Page 1

Contents

Section 1

Introduction

1.1 Overview of System Features .....................................................................................1-1

1.1.1 Compatible Modules ........................................................................................1-2

1.1.2 Accessory Enclosure ........................................................................................ 1-5

1.2 How to Use this Manual .............................................................................................. 1-5

1.3 How to Contact Silent Knight ...................................................................................... 1-5

1.4 Agency Requirements .................................................................................................. 1-6

1.4.1 Telephone Requirements ................................................................................. 1-6

1.4.2 FCC Warning ................................................................................................... 1-6

1.4.3 UL Requirements ............................................................................................. 1-7

1.4.3.1 Household Burglary Warning System ................................................... 1-8

1.4.3.2 Grade A Mercantile ...............................................................................1-8

1.4.3.3 Commercial & Residential Fire Di gital Alarm Communicator Transmitter

Hardware: ............................................................................................................ 1-9

Programming: ......................................................................................................1-9

1.4.3.4 Access Control UL-294 .........................................................................1-9

.................................................................................................................1-1

(DACT) UL 864, NFPA 72 (Chapter 4) 1-9

Section 2

Quick Start

2.1 Setting System Time and Date ..................................................................................... 2-2

To set the time: .................................................................................................... 2-2

To set the date: ...................................................................................................2-2

2.2 Sending Data to the Panel ............................................................................................ 2-3

2.3 Identifying Serial Numbers and Revision Levels ........................................................2-4

2.3.1 Operating System Revision Level ................................................................... 2-4

2.3.2 Hardware Revision Levels and Serial Numbers ..............................................2-4

2.4 Installation Records ..................................................................................................... 2-4

2.4.1 Serial Number Quick Reference ......................................................................2-5

2.4.1.1 Zone Record .......................................................................................... 2-6

150961 i

....................................................................................................................2-1

Page 2

Model 4821/4820 Control/Communicator Installation Manual

Section 3

Access Control Installation and Operation

3.1 Model 4421 Installation ............................................................................................... 3-1

3.1.1 Model 4421 Connection to the 4821 ................................................................ 3-3

3.1.2 4205 Touchpad Connection to 4421 ................................................................ 3-4

3.2 Card/Proximity Reader Installation .............................................................................3-5

3.2.1 Card Reader Specifications .............................................................................. 3-5

3.2.2 Mounting ..........................................................................................................3-5

3.2.3 Wiring the 4300 Swipe Card Reader ...............................................................3-7

3.2.4 Wiring the 4330, 4340 and 4350 ProximityReaders ........................................ 3-8

3.3 Wiring the 4860C Touchpad for Door Access ............................................................ 3-9

3.4 Access Control Operation .......................................................................................... 3-10

3.4.1 Access Control Touchpad Menus ..................................................................3-10

3.4.2 End-User Operation .......................................................................................3-11

3.4.3 Manually Changing Door Schedules .............................................................3-12

3.4.4 Viewing Door Status ...................................................................................... 3-12

............................ 3-1

3.4.5 Anti-Passback Feature ................................................................................... 3-13

3.4.6 Anti-Passback Operations .............................................................................. 3-14

3.4.7 Bulk Loading Access Cards ........................................................................... 3-14

3.5 Egress Fail-safe Override Application .......................................................................3-15

Section 4

Control Panel Description and Installation

4.1 Environmental Specifications ......................................................................................4-1

4.2 Electrical Specifications ..............................................................................................4-1

4.3 Board Layout ............................................................................................................... 4-2

4.4 Terminal Strip Description .......................................................................................... 4-3

4.5 Power Limiting Circuits ............................................................................................... 4-4

4.6 Power Switch ...............................................................................................................4-5

4.7 Mounting the Model 4821/4820 Panel ........................................................................ 4-5

4.8 Wire Routing ................................................................................................................4-6

4.9 Current Draw Worksheets ........................................................................................... 4-7

............................ 4-1

4.9.1 Sample Worksheets ........................................................................................ 4-7

ii 150961

Page 3

Contents

4.9.2 Worksheet for Silent Knight Modules ............................................................ 4-9

4.9.3 Worksheet for Auxiliary Devices (not Silent Knight) ...................................4-10

4.9.4 Battery Calculation Worksheet ...................................................................... 4-11

4.9.5 Standby Current For DACT Compliant Installations .................................... 4-11

4.10 AC Power Transformer ..............................................................................................4-12

4.11 Backup Battery Connection .......................................................................................4-13

4.12 4195 Auxiliary Power Supply Installation ................................................................. 4-14

4.13 SBUS .........................................................................................................................4-15

4.13.1 SBUS Modules ..............................................................................................4-15

4.13.2 Distribution of Modules Between SBUS1 and SBUS2 ................................. 4-16

4.13.3 Number of SBUS Devices .............................................................................4-17

4.14 Touchpad Installation ................................................................................................4-18

4.14.1 Touchpad Specifications ................................................................................ 4-18

4.14.2 Mounting Touchpads .....................................................................................4-18

4.14.3 Wiring Touchpads .......................................................................................... 4-19

4.15 Zone Installation ........................................................................................................ 4-20

4.15.1 Zone Hardware Specifications ....................................................................... 4-20

4.15.2 Maximum Number of Zones per System ....................................................... 4-20

4.15.3 Zone Configuration ........................................................................................ 4-21

4.15.4 Zone Configuration Examples .......................................................................4-22

4.15.5 Wiring a 4860C as an Input Zone .................................................................. 4-24

4.15.6 Zone Response (Debounce) Speed ................................................................ 4-25

4.16 Smoke Detector Wiring and Operation ..................................................................... 4-26

4.16.1 Smoke Detector Compatibility ...................................................................... 4-26

4.16.1.1Smoke Reset Cycle .............................................................................. 4-26

4.16.1.2Smoke Verification Cycle ................................................................... 4-26

4.16.2 Four-Wire Smoke Detector Wiring ...............................................................4-27

4.17 Speaker Wiring .......................................................................................................... 4-28

4.17.1 Internal Speaker Wiring ................................................................................. 4-28

4.17.2 External Speaker Wiring ................................................................................4-28

4.18 Bell Wiring ................................................................................................................4-29

4.18.1 Residential Type Bell Wiring ........................................................................ 4-29

4.18.2 Commercial Bell Wiring ................................................................................ 4-30

4.19 4884 Bell Module wiring ........................................................................................... 4-31

150961 iii

Page 4

Model 4821/4820 Control/Communicator Installation Manual

4.20 Telephone Line Connection ....................................................................................... 4-32

4.20.1 Second Phone Line Monitor Connection (Model 4875) ................................ 4-33

4.20.2 Ground Start Relay Connection (Model 5211) .............................................. 4-34

4.21 Built-in Relay .............................................................................................................4-34

4.22 DACT Compliant Wiring .......................................................................................... 4-35

4.22.1 Trouble Output Relay .................................................................................... 4-35

4.22.2 Monitoring an Existing Fire Alarm Control ..................................................4-36

4.22.3 Monitoring A Sprinkler System ..................................................................... 4-37

Section 5

System Operation

5.1 Partitions and Areas .....................................................................................................5-1

5.2 Touchpad Models ........................................................................................................5-4

5.3 Display Messages ........................................................................................................ 5-5

5.3.1 Power Up Messages ......................................................................................... 5-5

5.3.2 Normal Display Messages ............................................................................... 5-6

5.3.3 System Status Messages .................................................................................. 5-6

5.4 Touchpad Buttons ........................................................................................................ 5-7

5.5 Toggle and Interactive Menu Operations .................................................................... 5-8

5.6 Interactive Menu Overview ......................................................................................... 5-9

5.7 System Operation Summary ......................................................................................5-10

5.8 System Maintenance Operations Summary ............................................................... 5-14

5.9 System Test Descriptions ........................................................................................... 5-16

5.9.1 Walk Test ....................................................................................................... 5-16

5.9.2 Dialer Test ...................................................................................................... 5-16

................................................................................................5-1

5.9.3 Dialer Reset .................................................................................................... 5-16

5.10 Communicating with the Computer ........................................................................... 5-17

5.10.1 Sending Data To and From the Panel ............................................................5-18

5.11 Audible Signals Description and How to Reset ......................................................... 5-19

iv 150961

Page 5

Section 6

Contents

Programming

6.1 Downloading ................................................................................................................6-1

6.2 Touchpad Programming ..............................................................................................6-1

6.2.1 General Operation ............................................................................................ 6-1

6.2.2 The Main Menu ............................................................................................... 6-2

6.2.2.1 1-Install Device ..................................................................................... 6-3

6.2.2.2 2-Edit System Options ........................................................................... 6-3

6.2.2.3 3-Edit Partition ......................................................................................6-4

6.2.2.4 4-Edit Ph. Lines ..................................................................................... 6-4

6.2.2.5 5-Reprt Accounts ................................................................................... 6-5

6.2.2.6 6-Print Accounts ....................................................................................6-5

6.2.2.7 7-Edit Profiles ........................................................................................ 6-6

6.2.2.8 Selecting Characters for Profile Names ................................................ 6-7

Using the LCD Prompts ...................................................................................... 6-7

Using the Chart (Table 6-3) ................................................................................ 6-8

6.2.2.9 8-Edit Schedules ....................................................................................6-9

.............................................................................................................6-1

6.2.2.109-Delete Options .................................................................................. 6-10

Activating Safe Mode ....................................................................................... 6-10

Quitting Safe Mode ........................................................................................... 6-10

6.3 Programmable Options .............................................................................................. 6-11

6.3.1 System Devices List ....................................................................................... 6-11

6.3.1.1 General System Options Screen .......................................................... 6-11

6.3.1.2 Dialer Screen .......................................................................................6-14

6.3.1.3 Devices Screen .................................................................................... 6-15

6.3.2 Partition List and Menus ................................................................................6-16

6.3.2.1 Partition Options Screen ...................................................................... 6-16

6.3.2.2 Touchpads / Card Readers Screen ....................................................... 6-20

6.3.2.3 Zones Screen ....................................................................................... 6-23

6.3.2.4 Reporting Accounts Screen .................................................................6-27

6.3.2.5 Areas Screen ........................................................................................ 6-30

6.3.3 Time Schedules Screen .................................................................................. 6-31

Time Ranges .....................................................................................................6-31

6.3.4 Universal Schedules ....................................................................................... 6-32

6.3.5 User Profiles Screen .......................................................................................6-33

6.3.6 Users Screen .................................................................................................. 6-34

150961 v

Page 6

Model 4821/4820 Control/Communicator Installation Manual

Section 7

Reporting

7.1 Compatible UL Listed Receivers ................................................................................. 7-1

7.2 SIA Event Codes .......................................................................................................... 7-2

7.3 Ademco Contact ID Event Codes ................................................................................ 7-6

7.4 ASCII Event Descriptions .........................................................................................7-10

.......................................................................................................................7-1

Section 8

Troubleshooting

8.1 Error Messages ............................................................................................................ 8-1

8.2 Before You Call Technical Support ............................................................................. 8-2

....................................................................................................8-1

vi 150961

Page 7

Section 1

Introduction

The Model 4821/4820 is a control/communicator for use in residential and commercial

security applications, commercial and residential fire applications. The Model 4821 includes a

sophisticated access control system, through which you can monitor and control user access to

specific areas of a building (see Section 3 for detailed information on access control).

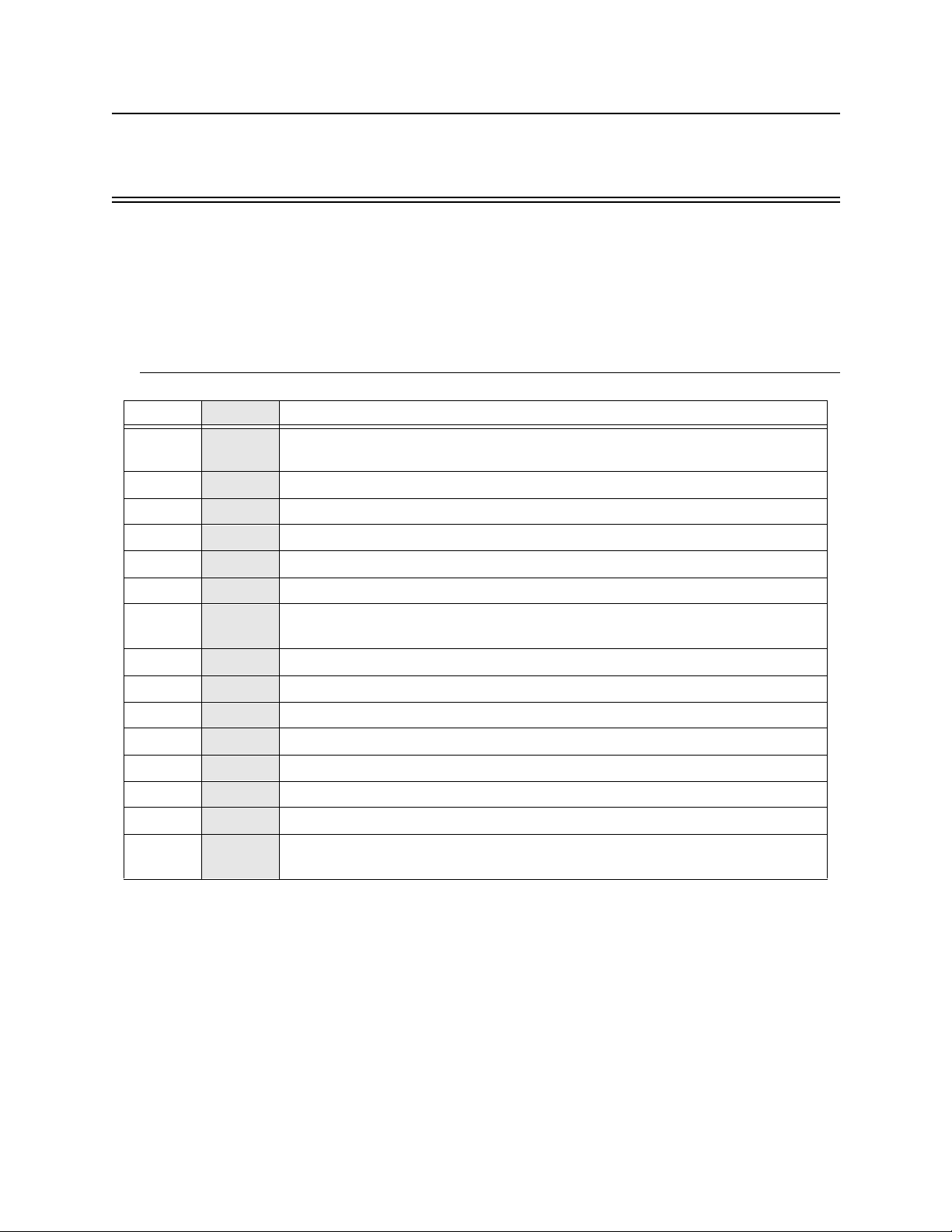

1.1 Overview of System Features

4820 4821 System Feature

3

3

3

3

3

3

3

3

3

3

3

3 Can use the Model 4421 Door Access Module as an expansion device.

3 8 partitions, 8 areas within each partition

3 32 reporting accounts

3 24 touchpads / card readers

3

3 100 User Profiles

3 1800 User Codes

3 50 Time Schedules (with 20 time ranges each)

3 8 Universal Schedules (with 20 time ranges each)

3

400 zones, 16 on 4821/4820 board, additional available with expansion devices

(Model 4815 zone expander, Model 4825 zone expander, Model 4860C touchpad)

8 reporting accounts

One monitored phone line on 4821/4820 board, expandable to two lines with Model

4875 Second Phone Line Expander

20 User Profiles

500 Users Codes

25 Time Schedules (with 20 time ranges each)

2.5 amps power available, expandable to 5.0 amps with 4195 Auxiliary Power

Module

The 4821 and 4820 are shipped with a Model 9227 transformer and 16 Model 7628EOL

resistors (each 4.7 k ohm).

150961 1-1

Page 8

Model 4821/4820 Control/Communicator Installation Manual

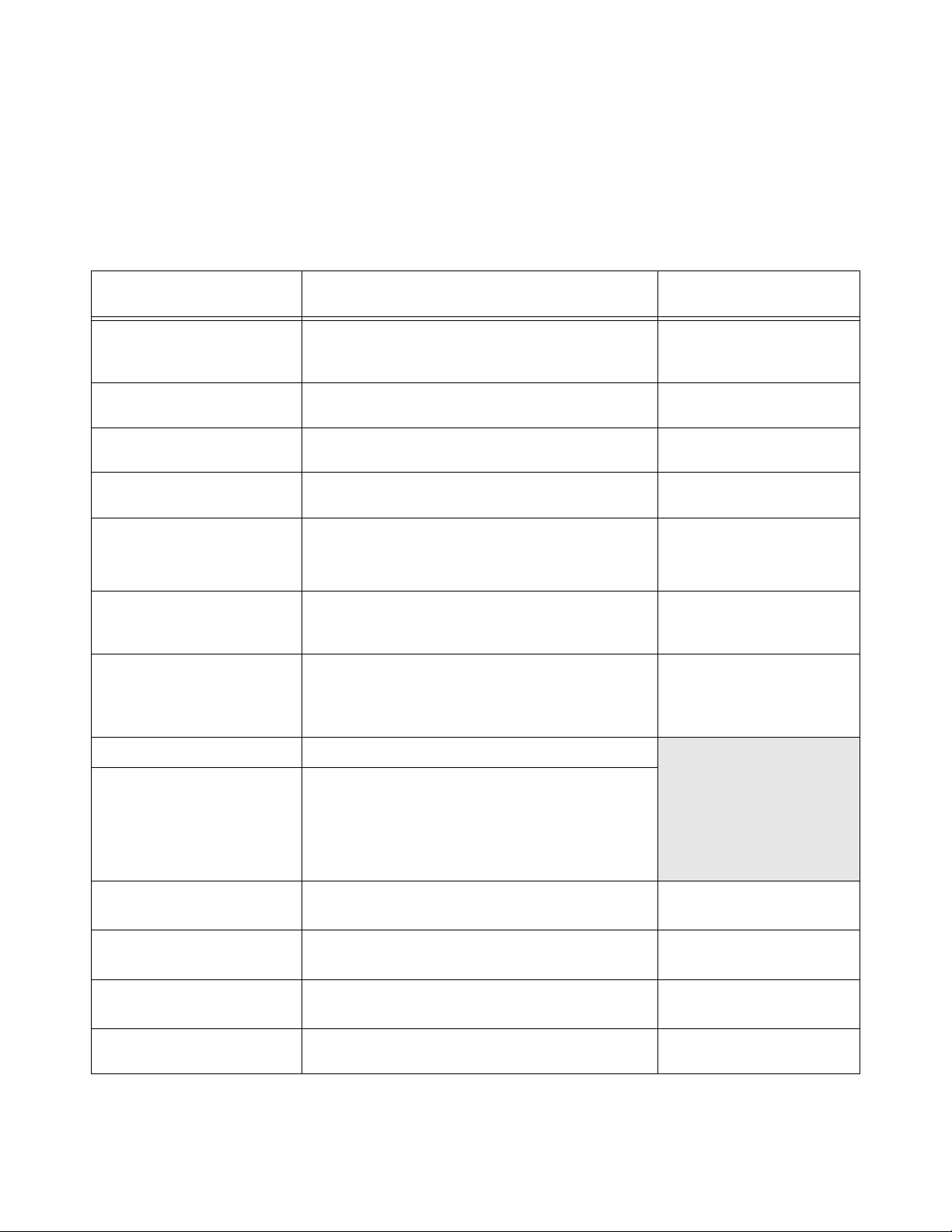

1.1.1 Compatible Modules

Table 1-1 shows the modules available for use with the 4821/4820. The third column of the

chart shows where to find installation instructions for the module. (See Figure 1-1 for a block

diagram or compatible units.)

Table 1-1: Modules Compatible with the Model 4821/4820

Model Description

4195 Auxiliary Power Supply Provides an additional 2.5 amps of power and allows

for a second 12-volt, 7.0 AH battery to be added to the

system.

4815 Serial Zone Expander 128-Zone Serial Expander. Used with SmartSensors.

4111 SmartSensors Serial sensors for use with the 4815.

4114 End-of-Line Resistor 1.43K ohm EOL resistor for use with Model 4111

SmartSensor. The 4114 is required for UL installations.

4181X10 Powerline Interface For connecting X10 modules to the 4880.

(Note: X10 modules are not UL listed for fire and

burglary applications.)

1 2

4205 Slimline Touchpad

For access control installations. Requires the 4421 Door

Access Module (see note 1 below). Cannot be us ed with

the 4820 control panel.

1

4300 Classic Wiegand Swipe

Card Reader

26-bit Wiegand type swipe card reader for indoor or

outdoor use. Has fully encapsulated head to withstand

tampering and environmental damage. Compatible with

4301 swipe cards.

1 3

4301 Wiegand Acces Card

1

4305 Proxima Clip-on Badge

1

Proximity Card,

4306 Proxima

For use with Model 4300 Card Swipe Reader.

For use with Model 4330/4340/4350 readers.

Laminated Vinyl Proximity

1

4308 Proxima Proximity

Card,

Key tag

1

4330 Proxima Mullion Mount

Mullion mount type reader, 26- or 34-bit selectable. Section 3.2.4 of this manual

Proximity Card Reader

1

4340 Proxima Standard Range

Standard range reader, 26- or 34-bit selectable. Section 3.2.4 of this manual

Proximity Card Reader

1

4350 Proxima Medium Range

Medium range reader, 26- or 34-bit selectable. Section 3.2.4 of this manual

Proximity Card Reader

1 3

4421 Door Access Module

Hardware interface for 26-bit or 34-bit Wiegand type

card readers and for the 4205 Slimline Touchpad.

See Section (for more

information)

Section 4.12 of this manual.

4815 Installation

section of

this binder (P/N 150909 ).

4815 Installation

section of

this binder (P/N 150909 ).

4815 Installation

section of

this binder (P/N 150909 ).

4880 Installation

section of

this binder (P/N 150912 ).

Section 3.1 of this manu al

Section 3.2.3 of this manual

Section 3.1 of this manu al

1-2 150961

Page 9

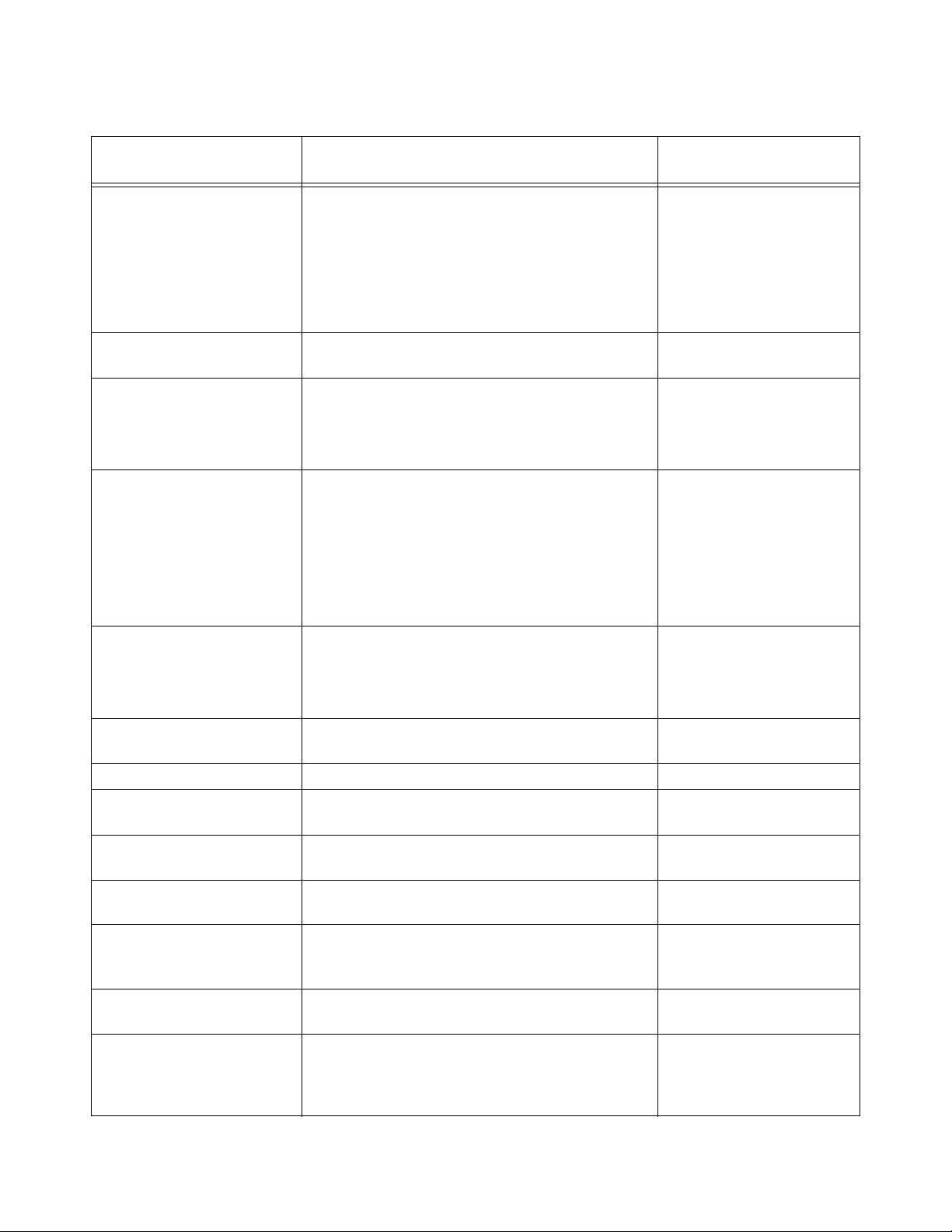

Table 1-1: Modules Compatible with the Model 4821/4820

Introduction

Model Description

4824 Serial/Printer Interface Provides one RS-232 serial por t and one par allel prin ter

port, which can be programmed to output events in

See Section (for more

information)

4824 Installation section of

this binder (P/N 150911).

English text or in either of the reporti ng formats (SIA or

Ademco Contact ID).

Can be used to send data to the panel for on-site

programming or for connection to a PC running

4850ACAS software.

4825 Hardwire Zone Expander 64-Zone Hardwire Expander. 4825 Installation section of

this binder (P/N 150910 ).

4880 Status Output Module Provides 16 outputs and 4 relays that are fully

programmable. Also provides an X10 interface.

4880 Installation section of

this binder (P/N 150912 ).

(Note: X10 modules are not UL listed for fire and

burglary applications.)

4860C Touchpad Fully featured commercial touchpad using an LCD to

annunciate alarms, troubles and other system messages.

Has 2 zone inputs that can be used for hardwiring any

type of zone input, or for door access. Has a built-in

card reader interface.

In this manual, refer to Section

4.14 for installation as a

system touchpad.

Section 3 and 5 for operation

of system touchpad.

Section 4.15.5 for installation

as a system zone.

4860R (gray) and 4860Rx

(bright white) Touchpad

Fully featured residential touchpad using an LCD to

annunciate alarms, troubles and other system messages.

Section 4.14 of this manual for

installat i on instructio ns .

4875 Second Ph one Line

Monitor

Only difference between these two models is color of

plastic. 4860R is gray; 4860Rx is bright white.

Provides termination for second phone line. Required if

two phone lines are used.

Section 4 of this manual for

operation instructions.

Section 4.20.1 of this manual.

4884 Bell Module Provides termination for a supervised bell Section 4.19 of this manual.

4890 Accessory Enclosure Secured cabinet to mount additional modules such as

Section 1.1.2 of this manual.

4815, 4421, 4880 etc. (Required for UL installations.)

5211 Ground Start Relay Required for applications usi ng a ground start telepho ne

Section 4.20.2 of this manual.

network. (Not UL listed.)

6712 Battery 12 VDC 7 amp hour Gell Cell battery for use with the

Section 4.11 of this manual.

4821/4820.

7628 End-of-Line Resistor 4.7 k ohms EOL resistor used for all input zones

Section 4.15 of this manual.

(except 4815 SmartSensor zones).

16 EOLs are shipped with the 4821/4820.

7860 Telephone Cord RJ31X cord for connecting phone line to the 4821/

Section 4.20 of this manual.

4820.

9000 Receiver For use with the SIA-20 format. Section 7 of this manual.

(Section 7 also lists other

receivers compatible with the

4821/4820.)

150961 1-3

Page 10

Model 4821/4820 Control/Communicator Installation Manual

1. Not UL listed with 4820 control panel.

2. Not UL listed for access control.

3. Can not be used with the 4820 control panel.

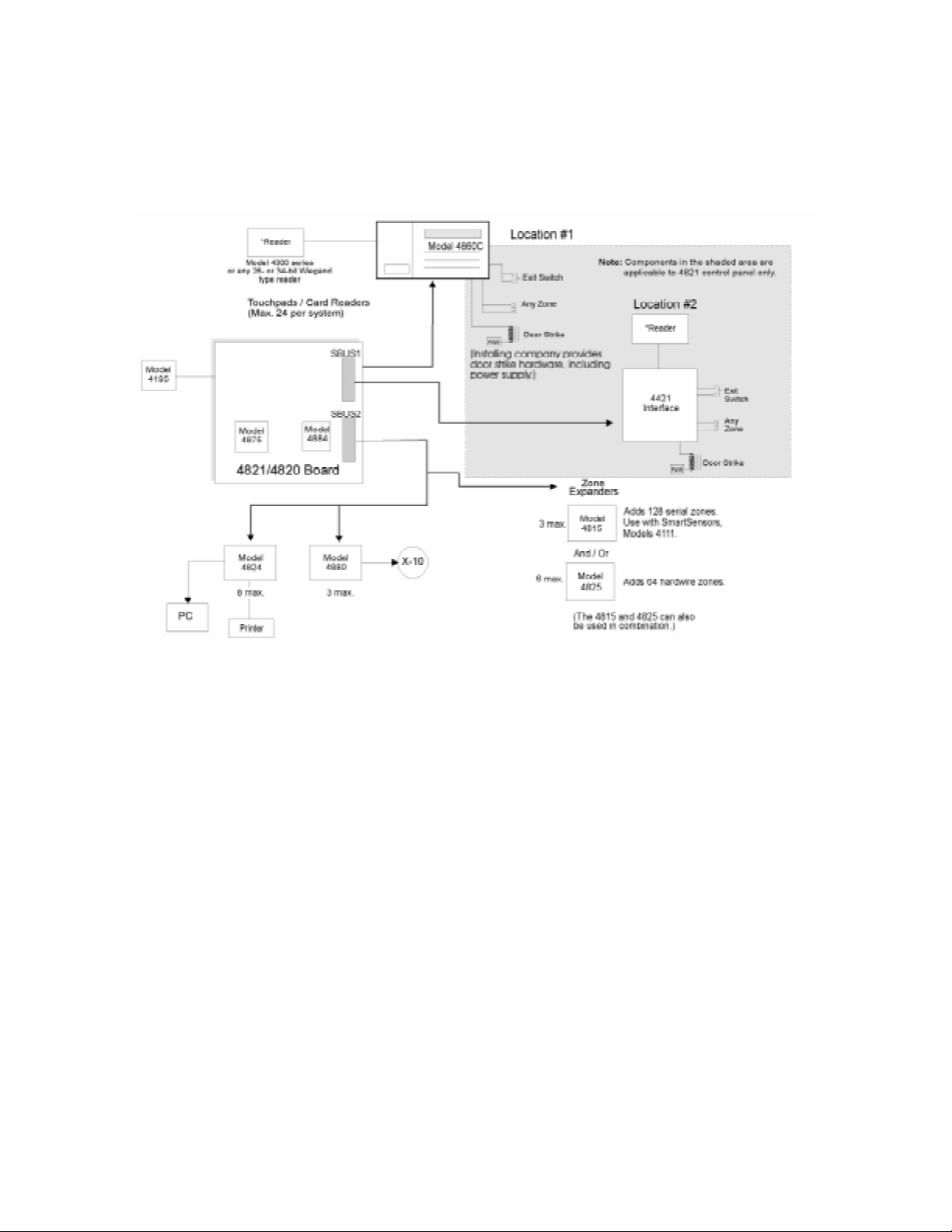

Figure 1-1 Model 4821/4820 and Compatible Modules

1-4 150961

Page 11

Introduction

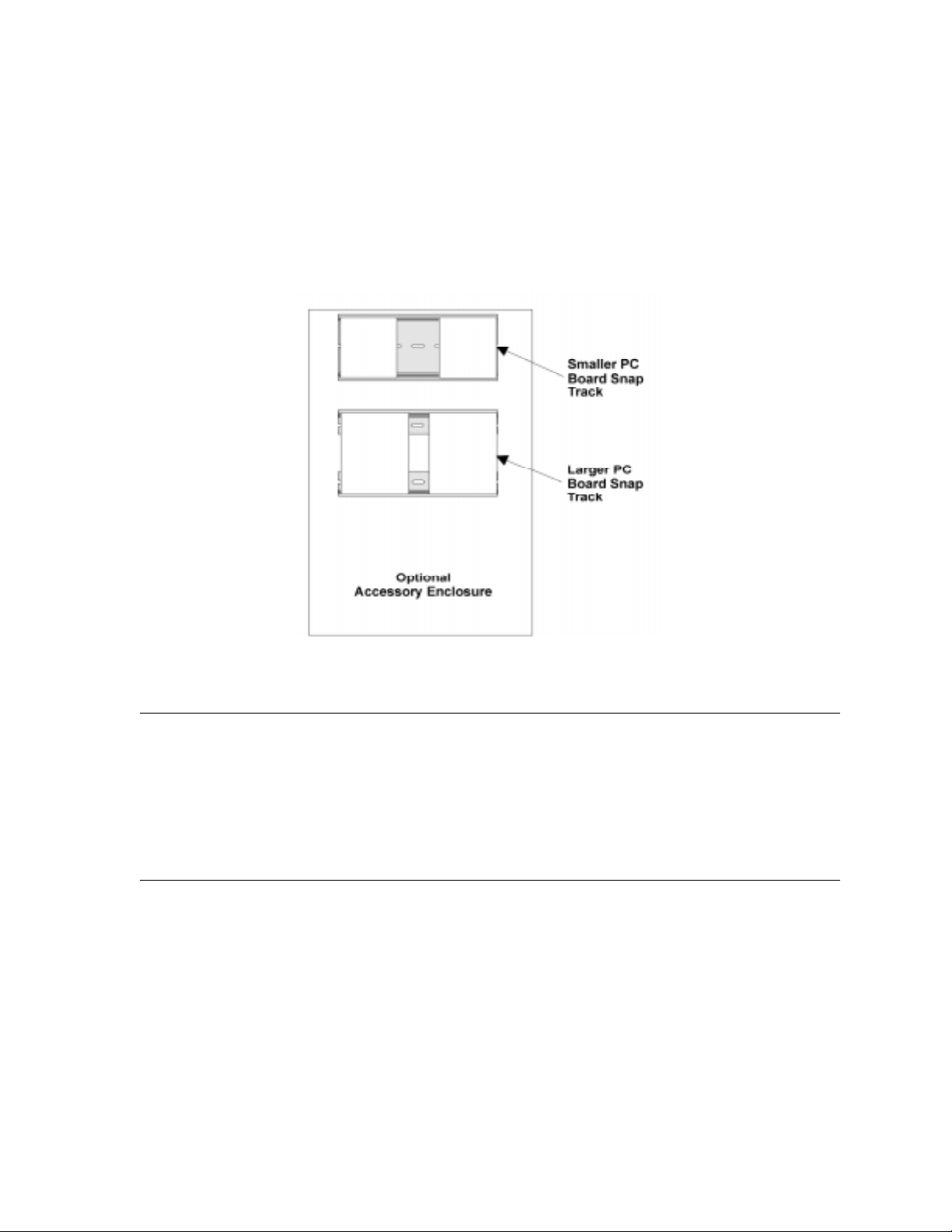

1.1.2 Accessory Enclosure

In applications where more than two additional 4815 modules are to be used in the control

panel “snap tracks”, a model 4890 alarm accessory enclosure is required. (See Section 1.4.3

for UL requirements.) The Model 4890 has the same dimensions as the 4821/4820 control

panel enclosure and contains two additional snap tracks. One snap track is designed for

smaller width boards such as the 4815 control module. The other snap track is sized to

accommodate the larger PC boards such as the 4824, 4880, and 4421 modules.

Figure 1-1 4890 Accessory Enclosure

1.2 How to Use this Manual

The manual uses the following conventions:

• A clear rectangle represents a touchpad button.

• Pages of the manual are numbered by section. For example, a page numbered as “5-1” is

Page 1 of Section 5.

1.3 How to Contact Silent Knight

If you have a question or encounter a problem not covered in this manual, contact: Silent

Knight Technical Support at 800-328-0103 (or 612-493-6455). To order parts, contact Silent

Knight Sales at 800-446-6444 (or 612-493-6435).

150961 1-5

Page 12

Model 4821/4820 Control/Communicator Installation Manual

1.4 Agency Requirements

1.4.1 Telephone Requirements

If requested by the telephone company, the following information must be provided before

connecting this device to the phone lines:

A. Manufacturer: Silent Knight Security Systems

B. Model Number: 4821/4820

C. FCC Registration Num be r: AC6USA-2275 5-AL-E

D. Type of jack (to be installed by the

telephone company):

Ringer equivalence: 0.9B

RJ31X

This device may not be connected directly to coin telephones or party line services.

This device cannot be adjusted or repaired in the field. In case of trouble with the device,

notify the installing company or return the device to the manufacturer:

Silent Knight Security Systems

7550 Meridian Circle

Maple Grove, MN 55369-4927

800-328-0103 or 612-493-6455

The telephone company may make changes in its facilities, equipment, or procedures that

could affect the operation of the equipment. If this happens, the telephone company will

provide advance notice to allow you to make the necessary modifications to maintain

uninterrupted service.

1.4.2 FCC Warning

This device has been verified to comply with FCC Rules Part 15. Operation is subject to the

two following conditions: (1) This device may not cause radio interference, and (2) This

device must accept any interference received including interference that may cause undesired

operation.

1-6 150961

Page 13

Introduction

1.4.3 UL Requirements

If installed in accordance with these requirements, the Model 4821/4820 is UL listed for

Grade A Mercantile, Local Police Station Connect with Basic Line Security, and Grade B and

C Central Station Service.

Follow the requirements below if you are installing a UL listed application. See Section

1.4.3.1 for Household Fire and Burglary Warning System installation requirements. See

Section 1.4.3.2 for Grade A Mercantile installation requirements.

1. The Model 4860C (commercial) or 4860R (residential) touchpad must be used. Each

SBUS must have at least one touchpad connected (minimum of two touchpads per installation).

2. Entry delays must not be longer than 45 seconds. An exit delay must not be longer than 60

seconds.

3. All panic zones (including touchpad panic zones) must be programmed as silent and invisible.

Note: Silent and invisible reports can be seen by pressing status or reviewing the event history.

4. The Audible Trouble Alert When Armed option (programmed in Area Menu) must be

selected.

5. Do NOT select the following optional features:

Automatic closing or opening (programmed in the Area Menu)

Swinger Bypass Timeout (programmed in Area Menu)

6. Partitions are allowed in UL burglary installations only if the protected premises falls

under one ownership and the operation of a single authority. An example of an acceptable

installation is a common building operated by one company which may need to subdivide

the system to allow independent entry and exit. A strip mall is an example of an application that would

zones. (See Item 9. below for additional information about partitioning.)

7. If the cross-alarm feature is used, it must be used only by detectors that share a common

field of view.

8. A complete functional checkout of the system must be performed any time the system is

programmed or reprogrammed. (Zone bypassing or other temporary changes necessary for

troubleshooting are an exception to this requirement.)

9. Bells must be the primary source of alarm annunciation. Speakers can be used as an additional source. Grade C Central Station installations are an exception; bells are not required

in these installations. In a multi-partition system, bells must be protected by a

24-hour circuit.

not

be allowed in a UL installation. Partitioning cannot be used for fire

10. Opening and closing signals must be enabled in a Central Station installation.

150961 1-7

Page 14

Model 4821/4820 Control/Communicator Installation Manual

11. In applications requiring more than two modules 4815 to be located in the control panel

snap track, a model 4890 alarm accessory enclosure is required. (See Section 1.1.2.)

12. Do not eliminate the default I/O programming script. Doing so could cause the bell sounds

to be deleted from the system.

Note: The script can be modified to include add itional functions, but the default statements must remain intact.

1.4.3.1 Household Burglary Warning System

If you are installing the 4821/4820 in a UL listed residential installation, follow the

requirement below in addition to those listed in Section 1.4.3.

The Audio Shutdown Delay option must be programmed as 4 minutes.

1.4.3.2 Grade A Mercantile

For a Grade A Mercantile listing, follow the requirements below in addition to those listed in

Section 1.4.3.

1. You must program a time schedule for auto testing to occur (programmed in Time

Schedules Menu).

2. The Audio Shutdown Delay option must be programmed to 15 minutes.

3. A listed tamper switch must protect the inside front door of the enclosure. This switch

must be connected to an intrusion input zone of the control unit which is programmed as a

perimeter zone.

4. All unused knockout holes on the cabinet must be plugged using bolts and washers.

(Model 7600 is a kit available from Silent Knight for this purpose.) See Section 4.7 for

installation instructions.

5. Four pan head screws #8x3”, type AB (thread forming tapping screws) must be placed in

the 4821/4820 cabinet cover to increase the panel’s attack resistance.

6. A separately listed Ademco AB-12 Bell in Box must be used with the control unit.

7. The tamper switches of the alarm bell must be connected to a 24-hour zone. No other initiating devices may be connected to this loop. The outer housing of the bell box must be

grounded. The bell circuit should be installed in accordance with UL requirements.

8. All bell wiring must be run in its own conduit and must be connected to the control unit

using its own knockout hole.

1-8 150961

Page 15

Introduction

1.4.3.3 Commercial & Residential Fi re Digital Alarm Communicator

Transmitter (DACT) UL 864, NFPA 72 (Chapter 4)

The DACT listing allows the 4821/4820 to be used to monitor an existing local fire alarm

control and/or a sprinkler system. For the 4821/4820 to be used as a DACT, the following

requirements must be complied with:

Hardware:

• A minimum of one 4860C Commercial Touchpad.

• Two 4165 Transformer Covers.

• A 4195 Auxiliary Power Supply.

• A 4875 Dual Phone Line Module.

• A 4884 Bell Module.

• Two 6712 12 VDC 7AH Standby Battery or Equivalent.

• Power switch bypass jumpers must not be cut.

Programming:

The following options must be selected when programming the control panel. (See Section 6

Programming for programming information.):

1. In the Low AC Report Time (Section 6.3.1.1) must be set between 6 and 12 hours.

2. In the Phone Line Enabled (Section 6.3.1.2) 2 Phone Lines option must be must be

selected.

3. In the Ground Start Telephone Network Used option (Section 6.3.1.2) must remain disabled.

4. In the Phone Line Monitor Enabled option (Section 6.3.1.2) the Line Monitor option must

be selected.

1.4.3.4 Access Control UL-294

All 4860C touchpads must be located within the protected premises. The 4820 is not li sted for

access control.(See Section 3 for access control installation information.)

150961 1-9

Page 16

Model 4821/4820 Control/Communicator Installation Manual

1-10 150961

Page 17

Section 2

Quick Start

This section is intended to help you determine if any problems exist with the system you are

about to install. Perform the steps below in the order shown here.

1. Wire a touchpad to one of the four-wire serial buses (SBUS). See Section 4.14 for more

information. (See Note below.)

2. Plug in the transformer and apply AC.

3. Hook up the battery.

4. The touchpad will initialize. Several messages, including the touchpad seria l number, will

display for approximately one second. When the message “482x Engaged” (x indicates

that the display would read 1 for a 4821, or 0 for a 4820) is displayed, it means the system

has booted up successfully. The default date and time is displayed.

5. Set system date and time. You may use the default code to test the system. See the instructions on the next page for more information.

If you are able to set the date and time successfully , it means the sy stem is up and running.

6. From here you can send your programmable options to the panel, if you have programmed

them through the Model 5580 Upload-Download Software. (See Section 2.2.)

Note: To at tach a t emporar y touchp ad to th e system, you do not need to kn ow its se rial n umber. To per manentl y

attach any SBUS device, including a touchpad, you must enter its serial number into the system.

150962 2-1

Page 18

Model 4821/4820 Control/Communicator Installation Manual

2.1 Setting System Time and Date

To set the time:

1. Press

2. At the menu prompt, enter to select “Time”.

3. Enter digit(s) for hour in 24-hour military format, then press .

4. Enter digit(s) for minute, then .

1 ENTER

[Code]. (Installer Code is factory-programmed as 1234.)

1

ENTER

ENTER

Note that if the “Auto DST Adjustment” feature has been enabled, a message will display

when you set the time.

Example:

To change the system time to 3:45 p.m., the keystrokes are:

1 ENTER 1

1 5 ENTER

4 5 ENTER

[Code]

To set the date:

1 ENTER

1. [Code]

2. At the menu prompt, enter to select “Date”.

3. Enter digit(s) for month, then press .

4. Enter digit(s) for date, then press .

5. Enter four digits for year, then press .

2

ENTER

ENTER

ENTER

Example:

To change the system date to July 15, 1996, the keystrokes are:

1 ENTER 2

[Code]

7 ENTER

1 5 ENTER

1 9 9 6 ENTER

2-2 150962

Page 19

2.2 Sending Data to the Panel

See Section 5.10 of this manual for complete information about communication.

Quick Start

1. Press

4 ENTER

[Installer or Maintenance Code]

2. At the menu, select:

1

for Internal Phone. This option is for downloading via the phone lines.

2

for 4824 Modem. With this type of communication, a Hayes compatible modem is con-

nected to both the 4824 and the PC, allowing for faster data transmission.

3

for 4824 Direct. This option is for directly connecting the 4824 to the computer using a

null modem cable (both the computer and the 4821/4820 are on-site).

3. If you select either 4824 option (2 or 3), you will be prompted to select the 4824 from the

list of 4824s installed in the system.

4. If the phone number that displays is not correct, enter the correct digits and press . (If

the phone number is correct, press to bypass this step.) If you have selected the 4824

ENTER

ENTER

Direct option, this step will not appear.

5. If the Account number that displays is not correct, enter the correct digits and press .

(If the account number is correct, press to bypass this step.)

ENTER

ENTER

6. The system will attempt to communicate. If the communication attempt was successful,

the panel will re-initialize. Do not power the system down during the re-initialization

period.

Note: If the 5580 has no task in its queue, the panel will always send an upload. The 5580 must have a download

in its queue for this account in order for the download to occur.

150962 2-3

Page 20

Model 4821/4820 Control/Communicator Installation Manual

S/N000006034821H.

1

2.3 Identifying Serial Numbers and R evis io n Leve ls

This section describes how to determine the levels of hardware and 4821/4820 software that

are used with your panel.

2.3.1 Operating System Revision Level

Press to see a display of the revision date.

4 STAT

16:51:03

Oct 19 1995

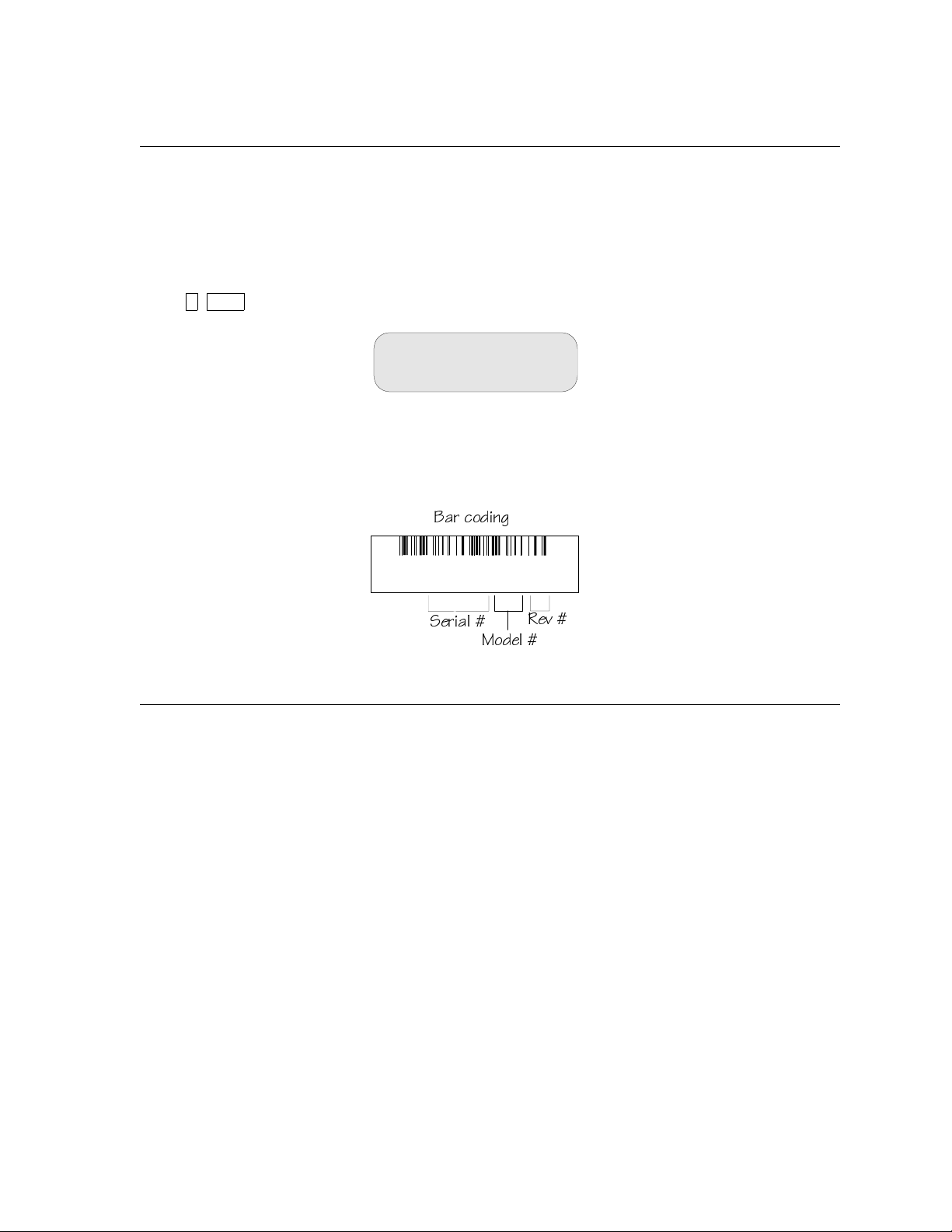

2.3.2 Hardware Revision Levels and Serial Numbers

Hardware revision levels and serial numbers are printed on labels on the circuit board. Look

for “S/N” followed by an 8-digit number.

2Qb S_TY^W

CUbYQ\

=_TU\

BUf

2.4 Installation Records

You can use the following pages to keep a record of options programmed for an installation.

You may want to use the charts for up-front planning of your installations. Copy the pages as

needed for all installations.

2-4 150962

Page 21

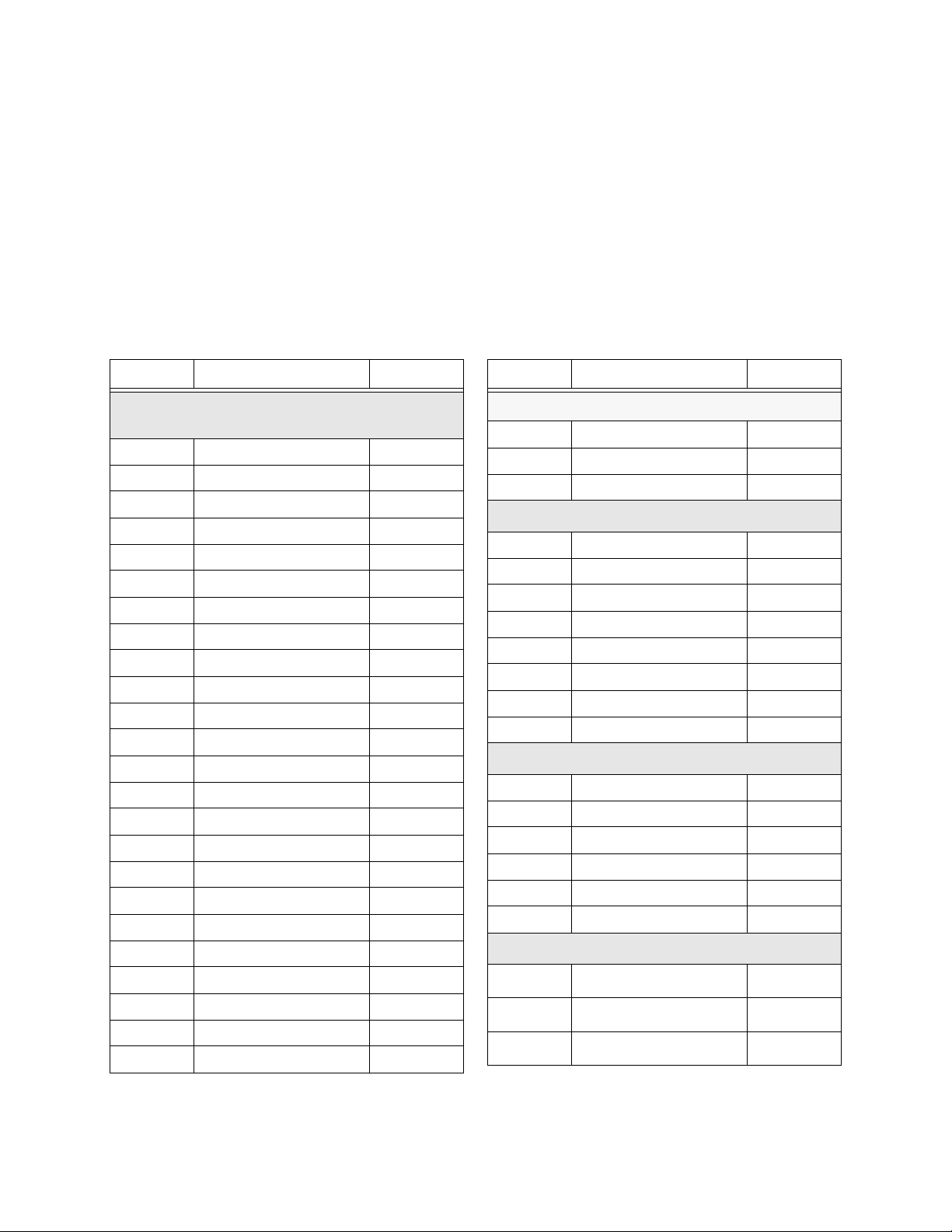

2.4.1 Serial Number Quick Reference

Use the chart below to keep track of hardware device serial numbers.

Customer Name __________________________________

Location ________________________________________

Account Number _________________________________

Installation Code _________________________________

Quick Start

Device # Description Serial #

4421 Door Access Module /

4860 Touchpads

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Device # Description Serial #

4880 Status Output Module

1

2

3

4824 Serial/Parallel Module

1

2

3

4

5

6

7

8

4825Hardwire Zone Expander

1

2

3

4

5

6

4815Serial Zone Expander

1

2

3

150962 2-5

Page 22

Model 4821/4820 Control/Communicator Installation Manual

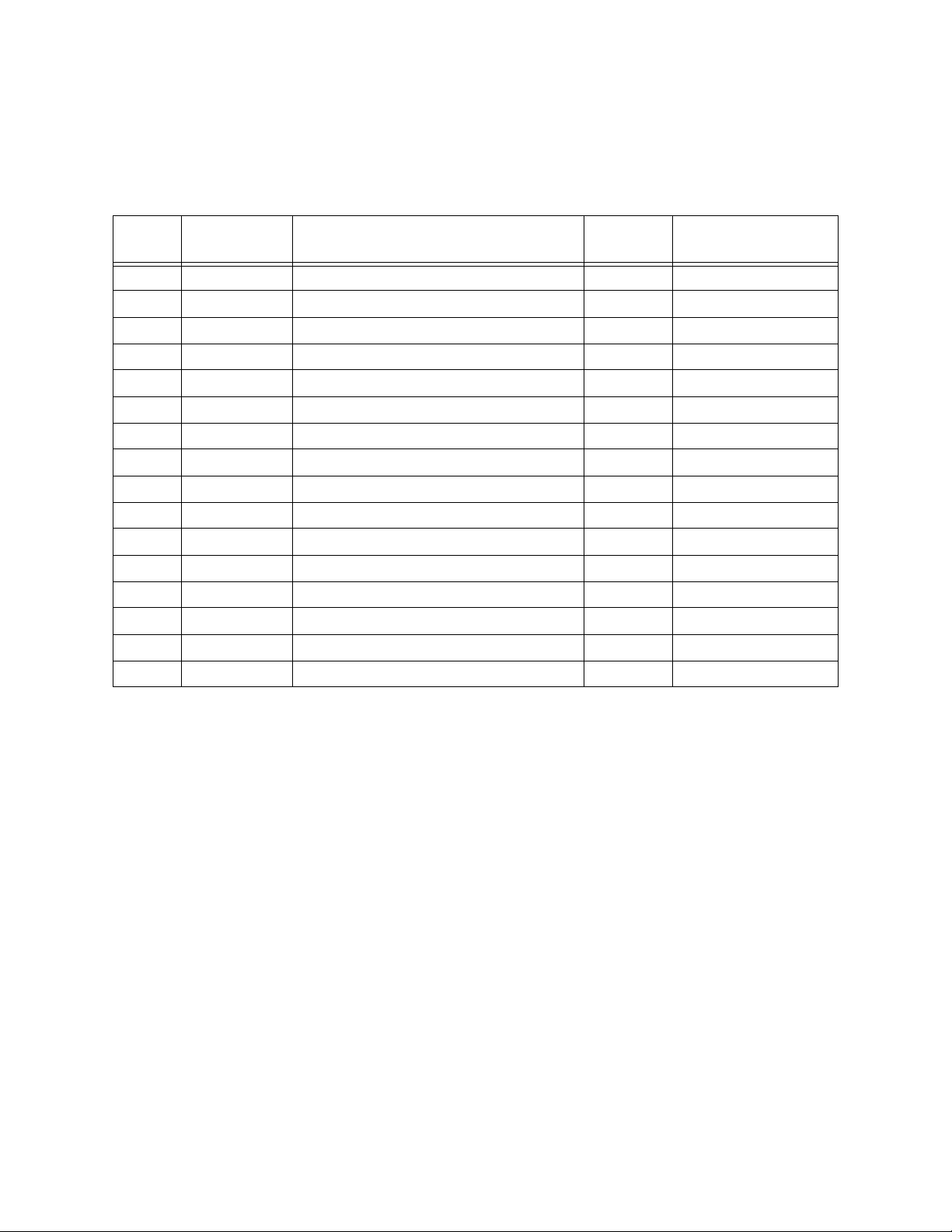

2.4.1.1 Zone Record

Use the charts in this section to record zone identification information.

Table 2-1: Internal Zones

Zone #

Hardware

Point

1 1 2 3 4 5 6 7 8

2 1 2 3 4 5 6 7 8

3 1 2 3 4 5 6 7 8

4 1 2 3 4 5 6 7 8

5 1 2 3 4 5 6 7 8

6 1 2 3 4 5 6 7 8

7 1 2 3 4 5 6 7 8

8 1 2 3 4 5 6 7 8

9 1 2 3 4 5 6 7 8

10 1 2 3 4 5 6 7 8

11 1 2 3 4 5 6 7 8

12 1 2 3 4 5 6 7 8

13 1 2 3 4 5 6 7 8

14 1 2 3 4 5 6 7 8

15 1 2 3 4 5 6 7 8

16 1 2 3 4 5 6 7 8

Location Partition # Areas

2-6 150962

Page 23

4825 Hardwire Zone Expander______Serial Number____________Device Number_____

Zone H/W Pt Location Partition Areas Zone H/W Pt Location Partition Areas

1 1 2 3 4 5 6 7 8 33 1 2 3 4 5 6 7 8

2 1 2 3 4 5 6 7 8 34 1 2 3 4 5 6 7 8

3 1 2 3 4 5 6 7 8 35 1 2 3 4 5 6 7 8

4 1 2 3 4 5 6 7 8 36 1 2 3 4 5 6 7 8

5 1 2 3 4 5 6 7 8 37 1 2 3 4 5 6 7 8

6 1 2 3 4 5 6 7 8 38 1 2 3 4 5 6 7 8

7 1 2 3 4 5 6 7 8 39 1 2 3 4 5 6 7 8

8 1 2 3 4 5 6 7 8 40 1 2 3 4 5 6 7 8

9 1 2 3 4 5 6 7 8 41 1 2 3 4 5 6 7 8

10 1 2 3 4 5 6 7 8 42 1 2 3 4 5 6 7 8

11 1 2 3 4 5 6 7 8 43 1 2 3 4 5 6 7 8

12 1 2 3 4 5 6 7 8 44 1 2 3 4 5 6 7 8

13 1 2 3 4 5 6 7 8 45 1 2 3 4 5 6 7 8

14 1 2 3 4 5 6 7 8 46 1 2 3 4 5 6 7 8

15 1 2 3 4 5 6 7 8 47 1 2 3 4 5 6 7 8

16 1 2 3 4 5 6 7 8 48 1 2 3 4 5 6 7 8

17 1 2 3 4 5 6 7 8 49 1 2 3 4 5 6 7 8

18 1 2 3 4 5 6 7 8 50 1 2 3 4 5 6 7 8

19 1 2 3 4 5 6 7 8 51 1 2 3 4 5 6 7 8

20 1 2 3 4 5 6 7 8 52 1 2 3 4 5 6 7 8

21 1 2 3 4 5 6 7 8 53 1 2 3 4 5 6 7 8

22 1 2 3 4 5 6 7 8 54 1 2 3 4 5 6 7 8

23 1 2 3 4 5 6 7 8 55 1 2 3 4 5 6 7 8

24 1 2 3 4 5 6 7 8 56 1 2 3 4 5 6 7 8

25 1 2 3 4 5 6 7 8 57 1 2 3 4 5 6 7 8

26 1 2 3 4 5 6 7 8 58 1 2 3 4 5 6 7 8

27 1 2 3 4 5 6 7 8 59 1 2 3 4 5 6 7 8

28 1 2 3 4 5 6 7 8 60 1 2 3 4 5 6 7 8

29 1 2 3 4 5 6 7 8 61 1 2 3 4 5 6 7 8

30 1 2 3 4 5 6 7 8 62 1 2 3 4 5 6 7 8

31 1 2 3 4 5 6 7 8 63 1 2 3 4 5 6 7 8

32 1 2 3 4 5 6 7 8 64 1 2 3 4 5 6 7 8

Page 24

4815 Expander Loop1 Addresses Serial Number ________Device Number____

Zone H/W Pt Location Partition Areas Zone H/W Pt Location Partition Areas

Loop1, Addr 1 1 2 3 4 5 6 7 8 Loop1, Addr 33 1 2 3 4 5 6 7 8

Loop1, Addr 2 1 2 3 4 5 6 7 8 Loop1, Addr 34 1 2 3 4 5 6 7 8

Loop1, Addr 3 1 2 3 4 5 6 7 8 Loop1, Addr 35 1 2 3 4 5 6 7 8

Loop1, Addr 4 1 2 3 4 5 6 7 8 Loop1, Addr 36 1 2 3 4 5 6 7 8

Loop1, Addr 5 1 2 3 4 5 6 7 8 Loop1, Addr 37 1 2 3 4 5 6 7 8

Loop1, Addr 6 1 2 3 4 5 6 7 8 Loop1, Addr 38 1 2 3 4 5 6 7 8

Loop1, Addr 7 1 2 3 4 5 6 7 8 Loop1, Addr 39 1 2 3 4 5 6 7 8

Loop1, Addr 8 1 2 3 4 5 6 7 8 Loop1, Addr 40 1 2 3 4 5 6 7 8

Loop1, Addr 9 1 2 3 4 5 6 7 8 Loop1, Addr 41 1 2 3 4 5 6 7 8

Loop1, Addr 10 1 2 3 4 5 6 7 8 Loop1, Addr 42 1 2 3 4 5 6 7 8

Loop1, Addr 11 1 2 3 4 5 6 7 8 Loop1, Addr 43 1 2 3 4 5 6 7 8

Loop1, Addr 12 1 2 3 4 5 6 7 8 Loop1, Addr 44 1 2 3 4 5 6 7 8

Loop1, Addr 13 1 2 3 4 5 6 7 8 Loop1, Addr 45 1 2 3 4 5 6 7 8

Loop1, Addr 14 1 2 3 4 5 6 7 8 Loop1, Addr 46 1 2 3 4 5 6 7 8

Loop1, Addr 15 1 2 3 4 5 6 7 8 Loop1, Addr 47 1 2 3 4 5 6 7 8

Loop1, Addr 16 1 2 3 4 5 6 7 8 Loop1, Addr 48 1 2 3 4 5 6 7 8

Loop1, Addr 17 1 2 3 4 5 6 7 8 Loop1, Addr 49 1 2 3 4 5 6 7 8

Loop1, Addr 18 1 2 3 4 5 6 7 8 Loop1, Addr 50 1 2 3 4 5 6 7 8

Loop1, Addr 19 1 2 3 4 5 6 7 8 Loop1, Addr 51 1 2 3 4 5 6 7 8

Loop1, Addr 20 1 2 3 4 5 6 7 8 Loop1, Addr 52 1 2 3 4 5 6 7 8

Loop1, Addr 21 1 2 3 4 5 6 7 8 Loop1, Addr 53 1 2 3 4 5 6 7 8

Loop1, Addr 22 1 2 3 4 5 6 7 8 Loop1, Addr 54 1 2 3 4 5 6 7 8

Loop1, Addr 23 1 2 3 4 5 6 7 8 Loop1, Addr 55 1 2 3 4 5 6 7 8

Loop1, Addr 24 1 2 3 4 5 6 7 8 Loop1, Addr 56 1 2 3 4 5 6 7 8

Loop1, Addr 25 1 2 3 4 5 6 7 8 Loop1, Addr 57 1 2 3 4 5 6 7 8

Loop1, Addr 26 1 2 3 4 5 6 7 8 Loop1, Addr 58 1 2 3 4 5 6 7 8

Loop1, Addr 27 1 2 3 4 5 6 7 8 Loop1, Addr 59 1 2 3 4 5 6 7 8

Loop1, Addr 28 1 2 3 4 5 6 7 8 Loop1, Addr 60 1 2 3 4 5 6 7 8

Loop1, Addr 29 1 2 3 4 5 6 7 8 Loop1, Addr 61 1 2 3 4 5 6 7 8

Loop1, Addr 30 1 2 3 4 5 6 7 8 Loop1, Addr 62 1 2 3 4 5 6 7 8

Loop1, Addr 31 1 2 3 4 5 6 7 8 Loop1, Addr 63 1 2 3 4 5 6 7 8

Loop1, Addr 32 1 2 3 4 5 6 7 8 Loop1, Addr 64 1 2 3 4 5 6 7 8

Page 25

4815 Expander Loop2

Zone H/W Pt Location Partition Areas Zone H/W Pt Location Partition Areas

Loop2, Addr 1 1 2 3 4 5 6 7 8 Loop2, Addr 33 1 2 3 4 5 6 7 8

Loop2, Addr 2 1 2 3 4 5 6 7 8 Loop2, Addr 34 1 2 3 4 5 6 7 8

Loop2, Addr 3 1 2 3 4 5 6 7 8 Loop2, Addr 35 1 2 3 4 5 6 7 8

Loop2, Addr 4 1 2 3 4 5 6 7 8 Loop2, Addr 36 1 2 3 4 5 6 7 8

Loop2, Addr 5 1 2 3 4 5 6 7 8 Loop2, Addr 37 1 2 3 4 5 6 7 8

Loop2, Addr 6 1 2 3 4 5 6 7 8 Loop2, Addr 38 1 2 3 4 5 6 7 8

Loop2, Addr 7 1 2 3 4 5 6 7 8 Loop2, Addr 39 1 2 3 4 5 6 7 8

Loop2, Addr 8 1 2 3 4 5 6 7 8 Loop2, Addr 40 1 2 3 4 5 6 7 8

Loop2, Addr 9 1 2 3 4 5 6 7 8 Loop2, Addr 41 1 2 3 4 5 6 7 8

Loop2, Addr 10 1 2 3 4 5 6 7 8 Loop2, Addr 42 1 2 3 4 5 6 7 8

Loop2, Addr 11 1 2 3 4 5 6 7 8 Loop2, Addr 43 1 2 3 4 5 6 7 8

Loop2, Addr 12 1 2 3 4 5 6 7 8 Loop2, Addr 44 1 2 3 4 5 6 7 8

Loop2, Addr 13 1 2 3 4 5 6 7 8 Loop2, Addr 45 1 2 3 4 5 6 7 8

Loop2, Addr 14 1 2 3 4 5 6 7 8 Loop2, Addr 46 1 2 3 4 5 6 7 8

Loop2, Addr 15 1 2 3 4 5 6 7 8 Loop2, Addr 47 1 2 3 4 5 6 7 8

Loop2, Addr 16 1 2 3 4 5 6 7 8 Loop2, Addr 48 1 2 3 4 5 6 7 8

Loop2, Addr 17 1 2 3 4 5 6 7 8 Loop2, Addr 49 1 2 3 4 5 6 7 8

Loop2, Addr 18 1 2 3 4 5 6 7 8 Loop2, Addr 50 1 2 3 4 5 6 7 8

Loop2, Addr 19 1 2 3 4 5 6 7 8 Loop2, Addr 51 1 2 3 4 5 6 7 8

Loop2, Addr 20 1 2 3 4 5 6 7 8 Loop2, Addr 52 1 2 3 4 5 6 7 8

Loop2, Addr 21 1 2 3 4 5 6 7 8 Loop2, Addr 53 1 2 3 4 5 6 7 8

Loop2, Addr 22 1 2 3 4 5 6 7 8 Loop2, Addr 54 1 2 3 4 5 6 7 8

Loop2, Addr 23 1 2 3 4 5 6 7 8 Loop2, Addr 55 1 2 3 4 5 6 7 8

Loop2, Addr 24 1 2 3 4 5 6 7 8 Loop2, Addr 56 1 2 3 4 5 6 7 8

Loop2, Addr 25 1 2 3 4 5 6 7 8 Loop2, Addr 57 1 2 3 4 5 6 7 8

Loop2, Addr 26 1 2 3 4 5 6 7 8 Loop2, Addr 58 1 2 3 4 5 6 7 8

Loop2, Addr 27 1 2 3 4 5 6 7 8 Loop2, Addr 59 1 2 3 4 5 6 7 8

Loop2, Addr 28 1 2 3 4 5 6 7 8 Loop2, Addr 60 1 2 3 4 5 6 7 8

Loop2, Addr 29 1 2 3 4 5 6 7 8 Loop2, Addr 61 1 2 3 4 5 6 7 8

Loop2, Addr 30 1 2 3 4 5 6 7 8 Loop2, Addr 62 1 2 3 4 5 6 7 8

Loop2, Addr 31 1 2 3 4 5 6 7 8 Loop2, Addr 63 1 2 3 4 5 6 7 8

Loop2, Addr 32 1 2 3 4 5 6 7 8 Loop2, Addr 64 1 2 3 4 5 6 7 8

Page 26

Model 4821 Control/Communicator Installation Manual

2-10 150962

Page 27

Section 3

Access Control Installation and Operation

This section of the manual describes the installation of access control hardware manufactured

by Silent Knight and applies to the 4821 control panel only. Section 4 of this m anual describes

installation of other required or optional hardware devices.

IMPORTANT!

All circuits are power limited, Class II.

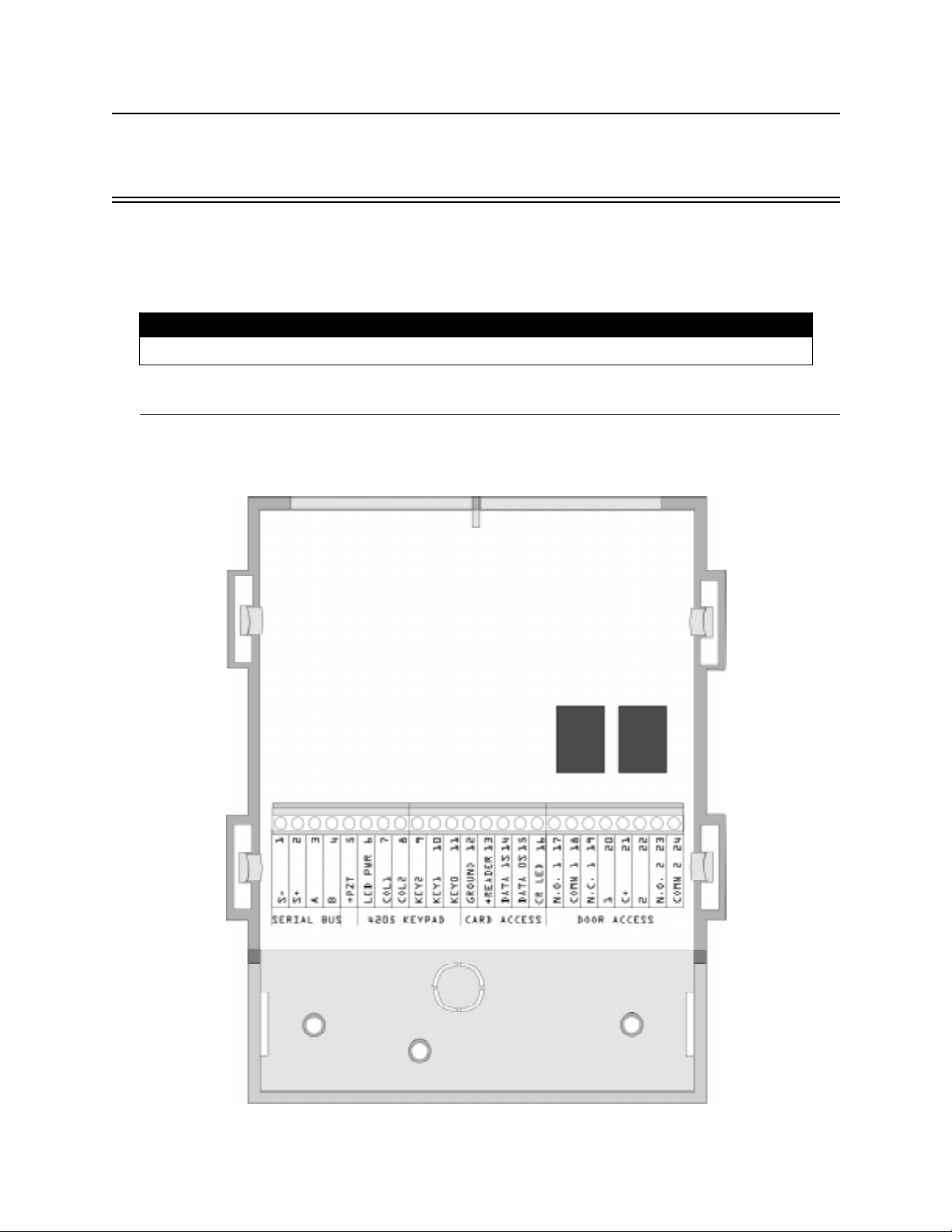

3.1 Model 4421 Installation

Figure 3-1 shows the layout of the 4421 board. Table 3-1 (next page) is a terminal strip

description.

Figure 3-1 Model 4421 Board Layout

150963 3-1

Page 28

Model 4821/4820 Control/Communicator Installation Manual

Table 3-1: Model 4421 Terminal Description

Name

Wire

Color

Terminal Description Electrical Rating

1 S- Expansion Bus (-) 0 VDC (circuit ground)

2 S+ Expansion Bus (+) 12 VDC, 1 Amp max.

3 A Expansion Bus (data) 5 VDC

4 B Expansion Bus (data) 5 VDC

5 +PZT PZT power output 4 VDC, 10 mA

6 LED PWR Brown 4205 LED output 8.3 VDC, 10 mA

7 COL1 Red 4205 column 1 output

8 COL0 Orange 4205 column 0 output

9 KEY2 Yellow 4205 row 4 input

10 KEY1 Green 4205 row 1 input

11 KEY0 Blue 4205 row 0 input

12 GROUND Black &

Circuit Ground

Shield

13

Red Card reader power output 5 VDC, 75 mA

+READER

14 DATA 1s White Card reader data 1’s input

15 DATA 0s Green Card reader data 0’s input

16 CR LED Brown Card reader LED output 3.75 VDC, 25 mA

17 N.O. 1 Relay Contact (Normally Open) #1 2.5 Amps max. @ 24 VDC

18 COMN 1 Relay Contact (Common) #1

19 N.C. 1 Relay Contact (Normally Closed) #1

20 1 Zone Input 1 14 VDC, 1.5 mA

21 C+ Zone power 12 VDC, 3.0 mA

22 2 Zone Input 2 14 VDC, 1.5 mA

23 N.O. 2 Relay Contact (Normally Open) #2 2.5 Amps max. @ 24 VDC

24 COMN 2 Relay Contact (Common) #2

3-2 150963

Page 29

Access Control Installation and Operat ion

3.1.1 Model 4421 Connection to the 4821

The 4421 Interface connects to the 4821 panel via the SBUS. Connect the 4421 to the panel as

shown in Figure 3-2. See Section 4 for complete information about SBUS device connections.

Figure 3-2 Wiring Diagram 4421of N to the Control Panel

150963 3-3

Page 30

Model 4821/4820 Control/Communicator Installation Manual

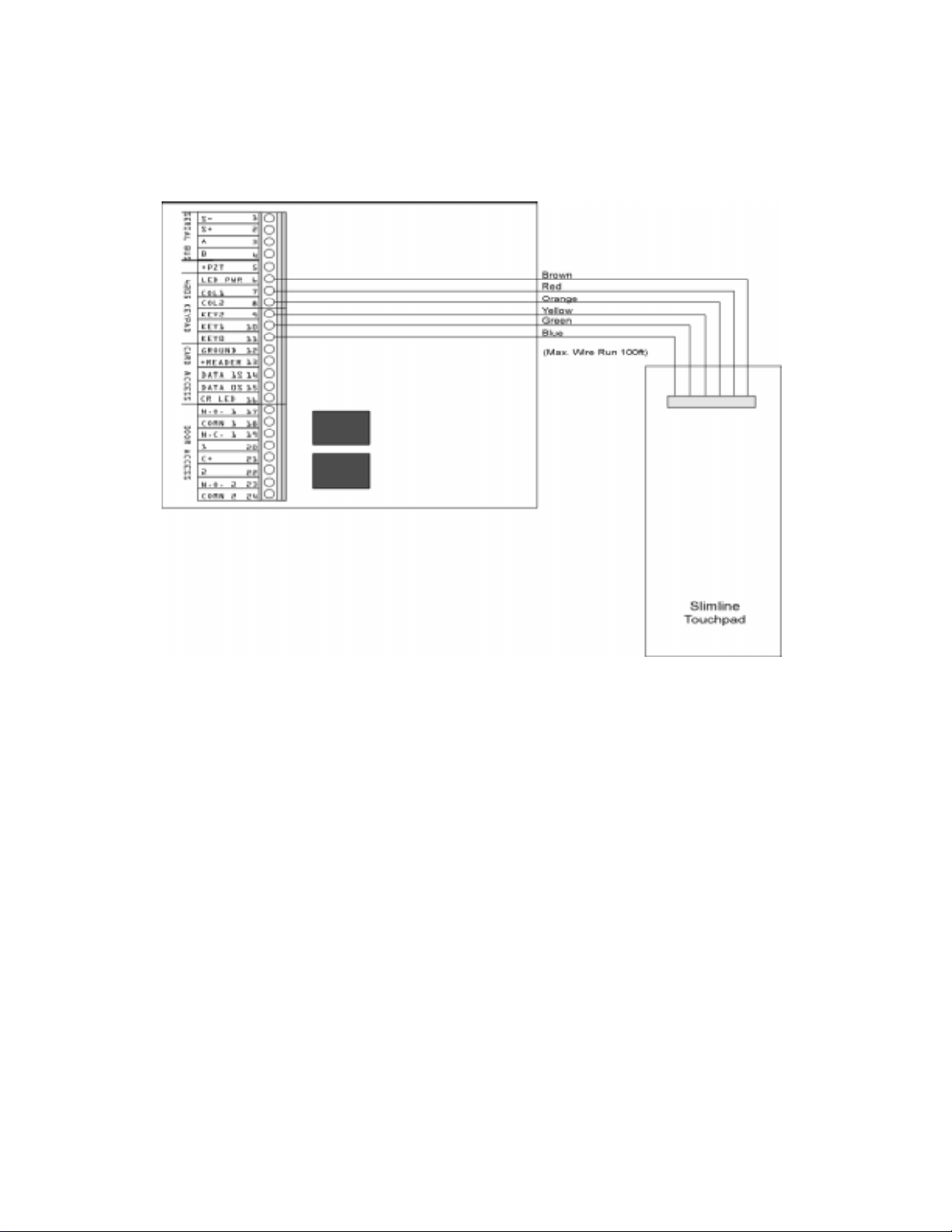

3.1.2 4205 Touchpad Connection to 4421

The 4205 Access Control Touchpad is connected to the 4421 as shown in Figure 3-3.

Figure 3-3 Model 4421 to 4205 Connection

Note: The Model 4205 is not UL listed for access control.

3-4 150963

Page 31

Access Control Installation and Operat ion

3.2 Card/Proximity Reader Installation

The Model 4421 Access Control Interface is compatible with 26-bit (plus a leading and trailing parity bits), 24-bit (plus a start-bit and a trailing parity bit), 32-bit, 34-bit (32 data plus a

start-bit and a trailing parity bit), and 34-bit (32 data plus a leading and trailing parity bit)

Wiegand-format readers. (See Figure Figure 3-4.) The following sections describe how to

install the 4300 series readers. Refer to device manual for other manufacturers’ products.

32 Bit

26 or 34 Bit

Figure 3-4 Block Diagram of Wiegand Formats

3.2.1 Card Reader Specifications

The 4300 Swipe Card Reader, and the 4330, 4340, and 4350 Proximity Readers require

shielded cable. The chart below shows the specifications.

Max. Reader to Receiver

Distance

Gauge Distance

24 AWG

18 AWG

24 AWG

18 AWG

24 AWG

18 AWG

24 AWG

18 AWG

85 m (270’)

137 m (450’)

85 m (270’)

137 m (450’)

85 m (270’)

137 m (450’)

85 m (270’)

137 m (450’)

Model

4300 5 VDC

4330 12 VDC

4340 12 VDC

4350 12 VDC

Supply

Voltage

(+ or -5%)

(+ or -5%)

(+ or -5%)

(+ or -5%)

Max.

Supply

Current

25 mA 48 mA 5 mA

80 mA 48 mA 5 mA

80 mA 48 mA 5 mA

150 mA 48 mA 5 mA

Output

Sink

Output

Source

Current

Output

Pulse

Width

20 µs typ.

20 µs typ.

20µs typ.

20µs typ.

Operating

Temp.

°

-40

to 130° F

-22° to 149° F

°

-22

to 149° F

°

-22

to 149° F

3.2.2 Mounting

Mount the 4300 series readers on any flat vertical surface.

Use two #10 bolts to mount the reader. Once the reader is mounted, cover the reader front by

applying the pressure-sensitive dress panel or label.

When mounting the proximity readers, use flat-head screws. Drill a one-quarter inch (0.6 cm)

or larger hole for the cable. Refer to the mounting template included with the reader for location of screw holes.

150963 3-5

Page 32

Model 4821/4820 Control/Communicator Installation Manual

If the card readers will be in a location where they will be exposed to snow, mount in a vertical position to prevent accumulated snow from clogging the card slot.

3-6 150963

Page 33

Access Control Installation and Operat ion

3.2.3 Wiring the 4300 Swipe Card Reader

Wire the swipe card reader to the 4421 Door Access Module as shown in Figure 3-5. The card

reader LED is on when the door relay is activated. The LED is off when the relay is deactivated or when there is no power. (The 4421 LED has the same meaning.)

Figure 3-5 Model 4421 to 4300 Connection

150963 3-7

Page 34

Model 4821/4820 Control/Communicator Installation Manual

3.2.4 Wiring the 4330, 4340 and 4350 ProximityReaders

Wire the Proximity Reader to the 4421 Door Access Module as shown in Figure 3-6. The card

reader LED is on when the door relay is activated. The LED is off when the relay is deactivated or there is no power. (The 4421 LED has the same meaning.)

Figure 3-6 Model 4330, 4340 and 4350 Connection

3-8 150963

Page 35

Access Control Installation and Operat ion

3.3 Wiring the 4860C Touchpad for Door Access

The 4860C commercial touchpad can be used as a door access station. The zone inputs on the

back of the touchpad can be wired to a door contact or could be used for any other purpose.

*Use Cable Assembly

130375

P/N

*Use Cable Assembly

130378

P/N

Figure 3-7 Wiring the 4860C Touchpad for Door Access

Connecting wires are included with the card readers.

N-750-

150963 3-9

Page 36

Model 4821/4820 Control/Communicator Installation Manual

ENTR

Table 3-2: Connector Descriptions

P2 (Card Reader) P4 (Door Access)

Pin

Number

1 Circuit Ground Black 1 C+ is +12V Brown

2 LED Brown 2 Zone Input 1 Red

3 Data 0’s Green 3 Relay Contact

4 Data 1’s White 4 Relay Contact

5 +5 VDC Red 5 Relay Contact

Description

(P/N 130375)

Wire Color

Pin

Number

6 Not used Blue

7 Zone Input 2 Violet

8 C+ is +12V Gray

Description

(Common)

(Normally Open)

(Normally Closed)

(P/N 130378)

Wire Color

Orange

Yellow

Green

3.4 Access Control Operation

This section of the manual describes operation of access control features. An overview of

these operations is included in the Operations Summary in Section 5 of this manual.

3.4.1 Access Control Touchpad Menus

DOOR BYPS DOOR ENTR

The

The

DOOR BYPS

Section 3.4.3 for more information). The

passback status (see Section 3.4.6). A brief summary of end-user operations are in section

3.4.2.

and

menu is for controlling door lock/unlock schedules from the touchpad (see

menus are for maintenance level access control operations.

DOOR

menu is for controlling users’ anti-

3-10 150963

Page 37

Access Control Installation and Operat ion

3.4.2 End-User Operation

Normal end-user door access operation (accessing a door, opening an outside door from

within, and so on) are described in the Census 4821 Owner’s Manual (P/N 150952). They are

summarized below:

Opening an access controlled door Present your card to the card reader. You will hear a c lick and the red

LED will turn green indicating that the door can be opened.

OR

DOOR

Press plus your PIN.

Opening an access controlled door for

another person (granting access)

Opening a high security door High security doors are used to secure areas within an installation

This operation would apply at a door station where a receptionist,

security guard, or other person “buzzes in” another person after

identification.

DOOR

Enter the device ID number of the door, then press

PIN. You may hear a click or buzzing sound indicating that the door

can be opened.

that not all employees are allowed to access. Both a card

are required to gain access.

Present your card. The touchpad will display

your PIN.

ENTER CODE

and your

and

a PIN

. Enter

150963 3-11

Page 38

Model 4821/4820 Control/Communicator Installation Manual

3.4.3 Manually Changing Door Schedules

DOOR BYPS

The menu is for changing door access schedules from the touchpad. You can use

this feature to temporarily override door schedules. Any operations made using the touchpad

will be overridden the next time the schedule for the door takes effect.

• From the touchpad assigned to the current door, press, [Maintenance or

DOOR BYPS

Installer’s Code]. The status of the door will display for a few seconds then a menu with

the options shown in the chart below will begin scrolling.

•From any touchpad, enter the device number of the door,

Installer’s Code]. For example, to access Door #4, press [Maintenance or

DOOR BYPS

4 DOOR BYPS

[Maintenance or

Installer’s Code].

The status of the door will display for a few seconds then a menu with the options shown in

the chart below will begin scrolling.

0 - Unlock Door Unlocks the door until the next scheduled lock time. Use this option to unlock a door

that is currently scheduled to be locked. All users will be able to access the door.

9 - Lock Door Locks the door until the next scheduled unlock time. Use this option to lock a door

that is currently scheduled to be unlocked. No users will be able to access the door

without a card or a code.

1 - To Sched Restores the selected door to its scheduled setting.

2 - All Sched Restore all door s to their scheduled settings.

3 - All Locked Lock all doors. Overrides all door schedules.

4 - Select Door Select another door to lock or unlock.

5 - Access Door Open a door to allow individual access (not the same as unlocking).

STAT - STATUS View the status of the door.

3.4.4 Viewing Door Status

Press to view the door status. A list of doors and their locked/unlocked status

displays.

3-12 150963

DOOR STAT

Page 39

Access Control Installation and Operat ion

3.4.5 Anti-Passback Feature

The anti-passback feature prevents users from giving access to others by “passing back” their

access cards. In a typical anti-passback installation, users must “register” themselves by

accessing a door programmed as Entry when they enter the building. They will only be

allowed to leave from a door programmed as Exit. A user cannot access an Entry door twice

consecutively. The menu allows users to be “forgiven” (allowed access even if

they have not exited properly) and provides other anti-passback options. See Section 3.4.6.

Figure 3-8 below shows an example of anti-passback application. In this example, employees

enter through an anti-passback doors (must enter and exit through separate doors). The manager’s entrance is not an anti-passback door, allowing employees to come and go freely.

Note: The anti-passback feature must be enabled through programming. See Section 6.

DOOR ENTR

Figure 3-8 Sample Anti-Passback Application

150963 3-13

Page 40

Model 4821/4820 Control/Communicator Installation Manual

3.4.6 Anti-Passback Operations

DOOR ENTR

The menu is for controlling the anti-passback feature. It allows you to change

users’ anti-passback status so that they can access or be prevented from accessing the system.

When you press [Maintenance or Installer’s Code], the following menu options

DOOR ENTR

display.

1 - User Status Use to check the user’s current status (for example, In or Out).

2 - Forgive Forgive means allow the user to enter or exit a door even though the system has

detected a problem with the users’ anti-passback status.

3 - Lockout User Change the user’s status so he or she will be unable to enter the building.

4 - Num User In Use this option to see how many users have “In” status.

5 - Forgive All Reset anti-passback status and allow all users to enter the next time they attempt.

MUTE - Exit Press to exit the menu.

3.4.7 Bulk Loading Access Cards

Bulk loading of access card allows you to enter multiple successive access cards in one procedure. Follow these steps to bulk load access cards:

1. This can be done by pressing .

7 ENTR

The display on the touchpad will read:

(OUFS 6FMFDUJPO (OUFS 6FMFDUJPO

&IBOHF VTFST

2. Press then enter the user ID you wish to start with followed by .

2 ENTR

(then)

%VML MPBE

The display on the touchpad will read:

3SPGJMF

3. When prompted, enter a profile number followed by the key.

ENTR

The display on the touchpad will read:

&BSE GPS ,E ;;;;

Note: XXXX equals the number entered in step 2.

4. Present a valid access card to the card reader.

The access card will be added to the syste m imm ediate ly followed by a success be ep. The

user ID will increase by one.

Note: If the card is already in the system, a failure beep sounds and you are taken back to step 2.

5. Repeat step 4 until all access cards are presented.

3-14 150963

Page 41

Access Control Installation and Operat ion

3.5 Egress Fail-safe Override Application

An egress fail-safe override is an optional configuration that can be used to give the installation an additional means of exit through access controlled doors in the case of power loss or a

system failure.

Use the following diagrams to configure your system for egress fail-safe override.

Note: In each of the diagrams the egress device can be a motion detector, a crash bar, a button, a beam, etc.

Figure 3-9 Fail-safe Override N.C. Configuration to a Door Access Module

150963 3-15

Page 42

Model 4821/4820 Control/Communicator Installation Manual

Note: Input 1 must be programmed for “Not re ady” on short.

Figure 3-10 Fail-safe Override N.O. Configuration to a Door Access Module

3-16 150963

Page 43

Access Control Installation and Operat ion

Figure 3-11 Fail-safe Override N.C. Configuration to a Touchpad

Figure 3-12 Fail-safe Override N.O. Configuration to a Touchpad

150963 3-17

Page 44

Model 4821/4820 Control/Communicator Installation Manual

3-18 150963

Page 45

Section 4

Control Panel Description and Installation

Warning:

To avoid the risk of electrical shock, do not apply power to the Model 4821/4820 until

you have read these instructions carefully.

This section describes how to install the control panel and some accessories, including compatible add-on modules, such as smoke detectors and signaling devices. In all cases, refer to

the compatible module’s installation manual for complete information. (Some Silent Knight

compatible modules have separate installation manuals. See Section 1.1.1 for location of

installation instructions for Silent Knight products.)

4.1 Environmental Specifications

• Temperature range is 32° to 120° F (0° to 49° C).

• Indoor use only.

• 85 percent non-condensing humidity.

• Non-corrosive environment.

4.2 Electrical Specifications

Line voltage: 110-120 VAC, 60 Hz

Transformer output:

(Model 9227)

Current requirements: 3.0A

Total alarm current: 2.25A

IMPORTANT!

All circuits are power limited, Class II, except for the battery leads.

18 VAC, 50 VA

150964 4-1

Page 46

Model 4821/4820 Control/Communicator Installation Manual

4.3 Board Layout

Figure 4-1 shows the Model 4821/4820 printed circuit board.

Figure 4-1 Model 4821/4820 Printed Circuit Board

4-2 150964

Page 47

Control Panel Description an d Installation

4.4 Terminal Strip Description

Table 4-1: Control Panel Terminal Descriptions

Name Terminal Description Electrical Ratings

AC AC Input 18 VAC, 60 Hz, 50VA

AC AC Input 18 VAC, 60 Hz, 50VA

EARTH Earth Ground 0 VDC

N.O. Relay Contact (Normally Open) 2.5 Amps max. @ 24VDC

COM Relay Contact (Common)

+12V Accessory Power (+) 12 VDC, 1 Amp max.

+SMK Smoke Detector Power (+) 12 VDC, 1 Amp max.

GND Circuit Ground 0 VDC

EXT SPK External Speaker (+) 8 ohm, 15 watt min. rating speaker output

INT1 SPK- Internal Speaker #1 (-)

INT+ Internal Speaker (+) (1) 8 ohm, 5 watt, or (3) 45 ohm, 1 watt

INT2 SPK- Internal Speaker #2 (-)

Must be connected to power limited sources only

S2- SBUS #2 (-) 0 VDC

S2+ SBUS #2 (+) 12 VDC, 1 Amp max.

A2 SBUS #2 (data) 5 VDC

B2 SBUS #2 (data) 5 VDC

S1- SBUS #1 (-) 0 VDC

S1+ SBUS #1 (+) 12 VDC, 1 Amp max.

A1 SBUS #1 (data) 5 VDC

B1 SBUS #1 (data) 5 VDC

1 Zone 1 Input 12 VDC, 50mA max.

.079 VDC Nominal

(Note that this zone is rated differently from other

inputs.)

C+ Zones 1 and 2 Power Output All zone power outputs: 12 VDC

Use ESL Model 449CT 4-wire smoke detector.

150964 4-3

Page 48

Model 4821/4820 Control/Communicator Installation Manual

Table 4-1: Control Panel Terminal Descriptions

Name Terminal Description Electrical Ratings

2 Zone 2 Input For zone 2-16 inputs:

3 Zone 3 Input

C+ Zones 3 and 4 Power Output

4 Zone 4 Input

5 Zone 5 Input

C+ Zones 5 and 6 Power Output

6 Zone 6 Input

7 Zone 7 Input

C+ Zones 7 and 8 Power Output

8 Zone 8 Input

9 Zone 9 Input

C+ Zones 9 and 10 Power Output

10 Zone 10 Input

12 VDC max. at 1.4 mA

11 Zone 1 1 Inp ut

C+ Zones 11 and 12 Power Output

12 Zone 12 Input

13 Zone 13 Input

C+ Zones 13 and 14 Power Output

14 Zone 14 Input

15 Zone 15 Input

C+ Zones 15 and 16 Power Output

16 Zone 16 Input

T-RING Telco Ring

T-TIP Telco Tip

P-RING Premises Ring

P-TIP Premises Tip

4.5 Power Limitin g Ci rcuits

The Model 4821/4820 is power-limited for over-current protection. When you remove the

short, circuits self-restore.

4-4 150964

Page 49

Control Panel Description an d Installation

4.6 Power Switch

The power switch is disabled by the power switch bypass jumpers, to enable the power switch

cut both jumpers. Make sure the power switch is off when you are installing the system. See

Figure 4-1 for location of the power switch and power switch bypass jumpers.

Note: The power switch bypass jumpers can not be cut for UL 864 and NFPA (Chapter 4) fire installations. (See

Section 1.4.3.5.)

4.7 Mounting the Model 4821/4820 Panel

When selecting a location to mount the Model 4821/4820, consider the following:

• Panel must be accessible to main drop wiring runs.

• Panel must be located well within the secured area, but must be accessible for testing and

service.

• See environmental specifications described in Section 4.1.

If you are installing a UL Grade A Mercantile installation, all unused knockout holes must be

plugged using bolts and washers. (Model 7600 is a kit available from Silent Knight for this

purpose. 6 sets per package.) Use the following steps to plug the knockout holes:

1. Remove all unused knockouts.

2. Install the carriage bolt and washers as shown in the diagram below. The smallest washer

should be placed

inside

the hole in the cabinet.

3. Firmly tighten the wing nut.

CABINET

CARRIAGE

BOLT

LARGE

WASHER

SMALL

WASHER

KNOCKOUT HOLE

Figure 4-2 Knockout Plug Installation

LARGE

WASHER

WING

NUT

150964 4-5

Page 50

Model 4821/4820 Control/Communicator Installation Manual

4.8 Wire Routing

Figure 4-3 is an example of how Model 4821/4820 wires should be routed through the cabinet

in order to maintain one-quarter inch spacing between power limited and non-power limited

circuits.

Figure 4-3 Sample Wire Routing

4-6 150964

Page 51

Control Panel Description an d Installation

4.9 Current Draw Worksheets

The current draw worksheets in this section are provided to help you calculate the number and

size of devices that will be used in an installation. Copy these sheets as needed.

Figure 4-4 and Figure 4-5 are sample worksheets. (They have already been filled out to serve

as examples.) Blank worksheets for your installations are in Sections 4.9.2 and 4.9.3.

4.9.1 Sample Worksheets

Figure 4-4 Sample Silent Knight Module Current Worksheet

150964 4-7

Page 52

Model 4821/4820 Control/Communicator Installation Manual

Figure 4-5 Sample Compatible Module Current Worksheet

4-8 150964

Page 53

Control Panel Description an d Installation

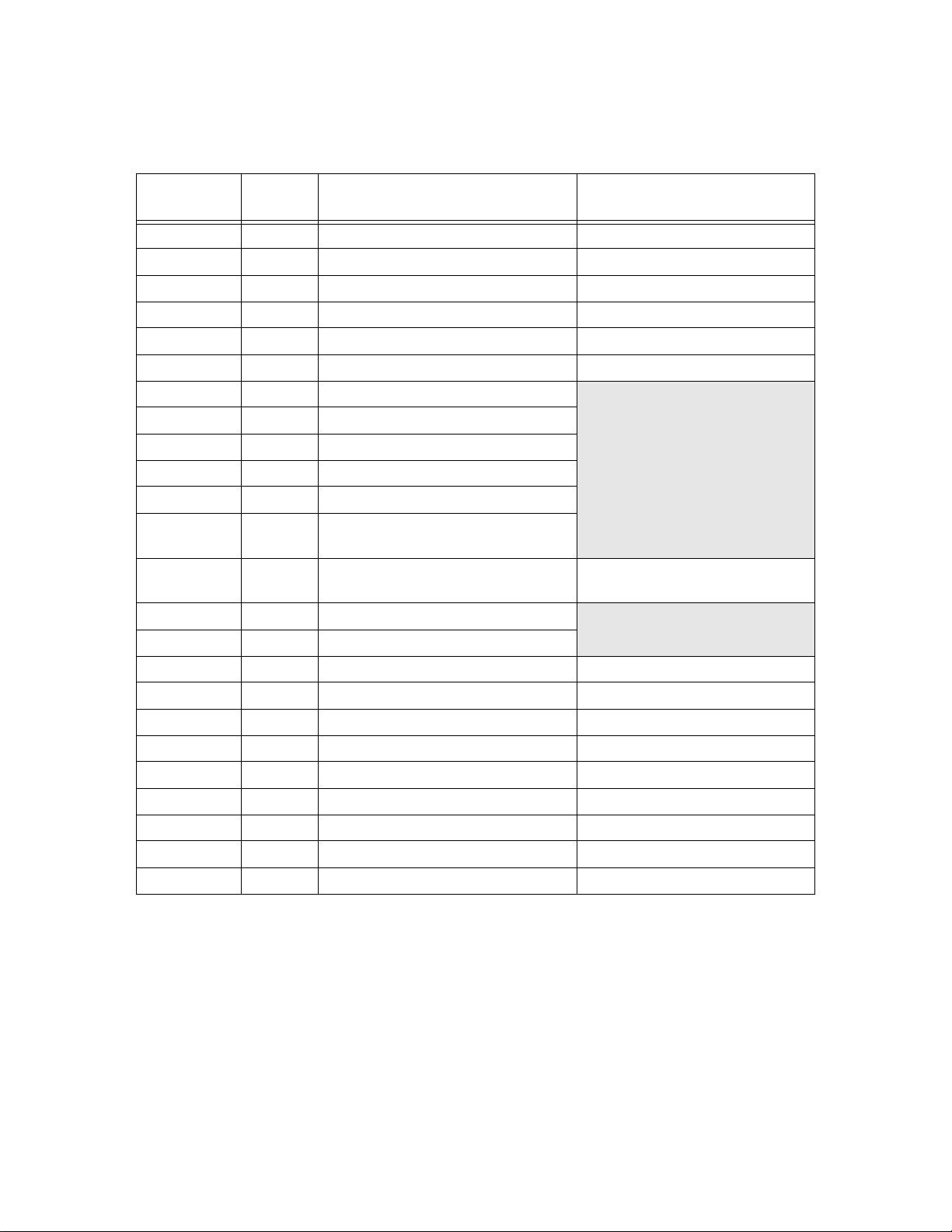

4.9.2 Worksheet for Silent Knight Modules

Table 4-2: Current Draw Worksheet for Optional Modules

Device

Model 4821/4820 Control/

Communicator

4421 Door Access Module

4860 Series Touchpad

4205 Touchpad (used with

the 4421)

4880 Status Output Module

4824 Serial/Parallel Interface

4815 Zone Expander

4825 Zone Expander

4875 Dual Phone Line

Monitor

4884 Bell Module

4300 Swipe Card Reader

4330 Proximity Reader

4340 Proximity Reader

4350 Proximity Reader

5211 Ground Start Relay

Number of

Devices

1 Standby: 100 mA 100 mA

(1 max.) Alarm: 120 mA 120 mA

(24 max.) Alarm 40 mA mA

(24 max.) Alarm: 90 mA mA

(24 max.) Alarm: 10 mA mA

(3 max.) Alarm: 140 mA mA

(8 max.) Alarm: 40 mA mA

(3 max.) Alarm: 80 mA mA

(6 max.) Alarm: 80 mA mA

1 Standby: 0 mA mA

(1 max.) Alarm: 18 mA mA

1 Standby: 5 mA mA

(1 max.) Alarm: 60 mA mA

(24 max.) Alarm: 25 mA mA

(24 max.) Active: 80 mA mA

(24 max.) Active: 80 mA mA

(24 max.) Active: 150 mA mA

1 Standby: 0 mA mA

(1 max.) Alarm: 18 mA mA

Current per Device

Standby 25 mA mA

Standby: 48 mA mA

Standby: 10 mA mA

Standby: 20 mA mA

Standby: 40 mA mA

Standby: 80 mA mA

Standby: 80 mA mA

Standby: 25 mA mA

Standby: 45 mA mA

Standby: 45 mA mA

Standby: 100 mA mA

Subtotal of current rati ngs for Silent Knight devices

Total

Standby

Current

mA

Standby

Total Alarm

Current

mA

Alarm

Note: Total of all 4421s and 4860s combined.

Note: The 4884 shares its power wi th the auxiliary output. The auxiliary output is rated at 1A total current for

all devices.

150964 4-9

Page 54

Model 4821/4820 Control/Communicator Installation Manual

4.9.3 Worksheet for Auxiliary Devices (not Silent Knight)

Use Table 4-3 for recording current draw for other devices compatible with the 4821/4820

that are not manufactured by Silent Knight (for example, signaling devices and smoke detectors). Copy this page if you need additional lines to list devices.

Table 4-3: Current Draw Worksheet for Other Devices

Row B

Number of

Device

Smoke Detectors

Signaling Dev i ces

Other Devices

Devices Current per Device

Refer to device manual for current ratings.

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Refer to device manual for alarm current ratings. Standby current is always 0 mA.

Alarm: mA

Alarm: mA mA

Alarm: mA mA

Alarm: mA mA

Refer to device manual for current ratings.

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Subtotal current ratings of all devices in Table 4-3.

Total

Standby

Current

mA

Standby

Total Alarm

Current

mA

mA

Alarm

Row A

Row C

Subtotal current ratings of SK devices from Table 4-2.

Total current ratings of all devices in system (Row A + Row B)

mA

Standby

mA

Standby

Alarm

Alarm

4-10 150964

mA

mA

Page 55

Control Panel Description an d Installation

4.9.4 Battery Calculation Worksheet

To ensure 24-hour standby, the total standby current must not exceed:

285 mA if a battery only is used.

450 mA if the Model 4195 Auxiliary Power Supply is used.

Total alarm current must not exceed 2.25 Amps.

Table 4-4: Battery Calculation Worksheet

Device

A

B

C Number of standby hours (for example, 24) H

D Multiply lines B and C AH

E

F Multiply lines B and E AH

G Add lines D and F AH

H

Total current used by 4821/4820

(from Table 4-3, Row C)

Total current ratings converted to amperes

(Line A x .001)

Alarm sounding period in hours

(For example, 5 minutes = .084 hours)

Multiply line G by 1.2

(T o tal ampere hou rs requ ired)

Standby

Current

mA mA

AA

AH

Alarm

Current

H

4.9.5 Standby Current For DACT Compliant Installations

In order to meet the 24-hour standby requirement the total standby current Must Not exceed

475mA for the system using both the 4821/4820 Control Panel and the 4195 Auxiliary Power

Supply. The combination of these supplies provides 14 amp hours of standby power.

If your system configuration exceeds 475 mA of standby current you must provide additional

power from an external power supply. Silent Knight has tested the following power supplies

for compatibility with the 4821/4820 Control Panel:

• Alarm Saf Model PS5-BFS-12-UL

• Altronix Model AL400ULX

150964 4-11

Page 56

Model 4821/4820 Control/Communicator Installation Manual

4.10 AC Power Transformer

The Model 9227 is an external transformer that is included with the 4821/4820. The transformer output is 18 VAC, 50VA and provides power and battery charging for the system. The

transformer plugs directly into a conventional 120 VAC unswitched outlet.

The earth terminal on the 4821/4820 main circuit board provides a convenient method for

connecting the 4821/4820 metal cabinet to an earth ground. (See Figure 4-6.)The earth connection is also used for increased transient protection on the telephone interface. All circuitry

in the Model 4821/4820 system is electrically isolated from this earth terminal on the 4821/