Silicon Laboratories Si4355, Si4455 Programming Manual

AN692

Si4355/Si4455 PROGRAMMING GUIDE

1. Introduction

This document provides an overview of how to configure and control the following EZRadio® chips:

Si4455 transceiver

Si4355 receiver

The following code examples are covered in this programming guide:

How to set up a continuous wave (CW) transmission.

How to set up a pseudo random (PN9) transmission.

How to transmit in TX direct mode.

How to receive in RX direct mode (for BER measurement).

How to transmit a simple packet in Packet Handler mode.

How to receive a simple packet in Packet Handler mode.

How to implement bidirectional variable length packet based communication.

2. Hardware Options

The source code is provided for two different hardware platforms:

RFStick

Wireless Motherboard + RF Pico Board

A separate Silicon Labs IDE workspace is provided for each example on the two platforms.

2.1. The RFStick Platform

Figure 1. RFStick

The RFStick is a basic demo system for the evaluation of the EZRadio chips. The board has two main parts, the

MCU part and the radio part. The MCU part of the board contains a Silicon Labs C8051F930 MCU and basic

human interface devices (four push-buttons, four LEDs, four switches and a buzzer). The radio part contains the

EZRadio chip, the matching circuit, and the antenna. The RF output is selectable via a 0 resistor between a PCB

antenna and an optional (unpopulated) 50 SMA output connector. The MCU is connected to the EZRadio chip

via an SPI bus and some other GPIOs (see Table 1). The RF section of the board can be broken off along a

perforation between the two rows of J3 and installed in the user’s own hardware as a radio module by utilizing the

remaining row of J3.

Table 1 contains the signal connections between the EZRadio chip and the MCU:

Rev 0.4 11/14 Copyright © 2014 by Silicon Laboratories AN692

AN692

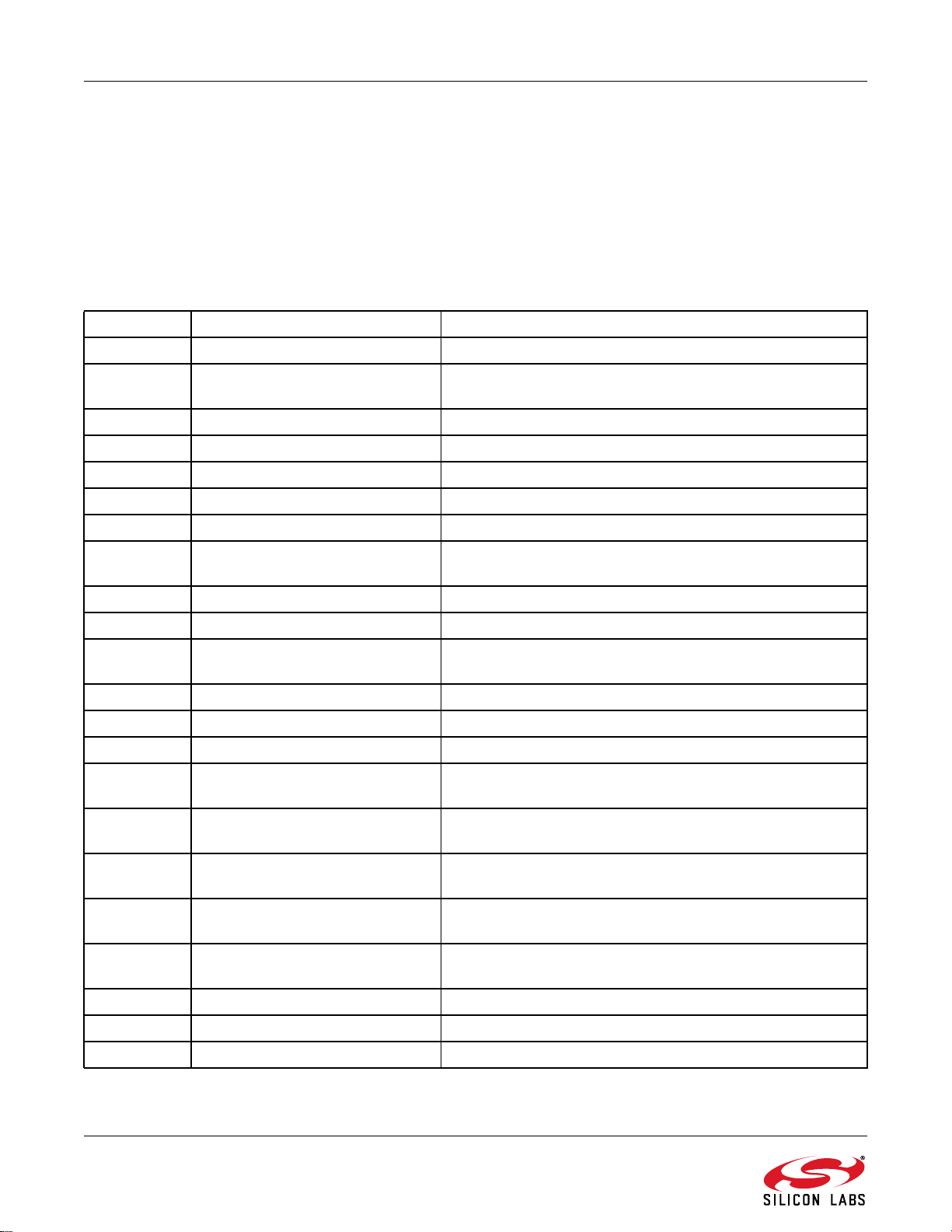

Table 1. Connections between the EZRadio Chip and the MCU

Si4355, Si4455 RFStick C80C51F930

Pin Number Pin Name Pin Function Connections

across J3

EP, 1, 6, 9 GND Ground 3–4 GND GND

7, 8 VDD Supply Voltage input 1–2 VDD VDD

12 NIRQ

2 SDN

16 NSEL SPI select input 11–12 NSEL P1.3

13 SCLK SPI clock input 17–18 SCLK P1.0

15 SDI SPI data input 13–14 MOSI P1.2

14 SDO SPI data output 15–16 MISO P1.1

10 GPIO_0 General Purpose I/O 23 x 24 GPIO_0/PB1 P0.0

11 GPIO_1 General Purpose I/O 21 x 22 GPIO_1/PB2 P0.1

19 GPIO_2 General Purpose I/O 9 x 10 GPIO_2/PB3 P0.2

20 GPIO_3 General Purpose I/O 7 x 8 GPIO_3/PB4 P0.3

Interrupt output,

active low

Shutdown input,

active high

19–20 NIRQ P1.4

5–6 SDN P1.5

Signal Name Pin Name

The four GPIO signals’ primary function is push button input to the MCU (PB1–PB4), so these signals are not

connected to the EZRadio chip by default (represented by x in Table 1). The user can connect them by soldering in

jumpers across the appropriate pins of J3.

2 Rev 0.4

AN692

2.1.1. Setting up and Connecting the RFStick to a PC

The power source of the board can be selected with the power-supply selector switch (S6). If S6 is in the Adapter

position, supply voltage is provided by a Toolstick Base Adapter that is connected to the J1 PCB edge connector. If

S6 is in the Battery position, the supply voltage is provided by two AAA batteries in the battery holder on the bottom

side of the board. Current consumption of the RF part (RFVDD) can be measured on J6. Since J6 is shorted by a

PCB track on the bottom side of the board, the user must cut the track if this feature is used.

Figure 2. How to Connect the RFStick to the PC

Steps for connecting to a PC:

Select the desired power source with S6 power selector switch.

Connect the J1 connector of the RFStick to the Toolstick Base Adapter.

Connect the Toolstick Base Adapter to the USB port of the PC.

Wait for Windows to install the driver of the Toolstick Base Adapter, if necessary.

The RFStick is available in three different frequency band versions from Silicon Labs as part of several EZRadio

kits (i.e., 434, 868, and 915 MHz).

Rev 0.4 3

AN692

2.2. The Wireless Motherboard Platform

The Wireless Motherboard (WMB) platform is a demo and development platform for the EZRadio and

EZRadioPRO radio ICs. It consists of a Wireless Motherboard and interchangeable MCU Pico Boards and RF Pico

Boards.

Figure 3. Wireless Motherboard Platform

Table 2. . Kits that Contain the Wireless Motherboard Platform

Part Number Kit Name

EZR-LCDK2W-434 EZRadio Two Way Link Development Kit 434 MHz

EZR-LCDK2W-868 EZRadio Two Way Link Development Kit 868 MHz

EZR-LCDK2W-915 EZRadio Two Way Link Development Kit 915 MHz

4012-LCDK1W-434 Si4012 EZRadio One Way Link Development Kit 434 MHz

4012-LCDK1W-915 Si4012 EZRadio One Way Link Development Kit 915 MHz

4 Rev 0.4

2.2.1. The Wireless Motherboard

AN692

Figure 4. Wireless Motherboard

The wireless motherboard contains four pushbuttons, four LEDs, and a buzzer as simple user interfaces. A

graphical LCD displays menu items for range testing purposes and a potentiometer demonstrates analog

capabilities of the MCU. A switch supports the power options of the MCU's built-in dc/dc converter. Using the

current measurement jumpers, current consumption can be measured separately either for the MCU, the radio, or

the peripherals. The motherboard contains test pins for all I/O pins of the MCU and for all digital pins of the radio. In

addition, there are SMA connectors for the GPIOs of the radio for test equipment connection. A USB

communication interface as well as a built-in Silicon Labs USB-to-C2 debug adapter are integrated onto the board

so that the wireless motherboard (WMB) can be directly connected via USB to the PC for downloading and

debugging code on the MCU.

The WMB also contains an interface connection to sensor modules. The RF pico boards can be connected to the

WMB through a connector pair.

Rev 0.4 5

AN692

2.2.2. Power Scheme

The power source of the platform can be selected with the power supply selector switch “SUPPLY SELECT” on the

WMB board. If this switch is in the ”USB” position, supply voltage is provided by the PC that is connected to the

”J16” mini USB connector. If this switch is in the ”BAT” position, the supply voltage is provided by two AA batteries

in the battery holder on the bottom side of the board. If the ”SUPPLY SELECT” switch is in the ”EXT” position,

supply voltage is provided by an external power source through the ”TP7” and “TP9” points.

Using the ”MCU dc/dc” switch, the internal dc/dc converter of the C88051F930 MCU on the MCU pico board can

be activated if the connected pico board supports this function. If the switch is in ”OFF” position, the MCU's dc/dc

converter is inactive and the supply voltage is only determined by the state of the “SUPPLY SELECT” switch.

Positioning the switch to either ”LDO (1.25 V)” or ”1 CELL” position will turn on the MCU's dc/dc converter by

connecting 1.25–1.5 V supply voltage to the VBAT pin and removing external power from the VDC pin. The MCU

will provide 1.9 V in default setting on its VDC pin to all the other connected loads. Since this current is limited, it

may be necessary to disconnect or disable some loading part of the board. For further details, see the MCU data

sheet and the board schematic. The board schematic can be found in the EZRadioPRO Development Kit User's

Guide. A complete CAD design pack of the board is also available at www.silabs.com.

2.2.3. RF Pico Board

Figure 5. RF Pico Board

The RF Pico Board is a radio module that contains an EZRadio IC, matching network, and pcb antenna. The RF

output is a 50 SMA output connector. The boards also have a factory loaded board identification memory (EBID)

that contains data that describes the board properties. Via the unified RF pico connector pair on the bottom side of

the board, any RF pico board can be connected to the WMB.

2.2.4. Setting up and Connecting the WMB to the PC

Steps for connecting the platform to the PC:

1. Connect an RF Pico Board to the WMB board through the CON1 and CON2 connectors.

2. Insert a UPPI-930-RF MCU pico board in the connectors J5, J6, J7, J8 on the WMB. The dotted corner of

the C8051F930 MCU has to point to the triangle symbol on the WMB.

3. Connect an antenna to the SMA connector on the RF Pico Board.

4. Select the desired power source with the SUPPLY SELECT switch.

5. Ensure that all the CURRENT MEASUREMENT jumpers are in place.

6. Connect the WMB board to a USB port of the PC.

7. Wait for Windows to install the driver of the debug interface if necessary.

6 Rev 0.4

AN692

3. Software Tools

Two software tools are provided by Silicon Labs to help EZRadio software development, the Wireless Development

Suite (WDS) and the Silicon Labs Integrated Development Environment (IDE), both available atwww.silabs.com.

3.1. Wireless Development Suite (WDS)

The recommended starting point for Si4355/4455 development is the WDS. It can be downloaded from

www.silabs.com.and can be installed on a PC. After connecting one of the hardware platforms described in this

document to the PC, WDS is able to identify the connected board by reading the EBID memories.

The Radio Configuration Application GUI is part of the WDS program. This setup interface provides an easy path to

quickly selecting and loading the desired configuration for the Si4355/4455 device. After the desired configuration

is selected, the EZConfig setup automatically creates the configuration data that can be used to configure the

EZRadio chip. The program then gives the option to directly configure the EZRadio chip of the connected

hardware, to modify a selected example code with the configuration and download it to the connected hardware, or

to launch Silicon Labs IDE with the new configuration data preloaded into the selected example project. For more

information on WDS and EZConfig usage, refer to the application notes “AN796: Wireless Development Suite

General Description” and “AN797: WDS User’s Guide for EZRadio Devices”, available at www.silabs.com.

Rev 0.4 7

AN692

Figure 6. Device Configuration Options

8 Rev 0.4

AN692

3.2. Silicon Labs IDE

The Silicon Laboratories Integrated Development Environment (IDE) is a standard tool for program development

for any Silicon Labs 8-bit MCUs, including the C8051F930 that is used on the hardware platforms described in this

document. The Silicon Laboratories IDE integrates a project manager, a source-code editor, source-level

debugger, and an in-system flash programmer. The IDE interfaces to third party development tool chains to provide

system designers a complete embedded software development environment. The Keil Demonstration Toolset

includes a compiler, linker, and assembler and easily integrates into the IDE.

3.2.1. Downloading and Running the Example Codes

1. Connect the hardware platform to the PC according to the description of the used platform.

2. Start Silicon Labs IDE (IDE 4.40 or higher required) on your computer.

3. Select Project→Open Project... to open a previously saved project.

4. Before connecting to the target device, several connection options may need to be set. Open the

Connection Options window by selecting Options→Connection Options... in the IDE menu.

5. Select USB Debug Adapter in the “Serial Adapter” section.

6. If more than one adapter is connected, choose the appropriate serial number from the drop-down list.

7. Check the “Power target after disconnect” if the target board is currently being powered by the USB Debug

Adapter. The board will remain powered after a software disconnect by the IDE.

8. Next, the correct “Debug Interface” must be selected. Check the C2 Debug Interface.

9. Once all the selections are made, click the OK button to close the window.

10. Click the Connect button in the toolbar or select Debug→Connect from the menu to connect to the

C8051F930 MCU of the platform.

11. Erase the flash of the C8051F930 MCU in the Debug→Download object code→ Erase all code space

menu item.

12. Download the desired example HEX file either by hitting the Download code (Alt+D) toolbar button or from

the Debug →Download object code menu item.

13. Hit the Disconnect toolbar button or invoke the Debug →Disconnect menu item to release the device from

halt and to let it run.

Rev 0.4 9

AN692

3.3. ToolStick Terminal

The ToolStick Terminal program provides the standard terminal interface to the target microcontroller's UART.

However, instead of requiring the usual RS-232 and COM port connection, ToolStick Terminal uses the USB

interface of the ToolStick Base Adapter to provide the same functionality. The firmware on the target microcontroller

does not need to be customized to use the UART and communicate with ToolStick Terminal. The firmware on the

microcontroller should write to the UART as it would in any standard application and all of the translation is handled

by the ToolStick Base Adapter.

The ToolStick Base Adapter is integrated on the WMB and is also part of the RFStick platform as a separate

device.

The ToolStick Terminal program is part of the Silicon Labs IDE and is also available as a separate application. Both

can be installed as part of the Silicon Labs 8-bit Microcontroller Studio from:

http://www.silabs.com/products/mcu/Pages/8-bit-microcontroller-software.aspx

The IDE and its built in ToolStick Terminal can communicate with the target MCU simultaneously on the C2

interface and on the UART respectively.

To use the ToolStick Terminal in the IDE (above v4.60.00), follow these steps:

1. Open the Silabs IDE from the Start Programs Silicon Laboratories menu.

2. Go to the OptionsConnection Options menu and select the desired ToolStick Base Adapter from the drop

down list.

3. Click on the Connect button to connect the IDE to the target MCU via the C2 interface.

4. From the Tools menu, start the Toolstick Terminal. In the top left-hand corner of the Terminal application, go

to the ToolStickSettings menu and set the communication parameters. Now the ToolStick Terminal is

ready for use. In the "Receive Data" window, text indicating the received characters will appear.

In addition to the standard two UART pins (TX and RX), there are two GPIO/UART handshaking pins on the

ToolStick Base Adapter. On both the WMB and RFStick platforms GPIO0 is used for the internal purpose of the

WDS to select between the C2 interface of the target MCU and the EBID MCU. GPIO1 is not connected. Although

the separate ToolStick Terminal application provides the functionality to control these GPIOs, default settings for

GPIO0 should not be changed.

10 Rev 0.4

AN692

4. Using the Si4355/Si4455 Radios

Si4355 and Si4455 are easy-to-use radio chips that combine plug-and-play simplicity with the flexibility needed to

handle a wide variety of applications. This chapter describes how to operate the Si4355/Si4455 radios.

4.1. Radio Hardware Interface

The Si4355/Si4455 radios have several pins to interface to a host MCU. Four pins, SDI, SDO, SCLK, NSEL, are

used to control the radio over the SPI bus. The user has access to an Application Programming Interface (API) via

the SPI bus, which is described in section “4.2. Application Programming Interface”. The Shutdown (SDN) pin is

used to completely disable the radio (when the pin is pulled high) and put the device into the lowest power

consumption state. After the SDN pin is pulled low, the radio wakes up and performs a Power On Reset. It takes

about 1 ms until the chip is ready to receive commands on the SPI bus (GPIO1 pin goes high when the radio is

ready for receiving SPI commands). When SDN is high and the radio is in shutdown state, the GPIOs are set to

drive an output low level. The radio has an interrupt output pin, NIRQ, which can be used to promptly notify the

host MCU of various events. The NIRQ pin is active low, and goes back to high if the pending interrupt flag was

cleared by reading the appropriate Interrupt Pending registers.

Table 3. Serial Peripheral Interface Signals

Radio Pin Signal Description

SCLK Serial Clock Output From Master

SDI Master Output, Slave Input

SDO Master Input, Slave Output

NSEL Slave Select, Active Low

Figure 7. Connections between the Radio Chip and the Host Microcontroller

Rev 0.4 11

AN692

4.2. Application Programming Interface

The programming interface allows the user to do the following:

Send commands to the radio.

Read status information.

Set and get radio parameters.

Handle the Transmit and Receive FIFOs.

The API commands are listed in the following table:

Table 4. List of the Radio API Commands

Command ID Radio API Command Description

0x00 NOP No operation command

0x02 POWER_UP

0x01 PART_INFO Reports basic information about the device

0x10 FUNC_INFO Returns the function revision information of the device

0x11 SET_PROPERTY Sets the value of a property

0x12 GET_PROPERTY Retrieves a property's value

0x13 GPIO_PIN_CFG Configures the GPIO pins

0x15 FIFO_INFO

0x19 EZCONFIG_CHECK Validates the EZConfig array was written correctly

0x20 GET_INT_STATUS Returns the interrupt status byte

0x31 START_TX

0x32 START_RX Switches to RX state

0x33 REQUEST_DEVICE_STATE Request current device state

0x34 CHANGE_STATE Update state machine entries

0x44 READ_CMD_BUFF

0x50 FRR_A_READ

0x51 FRR_B_READ

0x53 FRR_C_READ

0x57 FRR_D_READ

0x66 EZCONFIG_SETUP Configures device using EZConfig array

0x66 WRITE_TX_FIFO Writes TX data buffer (max. 64 bytes, Si4455 only)

0x77 READ_RX_FIFO Reads RX data buffer (max. 64 bytes)

Powerup device and mode selection. Modes include operational function

Provides access to transmit and receive FIFO counts and

reset

Switches to TX state and starts packet transmission

(Si4455only)

Returns Clear to Send (CTS) value and the result of the previous command

Reads the fast response registers (FRR) starting with

FRR_A.

Reads the fast response registers (FRR) starting with

FRR_B.

Reads the fast response registers (FRR) starting with

FRR_C.

Reads the fast response registers (FRR) starting with

FRR_D.

12 Rev 0.4

The API properties are listed in Table 5.

Table 5. List of the Radio API Properties

AN692

Property

Group

0x01 0x00 INT_CTL_ENABLE Interrupt enable property 0x04

0x01 0x01 INT_CTL_PH_ENABLE Packet handler interrupt enable property 0x00

0x01 0x02 INT_CTL_MODEM_ENABLE Modem interrupt enable property 0x00

0x01 0x03 INT_CTL_CHIP_ENABLE Chip interrupt enable property 0x04

0x02 0x00 FRR_CTL_A_MODE Fast Response Register A Configuration 0x01

0x02 0x01 FRR_CTL_B_MODE Fast Response Register B Configuration 0x02

0x02 0x02 FRR_CTL_C_MODE Fast Response Register C Configuration 0x09

0x02 0x03 FRR_CTL_D_MODE Fast Response Register D Configuration 0x00

0x22 0x01 PA_PWR_LVL PA Level Configuration 0x7F

0x24 0x03 EZCONFIG_XO_TUNE

0x40 0x00 FREQ_CONTROL_INTE Frac-N PLL integer number 0x3C

0x40 0x01 FREQ_CONTROL_FRAC_2 Byte 2 of Frac-N PLL fraction number 0x08

Number Name Description Default

Configure crystal oscillator frequency tuning

bank

0x40

0x40 0x02 FREQ_CONTROL_FRAC_1 Byte 1 of Frac-N PLL fraction number 0x08

0x40 0x03 FREQ_CONTROL_FRAC_0 Byte 0 of Frac-N PLL fraction number 0x08

0x40 0x04

0x40 0x05

The following sections describe the SPI transactions of sending commands and getting information from the chip.

4.2.1. Sending Commands to a Radio

The behavior of the radio can be changed by sending API commands to the radio (e.g., changing the power states,

start packet transmission, etc.). The radio can be configured through several "properties". The properties represent

radio configuration settings, such as interrupt settings, modem parameters, packet handler settings, etc., and can

be set and read via API commands. For most of the commands, the host MCU does not expect any response from

the radio chip. Other commands are used to read back a property from the chip, such as checking the interrupt

status flags, reading the transmit/receive FIFOs.

After the radio receives a command, it processes the request. During this time, the radio is not capable of receiving

a new command. The host MCU must identify when the next command can be sent. The Clear to Send (CTS)

signal shows the actual status of the command buffer of the radio. It can be monitored over the SPI or on GPIOs, or

the chip can generate an interrupt if it is ready to receive the next command. These three options are detailed

below.

FREQ_CONTROL_CHANNEL_-

STEP_SIZE_1

FREQ_CONTROL_CHANNEL_-

STEP_SIZE_0

Byte 1 of channel step size

Byte 0 of channel step size

0x00

0x00

Rev 0.4 13

AN692

4.2.2. Checking that the Radio is Ready to Receive Commands

4.2.2.1. Software Polling Method

To ensure the radio is ready to receive the next command, the host MCU must pull down the NSEL pin to monitor

the status of CTS over the SPI port. The 0x44 command ID has to be sent, and eight clock pulses have to be

generated, on the SCLK pin. During the additional eight clock cycles, the radio clocks out the CTS as a byte on the

SDO pin. When completed, the NSEL should be pulled back to high. If the CTS byte is 0xFF, then the radio

processed the last command successfully and is ready to receive the next command; in any other case, the CTS

read procedure has to be repeated from the beginning as long as the CTS byte is not 0xFF.

Figure 8. Polling the Radio Availability

4.2.2.2. GPIO Checking Method

Any GPIO can be configured for monitoring the CTS. GPIOs can be configured to go either high or low when the

chip completes the command. The function of the GPIOs can be changed by the GPIO_PIN_CFG command. By

default, GPIO1 is set as “High when command completed, low otherwise” after Power On Reset. Therefore, this pin

can be used for monitoring the CTS right after Power On Reset and to identify when the chip is ready to boot up.

4.2.2.3. NIRQ Interrupt Checking Method

The radio asserts the CHIP_READY interrupt flag if a command is completed. The interrupt flag can be monitored

by either the GET_CHIP_STATUS or the GET_INT_STATUS command. Apart from monitoring the interrupt flags,

the radio may pull down the NIRQ pin if this feature is enabled. If a new command is sent while the CTS is

asserted, then the radio ignores the new command. The Si446x can generate an interrupt to communicate this

error to the MCU by the CMD_ERROR interrupt flag in the CHIP_STATUS group. The interrupt flag has to be read

(by issuing a GET_CHIP_STATUS or GET_INTERRUPT_STATUS command) to clear the pending interrupt and

release the NIRQ pin. No other action is needed to reset the command buffer of the radio; however, after a

CMD_ERROR, the host MCU should repeat the new command after the radio has processed the previous one.

All the commands that are sent to the radio have the same structure. After pulling down the NSEL pin of the radio,

the command ID should be sent first. The commands may have up to 15 input parameters.

Figure 9. Host MCU Sends Command to Radio

14 Rev 0.4

AN692

4.2.3. Getting a Command Response from Radio

Reading from the radio requires several steps to be followed. The host MCU should send a command with the

address it requests to read. The radio holds the CTS while it retrieves the requested information. Once the CTS is

set (0xFF), the host MCU can read the answer from the radio.

Figure 10. Read Procedure

If the CTS is polled on the GPIOs, or the radio is configured to provide interrupt if the answer is available, then the

response can be read out from the radio with the following SPI transaction:

Figure 11. Read the Response from Radio

If the CTS is polled over the SPI bus, first the host MCU should pull the NSEL pin low. This action should be

followed by sending out the 0x44 Read command ID and providing an additional eight clock pulses on the SCLK

pin. The radio will provide the CTS byte on its SDO pin during the additional clock pulses. If the CTS byte is 0x00,

then the response is not yet ready and the host MCU should pull up the NSEL pin and repeat the procedure from

the beginning as long as the CTS byte is not 0xFF. If CTS is 0xFF, then the host MCU should keep the NSEL pin

low and provide clock cycles on the SCLK pin, as many as the data to be read out requires. The radio will clock out

the requested data on its SDO pin during the additional clock pulses.

Rev 0.4 15

AN692

Figure 12. Monitor CTS and Read the Response on the SPI Bus

Reading the response from the radio can be interrupted earlier. For example, if the host MCU asked for five bytes

of response, it may read fewer bytes in one SPI transaction. As long as a new command is not sent, the radio

keeps the response for the last request in the command buffer. The host MCU can re-read the response in a new

SPI transaction. In such a case, the response is always provided from the first byte.

Notes:

Up to 16 bytes of response can be read from the radio in one SPI transaction. If more bytes are read, the

radio will provide the same 16 bytes of response in a circular manner.

If the command has N bytes of response, but the host MCU provides less than N bytes of clock pulses

during the read sequence, it causes no issue for the radio. The response buffer is reset if a new command

is issued.

If the command has N bytes of response, but, during the read sequence, the host MCU provides more than

N bytes of clock pulses, the radio will provide unpredictable bytes after the first N bytes. The host MCU

does not need to reset the SPI interface; it happens automatically if NSEL is pulled low before the next

command is sent.

16 Rev 0.4

AN692

4.2.4. Using Fast Response Registers

There are several types of status information that can be read out from the radio faster. The FRR_CTL_x_MODE

(where x can be A, B, C or D) properties define what status information is assigned to a given fast response

register (FRR). The actual value of the registers can be read by pulling down the NSEL pin, issuing the proper

command ID, and providing an additional eight clock pulses on the SCLK pin. During these clock pulses, the radio

provides the value of the addressed FRR. The NSEL pin has to be pulled high after finishing the register read.

Figure 13. Reading a Single Fast Response Register

It is also possible to read out multiple FRRs in a single SPI transaction. The NSEL pin has to be pulled low, and

one of the FRRs has to be addressed with the proper command ID. Providing an additional 8 x N clock cycles will

clock out an additional N number of FRRs. After the fourth byte is read, the radio will provide the value of the

registers in a circular manner. The reading stops by pulling the NSEL pin high.

Figure 14. Reading More Fast Response Registers in a Single SPI Transaction

Note: If the pending interrupt status register is read through the FRR, the NIRQ pin does not go back to high. The pending

interrupt registers have to be read by a Get response to a command sequence in order to release the NIRQ pin.

Rev 0.4 17

AN692

4.2.5. Write and Read the FIFOs

There are two 64-byte FIFOs for RX and TX data in the Si4x55.

To fill data into the transmit FIFO, the host MCU should pull the NSEL pin low and send the 0x66 Transmit FIFO

Write command ID followed by the bytes to be filled into the FIFO. Finally, the host MCU should pull the NSEL pin

high. Up to 64 bytes can be filled into the FIFO during one SPI transaction.

Figure 15. Transmit FIFO Write

If the host MCU needs to read the receive FIFO, it has to pull the NSEL pin low and send the 0x77 Receive FIFO

Read command ID. The MCU should provide as many clock pulses on the SCLK pin as necessary for the radio to

clock out the requested amount of bytes from the FIFO on the SDO pin. Finally, the host MCU should pull up the

NSEL pin.

Figure 16. Receive FIFO Read

If more than 64 bytes are written into the Transmit FIFO, then a FIFO overflow occurs. If more bytes are read from

the Receive FIFO than it holds, then FIFO underflow occurs. In either of these cases, the

FIFO_UNDERFLOW_OVERFLOW_ERROR interrupt flag will be set. The radio can also generate an interrupt on

the NIRQ pin if this flag is enabled. The interrupt flag has to be read, by issuing a GET_CHIP_STATUS or

GET_INTERRUPT_STATUS command, to clear the pending interrupt and release the NIRQ pin.

18 Rev 0.4

AN692

4.3. State Transitions of the EZRadio Devices

Ready state is designed to give a fast transition time to TX or RX state with reasonable current consumption. In this

mode the crystal oscillator remains enabled reducing the time required to switch to TX or RX mode by eliminating

the crystal start-up time. An automatic sequencer will put the chip into RX or TX from any state. It is not necessary

to manually step through the states. Although it is not shown in the diagram, any of the lower power states can be

returned to automatically after RX or TX.

Figure 17. Operational States and Current Consumption

Rev 0.4 19

AN692

State/Mode Response Time to

Table 6. Switching Times between Radio States

TX RX

Shutdown 15 ms 15 ms

Sleep 440 μs 440 μs

SPI Active 340 μs 340 μs

Ready 126 μs 122 μs

TX Tune 58 μs N/A

RX Tune N/A

TX N/A

RX 130 μs 75 μs

Notes:

1. This state change is not possible in the RF chip.

2. While the chip is in sleep state, the NSEL pin has to stay in high state. If the host processor is not able to provide this

during sleep, a pullup resistor can be necessary on the NSEL pin.

1

1

74 μs

138 μs

Figure 18. Supply Current versus Time Diagram from Shutdown to RF initialized Ready State

20 Rev 0.4

AN692

Figure 19. Supply Current versus Time Diagram from Shutdown to Standby State

Figure 20. Supply Current versus Time Diagram from Shutdown to TX State

Rev 0.4 21

Loading...

Loading...