Page 1

Operating and Mounting Instructions

Flow In Premium

For the following

models:

FLIK 854 ES

YT610.3413.01.04

Read the instructions before beginning any work!

Page 2

SILVERLINE

Küchengeräte und Handel GmbH Lilienthalstraße 26 41515 Grevenbroich

Phone: +49 2181 75668-0

Telefax: +49 2181 75668-11

E-Mail: info@silverline24.deInternet: www.silverline24.de Original

document

1, de_DE

©SILVERLINE Küchengeräte und Handel GmbH 2017

Flow In Premium 02/07/20182

Page 3

Supplementary instructions

Introduction

Thank you for choosing to purchase an extractor

hood (hereinafter referred to as the "Appliance")

from SILVERLINE.

This manual describes several cooker hoods, which

may vary in color, width, number of lighting xtures

and / or metal grease lters.

These instructions and safety instructions give you

all the information you need for safe installation and

trouble-free, safe operation.

Read these instructions and the safety instruc-

tions completely before using the device.

Keep the instructions well.

If you pass on the device, also include this

manual and the safety instructions.

Failure to follow these instructions could result

in serious injury or damage to the unit.

We assume no liability for damages resulting

from non-compliance with this manual.

The illustrations in this manual are for illustrative purposes. The illustrations show a possible version of the

device. All descriptions or illustrations also apply to the

other versions.

Further information on products, accessories, spare parts and services can be

found on the Internet atwww.silverline24.

de.

Copyright

Customer Service Hotline (for Germany, Austria, Switzerland, France, Belgium, Netherlands

and Luxembourg)

Order Hotline (for Germany, Austria, Switzerland, France, Belgium, Netherlands and

Luxembourg)

This manual is protected by copyright.

The handover of this manual to third parties, duplica-

tion in any form - even in extracts - as well as the utilization and/or communication of the contents are without written permission of SILVERLINE Küchengeräte

und Handel GmbH ("manufacturer") except for internal

purposes not allowed. Violations require compensation. The manufacturer reserves the right to assert

additional claims.

Phone (Customer service

hotline)

Fax +49 (0) 2181-75668-33

e-mail kundendienst@silverline24.de

Phone (Order hotline) +49 (0) 2181-75668-0

Fax +49 (0) 2181-75668-11

E-mail info@silverline24.de

+49 (0) 2181-75668-350

Flow In Premium02/07/2018 3

Page 4

Table of contents

Table of contents

1 SAFETY.............................................................................. 7

1.1 Precaution before startup................................................. 7

1.2 General safety information............................................... 7

1.3 Protection against damage.............................................. 8

1.4 Precautions on equipment failure.................................... 9

1.5 Protection againstfurther dangers................................... 9

2 DEVICE DESCRIPTION........................................................ 10

2.1 Technical Description....................................................... 10

3 Control panel........................................................................ 11

4 OPERATION OF THE COOKING FIELD.............................. 12

4.1 Ventilation........................................................................ 12

5 COMMISSIONING THE COOKING FIELD........................... 13

5.1 Before the rst heating.................................................... 13

5.2 Induction principle........................................................... 13

5.3 Function of the sensor panels.......................................... 13

5.4 Switch hob on and off...................................................... 13

5.5 Pan recognition................................................................ 14

5.6 Residual heat indicator..................................................... 14

5.7 Power Function................................................................ 15

5.8 Timer................................................................................ 15

5.9 Bridge function................................................................. 17

5.10 Locking of the hob......................................................... 17

6 COOK RECOMMENDATIONS............................................. 19

6.1 Cookware......................................................................... 19

6.2 Crockery size................................................................... 20

6.3 Setting.............................................................................. 20

7 CLEANING AND CARE........................................................ 21

8 ENVIRONMENTAL PROTECTION....................................... 22

9 WHAT TO DO IF.................................................................... 23

10 INSTALLATION INSTRUCTIONS......................................... 26

11 ELECTRICAL CONNECTION.............................................. 27

12 Device description.............................................................. 29

12.1 The device.................................................................... 29

12.2 Operating unit............................................................... 29

12.3 Scope of delivery.......................................................... 30

13 For your safety...................................................................... 32

13.1 Symbols in this manual................................................. 32

13.2 Intended Use................................................................. 34

13.3 Children and persons with limited perception................ 34

13.4 Fire hazard..................................................................... 34

Flow In Premium 02/07/20184

Page 5

Table of contents

1.5 Room-air-dependent replace

(only with exhaust air operation) ......................... 35

1.6 Power supply ...................................................... 35

1.7 Transportation. .................................................... 36

1.8 Defect. ................................................................ 36

1.9 Cleaning.............................................................. 36

13 Service ............................................................... 37

1.1 Safety during operation ...................................... 37

1.2 Switch fan on / off ............................................... 37

14.2.1 About the operating unit ..................................... 37

14.3 Changing the fan power level ............................. 38

14.3.1 About the operating unit ..................................... 38

1.4 Turning the delayed shut-off automatic on/off ..... 38

1.5 To clear the fat lter saturation indicator ............. 39

14 Maintenance, cleaning and care...................... 40

1.1 Maintenance. ...................................................... 40

1.1.1 Maintenance intervals ......................................... 40

1.1.2 Metal grease lter cleaning ................................. 41

1.1.3 Clean or replace activated carbon lter .............

(recirculation only) .............................................. 43

1.2 Cleaning and care............................................... 44

1.2.1 Cleaning supplies/utensils .................................. 44

1.2.2 Cleaning the device from the outside ................. 45

1.2.3 Maintain the device ............................................. 45

15 Error messages................................................. 46

1.1 How to behave in case of errors ......................... 46

1.2 Error table ........................................................... 46

17 Accessories and spare parts ........................... 48

17.1 Accessories and spare parts order ..................... 48

17.2 Accessories ........................................................ 48

17.2.1 Accessories circulating air exhaust circuit .......... 48

17.2.2 Accessories exhaust air operation ...................... 49

17.2.3 Acessories recirculating air operation ................. 50

17.2.4 Cleaning-/Care products ..................................... 51

17.3 Hood Accessories .............................................. 51

18 Disassembly and disposal ............................... 52

18.1 Disassembly ....................................................... 52

18.1.1 Safety during disassembly .................................. 52

18.1.2 Disassemble the device ...................................... 52

18.2 Disposal ............................................................. 54

19 Technical specications .................................. 55

20 Nameplate.......................................................... 56

21 Warranty ............................................................ 57

Flow In Premium02/07/2018 5

Page 6

Table of contents

22 Unpacking and assembling ............................. 60

22.2.1 Unpacking ...............................................60

22.2.2 Note before assembling ...........................61

22.2.1 Exhaust air operation ...............................61

22.2.2 Recirculating air operation ........................62

22.2.3 Power supply connection .........................63

22.3 Assembling the device .............................63

22.3.1 Assembling diagram .................................63

22.3.2 Assemble the reducing adapter (for exhaust

air operation with Ø125 mm air duct only) ...........65

22.3.3 Assembling the hob ..................................66

22.3.4 Install window tilt switch (for exhaust

air operation only). ...................................67

22.3.5 Establish power supply ............................68

22.3.6 Connect exhaust duct .............................

(for exhaust air operation only) ................68

22.4 Cleaning the extractor hood .....................69

Flow In Premium 02/07/20186

Page 7

1 SAFETY

1.1 Precaution before commissioning

SAFETY

General safety information

• Remove all parts of the packaging.

• The device may only be installed and connected by a

qualied electrician. The manufacturer can not be held responsible for damage caused by errors during installation

or connection. Only use the device when it is installed.

• The device may only be used if it is straightened up and

installed in a piece of furniture and a conrmed and adapted work plan is used.

• This appliance may only be used for household cooking

and frying and is not intended for commercial use.

• Remove all labels and stickers from the glass.

• The device must not be altered.

Do not use the hob as a work or storage surface.

• Safety is only guaranteed if the device is connected to a

protective conductor which complies with the valid regula-

tions.

• The device must not be connected to the electrical net-

work via an extension cable.

• The appliance must not be used over a dishwasher or

tumble dryer: the released water vapor could damage the

electronics.

• Do not switch on the device via an external timer or a

separate remote control.

1.2 General safety instructions

Switch off the cooking zones after each use.

Overheated fats and oils ignite quickly. When preparing

food in fat or oil (such as French fries), you should watch

the cooking process.

When cooking and frying, the cooking zones become hot.

Therefore beware of burns during and after using the

device.

Make sure that no electrical cable comes into contact with

the glass or hot cooking zone from a stand-alone or built-

in appliance.

Magnetic objects such as credit cards, oppy disks, cal-

culators, may not be in close proximity to the switched-on

device. Their function could be impaired.

Metallic objects such as knives, forks, spoons and pots

should not be placed on the hob as they could get hot.

Flow In Premium02/07/2018 7

Page 8

SAFETY

Protection against damage

1.3 Protection against damage

Generally, do not place metallic objects (eg, spoons, pot

covers, etc.) on the induction surface as they may heat up

during operation.

Never cover the cooking surface with a rag or a protective

foil; These could get very hot and catch re.

This device may be used by children from 8 years old and

above and by persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge, if

they have been supervised or instructed in the safe use of

the device and understand the resulting hazards.

Children should not play with the appliance.

Cleaning and user maintenance may not be performed by

children without supervision.

Do not use pots or pans with unpolished or damaged

oors (such as cast iron). These can scratch the glass

ceramic panes.

Note that even grains of sand can cause scratches.

Glass ceramic is insensitive to temperature shocks and

very resistant, but not unbreakable. Especially sharp and

hard objects that fall on the cooking surface can damage

them.

Do not knock pots and edges against the glass.

Do not use the cooking zones with empty cookware.

Avoid sugar, plastic or aluminum foil on the hot cook-

ing zones. These substances melt, stick and can cause

cracks, breaks or other permanent changes in the glass

when cooled. If you still get to the hot cooking zones,

please switch off the appliance and remove it while it is

still hot. Since the cooking zones are hot, there is a risk of

burns.

Never place hot cookware on the controller. The electron-

ics under the glass could be damaged.

Do not place anything on the hob.

If there is a drawer under the built-in unit, care must be

taken to ensure a minimum distance of 2 cm between the

underside of the unit and the drawer contents, as other-

wise ventilation of the unit is not guaranteed.

Do not store ammable objects (eg spray cans) in this

drawer. The possible cutlery boxes in the drawer must be

made of heat-resistant material.

Do not heat closed containers (such as cans) on the cook-

ing zones. Due to the corresponding overpressure, the

containers or cans can burst and there is a risk of injury!

Flow In Premium 02/07/20188

Page 9

1.4 Precautions on equipment failure

• If an error is detected, the device must be switched off

and disconnected from the mains.

• If breaks, jumps or cracks occur on the glass: switch off

the hob immediately, unscrew or remove the fuse for the

hob and contact our customer service or your dealer.

• Repairs to the device may only be carried out by quali-

ed personnel.

•WARNING: If the glass surface has cracked, switch off

the device to avoid the risk of electric shock.

1.5 Protection against further dangers

• Make sure that the cookware is always centered on the

cooking zone. The bottom of the pan must cover as much

of the cooking zone as possible.

For people with a pacemaker: there is an electromagnetic

eld in the vicinity of the switched-on device, which could

possibly impair the pacemaker. If in doubt, please contact

the manufacturer of the pacemaker or your doctor.

• Do not use syntetique or aluminum area: You could

merge on the cooking zone.

• Do not try to extinguish a re with water, but switch off

the appliance and cover the ame with a lid or a re blan-

ket.

SAFETY

Protection against further dangers

ATTENTION!

THE USE OF BAD POTS OR ADAPTER DISC

FOR INDUCTION LEADS TO AN ADVANTAGEOUS TERMINATION OF WARRANTY. THE

MANUFACTURER IS NOT LIABLE FOR ANY

DAMAGE CAUSED BY THE COOKING FIELD

OR ITS ENVIRONMENT.

Flow In Premium02/07/2018 9

Page 10

DEVICE DESCRIPTION

Technical description

1 DEVICE DESCRIPTION

2.1 Technical description

Type PHT874S

Total power 7100 W

Energy consumption of the

hob EChob **

Cooking zone front left

Cookware bottom diameter,

max.

Nominal power * 1400 W

Booster performance * 2000 W

Energy consumption ECcw ** 181 Wh/kg

Cooking zone in the back

left

Cookware bottom diameter,

max.

Nominal power * 1400 W

Booster performance * Energy consumption ECcw ** 177.3 Wh/kg

Cooking zone in the back

right

Cookware bottom diameter,

max.

Nominal power * 2300 W

Booster performance * 3000 W

Energy consumption ECcw ** 168.4 Wh/kg

Cooking zone front right

Cookware bottom diameter,

max.

Nominal power * 1400 W

Booster performance * Energy consumption ECcw ** 181.9 Wh/kg

* These powers may deviate, depending on the form, magnitude

and quality of the pot.

** Calculated according to the method to measure the performance characteristics (EN 60350-2) .

177.2 Wh/kg

Ø 175 mm

Ø 175 mm

Ø 215 mm

Ø 175 mm

Flow In Premium 02/07/201810

Page 11

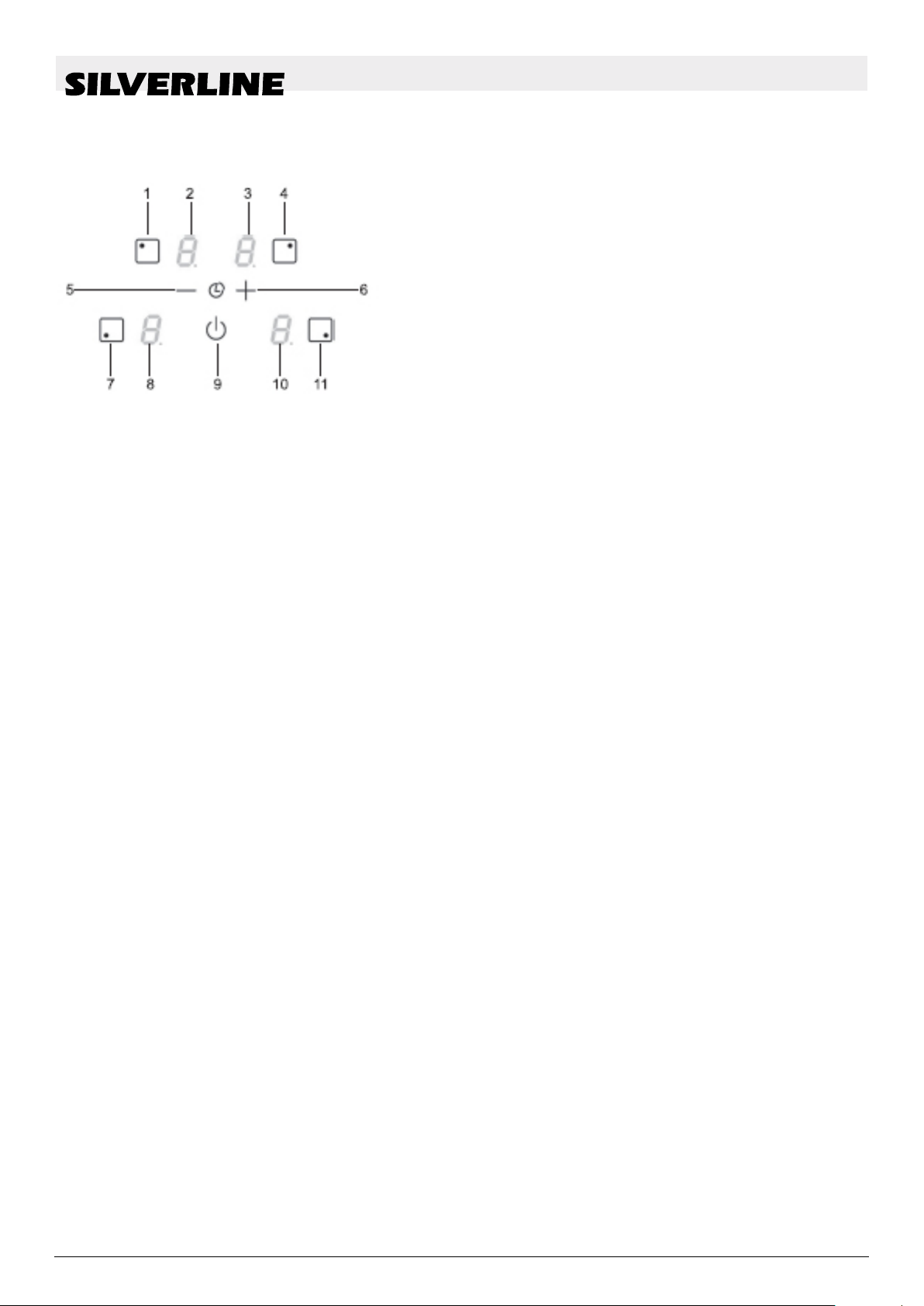

3 Control panel

Fig. 1

Control panel

1 Selection button

2 Timer and power indicator

3 Timer and power indicator

4 Selection button

5 [-]Timer button

6 [+]Timer button

7 Selection button

8 Power Meters

9 On / Off button

10 Cooking zone light

11 Selection button

Flow In Premium02/07/2018 11

Page 12

OPERATION OF THE COOKING FIELD

Ventilation

4 OPERATION OF THE COOKING FIELD

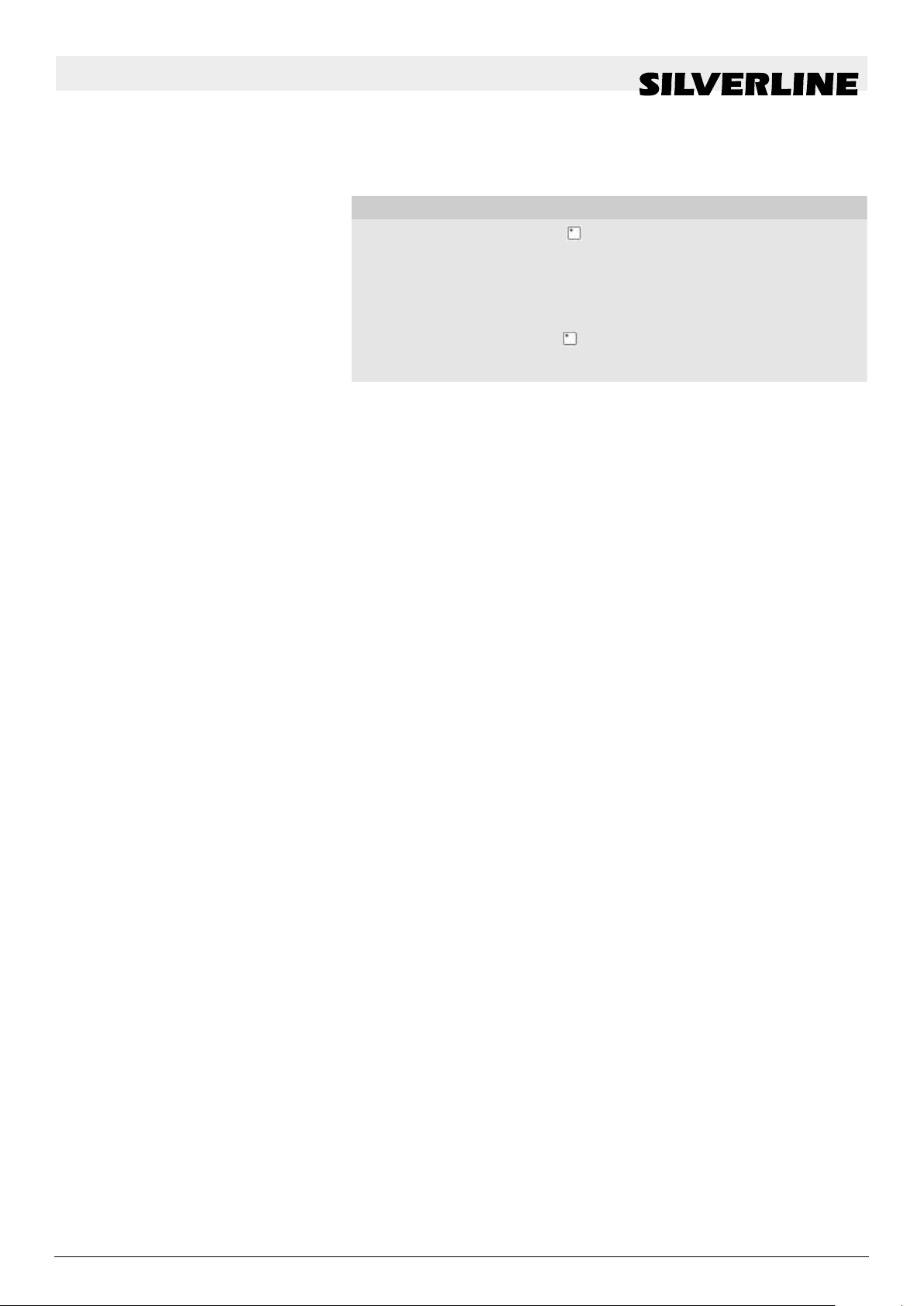

Display

Display Designation Function

0 Zero The cooking area is activated

1.....9 Performance levels Power adjustment

U Pot detection Pot is not put on or

E Error display Electronic error

H Residual heat Cooking area is hot

P Booster The booster power is

L Locking The recess is secured.

∏ Bridge 2 Cooking zones are bridged.

unsuitable

activated.

4.1 Ventilation

The fan works automatically. It starts at low speed as soon

as the values released by the electronics exceed a certain

threshold. The higher speed is set when the induction hob is

used intensively.

The fan reduces its speed and shuts off automatically as

soon as the electronics have cooled down sufciently.

Flow In Premium 02/07/201812

Page 13

COMMISSIONING THE COOKING FIELD

5 COMMISSIONING THE COOKING FIELD

5.1 Before the rst heating

First clean your device with a damp cloth, then dry it. Do not use

any detergent that could cause a bluish tint on the glazed surface.

5.2 Induction principle

Below each cooking zone is an induction coil. When the cooking

zone is turned on, this coil generates a magnetic eld. The magnetic eld induces eddy currents in the bottom of the pot, which must

be magnetic. This heats the bottom of the pot. The cooking zone

heats up only indirectly by the heat given off by the pot. The induction cooking zones only work with magnetic cookware:

• Suitable magnetic bottom induction cookware such as

e.g. Cast iron, steel, enameled steel, stainless steel with

magnetic base.

• Unsuitable induction cookware: Copper, aluminum,

glass, wood, earthenware, ceramics, non-magnetic stain-

less steel. The induction cooking zone is automatically

adjusted to the size of the cookware. The cookware must

not fall below a certain bottom diameter, otherwise the

induction does not switch on. Each pot bottom diameter

must have a minimum size, depending on the size of the

cooking zone. If induction cookware is not suitable, the

display will show [ U ].

Switch hob on and off

5.3 Function of the sensor switch panel

The stove is controlled via the sensor buttons. These react to slight

contact of the glass with the nger. If you touch the buttons for

about one second, the control commands will be executed. Each

reaction of the panels is acknowledged with an acoustic and / or

visual signal.

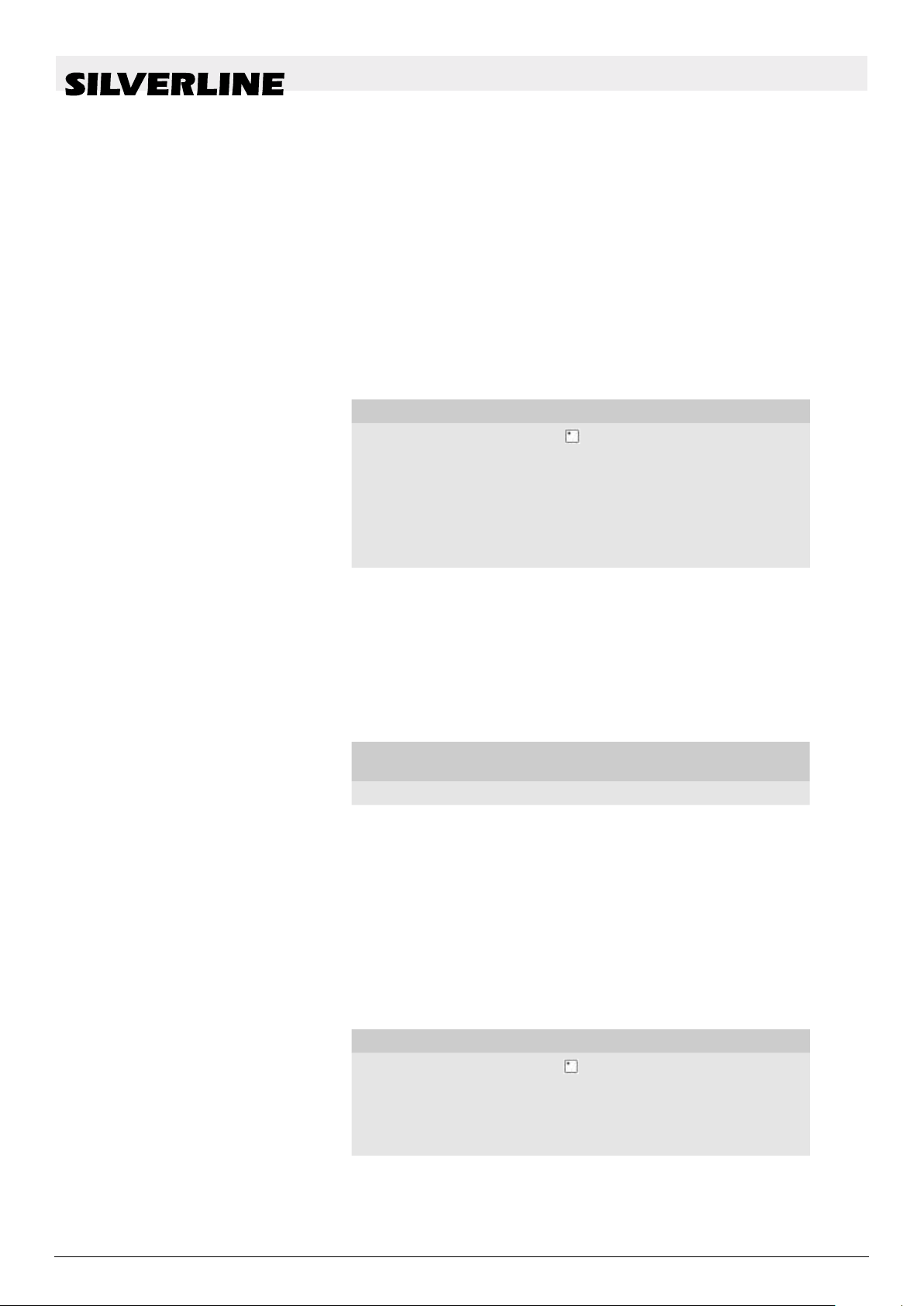

5.4 Switch hob turn on/ turn off

Hob : turn on/ turn off :

Activity Control panel Display

Turn on

Turn off

Cooking zone : turn on/ turn off :

Press [ ]

Press [ ]

4 x [ 0 ]

none or [ H ]

Flow In Premium02/07/2018 13

Page 14

COMMISSIONING THE COOKING FIELD

Residual heat warning indicator

Activity Control panel Display

Choices of the

cooking zone

Increase performance

Reduce power Press [-] [ 9 ] to [ 1 ]

Turn off

If no further input is made, the hob will switch off after approx.

20 seconds for safety reasons and the zeroes will go out.

5.5 Pot detection

Press [ ]

Press [+] [ 1 ] to [ 9 ]

Press [

or press [-]

] and [-] together

4 x [ 0 ]

[ 0 ] or [ H ]

The pot detection ensures perfect safety. The induction does

not work:

• If there is no cookware on the cooking zone or if a pot not suit-

able for induction is used. In diesem Fall kann die Leistungsstufe

nicht erhöht werden und das [ U ] Symbol erscheint in der Anzeige. The [U] disappears when a pot is put back on the cooking

zone.

• If the pot is removed from the cooking zone during cooking, the

cooking zone switches off immediately and the display shows

[U]. The [U] disappears when a pot is put back on the cooking

zone. The cooking zone continues with the previously set power

level.

After use, switch off the cooking zone so that the pan detection

[U] no longer appears.

5.6 Residual heat warning indicator

After switching off the cooking zones or the hob, the residual

heat of the still hot cooking zones is indicated by a [H]. The

[H] goes out when the cooking zones can be touched without

danger. As long as the residual heat indicator is lit, the cooking

zones should not be touched and no heat-sensitive objects

should be placed on it:

Burn hazard!

Flow In Premium 02/07/201814

Page 15

5.7 Power function

COMMISSIONING THE COOKING FIELD

Two cooking zones are equipped with a power function, i.e.

with a power boost. When switched on, these cooking zones

work at extra power for a period of 5 minutes at power level

[P]. The power function is designed to allow you, for example,

to heat large quantities of water quickly, such as boiling pasta

water.

Power: switch on / off:

Activity Control panel Display

Choices of the

cooking zone

Increase

performance

Turn on power Press [+] [P] for 5 min

Press [ ]

Press [+] [ 1 ] to [ 9 ]

4 x [ 0 ]

Timer

5.8 Timer

Turn off power Press [+] [ 9 ]

Automatic control of the power:

The hob is equipped with a high performance. In order not to

exceed this maximum power, the electronics automatically

reduce the cooking level of another cooking zone when the

power function is activated. This cooking zone will then ash

[9] and show the reduced power [7].

Selected cooking zone Other cooking zone (e.g.

Performance level 9)

[ P ] shines [9] is reduced to [7]

With the integrated timer, a cooking time of 1 to 99 minutes

can be set on all four cooking zones. Each cooking zone may

have a different setting.

Switching on or changing the duration:

Activity Control panel Display

Select the cooking

zone

Select power On [ + ] [ 1 ] … [ 9 ] [ P ]

Select timer Press [-] and [+] Timer [00] min

Flow In Premium02/07/2018 15

Press [ ]

[ 0 ]

Page 16

COMMISSIONING THE COOKING FIELD

Timer

Activity Control panel Display

Shorten the time Press [+] from [30] to

29,28,27 ...

Extend time Press [+] The time is ex-

tended

After a few seconds, the ashing stops.

Fourth and the time starts

The duration is

active

Switch off timer:

Activity Control panel Display

Select the

cooking zone

Press [

]

[ 0 ]

Select timer Press [-] and [+] Remaining time

Switch off the

On [ - ] [00] then «off»

timer

If several timers are in operation, you only need to repeat this

operation several times.

Automatic switch off:

When the programmed cooking time has elapsed, [00] will

ash and an acoustic signal will sound. To turn off the beep

and the ashing, just press any key.

Timer as egg timer:

Activity Control panel Display

Switch on the hob

Press ]drücken

Cooking zone

light

Select timer Press [-] and [+] [00] Minutes

Shorten the time Press [+] from [30] to

29,28,27 ...

Extend time Press [+] The time is ex-

tended

After a few seconds, the ashing of the timer lamp stops and the

cooking zone lights go out. When the programmed cooking time

has elapsed, [00] will ash and an audible signal will sound.

To turn off the beep and the ashing, just press any key.

Flow In Premium 02/07/201816

Page 17

5.9 Bridge function

COMMISSIONING THE COOKING FIELD

Locking of the hob

This function allows a bridging of the left cooking zones with the

same functionalities as a cooking zone. Booster function is not

allowed.

Activity Control panel Display

Switch on the hob

Turn bridge on On the 2 left cooking

Press

zones

Press key simultane-

ously

Cooking zone

light

[0] on the front

Cooking zones

and

[Π] on the rear

cooking zones.

5.10 Locking of the hob

Increase performance

Turn off bridge On the 2 left cooking

To avoid a change in the cooking zone setting,

e.g. when cleaning the glass, the operation buttons (except the [

] button) can be locked.

Activate locking:

Activity Control panel Display

Turn on the

trough

Lock the trough Press together

Switch off locking:

Press [+] [ 1 ] to [ 9 ]

zones

Press key simultane-

ously

Press [

[-] and [

front right

Press [

]

] at the

]

[0] or [H] on the 2

Cooking zones

4 x [0] or [H]

No change

4 x [ L ]

Activity Control panel Display

Turn on the

trough

In the 5 seconds after switching on the trough

Flow In Premium02/07/2018 17

Press [

]

[L] on all

display

Page 18

COMMISSIONING THE COOKING FIELD

Locking of the hob

Activity Control panel Display

Locking Together on [-] 4 x [0] or [H]

switch off

and [ ] in front

no indication

press right

Press [-]

Flow In Premium 02/07/201818

Page 19

6 COOKING RECOMMENDATIONS

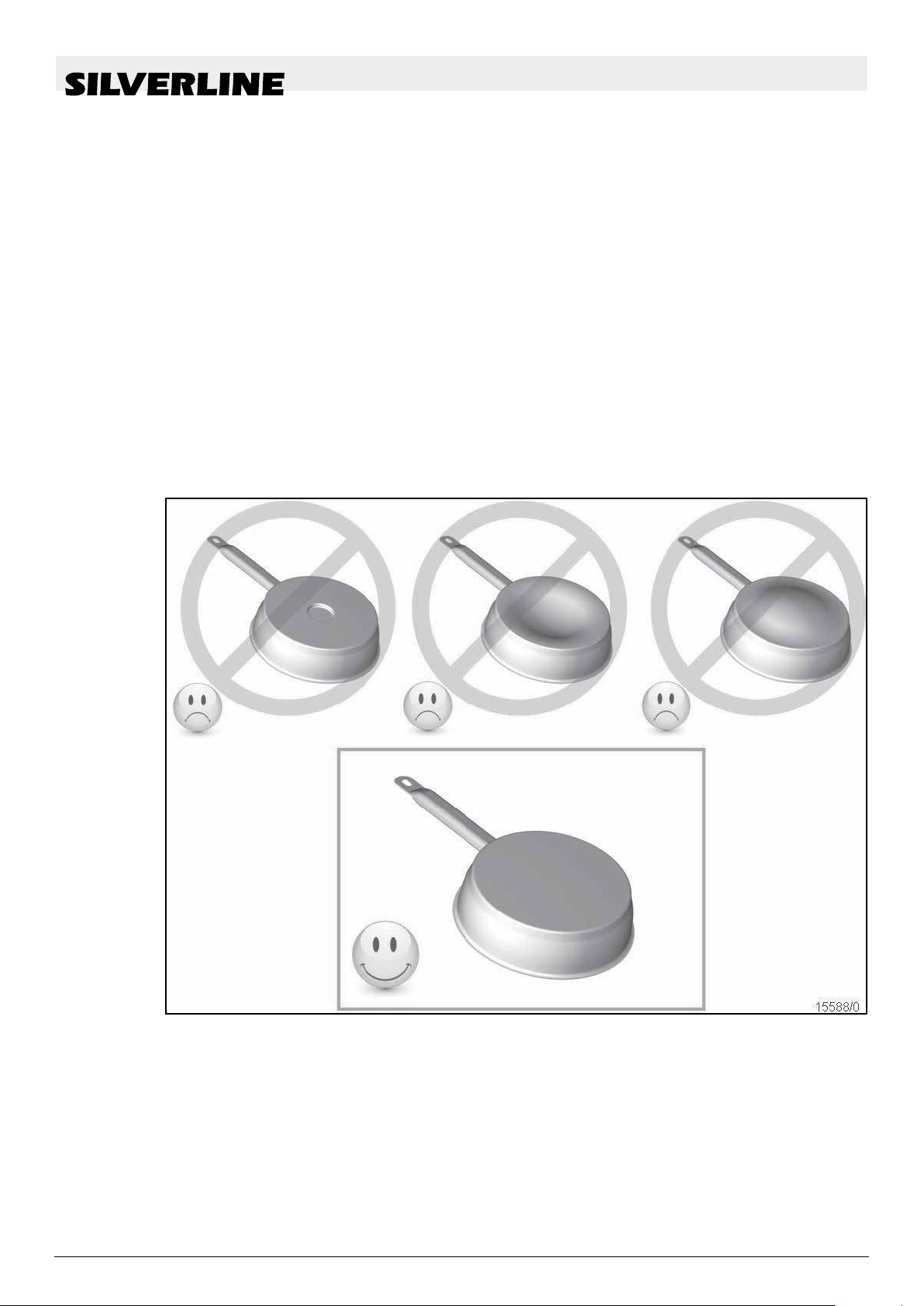

6.1 Cookware

Suitable materials: Steel, enamelled steel, cast iron, magnetic

steel stainless steel, aluminium with magnetic bottom. Unsuitable

materials: Aluminum and stainless steel without magnetic bottom,

copper, brass, glass, stoneware, porcelain The pot manufacturers

specify whether their products are induction-suitable. To check the

induction compatibility of the pots:

Fill the dishes with some water and place it on the induc-

tion cooking zone. Switch the cooking zone to power level

[9]. This water must be warm in a few seconds.

Hold a magnet to the bottom of the dish. If the magnet sticks,

the dishes are suitable.

Some pots may generate noise when placed on an induction

cooking zone. This noise in no case implies a fault of the device

and does not affect its functioning.

COOK RECOMMENDATIONS

Cookware

Flow In Premium02/07/2018 19

Page 20

COOK RECOMMENDATIONS

Setting ranges

6.2 Crockery size

6.3 Setting ranges

The cooking zones automatically adjust to the bottom of the pan

to a certain limit. The cookware must not fall below a certain

bottom diameter, otherwise the induction does not switch on.

Always center the pot in the center of the cooking zone for best

efciency.

(this informations are reference values)

1 to 2 Melting, dissolving, prepara-

tion

2 to 3 Sources, thawing, keeping

warm

3 to 4 Steaming, stewing Fish, vegetables,

4 to 5 Stewing, swelling, thawing Fish, vegetables,

6 to 7 Parboiling, simmering Meat, liver, eggs,

7 to 8 Gentle roast Fish, schnitzel,

9 Baking, cooking Steaks, omelette

P Cook Large quanti-

Sauces, butter,

chocolate gelatin

yoghurt,

Rice, Frozen

meal, sh,

vegetables

fruits

pasta, cereals,

legumes, frozen

foods

sausage goulash,

roulades

bratwurst, fried

eggs

pancakes, lentils

ties of water

Flow In Premium 02/07/201820

Page 21

7 CLEANING AND CARE

Let the device cool down, there could be a risk of burns.

Always clean the dirty hob regularly. Use a damp cloth and

To clean the device, it must be switched off.

Cleaning the device with a steam cleaner or

Never use abrasive or aggressive cleaning agents such as

Then rub the hob with a clean cloth.

Remove sugar, plastic or aluminium foil immediately

CLEANING AND CARE

a little detergent.

cleaner is not permitted for safety reasons

detergents. Grill and oven sprays, stain

ing sand or sponges with scratching

after switching off the cooking zones.

surfaces

high-pressure

.

or rust remover, scour-

Flow In Premium02/07/2018 21

Page 22

ENVIRONMENTAL PROTECTION

8 ENVIRONMENTAL PROTECTION

The packaging materials are environmentally friendly and

recyclable.

Electrical and electronic devices still contain valuable mate-

rials. But you also get harmful substances that are neces-

sary for their function and safety

Therefore never put your old appliance in the residual

waste.

Instead, use the collection center sat up by your municipal-

ity for returning and recycling old electrical and electronic

equipment.

Flow In Premium 02/07/201822

Page 23

9 WHAT TO DO IF…

WHAT TO DO IF…

[E4] appears in the display:

The hob must be recongured. Please follow the instructions

below:

I) Remove all pots from your hob

II) The hob must rst be disconnected from the power sup-

ply: remove the connection cable or switch off the fuse on

the control panel.

III) Turn the power back on.

IV) Process

Disconnect the connection cable or switch off the fuse on the

control panel. Take a pot with magnetic base (diameter > 16

cm). Start programming at the latest 2 minutes after switching on

again Do not press [

V) to delete the existing conguration

1) Press and hold the [-] button

2) With your other nger, press the [O] key (a -> b -> c -> d) one

after the other, counterclockwise. A double "beep" means that

an error has occurred. In this case, start from point 1 again.

3)

Release the button. Then press the [-] and [+] buttons

simultaneously until ashing [E] icons appear.

]

4) Expect the [E] to stay xed

5) [E] will automatically become [C] symbols. The deletion

process is done.

VI) Reconguration of the hob

1) Take a pot with magnetic bottom (diameter

> 16 cm)

2) Select a cooking zone operation when pressing the [O]. 3)

Place the pot on the appropriate cooking zone. 4) Wait until [C]

changes to [-]. The cooking zone is congured.

5) Repeat this process for each cooking zone.

6) The cooking zones are congured as soon as nothing is

displayed. Use the same pot to perform the entire conguration. During conguration, no additional pots should rest on

the trough. If the [E4] indicator remains, contact your service

representative.

Do not switch on the hob or the cooking zones:

The trough is incorrectly connected to the mains.

The backup of the house installation is not inserted correctly.

The hob is locked.

The sensor keys are covered with water or dirt.

A cookware covers the buttons.

The display shows [U]:

Flow In Premium02/07/2018 23

Page 24

WHAT TO DO IF…

The cookware is not on the cooking zone.

The cookware is not induction-suitable

The pot bottom diameter is too small for this cooking zone.

A cooking zone or the entire trough switches off:

The safety shutdown has triggered it.

This is activated if you forget to switch off a cooking zone.

This shutdown is activated when several keys are covered.

A pot is empty and overheated.

Due to overheating, the electronics have automatically re-

duced or even switched off the power automatically

The cooling fan continues after switching off:

This is not a fault, the fan runs until the unit has cooled down.

The fan switches off automatically.

The cooling fan continues after switching off:

This is not a fault, the fan runs until the unit has cooled down.

The fan switches off automatically.

The automatic warm-up does not switch on:

The cooking zone is still hot [H]

The highest power level is switched on [9]

The order display [L]:

See the chapter Locking the hob.

The order display [U]:

See the chapter on keeping warm.

The order advertisement [II]:

See the chapter Pause function.

Display [Π]:

• See the chapter Bridge function in the chapter.

The display will show [ ] or [Er03]:

An object or a liquid covers the keys. The display

as soon as the keys are released or

The display will show [E2] or [E H]:

The hob is overheated, let it cool down rst, and then turn it

back on

The display shows [E3]:

The pot does not t, change the pot.

cleaned.

disappears

The display shows [E6]:

Faulty electrical network. Check the frequency and voltage of

the electrical network.

Flow In Premium 02/07/201824

Page 25

WHAT TO DO IF…

The display will show [E8]:

The air inlet of the fan is clogged, free it.

The display will show [E C]:

• Error in the conguration. Initialize the hob again, see chap-

ter "The [E 4] appears."

If any of the above signs persist, call for service.

Flow In Premium02/07/2018 25

Page 26

INSTALLATION INSTRUCTIONS

10 INSTALLATION INSTRUCTIONS

Assembly and connection may only be carried out by an authorized specialist. The user must ensure that the standards in force

at his place of residence are observed.

After removing the protective foil (3), stick the seal (2) with a

distance of 2 mm from the outside of the glass.

Installation:

Type Mounting dimensions

PHT874S 750 x 490 mm

The distance from the cutout to a wall and / or a piece

of furniture must be at least 50 mm.

This appliance is of type Y for protection against re hazards.

Only appliances of this type may be installed on one side

tall cabinets or walls,

The worktop should be nished with heat-resistant adhesive

(100°C).

The wall end strips must be heat resistant

The hob must not be installed above stoves without fans,

dishwashers, washing or drying equipment.

In order to achieve sufcient ventilation of the electronics in the

hob, an air space of 20 mm is necessary under the trough.

If there is a drawer under the hob, do not store ammable objects,

e.g. spray cans in the drawer.

It must be ensured that the connection cable of the hob is

not exposed to mechanical stress, e.g. through drawers,

after installation.

The cut surfaces should be sealed with special varnish,

silicone rubber or cast resin to prevent swelling due to mois-

ture. Be sure to stick the supplied sealing tape carefully.

ATTENTION:use only protective grids offered by the man-

ufacturer or approved by him for use with the hob.

but the other side must be unobstructed.

of

Flow In Premium 02/07/201826

Page 27

11 ELECTRICAL CONNECTION

To connect the device to the electrical network, hire an

electrician who knows the local regulations

trical supply companies

The contact protection of operationally isolated parts must be

ensured after installation.

You will nd on the nameplate whether the required connec-

tion data correspond to those of the network

The device must be able to be disconnected by isolators

poles of the mains. When switched off, there must be a

tact gap of 3 mm. LS-switches, fuses, RCD's and contactors are considered as suitable separation devices

The installation must be protected by fuses. Electrical cables

must be perfectly covered by installation.

If the device is not equipped with an accessible plug, other

separation options must be considered for xed installation

in accordance with the installation instructions.

The supply cable must be installed so that the hot parts of the

hob are not touched.

Attention !

This device is only designed for a power supply of 230 V ~ 50/60

Hz. Always connect the earth together. Note the connection

diagram. The connection box is located on the underside of the

device. To open the case, use a screwdriver and slide it into the

slots provided.

ELECTRICAL CONNECTION

of the local elec-

and carefully observes them.

all

con-

Network Connection Diameter Electric

wire

230V~

50/60Hz

400V~

50/60Hz

(*) according to EN 60 335-2-6 standard

Connection of the hob:

For the various connection options, use the brass bridge terminals

located in the housing.

Monophases 230V ~ 1P + N

1 Phase

+ N

2 Phasen

+ N

3 x 2.5

mm²

4 x 1.5

mm²

H 05

VV - F

H 05

RR - F

H 05

VV - F

H 05

RR - F

Fuse

25 A *

16 A *

Flow In Premium02/07/2018 27

Page 28

POWER CONNECTION

Bring a pole bridge between terminals 1 and 2. Attach the ground

to the earth terminal, neutral to terminal 4, phase L to terminal 1

or 2.

Biphases 400V ~ 2P + N

Attach the ground to the earth terminal, neutral to terminal 4,

phase L1 to terminal 1, and phase L2 to terminal 2.

Attention ! Unscrew the screws from the housing more than

necessary. Then insert the wires correctly and tighten the

screws

Flow In Premium 02/07/201828

Page 29

12 Device description

12.1 The device

Device description

Operating unit

Fig. 2: Description of the range hood

1 Cooking eld suction

2 Induction cooking eld

3 Engine box

4 Circulation fan box (special accessories)

12.2 Controlunit

Fig. 3:Touch control LED Electronics

1 Unlocking

2 Reduce fan level

3 LED display

4 Increase fan level

5 Delayed automatic shutoff

Flow In Premium02/07/2018 29

Page 30

Device description

Purchased parts package

12.3 Purchased parts package

Control electronics housing

1 Elektronics box

Extractor hood body

1 Glass cover

2 Stainless steel cover

3 Exhaust air tting

4 Cooking eld suction

Engine box

1 Glass cover

2 Stainless steel cover

3 Exhaust air tting

4 Cooking eld suction

Flow In Premium 02/07/201830

Page 31

Device description

Purchased parts package

Fig. 4: Purchased parts package

1 Cooking eld suction

2 Exhaust air tting

3 Elektronics box

4 Engine

5 Screws

6 Screws

7 Screws

8 Operating Guide

Flow In Premium02/07/2018 31

Page 32

For your safety

Symbols in these instructions

13 For your safety

13.1 Symbols in this manual

Safety instructions

Safety instructions are labelled with symbols in this manual. The safety instructions are introduced by signal words that express the extent

of the hazard.

DANGER!

This combination of symbol and signal word indicates an immediately dangerous situation which

will lead to death or serious injuries if not avoided.

WARNING!

This combination of symbol and signal word indicates a possibly dangerous situation which may

lead to death or serious injuries if not avoided.

ATTENTION

This combination of symbol and signal word indicates a possibly dangerous situation which may

lead to minor or light injuries if not avoided.

PLEASE NOTE!

This combination of symbol and signal word

indicates a possibly dangerous situation which

may lead to material damage

if not avoided.

Tips and recommendations

Special safety instructions

This symbol highlights useful tips and recommen-

dations as well as information for efcient and

trouble-free operation.

To draw attention to special dangers, the following symbols are used

in safety instructions:

Flow In Premium 02/07/201832

Page 33

Safety instructions

within handling instructions

For your safety

Symbols in these instructions

Warning signs Type of danger or hazard

Warning of dangerous electrical voltage.

Warning of ammable substances.

Warning of a danger zone

Safety instructions may in particular refer to certain handling instructions. Such safety instructions are embedded in the handling instructions, so that they do not interrupt the reading uency while performing the action. The above-described signal words will be used.

Further labelling

Beispiel:

Loosen the screw.

ATTENTION

Risk of jamming on the lid!

Close the lid carefully.

Tighten the screw.

The following signs and highlighting are used for identifying handling

instructions, result descriptions, bullet lists, references, and other

elements in these operating instructions:

Labelling Explanation

Step-by-step handling instructions

ð

Results of handling instructions

Reference to sections of this manual

and other relevant documents

Bullet lists without a determined order

Flow In Premium02/07/2018 33

Page 34

For your safety

Fire hazard!

13.2 Intended use

The extractor hood is intended for suctioning of any vapour and

steam caused by cooking or frying or preparing otherwise food on

an electric or gas range in private households. The device is not

intended for any commercial usage or any outdoor usage.

Any differing usage is deemed deviating from the intended purpose

and therefore prohibited. We accept no liability for any damages

incurred by any usage that deviates from the intended purpose.

Specically, the following shall be prohibited:

The use outdoors or in the industrial area

The autonomous remodeling or repair of the device n The oper-

ation without metal grease lter

Flambéing

Exhaust air fan operation without window ip switch while simul-

taneously using any replace, furnace, or oven operated with

ambient air

Usage for room air conditioning / ventilation, such as in continu-

ous operation, instead of a fan or adequate ventilation

13.3 Children and persons with limited perception

This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory, or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction by a person responsible

for their safety concerning the use of the appliance in a safe way

and understand the hazards involved.

Children should not play with the appliance.

Do not allow children to play the with packaging materials. Dan-

ger of suffocation.

Cleaning and user maintenance may not be performed by chil-

dren, unless they are older than 8 years and supervised by a

person responsible for their safety.

Keep the appliance and the power cable out of reach of children

that are 8 years or younger.

Keep children away from the device’s lamps until these have

cooled down. Danger of burning and serious injuries.

13.4 Fire/Fire hazard

Do not ambé any food beneath the device.

Deep frying of any food requires your constant monitoring.

Clean the device surface regularly, to remove any fat residues.

Flow In Premium 02/07/201834

Page 35

For your safety

Clean the metal grease lter at least every other week to pre-

vent the built-up of fat residues on the metal grease lter. These

residues may catch re or ignites spontaneously. Replace the

metal grease lter regularly and/or if needed.

To avoid generating excessive heat, do never operate any cook-

ing zone without a pot or pan or other cookware on it.

Never use open re near the devise.

Never leave hot oil or fat unattended. Do never use water when

trying to extinguish any re caused by oil or fat.

13.5 Room-air-dependent replace (only with exhaust air operation)

If the device is operated in the exhaust air mode and the room

air-dependent replaces are used (eg gas, oil, wood or coal red

heaters, instantaneous water heaters, domestic water heaters or

stoves with replaces), the appliance will deprive the kitchen and

adjacent rooms of room air (Fig. 5). This may cause toxic combus-

tion gases from the chimney or the exhaust air shaft to ow back

into the living areas inside the apartment. Danger of suffocation.

Power Supply

Fig. 5: Fireplace, furnace, or oven

operated with ambient air

Fig. 6: Using a window ip switch

13.6 Power supply

Therefore, you must in particular make sure of:

Use a window toggle switch to allow fresh air to ow in(-

Fig.6).

A fresh air/ exhaust air wall sleeve does not provide sufcient

air supply. Please consult your competent chimney sweeper

who will evaluate the air supply and consumption in your

apartment.

The underpressure inside the room where the replace, fur-

nace, or oven is located must not be less than 4 Pa.

When using the device in the circulation fan operation modus, you

do not need pay any particular attention to the air supply and consumption in your apartment.

The device is powered by electricity; therefore, the danger of an

electric shock persists. Pay particular attention to the following:

If an additional socket is required to connect the device, you

need to engage a professional electrician to perform the re-

spective installation.

You will never touch the plug with wet hands.

You will pay special attention to prevent the bending or jam-

ming of the power cable.

Flow In Premium02/07/2018 35

Page 36

For your safety

Cleaning

13.7 Transport

13.8 Defect

You will pull the mains plug out of the socket in order to discon-

nect the device.

You will only operate the device, if the voltage value stated

on the nameplate coincides with the voltage available at your

socket. The inappropriate voltage may severely damage the

appliance. If you have any questions, please consult a profes-

sional electrician.

While transporting the device in your car, make sure that is

properly secured to protect all passengers from harm or injury.

Use the original packaging, when transporting the device.

Store the packaging for this purpose.

If the device is faulty or damaged, do not attempt to repair it yourself.

Any faulty or damaged power cable or plug must be replaced

to prevent any risk of electric shock. Call the customer service

department ( Ä „CustomerService Hotline (for Germany, Aus-

tria, Switzerland, France, Belgium, Netherlands and Luxem-

bourg)” on page 3).

In order to prevent the danger of electric shock, do never turn

a faulty or damaged device on. Ziehen Sie den Netzstecker

oder schalten Sie die Sicherung im Sicherungskasten aus. Call

the customer service department ( Ä „CustoService Hotline

(for Germany, Austria, Switzerland, France, Belgium, Nether-

lands and Luxembourg)” on page 3).

Always replace defect lamps to prevent overloading the re-

maining lamps.

13.9 Cleaning

Do not you any aggressive or abrasive cleaning agents, since

those may damage the device surface.

Do not you any sharp or pointed object, since those may

scratch the device surface.

Do not use a high pressure or steam cleaner, since the pene-

trating humidity may cause an electric shock.

Observe the cleaning intervals for metal grease lters indicated

in this operating manual. Otherwise, the risk of re hazard will

occur.

Flow In Premium 02/07/201836

Page 37

14 Operation

14.1 Ensuring safe control and operation

WARNING!

Risk of injury due to improper operation!

Improper operation will cause the danger of

serious injuries and property damage.

– Check the device before every use. A faulty or

damaged device must not be used.

– Do not place any objects on the device, since

they may fall down.

– Do never operate the device without the

metal grease lter. Risk of re hazard.

– Switch the device always on, to prevent corro-

sion damages caused by condensation.

Operation

Turning on/off the fan > concerning the control unit

14.2 Switch fan on / off

14.2.1 About the control unit

Switching on the fan

Fig. 7: Fan On/Off

You may turn the fan on/off using the control unit or the remote

control.

Turn the fan on when you start cooking and wait

10-15 after you nished, before turning off the

device.

This will ensure the best possible removal of cooking

vapours.

1.

2.

When the device is not in operation, the digital display is

in standby mode and appears as a dot. As soon as any button is

pressed, a ashing “L” (i.e. lock) appears 3x on the digital display.

After that, press and hold down the timer button until

“0'” appears on the digital display (Fig. 7/1).

The fan has been unlocked

3. After unlocking the fan, you can use the + and - but-

tons to set the speed of the fan (Fig.7 / 2,4).

Now setting up the fan operation speed is completed.

Flow In Premium02/07/2018 37

Page 38

Operation

Turning the delayed shut-off automatic on/off

14.3 Change the power level of the fan

You may change the fan power level and set up the desired

level by using the control unit or the remote control.

14.3.1 About the control unit

Fig. 8: Multi-level switch for the fan

2. Increase the fan speed by pressing the

button ‚+‘ (Fig.8/4).

Fan level has been increased.

ð

3. Reduce the fan speed by pressing the

button

‚-‘(Fig.8/2).

Fan level has been reduced.

If for 10 minutes, no button has been pressed, the

device will switch into the standby mode and get

locked.

To turn off the fan, press the button until “0” appears on the digital display.

14.4 Turning the delayed shut-off automatic on/off

If while the device is running on any level, the button is pressed,

the 15 minutes timer will be activated. As soon as the timer starts

counting down, the speed value on the digital display will start

ashing. After 15 minutes, all functions that were activated prior to

the timer, will shut down.

Turning the delayed shut-off automatic on

1.

Press the Timer button Fig. 9/5).

Delayed shut-off automatic has been activated.The engine

will automatically shut down after 15

When the delayed shut-off automatic

has been activated, the speed value on

the digital display will start ashing.

minutes.

Fig. 9: Turning the delayed shut-off automatic on/off

Turning the delayed shut-off automatic off

2. Press the sensor button again (Fig.9/5).

Delayed shut-off automatic has been deactivated.

Flow In Premium 02/07/201838

Page 39

14.5 To clear the fat lter saturation indicator

When the digital screen is displayed, the metal grease lter must be cleaned(Fig.10). To delete the metal grease lter

cleaning prompt, proceed as follows:

To delete the fat lter saturation indicator (Fig. 10/2)

press and hold the '-' key while the trigger is off but in the

ejected state until 'E' appears on the screen.

Now the metal grease lter cleaning prompt has been

deleted.

Fig. 10: Deleting the metal grease lter cleaning prompt warning

Operation

To clear the fat lter saturation indicator

Flow In Premium02/07/2018 39

Page 40

Maintenance, cleaning, and care

Maintenance > maintenance intervals

15 Care, Cleaning and maintenance

15.1 Care

Electrical voltage

DANGER!

Danger to life due to high voltage!

There is an immediate risk of fatal injury in

case of contact with live parts of the device.

– Pull out the mains plug from the socket or

switch off the fuse inside the fuse box, before initiating any maintenance or cleaning

work.

Maintenance intervals

PLEASE NOTE!

The device performance will be negatively im-

pacted by any non-compliance with the maintenance intervals!

In case of overlong use, the metal grease lter as

well as the activated carbon lter will be clogged

with fat and dirt particles, which will negatively

impact the device performance.

– Please observe all maintenance intervals

specied in this manual.

15.1.1 Maintenance intervals

Interval Maintenance task

after assembling and in case of heavy contamination

after cleaning the extractor hood Servicing the device.

every other week or when the grease lter prompt

appears

Outside cleaning of the device.

Cleaning the metal grease lter.

every 3 month or in case of decreasing performance

Cleaning or replacing the activated carbon lter (for circulation fan operation only).

Flow In Premium 02/07/201840

Page 41

15.1.2 Device dimensions

Remove the metal grease lter

Maintenance, cleaning, and care

Maintenance > Cleaning the metal grease lter

WARNING!

Fire hazard due to grease and fat residues

inside the metal grease lter!

There is a risk of re due to fatty deposits in

the metal grease lter!

– Clean the metal grease lter as soon as the

instruction for cleaning the lter appears or at

least every 2 weeks.

– Never operate the extractor without the metal

grease lter.

The metal grease lter retains solid components from vapors in

the kitchen (such as oil or dust) and greatly reduces fume hood

contamination.

Fig. 11: Removing the metal cover

1 Cover

2 Extractor hood box

Fig. 12: Removal of metal grease lters

1 Cleaning the metal grease lter

1.

Remove the metal cover on the air inlet duct of

your hood box (Fig.11).

2. Remove the metal grease lter by moving it in the direction

of the arrow. Make sure the metal grease lter does not fall

off.

3.

it

(Fig. 12).

4. Rinse the metal lter by hand or in the dish-

Lay the metal grease lter forward and remove

washer.

Flow In Premium02/07/2018 41

Page 42

Maintenance, cleaning, and care

Maintenance > Cleaning the metal grease lter

Manual Cleaning

5.

PLEASE NOTE!

Damage due to incorrect cleaning or due to the

use of unsuitable cleaning agents!

Cleaning in the dishwasher

After cleaning

Inserting the metal grease lter

Let the metal grease lter soak in warm soap water and clean it using

a soft brush.

6. 6. Rinse with water the metal grease lter with warm water.

7.

8.

9.

10.

11. Clearing the warning for cleaning the metal

12. Close the metal grease lter lid of the extractor

Place the metal grease lter loosely and

vertically without adding other tableware into the

dishwasher.

Start any program with a temperature of no higher than

55°C.

Due to the cleaning in the dishwasher, the

lter parts may experience slight changes in

their colour.

This does not affect function or perfor-

mance to the metal grease lter.

Put the metal grease lter on a on an absor-

bent pad

Move the metal grease lter in the direction

of the arrow and insert it into the air extraction

ductFig.13).

grease lter

hood

(Fig.13).

Fig. 13: Inserting the metal grease lter

Flow In Premium 02/07/201842

Page 43

Maintenance, cleaning, and care

Maintenance> Clean or replace activated carbon lter (only recirculation mode)

Cleaning the drip tray

13.

Fig. 14

1 Extractor hood box

2 Equipment slot

To keep water and food waste, the hat box has a slot inside

(Fig. 14/2).

How to clean the inner box;

Pull up inside the device slot (Fig. 14).

The hood box can be cleaned in the dishwasher.

After cleaning, insert the inner box again.

15.1.3 Clean or replace activated carbon lter (recirculation only)

1. Take out the activated carbon lter (Fig. 15/2) in

the direction of the arrow towards the front.

magnets) ( Fig. 15).

(is held with

Fig. 15

1 Activated carbon lter housing

2 Activated carbon lter with frame

Fig. 16

2.

Unscrew the connecting screw (Fig. 16/1) (Fig.16).

ATTENTION!

Place the case on a rm surface, then push

the lter down slightly to remove it.

Flow In Premium02/07/2018 43

Page 44

Maintenance, cleaning, and care

Cleaning and maintenance > Cleaning agents/devices

1 Connecting screw

2 Activated carbon lter

Fig. 17

Inserting the activated carbon lter

3.

4.

5.

Remove the activated carbon lter from the lter

frame as shown on (Fig. 17)

Allow the activated carbon lter to regenerate for one

hour inside the baking oven at about 200°C. After cooling

down, re-insert the lter into the hood.

This procedure may be repeated not more than 10 times,

after that lter must be replaced by a new one.

Re-insert the activated carbon lter by performing the

previous steps in reverse order.

.

15.2 Cleaningand care

15. 2 .1 Cleaningsupplies/utensils

PLEASE NOTE!

Property damage due to unsuitable cleaning proce-

dures!

Unsuitable cleaning procedures may result in

property damages.

– Always use the cleaning agents/devices

specied in this operating manual only.

– Do not use a high pressure or steam cleaner.

– Never use aggressive and abrasive cleaning

agents or sharp and pointed objects.

– Before you start cleaning, take off any jewel-

lery, to prevent scratching the surfaces.

For the different surface type, please use the in following specied cleaning agents/devices:

Flow In Premium 02/07/201844

Page 45

Maintenance, cleaning, and care

Cleaning and care > Servicing the device

Surface Cleaning agent Cleaning implement

Stainless steel

Glass

lacquered surfaces

Stainless steel detergent soft cloth

Soft sponge

glass cleaning product

warm soap water

warm soap water soft cloth

soft cloth

Soft sponge

15.2.2 Clean the device from the outside

6. Apply the respective cleaning agent (stainless steel or

glass) with a soft cloth.

7.

8. Maintain the device.

Wipe the device thoroughly dry using a soft cloth.

15.2.3 Maintaining the device

To prevent the fast re-soling of the stainless steel parts, the

treatment with a stainless steel care spray is necessary.

9.

10.

Apply with a soft cloth the stainless steel care spray in

a very thin layer on the stainless steel parts of the device.

Lacquered surfaces do not require any additional care

(do never apply any stainless steel care spray on such

surfaces)

Flow In Premium02/07/2018 45

Page 46

Error messages

Error table

16 Error messages

16.1 How to behave in case of errors

The following rule always applies:

Always perform the repair steps specied in this operating

manual only.

Für weitere Reparaturen kontaktieren Sie den Kunden-

dienst

Ä „Customer Service Hotline (for Germany,

Austria,

Luxembourg)”

WARNING!

Danger of injuries due to using a defective

device!

A defective device may cause serious injuries.

– Do never use a defective device.

– Pull out the mains plug from the socket

or switch off the fuse inside the fuse box,

before searching for possible errors.

Switzerland, France, Belgium, Netherlands and

on page 3.

Inappropriately performed repairs will void

the manufacturer's warranty.

16.2 Error table

In all technical devices, errors might occur. These represent not always

necessarily a defect of the device.

Therefore, you should consult the following table and check whether you

can x the error yourself.

Error description Cause Solution/remedy

Device does not function No connection to the

Loss of performance

efciency / increased

operating noise

mains power supply

Defective fuse Check the fuse inside your fuse box.

Power failure Check the function of other electric equipment.

Dirtied metal grease lters Clean the metal grease lters

Dirtied activated carbon lter

pad (for circulation fan only)

Connect the device to the mains power supply.

Clean the activated carbon lter pad or replace it

with a new one.

Exhaust air duct

cross-section too small;

(less than Ø 150 mm)

Flow In Premium 02/07/201846

Ask a professional technician to check the exhaust

air duct cross-section size.

Page 47

Error messages

If you cannot solve the issue using the present

table, call the customer service department

( Ä „Customer Service Hotline (for Germany,

Austria,Switzerland, France, Belgium,Netherlands

and Luxembourg)” on page 3).

Error table

Flow In Premium02/07/2018 47

Page 48

Accessories and spare parts

Accessories > Accessories circulation/exhaust air fan control

17 Accessories and spare parts

17.1 Ordering accessories and spare parts

WARNING!

Danger of injury through the use of unsuitable

accessories or spare parts!

Using unsuitable or faulty accessories or spare

parts may compromise your safety and cause you

damage, malfunctions or complete failure of the

device.

– Only use original SILVERLINE spare parts or

accessories approved by SILVERLINE.

–

In case of any uncertainties, always

call the customer service department

„Customer service -Hotline (forGermany,

Austria,Switzerland, France, Belgium, Netherlands and Luxembourg)”

on page 3.

Ä

For more information, please visit www.

silverline24.de.

Purchase any spare parts or accessories either through your

retail dealer or the service department

Hotline (for

erlands and Luxembourg)” on page.

Germany, Austria,Switzerland, France, Belgium, Neth-

The use of not authorised spare parts and

accessories authorised will void the warranty

granted by the manufacturer.

17.2 Accessories

17.2.1 Accessories circulating air exhaust circuit

Ä „Customer Service

Flow In Premium 02/07/201848

Page 49

17.2.2 Accessories exhaust air fan operation

Window ip switch with cable

Fig. 18 Item no.: FKS cable

Accessories and spare parts

Accessories > accessories exhaust air fan operation

Fig. 18: Window ip switch with

cable

Radio-operated window ip switch

Fig. 19: Radio-operated window ip switch

Fig. 19 Item no.: FFKSL

Flow In Premium02/07/2018 49

Page 50

Accessories and spare parts

Accessories > accessories circulation fan operation

Fig. 20: Exhaust gas temperature

sensor device with ATW CABLE

Fig. 20

Fig. 21 Item no.: ATW RADIO

Item no.: ATW CABLE

Fig. 21: Exhaust gas temperature sensor device with ATW-RADIO

17.2.3 Accessories recirculating air operation

Activated carbon lter

Fig. 22 U-START 811, Item no.:

Fig. 22: Activated carbon lter

Flow In Premium 02/07/201850

YM974.3413.01

.

Page 51

Activated carbon lter

Accessories and spare parts

Extractor hood accessories

Fig. 23

17.2.4 Cleaning/care products

Stainless steel care spray

Fig. 24: Stainless steel care spray

Fig. 23

Fig. 24

AF 811, Item no.:

YM974.3413.02

PS 500, Item no.: YT950.0000.05

17.3 Extractor hood accessories

High quality metal grease lters

Fig. 25: High quality metal grease lters

Fig. 25

Ask your specialised kitchen equipment

retailer for a metal grease lter tting for you

extractor hood. Alternatively, you may nd

the required information on our website www.

silverline24.de.

Item no.: YT142.3413.01

Flow In Premium02/07/2018 51

Page 52

Disassembly and disposal

Disassembly > dismantling the device

18 Disassembly and disposal

18.1 Dismantling

18.1.1 Safety during disassembly

High self weight

ATTENTION

Risk of injury caused by device falling down!

The heavy device weight may cause the risk of

injuries.

– Always ask a another person to secure the

device, while assembling or disassembling it.

18.1.2 Disassembling the device

1. Move the activated carbon lter (Fig. 26/2) towards

Fig. 26

1 Activated carbon lter housing

2 Activated carbon lter

ATTENTION

Disconnect the device from the mains

power supply.

the direction of the error (Abb.26).

Flow In Premium 02/07/201852

Page 53

Fig. 27

1 Activated carbon lter housing

2 Connecting screw

Disassembly and disposal

Disassembly > Dismantling the device

2. Unscrew the connecting screw(Fig.27/1) and re-

move the activated carbon lter housing (Fig.27).

4. Loosen the screws A, B, C, D, E, F of the air extraction

connection on the motor(Fig. 28).

5.

Disconnect the power connection of the device and

remove the motor.

Fig. 28

Fig. 29

1 Mounting screws of the device

2 Equipment

Fig. 30

1 Assembly screws

2 Hood use

3 Mounting screws

7. Loosen the mounting screws(Fig. 29 /1).

9.

Turn the clamping screws and remove the cap insert

(Fig. 30).

10. Remove the connecting piece on the hood insert (Fig.

30).

Flow In Premium02/07/2018 53

Page 54

Disassembly and disposal

Disposal

18.2 Disposal

Packaging

Fig. 31: Recycling

Extractor hood

Fig. 32: Electrical scrap

The symbol in Fig. 31 refers to the environment-friendly, re-usable

materials of the packaging. Dispose such material in the disposal

container expressively specied for this purpose only.

Device marked with the symbol in Fig. 32 must not be disposed

into the regular household waste, but delivered to the indicated

recycling centres for electric and electronic devices.

ENVIRONMENT!

Danger to the environment resulting from

wrongful disposal!

The wrongful disposal can cause hazards for the

environment.

– The disposal of electrical scrap and electron-

ic components must always be carried out by

properly authorised specialist companies.

– If in doubt, contact your local administration

or a local specialist company for disposal and

recycling for more information.

Activated carbon lter pad (for circulation

fan operation only) The discarded activated carbon lter pads may

be disposed into the household waste.

Activated carbon lter honeycomb lter

(for circulation fan operation only) Discarded honeycomb lter may

be disposed into the household waste.

Flow In Premium 02/07/201854

Page 55

Technical specications

19 Technical specications

Versions FLIK 854 ES

Order numbers FLIK 854 ES

Design type Cooking eld air duct

Operating mode Exhaust air fan or circulation fan operation

Dimensions (W x D) [mm] 780 x 520

Weight [kg] 20 / 25

Power supply connection 220–240 V~/50 Hz

Engine power output [W] 155 W

Overall performance [W] 155 W

Connection exhaust air duct

Exhaust air discharge power Min./Max. Normal operation 386/473 m3/h

Noise impact [dB(A) with power level 2] Min./Max. Normal operation 67/66 dB(A)

Ø

*Pursuant to EU regulation 65/2014 – EN61591, EN60704-2-13,

*Pursuant to EU regulation 65/2014 – EN61591, EN60704-2-13,

150 mm

EN50554.

EN50554.

Cleaning the metal grease lter dishwasher-proof

Number of activated carbon lter (circu-

lation fan operation)

Protection class 1

Subject to technical changes!

1

Flow In Premium02/07/2018 55

Page 56

Type plate

20 Nameplate

The type plate is located behind the metal grease lter

inside the hood body and contains the above listed information:

Fig. 33: Type plate (Example)

1 Model name

2 Item number

3 Manufacturer

4 Revision number

5 Serial number

6 Customer service

7 Technical specications

Flow In Premium 02/07/201856

Page 57

21 Warranty

Warranty

In Germany, Austria, Switzerland, France, Belgium, Netherlands

and Luxembourg

In accordance with the following provisions, we guarantee the end

customer that the device delivered to the end customer will be free

of material or processing defects within a period of 2 years from

delivery (guarantee period).

Warranty claims can only be made within a period of max. 2 years

from date of delivery.

Within this warranty period, we will, at our discretion, repair or replace

the device, free of charge, any defects resulting from material or

manufacturing defects. Other claims of the end customer against us,

in particular for damages, are excluded. The contractual or legal rights

of the customer to the respective seller are not affected by this guarantee.

This guarantee is only valid if

the device does not show any signs of damage or signs of wear

caused by a use which deviates from the normal requirements

and specications of the manufacturer (according to the user

manual),

the value or serviceability of the device is not only negligibly

affected by the defect,

the device is subject to visible external damage before assembly,

the device does not have any features that indicate repairs or

other intervention by workshops

er,

the product has no defects and consequential damage caused

by incorrect or insufciently

by the incorrect or insufciently dimensioned exhaust air duct,

the fabrication number has not been removed or made

illegible,

the device or accessories are freely accessible.

The warranty does not cover wear parts, lters used, easily breakable

parts such. As glass or plastic or incandescent bulbs with the exception that the bulbs initial equipment a guarantee of 8 days is granted.

Any claims arising from this warranty assume that the end customer

has contacted their locally responsible service representative (mentioned in the user manual) and has given them the opportunity to conduct a (telephone) fault analysis within a period of 7 days. Any claims

arising from this warranty may then only be asserted by handing over

or sending the device either to the repair centre by named by the customer service or the manufacturer’s own local service centre, provided

that customer service has declared the complaint as being

not authorized by the manufactur-

dimensioned exhaust air duct,

Flow In Premium02/07/2018 57

Page 58

Warranty

justied. A condition of the warranty claim is still the submission of the

original invoice and the delivery note with delivery date. We assume

the costs of an on-site service. however, if the customer service re-

sponsible for the consignment calls the end customer a specic freight

carrier and the customer uses another freight carrier, we will not be

able to meet the costs of the consignment. The end customer is not

entitled to return the unit at our expense, unless we agree to reimburse

the customer in writing. Otherwise, we reserve the right to charge the

transport costs to the end customer.

If warranty claims are asserted and if, during the testing of the unit by

us or the responsible customer service, it is found that no fault has

occurred or the warranty claim is not met for any of the above reasons,

we are entitled to charge a service fee of EUR 75,00 to raise. This

does not apply if the end customer proves that he was unable to recognize under the circumstances that the warranty claim did not exist.

This warranty applies to the extent and under the above conditions (including submission of proof of purchase and delivery even in the case

of resale) for any subsequent future owner of the equipment.

To assert warranty claims, we also need to provide the following information:

Name, address and telephone of the end customer

Information about the person / company who carried out the

installation

Information on the nameplate inside the device (part number,

model drawing, revision number, serial number)

Day of installation at the end customer

Detailed description of the defect

These warranty conditions apply to devices purchased in Germany,

Austria, Switzerland, France, Belgium, Netherlands and Luxembourg.

For devices used abroad that have the technical prerequisites (eg

voltage, frequency, etc.) for the corresponding country and that are

suitable for the respective climatic and environmental conditions, these

terms of guarantee also apply insofar as we comply with have a customer service network in the respective country.

This guarantee is subject to the law of the Federal Republic of Germany.

Enter your device data here:

Item number

Model name

Revision number

Serial number

Date of purchase / day of

installation

Flow In Premium 02/07/201858

Page 59

For any questions concerning complaints,

please call the customer service department

Ä „Customer service hotline (for Germany, Aus-

tria,Switzerland, France,Belgium, Netherlands and

Luxembourg)”

on page 3).

Warranty

(

Flow In Premium02/07/2018 59

Page 60

Unpacking and assembling

Unpacking

22 Unpacking and assembling

22.1 Unpacking

All parts of the extractor hood are shipped packed together in cardboard

box.

WARNING!

Danger of suffocation if children play with the

packaging material!

Children that play with the packaging material are

in der danger of accidental suffocation.

– Storage the packaging material out of the

reach of children or persons that may no understand theses dangers.

1. Unpack the extractor hood and all further parts in-

cluded in the box and check the content for complete-