Page 1

...the world's most energy friendly microcontrollers

EFM32 USB Smart Card Reader

AN0820 - Application Note

Introduction

This application note gives an overview of the ISO/IEC-7816 smart card standard

and a short introduction to the communication and protocol of a smart card. Along

with this document there is a working example of a smart card-reader, implemented

using the EFM32. The included software example implements a USB-CCID card

reader device using the STK3700 Giant Gecko Starter Kit. The software example is

developed and tested with an ACS (Advanced Card Systems Ltd.) ACOS-1/3 type of

smart card.

This application note includes:

• This PDF document

• Source files (zip)

• Example C-code

• Multiple IDE projects

Page 2

...the world's most energy friendly microcontrollers

1 Smart Card Introduction

A smart card, chip card or integrated circuit card (ICC) is a device that includes an embedded integrated

circuit chip that can be either a secure microcontroller or equivalent intelligence with internal memory

or a memory chip alone. The card is connected to a reader via direct physical contact or via a remote

contactless RF interface. With the usage of an embedded microcontroller, smart cards have the ability

to store large amounts of data, carry out their own on card functions (such as encryption and mutual

authentication) and interact intelligently with a smart card reader.

Smart card technology conforms to international standards (ISO 7816 and ISO 14443) and is available

in a variety of form factors, including plastic cards, fobs, SIM cards used in GSM mobile phones, and

USB tokens.

Smart cards are used in many applications worldwide, including:

• Secure ID - employee ID badges, citizen ID documents, electronic passports, driver's licenses, online

authentication devices

• Healthcare - citizen health ID cards, physician ID cards, portable medical records cards

• Payment - contact and contactless credit/debit cards, transit payment cards

• Telecom - GSM Subscriber Identity Modules, pay telephone payment cards

The scope of this application note is to give an overview of the different parts of the ISO 7816 standard,

governing physical contact smart cards themselves and smart card interface devices or readers. The

EFM32 microcontroller is used to implement a USB-enabled smart card reader and the included software

example utilizes the EFM32 USART's 7816 smart card mode for automatic parity generation/check and

ACK/NACK generation.

2014-01-23 - an0820_Rev1.00 2

www.silabs.com

Page 3

...the world's most energy friendly microcontrollers

2 The ISO 7816 Standard

ISO/IEC 7816, (only referred to as ISO 7816 from here on) is an international standard related to

electronic identification cards with contacts, especially smart cards, managed jointly by the International

Organization for Standardization (ISO) and the International Electro-technical Commission (IEC). The

full standard is available through www.iso.org, (See Reference 4 (p. 20) ).

2.1 Different Parts of the 7816-Standard

The standard currently has 15 parts (or levels), but only 2 of them, part 3 and part 4, are relevant for this

application note. The first 5 parts of the standard are listed here:

• 7816-1: Physical characteristics.

Describes the physical characteristics of integrated circuit cards, from environment exposure limits to

degree of bending or flexing; important for manufacturers in their choice of materials and establishing

a process that embeds the integrated circuit into the card

• 7816-2: Cards with contacts - Dimensions and location of the contacts.

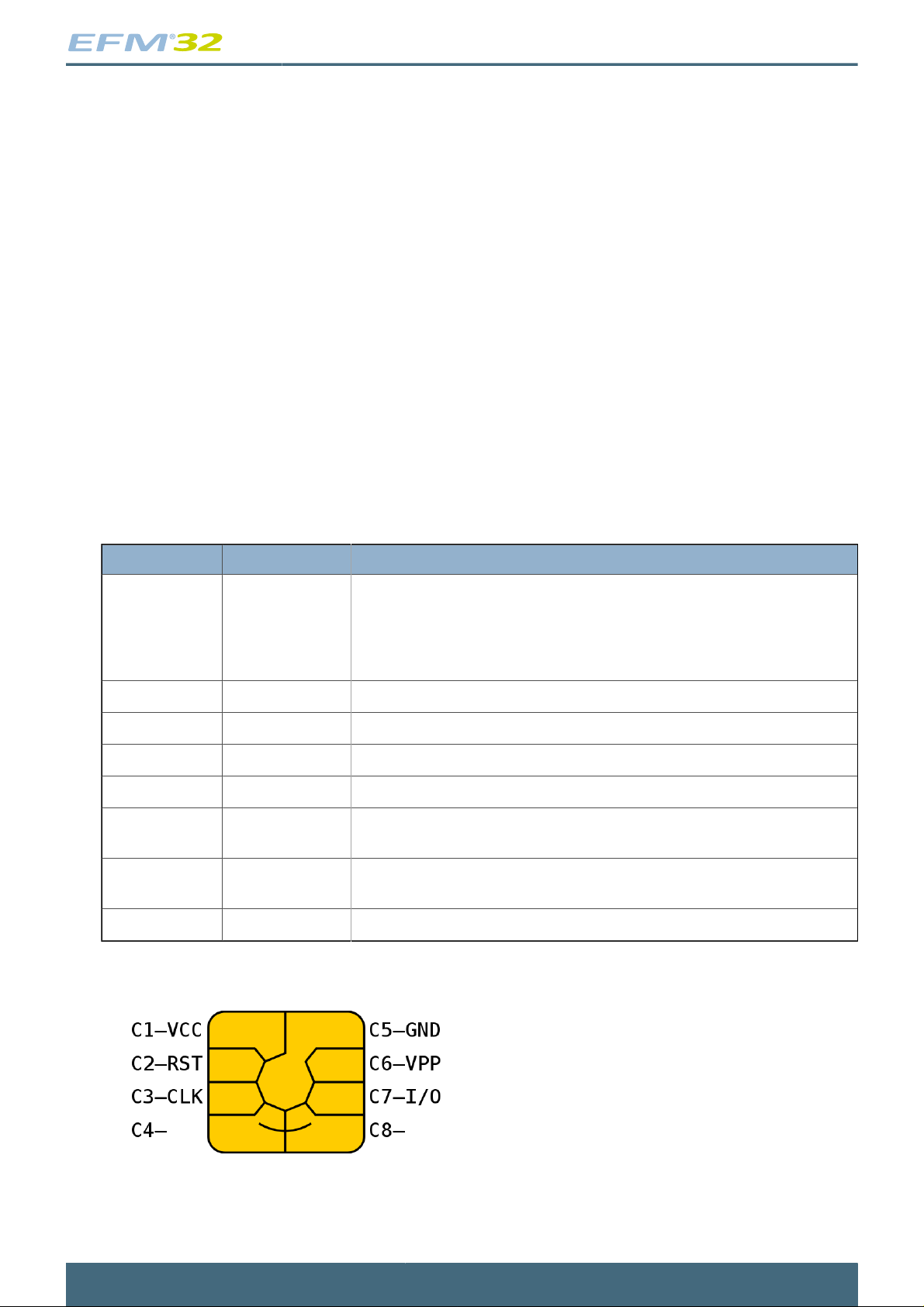

The following table contains the contact definition of the electrical contacts, according to ISO7816-2:

Table 2.1. Smart Card Electrical Connection

Contact Designation Use

C1 V

C2 RST Reset line (from reader to card)

C3 CLK Clock signal line (from reader to card)

C4 RFU Reserved for future use

C5 GND Common ground of contact reader and card

C6 V

C7 I/O Input/output data line that provides a half-duplex communication

C8 RFU Reserved for future use

cc

pp

Power connection through which operating power is supplied to the

microprocessor chip in the card (typically a reader must support up to

5V, max 200mA draw, but the device implemented in this example only

supports 3.3V since that is the operating voltage of the EFM32 on the

STK3700 starter kit.)

Higher voltage used to program EEPROM of older chips. Usually Not

used.

channel between the reader and the smart card

Figure 2.1. Smart Card Physical Connections

Figure 2.1 (p. 3) shows a typical pad layout of the contacts on the smart card.

2014-01-23 - an0820_Rev1.00 3

www.silabs.com

Page 4

...the world's most energy friendly microcontrollers

• 7816-3: Cards with contacts - Electrical interface and transmission protocols.

Describes the electrical levels and waveforms, as well as the physical layer of the communication

protocol. This part includes specification of clock generation, reset sequence, baud rate, frame and

parity check as well as negotiation of parameters related to the communication.

• 7816-4: Organization, security and commands for interchange.

It specifies the contents of command-response pairs exchanged at the interface, means of retrieval

of data elements and data objects in the card, applications and data in the card, access methods to

files and data in the card including a security architecture.

• 7816-5: Registration of application providers.

Defines how to use an application identifier to ascertain the presence of and/or perform the retrieval

of an application in a card. ISO/IEC 7816-5:2004 shows how to grant the uniqueness of application

identifiers.

The rest of the 7816 standard deals with security protocols, card management and life-cycle

management, cryptographic considerations and also newer types of smart card interfaces, including

synchronous communication and USB-enabled cards.

Since a USB CCID device operates as a bridge, relaying packets between host computer and smart

card, this application note will mainly relate to the electrical waveforms and transportation of messages

described in part 3 and 4 of the standard. These parts are discussed in detail in the following sections.

2.2 Part 3; Electrical Signal and Transmission Protocol

Communication with the smart card takes place over a single bi-directional, half-duplex data line. The

voltage levels for high / low states is the same as the supply voltage to the smart card. The direction

of communication is assumed to be known a-priori by both master (reader) and slave (smart card).

Parameters such as protocol format, type of smart card, baud rate and other electrical parameters are

read out of the smart card right after reset. This is known as the Answer to Reset or ATR. Based on the

information given in the ATR, the reader can adapt to the transmission format supported by the card.

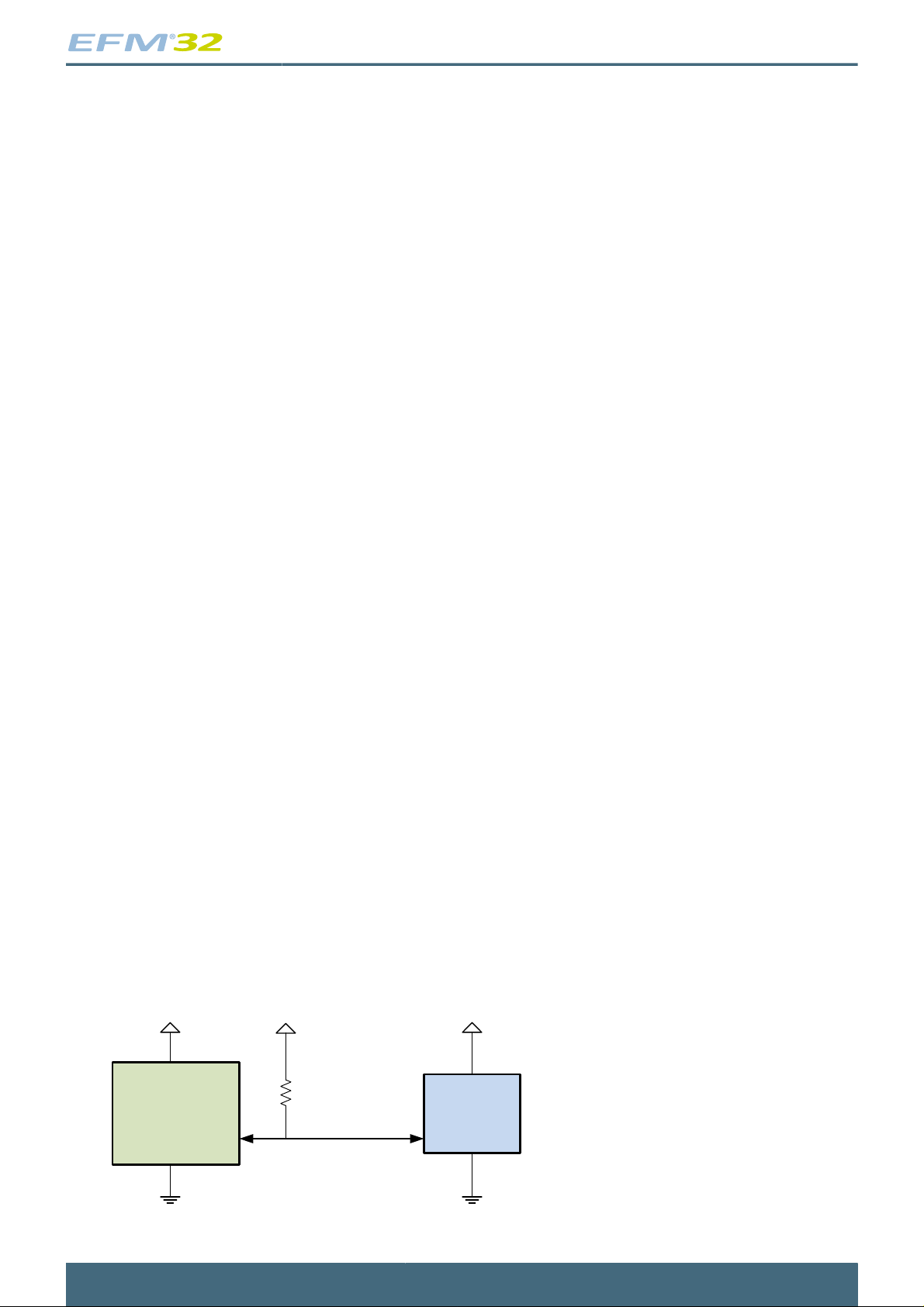

2.2.1 Electrical Connection of the Bi-directional Data Interface

Since the data communication is bi-directional, the terminal is often configured to transmit data through

an open-drain output. This means that it can pull the data line low, but it needs a pull-up resistor to go

high again. And in the same way, the smart card can pull the line low, but needs the pull-up to take the

line high again. Some interface-devices use more clever ways of doing this to achieve faster rise-times,

but for the EFM32 implementation of the bi-directional data line the following configuration is used:

Figure 2.2. Bi-directional Data Line with Pull-Up Resistor

Smart

R

pull

Smart

Card

Card

Terminal

2014-01-23 - an0820_Rev1.00 4

Data- line

www.silabs.com

Page 5

...the world's most energy friendly microcontrollers

The pull resistor used in the EFM32-implementation is the internal pull-up in the EFM32's GPIO pin.

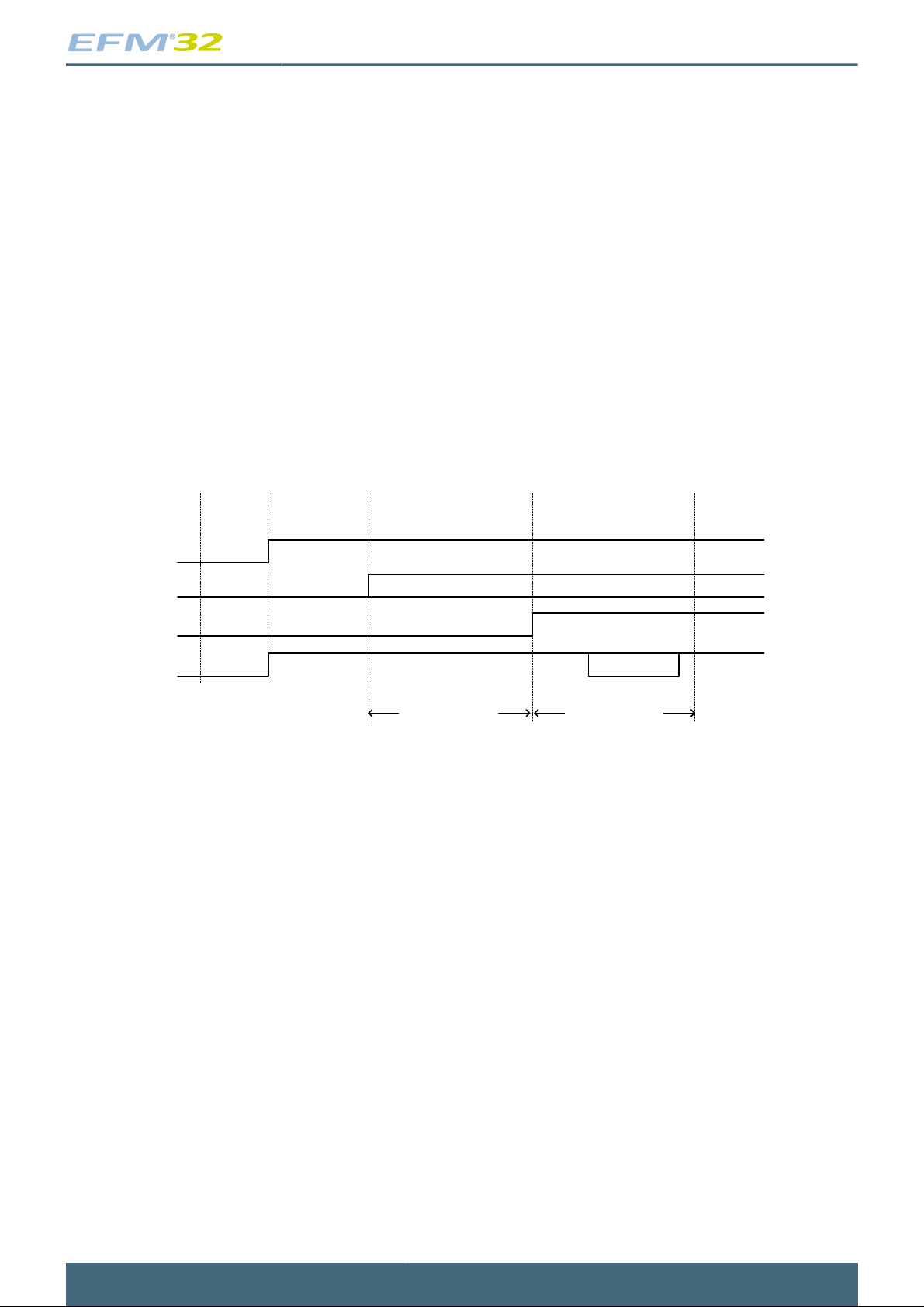

2.2.2 Power Up, Clock and Reset

When a card is inserted into the reader, all the contacts are disconnected from the terminal/reader,

including ground. The reason for this is that the contacts in the terminal slide over the smart card contacts

while the card is inserted. Applying power to the wrong pins could in theory damage the card or the

reader. When the card is properly inserted, there is usually an electrical contact that breaks connection,

indicating to the reader that the card is fully inserted. Now the reader initiates a power on and reset

sequence.

The interface is responsible for the timing of the sequence. The most important parameters are the clockcycle count before and after reset is released. The interface should enable the clock and keep it running

for 40k cycles before reset is released. After reset, the card must respond with its ATR within a window

of 400-40000 clock cycles. The timing is illustrated in Figure 2.3 (p. 5)

Figure 2.3. Answer to Reset Sequence

Vcc

Clk

Reset

IO

Card

Inserted

Power

enabled, IO-

pin pulled high

Clock

Started

Clock Running

Wait 40 000

clock cycles

Reset

Released

ATR

Received

ATR-Data

< 40 000

clock cycles

2.2.3 Byte Transfers

During the power on and reset sequence, the smart card answers with its "Answer to Reset". The

transmission of this first data-packet is carried out with default communication parameters listed below:

• Baud rate = F

• 8 data bits.

• 1 start bit.

• 1 parity bit, even.

• 1.5 stop bits (guard period for Ack/Nack).

• Coding of 0's and 1's: This can vary, the correct naming of this is: "Direct" or "Inverse" convention. It

is based on the very first character transmitted, called TS. "Direct" indicated by TS=HLHHLHHHLLH

(H = Vdd, L = GND) means that the following data is transferred as 0=GND, 1=Vdd and with the least

significant bit first. For the Inverse convention, indicated by TS=HLHHLLLLLLH, data is transmitted

with most significant bit first and 0=Vdd, 1=GND.

/372. Clock should be approximately 3.57 MHz, resulting in 9.6 kBaud/s.

clock

Using the above parameters, the interface must also adhere to the Ack/Nack of bytes, based on the

parity bit. A Nack is indicated when the receiver pulls the data line low in the guard period after the parity

bit is transmitted. If this happens, the transmitter should immediately retransmit the last byte.

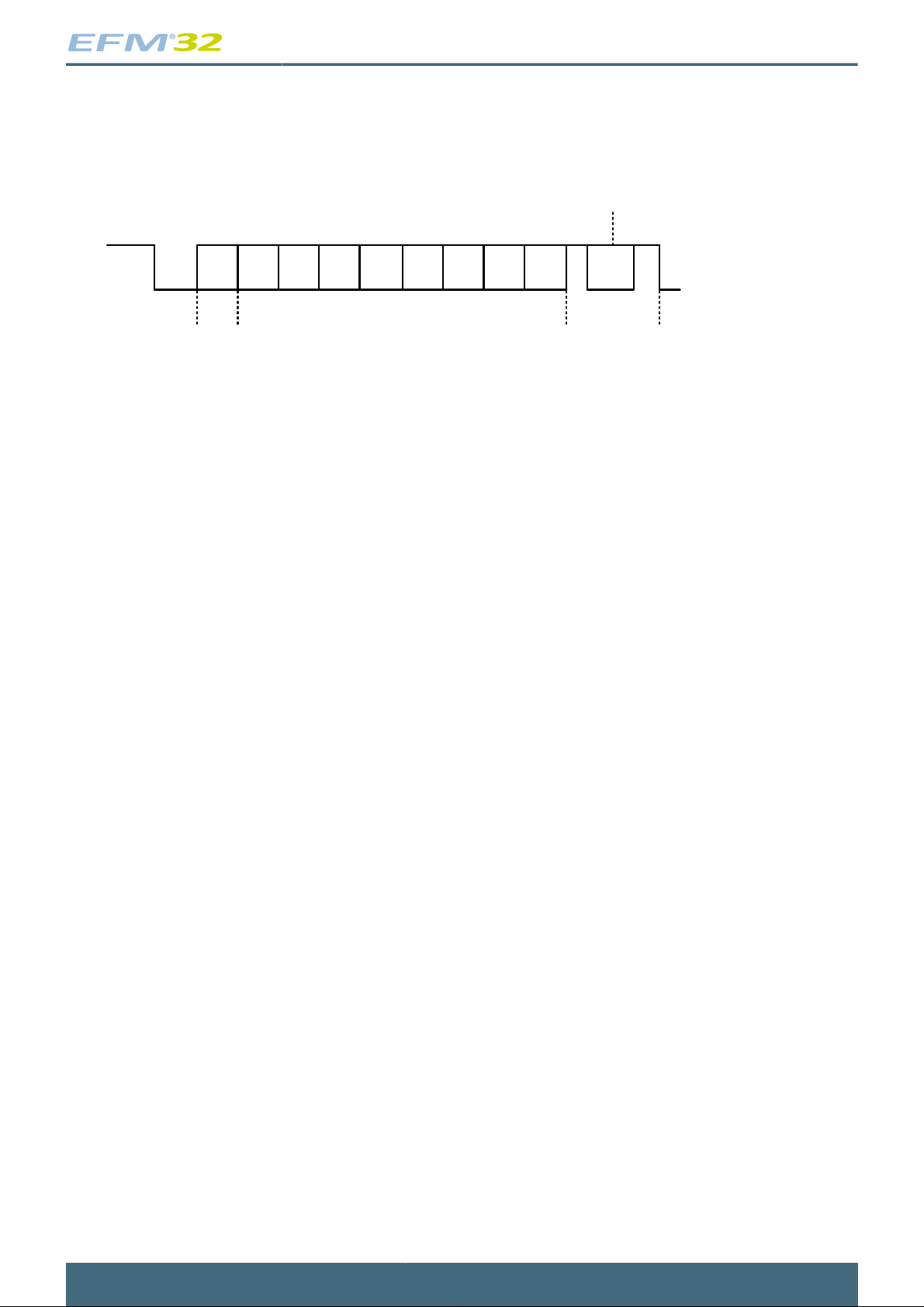

One bit-period is called an "Elementary Time Unit" or ETU, this is used throughout the 7816 standard as a

basis for defining the timing of the protocol. An illustration of one transmitted byte is given in Figure 2.4 (p.

6) .

2014-01-23 - an0820_Rev1.00 5

www.silabs.com

Page 6

...the world's most energy friendly microcontrollers

Figure 2.4. Byte Transmission, Parity and Elementary Time Unit

Line pulled

low in case

of error

Start bit

8 bit Frame Parity bit

S 1 2 3 4 5 6 7 8 P Err

ETU

Guard Period

Elementary

Time Unit

Note that this byte-format with parity error detection is always used during the Answer to Reset, but only

for further communication if the selected protocol is "T=0" (based on what is indicated in the ATR). What

T=0 protocol means and why it is called that is explained in Section 2.3 (p. 6) .

2.2.4 Answer to Reset

The Answer to Reset is a string of 33 or fewer characters (bytes). With naming as defined in ISO 7816-3,

the ATR consists of the following mandatory and optional characters:

• TS - a mandatory initial character, conveying byte-format, (the direct or inverse convention).

• T0 - a mandatory format character, indicating the contents of the ATR.

• TAi, TBi, TCi, TDi - optional interface characters, these characters indicate supported clock speeds,

voltage levels and protocols supported by the card. Since they are optional, if not given, the card

reader must continue with the default protocol used during the ATR sequence.

• T1, T2, TK - optional historical characters, these characters typically hold information about the card

manufacturer, type of card (size etc.), version number and the state of the card.

• TCK - a conditional check character, presence of this byte is indicated by the optional interface

characters, if present, it is exclusive OR of all the bytes in the ATR, excluding TS and TCK.

This document will not go further into the meaning of these characters, please refer to the ISO 7816-3

Standard for more information, (Reference 1 (p. 20) ).

2.3 Part 4; Commands and Exchange of Data Packets

The previous section described how the first basic communication channel is established between the

card and the reader. The channel is a half-duplex, physical channel. Part 4 of the ISO 7816 standard

defines the link-level protocols on top of this physical channel. The link-level protocol provides an errorfree communication channel for the application-level protocol. This section describes the message

structure consisting of application protocol data units (APDUs), which are exchanged between the reader

application and the smart card application by the link-level protocol. Since only one type of the link-level

protocol is supported by the EFM32-reader-implementation (T=0), this will be described in more detail

than the others.

2014-01-23 - an0820_Rev1.00 6

www.silabs.com

Page 7

...the world's most energy friendly microcontrollers

Part 4 of the 7816 standard also defines a file system API to manipulate files and a security service API

allowing smart card and reader to mutually authenticate with each other. This is not discussed further

in this application note.

2.3.1 Protocol Data Units

The data units transmitted in the link-layer protocol is called transmission protocol data units (TPDUs).

These are the packets of data going between the reader and the smart card. On top of these are

the APDUs, which comes directly from the application layer of the protocol. The APDUs are usually

transmitted unaltered by the smart card interface device, but this depends on the level of automatism

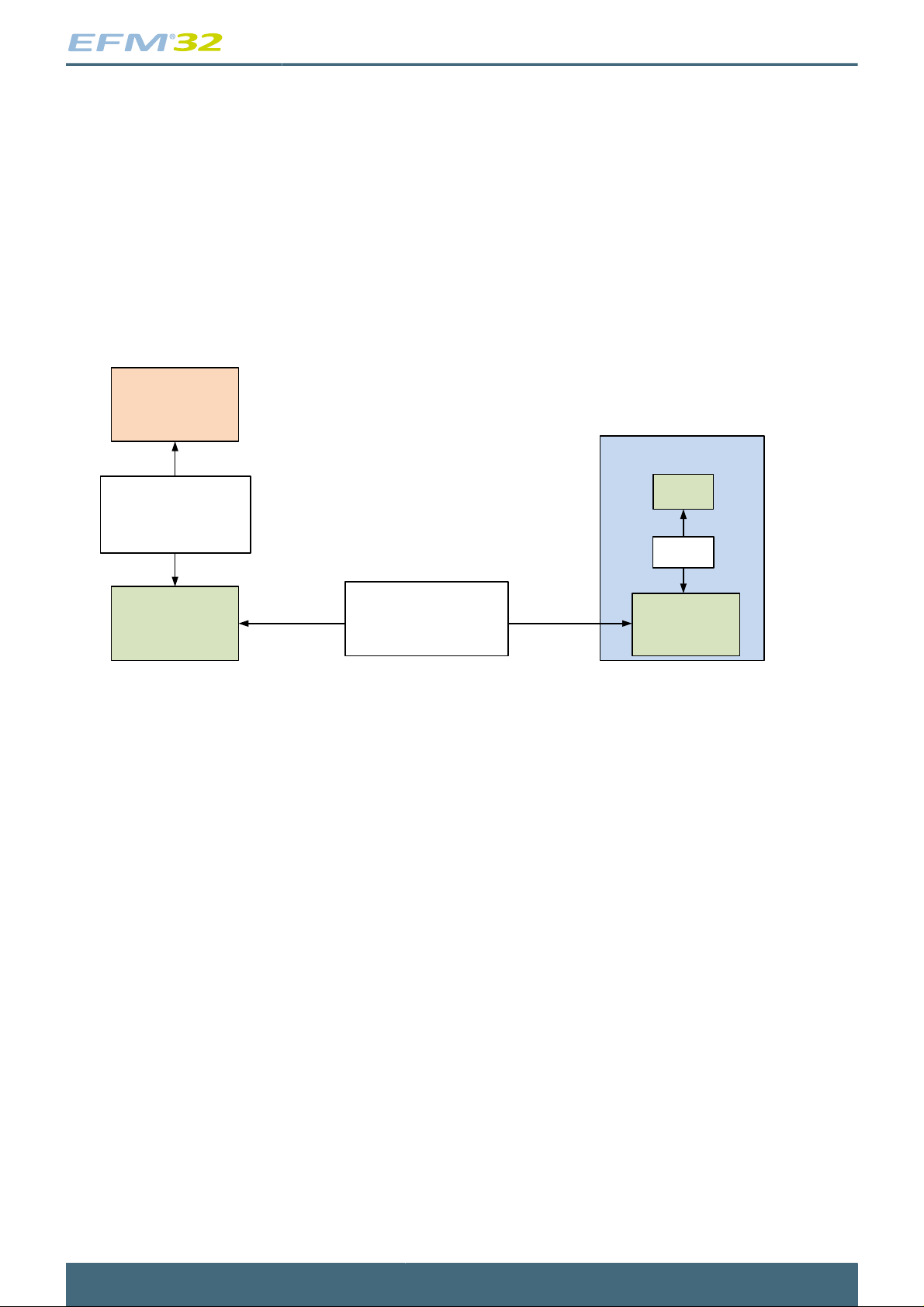

supported by the reader. This naming convention is illustrated in Figure 2.5 (p. 7) .

Figure 2.5. Protocol Data Units and Where they Apply

Host Application

Smart Card

Application Protocol

Data Units

(APDU)

Smart Card

Reader

Transmission Protocol

Data Units

(TPDU)

CPU

APDU

Physical/Link-

Layer

2.3.2 T=0 Protocol Introduction

The link-layer protocol is usually one of two variants, either a byte-oriented protocol with error handling

performed on each byte by using a parity bit, or a block-oriented protocol with checksum-based error

detection. The first one, the byte-oriented protocol is called "T=0". The name comes from the indication

of this protocol in the ATR by having one of the bits in one of the T-characters equal to 0. The blockoriented protocol is called "T=1". In fact there is even a T=2 protocol for full-duplex interfaces, with

T=3-15 reserved for future protocols.

The T=0 protocol re-uses the same byte-transmission format used during the ATR-sequence. The

parity error detection and retransmission at byte-level is also re-used. The TPDU-messages exchanged

between reader and smart card has two distinct structures, based on the direction of communication:

• A command, this is sent from reader to smart card. Consists of at least 5 characters named: CLA,

INS, P1, P2, P3, in addition comes a number of data bytes if writing to the smart card.

• CLA: Class designation of the command set to establish a collection of instructions.

• INS: The INS byte is used to identify a specific instruction within a class of instructions identified

by the CLA value.

• P1: Used to specify the addressing used by the [CLA, INS] instruction.

• P2: Also used to specify the addressing used by the [CLA, INS] instruction.

• P3: Specifies the number of data bytes transferred to or from the card as part of the [CLA, INS]

instruction execution.

• A response, this is sent from smart card to reader. Consists of 1 or 2 status characters named SW1

and SW2, in addition comes a number of data bytes if reading from the smart card. The SW1 byte

is also called "procedure-byte" if it is just an ACK or NULL character, indicating that the card is not

finished with the transaction.

2014-01-23 - an0820_Rev1.00 7

www.silabs.com

Page 8

...the world's most energy friendly microcontrollers

• SW1: Status response of the current command. 0x90 means success for example. If this byte is

equal to for instance 0x60=NULL or the INS sent in the command, it means the card need more

time to process the command or that it has more data to receive/send. This character is then called

a procedure byte.

• SW2: (optional) also conveys a status response to the reader

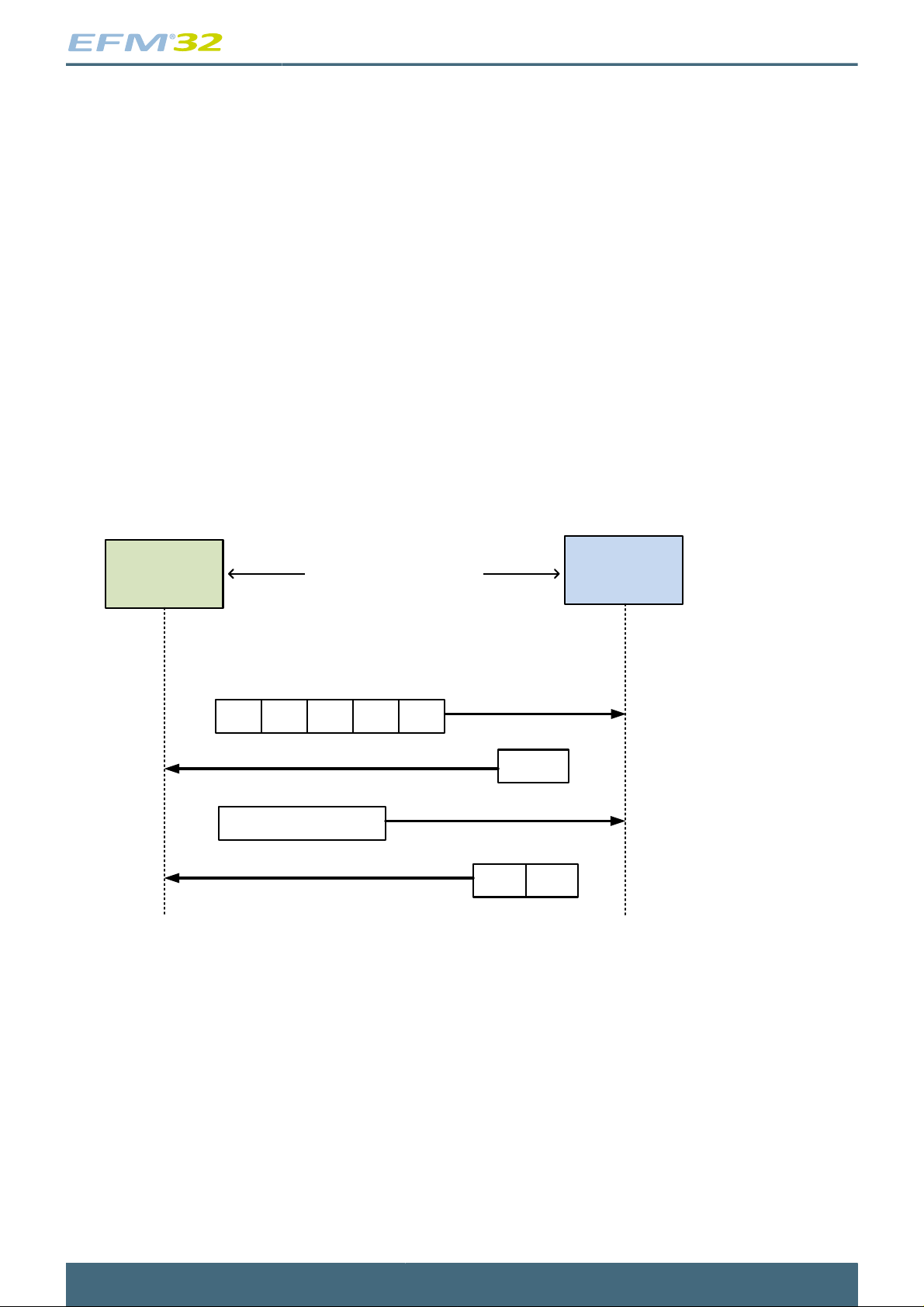

The flow of communication is handled by the reader depending on the first SW1 character of the smart

card-response. All transfers are initiated by the reader and followed by a response from the smart card.

In some cases, depending on SW1, the reader should wait for further bytes, in other cases it should

forward the SW1 and possibly SW2 characters and any read data bytes to the host application.

In the case of SW1 indicating that the reader should wait for further data or the smart card needs more

processing time, the SW1 is called a "procedure byte", indicating that it should not be forwarded to the

host application as a response. Figure 2.6 (p. 8) illustrates how transmission of a data packet to

the smart card looks like, following the T=0 protocol. In fact, for the T=0 protocol, the bytes of the APDU

directly overlays the bytes of the TPDU, this means that the APDU in Figure 2.6 (p. 8) simply

consists of CLA, INS, P1, P2, P3 and DATA in that order. Further, the APDU going back to the application

is simply SW1 and SW2.

Figure 2.6. Host Sends Data to Card

Smart Card

Terminal

7816- 3, T=0 Protocol

Smart Card

CLA INS P1 P2 P3

Procedure

byte

DATA

SW1 SW2

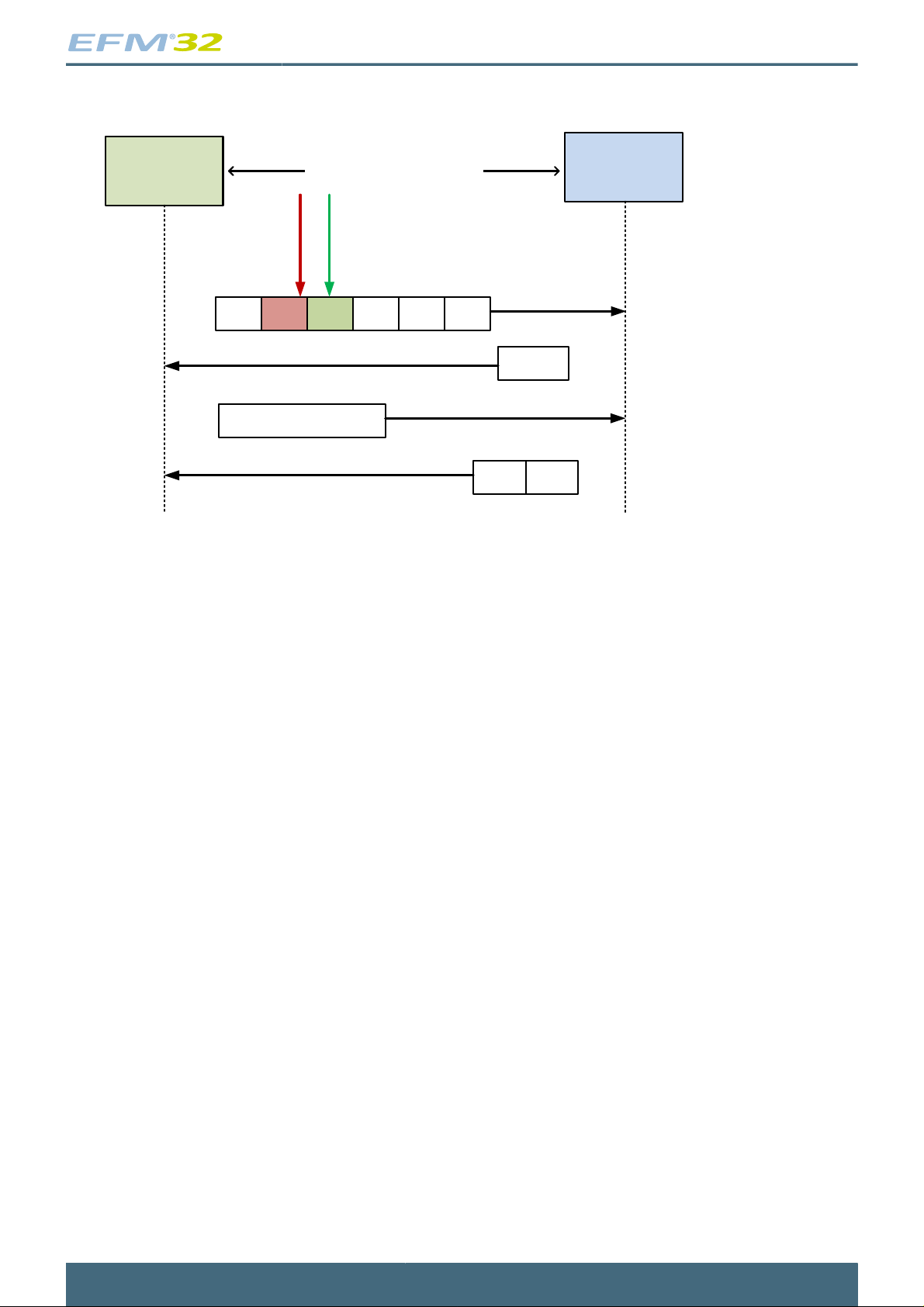

In the case of error on one byte using the T=0 protocol, the failing byte is retransmitted immediately by

the reader, this is illustrated in Figure 2.7 (p. 9) . Since the error detection is a single parity bit, this

will fail if there is an even number of bits flipped in the character transmitted. This is one of the limitations

of the T=0 protocol.

2014-01-23 - an0820_Rev1.00 8

www.silabs.com

Page 9

...the world's most energy friendly microcontrollers

Figure 2.7. Parity Error and Re-transmission for the T=0 Protocol

Smart Card

Terminal

7816- 3, T=0 Protocol

Parity

Error

CLA INS P1 P2 P3

Single Byte

Retransmitted

INS

Procedure

byte

Smart Card

DATA

SW1 SW2

For further explanation of CLA the (class byte), INS (instruction) and P1-3 (parameters) and their

contents in the T=0 protocol, please see the 7816 standard, (Reference 4 (p. 20) ).

2.3.3 T=1 Protocol Introduction

The T=1 protocol is more complex than the T=0 protocol. The physical interface is still half-duplex and

uses the same configuration as T=0. T=1 is actually built on top of T=0, but it does not use the T=0

error correction functionality, rather it uses a block oriented protocol. The main benefits of T=1 is the

block-oriented error detection mechanism which provides much better error detection and correction

capabilities than T=0. For more information about this protocol, please see Reference 2 (p. 20) .

2014-01-23 - an0820_Rev1.00 9

www.silabs.com

Page 10

...the world's most energy friendly microcontrollers

3 EFM32 USB CCID Implementation

The USB CCID (Circuit Card Interface Device) smart card reader in the attached software example,

implements a T=0 interface device only (byte-level transmission protocol, as defined in ISO/IEC 7816-3).

This means that the higher level details of the communication with the smart card (authentication, file

access etc.) is handled by the USB Host, which usually is a PC. Most of the protocol negotiation is also

handled by the host. The EFM32's job is to act as a USB - smart card bridge, transferring data packets

between the two and only handle T=0 protocol error conditions. For a complete implementation, other

error conditions such as electrical faults should also be detected and responded to accordingly, usually

by disconnecting the card immediately.

Figure 3.1 (p. 10) gives an overview of what is covered by the USB CCID standard (see Reference

1 (p. 20) ). It only covers the interface and protocol handling the transmission of APDU-packets

between the card reader and the USB host. The EFM32 implementation also includes the T=0 interface

protocol for communication with the smart card itself. From here on the EFM32 card reader is referred

to as the CCID.

Figure 3.1. Smart Card USB CCID Device Class Standard

USB CCID

Device Class

Standard

EFM32 Smart Card

Reader

3.1 USB CCID Standard

The CCID Standard (Reference 1 (p. 20) ) covers the USB communication including USB pipes used,

message formats, as well as all error conditions needed for conveying APDUs between the application

running on the USB host and the CCID. The format of the messages, message sizes and error-conditions

change according to the protocol used to communicate between the CCID and the smart card. This

makes it possible for the CCID to implement a high degree of automatism in the interaction with the

smart card. For instance, for T=1, which is block oriented, larger blocks of data can be transferred in

each USB packet to increase speed.

The CCID uses one Bulk-OUT Endpoint, one Bulk-In Endpoint and also one optional Interrupt Endpoint

to communicate with the host. Each message sent between Host and CCID contains a header which has

2014-01-23 - an0820_Rev1.00 10

www.silabs.com

Page 11

...the world's most energy friendly microcontrollers

a fixed length and a data field with variable length. Many of the messages consists only of the header.

Since the implementation in this application note only implements the T=0 protocol, the data field in the

USB messages typically map directly to the APDU-message going to/from the smart card.

A detailed description of the CCID standard is outside the scope of this document. For detailed

description of the CCID Class Descriptor, exact message format, status/error codes and sequence

diagrams, please refer to the specification, (Reference 1 (p. 20) ). An overview of some

implementation details, state-diagrams and sequence diagrams are given later in this chapter.

3.2 Connection of Smart Card to the STK

The EFM32 peripheral used for the physical layer is the USART which has a special 7816 smart card

mode to make the T=0 error detection and retransmission happen in hardware. An additional clock signal

is also required for the card, which is generated using a timer. As the serial communication is a single

line, half duplex, both the TX and the RX pins of the interface are tied together to the smart card I/O line,

this is done internally in the EFM32, using the loop back feature of the asynchronous serial interface.

According to ISO-7816 part 3, the nominal bit duration used on the I/O line is defined as one Elementary

Time Unit (ETU) and the initial ETU is 1/9600 s. For simplicity reasons, only the 9600 bps speed is

implemented. Further the bytes are transmitted using 8 data bits, 1 bit even parity and 1.5 stop bits, as

this matches the required format of the 7816 standard.

USART1 in asynchronous mode is used and TIMER0 provides the required clock signal. The clock

frequency is fixed to 3.5712 MHz which is the baud rate multiplied by 372. This is the default factor of

difference between baud rate and clock speed in the 7816 standard.

Further there is a reset pin and power pins allocated as well as a card-insertion detection pin. The 7816

standard defines that the card reader should physically power off the card if ordered to do so by the

host or if card-removal is detected.

The insertion detection pin is usually a separate electrical switch within the smart card socket. It is not

connected directly to the smart card. It is usually a normally closed switch, which opens when a smart

card is inserted all the way in the socket. In this example it is connected to both EFM32 GND and a

gpio-pin with a pull-up. When a card is inserted and the switch breaks the connection, it is expected that

this pin is pulled up. Therefore make sure to connect the other side of the insertion detection switch of

the card socket to EFM32-ground, not the GND pin of the smart card, as this can be tri-stated when

the card is not inserted.

All the pins used are located on the STK3700 expansion header, the exact pins used are described by

the following table:

Table 3.1. STK3700 Smart Card Pinout Description

EFM32GG990F1024 Smart Card Pin Functionality

PD2 C3 CLK Clock

PD0 C7 I/O line TX/RX Serial Data

PD5 C2 Reset Card reset

PD3 C1 V

PD4 C5 GND Ground pin of card

PD1 Insertion Detection Insertion Detect Pin, high

GND Insertion Detection Insertion Detect Pin, low

1

In this application example, a GPIO pin is used directly as the card power supply, hence the card Vcc is limited to 3.3V. For 5V

cards, the same application can be used with GPIO pin driving a hardware switch that provides Vcc=5V to the card.

2014-01-23 - an0820_Rev1.00 11

cc

Card Power Supply

side

side

www.silabs.com

1

Page 12

...the world's most energy friendly microcontrollers

The following picture illustrates how a physical smart card connector can be hooked up to the starter kit

on the above mentioned pins with some short wires.

Figure 3.2. Physical Connection of Card Socket with EFM32 Starterkit

3.3 Software Implementation

3.3.1 Supported Protocols and Cards

To make the software example as simple as possible, only a single communication protocol is supported,

the T=0 protocol. The CCID-standard also has optional lengths of APDU-packages, only the short type is

supported in this implementation. During development of the software, only cards from ACS, specifically

ACOS1 smart cards where used for testing. Other cards that support the same protocol should however

work, depending on host-side smart card driver and software.

Since the firmware on the EFM32 itself is basically only shuffling data-packets back and forth between

the smart card and the host computer, virtually any card supporting the correct speed and T=0 protocol

should be able to communicate with the host computer.

3.3.2 Software Algorithm

The software algorithm is based on a simple state machine function executed at regular intervals. About

every 10ms in this implementation, but anything down to 5-10 times per second should be OK. There are

no strict limitations on response time in the USB CCID-standard. The only time USB-interrupt messages

are sent, are upon card insertion or removal. All other communication happens through BulkIN/OUTendpoints.

Every time the CCID_Handler()-function is called, it steps the state-machine in Figure 3.3 (p. 13)

one step forward. All the actual CCID operations and communication with the smart card happens in the

"Handle USB-messages and CCID protocol"-transition.

2014-01-23 - an0820_Rev1.00 12

www.silabs.com

Page 13

...the world's most energy friendly microcontrollers

Figure 3.3. Card Detection and Notification Interrupt

Card Inserted

Usb- int: Notify

Slot Change

Wait for

Card

No Card

Card

Present

Card Removed

Usb- int: Notify

Slot Change

Handle USB-

messages and

CCID protocol

When one loop of the CCID_Handler is executed and the CCID either waits for a card or a card is present,

it reads one incoming USB-message and takes the necessary action. The three BulkOUT-messagetypes requiring any interaction with the card is the PC_to_Rdr_PowerOn/Off and PC_to_Rdr_XfrBlockmessages, see Reference 1 (p. 20) for more info.

The PowerOn message from the PC, requests the CCID to apply power to the smart card and it expects

the ATR in response.

The PowerOff message from the PC, requests the CCID to power off the smart card and expects only

a status message in return, indicating the new powered off state.

All actual communication with the card after the Answer to Reset, happens upon XfrBlock messages

from the PC. Each XfrBlock message contains one APDU which the CCID must send to the smart card

and in turn receive a response from the smart card which is sent back to the PC. Many APDUs only

expects the two status-bytes SW1 and SW2 as response. Some requests additional data and some has

data to write to the card. Figure 3.4 (p. 14) illustrates the communication procedure that the CCID

performs when it has an APDU that is to be sent to the smart card. Note that procedure byte 0x60 has

preference over 0x6X. "INS" refers to the instruction character in the APDU received from the host.

2014-01-23 - an0820_Rev1.00 13

www.silabs.com

Page 14

...the world's most energy friendly microcontrollers

Figure 3.4. Function Handling Command and Data Transfer with Smart Card

Send Command

Header

(CLA, INS, P1- P3)

Wait for Procedure

Byte from Card

Yes

No

If P- Byte =

NULL (0x60)

No

If P- Byte = INS

Yes

Send/ Receive

Data to/ from Card

Wait for

SW1, SW2 and

Return

2014-01-23 - an0820_Rev1.00 14

www.silabs.com

Page 15

...the world's most energy friendly microcontrollers

3.4 Typical Transaction Sequences

To further understand the typical communication pattern between both the PC and the CCID and

between the CCID and the smart card, it helps to look at how the transaction sequences play out

over time. This section has a couple of example-sequences indicating the difference between the

APDU- and TPDU-exchanges. Notice that all of these sequences follows the T=0 protocol. Also note

that the transaction diagram on the USB-side is simplified to only show the APDU-content of the

PC_to_RDR_XfrBlock USB-BulkOut messages, in addition these USB-messages actually contains a

fixed-length header-field with message-type, sequence numbering, status-bytes and so forth.

3.4.1 Sending Data to Card

When the host has data it wants to write to the smart card, it sends an APDU with data appended after

the mandatory CLA,INS,P123-header. The CCID sends first only the header to the smart card, it then

waits for a procedure byte, indicating what further action the CCID should take. See state-diagram in

Figure 3.4 (p. 14) for how the send-APDU function is implemented in the EFM32-based CCID.

If the procedure byte indicates that the smart card is ready to receive data, the CCID proceeds with

sending the data to the smart card. It then waits for a further procedure byte. Note that in the case

of successful transaction, the procedure byte is in fact the SW1-character and therefore part of the

response expected from the host. The CCID fetches the SW2 character as well and sends both SW1

and SW2 back to the host. See Figure 3.5 (p. 15) for an example-transaction of this sequence.

Figure 3.5. Host Sends Data to Card

Host- PC

CLA INS P1 P2 P3

DATA

SW1 SW2

3.4.2 Receiving Data from Card

EFM32

CCID

Reader

7816- 3, T= 0 ProtocolUSB

CLA INS P1 P2 P3

DATA

Procedure

byte

SW1 SW2

Smart Card

When the host has data it wants to read from the smart card it sends an APDU containing just a header,

which the CCID forwards directly to the smart card. The CCID must interpret the content of the APDU

to know that it is supposed to read data from the smart card and how many bytes it is supposed to

read. The CCID then waits for a procedure byte, and if indicating a data transmission the smart card

proceeds to send data after that the procedure byte. At the end of the data, the two status bytes, SW1

and SW2 are appended.

The CCID-response to the host is the data it received and the SW1 and SW2 bytes appended to the

end of the data. Figure 3.6 (p. 16) illustrates this smart card read transaction.

2014-01-23 - an0820_Rev1.00 15

www.silabs.com

Page 16

...the world's most energy friendly microcontrollers

Figure 3.6. Host Requests and Receives Data from Card

Host- PC

CLA INS P1 P2 P3

EFM32

CCID

Reader

CLA INS P1 P2 P3

SW1 SW2DATA

7816- 3, T= 0 ProtocolUSB

Procedure

DATA

SW1 SW2

Smart Card

byte

3.4.3 Insertion and Removal of Card

Figure 3.7 (p. 17) Illustrates the transaction patterns in the previous section with the addition of

insertion and removal of the card. Notice that the CCID does not power up the card until it receives a

PowerOn messages from the host. The CCID can implement automatic power on at insertion of a card,

but must then also advertise this feature in the USB-descriptor.

When the card is removed, the CCID should power off the card to protect from damage. It advertises that

the card is removed, and typically receives a power off message from the host. The CCID then replies

with a slotStatus message indicating that the card is not in the slot and that the slot is powered off.

2014-01-23 - an0820_Rev1.00 16

www.silabs.com

Page 17

...the world's most energy friendly microcontrollers

Figure 3.7. Sequence with Card Insertion, Removal and Simple Command

Host- PC

Bulk- OUT

IccPowerOn

Bulk- OUT

XfrBlock- Card

Cmd (no data)

Bulk- OUT

IccPowerOff

Interrupt – IN

NotifySlotChange

Bulk- IN

DataBlock-

AnswerToReset

Bulk- IN

DataBlock- Cmd

Response (SW1, SW2)

Interrupt – IN

NotifySlotChange

EFM32

CCID

Reader

7816- 3, T= 0 ProtocolUSB

Card Insertion Detected

Power On,

Enable Clock,

Release Reset

CLA INS P1 P2 P3

Card Removal Detected

Assert Reset,

Disable Clock,

Power Off

Smart Card

Answer To Reset

SW1 SW2

Bulk- IN

SlotStatus-

Card Removed

3.4.4 Timeout and Error Conditions

It can happen that the smart card stops responding or is malfunctioning in another way. To handle

this, the CCID should implement timeouts and error counters that signals the host with the appropriate

messages in the event of a malfunction. The EFM32 CCID-implementation includes some simple error

counters and timeout counters for this purpose, but it does not implement all the error conditions indicated

in the USB-CCID standard. It is usually ok to escalate many of the specific errors to timeout error as this

will trigger a power off of the smart card, which is always safe to do upon error conditions.

3.5 Use the Smart Card Reader with a PC

In order to make useful communication between a PC and the smart card happening, the host-computer

need software that can interact with the card. Typically, a windows PC will recognize the card-reader

as a smart card interface device. To get further, special software adapted to each different smart card

is needed. For the ACOS1/3 type of cards, there exists simple example software to store and retrieve

data on the smart card. One such software, available for free at the time of writing, which works with this

implementation is the "SmartCache"-software, (see Reference 3 (p. 20) ). This enables initialization

of the card, simple authentication with the card and storing/retrieving of data on the smart card itself.

Below is a screenshot of the "smart cache" application in action. The output is the result of probing an

already initialized ACOS1 smart card and reading out the answer to reset (ATR), as well as initialization

date and card-ID and card owner. Notice the authentication happening after the ATR is read out, but

before card ID and owner is available. It is necessary to put in the pin/password that was configured

when the card was initialized to get past the authentication. The pin/password can be changed later.

2014-01-23 - an0820_Rev1.00 17

www.silabs.com

Page 18

...the world's most energy friendly microcontrollers

Figure 3.8. SmartCache Application, result of "Get Info"-command

From the command prompt in windows, one can also retrieve the "Answer to Reset" of the smart card

by typing "certutil -scinfo".

Figure 3.9. Windows Command Prompt with output from "certutil -scinfo"

The screenshot above demonstrates use of the windows certutil function to read the smart card answer

to reset. This will verify that the USBCCID-device registered correctly with the Windows USBCCIDdriver. The errors above is likely to pop up if the inserted card is not initialized and prepared for further

certificate handling in Windows.

3.6 Limitations

There are some limitations with this implementation of a smart card reader that is important to be aware

of. First, the software only handles error- and warning-messages from the card in a simple way. Most of

2014-01-23 - an0820_Rev1.00 18

www.silabs.com

Page 19

...the world's most energy friendly microcontrollers

the responsibility of detecting errors is left to the host-computer, based on the responses given by the

card. There are no automatic negotiation of parameters and only a minimum sub-set of communication

protocols are implemented.

3.6.1 Adding a Level Translator and Protection Circuit

When connecting the smart card directly to the EFM32, it will only support 3.3V cards, smart cards

requiring 5V will not work when connected directly. Some cards need Vpp (programming voltage pin)

to be set to a higher programming voltage when writing to the card. This functionality is not supported

by the software and the Vpp pin is in fact not connected at all in this implementation. Also, there are

no additional ESD-protection or signal-conditioning when directly connected to the EFM32, which might

make the implementation more prone to electrical faults. There exists conditioning-devices that can

be connected between the mcu and the smart card, which handles ESD, signal conditioning and the

different voltage levels in a proper manner, see Figure 3.10 (p. 19) .

For further protection of the interface device and also adding support for different voltage levels, a

level translator circuit can be added between the EFM32 and the smart card itself. A typical connection

diagram for such a circuit is exemplified below.

Figure 3.10. Typical Connection Diagram with Level Translator and Protection Circuit

1.8- 5V

Reset

Clock

Data

GND

Smart Card

EFM32

3.3V

Reset

Clock

Data

Shutdown

Level-

Shift and

ESD

protection

Some simple level translators and protection devices for smart card interfaces exists. Two examples

of such a circuits are the Maxim DS8313/DS8314 devices and the Micrel MIC4555. These are analog

interface circuits with higher ESD protection than a typical microcontroller and also level-translating up

to 5V.

2014-01-23 - an0820_Rev1.00 19

www.silabs.com

Page 20

...the world's most energy friendly microcontrollers

4 References

1. Universal Serial Bus Device Class: Smart Card CCID Specification for Integrated Circuit(s) Cards

Interface Devices, Rev 1.1, 2005.

http://www.usb.org/developers/devclass_docs/DWG_Smart-Card_CCID_Rev110.pdf

2. Online version of ISO 7816 Standard:

http://www.cardwerk.com/smartcards/smartcard_standard_ISO7816.aspx

3. "Smart Cache" Windows software tool for storing data on ACOS-1/3 smart cards:

http://www.smartcache.net/

4. The home of the ISO-7816 standard:

http://www.iso.org

5. ACOS3 Smart Cards:

http://www.acs.com.hk/en/products/19/acos3-microprocessor-card/

2014-01-23 - an0820_Rev1.00 20

www.silabs.com

Page 21

5 Revision History

5.1 Revision 1.00

2014-01-23

Initial revision.

...the world's most energy friendly microcontrollers

2014-01-23 - an0820_Rev1.00 21

www.silabs.com

Page 22

...the world's most energy friendly microcontrollers

A Disclaimer and Trademarks

A.1 Disclaimer

Silicon Laboratories intends to provide customers with the latest, accurate, and in-depth documentation

of all peripherals and modules available for system and software implementers using or intending to use

the Silicon Laboratories products. Characterization data, available modules and peripherals, memory

sizes and memory addresses refer to each specific device, and "Typical" parameters provided can and

do vary in different applications. Application examples described herein are for illustrative purposes

only. Silicon Laboratories reserves the right to make changes without further notice and limitation to

product information, specifications, and descriptions herein, and does not give warranties as to the

accuracy or completeness of the included information. Silicon Laboratories shall have no liability for

the consequences of use of the information supplied herein. This document does not imply or express

copyright licenses granted hereunder to design or fabricate any integrated circuits. The products must

not be used within any Life Support System without the specific written consent of Silicon Laboratories.

A "Life Support System" is any product or system intended to support or sustain life and/or health, which,

if it fails, can be reasonably expected to result in significant personal injury or death. Silicon Laboratories

products are generally not intended for military applications. Silicon Laboratories products shall under no

circumstances be used in weapons of mass destruction including (but not limited to) nuclear, biological

or chemical weapons, or missiles capable of delivering such weapons.

A.2 Trademark Information

Silicon Laboratories Inc., Silicon Laboratories, Silicon Labs, SiLabs and the Silicon Labs logo, CMEMS®,

EFM, EFM32, EFR, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most

energy friendly microcontrollers", Ember®, EZLink®, EZMac®, EZRadio®, EZRadioPRO®, DSPLL®,

ISOmodem®, Precision32®, ProSLIC®, SiPHY®, USBXpress® and others are trademarks or registered

trademarks of Silicon Laboratories Inc. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or

registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products

or brand names mentioned herein are trademarks of their respective holders.

2014-01-23 - an0820_Rev1.00 22

www.silabs.com

Page 23

...the world's most energy friendly microcontrollers

B Contact Information

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

Please visit the Silicon Labs Technical Support web page:

http://www.silabs.com/support/pages/contacttechnicalsupport.aspx

and register to submit a technical support request.

2014-01-23 - an0820_Rev1.00 23

www.silabs.com

Page 24

...the world's most energy friendly microcontrollers

Table of Contents

1. Smart Card Introduction ............................................................................................................................. 2

2. The ISO 7816 Standard ............................................................................................................................. 3

2.1. Different Parts of the 7816-Standard .................................................................................................. 3

2.2. Part 3; Electrical Signal and Transmission Protocol ............................................................................... 4

2.3. Part 4; Commands and Exchange of Data Packets ............................................................................... 6

3. EFM32 USB CCID Implementation ............................................................................................................. 10

3.1. USB CCID Standard ...................................................................................................................... 10

3.2. Connection of Smart Card to the STK ............................................................................................... 11

3.3. Software Implementation ................................................................................................................ 12

3.4. Typical Transaction Sequences ....................................................................................................... 15

3.5. Use the Smart Card Reader with a PC ............................................................................................. 17

3.6. Limitations ................................................................................................................................... 18

4. References ............................................................................................................................................. 20

5. Revision History ...................................................................................................................................... 21

5.1. Revision 1.00 ............................................................................................................................... 21

A. Disclaimer and Trademarks ....................................................................................................................... 22

A.1. Disclaimer ................................................................................................................................... 22

A.2. Trademark Information ................................................................................................................... 22

B. Contact Information ................................................................................................................................. 23

B.1. ................................................................................................................................................. 23

2014-01-23 - an0820_Rev1.00 24

www.silabs.com

Page 25

...the world's most energy friendly microcontrollers

List of Figures

2.1. Smart Card Physical Connections .............................................................................................................. 3

2.2. Bi-directional Data Line with Pull-Up Resistor ............................................................................................... 4

2.3. Answer to Reset Sequence ...................................................................................................................... 5

2.4. Byte Transmission, Parity and Elementary Time Unit ..................................................................................... 6

2.5. Protocol Data Units and Where they Apply .................................................................................................. 7

2.6. Host Sends Data to Card ......................................................................................................................... 8

2.7. Parity Error and Re-transmission for the T=0 Protocol ................................................................................... 9

3.1. Smart Card USB CCID Device Class Standard ........................................................................................... 10

3.2. Physical Connection of Card Socket with EFM32 Starterkit ........................................................................... 12

3.3. Card Detection and Notification Interrupt ................................................................................................... 13

3.4. Function Handling Command and Data Transfer with Smart Card ................................................................... 14

3.5. Host Sends Data to Card ....................................................................................................................... 15

3.6. Host Requests and Receives Data from Card ............................................................................................. 16

3.7. Sequence with Card Insertion, Removal and Simple Command ...................................................................... 17

3.8. SmartCache Application, result of "Get Info"-command ................................................................................. 18

3.9. Windows Command Prompt with output from "certutil -scinfo" ........................................................................ 18

3.10. Typical Connection Diagram with Level Translator and Protection Circuit ........................................................ 19

2014-01-23 - an0820_Rev1.00 25

www.silabs.com

Page 26

...the world's most energy friendly microcontrollers

List of Tables

2.1. Smart Card Electrical Connection .............................................................................................................. 3

3.1. STK3700 Smart Card Pinout Description ................................................................................................... 11

2014-01-23 - an0820_Rev1.00 26

www.silabs.com

Page 27

Loading...

Loading...