Page 1

Ember EM358x

EMBER

This reference manual accompanies several documents to provide the complete description of Ember

devices. In the event that the device data sheet and this document contain conflicting information, the device data

sheet should be considered the authoritative source.

EM358X REFERENCE MANUAL

®

EM358x

®

Rev 0.4 8/13 Copyright © 2013 by Silicon Laboratories EM358x

This information applies to a product under development. Its characteristics and specifications are subject to change without notice.

Page 2

EM358x

2 Rev. 0.4

Page 3

EM358x

TABLE OF CONTENTS

1 Related Documents and Conventions ............................................................................... 8

1.1 Related Documents ........................................................................................................ 8

1.1.1 EM358x Data Sheet ............................................................................................ 8

1.1.2 ZigBee Specification ........................................................................................... 8

1.1.3 ZigBee PRO Stack Profile ................................................................................... 8

1.1.4 ZigBee Stack Profile ............................................................................................ 8

1.1.5 Bluetooth Core Specification ............................................................................... 8

1.1.6 IEEE 802.15.4-2003 ............................................................................................ 8

1.1.7 IEEE 802.11g ...................................................................................................... 8

1.1.8 USB 2.0 Specification ......................................................................................... 8

1.1.9 ARM® Cortex™-M3 Reference Manual ............................................................... 8

1.2 Conventions .................................................................................................................... 9

2 ARM® Cortex™-M3 and Memory Modules ....................................................................... 12

2.1 ARM® Cortex™-M3 Microprocessor ............................................................................. 12

2.2 Embedded Memory ...................................................................................................... 13

2.2.1 Flash Memory ................................................................................................... 14

2.2.2 RAM .................................................................................................................. 17

2.2.3 Registers ........................................................................................................... 17

2.3 Memory Protection Unit ................................................................................................ 18

3 Interrupt System ................................................................................................................ 19

3.1 Nested Vectored Interrupt Controller (NVIC) ................................................................ 19

3.2 Event Manager ............................................................................................................. 22

3.3 Non-maskable Interrupt (NMI) ...................................................................................... 24

3.4 Faults ............................................................................................................................ 25

3.5 Registers ....................................................................................................................... 26

4 Radio Module ..................................................................................................................... 33

4.1 Receive (Rx) Path ......................................................................................................... 33

4.1.1 Rx Baseband .................................................................................................... 33

4.1.2 RSSI and CCA .................................................................................................. 34

4.2 Transmit (Tx) Path ........................................................................................................ 34

4.2.1 Tx Baseband ..................................................................................................... 34

4.2.2 TX_ACTIVE and nTX_ACTIVE Signals ............................................................ 34

4.3 Calibration ..................................................................................................................... 34

4.4 Integrated MAC Module ................................................................................................ 34

4.5 Packet Trace Interface (PTI) ......................................................................................... 35

4.6 Random Number Generator ......................................................................................... 35

5 System Modules ................................................................................................................ 36

5.1 Power domains ............................................................................................................. 37

5.1.1 Internally regulated power ................................................................................. 37

5.1.2 Externally regulated power ................................................................................ 37

5.2 Resets ........................................................................................................................... 37

5.2.1 Reset Sources .................................................................................................. 37

5.2.2 Reset Recording ............................................................................................... 39

5.2.3 Reset Generation Module ................................................................................. 39

5.3 Clocks ........................................................................................................................... 40

Rev. 0.4 3

Page 4

EM358x

5.3.1 High-Frequency Internal RC Oscillator (OSCHF) .............................................. 42

5.3.2 High-Frequency Crystal Oscillator (OSC24M) .................................................. 42

5.3.3 Low-Frequency Internal RC Oscillator (OSCRC) .............................................. 43

5.3.4 Low-Frequency Crystal Oscillator (OSC32K) .................................................... 43

5.3.5 Clock Switching ................................................................................................. 44

5.4 System Timers .............................................................................................................. 44

5.4.1 Watchdog Timer ................................................................................................ 44

5.4.2 Sleep Timer ....................................................................................................... 45

5.4.3 Event Timer ....................................................................................................... 45

5.5 Power Management ...................................................................................................... 45

5.5.1 Wake Sources ................................................................................................... 45

5.5.2 Basic Sleep Modes ........................................................................................... 47

5.5.3 Further options for deep sleep .......................................................................... 47

5.5.4 RAM Retention in deep sleep ........................................................................... 48

5.5.5 Use of debugger with sleep modes ................................................................... 48

5.5.6 Registers ........................................................................................................... 49

5.6 Security Accelerator ...................................................................................................... 50

6 Integrated Voltage Regulator ........................................................................................... 51

7 GPIO (General Purpose Input / Output) ........................................................................... 52

7.1 GPIO Ports ................................................................................................................... 52

7.2 Configuration ................................................................................................................ 53

7.3 Forced Functions .......................................................................................................... 54

7.4 Reset ............................................................................................................................ 55

7.5 Boot Configuration ........................................................................................................ 55

7.6 GPIO Modes ................................................................................................................. 56

7.6.1 Analog Mode ..................................................................................................... 56

7.6.2 Input Mode ........................................................................................................ 56

7.6.3 SWDIO Mode .................................................................................................... 57

7.6.4 Output Mode ..................................................................................................... 57

7.6.5 Alternate Output Mode ...................................................................................... 57

7.6.6 Alternate Output SPI Slave MISO Mode ........................................................... 57

7.7 Wake Monitoring ........................................................................................................... 58

7.8 External Interrupts ........................................................................................................ 58

7.9 Debug Control and Status ............................................................................................. 59

7.10 GPIO Signal Assignment Summary ............................................................................ 59

7.11 Registers .................................................................................................................... 61

8 Serial Controllers .............................................................................................................. 74

8.1 Overview ....................................................................................................................... 74

8.2 Configuration ................................................................................................................ 75

8.2.1 Registers ........................................................................................................... 76

8.3 SPI - Master Mode ........................................................................................................ 80

8.3.1 GPIO Usage ...................................................................................................... 80

8.3.2 Set Up and Configuration .................................................................................. 80

8.3.3 Operation .......................................................................................................... 81

8.3.4 Interrupts ........................................................................................................... 82

8.3.5 Registers ........................................................................................................... 83

4 Rev. 0.4

Page 5

EM358x

8.4 SPI - Slave Mode .......................................................................................................... 88

8.4.1 GPIO Usage ...................................................................................................... 88

8.4.2 Set Up and Configuration .................................................................................. 88

8.4.3 Operation .......................................................................................................... 89

8.4.4 DMA .................................................................................................................. 90

8.4.5 Interrupts ........................................................................................................... 90

8.4.6 Registers ........................................................................................................... 90

8.5 TWI - Two Wire serial Interfaces ................................................................................... 90

8.5.1 GPIO Usage ...................................................................................................... 91

8.5.2 Set Up and Configuration .................................................................................. 91

8.5.3 Constructing Frames ......................................................................................... 91

8.5.4 Interrupts ........................................................................................................... 93

8.5.5 Registers ........................................................................................................... 94

8.6 UART - Universal Asynchronous Receiver / Transmitter .............................................. 97

8.6.1 GPIO Usage ...................................................................................................... 97

8.6.2 Set Up and Configuration .................................................................................. 97

8.6.3 FIFOs ................................................................................................................ 99

8.6.4 RTS/CTS Flow control ...................................................................................... 99

8.6.5 DMA ................................................................................................................ 100

8.6.6 Interrupts ......................................................................................................... 100

8.6.7 Registers ......................................................................................................... 102

8.7 DMA Channels ............................................................................................................ 106

8.7.1 Registers ......................................................................................................... 107

9 USB Device ...................................................................................................................... 124

9.1 Overview ..................................................................................................................... 124

9.2 Host Drivers ................................................................................................................ 124

9.3 References ................................................................................................................. 124

9.4 GPIO Usage and USB Pin Assignments..................................................................... 124

9.5 Application Schematics ............................................................................................... 125

9.6 Endpoints .................................................................................................................... 125

9.7 Buffers and DMA ........................................................................................................ 126

9.8 Set Up and Configuration ............................................................................................ 126

9.9 DMA Usage and Transfers ......................................................................................... 128

9.10 Enumeration ............................................................................................................. 128

9.11 Normal COM Port Operation .................................................................................... 128

9.12 Suspend and Resume .............................................................................................. 128

9.13 Interrupts .................................................................................................................. 128

9.13.1 Registers ......................................................................................................... 129

10 General Purpose Timers (TIM1 and TIM2) ..................................................................... 139

10.1 Introduction ............................................................................................................... 139

10.2 GPIO Usage ............................................................................................................. 140

10.3 Timer Functional Description .................................................................................... 141

10.3.1 Time-Base Unit ............................................................................................... 141

10.3.2 Counter Modes ............................................................................................... 142

10.3.3 Clock Selection ............................................................................................... 147

10.3.4 Capture/Compare Channels ........................................................................... 150

Rev. 0.4 5

Page 6

EM358x

10.3.5 Input Capture Mode ........................................................................................ 151

10.3.6 PWM Input Mode ............................................................................................ 152

10.3.7 Forced Output Mode ....................................................................................... 152

10.3.8 Output Compare Mode .................................................................................... 153

10.3.9 PWM Mode ..................................................................................................... 154

10.3.10One-Pulse Mode ............................................................................................ 156

10.3.11Encoder Interface Mode ................................................................................. 158

10.3.12Timer Input XOR Function ............................................................................. 159

10.3.13Timers and External Trigger Synchronization ................................................ 160

10.3.14Slave Mode: Reset Mode ............................................................................... 160

10.3.15Timer Synchronization ................................................................................... 162

10.3.16Timer Signal Descriptions .............................................................................. 166

10.4 Interrupts .................................................................................................................. 167

10.5 Registers .................................................................................................................. 168

11 ADC (Analog to Digital Converter) ................................................................................. 195

11.1 Setup and Configuration ........................................................................................... 195

11.1.1 GPIO Usage .................................................................................................... 196

11.1.2 Voltage Reference .......................................................................................... 196

11.1.3 Offset/Gain Correction .................................................................................... 196

11.1.4 DMA ................................................................................................................ 196

11.1.5 ADC Configuration Register ............................................................................ 197

11.2 Interrupts .................................................................................................................. 199

11.3 Operation .................................................................................................................. 200

11.4 Calibration ................................................................................................................ 200

11.5 ADC Key Parameters ............................................................................................... 201

11.6 Registers .................................................................................................................. 206

12 Trace Port Interface Unit (TPIU) ..................................................................................... 218

13 Instrumentation Trace Macrocell (ITM) .......................................................................... 219

14 Embedded Trace Macrocell (ETM) ................................................................................. 220

15 Data Watchpoint and Trace (DWT) ................................................................................. 221

16 Flash Patch and Breakpoint (FPB) ................................................................................. 222

17 Serial Wire and JTAG (SWJ) Interface ........................................................................... 223

A. Register Address Table .................................................................................................. 224

6 Rev. 0.4

Page 7

EM358x

Rev. 0.4 7

Page 8

EM358x

1 Related Documents and Conventions

1.1 Related Documents

This reference manual accompanies several documents to provide the complete description of the Ember

EM358x devices.

1.1.1 EM358x Data Sheet

The Silicon Laboratories EM358x data sheet provides the configuration information for the EM358x.

1.1.2 ZigBee Specification

The core ZigBee specification (Document 053474) defines ZigBee's smart, cost-effective and energy-efficient

mesh network. It can be downloaded from the ZigBee website (111.zigbee.org). ZigBee Alliance membership is

required.

1.1.3 ZigBee PRO Stack Profile

The ZigBee PRO Stack Profile specification (Document 074855) is optimized for low power consumption and to

support large networks with thousands of devices. It can be downloaded from the ZigBee website

(111.zigbee.org). ZigBee Alliance membership is required.

1.1.4 ZigBee Stack Profile

The ZigBee Stack Profile specification (Document 064321) is designed to support smaller networks with hundreds

of devices in a single network. It can be downloaded from the ZigBee website (111.zigbee.org). ZigBee Alliance

membership is required.

1.1.5 Bluetooth Core Specification

The Bluetooth specification is the global short-range wireless standard enabling connectivity for a broad range of

electronic devices. Version 2.1 + EDR (Enhanced Data Rate) can be found here:

http://www.bluetooth.org/docman/handlers/downloaddoc.ashx?doc_id=241363

1.1.6 IEEE 802.15.4-2003

This standard defines the protocol and compatible interconnection for data communication devices using low data

rate, low power and low complexity, short-range radio frequency (RF) transmissions in a wireless personal area

network (WPAN). It can be found here:

IEEE 802.15.4-2003 (http://standards.ieee.org/getieee802/download/802.15.4-2003.pdf)

1.1.7 IEEE 802.11g

This version provides changes and additions to support the further higher data rate extension for operation in the

2.4 GHz band. It can be found here:

standards.ieee.org/getieee802/download/802.11g-2003.pdf

1.1.8 USB 2.0 Specification

The Universal Serial Bus Revision 2.0 specification provides the technical details to understand USB

requirements and design USB compatible products. The main specification (usb_20.pdf) is part of the zipfile found

here:

http://www.usb.org/developers/docs/usb_20_101111.zip

®

1.1.9 ARM

ARM-specific features like the Nested Vector Interrupt Controller are described in the ARM

reference documentation. The online reference manual can be found here:

http://infocenter.arm.com/help/topic/com.arm.doc.subset.cortexm.m3/index.html#cortexm3

Cortex™-M3 Reference Manual

®

Cortex™-M3

8 Rev. 0.4

Page 9

1.2 Conventions

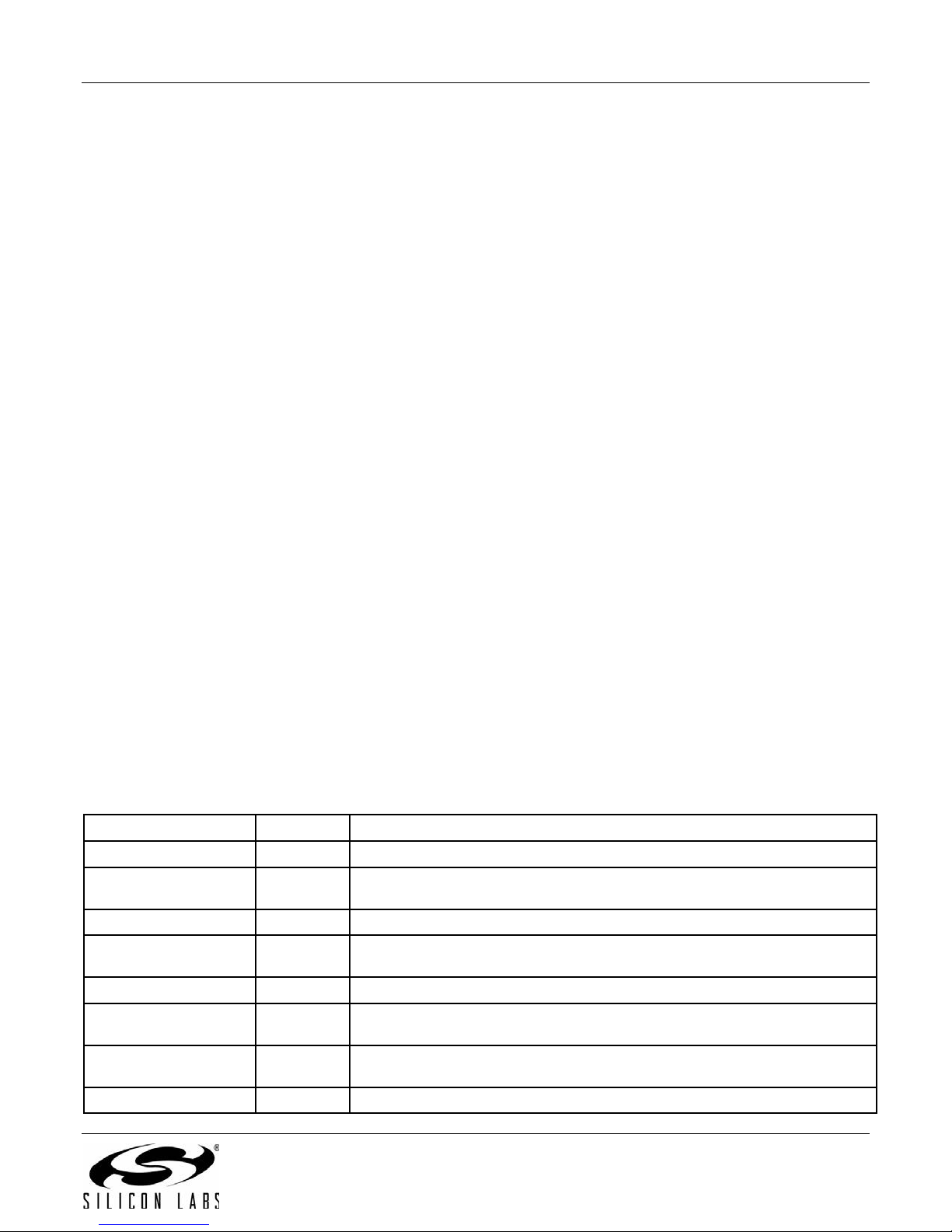

Abbreviations and acronyms used in this data sheet are explained in Table 1-1.

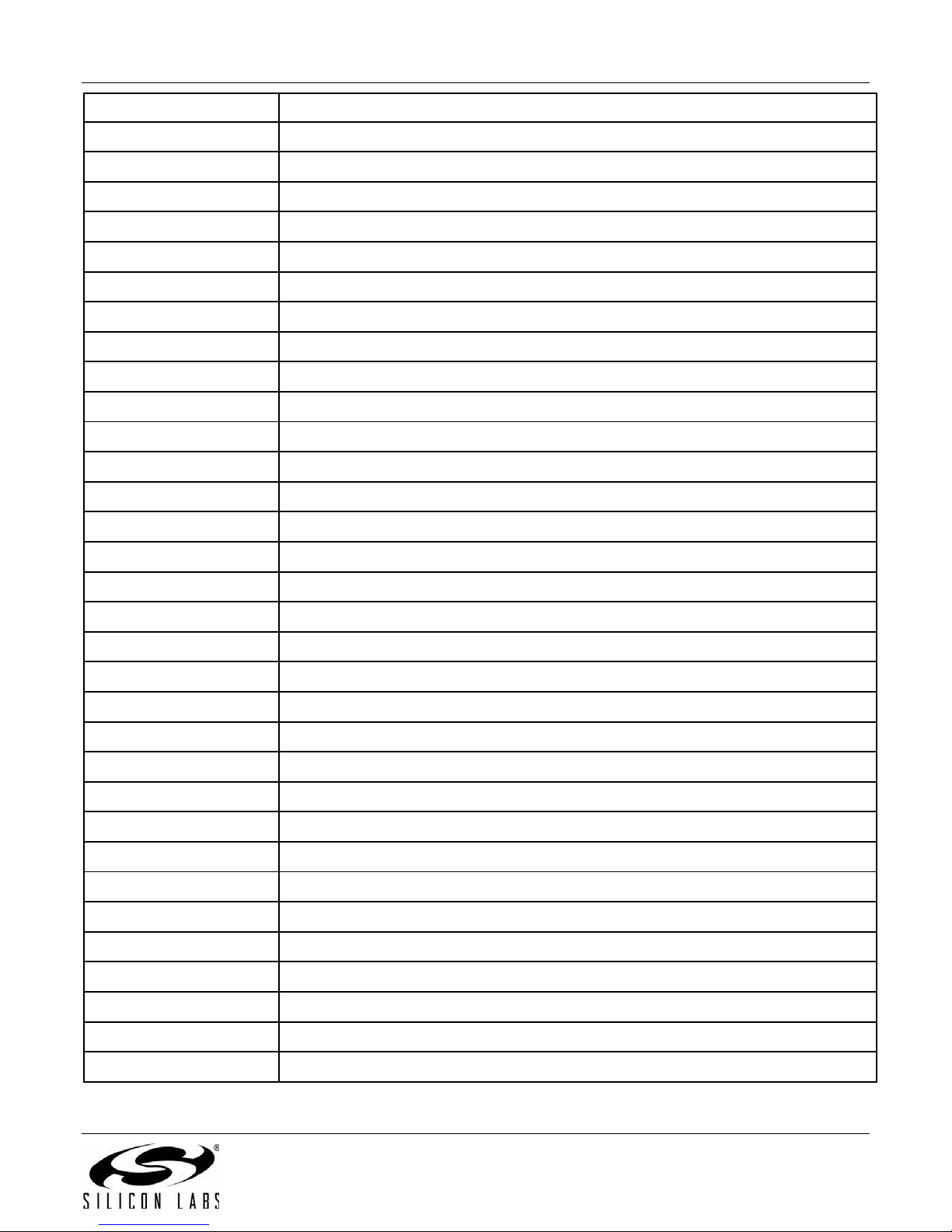

Table 1-1. Acronyms and Abbreviations

Acronym/Abbreviation Meaning

ACK Acknowledgement

ADC Analog to Digital Converter

AES Advanced Encryption Standard

AGC Automatic Gain Control

AHB Advanced High Speed Bus

APB Advanced Peripheral Bus

CBC-MAC Cipher Block Chaining—Message Authentication Code

CCA Clear Channel Assessment

CCM Counter with CBC-MAC Mode for AES encryption

CCM* Improved Counter with CBC-MAC Mode for AES encryption

EM358x

CIB Customer Information Block

CLK1K 1 kHz Clock

CLK32K 32.768 kHz Crystal Clock

CPU Central Processing Unit

CRC Cyclic Redundancy Check

CSMA-CA Carrier Sense Multiple Access-Collision Avoidance

CTR Counter Mode

CTS Clear to Send

DNL Differential Non-Linearity

DMA Direct Memory Access

DWT Data Watchpoint and Trace

EEPROM Electrically Erasable Programmable Read Only Memory

EM Event Manager

ENOB effective number of bits

ESD Electro Static Discharge

ESR Equivalent Series Resistance

ETR External Trigger Input

FCLK ARM® CortexTM-M3 CPU Clock

FIB Fixed Information Block

FIFO First-in, First-out

Rev. 0.4 9

Page 10

EM358x

Acronym/Abbreviation Meaning

FPB Flash Patch and Breakpoint

GPIO General Purpose I/O (pins)

HF High Frequency

I2C Inter-Integrated Circuit

IDE Integrated Development Environment

IF Intermediate Frequency

IEEE Institute of Electrical and Electronics Engineers

INL Integral Non-linearity

ITM Instrumentation Trace Macrocell

JTAG Joint Test Action Group

LF Low Frequency

LNA Low Noise Amplifier

LQI Link Quality Indicator

LSB Least significant bit

MAC Medium Access Control

MFB Main Flash Block

MISO Master in, slave out

MOS Metal Oxide Semiconductor (P-channel or N-channel)

MOSI Master out, slave in

MPU Memory Protection Unit

MSB Most significant bit

MSL Moisture Sensitivity Level

NACK Negative Acknowledge

NIST National Institute of Standards and Technology

NMI Non-Maskable Interrupt

NVIC Nested Vectored Interrupt Controller

OPM One-Pulse Mode

O-QPSK Offset-Quadrature Phase Shift Keying

OSC24M High Frequency Crystal Oscillator

OSC32K Low-Frequency 32.768 kHz Oscillator

OSCHF High-Frequency Internal RC Oscillator

OSCRC Low-Frequency RC Oscillator

PA Power Amplifier

10 Rev. 0.4

Page 11

Acronym/Abbreviation Meaning

PCLK Peripheral clock

PER Packet Error Rate

PHY Physical Layer

PLL Phase-Locked Loop

POR Power-On-Reset

PRNG Pseudo Random Number Generator

PSD Power Spectral Density

PTI Packet Trace Interface

PWM Pulse Width Modulation

QFN Quad Flat Pack

RAM Random Access Memory

RC Resistive/Capacitive

RF Radio Frequency

EM358x

RMS Root Mean Square

RoHS Restriction of Hazardous Substances

RSSI Receive Signal Strength Indicator

RTS Request to Send

Rx Receive

SYSCLK System clock

SDFR Spurious Free Dynamic Range

SFD Start Frame Delimiter

SINAD Signal-to-noise and distortion ratio

SPI Serial Peripheral Interface

SWJ Serial Wire and JTAG Interface

THD Total Harmonic Distortion

TRNG True random number generator

TWI Two Wire serial interface

Tx Transmit

UART Universal Asynchronous Receiver/Transmitter

UEV Update event

USB Universal Serial Bus

VCO Voltage Controlled Oscillator

Rev. 0.4 11

Page 12

EM358x

2 ARM® Cortex™-M3 and Memory Modules

This chapter discusses the ARM® CortexTM-M3 Microprocessor, and reviews the EM358x’s flash and RAM

memory modules as well as the Memory Protection Unit (MPU).

2.1 ARM® Cortex™-M3 Microprocessor

The EM358x integrates the ARM® CortexTM-M3 microprocessor, revision r1p1, developed by ARM Ltd., making

the EM358x a true System-on-Chip solution. The ARM

architecture processor that has separate internal program and data buses, but presents a unified program and

data address space to software. The word width is 32 bits for both the program and data sides. The ARM

TM

Cortex

The ARM

-M3 allows unaligned word and half-word data accesses to support efficiently-packed data structures.

®

CortexTM-M3 clock speed is configurable to 6 MHz, 12 MHz, or 24 MHz. For normal operation 24 MHz

is preferred over 12 MHz due to improved performance for all applications and improved duty cycling for

applications using sleep modes. The 6 MHz operation can only be used when radio operations are not required

since the radio requires an accurate 12 MHz clock.

®

The ARM

CortexTM-M3 in the EM358x has also been enhanced to support two separate memory protection

levels. Basic protection is available without using the MPU, but normal operation uses the MPU. The MPU allows

for protecting unimplemented areas of the memory map to prevent common software bugs from interfering with

software operation. The architecture could also allow for separation of the networking stack from the application

code using a fine granularity RAM protection module. Errant writes are captured and details are reported to the

developer to assist in tracking down and fixing issues.

®

CortexTM-M3 is an advanced 32-bit modified Harvard

®

12 Rev. 0.4

Page 13

2.2 Embedded Memory

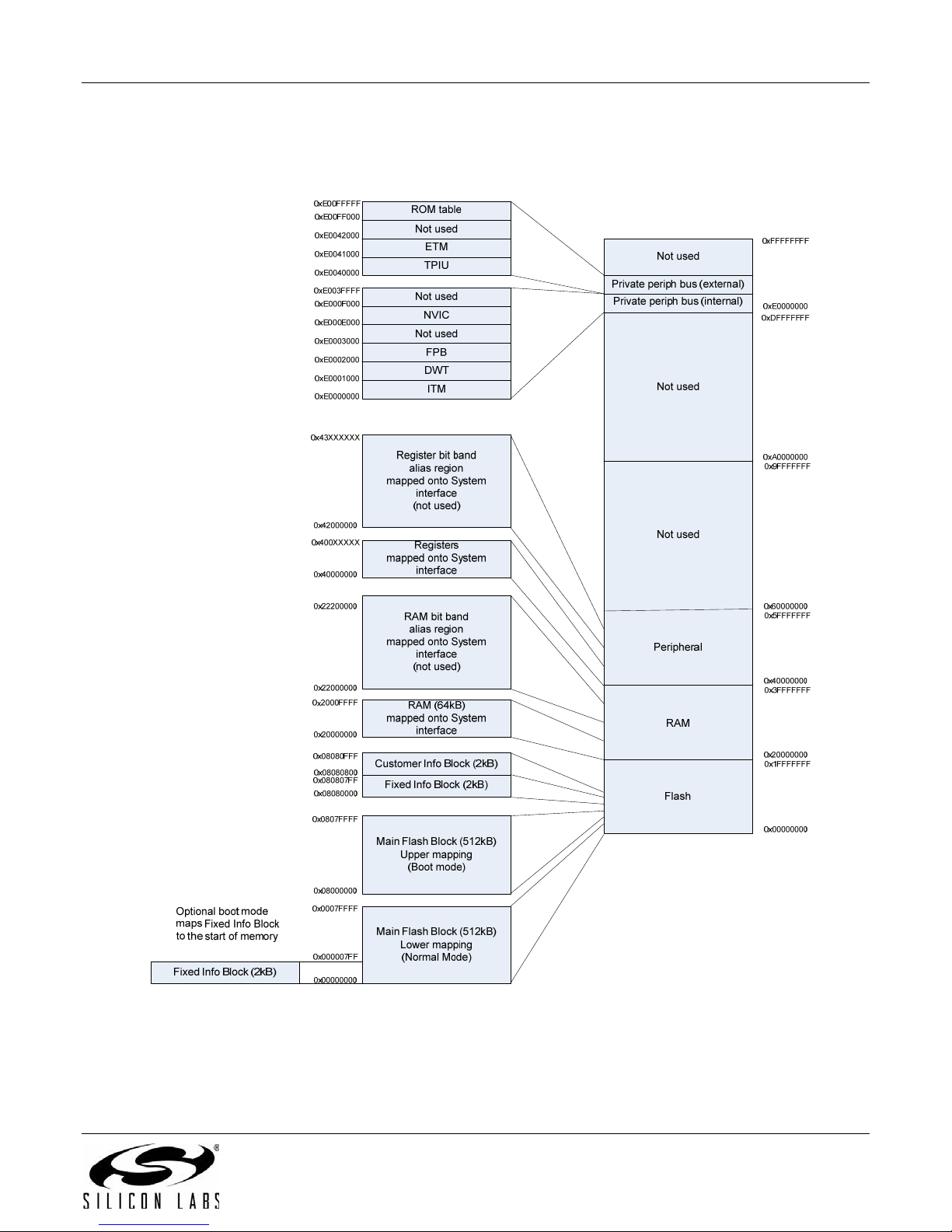

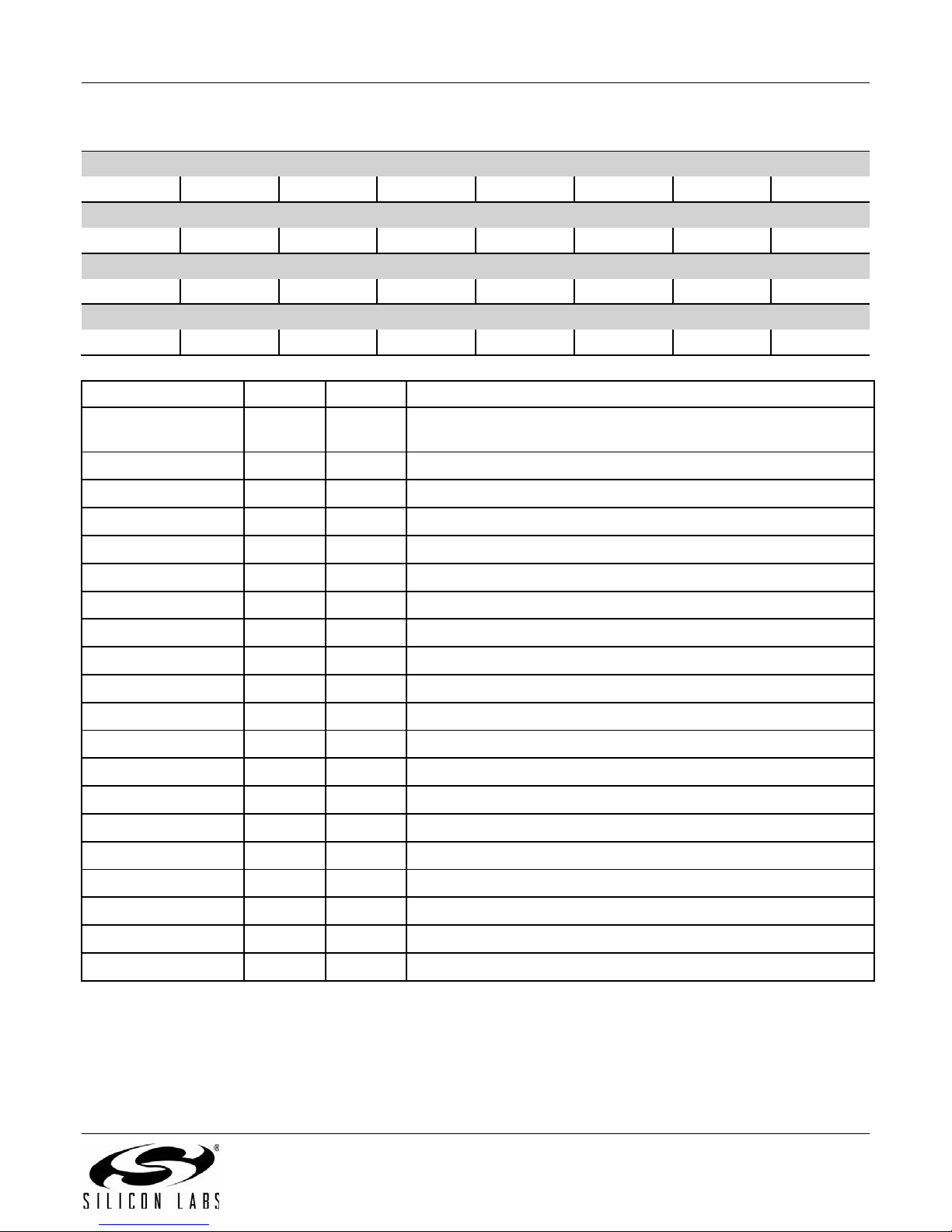

Figure 2-1 shows the EM358x ARM® CortexTM-M3 memory map.

EM358x

Figure 2-1. EM358x ARM® CortexTM-M3 Memory Map

Rev. 0.4 13

Page 14

EM358x

2.2.1 Flash Memory

2.2.1.1 Flash Overview

The EM358x provides a total of either 256 or 512 kB of flash memory. The flash memory is provided in three

separate blocks:

Main Flash Block (MFB)

Fixed Information Block (FIB)

Customer Information Block (CIB)

The MFB is divided into 2048-byte pages. The EM358x has either 128 or 256 pages. The CIB is a single 2048byte page. The FIB is a single 2048-byte page. The smallest erasable unit is one page and the smallest writable

unit is an aligned 16-bit half-word. The flash is rated to have a guaranteed 20,000 write/erase cycles. The flash

cell has been qualified for a data retention time of >100 years at room temperature.

Flash may be programmed either through the Serial Wire/JTAG interface or through bootloader software.

Programming flash through Serial Wire/JTAG requires the assistance of RAM-based utility code. Programming

through a bootloader requires Ember software for over-the-air loading or serial link loading.

2.2.1.2 Main Flash Block

The start of the MFB is mapped to both address 0x00000000 and address 0x08000000 in normal boot mode, but

is mapped only to address 0x08000000 in FIB monitor mode (see also section 7.5, Boot Configuration in Chapter

7, GPIO). Consequently, it is recommended that software intended to execute from the MFB is designed to

operate from the upper address, 0x08000000, since this address mapping is always available in all modes.

The MFB stores all program instructions and constant data. A small portion of the MFB is devoted to non-volatile

token storage using the Ember Simulated EEPROM system.

2.2.1.3 Fixed Information Block

The 2 kB FIB is used to store fixed manufacturing data including serial numbers and calibration values. The start

of the FIB is mapped to address 0x08080000. This block can only be programmed during production by Silicon

Labs.

The FIB also contains a monitor program, which is a serial-link-only way of performing low-level memory access.

In FIB monitor mode (see section 7.5, Boot Configuration in Chapter 7, GPIO), the start of the FIB is mapped to

both address 0x00000000 and address 0x08080000 so the monitor may be executed out of reset.

2.2.1.4 Customer Information Block

The 2048 byte CIB can be used to store customer data. The start of the CIB is mapped to address 0x08080800.

The CIB cannot be executed.

The first eight half-words of the CIB are dedicated to special storage called option bytes. An option byte is a 16 bit

quantity of flash where the lower 8 bits contain the data and the upper 8 contain the inverse of the lower 8 bits.

The upper 8 bits are automatically generated by hardware and cannot be written to by the user, see Table 2-1.

The option byte hardware also verifies the inverse of each option byte when exiting from reset and generates an

error, which prevents the CPU from executing code, if a discrepancy is found. All of this is transparent to the user.

14 Rev. 0.4

Page 15

EM358x

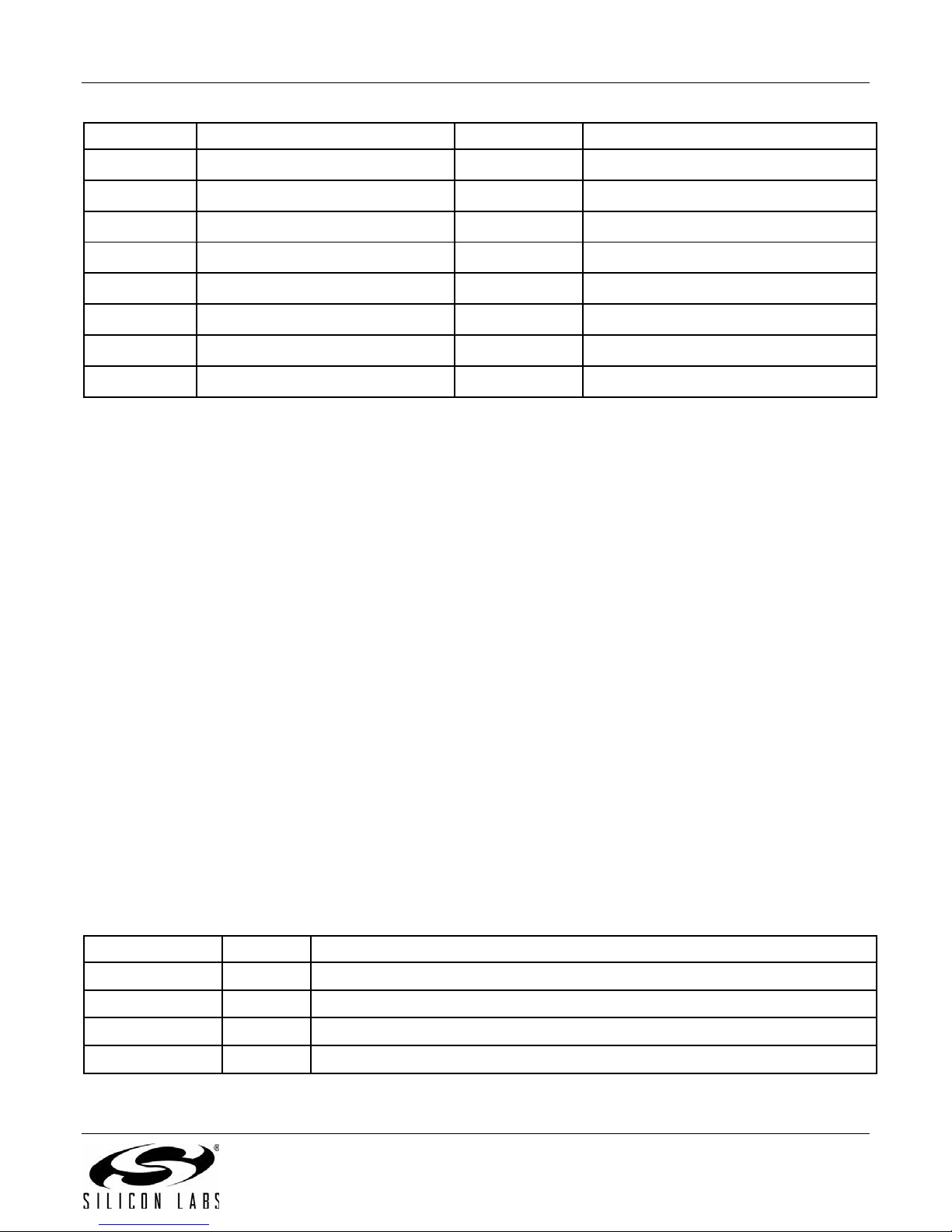

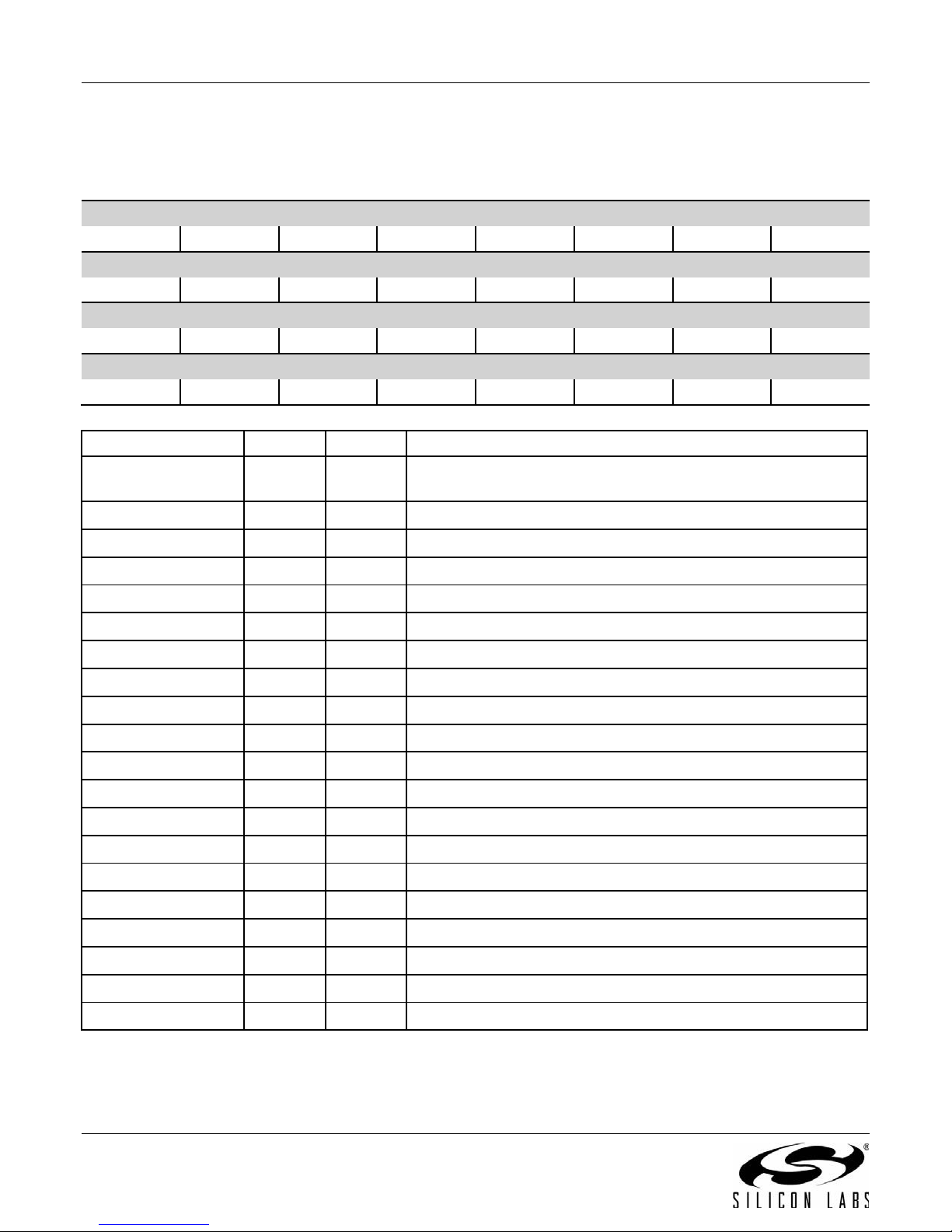

Table 2-1. Option Byte Storage

Address bits [15:8] bits [7:0] Notes

0x08080800 Inverse Option Byte 0 Option Byte 0 Configures flash read protection

0x08080802 Inverse Option Byte 1 Option Byte 1 Reserved

0x08080804 Inverse Option Byte 2 Option Byte 2 Available for customer use1

0x08080806 Inverse Option Byte 3 Option Byte 3 Available for customer use1

0x08080808 Inverse Option Byte 4 Option Byte 4 Configures flash write protection

0x0808080A Inverse Option Byte 5 Option byte 5 Configures flash write protection

0x0808080C Inverse Option Byte 6 Option Byte 6 Configures flash write protection

0x0808080E Inverse Option Byte 7 Option Byte 7 Configures flash write protection

1

Option bytes 2 and 3 do not link to any specific hardware functionality other than the option byte loader. Therefore, they are best used

for storing data that requires a hardware verification of the data integrity.

Table 2-2 shows the mapping of the option bytes that are used for read and write protection of the flash. Each bit

of the flash write protection option bytes protects a 4 page region of the main flash block. The EM358x has up to

32 regions and therefore option bytes 4, 5, 6, and 7 control flash write protection. These write protection bits are

active low, and therefore the erased state of 0xFF disables write protection. Like read protection, write protection

only takes effect after a reset. Write protection not only prevents a write to the region, but also prevents page

erasure.

Option byte 0 controls flash read protection. When option byte 0 is set to 0xA5, read protection is disabled. All

other values, including the erased state 0xFF, enable read protection when coming out of reset. The internal state

of read protection (active versus disabled) can only be changed by applying a full chip reset. If a debugger is

connected to the EM358x, the intrusion state is latched. Read protection is combined with this latched intrusion

signal. When both read protection and intrusion are set, all flash is disconnected from the internal bus. As a side

effect, the CPU cannot execute code since all flash is disconnected from the bus. This functionality prevents a

debug tool from being able to read the contents of any flash. The only means of clearing the intrusion signal is to

disconnect the debugger and reset the entire chip using the nRESET pin. By requiring a chip reset, a debugger

cannot install or execute malicious code that could allow the contents of the flash to be read.

The only way to disable read protection is to program option byte 0 with the value 0xA5. Option byte 0 must be

erased before it can be programmed. Erasing option byte 0 while read protection is active automatically masserases the main flash block. By automatically erasing main flash, a debugger cannot disable read protection and

readout the contents of main flash without destroying its contents.

In general, if read protection is active then write protection should also be active. This prevents an attacker from

reprogramming flash with malicious code that could readout the flash after the debugger is disconnected. To

obtain fully protected flash, both read protection and write protection should be active.

Table 2-2. Option Byte Write Protection Bit Map

Option Byte Bit Notes

Option Byte 0 bit [7:0] Read protection of all flash (MFB, FIB, CIB)

Option Byte 1 bit [7:0] Reserved for Silicon Labs use

Option Byte 2 bit [7:0] Available for customer use

Option Byte 3 bit [7:0] Available for customer use

Rev. 0.4 15

Page 16

EM358x

Option Byte Bit Notes

Option Byte 4 bit [0] Write protection of address range 0x08000000 – 0x08003FFF

bit [1] Write protection of address range 0x08004000 – 0x08007FFF

bit [2] Write protection of address range 0x08008000 – 0x0800BFFF

bit [3] Write protection of address range 0x0800C000 – 0x0800FFFF

bit [4] Write protection of address range 0x08010000 – 0x08013FFF

bit [5] Write protection of address range 0x08014000 – 0x08017FFF

bit [6] Write protection of address range 0x08018000 – 0x08013FFF

bit [7] Write protection of address range 0x0801C000 – 0x0801FFFF

Option Byte 5 bit [0] Write protection of address range 0x08020000 – 0x08023FFF

bit [1] Write protection of address range 0x08024000 – 0x08027FFF

bit [2] Write protection of address range 0x08028000 – 0x0802BFFF

bit [3] Write protection of address range 0x0802C000 – 0x0802FFFF

bit [4] Write protection of address range 0x08030000 – 0x08033FFF

bit [5] Write protection of address range 0x08034000 – 0x08037FFF

bit [6] Write protection of address range 0x08038000 – 0x0803BFFF

bit [7] Write protection of address range 0x0803C000 – 0x0803FFFF

Option Byte 6 bit [0] Write protection of address range 0x08040000 – 0x08043FFF

bit [1] Write protection of address range 0x08044000 – 0x08047FFF

bit [2] Write protection of address range 0x08048000 – 0x0804BFFF

bit [3] Write protection of address range 0x0804C000 – 0x0804FFFF

bit [4] Write protection of address range 0x08050000 – 0x08053FFF

bit [5] Write protection of address range 0x08054000 – 0x08057FFF

bit [6] Write protection of address range 0x08058000 – 0x0805BFFF

bit [7] Write protection of address range 0x0805C000 – 0x0805FFFF

Option Byte 7 bit [0] Write protection of address range 0x08060000 – 0x08063FFF

bit [1] Write protection of address range 0x08064000 – 0x08067FFF

bit [2] Write protection of address range 0x08068000 – 0x0806BFFF

bit [3] Write protection of address range 0x0806C000 – 0x0806FFFF

bit [4] Write protection of address range 0x08070000 – 0x08073FFF

bit [5] Write protection of address range 0x08074000 – 0x08077FFF

bit [6] Write protection of address range 0x08078000 – 0x0807BFFF

bit [7] Write protection of address range 0x0807C000 – 0x0807FFFF

16 Rev. 0.4

Page 17

EM358x

2.2.1.5 Simulated EEPROM

Ember software reserves 8 kB of the main flash block as a simulated EEPROM storage area for stack and

customer tokens. The simulated EEPROM storage area implements a wear-leveling algorithm to extend the

number of simulated EEPROM write cycles beyond the physical limit of 20,000 write cycles for which each flash

cell is qualified.

2.2.2 RAM

2.2.2.1 RAM Overview

The EM358x has either 32 or 64 kB of static RAM on-chip. The start of RAM is mapped to address 0x20000000.

Although the ARM

does not permit use of the bit-band feature.

The RAM is physically connected to the AHB System bus and is therefore accessible to both the ARM

M3 microprocessor and the debugger. The RAM can be accessed for both instruction and data fetches as bytes,

half words, or words. The standard MPU configuration does not permit execution from the RAM, but for special

purposes the MPU may be disabled. To the bus, the RAM appears as 32-bit wide memory and in most situations

has zero wait state read or write access. In the higher CPU clock mode the RAM requires one wait state. This is

handled by hardware transparent to the user application with no configuration required.

2.2.2.2 Direct Memory Access (DMA) to RAM

Several of the peripherals are equipped with DMA controllers allowing them to transfer data into and out of RAM

autonomously. This applies to the radio (802.15.4-2003 MAC), general purpose ADC, USB device controller and

the two serial controllers. In the case of the serial controllers, the DMA is full duplex so that a read and a write to

RAM may be requested at the same time. Thus there are six DMA channels in total. See Chapter 8, Section 8.7

and Chapter 11, Section 11.1.4 for a description of how to configure the serial controllers and ADC for DMA

operation. The DMA channels do not use AHB system bus bandwidth as they access the RAM directly.

The EM358x integrates a DMA arbiter that ensures fair access to the microprocessor as well as the peripherals

through a fixed priority scheme appropriate to the memory bandwidth requirements of each master. The priority

scheme is as follows, with the top peripheral being the highest priority:

1. USB Device Controller (where applicable)

2. General Purpose ADC

3. Serial Controller 2 Receive

4. Serial Controller 2 Transmit

5. MAC

6. Serial Controller 1 Receive

7. Serial Controller 1 Transmit

®

CortexTM-M3 allows bit band accesses to this address region, the standard MPU configuration

®

CortexTM-

2.2.2.3 RAM Memory Protection

The EM358x integrates a memory protection mechanism through the ARM® CortexTM-M3 Memory Protection Unit

(MPU) described in the Memory Protection Unit section. The MPU may be used to protect any area of memory.

MPU configuration is normally handled by Ember software.

2.2.3 Registers

Appendix A, Register Address Table provides a short description of all application-accessible registers within the

EM358. Complete descriptions are provided at the end of each applicable peripheral’s description. The registers

are mapped to the system address space starting at address 0x40000000. These registers allow for the control

and configuration of the various peripherals and modules. The CPU only performs word-aligned accesses on the

system bus. The CPU performs a word aligned read-modify-write for all byte, half-word, and unaligned writes and

a word-aligned read for all reads. Silicon Labs recommends accessing all peripheral registers using word-aligned

addressing.

As with the RAM, the peripheral registers fall within an address range that allows for bit-band access by the ARM

TM

Cortex

Rev. 0.4 17

-M3, but the standard MPU configuration does not allow access to this alias address range.

®

Page 18

EM358x

2.3 Memory Protection Unit

The EM358x includes the ARM® CortexTM-M3 Memory Protection Unit, or MPU. The MPU controls access rights

and characteristics of up to eight address regions, each of which may be divided into eight equal sub-regions.

Refer to the ARM

Ember software configures the MPU in a standard configuration and application software should not modify it. The

configuration is designed for optimal detection of illegal instruction or data accesses. If an illegal access is

attempted, the MPU captures information about the access type, the address being accessed, and the location of

the offending software. This simplifies software debugging and increases the reliability of deployed devices. As a

consequence of this MPU configuration, accessing RAM and register bit-band address alias regions is not

permitted, and generates a bus fault if attempted.

®

CortexTM-M3 Technical Reference Manual (DDI 0337A) for a detailed description of the MPU.

18 Rev. 0.4

Page 19

EM358x

3 Interrupt System

The EM358x’s interrupt system is composed of two parts: a standard ARM® CortexTM-M3 Nested Vectored

Interrupt Controller (NVIC) that provides top-level interrupts, and a proprietary Event Manager (EM) that provides

second-level interrupts. The NVIC and EM provide a simple hierarchy. All second-level interrupts from the EM

feed into top-level interrupts in the NVIC. This two-level hierarchy allows for both fine granular control of interrupt

sources and coarse granular control over entire peripherals, while allowing peripherals to have their own interrupt

vector.

The Nested Vectored Interrupt Controller (NVIC) section provides a description of the NVIC and an overview of

the exception table (ARM nomenclature refers to interrupts as exceptions). The Event Manager section provides a

more detailed description of the Event Manager including a table of all top-level peripheral interrupts and their

second-level interrupt sources.

In practice, top-level peripheral interrupts are only used to enable or disable interrupts for an entire peripheral.

Second-level interrupts originate from hardware sources, and therefore are the main focus of applications using

interrupts.

3.1 Nested Vectored Interrupt Controller (NVIC)

The ARM® CortexTM-M3 Nested Vectored Interrupt Controller (NVIC) facilitates low-latency exception and

interrupt handling. The NVIC and the processor core interface are closely coupled, which enables low-latency

interrupt processing and efficient processing of late-arriving interrupts. The NVIC also maintains knowledge of the

stacked (nested) interrupts to enable tail-chaining of interrupts.

®

The ARM

management. In addition to the 10 standard interrupts, it contains 18 individually vectored peripheral interrupts

specific to the EM358x.

The NVIC defines a list of exceptions. These exceptions include not only traditional peripheral interrupts, but also

more specialized events such as faults and CPU reset. In the ARM

considered an exception of the highest priority, and the stack pointer is loaded from the first position in the NVIC

exception table. The NVIC exception table defines all exceptions and their position, including peripheral interrupts.

The position of each exception is important since it directly translates to the location of a 32-bit interrupt vector for

each interrupt, and defines the hardware priority of exceptions. Each exception in the table is a 32-bit address that

is loaded into the program counter when that exception occurs. Table 3-1 lists the entire exception table.

Exceptions 0 (stack pointer) through 15 (SysTick) are part of the standard ARM

exceptions 16 (Timer 1) through 35 (USB, where applicable) are the peripheral interrupts specific to the EM358x

peripherals. The peripheral interrupts are listed in greater detail in Table 3-2.

CortexTM-M3 NVIC contains 10 standard interrupts that are related to chip and CPU operation and

®

CortexTM-M3 NVIC, a CPU reset event is

®

CortexTM-M3 NVIC, while

Table 3-1. NVIC Exception Table

Exception Position Description

-

Reset

NMI

Hard Fault

Memory Fault

Bus Fault

Usage Fault

-

Rev. 0.4 19

0

1

2

3

4

5

6

7-10

Stack top is loaded from first entry of vector table on reset.

Invoked on power up and warm reset. On first instruction, drops to lowest

priority (Thread mode). Asynchronous.

Cannot be stopped or preempted by any exception but reset. Asynchronous.

All classes of fault, when the fault cannot activate because of priority or the

Configurable Fault handler has been disabled. Synchronous.

MPU mismatch, including access violation and no match. Synchronous.

Pre-fetch, memory access, and other address/memory-related faults.

Synchronous when precise and asynchronous when imprecise.

Usage fault, such as ‘undefined instruction executed’ or ‘illegal state transition

attempt’. Synchronous.

Reserved.

Page 20

EM358x

Exception Position Description

SVCall

Debug Monitor

-

PendSV

SysTick

Timer 1

Timer 2

Management

Baseband

Sleep Timer

Serial Controller 1

Serial Controller 2

Security

MAC Timer

MAC Transmit

MAC Receive

ADC

IRQA

IRQB

IRQC

IRQD

Debug

-

-

USB

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

System service call with SVC instruction. Synchronous.

Debug monitor, when not halting. Synchronous, but only active when enabled. It

does not activate if lower priority than the current activation.

Reserved.

Pendable request for system service. Asynchronous and only pended by software.

System tick timer has fired. Asynchronous.

Timer 1 peripheral interrupt.

Timer 2 peripheral interrupt.

Management peripheral interrupt.

Baseband peripheral interrupt.

Sleep Timer peripheral interrupt.

Serial Controller 1 peripheral interrupt.

Serial Controller 2 peripheral interrupt.

Security peripheral interrupt.

MAC Timer peripheral interrupt.

MAC Transmit peripheral interrupt.

MAC Receive peripheral interrupt.

ADC peripheral interrupt.

IRQA peripheral interrupt.

IRQB peripheral interrupt.

IRQC peripheral interrupt.

IRQD peripheral interrupt.

Debug peripheral interrupt.

Reserved.

Reserved.

USB peripheral interrupt (where applicable).

The NVIC also contains a software-configurable interrupt prioritization mechanism. The Reset, NMI, and Hard

Fault exceptions, in that order, are always the highest priority, and are not software-configurable. All other

exceptions can be assigned a 5-bit priority number, with low values representing higher priority. If any exceptions

have the same software-configurable priority, then the NVIC uses the hardware-defined priority. The hardwaredefined priority number is the same as the position of the exception in the exception table. For example, if IRQA

and IRQB both fire at the same time and have the same software-defined priority, the NVIC handles IRQA, with

priority number 28, first because it has a higher hardware priority than IRQB with priority number 29.

20 Rev. 0.4

Page 21

EM358x

The top-level interrupts are controlled through five ARM® CortexTM-M3 NVIC registers: INT_CFGSET,

INT_CFGCLR, INT_PENDSET, INT_PENDCLR, and INT_ACTIVE. Writing 0 into any bit in any of these five

register is ineffective.

INT_CFGSET - Writing 1 to a bit in INT_CFGSET enables that top-level interrupt.

INT_CFGCLR - Writing 1 to a bit in INT_CFGCLR disables that top-level interrupt.

INT_PENDSET - Writing 1 to a bit in INT_PENDSET triggers that top-level interrupt.

INT_PENDCLR - Writing 1 to a bit in INT_PENDCLR clears that top-level interrupt.

INT_ACTIVE cannot be written to and is used for indicating which interrupts are currently active.

INT_PENDSET and INT_PENDCLR set and clear a simple latch; INT_CFGSET and INT_CFGCLR set and clear

a mask on the output of the latch. Interrupts may be pended and cleared at any time, but any pended interrupt will

not be taken unless the corresponding mask (INT_CFGSET) is set, which allows that interrupt to propagate. If an

INT_CFGSET bit is set and the corresponding INT_PENDSET bit is set, then the interrupt will propagate and be

taken. If INT_CFGSET is set after INT_PENDSET is set, then the interrupt will also propagate and be taken.

Interrupt flags (signals) from the top-level interrupts are level-sensitive.

The second-level interrupt registers, which provide control of the second-level Event Manager peripheral

interrupts, are described in the Event Manager section.

®

For further information on the NVIC and ARM

Reference Manual and the ARM ARMv7-M Architecture Reference Manual.

CortexTM-M3 exceptions, refer to the ARM® CortexTM-M3 Technical

Rev. 0.4 21

Page 22

EM358x

3.2 Event Manager

While the standard ARM® CortexTM-M3 Nested Vectored Interrupt Controller provides top-level interrupts into the

CPU, the proprietary Event Manager provides second-level interrupts. The Event Manager takes a large variety of

hardware interrupt sources from the peripherals and merges them into a smaller group of interrupts in the NVIC.

Effectively, all second-level interrupts from a peripheral are “OR’d” together into a single interrupt in the NVIC. In

addition, the Event Manager provides missed indicators for the top-level peripheral interrupts with the register

INT_MISS.

The description of each peripheral’s interrupt configuration and flag registers can be found in the chapters of this

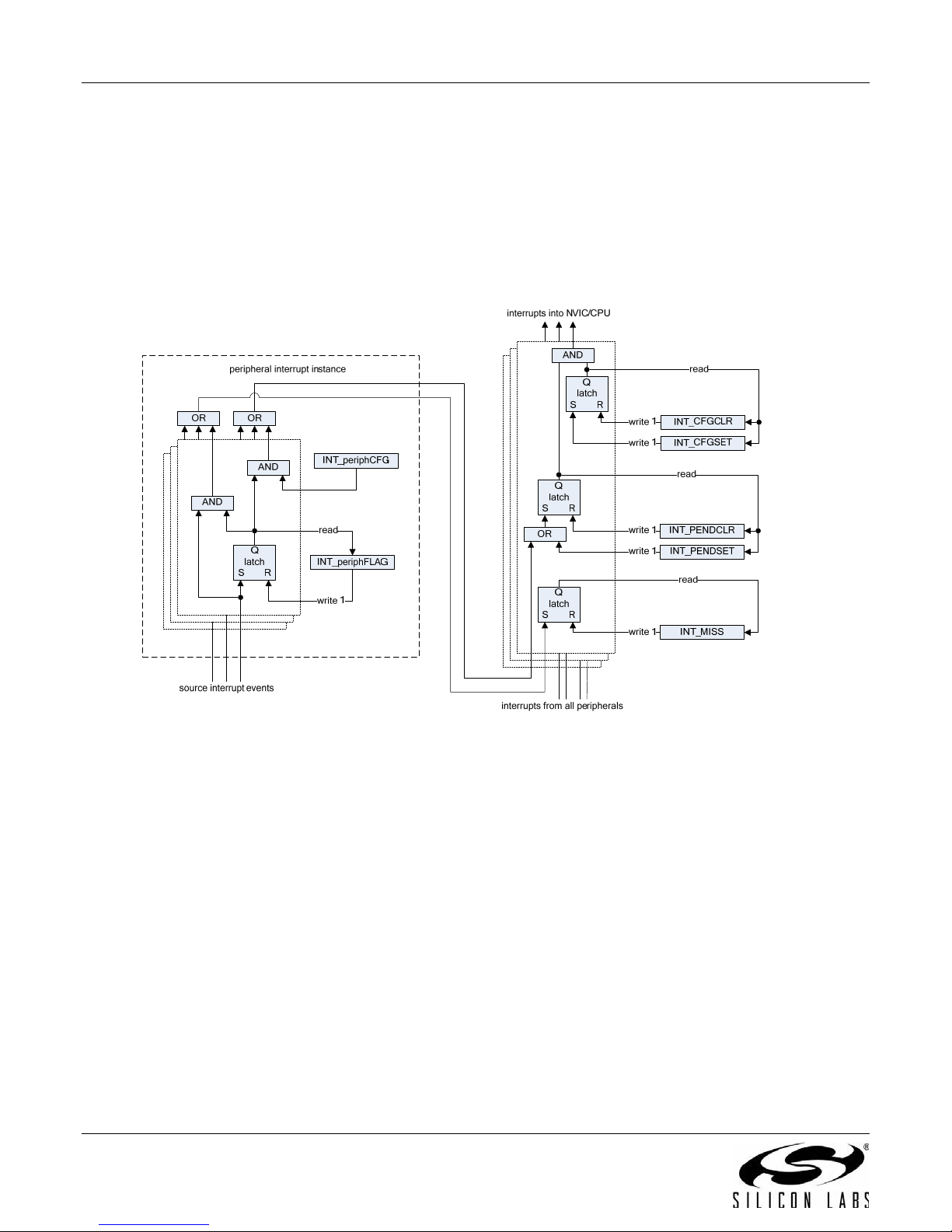

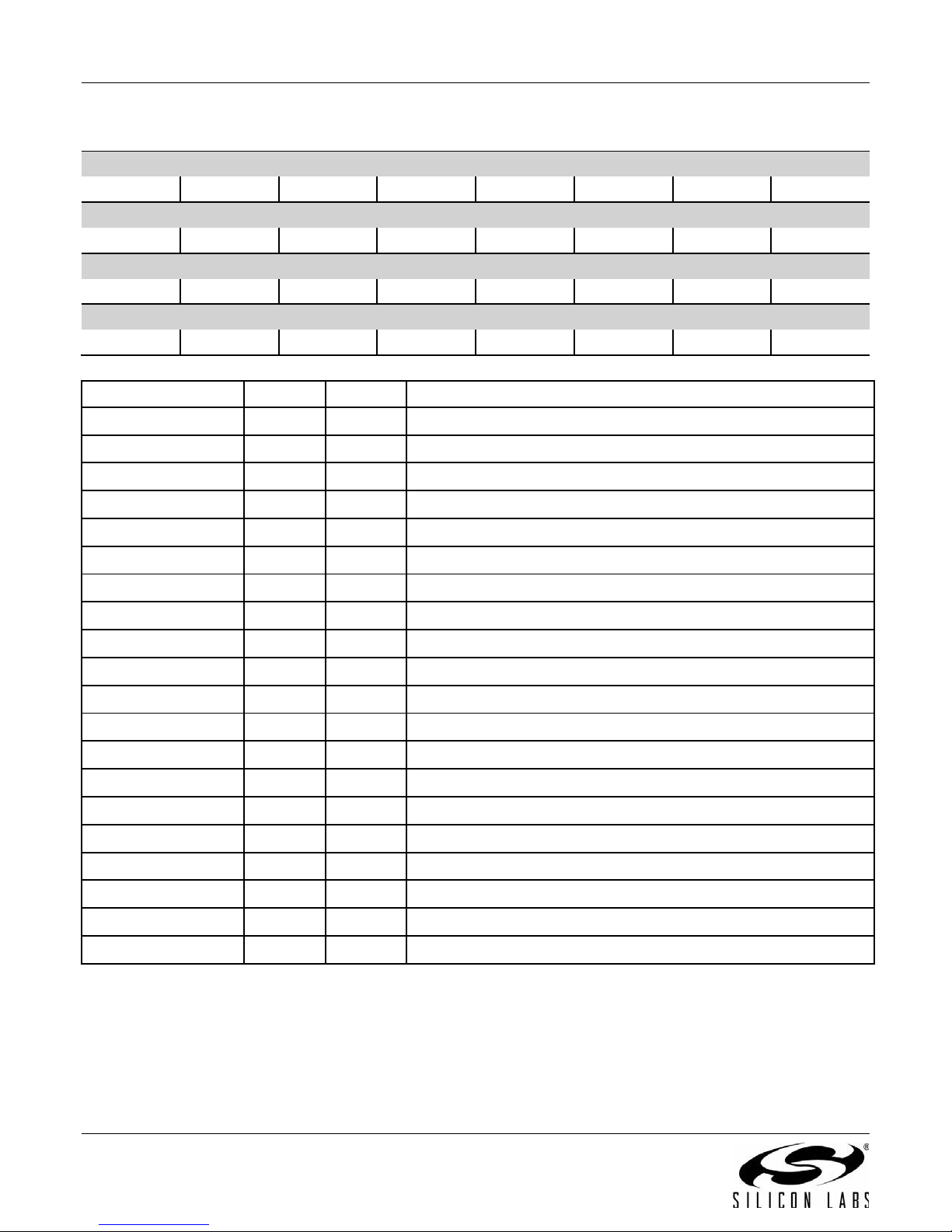

reference manual describing each peripheral. Figure 3-1 shows the Peripheral Interrupts Block Diagram.

Figure 3-1. Peripheral Interrupts Block Diagram

Given a peripheral, ‘periph’, the Event Manager registers (INT_periphCFG and INT_periphFLAG) follow the form:

INT_periphCFG enables and disables second-level interrupts. Writing 1 to a bit in the INT_periphCFG register

enables the second-level interrupt. Writing 0 to a bit in the INT_periphCFG register disables it. The

INT_periphCFG register behaves like a mask, and is responsible for allowing the INT_periphFLAG bits to

propagate into the top-level NVIC interrupts.

INT_periphFLAG indicates second-level interrupts that have occurred. Writing 1 to a bit in a INT_periphFLAG

register clears the second-level interrupt. Writing 0 to any bit in the INT_periphFLAG register is ineffective. The

INT_periphFLAG register is always active and may be set or cleared at any time, meaning if any second-level

interrupt occurs, then the corresponding bit in the INT_periphFLAG register is set regardless of the state of

INT_periphCFG.

If a bit in the INT_periphCFG register is set after the corresponding bit in the INT_periphFLAG register is set then

the second-level interrupt propagates into the top-level interrupts. The interrupt flags (signals) from the secondlevel interrupts into the top-level interrupts are level-sensitive. If a top-level NVIC interrupt is driven by a secondlevel EM interrupt, then the top-level NVIC interrupt cannot be cleared until all second-level EM interrupts are

cleared.

22 Rev. 0.4

Page 23

EM358x

The INT_periphFLAG register bits are designed to remain set if the second-level interrupt event re-occurs at the

same moment as the INT_periphFLAG register bit is being cleared. This ensures the re-occurring second-level

interrupt event is not missed.

If another enabled second-level interrupt event of the same type occurs before the first interrupt event is cleared,

the second interrupt event is lost because no counting or queuing is used. However, this condition is detected and

stored in the top-level INT_MISS register to facilitate software detection of such problems. The INT_MISS register

is “acknowledged” in the same way as the INT_periphFLAG register—by writing a 1 into the corresponding bit to

be cleared.

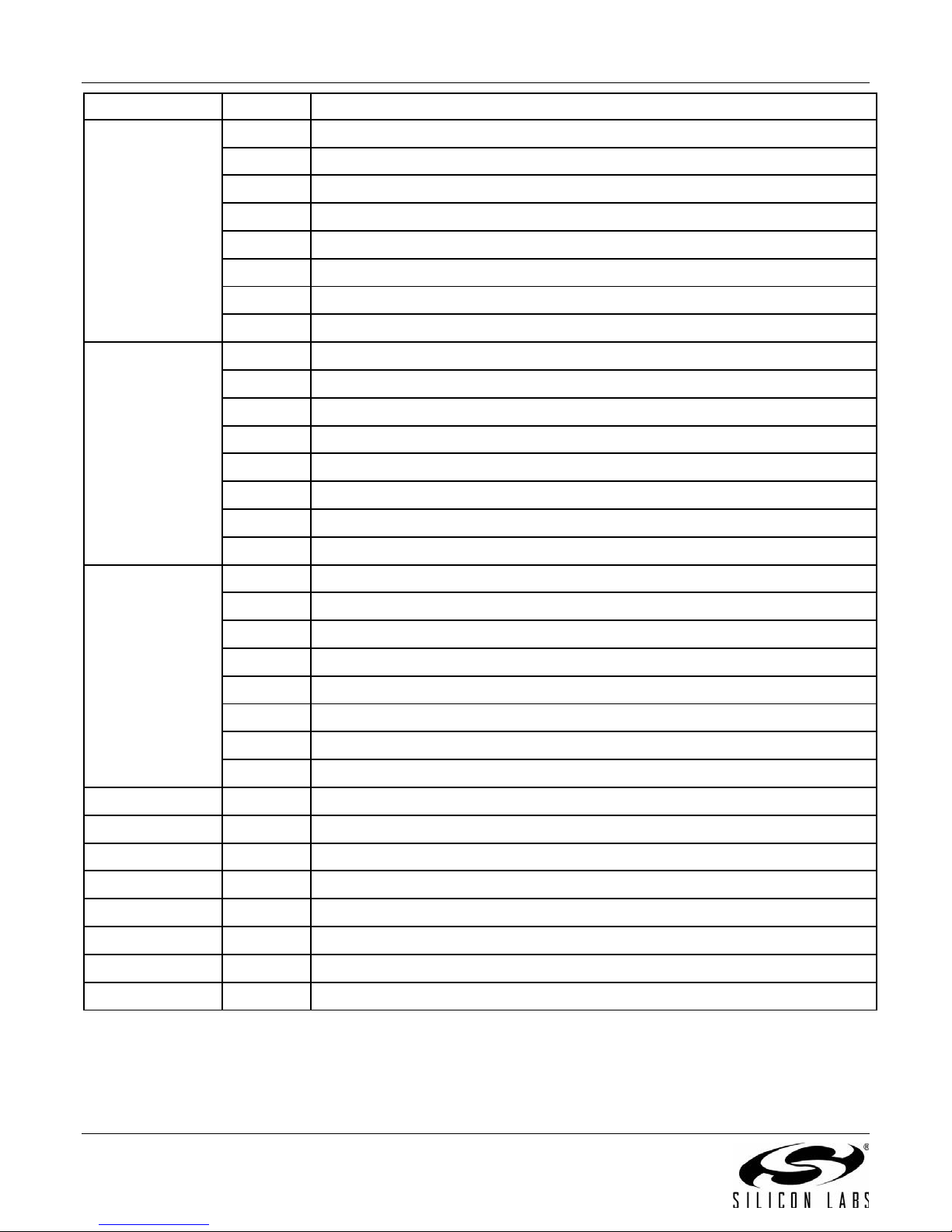

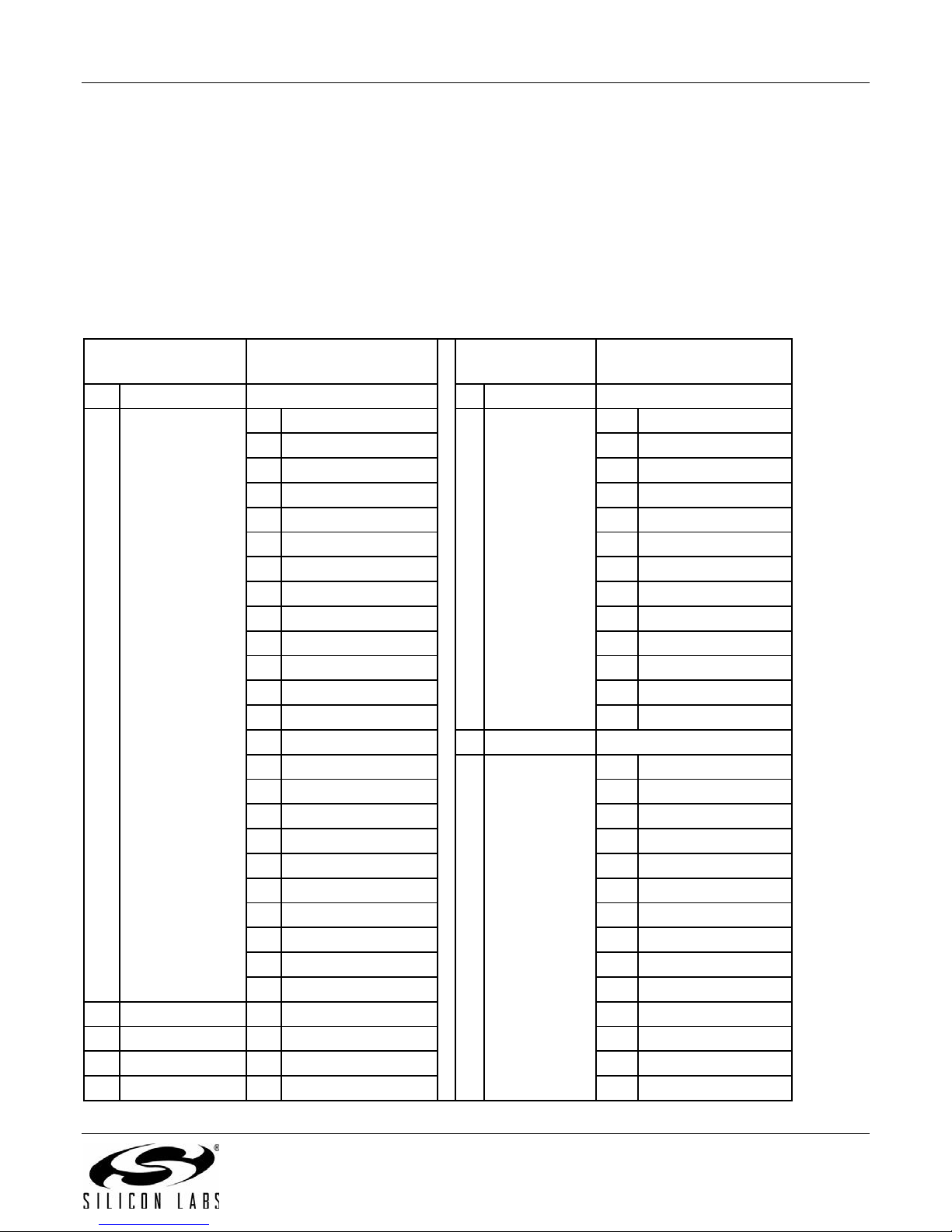

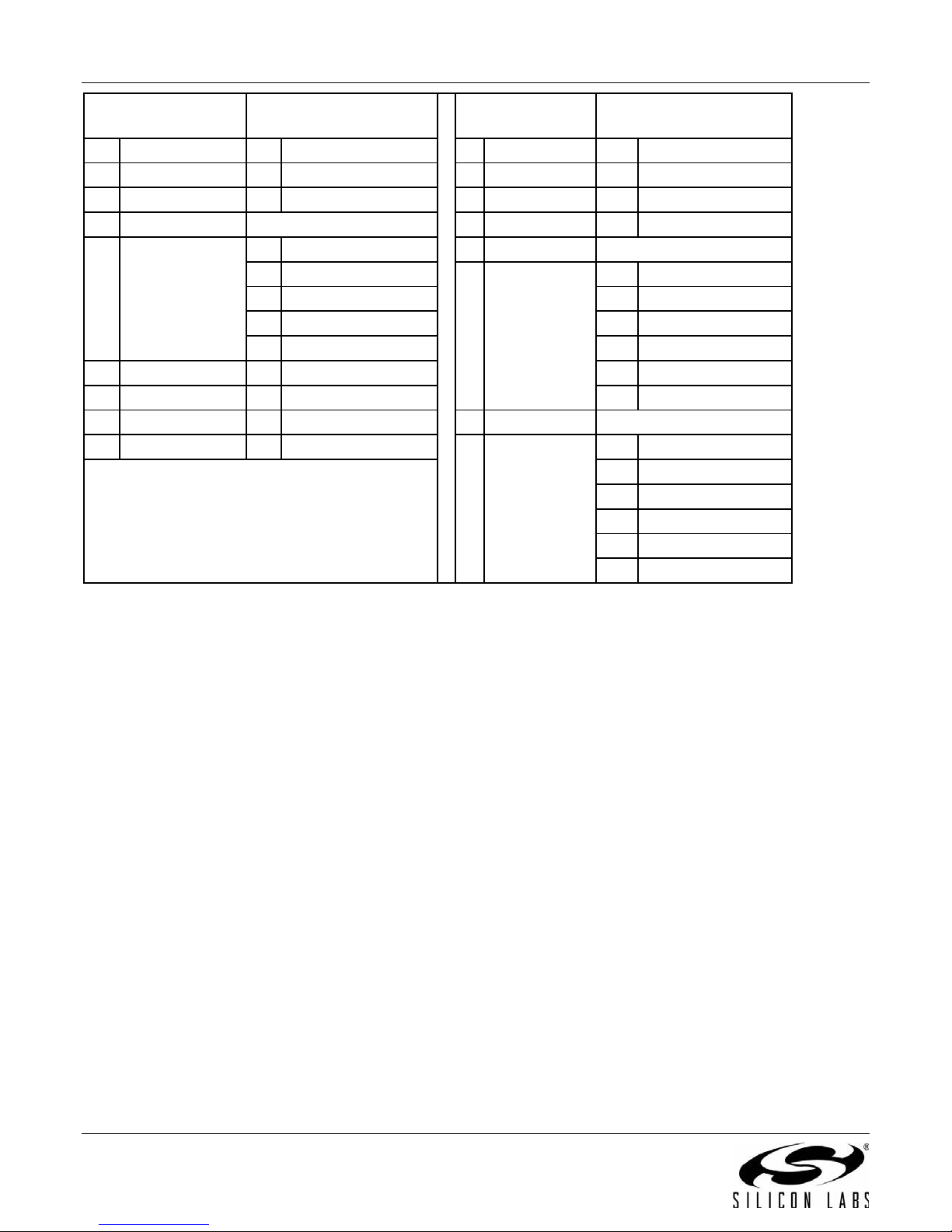

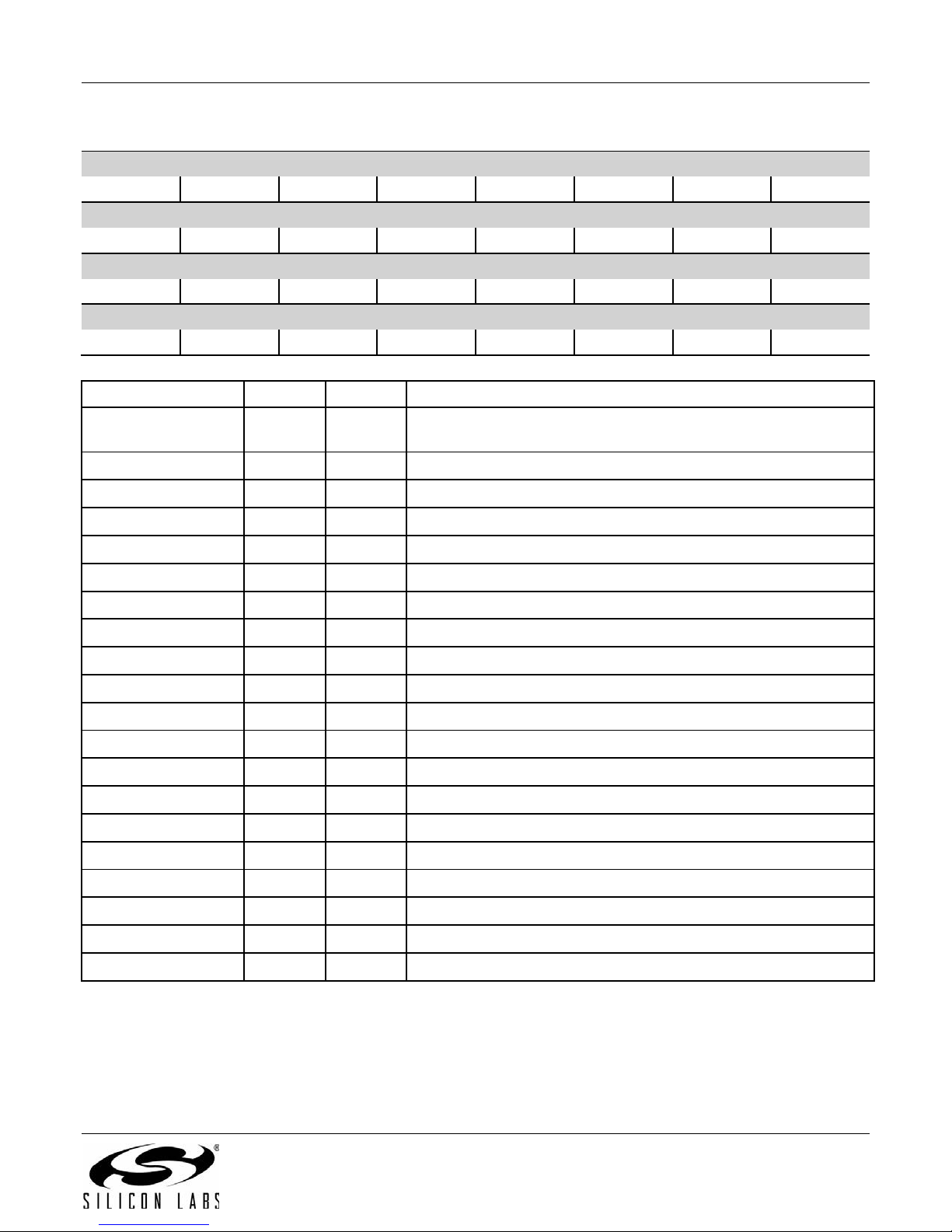

Table 3-2 provides a map of all peripheral interrupts. This map lists the top-level NVIC Interrupt bits and, if there is

one, the corresponding second-level EM Interrupt register bits that feed the top-level interrupts.

Table 3-2. NVIC and EM Peripheral Interrupt Map

NVIC Interrupt

(top-level)

19 INT_USB INT_USBFLAG Register 6 INT_SC2 INT_SC2FLAG register

23 INT_USBWAKEUP 12 INT_SCTXULDB

18 Reserved 4 INT_SCTXUND

17 Reserved 3 INT_SCRXOVF

16 INT_DEBUG 2 INT_SCTXIDLE

15 INT_IRQD 1 INT_SCTXFREE

EM Interrupt

(second-level)

22 INT_USBRESUME 11 INT_SCTXULDA

21 INT_USBSUSPEND 10 INT_SCRXULDB

20 INT_USBRESET 9 INT_SCRXULDA

19 INT_USBSOF 8 INT_SCNAK

18 INT_USBNAK 7 INT_SCCDMFIN

17 INT_USBPIPERXOVF 6 INT_SCTXFIN

16 INT_USBPIPETXUND 5 INT_SCRXFIN

15 INT_USBBUFRXOVF 4 INT_SCTXUND

14 INT_USBBUFTXUND 3 INT_SCRXOVF

13 INT_USBRXVALIDEP6 2 INT_SCTXIDLE

12 INT_USBRXVALIDEP5 1 INT_SCTXFREE

11 INT_USBRXVALIDEP4 0 INT_SCRXVAL

10 INT_USBRXVALIDEP3 5 INT_SC1 INT_SC1FLAG register

9 INT_USBRXVALIDEP2 14 INT_SC1PARERR

8 INT_USBRXVALIDEP1 13 INT_SC1FRMERR

7 INT_USBRXVALIDEP0 12 INT_SCTXULDB

6 INT_USBTXACTIVEEP6 11 INT_SCTXULDA

5 INT_USBTXACTIVEEP5 10 INT_SCRXULDB

4 INT_USBTXACTIVEEP4 9 INT_SCRXULDA

3 INT_USBTXACTIVEEP3 8 INT_SCNAK

2 INT_USBTXACTIVEEP2 7 INT_SCCDMFIN

1 INT_USBTXACTIVEEP1 6 INT_SCTXFIN

0 INT_USBTXACTIVEEP0 5 INT_SCRXFIN

NVIC Interrupt

(top-level)

EM Interrupt

(second-level)

Rev. 0.4 23

Page 24

EM358x

NVIC Interrupt

(top-level)

14 INT_IRQC 0 INT_SCRXVAL

13 INT_IRQB 4 INT_SLEEPTMR

12 INT_IRQA 3 INT_BB

11 INT_ADC INT_ADCFLAG register 2 INT_MGMT

4 INT_ADCOVF 1 INT_TMR2 INT_TMR2FLAG register

10 INT_MACRX 1 INT_TMRCC1IF

9 INT_MACTX 0 INT_TMRUIF

8 INT_MACTMR 0 INT_TMR1 INT_TMR1FLAG register

7 INT_SEC 6 INT_TMRTIF

4 INT_TMRCC4IF

EM Interrupt

(second-level)

3 INT_ADCSAT 6 INT_TMRTIF

2 INT_ADCULDFULL 4 INT_TMRCC4IF

1 INT_ADCULDHALF 3 INT_TMRCC3IF

0 INT_ADCDATA 2 INT_TMRCC2IF

NVIC Interrupt

(top-level)

EM Interrupt

(second-level)

3 INT_TMRCC3IF

2 INT_TMRCC2IF

1 INT_TMRCC1IF

0 INT_TMRUIF

3.3 Non-maskable Interrupt (NMI)

The non-maskable interrupt (NMI) is a special case. Despite being one of the 10 standard ARM® CortexTM-M3

NVIC interrupts, it is sourced from the Event Manager like a peripheral interrupt. The NMI has two second-level

sources; failure of the 24 MHz crystal and watchdog low water mark.

1. Failure of the 24MHz crystal: If the EM358x’s main clock, SYSCLK, is operating from the 24 MHz crystal and

the crystal fails, the EM358x detects the failure and automatically switches to the internal 12 MHz RC clock.

When this failure detection and switch has occurred, the EM358x triggers the CLK24M_FAIL second-level

interrupt, which then triggers the NMI.

2. Watchdog low water mark: If the EM358x’s watchdog is active and the watchdog counter has not been reset

for nominally 1.792 seconds, the watchdog triggers the WATCHDOG_INT second-level interrupt, which then

triggers the NMI.

24 Rev. 0.4

Page 25

EM358x

3.4 Faults

Four of the exceptions in the NVIC are faults: Hard Fault, Memory Fault, Bus Fault, and Usage Fault. Of these,

three (Hard Fault, Memory Fault, and Usage Fault) are standard ARM

The Bus Fault, though, is derived from EM358x-specific sources. The Bus Fault sources are recorded in the

SCS_AFSR register. Note that it is possible for one access to set multiple SCS_AFSR bits. Also note that MPU

configurations could prevent most of these bus fault accesses from occurring, with the advantage that illegal

writes are made precise faults. The four bus faults are:

WRONGSIZE – Generated by an 8-bit or 16-bit read or write of an APB peripheral register. This fault can also

result from an unaligned 32-bit access.

PROTECTED – Generated by a user mode (unprivileged) write to a system APB or AHB peripheral or

protected RAM (see Chapter 2, Section 2.2.2.3).

RESERVED – Generated by a read or write to an address within an APB peripheral’s 4 kB block range, but

the address is above the last physical register in that block range. Also generated by a read or write to an

address above the top of RAM or flash.

MISSED – Generated by a second SCS_AFSR fault. In practice, this bit is not seen since a second fault also

generates a hard fault, and the hard fault preempts the bus fault.

®

CortexTM-M3 exceptions.

Rev. 0.4 25

Page 26

EM358x

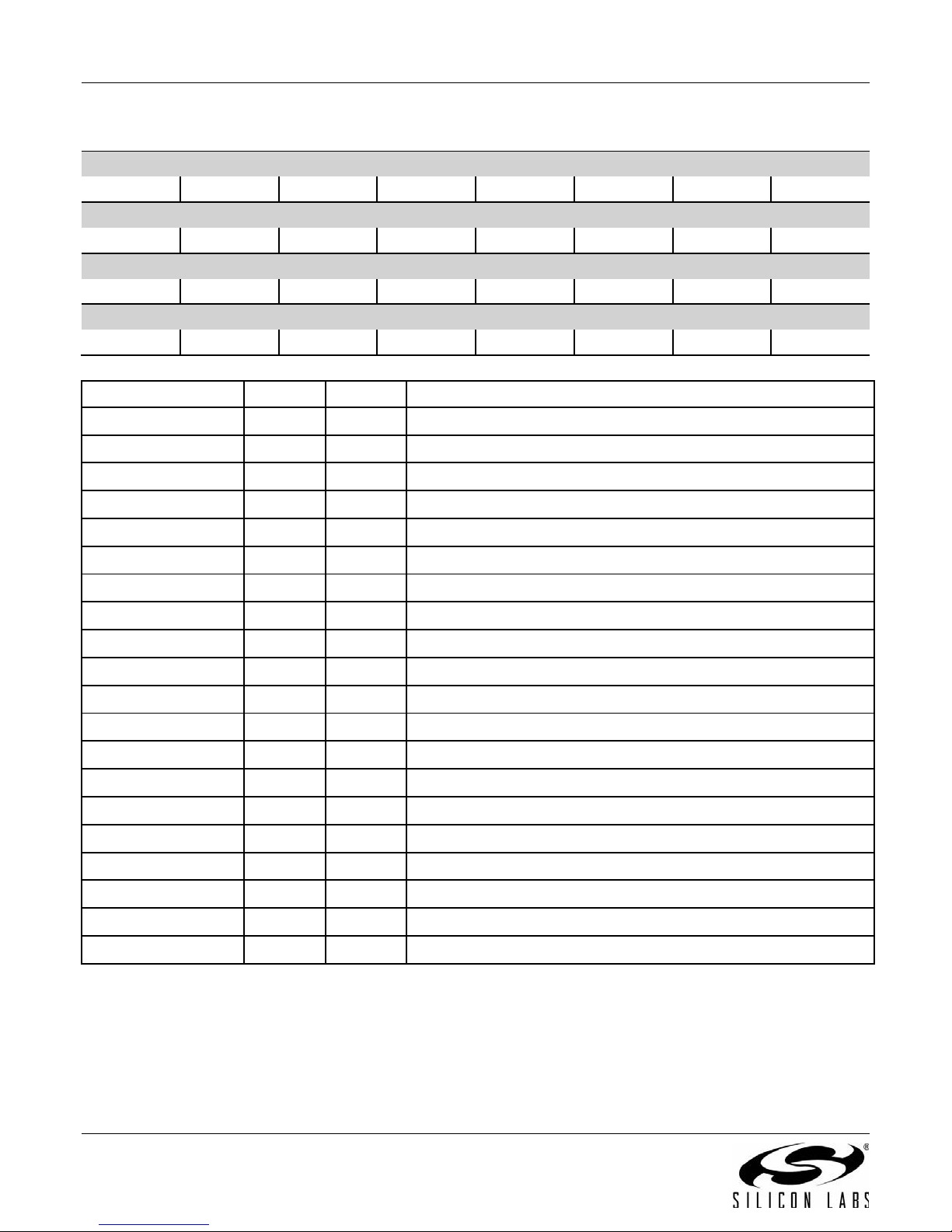

3.5 Registers

INT_CFGSET

Top-Level Set Interrupts Configuration Register Address: 0xE000E100 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_USB INT_RSVD18 INT_RSVD17 INT_DEBUG

15 14 13 12 11 10 9 8

INT_IRQD INT_IRQC INT_IRQB INT_IRQA INT_ADC INT_MACRX INT_MACTX INT_MACTMR

7 6 5 4 3 2 1 0

INT_SEC INT_SC2 INT_SC1 INT_SLEEPTMR INT_BB INT_MGMT INT_TIM2 INT_TIM1

Bitname Bitfield Access Description

INT_USB [19] RW Write 1 to enable USB interrupt. (Writing 0 has no effect.) (where

applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_DEBUG [16] RW Write 1 to enable debug interrupt. (Writing 0 has no effect.)

INT_IRQD [15] RW Write 1 to enable IRQD interrupt. (Writing 0 has no effect.)

INT_IRQC [14] RW Write 1 to enable IRQC interrupt. (Writing 0 has no effect.)

INT_IRQB [13] RW Write 1 to enable IRQB interrupt. (Writing 0 has no effect.)

INT_IRQA [12] RW Write 1 to enable IRQA interrupt. (Writing 0 has no effect.)

INT_ADC [11] RW Write 1 to enable ADC interrupt. (Writing 0 has no effect.)

INT_MACRX [10] RW Write 1 to enable MAC receive interrupt. (Writing 0 has no effect.)

INT_MACTX [9] RW Write 1 to enable MAC transmit interrupt. (Writing 0 has no effect.)

INT_MACTMR [8] RW Write 1 to enable MAC timer interrupt. (Writing 0 has no effect.)

INT_SEC [7] RW Write 1 to enable security interrupt. (Writing 0 has no effect.)

INT_SC2 [6] RW Write 1 to enable serial controller 2 interrupt. (Writing 0 has no effect.)

INT_SC1 [5] RW Write 1 to enable serial controller 1 interrupt. (Writing 0 has no effect.)

INT_SLEEPTMR [4] RW Write 1 to enable sleep timer interrupt. (Writing 0 has no effect.)

INT_BB [3] RW Write 1 to enable baseband interrupt. (Writing 0 has no effect.)

INT_MGMT [2] RW Write 1 to enable management interrupt. (Writing 0 has no effect.)

INT_TIM2 [1] RW Write 1 to enable timer 2 interrupt. (Writing 0 has no effect.)

INT_TIM1 [0] RW Write 1 to enable timer 1 interrupt. (Writing 0 has no effect.)

26 Rev. 0.4

Page 27

EM358x

INT_CFGCLR

Top-Level Clear Interrupts Configuration Register Address: 0xE000E180 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_USB INT_RSVD18 INT_RSVD17 INT_DEBUG

15 14 13 12 11 10 9 8

INT_IRQD INT_IRQC INT_IRQB INT_IRQA INT_ADC INT_MACRX INT_MACTX INT_MACTMR

7 6 5 4 3 2 1 0

INT_SEC INT_SC2 INT_SC1 INT_SLEEPTMR INT_BB INT_MGMT INT_TIM2 INT_TIM1

Bitname Bitfield Access Description

INT_USB [19] RW Write 1 to disable USB interrupt. (Writing 0 has no effect.) (where

applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_DEBUG [16] RW Write 1 to disable debug interrupt. (Writing 0 has no effect.)

INT_IRQD [15] RW Write 1 to disable IRQD interrupt. (Writing 0 has no effect.)

INT_IRQC [14] RW Write 1 to disable IRQC interrupt. (Writing 0 has no effect.)

INT_IRQB [13] RW Write 1 to disable IRQB interrupt. (Writing 0 has no effect.)

INT_IRQA [12] RW Write 1 to disable IRQA interrupt. (Writing 0 has no effect.)

INT_ADC [11] RW Write 1 to disable ADC interrupt. (Writing 0 has no effect.)

INT_MACRX [10] RW Write 1 to disable MAC receive interrupt. (Writing 0 has no effect.)

INT_MACTX [9] RW Write 1 to disable MAC transmit interrupt. (Writing 0 has no effect.)

INT_MACTMR [8] RW Write 1 to disable MAC timer interrupt. (Writing 0 has no effect.)

INT_SEC [7] RW Write 1 to disable security interrupt. (Writing 0 has no effect.)

INT_SC2 [6] RW Write 1 to disable serial controller 2 interrupt. (Writing 0 has no effect.)

INT_SC1 [5] RW Write 1 to disable serial controller 1 interrupt. (Writing 0 has no effect.)

INT_SLEEPTMR [4] RW Write 1 to disable sleep timer interrupt. (Writing 0 has no effect.)

INT_BB [3] RW Write 1 to disable baseband interrupt. (Writing 0 has no effect.)

INT_MGMT [2] RW Write 1 to disable management interrupt. (Writing 0 has no effect.)

INT_TIM2 [1] RW Write 1 to disable timer 2 interrupt. (Writing 0 has no effect.)

INT_TIM1 [0] RW Write 1 to disable timer 1 interrupt. (Writing 0 has no effect.)

Rev. 0.4 27

Page 28

EM358x

INT_PENDSET

Top-Level Set Interrupts Pending Register Address: 0xE000E200 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_USB INT_RSVD18 INT_RSVD17 INT_DEBUG

15 14 13 12 11 10 9 8

INT_IRQD INT_IRQC INT_IRQB INT_IRQA INT_ADC INT_MACRX INT_MACTX INT_MACTMR

7 6 5 4 3 2 1 0

INT_SEC INT_SC2 INT_SC1 INT_SLEEPTMR INT_BB INT_MGMT INT_TIM2 INT_TIM1

Bitname Bitfield Access Description

INT_USB [19] RW Write 1 to pend USB interrupt. (Writing 0 has no effect.) (where applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_DEBUG [16] RW Write 1 to pend debug interrupt. (Writing 0 has no effect.)

INT_IRQD [15] RW Write 1 to pend IRQD interrupt. (Writing 0 has no effect.)

INT_IRQC [14] RW Write 1 to pend IRQC interrupt. (Writing 0 has no effect.).

INT_IRQB [13] RW Write 1 to pend IRQB interrupt. (Writing 0 has no effect.)

INT_IRQA [12] RW Write 1 to pend IRQA interrupt. (Writing 0 has no effect.)

INT_ADC [11] RW Write 1 to pend ADC interrupt. (Writing 0 has no effect.)

INT_MACRX [10] RW Write 1 to pend MAC receive interrupt. (Writing 0 has no effect.)

INT_MACTX [9] RW Write 1 to pend MAC transmit interrupt. (Writing 0 has no effect.)

INT_MACTMR [8] RW Write 1 to pend MAC timer interrupt. (Writing 0 has no effect.)

INT_SEC [7] RW Write 1 to pend security interrupt. (Writing 0 has no effect.)

INT_SC2 [6] RW Write 1 to pend serial controller 2 interrupt. (Writing 0 has no effect.)

INT_SC1 [5] RW Write 1 to pend serial controller 1 interrupt. (Writing 0 has no effect.)

INT_SLEEPTMR [4] RW Write 1 to pend sleep timer interrupt. (Writing 0 has no effect.)

INT_BB [3] RW Write 1 to pend baseband interrupt. (Writing 0 has no effect.)

INT_MGMT [2] RW Write 1 to pend management interrupt. (Writing 0 has no effect.)

INT_TIM2 [1] RW Write 1 to pend timer 2 interrupt. (Writing 0 has no effect.)

INT_TIM1 [0] RW Write 1 to pend timer 1 interrupt. (Writing 0 has no effect.)

28 Rev. 0.4

Page 29

EM358x

INT_PENDCLR

Top-Level Clear Interrupts Pending Register Address: 0xE000E280 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_USB INT_RSVD18 INT_RSVD17 INT_DEBUG

15 14 13 12 11 10 9 8

INT_IRQD INT_IRQC INT_IRQB INT_IRQA INT_ADC INT_MACRX INT_MACTX INT_MACTMR

7 6 5 4 3 2 1 0

INT_SEC INT_SC2 INT_SC1 INT_SLEEPTMR INT_BB INT_MGMT INT_TIM2 INT_TIM1

Bitname Bitfield Access Description

INT_USB [19] RW Write 1 to unpend USB interrupt. (Writing 0 has no effect.) (where

applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_DEBUG [16] RW Write 1 to unpend debug interrupt. (Writing 0 has no effect.)

INT_IRQD [15] RW Write 1 to unpend IRQD interrupt. (Writing 0 has no effect.)

INT_IRQC [14] RW Write 1 to unpend IRQC interrupt. (Writing 0 has no effect.)

INT_IRQB [13] RW Write 1 to unpend IRQB interrupt. (Writing 0 has no effect.)

INT_IRQA [12] RW Write 1 to unpend IRQA interrupt. (Writing 0 has no effect.)

INT_ADC [11] RW Write 1 to unpend ADC interrupt. (Writing 0 has no effect.)

INT_MACRX [10] RW Write 1 to unpend MAC receive interrupt. (Writing 0 has no effect.)

INT_MACTX [9] RW Write 1 to unpend MAC transmit interrupt. (Writing 0 has no effect.)

INT_MACTMR [8] RW Write 1 to unpend MAC timer interrupt. (Writing 0 has no effect.)

INT_SEC [7] RW Write 1 to unpend security interrupt. (Writing 0 has no effect.)

INT_SC2 [6] RW Write 1 to unpend serial controller 2 interrupt. (Writing 0 has no effect.)

INT_SC1 [5] RW Write 1 to unpend serial controller 1 interrupt. (Writing 0 has no effect.)

INT_SLEEPTMR [4] RW Write 1 to unpend sleep timer interrupt. (Writing 0 has no effect.)

INT_BB [3] RW Write 1 to unpend baseband interrupt. (Writing 0 has no effect.)

INT_MGMT [2] RW Write 1 to unpend management interrupt. (Writing 0 has no effect.)

INT_TIM2 [1] RW Write 1 to unpend timer 2 interrupt. (Writing 0 has no effect.)

INT_TIM1 [0] RW Write 1 to unpend timer 1 interrupt. (Writing 0 has no effect.)

Rev. 0.4 29

Page 30

EM358x

INT_ACTIVE

Top-Level Active Interrupts Register Address: 0xE000E300 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_USB INT_RSVD18 INT_RSVD17 INT_DEBUG

15 14 13 12 11 10 9 8

INT_IRQD INT_IRQC INT_IRQB INT_IRQA INT_ADC INT_MACRX INT_MACTX INT_MACTMR

7 6 5 4 3 2 1 0

INT_SEC INT_SC2 INT_SC1 INT_SLEEPTMR INT_BB INT_MGMT INT_TIM2 INT_TIM1

Bitname Bitfield Access Description

INT_USB [19] RW USB interrupt active (where applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_DEBUG [16] R Debug interrupt active.

INT_IRQD [15] R IRQD interrupt active.

INT_IRQC [14] R IRQC interrupt active.

INT_IRQB [13] R IRQB interrupt active.

INT_IRQA [12] R IRQA interrupt active.

INT_ADC [11] R ADC interrupt active.

INT_MACRX [10] R MAC receive interrupt active.

INT_MACTX [9] R MAC transmit interrupt active.

INT_MACTMR [8] R MAC timer interrupt active.

INT_SEC [7] R Security interrupt active.

INT_SC2 [6] R Serial controller 2 interrupt active.

INT_SC1 [5] R Serial controller 1 interrupt active.

INT_SLEEPTMR [4] R Sleep timer interrupt active.

INT_BB [3] R Baseband interrupt active.

INT_MGMT [2] R Management interrupt active.

INT_TIM2 [1] R Timer 2 interrupt active.

INT_TIM1 [0] R Timer 1 interrupt active.

30 Rev. 0.4

Page 31

EM358x

INT_MISS

Top-Level Missed Interrupts Register Address: 0x4000A820 Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 INT_MISSUSB INT_RSVD18 INT_RSVD17 0

15 14 13 12 11 10 9 8

INT_MISSIRQD INT_MISSIRQC INT_MISSIRQB INT_MISSIRQA INT_MISSADC INT_MISSMACRX INT_MISSMACTX INT_MISSMACTMR

7 6 5 4 3 2 1 0

INT_MISSSEC INT_MISSSC2 INT_MISSSC1 INT_MISSSLEEP INT_MISSBB INT_MISSMGMT 0 0

Bitname Bitfield Access Description

INT_MISSUSB [19] RW USB interrupt missed (where applicable)

INT_RSVD18 [18] RW Reserved: this bit should be ignored.

INT_RSVD17 [17] RW Reserved: this bit should be ignored.

INT_MISSIRQD [15] RW IRQD interrupt missed.

INT_MISSIRQC [14] RW IRQC interrupt missed.

INT_MISSIRQB [13] RW IRQB interrupt missed.

INT_MISSIRQA [12] RW IRQA interrupt missed.

INT_MISSADC [11] RW ADC interrupt missed.

INT_MISSMACRX [10] RW MAC receive interrupt missed.

INT_MISSMACTX [9] RW MAC transmit interrupt missed.

INT_MISSMACTMR [8] RW MAC Timer interrupt missed.

INT_MISSSEC [7] RW Security interrupt missed.

INT_MISSSC2 [6] RW Serial controller 2 interrupt missed.

INT_MISSSC1 [5] RW Serial controller 1 interrupt missed.

INT_MISSSLEEP [4] RW Sleep timer interrupt missed.

INT_MISSBB [3] RW Baseband interrupt missed.

INT_MISSMGMT [2] RW Management interrupt missed.

Rev. 0.4 31

Page 32

EM358x

SCS_AFSR

Auxiliary Fault Status Register Address: 0xE000ED3C Reset: 0x0

31 30 29 28 27 26 25 24

0 0 0 0 0 0 0 0

23 22 21 20 19 18 17 16

0 0 0 0 0 0 0 0

15 14 13 12 11 10 9 8

0 0 0 0 0 0 0 0

7 6 5 4 3 2 1 0

0 0 0 0 WRONGSIZE PROTECTED RESERVED MISSED

Bitname Bitfield Access Description

WRONGSIZE [3] RW A bus fault resulted from an 8-bit or 16-bit read or write of an APB

peripheral register. This fault can also result from an unaligned 32-bit

access.

PROTECTED [2] RW A bus fault resulted from a user mode (unprivileged) write to a system APB

or AHB peripheral or protected RAM.

RESERVED [1] RW A bus fault resulted from a read or write to an address within an APB

peripheral's 4 kB block range, but above the last physical register in that

block. Can also result from a read or write to an address above the top of

RAM or flash.

MISSED [0] RW A bus fault occurred when a bit was already set in this register.

32 Rev. 0.4

Page 33

4 Radio Module

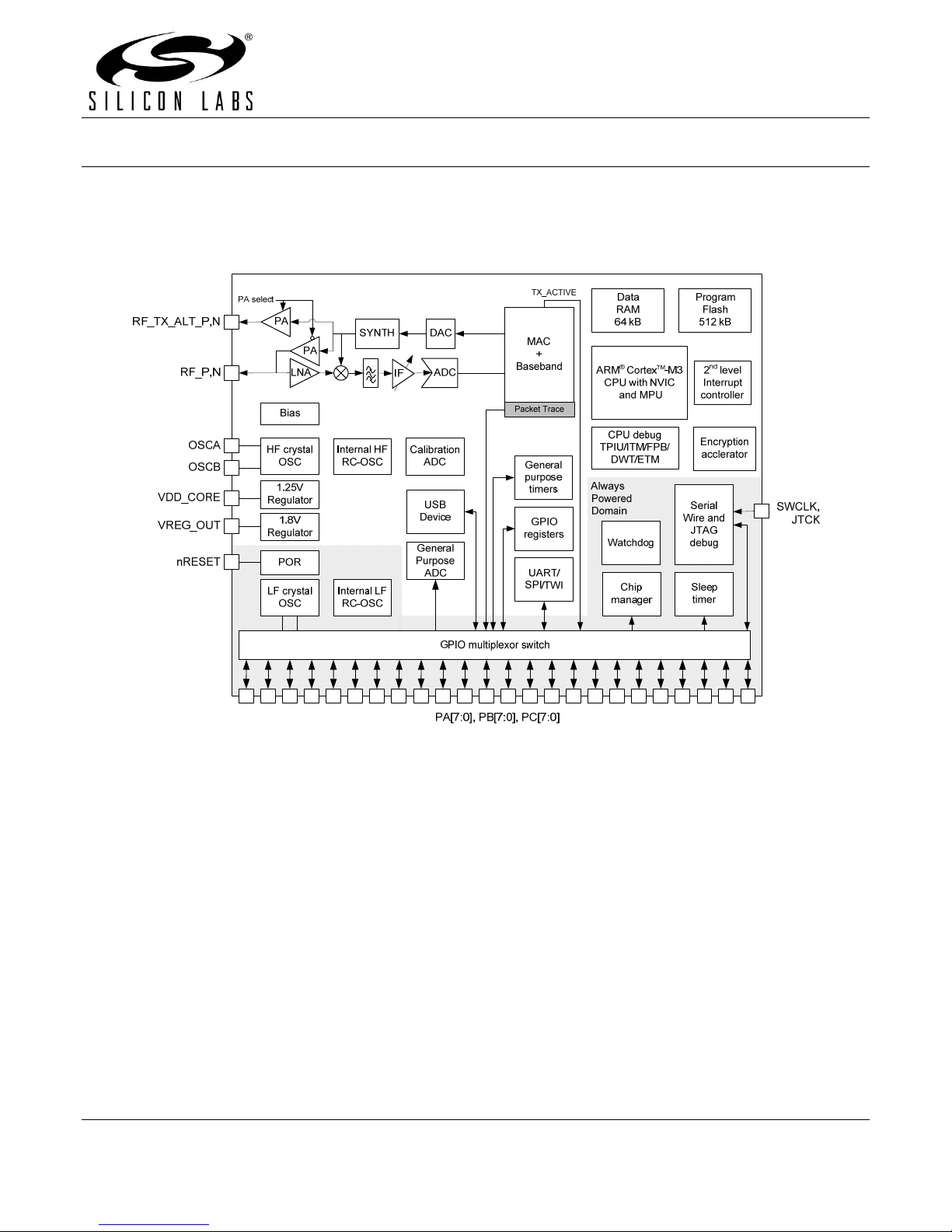

The radio module consists of an analog front end and digital baseband as shown in Figure 4-1.

EM358x

Figure 4-1. EM358 Block Diagram

4.1 Receive (Rx) Path

The Rx path uses a low-IF, super-heterodyne receiver that rejects the image frequency using complex mixing and

polyphase filtering. In the analog domain, the input RF signal from the antenna is first amplified and mixed down

to a 4 MHz IF frequency. The mixers’ output is filtered, combined, and amplified before being sampled by a 12

MSPS ADC. The digitized signal is then demodulated in the digital baseband. The filtering within the Rx path

improves the EM358x’s co-existence with other 2.4 GHz transceivers such as Zigbee/ 802.15.4-2003, IEEE

802.11-2007, and Bluetooth radios. The digital baseband also provides gain control of the Rx path, both to enable

the reception of small and large wanted signals and to tolerate large interferers.

4.1.1 Rx Baseband

The EM358x Rx digital baseband implements a coherent demodulator for optimal performance. The baseband

demodulates the O-QPSK signal at the chip level and synchronizes with the IEEE 802.15.4-2003-defined

preamble. An automatic gain control (AGC) module adjusts the analog gain continuously every ¼ symbol until the

preamble is detected. Once detected, the gain is fixed for the remainder of the packet. The baseband despreads

the demodulated data into 4-bit symbols. These symbols are buffered and passed to the hardware-based MAC

module for packet assembly and filtering.

In addition, the Rx baseband provides the calibration and control interface to the analog Rx modules, including

the LNA, Rx baseband filter, and modulation modules. The Ember software includes calibration algorithms that

use this interface to reduce the effects of silicon process and temperature variation.

Rev. 0.4 33

Page 34

EM358x

4.1.2 RSSI and CCA

The EM358x calculates the RSSI over every 8-symbol period as well as at the end of a received packet. The

linear range of RSSI is specified to be at least 40 dB over temperature. At room temperature, the linear range is

approximately 60 dB (-90 dBm to -30 dBm input signal).

The EM358x Rx baseband provides support for the IEEE 802.15.4-2003 RSSI CCA method. Clear channel

reports busy medium if RSSI exceeds its threshold.

4.2 Transmit (Tx) Path

The EM358x Tx path produces an O-QPSK-modulated signal using the analog front end and digital baseband.

The area- and power-efficient Tx architecture uses a two-point modulation scheme to modulate the RF signal

generated by the synthesizer. The modulated RF signal is fed to the integrated PA and then out of the EM358x.

4.2.1 Tx Baseband

The EM358x Tx baseband in the digital domain spreads the 4-bit symbol into its IEEE 802.15.4-2003-defined 32chip sequence. It also provides the interface for the Ember software to calibrate the Tx module to reduce silicon

process, temperature, and voltage variations.

4.2.2 TX_ACTIVE and nTX_ACTIVE Signals

For applications requiring an external PA, two signals are provided called TX_ACTIVE and nTX_ACTIVE. These

signals are the inverse of each other. They can be used for external PA power management and RF switching

logic. In transmit mode the Tx baseband drives TX_ACTIVE high, as described in Table 7-5, GPIO Signal

Assignments. In receive mode the TX_ACTIVE signal is low. TX_ACTIVE is the alternate function of PC5, and