Page 1

WARNING!

Please read and understand this owner’s

manual before taking your new

pistol out of the box. It is vital to your safety

and to the safety of others that you

accurately follow the information contained

in this manual, as well as the information

supplied by the ammunition manufacturer. If

you have any questions, please call or

write:

SIG SAUER Inc.

18 Industrial Drive, Exeter, NH 03833

(603) 772-2302

Page 2

Table of contents

1 General instructions 2

1.1 Congratulations 2

1.2 Firearms safety is your responsibility 2

2 Safety regulations 3

2.1 Safety indications 4

3 Product description 6

3.1 Main parts 6

3.2 Technical data 6

4 Transporting the pistol 7

5 Safety mechanisms 7

5.1 Manual safety 7

5.2 Integral safety lock (key operated) 7

5.2.1 Magazine safety 8

6 Handling the pistol 8

6.1 General 8

6.2 Ammunition 8

6.3 Loading the magazine 9

6.4 Loading the pistol (ready for firing) 10

6.5 Firing 11

6.6 Reloading during firing 12

6.7 Unloading the pistol; magazine

not empty 12

6.8 Unloading the pistol; magazine

empty, slide open 13

7Conversion 14

7.1 Conversion to Standard version 14

7.1.1 Removing the counterweight 14

7.1.2 Installing the counterweight 14

7.2 Conversion to Standard version 15

7.2.1 Removing the threaded cap 15

7.2.2 Installing the threaded cap 15

7.3 Exchanging the barrel 15

8 Sight adjustment 16

8.1 Sight adjustment for windage 16

8.1.1 Rear sight adjustment 16

8.2 Sight adjustment for elevation 16

9 Pistol maintenance 17

9.1 Field stripping the pistol 17

9.2 Cleaning the pistol 18

9.3 Pistol assembly 19

9.4 Functional check 20

9.5 Care of the pistol 21

10 Service and repairs 21

10.1 Fault detection, fault removal 21

10.2 Safekeeping and storage of pistol 23

10.3 Shipping the pistol 23

10.3.1Warranty Statement 23

11 Scope of supply 24

11.1 Standard version 24

11.2 Sport version 24

11.3 Silencer version 24

11.4 Conversion set Sport version 24

11.5 Conversion set Silencer version 24

12 Accessories 24

13 Disposal 24

14 List of replacement parts 24

Inhaltsverzeichnis

1 US 06.01

Page 3

General instructions

1 General instructions

1.1 Congratulations

You are now the owner of one of the world's finest

and most superbly engineered firearms. The

SIGSAUER

designed and crafted to meet the stringent

requirements of law enforcement agencies and

the military. Used with the proper ammunition and

given reasonable maintenance, it will serve you

dependably for many years.

To make sure you get the best performance

and reliability from your pistol, please read

and follow the procedures outlined in this

manual.

You'll notice that we place a heavy emphasis on

safe firearms handling. Like any other mechanical

devices, such as automobiles or power tools, high

quality firearms are inherently safe unless they are

handled in a careless or irresponsible manner.

Always remember that you, the owner, are the

ultimate firearms safety device.

®

Semiautomatic Pistol has been

1.2 Firearms safety is your responsibility

WARNING!

Uncontrolled shot discharge with pistol

safety off

Possibly death or serious injuries

PISTOLS are classified as FIREARMS and are

sold by us with the specific understanding that

we are not responsible in any manner

whatsoever for their safe handling or resale

under local laws and regulations.

SIG SAUER shall not be responsible in any

manner whatsoever for malfunctioning of the

firearm, for physical injury or for property

damage resulting in whole or in part from

1. criminal or negligent discharge,

2. improper or careless handling,

3. unauthorized modifications,

4. defective, improper, hand-loaded, or

reloaded ammunition,

5. corrosion,

6. neglect, or

7. other influences beyond our direct and

immediate control.

This limitation applies regardless of whether

liability is asserted on the basis of contract,

negligence or strict liability (including any failure

to warn).

Under no circumstances shall SIG SAUER be

liable for incidental or consequential damages,

such as loss of use of property, commercial loss

and loss of earnings or profits.

2US06.01

Page 4

Safety regulations

2 Safety regulations

•

Never use the pistol under the influence of

drugs or alcohol, while ill or suffering other

such difficulties. These conditions can impair

your powers of judgment and reflexes.

• Always think of the pistol as being loaded and

with the safety off until you have established

the opposite through the unloading procedure.

• Allows keep the muzzle of the pistol in a safe

direction with all handling. A safe direction is

towards an area where there are no people,

other life forms or property that is not a

recognized target.

• Never point the pistol at doors, panes of glass,

walls, concrete, stone or flat surfaces (water

included). A bullet can penetrate such surfaces

or be ricocheted in an unsafe direction.

• Never aim at yourself or other life forms.

• Never rely on safety mechanisms alone.

Safety mechanisms are not a substitute for

careful, correct and secure handling of the

pistol.

• Always treat your pistol as if the safety

mechanisms were not functioning. The best

safety precaution is a correct, well-trained and

safe handling of the pistol.

• Never shoot with a pistol which has been

penetrated by water, sand, dirt or other foreign

bodies.

• Never decock the hammer by holding on to the

hammer and pulling the trigger at the same

time.

• Never let a loaded pistol out of your hand.

pistol, by reading the corresponding

instructions.

• Never leave the pistol lying unattended.

Unauthorized persons could cause damage

with it, threaten or kill other people, for which

you could be held liable.

• Never store the pistol loaded, but remove the

magazine and verify that there is no cartridge

left in the chamber of the barrel by following

the unloading procedure.

• Always keep the pistol and the ammunition

separate from one another, and ensure that

neither is obtained by unauthorized persons or

children.

Please read and understand these instructions

carefully before each and every handling of the

SIG SAUER Pistol.

• Always unload the pistol immediately after

firing, before putting the pistol away, putting

into a holster or handing it to another

authorized person.

• Never give the pistol to a person who has not

thoroughly familiarized himself or herself with

the safety instructions and handling of the

3 US 06.01

Page 5

Safety regulations

2.1 Safety indications In the individual sections of these

instructions, the following safe ty indications

alert you to risks:

WARNING!

Information on dangers, which if not

scrupulously observed, can lead to severe

bodily harm or death.

CAUTION!

Information on dangers, which if not

scrupulously observed, can lead to bodily harm,

damage to property and damage to the pistol.

CAUTION!

Information on technical requirements, which if

not scrupulously observed, can lead to damage

to the pistol.

• Each of these safety indications consists of:

– a headline with a signal word, a signal

pictorial and a corresponding color code

– a description of the danger type and source

– a description of possible consequences if

the safety indications message is ignored

– a description of actions or regulations for

danger prevention

4US06.01

Page 6

Product description

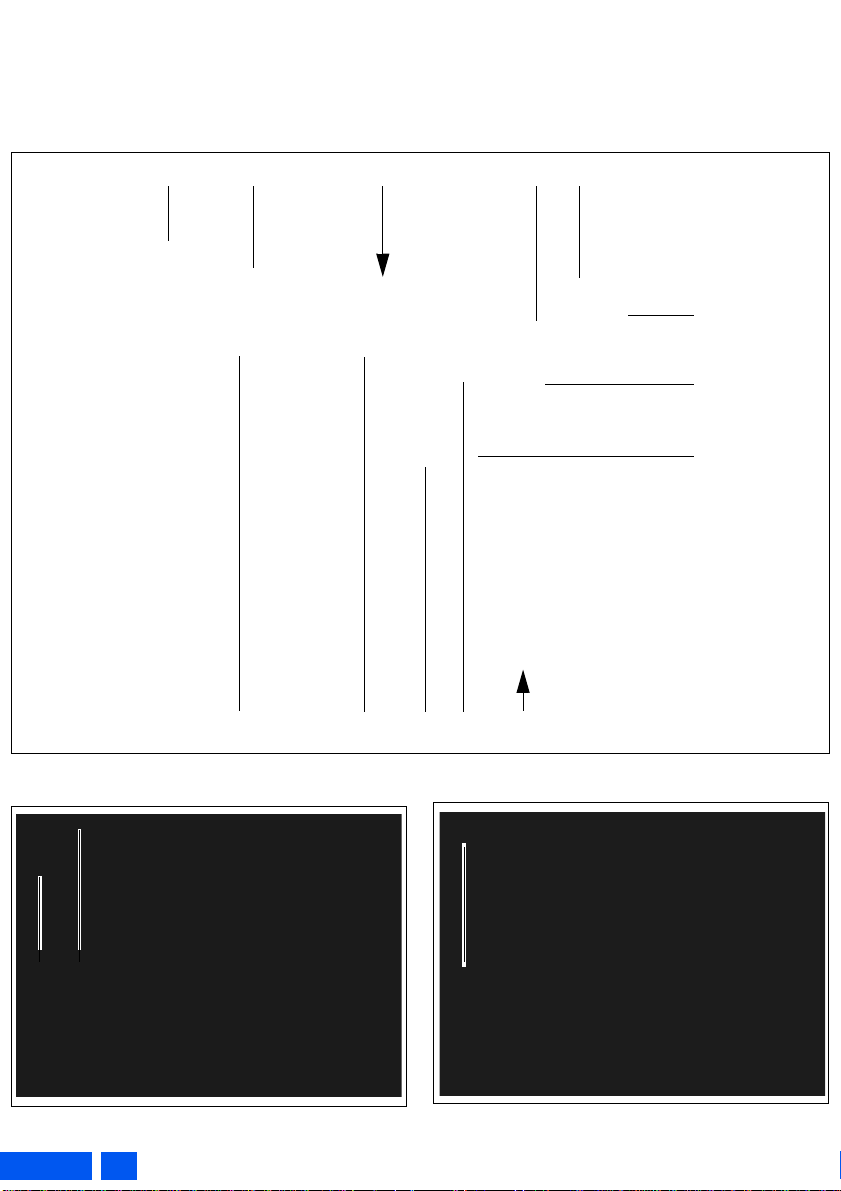

54

46

6

29

18

43

5115 2014016

Fig. 1, Standard version

eil

77 78

Fig. 2, Sport version

81

Fig. 3, Silencer version

5 US 06.01

Page 7

Product description

3 Product description

3.1 Main parts Item Description Item Description

1 Barrel block 29 Hammer

4 Slide 40 Decocking lever

5 Front sight A, B, C 43 Magazine catch

6 Rear sight 46 Manual safety

15 Frame 51 Magazine

16 Tak ed o w n lever

18 Slide catch lever

20 Trigger

a. only Sport version

b. only Silencer version

77 Counterweight

78 Cap

a

81 Threaded cap

3.2 Technical data

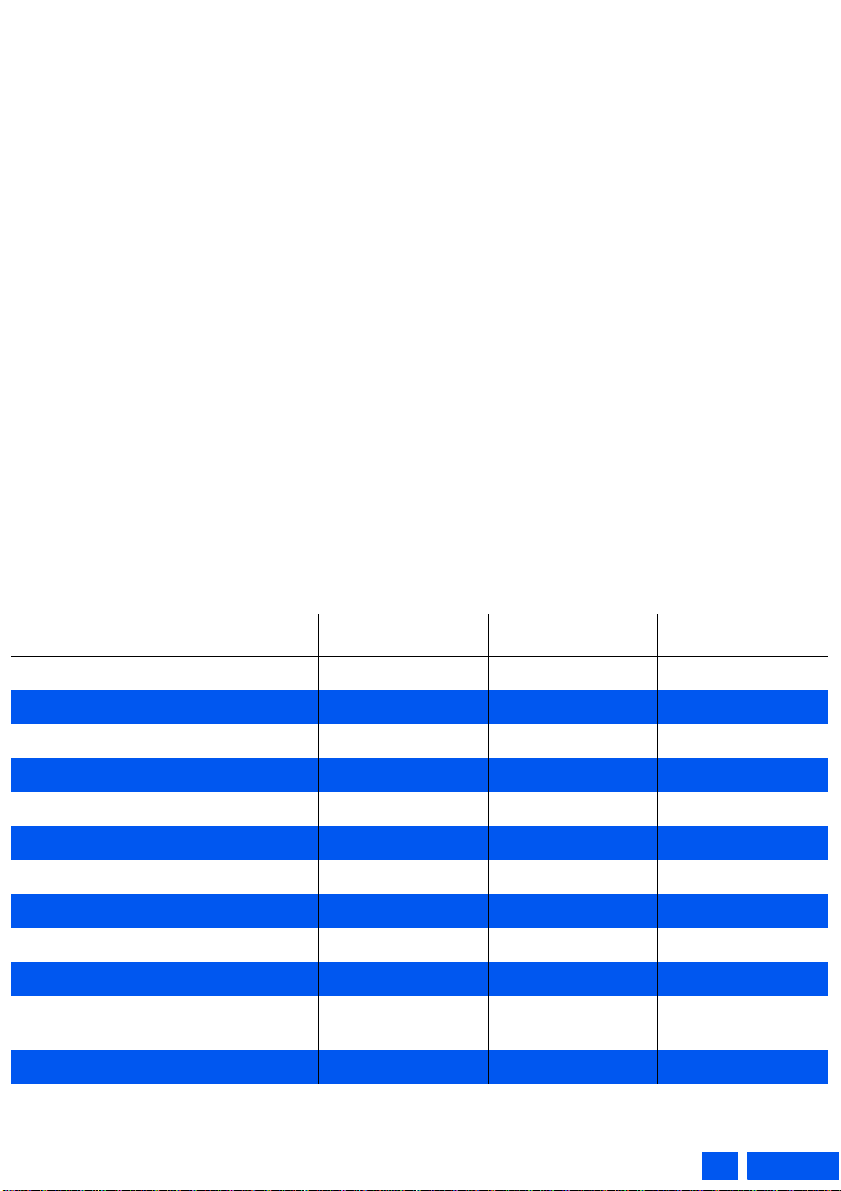

Technical data Standard version Sport version Silencer version

a

b

Calibre .22 Long Rifle .22 Long Rifle .22 Long Rifle

Overall length 7.2 in 207 in 207 in

Overall height 5.3 in 5.3 in 5.3 in

Overall width 1.5 in 1.5 in 1.5 in

Barrel length 3.9 in 4.9 in 4.9 in

Rifling length 1 in 15, right 1 in 15, right 1 in 15, right

Number of grooves 6 6 6

Sight base 7.2 in 6.5 in 7.2 in

Weight without magazine 22.9 oz. 26.1 oz. 22.9 oz.

Magazine weight, empty 1.7 oz. 1.7 oz. 1.7 oz.

Trigger pool, approx. SA 4.0 lbs

DA 12.1 lbs

SA 4.0 lbs

DA 12.1 lbs

SA 4.0 lbs

DA 12.1 lbs

Magazine capacity/rounds 10 10 10

Subject to change without notice

6US06.01

Page 8

Transport Safety mechanisms

4 Transporting the pistol

WARNING!

Uncontrolled discharge of shot

May lead to death or severe injuries

• For your own safety and the safety of others,

always transport the pistol unloaded (see

section 6.7 and 6.8), decocked and closed.

• Never carry a pistol with the hammer cocked

and a round in the chamber.

• Always carry the pistol so that if you fall or

slip, you always maintain control of the

muzzle.

• Transport the pistol separate from the

ammunition, in a locked case.

• Keep the firearm out of the reach of children,

and other inexperienced or unauthorized

persons.

• Follow all applicable Federal, State, & local

regulations regarding the transport of

firearms.

5 Safety mechanisms

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Never completely trust any safety

mechanism. Any safety mechanism can

break down or malfunction. The safest pistol

is one that is fully unloaded.

5.1 Manual safety Engaging manual safety:

1. Push the safety lever (manual safety) 46 down

fully to engage (see Fig. 6 on page 13). This

prevents firing of the pistol.

Disengaging manual safety:

1. Push safety lever (manual safety) 46 up fully to

disengage (see Fig. 6 on page 13). Red dot is

visible. This allows the pistol to be fired.

5.2 Integral safety lock (key operated)

Locking: (see Fig. 5, on page 8)

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Pistol must be decocked.

1. Insert key into opening at bottom rear of the

grip.

2. Push key to depress lock and rotate 90

degrees.

3. Remove key leaving end of lock below the grip

surface (see Fig. 5, on page 8, right).

This locking feature prevents the firing of th e

pistol.

Unlocking: (see Fig. 4, left/right)

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Pistol must be decocked.

1. Insert key into opening at bottom rear of grip.

Push key to depress lock and rotate 90

degrees.

7 US 06.01

Page 9

Safety mechanisms Handling

2. Remove key leaving end of lock flush or even

with bottom of grip (see Fig. 4, right).

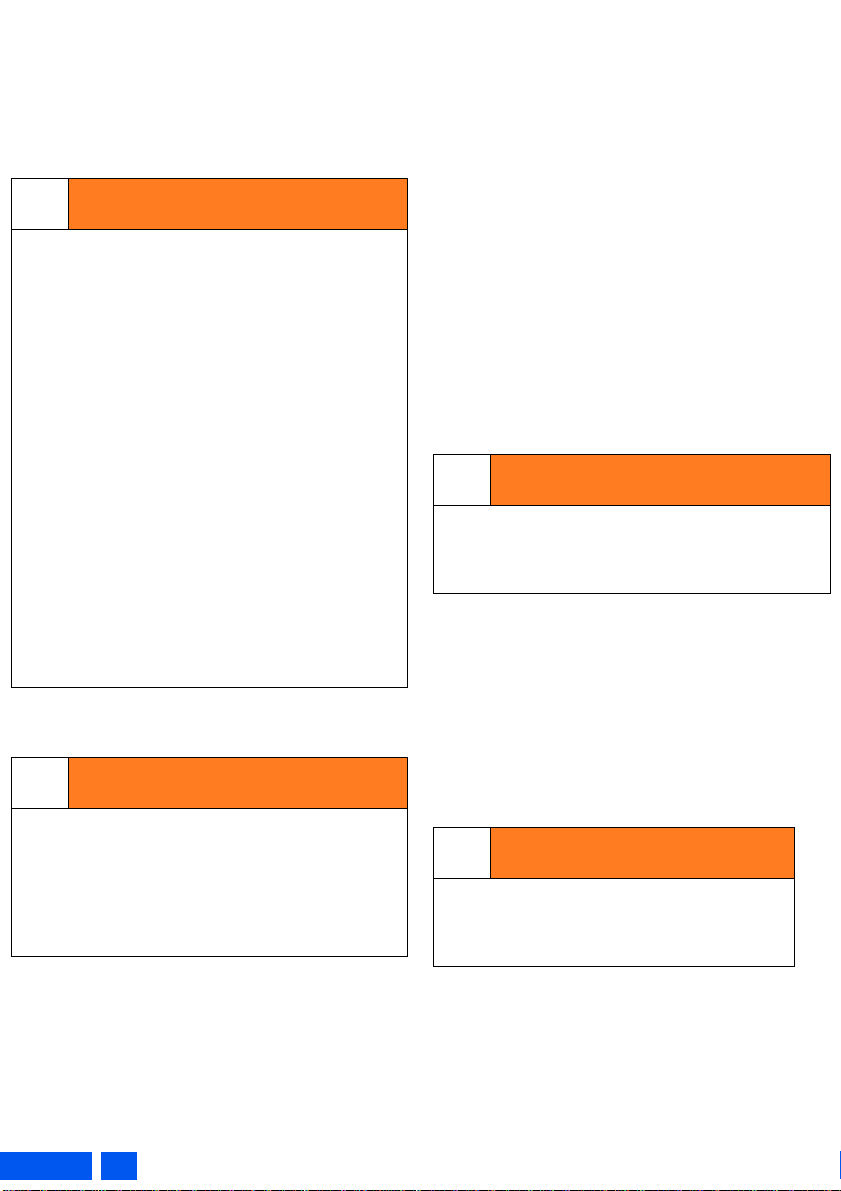

Fig. 4, decocked (left), unlocked (right)

Fig. 5, secured (left), locked (right)

5.2.1 Magazine safety

Removing the magazine fully from the pistol

prevents the pistol from being fired. The magazine

must be fully inserted into the magazine well in

order to fire the pistol.

6 Handling the pistol

6.1 General

The pistol is generally delivered preserved with a

thin, protective grease and oil coating and must be

stripped before being used for the first time,

protective oil or grease removed and lubricated

again. “First use“ (see section 9).

Procedure:

1. Strip pistol (see section 9.1).

2. Clean and relubricate pistol (see section 9.2).

3. Assemble pistol (see section 9.3).

6.2 Ammunition

WARNING!

Inadmissible ammunition

Possibly death or serious injuries and

damage to the pistol

• For your pistol, use only commercial grade

ammunition in its original packing for which

corresponds with the calibre of the pistol. The

correct calibre is imprinted on the pistol .22

Long Rifle.

• Never use reloaded, “refurbished”, hand-

loaded, non-standard ammunition or

ammunition of a different calibre.

• Never use dirty, wet, corroded, bent,

damaged or oiled ammunition.

• Never leave the ammunition lying

unattended.

8US06.01

Page 10

Handling

Information:

The .22 LR ammunition spectrum ranges from

very light loads for single loader guns to sport

load, utility load and on through to high speed

rounds. Unfortunately, however, it is not possible

to adjust a semi-automatic gun to all loads.

We have therefore decided to make an adjustment

to the loads that have priority for use with the

MOSQUITO, which are the two major groups,

utility and high-speed rounds. So to increase the

round compatibility, we provide two slide springs

for every pistol. The bigger bored version is

designed for high-speed loads and is fitted in the

pistol with delivery. The simple coiled smaller

spring (marked white) is for standard loads and is

supplied with the pistol.

Tip:

It has been proven that many types of utility

rounds function more smoothly if the rounds are

lightly oiled.

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Never oil high-speed rounds, as the

pistol can unbolt too quickly while

shooting.

6.3 Loading the magazine Procedure:

1. Place round on feeder close to the magazine

lips.

2. Push the side lock on the magazine down.

3. Only load the number of rounds that are to be

shot (max.10 rounds).

The number of inserted rounds can be determined

through the slot on the magazine.

9 US 06.01

Page 11

Handling

6.4 Loading the pistol (ready for firing) Procedure:

WARNING!

Lacking in awareness of potential dangers

Possibly death or serious injuries

• Never load or unload the pistol inside a

vehicle, inside a building or any other

enclosed space (except in a designated firing

range).

• Before loading always wipe off any excess

grease and oil and check to see if there are

any foreign objects/ material in the barrel.

• Always keep the muzzle of the pistol pointed

in a safe direction.

• Do not put your finger on the trigger. Keep

your finger outside the trigger guard.

• Only insert the loaded magazine immediately

before firing.

• Never cock the hammer back by hand, in

order to prevent the unintentional discharge

of the pistol.

• Never rely on the safety mechanisms alone.

Safety mechanisms are not a substitute for

careful and proper handling of the pistol.

• Never let a loaded pistol out of your hand.

1. Point pistol in a safe direction.

2. Insert full magazine and ensure that it is fully

engaged.

3. Pull slide back fully and release.

– The pistol is loaded and ready for firing in

the single action (cocked) mode.

– The pistol can now be decocked using the

decocking lever. It is then loaded, decocked

and ready for firing in the double action

(decocked) mode.

– The pistol is decocked and ready for firing.

10US06.01

Page 12

Handling

6.5 Firing

WARNING!

Lacking in awareness of potential dangers

Possibly death or serious injuries

• Ensure that the target and surroundings allow

shots to be fired without danger.

• Be certain when firing that your fingers,

hands or other parts of the body are not in

front of, above or beside the barrel muzzle or

the ejector port.

• Never allow a person to stand next to you

where they could be hit by ejected cartridge

cases.

• When shooting, always wear ear protection

and protective eye glasses. Inform other

people close to you about the need to wear

ear protection.

• Stop shooting immediately and unload the

pistol if you suspect that a round is not

inserted correctly, a case is jammed, a round

may have blocked the barrel or a shot sounds

or gives the sensation that it may be “weak”

or unusual.

• Never try to dislodge a blockage by firing

another round.

WARNING!

Missing Dry Fire Plug

Dry firing can cause damage to your pistol

and create an unsafe condition

• Only dry fire your pistol with the Dry Fire Plug

installed in the chamber and the manual

safety off. Observe safe handling procedures

when dry firing – keep the muzzle pointed in a

safe direction!

Procedure:

1. Aim pistol at a safe target.

2. Place finger on trigger and squeeze the trigger

(activates firing).

3. Keep the pistol aimed at the target and fire

further shots as required.

4. Remove magazine and unload pistol. If the

magazine has been shot empty, the slide

remains in the open position. Reload pistol if

further shots are to be fired.

WARNING!

Pistol is ready to fire

Possibly death or serious injuries

• Double action/single action pistols are in a

cocked and ready to fire status after each

firing.

• If you want to interrupt shooting, you must

action the decocking lever to lower the

hammer. The pistol is then in the loaded,

decocked and ready to fire status.

• Once you decide to stop shooting

immediately unload the pistol.

11 US 06.01

Page 13

Handling

6.6 Reloading during firing

The slide is held in the open position.

WARNING!

Lacking in awareness of potential dangers

Possibly death or serious injuries

• Never let the pistol out of your hand.

• Keep the pistol aimed at the safe target.

Procedure:

1. Remove the empty magazine.

2. Insert full magazine and ensure that it is fully

engaged.

3. Depress slide catch lever or retract slide fully

and release.

– The pistol is loaded and ready to fire.

– The pistol can also be decocked using the

decocking lever.

– The pistol is now loaded, decocked and

ready to fire.

6.7 Unloading the pistol; magazine not empty

WARNING!

Pistol is ready to fire

Possibly death or serious injuries

• Never let the pistol out of your hand before it

is unloaded.

• The pistol is loaded; a round is in the

chamber.

• Perform the unloading action with only two

fingers from the rear.

• Never place your hand over the slide

opening.

Procedure:

1. Keep the pistol muzzle pointed in a safe

direction.

2. Press the decocking lever; the hammer is

lowered and held in the safety notch.

3. Depress magazine catch and remove

magazine.

4. Retract slide fully and engage the slide catch

lever. The round is ejected and the slide is held

in the open position.

5. Check (visually and manually with appropriate

aid) to ensure that the round has been ejected

and that there is no round in the chamber (see

Fig. 6).

6. Depress slide catch lever - the slide closes.

7. Depress decocking lever - hammer lowers.

8. Empty magazine.

9. Pick up ejected round and clean pistol.

The pistol is unloaded and decocked.

12US06.01

Page 14

Handling

WARNING!

6.8 Unloading the pistol; magazine em pty, slide open

Not properly cleaned pistol

Possibly death or serious injuries, damage

to the pistol

• The pistol must be cleaned after each firing.

(see section 9.2).

Fig. 6

WARNING!

Pistol is loaded

Possibly death or serious injuries

• You must not let the pistol out of your hand

until the magazine has been removed and

the pistol is unloaded.

Procedure:

1. Keep the pistol muzzle pointed in a safe

direction.

2. Press magazine catch and remove magazine.

3. Check (visually and manually with appropriate

aid) to ensure that there is no round in the

chamber (see Fig. 6).

4. Depress slide catch lever - the slide closes.

5. Depress decocking lever - hammer lowers.

The pistol is unloaded and decocked.

WARNING!

Decocking lever

Possibly death or serious injuries

• Always use the decocking lever to decock

your SIG SAUER pistol. This is the only way

to safely lower the hammer from the cocked

position and prevent an accidental discharge.

• Never lower the hammer by pulling the

trigger and attempting to ease the hammer

forward manually.

• Manually lowering the hammer is

dangerous and prevents full application of

the pistol's safety features - the consequence

can be serious injury or death - only and

ALWAYS use the decocking lever!

13 US 06.01

Page 15

Conversion

7 Conversion

7.1 Conversion to Standard version Procedure:

1. Remove the front sight 5 and insert the cap 78

into the notch of the slide.

2. Disassemble the pistol (see chapter 9.1).

3. Exchange the barrel of the Standard version

1a with the barrel of the Sport version 1b

(see chapter 7.3).

4. Reassemble the pistol

(see chapter 9.3).

5. Install the counterweight 77

(see chapter 7.1.2).

6. Insert the front sight 5 into the notch of the

counterweight.

78

5

77

7.1.1 Removing the counterweight Procedure:

1. Release the threaded pin 79 using the allen

wrench 80 and remove it (see Fig. 8).

2. Remove the counterweight 77.

7.1.2 Installing the counterweight

Procedure:

1. Attach the counterweight 77.

CAUTION!

Possible damage to the pistol

• Do not tighten the threaded pin too tight.

2. Fix the counterweight with the threaded pin 79.

For this use the allen wrench 80 provided.

abziehen.

Fig. 7, Sport version

7. Sight correction (see chapter 8).

777980

Fig. 8

14US06.01

Page 16

Conversion

7.2 Conversion to Standard version Procedure:

1. Disassemble the pistol (see chapter 9.1).

2. Exchange the barrel of the Standard version

1a with the barrel of the Silencer version 1c

(see chapter 7.3).

3. Reassemble the pistol

(see chapter 9.3).

4. Install the threaded cap 81

(see chapter 7.2.2).

7.2.1 Removing the threaded cap

Procedure:

1. Release the threaded cap 81 using the

assembly wrench 82 provided and remove it.

7.2.2 Installing the threaded cap

1. Attach the threaded cap 81 and tighten it with

the assembly wrench 82 provided.

81

82

7.3 Exchanging the barrel Procedure:

1. Release the screw 66 and remove the

takedown lever 16.

2. Release the screw 58 of the frame 15 and

remove it.

3. Lift the barrel 1a and take out the takedown

lever insert 25.

1a

25

66

58

15

16

Fig. 10

4. Insert the takedown lever insert into the barrel

1b (Sport version) or

1c (Silencer version).

5. Insert the barrel into the frame.

Fig. 9

CAUTION!

Possible damage to the pistol

• Do not tighten the screws too tight.

Notice:

Before inserting the screws 58 and 66 apply

Loctite to the thread.

15 US 06.01

Page 17

Sight

6. Place the screw 58 in the frame and tighten it.

7. Use screw 66 to fix the takedown lever 25 with

the frame.

8 Sight adjustment

CAUTION!

Possibly damage to the pistol

• Any adjustment to sights should only be done

on an unloaded pistol, by an armorer,

gunsmith or other qualified person.

8.1 Sight adjustment for windage

8.1.1 Rear sight adjustment

CAUTION!

Possibly damage to the pistol when turning

the adjusting screw clockwise

• Turn the adjusting screw clockwise only until

you notice a light resistance. Do not turn the

screw any further!

• The rear sight must not exceed the edge

shown in Fig. 12.

Turning the lateral adjusting screw clockwise one

full rotation moves the point of impact

approximately 3 inches to the left at a distance of

25 yards.

Turning the lateral adjusting screw counter

clockwise one full rotation moves the point of

impact approximately 3 inches to the right at a

distance of 25 yards.

!

Fig. 11

!

Fig. 12

8.2 Sight adjustment for elevation

Your pistol includes two additional front sights of

different heights.

Changing to the higher front sight lowers the

point of impact approximately 7.5 inches at 25

yards.

Changing to the lower front sight raises the

point of impact approximately 7.5 inches at 25

yards.

16US06.01

Page 18

Maintenance

9 Pistol maintenance

WARNING!

Pistol is ready to fire

Possibly death or serious injuries

• Magazine must be removed from the pistol.

• Before field stripping your pistol for cleaning,

verify again that it is not loaded (see sections

6.7 and 6.8).

• Do not put your fingers into the slide.

9.1 Field stripping the pistol

Procedure:

1. Unload pistol (see sections 6.7 and 6.8).

2. Remove the threaded cap of the Silencer

version (see chapter 7.2.1), resp. the

counterweight of the Sport version (see

chapter 7.1.1).

3. Retract slide 4 fully and lock open by engaging

the slide catch lever 18 (see Fig. 13).

4

18

1.

5. Depress slide catch lever to close slide.

6. Rotate takedown lever 16 clockwise 180° until

it points forward (see Fig. 14).

16

Fig. 14

7. Retract slide fully; lift rear of slide until clear of

frame and slowly move slide group forward

towards muzzle end of pistol (see Fig. 15 and

Fig. 16).

Fig. 15

2.

Fig. 13

4. Check to ensure there is no round in the

chamber.

Fig. 16

17 US 06.01

Page 19

Maintenance

8. Remove slide assembly (slide, recoil spring

guide and recoil spring) from the barrel

muzzle.

This level of stripping is sufficient for a thorough

cleaning after firing.

CAUTION!

Possibly damage to the pistol

• Further dismantling of the pistol may only be

carried out by qualified armorers and

gunsmiths.

9.2 Cleaning the pistol

CAUTION!

Possibly damage to the pistol

• Never clean the barrel from the front (muzzle

end) and never use steel brushes, as these

can damage the smooth surface of the barrel.

Use a suitable cleaning rod and brush

designed for .22 caliber.

• Solvents can damage the surface of the

pistol. Before using a cleaning or solvent

agent, take note of the instructions and

warnings provided by the manufacturer.

Procedure:

1. Moisten cleaning brushes with gun oil and

insert into the barrel through the chamber.

Carefully remove all powder residue and dirt in

the barrel and chamber with the cleaning

brush.

2. Remove powder residue and oil using from the

chamber and barrel using a cleaning patch.

3. Clean external surfaces of the barrel with a

brush that has been moistened with gun oil.

4. Wipe off frame, slide, recoil spring guide and

recoil spring with a cloth lightly coated with gun

oil or grease.

5. Lightly oil barrel bore and chamber. Be sure to

remove excess lubricant.

43a/b 2

15

1a

51

Fig. 17, Cleaning Standard version

18US06.01

Page 20

Maintenance

3a/b

4

15

79

80

Fig. 18, Cleaning Sport version

43a/b

81

5182

51

1c

1b

2

9.3 Pistol assembly

Procedure:

1. Inspect the pistol interior and remove any

foreign matter.

2. Slide recoil spring 3 onto the spring guide 2.

3. Insert spring guide with recoil spring into the

frame 15. The flat portion of the recoil spring

guide faces the rear of the pistol.

CAUTION!

Frame, recoil spring guide and recoil spring

are loosely connected

Possibly damage to the pistol and bodily

harm

• Careful handling of the slide and the parts

connected to the recoil spring.

4. Slip slide over the recoil spring and recoil

2

spring guide.

5. Retract the slide fully to the rear and down until

the slide guide can click into the frame guide.

6. Slowly move the slide forward until closed.

7. Install the threaded cap of the Silencer version

(see chapter 7.2.2), resp. the counterweight of

the Sport version (see chapter 7.1.2).

8. Rotate the takedown lever counter clockwise

180° until it points towards the rear of the

pistol.

Note:

The pistol is unloaded and decocked.

Fig. 19, Cleaning Silencer version

19 US 06.01

Page 21

Maintenance

9.4 Functional check Note:

The check of all functions must be made on the

assembled pistol:

• to determine any causes of malfunctioning,

• after completion of repairs,

• and after each cleaning and assembly of the

pistol.

Procedure:

1. Ensure the magazine is removed and pistol is

unloaded (see sections 6.7 and 6.8).

2. Check spring tension of the recoil spring and

slide cycling (no binding).

– Retract slide fully and release.

– Verify slide closes rapidly and fully under

spring tension.

– Repeat check again.

3. Check double action (DA).

– Insert empty magazine (gun has a

magazine safety).

– Pull trigger fully with decocked hammer.

– Verify hammer travels fully to rear and

releases. Hammer should impact firing pin

with adequate force. Hammer should reset

into safety intercept notch (verify by

pressing back of hammer).

4. Check trigger path and trigger interruption.

– Insert empty magazine (gun has a

magazine safety).

– Pull trigger fully to rear and hold.

– Retract slide fully and release.

– Verify hammer remains cocked to rear;

release trigger

5. Check single action trigger function (SA).

– Insert empty magazine (gun has a

magazine safety).

– Pull trigger fully

– Hammer should fall & impact firing pin with

adequate force. Hammer should reset into

safety intercept notch.

6. Check decocking lever and hammer safety

intercept notch.

– Remove magazine

– Cock hammer by retracting slide fully and

releasing.

– Depress decocking lever to lower hammer.

– Verify hammer is locked in safety intercept

notch by pushing back of hammer.

7. Check slide catch lever.

– Insert empty magazine; retract slide fully

and release

– Check that the slide remains locked to the

rear.

– Depress slide catch lever.

– Verify slide closes fully and with adequate

force.

– Depress decocking lever. Remove

magazine.

8. Check magazine.

– Inspect the magazine tube (lips and

floorplate) for signs of damage or dirt.

– Verify that magazine floorplate is properly

secured.

– Verify the feeder is under sufficient spring

tension and is not binding during

movement.

– Insert the magazine into the pistol

magazine well and ensure there is no

binding.

– Ensure the magazine catch does not bind

when depressed and released.

9. Check external condition of the pistol.

– Inspect front sight, rear sight, grip plates

and takedown lever for damage and dirt.

– Verify tightness of sights and grip plates.

20US06.01

Page 22

Maintenance Servicing

9.5 Care of the pistol

CAUTION!

Neglecting the pistol

Possibly damage to the pistol and bodily

harm

• Always keep your pistol clean and in good

working order.

• Clean the pistol after 250 rounds, before

every ammunition type change and after

every use. The chamber in particular must be

thoroughly cleaned.

• Never change or repair parts of your pistol

yourself.

• Have your pistol checked once a year by a

qualified gunsmith or armorer, as defects,

wear and tear, corrosion etc. may not always

be visible from the exterior.

• For repair or service work, we recommend

that you return your pistol to SIG SAUER.

• If you order replacement parts without

returning the pistol, you are responsi bl e for

ordering the correct replacement part and its

installation by a qualified gunsmith or

armorer.

SIG SAUER cannot be held liable for pistol

faults or malfunctions if the pistol has been

modified or parts have been installed or

repaired by third parties.

10 Service and repairs

10.1 Fault detection, fault removal

Faults can be prevented with the proper

maintenance of the pistol (cleaning and

inspection). Should, however, a malfunction occur

while firing, proceed as follows:

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Keep the pistol pointed in a safe firing

direction and remove your finger from the

trigger while you carry out the steps shown

below.

1. Remove the magazine.

2. Retract the slide fully and lock to the rear

(open) using the slide catch lever.

3. Check (visually and manually with appropriate

aid) to ensure there is no round, bullet, case or

foreign bodies in the chamber or in the barrel

bore. If a bullet is lodged in the barrel bore,

strip the pistol and have the bullet removed by

a qualified gunsmith using the proper tools.

4. Remove all ammunition & foreign matter.

Clean, lubricate and assemble pistol.

5. Have pistol checked by a gunsmith or armorer.

21 US 06.01

Page 23

Servicing

Part/fault Possible cause of fault/defect Possible fault/defect removal

Ammunition feeding:

Failure to feed.

Failure to chamber.

Slide:

Slide does not close properly.

Case ejection:

Empty case remains in the

chamber or gets stuck in ejector

port.

Misfiring:

Hammer hits; no discharge.

Magazine is not inserted

correctly, deformed or dirty.

Pistol or rounds dirty or greased

too much.

Large (heavy) slide spring

installed and standard

ammunition used.

Pistol defective.

Pistol or rounds dirty or greased

too much.

Pistol defective.

Underloaded ammunition.

Recoil not sufficient due to dirt.

Pistol defective.

Firing pin sticks in the

firing pin guide.

Ammunition fault.

Pistol defective.

Insert magazine correctly or

replace it.

Strip, clean and lubricate pistol,

clean or replace ammunition.

Small (light) slide spring

mounted.

Repair by manufacturer.

Strip, clean and lubricate pistol,

clean or replace ammunition.

Repair by manufacturer.

Replace ammunition.

Strip, clean and lubricate pistol.

Repair by manufacturer.

Strip, clean and lubricate pistol.

Have pistol checked by armorer.

Manually cycle slide to load new

round

Repair by manufacturer.

22US06.01

Page 24

Servicing

10.2 Safekeeping and storage of pistol

WARNING!

Uncontrolled shot discharge

Possibly death or serious injuries

• Only store your pistol unloaded and cleaned.

• Keep your pistol separate from ammunition

and locked away. The pistol and ammunition

must always be in a place inaccessible to

children and unauthorized persons.

10.3 Shipping the pistol Note:

• Familiarize yourself with all laws and

regulations governing shipping and transport

of firearms.

1. Check pistol to ensure it is unloaded and

decocked.

2. Pack the pistol well (if possible in the original

packaging) to prevent damage during

shipment. If returning in original case, cover

the case with a second outer layer.

Ammunition and accessories (other than

magazines) should not be included in the

package.

3. Enclose a letter with the following information:

– Your name

– Your address

– Your telephone number, at which you can

be contacted during the day

– A detailed description of the problems

encountered or the work that is to be carried

out.

4. Send the pistol insured and postage paid

(parcels with incorrect postage will not be

accepted) to:

SIG SAUER Inc.

Attn.: Service Department

18 Industrial Drive

Exeter, NH 03833/USA

Phone 603-772-2302

Fax 603-772-9082

Before returning the firearm contact Customer

Service at (603) 772-2302 for an RMA number.

Clearly mark the number on the outside of your

package – this number will assist us in tracking the

status of your return.

10.3.1Warranty Statement

Based on Magnuson-Moss Warranty Act,

SIG SAUER. offers no express warranty on their

product line. However, SIG SAUER recognizes

its obligations concerning service to owners of

SIG SAUER products. SIG SAUER stands

behind its products and will continue to provide

service to their product line as they have over the

years. SIG SAUER products will be serviced for

a period of one year from date of retail purchase,

for defects in materials or workmanship, at no

charge to the purchaser.

– Be sure to retain your sales slip as proof of

purchase date when making a claim.

23 US 06.01

Page 25

Scope of supply Accessories

11 Scope of supply

11.1 Standard version

1 Pistol

1 Magazine

1 Gun case

1 Safety & Handling booklet

1 Test group card

1 Cable lock

1 Dry fire plug

1 SIG SAUER gun oil

2 Exchangeable front sights

1 Recoil spring

1 Key (integral lock)

11.2 Sport version

As Standard version and additionally:

1 x Allen wrench

11.3 Silencer version

As Standard version and additionally:

1 x Assembly wrench

11.4 Conversion set Sport version

1 x Barrel Sport version

1 x Counterweight

1 x Cap

1 x Threaded pin

1 x Allen wrench

11.5 Conversion set Silencer version

1 x Barrel Silencer version

1 x Threaded cap

1 x assembly wrench

12 Accessories

•

Case locks

• SIG SAUER gun oil

• Leather holsters

• Kydex holsters

• X-POINT sights

• Mount for X-POINT sights

13 Disposal

•

Comply with all Federal, State & local laws

regarding the disposal of handguns.

14 List of replacement parts

Required information when ordering

replacement parts

– Pistol type (calibre, description of type)

– Pistol number

– Item number

– Part designation

24US06.01

Page 26

List of replacement parts

ItemDescription

1a Barrel

1b Barrel

1c Barrel

a

b

c

2 Recoil spring guide

3a Recoil spring, white

(standard)

3b Recoil spring (high velocity)

4 Slide

5a Front sight A

5b Front sight B

5c Front sight C

6 Rear Sight

7 Slide breech block pin

8 Trigger bar spring

9 Breech block

10 Extractor

11 Firing pin

12 Firing pin spring

13 Safety lock

14 Safety lock spring

15 Frame

16 Takedown lever

17 Striker pin for integral safety

lock

18 Slide catch lever

19 Slide catch lever spring

20 Trigger

21 Trigger pivot

22 Trigger bar

23 Lock

24 Sear

25 Takedown lever insert

27 Spring for integral safety

lock

28 Safety lever

29 Hammer

30 Spring for safety lever

ItemDescription

31 Ball for safety lever

32 Ejector

33 Hammer strut

34 Mainspring

35 Action casing half (left)

36 Ball centering

37 Action casing half (right)

38 Extractor spring

39 Magazine safety

40 Decocking lever

41 Decocking lever bearing

42 Decocking lever spring

43 Magazine catch

44 Safety lever (Manual

safety), right

45 Magazine catch spring

46 Safety lever (Manual

safety), left

47 Feeder axle

48 Grip plate, right

49 Grip plate, left

50 Grip plate screws

51 Magazine tube

52 Magazine spring

53 Feeder

54 Magazine floor plate

55 Floorplate insert

56 Threaded socket for grip

plates

57 Retainer

58 Screw for grip

59 Hammer reset spring

60 Hammer pivot pin

61 Hammer strut pin

62 Trigger bar pin

63 Spring for magazine safety

ItemDescription

64 Sa fety lever pin

65 Mag azine safety pivot pin

66 Screw for decockin g lever

67 Screw for safety lever

68 Adjusting screw

69 Key

70 Main spring washer

71 Main spring washer

72 Key ring

73 Extractor guide

74 Extractor pivot pin

75 Breech block pin

76 Breech block spring

77 Counterweight

78 Cap

b

79 Threaded pin

80 Allen wrench

81 Threaded cap

82 Assembly wrench

a. Standard version

b. Sport version

c. Silencer version

b

b

b

c

c

25 US 06.01

Page 27

List of replacement parts

Fig. 20, Spare parts for MOSQUITO

26US06.01

Page 28

SIG SAUER, Inc.

18 Industrial Drive

Exeter, NH 03833

Phone: 603-772-2302

Fax: 603-772-9082

www.sigsauer.com

Loading...

Loading...