Page 1

EFM8 Sleepy Bee Family

EFM8SB2 Reference Manual

The EFM8SB2, part of the Sleepy Bee family of MCUs, is the

world’s most energy friendly 8-bit microcontrollers with a comprehensive feature set in small packages.

These devices offer lowest power consumption by combining innovative low energy techniques and short wakeup times from energy saving modes into small packages, making

them well-suited for any battery operated applications. With an efficient 8051 core, 6-bit

current reference, and precision analog, the EFM8SB2 family is also optimal for embedded applications.

EFM8SB2 applications include the following:

• Hand-held devices

Industrial controls

•

CIP-51 8051 Core

Flash Program

Memory

(up to 64 KB)

Core / Memory Clock Management

(25 MHz)

RAM Memory

(4352 bytes)

• Battery-operated consumer electronics

•

Sensor interfaces

External

Oscillator

Debug Interface

with C2

External 32 kHz

RTC Oscillator

Low Power 20

MHz RC

Oscillator

High Frequency

24.5 MHz RC

Oscillator

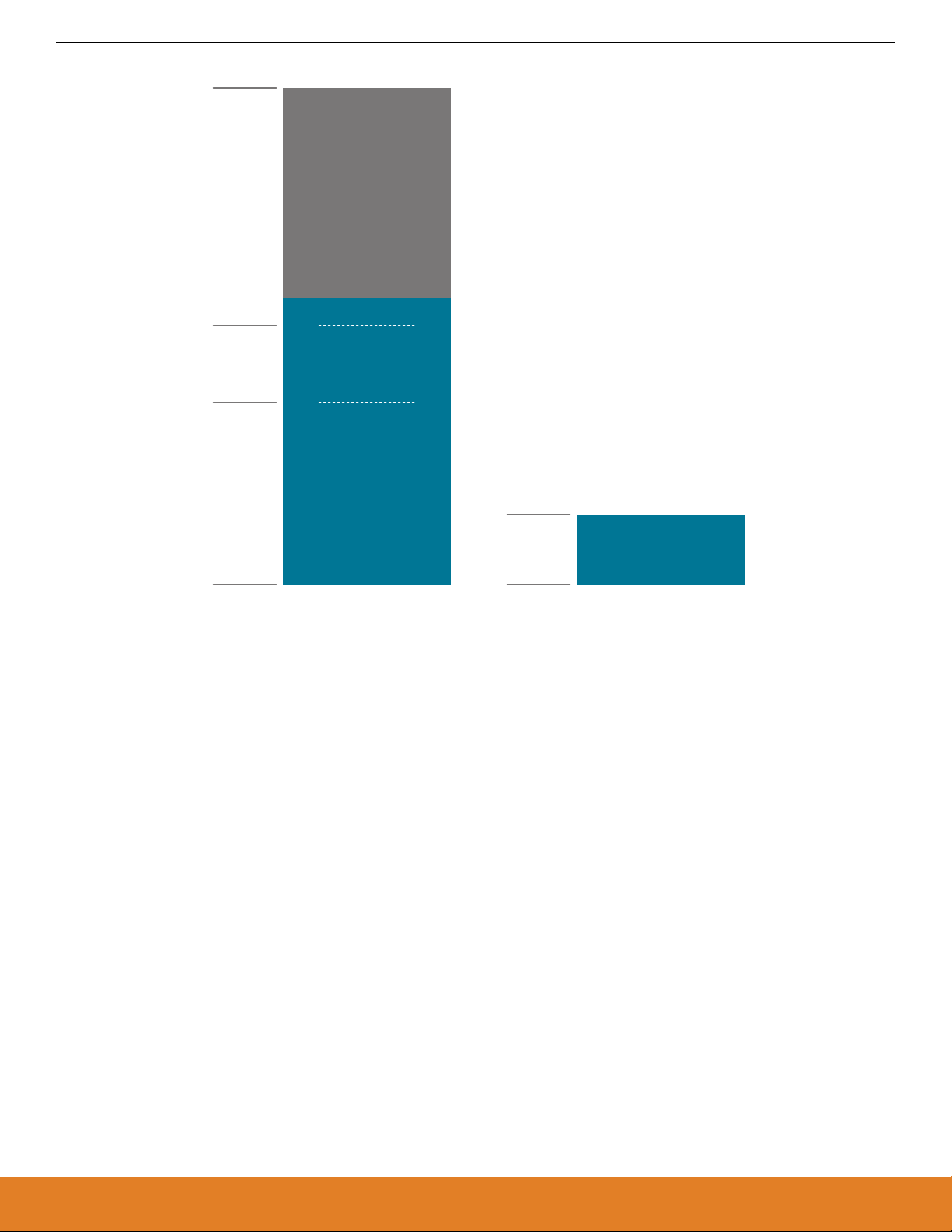

ENERGY FRIENDLY FEATURES

• Lowest MCU sleep current with supply

brownout detection (50 nA)

•

Lowest MCU active current with these

features (170 μA / MHz at 24.5 MHz clock

rate)

• Lowest MCU sleep current using internal

RTC operating and supply brownout

detection (<300 nA)

• Ultra-fast wake up for digital and analog

peripherals (< 2 μs)

• Integrated low drop out (LDO) voltage

regulator to maintain ultra-low active

current at all voltages

Energy Management

Internal LDO

Regulator

Brown-Out Detector

Power-On Reset

8-bit SFR bus

Serial Interfaces Timers and Triggers Analog Interfaces

UART

2

I

C / SMBus

Lowest power mode with peripheral operational:

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1

2 x SPI

IdleNormal Suspend Sleep

External

Interrupts

General

Purpose I/O

Pin Reset

Pin Wakeup

Timers

0/1/2/3

Watchdog

Timer

PCA/PWM

Real Time

Clock

ADC

Comparator 1

Internal Current Reference

Comparator 0

Internal Voltage

Reference

SecurityI/O Ports

16/32-bit CRC

Page 2

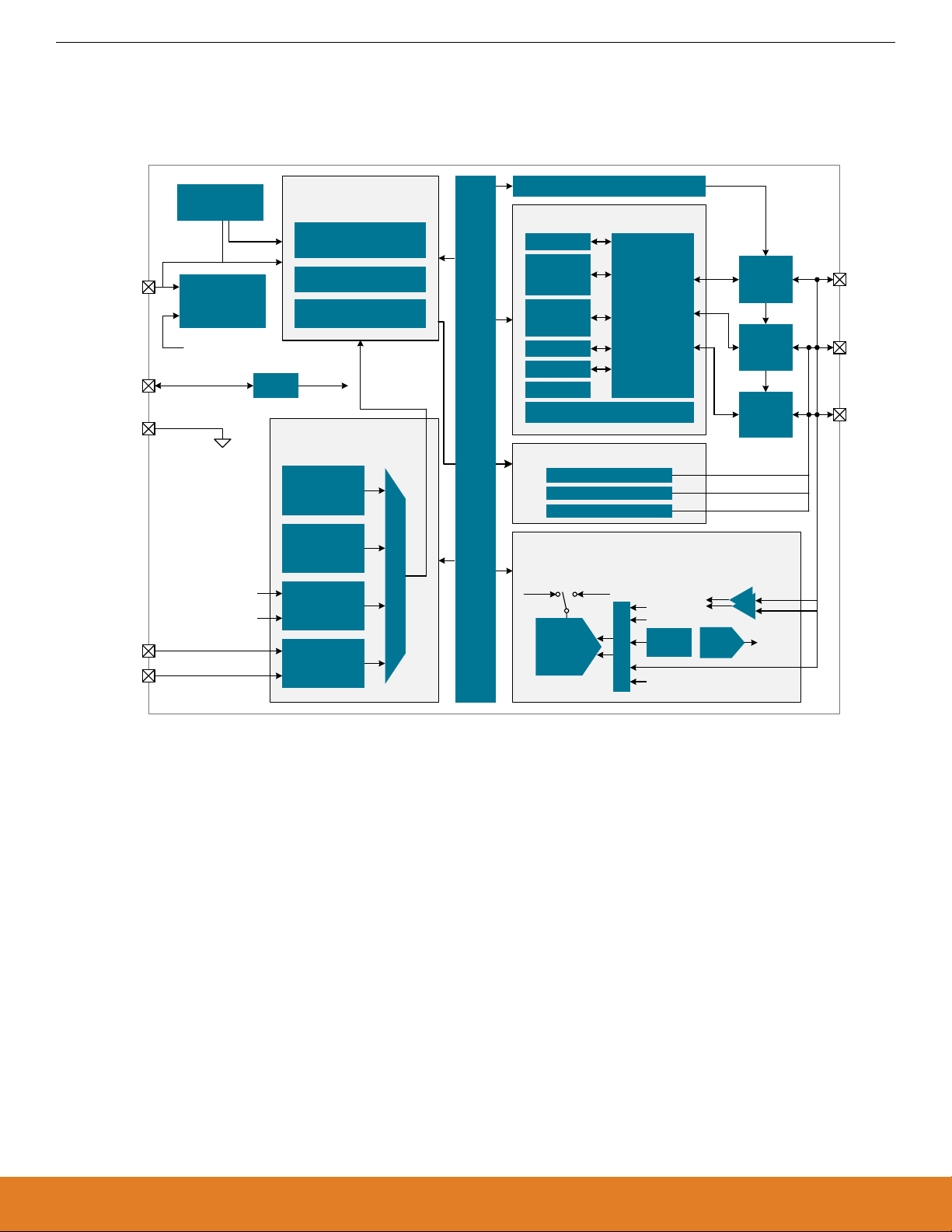

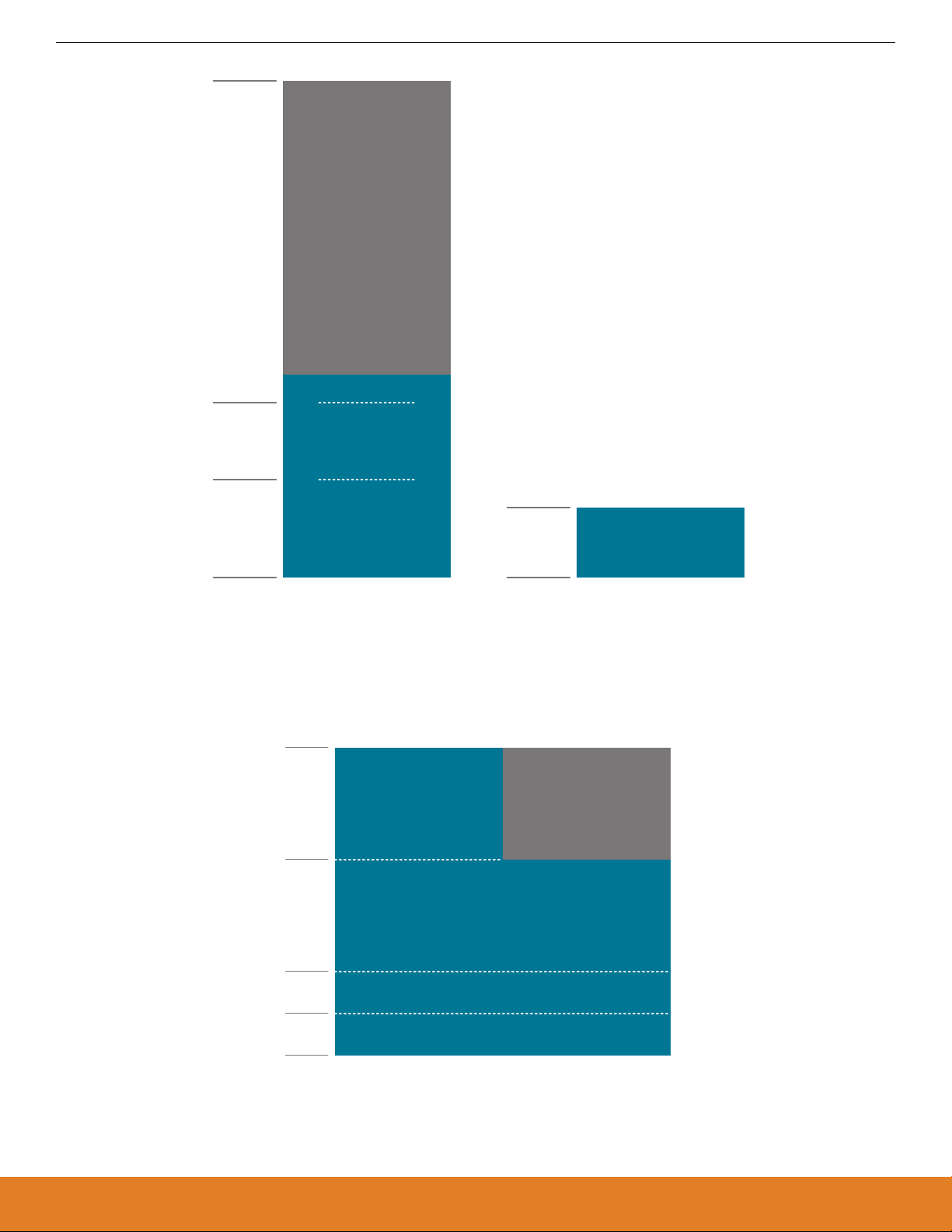

1. System Overview

1.1 Introduction

EFM8SB2 Reference Manual

System Overview

C2CK/RSTb

VDD

GND

XTAL3

XTAL4

Power On

Reset/PMU

Debug /

Programming

Hardware

C2D

Power Net

Analog

Power

Wake

Reset

XTAL1

XTAL2

CIP-51 8051 Controller

Core

64/32/16 KB ISP Flash

Program Memory

256 Byte SRAM

4096 Byte XRAM

VREG

Digital

Power

System Clock

Configuration

Precision

24.5 MHz

Oscillator

Low Power

20 MHz

Oscillator

External

Oscillator

Circuit

RTC

Oscillator

SYSCLK

SFR

Bus

Port I/O Configuration

Digital Peripherals

UART

Timers 0,

1, 2, 3

Priority

PCA/WDT

SMBus

SPI 0,1

CRC

Crossbar Control

Crossbar

Decoder

External Memory Interface

Control

Address

Data

Analog Peripherals

VREF

External

VREF

10-bit

300ksps

ADC

AMUX

VDD

VREF

Temp

Sensor

GND

Internal

Port 0

Drivers

Port 1

Drivers

Port 2

Drivers

Comparators

+

+

-

-

6-bit

IREF

P0.n

P1.n

P2.n

IREF0

Figure 1.1. Detailed EFM8SB2 Block Diagram

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 1

Page 3

EFM8SB2 Reference Manual

System Overview

1.2 Power

internal circuitry draws power from the VDD supply pin. External I/O pins are powered from the VIO supply voltage (or VDD on devi-

All

ces without a separate VIO connection), while most of the internal circuitry is supplied by an on-chip LDO regulator. Control over the

device power can be achieved by enabling/disabling individual peripherals as needed. Each analog peripheral can be disabled when

not in use and placed in low power mode. Digital peripherals, such as timers and serial buses, have their clocks gated off and draw little

power when they are not in use.

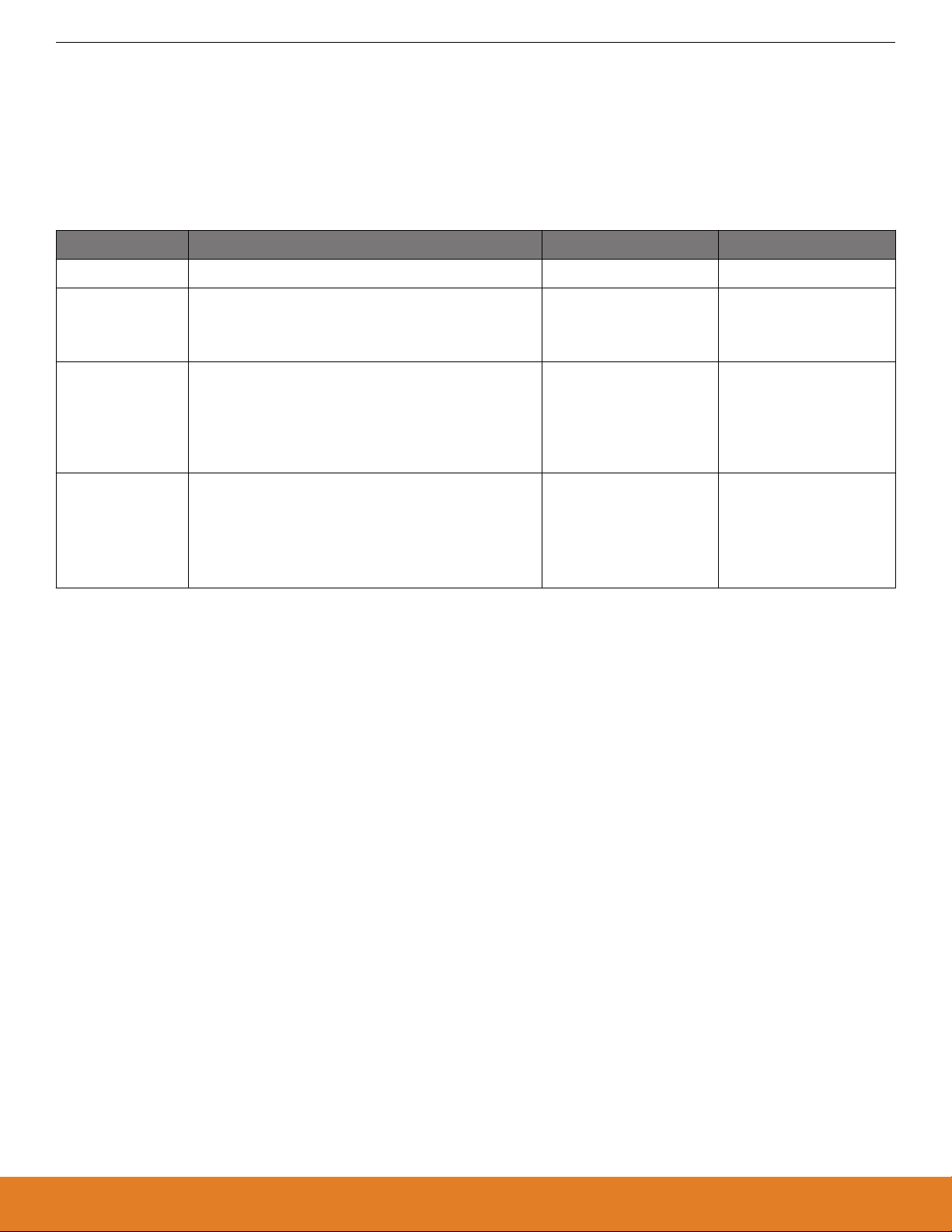

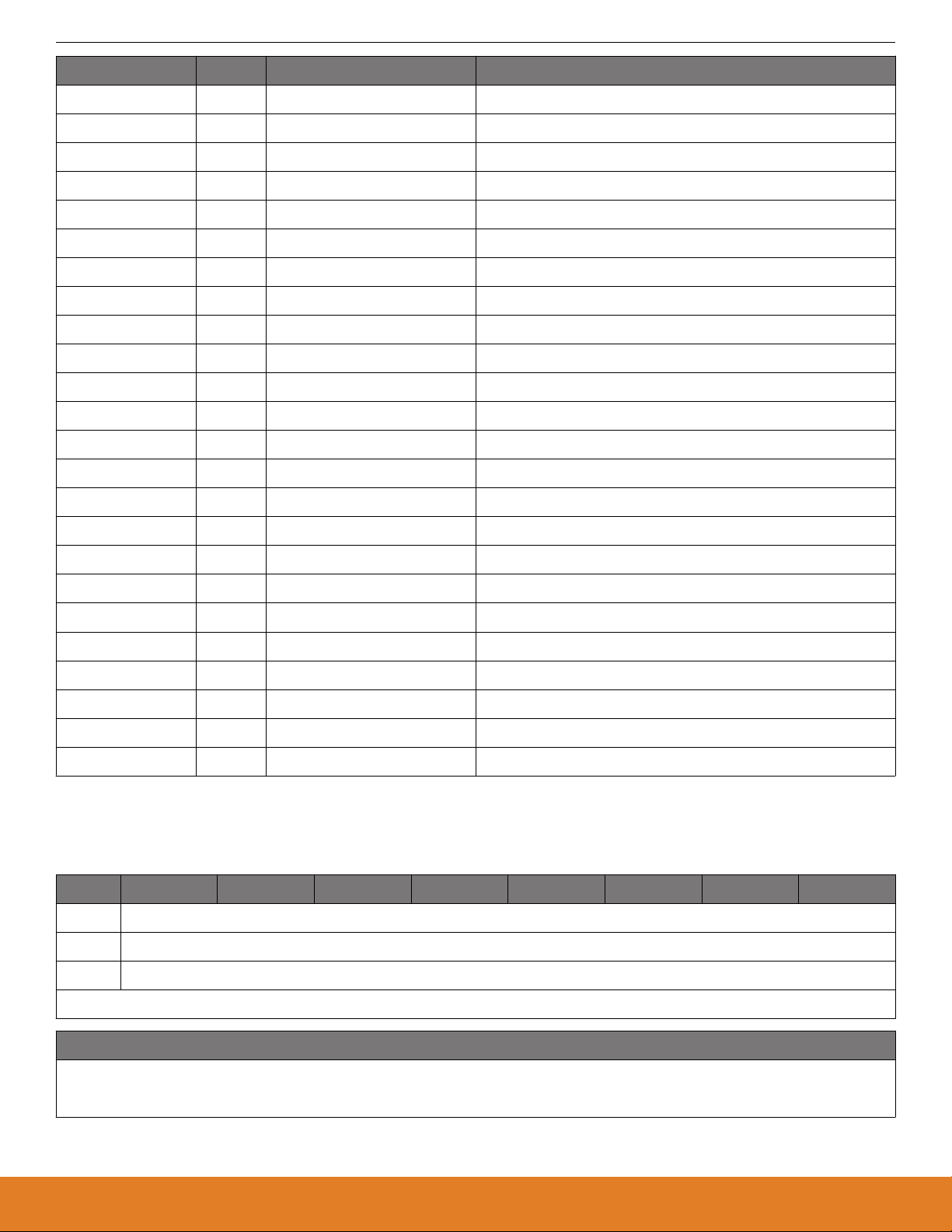

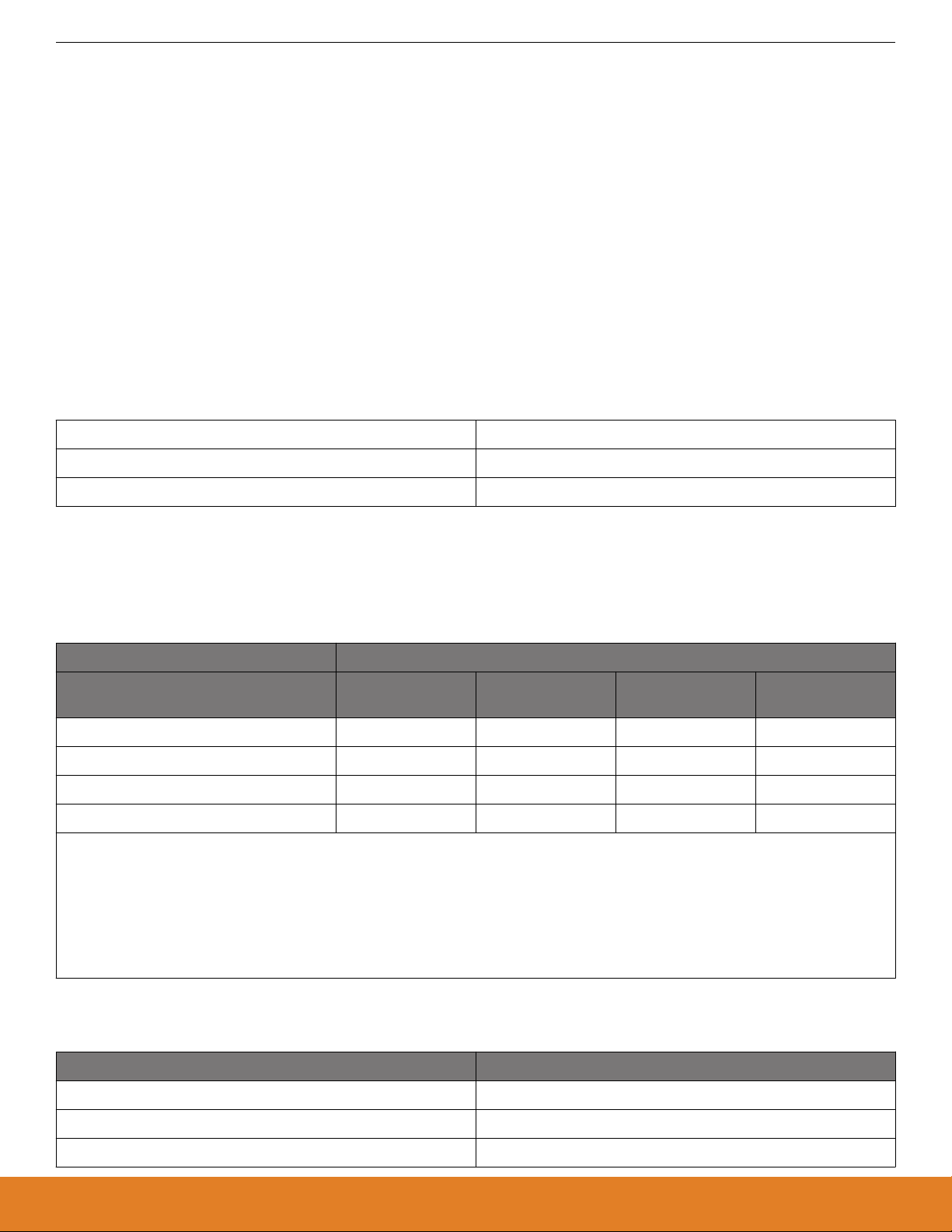

Table 1.1. Power Modes

Power Mode Details Mode Entry Wake-Up Sources

Normal Core and all peripherals clocked and fully operational — —

Idle • Core halted

•

All peripherals clocked and fully operational

Set IDLE bit in PCON0 Any interrupt

• Code resumes execution on wake event

Suspend • Core and digital peripherals halted

•

Internal oscillators disabled

• Code resumes execution on wake event

1. Switch SYSCLK to

HFOSC0 or LPOSC0

2.

Set SUSPEND bit in

PMU0CF

• RTC0 Alarm Event

• RTC0 Fail Event

• Port Match Event

• Comparator 0 Rising

Edge

Sleep • Most internal power nets shut down

•

Select circuits remain powered

• Pins retain state

• All RAM and SFRs retain state

• Code resumes execution on wake event

1. Disable unused analog peripherals

2.

Set SLEEP bit in

PMU0CF

• RTC0 Alarm Event

• RTC0 Fail Event

• Port Match Event

• Comparator 0 Rising

Edge

1.3 I/O

Digital

and analog resources are externally available on the device’s multi-purpose I/O pins. Port pins P0.0-P2.6 can be defined as general-purpose I/O (GPIO), assigned to one of the internal digital resources through the crossbar or dedicated channels, or assigned to an

analog function. Port pin P2.7 can be used as GPIO. Additionally, the C2 Interface Data signal (C2D) is shared with P2.7.

• Up to 24 multi-functions I/O pins, supporting digital and analog functions.

• Flexible priority crossbar decoder for digital peripheral assignment.

• Two drive strength settings for each pin.

• Two direct-pin interrupt sources with dedicated interrupt vectors (INT0 and INT1).

• Up to 16 direct-pin interrupt sources with shared interrupt vector (Port Match).

1.4 Clocking

The CPU core and peripheral subsystem may be clocked by both internal and external oscillator resources. By default, the system

clock comes up running from the 20 MHz low power oscillator divided by 8.

• Provides clock to core and peripherals.

• 20 MHz low power oscillator (LPOSC0), accurate to +/- 10% over supply and temperature corners.

• 24.5 MHz internal oscillator (HFOSC0), accurate to +/- 2% over supply and temperature corners.

• External RTC 32 kHz crystal.

• External RC, C, CMOS, and high-frequency crystal clock options (EXTCLK).

• Clock divider with eight settings for flexible clock scaling: Divide the selected clock source by 1, 2, 4, 8, 16, 32, 64, or 128.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 2

Page 4

EFM8SB2 Reference Manual

System Overview

1.5 Counters/Timers and PWM

Real Time Clock (RTC0)

RTC is an ultra low power, 36 hour 32-bit independent time-keeping Real Time Clock with alarm. The RTC has a dedicated 32 kHz

The

oscillator. No external resistor or loading capacitors are required, and a missing clock detector features alerts the system if the external

crystal fails. The on-chip loading capacitors are programmable to 16 discrete levels allowing compatibility with a wide range of crystals.

The RTC module includes the following features:

• Up to 36 hours (32-bit) of independent time keeping.

• Support for external 32 kHz crystal or internal self-oscillate mode.

• Internal crystal loading capacitors with 16 levels.

• Operation in the lowest power mode and across the full supported voltage range.

• Alarm and oscillator failure events to wake from the lowest power mode or reset the device.

Programmable Counter Array (PCA0)

The programmable counter array (PCA) provides multiple channels of enhanced timer and PWM functionality while requiring less CPU

intervention than standard counter/timers. The PCA consists of a dedicated 16-bit counter/timer and one 16-bit capture/compare module for each channel. The counter/timer is driven by a programmable timebase that has flexible external and internal clocking options.

Each capture/compare module may be configured to operate independently in one of five modes: Edge-Triggered Capture, Software

Timer, High-Speed Output, Frequency Output, or Pulse-Width Modulated (PWM) Output. Each capture/compare module has its own

associated I/O line (CEXn) which is routed through the crossbar to port I/O when enabled.

• 16-bit time base.

• Programmable clock divisor and clock source selection.

• Up to six independently-configurable channels

• 8, 9, 10, 11 and 16-bit PWM modes (edge-aligned operation).

• Frequency output mode.

• Capture on rising, falling or any edge.

• Compare function for arbitrary waveform generation.

• Software timer (internal compare) mode.

• Integrated watchdog timer.

Timers (Timer 0, Timer 1, Timer 2, and Timer 3)

Several counter/timers are included in the device: two are 16-bit counter/timers compatible with those found in the standard 8051, and

the rest are 16-bit auto-reload timers for timing peripherals or for general purpose use. These timers can be used to measure time intervals, count external events and generate periodic interrupt requests. Timer 0 and Timer 1 are nearly identical and have four primary

modes of operation. The other timers offer both 16-bit and split 8-bit timer functionality with auto-reload and capture capabilities.

Timer 0 and Timer 1 include the following features:

• Standard 8051 timers, supporting backwards-compatibility with firmware and hardware.

• Clock sources include SYSCLK, SYSCLK divided by 12, 4, or 48, the External Clock divided by 8, or an external pin.

• 8-bit auto-reload counter/timer mode

• 13-bit counter/timer mode

• 16-bit counter/timer mode

• Dual 8-bit counter/timer mode (Timer 0)

Timer 2 and Timer 3 are 16-bit timers including the following features:

• Clock sources include SYSCLK, SYSCLK divided by 12, or the External Clock divided by 8.

• 16-bit auto-reload timer mode

• Dual 8-bit auto-reload timer mode

• Comparator 0 or RTC0 capture (Timer 2)

• Comparator 1 or EXTCLK/8 capture (Timer 3)

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 3

Page 5

EFM8SB2 Reference Manual

System Overview

Watchdog Timer (WDT0)

device includes a programmable watchdog timer (WDT) integrated within the PCA0 peripheral. A WDT overflow forces the MCU

The

into the reset state. To prevent the reset, the WDT must be restarted by application software before overflow. If the system experiences

a software or hardware malfunction preventing the software from restarting the WDT, the WDT overflows and causes a reset. Following

a reset, the WDT is automatically enabled and running with the default maximum time interval. If needed, the WDT can be disabled by

system software. The state of the RSTb pin is unaffected by this reset.

The Watchdog Timer integrated in the PCA0 peripheral has the following features:

• Programmable timeout interval

• Runs from the selected PCA clock source

• Automatically enabled after any system reset

1.6 Communications and Other Digital Peripherals

Universal Asynchronous Receiver/Transmitter (UART0)

UART0 is an asynchronous, full duplex serial port offering modes 1 and 3 of the standard 8051 UART. Enhanced baud rate support

allows a wide range of clock sources to generate standard baud rates. Received data buffering allows UART0 to start reception of a

second incoming data byte before software has finished reading the previous data byte.

The UART module provides the following features:

• Asynchronous transmissions and receptions

• Baud rates up to SYSCLK/2 (transmit) or SYSCLK/8 (receive)

• 8- or 9-bit data

• Automatic start and stop generation

Serial Peripheral Interface (SPI0 and SPI1)

The serial peripheral interface (SPI) module provides access to a flexible, full-duplex synchronous serial bus. The SPI can operate as a

master or slave device in both 3-wire or 4-wire modes, and supports multiple masters and slaves on a single SPI bus. The slave-select

(NSS) signal can be configured as an input to select the SPI in slave mode, or to disable master mode operation in a multi-master

environment, avoiding contention on the SPI bus when more than one master attempts simultaneous data transfers. NSS can also be

configured as a firmware-controlled chip-select output in master mode, or disabled to reduce the number of pins required. Additional

general purpose port I/O pins can be used to select multiple slave devices in master mode.

The SPI module includes the following features:

• Supports 3- or 4-wire operation in master or slave modes.

• Supports external clock frequencies up to SYSCLK / 2 in master mode and SYSCLK / 10 in slave mode.

• Support for four clock phase and polarity options.

• 8-bit dedicated clock clock rate generator.

• Support for multiple masters on the same data lines.

System Management Bus / I2C (SMB0)

The SMBus I/O interface is a two-wire, bi-directional serial bus. The SMBus is compliant with the System Management Bus Specification, version 1.1, and compatible with the I2C serial bus.

The SMBus module includes the following features:

• Standard (up to 100 kbps) and Fast (400 kbps) transfer speeds.

• Support for master, slave, and multi-master modes.

• Hardware synchronization and arbitration for multi-master mode.

• Clock low extending (clock stretching) to interface with faster masters.

• Hardware support for 7-bit slave and general call address recognition.

• Firmware support for 10-bit slave address decoding.

• Ability to inhibit all slave states.

• Programmable data setup/hold times.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 4

Page 6

EFM8SB2 Reference Manual

System Overview

External Memory Interface (EMIF0)

External Memory Interface (EMIF) enables access of off-chip memories and memory-mapped devices connected to the GPIO

The

ports. The external memory space may be accessed using the external move instruction (MOVX) with the target address specified in

either 8-bit or 16-bit formats.

• Supports multiplexed memory access.

• Four external memory modes:

• Internal only.

• Split mode without bank select.

• Split mode with bank select.

• External only

• Configurable ALE (address latch enable) timing.

• Configurable address setup and hold times.

• Configurable write and read pulse widths.

16/32-bit CRC (CRC0)

The cyclic redundancy check (CRC) module performs a CRC using a 16-bit or 32-bit polynomial. CRC0 accepts a stream of 8-bit data

and posts the result to an internal register. In addition to using the CRC block for data manipulation, hardware can automatically CRC

the flash contents of the device.

The CRC module is designed to provide hardware calculations for flash memory verification and communications protocols. The CRC

module includes the following features:

• Support for CCITT-16 polynomial (0x1021).

• Support for CRC-32 polynomial (0x04C11DB7).

• Byte-level bit reversal.

• Automatic CRC of flash contents on one or more 1024-byte blocks.

• Initial seed selection of 0x0000/0x00000000 or 0xFFFF/0xFFFFFFFF.

1.7 Analog

Programmable Current Reference (IREF0)

The programmable current reference (IREF0) module enables current source or sink with two output current settings: Low Power Mode

and High Current Mode. The maximum current output in Low Power Mode is 63 µA (1 µA steps) and the maximum current output in

High Current Mode is 504 µA (8 µA steps).

The IREF module includes the following features:

• Capable of sourcing or sinking current in programmable steps.

• Two operational modes: Low Power Mode and High Current Mode.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 5

Page 7

EFM8SB2 Reference Manual

System Overview

10-Bit Analog-to-Digital Converter (ADC0)

ADC is a successive-approximation-register (SAR) ADC with 10- and 8-bit modes, integrated track-and hold and a programmable

The

window detector. The ADC is fully configurable under software control via several registers. The ADC may be configured to measure

different signals using the analog multiplexer. The voltage reference for the ADC is selectable between internal and external reference

sources.

• Up to 22 external inputs.

• Single-ended 10-bit mode.

• Supports an output update rate of 300 ksps samples per second.

• Operation in low power modes at lower conversion speeds.

• Asynchronous hardware conversion trigger, selectable between software, external I/O and internal timer sources.

• Output data window comparator allows automatic range checking.

• Support for burst mode, which produces one set of accumulated data per conversion-start trigger with programmable power-on settling and tracking time.

• Conversion complete and window compare interrupts supported.

• Flexible output data formatting.

• Includes an internal 1.65 V fast-settling reference and support for external reference.

• Integrated temperature sensor.

Low Current Comparators (CMP0, CMP1)

Analog comparators are used to compare the voltage of two analog inputs, with a digital output indicating which input voltage is higher.

External input connections to device I/O pins and internal connections are available through separate multiplexers on the positive and

negative inputs. Hysteresis, response time, and current consumption may be programmed to suit the specific needs of the application.

The comparator module includes the following features:

• Up to 12 external positive inputs.

• Up to 11 external negative inputs.

• Additional input options:

• Capacitive Sense Comparator output.

• VDD.

• VDD divided by 2.

• Internal connection to LDO output.

• Direct connection to GND.

• Synchronous and asynchronous outputs can be routed to pins via crossbar.

• Programmable hysteresis between 0 and +/-20 mV.

• Programmable response time.

• Interrupts generated on rising, falling, or both edges.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 6

Page 8

EFM8SB2 Reference Manual

System Overview

1.8 Reset Sources

Reset circuitry allows the controller to be easily placed in a predefined default condition. On entry to this reset state, the following occur:

The core halts program execution.

•

• Module registers are initialized to their defined reset values unless the bits reset only with a power-on reset.

• External port pins are forced to a known state.

• Interrupts and timers are disabled.

All registers are reset to the predefined values noted in the register descriptions unless the bits only reset with a power-on reset. The

contents of RAM are unaffected during a reset; any previously stored data is preserved as long as power is not lost. The Port I/O latches are reset to 1 in open-drain mode. Weak pullups are enabled during and after the reset. For Supply Monitor and power-on resets,

the RSTb pin is driven low until the device exits the reset state. On exit from the reset state, the program counter (PC) is reset, and the

system clock defaults to an internal oscillator. The Watchdog Timer is enabled, and program execution begins at location 0x0000.

Reset sources on the device include the following:

• Power-on reset

• External reset pin

• Comparator reset

• Software-triggered reset

• Supply monitor reset (monitors VDD supply)

• Watchdog timer reset

• Missing clock detector reset

• Flash error reset

• RTC0 alarm or oscillator failure

1.9 Debugging

The EFM8SB2 devices include an on-chip Silicon Labs 2-Wire (C2) debug interface to allow flash programming and in-system debugging with the production part installed in the end application. The C2 interface uses a clock signal (C2CK) and a bi-directional C2 data

signal (C2D) to transfer information between the device and a host system. See the C2 Interface Specification for details on the C2

protocol.

1.10 Bootloader

All devices come pre-programmed with a UART bootloader. This bootloader resides in flash and can be erased if it is not needed.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 7

Page 9

EFM8SB2 Reference Manual

Memory Organization

2. Memory Organization

2.1 Memory Organization

The memory organization of the CIP-51 System Controller is similar to that of a standard 8051. There are two separate memory

spaces: program memory and data memory. Program and data memory share the same address space but are accessed via different

instruction types. Program memory consists of a non-volatile storage area that may be used for either program code or non-volatile

data storage. The data memory, consisting of "internal" and "external" data space, is implemented as RAM, and may be used only for

data storage. Program execution is not supported from the data memory space.

2.2 Program Memory

The CIP-51 core has a 64 KB program memory space. The product family implements some of this program memory space as in-system, re-programmable flash memory. Flash security is implemented by a user-programmable location in the flash block and provides

read, write, and erase protection. All addresses not specified in the device memory map are reserved and may not be used for code or

data storage.

MOVX Instruction and Program Memory

The MOVX instruction in an 8051 device is typically used to access external data memory. On the devices, the MOVX instruction is

normally used to read and write on-chip XRAM, but can be re-configured to write and erase on-chip flash memory space. MOVC instructions are always used to read flash memory, while MOVX write instructions are used to erase and write flash. This flash access

feature provides a mechanism for the product to update program code and use the program memory space for non-volatile data storage.

2.3 Data Memory

The RAM space on the chip includes both an "internal" RAM area which is accessed with MOV instructions, and an on-chip "external"

RAM area which is accessed using MOVX instructions. Total RAM varies, based on the specific device. The device memory map has

more details about the specific amount of RAM available in each area for the different device variants.

Internal RAM

There are 256 bytes of internal RAM mapped into the data memory space from 0x00 through 0xFF. The lower 128 bytes of data memory are used for general purpose registers and scratch pad memory. Either direct or indirect addressing may be used to access the lower

128 bytes of data memory. Locations 0x00 through 0x1F are addressable as four banks of general purpose registers, each bank consisting of eight byte-wide registers. The next 16 bytes, locations 0x20 through 0x2F, may either be addressed as bytes or as 128 bit

locations accessible with the direct addressing mode.

The upper 128 bytes of data memory are accessible only by indirect addressing. This region occupies the same address space as the

Special Function Registers (SFR) but is physically separate from the SFR space. The addressing mode used by an instruction when

accessing locations above 0x7F determines whether the CPU accesses the upper 128 bytes of data memory space or the SFRs. Instructions that use direct addressing will access the SFR space. Instructions using indirect addressing above 0x7F access the upper

128 bytes of data memory.

General Purpose Registers

The lower 32 bytes of data memory, locations 0x00 through 0x1F, may be addressed as four banks of general-purpose registers. Each

bank consists of eight byte-wide registers designated R0 through R7. Only one of these banks may be enabled at a time. Two bits in

the program status word (PSW) register, RS0 and RS1, select the active register bank. This allows fast context switching when entering

subroutines and interrupt service routines. Indirect addressing modes use registers R0 and R1 as index registers.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 8

Page 10

EFM8SB2 Reference Manual

Memory Organization

Bit Addressable Locations

addition to direct access to data memory organized as bytes, the sixteen data memory locations at 0x20 through 0x2F are also ac-

In

cessible as 128 individually addressable bits. Each bit has a bit address from 0x00 to 0x7F. Bit 0 of the byte at 0x20 has bit address

0x00 while bit 7 of the byte at 0x20 has bit address 0x07. Bit 7 of the byte at 0x2F has bit address 0x7F. A bit access is distinguished

from a full byte access by the type of instruction used (bit source or destination operands as opposed to a byte source or destination).

The MCS-51™ assembly language allows an alternate notation for bit addressing of the form XX.B where XX is the byte address and B

is the bit position within the byte. For example, the instruction:

Mov C, 22.3h

moves the Boolean value at 0x13 (bit 3 of the byte at location 0x22) into the Carry flag.

Stack

A

programmer's stack can be located anywhere in the 256-byte data memory. The stack area is designated using the Stack Pointer

(SP) SFR. The SP will point to the last location used. The next value pushed on the stack is placed at SP+1 and then SP is incremented. A reset initializes the stack pointer to location 0x07. Therefore, the first value pushed on the stack is placed at location 0x08, which

is also the first register (R0) of register bank 1. Thus, if more than one register bank is to be used, the SP should be initialized to a

location in the data memory not being used for data storage. The stack depth can extend up to 256 bytes.

External RAM

On devices with more than 256 bytes of on-chip RAM, the additional RAM is mapped into the external data memory space (XRAM).

Addresses in XRAM area accessed using the external move (MOVX) instructions.

Note: The 16-bit MOVX write instruction is also used for writing and erasing the flash memory. More details may be found in the flash

memory section.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 9

Page 11

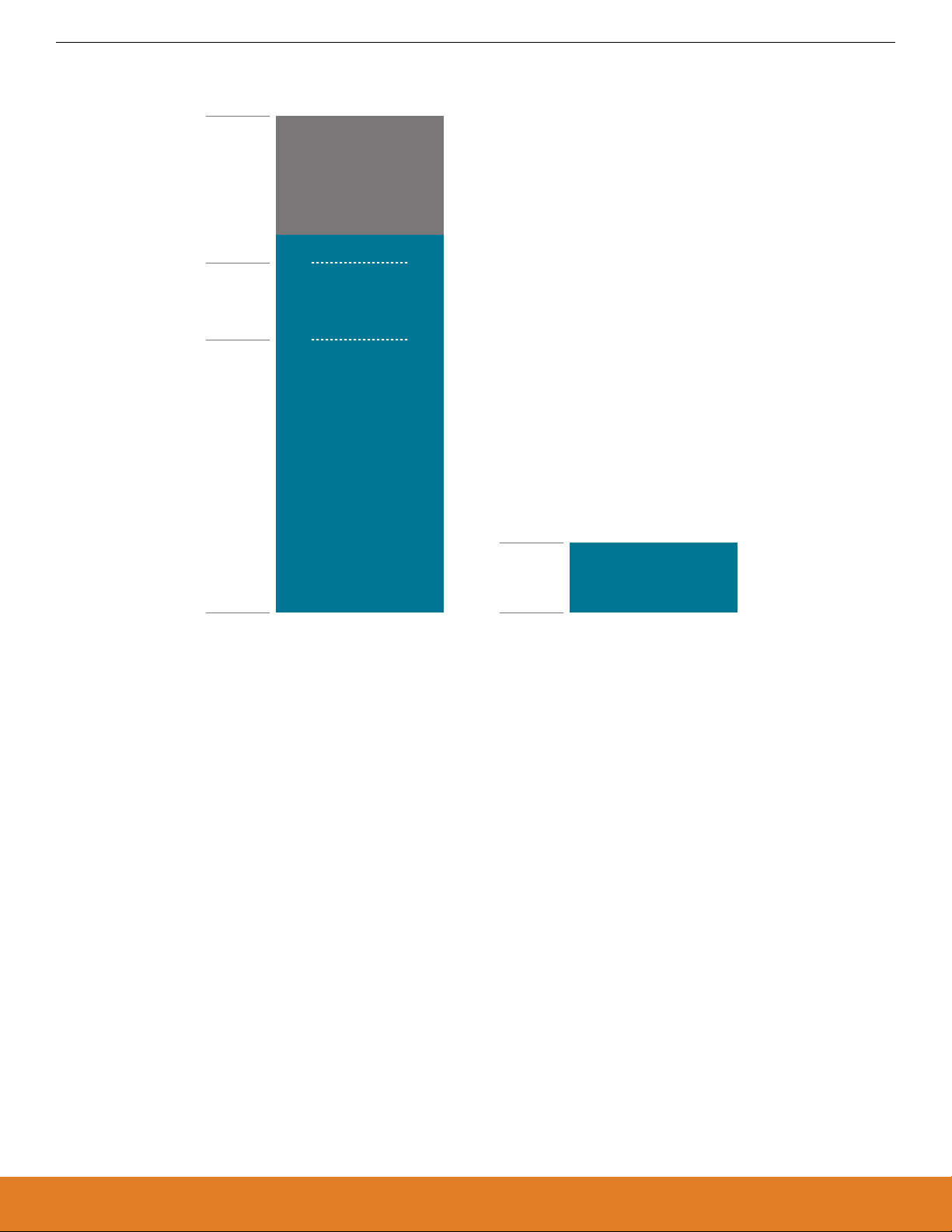

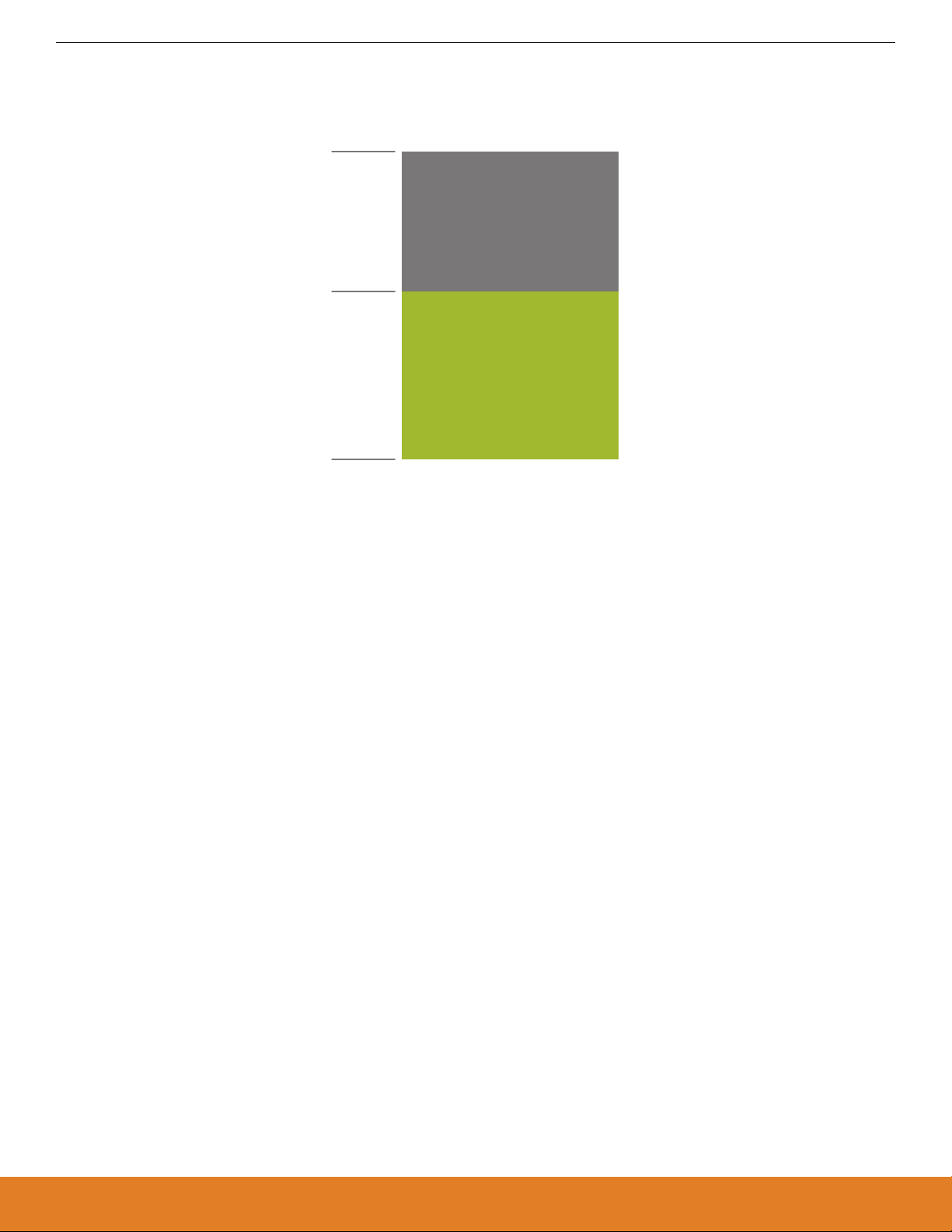

2.4 Memory Map

EFM8SB2 Reference Manual

Memory Organization

0xFFFF

Reserved

0xFBFF Lock Byte

0xFBFE

Security Page

1024 Bytes

0xF800

0x0000

63 KB Flash

(63 x 1024 Byte pages)

0x03FF

0x0000

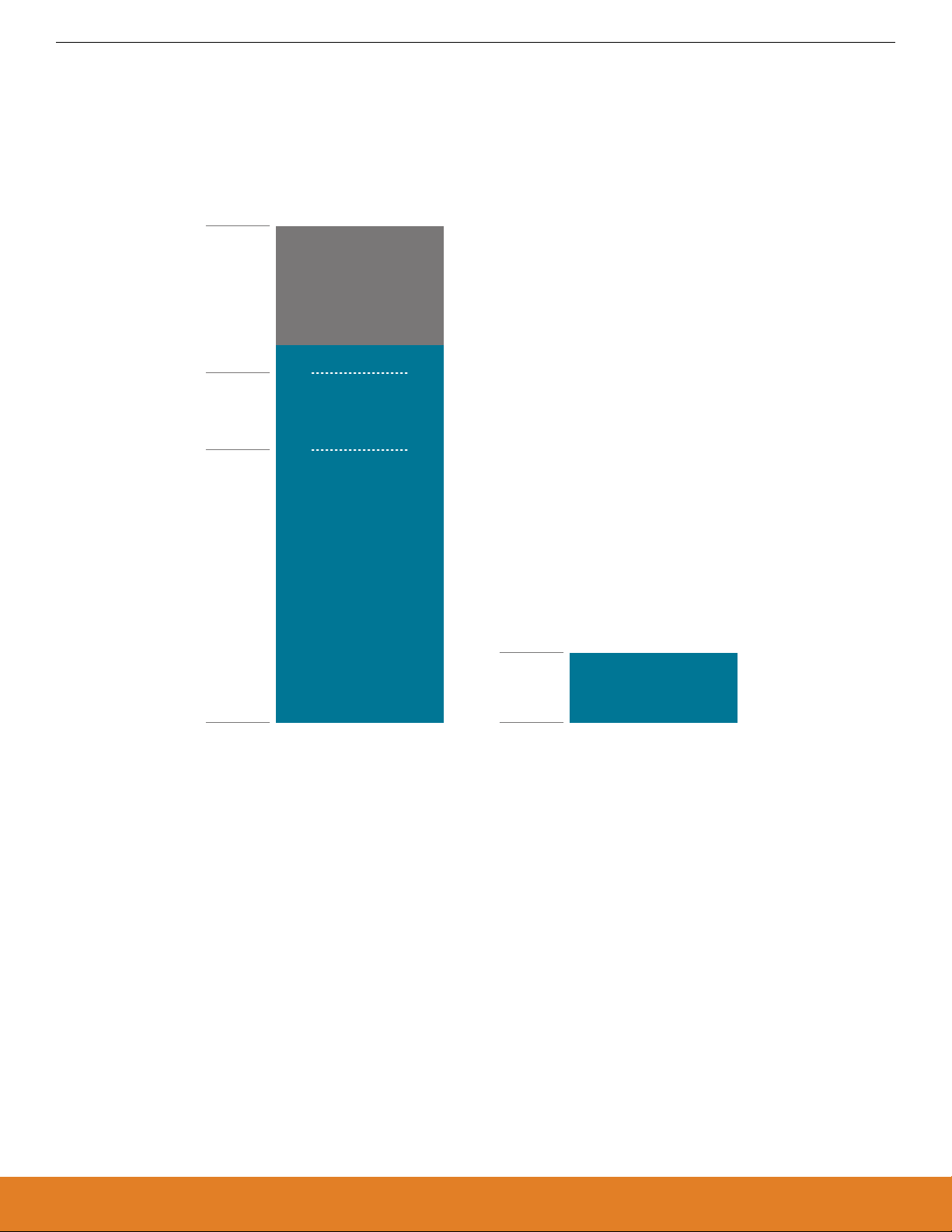

Figure 2.1. Flash Memory Map — 64 KB Devices

Scratchpad

1024 Bytes

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 10

Page 12

0xFFFF

Reserved

0x7FFF Lock Byte

0x7FFE

Security Page

1024 Bytes

0x7C00

EFM8SB2 Reference Manual

Memory Organization

0x0000

32 KB Flash

(32 x 1024 Byte pages)

0x03FF

0x0000

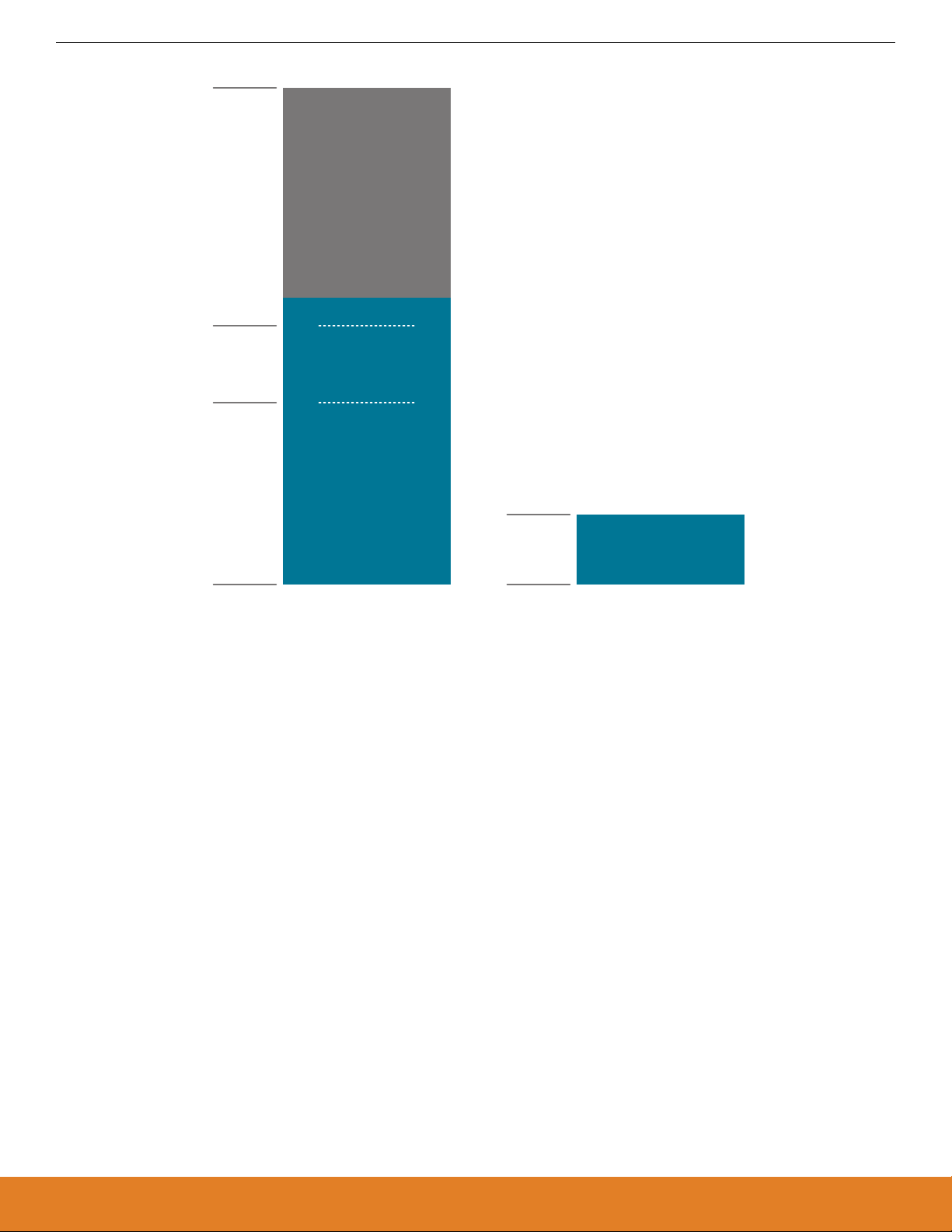

Figure 2.2. Flash Memory Map — 32 KB Devices

Scratchpad

1024 Bytes

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 11

Page 13

0xFFFF

Reserved

0x3FFF Lock Byte

0x3FFE

Security Page

1024 Bytes

0x3C00

EFM8SB2 Reference Manual

Memory Organization

0x0000

16 KB Flash

(16 x 1024 Byte pages)

0x03FF

0x0000

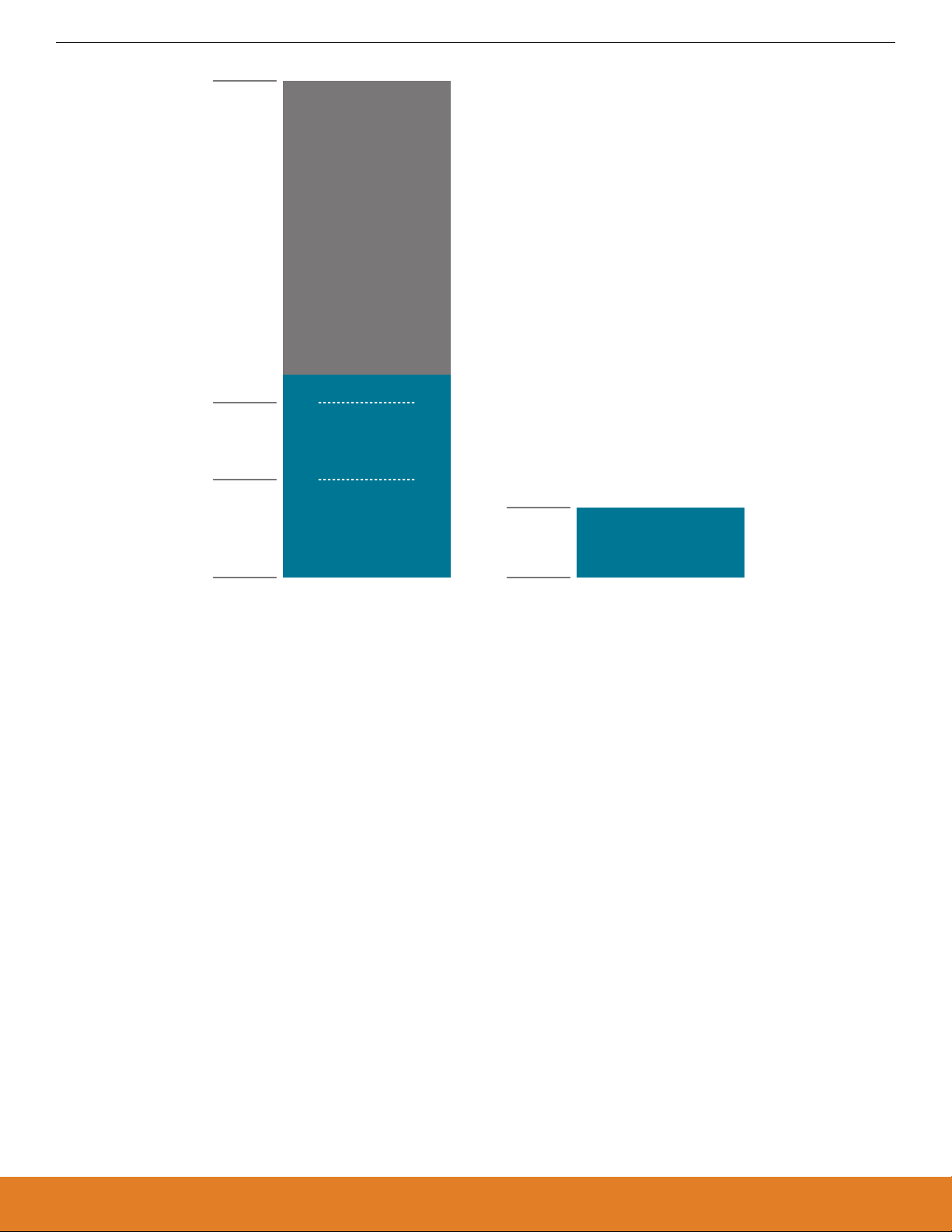

Figure 2.3. Flash Memory Map — 16 KB Devices

On-Chip RAM

Accessed with MOV Instructions as Indicated

0xFF

Upper 128 Bytes

RAM

(Indirect Access)

Special Function

Registers

(Direct Access)

0x80

0x7F

Lower 128 Bytes RAM

(Direct or Indirect Access)

0x30

0x2F

0x20

0x1F

0x00

General-Purpose Register Banks

Bit-Addressable

Scratchpad

1024 Bytes

Figure 2.4. Direct / Indirect RAM Memory

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 12

Page 14

0xFFFF

0x1000

0x0FFF

0x0000

EFM8SB2 Reference Manual

Memory Organization

On-Chip XRAM

Accessed with MOVX Instructions

Shadow XRAM

Duplicates 0x0000-0x0FFF

On 4096 B boundaries

XRAM

4096 Bytes

Figure 2.5. XRAM Memory

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 13

Page 15

EFM8SB2 Reference Manual

Special Function Registers

3. Special Function Registers

3.1 Special Function Register Access

The direct-access data memory locations from 0x80 to 0xFF constitute the special function registers (SFRs). The SFRs provide control

and data exchange with the CIP-51's resources and peripherals. The CIP-51 duplicates the SFRs found in a typical 8051 implementation as well as implementing additional SFRs used to configure and access the sub-systems unique to the MCU. This allows the addi-

tion of new functionality while retaining compatibility with the MCS-51 ™ instruction set.

The SFR registers are accessed anytime the direct addressing mode is used to access memory locations from 0x80 to 0xFF. SFRs

with addresses ending in 0x0 or 0x8 (e.g., P0, TCON, SCON0, IE, etc.) are bit-addressable as well as byte-addressable. All other SFRs

are byte-addressable only. Unoccupied addresses in the SFR space are reserved for future use. Accessing these areas will have an

indeterminate effect and should be avoided.

SFR Paging

The CIP-51 features SFR paging, allowing the device to map many SFRs into the 0x80 to 0xFF memory address space. The SFR

memory space has 256 pages. In this way, each memory location from 0x80 to 0xFF can access up to 256 SFRs. The EFM8SB2

devices utilize multiple SFR pages. All of the common 8051 SFRs are available on all pages. Certain SFRs are only available on a

subset of pages. SFR pages are selected using the SFRPAGE register. The procedure for reading and writing an SFR is as follows:

1. Select the appropriate SFR page using the SFRPAGE register.

2. Use direct accessing mode to read or write the special function register (MOV instruction).

The SFRPAGE register only needs to be changed in the case that the SFR to be accessed does not exist on the currently-selected

page. See the SFR memory map for details on the locations of each SFR. It is good practice inside of interrupt service routines to save

the current SFRPAGE at the beginning of the ISR and restore this value at the end.

Interrupts and SFR Paging

In any system which changes the SFRPAGE while interrupts are active, it is good practice to save the current SFRPAGE value upon

ISR entry, and then restore the SFRPAGE before exiting the ISR. This ensures that SFRPAGE will remain at the desired setting when

returning from the ISR.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 14

Page 16

EFM8SB2 Reference Manual

Special Function Registers

3.2 Special Function Register Memory Map

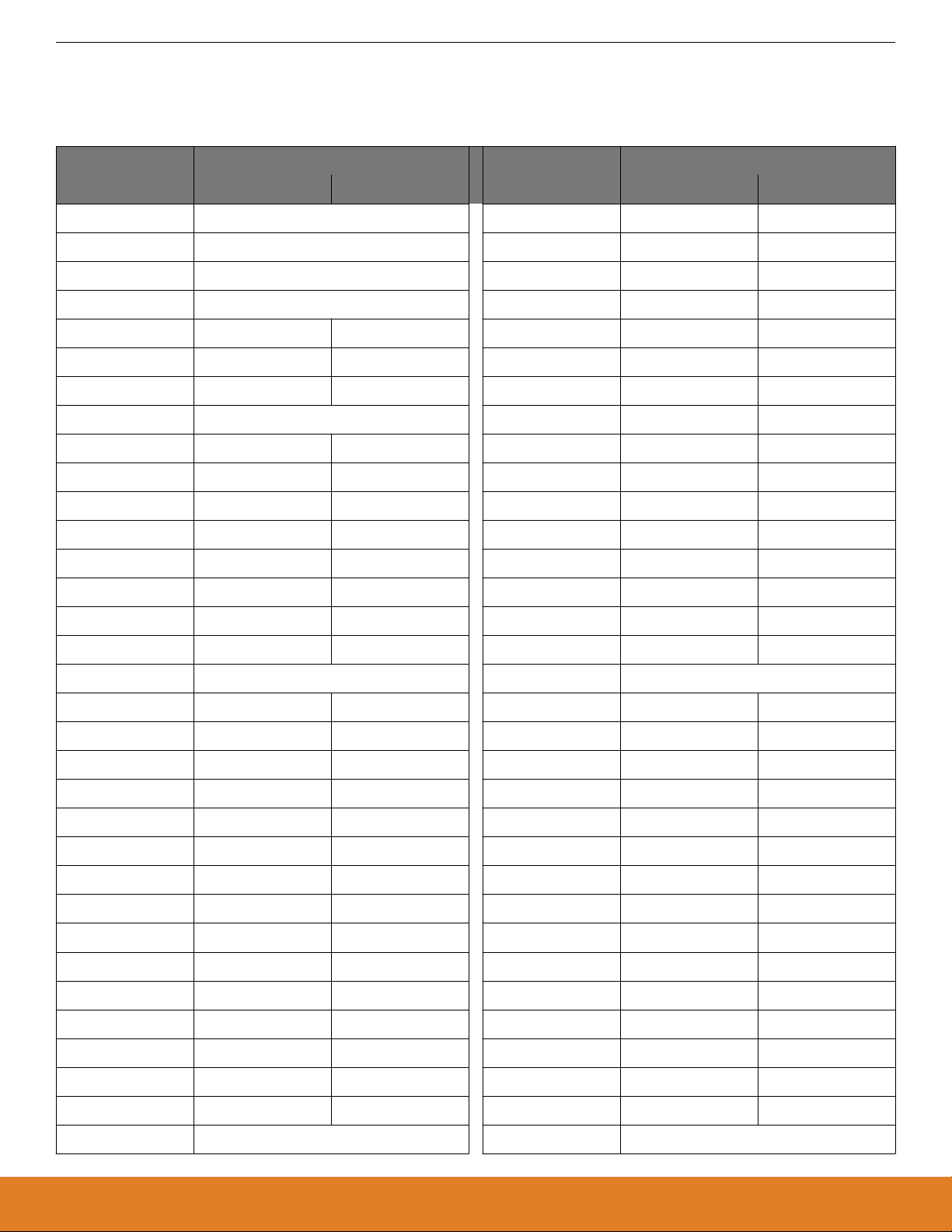

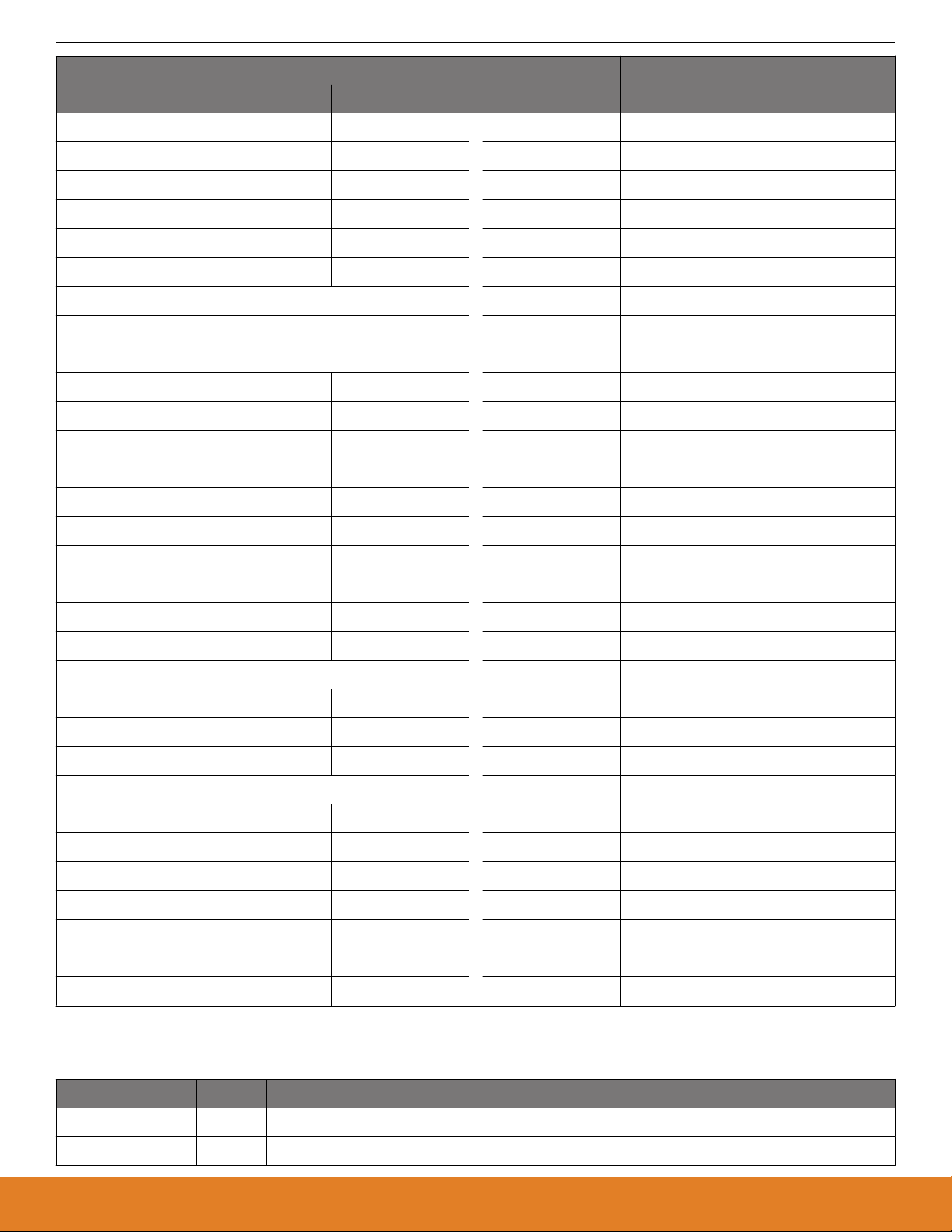

Table 3.1. Special Function Registers by Address

Address SFR Page Address SFR Page

(*bit-addressable) 0x00 0x0F (*bit-addressable) 0x00 0x0F

0x80* P0 0xC0* SMB0CN0 -

0x81 SP 0xC1 SMB0CF -

0x82 DPL 0xC2 SMB0DAT -

0x83 DPH 0xC3 ADC0GTL -

0x84 SPI1CFG - 0xC4 ADC0GTH -

0x85 SPI1CKR TOFFL 0xC5 ADC0LTL -

0x86 SPI1DAT TOFFH 0xC6 ADC0LTH -

0x87 PCON0 0xC7 P0MASK -

0x88* TCON - 0xC8* TMR2CN0 -

0x89 TMOD - 0xC9 REG0CN -

0x8A TL0 - 0xCA TMR2RLL -

0x8B TL1 - 0xCB TMR2RLH -

0x8C TH0 - 0xCC TMR2L -

0x8D TH1 - 0xCD TMR2H -

0x8E CKCON0 - 0xCE PCA0CPM5 -

0x8F PSCTL - 0xCF P1MAT -

0x90* P1 0xD0* PSW

0x91 TMR3CN0 CRC0DAT 0xD1 REF0CN -

0x92 TMR3RLL CRC0CN0 0xD2 PCA0CPL5 -

0x93 TMR3RLH CRC0IN 0xD3 PCA0CPH5 -

0x94 TMR3L - 0xD4 P0SKIP -

0x95 TMR3H CRC0FLIP 0xD5 P1SKIP -

0x96 - CRC0AUTO 0xD6 P2SKIP -

0x97 - CRC0CNT 0xD7 P0MAT -

0x98* SCON0 - 0xD8* PCA0CN0 -

0x99 SBUF0 - 0xD9 PCA0MD -

0x9A CMP1CN0 - 0xDA PCA0CPM0 -

0x9B CMP0CN0 - 0xDB PCA0CPM1 -

0x9C CMP1MD - 0xDC PCA0CPM2 -

0x9D CMP0MD - 0xDD PCA0CPM3 -

0x9E CMP1MX - 0xDE PCA0CPM4 -

0x9F CMP0MX - 0xDF PCA0PWM -

0xA0* P2 0xE0* ACC

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 15

Page 17

EFM8SB2 Reference Manual

Special Function Registers

Address SFR Page Address SFR Page

(*bit-addressable) 0x00 0x0F (*bit-addressable) 0x00 0x0F

0xA1 SPI0CFG - 0xE1 XBR0 -

0xA2 SPI0CKR - 0xE2 XBR1 -

0xA3 SPI0DAT - 0xE3 XBR2 -

0xA4 P0MDOUT P0DRV 0xE4 IT01CF -

0xA5 P1MDOUT P1DRV 0xE5 -

0xA6 P2MDOUT P2DRV 0xE6 EIE1

0xA7 SFRPAGE 0xE7 EIE2

0xA8* IE 0xE8* ADC0CN0 -

0xA9 CLKSEL 0xE9 PCA0CPL1 -

0xAA EMI0CN - 0xEA PCA0CPH1 -

0xAB EMI0CF - 0xEB PCA0CPL2 -

0xAC RTC0ADR - 0xEC PCA0CPH2 -

0xAD RTC0DAT - 0xED PCA0CPL3 -

0xAE RTC0KEY - 0xEE PCA0CPH3 -

0xAF EMI0TC - 0xEF RSTSRC -

0xB0* SPI1CN0 - 0xF0* B

0xB1 XOSC0CN - 0xF1 P0MDIN -

0xB2 HFO0CN - 0xF2 P1MDIN -

0xB3 HFO0CAL - 0xF3 P2MDIN -

0xB4 - 0xF4 SMB0ADR -

0xB5 PMU0CF - 0xF5 SMB0ADM -

0xB6 FLSCL - 0xF6 EIP1

0xB7 FLKEY - 0xF7 EIP2

0xB8* IP 0xF8* SPI0CN0 -

0xB9 IREF0CN0 - 0xF9 PCA0L -

0xBA ADC0AC ADC0PWR 0xFA PCA0H -

0xBB ADC0MX - 0xFB PCA0CPL0 -

0xBC ADC0CF - 0xFC PCA0CPH0 -

0xBD ADC0L ADC0TK 0xFD PCA0CPL4 -

0xBE ADC0H - 0xFE PCA0CPH4 -

0xBF P1MASK - 0xFF VDM0CN -

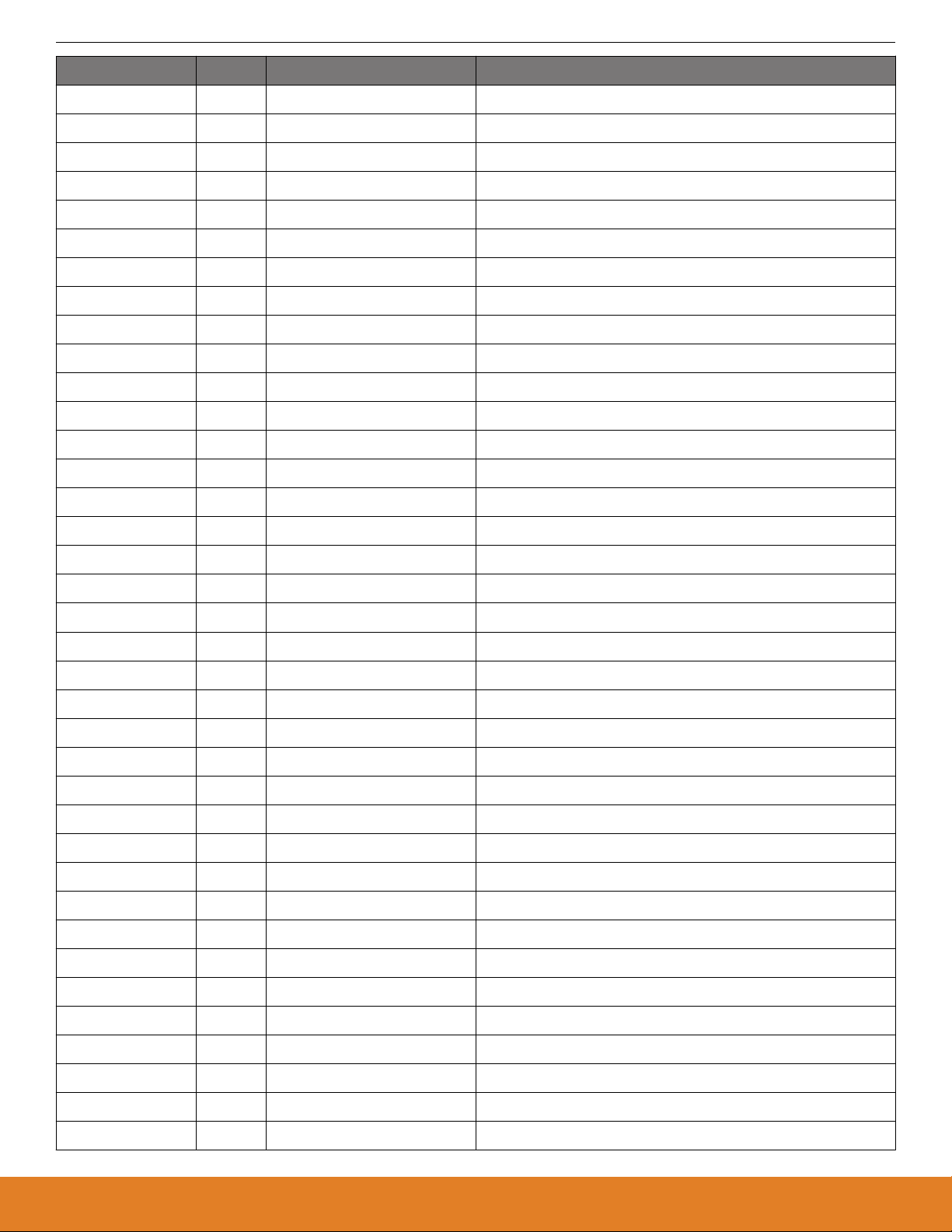

Table 3.2. Special Function Registers by Name

Register Address SFR Pages Description

ACC 0xE0 ALL Accumulator

ADC0AC 0xBA 0x00 ADC0 Accumulator Configuration

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 16

Page 18

Register Address SFR Pages Description

ADC0CF 0xBC 0x00 ADC0 Configuration

ADC0CN0 0xE8 0x00 ADC0 Control 0

ADC0GTH 0xC4 0x00 ADC0 Greater-Than High Byte

ADC0GTL 0xC3 0x00 ADC0 Greater-Than Low Byte

ADC0H 0xBE 0x00 ADC0 Data Word High Byte

ADC0L 0xBD 0x00 ADC0 Data Word Low Byte

ADC0LTH 0xC6 0x00 ADC0 Less-Than High Byte

ADC0LTL 0xC5 0x00 ADC0 Less-Than Low Byte

ADC0MX 0xBB 0x00 ADC0 Multiplexer Selection

ADC0PWR 0xBA 0x0F ADC0 Power Control

ADC0TK 0xBD 0x0F ADC0 Burst Mode Track Time

B 0xF0 ALL B Register

CKCON0 0x8E 0x00 Clock Control 0

EFM8SB2 Reference Manual

Special Function Registers

CLKSEL 0xA9 ALL Clock Select

CMP0CN0 0x9B 0x00 Comparator 0 Control 0

CMP0MD 0x9D 0x00 Comparator 0 Mode

CMP0MX 0x9F 0x00 Comparator 0 Multiplexer Selection

CMP1CN0 0x9A 0x00 Comparator 1 Control 0

CMP1MD 0x9C 0x00 Comparator 1 Mode

CMP1MX 0x9E 0x00 Comparator 1 Multiplexer Selection

CRC0AUTO 0x96 0x0F CRC0 Automatic Control

CRC0CN0 0x92 0x0F CRC0 Control 0

CRC0CNT 0x97 0x0F CRC0 Automatic Flash Sector Count

CRC0DAT 0x91 0x0F CRC0 Data Output

CRC0FLIP 0x95 0x0F CRC0 Bit Flip

CRC0IN 0x93 0x0F CRC0 Data Input

DPH 0x83 ALL Data Pointer High

DPL 0x82 ALL Data Pointer Low

EIE1 0xE6 ALL Extended Interrupt Enable 1

EIE2 0xE7 ALL Extended Interrupt Enable 2

EIP1 0xF6 ALL Extended Interrupt Priority 1

EIP2 0xF7 ALL Extended Interrupt Priority 2

EMI0CF 0xAB 0x00 External Memory Configuration

EMI0CN 0xAA 0x00 External Memory Interface Control

EMI0TC 0xAF 0x00 External Memory Timing Control

FLKEY 0xB7 0x00 Flash Lock and Key

FLSCL 0xB6 0x00 Flash Scale

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 17

Page 19

Register Address SFR Pages Description

HFO0CAL 0xB3 0x00 High Frequency Oscillator Calibration

HFO0CN 0xB2 0x00 High Frequency Oscillator Control

IE 0xA8 ALL Interrupt Enable

IP 0xB8 ALL Interrupt Priority

IREF0CN0 0xB9 0x00 Current Reference Control 0

IT01CF 0xE4 0x00 INT0/INT1 Configuration

P0 0x80 ALL Port 0 Pin Latch

P0DRV 0xA4 0x0F Port 0 Drive Strength

P0MASK 0xC7 0x00 Port 0 Mask

P0MAT 0xD7 0x00 Port 0 Match

P0MDIN 0xF1 0x00 Port 0 Input Mode

P0MDOUT 0xA4 0x00 Port 0 Output Mode

P0SKIP 0xD4 0x00 Port 0 Skip

EFM8SB2 Reference Manual

Special Function Registers

P1 0x90 ALL Port 1 Pin Latch

P1DRV 0xA5 0x0F Port 1 Drive Strength

P1MASK 0xBF 0x00 Port 1 Mask

P1MAT 0xCF 0x00 Port 1 Match

P1MDIN 0xF2 0x00 Port 1 Input Mode

P1MDOUT 0xA5 0x00 Port 1 Output Mode

P1SKIP 0xD5 0x00 Port 1 Skip

P2 0xA0 ALL Port 2 Pin Latch

P2DRV 0xA6 0x0F Port 2 Drive Strength

P2MDIN 0xF3 0x00 Port 2 Input Mode

P2MDOUT 0xA6 0x00 Port 2 Output Mode

P2SKIP 0xD6 0x00 Port 2 Skip

PCA0CN0 0xD8 0x00 PCA Control 0

PCA0CPH0 0xFC 0x00 PCA Channel 0 Capture Module High Byte

PCA0CPH1 0xEA 0x00 PCA Channel 1 Capture Module High Byte

PCA0CPH2 0xEC 0x00 PCA Channel 2 Capture Module High Byte

PCA0CPH3 0xEE 0x00 PCA Channel 3 Capture Module High Byte

PCA0CPH4 0xFE 0x00 PCA Channel 4 Capture Module High Byte

PCA0CPH5 0xD3 0x00 PCA Channel 5 Capture Module High Byte

PCA0CPL0 0xFB 0x00 PCA Channel 0 Capture Module Low Byte

PCA0CPL1 0xE9 0x00 PCA Channel 1 Capture Module Low Byte

PCA0CPL2 0xEB 0x00 PCA Channel 2 Capture Module Low Byte

PCA0CPL3 0xED 0x00 PCA Channel 3 Capture Module Low Byte

PCA0CPL4 0xFD 0x00 PCA Channel 4 Capture Module Low Byte

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 18

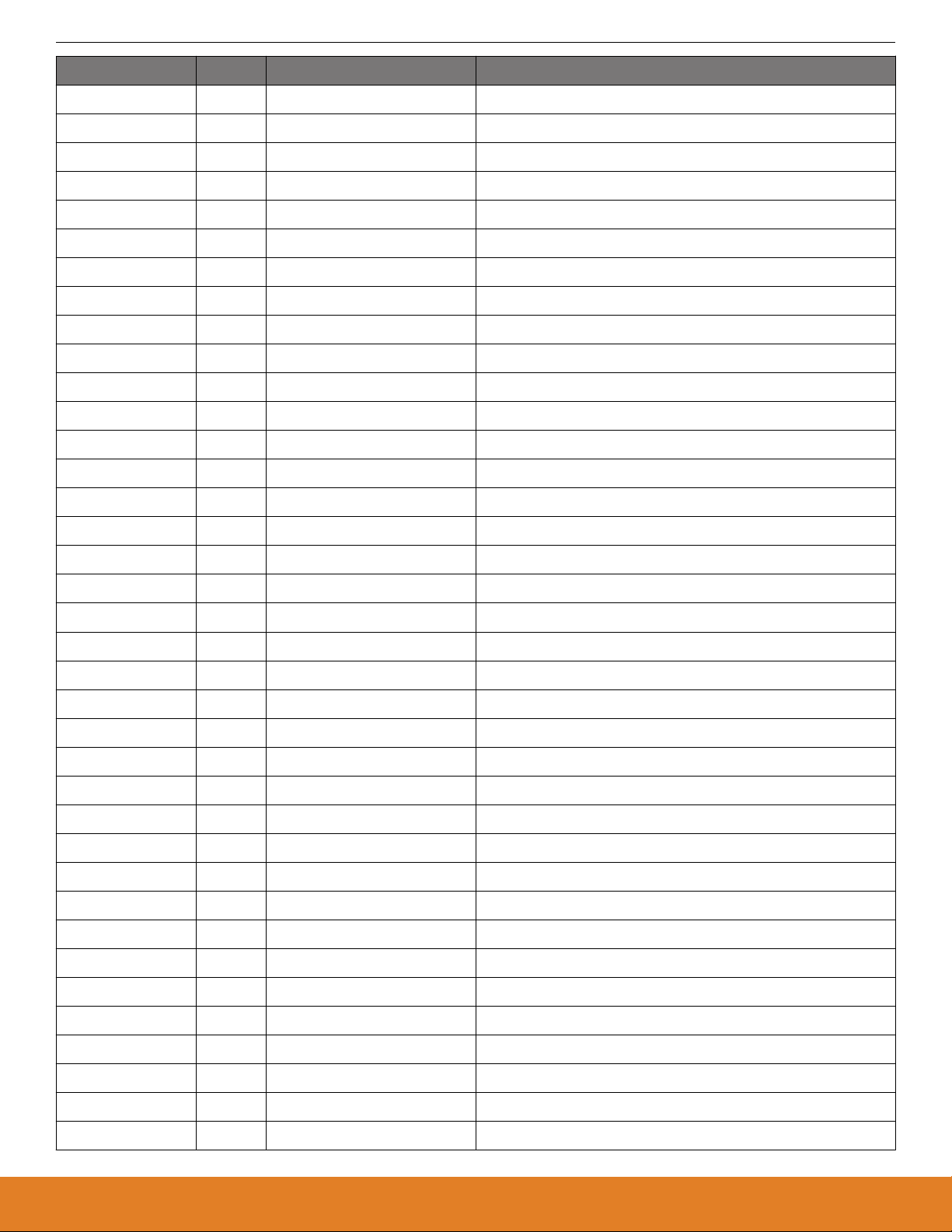

Page 20

Special Function Registers

Register Address SFR Pages Description

PCA0CPL5 0xD2 0x00 PCA Channel 5 Capture Module Low Byte

PCA0CPM0 0xDA 0x00 PCA Channel 0 Capture/Compare Mode

PCA0CPM1 0xDB 0x00 PCA Channel 1 Capture/Compare Mode

PCA0CPM2 0xDC 0x00 PCA Channel 2 Capture/Compare Mode

PCA0CPM3 0xDD 0x00 PCA Channel 3 Capture/Compare Mode

PCA0CPM4 0xDE 0x00 PCA Channel 4 Capture/Compare Mode

PCA0CPM5 0xCE 0x00 PCA Channel 5 Capture/Compare Mode

PCA0H 0xFA 0x00 PCA Counter/Timer High Byte

PCA0L 0xF9 0x00 PCA Counter/Timer Low Byte

PCA0MD 0xD9 0x00 PCA Mode

PCA0PWM 0xDF 0x00 PCA PWM Configuration

PCON0 0x87 ALL Power Control 0

PMU0CF 0xB5 0x00 Power Management Unit Configuration

EFM8SB2 Reference Manual

PSCTL 0x8F 0x00 Program Store Control

PSW 0xD0 ALL Program Status Word

REF0CN 0xD1 0x00 Voltage Reference Control

REG0CN 0xC9 0x00 Voltage Regulator Control

RSTSRC 0xEF 0x00 Reset Source

RTC0ADR 0xAC 0x00 RTC Address

RTC0DAT 0xAD 0x00 RTC Data

RTC0KEY 0xAE 0x00 RTC Lock and Key

SBUF0 0x99 0x00 UART0 Serial Port Data Buffer

SCON0 0x98 0x00 UART0 Serial Port Control

SFRPAGE 0xA7 ALL SFR Page

SMB0ADM 0xF5 0x00 SMBus 0 Slave Address Mask

SMB0ADR 0xF4 0x00 SMBus 0 Slave Address

SMB0CF 0xC1 0x00 SMBus 0 Configuration

SMB0CN0 0xC0 0x00 SMBus 0 Control

SMB0DAT 0xC2 0x00 SMBus 0 Data

SP 0x81 ALL Stack Pointer

SPI0CFG 0xA1 0x00 SPI0 Configuration

SPI0CKR 0xA2 0x00 SPI0 Clock Rate

SPI0CN0 0xF8 0x00 SPI0 Control

SPI0DAT 0xA3 0x00 SPI0 Data

SPI1CFG 0x84 0x00 SPI1 Configuration

SPI1CKR 0x85 0x00 SPI1 Clock Rate

SPI1CN0 0xB0 0x00 SPI1 Control

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 19

Page 21

Register Address SFR Pages Description

SPI1DAT 0x86 0x00 SPI1 Data

TCON 0x88 0x00 Timer 0/1 Control

TH0 0x8C 0x00 Timer 0 High Byte

TH1 0x8D 0x00 Timer 1 High Byte

TL0 0x8A 0x00 Timer 0 Low Byte

TL1 0x8B 0x00 Timer 1 Low Byte

TMOD 0x89 0x00 Timer 0/1 Mode

TMR2CN0 0xC8 0x00 Timer 2 Control 0

TMR2H 0xCD 0x00 Timer 2 High Byte

TMR2L 0xCC 0x00 Timer 2 Low Byte

TMR2RLH 0xCB 0x00 Timer 2 Reload High Byte

TMR2RLL 0xCA 0x00 Timer 2 Reload Low Byte

TMR3CN0 0x91 0x00 Timer 3 Control 0

EFM8SB2 Reference Manual

Special Function Registers

TMR3H 0x95 0x00 Timer 3 High Byte

TMR3L 0x94 0x00 Timer 3 Low Byte

TMR3RLH 0x93 0x00 Timer 3 Reload High Byte

TMR3RLL 0x92 0x00 Timer 3 Reload Low Byte

TOFFH 0x86 0x0F Temperature Sensor Offset High

TOFFL 0x85 0x0F Temperature Sensor Offset Low

VDM0CN 0xFF 0x00 VDD Supply Monitor Control

XBR0 0xE1 0x00 Port I/O Crossbar 0

XBR1 0xE2 0x00 Port I/O Crossbar 1

XBR2 0xE3 0x00 Port I/O Crossbar 2

XOSC0CN 0xB1 0x00 External Oscillator Control

3.3 SFR Access Control Registers

3.3.1 SFRPAGE: SFR Page

Bit 7 6 5 4 3 2 1 0

Name SFRPAGE

Access RW

Reset 0x00

SFR Page = ALL; SFR Address: 0xA7

Bit Name Reset Access Description

7:0 SFRPAGE 0x00 RW SFR Page.

Specifies the SFR Page used when reading, writing, or modifying special function registers.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 20

Page 22

EFM8SB2 Reference Manual

Flash Memory

4. Flash Memory

4.1 Introduction

On-chip, re-programmable flash memory is included for program code and non-volatile data storage. The flash memory is organized in

1024-byte pages. It can be erased and written through the C2 interface or from firmware by overloading the MOVX instruction. Any

individual byte in flash memory must only be written once between page erase operations.

0xFFFF

Reserved

0xFBFF Lock Byte

0xFBFE

Security Page

1024 Bytes

0xF800

0x0000

63 KB Flash

(63 x 1024 Byte pages)

0x03FF

0x0000

Figure 4.1. Flash Memory Map — 64 KB Devices

Scratchpad

1024 Bytes

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 21

Page 23

0xFFFF

Reserved

0x7FFF Lock Byte

0x7FFE

Security Page

1024 Bytes

0x7C00

EFM8SB2 Reference Manual

Flash Memory

0x0000

32 KB Flash

(32 x 1024 Byte pages)

0x03FF

0x0000

Figure 4.2. Flash Memory Map — 32 KB Devices

Scratchpad

1024 Bytes

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 22

Page 24

0xFFFF

Reserved

0x3FFF Lock Byte

0x3FFE

Security Page

1024 Bytes

0x3C00

EFM8SB2 Reference Manual

Flash Memory

16 KB Flash

(16 x 1024 Byte pages)

0x0000

Figure 4.3. Flash Memory Map — 16 KB Devices

4.2 Features

The flash memory has the following features:

Up to 64 KB organized in 1024-byte sectors.

•

• In-system programmable from user firmware.

• Security lock to prevent unwanted read/write/erase access.

• 1024 bytes of non-volatile data storage in the Scratchpad.

0x03FF

0x0000

Scratchpad

1024 Bytes

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 23

Page 25

EFM8SB2 Reference Manual

Flash Memory

4.3 Functional Description

4.3.1 Security Options

CIP-51 provides security options to protect the flash memory from inadvertent modification by software as well as to prevent the

The

viewing of proprietary program code and constants. The Program Store Write Enable (bit PSWE in register PSCTL) and the Program

Store Erase Enable (bit PSEE in register PSCTL) bits protect the flash memory from accidental modification by software. PSWE must

be explicitly set to 1 before software can modify the flash memory; both PSWE and PSEE must be set to 1 before software can erase

flash memory. Additional security features prevent proprietary program code and data constants from being read or altered across the

C2 interface.

A Security Lock Byte located in flash user space offers protection of the flash program memory from access (reads, writes, or erases)

by unprotected code or the C2 interface. See the specific device memory map for the location of the security byte. The flash security

mechanism allows the user to lock "n" flash pages, starting at page 0, where "n" is the 1s complement number represented by the

Security Lock Byte.

Note: The page containing the flash Security Lock Byte is unlocked when no other flash pages are locked (all bits of the Lock Byte are

1) and locked when any other flash pages are locked (any bit of the Lock Byte is 0).

Table 4.1. Security Byte Decoding

Security Lock Byte 111111101b

1s Complement 00000010b

Flash Pages Locked 3 (First two flash pages + Lock Byte Page)

The level of flash security depends on the flash access method. The three flash access methods that can be restricted are reads,

writes,

and erases from the C2 debug interface, user firmware executing on unlocked pages, and user firmware executing on locked

pages.

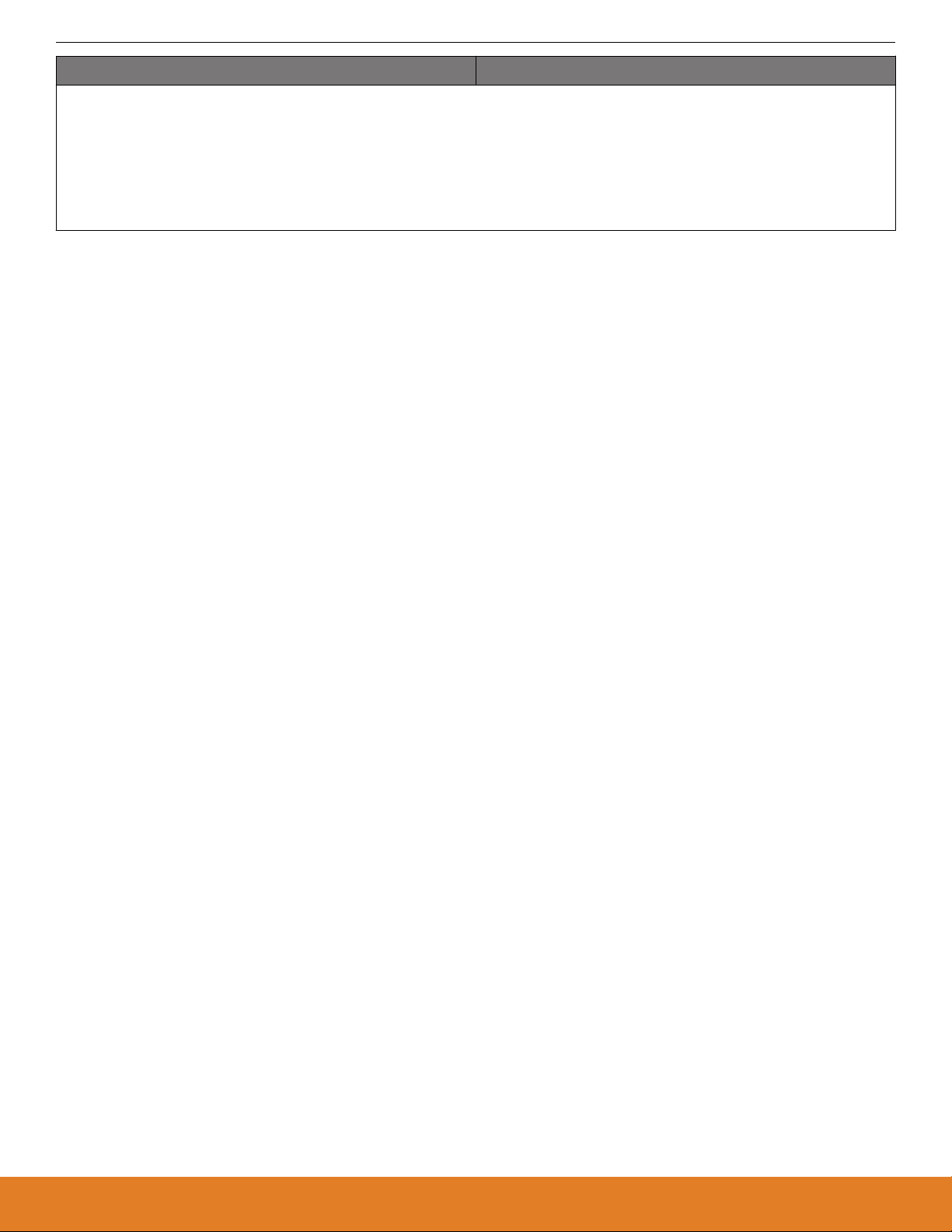

Table 4.2. Flash Security Summary—Firmware Permissions

Permissions according to the area firmware is executing from:

Target Area for Read / Write / Erase Unlocked User

Page

Locked User Page Unlocked Data

Page

Locked Data Page

Any Unlocked Page [R] [W] [E] [R] [W] [E] [R] [W] [E] [R] [W] [E]

Locked Page (except security page) reset [R] [W] [E] reset [R] [W] [E]

Locked Security Page reset [R] [W] reset [R] [W]

Reserved Area reset reset reset reset

[R] = Read permitted

[W] = Write permitted

[E] = Erase permitted

reset = Flash error reset triggered

n/a = Not applicable

Table 4.3. Flash Security Summary—C2 Permissions

Target Area for Read / Write / Erase Permissions from C2 interface

Any Unlocked Page [R] [W] [E]

Any Locked Page Device Erase Only

Reserved Area None

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 24

Page 26

EFM8SB2 Reference Manual

Flash Memory

Target Area for Read / Write / Erase Permissions from C2 interface

[R] = Read permitted

[W] = Write permitted

[E] = Erase permitted

Device Erase Only = No read, write, or individual page erase is allowed. Must erase entire flash space.

None = Read, write and erase are not permitted

4.3.2 Programming the Flash Memory

Writes

to flash memory clear bits from logic 1 to logic 0 and can be performed on single byte locations. Flash erasures set bits back to

logic 1 and occur only on full pages. The write and erase operations are automatically timed by hardware for proper execution; data

polling to determine the end of the write/erase operation is not required. Code execution is stalled during a flash write/erase operation.

The simplest means of programming the flash memory is through the C2 interface using programming tools provided by Silicon Labs or

a third party vendor. Firmware may also be loaded into the device to implement code-loader functions or allow non-volatile data storage. To ensure the integrity of flash contents, it is strongly recommended that the on-chip supply monitor be enabled in any system that

includes code that writes and/or erases flash memory from software.

4.3.2.1 Flash Lock and Key Functions

Flash writes and erases by user software are protected with a lock and key function. The FLKEY register must be written with the correct key codes, in sequence, before flash operations may be performed. The key codes are 0xA5 and 0xF1. The timing does not matter, but the codes must be written in order. If the key codes are written out of order or the wrong codes are written, flash writes and

erases will be disabled until the next system reset. Flash writes and erases will also be disabled if a flash write or erase is attempted

before the key codes have been written properly. The flash lock resets after each write or erase; the key codes must be written again

before another flash write or erase operation can be performed.

4.3.2.2 Flash Page Erase Procedure

The flash memory is erased one page at a time by firmware using the MOVX write instruction with the address targeted to any byte

within the page. Before erasing a page of flash memory, flash write and erase operations must be enabled by setting the PSWE and

PSEE bits in the PSCTL register to logic 1 (this directs the MOVX writes to target flash memory and enables page erasure) and writing

the flash key codes in sequence to the FLKEY register. The PSWE and PSEE bits remain set until cleared by firmware.

Erase operation applies to an entire page (setting all bytes in the page to 0xFF). To erase an entire page, perform the following steps:

1. Disable interrupts (recommended).

2. Write the first key code to FLKEY: 0xA5.

3. Write the second key code to FLKEY: 0xF1.

4. Set the PSEE bit (register PSCTL).

5. Set the PSWE bit (register PSCTL).

6. Using the MOVX instruction, write a data byte to any location within the page to be erased.

7. Clear the PSWE and PSEE bits.

4.3.2.3 Flash Byte Write Procedure

The flash memory is written by firmware using the MOVX write instruction with the address and data byte to be programmed provided

as normal operands in DPTR and A. Before writing to flash memory using MOVX, flash write operations must be enabled by setting the

PSWE bit in the PSCTL register to logic 1 (this directs the MOVX writes to target flash memory) and writing the flash key codes in

sequence to the FLKEY register. The PSWE bit remains set until cleared by firmware. A write to flash memory can clear bits to logic 0

but cannot set them. A byte location to be programmed should be erased (already set to 0xFF) before a new value is written.

To write a byte of flash, perform the following steps:

1. Disable interrupts (recommended).

2. Write the first key code to FLKEY: 0xA5.

3. Write the second key code to FLKEY: 0xF1.

4. Set the PSWE bit (register PSCTL).

5. Clear the PSEE bit (register PSCTL).

6. Using the MOVX instruction, write a single data byte to the desired location within the desired page.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 25

Page 27

EFM8SB2 Reference Manual

Flash Memory

7. Clear the PSWE bit.

4.3.3 Flash Write and Erase Precautions

system which contains routines which write or erase flash memory from software involves some risk that the write or erase routines

Any

will execute unintentionally if the CPU is operating outside its specified operating range of supply voltage, system clock frequency or

temperature. This accidental execution of flash modifying code can result in alteration of flash memory contents causing a system failure that is only recoverable by re-flashing the code in the device.

To help prevent the accidental modification of flash by firmware, hardware restricts flash writes and erasures when the supply monitor is

not active and selected as a reset source. As the monitor is enabled and selected as a reset source by default, it is recommended that

systems writing or erasing flash simply maintain the default state.

The following sections provide general guidelines for any system which contains routines which write or erase flash from code. Additional flash recommendations and example code can be found in AN201: Writing to Flash From Firmware, available from the Silicon

Laboratories website.

Voltage Supply Maintenance and the Supply Monitor

• If the system power supply is subject to voltage or current "spikes," add sufficient transient protection devices to the power supply to

ensure that the supply voltages listed in the Absolute Maximum Ratings table are not exceeded.

• Make certain that the minimum supply rise time specification is met. If the system cannot meet this rise time specification, then add

an external supply brownout circuit to the RSTb pin of the device that holds the device in reset until the voltage supply reaches the

lower limit, and re-asserts RSTb if the supply drops below the low supply limit.

• Do not disable the supply monitor. If the supply monitor must be disabled in the system, firmware should be added to the startup

routine to enable the on-chip supply monitor and enable the supply monitor as a reset source as early in code as possible. This

should be the first set of instructions executed after the reset vector. For C-based systems, this may involve modifying the startup

code added by the C compiler. See your compiler documentation for more details. Make certain that there are no delays in software

between enabling the supply monitor and enabling the supply monitor as a reset source.

Note: The supply monitor must be enabled and enabled as a reset source when writing or erasing flash memory. A flash error reset

will occur if either condition is not met.

• As an added precaution if the supply monitor is ever disabled, explicitly enable the supply monitor and enable the supply monitor as

a reset source inside the functions that write and erase flash memory. The supply monitor enable instructions should be placed just

after the instruction to set PSWE to a 1, but before the flash write or erase operation instruction.

• Make certain that all writes to the RSTSRC (Reset Sources) register use direct assignment operators and explicitly do not use the

bit-wise operators (such as AND or OR). For example, "RSTSRC = 0x02" is correct. "RSTSRC |= 0x02" is incorrect.

• Make certain that all writes to the RSTSRC register explicitly set the PORSF bit to a 1. Areas to check are initialization code which

enables other reset sources, such as the Missing Clock Detector or Comparator, for example, and instructions which force a Software Reset. A global search on "RSTSRC" can quickly verify this.

PSWE Maintenance

• Reduce the number of places in code where the PSWE bit (in register PSCTL) is set to a 1. There should be exactly one routine in

code that sets PSWE to a 1 to write flash bytes and one routine in code that sets PSWE and PSEE both to a 1 to erase flash pages.

• Minimize the number of variable accesses while PSWE is set to a 1. Handle pointer address updates and loop variable maintenance

outside the "PSWE = 1;... PSWE = 0;" area.

• Disable interrupts prior to setting PSWE to a 1 and leave them disabled until after PSWE has been reset to 0. Any interrupts posted

during the flash write or erase operation will be serviced in priority order after the flash operation has been completed and interrupts

have been re-enabled by software.

• Make certain that the flash write and erase pointer variables are not located in XRAM. See your compiler documentation for instructions regarding how to explicitly locate variables in different memory areas.

• Add address bounds checking to the routines that write or erase flash memory to ensure that a routine called with an illegal address

does not result in modification of the flash.

System Clock

• If operating from an external crystal-based source, be advised that crystal performance is susceptible to electrical interference and is

sensitive to layout and to changes in temperature. If the system is operating in an electrically noisy environment, use the internal

oscillator or use an external CMOS clock.

• If operating from the external oscillator, switch to the internal oscillator during flash write or erase operations. The external oscillator

can continue to run, and the CPU can switch back to the external oscillator after the flash operation has completed.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 26

Page 28

EFM8SB2 Reference Manual

Flash Memory

4.3.4 Minimizing Flash Read Current

The flash memory is responsible for a substantial portion of the total digital supply current when the device is executing code. Below are

suggestions to minimize flash read current.

Use low power modes while waiting for an interrupt, rather than polling the interrupt flag.

1.

2. Disable the one-shot timer.

3. Reduce the number of toggling address lines for short code loops.

Using Low Power Modes

To reduce flash read current, use idle, suspend, or sleep modes while waiting for an interrupt, rather than polling the interrupt flag. Idle

mode is particularly well-suited for use in implementing short pauses, since the wake-up time is no more than three system clock cycles. See the Power Management chapter for details on the various low-power operating modes.

Disabling the One-Shot Timer

The flash has a one-shot timer that saves power when operating at system clock frequencies of 10 MHz or less. The one-shot timer

generates a minimum-duration enable signal for the flash sense amps on each clock cycle in which the flash memory is accessed. This

allows the flash to remain in a low power state for the remainder of the long clock cycle.

At clock frequencies above 10 MHz, the system clock cycle becomes short enough that the one-shot timer no longer provides a power

benefit. Disabling the one-shot timer at higher frequencies reduces power consumption. The one-shot is enabled by default, and it can

be disabled (bypassed) by setting the BYPASS bit in the FLSCL register. To reenable the one-shot, clear the BYPASS bit to logic 0.

Reduce Toggling Lines in Loops

Flash read current depends on the number of address lines that toggle between sequential flash read operations. In most cases, the

difference in power is relatively small (on the order of 5%).

The flash memory is organized in rows of 128 bytes. A substantial current increase can be detected when the read address jumps from

one row in the flash memory to another. Consider a 3-cycle loop (e.g., SJMP $, or while(1);) which straddles a flash row boundary. The

flash address jumps from one row to another on two of every three clock cycles. This can result in a current increase of up 30% when

compared to the same 3-cycle loop contained entirely within a single row.

To minimize the power consumption of small loops, it is best to locate them within a single row, if possible. To check if a loop is contained within a flash row, divide the starting address of the first instruction in the loop by 128. If the remainder (result of modulo operation) plus the length of the loop is less than 127, then the loop fits inside a single flash row. Otherwise, the loop will be straddling two

adjacent flash rows. If a loop executes in 20 or more clock cycles, then the transitions from one row to another will occur on relatively

few clock cycles, and any resulting increase in operating current will be negligible.

4.3.5 Scratchpad

An additional scratchpad area is available for non-volatile data storage. It is accessible at addresses 0x0000 to 0x03FF when the SFLE

bit is set to 1. The scratchpad area cannot be used for code execution. The scratchpad is locked when all other flash pages are locked,

and it is erased when a Flash Device Erase command is performed.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 27

Page 29

EFM8SB2 Reference Manual

Flash Memory

4.4 Flash Control Registers

4.4.1 PSCTL: Program Store Control

Bit 7 6 5 4 3 2 1 0

Name Reserved SFLE PSEE PSWE

Access R RW RW RW

Reset 0x00 0 0 0

SFR Page = 0x0; SFR Address: 0x8F

Bit Name Reset Access Description

7:3 Reserved Must write reset value.

2 SFLE 0 RW Scratchpad Flash Memory Access Enable.

When this bit is set, flash MOVC reads and MOVX writes from user software are directed to the Scratchpad flash sector.

Flash accesses outside the address range 0x0000-0x01FF should not be attempted and may yield undefined results when

SFLE is set to 1.

Value Name Description

0 SCRATCHPAD_DISA-

Flash access from user software directed to the Program/Data Flash sector.

BLED

1 SCRATCHPAD_ENA-

Flash access from user software directed to the Scratchpad sector.

BLED

1 PSEE 0 RW Program Store Erase Enable.

Setting this bit (in combination with PSWE) allows an entire page of flash program memory to be erased. If this bit is logic 1

and

flash writes are enabled (PSWE is logic 1), a write to flash memory using the MOVX instruction will erase the entire

page that contains the location addressed by the MOVX instruction. The value of the data byte written does not matter.

Value Name Description

0 ERASE_DISABLED Flash program memory erasure disabled.

1 ERASE_ENABLED Flash program memory erasure enabled.

0 PSWE 0 RW Program Store Write Enable.

Setting this bit allows writing a byte of data to the flash program memory using the MOVX write instruction. The flash location should be erased before writing data.

Value Name Description

0 WRITE_DISABLED Writes to flash program memory disabled.

1 WRITE_ENABLED Writes to flash program memory enabled; the MOVX write instruction targets flash

memory.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 28

Page 30

EFM8SB2 Reference Manual

Flash Memory

4.4.2 FLKEY: Flash Lock and Key

Bit 7 6 5 4 3 2 1 0

Name FLKEY

Access RW

Reset 0x00

SFR Page = 0x0; SFR Address: 0xB7

Bit Name Reset Access Description

7:0 FLKEY 0x00 RW Flash Lock and Key Register.

Write:

This

register provides a lock and key function for flash erasures and writes. Flash writes and erases are enabled by writing

0xA5 followed by 0xF1 to the FLKEY register. Flash writes and erases are automatically disabled after the next write or

erase is complete. If any writes to FLKEY are performed incorrectly, or if a flash write or erase operation is attempted while

these operations are disabled, the flash will be permanently locked from writes or erasures until the next device reset. If an

application never writes to flash, it can intentionally lock the flash by writing a non-0xA5 value to FLKEY from firmware.

Read:

When read, bits 1-0 indicate the current flash lock state.

00: Flash is write/erase locked.

01: The first key code has been written (0xA5).

10: Flash is unlocked (writes/erases allowed).

11: Flash writes/erases are disabled until the next reset.

4.4.3 FLSCL: Flash Scale

Bit 7 6 5 4 3 2 1 0

Name Reserved BYPASS Reserved

Access R RW R

Reset 0 0 0x00

SFR Page = 0x0; SFR Address: 0xB6

Bit Name Reset Access Description

7 Reserved Must write reset value.

6 BYPASS 0 RW Flash Read Timing One-Shot Bypass.

Value Name Description

0 ONE_SHOT The one-shot determines the flash read time. This setting should be used for op-

erating frequencies less than 14 MHz.

1 SYSCLK The system clock determines the flash read time. This setting should be used for

frequencies greater than 14 MHz.

5:0 Reserved Must write reset value.

When changing the BYPASS bit from 1 to 0, the third opcode byte fetched from program memory is indeterminate. Therefore, the

operation which clears the BYPASS bit should be immediately followed by a benign 3-byte instruction whose third byte is a don't care.

An

example of such an instruction is a 3-byte MOV that targets the CRC0FLIP register. When programming in C, the dummy value

written to CRC0FLIP should be a non-zero value to prevent the compiler from generating a 2-byte MOV instruction.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 29

Page 31

EFM8SB2 Reference Manual

Device Identification

5. Device Identification

5.1 Unique Identifier

A 32-bit unique identifier (UID) is pre-loaded upon device reset into the last four bytes of the XRAM area on all devices. The UID can be

read by firmware using MOVX instructions and through the debug port.

As the UID appears in RAM, firmware can overwrite the UID during normal operation. The bytes in memory will be automatically reinitialized with the UID value after any device reset. Firmware using this area of memory should always initialize the memory to a known

value, as any previous data stored at these locations will be overwritten and not retained through a reset.

Table 5.1. UID Location in Memory

Device XRAM Addresses

EFM8SB20F64G

EFM8SB20F32G

(MSB) 0x0FFF, 0x0FFE, 0x0FFD, 0x0FFC (LSB)

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 30

Page 32

EFM8SB2 Reference Manual

Interrupts

6. Interrupts

6.1 Introduction

The MCU core includes an extended interrupt system supporting multiple interrupt sources and priority levels. The allocation of interrupt

sources between on-chip peripherals and external input pins varies according to the specific version of the device.

Interrupt sources may have one or more associated interrupt-pending flag(s) located in an SFR local to the associated peripheral.

When a peripheral or external source meets a valid interrupt condition, the associated interrupt-pending flag is set to logic 1.

If interrupts are enabled for the source, an interrupt request is generated when the interrupt-pending flag is set. As soon as execution of

the current instruction is complete, the CPU generates an LCALL to a predetermined address to begin execution of an interrupt service

routine (ISR). Each ISR must end with an RETI instruction, which returns program execution to the next instruction that would have

been executed if the interrupt request had not occurred. If interrupts are not enabled, the interrupt-pending flag is ignored by the hardware and program execution continues as normal. The interrupt-pending flag is set to logic 1 regardless of whether the interrupt is enabled.

Each interrupt source can be individually enabled or disabled through the use of an associated interrupt enable bit in the IE and EIEn

registers. However, interrupts must first be globally enabled by setting the EA bit to logic 1 before the individual interrupt enables are

recognized. Setting the EA bit to logic 0 disables all interrupt sources regardless of the individual interrupt-enable settings.

Some interrupt-pending flags are automatically cleared by the hardware when the CPU vectors to the ISR or by other hardware conditions. However, most are not cleared by the hardware and must be cleared by software before returning from the ISR. If an interruptpending flag remains set after the CPU completes the return-from-interrupt (RETI) instruction, a new interrupt request will be generated

immediately and the CPU will re-enter the ISR after the completion of the next instruction.

6.2 Interrupt Sources and Vectors

The CIP51 core supports interrupt sources for each peripheral on the device. Software can simulate an interrupt for many peripherals

by setting any interrupt-pending flag to logic 1. If interrupts are enabled for the flag, an interrupt request will be generated and the CPU

will vector to the ISR address associated with the interrupt-pending flag. Refer to the data sheet section associated with a particular onchip peripheral for information regarding valid interrupt conditions for the peripheral and the behavior of its interrupt-pending flag(s).

6.2.1 Interrupt Priorities

Each interrupt source can be individually programmed to one of two priority levels: low or high. A low priority interrupt service routine

can be preempted by a high priority interrupt. A high priority interrupt cannot be preempted. Each interrupt has an associated interrupt

priority bit in the IP and EIPn registers, which are used to configure its priority level. Low priority is the default. If two interrupts are

recognized simultaneously, the interrupt with the higher priority is serviced first. If both interrupts have the same priority level, a fixed

order is used to arbitrate, based on the interrupt source's location in the interrupt vector table. Interrupts with a lower number in the

vector table have priority.

6.2.2 Interrupt Latency

Interrupt response time depends on the state of the CPU when the interrupt occurs. Pending interrupts are sampled and priority decoded on every system clock cycle. Therefore, the fastest possible response time is 5 system clock cycles: 1 clock cycle to detect the

interrupt and 4 clock cycles to complete the LCALL to the ISR. If an interrupt is pending when a RETI is executed, a single instruction is

executed before an LCALL is made to service the pending interrupt. Therefore, the maximum response time for an interrupt (when no

other interrupt is currently being serviced or the new interrupt is of greater priority) occurs when the CPU is performing an RETI instruction followed by a DIV as the next instruction. In this case, the response time is 18 system clock cycles: 1 clock cycle to detect the

interrupt, 5 clock cycles to execute the RETI, 8 clock cycles to complete the DIV instruction and 4 clock cycles to execute the LCALL to

the ISR. If the CPU is executing an ISR for an interrupt with equal or higher priority, the new interrupt will not be serviced until the

current ISR completes, including the RETI and following instruction. If more than one interrupt is pending when the CPU exits an ISR,

the CPU will service the next highest priority interrupt that is pending.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 31

Page 33

EFM8SB2 Reference Manual

6.2.3 Interrupt Summary

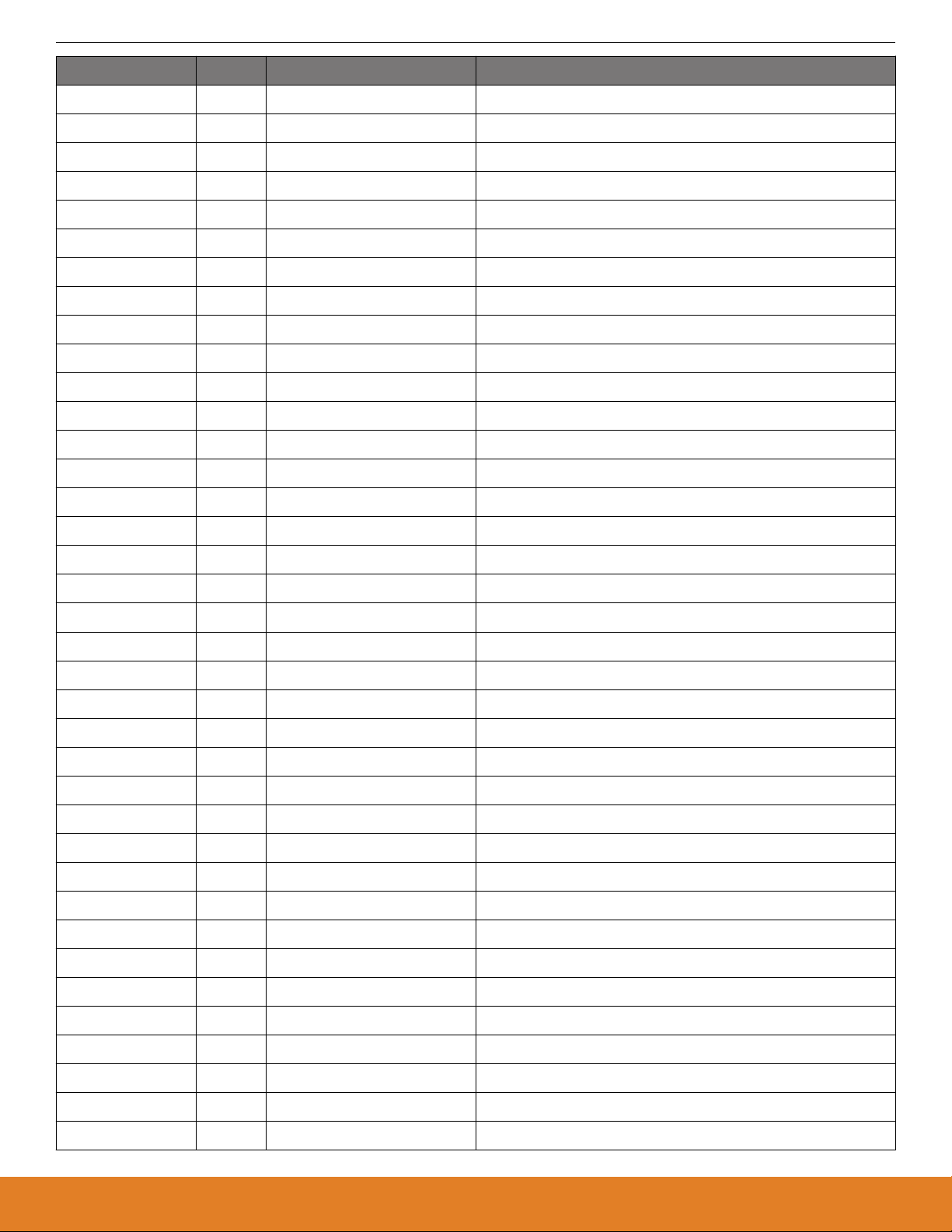

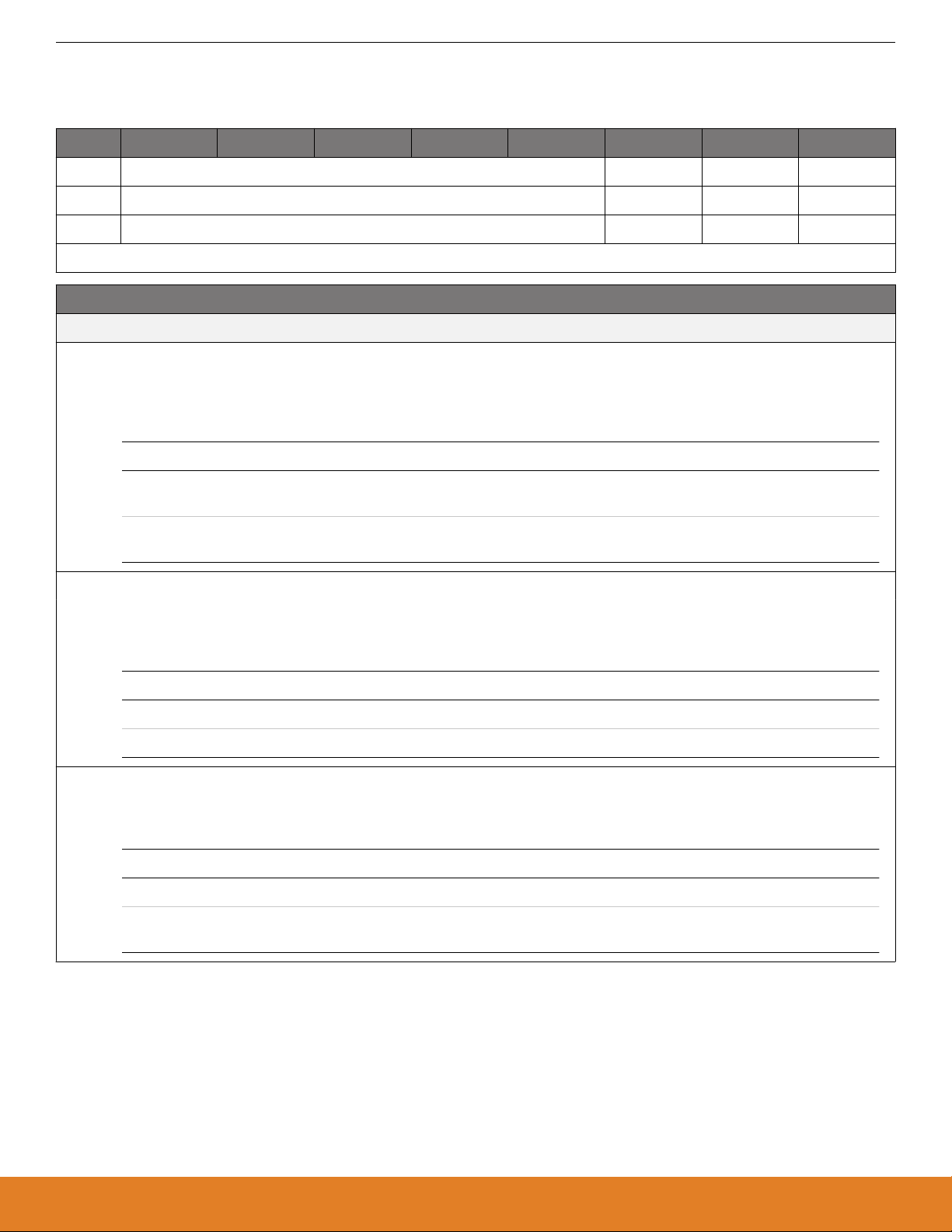

Table 6.1. Interrupt Priority Table

Interrupt Source Vector Priority Primary Enable Auxiliary Enable(s) Pending Flag(s)

Reset 0x0000 Top - - -

External Interrupt 0 0x0003 0 IE_EX0 - TCON_IE0

Timer 0 Overflow 0x000B 1 IE_ET0 - TCON_TF0

External Interrupt 1 0x0013 2 IE_EX1 - TCON_IE1

Timer 1 Overflow 0x001B 3 IE_ET1 - TCON_TF1

UART 0 0x0023 4 IE_ES0 - SCON0_RI

SCON0_TI

Interrupts

Timer 2 Overflow 0x002B 5 IE_ET2 TMR2CN0_TF2CEN

TMR2CN0_TF2LEN

TMR2CN0_TF2H

TMR2CN0_TF2L

SPI0 0x0033 6 IE_ESPI0 - SPI0CN0_MODF

SPI0CN0_RXOVRN

SPI0CN0_SPIF

SPI0CN0_WCOL

SMBus 0 0x003B 7 EIE1_ESMB0 - SMB0CN0_SI

RTC0 Alarm 0x0043 8 EIE1_ERTC0A - RTC0CN0_ALRM

ADC0 Window Compare 0x004B 9 EIE1_EWADC0 - ADC0CN0_ADWINT

ADC0 End of Conversion 0x0053 10 EIE1_EADC0 - ADC0CN0_ADINT

PCA0 0x005B 11 EIE1_EPCA0 PCA0CPM0_ECCF

PCA0CPM1_ECCF

PCA0CPM2_ECCF

PCA0CPM3_ECCF

PCA0CPM4_ECCF

PCA0CPM5_ECCF

PCA0CN0_CCF0

PCA0CN0_CCF1

PCA0CN0_CCF2

PCA0CN0_CCF3

PCA0CN0_CCF4

PCA0CN0_CCF5

PCA0CN0_CF

Comparator 0 0x0063 12 EIE1_ECP0 CMP0MD_CPFIE

CMP0MD_CPRIE

Comparator 1 0x006B 13 EIE1_ECP1 CMP1MD_CPFIE

CMP1MD_CPRIE

Timer 3 Overflow 0x0073 14 EIE1_ET3 TMR3CN0_TF3CEN

TMR3CN0_TF3LEN

Supply Monitor Early

0x007B 15 EIE2_EWARN - VDM0CN_VDDOK

CMP0CN0_CPFIF

CMP0CN0_CPRIF

CMP1CN0_CPFIF

CMP1CN0_CPRIF

TMR3CN0_TF3H

TMR3CN0_TF3L

Warning

Port Match 0x0083 16 EIE2_EMAT - -

RTC0 Oscillator Fail 0x008B 17 EIE2_ERTC0F - RTC0CN0_OSCFAIL

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 32

Page 34

EFM8SB2 Reference Manual

Interrupt Source Vector Priority Primary Enable Auxiliary Enable(s) Pending Flag(s)

SPI1 0x0093 18 EIE2_ESPI1 - SPI1CN0_MODF

SPI1CN0_RXOVRN

SPI1CN0_SPIF

SPI1CN0_WCOL

Interrupts

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 33

Page 35

EFM8SB2 Reference Manual

Interrupts

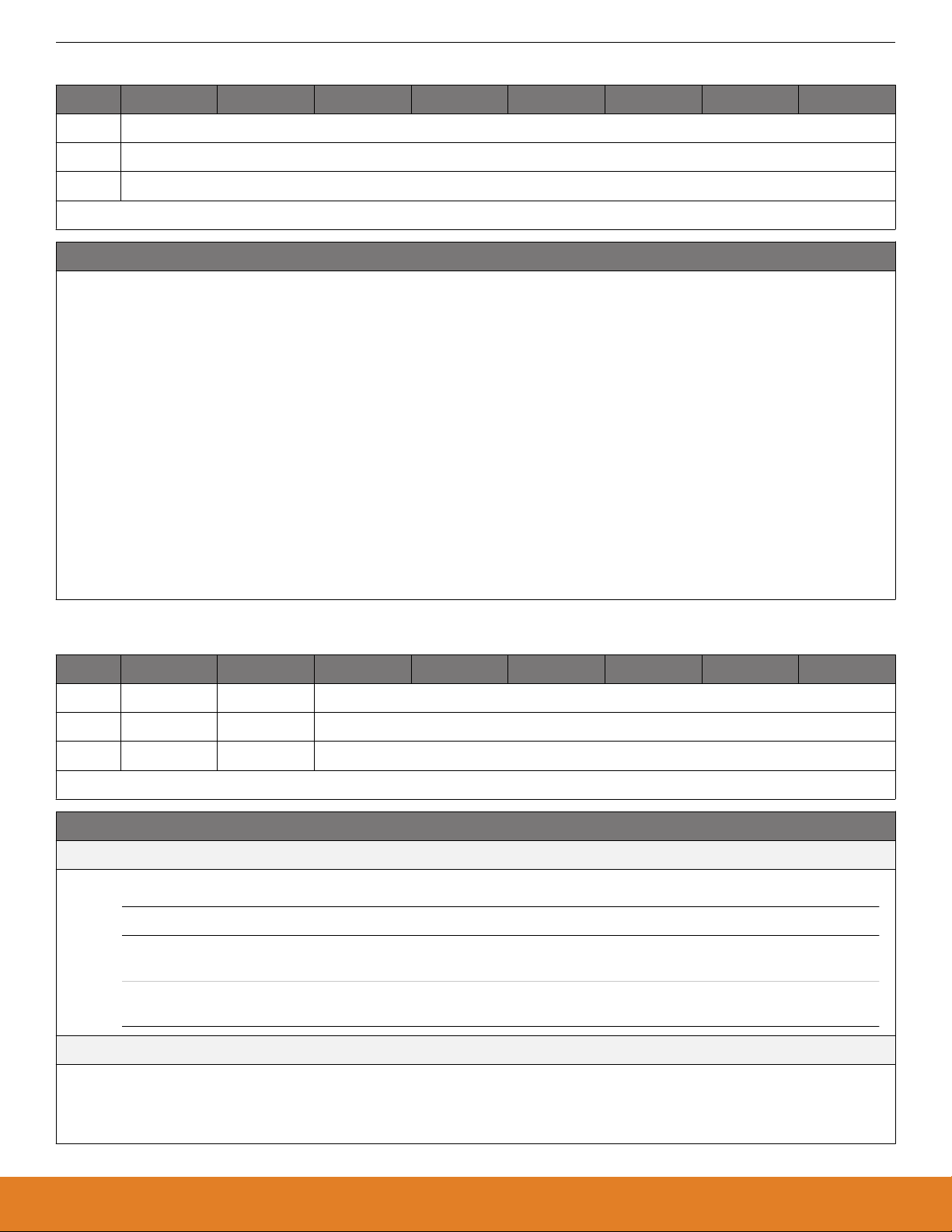

6.3 Interrupt Control Registers

6.3.1 IE: Interrupt Enable

Bit 7 6 5 4 3 2 1 0

Name EA ESPI0 ET2 ES0 ET1 EX1 ET0 EX0

Access RW RW RW RW RW RW RW RW

Reset 0 0 0 0 0 0 0 0

SFR Page = ALL; SFR Address: 0xA8 (bit-addressable)

Bit Name Reset Access Description

7 EA 0 RW All Interrupts Enable.

Globally enables/disables all interrupts and overrides individual interrupt mask settings.

Value Name Description

0 DISABLED Disable all interrupt sources.

1 ENABLED Enable each interrupt according to its individual mask setting.

6 ESPI0 0 RW SPI0 Interrupt Enable.

This bit sets the masking of the SPI0 interrupts.

Value Name Description

0 DISABLED Disable all SPI0 interrupts.

1 ENABLED Enable interrupt requests generated by SPI0.

5 ET2 0 RW Timer 2 Interrupt Enable.

This bit sets the masking of the Timer 2 interrupt.

Value Name Description

0 DISABLED Disable Timer 2 interrupt.

1 ENABLED Enable interrupt requests generated by the TF2L or TF2H flags.

4 ES0 0 RW UART0 Interrupt Enable.

This bit sets the masking of the UART0 interrupt.

Value Name Description

0 DISABLED Disable UART0 interrupt.

1 ENABLED Enable UART0 interrupt.

3 ET1 0 RW Timer 1 Interrupt Enable.

This bit sets the masking of the Timer 1 interrupt.

Value Name Description

0 DISABLED Disable all Timer 1 interrupt.

1 ENABLED Enable interrupt requests generated by the TF1 flag.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 34

Page 36

Bit Name Reset Access Description

2 EX1 0 RW External Interrupt 1 Enable.

This bit sets the masking of External Interrupt 1.

Value Name Description

0 DISABLED Disable external interrupt 1.

1 ENABLED Enable interrupt requests generated by the INT1 input.

1 ET0 0 RW Timer 0 Interrupt Enable.

This bit sets the masking of the Timer 0 interrupt.

Value Name Description

0 DISABLED Disable all Timer 0 interrupt.

1 ENABLED Enable interrupt requests generated by the TF0 flag.

0 EX0 0 RW External Interrupt 0 Enable.

This bit sets the masking of External Interrupt 0.

EFM8SB2 Reference Manual

Interrupts

Value Name Description

0 DISABLED Disable external interrupt 0.

1 ENABLED Enable interrupt requests generated by the INT0 input.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 35

Page 37

EFM8SB2 Reference Manual

Interrupts

6.3.2 IP: Interrupt Priority

Bit 7 6 5 4 3 2 1 0

Name Reserved PSPI0 PT2 PS0 PT1 PX1 PT0 PX0

Access R RW RW RW RW RW RW RW

Reset 1 0 0 0 0 0 0 0

SFR Page = ALL; SFR Address: 0xB8 (bit-addressable)

Bit Name Reset Access Description

7 Reserved Must write reset value.

6 PSPI0 0 RW Serial Peripheral Interface (SPI0) Interrupt Priority Control.

This bit sets the priority of the SPI0 interrupt.

Value Name Description

0 LOW SPI0 interrupt set to low priority level.

1 HIGH SPI0 interrupt set to high priority level.

5 PT2 0 RW Timer 2 Interrupt Priority Control.

This bit sets the priority of the Timer 2 interrupt.

Value Name Description

0 LOW Timer 2 interrupt set to low priority level.

1 HIGH Timer 2 interrupt set to high priority level.

4 PS0 0 RW UART0 Interrupt Priority Control.

This bit sets the priority of the UART0 interrupt.

Value Name Description

0 LOW UART0 interrupt set to low priority level.

1 HIGH UART0 interrupt set to high priority level.

3 PT1 0 RW Timer 1 Interrupt Priority Control.

This bit sets the priority of the Timer 1 interrupt.

Value Name Description

0 LOW Timer 1 interrupt set to low priority level.

1 HIGH Timer 1 interrupt set to high priority level.

2 PX1 0 RW External Interrupt 1 Priority Control.

This bit sets the priority of the External Interrupt 1 interrupt.

Value Name Description

0 LOW External Interrupt 1 set to low priority level.

1 HIGH External Interrupt 1 set to high priority level.

1 PT0 0 RW Timer 0 Interrupt Priority Control.

This bit sets the priority of the Timer 0 interrupt.

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 36

Page 38

Bit Name Reset Access Description

Value Name Description

0 LOW Timer 0 interrupt set to low priority level.

1 HIGH Timer 0 interrupt set to high priority level.

0 PX0 0 RW External Interrupt 0 Priority Control.

This bit sets the priority of the External Interrupt 0 interrupt.

Value Name Description

0 LOW External Interrupt 0 set to low priority level.

1 HIGH External Interrupt 0 set to high priority level.

EFM8SB2 Reference Manual

Interrupts

silabs.com | Smart. Connected. Energy-friendly. Rev. 0.1 | 37

Page 39

EFM8SB2 Reference Manual

Interrupts

6.3.3 EIE1: Extended Interrupt Enable 1

Bit 7 6 5 4 3 2 1 0

Name ET3 ECP1 ECP0 EPCA0 EADC0 EWADC0 ERTC0A ESMB0

Access RW RW RW RW RW RW RW RW

Reset 0 0 0 0 0 0 0 0

SFR Page = ALL; SFR Address: 0xE6

Bit Name Reset Access Description

7 ET3 0 RW Timer 3 Interrupt Enable.