Page 1

®

OWNERS MANUAL: HANDLING & SAFETY INSTRUCTIONS

READ THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL CAREFULLY

BEFORE USING THIS FIREARM; DO NOT DISCARD THIS MANUAL.

This instruction manual should always accompany this firearm and be transferred with it upon

ownership, or when the firearm is loaned or presented to another person.

Page 2

Certain states require, by law, that their own specified warning notices, in larger-than-normal type be conspicuously included

by the manufacturer, distributor, or retail dealer with firearms sold in that state. SIG SAUER sells its products in compliance with

applicable laws and regulations. Because our products may be sold in these states, we include the following:

CALIFORNIA:

State-By-State Warnings

WARNING

“Children are attracted to and can operate firearms that

can cause severe injuries or death. Prevent child access by

always keeping guns locked away and unloaded when not in

use. If you keep a loaded firearm where a child obtains and

improperly uses it, you may be fined or sent to prison.”

CONNECTICUT:

“UNLAWFUL STORAGE OF A LOADED FIREARM MAY RESULT IN IMPRISONMENT OR FINE.”

ADVERTENCIA

“A los niños atraen las amas de fuego y las pueden hacer

funcionar. Ellos pueden causarse lesions graves y la muerte.

Evite que los niños tengan accesso a las armas de fuego

guardándolas siepre con llave y descargadas cuando no las

esté utilizando. Si usted tiene una arma de fuego cargada

en un lugar en que un niño tiene accesso a ella y la usa

indebidamente, le pueden dar una multa o enviarlo a la

carcel.”

FLORIDA:

“IT IS UNLAWFUL, AND PUNISHABLE BY IMPRISONMENT AND FINE, FOR ANY ADULT TO STORE OR LEAVE A FIREARM IN ANY

PLACE WITHIN THE REACH OR EASY ACCESS OF A MINOR UNDER 18 YEARS OF AGE OR TO KNOWINGLY SELL OR OTHERWISE

TRANSFER OWNERSHIP OR POSSESSION OF A FIREARM TO A MINOR OR A PERSON OF UNSOUND MIND.”

2

www.sigsauer.com

Page 3

MAINE:

“ENDANGERING THE WELFARE OF A CHILD IS A CRIME. IF YOU LEAVE A FIREARM AND AMMUNITION WITHIN EASY ACCESS

OF A CHILD, YOU MAY BE SUBJECT TO FINE, IMPRISONMENT OR BOTH. KEEP FIREARMS AND AMMUNITION SEPARATE. KEEP

FIREARMS AND AMMUNITION LOCKED UP. USE TRIGGER LOCKS.”

MARYLAND:

“WARNING: Children can operate firearms which may cause death or serious injury. It is a crime to store or leave a loaded

firearm in any location where an individual knew or should have known that an unsupervised minor would gain access to the

firearm. Store your firearm responsibly!”

MASSACHUSETTS:

“WARNING FROM THE MASSACHUSETTS ATTORNEY GENERAL: This handgun is not equipped with a device that fully blocks use

by unauthorized users. More than 200,000 firearms like this one are stolen from their owners every year in the United States.

In addition, there are more than a thousand suicides each year by younger children and teenagers who get access to firearms.

Hundreds more die from accidental discharge. It is likely that many more children sustain serious wounds, or inflict such wounds

accidentally on others. In order to limit the chance of such misuse, it is imperative that you keep this weapon locked in a secure

place and take other steps necessary to limit the possibility of theft or accident. Failure to take reasonable preventative steps may

result in innocent lives being lost, and in some circumstances may result in your liability for these deaths.”

“IT IS UNLAWFUL TO STORE OR KEEP A FIREARM, RIFLE, SHOTGUN OR MACHINE GUN IN ANY PLACE UNLESS THAT WEAPON IS

EQUIPPED WITH A TAMPER RESISTANT SAFETY DEVICE OR IS STORED OR KEPT IN A SECURELY LOCKED CONTAINER.”

NEW JERSEY:

“IT IS A CRIMINAL OFFENSE TO LEAVE A LOADED FIREARM WITHIN EASY ACCESS OF A MINOR.”

www.sigsauer.com

3

Page 4

NEW YORK CITY, NY:

“THE USE OF A LOCKING DEVICE OR SAFETY LOCK IS ONLY ONE ASPECT OF RESPONSIBLE FIREARMS STORAGE. FOR INCREASED

SAFETY, FIREARMS SHOULD BE STORED UNLOADED AND LOCKED IN A LOCATION THAT IS BOTH SEPARATE FROM THEIR

AMMUNITION AND INACCESSIBLE TO CHILDREN AND OTHER UNAUTHORIZED PERSONS.”

NORTH CAROLINA:

Any person who resides in the same premises as a minor, owns or possesses a firearm, and stores or leaves the firearm (i)

in a condition that the firearm can be discharged and (ii) in a manner that the person knew or should have known that an

unsupervised minor would be able to gain access to the firearm, is guilty of a Class 1 misdemeanor if a minor gains access to

the firearm without the lawful permission of the minor’s parents or a person having charge of the minor and the minor:

(1) Possesses it in violation of G.S. 14-269.2(b)

(2) Exhibits it in a public place in a careless, angry, or threatening manner;

(3) Causes personal injury or death with it not in self defense; or

(4) Uses it in the commission of a crime.

TEXAS:

“IT IS UNLAWFUL TO STORE, TRANSPORT, OR ABANDON AN UNSECURED FIREARM IN A PLACE WHERE CHILDREN ARE LIKELY TO

BE AND CAN OBTAIN ACCESS TO THE FIREARM.”

WISCONSIN:

“IF YOU LEAVE A LOADED FIREARM WITHIN THE REACH OR EASY ACCESS OF A CHILD YOU MAY BE FINED OR IMPRISONED OR

BOTH IF THE CHILD IMPROPERLY DISCHARGES, POSSESSES, OR EXHIBITS THE FIREARM.”

Please check with your licensed retailer, state police, or local police for additional warnings, which may be required by local

law or regulation. Such regulations change constantly, and local authorities are in the best position to advise you on such legal

matters.

4

www.sigsauer.com

Page 5

THE BASIC RULES OF SAFE FIREARMS HANDLING

1. ALWAYS treat every gun as if it were loaded.

2. ALWAYS be sure the barrel is clear of any obstruction.

3. ALWAYS be sure of your backstop, what lies beyond, and the safety of bystanders before you shoot.

4. ALWAYS use clean, dry, original factory-made ammunition of the proper type and caliber for your gun.

5. ALWAYS wear ear protection and safety glasses when shooting.

6. ALWAYS carry your gun so that you can control the direction of the muzzle if you fall or stumble.

7. NEVER shoot at a flat surface or water.

8. DO NOT leave an unattended gun loaded. Guns and ammunition should be stored separately, locked if possible, beyond the

reach of children, careless adults, and unauthorized users.

9. NEVER allow your firearm to be used by anyone who has not read and understood this operator’s manual.

10. DO NOT point any gun, loaded or unloaded, at any undesired target.

11. NEVER fire your rifle near an animal unless it is trained to accept the noise: an animal’s startled reaction could injure it or

cause an accident.

12. NEVER drink alcoholic beverages or take drugs before or during shooting, as your vision and judgment could be seriously

impaired, making your gun handling unsafe.

www.sigsauer.com

5

Page 6

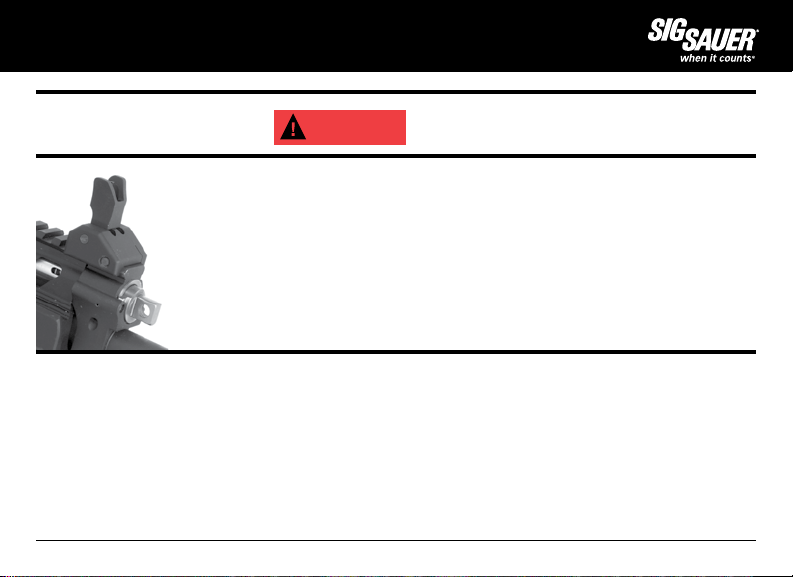

WARNING - LOCKING DEVICES

This firearm was originally sold with a key- operated locking device. While it can help provide secure

storage for your unloaded firearm, any locking device can fail. All guns are designed to fire if they

are loaded and the trigger is pulled. Therefore, never install the locking device inside the trigger

guard or in any way that makes it possible to pull the trigger! Do not leave the keys in the lock.

The ultimate responsibility for secure storage of any firearm must depend upon its owner and his

or her individual circumstances. Firearms should be stored unloaded, in a secure location, separate

from their ammunition.

NEVER INSTALL THE LOCKING DEVICE

INSIDE THE TRIGGER GUARD

To maximize effectiveness and reduce the chances of malfunction or damage to a firearm, ALWAYS

refer to the locking device’s manufacturer directions for installation and removal of the device.

6

www.sigsauer.com

Page 7

FIREARMS SAFETY IS YOUR RESPONSIBILITY

This owner’s manual is designed to assist you in learning how to use and care for your SIG SAUER® rifle properly.

Only when you are certain that you fully understand this manual and can properly carry out its instructions, should you practice

loading and firing your firearm with live ammunition. Having a gun in your possession is a full-time job; you cannot guess and

you cannot forget. You must know how to use your firearm safely.

If you have any doubts about your ability to handle or use this firearm safely, you should seek supervised instruction.

The Sig Sauer Academy™ provides all levels of firearms safety and skill training, from beginner to expert.

For more information contact:

www.sigsaueracademy.com • (603) 610-3400

Main campus: Epping, New Hampshire

Satellite Facilities: Range 82, Midland, VA

NRA Whittington Center, Raton, NM

SAFETY MUST BE THE FIRST AND CONSTANT CONSIDERATION OF

EVERY PERSON WHO HANDLES FIREARMS AND AMMUNITION.

For more information about safety, responsible firearms ownership, and shooting sports, contact: National Rifle Association

(NRA) of America, 11250 Waples Mill Road, Fairfax, VA 22030-7400 • 1-800-672-3888 • www.nra.com

www.sigsauer.com

7

Page 8

TABLE OF CONTENTS

Topic Page

State-By-State Warnings ................................................................2-4

The Basic Rules of Safe Firearms Handling ................................................. 5

Locking Device ......................................................................... 6

General Safety Information and Mechanical Characteristics ................................... 13

1.0 Safety Information .................................................................. 13

1.1. Protect Your Eyes And Ears ..................................................... 14

2.0 Mechanical Characteristics and Weapon Theory .......................................... 14

2.1. Weapon Description ............................................................ 14

2.1.1 General ..................................................................... 14

2.1.2 Barrel With Receiver And Gas System ............................................. 15

2.1.3 Bolt ......................................................................... 16

2.1.4 Handguards .................................................................. 17

2.1.5 Trigger Casing Assembly And Butt Stock .......................................... 18

2.1.6 Gas Valve Position ............................................................20

2.1.7 Butt Stock Operation .......................................................... 22

2.1.8 Sights ....................................................................... 23

BUIS Installation ................................................................... 24

2.1.10 Magazine ................................................................... 26

Operation of Safety .................................................................... 26

8

www.sigsauer.com

Page 9

Topic Page

Operation of Safety in Select Fire Version .................................................. 28

The Bolt Catch Lever .................................................................. 32

Ammunition .......................................................................... 33

To Load and Fire (With Magazine) ........................................................ 37

3.0 Handling .......................................................................... 37

3.1 Important Instructions ........................................................... 37

3.2 Loading The Rifle ............................................................... 38

3.3 Loading The Magazine ........................................................... 39

3.4 Changing the Magazine .......................................................... 39

3.5 Reloading ..................................................................... 40

To Unload Magazine and Rifle ............................................................ 43

4.0 Unloading ......................................................................... 43

To Extract and Eject a Chambered Cartridge ............................................ 45

To Clear a Malfunction (“Jam”) ...................................................... 46

5.0 Procedures In Case Of Malfunction .................................................... 46

To Minimize Malfunctions (“Jams”) ................................................... 48

6.0 Field Strip Disassembly .............................................................. 49

6.1 Reassembly ................................................................... 56

6.2 Function Check ................................................................ 61

www.sigsauer.com

9

Page 10

Topic Page

Magazine Inspection and Care ........................................................... 63

Care and Cleaning ...................................................................64

Transportation & Storage ................................................................ 64

7.0 Sight Options ...................................................................... 65

Troubleshooting ....................................................................... 66

8.0 Maintenance ....................................................................... 68

8.1 Cleaning ...................................................................... 69

Service and Parts Policy ...............................................................73

Shipping Firearms for Repair ............................................................ 74

Ordering Parts ....................................................................... 75

9.0 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.1 SIG556xi Select Fire Upper Parts List & Diagram ...................................... 78

9.2 SIG556xi Select Fire Lower Parts List & Diagram ...................................... 80

Warranty Information ................................................................. 82

10

www.sigsauer.com

Page 11

WARNINGS OF GREAT IMPORTANCE

ARE FOUND WITHIN THIS MANUAL

Locking Devices 6

Alterations 12

Sights 25

Manual Safety 33

Ammunition 33, 36

Lead Exposure 36

Handling 37, 42

OTHER CAUTIONS AND WARNINGS APPEAR THROUGHOUT THE MANUAL

Loading 38

Firing 42

Unloading 44

Storage 65

Parts Purchasers 72

Shipping 75

FIREARMS ARE DANGEROUS WEAPONS

READ THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL

THOROUGHLY AND CAREFULLY BEFORE USING.

www.sigsauer.com

11

Page 12

WARNING - ALTERATIONS

This product was designed to function properly in its original condition.

Alterations can make it unsafe. Do not alter any part or add or substitute any

parts or accessories not manufactured by SIG SAUER Inc. to be compatible

with this firearm.

DO NOT ALTER ANY GUN

12

www.sigsauer.com

Page 13

GENERAL SAFETY INFORMATION AND MECHANICAL CHARACTERISTICS

1.0 Safety Information

The safety warnings in this manual are important. By understanding the dangers inherent in the use of any firearm, and by

taking the precautions described herein, you can enjoy a greater level of safety in the use of your rifle. Failure to heed any of

these warnings may result in serious injury to you or others, as well as severe damage to the firearm or other property. SIG

SAUER Inc. shall not be responsible in any manner whatsoever for malfunctioning of the firearm, physical injury or property

damage resulting in whole or in part from:

1) criminal or negligent discharge;

2) improper or careless handling;

3) unauthorized modifications;

4) defective, improper, hand-loaded, or reloaded ammunition;

5) corrosion;

6) neglect; or

7) other influences beyond our direct and immediate control.

This limitation applies regardless of whether liability is asserted on the basis of contract, negligence, or strict liability (including

any failure to warn). Under no circumstance shall SIG SAUER Inc. be liable for incidental or consequential damages, such as loss

of use of property, commercial loss, and loss of earnings or profits.

www.sigsauer.com

13

Page 14

1.1 Protect Your Eyes And Ears

Always wear safety glasses and ear plugs or “earmuff” type protectors whenever you are shooting. Always make certain that

persons close to you are similarly protected. Unprotected eyes may be injured by powder, gas, carbon residue, lubricant,

metallic particles, or similar debris which may emanate occasionally from any firearm in normal use. Without ear protection,

repeated exposure to shooting noise may lead to cumulative, permanent hearing loss.

2.0. Mechanical Characteristics and Weapon Theory

2.1 Weapon Description

2.1.1 General

The SIG556xi Rifle is a gas operated firearm with a rotary bolt mechanism capable of semi-automatic, or automatic operation.

Semi-automatic means one round will fire each time the trigger is pulled until the magazine is emptied of ammunition.

Automatic means the rifle will continue to fire as long as the trigger is depressed or the magazine is emptied of ammunition.

The rifle is designed to be chambered in 5.56mm NATO, 7.62x39mm or .300 Blackout. Use only ammunition of the caliber for

which your firearm is chambered.

14

www.sigsauer.com

Page 15

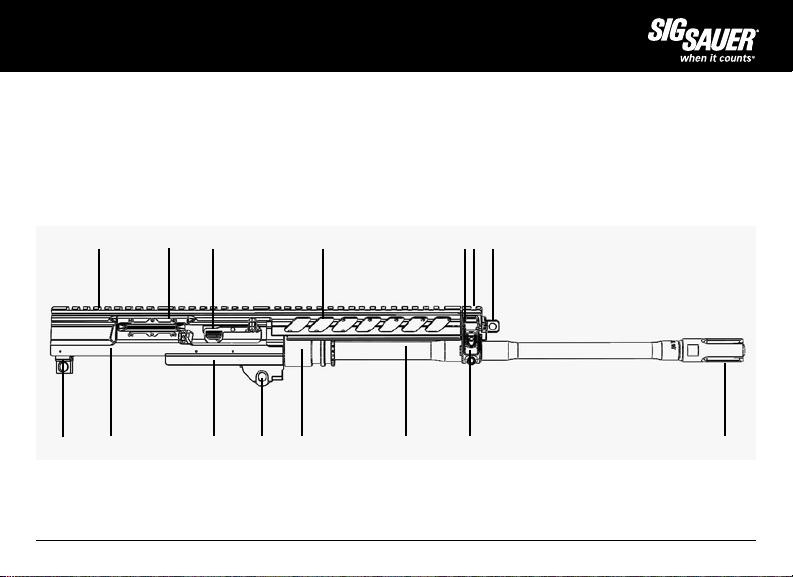

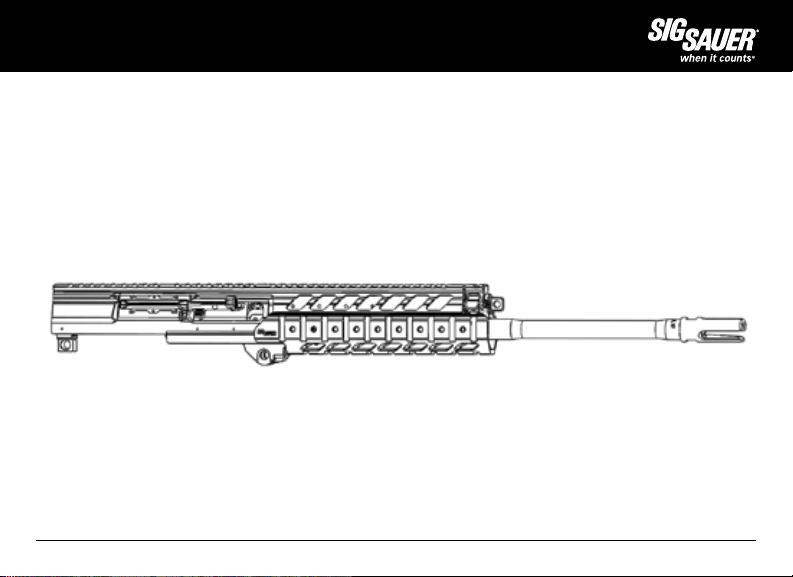

2.1.2 Barrel With Receiver And Gas System

The barrel is mechanically mated to the receiver. The flash suppressor is screwed onto the muzzle end of the barrel which

features a 0.5 x 28 TPI thread pattern. The gas block, which is fixed on the barrel, contains the gas port, locates the gas system

(gas tube and operating rod), accepts the front sight and also serves as support for the handguards. The receiver guides the

bolt and bolt carrier, and houses the locking system. An accessory mounting rail is fixed to the upper part of the receiver,

providing an attachment point for sighting systems and other accessories.

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15

1 Accessory Rail

2 Bolt Cover

3 Charging Handle Catch

4 Gas Tube

5 Operating Rod

(inside gas tube

6 Front Sight Rail

7 Gas Valve

8 Takedown Pin Hole

9 Receiver

10 Bolt & Bolt Carrier (hidden)

11 Pivot Pin Hole

www.sigsauer.com

12 Barrel Nut

13 Barrel

14 Gas Block

15 Flash Suppressor

15

Page 16

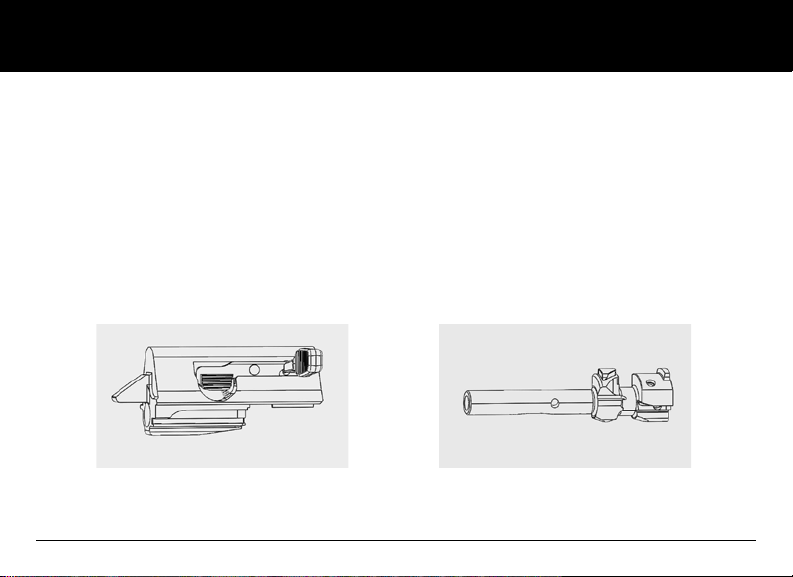

2.1.3 Bolt

The bolt consists of two main parts:

• Bolt Carrier

• Bolt Head

a. Bolt Carrier: The bolt carrier guides the bolt head, controls the locking and unlocking by means of the cam, holds the

operating rod, and cocks the hammer.

b. Bolt Head: The bolt head locks the bolt assembly, houses the firing pin and extractor and feeds the cartridges from the

magazine to the chamber.

BOLT CARRIER BOLT HEAD

16

www.sigsauer.com

Page 17

2.1.4 Handguards

The handguards protect the barrel and the gas system from damage and provide protection from burning. The integrated

accessory mounting slots provide attachment points for various devices once 1913 rail sections are attached, , such as lights,

lasers, sights, and bipods.

ALUMINUM HANDGUARD

www.sigsauer.com

17

Page 18

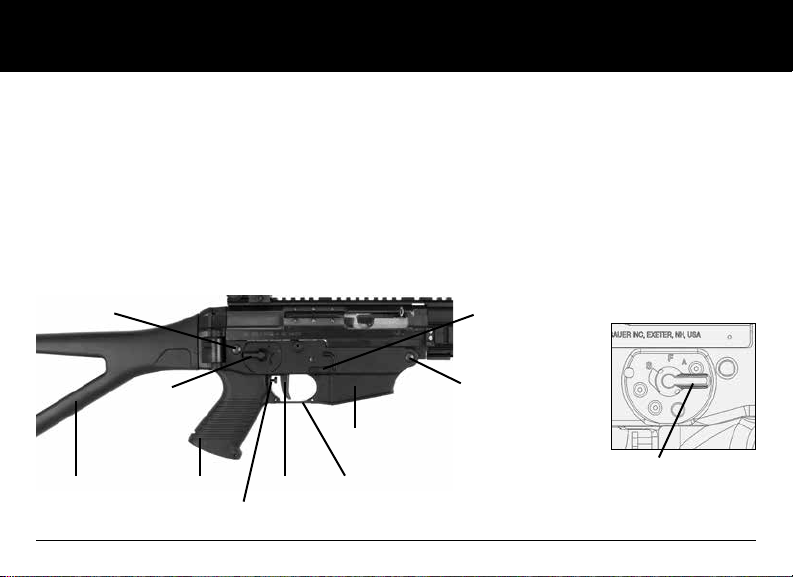

2.1.5 Trigger Casing Assembly and Butt Stock

The trigger casing assembly contains the internal components of the firing and safety mechanisms, bolt catch, magazine well,

magazine release, and butt stock assembly.

The safety lever, located on both sides of the trigger casing, can be set to three positions (Auto or 2 position Semi-only):

Position “S”: The weapon is locked in the safe position.

Position “F”: The weapon will fire semi auto.

Position “A”: The weapon fires in the full auto mode.

TAKEDOWN PIN

SAFETY

LEVERS

MAGAZINE WELL

BUTT STOCK RIFLE GRIP TRIGGER TRIGGER GUARD

PRESSURE POINT SCREW

18

www.sigsauer.com

MAGAZINE

RELEASE

PIVOT PIN

LEFT SIDE

SAFETY LEVERS

Page 19

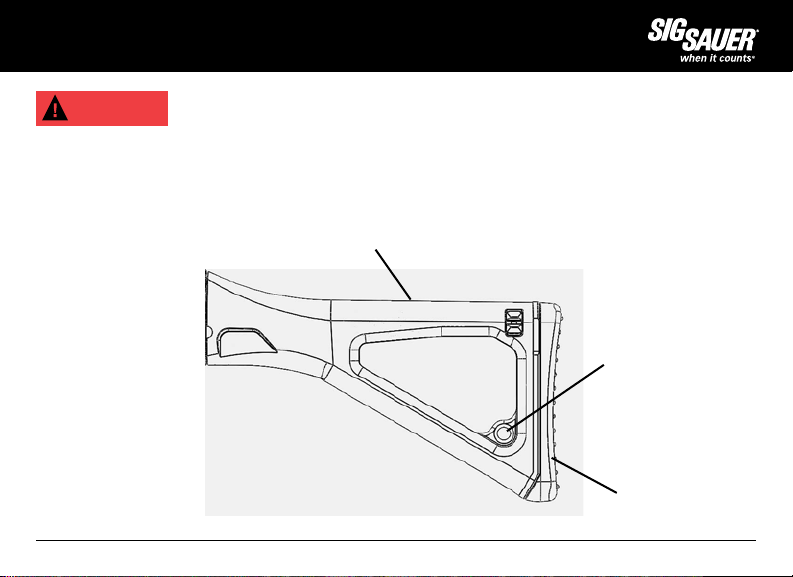

WARNING – Be careful of accidental discharges when inserting gloved fingers into the trigger guard.

The SIG556xi rifle is equipped with a side folding stock, featuring integral sling attachment points.

CHEEK REST

SLING ATTACHMENT

RECOIL PAD

www.sigsauer.com

19

Page 20

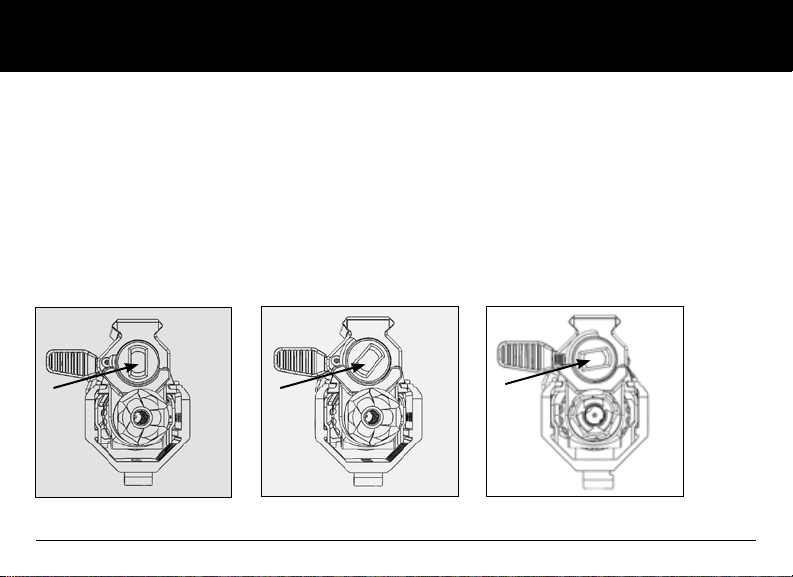

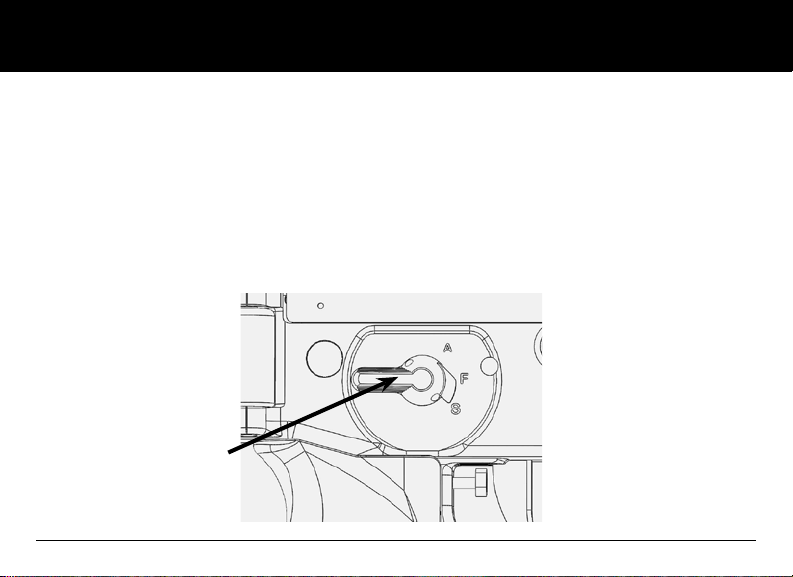

2.1.6 Gas Valve Position

The gas volume required for the function of the SIG556xi rifle can be controlled by the gas valve. The gas valve has three

positions:

a. Position 1 (Rib of gas valve in vertical position).

Under normal conditions, the gas valve should remain in Position 1. This will give the best all-around performance and

function.

b. Position 2 (Rib of gas valve in the slanted position).

c. Position 3 (Suppressed Setting)

POSITION 1 - RIB VERTICAL

20

POSITION 2 - RIB SLANTED POSITION 3 - SUPPRESSED

www.sigsauer.com

Page 21

If cycling or ejection problems are encountered due to heavy fouling, the gas valve can be moved to Position 2 by rotating

clockwise as far as the stop. In this position, a larger gas volume is released against the operating rod. The need to use the

gas valve in Position 2 is an indication that the rifle requires cleaning.

CAUTION

In the case of a hot or heavily fouled weapon, use a cartridge or auxiliary aid to prevent burns to your fingers.

-

NOTICE

Firing with the gas valve in Position 2 is an exception. As soon as normal function returns, the gas valve must

-

be returned to Position 1. Continued operation with the gas valve in Position 2 will increase recoil and

place unnecessary stress on the rifle. The rifle should be cleaned as soon as conditions permit.

WARNING

- Always ensure the rifle is unloaded and clear of ammunition when

manipulating the gas valve.

www.sigsauer.com

21

Page 22

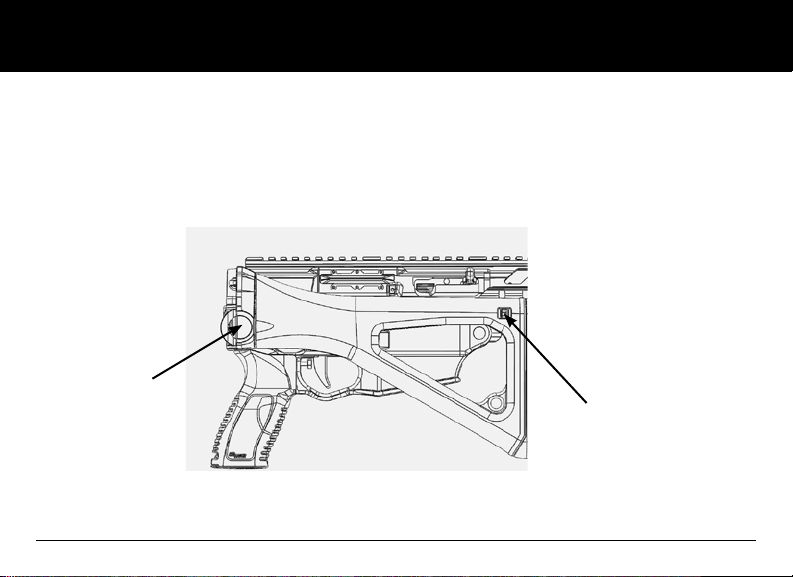

2.1.7 Butt Stock Operation

1. The butt stock provides for easy adjustment of length to accommodate the individual shooter or for storage.

2. To fold the stock, depress the latch on the left side of the rifle unlocking the stock. Fold the stock to the right until it latches

on the hook located at the rear of the handguard. Ensure the stock is locked prior to firing the rifle in this configuration.

2.1.8 Sights

STOCK LATCH

CLAW HOOK

22

www.sigsauer.com

Page 23

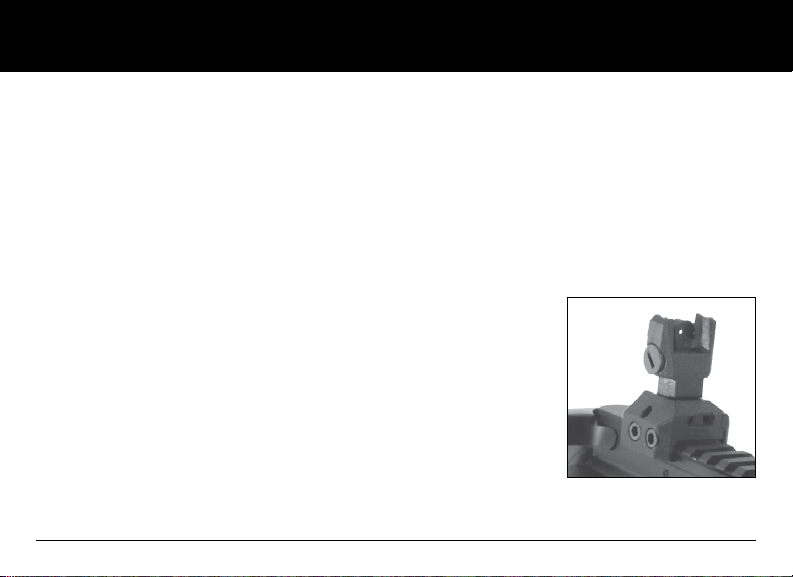

Front Sight Elevation Adjustment

Elevation adjustments are made to the front sight upon initial zeroing of the rifle. An M16A2/

M4 type front sight tool can be used to make sight adjustments.

Rotating the front sight post clockwise lowers the front sight post resulting in the impact of the

bullet to move upward on the target.

Rotating the front sight counterclockwise raises the front sight post resulting in the impact of

the bullet to move downward on the target.

www.sigsauer.com

23

Page 24

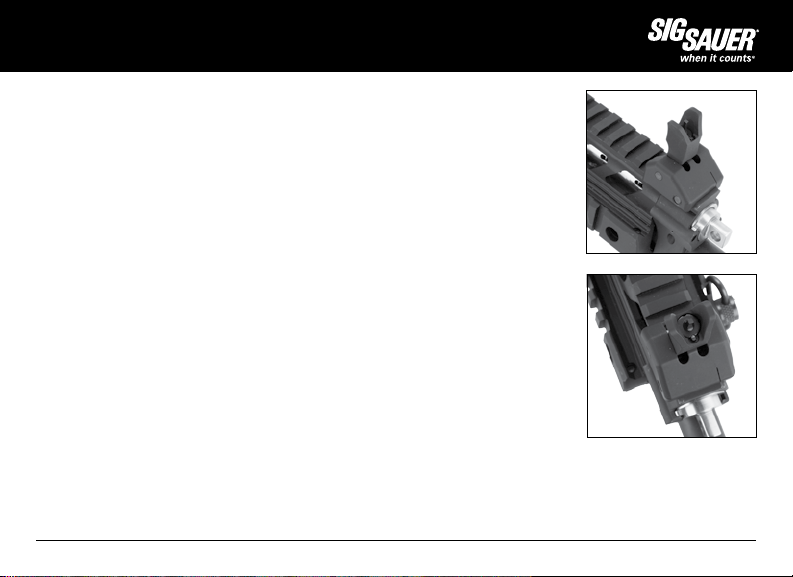

BUIS Installation on the SIG556xi

The SIG556xi is equipped with the SIG BUIS. This rear sight offers a rapid adjustment for range and an additional knob for windage. It also allows for a battesight zero to be set by the operator.

To Install:

1. The sight must be mounted in the second to last slot of the top M1913 Rail.

2. Set the sight in the rail slot with the windage knob to the right/range scale to the left.

3. Pull the sight back rearward in the slot until it stops.

4. Tighten the retaining screw until snug then an additional ¼ turn using an 1/8” hex wrench.

To Zero the BUIS:

Use an M4 25m zero target at a known distance of 25m:

1. Turn the range knob to 300m (Do not use the fine line between 300 and 400

as this is for a rifle length sight radius).

2. Fire a three round shot group.

3. Correct elevation with the front sight post.

4. Correct windage with the windage knob on the BUIS

5. Re-fire another 3 round group and make corrections.

24

www.sigsauer.com

Page 25

WARNING - SIGHTS

Do not adjust or otherwise manipulate any sight system on the rifle without first confirming the

magazine is removed, the safety lever is on “SAFE” and the rifle is fully unloaded.

Failure to heed this warning could result in unintentional discharge, resulting in injury or death.

UNLOAD RIFLE BEFORE MANIPULATING SIGHTS.

www.sigsauer.com

25

Page 26

2.1.10 Magazine

The Rifle ships with one (1) 30-round magazine. The SIG556xi is compatible with M16/AR-15 type magazines. The 556xi Russian

will use most AK47 type magazines.

OPERATION OF SAFETY

The SIG556xi has a manual safety which is located on the left and right side of the trigger casing, just forward of the rifle grip

and above the trigger. The safety levers may be operated from either side.

SAFETY LEVER

(RIGHT SIDE OF RIFLE)

26

www.sigsauer.com

Page 27

The safety is “ON” when the safety lever is in the “S” (SAFE)

position and the trigger guard is closed. In this position, the rifle cannot be

fired with a normal pull of the trigger.

The safety lever should always be in the “S” (SAFE) position except when the

shooter is actually firing the rifle. The safety lever should be moved to the “S”

(SAFE) position whenever the shooter ceases firing, even temporarily.

The safety is “OFF” when the safety lever is in the “F” (FIRE)

position “A” (AUTO). When the safety lever is in the “F” (FIRE) position the rifle

will fire in the semi-automatic mode each time the trigger is pulled until all the

ammunition is expended.

MANUAL SAFETY ON

MANUAL SAFETY OFF

www.sigsauer.com

27

Page 28

OPERATION OF SAFETY FOR SELECT FIRE VERSIONS

The SIG556xi Select Fire has a manual safety which is located on the left and right side of the trigger casing, just forward of the

rifle grip and above the trigger. The safety levers may be operated from either side.

The safety is “on” when the safety lever is in the “S” (SAFE) position and the trigger guard is closed. In this

position, the rifle cannot be fired with a normal pull of the trigger.

LEFT SIDE VIEW

28

www.sigsauer.com

MANUAL SAFETY LEVER

(RIGHT SIDE OF RIFLE)

Page 29

WARNING

DO NOT TOUCH THE TRIGGER

UNTIL YOU ARE ACTUALLY READY TO FIRE THE RIFLE.

The safety lever should always be in the “S” (SAFE) position except when the shooter is actually firing the rifle. The safety lever

should be moved to the “S” (SAFE) position whenever the shooter ceases firing, even temporarily.

The safety is “OFF”when the safety lever is in the “F” (FIRE), “A” (AUTOMATIC) positions. When the

safety lever is in the “F” position the rifle will fire in the semiautomatic mode each time the trigger is pulled until all the

ammunition is expended. When the safety lever is in the “A” position the rifle will continue to fire until the trigger is released

or all ammunition is expended. Releasing the trigger in “A” mode will interrupt firing until the trigger is again depressed.

www.sigsauer.com

29

Page 30

⤴

LEFT SIDE VIEW

⤴

SEMI-AUTO

RIGHT SIDE VIEW

AUTOMATIC

⤴

⤴

SEMI-AUTO

30

www.sigsauer.com

AUTOMATIC

Page 31

WARNING - MANUAL SAFETY

Keep the safety “ON” unless actually firing. Always move the safety to its

intended position and check it. The safety is not “ON” unless it is completely

“ON.” Never depend on a safety mechanism or any other mechanical device to

justify careless handling or permitting the rifle to point in an unsafe direction.

The only “safe” rifle is one in which the bolt is open, the chamber is empty, and

there is no magazine in the gun.

KNOW HOW TO USE THE SAFETY

www.sigsauer.com

31

Page 32

Bolt Catch Lever

The SIG556xi rifle is equipped with a bolt catch lever. The purpose of the bolt catch

lever is two-fold. The bolt catch may be manually engaged with the bolt pulled to the

rear (open position). This action locks the bolt open, allowing an unobstructed view

of the chamber area. During firing, with a magazine inserted, the bolt catch will lock

the bolt open after the last round in the magazine has been expended, giving a visual

indication the magazine is empty and allowing the shooter to visually check that the

chamber is clear. The bolt is engaged by the bolt catch lever when the bolt catch lever

is pushed upward by the magazine follower during the cycle of operation. The bolt can

be manually released (closed) by either depressing the bolt catch lever or by pulling

rearward on the charging handle and releasing.

WARNING

Dropping or jarring the rifle with the bolt locked open can cause the bolt catch lever to disengage. If a magazine, loaded

-

with ammunition, is inserted in the rifle when this occurs, a round will chamber with the potential for an unintentional

discharge. ALWAYS handle the rifle as if loaded whenever a magazine is inserted in the rifle. ALWAYS place the safety lever in

the “S” (SAFE) position and unload the rifle whenever shooting is complete.

32

www.sigsauer.com

Page 33

Ammunition

1. Use only high quality, original, factory-manufactured ammunition. Do not use cartridges that are dirty, wet, corroded, bent,

or damaged. Do not oil cartridges. Do not spray aerosol-type lubricants, preservative, or cleaners directly onto cartridges or

where excess spray may flow into contact with cartridges. Lubricant or other foreign matter on cartridges can cause potentially

dangerous ammunition malfunctions. Use only ammunition of the caliber for which your firearm is chambered. The proper

caliber is permanently engraved on your firearm; never attempt to use ammunition of any other caliber.

WARNING

2. The use of reloaded, “remanufactured” hand-loaded, or other non-standard ammunition voids all warranties. Reloading is a

science and improperly loaded ammunition can be extremely dangerous. Severe damage to the firearm and serious injury to

the shooter or to others may result. Always use ammunition that complies with the industry performance standards established

by the Sporting Arms and Ammunition Manufacturers’ Institute, Inc. of the United States (SAAMI) or ammunition manufactured

to military specifications.

WARNING - AMMUNITION (CARTRIDGE) NOTICE

INJURY WHATSOEVER OCCURRING IN CONNECTION WITH, OR AS A RESULT OF, THE USE IN ANY SIG SAUER

SIG SAUER Inc. SPECIFICALLY DISCLAIMS RESPONSIBILITY FOR ANY DAMAGE OR

FIREARM OF FAULTY, NON-STANDARD, “REMANUFACTURED” HAND LOADED (RELOADED) AMMUNITION, OR

CARTRIDGES OTHER THAN THOSE FOR WHICH THE FIREARM WAS ORIGINALLY CHAMBERED.

www.sigsauer.com

33

Page 34

WARNING

3. Firearms may be severely damaged and serious injury to the shooter or to others may result from any condition causing

excessive pressure inside the chamber or barrel during firing. Excessive pressure can be caused by obstructions in the barrel,

propellant powder overloads, the use of incorrect cartridges or defectively assembled cartridges. In addition, the use of a dirty,

corroded, or damaged cartridge can lead to a burst cartridge case and consequent damage to the firearm and personal injury

from the sudden escape of high-pressure propellant gas within the firearm’s mechanism.

4. Immediately stop shooting and check the barrel for a possible obstruction whenever:

• You have difficulty in, or feel unusual resistance in, chambering a cartridge;

• A cartridge misfires (does not go off);

• The mechanism fails to extract a fired cartridge case;

• Unburned grains of propellant powder are discovered spilled in the mechanism;

• A shot sounds weak or abnormal. In such cases it is possible that a bullet is lodged part way down the barrel.

• Firing a subsequent bullet into the obstructed barrel can wreck the firearm and cause serious injury to the shooter or to

bystanders.

5. Bullets can become lodged in the barrel:

• If the cartridge has been improperly loaded without propellant powder, or if the powder fails to ignite (ignition of the

cartridge primer alone will push the bullet out of the cartridge case, but usually does not generate sufficient energy to

expel the bullet completely from the barrel);

• If the bullet is not properly seated in the cartridge case, when such a cartridge is extracted from the chamber without

being fired, the bullet may be left behind in the bore at the point where the rifling begins. Subsequent chambering of

another cartridge may push the first bullet further into the bore.

34

www.sigsauer.com

Page 35

6. If there is any reason to suspect that a bullet is obstructing the barrel, immediately unload the firearm and look through the

bore. It is not sufficient to merely look in the chamber. A bullet may be lodged some distance down the barrel where it cannot

easily be seen.

WARNING

IF A BULLET IS IN THE BORE, DO NOT ATTEMPT TO SHOOT IT OUT BY USING ANOTHER CARTRIDGE OR BY

BLOWING IT OUT WITH A BLANK OR ONE FROM WHICH THE BULLET HAS BEEN REMOVED. SUCH TECHNIQUES CAN

GENERATE EXCESSIVE PRESSURE, WRECK THE FIREARM, AND CAUSE SERIOUS PERSONAL INJURY.

If the bullet can be removed with a cleaning rod, clean any unburned powder grains from the bore, chamber, and mechanism

before resuming shooting. If the bullet cannot be dislodged by tapping it with a cleaning rod, take the firearm to a gunsmith.

7. Dirt, corrosion, or other foreign matter on a cartridge can impede complete chambering and may cause the cartridge case to

burst upon firing. The same is true of cartridges which are damaged or deformed.

8. Do not oil cartridges, and be sure to wipe the chamber clean of any oil or preservative before commencing to shoot. Oil

interferes with the friction between cartridge case and chamber wall that is necessary for safe functioning, and subjects the

firearm to stress similar to that imposed by excessive pressure.

9. Use lubricants sparingly on the moving parts of your firearm. Avoid excessive spraying of any aerosol gun care product,

especially where it may get on ammunition. All lubricants and aerosol spray lubricants in particular can penetrate cartridge

primers and cause misfires. Some highly penetrative lubricants can also migrate inside cartridge cases and cause deterioration

of the propellant powder; on firing, the powder may not ignite. If only the primer ignites, there is danger that the bullet may

become lodged in the barrel.

www.sigsauer.com

35

Page 36

WARNING - AMMUNITION

Death, serious injury, and damage can result from the use of wrong ammunition, bore

obstructions, powder overloads, or incorrect cartridge components. Always wear shooting

glasses and hearing protectors.

IMPROPER AMMUNITION DESTROYS GUNS

WARNING - LEAD EXPOSURE

Discharging firearms in poorly ventilated areas, cleaning firearms, or handling ammunition may result

in exposure to lead and other substances known to the state of California to cause birth defects,

reproductive harm, and other serious physical injury. Maintain adequate ventilation at all times. Wash

hands thoroughly after exposure.

SHOOTING OR CLEANING GUNS MAY EXPOSE YOU TO LEAD

36

www.sigsauer.com

Page 37

TO LOAD AND FIRE (WITH MAGAZINE)

3.0 Handling

3.1 Important Instructions

• Before manipulating the weapon, ensure the safety lever is in the “S” (SAFE) position and the trigger guard is in the closed

position.

• Use only factory-new ammunition which corresponds to the caliber of the weapon.

• During all manipulations of the rifle, point the weapon in a safe direction.

• Do not place your finger on the trigger until the target has been verified and you intend to shoot.

• Do not load the weapon until immediately before use.

• Unload the weapon immediately after shooting is finished.

• Remove the bolt carrier assembly and magazine from the weapon prior to transportation.

Never carry the rifle loaded with the safety lever in the “F” (FIRE) position. If dropped or struck with the safety off

(“F”), the rifle may fire. Such a discharge can occur with or without the trigger being directly struck or touched. Never rest a loaded

rifle against any object (wall, tree, fence, vehicle, etc.) because there is always the possibility that the rifle will be jarred or slide from

its position and fall with sufficient force to discharge. Keep the safety lever on “S” (SAFE) unless actually firing.

WARNING - HANDLING

ANY GUN MAY FIRE IF DROPPED

www.sigsauer.com

37

Page 38

3.2 Loading The Rifle

1. Ensure the safety lever is in the “S” (SAFE) position;

2. Insert the magazine and check that it is properly seated;

3. Bolt forward: Pull the charging handle back fully and release; or

4. Bolt locked open: Depress bolt catch fully to release bolt.

WARNING

DO NOT LOAD A RIFLE WITH A HOT CHAMBER BECAUSE A ROUND MAY

“COOK” OFF (i.e., a round may detonate (fire) unexpectedly just because it

is exposed to the heat of the rifle’s chamber).

38

www.sigsauer.com

Page 39

3.3 Loading The Magazine

1. Ensure the magazine is the proper type and caliber for the rifle;

2. Hold the magazine vertically;

3. Place a round between the feed lips and press down - ensure the bullet is facing the front of the magazine; and

4. Place the next round on top of the previous round and repeat until the desired number of rounds are loaded.

3.4 Changing The Magazine

1. Ensure the safety lever is in the “S” (SAFE) position;

2. Remove the magazine by depressing the magazine catch; on 556xi Russian model, magazine can be released by pushing the

mag release lever forward to release magazine;

3. Insert loaded magazine and check that it is properly seated.

www.sigsauer.com

39

Page 40

3.5 Reloading (Rifle Empty, Bolt Locked Open)

1. Ensure the safety lever is in the “S” (SAFE) position;

2. Remove the magazine by pressing the magazine catch;

3. Insert a loaded magazine and check that it is properly seated;

4. Release the bolt catch fully by:

a. Depress the bolt catch upward; or

b. Pull the charging handle back slightly and release.

Always make sure the muzzle is pointed in a safe direction!

WARNING

Never attempt to load or unload any firearm inside a vehicle, building, or other confined

space (except a properly constructed shooting range). Enclosed areas frequently offer no

completely safe direction to point the firearm; if an accidental discharge occurs, there is

great risk of bodily injury or property damage.

Before loading, always clean all grease and oil from the bore and chamber, and check to be

certain that no obstruction is in the barrel. Any foreign matter in the barrel could result in a

bulged or burst barrel or other damage to the firearm, and could cause serious injury to the

shooter or to others.

Keep the muzzle pointed in a safe direction and your finger away from the trigger when

cocking any firearm.

40

www.sigsauer.com

BOLT CATCH

CHARGING HANDLE

Page 41

Never carry or leave unattended any firearm which is cocked and ready to fire! When cocked, it could fire from slight pressure

on the trigger. An accidental discharge could easily result if you fall or drop the firearm, or if the firearm is struck or disturbed

by someone or something.

WARNING

Never fire any firearm with your finger, hand, face, or other part of your body over or adjacent to the ejection port, or in any

position where you may be struck by reciprocating movement of the breech. Both the ejection of empty cartridge cases and

the movement of the breech are part of the normal operating cycle of firearms, and pose no safety hazard to the shooter if

the firearm is held in a normal grip and fired at arm’s length.

Never allow other persons to stand beside you where they might be struck by an ejected cartridge case. The case is hot,

and may be ejected with sufficient force to cause a burn, cut or injury to an unprotected eye. Make certain there is a clear,

unobstructed path for safe ejection of the fired case. Remember, the case may bounce off a hard object nearby and strike you

or someone else.

If, while shooting, your firearm develops a mechanical malfunction or binding, or “spits” powder/gas, or if a cartridge primer

is punctured or a cartridge case is bulged or ruptured, or if the report on firing does not sound quite right, STOP SHOOTING

IMMEDIATELY! It may be dangerous to continue. UNLOAD THE FIREARM — do NOT try “one more shot”. Take the firearm and

the ammunition to a gunsmith for examination.

While shooting any firearm, an unfired cartridge or fired cartridge case may occasionally become jammed between the bolt

and the barrel. Clear the jam as follows, WHILE KEEPING THE MUZZLE POINTED IN A SAFE DIRECTION: Remove the magazine,

then pull back the bolt by way of the charging handle and lock it to the rear by pushing up the slide catch. The jammed

cartridge or case now can be removed by shaking it out or picking it out.

www.sigsauer.com

41

Page 42

WARNING - FIRING

The bolt automatically opens and shuts quickly while firing. Keep face and

hands away from it. Hot brass and powder gas is ejected quickly and can

burn you. The rifle should be fired from the right shoulder. Always wear

shooting glasses and hearing protectors.

BOLT OPENS FAST – HOT BRASS EJECTED

WARNING - HANDLING

If dropped or struck with the safety “off,” the rifle may fire. Keep chamber empty unless actually firing!

Keep safety in the “S” (SAFE) position unless actually firing!

ANY GUN MAY FIRE IF DROPPED

42

www.sigsauer.com

Page 43

TO UNLOAD MAGAZINE AND RIFLE

4.0 Unloading

1. Ensure the safety lever is in the “S” (SAFE) position.

2. Ensure bolt is locked open (chamber visible);

3. Remove magazine by depressing the magazine catch;

and

4. Verify the chamber is empty, both visually and physically.

Always make sure the muzzle is pointed in a safe direction!

Remember to clear the chamber after the magazine has

been removed.

Never assume that any gun is unloaded until you have

personally checked it, visually and physically!

After every shooting practice, make a final check to be certain the firearm is unloaded before leaving the range.

www.sigsauer.com

43

Page 44

WARNING - UNLOADING

Removing cartridges from the magazine does not prevent the rifle from being

fired! When there is a cartridge in the chamber and the safety lever is in the

“F” (FIRE) position, the cartridge will discharge if the trigger is pulled. It is

absolutely essential for the user to know how to completely unload the rifle.

“Completely” means emptying the magazine and removing a chambered

cartridge. The safety lever should always be in the “S” (SAFE) position

when the rifle is being unloaded.

THE RIFLE WILL FIRE EVEN

IF THE MAGAZINE IS EMPTY OR REMOVED

44

www.sigsauer.com

Page 45

TO EXTRACT AND EJECT A CHAMBERED CARTRIDGE

When the rifle is fired, the same gas pressure which drives the bullet forward also acts through the cartridge case to push the

bolt to the rear. That action causes extraction and ejection of the fired case. But, when the bolt is operated by hand, there can

be a failure to extract the cartridge from the chamber, or a failure to eject the cartridge clear of the rifle. These failures usually

are the result of the bolt not being pulled rearward vigorously, coupled with an accumulation of firing residue in the chamber.

From the foregoing it is clear that the gun user must:

1. Always visually check the chamber after opening the bolt to eject a chambered cartridge. If the bolt is not vigorously

retracted when being operated by hand, the extracted cartridge can be “ejected” into the magazine area instead of outside

the rifle. (Remember that the magazine should be removed prior to unloading the chamber.)

2. Thoroughly clean the chamber and the extractor as often as necessary to prevent accumulation of grease and dirt.

3. If an empty magazine is in the rifle when the bolt is being hand retracted to extract a cartridge, the cartridge may drop on

top of the magazine. Then, when the bolt goes forward, the cartridge will be chambered again! Always remove the magazine

before clearing the chamber, and visually ensure that no cartridges remain in the rifle.

www.sigsauer.com

45

Page 46

TO CLEAR A MALFUNCTION (“JAM”)

5.0 Procedures In Case Of Malfunction

Should the rifle fail to fire, perform the following actions:

• Cycle the bolt; and

• Continue firing.

If the rifle does not fire after cycling the bolt:

• Insert a fresh magazine;

• Cycle the bolt; and

• Continue firing.

If the rifle still does not fire:

• Put safety lever in the “S” (SAFE) position;

• Remove magazine;

• Lock the bolt to the rear;

• Ensure the chamber is clear of all ammunition and foreign matter (visual & physical check);

• Turn gas valve on Position 2 when weapon is heavily fouled;

• Insert fresh magazine;

• Release bolt; and

• Place safety lever in the “F” (FIRE) position, continue firing.

46

www.sigsauer.com

Page 47

If the rifle still will not fire:

• Put safety lever in the “S” (SAFE) position;

• Unload per section 4.0;

• Clean weapon per section 8.1;

• Load; and

• Place safety lever on position “F” (FIRE), and continue firing.

If the rifle malfunction cannot be corrected, the rifle should be returned to SIG SAUER Inc. for evaluation by a factory trained

technician.

In the case of a malfunction, the following steps must be followed:

• If the weapon cannot be unloaded immediately and there is any danger of self-ignition due to a hot barrel, wait at

least 15 minutes before manipulating the weapon.

• The weapon must remain pointed in a safe direction as long as it is loaded.

WARNING

If your rifle stops firing with a live round in the chamber of a hot barrel (a misfire or jam), remove the round

immediately. If you cannot remove the round within 10 seconds, remove the magazine and wait at least 15

minutes with the rifle pointing in a safe direction. This way, neither the user nor any other person would be

injured by the possibility of a round “cooking-off” (a round detonating due to the heat of the barrel). Keep your

face away from the ejection port while clearing a hot chamber.

www.sigsauer.com

47

Page 48

WARNING

A cartridge fires when the firing pin impacts the primer, and also can be “discharged” before it is chambered

if its primer receives a sharp blow. If a cartridge hangs up, jams, or binds when being chambered or when

fed from the magazine into the chamber, do not attempt force it into the chamber by pushing or striking the

charging handle. Any jam or feeding problem is a signal to immediately stop using the rifle until the issue

can be determined. Most failures of a cartridge to feed or to chamber are caused by a damaged magazine,

improper handling, or defective ammunition. Cartridge jams can result in the potentially dangerous situation of

a cartridge discharging before it is chambered. If this occurs, the cartridge case will rupture and its fragments

will fly out of the rifle with sufficient force to cause injury. Always wear shooting glasses and hearing

protectors, and keep your face away from the chamber!

TO MINIMIZE MALFUNCTIONS (“JAMS”)

Malfunctions can largely be avoided by cleaning the rifle per section 8.1:

• After each firing session;

• When performance requires switching the gas valve to position 2;

• Whenever a buildup of firing residue is suspected; or

• Whenever the rifle is exposed to extreme environmental

conditions (rain, snow, freezing temperatures, etc.).

48

www.sigsauer.com

Page 49

TO DISASSEMBLE

6.0 Field Strip Disassembly

1. Unload rifle (see section 5.0) – visually and physically check to ensure

the rifle is clear of all ammunition;

2. Ensure the bolt is forward;

3. Retract the takedown pin (rear pin) – this pin is captured and does

not fully remove;

4. Retract the pivot pin (front pin). This pin is captured and does not

fully remove.

TAKEDOWN

PIN

STEP 3

5. Separate the trigger casing from the receiver;

www.sigsauer.com

PIVOT PIN

STEP 4

49

Page 50

6. Depress the charging handle catch and remove the charging handle;

STEP 6

7. Using the charging handle, push the bolt carrier assembly to the rear and remove it from the receiver;

8. Rotate the bolt head counterclockwise until the lug clears the cam and pull to remove it from the bolt carrier;

STEP 7

⤴

STEP 8

50

www.sigsauer.com

Page 51

9. Handguard Removal:

NOTICE

DO NOT REMOVE THE HANDGUARD ASSEMBLY UNLESS THE UPPER AND LOWER RECEIVERS ARE SEPARATED. REMOVAL OF

THE HANDGUARD WILL EXPOSE THE PUSHROD ASSEMBLY. SHOULD THE RIFLE FALL OR STRIKE A HARD SURFACE, THE PUSHROD

ASSEMBLY COULD BE DAMAGED EFFECTING OPERATION OF THE RIFLE. SEPARATING THE RECEIVERS REDUCES THE OVERALL

WEIGHT OF THE RIFLE REDUCING THE RISK OF DAMAGE SHOULD THE RIFLE FALL OR STRIKE A HARD OBJECT OR SURFACE.

EXPLODED VIEW OF HANDGUARD

www.sigsauer.com

51

Page 52

a. Push out pivot pin.

b. Slide handguard off toward

muzzle of barrel.

C. Remove the upper rail section.

Note: The flip up front sight (if installed)

will have to be removed to left off the

upper rail section.

STEP 9C REMOVAL OF THE LOWER HANDGUARD SECTION

10. Lift upper handguard at the rear and

pull away from gas block;

STEP 10 REMOVAL OF UPPER RAIL SECTION

52

www.sigsauer.com

Page 53

11. Depress the detent and rotate the gas valve until the

flange is clear and the valve can be pulled forward out of

the gas tube;

STEP 11

12. Push the operating rod assembly forward and remove from the gas tube;

⤴

STEP 12

www.sigsauer.com

STEP 13

53

Page 54

13. Pull the gas tube forward out of the gas block;

14. Remove the firing pin:

a. Depress the firing pin by pressing the rear of the bolt head against a flat surface until

flush and hold;

b. Remove the firing pin stud using an aid (small punch, nail, or pencil) and SLOWLY raise

the bolt head until tension is released on the firing pin spring; and

c. Remove firing pin and firing pin spring from the bolt head.

STEP 15B

STEP 15C

CAUTION

The firing pin is under spring tension when installed in the bolt head. Use caution during removal to prevent

injury to yourself and others. The use of eye protection is recommended.

54

www.sigsauer.com

Page 55

www.sigsauer.com

55

Page 56

6.1 Reassembly

The rifle should always be reassembled in the reverse order of disassembly:

1. Install the firing pin:

a. Insert the firing pin and firing spring into the bolt head. The spring should be at the rear. Ensure that the notch on the

firing pin is aligned with the firing pin stud.

b. With one hand, place the bolt head (firing pin at the bottom) on a flat surface and depress the firing pin until the notch

in the firing pin is aligned with the hole in the bolt shaft for the firing pin stud.

c. With the other hand, insert the firing pin stud and release tension on the firing pin. Ensure the firing pin stud is

centered.

2. Install the gas tube:

a. Slide the gas tube back through the gas block positioning the flange so it fits flush against the gas block.

STEP 2

56

www.sigsauer.com

Page 57

3. Install the operating rod assembly:

a. Insert the operating rod assembly into the gas tube. Ensure the end with the charging handle notch enters first, notch

facing down.

b. Push the operating rod in until fully seated. The operating rod should move freely through the gas tube.

⤴

STEP 3

4. Install the gas valve:

a. Install the gas valve positioning the flange so the valve contacts the gas tube flange.

b. Rotate the valve to the right until it stops against the detent.

c. Depress the detent and continue to rotate the gas valve until the flange of the gas valve is now in the slot of the gas

block.

d. Release the detent and rotate the gas valve to the “Normal” position.

e. Check rotation from “Normal” to “Adverse”. The valve should move freely.

www.sigsauer.com

STEP 4

57

Page 58

5. Install the handguard:

a. Place top portion of handguard back in place on upper receiver, and fit behind gas block.

STEP 5A PLACING TOP PORTION OF HANDGUARD IN PLACE

b. Slide the lower handguard in channel and slide rearward until stops.

58

www.sigsauer.com

Page 59

6. Assemble the bolt head and bolt carrier:

a. Place the bolt carrier in your hand, upside down, cam to the front.

b. With the notch facing up, slide the bolt head shaft fully into the bolt carrier.

c. Rotate the bolt head to the left until the notch rests in the cam.

d. Press forward on the firing pin until the bolt head is fully forward.

7. Install the bolt assembly into the receiver:

a. Hold the receiver muzzle down.

b. Holding the bolt carrier, align the left lug on the bolt head with the lug channel in the receiver.

c. Ease the bolt assembly forward until the left and right receiver rails are riding in the rail channels on the bolt carrier.

d. Release the bolt carrier — it should drop freely into the receiver until the bolt is fully locked.

e. The charging handle can be installed on the left side or the right side of the bolt carrier. Depress the charging handle

catch and insert the charging handle into the slot on the bolt carrier.

f. Release the charging handle catch. Tug on the charging handle to ensure it is secured by the charging handle catch.

g. Verify correct installation by pulling the bolt to the rear — it should be connected to the operating rod and move under

the tension of the recoil spring.

www.sigsauer.com

59

Page 60

8. Connect trigger casing assembly to receiver assembly:

a. Mate the receiver and trigger casing together at the front takedown pin, ensuring the pivot pin holes overlap.

b. Install the pivot pin from the right side and secure the pivot pin screw.

c. Rotate the trigger casing until the rear takedown pin holes in the trigger casing assembly and receiver are aligned.

d. Press the rear takedown pin in fully

9. Perform a function check in accordance with Section 6.2.

60

www.sigsauer.com

Page 61

6.2 Function Check

Each time the weapon is stripped, verify its functions as follows:

Sequence of Procedure

1. Unload in accordance with section 4.0.

2. Remove magazine.

3. Ensure that charging handle is forward and bolt is closed.

4. Functions:

a. With safety lever on “S” execute loading cycle, pull the trigger. • Hammer must not drop, the trigger must be blocked.

b. With safety lever on “F”, pull the trigger and hold it back. • Hammer must drop.

With the trigger held down, cycle the weapon once. • Hammer must not drop.

Release the trigger and pull it again. • Hammer must drop.

NOTE: Steps c, d and e apply only to Select-Fire rifles. For Semi-Auto proceed to Step 6.

www.sigsauer.com

61

Page 62

For Select-Fire rifles only:

c. Cycle the action (for Select-Fire rifles)

d. Safety lever on “F” FIRE, pull the trigger and hold it back. • Hammer must drop.

With hammer held back, cycle the action (allow bolt to slide forward slowly). • Hammer must drop immediately as the

bolt locks up.

Repeat the loading cycle. • On the third loading cycle, the hammer must not drop.

Release the trigger.

e. With safety lever on “A”, repeat procedure as under “3”. • Hammer must drop each time. f) Cycle the trigger several

times to verify tension and movement of the pressure point spring.

WARNING

Visually and physically verify the magazine is empty before performing the

next step.

6. Insert empty magazine, check that it is firmly seated.

7. Bolt catch

a. Cycle action (charging handle to rear). • Bolt must be caught in its rear position.

b. Release bolt catch. • Bolt must release and fully close.

c. Pull the trigger, apply the safety lever.

62

www.sigsauer.com

Page 63

MAGAZINE INSPECTION AND CARE

Inspect the magazine frequently. The magazine follower must move freely and have adequate spring tension so that each

cartridge is quickly raised to the feeding position. The magazine lips should be clean and free of cracks, dents, or nicks, so that

cartridges are held in their proper feeding position.

When cleaning is necessary, use a solvent that will not rust the metal components or adversely affect the magazine follower.

After the magazine has been soaked in solvent to loosen foreign matter, be certain to shake it vigorously (with the loading

opening away from you) to remove solvent or residue from within the magazine.

magazine can “kill” or weaken cartridge primers, which can result in failures to fire or other possibly dangerous

malfunctions, such as leaving a bullet in the bore!

After cleaning, always check to be certain that the magazine follower movement and spring tension are correct, and that

no solvent or debris remain. Improper reassembly of the magazine spring can cause a potentially dangerous

malfunction. If cleaning does not restore proper tension, or if you experience a problem with the magazine, do

not use it. Get a new one.

Penetrating oils and solvent inside a

DAMAGED, NON-STANDARD, OR IMPROPERLY ASSEMBLED MAGAZINES

SHOULD NOT BE USED. THEY CAN CAUSE THE RIFLE TO MALFUNCTION.

www.sigsauer.com

63

Page 64

CARE AND CLEANING

1. Your rifle is delivered factory packaged and preserved with a light coating of protective grease and oils. Before loading make

certain that all packing grease and oil has been cleaned from the bore and exposed mechanism.

2. Before you begin to disassemble your firearm for cleaning, always double-check to make sure it is unloaded!

3. After cleaning always check to be sure that no cleaning patch or other obstruction remains in the bore or

chamber!

4. For maintenance guidelines, see section 9.0

Transportation and Storage

When transporting your firearm to and from shooting activities, keep it unloaded for your safety and for the safety of others.

When storing your firearm, keep it separated from ammunition, under lock and key if possible, and out of the reach of children

and other inexperienced or unauthorized persons.

64

www.sigsauer.com

Page 65

WARNING - STORAGE:

Never place or store any firearm in such a manner that it may be dislodged. Firearms should

always be stored securely and unloaded, away from children and other unauthorized users.

Use the locking device originally supplied with this firearm for storage. The use of a locking

device or safety lock is only one aspect of responsible firearms storage. For increased safety,

firearms should be stored unloaded and locked in a location that is both separate from their

ammunition and inaccessible to children and any other unauthorized person.

STORE SECURELY & UNLOADED

7.0 Sight Options

1. The SIG556xi rifle is equipped with accessory mounting rails that allow a wide variation of sighting systems to be utilized. The

gas block provides a Picatinny mount that allows installation of a front sight. This optional front sight can be combined with a fixed

type rear sight designed for mounting on the receiver accessory rail.

2. Always follow the manufacturer’s instructions when mounting a sighting system.

3. ALWAYS ensure the rifle is unloaded and clear of ammunition when installing or removing a sighting system or other accessory.

www.sigsauer.com

65

Page 66

Troubleshooting Guide

Malfunction Cause Correction

Feed

No round fed into the chamber Magazine not properly inserted

Bolt does not close easily or

completely

Extraction/Ejection

After firing, the case stays in the

chamber or is jammed in the

ejection port

or magazine is deformed or dirty

Rifle or cartridge is fouled (dirty) or

rifle is too heavily lubricated

Incorrect ammunition Replace ammunition

Rifle requires service Return to SIG SAUER

Insufficient recoil due to dirt Clean and lubricate the rifle

Light hold or limp wrist Solid grip, rigid hold

Low-powered ammunition Change ammunition

Rifle requires service Return to SIG SAUER

Insert magazine properly or change magazine

Clean and lubricate rifle and/or replace the

ammunition

66

www.sigsauer.com

Page 67

Malfunction Cause Correction

Ignition

Hammer drops but round does

not fire

Firing pin obstructed Inspect, clean and lubricate the rifle

Faulty ammunition Manually cycle in next round

Rifle requires service Return to SIG SAUER

www.sigsauer.com

67

Page 68

MAINTENANCE

8.0 Maintenance

All firearms require periodic maintenance and inspection which may reveal a need for adjustment or repair. Have your

firearm checked by a competent gunsmith annually even if it seems to be working well, since breakage, improper functioning

or corrosion of some components may not be apparent from external examination. If you notice any mechanical

malfunction, DO NOT continue to use the firearm. UNLOAD the firearm and take it to a competent gunsmith

immediately for a thorough examination. Similarly, if water, sand, or other foreign matter enters the internal mechanism,

immediately dismantle the firearm for a complete and thorough cleaning.

WARNING

Failure to keep your firearm clean and in proper working order can lead to a potentially dangerous condition

and an accident causing serious bodily injury or property damage may result.

68

www.sigsauer.com

Page 69

8.1 Cleaning

The SIG556xi rifle must be cleaned after each shooting session or whenever performance is suspect. Clean the rifle as follows:

1. Unload the weapon per Section 4.0;

2. Field strip the weapon per Section 6.0;

3. Clean the barrel and chamber from the rear;

4. Clean other parts of the rifle, using care to remove carbon and firing residue. Pay particular attention to the operating rod,

gas valve, and chamber areas;

5. Lightly lubricate areas of metal contact with a high quality firearms lubricant or grease, paying particular attention to the

bolt/bolt carrier, receiver rails, operating rod, and gas valve;

6. Apply a light coating of high quality firearms lubricant or grease to exposed metal surfaces to enhance corrosion

protection;

7. Reassemble the rifle per section 6.1; and

8. Perform a function check in accordance with section 6.2.

www.sigsauer.com

69

Page 70

SERVICE AND PARTS POLICY

Parts Policy

Our Service Department maintains a full complement of replacement parts. Even though most gunsmiths have the

knowledge, training, and the ability to make necessary repairs to your firearm, the skill and workmanship of any particular

gunsmith is totally beyond our control.

Should your firearm ever require service, we strongly recommend that you return it to SIG SAUER Inc. (see page 74). A firearm

is a precision instrument and some replacement parts will require individual fitting to ensure correct operation. A wrong part,

improper fitting, or incorrect mechanical adjustment may result in an unsafe condition or dangerous malfunction, damage to

the firearm, or cause possible serious injury to the shooter or others.

IF ANY PART IS ORDERED WITHOUT RETURNING THE FIREARM TO SIG SAUER Inc., the customer bears full

responsibility for ensuring that the part supplied is correct for their particular firearm and is properly installed and fitted by a

qualified gunsmith.

SIG SAUER INC. CANNOT BE RESPONSIBLE FOR THE FUNCTIONING OF ANY FIREARM IN WHICH REPLACEMENT

PARTS ARE INSTALLED BY OTHERS.

70

www.sigsauer.com

Page 71

WARNING - PARTS PURCHASE:

It is the purchaser’s responsibility to be absolutely certain that any parts ordered from the factory

are correctly fitted and installed. Firearms are complicated mechanisms and IMPROPER FITTING

OF PARTS MAY RESULT IN A DANGEROUS MALFUNCTION, DAMAGE TO THE FIREARM,

AND SERIOUS INJURY TO THE SHOOTER AND OTHER PERSONS. The purchaser and installer

of parts must accept full responsibility for the correct adjustment and functioning of the rifle after

such installation.

PARTS MUST FIT CORRECTLY

www.sigsauer.com

71

Page 72

Thispageintentionallyleftblank.

72

www.sigsauer.com

Page 73

Service Policy

If you have questions concerning the performance or servicing of your rifle, please write or call:

SIG SAUER Inc.

Attention: Customer Service

72 Pease Boulevard, Newington, NH 03801

Phone: (603) 610-3000 ext. 3

Fax: (603) 766-7002

IF YOU DO NOT UNDERSTAND THE INSTRUCTIONS FOR OPERATING YOUR RIFLE, IT IS YOUR RESPONSIBILITY TO CALL OUR

CUSTOMER SERVICE DEPARTMENT AT (603) 610-3000 EXT. 3 BEFORE USING YOUR RIFLE.

www.sigsauer.com

73

Page 74

Shipping Firearms for Repair

Returning Your Firearm For Service In the event you need to return your rifle to the SIG SAUER Service Department, here’s what

to do:

1. The first step is to contact Customer Service at (603) 610-3000 EXT. 3 for an RMA number. This number allows SIG SAUER to

track the status of your return from its receipt at SIG SAUER through its return to you. Please do not send your firearm until you

obtain an RMA number.

2. Make sure that the chamber and magazine(s) are unloaded and that no ammunition is included with your returned firearm.

3. Package the firearm securely to prevent damage. Enclose a letter which includes your name, street address, daytime phone

number, model and serial number, and a detailed description of the problem you have experienced or the work you want

performed. With the exception of extra magazines, do not include scopes, mounts, or other accessories.

4. Generally, an individual may ship firearms to the manufacturer for repair or service. Some states and localities, however,

prohibit this. If you live in such an area, the firearms must be shipped by and returned to a Federally Licensed Firearms Dealer.

5. Federal law prohibits persons who do not possess a Federal Firearms License from shipping a firearm via the U.S. Postal Service.

(Note: any shipment of firearms outside U.S. borders is subject to the export laws of the United States and to the valid laws of the

specific country, which you must strictly follow; prior to exporting any firearm you should seek legal counsel.)

6. SIG SAUER is not responsible for any firearm until it is received, nor for damage incurred during shipment.

74

www.sigsauer.com

Page 75

7. Ship your firearms insured and prepaid (we do not accept collect shipments) to:

SIG SAUER Inc.

Attention: Service Department

18 Industrial Drive Exeter, NH 03833

This instruction manual should always accompany this rifle and be transferred with it upon change of ownership.

WARNING - SHIPPING

WARNING: BEFORE SHIPPING ANY FIREARM, BE ABSOLUTELY CERTAIN THAT THE FIREARM AND ITS

MAGAZINE ARE UNLOADED. DO NOT SHIP AMMUNITION WITH A FIREARM.

ORDERING PARTS

In the event you want to order parts for your SIG556xi rifle, contact Customer Service at (603) 610-3000 ext. 3.

Have available the serial number of your rifle and the part diagram number for the part(s) you wish to order. A parts list and

diagram of the rifle is provided in sections 9.1 and 9.2.

Please refer to the Service & Parts Policy on page 71.

www.sigsauer.com

75

Page 76

9.0 Technical Specifications

CALIBER

OVERALL LENGTH

(STOCK EXTENDED)

OVERALL LENGTH (W/

STOCK FOLDED)

BARREL LENGTH W/O

FLASH SUPPRESSOR

LANDS & GROOVES

RATE OF TWIST

WEIGHT

(W/O MAGAZINE)

TRIGGER WEIGHT

(nearest .01 kg & .1 lb)

520.7mm (20.5 in) 757mm (29.8 in) 911mm (35.875 in)

254mm (10 in) 254mm (10 in) 407mm (16.0 in)

2.85 kg (6.3 lbs) 3.17kg (7.0 lbs) 3.22 kg (7.1 lbs)

PISTOL SBR PATROL

5.56x45mm NATO or 7.62x39 Russian

N/A 520.7mm (20.5 in) 670mm (26.375 in)

6 6 6

1:178mm/7 in 7.62x39 Russian 1:178mm/9.5in

2.50 – 4.31 kg (5.5 -9.5 lbs)

76

www.sigsauer.com

Page 77

PISTOL SBR PATROL

CYCLIC RATE

SIGHT RADIUS

HEIGHT

UPPER RECEIVER

RAIL LENGTH

TOP FOREARM

RAIL LENGTH

TOTAL TOP RAIL LENGTH

(Including Gas Block)

MUZZLE THREAD

All specifications are approximate and will vary with configuration. Specifications subject to change without notice.

620-750 rpm 620-750 rpm 620-750 rpm

386mm (15.2in) 386mm (15.2in)

Classic: 463mm (18.25in)

185.5mm (7.3 in)

175mm (6.9 in)

175mm (6.9 in)

376mm (14.8 in)

½-28 UNEF 5/8-24 UN

386mm (15.2in)

www.sigsauer.com

77

Page 78

9.1 SIG556xi Upper Parts List & Diagram

1 FLASH SUPPRESSOR, EXTENDED

2 STOP PIN SPRING PIN

3 PIN STOP

4 STOP PIN SPRING

5 GAS VALVE, FULL

6 PIN, GAS BLOCK RETAINING

7 BLOCK, GAS

8 NUT, BARREL

9 SHORT OP ROD

10 BARREL, 5.56 NATO, 16 IN

11 SHORT RECOIL SPRING

12 PIN, SLOTTED SPRING 3/32” X 5/8”

13 WASHER, OP ROD, 556-1

14 OPERATING ROD END

15 GAS TUBE

16 UPPER RECEIVER

17 CONTINUOUS TOP RAIL HANDGUARD

18 SIGHT RAIL SCREW

19 DUST COVER RETAINING CLIP

20 COVER, DUST OVERMOLD

21 PIN, EXTRACTOR

22 EXTRACTOR, 556-1

23 EXTRACTOR SPRING

24 AMBIDEXTROUS CHARGING HANDLE

25 BOLT, 556, NON-HELIX

26 FIRING PIN STUD

27 FIRING PIN SPRING

28 FIRING PIN

29 CHARGING HANDLE CATCH SPRING

30 CHARGING HANDLE CATCH

31 CHARGING HANDLE CATCH PIN

32 BOLT CARRIER

33 HANDGUARD SUPPORT PIN

34 PIN, BARREL INDEXING

35 LOWER MODULAR HANDGUARD RAIL

78

www.sigsauer.com

Page 79

www.sigsauer.com

79

Page 80

9.2 SIG556xi Select Fire Lower Parts List & Diagram

1 TRIGGER CASING, SEMI, HINGED

2 HANDGUARD, PLASTIC

3 LEFT MAG RELEASE, AMBI

4 MAG RELEASE SPRING

5 RIGHT MAG RELEASE, AMBI

6 AMBI MAG RELEASE, ALLEN NUT

7 FRONT TAKE DOWN PIN

8 TAKE DOWN PIN PLUNGER

9 TAKE DOWN PLUNGER SPRING

10 RELEASE BAR

11 STUD, RELEASE BAR

12 RETAINING RING

13 SLING CAP

14 SLING PIN

15 STOP NUT

16 PRESSURE POINT SPRING

17 BUSHING, PRESSURE POINT

SCREW

18 PRESSURE POINT SCREW

19 HAMMER SPRING

20 HAMMER, AUTO

21 HAMMER PIVOT PIN

22 SAFETY DETENT SPRING

23 TRIGGER PIVOT PIN

24 TRIGGER SPRING

25 SEAR, AUTO

26 SEAR

27 TRIGGER

28 FIRE PAWL BUSHING

29 TRIGGER BUSHING

30 FIRE PAWL SPRING

31 SEAR SPRING

32 BOLT CATCH PIN

33 CATCH, BOLT, CASTING

34 PIN, SAFETY SHAFT

35 SAFETY LEVER

36 SAFETY SHAFT AUT

37 HINGE PIN

38 HINGE DISC SPRING

39 STOCK ASSEMBLY

40 STOCK LATCH PIN

41 SPRING, FOLDING STOCK

42 STOCK LATCH

43 MAGAZINE 30 RD

44 CHEEK RISER

45 BUFFER PLATE

46 TRIGGER CASING PLUG

47 REAR TAKE DOWN PIN

48 556XI PLASTIC GRIP CAP

49 AMBI MAG RELEASE, ROD

50 BUSHING, SAFETY SHAFT AUTO

51 PISTOL GRIP BOLT

52 BOLT CATCH SPRING

80

www.sigsauer.com

Page 81

www.sigsauer.com

81

Page 82

SIG SAUER® Limited Lifetime Firearms Warranty

SIG SAUER warrants that the enclosed firearm was originally manufactured free of defects in material, workmanship and

mechanical function. For the lifetime of the original purchaser, SIG SAUER agrees to correct any defect in the firearm for

the original purchaser by repair, adjustment or replacement, at SIG SAUER’s option, with the same or comparable quality

components (or by replacing the firearms at SIG SAUER’s option); provided, however, that the firearm is returned unloaded and

freight prepaid to SIG SAUER at 18 Industrial Drive, Exeter, NH 03833.

This limited warranty is null and void if the firearm has been misused, damaged (by accident or otherwise), fired with

handloaded, reloaded or improper ammunition, fired with an obstruction in the barrel, damaged through failure to provide

reasonable and necessary maintenance as described in the manual accompanying the firearm, or if unauthorized repair or any

alteration, including of a cosmetic nature, has been performed on the firearm. This limited warranty does not apply to normal

wear and tear of any parts.

Subject to the foregoing, this limited warranty confers the right to have the covered firearm or its parts repaired, adjusted or

replaced exclusively upon the original purchaser, which right is not transferable to any other person. No implied warranties of

any kind are made herein and this warranty does not apply to any accessory items attached or appurtenant to the firearm. In

no event shall SIG SAUER be liable for any incidental or consequential damages arising from or in connection with this limited

warranty.

82

www.sigsauer.com

Page 83

Notes:

www.sigsauer.com

83

Page 84

P/N 1540175 REV 04

www.sigsauer.com

FOR PRODUCT SERVICE ON THIS MODEL,

PLEASE CALL (603) 610-3000 EXT. 3

72 Pease Boulevard, Newington, NH 03801 USA

Loading...

Loading...