: EN 55024

EN 61000-3-2

EN 61000-3-3

Transportation: IEC 68-2-31, IEC 68-2-32

ELECTRICAL

Input/Output: 3-channel fibre optic link

Control: Panel (keypad), remote control

27

Page 30

DIGIOPTIC™ IMAGE PROCESSOR

ELECTRICAL

Input signals:

• 2 COMPOSITE VIDEO (CVBS)

RCA type connectors, gold-plated

1.0 Vpp / 75 Ω, negative synchronisation

• 2 S-VIDEO (Y/C)

4-pin mini-DIN connectors

Y: 1.0 Vpp / 75 Ω, negative synchronisation

C: 0.286 Vpp / 75 Ω, [NTSC nominal burst level]

0.3 Vpp / 75 Ω [PAL, SECAM nominal burst level]

• 4 COMPONENTS (Y/Cr/Cb/H/V) - RGBHV

3 sets of 5 RCA connectors, gold-plated

1 set of 5 BNC type connectors, gold-plated

- Components signal

Y: 1.0 Vpp / 75 Ω, negative or 3-level synchronisation

[HDTV]

Cr,Cb: 0.7 Vpp / 75 Ω

- RGB signal

R,B: 0.7 Vpp / 75 Ω

G: 0.7 Vpp / 75 Ω, separate H/V Sync or H+V Sync

1.0 Vpp / 75 Ω, negative or 3-level synchronisation

[HDTV]

H,V: positive or negative TTL, 0.3-5 Vpp / 1 kΩ

• 2 RGBHV (analogue RGB)

female DB15HD connectors

R,B: 0.7 Vpp / 75 Ω

G: 0.7 Vpp / 75 Ω, separate H/V Sync or H+V Sync

1.0 Vpp / 75 Ω, negative or 3-level synchronisation

[HDTV]

H,V: positive or negative TTL, 0.3-5 Vpp / 1 kΩ

• 1 DVI (digital RGB)

DVI-D female connector

Input/Output: 3-channel fibre optic link

Control: Remote control, via RS232 from PC or

home automation devices

Horizontal frequency: from 15 to 110 kHz (up to UXGA, 85 Hz)

Vertical frequency: 48 -100 Hz

Video standards: automatically selected (PAL B, G, H, I, M,

N, 60, SECAM, NTSC 3.58 and 4.43)

High definition video: ATSC HDTV (480p, 720p, 1080i, 1080p)