Page 1

Content

Section 1

Overview

1.1 SK-4224 Description ................................. ..... ...... ....................................................................................1-1

1.2 How to Contact Silent Knight ..................................................................................................................1-1

......................................................................................................................................................1-1

Section 2

Agency Requirements

2.1 FCC Warning ...........................................................................................................................................2-1

2.2 Underwriters Laboratories (UL) ..............................................................................................................2-1

2.2.1 Requirements for All Installations ....................................................................................................2-1

2.2.2 Requirements for Local Protected Fire Alarm Systems ...................................................................2-1

............................................................................................................... 2-1

Section 3

Before You Begin Installing

3.1 What's in the Box? ...................................................................................................................................3-1

3.2 Optional Accessories ................................................................................................................................ 3-2

3.3 SK-4224 Board Layout ................. ...... ...... ...............................................................................................3-3

3.4 Electrical Specifications ...........................................................................................................................3-4

3.5 Environmental Specifications ..................................................................................................................3-4

3.6 Mounting the SK-4224 .............................................................................................................................3-5

3.7 Assembly ..................................................................................................................................................3-6

3.8 Wiring Specifications ...............................................................................................................................3-7

3.9 Calculating Current Draw and Standby Battery ......................................................................................3-8

3.9.1 Worksheet Requirements ......................................... .........................................................................3-8

Filling in the Current Draw Worksheet, Table 3-6 (Section 3.9.3) ............................................... 3-8

3.9.2 Maximum Battery Standby Load ......................................................................................................3-8

3.9.3 Current Draw Worksheet ..................................................................................................................3-9

...............................................................................................3-1

Section 4

Hardware Installation

4.1 AC Power ................................................................................................................................................. 4-1

4.2 Battery Connection ..................................................................................................................................4-2

4.3 Initiation Circuit Installation ....................................................................................................................4-3

4.3.1 Contact Wiring ..................................................................................................................................4-3

4.3.2 Two-Wire Smoke Detector Wiring ................................................................................................... 4-3

4.3.3 Class A Smoke Detector Installation ................................................................................................4-4

4.3.4 Four-Wire Smoke Detector ............................................................................................................... 4-5

4.3.5 Notification Circuit Installation ........................................................................................................ 4-6

4.3.6 Class A Notification Circuit Installation ..........................................................................................4-7

4.4 Alarm and Trouble Relays .......................................................................................................................4-7

4.5 Auxiliary Power Circuit ...........................................................................................................................4-7

151068 i

..................................................................................................................4-1

Page 2

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.6 Door Release Wiring ................................................................................................................................4-8

4.7 Optional Accessories Installation .............................................................................................................4-9

4.7.1 Installing the Serial Driver Board (Model SK-2884) .......................................................................4-9

Wiring the SK-2884 to an Expansion Device .............................................................................4-10

4.7.2 SK-2865 LED Annunciator Installation .........................................................................................4-10

SK-2865 Electrical Specification ...................................................... ..... ...... ............................. ..4-10

Wiring the SK-2865 to the SK-2884 ...........................................................................................4-10

Setting the SK-2865’s address .................................................................................................... 4-12

Mounting the SK-2865 ................................................................................................................4-12

Section 5

Notification Expansion Mode

5.1 Class A Notification Expansion Wiring ...................................................................................................5-1

5.2 Class B Notification Expansion Wiring ...................................................................................................5-2

...........................................................................................5-1

Section 6

System Configuration

................................................................................................................6-1

Section 7

System Operation

7.1 Meaning of LEDs .....................................................................................................................................7-1

7.2 Operation Keys (Switches) ......................................................................................................................7-3

............................................................................................................................7-1

Appendix A

Compatible Devices

A.1 Smoke Detectors ..................................................................................................................................... A -1

A.1.1 Enhanced Mode ............................................................................................................................ A-1

A.1.2 Two-Wire Smoke Detectors .........................................................................................................A-2

Four-Wire Smoke Detectors ......................................................................................................... A-3

A.2 Notification Appliances .......................................................................................................................... A-4

..................................................................................................................... A-1

ii 151068

Page 3

Section 1

Overview

1.1 SK-4224 Description

The Model SK-4224 is a four zone, 24-volt fire control panel having the following features:

• Zone inputs can be configured as:

Four Class B zones

Or

Two Class A zones

• 2.5 amp power supply

• Two notification circuits rated at 2.5 amp max.

• Dedicated alarm and trouble relays

• Auxiliary power output (.5 amp max.) for powering special applications, such as door

holders.

• Enhanced Verification Mode, a built-in feature that distinguishes two-wire smoke detectors from pull stations.

• Housed in a 12.75"W x 15"H x 3.25"D metal cabinet

• Cabinet supports two 7.0 AH backup batteries

1.2 How to Contact Silent Knight

If you have a question or encounter a problem not covered in this manual, contact Silent

Knight Technical Support at 800-328-0103 (or 612-493-6455). To order parts, contact Silent

Knight Sales at 800-446-6444 (or 612-493-6435).

151068 1-1

Page 4

Model SK-4224 Fire Control Panel Installation/Operation Manual

1-2 151068

Page 5

Section 2

Agency Requirements

2.1 FCC Warning

This device has been verified to comply with FCC Rules Part 15. Operation is subject to the

two following conditions: (1) This device may not cause radio interference, and (2) This

device must accept any interference received, including interference that may cause undesired

operation.

2.2 Underwriters Laboratories (UL)

The SK-4224 is UL listed as a control unit for use in NFPA 72 systems. If the SK-4224 and

its accessories are to be used as part of a UL installation, carefully read the UL requirements

in this section. For more information on NFPA 72 standards, refer to the NFPA National Fire

Alarm Code, 1996 Edition.

2.2.1 Requirements for All Installations

General requirements are described in this section. When installing an individual device,

refer to the specific section of the manual for additional requirements.

1. All field wiring must be installed in accordance with NFPA 70 National Electric Code.

2. Use UL listed smoke detectors and notification appliances compatible with the SK-4224

from those specified in the Appendix to this manual.

3. If you are using the smoke verification feature:

• Do not use smoke detectors with built-in alarm verification.

• Select "Enhanced Mode" if the installation includes pull stations or water flow

switches.

4. A full system checkout must be performed any time the panel is programmed.

5. UL installations using Class B wiring require the use of a Model 7628 EOL resistor

assembly.

2.2.2 Requirements for Local Protected Fire Alarm

Systems

At least one UL listed supervised notification appliance must be used.

151068 2-1

Page 6

Model SK-4224 Fire Control Panel Installation/Operation Manual

2-2 151068

Page 7

Section 3

g

Before You Begin Installin

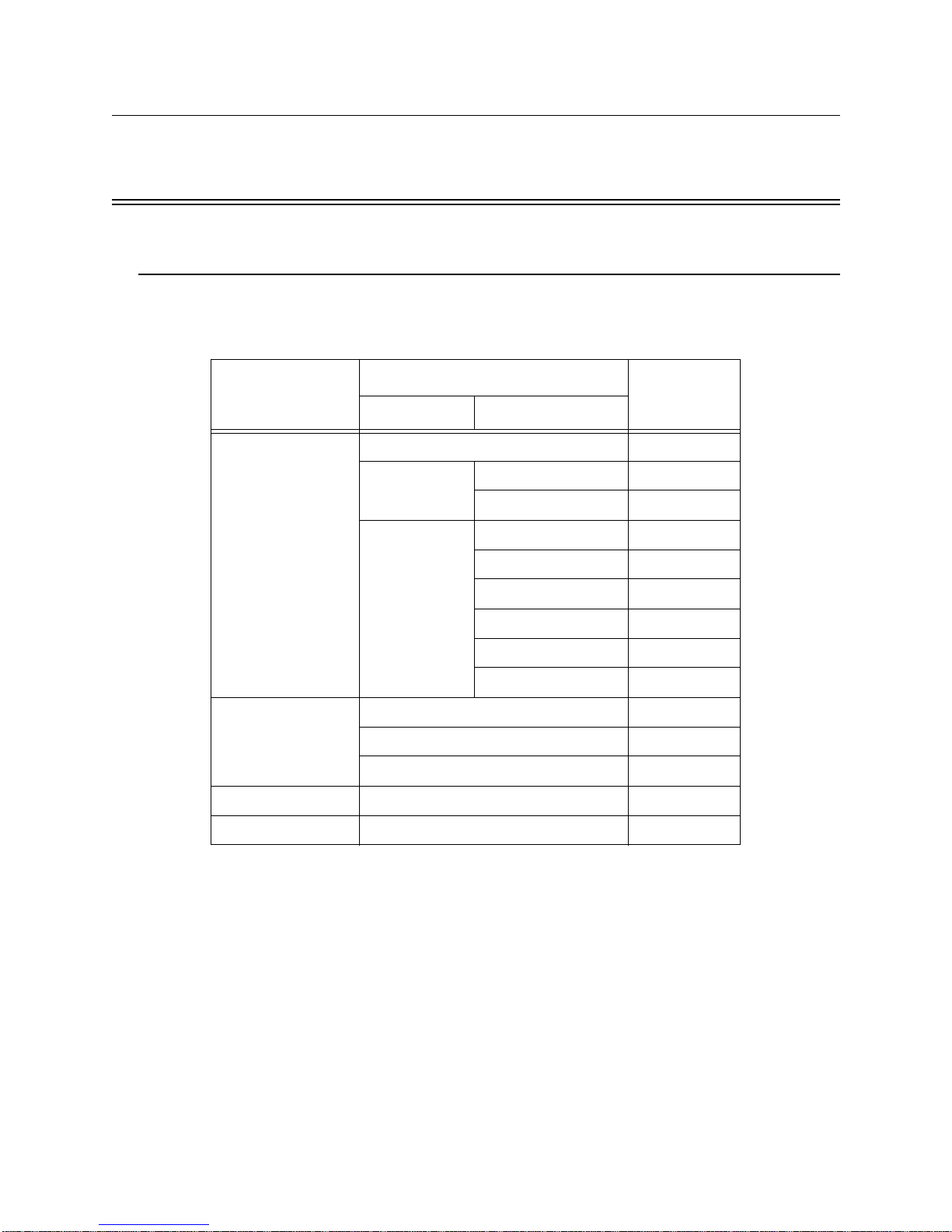

3.1 What's in the Box?

The Model SK-4224 ships with the following hardware:

Table 3-1: Contents of Shipping Box

Containing

Main Part

Part Quantity/Item

1 Cabinet 122509

Panel Bag 1 Control Board 204224

1 Installation Manual 151068

2 #8 Screws 119152

2 #8 Nuts 119538

Hardware Bag

120 Vrms @ 60Hz 115061

1 Transformer

230 Vrms at 50Hz 115031

1 Viewing Bezel 122508

3 Self-tapping Scr e ws 119296

1 Earth Ground Wire 140668

1 Battery Wire Harness 130420

1 battery Jumper 140694

or a

Model

Number

6 End-of-line Resistors 111682

Note: See Section 3.7 for assembl y i nstructions.

151068 3-1

Page 8

Model SK-4224 Fire Control Panel Installation/Operation Manual

3.2 Optional Accessories

Table 3-2 is a list of optional accessories that can be used with the Model SK-4224 Fire

Control Panel.

Table 3-2: Option Accessories for the SK-4224

Model

Number

SK-2884 Serial Driver Board Used to interface all SK-4224expansion device to the SK-

*SK-2880 Input/Output (I/O) Module Used to drive customized annunciators and interface devices.

*SK-2865 LED Annunciator Remote LED annunciator with Silence and Reset keyswitch

*SK-2104 Diale r Used to communicate alarms, tr ouble and supervisories to

7628 UL listed End-of-line

(EOL) Resistor.

Name Description

4224 panel. Supports1 Dialer (Model 2104) and any

combination of 4 LED Annunciators (Model 2865) or I/O

Modules (Model 2880).

inputs.

central station. Offe rs 5 different reporting f ormats 3/1, 4/2,

BFSK, SIA, and Contact ID.

EOL resistor required for UL installations.

* Require a SK-2884 to operate with the SK-4224 control panel.

3-2 151068

Page 9

Before You Begin Installing

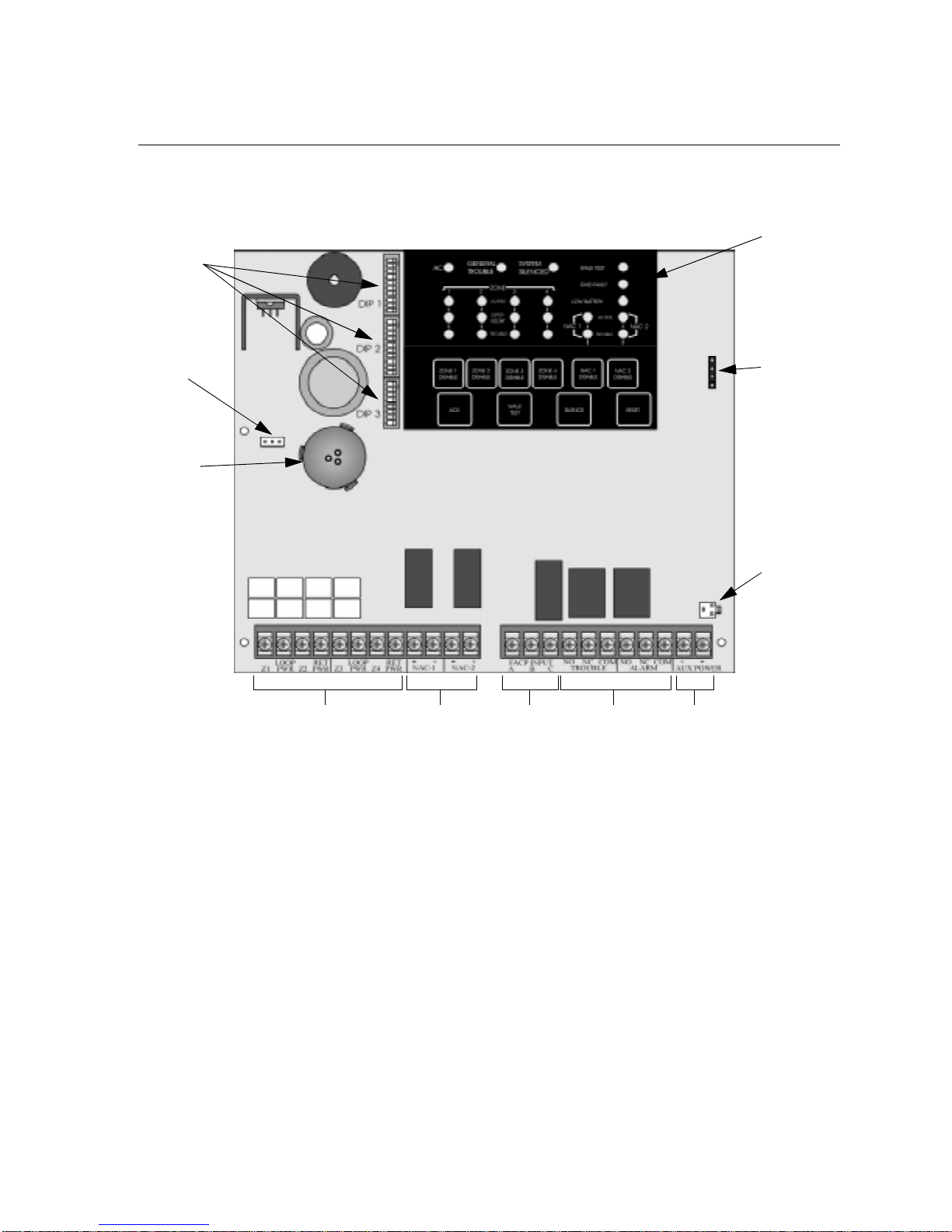

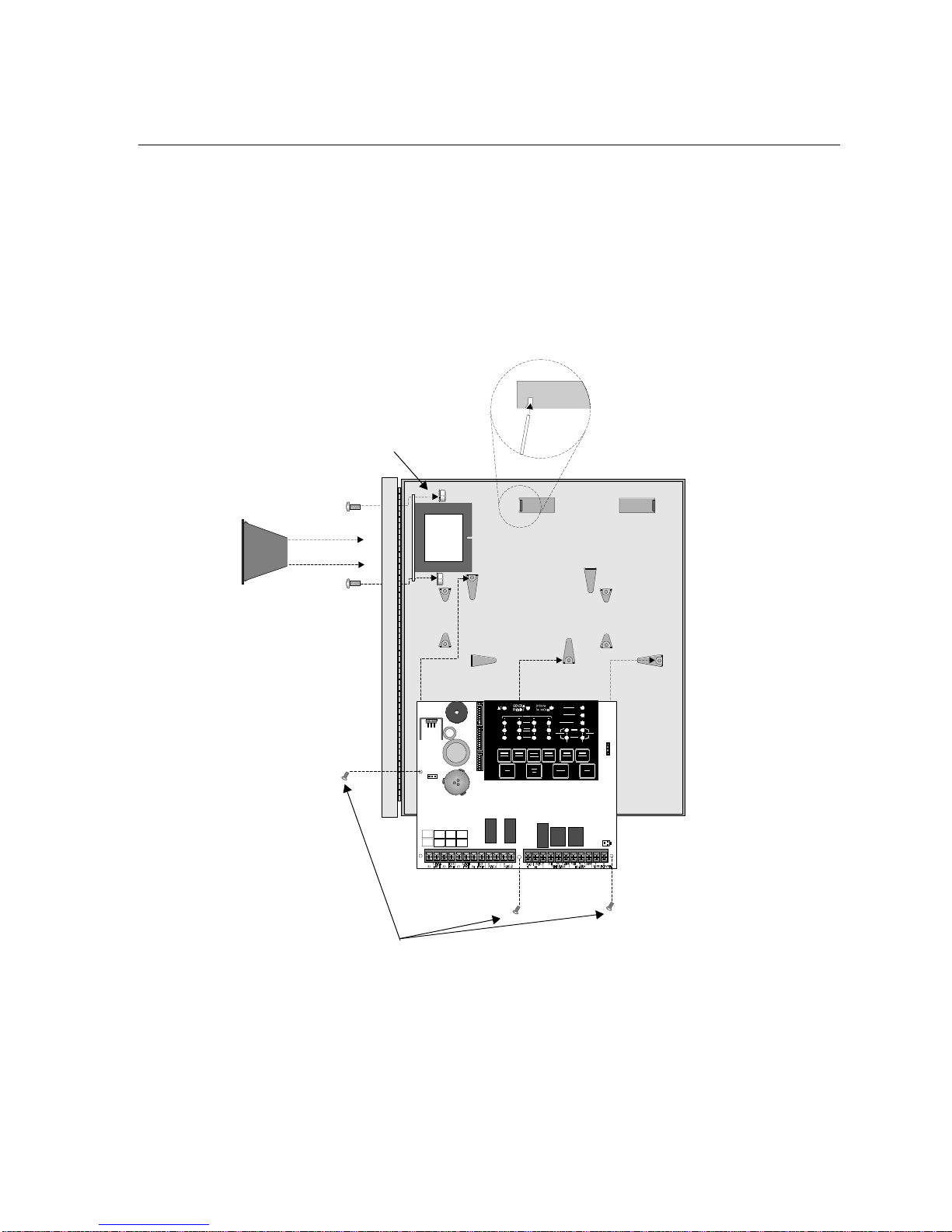

3.3 SK-4224 Board Layout

Figure 3-1 shows the SK-4224 circuit board including location of terminals, connectors, dip

switches, and LEDs.

Programming

DIP Switches

AC Power

Connector

On-Board

Piezo Sounder

Annunciator

SK-2884

Serial

Interface

Connector

Backup

Battery

Connector

Zone Inputs

4 Class B or

2 Class A Inputs

Figure 3-1 Model SK-4224 Layout

2 Notification

Appliance

Circuits

Notification

Expansion

Inputs

Trouble &

Alarm Relays

Auxiliary

Power

Output

151068 3-3

Page 10

Model SK-4224 Fire Control Panel Installation/Operation Manual

3.4 Electrical Specifications

Table 3-3: Electrical Specifications

Circuit Rating

Primary AC *120 Vrms at 60 Hz, or 230 Vrms at 50 Hz

@ 1.5 Amps

Total External DC Load 2.5A @ 24 VDC

+24V Auxiliary Power 19.8 V to 28.0 V, 0.5 A max.

Trouble & Alarm Relays 2.5 A @ 30 VDC resistive

Notification Appliance Power 19.8 V to 28.0 V, 2.5 A max.

Smoke Detector Power 19.8 V to 28.0 V, 1.0 A max.

Battery Charging Voltage 27.0 - 27.6 V

Maximum Battery Charging Current 750 mA

Minimum Low Battery Detect 20.4 V

Minimum Low AC Detect 100 Vrms at 60 Hz, full load

Note: * When ordering, specify your voltage requirements.

3.5 Environmental Specifications

Table 3-4: Environmental Specifications

Storage Temperature: -4° - 167° F (-20 - 75° C)

Operating Temperature: 32° - 120° F (0° - 49° C)

Humidity: 10 - 85% non-condensing

It is important to protect the SK-4224 control panel from water. To prevent water damage, the

following conditions should be AVOIDED when mounting the units:

• Do not mount directly on exterior walls, especially masonry walls (condensation)

• Do not mount directly on exterior walls below grade (condensation)

• Protect from plumbing leaks

• Protect from splash caused by sprinkler system inspection ports

• Do not mount in areas with humidity-generating equipment (such as dryers, production

machinery)

3-4 151068

Page 11

Before You Begin Installing

3.6 Mounting the SK-4224

Read the environmental specifications in Section 3.5 before mounting the cabinet.

The panel should be accessible to main drop wiring runs. It should be mounted as close to the

center of the building as possible and located within a secured area, but should be accessible

for testing and service. End-users responsible for maintaining the panel should be able to hear

alarms and troubles. When selecting a location, keep in mind that the panel itself is the main

source of alarm and trouble annunciation.

Mount the cabinet so it is firmly secured to the wall surface. When mounting the cabinet on

concrete, especially when moisture is expected, attach a piece of 3/4-inch plywood to the

concrete surface and then attach the cabinet to the plywood. Also mount any other modules to

the plywood.

Follow these steps to mount the control panel cabinet:

1. Place the cabinet on the mounting surface, level the cabinet and mark the top two

mounting holes.

2. Screw the top two mount screws about 3/4 of the way into the mounting surface.

3. Hang the control panel cabinet on the top mounting screws through the top mounting

screw keyholes.

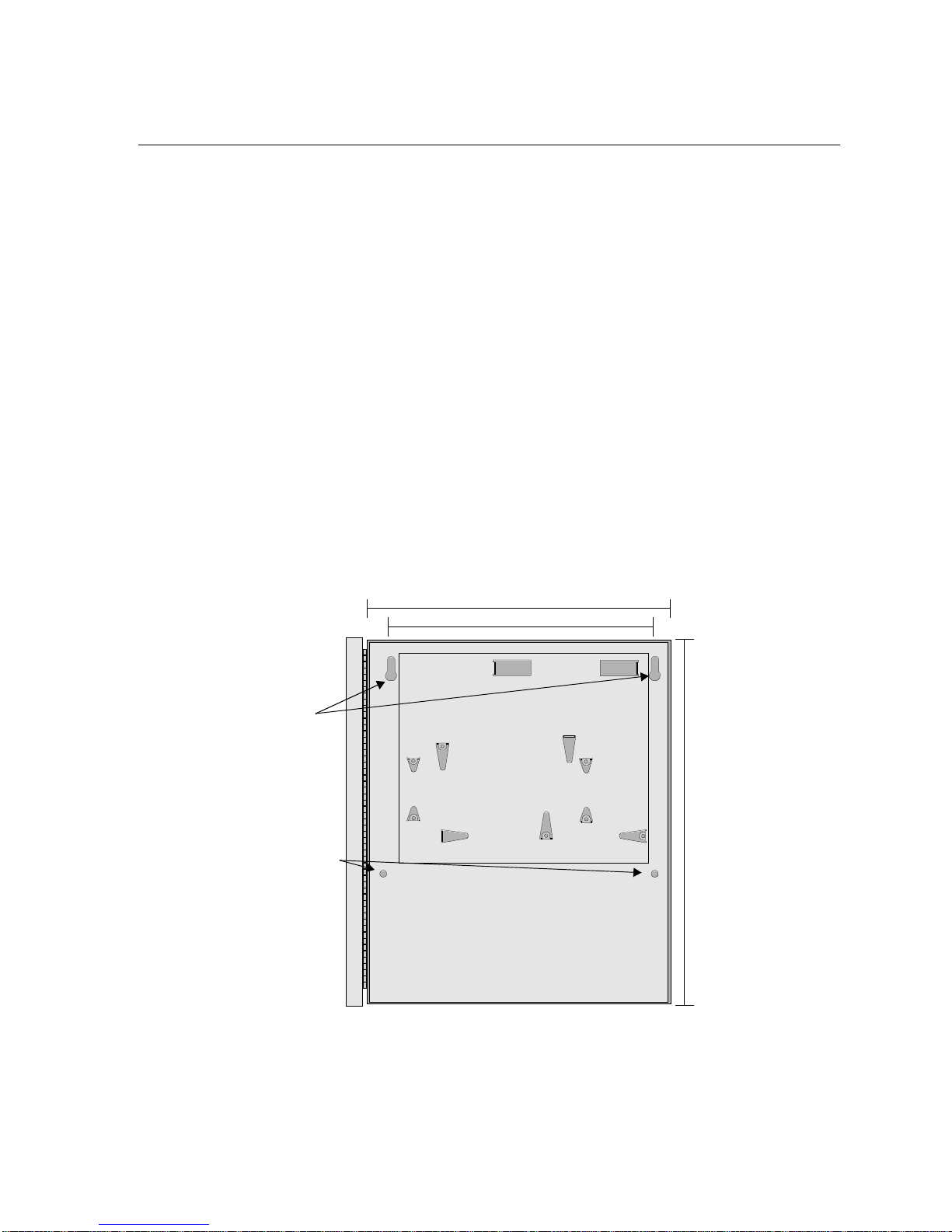

12-1/2”

11”

Top Mounting

Screw Keyholes

15”

Bottom

Mounting Holes

4. Insert the bottom two mounting screws into the cabinet’s bottom mounting holes.

5. Tighten all four mounting screws until the cabinet is properly secured.

6. Insert all cabinet components. See Section 3.7.

151068 3-5

Figure 3-2 Cabinet Mounting Holes

Page 12

Model SK-4224 Fire Control Panel Installation/Operation Manual

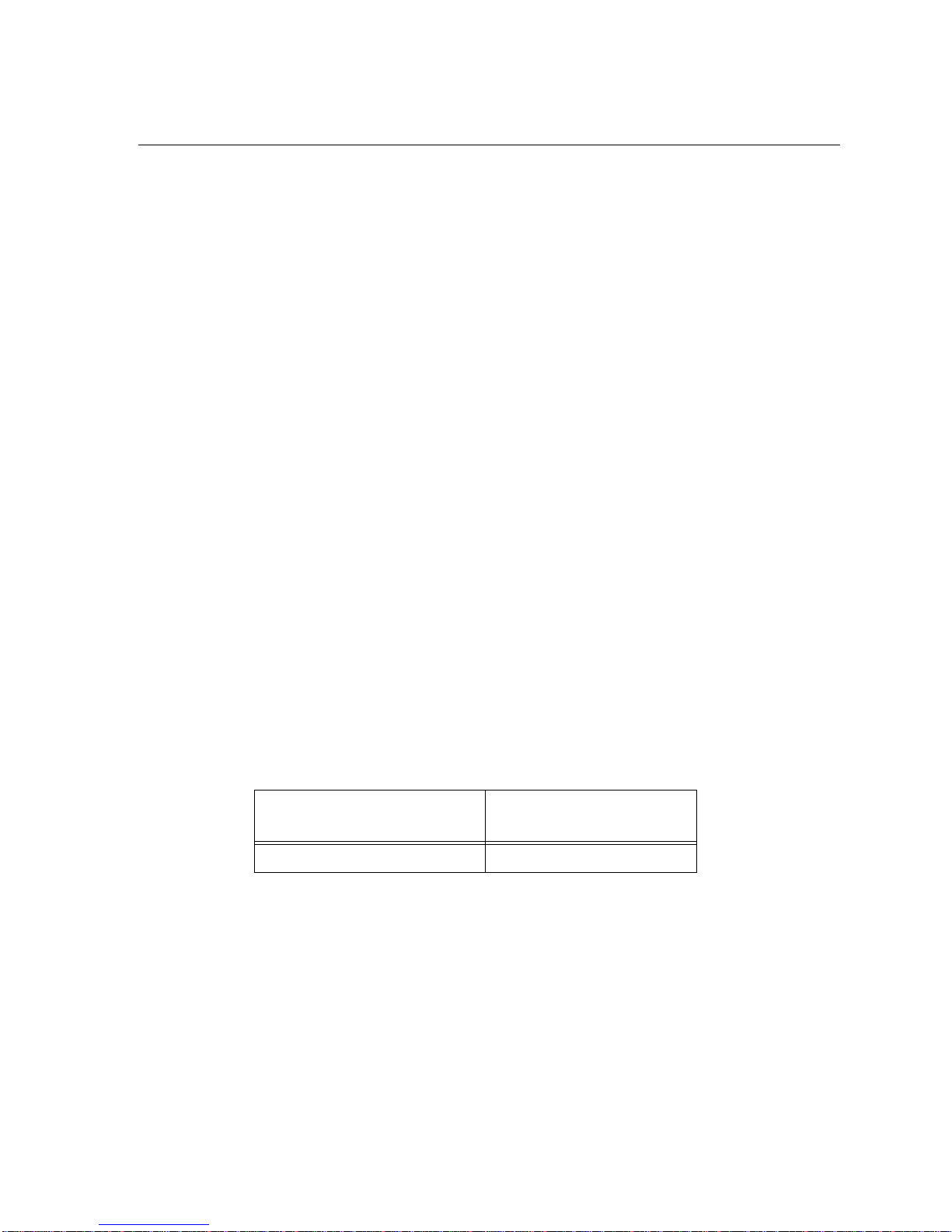

3.7 Assembly

The components listed in Table 3-1 are all packed with in the cabinet and require some

assembly. Follow these steps to assemble the cabinets inside the cabinet:

1. Remove keys from small manila envelope taped to the top of the cabinet.

2. Unlock the cabinet door.

3. Remove the packing material and the SK-4224 components.

4. Snap the bezel into the opening in the front of the cabinet. See Figure 3-3.

Side View of

Transformer

Installation

Slotted Stand-Off

Bezel Insertion

CPU Mounting

Screws

Figure 3-3 Assembly Diagram for the SK-4224

Note: The bezel will fit in only one way.

5. With the t wo #8 Screws and the two #8 nuts (with built in washers), mount the transformer

in the holes in the upper left hand corner of the cabinet. See Figure 3-3.

6. With the three Self-trapping screws mount the control board on the cabinet stand-offs.

Note: See Section 4 for transformer connections and battery connections.

3-6 151068

Page 13

Before You Begin Installing

3.8 Wiring Specifications

Induced noise (transfer of electrical energy from one wire to another) can cause false alarms

or interfere with control panel operation in other ways.

To avoid induced noise, follow these guidelines:

• Isolate input wiring from high current output and power wiring. Do not pull one multiconductor cable for the entire panel. Instead, separate the wiring as follows:

High current input/output: AC power and notification device wiring

Low current input/output: Annunciator and zone loop wiring

• Do not pull wires from different groups through the same conduit. If you must run them

together, do so for as short a distance as possible or use shielded cable. Connect the shield

to circuit ground at the panel. You must route high and low voltages separately.

• Route the wiring within the cabinet around the perimeter of the cabinet. It should not cross

the printed circuit board where it could induce noise into the sensitive microelectronics or

pick up unwanted RF noise from the high speed circuits. See Figure 3-4 for an example.

• High frequency noise, such as that produced by the inductive reactance of a speaker or

bell, can also be reduced by running the wire through ferrite shield beads or by wrapping it

around a ferrite toroid.

151068 3-7

Figure 3-4 Wire Routing Example

Page 14

Model SK-4224 Fire Control Panel Installation/Operation Manual

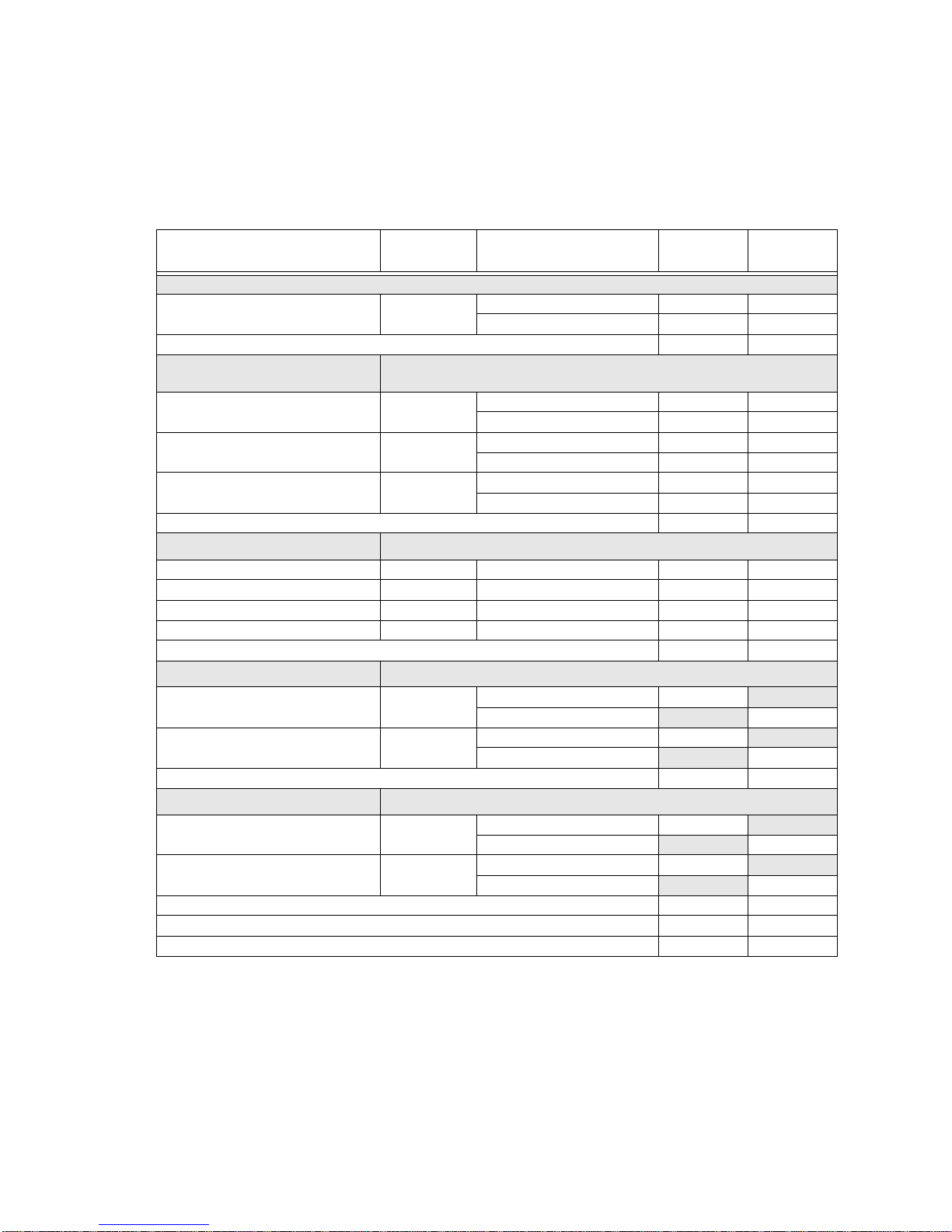

3.9 Calculating Current Draw and Standby Battery

This section is for helping you determine the current draw and standby battery needs for your

installation.

3.9.1 Worksheet Requirements

The following steps must be taken when determining SK-4224 current draw and standby

battery requirements.

Filling in the Current Draw Worksheet, Table 3-6 (Section 3.9.3)

1. For the SK-4224, the worst case current draw is listed for the panel and is recorded in the

table at Line A.

2. Add up the current draw for all smoke detectors and record in the table at Line B.

3. Add up all notification appliance loads and record in the table at Line C.

4. Any additional devices should be recorded at Line D.

5. Make sure that the alarm current without the panel (Lines B-D) does not exceed 2.5 A.

The total alarm current (including the panel, Lines A-D) should not exceed 2.75 A.

6. Complete the remaining instructions in Table 2 for determining battery size requirements.

3.9.2 Maximum Battery Standby Load

Table 3-5 shows the maximum battery standby load for the SK-4224 based on 24 hours of

standby. The standby load calculations of line D in the Current Draw Calculation Worksheet

(Table 3-6) must be less than the number shown in Table 3-5 for the battery size used and

standby hours required.

Table 3-5: Maximum Battery Standby Load

Rechargeable Battery Size

7 AH 270 mA

Max. Load for 24 hrs.

Standby, 5 mins. Alarm

3-8 151068

Page 15

Before You Begin Installing

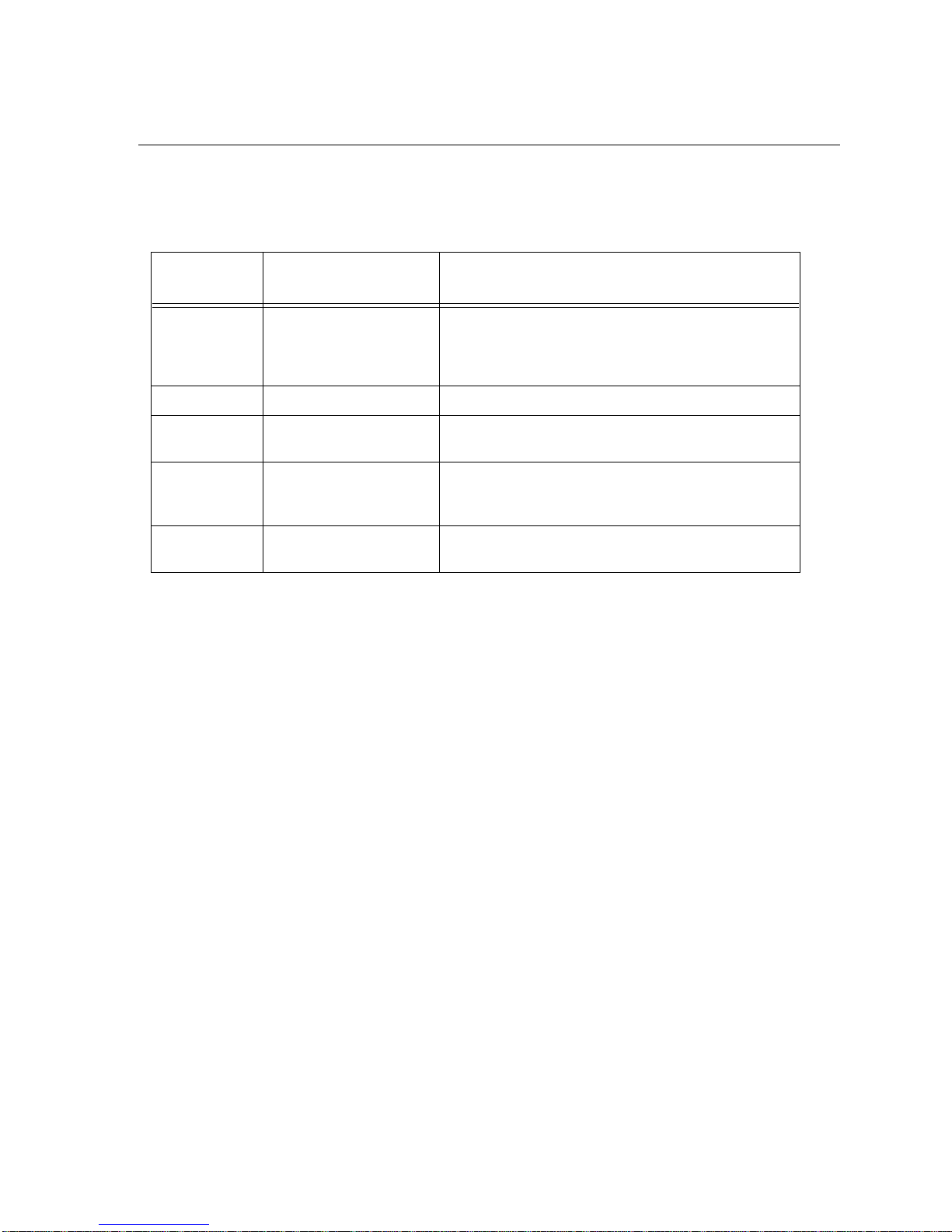

3.9.3 Current Draw Worksheet

Use this worksheet to determine current requirements during alarm/battery standby operation.

(Copy this page if additional space is required.)

Table 3-6: Current Draw Calculations

Device

For each device, use this formula: This Column X This column = Current per number of devices

SK-4224 Panel 1

A Current Subtotals:

Smoke Detectors

B Current Subtotals:

Notification Devices

C Current Subtotals:

Accesory Devices

SKC-2884

SKC-2865

D Current Subtotals:

*Additional Devices

E Current Subtotals:

Total current rating of all devices in system (add A throug h E): mA mA

F

Total current ratings converted to amperes (x .001): A A

Number of

Devices

Refer to device manual for current ratings. See Appendix to this manual for

max. # per loop.

Refer to device manual for number of devices and current ratings.

Current per Device

Standby: 125 mA 125 mA

Alarm: 250 mA 250 mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Alarm: mA mA

Alarm: mA mA

Alarm: mA mA

Alarm: mA mA

Standby: 10 mA mA

Alarm: 10 mA mA

Standby: 35 mA mA

Alarm: 75 mA mA

Standby: mA mA

Alarm: mA mA

Standby: mA mA

Alarm: mA mA

Standby

Current

125 mA 250 mA

mA mA

mA mA

mA mA

mA mA

Alarm

Current

*Note:If you are usin g do or ho lders, you do not need t o consider door holde r current for alarm/ba tt er y s ta ndb y,

because power is removed during that time. However, during normal operation, door ho lders draw current

and must be included in the total current that can be drawn from the pane l.

151068 3-9

Page 16

Model SK-4224 Fire Control Panel Installation/Operation Manual

3-10 151068

Page 17

Section 4

Hardware Installation

4.1 AC Power

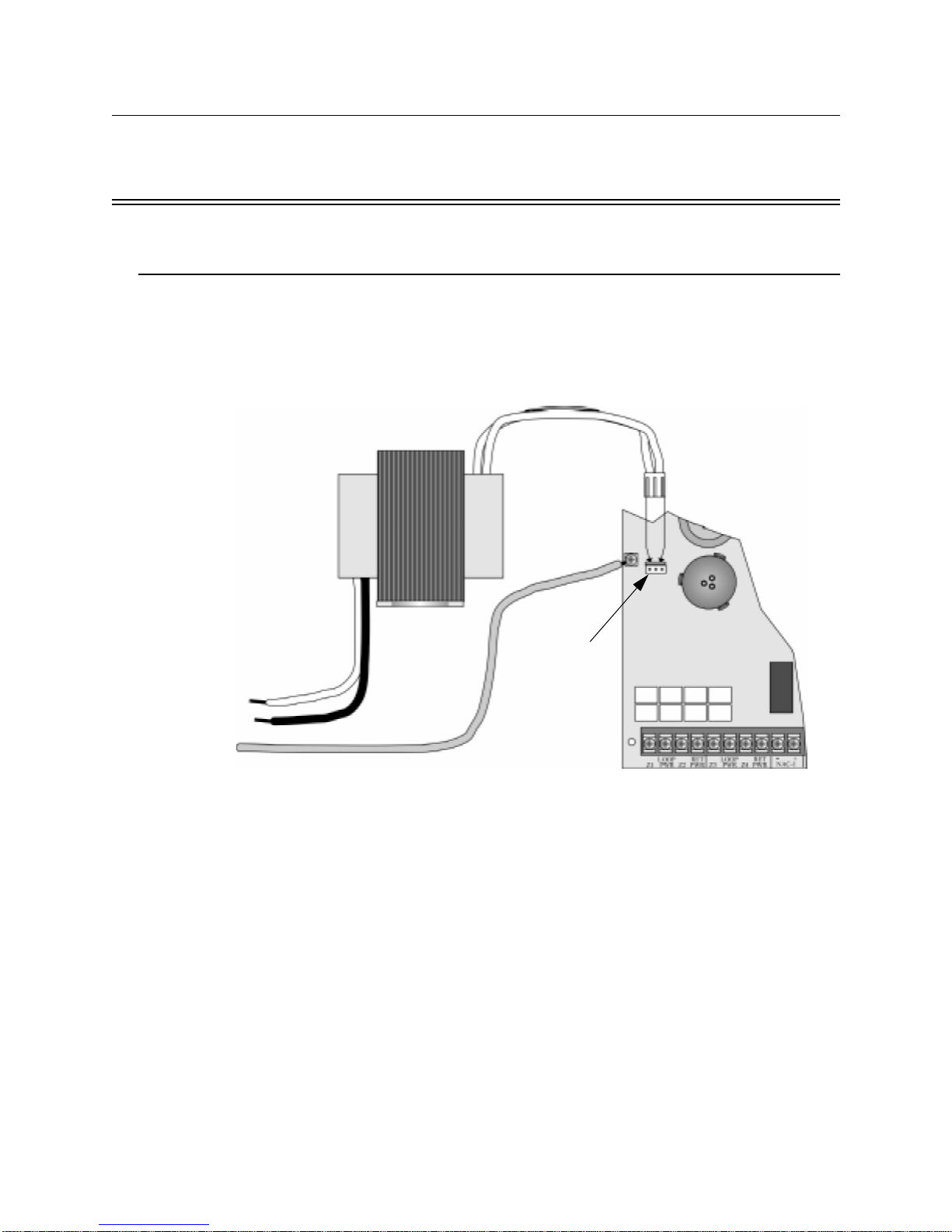

At installation, connect the transformer AC inputs to the AC power source as shown in Figure

4-1. It may be necessary for a professional electrician to make this connection.

The AC inputs are rated as 120 VAC, 60 Hz (for transformer P/N 115061) or 230 VAC,50 Hz

(for transformer P/N 115031). See Table 3-1 for more information.

To AC

Power

White

Black

Green

Earth Ground

Transformer

Figure 4-1 AC Power Connection

Yellow

AC Power

Connector

Control Panel

151068 4-1

Page 18

Model SK-4224 Fire Control Panel Installation/Operation Manual

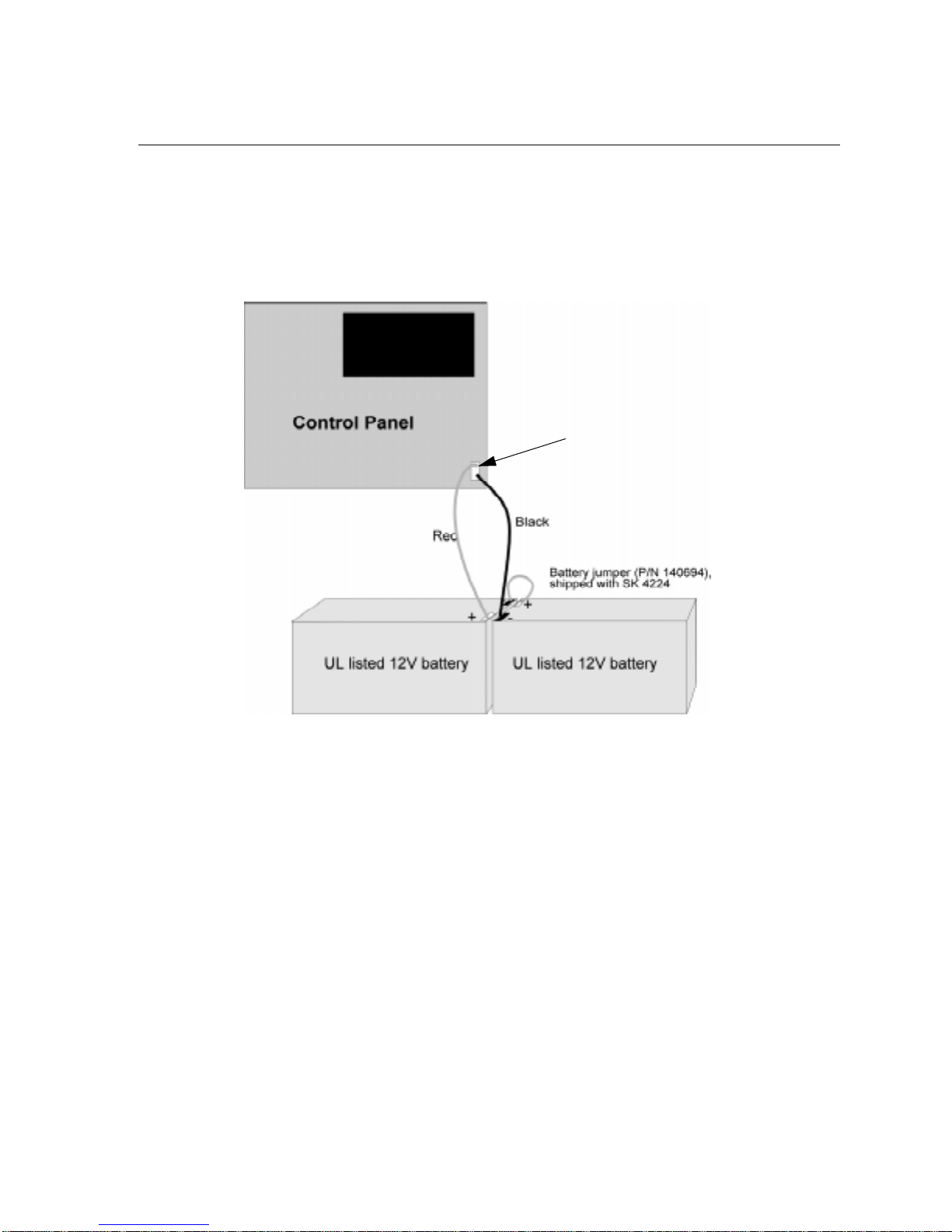

4.2 Battery Connection

The SK-4224 battery charge capacity is 7.0 AH. Use two 12V batteries of the same AH rating.

Determine the correct AH rating as per your current load calculation (see Table 3-6).

Wire batteries in series to produce a 24-volt equivalent. Do not parallel batteries to increase

the AH rating.

Note: The SK-4224 cabinet supports two 7.0 AH batteries.

Backup Battery

Connector

Figure 4-2 Battery Connection

4-2 151068

Page 19

Hardware Installation

4.3 Initiation Circuit Installation

4.3.1 Contact Wiring

Wire normally open contacts as shown in Figure 4-3. This is the type of wiring that would

typically be used for water flow switches, heat detectors and other normally open devices.

Figure 4-3 N.O. Contact Wiring

4.3.2 Two-Wire Smoke Detector Wiring

Figure 4-4 shows how to connect two-wire smoke detectors to the SK-4224 loops. The figure

uses Silent Knight's SLK-24F with HSB-224 base as an example. You can use any detector

that has been UL listed for compatibility with the SK-4224. Refer to the Appendix for a list of

compatible devices. Refer to Section 6 for configuration options.

Figure 4-4 Two-Wire Smoke Detector Wiring

151068 4-3

Page 20

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.3.3 Class A Smoke Detector Installation

Figure 4-5 illustrates how to connect a UL listed smoke detector to the SK-4224 in a Class A

configuration. Refer to the Appendix for a list of compatible devices. Information on selecting

zone configuration options is in Section 6.

Figure 4-5 Class A Smoke Detector Wiring

4-4 151068

Page 21

Hardware Installation

4.3.4 Four-Wire Smoke Detector

Figure 4-6 shows how to connect four-wire smoke detectors to the SK-4224 loops. The figure

uses Silent Knight's SLK-24F with HSC-4R base as an example. You can use any UL listed

device. Refer to the Appendix for a list of compatible devices. Information on selecting zone

configuration options is in Section 6.

Figure 4-6 Four-Wire Smoke Detector Wiring

151068 4-5

Page 22

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.3.5 Notification Circuit Installation

Notification appliances used with the SK-4224 must be UL listed for compatibility with the

SK-4224. Refer to the list in the Appendix at the end of this manual for a list of compatible

devices.

For proper operation, you must use polarized notification devices with a model 7628 4.7k

ohm end-of-line (EOL) resistor on each loop. Select ANSI output pattern, if desired. Output is

configured as steady (continuous sound) at the factory. See Section 6 for information on

changing the pattern.

Figure 4-7 Notification Circuit Installation

4-6 151068

Page 23

Hardware Installation

4.3.6 Class A Notification Circuit Installation

For proper operation, you must use polarized notification devices. Select ANSI output pattern,

if desired. Output is configured as steady (continuous sound) at the factory. See Section 6 for

information on changing the pattern.

Figure 4-8 Class A Notification Circuit

4.4 Alarm and Trouble Relays

The SK-4224 has built-in relays for alarm and trouble. The alarm relay is energized during

any alarm condition. The trouble relay is energized during any trouble or supervisory trouble

condition. Each relay has three terminals (N.O., Common, and N.C.). Refer to Figure 3-1 for

location of these terminals.

4.5 Auxiliary Power Circuit

The SK-4224 has a power limited auxiliary power circuit which can source up to .5A. The

terminal is labeled “AUX PWR”. Refer to Figure 3-1 for location of this terminal.

151068 4-7

Page 24

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.6 Door Release Wiring

Figure 4-9 shows how to configure a door release using an ESL DH series door holder.

Figure 4-9 Door Release Wiring

4-8 151068

Page 25

Hardware Installation

4.7 Optional Accessories Installation

This section describes how to install the optional accessories compatible with the SK-4224

control panel.

4.7.1 Installing the Serial Driver Board (Model SK-2884)

The SK-2884 is required if the installation uses any SK-4224 expansion devices such as

Model SKC-2880 (I/O Module), Model SK-2865 (LED Annunciator), or Model 2104 (Dialer

Board). The SK-2884 interfaces all the expansion devices to the SK-4224 control panel.

Follow these steps to install the SK-2884 Serial Driver Board:

1. Unplug the AC power connector from the SK-4224 control panel. See Figure 4-1.

2. Unplug the backup battery connector from the SK-4224 control panel. See Figure 4-2.

3. Plug the SK-2884 Serial board on SK-4224 control panel by aligning the 4-pin connector

and the three stand-offs with their respective receptors. See Figure 4-10.

Figure 4-10 SK-2884 Connector and Stand-off alignment

4. Reconnect the AC power connector to the SK-4224 control panel. See Figure 4-1.

5. Reconnect the backup battery connector to the SK-4224 control panel. See Figure 4-2.

151068 4-9

Page 26

Model SK-4224 Fire Control Panel Installation/Operation Manual

Wiring the SK-2884 to an Expansion Device

The SK-2884 uses a three wire connection to all of the SK-4224 compatible expansion

devices (see Table 3-2).

Connect all the expansion devices to the SK-2884 as follows:

Table 4-1: SK-2884 Wiring Connections

SK-2884

Terminals

--

++

D (Data) D (Data)

SK-4224 Expansion

To

Device Terminal

4.7.2 SK-2865 LED Annunciator Installation

This section describes how to install the SK-2865 LED annunciator. The SK-2865 is used as a

remote LED annunciator unit for the SK-4224.

SK-2865 Electrical Specification

Circuit Rating

Ω

Ω

Ω

Max Loop Re sistance:

Max. Current:

Data 50

-50

+50

Alarm: 75 mA

Standby: 35 mA

Operating V oltage: 24 VDC

Wiring the SK-2865 to the SK-2884

Follow these steps to properly wire the SK-2865 to the SK-2884:

1. Unplug the AC power connector from the SK-4224 control panel. See Figure 4-1.

2. Unplug the backup battery connector from the SK-4224 control panel. See Figure 4-2.

4-10 151068

Page 27

3. Terminate the wiring as shown in Figure 4-11. See also Table 4-2.

SK-2884

SK-2865

Supervised

Power Limited

Hardware Installation

Figure 4-11 SK-2865 Connection to the SK-2884

Table 4-2: SK-2865 Wiring Connections

SK-2865

Terminals

D (Data) D (Data)

++

--

SK-2884 Terminals

151068 4-11

Page 28

Model SK-4224 Fire Control Panel Installation/Operation Manual

Setting the SK-2865’s address

The range of valid addresses is 0-3. Each device requires a unique address. Set the dip

switches as shown in Table 4-3. See also Figure 4-11.

Table 4-3: SK-2865 Addresses Per Dip Switch Setting

Dip Switch Position

Both Open (off) 0

One Closed (on) 1

Two Closed (on) 2

Both Closed (on) 3

Equivalent

Address

Mounting the SK-2865

The SK-2865 mounts into a standard 4” square electrical box.

Follow these steps to mount the SK-2865:

1. Make sure that the SK-2865 is properly wired to the control panel. See Figure 4-11.

2. Slide the printed annunciator label into place on the SK-2865. The label fits in between the

LEDs and the clear plastic plate.

3. Place the SK-2865 into the 4” square electrical box. See Figure 4-12.

Slide Printed

Annunciator

Label In

4” Square

Electrical Box

Cover Plate

Screw

SK-2865

Cover Plate

Figure 4-12 Mounting the SK-2865

4. Place the cover plate over the top of the SK-2865 and align the holes. See Figure 4-12.

5. Insert the four cover plate screws into the four screw holes on the 4” square electrical box.

6. Screw the four cover plate screws into the cover plate until the cover plate fits firmly

against the SK-2865 and the electrical box. Do not over tighten.

4-12 151068

Page 29

Hardware Installation

4.7.3 SK-2880 Installation

The SK-2880 is an Input/Output module. The SK-2880 has 33 pre-defined open collector

outputs (see Table 4-6) that can be used to drive LEDs, interface with other controls or

systems, or control one of the three built-in Form C relays. See Figure 4-13, Figure 4-15 and

Figure 4-16.

The SK-2880 also has two supervised inputs used for Reset and Silence. See Figure 4-16.

Serial Communication

Terminals

Open Collector

Outputs

Terminal

Strip 2

Reset/Silence

Switch Inputs

Figure 4-13 Components of the SK-2880 I/O Module

SK-2880 Specifications

Terminal

Strip 1

Form C

Relay 1

Form C

Relay 2

Table 4-4: Specifications

Status

LED

Form C

Relay 3

Max. Loop Resistance:

Max. Current:

Operating Voltage: 24 VDC

Operating Temperature: 32° - 120° F (0° - 49° C)

Form C Relays 2.5 A @ 30 VDC Resistive

151068 4-13

Circuit Rating

Data 25

-25

+25

Alarm: 35 mA

Standby: 35 mA

Open Collector: 175 mA

Ω

Ω

Ω

Page 30

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.7.3.1 Connecting the SK-2880 to the SK-2884

The control panel communicates to the I/O module through the Serial Interface Board (see

also Section 4.7.1). Figure 4-14 illustrates how to properly wire the I/O module to the Serial

Interface Board.

Supervised

Power Limited

SK-2884

SK-2880

Figure 4-14 I/O Module Wiring

4.7.3.2 Setting the SK-2880 Address

The range of valid addresses is 0-3. Each device requires a unique address. Set the dip

switches as shown in Table 4-5. See Figure 4-14 for dip switch location.

Table 4-5: SK-2880 Addresses Per Dip Switch Setting

Dip Switch Position Address

Both Open (off) 0

One Closed (on) 1

Two Closed (on) 2

Both Closed (on) 3

4-14 151068

Page 31

Hardware Installation

4.7.3.3 Open Collector Outputs (P1, P2, and P3)

Each pin on the Pin Connectors (P1, P2, and P3) have a predefined output. Table 4-6 lists the

Pin Connectors and describes what each pin outputs.

Table 4-6: Pin-outs for Open Collector Outputs

Pin

Connector

P1

Pin 2

Pin Number Output Description

Pin 1 Zone 1 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 1.

Pin 2 Zone 1 Trouble Outputs when a trouble condition exists on Zone 1.

Pin 3 Zone 1 Clean-Me Trouble

Pin 4 Zone 2 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 2.

Pin 5 Zone 2 Trouble Outputs when a trouble condition exists on Zone 2.

Pin 6 Zone 2 Clean-Me Trouble

Pin 7 Zone 3 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 3.

Pin 8 Zone 3 Trouble Outputs when a trouble condition exists on Zone 3.

Pin 9 Zone 3 Clean-Me Trouble

Pin 10 Zone 4 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 4.

Pin 11 Zone 4 Trouble Outputs when a trouble condition exists on Zone 4.

Pin 12 Zone 4 Clean-Me Trouble

Pin 1 Zone 5 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 5.

Pin 2 Zone 5 Trouble Outputs when a trouble condition exists on Zone 5.

Pin 3 Zone 5 Clean-Me Trouble

Pin 4 Zone 6 Alarm/Supervisory Outputs when there is an alarm or supervisory on Zone 6.

Pin 5 Zone 6 Trouble Outputs when a trouble condition exists on Zone 6.

Pin 6 Zone 6 Clean-Me Trouble

Pin 7 Zone 1 & 2 Pre-Alarm

Pin 8 Zone 3 & 4 Pre-Alarm

Pin 9 Zone 5 & 6 Pre-Alarm

Pin 10 Unused Not Used.

Pin 11 +24 VDC Positive 24 DC voltage output.

Pin 12 GND Circuit Ground

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 1.

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 2.

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 3.

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 4.

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 5.

Outputs when a “Clean-Me” type detector indicates a

Clean-me trouble on Zone 6.

Outputs when zones 1 or 2 is in alarm (not both), and

cross alarm for zones 1 and 2 is enabled.

Outputs when zones 3 or 4 is in alarm (not both), and

cross alarm for zones 3 and 4 is enabled.

Outputs when zones 5 or 6 is in alarm (not both), and

cross alarm for zones 5 and 6 is enabled.

151068 4-15

Page 32

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table 4-6: Pin-outs for Open Collector Outputs

Pin

Connector

Pin 3

Pin Number Output Description

Pin 1 NAC 1 Trouble Outputs when a trouble condition exists on NAC 1.

Pin 2 NAC 2 Trouble Outputs when a trouble condition exists on NAC 2.

Pin 3 NAC 3 Trouble Outputs when a trouble condition exists on NAC 3.

Pin 4 Dialer Trouble

Pin 5 Expander Trouble

Pin 6 Alarm Silenced Outputs when an alarm has been silenced.

Pin 7 Low AC

Pin 8 Low Battery

Pin 9 Ground Fault

Pin 10 Walk Test Active Outputs when the control panel is in walk test mode.

Pin 11 Piezo Output

Pin 12 Local Trouble

Outputs when any type of trouble occurs with the dialer,

such as, no line voltage or a communication failure.

Outputs when one of the Serial Devices connected to the

control panel is in trouble .

Outputs if the control panel looses AC power or AC

power drops below the cont r ol panels low AC threshold .

Outputs when the backup battery voltage drops below

20.4 VDC.

Outputs when the control panel detects a ground fault

condition.

Outputs correspond to any trouble condition output from

the control panel.

Outputs if the end-of-line resistor on the Reset or silence

inputs not detected or if a seria l communication problem

occurs between this device and the control panel.

Wiring SK-2880 Open Collector Outputs

Figure 4-15 illustrates examples of how to configure the open collector outputs on the I/O

module for your uses.

LED

Dry Contact Relay

Figure 4-15 Output Configurations

Current Limiting

Resistor 1 K

To P2, Pin 11 or

C+ on Terminal Strip 2

Ω

4-16 151068

Page 33

Hardware Installation

4.7.3.4 SK-2880 Input Switches and Relay Wiring

This section describes the components of terminal strip 2 (see Figure 4-13) on the SK-2880.

T erminal strip 2 provides two input switches (Reset & Silence) and three Form C relay. Figure

4-16 illustrates how to configure the inputs switches and the Form C Relays.

Any Open

Collector Output

4.7 K

UL

Listed

EOL

Ω

Model

7628

Use Either

Configuration

Supervised

Power Limited

4.7 K

Ω

Normally

Open Contact

To

Input

or

Supervised

Power Limited

To

Normally

Closed Contact

Input

Figure 4-16 Wiring Examples for Input Switches and Form C Relays

151068 4-17

Page 34

Model SK-4224 Fire Control Panel Installation/Operation Manual

4.7.3.5 Mounting the SK-2880

The I/O module must be mounted in a UL Listed enclosure.

Follow these steps to mount the SK-2880:

1. Remove the SK-2880’s cover. A small screw driver can be used.

2. Remove the SK-2880 circuit board from the base by pushing outward on the base retaining tabs and lift the circuit board out. See Figure 4-17.

Circuit

Board

Base

Retaining

Tabs

Base

Figure 4-17 Circuit Board and Plastic Base Components

3. Mount the plastic base in a UL listed enclosure using any of the mounting holes in the

plastic base. See Figure 4-18 for locations of base mounting holes.

Mounting

Holes

Mounting

Holes

Mounting

Holes

Verify the proper wire termination and then snap the I/O module cover in place.

4-18 151068

Figure 4-18 Base Mounting Holes

Page 35

Section 5

Notification Expansion Mode

The SK-4224 can be used to expand the power capabilities of an existing system’s notification

circuits. The SK-4224 does this buy connecting the notification circuits of an existing or host

fire alarm control panel to the FACP input of the SK-4224, which can trigger the SK-4224

notification cicuits when the host panel goes into alarm.

Note: The SK-4224 does not go into the alarm state when the host control panel triggers the SK-4224’s

notification cicuits.

5.1 Class A Notification Expansion Wiring

Figure 5-1 shows Class supervised wiring from a host panel to the SK-4224 control board.

Observe the proper polarity when making wire connections and follow these requirements:

• When wiring to terminal B on the SK-4224, you must use two separate wires. Do not loop

a single wire or twist two conductors together.

• FACP input 20.4 VDC to 26.4 VDC.

• Do not use notification appliances on Class A circuits connected to the SK-4224 FACP

input. The SK-4224 will detect voltage across the input circuits, but is not designed to pass

the added current load from the notification appliances.

Figure 5-1 Class A Supervised Notification Expansion Configuration

151068 5-1

Page 36

Model SK-4224 Fire Control Panel Installation/Operation Manual

5.2 Class B Notification Expansion Wiring

Figure 5-2 shows Class B supervised wiring from a host fire alarm control panel to the SK4224 control panel. Use an EOL resistor as shown in to supervise the FACP input. The host

fire alarm control panel may use an EOL with a value other than 4.7 KΩ, used by the SK-

4224. In this case, use an UL listed EOL for the host panel you are using.

Figure 5-2 Class B Supervised Notification Expansion Configuration

5-2 151068

Page 37

Section 6

System Configuration

To configure the SK-4224 system set the dipswitch that controls the option you want to

select. The following chart shows how to program the dipswitches that control system, zone,

and notification appliance operation. Refer to Figure 3-1 for location of the dipswitches.

Important!

When you change a dipswitch, be sure to perform a system reset (press [RESET]) or power

down the panel. Dipswitch changes will have no effect until after the system has been reset.

Table 6-1: System Configuration

To Enable

Enhanced mode (dipswitch ON). Use when both pull

stations and detectors will be used in the same zone.

Normal mode (dipswitch OFF). Use when 4-wire smoke

detectors and smoke verificat ion are used in the same

zone.

Alarm verification

Note:

Do not use with smoke detectors that have verification built-in.

Zone Type

Alarm delay options

Note:

Alarm delay options is to

be used with water flow

devices only. If the device

has a built-in delay time

the total delay time (device delay + progr ammed

delay) can not exceed 120

seconds.

To Enable For NAC 1 (DIP 3) For NAC 2 (DIP 3) DIP Position

Fire alarm SW 3 SW8 SW 3 SW8 OFF

Supervisory SW 3 SW8 SW 3 SW8 ON

No delay SW4

30 second delay SW4

60 second delay SW4

90 second delay SW4

Dip Switch 1 Dip Switch 2

For Zone 1 For Zone 2 For Zone 3 For Zone 4 DIP Position

SW1 SW6 SW1 SW6 ON = E nhanced

OFF = Normal

SW 2 SW 7 SW 2 SW 7 ON = Verification zone

OFF = No verification

SW5

SW5

SW5

SW5

SW9

SW10

SW9

SW10

SW9

SW10

SW9

SW10

SW4

SW5

SW4

SW5

SW4

SW5

SW4

SW5

SW9

SW10

SW9

SW10

SW9

SW10

SW9

SW10

OFF

OFF

ON

OFF

OFF

ON

ON

ON

Silencing

ANSI pattern

151068 6-1

SW 1 SW 3 ON = Can be silenced

OFF = No silence

SW 2 SW 4 ON = ANSI

Off = Steady

Page 38

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table 6-1: System Configuration

To Enable For Entire Panel (DIP 3) DIP Position

SW5

Serial Accessory Devices

*SW6

AC loss report delay SW7

Input Output Circuits Class A / Class B Enable SW8

* Serial Dialer not available at this time.

ON = Serial Annunciator connected to the control panel.

OFF = No Serial Annunciator connected to the control

panel.

ON = Serial Dialer connected to the control panel

OFF = No Serial Dialer connected to the control panel.

ON = 6 hour delay on AC loss report.

OFF = No delay on AC.

Note: If there is not a serial dialer connected to the con-

trol panel this should be se t t o t he OFF po sitio n.

ON = Class A configuration for both the input and

output circuits.

OFF = Class B configuration for both the input and

output circuits.

6-2 151068

Page 39

Section 7

System Operation

The annunciator on the SK-4224 board is used for all system operation. It contains the

switches for enabling silencing, resetting, and so on. The LEDs that indicate system status are

also located on the annunciator.

Figure 7-1 On-Board Annunciator

7.1 Meaning of LEDs

The chart below explains the meaning of LEDs on the system board.

Table 7-1: Meaning of LEDs

LED (Color) Function Comments

AC (green) ON = Good AC

OFF = Low AC trouble condition and it was acknowledged

FLASHING = Unacknowledged AC Low trouble condition

GENERAL TROUBLE

(yellow)

WALK TEST (yellow) ON = Walk test is in progress

ON = System trouble

OFF = System OK

FLASHING = At least one serial device is in trouble

DOUBLE FLASHING = Two types of serial devices are in trouble.

OFF = Wa lk test is off.

FLASHING = Walk test is on and at least one zone is not ready

If flashing press the ACK button to

acknowledged the condition.

Allow approximately 47 seconds between

detector tests.

In walk test when a detector is tripped it

will cause an alarm for t wo sec ond s, th e n

the control panel will drop power to the

loop for seven seconds to reset the

detector. Then an additional 38 seconds is

needed to restore the detect or.

If verification is used the time between

detector test will be about 2 minute and

30 seconds.

151068 7-1

Page 40

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table 7-1: Meaning of LEDs

LED (Color) Function Comments

GND FAULT (yellow) ON = Ground fault condition exists and was acknowledged

OFF = No fault

FLASHING = A ground f a ult condition det ected

LOW BATTERY (yellow) ON = Battery low condition that has been acknowledged

OFF = Good battery condition

FLASHING = Battery low condition

ALARM (red) ON = Zone in alarm which has been acknowledged

OFF = No Alarm

FLASHING = Zone in alarm has not yet been acknowledged

SUPERVISORY

(yellow)

ZONE 1

and

ZONE 2

NAC 1

and

NAC 2

SYSTEM SILENCED

(yellow)

TROUBLE

(yellow)

ACTIVE (yellow) ON = NAC is active during an alarm

TROUBLE

(yellow)

ON = Zone has a supervisory condition which has been

acknowledged (self-restoring condition)

OFF = No supervisory condition exists

FLASHING = Supervisor y trouble detected on that zone that has

not yet been acknowledged

ON = Zone has a trouble condition which has been acknowledged

OFF = No zone trouble

FLASHING = Zone has a trouble condition not yet acknowledged

DOUBLE FLASHING = Zone was disabled

CLEAN ME FLASHING = Indicates that the smoke detector needs

cleaning

OFF = NAC is not active during alarm

ON = NAC has a trouble condition and was acknowledged

OFF = No trouble condition

FLASHING = NAC is in trouble

DOUBLE FLASHING = Circuit was disabled

ON = System audible output has been silenced

OFF = Nothing silenced

FLASHING = Partially silenced

If flashing press the ACK button to

acknowledged the condition.

If flashing press the ACK button to

acknowledged the condition.

If flashing press the ACK button to

acknowledged the condition.

If flashing press the ACK button to

acknowledged the condition.

If flashing press the ACK button to

acknowledged the condition.

A “Clean Me Flash” is a flash with a long

LED on Time and a short LED off time

indicating that the smoke d etector needs

cleaning. Applies only to smoke detectors

with the CLEAN ME feature. The “Clean

Me” flash starts after the tr ouble

condition has been acknowledge.

If flashing press the ACK button to

acknowledged the condition.

Audible trouble activations will clear

automatically when the condition resets.

Audible alarm signals have to be

manually reset.

Note:

general trouble condition.

Silencing an alarm will cause a

7-2 151068

Page 41

System Operation

7.2 Operation Keys (Switches)

All system operation are performed from the on-board keys (switches) as described in the

chart below.

Table 7-2: Operations and Instructions

Operation Keystrokes

Disable notification appliance

circuit.

To re-enable the circuit, press [NAC

DISABLE] again.

Disable a zone

To re-enable the circuit, press

[ZONE DISABLE] again.

Begin Walk Test Press [WALK TEST]. Walk Test LED turns on.

End Walk Test

(The test ends automatically a fte r 1 0

minutes of no system activity.)

Acknowledge condition (alarm,

supervisory, trouble)

Silence Panel Press [SILENCE]. This will silence the on-board PZT and all active NAC circuits

Perform system reset Press [RESET]. Resets alarms, supervisories, troubles and all LEDs.

Press the appropriate [NAC DISABLE] key. The NAC circuit will be disabled and

the corresponding TROUBLE LED will Double Flash. This function is not

available during an alarm condition.

Press the appropriate [ZONE DISABL E] key. The zone will be disabled and the

corresponding TROUBLE LED will Double Flash. This function is not available

during an alarm or supervisory condition.

Note:

pervisory condition.

Press [WALK TEST].

NOTE: The Walk Test feature is not operational during an alarm, supervisory or

any system trouble condition.

Press [ACK]. The corresponding LED will change from blinking to steady for the

duration of the condition. Except for CLEAN ME trouble indications.

that have been confi gured as "silenceable".

Walk test will not activate if th e c on trol pa nel h a s a t rou ble, a la rm , o r su-

151068 7-3

Page 42

Model SK-4224 Fire Control Panel Installation/Operation Manual

7-4 151068

Page 43

Appendix A

Compatible Devices

This section of the manual lists devices (smoke detectors and notification appliances) that are

compatible with the SK-4224. Contact Silent Knight if you have a question about whether a

device not listed here is compatible.

A.1 Smoke Detectors

This section of the manual contains information about smoke detectors that are compatible

with the SK-4224.

SK-4224

Identifier

Voltage Range

Note: The maximum number of smoke det ect o rs pe r zone i s dete r min ed by bot h the curre nt draw and the imped-

ance of the smoke detector. If too many smoke detectors are used on any zone, false alarms could occur.

Do not mix different models of detectors on any zone; false alarms could occur.

24F

16.2-27.3 VDC

A.1.1 Enhanced Mode

Enhanced mode allows the installer to use pull stations on a loop that has been programmed

for Enhanced Alarm Verification. If a single detector goes into alarm it will start the alarm

verification cycle. If a pull station is activated any time during the alarm verification cycle and

after the control panel re-applies loop power (power will drop for seven seconds to restore

detector during verification), the panel will go into immediate alarm and discontinue the

verification cycle.

Warning! Do not mix different models or manufacturers of smoke detectors on the input loops.

151068 A-1

Page 44

Model SK-4224 Fire Control Panel Installation/Operation Manual

A.1.2 Two-Wire Smoke Detectors

The table below lists two-wire smoke detectors that are compatible with the SK-4224. The

table is organized by manufacturer. The columns show the number of detectors per loop that

can be used.

Note: The check mark by manufacturers name indicates that this device can be used in enhanced mode.

Table A-1: Compatible Two-W ire Smoke Detectors

Manufacturer

Apollo

Detection Systems

ESL

Enhance

Mode

Compatible

Model Name or Number

(Base model name or number in

parentheses.)

55000-350 (45681-200) 55000-350 45681-200 24 / loop

55000-250 (45681-200) 55000-250 45681-200 24 / loop

DS250 (MB2W or MB 2WL) B A 18 / loop

DS250HD (MB2W or MB2WL) B A 18 / loop

DS250TH (MB2W or MB2WL) B A 18 / loop

429C (S10A) N/A S10A 30 / loop

429CRT (S11A) N/A S11A 30 / loop

429CST (S11A) N/A S11A 30 / loop

429CT (S10A) N/A S10A 30 / loop

609U01-11 S10 S00 40 / loop

609U02-11 S10 S00/S03 40 / loop

611U (601U or 602U) S10 S00/S03 40 / loop

611UD (601U or 602U) S10 S00/S03 40 / loop

611UT (601U or 602U) S10 S00/S03 40 / loop

612U (601U or 602U) S10 S00/S03 40 / loop

Compatibility ID

# per Loop

Head Base

612UD (601U or 602U) S10 S00/S03 40 / loop

711U (701E or 701U) N/A S10A 25 / loop

712U (701E or 701U) N/A S10A 25 / loop

713-5U (702E or 70 1U) N/A S10A 25 / loop

ESL

(Cont.)

Falcon

713-6U (702E or 70 1U) N/A S10A 25 / loop

721-U (S10A) N/A S10A 30 / loop

721-UT (S10A) N/A S10A 30 / loop

525 FDT1 N/A 17 / loop

525T FDT1 N/A 17 / loop

A-2 151068

Page 45

Table A-1: Compatible Two-W ire Smoke Detectors

Compatible Devices

Enhance

Manufacturer

System Sensor

Mode

Compatible

Four-Wire Smoke Detectors

Table A-2: Compatible Four-Wire Smoke Detectors

Manufacturer Model

Silent Knight

Detection Systems

Model Name or Number

(Base model name or number in

parentheses.)

1400 A N/A 20 / loop

1451 (B401B) A A 20 / loop

2300T A N/A 20 / loop

2300 A N/A 20 / loop

2300TB A N/A 20 / loop

2451 (B401B) A N/A 20 / loop

2451DH (DH 400) A N/A 20 / loop

2451TH (B401B) A N/A 20 / loop

SD-P24F with SD-B4@ base

DS200/DS200HD

MB200

Compatibility ID

# per Loop

Head Base

ESL

Gentex

System Sensor

445 Series

449 Series

624

824

2040-24 Power Supervision Unit

1851B

2851/2851BTH

DH200ADCD

151068 A-3

Page 46

Model SK-4224 Fire Control Panel Installation/Operation Manual

A.2 Notification Appliances

The chart below lists notification appliances compatible with the SK-4224.

Note: Units that operate at 12 or 24 VDC must be selected for 24 VDC operation.

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Faraday 446X 12/24VDC Vibrating Bell

Faraday 476X 12/24VDC Vibrating Bell

Faraday 477X 12/24VDC Singl e Stroke Bell

Faraday 5 303B-0-14-( )-DC Chime (flush)

Faraday 5 304B-0-14-( )-DC Ch ime (surface)

Faraday 5305B-0-4-( )-DC Chime (ceiling)

Faraday 5306B-0-14-( )-24-DC Chime/Strobe (flush)

Faraday 5307B-0-14-( )-24-DC Chime/Strobe (surface)

Faraday 5308B-0-4-( )-24-DC Chime/Strobe (ceiling)

Faraday 5333B-0-14-24-DC Multi-Tone Horn (flush)

Faraday 5 334B-0-14-24-DC Multi-To ne Horn (surface)

Faraday 5336B-( )-14-24-DC Multi-Tone Horn/Strobe (flush)

Faraday 5337B-( )-14-24-DC Multi-Tone Horn/Strobe (surface)

Faraday 5338B-( )-4-24-DC Multi-Tone Horn/Strobe (ceiling)

Faraday 5343B-0-14-24-DC Single Tone Horn/Strobe (flush)

Faraday 5344B-0-14-24-DC Single Tone Horn/Strobe (surface)

Faraday 5345B-0-4-24-DC Single Tone Horn/Strobe (ceiling)

Faraday 5348B-( )-4-24-DC Single Tone Horn/Strobe (ceiling)

Faraday 5373B-0-14-24-DC 8-Tone Horn/Strobe (flush)

Faraday 5374B-0-14-24-DC 8-Tone Horn/Strobe (surface)

Faraday 5375B-0-4-24-DC 8-Tone Horn/Strobe (ceiling)

Faraday 5376B-0-14-24-DC 8-Tone Horn/Strobe (flush)

Faraday 5377B-0-14-24-DC 8-Tone Horn/Strobe (surface)

Faraday 5378B-0-4-24-DC 8-Tone Horn/Strobe (ceiling)

Faraday 5405B-0-14-24-DC S ync Control Unit

Faraday 5508B-( )-14-24-DC Single Gang Sync Strobe (flush)

Faraday 5521B-( )-14-24-DC 4” Square Sync Strobe (surface)

A-4 151068

Page 47

Compatible Devices

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Faraday 5522B-( )-14-24-DC 4” Square Sync Strobe (flush)

Faraday 6126B-U-14-24 VDC Horn/Strobe

Faraday 6223B-0-14-24-DC Horn (flush)

Faraday 6224B-0-14-24-DC Horn (surface )

Faraday 6225B-0-4-24-DC Horn (ceiling)

Faraday 6226B-( )-14-24-DC Horn/Strobe (flush)

Faraday 6227B-( )-14-24-DC Horn/Strobe (surface)

Faraday 6228B-( )-4-24-DC Horn/Strobe (ceiling)

Faraday 6243B-0-14-24-DC Electron -Mechanical Horn (flush)

Faraday 6244B-0-14-24-DC Electron -Mechanical Horn (surface)

Faraday 6245B-0-4-24-DC Electron-Mechanical Horn (ceiling)

Faraday 6246B-( )-14-24-DC Electron-Mechanical Horn/Strobe (flush)

Faraday 6247B-( )-14-24-DC Electron-Mechanical Horn/Strobe (surface)

Faraday 6248B-( )-4-24-DC Electron-Mechanical Horn/Strobe (ceiling)

Faraday 6300B-0-14-24-DC Mini-Horn (flush)

Faraday 6301B-0-14-24-DC Mini-Horn (surface)

Faraday 6302B-( )-4-24-DC Mini-Horn (ceiling)

Faraday 6310B-0-14-24-DC Mini-Horn/Strobe/Strobe (flush)

Faraday 6311B-0-14-24-DC Mini-Horn/Strobe/Strobe (surface)

Faraday 6312B-( )-14-24-DC Mini-Horn/Strobe/Strobe (ceiling)

Faraday 6320B-0-14-24-DC Sync Mi ni Horn/Strobe (1 gang)

Faraday 6321B-0-14-24-DC Sync Mini Horn/Strobe (1,2 gang)

Faraday 6322B-( )-14-24-DC Mini Horn/Sync Strobe (1,2 gang, 4SQ)

Federal Signa l 450 Horn

Federal Signa l VALS Horn/Strobe

Gentex GX90-4 Horn

Gentex GXS-4-15-1 Strobe

Gentex GXS-4-1575 Strobe

Gentex GX90S-4-15 Horn

Gentex GX90S-4-1575 Horn

Gentex HG124 Horn

Gentex SHG24-1575 Horn/Strobe

151068 A-5

Page 48

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Gentex SHG24-15 Horn/Strobe

Gentex GMH-24-X Horn

Gentex GMS-24-X Horn/Strobe

Gentex GMS-24-X Horn/Strobe

Gentex G0T24 Horn

Gentex G0S24-X Horn

Gentex WGMS-24-X Horn/Strobe

System Sensor MASS241 Horn/Strobe

System Sensor MASS24110ADA Horn/Strobe

System Sensor MASS2415ADA Horn/Strobe

System Sensor MASS2475ADA Horn/Strobe

System Sensor SS4110ADA Strobe

System Sensor SS2415ADA Strobe

System Sensor SS2475ADA Strobe

System Sensor PS2415ADA Mini-Horn/Strobe

System Sensor PS241575ADA Mini-Horn/Strobe

System Sensor PS24110ADA Mini-Horn/Strobe

System Sensor PS2475ADA Mini-Horn/Strobe

Wheelock 46T-G4-24-R Bell

Wheelock 46T-G6-24-R Bell

Wheelock 46T-G10-24-R Bell

Wheelock 46T-G6-24-WS-24-HF-R Strobe/Bell

Wheelock 46T-G10-24-WS-24-HF-R Strobe/Bell

Wheelock 46T-G6-24-WH-24-HF-R Strobe/Bell

Wheelock 46T-G10-24-WH-24-HF-R Strobe/Bell

Wheelock 7001T-12\24-W-FR Strobe Horn

Wheelock 7002T-12\24-W-FR Strobe Horn

Wheelock AES-DL1-R Multitone Horn

Wheelock AES-EL1-R Multitone Horn

Wheelock AES-DL1-WS-24-VF-R Multitone Horn

Wheelock AES-EL1-WS-24-VF-R Multitone Horn

Wheelock AES-DL1-WH-24-VF-R Multitone Horn

A-6 151068

Page 49

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock AES-EL1-WH-24-VF-R Multitone Horn

Wheelock AES-DL1-WM-24-VF-R Multitone Horn

Wheelock AES-EL1-WM-24-VF-R Multitone Horn

Wheelock AH-24-R Horn

Wheelock AH-24WP-R Horn

Wheelock AMT-12\24-R Strobe Horn

Wheelock AMT-24-LS-VFR Strobe Horn

Wheelock AMT-24-LSM-VFR Strobe Horn

Wheelock AMT-24-IS-VFR Strobe Horn

Wheelock AS2415W-F R Audible Strobe

Wheelock AS241575W-FR Audible Strobe

Wheelock AS2430W-F R Audible Strobe

Compatible Devices

Wheelock AS2475W-F R Audible Strobe

Wheelock AS24110W-FR Audible Strobe

Wheelock AS2415C-FW Audible Strobe

Wheelock AS2430C-FW Audible Strobe

Wheelock AS2475C-FW Audible Strobe

Wheelock AS24100C- FW Audible Strobe

Wheelock AS-2415-VFR Strobe Horn

Wheelock AS-241575-VFR Strobe Horn

Wheelock AS-2430-VFR Strobe Horn

Wheelock AS-2475-VFR Strobe Horn

Wheelock AS-24110-HFR Strobe Horn

Wheelock SM-12/24-R Strobe Horn Controller

Wheelock DSM-12/24-R Strobe Horn Controller

Wheelock CF-BF1 Chime

Wheelock CF-BF1-R Chime

Wheelock CH70-24-R Chime

Wheelock CH90-24-W Chime

Wheelock CH70-2415W-FR Chime Strobe

Wheelock CH70-241575W-FR Chime Strobe

Wheelock CH70-2430W-FR Chime Strobe

151068 A-7

Page 50

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock CH70-2475W-FR Chime Strobe

Wheelock CH70-24110W-FR Chime Strobe

Wheelock CH-CF1 Chime

Wheelock CH-CF1-R Chime

Wheelock CH-CF1-W Chime

Wheelock CH-DF1 Chime

Wheelock CH-DF1-R Chime

Wheelock CH-BF1-WS-24-HF-R Strobe Chime

Wheelock CH-CF1-LS-24 Strobe Chime

Wheelock CH-CF1-MS-24 Strobe Chime

Wheelock CH-CF1-IS-24 Strobe Chime

Wheelock CH-CF1-LS-24-CFW Strobe Chime

Wheelock CH-CF1-MS-24-CFW Strobe Chime

Wheelock CH-CF1-IS-24-CFW Strobe Chime

Wheelock CH-CF1-WS-24-CF-W Strobe Chime

Wheelock CH-DF1-LS-24 Strobe Chime

Wheelock CH-DF1-MS-24 Strobe Chime

Wheelock CH-DF1-IS-24 Strobe Chime

Wheelock CH-DF1-LS-24-VFR Strobe Chime

Wheelock CH-DF1-LSM-24-VFR Strobe Chime

Wheelock CH-DF1-MS-24-VFR Strobe Chime

Wheelock CH-DF1-IS-24-VFR Strobe Chime

Wheelock CH-DF1-WM-24-VFR Strobe Chime

Wheelock CH-DF1-WS-24-VF-R Strobe Chime

Wheelock DSM-12/24 Sync Module

Wheelock EH-DL1-R Electronic Horn

Wheelock EH-EL1-R Electronic Horn Elect r onic Horn

Wheelock EHS-DL1-W-VF-R Strobe Horn (single input)

Wheelock EHS-EL1-W-VF-R Strobe Horn (single input)

Wheelock E H-DL1-WS-24-VF-R Strobe Horn (dual input)

Wheelock E H-EL1-WS-24-VF-R Strobe Horn (dual input)

Wheelock E H-DL1-WH-24-VF-R Strobe Horn (dual input)

A-8 151068

Page 51

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock E H-EL1-WH-24-VF-R Strobe Horn (dual input)

Wheelock E H-DL1-WM-24-VF-R Strobe Horn (dual input)

Wheelock E H-EL1-WM-24-VF-R Strobe Horn (dual input)

Wheelock HSW-24-HFR Remote Strobe

Wheelock HS2W-24 -HFR Remote Strobe

Wheelock HSPW-24-HFR Remote Strobe

Wheelock IS-24-VFR Remote Strobe

Wheelock IS1-24-VFR Remote Strobe

Wheelock IS3-24-VFR Remote Strobe

Wheelock ISP-24-HFR Remote Strobe

Wheelock LS-24-VFR Remote Strobe

Wheelock LS1-24-VFR Remote Strobe

Compatible Devices

Wheelock LS3-24-VFR Remote Strobe

Wheelock LSP-24-HFR Remote Strobe

Wheelock LSM-24-VFR Remote Strobe

Wheelock LS1M-24-VFR Remote Strobe

Wheelock LS3M-24-VFR Remote Strobe

Wheelock LSPM-24-VFR Remote Strobe

Wheelock MS-24-VFR Remote Strobe

Wheelock MS1-24-VFR Remote Strobe

Wheelock MS3-24-VFR Remote Strobe

Wheelock MSP-24-HFR Remo te Strobe

Wheelock MB-G6-24-R Motor Bell

Wheelock MB-G10-24-R Motor Bell

Wheelock MBS-G6-24-W-HF-R Motor Bell with Strobe

Wheelock MBS-G10-24-W-HF-R Motor Bell with Strobe

Wheelock MIZ-24-R Mini-Horn

Wheelock MIZ-24-W Mini-Horn

Wheelock MIZ-24-LS-VFR Mini-Horn/Strobe

Wheelock MIZ-24-LSM-VFR Mini-Horn/Strobe

Wheelock MIZ-24-MS-VFR Mini-Horn/Strobe

Wheelock MIZ-24-HSW-HFR Mini-Horn/Strobe

151068 A-9

Page 52

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock MIZ-24-IS-VFR Mini-Horn/Strobe

Wheelock MIZ-24-WS-VF-R Mini-Horn/Strobe

Wheelock MIZ-24-WS-VF-W Mini-Horn/Strobe

Wheelock MIZ-24-WH-VF-W Mini-Horn/Strobe

Wheelock MIZ-24-WM-VF-W Mini-Horn/Strobe

Wheelock MT-12/24-R Strobe Horn

Wheelock MT4-12/24-R Multitone Appliance

Wheelock MT4-115-R Multitone Appliance

Wheelock MT-24-LS-VFR Strobe Horn

Wheelock MT-24-LSM-VFR Strobe Horn

Wheelock MT-24-MS-VFR Strobe Horn

Wheelock MT-24-IS-VFR Strobe Horn

Wheelock MT-24-SL-VFR Strobe Horn

Wheelock MT-24-SLM-VFR Synch. Multitone Strobe

Wheelock MT-24-WM Strobe

Wheelock MT-24-WM-VF-R Horn

Wheelock MT-24-WM-VFR Strobe Horn

Wheelock NH-12/24-R Horn

Wheelock NS-2415W-FR Strobe Horn

Wheelock NS-241575W-FR Strobe Horn

Wheelock NS-2430W-FR Strobe Horn

Wheelock NS-2475W-FR Strobe Horn

Wheelock NS-24110W-FR Strobe Horn

Wheelock NS4-2415W-FR Strobe Horn

Wheelock NS4-241575W-FR Strobe Horn

Wheelock NS4-2430W-FR Strobe Horn

Wheelock NS4-2475W-FR Strobe Horn

Wheelock NS4-24110W-FR Strobe Horn

Wheelock RS-2415W-FR Strobe

Wheelock RS-2415W-FR Strobe

Wheelock RS-241575W-FR Strobe

Wheelock RS-2415-HFR Strobe

A-10 151068

Page 53

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock RSP-2415-VFR Strobe

Wheelock RS-241575-VFR Strobe

Wheelock RSP-241575-VFR Strobe

Wheelock RS-2430-VFR Strobe

Wheelock RS-2430-HFR Strobe

Wheelock RS-2475-VFR Strobe

Wheelock RSP-2475-HFR Strobe

Wheelock RS-24110-HFR Strobe

Wheelock RSP-24110-HFR Strobe

Wheelock RSS-2415W-FR Strobe

Wheelock RSS-241575W-FR Strobe

Wheelock RSS-2430W-FR Strobe

Compatible Devices

Wheelock RSS-2475W-FR Strobe

Wheelock RSS-24110W-FR Strobe

Wheelock RSS-2415C-FW Strobe

Wheelock RSS-2430C-FW Strobe

Wheelock RSS-2475C-FW Strobe

Wheelock RSS-24100C-FW Strobe

Wheelock RSSP-2415W-FR Strobe

Wheelock RSSP-241575-FR Strobe

Wheelock RSSP-2430W-FR Strobe

Wheelock RSSP-2475W-FR Strobe

Wheelock RSSP-24110W-FR Strobe

Wheelock SL-24-VFR Synchronized Remote Strobe

Wheelock SL1-24-VFR Synchronized Remote Strobe

Wheelock SL3-24-VFR Synchronized Remote Strobe

Wheelock SLP-24-VFR Synchronized Remote Strobe

Wheelock SLM-24-VFR Synchronized Remote Strobe

Wheelock SL1M-24-VFR Synchronized Remote Strobe

Wheelock SL3M-24-VFR Synchronized Remote Strobe

Wheelock SLPM-24-VFR Synchronized Remote Strobe

Wheelock SHW-24-VFR Synchronized Remote Strobe

151068 A-11

Page 54

Model SK-4224 Fire Control Panel Installation/Operation Manual

Table A-3: Compatible Notification Devices

Manufacturer Model Type

Wheelock SH2W-24-V FR Synchronized Remote Strobe

Wheelock SHPW-24-VFR Synchronized Remote Strobe

Wheelock SCM-24-R Controller for Synchronized Strobes

Wheelock SM-12/24-R Sync Module

Wheelock SR-2415-VFR Sync Strobe

Wheelock SRP-2415-HFR Sync Strobe

Wheelock SR-241575-VFR Sync Strobe

Wheelock SRP-241575-VFR Sync Strobe

Wheelock SR-2475-VFR Sync Strobe

Wheelock SR-2475-HFR Sync Strobe

Wheelock SR-24110-HFR Sync Strobe

Wheelock SRP-24110-HFR Sync Strobe

Wheelock V7001T-12\24-W-FR Strobe Horn

Wheelock WM3T-24-FR Remote Strobe

Wheelock WM3T-24-VFR Remote Strobe

Wheelock WS1T-24-FR Strobe

Wheelock WS3T-24-FR Strobe

Wheelock WST-24-FR Strobe

A-12 151068

Page 55

Silent Knight Fire Product Warranty and Return Policy

General Terms and Conditions

• All new fire products manufactured by Silent Knight after September 1, 1997 have a

limited warranty period of 18 months from the date of manufacture against defects in

materials and workmanship. See limited warranty statement for details.

• This limited warranty does not apply to those products that are damaged due to misuse,

abuse, negligence, or have been modified in any manner whatsoever.

Repair and RA Procedure

• All products that are returned to Silent Knight for credit or repair require a RA (Return

Authorization) number. Call Silent Knight Cust omer Service at 800-446-6444 or 612-4936435 between 8:00 A.M. and 5:00 P.M. CST, Monday through Friday to obtain a return

authorization number. Silent Knight Technical Support is available at 800-328-0103

between 8:00 A.M. and 7:00 P.M. CST, Monday through Friday.

• RA number must be prominently displayed on the outside of the shipping box. See return

address example under Advanced Replacement Policy.

• All products returned to Silent Knight must be sent freight pre-paid. After product is

processed, Silent Knight will pay for shipping product back to customer.

• Return the Silent Knight product circuit board only. Products that are returned in cabinets

will be charged an additional $20 to cover the extra shipping and handling costs over

board only returns. Do not return batteries. Silent Knight has the authority to determine if

a product is repairable. Products that are deemed un-repairable will be returned to the

customer.

• Product that is returned that has a board date code more than 18 months from date of

manufacture will be repaired and the customer will be assessed the standard Silent Knight

repair charge for that model.

• A detailed description of the problem should be included with each return.

Advanced Replacement Policy

• Silent Knight offers an option of advance replacement for fire product printed circuit

boards that fail during the 18 month warranty period.

• For advance replacement of a defective board call Silent Knight at 800-446-6444 or

612-493-6435 to obtain a RA (Return Authorization) number and request advanced

replacement.

• Customers must use a MasterCard or Visa credit card to get an advance replacement.

151068

Page 56

Model SK-4224 Fire Control Panel Installation/Operation Manual

• A new or refurbished board will be shipped to the customer . The customer will initially be

billed for the replacement board but a credit will be issued after the repairable board is

received at Silent Knight.

• The defective board must be returned within 30 days of shipment of replacement board for

customer to receive credit. No credit will be issue d if the returned bo ard was da maged due

to misuse or abuse.

• Repairs and returns should be sent to:

Silent Knight

Attn: Repair Department

7550 Meridian Circle

Maple Grove, MN 55369-4927

RA Number:___________________

Limited Warranty

Silent Knight warrants that the products of its manufacture shall be free from defects in materials or

workmanship for 18 months from the manufacturing date code on the printed circuit board, if such

goods have been properly installed, are subject to normal proper use, and have not been modified in

any manner whatsoever. Upon return of the defective product to the nearest Silent Knight, Silent

Knight will, at its sole discr etio n, eit her repai r or repla ce, at no cost, such go ods as may be o f defe ctive

material or workmanship. Customers outside the United States are to return products to their

distributor for repair.

SILENT KNIGHT SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIA L DAMAGES ARISING FROM LOSS OF PROPERTY OR

OTHER DAMAGE OR LOSSES OWING TO THE FAILURE OF SILENT KNIGHT SECURITY

SYSTEMS PRODUCTS BEYOND THE COST OF REPAIR OR REPLACEMENT OF ANY

DEFECTIVE PRODUCTS.

SILENT KNIGHT MAKES NO WARRANTY OF FITNESS OR MERCHANTABILITY AND NO

OTHER WARRANTY, ORAL OR WRITTEN, EXPRESS OR IMPLIED, BEYOND THE 18

MONTH WARRANTY EXPRESSLY SPECIFIED HEREIN.

151068

Page 57

SK-4224 BasicOperating Instructions P/N 151066

These instructions must be framed and displayed next to the SK-4224 panel in accordance

with NFPA 72 fire code for Local Fire Alarm System.

LED (Color) Function Comments

AC (green) ON = Good AC

GENERAL TROUBLE (yellow) ON = System trouble

WALK TEST (yellow) ON = Walk test is in progress

GND FAULT (yellow) ON = Ground fault condition exists and was acknowledged

LOW BATTERY (yellow) ON = Battery low condition that has been acknowledged

ZONE 1

and

ZONE 2

NAC 1 and

NAC 2

Cut Along the Dotted Line

SYSTEM SILENCED (yellow) ON = System audio output has been silenced

ALARM (red) ON = Zone in alarm which has been acknowledged

SUPERVISORY

(yellow)

TROUBLE (yellow) ON = Zone has a trouble condition which has been acknowledged

ACTIVE (yellow) ON = NAC is active during an alarm

TROUBLE (yellow) ON = NAC has a trouble condition and was acknowledged

OFF = Low AC trouble condition and it was acknowledged

FLASHING = Unacknowledged AC Low trouble condition

OFF = System OK

FLASHING = At least one serial device is in trouble

DOUBLE FLASHING = Two types of serial devices are in trouble.

OFF = Walk tes t is off.

FLASHING = Walk test is on and at least one zone is not ready

OFF = No fault

FLASHING = A ground fault condition detected

OFF = Good battery condition

FLASHING = Battery low condition

OFF = No Alarm

FLASHING = Zone in alarm has not yet been acknowledged

ON = Zone has a supervisory condition which has been acknowledged (selfrestoring condition)

OFF = No supervisory condition exists

FLASHING = Supervisory trouble detected on that zone that has not yet been

acknowledged

OFF = No zone trouble

FLASHING = Zone has a trouble condition not yet acknowledged

DOUBLE FLASHING = Zone was disabled

CLEAN ME FLASHING = Indicates that the smoke detector needs cleaning A “Clean Me Flash” is a flash with a long LED on Time and a short

OFF = NAC is not active during alarm

OFF = No trouble condition

FLASHING = NAC is in trouble

DOUBLE FLASHING = Circuit was disabled

OFF = Nothing silenced

FLASHING = Partially silenced

If flashing press the ACK button to acknowledged the condition.

Allow approximately 47 seconds between detector tests.

In walk test when a detector is tripped it will cause an alarm for two

seconds, then the control panel will drop power to the loop for seven

seconds to reset the detector. Then an additional 38 seconds is needed

to restore the detector.

If verification is used the time between detector test will be about 2

minute and 30 seconds.

If flashing press the ACK button to acknowledged the condition.

If flashing press the ACK button to acknowledged the condition.

If flashing press the ACK button to acknowledged the condition.

If flashing press the ACK button to acknowledged the condition.

If flashing press the ACK button to acknowledged the condition.

LED off time indicating that the smoke detector needs cleaning.

Applies only to smoke detectors with the CLEAN ME feature. The

“Clean Me” flash starts after the trouble condition has been

acknowledge.

If flashing press the ACK button to acknowledged the condition.

When condition that caused audio activation clears, this condition will

clear automatically.