Page 1

Instruction manual

Page 2

Caution !

Please always read this instruction

manual entirely, before using the

rifle. The rifle may only be passed

on together with this instruction

manual.

As a supporting measure to this

instruction manual, please ask

your dealer to explain your rifle to

you in detail and let him instruct

you about its use.

2

Page 3

Contents

Page

Safety rules 4 – 5

11. Assembling, taking down 6 – 7

12. Safety system and bolt handle lock 8 – 9

13. Loading the rifle 10

14. Firing and repeating 10

15. Unloading 11

16. Removing and replacing the bolt assembly 11

17. Changing the barrel 12

18. Changing the bolt head 13 – 15

19. Removing / changing the fore-end 16

10. The trigger assembly 17

11. Open sights (adjustable) 17

12. Mounting the telescopic sight 18

13. Mounting the fixed scope mount 19

14. Caliber group table 20

15. Case 21

16. Care and maintenance 21

17. Operating and functional parts of the bolt assembly 22

18. Warranty conditions 23

3

Page 4

Safety rules

Your new Blaser bolt action rifle model

R 93 differs from other repeaters through

a number of special design features.

Although your Blaser firearm exhibits

additional safety features, do not forget

that you must take care when handling

firearms and also observe the statutory

regulations.

First of all, check you have the right user

manual: the model name R 93 and cali-

english

ber can be found on the left side of the

barrel at the rear.

General safety rules for handling

firearms

- Make sure the firearm and ammunition

never get into unauthorized hands.

- Always store firearm and ammunition

under lock and key in separate cabinets

that are not accessible to unauthorized

persons.

- Observe current statutory regulations

for the carrying and safekeeping of

firearms and ammunition.

- Make sure you are thoroughly familiar

with how to handle your firearm and,

with the firearm unloaded, practice all

of the functions and the actions you

will need to make, before you carry it.

- Always treat any firearm as loaded and

ready to shoot. If you are not certain of

its status, check by opening the bolt

and looking in the magazine and

cartridge chamber (barrel). You should

handle an unloaded firearm in the

same way as a loaded one.

4

Page 5

Safety rules

- Whenever holding the rifle, always

point the muzzle in a safe direction to

ensure you neither injure people nor

damage property.

- Before loading, check the barrel for

obstructions and make sure no foreign

matter (water, snow, soil) can get into

the barrel after loading, too.

- Only use CIP-approved ammunition

which is in good condition and check

that the ammunition is correct for the

caliber of the rifle. Wrongly re-loaded

ammunition can damage your rifle and

cause serious injury.

- Do not load your rifle until just before

you fire it.

- Do not cock your rifle (take off safety)

until you are ready to fire. When

cocking (taking off safety), point the

muzzle in a safe direction.

- Before making each shot, check the

terrain in front of and behind the target.

- Aim your rifle only at targets you have

definitely identified.

- Keep your finger away from the trigger

unless you wish to fire the rifle.

- If a cartridge fails, wait approximately

60 seconds before opening the breech

to avoid danger from a cartridge that

may be late firing.

- Always wear ear defenders when firing

(ear plugs).

Unload your gun

- before negotiating obstacles

- before climbing into or leaving raised

blinds

- before entering a building

- before climbing into a vehicle

- before entering a town or village

- if you temporarily put the rifle down

or hand it to someone.

5

Page 6

1. Assembling, taking down

english

fig. 1 fig. 2

fig. 3

- Drop the magazine into the receiver

with the magazine lips upwards

(fig. 3).

1.1 Assembling

- Remove the large allen key (SW 4)

from its pocket in the shipping carton.

With the barrel screw studs pointing

down, insert the barrel into the receiver (fig. 1).

6

- Then, insert the allen key into the holes

on the bottom of the fore-end and

tighten the two allen screws equally

locking the barrel and receiver together

(fig. 2). Do not use any extension tools

on the allen key to tighten screws.

Good hand tightness is sufficient.

Page 7

1. Assembling, taking down

fig. 4

- Push the magazine down to the

bottom of the receiver - with your

thumb - and hold! (fig. 4).

- Place both bolt rails parallel on the rear

end of the receiver and insert the bolt

by sliding the bolt rails forward. Push

forward on the bolt handle until the

bolt is closed completely.

- To remove the bolt, magazine

and barrel read chapter 6 and 7 of

instructions.

WARNING:

Always make sure the bolt handle is

locked in the back position when installing the bolt assembly, i.e. at an angle of

approx. 45°. If the bolt handle is close to

vertical, you cannot mount the bolt

assembly. Pull the bolt handle back until

it engages in the 45° position.

WARNING:

When assembling the rifle, ensure that

the barrel, bolt and magazine all match

and are of the correct caliber.

1.2 Taking down

- Push the safety slide forward slightly

with the thumb (approx. 1/16“),

simultaneously pulling the bolt handle

back with forefinger and middle finger

(unlocking - fig. 9).

Then pull the bolt all the way straight

back.

- Unload the rifle (see chapter 5).

- Push down and hold the bolt stop pin

(fig. 10) simultaneously withdrawing

the bolt assembly with the other hand.

- With the 4 mm AF allen key supplied,

undo the two barrel attachment

screws.

- Remove the barrel.

7

Page 8

2. Safety system and bolt handle lock

2.1 Safety system

The safety system of the Blaser R 93 bolt

action rifle is centered on the uncocked

firing spring: you operate the safety slide

to cock the firing spring just before firing

the rifle or to release it again. When

repeating, it remains cocked. With the

safety slide released, the bolt handle is

simultaneously locked to prevent accidental opening of the bolt when carrying

the rifle, provided this was fully closed.

WARNING:

When cocking and uncocking, keep your

fingers off the trigger (unlike firearms

with a hammer which you may be used

to). In the case of a Blaser rifle, this will

discharge a shot!

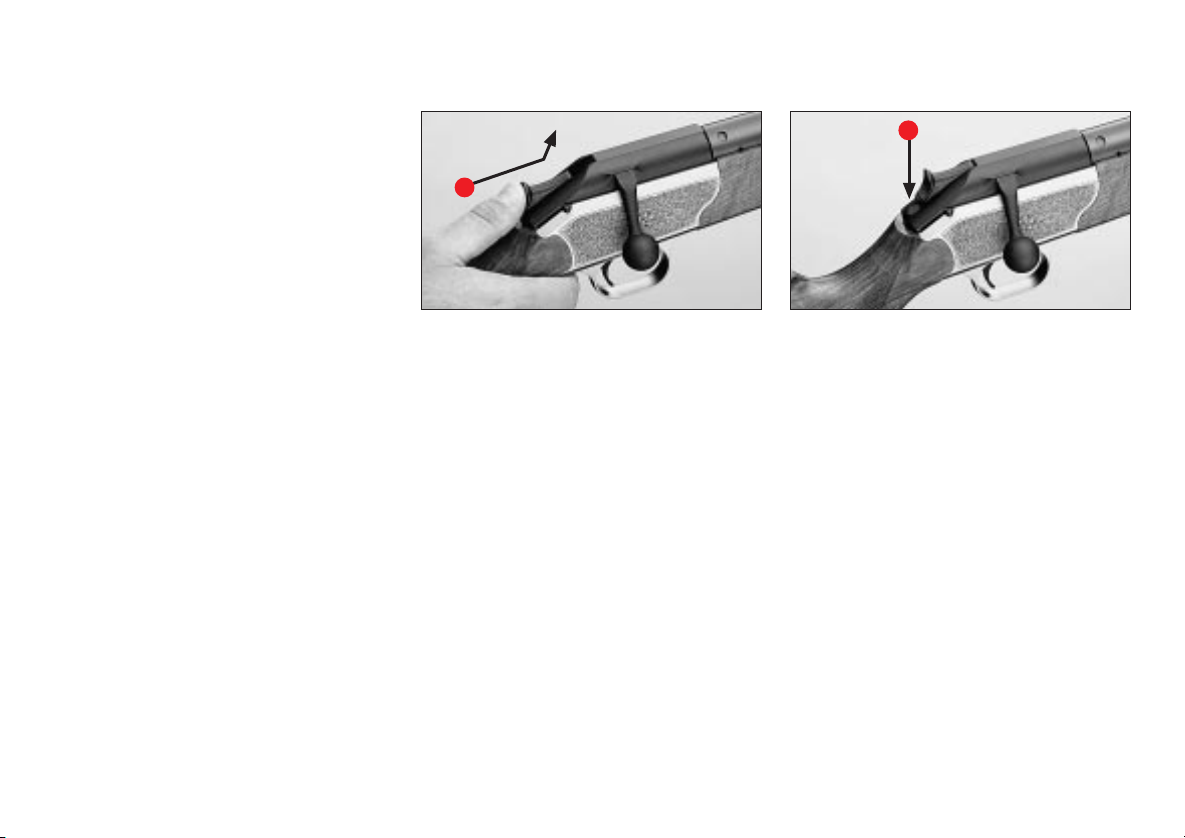

fig. 5 fig. 6

2.2 Cocking (taking off safety)

- Press your thumb right into the ribbed

finger recess.

- Slide the safety slide forwards firmly

with the thumb as far as the stop and

lift off the thumb to allow the slide to

engage in the cocked position (fig. 5).

You should see a red warning dot

behind the slide to indicate the

„Off safe“ position (fig. 6).

8

Page 9

2. Safety system and bolt handle lock

fig. 7 fig. 8 fig. 9

2.3 Uncocking

(»breech in safe position«)

- Press with your thumb firmly on the

safety slide towards the front/bottom

position (unlock - fig. 7) and let it slide

back into its original position (fig. 8).

2.4 Bolt handle lock

Prevents accidental opening of the bolt.

It is automatically activated when the rifle

is uncocked and fully locked.

2.5 In the „On Safe“ position the bolt

handle is locked

- To open the bolt (for loading and

unloading) in the „On Safe“ position,

push the safety slide with your thumb

1/16" forward, hold and simultaneously pull bolt handle backwards (fig.9),

then open bolt all the way.

9

Page 10

3. Loading the rifle

4. Firing and repeating

- Pull back the slide („On safe“)

- Open the bolt (see chapter 2.5)

- Place a cartridge onto the magazine

and press firmly downwards - with

the thumbs if necessary - so that it

snaps through the magazine lips.

Capacity of magazine: 3 cartridges.

Exceptions are as follows:

Caliber group

Mini = 4 cartridges

Ultra Magnum = 2 cartridges

Swiss = single shot

Shotgun = single shot

Hornet = single shot

- Should you wish, you can insert a

further cartridge in the chamber by

hand.

- Press down the cartridges in the magazine with the thumb and push the bolt

handle forward all the way with the

other hand until it locks.

CHECK THAT:

The red dot is not visible, bolt handle is

all the way forward. The rifle is now

loaded, uncocked and locked to prevent

accidental opening.

10

- Cock the rifle by pushing the safety

slide forward with the thumb

(take off safety - see chapter 2.2).

- Sight the target and fire.

- Repeating: Pull back the bolt as far as

the bolt stop allows and then push it

forward again.

IMPORTANT:

If the bolt handle is not in its most forward position, the rifle will not fire for

safety reasons.

Should you wish to reload for a repeat

shot very quietly, push the bolt with the

thumb more at the top of the bolt handle, pressing the ball of the bolt handle

forwards with the ball of the thumb.

WARNING:

When the safety slide is locked in the

forward position the rifle is cocked automatically with each reload action. When

you do not want to fire any more, you

simply move the safety slide immediately

backwards (safety on).

WARNING:

Always wait until you are ready to fire

before cocking the rifle. If, after firing,

the rifle is cocked again when you are

not yet ready to shoot, simply uncock the

rifle by moving the safety slide back

(safety on).

Page 11

5. Unloading the rifle

6. Removing and replacing the bolt assembly

- Remove your finger from the trigger

and point the rifle in a safe direction.

- Move the safety slide in the „On Safe“

position (as in chapter 2.3)

- To remove cartridge from chamber,

push the safety slide 1/16" forward

with your thumb, hold and pull bolt

handle backwards, then open bolt

slowly until the cartridge can be

grasped with the fingers before it

clears the receiver.

- Remove the cartridge from the firearm.

- With the bolt open, point rifle barrel

upwards. With your finger push the

cartridge in the magazine forward until

it snaps out of the magazine lips, then

remove cartridge from the receiver.

Repeat procedure until magazine and

chamber are empty.

Warning:

Make sure there are no cartridges left in

the chamber or magazine.

fig. 10

6.1 Removing the bolt assembly

- Unload the rifle (see chapter 5).

- Pull the bolt assembly all the way back.

- Push down and hold the bolt stop pin

(fig. 10) and simultaneously withdraw

the bolt assembly backwards with the

other hand.

Note: A number of short-case calibers

(.222 Rem., .22-250, .243 Win., 6x62

Frères, 6.5x55, 6.5x57, 7x57, 7.5x55,

.308 Win. and 8x57 IS) have a moving

bolt stop integrated into the magazine

on the right hand side. To remove the

bolt assembly from the rifle if you are

using one of the above calibers:

- Press the right magazine lip inwards.

This puts the short-case bolt stop out

of operation.

- Pull the bolt backwards until the

normal bolt stop takes effect.

- Then press in and hold the bolt stop

pin (fig. 10) and simultaneously

withdraw the bolt assembly backwards

with the other hand.

6.2 Installing the bolt assembly

- Push the magazine down to the

bottom of the receiver and hold it

there.

- Carefully position the ends of the two

slide rails onto the rear end of the

receiver in line with the bolt guide.

- Push the bolt assembly forward to fit

into the guide on the receiver.

- Do not use force when doing this! If

the bolt assembly does not slide on

smoothly, try again taking more care.

11

Page 12

7. Changing the barrel

There are 8 caliber groups available (see

table on page 42). When changing the

barrel to a different caliber group, you

will also have to change the bolt head to

suit the caliber group of the barrel you

have chosen to use. The table on page

42 shows the correct components to be

used together. In addition, bolt heads

and barrels are stamped with markings

which identify the caliber group (fig. 11).

english

Take a final check that these markings

match after the rifle is assembled.

Caliber group markings:

Hornet Marking HO

Mini Marking MI

Standard Marking ST

Medium Marking ME

Magnum Marking MA

Ultra Magnum Marking UM

Swiss Marking CH

Shotgun Marking 28

Make sure you also use the correct

magazine to match the caliber of the

barrel. The caliber marking can be

found on the side of the magazine.

Note: Single-shot inserts are supplied

with barrels in the calibers .22 Hornet,

28/70 and 10.3x60R. Magazines are not

available for these.

Changing the barrel:

- Unload the rifle (see chapter 5).

- Remove the bolt assembly

(see chapter 6.1).

- Remove the magazine (remove the

scope if fitted, see chapter 12.2 or

13.2 as appropriate).

- Fully undo both attachment screws

with the 4 mm AF allen key, these are

captive so cannot be lost.

- Lift the barrel out of the receiver.

- Place the new barrel in the bed of the

receiver.

- Tighten both barrel attachment

screws hand-tight with the allen key.

MAMA

fig.11

- Insert a magazine matching the caliber

of the barrel into the magazine housing.

- Check that the marking stamped on

the bolt head (HO, MI, ST, ME, MA,

UM, CH, 28, see chapter 7 and fig.

11) matches the caliber group of the

barrel.

- If you have to change the bolt head in

the bolt assembly, see chapter 8.

Note:

Always keep the barrel bedding clean.

Excessive oil or grease between the barrel

and receiver will impair the accuracy of

the rifle.

12

Page 13

8. Changing the bolt head

fig.12 fig.13 fig.14

8.1 Changing the bolt head

It is advisable to have this operation

explained by your gunsmith.

- Unload the rifle (see chapter 5).

- Remove the bolt assembly from the

rifle (see chapter 6.1).

- Place bolt assembly upside down on a

flat surface.

- With a small screwdriver or similar tool

push the retaining latch to the left side

and up (fig. 12).

- Grasp the retaining latch with thumb

and forefinger and push to the left.

With your other hand pull the bolt

head out of the bolt assembly

(fig. 13).

8.2 Installing the bolt head

- Grip the new bolt head to be installed

and line up the two grooves of the

expanding shell and bolt head by turning them in relation to each other

(fig. 14).

- Lift the retaining latch in the

bolt housing.

- Now insert the bolt head with the

groove facing exactly upwards into the

bolt housing over the firing pin as far

as the stop and hold it there.

13

Page 14

8. Changing the bolt head

fig.15 fig.16 fig.17

english

Note: To make this process easier, jiggle

the firing mechanism up and down with

the thumb of the other hand (fig. 15).

- Flip the retaining latch down again and

push it back into its recess so that it

snaps into position (fig. 16).

Warning: If the retaining latch is not

in the correct position, a warning pin will

project from the outside of the rail

(fig. 17).

14

Page 15

8. Changing the bolt head

rivet

fig.18 fig.19

The bolt assembly can only be inserted

in the receiver when the warning pin

is flush in the bolt rail (fig. 18), indicating that the retaining latch is seated

correctly.

Warning:

The bolt head assembly consists of two

major parts: The bolt head and the surrounding expanding shell.

These two parts are bound together by

a rivet (fig. 19). It is strictly forbidden to

Note: Bolt heads for left-hand bolts are

stamped »L« below the caliber group

marking.

loosen that rivet!

Firing the rifle with the expanding shell

removed, will inevitably cause the blow-

out of the bolt head assembly and injury

or death to the shooter or bystanders!

bolt head

expanding shell

15

Page 16

9. Removing /

changing the fore-end

fig. 20

The Safari and Match versions of the

Blaser R 93 repeating rifle have a special,

wide fore-end. Therefore, should you

wish to fit a Safari or Match barrel to the

R 93 basic version, you will have to change the fore-end.

Removing or changing the fore-end:

- Unload rifle (as in chapter 5).

- Use allen key (SW4) to unscrew the two

barrel attachment screws holding barrel

and receiver together.

- Lift off the barrel.

- Using the long allen key (SW4) to

unscrew fore-end screw (fig. 20).

- Pull the fore-end off.

- To assemble the fore-end reverse above

instructions.

- Ensure that the spacer is in the correct

position.

16

Page 17

10. Trigger assembly

11. Open sights

(adjustable)

11.

The Blaser R 93 bolt action rifle is

equipped with a light and crisp trigger.

The trigger resistance is adjusted at the

factory to virtually the lightest setting

allowable under international safety

standards. The setting can and may only

be altered by the factory or by your

authorized Blaser dealer following factory

instructions.

11.1 Front sight for height adjustment

- Insert the 1.5 mm AF allen key in the

hole of the mounting saddle in front

of the sight and turn the allen screw

in the appropriate direction:

- Front sight (spring-loaded)

screw out = point of impact lower

screw in = point of impact higher

11.2 Rear sight (notch) for side

adjustment

- The sight has holes left and right for a

1.5 mm allen key.

- To alter the point of impact

to the left

Undo the right stud screw, screw in

the left stud screw.

- To alter the point of impact

to the right

Undo the left stud screw, screw in the

right stud screw.

Screw the stud screws in with

sensitivity.

17

Page 18

12. Mounting the telescopic sight

The R 93 barrels are equipped with

notches to accept Blaser QD scope mount

bases for 1“, 26 mm or 30 mm rings or

rail or Zeiss ZM rail. It is assumed that an

authorized dealer has fitted your scope

correctly to match the barrel.

12.1 Mounting the scope

- Flip open the covers of the front and

rear locking lever, then thumb these

english

fully up and forward.

- Take the center tube of the scope in

your right hand and hold it so that you

can reach the front lever with your

thumb (fig. 21).

- Grasp the stock with your left hand

and steady the stock against your

upper thigh.

- Carefully locate the two round locating

pins of the scope mount in the oval

notches milled into the top right of the

barrel. Tilt scope to the left and hold it

in that position.

- First thumb the front lever (fig. 22)

then the rear lever back and down as

far as they can go. If you need to apply

either no force or a lot of force when

doing this, then the mount is adjusted

wrongly. In either case, get your authorized dealer to adjust it to the factory

specifications. The force required to

close the locking levers should be

about the same as that of the safety

slide.

- Now close the covers of both locking

levers.

Make sure the mounting faces are

clean and free of grease!

12.2 Removing the scope

- Grasp the fore-end with the left hand

and steady the rifle on your upper

thigh.

- Flip open the covers of the two

locking levers.

- First release the rear locking lever

by thumbing it forwards as far as it

can go.

- Grasp the center tube of the scope

mount with the right hand.

- Now release the front locking lever by

thumbing it forwards and upwards as

far as it can go.

- Remove the scope upwards and to the

right.

18

fig. 21 fig. 22

Page 19

13. Mounting the fixed scope mount

13.1 Mounting the scope

- Loosen the two screws on the side of

the mount a few turns with an 1/8“

allen key.

- Grasp the centre tube of the scope

with the right hand above the mount.

- Hold the fore-end of the rifle with your

left hand and steady the stock against

your upper thigh.

- Carefully locate the two round locating

pins of the scope mount in the oval

notches milled into the top right of the

barrel. Tilt scope to the left and hold it

in that position.

- Tighten the two screws on the side of

the mount hand tight with an 1/8“

allen key.

Make sure the mounting faces are

clean and free of grease!

13.2 Removing the scope

- Grasp the rifle with your left hand

around the fore-end and scope,

steadying the rifle on your upper thigh.

- Loosen the two screws on the side of

the mount a few turns with an 1/8“

allen key.

- Remove the scope.

19

Page 20

14. Caliber group table

Hornet

„HO“:

.22 Hornet

Mini

„MI“:

.222 Rem.

.222 Rem. Mag.

Standard

„ST“:

.22-250

5,6x57

.243 Win.

6 mm Rem.

6x62 Frères

.25-06

6,5x55

6,5x57

6,5x65 RWS

.270 Win.

.280 Rem.

7x57

7x64

.308 Win.

.30-06

8x57 IS

9,3x62

Medium

„ME“:

6,5x68

7,5x55

8x68 S

9,3x64

Magnum

„MA“:

.257 Weath.

Mag.

.264 Win. Mag.

7 mm Rem. Mag.

.300 Win. Mag.

.300 Weath.

Mag.

.338 Win. Mag.

.375 H & H

.416 Rem. Mag.

Ultra Magnum

„UM“:

.300 Rem. Ultra

Mag.

Swiss

„CH“:

10,3x60 R

Shotgun

„28“:

28/70

20

Some of the listed calibers may not be available.

Page 21

15. Case

16. Care and maintenance

The R 93 together with extra barrel,

2 scopes and accessories for travelling is

securely stowed in a double-shell ABS

carrying case with 3 locks.

Always make sure you use suitable

materials that are intended for the

purpose of cleaning rifles.

Barrels:

After firing, prior to storing for long

periods and after carrying the rifle, treat

barrels and cartridge chamber with suitable gun oil, particularly when conditions

are damp or wet. Make sure you

thoroughly remove excess oil from barrels

and cartridge chamber before firing.

With a heavy build-up of cartridge deposits, we recommend treating these parts

with chemical barrel cleaners.

WARNING:

Make sure you read and adhere to the

instructions and warnings given by the

manufacturer of the cleaning agent.

Metal parts:

Always keep all metal parts of the rifle

clean and lightly oiled.

Stock:

The wooden stocks of all Blaser hunting

rifles have an oil finish. We recommend

regular treatment with a good quality

stock oil or wax.

Gun oil is unsuitable for stock care!

Optics:

Refer to the service instructions of the

manufacturer.

Maintenance:

Take your rifle to your gun dealer for

examination and maintenance before the

hunting season and before hunting trips.

Like your automobile, your rifle is an item

of equipment that needs regular maintenance and inspection.

21

Page 22

17. Operating and functional parts of the bolt assembly

Safety slide down

- uncocked position

= safety on

Finger recess

Bolt handle

Warning pin of

retaining latch

Guide rail

Butt stock

Safety slide up

- cocked position

= safety off

Bolt stop pin Trigger Trigger guard Receiver Fore-end

Opening aidBreech lock

Expanding shell

Bolt head with radial lock

outer collar

EjectorExtractor

Magazine

Cartridge chamber

with radial lock inner

collar

Pin notch of

scope mount

Barrel

22

Page 23

18. Warranty conditions

1. Manufacturer’s warranty

The warranty of Blaser Jagdwaffen GmbH supplements the statutory warranty rights through the

dealer, under the condition that the accompanying warranty card is received at Blaser

Jagdwaffen GmbH fully completed within ten

days of the purchase date. The warranty applies

only to the original purchaser who resides in the

country of purchase.

The warranty relates exclusively to the metal and

synthetic parts of the gun and to original Blaser

scope mounts, but not to the sight optics.

Wooden parts require special care and as a natural product are subject to natural changes which

rule out a warranty for them.

The warranty period is ten years and starts on the

purchase date. The warranty covers all defects and

damage to the rifle (metal and synthetic parts)

which are demonstrably due to material or production defects. In such cases, the manufacturer

will pay the costs of materials and labor. For the

warranty work to be carried out, the rifle is to be

handed in to the authorized dealer or to the production company in Isny.

The customer bears the risk and cost of transport

of the rifle to and from the dealer or production

company. The warranty will be implemented at

the manufacturer’s option by repair or the replacement of faulty parts, replaced parts become the

property of the manufacturer.

2. Warranty on the performance of the bolt

assembly

The shooting accuracy of a rifle depends on many

factors. The most important factor is the ammunition. Not every barrel will fire equally well with

every type of ammunition, there can be considerable performance variations. The sight optics and

their mounting are just as important. Parallax,

loose graticules, defects in graticule adjustment

and incorrect mounting are the most frequently

occurring causes for an unsatisfactory shooting

performance. For that reason, you are advised to

use a branded scope that is mounted by a specialist and to find the best ammunition for your rifle

by testing several types. Ammunition of the same

make and quality can have a different shooting

performance and different point of impact from

one production facility to another and from one

rifle to another.

With the optimal choice of ammunition, sight

optics and mounting, we guarantee the excellent

shooting performance of our rifles.

Complaints concerning shooting performance

must be made in writing within 20 days of the

date of purchase. We reserve the right to pass the

rifle for inspection to an independent institute

(DEVA or national test firing body). Should this

institute confirm that the firearm has an excellent

shooting performance, we are entitled to demand

payment from the customer for the cost of this.

3. Scope of the warranty

Claims under the warranty do not bring about any

extension or renewal of the warranty period either

for the rifle or for fitted replacement parts. The

warranty period for fitted replacement parts ends

with the warranty period for the overall rifle.

The warranty is not valid in the event of:

- Damage due to normal wear and tear, through

non-observance of the instruction manual or

through improper use or handling and when

the rifle shows physical damage of whatever

kind.

- Damage due to acts of God or environmental

effects.

- Repairs, machining or modifications to the rifle

by workshops or other persons not authorized

to perform these.

- Use of re-loaded or non-CIP-approved ammunition.

- Burnishing carried out by third parties.

- The warranty is not valid for optical sight devices and scope mountings of manufacturers

other than Blaser.

Further or other claims, especially those for compensation for damage arising outside the rifle

(i.e. consequential damage) are - provided no liability is enacted by statute - excluded.

23

Page 24

Blaser Jagdwaffen GmbH

D-88316 Isny

GERMANY

Loading...

Loading...