Page 1

©2019 Silicon Labs

ETRX35x Product Manual

Telegesis

TG-ETRX35X-PM-010-121

ETRX351 and ETRX357 Product Manual 1.21

ETRX35x ZIGBEE MODULES

PRODUCT MANUAL

Page 2

ETRX351 and ETRX357

©2019 Silicon Labs

- 2 -

ETRX35x Product Manual (Rev 1.21)

Table of Contents

1 INTRODUCTION ................................................................................................................. 5

1.1 Hardware Description ....................................................................................................... 5

2 PRODUCT APPROVALS ........................................................................................................ 6

2.1 FCC Approvals ................................................................................................................. 6

FCC Labelling Requirements ........................................................................................... 7

2.2 IC (Industry Canada) Approvals............................................................................................ 7

2.3 European Certification (ETSI) ........................................................................................... 8

2.4 ICASA Approvals .............................................................................................................. 8

2.5 Australia and New Zealand (C-Tick) ................................................................................. 8

2.6 Brazil ................................................................................................................................ 9

2.7 Declarations of Conformity ............................................................................................... 9

2.8 IEEE 802.15.4 .................................................................................................................. 9

2.9 The Zigbee Protocol ....................................................................................................... 10

3 MODULE PINOUT ................................................................................................................. 11

4 HARDWARE DESCRIPTION ............................................................................................ 13

4.1 Hardware Interface ......................................................................................................... 13

5 FIRMWARE DESCRIPTION .............................................................................................. 14

5.1 Token Settings ............................................................................................................... 15

5.2 C

ustom Fir mware ........................................................................................................... 15

5.3 Software Interface .......................................................................................................... 16

6 ABSOLUTE MAXIMU M RATINGS ................................................................................. 17

6.1 Environmental Characteristics ........................................................................................ 17

6.2 Recommended Operating Conditions ............................................................................. 17

7 DC ELECTRICAL CHARACTERISTICS ........................................................................... 18

8 DIGITAL I/O SPECIFICATIONS ........................................................................................ 20

9 A/D CONVERTER CHARACTERISTICS ........................................................................ 21

10 AC ELECTRICAL CHARACTERISTICS ......................................................................... 21

10.1 TX Power Characteristics ............................................................................................... 23

11 PHYSICAL DIMENSIONS ................................................................................................. 25

12 RECOMMENDED SOLDERING TEMPERATURE PROFILE ............................................ 27

13 PRODUCT LABEL DRAWING .......................................................................................... 28

14 RECOMMENDED FOOTPRINT ........................................................................................ 29

14.1 Pad dimensions

.................................................................

14.2 Recommended Placement.................................................................................................. 30

14.3 Example carrier board .................................................................................................... 32

15 RELIABILITY TESTS ............................................................................................................ 33

16 APPLICATION NOTES .................................................................................................. 33

16.

1 Safety Precautions ......................................................................................................... 33

16.2 Design Engineering Notes .................................................................................................. 33

............................................. 29

Page 3

ETRX351 and ETRX357

©2019 Silicon Labs

- 3 -

ETRX35x Product Manual (Rev 1.21)

16.3 Storage Conditions ......................................................................................................... 34

17 PACKAGING .................................................................................................................... 34

17.1 Embossed Tape ............................................................................................................. 34

17.2 Component Orientation .................................................................................................. 35

17.3 Reel Dimensions ............................................................................................................ 35

17.4 Packaging - bag .................................................................................................................. 37

17.5 Packaging – carton ......................................................................................................... 37

18 ORDERING INFORMATION ............................................................................................. 38

19 ROHS DECLARATION .......................................................................................................... 39

20 DATA SHEET STATUS .................................................................................................... 39

21 RELATED DOCUMENTS .................................................................................................. 39

Page 4

©2019 Silicon Labs

- 4 -

ETRX35x Product Manual (Rev 1.21)

Image not shown actual size; enlarged to show detail.

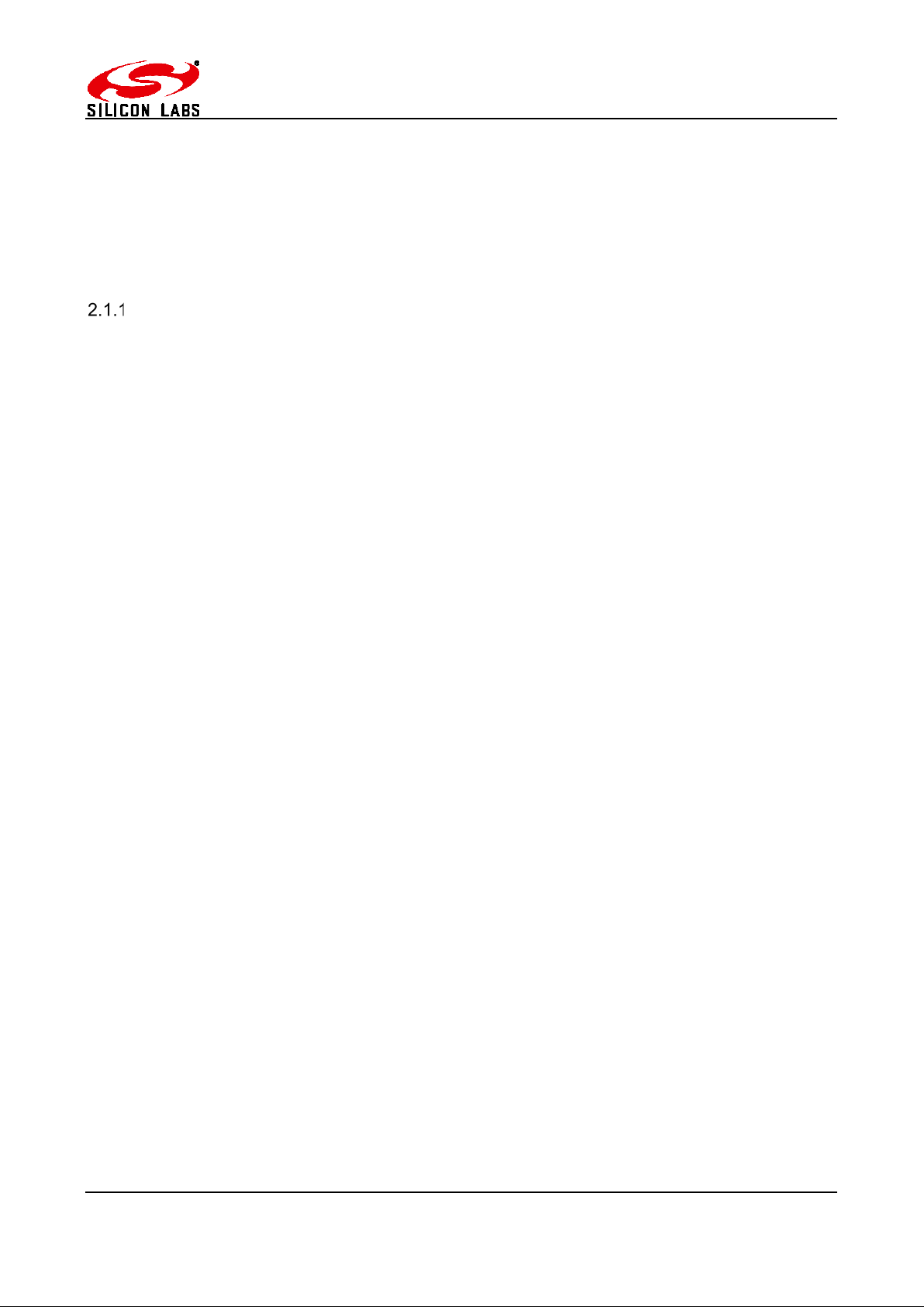

Module Features

• Small form factor, SMT module 25mm x 19mm

• Side Castellations for easy soldering and optical

inspection

• 2 antenna options: Integrated chip antenna or U.FL

coaxial connector

• Industry’s first ARM® Cortex-M3 based family of Zigbee

modules

• Industry standard JTAG Programming and real time

network level debugging via the Ember InSight Port

• 192kB (ETRX357) and 128kB (ETRX351) flash and

12kbytes of RAM

• Lowest Deep Sleep Current of sub 1µA and multiple

sleep modes

• Wide supply voltage range (2.1 to 3.6V)

• Optional 32.768kHz watch crystal can be added

externally

• Module ships with standard Telegesis AT-style command

interface based on the Zigbee PRO feature set

• Can act as an End Device, Router or Coordinator

• 24 general-purpose I/O lines including analogue inputs

(all GPIOs of the EM35x are accessible)

• Firmware upgrades via serial port or over the air

(password protected)

• Hardware supported encryption (AES-128)

• CE, FCC and IC compliance, FCC modular approval

• Operating temperature range: -40

• Long range version with a link budget of up to 124dB

available in the same form factor

°

C to +85°C

Radio Features

• Based on the Ember EM351 or EM357 single chip Zigbee

solutions

• 2.4GHz ISM Band

• 250kbit/s over the air data rate

• 16 channels (IEEE802.15.4 Channel 11 to 26)

• +3dBm output power ( +8dBm in boost mode)

• High sensitivity of -100dBm (-102dBm in boost mode)

typically @ 1% packet error rate

• RX Current: 26mA, TX Current: 31mA at 3dBm

• Robust Wi-Fi and Bluetooth coexistence

ETRX351 and ETRX357

The Telegesis ETRX351 and ETRX357 modules are low power

2.4GHz Zigbee modules, based on the latest Ember EM351 and

EM357 single chip Zigbee

rd

These 3

generation modules have been designed to be

integrated into any device without the need for RF experience

and expertise. Utilizing the EmberZNet Zigbee stack, the

ETRX35x enables you to add powerful wireless networking

capability to your products and quickly bring them to market.

The module’s unique AT-style command line interface allows

designers to quickly integrate Zigbee technology without

complex software engineering. For custom application

development the ETRX35x series integrates with ease into

Ember’s InSight development environment.

Suggested Applications

• AMR – Zigbee Smart Energy applications

• Wireless Alarms and Security

• Home/Building Automation

• Wireless Sensor Networks

• M2M Industrial Controls

• Lighting and ventilation control

• Remote monitoring

• Environmental monitoring and control

Development Kit

• New Development kit containing everything required to

set up a mesh network quickly and evaluate range and

performance of the ETRX35x and its long-range version.

• AT-style software interface command dictionary can be

modified for high volume customers.

• Custom software development available upon request.

Example AT-Style Commands

AT+BCAST Send a Broadcast

AT+UCAST:<address> Send a Unicast

AT+EN Establish PAN network

AT+JN Join PAN

At power-up the last configuration is loaded from non-volatile

S-Registers, which can eliminate the need for an additional

host controller.

TM

solutions.

Page 5

ETRX351 and ETRX357

©2019 Silicon Labs

- 5 -

ETRX35x Product Manual (Rev 1.21)

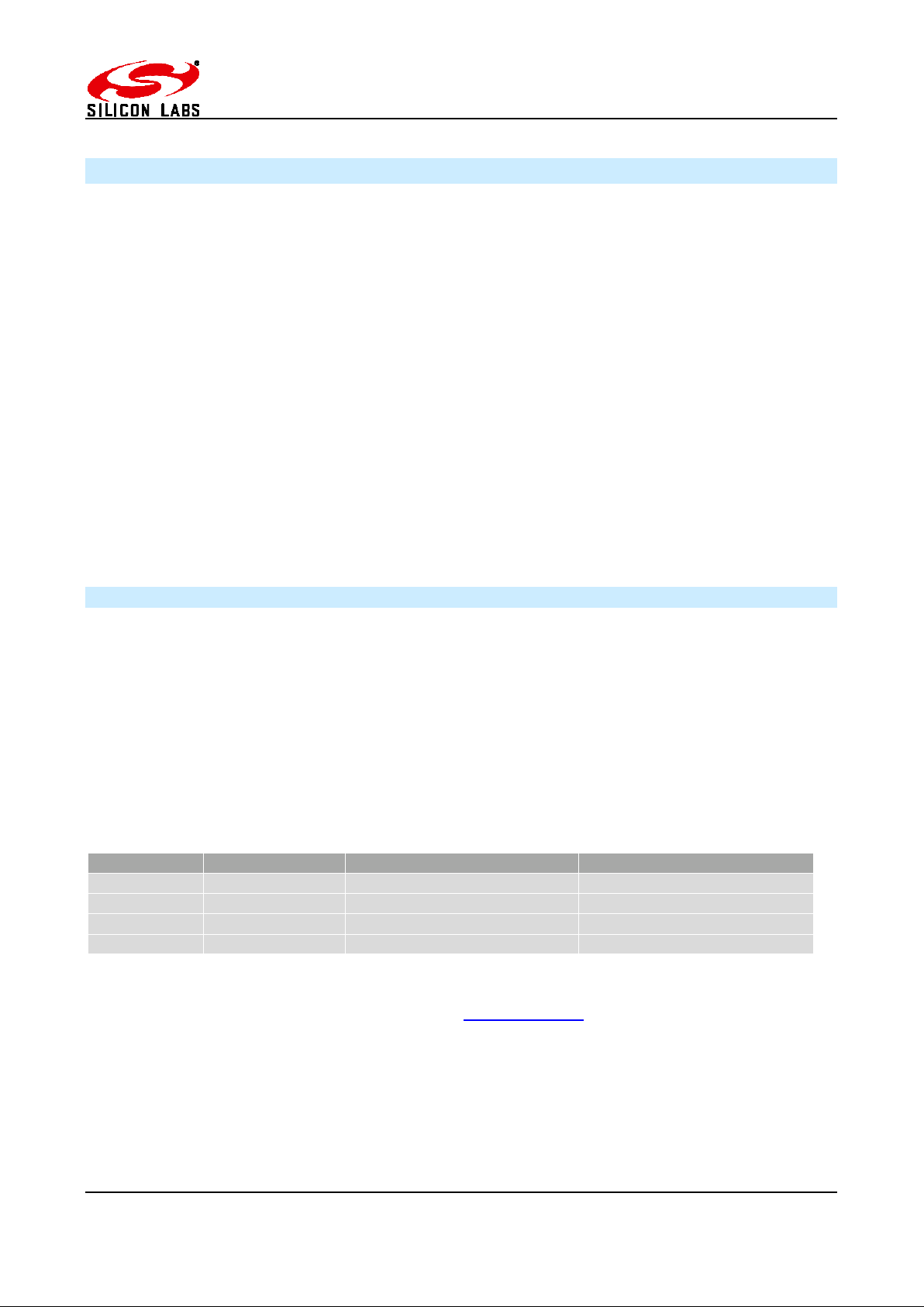

Module

Chip

Flash

RAM

ETRX351

EM351

128kB

12kB

ETRX351HR

EM351

128kB

12kB

ETRX357

EM357

192kB

12kB

ETRX357HR

EM357

192kB

12kB

1.1 Hardware Description

1 Introduction

This document describes the Telegesis ETRX351 and ETRX357 Zigbee modules which have been

designed to be easily integrated into another device and to provide a fast, simple and low cost

wireless mesh networking interface.

The Telegesis ETRX3 series modules are based on the Ember Zigbee platform consisting of the

single chip EM351 or EM357 combined with the Zigbee PRO compliant EmberZNet meshing stack.

Integration into a wide range of applications is made easy using a simple AT style command interface

and advanced hardware design.

The configurable functionality of the Telegesis AT Commandset often allows the ETRX3 series

Zigbee modules to be used without an additional host microcontroller saving even more integration

time and costs. In addition to the Telegesis AT Commandset, the ETRX351 and ETRX357 modules

can be used with custom-built firmware whilst representing an ideal platform for custom firmware

development in conjunction with the Ember development kits.

No RF experience or expertise is required to add this powerful wireless networking capability to your

products. The ETRX351 and ETRX357 offer fast integration opportunities and the shortest possible

time to market for your product.

The main building blocks of the ETRX351 and ETRX357 are the single chip EM351 and EM357

SoCs from Ember, a 24MHz reference crystal and RF front-end circuitry optimized for best RF

performance. The modules are available with on-board antenna or alternatively a U.FL coaxial

connector for attaching external antennae. Modules with the U.FL connector are identified by the

“HR” suffix.

The integrated antenna is an Antenova Rufa, and details of the radiation pattern etc are available

from the Antenova website Fehler! Verweisquelle konnte nicht gefunden werden..

The ETRX351 and ETRX357 are used for Zigbee (www.zigbee.org) applications. In case it is desired

to develop custom firmware instead of using the pre-loaded AT-Command interface, the Ember

InSight toolchain, consisting of InSight Desktop™ together with a comprehensive integrated

development environment (IDE), is required. The Ember development environment is currently not

suitable for developing an IEEE802.15.4-only application that does not use the Zigbee layer.

Table 1: Memories

Page 6

ETRX351 and ETRX357

©2019 Silicon Labs

- 6 -

ETRX35x Product Manual (Rev 1.21)

2.1 FCC Approvals

2 Product Approvals

Item

Part No.

Manufacturer

Type

Impedance

Gain

1

BT-Stubby (straight)

EAD Ltd. [6]

¼ Wave

50Ω

0dBi

BT-Stubby (rightangle)

50Ω

3

WH-2400-U2.5

Wellhope Wireless [7]

½ Wave

50Ω

2.5dBi

50Ω

2.1dBi

(peak)

The ETRX351 and ETRX357 as well as the ETRX351HR and ETRX357HR have been designed to

meet all national regulations for world-wide use. In particular the following certifications have been

obtained:

The Telegesis ETRX351 and ETRX357 with integrated Antenna as well as the ETRX351HR and the

ETRX357HR including the antennas listed in Table 2 have been tested to comply with FCC CFR

Part 15 (USA) The devices meet the requirements for modular transmitter approval as detailed in

the FCC public notice DA00.1407.transmitter. FCC statement:

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

FCC ID: S4GEM35XA

2

4 Rufa (on board) Antenova Chip

While the applicant for a device into which the ETRX351 (ETRX357) or ETRX351HR (ETRX357HR)

with an antenna listed in Table 2 is installed is not required to obtain a new authorization for the

module, this does not preclude the possibility that some other form of authorization or testing may

be required for the end product.

The FCC requires the user to be notified that any changes or modifications made to this device that

are not expressly approved by Telegesis (UK) Ltd. may void the user's authority to operate the

equipment.

When using the ETRX351HR and ETRX357HR with approved antennae, it is required to prevent

end-users from replacing them with non-approved ones. The module and associated antenna must

be installed to provide a separation distance of at least 20cm from all persons and must not transmit

simultaneously with any other antenna or transmitter.

EAD Ltd. [6] ¼ Wave

Table 2: Approved Antennae

0dBi

Page 7

ETRX351 and ETRX357

©2019 Silicon Labs

- 7 -

ETRX35x Product Manual (Rev 1.21)

2.2 IC (Industry Canada) Approvals

FCC Labelling Requirements

When integrating the ETRX351, ETRX357, ETRX351HR or ETRX357HR into a product it must be

ensured that the FCC labelling requirements are met. This includes a clearly visible label on the

outside of the finished product specifying the Telegesis FCC identifier (FCC ID: S4GEM35XA) as

well as the FCC notice shown on the previous page. This exterior label can use wording such as

“Contains Transmitter Module FCC ID: S4GEM35XA” or “Contains FCC ID:S4GEM35XA”

although any similar wording that expresses the same meaning may be used.

The Telegesis ETRX351 and ETRX357 with integrated Antenna as well as the ETRX351HR and the

ETRX357HR modules have been approved by Industry Canada to operate with the antenna types

listed in Table 2 with the maximum permissible gain and required antenna impedance for each

antenna type indicated. Antenna types not included in this list, having a gain greater than the

maximum gain indicated for that type, are strictly prohibited for use with this device.

IC-ID: 8735A-EM35XA

• This device complies with Industry Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) thi s device may not cause

interference, and (2) this device must accept any interference, including interference

that may cause undesired operation of the device.

• Und

•

•

The labelling requirements for Industry Canada are similar to those of the FCC. Again a clearly

visibly label must be placed on the outside of the finished product stating something like “Contains

Transmitter Module, IC: 8735A-EM35XA”, although any similar wording that expresses the same

meaning may be used.

The integrator is responsible for the final product to comply to IC ICES-003 and FCC Part 15, Sub.

B – Unintentional Radiators.

er Industry Canada regulations, this radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain approved for the transmitter by

Industry Canada. To reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that permitted for successful communication.

This module complies with FCC and Industry Canada RF radiation exposure limits

set forth for general population. To maintain compliance, this module must not be colocated or operating in conjunction with any other antenna or transmitter.

This device has been designed to operate with the antennas listed in Table 2, and

having a maximum gain of 2.5 dBi. A nte nn as not included in this list or having a gain

greater than 2.5 dBi are strictly prohibited for use with this device. The required

antenna impedance is 50 ohms.

Page 8

ETRX351 and ETRX357

©2019 Silicon Labs

- 8 -

ETRX35x Product Manual (Rev 1.21)

2.5 Australia and New Zealand (C-Tick)

2.4 ICASA Approvals

2.3 European Certification (ETSI)

The ETRX351, ETRX357, ETRX351HR and ETRX357HR modules are in conformity with the

essential requirements and other relevant requirements of the Radio Equipment Directive (RED)

(2014/53/EU). These include

•

Radio:

EMC:

•

EN 301 489-

EN 300 328 v2.1.1

EN 301 489-17 v3.1.1

1 V2.1.1

• Safety: IEC 60950-1:2005, IEC 60950-1:2005/AMD1:2009,

IEC 60950-1:2005/AMD2:2013

Please note that every application using the modules will need to perform the radio EMC tests on the

end product, according to EN 301 489-17. It is ultimately the responsibility of the manufacturer to

ensure the compliance of the end product. The specific product assembly may have an impact to RF

radiated characteristics, and manufacturers should carefully consider RF radiated testing with the

end-product assembly. A formal DoC is available via www.silabs.com

The modules are in conformity with the essential requirements and other relevant requirements of

the Radio Equipment Directive (RED) with the antennae listed in Table 2.

The ETRX351, ETRX357, ETRX351HR and ETRX357HR have been certified to be used in South

Africa.

The ETRX351, ETRX357, ETRX351HR and ETRX357HR have been certified to be used in Australia

and New Zealand.

In order to have a C-Tick mark on an end product integrating an ETRX35x device, a company must

comply with a or b below.

a). have a company presence in Australia.

b). have a company/distributor/agent in Australia that will sponsor the importing of the end product.

Page 9

ETRX351 and ETRX357

©2019 Silicon Labs

- 9 -

ETRX35x Product Manual (Rev 1.21)

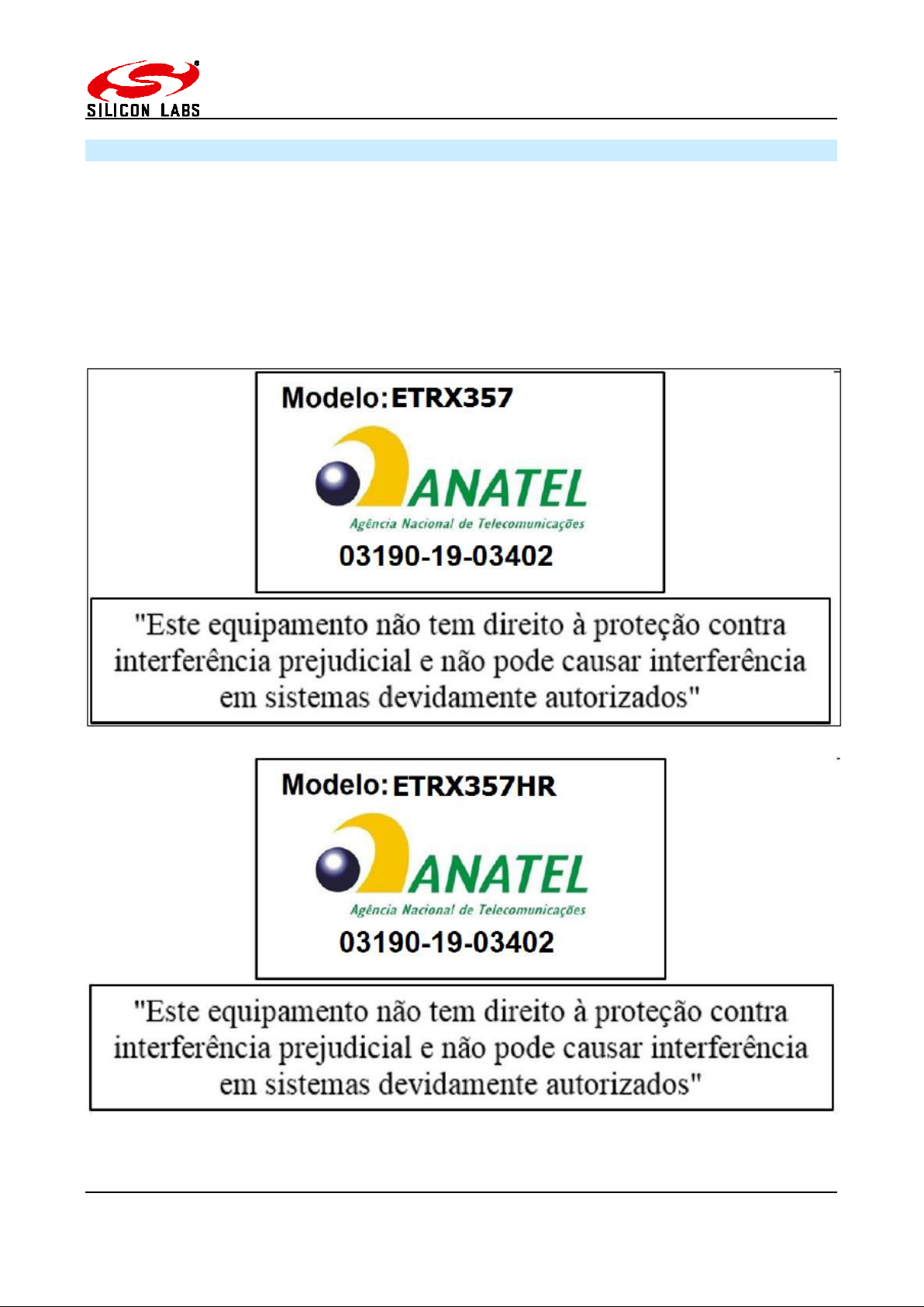

2.6 Brazil

The ETRX357 and ETRX357HR have been certified to be used in Brazil. The Anatel ID for both

module variants is 03190 -19-03402. To comply to Brazil ian regulations it is required to disp lay Anatel

related information including, but not limited to the graphics below in the end-product’s user guide.

Page 10

ETRX351 and ETRX357

©2019 Silicon Labs

- 10

ETRX35x Product Manual (Rev 1.21)

2.8 IEEE 802.15.4

2.7 Declarations of Conformity

Telegesis (UK) Ltd has issued Declarations of Conformity for all ETRX3 series Zigbee RF Modules,

which cover Radio Emissions, EMC and Safety. These documents are available from our website

or on request.

IEEE 802.15.4 is a standard for low data-rate, wireless networks (raw bit-rate within a radio packet

of 250kbps @2.4GHz) which focuses on low cost, low duty cycle, long primary battery life

applications as well as mains-powered applications. It is the basis for the open Zigbee Protocol.

Page 11

ETRX351 and ETRX357

©2019 Silicon Labs

- 10 -

ETRX35x Product Manual (Rev 1.21)

2.9 The Zigbee Protocol

The Zigbee Protocol is a set of standards for wireless connectivity for use between any devices over

short to medium distances. The specification was originally ratified in December 2004, paving the

way for companies to start making low-power networks a reality.

Zigbee uses the IEEE 802.15.4 radio specification running on the 2.4GHz band, plus three additional

layers for networking, security and applications. What makes the specification unique is its use of a

mesh network architecture which, in bucket chain style, passes data from one node to the next until

it lands at its destination. The network is self-healing and adapts its routing as link quality changes

or nodes move. Furthermore, nodes can be defined as End Devices which do not act as routers,

but can therefore be put into a low-power sleep state.

The enhanced version of the Zigbee standard (or Zigbee 2006) was released in December 2006,

adding new features and improvements to the only global wireless communication standard enabling

the development of easily deployable low-cost, low-power, monitoring and control products for

homes, commercial buildings and industrial plant monitoring. In 2007 the Zigbee Alliance introduced

the PRO featureset which offers advantages over earlier versions, including

• Truly self healing mesh networking

• Messages can now travel up to 30 hops

• Source-Routing for improved point to multipoint message transmission

• Improved security including Trust-Centre link keys

• New message types and options

The Telegesis AT-Commandset, which by default ships on all ETRX3 series products is based on

the ZigBee PRO featureset. For more information on the Telegesis AT-Commandset please refer to

the separate documentation at www.telegesis.com.

Page 12

ETRX351 and ETRX357

©2019 Silicon Labs

- 11 -

ETRX35x Product Manual (Rev 1.21)

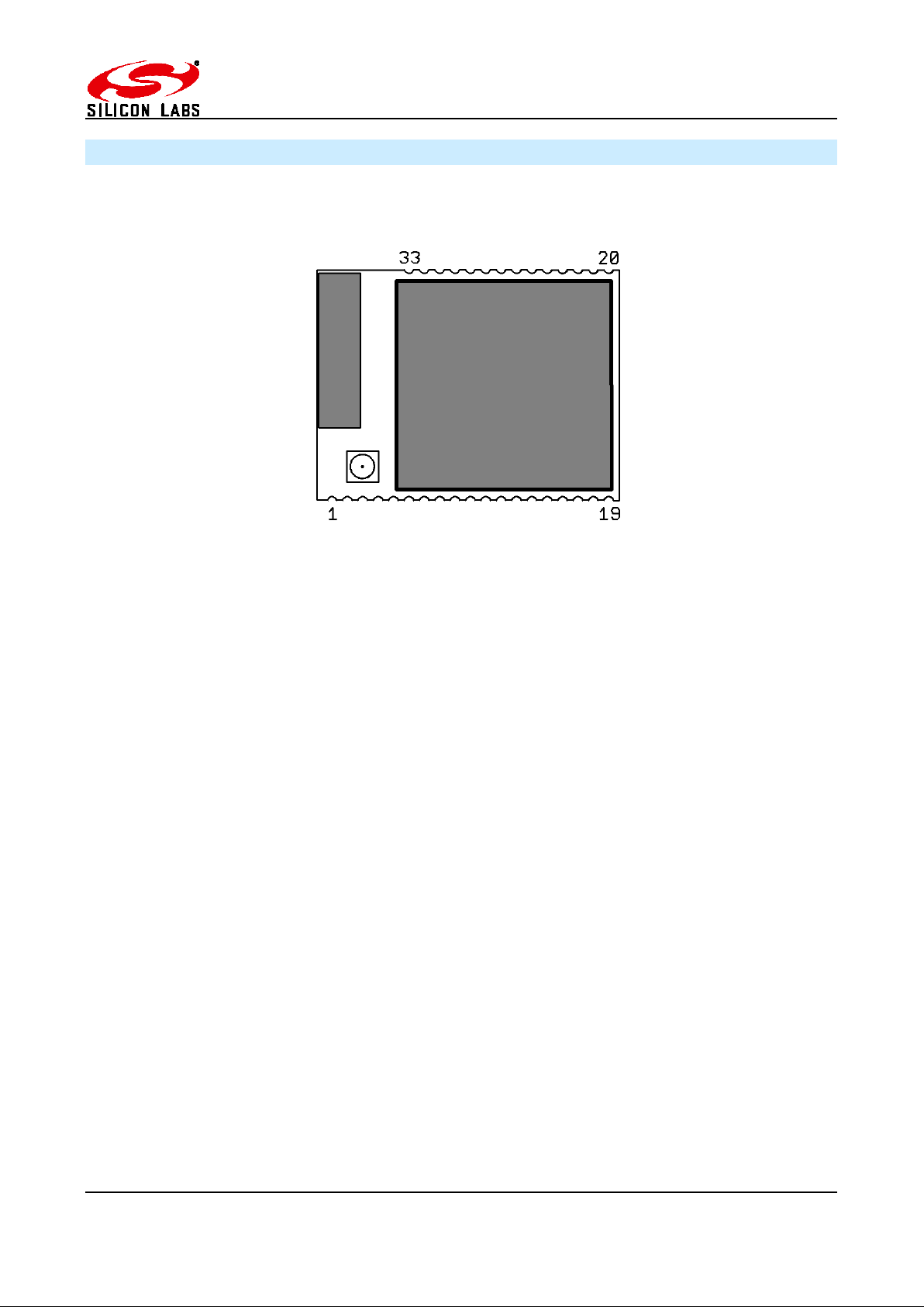

3 Module Pinout

Figure 1: ETRX3 series Module Pinout (top view)

The table below gives details about the pin assignment for direct SMD soldering of the ETRX3 series

modules to the application board. For more information on the alternate functions please refer to

[2]. Also refer to the Telegesis AT Commandset documentation and the Telegesis development kit

documentation to understand how the pre-programmed firmware makes use of the individual I/Os.

All GND pads are connected within the module, but for best RF performance all of them should be

grounded externally ideally to a ground plane.

“Important Note: If designers would like to keep open the option of using either standard or long

range modules in the same product please note the following. The ETRX35x series and the

ETRX35x-LRS series of modules are footprint compatible, but on the ETRX35x-LRS series pins PB0

and PC5 of the EM357 are used internally to control the front-end module and are not available to

the user.”

Page 13

ETRX351 and ETRX357

©2019 Silicon Labs

- 12 -

ETRX35x Product Manual (Rev 1.21)

ETRX35x

Pad

Name

EM35x Pin

Default use

Alternate Functions

1

GND

GND

GND

2

PC5 {1}

11 TX_ACTIVE

3

PC6

13

I/O

OSC32B, nTX_ACTIVE

4

PC7

14

I/O

OSC32A, OSC32_EXT

5

PA7 {5}

18

I/O

TIM1C4

6

PB3 {2,3}

19

I/O, CTS

SC1nCTS, SC1SCLK, TIM2C3

7

nReset {6}

12

nReset

8

PB4 {2,3}

20

I/O, RTS

TIM2C4, SC1nRTS, SC1nSSEL

9

PA0

21

I/O

TIM2C1, SC2MOSI

10

PA1

22

I/O

TIM2C3, SC2SDA, SC2MISO

11

PA2

24

I/O

TIM2C4, SC2SCL, SC2SCLK

12

PA3

25

I/O

SC2nSSEL, TRACECLK, TIM2C2

13

GND

GND

GND

14

PA4

26

I/O

ADC4, PTI_EN, TRACEDATA

15

PA5 {4}

27

I/O

ADC5, PTI_DATA, nBOOTMODE, TRACEDATA3

16

PA6 {5}

29

I/O

TIM1C3

17

PB1 {3}

30

TXD

SC1MISO, SC1MOSI, SC1SDA, SC1TXD, TIM2C1

18

PB2 {3}

31

RXD

SC1MISO, SC1MOSI, SC1SCL, SC1RXD, TIM2C2

19

GND

GND

GND

20

GND

GND

GND

21

JTCK

32 SWCLK

22

PC2

33

I/O

JTDO, SWO

23

PC3

34

I/O

JTDI

24

PC4

35

I/O

JTMS, SWDIO

25

PB0

36

I/O, IRQ

VREF, IRQA, TRACECLK, TIM1CLK, TIM2MSK

26

PC1

38

I/O

ADC3, SWO, TRACEDATA0

27

PC0 {5}

40

I/O

JRST, IRQD, TRACEDATA1

28

PB7 {5}

41

I/O

ADC2, IRQC, TIM1C2

29

PB6 {5}

42

I/O

ADC1, IRQB, TIM1C1

30

PB5

43

I/O

ADC0, TIM2CLK, TIM1MSK

31

GND

GND

GND

32

Vcc

Vcc

Vcc

33

GND

GND

GND

Table 3: Pin Information

Notes:

{1} When the alternate function is selected, TX_ACTIVE becomes an output that indicates that the EM35x

radio circuit is in transmit mode. PC5 is not usable on the long range version of the ETRX35x as this

GPIO is used internally as TX_ACTIVE to control the external RF frontend.

{2} The serial UART connections TXD, RXD, CTS and RTS are PB1, PB2, PB3 and PB4 respectively.

The device sends its data on TXD and receives on RXD.

{3} When using the Telegesis AT Commandset, RTS/CTS handshaking is selectable in firmware. See

the AT Command Manual.

{4} If PA5 is driven low at power-up or reset the module will boot up in the bootloader

{5} PA6, PA7, PB6, PB7 and PC0 can drive high current (see section 8)

{6} nRESET is level-sensitive, not edge-sensitive. The module is held in the reset state while nRESET is

low.

See also the table “Module pads and functions” in the ETRX357 Development Kit Product Manual.

Refer to Ember’s EM357 manual for details of the alternate functions and pin names.

Page 14

ETRX351 and ETRX357

©2019 Silicon Labs

- 13 -

ETRX35x Product Manual (Rev 1.21)

4.1 Hardware Interface

4 Hardware Description

integrated

antenna

Vreg

BALUN

Vcc

1,8Vdc

1V8

1V25

LDO

LDO

EM35x

I/O

UART

A/D

RESET

5 JTAG

I / O

RESET

programming

U.FL socket

rf

terminal

selection,

filtering and

matching

circuitry

24MHz

Figure 2: Hardware Diagram

The ETRX351, ETRX351HR, ETRX357 and ETRX357HR are based on the Ember EM351 and

EM357 respectively. The EM351 and EM357 are fully integrated 2.4GHz Zigbee transceivers with a

32-bit ARM

®

Cortex M3

TM

microprocessor, flash and RAM memory, and peripherals.

The industry standard serial wire and JTAG programming and debugging interfaces together with

the standard ARM system debug components help to streamline any custom software development.

In addition to this a number of MAC functions are also implemented in hardware to help maintaining

the strict timing requirements imposed by the Zigbee and IEEE802.15.4 standards.

The new advanced power management features allow faster wakeup from sleep and new power

down modes allowing this 3

modules on the market.

rd

generation module to offer a longer battery life than any 2

nd

generation

The EM35x has fully integrated voltage regulators for both required 1.8V and 1.25V supply voltages.

The voltages are monitored (brown-out detection) and the built in power-on-reset circuit eliminates

the need for any external monitoring circuitry. An optional 32.768 kHz watch crystal can be

connected externally to pads 3 and 4 in case more accurate timing is required. To utilize the external

watch crystal custom firmware is required.

All GPIO pins of the EM351 or EM357 are accessible on the module’s pads. Whether signals are

used as general purpose I/Os, or assigned to a peripheral function like ADC is set by the firmware.

When using the Telegesis AT Commandset please refer to the AT Commandset manual and the

development kit manual for this information and when developing custom firmware please refer to

the EM35x datasheet [2].

Page 15

ETRX351 and ETRX357

©2019 Silicon Labs

- 14 -

ETRX35x Product Manual (Rev 1.21)

5 Firmware Description

The modules will be pre-loaded with a standalone bootloader which supports over-the-air

bootloading as well as serial bootloading of new firmware.

In order to enter the standalone bootloader using a hardware trigger pull PA5 to ground and powercycle or reset the module. To avoid entering the standalone bootloader unintentionally make sure

not to pull this pin down during boot-up unless the resistance to ground is >10kΩ. (A pull-up is not

required).

In addition to the standalone bootloader the modules also contain the current release of the

Telegesis AT-style command interface as described in the Telegesis AT command dictionary and

the Telegesis user guide. Check www.telegesis.com

for updates. Each module comes with a unique

64-bit 802.15.4 identifier which is stored in non-volatile memory. The commands and responses

pass through the serial port of the ETRX35x as ASCII text, so a simple terminal application will

usually suffice. We provide Telegesis Terminal for interaction with the module but it is not an

essential feature.

The pre-loaded AT-style command interface firmware is based on the latest EmberZNet meshing

stack which implements routers/coordinators as well as (sleepy) end devices. [End devices have no

routing responsibility and therefore are allowed to go to sleep, whilst still being able to send and

receive messages via a parent router. In addition to classical sleepy and non-sleepy end devices

the module firmware also supports mobile (sleepy) end devices capable of changing their parent

quickly whenever they change their position within the network.]

A router is typically a mains powered device whilst a sleepy end device (SED) can be battery

powered.

The module is also able to act as a coordinator and Trust Centre through external host control. The

AT style command line supplies all the tools required to set up and manage a Zigbee network by

allowing easy access to the low-level functionality of the stack.

The Telegesis firmware uses the meshing and self healing EmberZNet PRO stack to overcome

many of the limitations of the tree network topology of the Zigbee 2006 stack by using the Zigbee

PRO featureset.

The Telegesis firmware allows low-level access to physical parameters such as channel and power

level. Parameters that define the functionality of the ETRX35x module and also allow standalone

functionality are saved in non-volatile memory organised in so-called S-Registers. The SPI and I2C

buses are not supported by the current firmware release, but can be used with custom firmware.

Page 16

ETRX351 and ETRX357

©2019 Silicon Labs

- 15 -

ETRX35x Product Manual (Rev 1.21)

Token

Description

TG Default

MFG_CIB_OBS

Option Bytes

<not written>

MFG_CUSTOM_VERSION

Optional Version Number

<not written>

MFG_CUSTOM_EUI_64

Custom EUI

<not written>

MFG_STRING

Device Specific String

TELEGESIS

MFG_BOARD_NAME

Hardware Identifier

<Order Code>

MFG_MANUF_ID

Manufacturer ID

0x1010

MFG_PHY_CONFIG

Default Power Settings

0xFF26

MFG_BOOTLOAD_AES_KEY

Bootloader Key

<not written>

MFG_EZSP_STORAGE

EZSP related

<not written>

MFG_CBKE_DATA

SE Security

<not written>

MFG_INSTALLATION_CODE

SE Installation

<not written>

MFG_OSC24M_BIAS_TRIM

Crystal Bias

<not written>

5.2 Custom Firmware

5.1 Token Settings

The ETRX3 Series Modules’ tokens will be pre-programmed with the settings shown in the table

below.

Table 4. Manufacturing tokens

For high volume customers the firmware can be customised on request. In addition to this the ETRX3

series of modules is an ideal platform for developing custom firmware. In order to develop custom

firmware the Ember Insig ht t oolchain is required.

Page 17

ETRX351 and ETRX357

©2019 Silicon Labs

- 16 -

ETRX35x Product Manual (Rev 1.21)

5.3 Software Interface

Using the default firmware the ETRX35x is controlled using a simple AT-style command interface

and (mostly) non-volatile S-Registers. In order to get a full listing of all the available AT-Commands,

please refer to the AT command dictionary document which corresponds to the firmware revision

you intend to use.

In addition to the command dictionary there are user guides explaining the features of the firmware

in more detail. If you need to find out which firmware resides on your module simply type “ATI”

followed by a carriage return and you will be prompted with the module’s manufacturing information.

The Development Kit manual describes how to upgrade the firmware either via a serial link or over

the air.

Page 18

ETRX351 and ETRX357

©2019 Silicon Labs

- 17 -

ETRX35x Product Manual (Rev 1.21)

No.

Item

Symbol

Absolute Maximum Ratings

Unit

1

Supply voltage

V

CC

-0.3 to +3.6

Vdc

2

Voltage on any Pad

V

in

-0.3 to V

CC

+0.3

Vdc

Voltage on any Pad pin (PA4, PA5,

the low voltage range selected

4

Module storage temperature range

T

stg

-40 to +105

°C

5

Reel storage temperature range

T

strgreel

0 to 75

°C

6

Operating temperature range

T

op

-40 to +85

°C

7

Input RF level

P

max

15

dBm

8

Reflow temperature

T

Death

Please refer to chapter 12

°C

No.

Item

Symbol

Absolute Maximum Ratings

Unit

1 ESD on any pad according to

description

2 ESD on non-RF pads accordi ng to

description

V 3 ESD on RF terminal according to

description

4

Moisture Sensitivity Level

MSL

MSL3

Min

Typ

Max

1

Supply voltage

V

CC

2.1 3.6

Vdc

2

RF Input Frequency

f

C

2405

2480

MHz

3

RF Input Power

p

IN

0

dBm

Operating temperature range

6.2 Recommended Operating Conditions

6.1 Environmental Characteristics

6 Absolute Maximum Ratings

3

PB5, PB6, PB7, PC1), when used as an

input to the general purpose ADC with

Table 5: Absolute Maximum Ratings

V

in

-0.3 to +2.0

Vdc

The absolute maximum ratings given above should under no circumstances be violated. Exceeding

one or more of the limiting values may cause permanent damage to the device.

Caution! ESD sensitive device. Precautions should be used when handling the device

in order to prevent permanent damage.

Human Body Model (HBM) circuit

Charged Device Model (CDM) circuit

Charged Device Model (CDM) circuit

Table 6: Absolute Maximum Ratings

V

THHBM

V

THCDM

V

THCDM

±2

±400

±225

kV

V

No.

4

Item

Conditon/

Remark

Table 7: Recommended Operating Conditions

Symbol

T

op

-40

Value Unit

+85 °C

Page 19

7 DC Electrical Characteristics

Condition /

Remark

Min

Typ

Max

1

Module supply voltage

VCC

2.1

3.6

Vdc

Deep Sleep Current

Quiescent current,

disabled

Quiescent current,

enabled

Quiescent current,

32.768kHz oscillator

Quiescent current

oscillator

Reset Current

Quiescent current

nReset asserted

Processor and Peripheral Currents

ARM® CortexTM M3,

RAM and flash memory

25°C, 12MHz

Core clock

ARM® CortexTM M3,

RAM and flash memory

25°C, 24MHz

Core clock

ARM® CortexTM M3,

sleep current

ARM® CortexTM M3,

sleep current

Per serial

clock rate

General purpose timer

current

Per timer at max.

clock rate

General purpose ADC

current

Max. Sample

rate, DMA

RX Current

Radio receiver MAC and

Baseband

ARM® CortexTM

M3 sleeping.

Receive current

consumption

Total, 12MHz

clock speed

Receive current

consumption

Total, 24MHz

clock speed

Receive current

BOOST MODE

Receive current

BOOST MODE

ETRX351 and ETRX357

= 3.0V, T

V

CC

= 25°C, NORMAL MODE (non-Boost) unless otherwise stated

AMB

No. Item

2

internal RC oscillator

3

internal RC oscillator

4

including

including internal RC

5

oscillator and 32.768kHz

6

7

8

Symbol Value Unit

I

0.4 µA

SLEEP

I

0.7 µA

SLEEP

I

1.0 µA

SLEEP

I

1.3 µA

SLEEP

I

1.2 2.0 mA

RESET

I

6.0 mA

MCU

I

7.5 mA

MCU

9

RAM and flash memory

10

RAM and flash memory

11 Serial controller current

12

13

14

15

16

17

consumption

18

consumption

25°C, 12MHz

Core clock

25°C, 6MHz Core

clock

controller at max.

Total, 12MHz

clock speed

Total, 24MHz

clock speed

I

3.0 mA

MCU

I

2.0 mA

MCU

ISC 0.2 mA

I

0.25 mA

TIM

I

1.1 mA

ADC

IRX 22 mA

IRX 25 mA

IRX 26.5 mA

IRX 27 mA

IRX 28.5 mA

©2019 Silicon Labs - 18 - ETRX35x Product Manual (Rev 1.21)

Page 20

ETRX351 and ETRX357

©2019 Silicon Labs

- 19 -

ETRX35x Product Manual (Rev 1.21)

TX Current

Transmit current

consumption

at +3dBm module

output power

Transmit Current

BOOST MODE

Transmit current

consumption

at +0dBm module

output power

Transmit current

consumption

at min. module

output power

From

event to 1

From last

deep sleep

5

19

20

consumption

21

22

Wake time from deep

23

sleep

24 Shutdown time

at +8dBm module

output power

wakeup

instruction into

st

Table 8: DC Electrical Characteristics

I

TXVCC

I

TXVCC

I

TXVCC

I

TXVCC

31 mA

42

28.5 mA

23.5 mA

100

mA

µs

µs

Please Note: The average current consumption during operation is dependent on the firmware and

the network load, therefore these figures are provided in the command dictionary of the respective

firmware.

Page 21

ETRX351 and ETRX357

©2019 Silicon Labs

- 20 -

ETRX35x Product Manual (Rev 1.21)

1

Low Schmitt switching

Schmitt input threshold

V

0.42 x

0.5 x V

Vdc

2

High Schmitt switching

Schmitt input threshold

V

0.62 x

0.8 x V

MHz

Input Pull-up resistor

value

Input Pull-down resistor

value

8

Standard current

pad

Standard current

pad

11

Output Source Current

High current pad (1)

I

OHH

8

mA

12

Output Sink current

High current pad (1)

I

OLH

8

mA

13

Total output current

I

OH

+ I

OL

40

mA

8 Digital I/O Specifications

The digital I/Os of the ETRX35x module

= 3.0V, T

V

CC

No. Item

threshold

threshold

3 Input current for logic 0

4 Input current for logic 1

5

6

7 Output voltage for logic 0

Output voltage for logic 1

= 25°C, NORMAL MODE unless otherwise stated

AMB

Condition/Remark

going from high to low

going from low to high

I

= 4mA (8mA) for

OL

standard (high

current) pads

I

= 4mA (8mA)for

OH

standard (high

current) pads

Symbol Value Unit

Min Typ Max

SWIL

SWIH

R

R

V

V

I

I

IL

IH

IPU

IPD

OL

OH

V

CC

V

CC

24 29 34 kΩ

24 29 34 kΩ

0

0.82 x

V

CC

CC

CC

-0.5 µA

0.5 µA

0.18 x V

CC

V

CC

V

V

9 Output Source Current

10 Output Sink current

Table 9. Digital I/O Specifications

Notes

1) High current pads are PA6, PA7, PB6, PB7, PC0

I

OHS

I

OLS

4 mA

4 mA

Page 22

ETRX351 and ETRX357

©2019 Silicon Labs

- 21 -

ETRX35x Product Manual (Rev 1.21)

No.

Item

1

A/D resolution

Up to 14 bits

2 A/D sample time for 7-bit conversion

5.33µs

3 A/D sample time for 14-bit conversion

682µs

4 Reference Voltage

1.2V

5

Max current drain from Vref pin

1mA

Min

Typ

Max

1

Frequency range

2400

2500

MHz

2

Sensitivity for 1% Packet Error Rate (PER)

-100

-94

dBm

3

Sensitivity for 1% Packet Error Rate (PER) BOOST MODE

-102

-96

dBm

4

Saturation (maximum input level for correct operation)

0

dBm

High-Side Adjacent Channel Rejection

(1% PER and desired signal –82dBm acc. to [1])

Low-Side Adjacent Channel Rejection

(1% PER and desired signal –82dBm acc. to [1])

2

nd

High-Side Adjacent Channel Rejection

(1% PER and desired signal –82dBm acc. to [1])

2

nd

Low-Side Adjacent Channel Rejection

(1% PER and desired signal –82dBm acc. to [1])

Channel Rejection for all other channels

(1% PER and desired signal –82dBm acc. to [1])

802.11g rejection centred at +12MHz or –13MHz

(1% PER and desired signal –82dBm acc. to [1])

Co-channel rejection

(1% PER and desired signal –82dBm acc. to [1])

Relative frequency error

(2x40ppm required by [1])

Relative timing error

(2x40ppm required by [1])

14

Linear RSSI range

40

dB

Output power at highest power setting

BOOST MODE

16

Output power at lowest power setting

-55

dBm

17

Error vector magnitude as per IEEE802.15.4

5

15

%

18

Carrier frequency error

-40 (1)

40 (1)

ppm

PSD mask relative

3.5MHz distance from carrier

PSD mask absolute

3.5MHz distance from carrier

10 AC Electrical Characteristics

9 A/D Converter Characteristics

The ADC is a first-order sigma-delta converter. For additional information on the ADC please refer

to section 10 of the EM35x datasheet.

Table 10. A/D Converter Characteristics

V

= 3.0V, T

CC

= 25°C, NORMAL MODE measured at 50Ω terminal load connected to the U.FL socket

AMB

No. Receiver Value Unit

5

6

7

8

9

10

11

12

13

15

NORMAL MODE

19

-120

-120

0

-20

41

44

53

52

40

36

-6

3

8

dB

dB

dB

dB

dB

dB

dBc

120 ppm

120 ppm

dBm

dB

20

Table 11. AC Electrical Characteristics

-30

dBm

Page 23

ETRX351 and ETRX357

©2019 Silicon Labs

- 22 -

ETRX35x Product Manual (Rev 1.21)

No.

Synthesiser Characteristics

Limit

Unit

Min

Typ

Max

22

Frequency range

2400

2500

MHz

23

Frequency resolution

11.7

kHz

24

Lock time from off state, with correct VCO DA C settings

100

µs

25

Relock time, channel change or Rx/Tx turnaround

100

µs

26

Phase noise at 100kHz offset

-75dBc/Hz

27

Phase noise at 1MHz offset

-100dBc/Hz

28

Phase noise at 4MHz offset

-108dBc/Hz

29

Phase noise at 10MHz offset

-114dBc/Hz

No.

Power On Reset (POR) Specifications

Limit

Unit

Min

Typ

Max

30

V

CC

POR release

0.62

0.95

1.2

Vdc

31

V

CC

POR assert

0.45

0.65

0.85

Vdc

No.

nRESET Specifications

Limit

Unit

Min

Typ

Max

32

Reset Filter Time constant

2.1

12

16

µs

33

Reset Pulse width to guarantee a reset

26

µs

34

Reset Pulse width guaranteed not to cause reset

0

1

µs

35

Input pull-up resistor value while the chip is not reset

24

29

34

kΩ

36

Input pull-up resistor value while the chip is reset

12

14.5

17

kΩ

Notes (1) Applies across the full ranges of rated temperature and supply voltage. Please Note: For the relationship between EM35x power settings and module output power please

relate to chapter 10.1 of this document. When developing custom firmware the output power settings

described in this document relate directly to the EM35x power settings accessible via the Ember

stack API.

Table 12: Synthesiser Characteristics

Table 13: Power On Reset Specifications

Table 14: nReset Specifications

Page 24

ETRX351 and ETRX357

©2019 Silicon Labs

- 23 -

ETRX35x Product Manual (Rev 1.21)

10.1 TX Power Characteristics

The diagrams below show the typical output power and module current in dependency on module

EM35x power setting. Power settings above 3dBm have Boost Mode enabled. Please note that the

output power is independent of the supply voltage as the radio is supplied by an internally regulated

voltage.

Figure 3: Output Power vs. Power Setting

Page 25

ETRX351 and ETRX357

©2019 Silicon Labs

- 24 -

ETRX35x Product Manual (Rev 1.21)

Transmit current A

Figure 4: Module Current vs. Power Setting

Page 26

ETRX351 and ETRX357

©2019 Silicon Labs

- 25 -

ETRX35x Product Manual (Rev 1.21)

Symbol

Explanation

Typical Distance

Tolerances

L

Length of the module

25.0mm

±0.13mm

W

Width of the module

19.0mm

±0.13mm

H

Height of the module

3.8mm

±0.1mm

A1

Distance centre of pad PCB edge

0.9mm

±0.13mm

A2

Pitch

1.27mm

n/a

R1

Keep-out Zone from corner of PCB

17.5mm

n/a

R2

Keep-out Zone from corner of PCB

4.1mm

n/a

X1

Distance centre of Antenna connector

PCB edge

3.8mm

±0.13mm

X2

Distance centre of Antenna connector

PCB edge

2.8mm

±0.13mm

11 Physical Dimensions

Figure 5: ETRX3 Physical Dimensions

Table 15: ETRX3 Physical Dimensions

For ideal RF performance when using the on-board antenna, the antenna should be located at the

corner of the carrier PCB. There should be no components, tracks or copper planes in the keep-out

area which should be as large as possible. When using the U.FL RF connector the keep-out area

does not have to be obeyed. Note: The modules’ transmit/receive range will depend on the antenna

used and also the housing of the finished product.

Page 27

ETRX351 and ETRX357

©2019 Silicon Labs

- 26 -

ETRX35x Product Manual (Rev 1.21)

Figure 6. Typical pad dimensions

Module weight: 2.9-3.0g depending on variant

Page 28

ETRX351 and ETRX357

©2019 Silicon Labs

- 27 -

ETRX35x Product Manual (Rev 1.21)

12 Recommended Soldering Temperature Profile

Recommended temperature profile

for reflow soldering

60 +60-20s

Temp

.[°C]

230°C -250°C max.

220°C

150°C – 200°C

90 ±30s

Time [s]

Figure 7. Recommended Reflow Profile

Use of “No-Clean” solder paste is recommended to avoid the requirement f or a cleaning process.

Cleaning the module is strongly discouraged because it will be difficult to ensure no cleaning agent

and other residuals are remaining underneath the shielding can as well as in the gap between the

module and the host board.

Please Note:

Maximum number of reflow cycles: 2

Opposite-side reflow is prohibited due to the module’s weight. (i.e. you must not place the

module on the bottom / underside of your PCB and re-flow).

Page 29

ETRX351 and ETRX357

©2019 Silicon Labs

- 28 -

ETRX35x Product Manual (Rev 1.21)

Imprint

Description

Model:ETRX357

Module Order Code.

CE

The CE Mark

QR Code

QR Code containing information in the format YYWWMMABCDE

YYWWTTTTTT

Serial Number Code in the format YYWWTTTTTT

TTTTTT: Manufacturing trace code. The first letter is the device revision

FCC ID: S4GEM35XB

The FCC ID

IC: 8735A-EM35XB

The IC ID

Anatel: 03190-19-

03402

The Anatel ID

13 Product Package Marking

Figure 8: Product Label

The characters “HR” are only present on the versions with the U.FL ant enna connector,

• YY: Last two digits of the assembly year

• WW: Two-digit workweek when the device was assembled

• MMABCDE: Silicon Labs unit code

• YY: Last two digits of the assembly year

• WW: Two-digit workweek when the device was assembled

•

Table 16: ETRX35x Label Details

Page 30

ETRX351 and ETRX357

©2019 Silicon Labs

- 29 -

ETRX35x Product Manual (Rev 1.21)

14 Recommended Footprint

14.1 Pad dimensions

In order to surface mount an ETRX3 series module, we recommend that you use pads which are

1mm wide and 1.2mm high. You must retain the keep-out zone shown in section 12, and ensure

that this keep-out area is free of components, copper tracks and/or copper planes/layers.

You must also ensure that there is no exposed copper on your layout which may contact with the

underside of the ETRX3 series module.

For best RF performance it is required to provide good ground connections to the ground pads of

the module. It is recommended to use multiple vias between each ground pad and a solid ground

plane to minimize inductance in the ground path.

The land pattern dimensions above serve as a guideline.

We recommend that you use the same pad dimensions for the solder paste screen as you have for

the copper pads. However these sizes and shapes may need to be varied depending on your

soldering processes and your individual production standards. We recommend a paste screen

thickness of 120μm to 150μm.

Figure 6 shows the typical pad dimensions of the module and Figure 10 - Figure 12 in section 14.2

show examples of how to align the module on its host PCB.

Figure 9: Recommended Footprint

Page 31

ETRX351 and ETRX357

©2019 Silicon Labs

- 30 -

ETRX35x Product Manual (Rev 1.21)

14.2 Recommended Placement

Although the undersides of the ETRX3 series modules are fully coated, no exposed copper, such as

uncovered through-hole vias, planes or tracks on your board component layer, should be located

below the ETRX3 series module in order to avoid ‘shorts’. All ETRX3 series modules use a multilayer

PCB containing an inner RF shielding ground plane, therefore there is no need to have an additional

copper plane directly under the ETRX3 series module.

When placing the module please either locate the antenna in the corner as shown in Figure 10 so

that the recommended antenna keepout zone is being followed, or add a no copper zone as

indicated in Figure 12.

Figure 10. Typical placement

Figure 11. How to not place the Module

Page 32

ETRX351 and ETRX357

©2019 Silicon Labs

- 31 -

ETRX35x Product Manual (Rev 1.21)

Figure 12. Adding a no copper / no component area

Page 33

ETRX351 and ETRX357

©2019 Silicon Labs

- 32 -

ETRX35x Product Manual (Rev 1.21)

14.3 Example carrier board

Since the RF performance of the module with the on board antenna is strongly dependent on the

proper location of the module on its carrier board, Figure 13 shows the reference carrier board which

was used during testing by Telegesis.

Figure 13. Reference Board

For best performance it is recommended to locate the antenna towards the corner of the carrier

board and to respect the recommended keep-out areas as described in section 11.

Finally to provide a good reference ground to the on board antenna, the carrier board should have

a ground plane spanning no less than 40 x 40mm. In many cases a smaller ground plane will suffice,

but degradation in radio performance could be the result.

Page 34

ETRX351 and ETRX357

©2019 Silicon Labs

- 33 -

ETRX35x Product Manual (Rev 1.21)

No

Item

Limit

Condition

1

Freq.:40Hz,Amplitude:1.5mm

Dropped onto hard wood from height of

50cm for 3 times

-40°C for 30min. and +85°C for 30min.;

each temperature 300 cycles

4

Moisture test

the same as the above

+60°C, 90% RH, 300h

5

Low temp. test

the same as the above

-40°C, 300h

6

High temp. test

the same as the above

+85°C, 300h

16.2 Design Engineering Notes

16.1 Safety Precautions

16 Application Notes

15 Reliability Tests

The measurements below have been conducted on random samples out of mass production and

passed after the module has been exposed to standard room temperature and humidity for 1 hour.

Vibration test

2 Shock test the same as the above

3 Heat cycle test the same as the above

Electrical parameter should be

in specification

Table 17: Reliability Tests

20min. / cycle,1hrs. each of X and Y axis

These specifications are intended to preserve the quality assurance of products as individual

components.

Before use, check and evaluate the module’s operation when mounted on your products. Abide

by these specifications when using the products. These products may short-circuit. If electrical

shocks, smoke, fire, and/or accidents involving human life are anticipated when a short circuit

occurs, then provide the following failsafe functions as a minimum:

(1) Ensure the safety of the whole system by installing a protection circuit and a protection

device.

(2) Ensure the safety of the whole system by installing a redundant circuit or another system

to prevent a single fault causing an unsafe status.

(1) Heat is the major cause of shortening the life of the modules. Avoid assembly and use

of the target equipment in conditions where the product’s temperature may exceed the

maximum allowable.

(2) Failure to do so may result in degrading of the product’s functions and damage to the

product.

(3) If pulses or other transient loads (a large load applied in a short time) are applied to the

products, before use, check and evaluate their operation when assembled onto your

products.

(4) These pr

shown below. Before using these products under such special conditions, check their

performance and reliability under the said special conditions carefully, to determine

whether or not they can be used in such a manner.

(5) In liquid, such as water, salt water, oil, alkali, or organic solvent, or in places where liquid

may splash.

oducts are not intended for other uses, other than under the special conditions

Page 35

ETRX351 and ETRX357

©2019 Silicon Labs

- 34 -

ETRX35x Product Manual (Rev 1.21)

17.1 Embossed Tape

17 Packaging

16.3 Storage Conditions

(6) In direct sunlight, outdoors, or in a dusty environment

(7) In an environment where condensation occurs.

(8) In an environment with a high concentration of harmful gas (e.g. salty air, HCl, Cl2, SO2,

H2S, NH3, and NOx)

(9) If an abnormal voltage is applied due to a problem occurring in other components or

circuits, replace these products with new products because they may not be able to

provide normal performance even if their electronic characteristics and appearances

appear satisfactory.

(10) Mechanical stress during assembly of the board and operation has to be avoided.

(11) Pressing on parts of the metal cover or fastening objects to the metal cover is not

permitted.

(1) The module must not be stressed mechanically during storage.

(2) Do not store these products in the following conditions or the performance characteristics

of the product, such as RF performance, may well be adversely affected:

(3) Storage in salty air or in an environment with a high concentration of corrosive gas, such

as Cl2, H2S, NH3, SO2, or NOX

(4) Storage in direct sunlight

(5) Storage in an environment where the temperature may be outside the range of 5°C to

35°C range, or where the humidity may be outside the 45 to 85% range.

(6) Storage (

before assembly of the end product) of the modules for more than one year

after the date of delivery at your company even if all the above conditions (1) to (3) have

been met, should be avoided.

(1) Dimensions of the tape

Page 36

ETRX351 and ETRX357

©2019 Silicon Labs

- 35 -

ETRX35x Product Manual (Rev 1.21)

17.3 Reel Dimensions

17.2 Component Orientation

θ= 10deg

No.

(2) Cover tape peel force

Force direction

Speed = 300mm/min.

Cover tape peel force

=0.098~0.68N (10~70g)

(3) Empty pockets

NB: Empty pockets in the populated area will be less than two per reel and those empty pockets

will not be consecutive.

Top cover tape will not obstruct the carrier tape holes and will not extend beyond the edges of

the carrier tape

Direction

(top view)

Component Orientation

(4) Quantity per reel: 600 pieces

(5) Marking: Part No. / Quantity / Lot No. and manufacturer part# with bar-code will be on

the reel

Page 37

ETRX351 and ETRX357

©2019 Silicon Labs

- 36 -

ETRX35x Product Manual (Rev 1.21)

Page 38

ETRX351 and ETRX357

©2019 Silicon Labs

- 37 -

ETRX35x Product Manual (Rev 1.21)

17.5 Packaging – carton

17.4 Packaging - bag

(6) Each reel will be packed in a hermetically-sealed bag containing desiccant and a

humidity indicator card

(7) Marking: Part No. / Quantity / Lot No. and manufacturer part# with bar-code

(8) Each reel and bag will be placed in a cardboard carton of nominal dimensions

343 x 338 x 68 mm.

(9) Weight of carton containing reel of 600 modules: 2.51kg approx.

Page 39

ETRX351 and ETRX357

©2019 Silicon Labs

- 38 -

ETRX35x Product Manual (Rev 1.21)

Ordering/Product Code

Description

18 Ordering Information

ETRX351

ETRX357

ETRX351HR

ETRX357HR

Telegesis Wireless Mesh Networking Module with Ember

Zigbee Technology:

• Based on Ember EM351 or EM357

• Telegesis AT Style Command Interpreter based on

• EmberZNet meshing and self-healing Zigbee PRO

stack

• Integrated 2.4GHz Antenna

Telegesis Wireless Mesh Networking Module with Ember

Zigbee Technology:

• Based on Ember EM351 or EM357

• Telegesis AT Style Command Interpreter based on

• EmberZNet meshing and self-healing Zigbee PRO

stack

• U.FL coaxial Antenna Connector

ETRX3DVK

Telegesis Development Kit with:

• 3 x ETRX35xDV Developm ent Boards

• 3 x USB cables

• 2 x ETRX35x on carrier boards

• 2 x ETRX35xHR on carrier boards

• 2 x ETRX35x-LR on carrier boards

• 2 x ETRX35xHR-LR on carrier boards

• 1 x ETRX2USB USB stick

• 2 x ½-wave antennae

• 2 x ¼-wave antennae

Notes:

• Customers’ PO’s must state the Ordering/Product Code.

• There is no “blank” version of the ETRX35x modules available. All Modules are pre-

programmed with the Telegesis AT style command interpreter based on the EmberZNet

stack. (In case it is desired to program c ust om f irm ware the pre-programmed firmware can

simply be overwritten).

Page 40

ETRX351 and ETRX357

©2019 Silicon Labs

- 39 -

ETRX35x Product Manual (Rev 1.21)

21 Related Documents

20 Data Sheet Status

19 RoHS Declaration

Declaration of environmental compatibility for supplied products:

Hereby we declare based on the declaration of our suppliers that this product does not contain any

of the substances which are banned by Directive 2011/65/EU (RoHS2) or if they do, contain a

maximum concentration of 0,1% by weight in homogeneous materials for:

• Lead and lead compounds

• Mercury and mercury compounds

• Chromium (VI)

• PBB (polybrominated biphenyl) category

• PBDE (polybrominated biphenyl ether) category

And a maximum concentration of 0.01% by weight in homogeneous materials for:

• Cadmium and cadmium compounds

Telegesis (UK) Ltd. reserves the right to change the specification without notice, in order to improve

the design and supply the best possible product. Please consult the most recently issued data sheet

before initiating or comp le ting a design.

[1] IEEE Standard 802.15.4 –2003 Wireless Medium Access Control (MAC) and Physical Layer

(PHY) Specifications for Low-Rate Wireless Personal Area Networks (LR-WPANs)

[2] Datasheet EM35x, Silicon Labs. (www.silabs.com)

[3] Datasheet U.FL-Series 2004.2 Hirose Ultra Small Surface Mount Coaxial Connectors - Low

Profile 1.9mm or 2.4mm Mated Height

[4] The Zigbee specification (www.zigbee.org)

[5] Specification for Antenova Rufa Antenna (www.antenova.com)

[6] Embedded Antenna design Ltd. (EAD Ltd.) (www.ead-ltd.com)

[7] Wellhope Communication Equipment (www.wellhope-wireless.com)

Page 41

Smart.

Connected.

Energy-Friendly.

Products

www.silabs.com/products

Disclaimer

Silicon Labs intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules available for system and software implementers using or

intending to use the Silicon Labs products. Characterization data, available modules and peripherals, memory sizes and memory addresses refer to each specific device, and "Typical"

parameters provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon Labs reserves the right to make changes without

further notice to the product information, specifications, and descriptions herein, and does not give warranties as to the accuracy or completeness of the included information. Without prior

notification, Silicon Labs may update product firmware during the manufacturing process for security or reliability reasons. Such changes will not alter the specifications or the performance

of the product. Silicon Labs shall have no liability for the consequences of use of the information supplied in this document. This document does not imply or expressly grant any license to

design or fabricate any integrated circuits. The products are not designed or authorized to be used within any FDA Class III devices, applications for which FDA premarket approval is required

or Life Support Systems without the specific written consent of Silicon Labs. A "Life Support System" is any product or system intended to support or sustain life and/or health, which, if it fails,

can be reasonably expected to result in significant personal injury or death. Silicon Labs products are not designed or authorized for military applications. Silicon Labs products shall under no

circumstances be used in weapons of mass destruction including (but not limited to) nuclear, biological or chemical weapons, or missiles capable of delivering such weapons. Silicon Labs

disclaims all express and implied warranties and shall not be responsible or liable for any injuries or damages related to use of a Silicon Labs product in such unauthorized applications.

Trademark Information

Silicon Laboratories Inc.® , Silicon Laboratories®, Silicon Labs®, SiLabs® and the Silicon Labs logo®, Bluegiga®, Bluegiga Logo®, ClockBuilder®, CMEMS®, DSPLL®, EFM®,

EFM32®, EFR, Ember®, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZRadio®, EZRadioPRO®,

Gecko®, Gecko OS, Gecko OS Studio, ISOmodem®, Precision32®, ProSLIC®, Simplicity Studio®, SiPHY®, Telegesis, the Telegesis Logo®, USBXpress® , Zentri, the Zentri logo and Zentri

DMS, Z-Wave®, and others are trademarks or registered trademarks of Silicon Labs. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or registered trademarks of ARM Holdings.

Keil is a registered trademark of ARM Limited. Wi-Fi is a registered trademark of the Wi-Fi Alliance. All other products or brand names mentioned herein are trademarks of their respective

holders.

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

Quality

www.silabs.com/quality

Support and Community

community.silabs.com

http://www.silabs.com

Loading...

Loading...