Page 1

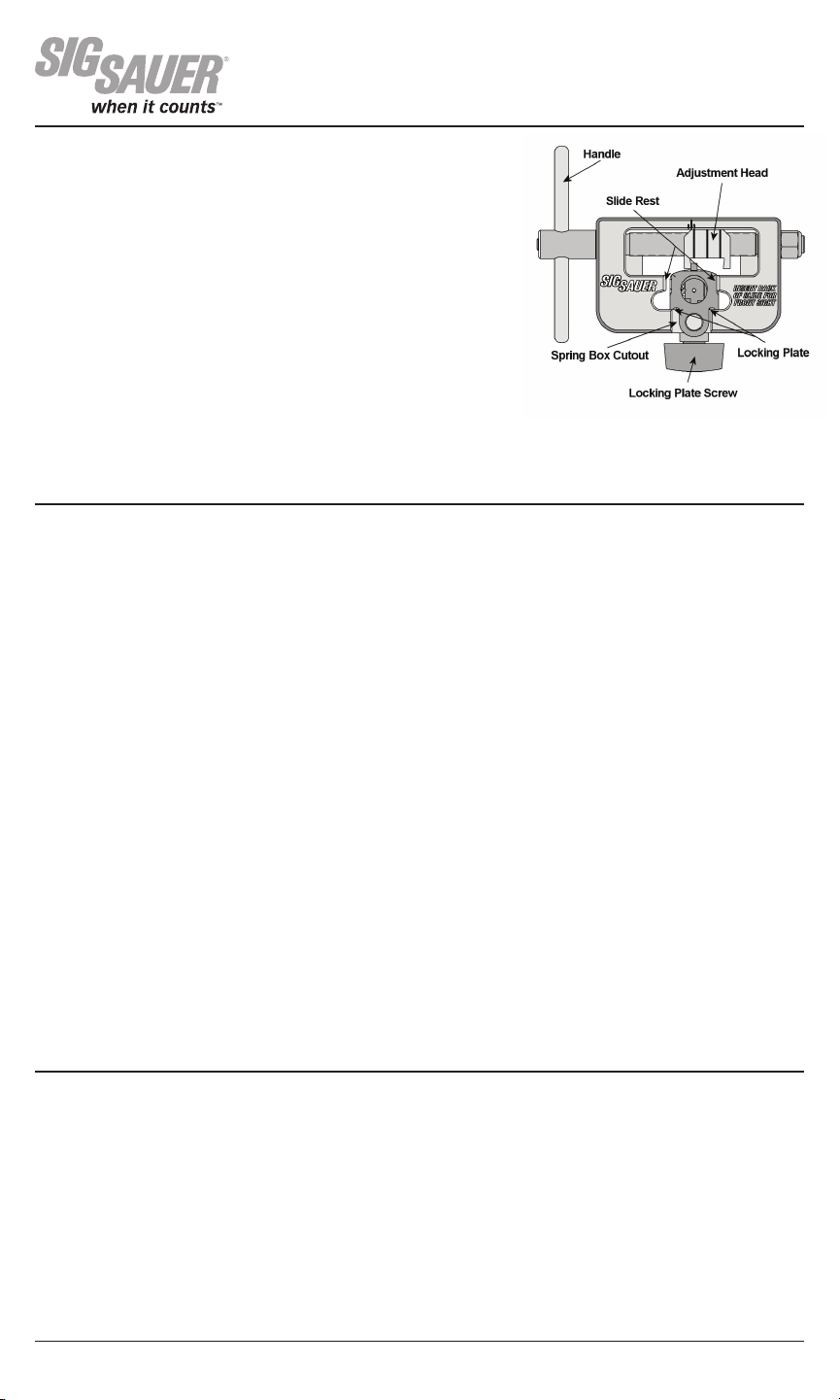

P250 SIGHT TOOL

The SIG SAUER® P250 Sight Tool will work on the P250 series

of pistols. This tool facilitates windage adjustment, removal

and installation of the P250 front sight for all caliber and slide

congurations. Different front sight heights are available for

elevation adjustments.

This tool is not for use with the P250 rear sight. The P250 rear

sight is not drift adjustable – all windage adjustments take place

with the front sight. The P250 rear sight can be replaced to

accommodate elevations adjustments outside the range of front

sight replacement. See the P250 Operators Manual that shipped

with your pistol for more information.

WARNING: Sight manipulations should ONLY be performed on

an unloaded rearm. Serious injury or death could occur if sight

manipulation is attempted on a loaded rearm.

INSTRUCTIONS FOR USE

To adjust front sight:

1. Center adjustment head above the sight tool

window.

2. Install the slide on the locking plate through the

front side of the tool.

3. Push the slide inward until the back of the spring

box makes contact with the spring box cutout in

the tool.

4. Depending upon the direction of desired sight

adjustment, move the slide right or left until it

bears against the slide rest (rounded face above

the angled surface of the spring box cutout) and

tighten the locking plate screw.

5. Turn the handle to adjust the front sight in the

desired direction.

To install front sight:

Note: Sight replacement should only be performed

by a certied armorer or someone with the proper

training.

1. Install the front sight from the left side of

the slide, as viewed from the rear (“shooters

perspective”)

2. Proper alignment of the sight in the slide dovetail

is required to prevent sight damage during installation. SIG SAUER recommends using a small

amount of lubrication in the slide dovetail to

ease installation. Seat the sight base in the slide

dovetail by lightly tapping the sight with a small

hammer before inserting in the sight tool.

3. Follow steps 3 thru 5 “front sight adjustment”.

Ensure the adjustment head is

correctly aligned with the front sight prior to fully

seating the slide in the sight tool.

Maintenance: There are no special lubrication or maintenance steps for this product. Oil impregnated

bronze bushings have been incorporated at both sides of the tool resulting in less vertical play, increasing

the smoothness of operation, and eliminating the need for oiling both ends of the shaft prior to each use.

SIG SAUER® LIMITED ONE YEAR WARRANTY

SIG SAUER® warrants that the enclosed accessory was originally manufactured free of defects in material, workmanship and

mechanical function, and agrees to correct these defects by repair, adjustment or replacement, at the option of SIG SAUER, with

items of the same or comparable quality; provided, however, that the accessory is returned freight prepaid to SIG SAUER at 18

Industrial Drive, Exeter, NH 03833 by the original purchaser within one year of the date of purchase.

This limited warranty is null and void if the accessory has been misused, damaged (by accident or otherwise), or if unauthorized

repair or any alteration, including of a cosmetic nature, has been performed on the accessory. This limited warranty does not apply

to normal wear and tear of any parts.

Subject to the foregoing, this limited warranty confers the right to have the covered accessory or its parts repaired, adjusted or

replaced exclusively by the original purchaser, which right is not transferable to any other person. NO IMPLIED WARRANTIES OF ANY

KIND, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE MADE HEREIN, and this

warranty does not apply to any accessory items attached or appurtenant to this accessory. In no event shall SIG SAUER be liable for

incidental or consequential damages arising from or in connection with this limited warranty.

CONTACT

18 Industrial Drive, Exeter, NH 03833 • (603) 772-2302 • www.sigsauer.com

PN 8500175 REV 1.0

Loading...

Loading...