Page 1

www.silverlinetools.com

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

3 años de garantía

*Registre su producto online durante

los primeros 30 días. Se aplican

términos y condiciones

3 jaar garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

3 anni di garanzia

*Registrare il vostro prodotto on-line entro

30 giorni. Termini e condizioni si applicano

Page 2

www.silverlinetools.com

S

I

L

V

E

R

L

I

N

E

R

A

N

G

E

261884

180mm

1010W Polisher

1010W Polisher

1010 W Polisseuse

Poliermaschine, 1010 W

Pulidora 1010 W

Lucidatore 1010W

1010 W polijstmachine

Page 3

2

8

9

2

1

3

5

7

6

4

Page 4

www.silverlinetools.com

3

English .................. 4

Français ................ 10

Deutsch ................. 16

Español ................. 22

Italiano .................. 28

Nederlands ............ 34

®

S

I

L

V

E

R

L

I

N

E

R

A

N

G

E

180mm

1010W Polisher

Page 5

4

GB

Description of Symbols

Carefully read and understand these instructions and any label attached

to the tool before use. Keep these instructions with the product for future

reference. Ensure all persons who use this product are fully acquainted with

these instructions.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Wear head protection.

Wear hand protection.

Read instruction manual.

Caution!

Toxic fumes or gases!

Double insulated for additional protection.

Conforms to relevant legislation and safety standards.

Environmental Protection

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your local authority or retailer for recycling advice.

Specification

Voltage: ........................................................230-240V~, 50Hz

Power: ...........................................................................1010W

No-load speed: ............................................... 1000-4500min

-1

Spindle thread: ..................................................................M14

Sanding pad diameter: .................................................180mm

Cable length: ....................................................................2.0m

Ingress protection: ............................................................. IP20

Protection class: ...............................................................

Weight: ..........................................................................2.26kg

Sound and vibration information:

Sound pressure LPA:..................... .................................88dB(A)

Sound power LWA:........................ .................................99dB(A)

Uncertainty K: .....................................................................3dB

Weighted vibration ah:.................... ............................5.79m/s²

Uncertainty K:............................. ..................................1.5m/s²

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

WARNING: Always wear ear protection where the sound level exceeds

85dB(A) and limit the time of exposure if necessary. If sound levels are

uncomfortable, even with ear protection, stop using the tool immediately

and check the ear protection is correctly fitted and provides the correct level

of sound attenuation for the level of sound produced by your tool.

WARNING: User exposure to tool vibration can result in loss of sense of

touch, numbness, tingling and reduced ability to grip. Long term exposure

can lead to a chronic condition. If necessary, limit the length of time

exposed to vibration and use anti-vibration gloves. Do not operate the tool

with hands below a normal comfortable temperature, as vibration will have

a greater effect. Use the figures provided in the specification relating to

vibration to calculate the duration and frequency of operating the tool.

Sound and vibration levels in the specification are determined according

to EN60745 or similar international standards. The figures represent

normal use for the tool in normal working conditions. A poorly maintained,

incorrectly assembled, or misused tool, may produce increa sed levels of

noise and vibration. www.osha.europa.eu provides information on sound

and vibration levels in the workplace that may be useful to domestic users

who use tools for long periods of time

General Safety

WARNING Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric shock, fire

and/or serious injury.

WARNING: This appliance is not intended for use by persons (including

children) with reduced, physical or mental capabilities or lack of experience

or knowledge unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children must be supervised to ensure that they do not play with the

appliance.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

Original Instructions

V Volts

~ Alternating current

A Ampere

n

o

No load speed

Hz Hertz

W, kW Watt, kilowatt

/min or min

-1

(revolutions or reciprocation) per minute

Page 6

www.silverlinetools.com

5

1010W Polisher 261884

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

a) Power tool plugs must match the outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

WARNING: When used in Australia or New Zealand, it is recommended that

this tool is ALWAYS supplied via Residual Current Device (RCD) with a rated

residual current of 30mA or less.

Personal Safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal

injury

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce

personal injuries

c) Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your finger

on the switch or energising power tools that have the switch on invites

accidents

d) Remove any adjusting key or wrench before turning the power tool

on. A wrench or a key left attached to a rotating part of the power tool

may result in personal injury

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situations

f) Dress properly. Do not wear loose clothing or jewellery. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving parts

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards

Power Tool Use & Care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool.Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect

the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance

with these instructions, taking into account the working conditions

and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of the

power tool is maintained.

WARNING: Before connecting a tool to a power source (mains switch power

point receptacle, outlet, etc.) be sure that the voltage supply is the same as

that specified on the nameplate of the tool. A power source with a voltage

greater than that specified for the tool can result in serious injury to the

user, and damage to the tool. If in doubt, do not plug in the tool. Using a

power source with a voltage less than the nameplate rating is harmful to

the motor.

Sanding Tool Safety

WARNING: Hold the power tool by insulated handles or gripping

surfaces only, because the sanding belt/sheet may contact its own

cord. Cutting a "live" wire may make exposed metal parts of the power tool

‘live’ and could give the operator an electric shock.

WARNING: Use clamps or another practical way to secure the

workpiece to a stable platform. Holding the workpiece by hand or against

the body makes it unstable and may lead to loss of control.

a. ALWAYS wear appropriate protective equipment, including a dust

mask with a minimum FFP2 rating, eye protection and ear

defenders

b. Ensure all people in the vicinity of the work area are also equipped

with suitable personal protective equipment

c. Take special care when sanding some woods (such as beech, oak,

mahogany and teak), as the dust produced is toxic and can cause

extreme reactions

d. NEVER use to process any materials containing asbestos. Consult a

qualified professional, if you are uncertain whether an object contains

asbestos

e. DO NOT sand magnesium or alloys containing a high percentage of

magnesium

f. Be aware of paint finishes or treatments that may have been

applied to the material that is being sanded. Many treatments can

create dust that is toxic, or otherwise harmful. If working on a

building constructed prior to 1960, there is an increased chance of

encountering lead-based paints

g. The dust produced when sanding lead-based paints is particularly

hazardous to children, pregnant women, and people with high

blood pressure. DO NOT allow these people near to the work area,

even if wearing appropriate personal protective equipment

h. Whenever possible, use a vacuum dust extraction system to

control dust and waste

i. Be especially careful when using a machine for both wood

and metal sanding. Sparks from metal can easily ignite wood dust.

ALWAYS clean your machine thoroughly to reduce the risk of fire

j. Empty the dust bag or container frequently during use, before

taking breaks and after completion of sanding. Dust may be an

explosion hazard. DO NOT throw sanding dust into an open fire.

Spontaneous combustion may occur when oil or water particles come

into contact with dust particles. Dispose of waste materials carefully and

in accordance with local laws and regulations.

k. Work surfaces and sandpaper can become very hot during use.

If there is evidence of burning (smoke or ash), from the work

surface, stop and allow the material to cool. DO NOT touch work

surface or sandpaper until they have had time to cool

l. DO NOT touch the moving sandpaper

m. ALWAYS switch off before you put the sander down

n. DO NOT use for wet sanding. Liquids entering the motor housing can

cause severe electric shocks

o. ALWAYS unplug the sander from the mains power supply before

changing or replacing sandpaper

Page 7

6

GB

p. Even when this tool is used as prescribed it is not possible to

eliminate all residual risk factors. If you are in any doubt as to safe

use of this tool, do not use it

Polisher Safety

• DO NOT use this polisher as an angle grinder

• ALWAYS read and understand all information supplied with polishing

pastes before use

• DO NOT smoke, eat, or drink when using this polisher

• NEVER attach any accessory with a maximum speed lower than the no

load speed of the machine

Product Familiarisation

Accessories (not shown)

• 1 x Spare carbon brushes

Intended Use

• Multi-purpose rotary polishing machine, used for light to medium duty

polishing tasks, using suitable polishing bonnets and compounds

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all

its features and functions

• Ensure that all parts of the tool are present and in good condition. If

any parts are missing or damaged, have such parts replaced before

attempting to use this tool

Before use

WARNING: ALWAYS disconnect the machine from the power supply before

fitting or removing backing pads or accessories.

Assembling the front handle

• The Front Handle (9) must be fitted to the machine before use

• Screw the Front Handle (9) clockwise into the mounting point on the gear

housing (see ‘Product Familiarisation’). Tighten by hand

• To remove the handle, unscrew anti-clockwise

Fitting the Backing Pad

• The Backing Pad (2) must be securely fitted to the Spindle (3) before use:

1. Engage the flat part of the Spindle (3) with a suitable spanner, and

hold in position

2. The backing pad can now be screwed onto the spindle and tightened

WARNING: The backing pad is tightened by hand. Take care not to crossthread or over-tighten.

3. Remove the spanner

Fitting bonnets, polishing sponges and discs

• The Hook and Loop Polishing Bonnet (1) and other polishing accessories,

such as polishing sponges (not included) can be pressed onto the face of

the Hook and Loop Backing Pad (2)

• Slowly pull the fitted attachment off the hook and loop backing pad to

remove

Note: Always make sure both hook and loop surfaces are free of dirt

and debris prior to attaching any items (also see remarks ‘Maintenance’

section).

Operation

WARNING: ALWAYS wear adequate protective equipment, including eye,

hand and hearing protection, when operating this machine. Use respiratory

protection where dust or fumes are produced.

Switching on and off

WARNING: Never switch the tool on or off when it is in contact with

the workpiece. This can cause serious injury to the operator and will

significantly shorten the service life of the On/Off Trigger Switch (8).

1. Connect the machine to the power supply

2. Hold the tool securely with both hands: one hand on the Main Handle

(7), the other hand on the Front Handle (9)

3. Squeeze the On/Off Trigger Switch (8) to start the tool

4. Allow the tool to reach the speed required before bringing the machine

into contact with the workpiece

5. Remove the polisher from the workpiece before switching off

6. To stop the machine, release the On/Off Trigger Switch

WARNING: ALWAYS wait until the machine has come to a standstill before

putting it down.

Adjusting the tool speed

• The speed of the machine is controlled using the Variable Speed Dial (6):

a higher number indicates a higher speed setting

WARNING: Always set the speed control dial to the correct speed for the

task at hand.

WARNING: Never exceed the maximum speed of the installed accessory.

Polishing tips

• Ensure that the area to be polished is clean and dry

• Choose only polishing compounds that are compatible with the material

to be polished, and with the method of application. Read and understand

all information supplied with your polishing compound before use

• If using polishing sponges, apply polishing compound evenly to the

polishing sponge and place the sponge against the work surface

• Hold the machine securely, using both hands, by the handles provided.

The polishing sponge should make only light contact with the work

surface

• Switch on the machine, and work across the surface using a wide

'sweeping' motion. Stop and apply extra compound as required

• When the entire surface has been covered, stop the machine and allow

the compound to dry (follow manufacturer’s guidance)

• Attach a clean polishing bonnet to the machine and work across the

surface as before, until all visible polishing compound is removed

Accessories

A range of accessories for your polisher, including lambswool bonnets,

polishing sponges and compounds, is available from your SILVERLINE

stockist. Spare parts can be obtained from www.toolsparesonline.com

Maintenance

WARNING: ALWAYS disconnect from the power supply before carrying out

any inspection, maintenance or cleaning.

General inspection

• Regularly check that all the fixing screws are tight

• Inspect the supply cord of the tool, prior to each use, for damage or wear.

Repairs should be carried out by an authorised Silverline service centre.

This advice also applies to extension cords used with this tool

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts

to wear quickly, and shorten the machine’s service life. Clean the body of

your machine with a soft brush, or dry cloth. If available, use clean, dry,

compressed air to blow through the ventilation holes

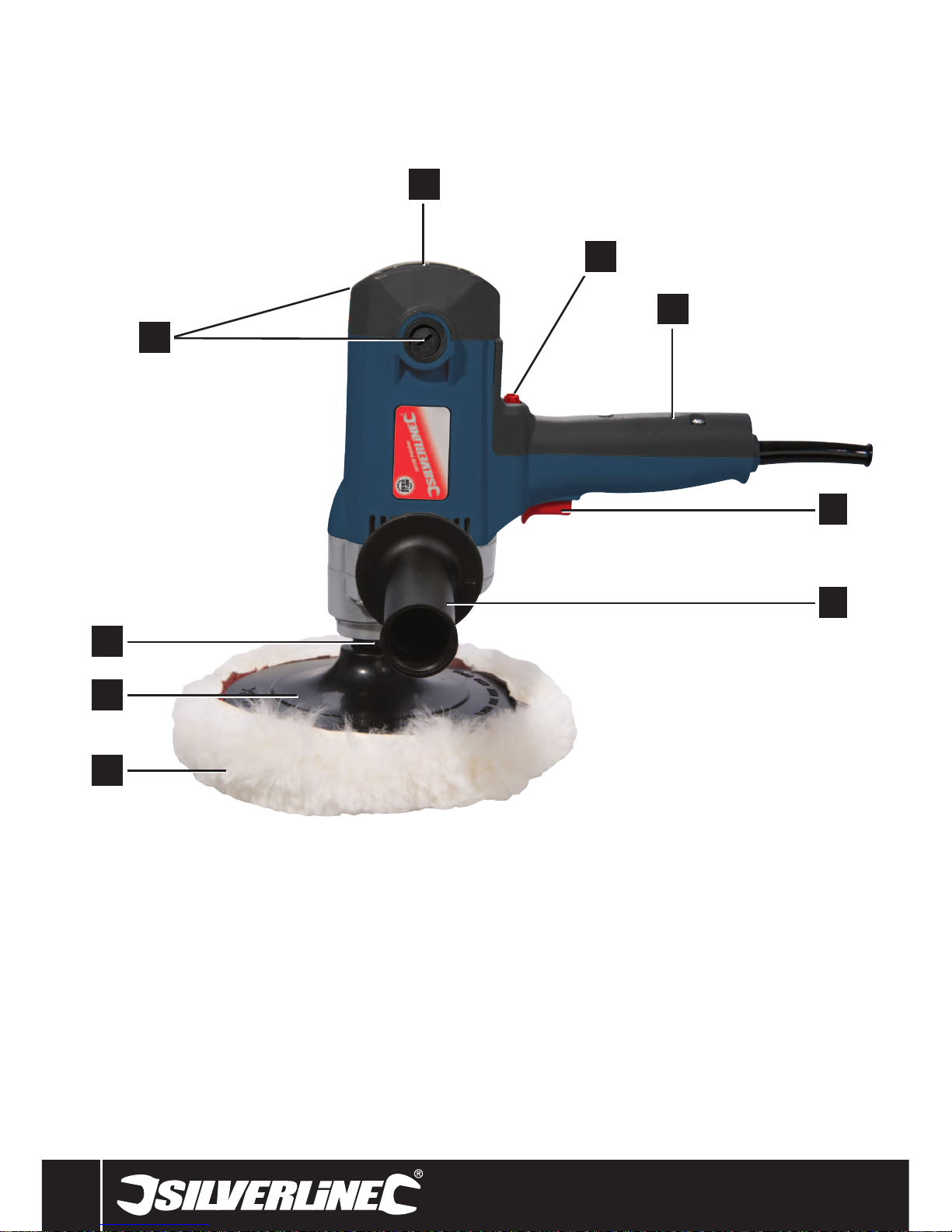

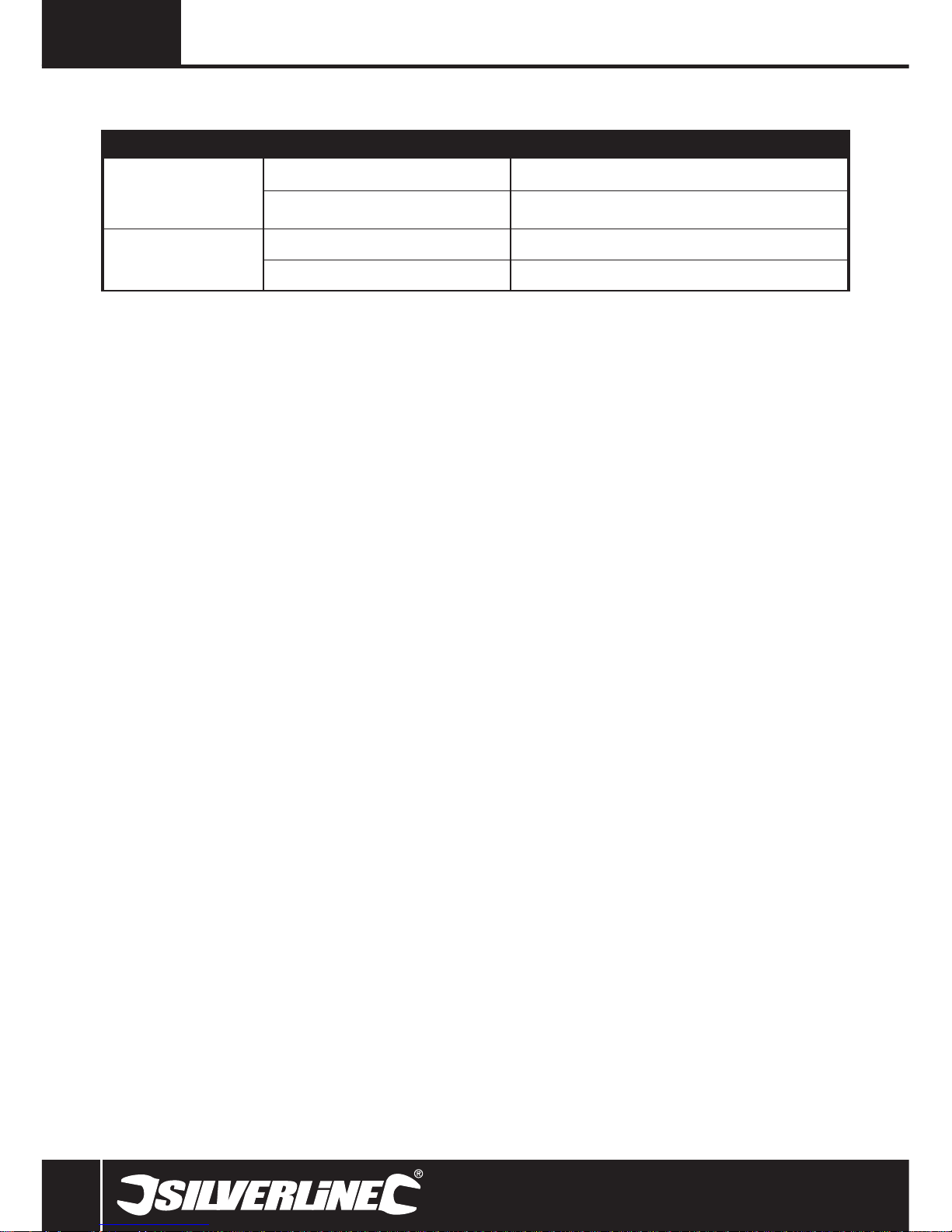

1 Hook & Loop Polishing Bonnet

2 Hook & Loop Backing Pad

3 Spindle

4 Brush Access Plugs

5 Motor Vents

6 Variable Speed Dial

7 Main Handle

8 On/Off Trigger Switch

9 Front Handle

Page 8

www.silverlinetools.com

7

1010W Polisher 261884

• Clean the tool casing with a soft damp cloth using a mild detergent. DO

NOT use alcohol, petrol or strong cleaning agents

• NEVER use caustic agents to clean plastic parts

Lubrication

• Slightly lubricate all moving parts at regular intervals with a suitable

spray lubricant

Brushes

• Over time the carbon brushes inside the motor may become worn

• Excessively worn brushes may cause loss of power, intermittent failure,

or visible sparking

• To replace the brushes, remove the Brush Access Plugs (4) from both

sides of the machine. Remove the worn brushes and replaced with new.

Replace brush access plugs. Alternatively, have the machine serviced at

an authorised Silverline service centre

Note: One set of spare brushes is supplied with this tool.

Hook and loop surfaces

• Hook and loop surfaces need to be clean, free of dirt and foreign matter,

such as hair, fibres, sand etc.

• In order to provide adequate adhesion for securing accessories, hook and

loop surfaces must be in good condition

• When used extensively, hooks and loops will become elongated or

broken, and the mechanism cannot provide the required strength of

adhesion anymore

Note: This polisher’s Hook & Loop Backing Pad (2) is NOT a warranty item.

Replacements can be obtained from www.toolsparesonline.com.

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

Always adhere to national regulations when disposing of power tools that

are no longer functional and are not viable for repair.

• Do not dispose of power tools, or other waste electrical and electronic

equipment (WEEE), with household waste

• Contact your local waste disposal authority for information on the correct

way to dispose of power tools

• Dispose of polishing compounds and used polishing sponges/bonnets

according to the compound manufacturer’s recommendations

Page 9

8

GB

Problem Possible cause Solution

No function when On/Off Trigger

Switch (8) is operated

No power Check power supply

Defective On/Off Trigger Switch

Replace the On/Off Trigger Switch at an authorised Silverline service

centre

Insufficient polishing results

Wrong speed settings Try different speeds, to determine best polishing performance

Polishing bonnet worn Fit a new polishing bonnet

Troubleshooting

Page 10

www.silverlinetools.com

9

1010W Polisher 261884

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that

Identification code: 261884

Description: 1010W Polisher

Conforms to the following directives and standards:

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

• RoHS Directive 2011/65/EU

• EN60745-1:2009+A11:2010

• EN60745-2-3:2011

• EN55014-1:2006+A1: 2009

• EN55014-2: 1997+A1:2001+A2: 2008

• EN61000-3-2: 2006+A1: 2009+A2: 2009

• EN61000-3-3:2008

Notified body: Intertek Testing Services Hangzhou.

The technical documentation is kept by: Silverline Tools

Date: 19/05/14

Signed:

Mr Darrell Morris

Managing Director

Name and address of the manufacturer:

Powerbox International Limited, Company No. 06897059. Registered address:

Central House, Church Street, Yeovil, Somerset BA20 1HH,

United Kingdom.

Terms & Conditions

Silverline Tools Guarantee

This Silverline product comes with a 3 year guarantee

Register this product at www.silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created in

PDF format for you to print out and keep with your purchase.

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the fault.

You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean and

safe state for repair, and should be packaged carefully to prevent damage or

injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized repair agents.

The repair or replacement of the product will not extend the period of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued,

will become the property of Silverline Tools.

The repair or replacement of your product under guarantee provides benefits

which are additional to and do not affect your statutory rights as a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse, neglect,

careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in these

guarantee conditions are not covered by the guarantee.

Battery Guarantee

Silverline batteries are guaranteed for 30 days. If a defect occurs on a

registered battery during the term of the Battery Guarantee, due to material

or manufacturing fault, then Silverline will replace it free of charge. This

guarantee does not apply to commercial use nor does it extend to normal

wear and tear or damage as a result of accident, abuse or misuse.

Page 11

Caractéristiques techniques

Tension: ...........................................................230-240 V~50 Hz

Puissance : ......................................................................1010 W

Vitesse à vide : ................................................. 1000-4500 min

-1

Filetage de l’arbre :........................... ...................................M14

Dimension du plateau :...................................................180 mm

Longueur du câble d’alimentation : ...................................2,0 m

Indice de protection : ............................................................IP20

Classe de protection : ..........................................................

Poids : .............................................................................2.26 kg

Informations sur le niveau d’intensité sonore et vibratoire

Pression sonore LPA : ..................................................... 88 dB(A)

Puissance sonore LWA : .................................................. 99 dB(A)

Incertitude K : .......................................................................3 dB

Vibration pondérée ah : .............................................. 5,79 m/s²

Incertitude K : ................................................................ 1,5 m/s²

Du fait de l’évolution constante de notre développement produits,

les caractéristiques techniques des produits Silverline peuvent

changer sans notification préalable.

L’intensité sonore peut dépasser 85 dB(A) et il est recommandé que

l’opérateur prenne des mesures de protection sonore.

10

F

Description des symboles

Lisez attentivement ce manuel ainsi que toute étiquette apposée sur l’outil

et assurez-vous d’en comprendre le sens avant utilisation. Rangez ces

consignes avec l’outil, pour référence ultérieure. Assurez-vous que toute

personne venant à utiliser cet outil ait attentivement pris connaissance de

ce manuel.

Port de protection auditive.

Port de lunettes de sécurité.

Port de masques respiratoires.

Port du casque.

Port de gants.

Lire le manuel d’instructions.

Attention!

Emanation d'échappement ou de gaz !

Construction de classe II

(Double isolation pour une protection supplémentaire)

Conforme à la réglementation et aux normes de sécurité

pertinentes.

Protection de l’environnement

Les produits électriques usagés ne doivent pas être jetés avec

les ordures ménagères. Veuillez les recycler dans les centres

prévus à cet effet. Pour de plus amples informations, veuillez

contacter votre municipalité ou point de vente.

ATTENTION : Portez toujours des protections auditives lorsque l’intensité

sonore dépasse 85 dB(A) et limitez la durée d’exposition si nécessaire. Si

l’intensité sonore est inconfortable, même avec des protections auditives,

arrêtez d’utiliser l’outil immédiatement et vérifiez que les protections

auditives soient bien mises et qu’elles soient adéquates avec le niveau

sonore produit par votre outil.

ATTENTION : L’exposition de l’usager aux vibrations de l’outil peut entrainer

une perte du sens du toucher, un engourdissement, des picotements et

ainsi réduire la capacité de préhension. Une exposition à long terme peut

entrainer des symptômes chroniques. Si nécessaire, limitez le temps

d’exposition aux vibrations et portez des gants anti-vibration. N’utilisez pas

cet outil avec vos mains sous des conditions en dessous de températures

normales, car l’effet vibratoire en est accentué. Utilisez les chiffres fournis

dans les Caractéristiques techniques concernant les vibrations pour calculer

la durée et la fréquence de l’utilisation de cet outil.

Les niveaux sonores et vibratoires des caractéristiques techniques sont

déterminés en fonction de la norme EN60745 ou normes internationales

similaires. Ces données correspondent à un usage normal de l’appareil,

et ce dans des conditions de travail normales. Un appareil mal entretenu,

mal assemblé ou mal utilisé peut augmenter les niveaux sonores et

vibratoires. Pour plus d’informations sur la directive des émissions sonores

et vibratoires, visitez le site http://osha.europa.eu/fr.

Consignes générales de sécurité

AVERTISSEMENT : Veuillez lire l’intégralité des consignes de sécurité et

des instructions. Le non-respect de ces consignes et instructions peut

entraîner un risque de choc électrique, d’incendie et/ou se traduire par des

blessures graves.

Attention : Cet appareil n’est pas conçu pour être utilisé par des personnes

(enfants compris) ayant des capacités physiques ou mentales réduites, ou

n’ayant pas la connaissance ou l’expérience requise, à moins d’être sous la

supervision d’une personne responsable de leur sécurité ou d’avoir reçu les

instructions nécessaires. Les enfants ne doivent pas s’approcher et jouer

avec cet appareil.

Veuillez conserver ces instructions et consignes de sécurité pour référence

ultérieure.

L’expression « appareil électrique » employée dans les présentes consignes

recouvre aussi bien les appareils filaires à brancher sur le secteur que les

appareils sans fils fonctionnant sous batterie.

Traductions des instructions originales

V Volts

~ Courant alternatif

A Ampère

n

o

Vitesse à vide

Hz Hertz

W, kW Watt, kilowatt

/min or min

-1

tour par minute

Page 12

www.silverlinetools.com

11

1010 W Polisseuse261884

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils électriques dans des environnements

explosifs, tels qu’à proximité de liquides, de gaz ou de poussières

inflammables. Les appareils électriques produisent des étincelles

susceptibles d’enflammer la poussière ou les vapeurs présentes.

c) Eloigner les enfants et les passants pendant l’utilisation d’un

appareil électrique. Ceux-ci peuvent provoquer une perte d’attention et

faire perdre la maîtrise de l’appareil.

Sécurité électrique

a) La prise d’un appareil électrique doit être adaptée à la prise du

secteur. Ne jamais modifier la prise en aucune façon. Ne jamais

utiliser d’adaptateur sur la prise électrique d’appareil mis à la terre. Des

prises non modifiées, adaptées aux boîtiers de prise de courant,

réduiront le risque de décharge électrique.

b) Eviter le contact corporel avec les surfaces mises à la terre telles

que tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de

décharge électrique est plus important si le corps est mis à la terre.

c) Ne pas exposer l’appareil électrique à la pluie ou à l’humidité.

L’infiltration d’eau dans un appareil électrique accroît le risque de

décharge électrique.

d) Ne pas maltraiter le cordon électrique. Ne jamais utiliser le cordon

électrique pour porter, tirer ou débrancher l’appareil. Protéger le

cordon électrique de la chaleur, du contact avec l’essence, des

bords tranchants et pièces rotatives. Un cordon électrique

endommagé ou entortillé accroît le risque de décharge électrique.

e) Lors d’une utilisation de l’appareil électrique en extérieur, se servir

d’une rallonge appropriée à une utilisation en extérieur. Cela réduit le

risque de décharge électrique.

f) Si une utilisation de l’appareil électrique dans un environnement

humide ne peut être évitée, utiliser une alimentation protégée par

un disjoncteur différentiel. L’utilisation d’un disjoncteur différentiel

réduit le risque de décharge électrique.

ATTENTION : Lorsque utilisé en Australie ou en Nouvelle Zélande, il est

recommandé que cet appareil soit toujours alimenté via un disjoncteur

différentiel ayant un courant résiduel de 30 mA ou moins.

Sécurité des personnes

a) Rester vigilant et faire preuve de bon sens lors de la manipulation

de l’appareil. Ne pas utiliser un appareil électrique lorsque l’on se

trouve dans un état de fatigue, ou sous l’influence de drogues,

d’alcool ou de médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut se traduire par des blessures

graves.

b) Porter un équipement de protection approprié. Toujours porter une

protection oculaire. Le port de masque à poussières, chaussures de

sécurité antidérapantes, casque de sécurité et protections antibruit

adaptés aux différentes conditions de travail réduit le risque de blessures

corporelles.

c) Eviter tout démarrage accidentel ou intempestif. S’assurer que

l’interrupteur marche-arrêt soit en position d’arrêt avant de

brancher l’appareil sur l’alimentation secteur ou d’installer la

batterie, de prendre l’appareil ou de le transporter. Porter un appareil

électrique tout en maintenant le doigt posé sur l’interrupteur ou brancher

un appareil électrique dont l’interrupteur est sur la position de

marche est source d’accidents.

d) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil électrique en marche. Une clé ou un instrument de réglage

laissé fixé à un élément en rotation de l’appareil électrique peut entraîner

des blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir

toujours en position stable permettant de conserver l’équilibre.

Cela permet de mieux contrôler l’appareil électrique dans des situations

inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements

amples ou des bijoux pendants. Eloigner cheveux, vêtements et

gants des pièces en mouvement. Les vêtements amples, les bijoux

pendants et cheveux longs peuvent être happés par les pièces en

rotation

g) Si l’appareil est pourvu de dispositifs destinés au raccord

d’équipements d’extraction et de récupération de la poussière/

sciure, s’assurer qu’ils soient bien fixés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les risques dus à la poussière.

Utilisation et entretien des appareils électriques

a) Ne pas forcer sur l’appareil électrique. Utiliser l’appareil électrique

approprié au travail à effectuer. Un appareil électrique adapté et

employé au rythme pour lequel il a été conçu permettra de réaliser

un travail de meilleure qualité et dans de meilleures conditions de

sécurité.

b) Ne pas utiliser un appareil électrique dont l’interrupteur marche arrêt est hors service. Tout appareil électrique dont la commande

ne s’effectue plus par l’interrupteur marche-arrêt est dangereux et doit

être réparé.

c) Débrancher l’appareil électrique ou démonter sa batterie avant

d’effectuer tout réglage ou changement d’accessoire et avant de

le ranger. De telles mesures préventives réduiront les risques de

démarrage accidentel.

d) Ranger les appareils électriques inutilisés hors de portée des

enfants et ne pas permettre l’utilisation de cet appareil aux

personnes non habituées à son maniement ou n’ayant pas lu les

présentes instructions. Les appareils électriques sont dangereux dans

les mains d’utilisateurs inexpérimentés.

e) Veiller à l’entretien des appareils électriques. Vérifier que les

éléments rotatifs soient bien alignés et non grippés. S’assurer de

l’absence de pièces cassées ou endommagées susceptibles de

nuire au bon fonctionnement de l'appareil. Si l’appareil électrique

est endommagé, le faire réparer avant toute utilisation. De

nombreux accidents sont dus à l’utilisation d’appareils électriques mal

entretenus.

f) Veiller à ce que les outils de coupe soient tenus affûtés et propres.

Des outils de coupe bien entretenus, aux tranchants bien affûtés,

sont moins susceptibles de se gripper et sont plus faciles à

contrôler.

g) Utiliser l’appareil électrique, les accessoires et outils à monter

conformément à ces instructions, en tenant compte des conditions

de travail et de la tâche à réaliser. Toute utilisation d’un appareil

électrique autre que celle pour laquelle il a été conçu peut entraîner des

situations à risque.

Entretien

a) Ne faire réparer votre appareil électrique que par un réparateur

qualifié utilisant uniquement des pièces de rechange identiques.

Cela permet de maintenir la sécurité d’utilisation de l’appareil électrique

ATTENTION : Avant de brancher un appareil sur une source d’alimentation

(prise secteur, groupe électrogène, etc.) assurez-vous que la tension

fournie soit la même que celle spécifiée sur la plaque de l’appareil. Une

source d’alimentation avec une tension supérieure à celle indiquée sur

l’appareil peut engendrer de sérieuses blessures pour l’utilisateur, et

endommager l’appareil. En cas de doute, ne branchez pas l’appareil. Une

source d’alimentation avec une tension inférieure à celle indiquée sur

l’appareil est néfaste pour le moteur.

Consignes de sécurité relatives aux

appareils de ponçage

ATTENTION : Tenez l’outil électrique par les poigné es isolées ou surfaces

de préhension uniquement, car la courroie ou la feuille abrasive pourrait

entrer en contact avec son propre câble d’alimentation. Couper un câble

« sous tension » pourrait mettre l’outil « sous tension » et donner un choc

électrique à l’utilisateur.

ATTENTION : Utilisez un serre-joint ou un étau pour maintenir la pièce de

travail sur une surface stable. Tenir la pièce de travail à la main ou contre le

corps la rend instable et peut causer une perte de contrôle.

a) Munissez-vous des équipements de sécurité appropriés, parmi lesquels

un masque contre les poussières d’une protection minimum FFP2, des

lunettes de sécurité et un casque anti-bruit.

b) Il vous appartient de veiller à ce que les personnes se trouvant à

proximité de votre zone de travail soient également protégées par des

équipements adéquats.

c) Observez une prudence particulière lors du ponçage de certaines

essences de bois (le hêtre, le chêne, l’acajou et le teck, par exemple)

car la poussière produite est toxique et peut provoquer des réactions

aiguës chez certaines personnes.

Page 13

12

F

d) Ne vous servez jamais de cet outil pour travailler sur des matériaux

contenant de l’amiante. Consultez un professionnel qualifié si vous

n’êtes pas sur si un objet contient de l’amiante.

e) Ne poncez pas le magnésium ni les alliages qui en contiennent une

proportion élevée.

f) Tenez compte des peintures de finition et des traitements qui peuvent

avoir été appliqués sur la matière à poncer. De nombreux traitements

peuvent produire une poussière toxique ou dangereuse pour la santé.

Si vous travaillez dans un bâtiment dont la construction est antérieure

à 1960, sachez que la présence de peintures à base de plomb est fort

probable.

g) La poussière produite par le ponçage des peintures à base de plomb est

particulièrement dangereuse pour les enfants, les femmes enceintes

et les personnes atteintes d’hypertension. Faites en sorte que ces

personnes se tiennent à l’écart de la zone de travail, même si elles

portent un équipement de protection adéquat.

h) Dans la mesure du possible, employez un système d’extraction des

poussières pour mieux contrôler la dispersion des poussières.

i) Observez la plus grande prudence lors de l’utilisation d’un même

appareil pour poncer le bois et le métal. Les étincelles du métal

peuvent aisément enflammer les poussières de bois. Nettoyez toujours

complètement l’outil pour réduire le risque d’incendie.

j) Videz le sac à poussière ou récipient fréquemment durant l’utilisation,

avant de prendre une pause et après avoir fini de poncer. La poussière

peut représenter un risque d’explosion. Ne jetez pas la poussière de

ponçage dans un feu. Une combustion spontanée peut se produire

lorsque des particules d’huile ou d’eau entrent en contact avec les

particules de poussière. Eliminez les déchets de ponçage avec

précaution et conformément aux lois et régulations locales.

k) Les surfaces de travail et le papier abrasif peuvent atteindre des

températures très élevées au cours du travail ; en cas de signe de

combustion (fumée ou cendre) de la surface de travail, arrêtez

l’opération en cours et attendez que le matériel refroidisse. Ne touchez

pas la surface de travail ni le papier abrasif avant qu’ils n’aient eu le

temps de refroidir.

l) Ne touchez pas la feuille de ponçage lorsqu’elle est en mouvement.

m) Éteignez toujours l’appareil avant de le déposer.

n) Ne vous servez pas de cet outil pour le ponçage humide. Les liquides

qui entrent dans le boitier moteur peuvent causer des chocs électriques

graves.

o) Débranchez toujours l’appareil avant de procéder au changement ou à

l’installation d’un accessoire.

p) Même lorsque l’outil est utilisé comme indiqué, il est impossible

d’éliminer tous les facteurs de risque résiduels. Si vous avez des doutes

quant à la manière sûre et correcte de procédez, il est recommandé de

ne pas utiliser cet outil.

Consignes de sécurité relatives aux

polisseuses

• Ne tentez jamais d'utiliser ce polissoir comme une meuleuse d’angle.

• Lisez et comprenez toute l'information fournie avec la pâte à polir avant

utilisation.

• Ne mangez pas, ne buvez pas et ne fumez pas dans la zone de travail.

• Ne fixez jamais un accessoire dont la vitesse maximale est inférieure à la

vitesse à vide de l’outil.

Accessoires (non illustrés)

• Clé, 1 paire de charbons de rechange

Usage conforme

Machine de polissage rotative polyvalente, pour les tâches légères et

moyennes de polissage, en utilisant des bonnets de polissage adaptés et

des pâtes de polissage.

Déballage

• Déballez et inspectez votre outil avec précaution. Familiarisez-vous avec

ses caractéristiques et fonctions.

• Assurez-vous que toutes les pièces de l’outil sont présentes et en bonne

condition. Si des pièces sont manquantes ou endommagées, faites-les

remplacer avant d’essayer d’utiliser cet outil.

Avant utilisation

ATTENTION : Déconnectez toujours la machine de l’alimentation électrique

avant de fixer ou d’enlever des plateaux supports ou des accessoires.

Fixer la poignée avant

• La poignée avant (9) doit toujours être fixée sur la machine avant

utilisation.

• Vissez la poignée avant (9) dans le sens horaire dans le point de fixation

sur le boîtier-moteur (voir ‘Se familiariser avec le produit). Serrez-la à

la main.

• Pour enlever la poignée, dévissez dans le sens antihoraire.

Installer le plateau support

• Le plateau support (2) doit être fixé de manière sure sur l’arbre (3) avant

utilisation :

1. Engagez la partie plate de l’arbre (3) avec une clé adéquate, et

maintenez en position.

2. Le plateau support peut à présent être vissé sur l’arbre et serré.

ATTENTION : Le plateau support se serre à la main. Faites attention de ne

pas fausser le filetage et de ne pas trop serrer.

3. Enlevez la clé.

Installer les bonnets de polissage, les tampons de

polissage, et les disques

• Le bonnet de polissage auto-agrippant (1) et les autres accessoires de

polissage, tels que les tampons de polissage (non fournis) peuvent être

pressés sur la surface du plateau support auto-agrippant (2).

• Tirez lentement l’accessoire installé du plateau support pour l’enlever.

Remarque : Assurez-vous toujours que les deux surfaces auto-agrippantes

soient exemptes de saleté et de débris avant d’installer les accessoires (voir

également la section ‘Entretien’).

1 Bonnet de polissage auto-agrippant

2 Plateau support auto-agrippant

3 Arbre

4 Cache d’accès aux charbons

5 Orifices de ventilation du moteur

6 Variateur de vitesse

7

Poignée principale

8

Gâchette marche-arrêt

9

Poignée avant

Présentation du produit

Page 14

www.silverlinetools.com

13

1010 W Polisseuse261884

Instructions d’utilisation

ATTENTION : Portez toujours un équipement de protection adapté,

comprenant lunettes de sécurité, gants et protection auditive lorsque

vous utilisez cette machine. Utilisez une protection respiratoire en cas de

production de poussière ou de fumée.

Mise en marche et arrêt

ATTENTION : N’allumez et n’éteignez jamais l’outil lorsqu’il est en contact

avec la pièce de travail. Ceci peut causer de graves blessures pour

l’utilisateur et réduit considérablement la durée de vie de la gâchette

marche-arrêt (8).

1. Connectez la machine à l’alimentation secteur.

2. Tenez la machine de manière sure à deux mains : une main sur la

poignée principale (7) et une main sur la poignée avant (9).

3. Appuyez sur la gâchette marche-arrêt (8) pour démarrer l’outil.

4. Laissez l’outil atteindre la vitesse requise avant de faire entrer la

machine en contact avec la pièce de travail.

5. Enlevez la polisseuse de la pièce de travail avant d’éteindre la

machine.

6. Pour éteindre la machine, relâchez la gâchette marche-arrêt.

ATTENTION : Attendez toujours que la machine s’arrête complètement

avant de la poser.

Réglage de la vitesse de l’outil

• La vitesse de la machine est contrôlée avec le variateur de vitesse (6) :

plus le nombre est élevé et plus la vitesse est élevée.

ATTENTION : Réglez toujours la vitesse correcte sur le variateur de vitesse

en fonction de la tâche à accomplir.

ATTENTION : Ne dépassez jamais la vitesse maximale de l’accessoire

installé.

Conseils pour le polissage

• Assurez-vous que la surface à polir soit propre et sèche.

• Choisissez des pâtes de polissage qui sont compatibles avec le matériau

à polir et avec la méthode d’application. Assurez-vous de bien lire et

comprendre toutes les informations fournies avec votre pâte de polissage

avant utilisation.

• Si vous utilisez des éponges de polissage, appliquez la pâte de polissage

uniformément sur l’éponge de polissage et placez l’éponge sur la surface

de travail.

• Tenez la machine fermement, en vous servant de vos deux mains, par

les poignées. L’éponge de polissage ne doit entrer que légèrement en

contact avec la surface de travail.

• Allumez la machine et déplacez-la sur toute la surface en décrivant

un large mouvement de « balayage ». Arrêtez et remettez de la pâte si

nécessaire.

• Lorsque toute la surface a été couverte, arrêtez la machine et laissez la

pâte sécher (suivez les instructions du fabricant).

• Installez un bonnet de polissage propre sur la machine et déplacez-le sur

toute la surface de nouveau, jusqu’à ce que toute trace visible de pate de

polissage ait été enlevée.

Accessoires

Une large gamme d’accessoires est disponible pour votre ponceuse

polisseuse chez votre revendeur Silverline comprenant des éponges de

polissage, des bonnets de polissage en laine d’agneau, et des pâtes de

polissage. Des pièces de rechange sont disponibles sur

www.toolsparesonline.com.

Entretien

ATENTION : Débranchez toujours de l’alimentation électrique avant

d’effectuer toute inspection, entretien ou nettoyage.

Inspection générale

• Vérifiez régulièrement que les vis de fixation soient bien serrées.

• Inspectez le câble d’alimentation de la machine régulièrement, avant

chaque utilisation, pour tout signe de dégât ou d’usure. Les réparations

doivent être effectuées par un centre de service agréé Silverline. Ce

conseil s’applique également aux rallonges utilisées avec cet outil.

Nettoyage

• Gardez l’appareil propre. La poussière et la saleté provoquent l’usure

rapide des éléments internes de l’appareil, ce qui réduit sa durabilité.

Utilisez une brosse souple ou un chiffon sec pour le nettoyage. Si

possible, nettoyez les orifices de ventilation à l’air comprimé propre et

sec.

• Nettoyez le boitier de la machine avec un chiffon doux et humide.

N’utilisez pas d’alcool, de pétrole ou de détergents forts.

• N’utilisez jamais d’agents caustiques sur les parties plastiques.

Lubrification

• Lubrifiez légèrement toutes les pièces en mouvement régulièrement avec

un lubrifiant à vaporiser adéquat.

Remplacer les balais

• Avec le temps, les balais de charbon du moteur s’usent.

• Si les balais sont excessivement usés, le rendement du moteur peut

diminuer, la machine peut ne pas démarrer ou une quantité anormale

d’étincelles peut être observée.

• Pour remplacer les balais, retirer les caches d’accès aux charbons (4) de

chaque côté de l’appareil. Enlever les deux balais usés, et remplacez-les

par les nouveaux. Replacez les caches d’accès aux charbons. Autrement,

vous pouvez toujours les faire remplacer dans un centre d’entretien

Silverline agréé.

Remarque : Une paire de balais de charbons de rechange est fournie avec

cet outil.

Surfaces auto-agrippantes

• Les surfaces auto-agrippantes doivent être propres, exemptes de saleté

et d’impuretés telles que cheveux, fibres, particules, etc.

• Pour maintenir une adhérence optimale en vue de la fixation

d’accessoires, les surfaces auto-agrippantes doivent être maintenues

en bon état.

• Une utilisation excessive entraine une élongation ou une rupture des

éléments auto-agrippants et le mécanisme ne sera plus en mesure de

fournir une force d’adhérence suffisante.

Remarque : Le plateau support auto-agrippant (2) de cette polisseuse

n’est pas couvert par la garantie. Des plateaux supports de rechange sont

disponibles sur www.toolsparesonline.com.

Rangement

Rangez cet outil et ses accessoires dans un endroit sûr, sec et hors de

portée des enfants.

Recyclage

Lorsque l’appareil n’est plus en état de fonctionner et qu’il n’est pas

réparable, recyclez l’appareil conformément aux régulations nationales.

• Ne jetez pas les outils électriques, batteries et autres équipements

électriques ou électroniques (DEEE) avec les ordures ménagères.

• Contactez les autorités locales compétentes en matière de gestion des

déchets pour vous informer de la procédure à suivre pour recycler les

outils électriques.

• Recyclez les pates de polissage et les éponges/bonnets de polissage

conformément aux recommandations du fabricant.

Page 15

14

F

Problème Cause possible Solution

L’appareil ne fonctionne pas

lorsque la gâchette marche/

arrêt (8) est actionnée

Aucune alimentation Vérifiez la source d’alimentation

Gâchette marche/arrêt défectueuse

Faites remplacer la gâchette marche/arrêt dans un centre de service

Silverline agréé

Résultat du polissage insuffisant

Mauvais réglage de la vitesse

Essayez différentes vitesses pour déterminer laquelle produit la

meilleure performance de polissage

Bonnet de polissage usé Montez un nouveau bonnet de polissage

En cas de problème

Page 16

www.silverlinetools.com

15

1010 W Polisseuse261884

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 261884

Description: 1010 W Polisseuse

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE

• Directive sur les basses tensions 2006/95/CE

• Directive sur la compatibilité électromagnétique 2004/108/CE

• Directive RoHS 2011/65/UE

• EN60745-1:2009+A11:2010

• EN60745-2-3:2011

• EN55014-1:2006+A1: 2009

• EN55014-2: 1997+A1:2001+A2: 2008

• EN61000-3-2: 2006+A1: 2009+A2: 2009

• EN61000-3-3:2008

Organisme notifié : Intertek Testing Services Hangzhou.

La documentation technique est conservée par : Silverline Tools

Date : 19/05/14

Signature :

Mr Darrell Morris

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Limited, numéro d’entreprise 06897059. Adresse

légale : Central House, Church Street, Yeovil, Somerset BA20 1HH,

United Kingdom.

Conditions de garantie des outils Silverline

Garantie Silverline

Ce produit Silverline bénéficie d’une garantie de 3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours suivant

l’achat afin de bénéficier de la garantie de 3 ans. La période de garantie

commence à partir de la date d’achat figurant sur votre facture d’achat.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le certificat de garantie en format PDF. Veuillez l’imprimer et le

conserver avec votre achat.

La période de garantie prend effet à compter de la date de l’achat en magasin,

comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat, retournez-le au

magasin où vous l’avez acheté, avec votre facture, en expliquant en détail le problème.

Le produit sera remplacé ou vous serez remboursé(e).

Si ce produit est défectueux après cette période de 30 jours, retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la période de

garantie.

Avant toute intervention sous garantie, vous devez présenter la facture d’achat

originale sur laquelle doivent figurer la date d’achat, votre nom, votre adresse et

le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de garantie seront

vérifiées par Silverline Tools pour établir si la défaillance du produit est liée à un vice

de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent être

convenablement propres et sûrs pour être réparés et devraient être emballés

soigneusement pour éviter tout dommage ou toute blessure pendant le transport. Nous

pouvons refuser les livraisons qui ne sont pas convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de réparation

agréés.

La réparation ou le remplacement du produit ne dépassera pas la période de

garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie seront

rectifiées par la réparation de l’outil, sans frais (hormis les frais de port) ou par son

remplacement par un outil en parfait état de fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous apporte

des avantages ; ces avantages s’ajoutent à vos droits statutaires en tant que

consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline Tools,

que les défaillances du produit ont été provoquées par un vice de matériau ou de

fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit engendrées

par :

L’usure normale provoquée par l’utilisation conforme aux instructions d’utilisation,

par exemple les lames, les charbons, les courroies, les ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les feuilles

abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou un

entretien négligent, une mauvaise utilisation, un manque d’entretien ou une

utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants véritables

de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que Silverline

Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances de l’outil

indiquées dans ces conditions de garantie ne sont pas couvertes par cette garantie.

Garantie batterie

Les batteries de Silverline sont garanties pour 30 jours. En cas de défaut sur une

batterie enregistrée lors de la période de garantie batterie, Silverline la remplacera

gratuitement. Cette garantie ne s’applique pas à l’utilisation commerciale et ne

s’étend pas non plus à l’usure normale ou aux dommages causés par des accidents,

des mauvais traitements ou une utilisation impropre.

Page 17

16

D

Beschreibung der Symbole

Lesen Sie diese Anweisungen sowie alle Informationen auf der Verpackung

und dem Gerätegehäuse aufmerksam durch, bevor Sie das Gerät betreiben.

Bewahren Sie diese Anleitung zum zukünftigen Nachschlagen zusammen

mit dem Gerät auf. Stellen Sie sicher, dass sich alle Personen, die das Gerät

verwenden, zuvor mit diesen Anweisungen vertraut machen.

Gehörschutz tragen.

Augenschutz tragen.

Atemschutz tragen.

Kopfschutz tragen.

Schutzhandschuhe tragen.

Bedienungsanleitung sorgfältig lesen.

Achtung, Gefahr!

Giftige Dämpfe oder Gase!

Schutzklasse II (doppelt isoliert)

Erfüllt die einschlägigen Rechtsvorschriften und

Sicherheitsnormen

Umweltschutz

Elektro-Altgeräte dürfen nicht über den Haushaltsmüll

entsorgt werden. Bitte nach Möglichkeit über entsprechende

Einrichtungen entsorgen. Lassen Sie sich diesbezüglich von

der zuständigen Behörde oder dem Händler beraten.

Technische Daten

Spannung ..............................................230–240 V~, 50 Hz

Leistung ................................................................. 1.010 W

Leerlaufdrehzahl .....................................1.000–4.500 min

-1

Spindelgewinde ............................................................ M14

Stützteller ........................................................... Ø 180 mm

Netzkabel ................................................................... 2,0 m

Schutzart ..................................................................... IP 20

Schutzklasse ...............................................................

Gewicht ................................................................... 2,26 kg

Geräusch- und Vibrationsinformationen:

Schalldruckpegel LPA...............................................88 dB(A)

Schallleistungspegel LWA .........................................99 dB(A)

Unsicherheit .............................................................3 dB(A)

Hand-Arm-Vibration ah.........................................5,79 m/s²

Unsicherheit ...........................................................1,5 m/s²

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte

können sich die technischen Daten von Silverline-Produkten ohne

vorherige Ankündigung ändern.

Der Schallintensitätspegel kann für den Bediener 85 dB(A)

übersteigen und Lärmschutzmaßnahmen sind notwendig.

WARNUNG: Tragen Sie in Bereichen, in denen der Lärmpegel 85 dB(A)

überschreitet, unbedingt angemessenen Gehörschutz und begrenzen Sie

nach Möglichkeit die Belastungsdauer. Sollte trotz Gehörschutz Unbehagen

irgendeiner Art auftreten, beenden Sie die Arbeit unverzüglich und

überprüfen Sie den Gehörschutz auf korrekten Sitz und Funktion und stellen

Sie sicher, dass dieser einen angemessenen Schutz für den Lärmpegel

bietet, der von den verwendeten Werkzeugen ausgeht.

WARNUNG: Bei der Benutzung mancher Werkzeuge wird der

Benutzer Vibrationen ausgesetzt, welche zum Verlust des Tastsinns, zu

Taubheitsgefühl, Kribbeln und zu einer Verminderung der Handgreifkraft

führen können. Langfristige Belastung kann zu chronischen Beschwerden

führen. Begrenzen Sie, falls nötig, die Exposition zu Vibrationen und tragen

Sie vibrationsmindernde Handschuhe. Verwenden Sie dieses Werkzeug

nicht mit kalten Händen, da Vibrationen bei Temperaturen unter dem

individuellen Komfortbereich eine stärkere Wirkung zeigen. Beurteilen Sie

die Vibrationsbelastung unter Zuhilfenahme der Technischen Daten des

jeweiligen Werkzeuges und bestimmen Sie die zulässige Belastungsdauer

und -häufigkeit.

Die in den Technischen Daten angegebenen Geräusch- und

Vibrationsinformationen werden nach EN 60745 bzw. vergleichbaren

internationalen Standards bestimmt. Die angegebenen Werte beziehen

sich auf eine normale Benutzung des Werkzeuges unter normalen

Arbeitsbedingungen. Schlecht gewartete, inkorrekt montierte und

unsachgemäß verwendete Werkzeuge können erhöhte Schallpegel und

Vibrationswerte aufweisen. Weitere Informationen zur EU-Vibrationsrichtlinie

und zu Schall- sowie Vibrationsbelastungen, die auch für Heimanwender

relevant sein können, finden Sie auf den Seiten der Europäischen Agentur

für Sicherheit und Gesundheitsschutz am Arbeitsplatz:

www.osha.europa.eu.

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können elektrischen Schlag, Brand und/oder schwere Verletzungen

verursachen.

Übersetzung des Originaltextes

V Volt

~ Wechselspannung

A Ampere

n

o

Leerlaufdrehzahl

Hz Hertz

W, kW Watt, kilowatt

/min or min

-1

(Umdrehungen) pro Minute

Page 18

www.silverlinetools.com

17

Poliermaschine, 1010 W 261884

WARNUNG! Dieses Gerät darf nicht von Personen (wie z.B. Kindern) mit

eingeschränkten körperlichen oder geistigen Fähigkeiten oder von Personen

ohne Erfahrung im Umgang mit einem solchen Gerät betrieben werden,

außer wenn sie von einer für ihre persönliche Sicherheit verantwortlichen

Person in der Benutzung unterwiesen worden sind und dabei beaufsichtigt

werden. Kinder müssen beaufsichtigt werden, um sicherzustellen, dass sie

das Gerät nicht als Spielzeug verwenden.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die

Zukunft auf.

Der in den Sicherheitshinweisen verwendete Begriff „Elektrowerkzeug“

bezieht sich auf netzbetriebene Elektrowerkzeuge (mit Netzkabel) und auf

akkubetriebene Elektrowerkzeuge (ohne Netzkabel).

Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet.

Unordnung oder unbeleuchtete Arbeitsbereiche können zu Unfällen

führen.

b) Arbeiten Sie mit dem Elektrowerkzeug nicht in

explosionsgefährdeter Umgebung, in der sich brennbare

Flüssigkeiten, Gase oder Stäube befinden. Elektrowerkzeuge erzeugen

Funken, die den Staub oder die Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen während der Benutzung des

Elektrowerkzeugs fern. Bei Ablenkung können Sie die Kontrolle über

das Gerät verlieren.

Elektrische Sicherheit

a) Der Anschlussstecker des Elektrowerkzeuges muss in die

Steckdose passen. Der Stecker darf in keiner Weise verändert

werden. Verwenden Sie keine Adapterstecker gemeinsam mit

schutzgeerdeten Elektrowerkzeugen. Unveränderte Stecker und

passende Steckdosen verringern das Risiko eines elektrischen Schlages.

b) Vermeiden Sie Körperkontakt mit geerdeten Oberflächen wie von

Rohren, Heizungen, Herden und Kühlschränken. Es besteht ein

erhöhtes Risiko durch elektrischen Schlag, wenn Ihr Körper geerdet ist.

c) Halten Sie Elektrowerkzeuge von Regen oder Nässe fern. Das

Eindringen von Wasser in ein Elektrowerkzeug erhöht das Risiko eines

elektrischen Schlages.

d) Zweckentfremden Sie das Kabel nicht, um das Elektrowerkzeug

zu tragen, aufzuhängen oder um den Stecker aus der Steckdose

zu ziehen. Halten Sie das Kabel fern von Hitze, Öl, scharfen Kanten

oder sich bewegenden Geräteteilen. Beschädigte oder verwickelte

Kabel erhöhen das Risiko eines elektrischen Schlages.

e) Wenn Sie mit einem Elektrowerkzeug im Freien arbeiten, verwenden

Sie nur Verlängerungskabel, die auch für den Außenbereich

geeignet sind. Die Anwendung eines für den Außenbereich geeigneten

Verlängerungskabels verringert das Risiko eines elektrischen Schlages.

f) Wenn der Betrieb des Elektrowerkzeuges in feuchter

Umgebung nicht vermeidbar ist, verwenden Sie einen

Fehlerstromschutzschalter. Der Einsatz eines

Fehlerstromschutzschalters vermindert das Risiko eines elektrischen

Schlages.

WARNUNG! In Australien und Neuseeland darf dieses Gerät nur

unter Verwendung einer Fehlerstromschutzeinrichtung (FI-Schalter)

mit einem Bemessungsfehlerstrom von höchstens 30 mA an die

Spannungsversorgung angeschlossen werden.

Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen

Sie mit Vernunft an die Arbeit mit einem Elektrowerkzeug. Benutzen

Sie kein Elektrowerkzeug, wenn Sie müde sind oder unter dem

Einfluss von Drogen, Alkohol oder Medikamenten stehen. Ein

Moment der Unachtsamkeit beim Gebrauch des Elektrowerkzeuges kann

zu ernsthaften Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine

Schutzbrille. Das Tragen persönlicher Schutzausrüstung, wie

Staubmaske, rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des Elektrowerkzeuges, verringert

das Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern

Sie sich, dass das Elektrowerkzeug ausgeschaltet ist, bevor Sie

es an die Stromversorgung und/oder den Akku anschließen, es

aufnehmen oder tragen. Wenn Sie beim Tragen des Elektrowerkzeuges

den Finger am Schalter haben oder das Gerät eingeschaltet an die

Stromversorgung anschließen, kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor

Sie das Elektrowerkzeug einschalten. Ein Werkzeug oder Schlüssel,

der sich in einem drehenden Geräteteil befindet, kann zu Verletzungen

führen.

e) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für

einen sicheren Stand und halten Sie jederzeit das Gleichgewicht.

Auf diese Weise lässt sich das Elektrowerkzeug in unerwarteten

Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lockere Kleidung, Schmuck oder lange Haare

können von sich bewegenden Teilen erfasst werden.

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden

können, vergewissern Sie sich, dass diese angeschlossen sind und

richtig verwendet werden. Verwendung einer Staubabsaugung kann

Gefährdungen durch Staub verringern.

Verwendung und Behandlung des Elektrowerkzeugs

a) Überlasten Sie das Gerät nicht. Verwenden Sie für Ihre Arbeit das

dafür bestimmte Elektrowerkzeug. Mit dem passenden

Elektrowerkzeug arbeiten Sie besser und sicherer im angegebenen

Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug, dessen Schalter defekt ist.

Ein Elektrowerkzeug, das sich nicht mehr ein- oder ausschalten lässt, ist

gefährlich und muss repariert werden.

c) Ziehen Sie den Stecker aus der Steckdose und/oder entfernen Sie

den Akku, bevor Sie Geräteeinstellungen vornehmen, Zubehörteile

wechseln oder das Gerät weglegen. Diese Vorsichtsmaßnahme

verhindert den unbeabsichtigten Start des Elektrowerkzeuges.

d) Bewahren Sie unbenutzte Elektrowerkzeuge außerhalb der

Reichweite von Kindern auf. Lassen Sie Personen das Gerät nicht

benutzen, die mit diesem nicht vertraut sind oder diese

Anweisungen nicht gelesen haben. Elektrowerkzeuge sind gefährlich,

wenn sie von unerfahrenen Personen benutzt werden.

e) Pflegen Sie Elektrowerkzeuge mit Sorgfalt. Kontrollieren Sie, ob

bewegliche Teile einwandfrei funktionieren und nicht klemmen,

ob Teile gebrochen oder so beschädigt sind, dass die Funktion des

Elektrowerkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile

vor dem Einsatz des Gerätes reparieren. Viele Unfälle haben ihre

Ursache in schlecht gewarteten Elektrowerkzeugen.

f) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich

weniger und sind leichter zu führen.

g) Verwenden Sie Elektrowerkzeug, Zubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen. Berücksichtigen Sie dabei die

Arbeitsbedingungen und die auszuführende Tätigkeit. Der Gebrauch

von Elektrowerkzeugen für andere als die vorgesehenen Anwendungen

kann zu gefährlichen Situationen führen.

Service

a) Lassen Sie Ihr Elektrowerkzeug nur von qualifiziertem Fachpersonal

und nur mit Original-Ersatzteilen reparieren. Damit wird sichergestellt,

dass die Sicherheit des Elektrowerkzeuges erhalten bleibt.

WARNUNG! Stellen Sie vor Anschluss eines Werkzeugs an eine Stromquelle

(Steckdose, Stromanschluss u.ä.) sicher, dass die Netzspannung der auf

dem Typenschild des Werkzeugs angegebenen Spannung entspricht.

Eine Stromquelle mit einer höheren Spannung als der für das Werkzeug

spezifizierten Spannung kann zu schweren Verletzungen des Bedieners

sowie Beschädigung des Werkzeugs führen. Schließen Sie das Werkzeug

im Zweifelsfall nicht an. Eine niedrigere Spannung als auf dem Typenschild

angegeben schadet dem Motor.

Zusätzliche Sicherheitshinweise für

Schleifgeräte

WARNUNG! Halten Sie das Elektrowerkzeug nur an den isolierten

Handgriffen bzw. Griffflächen, denn das Schleifband/-blatt könnte

mit dem Netzkabel in Kontakt kommen. Wird eine spannungsführende

Leitung beschädigt, können dadurch freiliegende Metallteile des

Elektrowerkzeugs unter Spannung gesetzt werden und dem Bediener einen

Stromschlag versetzen.

WARNUNG! Setzen Sie Schraubzwingen o.ä. ein, um das Werkstück an

einer stabilen Arbeitsfläche zu fixieren. Wird das Werkstück mit der Hand

oder gegen den Körper gehalten, ist es nicht stabil genug und es kann zu

einem Verlust der Kontrolle über das Gerät kommen.

Page 19

18

D

a) Tragen Sie stets geeignete persönliche Schutzausrüstung