Instruction manual

WARNING !

Please read and understand this

i n s t ruction manual entire l y, bef o re using the rifle. Keep this

manual with your fire a rm. Upon

change of ownership, transfer

this manual with the fire a rm .

As a supporting measure to this

i n s t ruction manual, please ask

your dealer to explain your rifle

to you in detail and let him ins t ruct you about its use.

CAUTION!

Please always read this instruction manual

entirely, before using the break action

single shot rifle. The break action single

shot rifle may only be passed on together

with this instruction manual.

As a supporting measure to this

instruction manual, please ask your

dealer to explain your break action

single shot rifle to you in detail and

let him instruct you about its use.

2

Table of Contents

Page

General Safety Rules 4-5

Description of the individual parts of the firearm 6

11. Assembling the rifle 7-8

12. Disassembling the rifle 9-12

13. Operating and handling 13-18

14. Front sight and rear sight 19

15. Mounting the scope 20-21

16. Care and maintenance 22

17. Warranty conditions 23

3

Safety Rules

Due to its special design characteristics,

your new Blaser single shot rifle K 95

differs from other single shot rifles. The

improved safety features of your Blaser

rifle must however, never induce you to

disregard the required care and legal

provisions for handling arms.

Please check first, whether you have the

correct instruction manual.

The type designation K 95 and the

indication of the calibre are displayed on

the left side of the barrel, at the rear.

General safety rules for handling

firearms

- Make sure the firearm and ammunition

never get into unauthorized hands.

- Always store firearm and ammunition

under lock and key in separate cabinets

that are not accessible to unauthorized

persons.

- Observe current statutory regulations

for the carrying and safekeeping of

firearms and ammunition.

- Make sure you are thoroughly familiar

with how to handle your firearm and,

with the firearm unloaded, practice all

of the functions and the actions you

will need to make, before you carry it.

- Always treat any firearm as loaded and

ready to shoot. If you are not certain of

its status, check by opening the bolt

and looking in the magazine and

cartridge chamber (barrel). You should

handle an unloaded firearm in the same

way as a loaded one.

4

Safety Rules

- Whenever holding the rifle, always

point the muzzle in a safe direction to

ensure you neither injure people nor

damage property.

- Before loading, check the barrel for

obstructions and make sure no foreign

matter (water, snow, soil) can get into

the barrel after loading, too.

- Only use CIP-approved ammunition

which is in good condition and check

that the ammunition is correct for the

caliber of the rifle. Wrongly re-loaded

ammunition can damage your rifle and

cause serious injury.

- Do not load your rifle until just before

you fire it.

- Do not cock your rifle (take off safety)

until you are ready to fire. When

cocking (taking off safety), point the

muzzle in a safe direction.

- Before making each shot, check the

terrain in front of and behind the

target.

- Aim your rifle only at targets you have

definitely identified.

- Keep your finger away from the trigger

unless you wish to fire the rifle.

- If a cartridge fails, wait approximately

60 seconds before opening the breech

to avoid danger from a cartridge that

may be late firing.

- Always wear ear defenders when firing

(ear plugs).

Unload your gun

- before negotiating obstacles

- before climbing into or leaving raised

blinds

- before entering a building

- before climbing into a vehicle

- before entering a town or village

- if you temporarily put the rifle down

or hand it to someone.

5

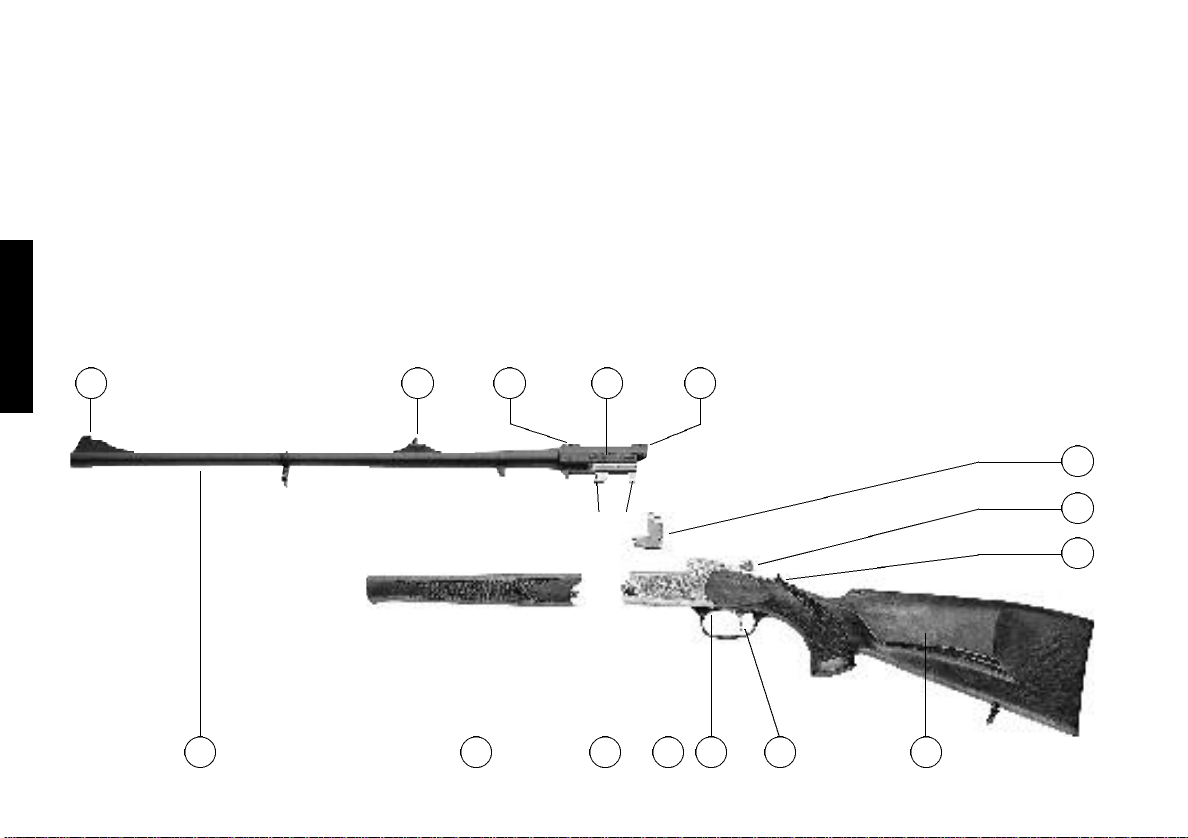

Description of the individual parts of the firearm

1 Front sight

2 Rear sight

3 Pin notches for the original Blaser

saddle mount (DBP)

4 Indication of model and calibre

5 Breech block

6 Top lever

17 Safety slide

18 Stock

19 Trigger

10 Block release

11 Receiver

12 Barrel lugs

13 Fore-end

14 Barrel

421 3 3

5

6

7

13

6

11 1014 812

9

1. Assembling the rifle

1.1. Hooking in barrel

This is only possible with the fore-end

removed.

Pull out extractor all the way to the stop.

Do not touch top lever. Place the

foremost barrel lug on the hinge pin. Due

to the tight fit, you have to proceed carefully. Grip barrel lug part and receiver with

one hand, press the barrel lug into its

bed, closing the rifle at the same time.

Hooking in the barrel requires a certain

degree of skill; but please refrain from

using force! The best solution is, to ask an

expert to show you the procedure and to

do it in his presence several times.

CAUTION:

In the event of unskilful handling, the

breech block may, when the barrel is

tilted, slip out of its slightly inclined position (pointing to the front) and snap

backwards into a vertical position (green

dot on the left side of the breech block is

not visible any longer). If this happens,

the rifle cannot be closed any more.

In this case push the top lever all the way

to the right, and with the other hand,

return the breech block into its slightly

inclined position (to the front).

7

1. Assembling the rifle

1.2 Attaching fore-end

Place the fore-end over the hinge pin,

flush with the receiver, and tilt it towards

the barrel all the way to the stop. We

recommend to lift the flap of the fore-end

with the forefinger and hold it in this

position. Press down the fore-end.

The flap of the fore-end snaps into place.

Close the flap of the fore-end completely.

The fore-end is now latched.

8

CAUTION!

Unload your rifle prior to disassembly

(refer to page 17).

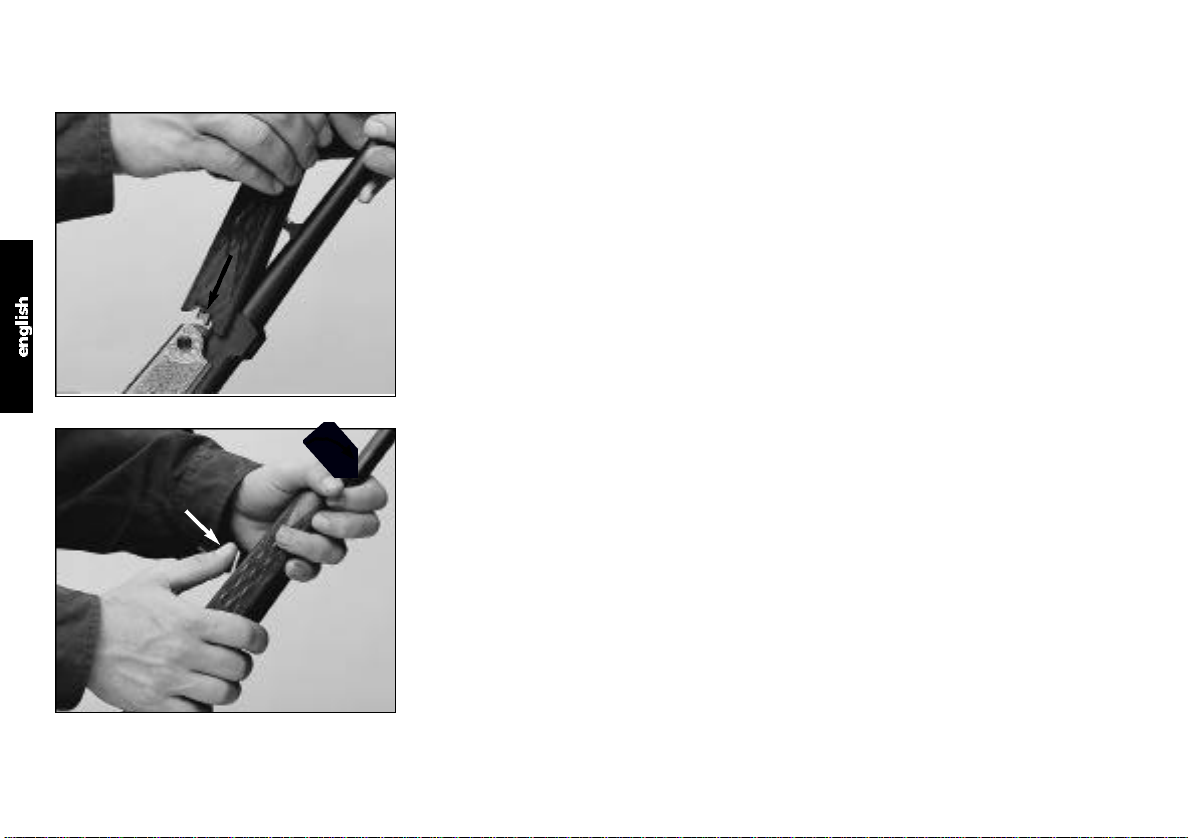

2.1. Taking off the fore-end

Support the rifle on your thigh. Pull out

the flap on the fore-end with one hand.

You may take off the fore-end now.

Facilitate pulling off the fore-end by

pressing it away from the barrel at the top

with your other hand.

2. Disassembling the rifle

9

2. Disassembling the rifle

2.2 Hooking off the barrel

This is only possible with the fore-end

removed.

Push the top lever all the way to the right

and keep it in this position.

Tilt the barrel all the way downwards,

unlatching the barrel lug.

10

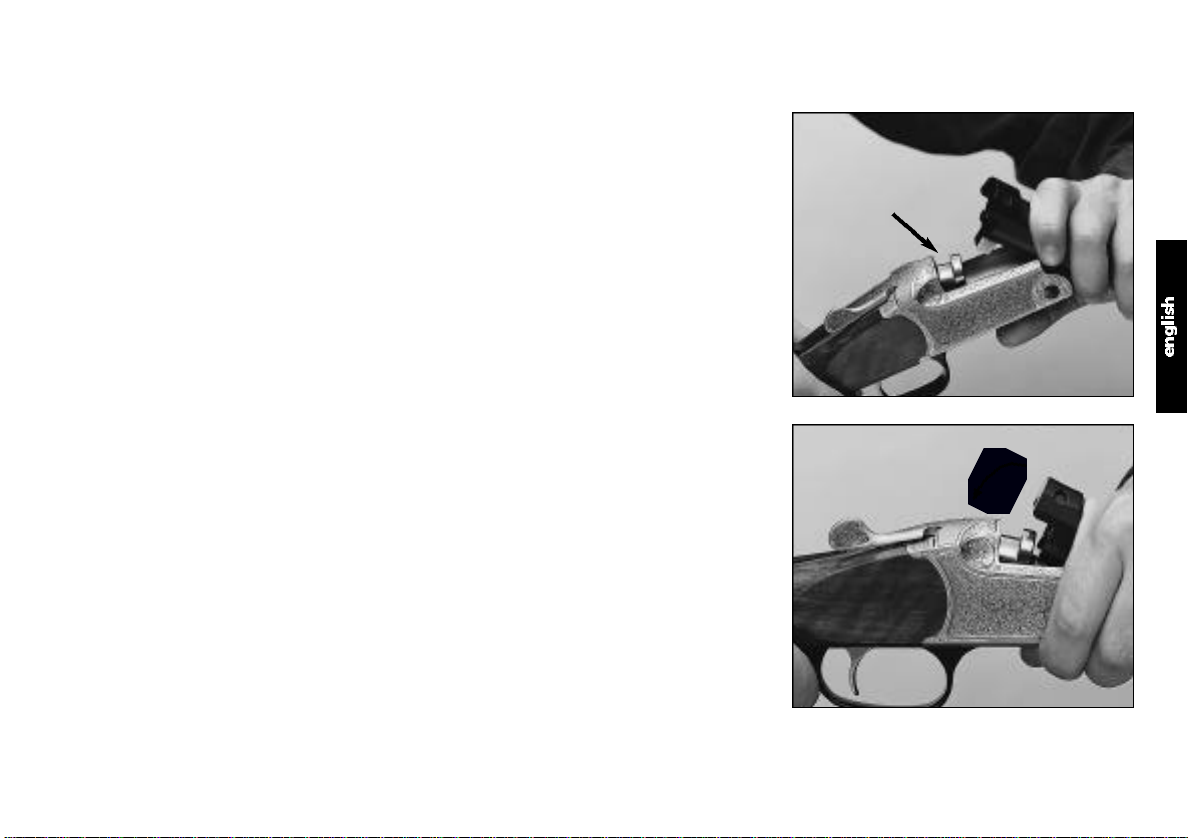

2.3. Removing breech block

(with barrel detached)

This is only required, when you want to

clean the rifle thoroughly or safeguard it

against unauthorized use by removing the

breech block.

Press the block release button »A« beside

the trigger and keep it pressed down.

Now push the top lever to the right

simultaneously, until the breech block

unlatches.

When unlatching, the block jumps

forward a bit and can now be removed

towards the front.

2. Disassembling the rifle

A

11

2. Disassembling the rifle

W

A

2.4 Reinserting breech block

Place the breech block with the

semicircular shaft bearing »W« on the

shaft at the bottom of the receiver and tilt

it backwards. Press the block release

button »A« beside the trigger and keep it

pressed

down. Now, the top lever can be pushed

all the way to the right (slightly further

than for opening the rifle). Hold the top

lever in this position, you may now release the locking button »A«. Press the

breech block down into the receiver at

the back and release the top lever.

If you tilt the breech block all the way to

the back during assembly (green dot on

the left is not visible any more), push the

top lever to the right again (without

pressing the block release button) and let

the block snap into its slightly tilted

position by pushing it slightly towards the

front. In this position, the rifle can be

closed

(green dot is visible).

12

WARNING:

Do not move the safety to the

“off safe“ position until you are ready

to fire.

Keep your finger away from the trigger

unless you wish to fire the rifle.

When you interrupt or finish firing

move the safety slide immediately backwards in the “on safe“ position.

Before making each shot, check the terrain in front of and behind the

target.

Ensure that the target and the environment allow shots to be fired without

danger.

Always wear ear protection and safety

glasses when shooting. Alert bystanders

to the importance of wearing ear protection.

If a cartridge fails, wait approximately

60 seconds before opening the breech

to avoid danger from a cartridge that

may be late firing.

Always keep muzzle of the rifle pointed

in a safe direction.

Before loading, always wipe off any excess grease and oil, then verify that

there is no obstruction in the chamber

or the trigger guard.

Do not place your finger on trigger,

keep it outside of the trigger guard.

Never load or unload the rifle inside a

vehicle, inside a building or other confined space (except in a designated firing range).

Do not load the rifle by inserting the

magazine until immediately before

shooting.

Never rely on safety mechanisms. They

are never a substitute for careful and

correct handling of your rifle.

Never let a loaded rifle out of your

hands.

3. Operating and handling

3.1. Opening the rifle

Push the top lever all the way to the right

and keep it in this position.

The breech block now releases the barrel,

the rifle can be opened.

WARNING:

You should never point the muzzle at anything, unless you are planning

to shoot, especially when you are loading and unloading the rifle. Muzzle direction could be the difference between LIFE and DEATH.

13

3. Operating and handling

14

3.2 Closing the rifle

Do not touch the top lever. Grip barrel

and swivel stock upwards. The breech

block snaps into place in the barrel and is

latched by the breech wedge. Check,

whether the top lever is locked, by pushing it slightly to the left. The rifle cannot

be cocked if the lever is in an unlocked

position. To lock the top lever, a small

degree of force is required, particularly

with new rifles. This is due to the precise

fit of the breech wegde.

CAUTION:

In the event of unskilful handling, the

breech block may, when the barrel is

tilted, slip out of its slightly inclined

position (pointing to the front) and snap

backwards into a vertical position (green

dot on the left side of the breech block is

not visible any longer). If this happens,

the

rifle cannot be closed any more.

In this case push the top lever all the way

to the right and with the other hand,

return the breech block into its slightly

inclined position (to the front).

3.3. Cocking the lock

(putting the rifle „off safe“)

Press the safety slide forward until it

snaps into position.

CAUTION:

Safety slide to the front:

The breech is closed.

The lock is cocked.

If loaded, the rifle is now ready to fire!

3. Operating and handling

15

3. Operating and handling

3.4. Uncocking the lock

(putting the rifle „on safe“)

With your thumb, simply pull the safety

slide backwards against a slight resistance

and let is slide back.

With a bit of practice, this can be done

without a sound.

CAUTION:

Do not touch the trigger under any

circumstances, this would fire the rifle!

Safety slide in its rear position:

The lock is uncocked.

The rifle is safe.

You may also uncock your rifle by pushing

the top lever to the right.

The safety slide will then slide back.

This will be more noisy.

Always use ammunition that complies with

the performance standards established by the

Sporting Arms and Ammunition Manufacturers’ Institute, Inc. of the United States (SAAMI)

3.A Ammunition

WARNING:

Use only commercially available, SAAMI

proofed ammunition in the original

packaging, and which matches the caliber of your rifle. The correct caliber is

stamped on the left side of the rifle barrel at the rear.

Never use reloaded, “refurbished“,

hand-loaded, non-standard ammunition, or ammunition of a different

caliber.

Never use dirty, wet, corroded, bent,

damaged or oiled ammunition.

Never leave ammunition unattended.

WARNING

16

3. Operating and handling

3.5. Loading the rifle

Remove the oil from barrel and chamber

and check it for foreign obstacles. Make

absolutely sure, that the ammunition

corresponds with the calibre of your rifle.

Insert the correct cartridge into the magazine. Close the rifle.

3.6. Firing a shot

Initial situation: The rifle is loaded and

locked. The lock is not cocked.

Surroundings, background and aim are

clearly

discernible. Cock the lock (safety slide

all the way to the front). Fire the shot by

actuating the fine trigger.

During the shot, the cocking slide snaps

back into its original position, due to the

recoil.

3.7. Trigger

CAUTION:

The Blaser single shot rifle model K 95 is

equipped with a fine trigger. The trigger

pull is adjusted at the plant closely to the

finest possible adjustment as provided by

international safety standards.

The adjustment can and may only be

altered by the manufacturer.

CALIFORNIA PROPOSITION 65 WARNING

Discharging firearms in poorly ventilated areas, cleaning firearms, or handling ammunition may result in exposure to lead and other substances known to cause birth

defects, reproductive harm, and other serious physical injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

WARNING

Using the WRONG ammunition could destroy your rifle

and cause serious personal injury or death. If a bullet is in

the bore, do not attempt to shoot it out by using another

cartridge. This can generate excessive pressure, damage

the firearm and cause serious personal injury.

17

3. Operating and handling

3.8 Unloading the rifle

Open the rifle.

(see 3.1.)

When the barrel is tilted, the cartridge

extractor pulls out the cartridge from the

magazine, so that it can be taken out by

hand.

18

4. Open sights

Due to differing sighting habits and requirements, the rifle is tested and adjusted through open sighting in the plant

to an approximate degree of accuracy

only. Accurate test-shooting by adjusting

rear and front sight should be performed

by you, together with your dealer, to

allow the sighting to be tailored to your

personal requirements.

4.1. Front sight for height adjustment

- Insert the 1.5 mm AF allen key into the

hole of the front sight base and turn

the allen screw as required:

- Front sight (spring-loaded)

screw out = point of impact lower

screw in = point of impact higher

4.2. Rear sight (notch) for side

adjustment

- The sight has holes left and right for a

1.5 mm allen key

- Point of impact more to the left: loosen

allen screw on the right side, tighten

allen screw on the left side.

- Point of impact more to the right:

loosen allen screw on the left side,

tighten allen screw on the right side.

Please tighten allen screws with

sensitivity.

19

5. Mounting the scope

The K 95 has been prepared for the

original Blaser saddle mount (DBP). We

assume that an authorized dealer has

fitted your scope correctly to match the

barrel.

5.1. Mounting the scope:

- Flip the covers of the front and rear

locking lever open, ensuring that both

of them are swivelled fully forward/up.

- Grip the rifle at the fore-end with your

left hand and support stock on your

thigh.

- Grip the scope at the centre tube above

the mount with your right hand in such

a manner, that you can reach the front

locking lever with your thumb.

- Carefully place the two round pins of

the scope mount into the two oval

notches in the upper right side of the

barrel. Tilt scope to the left and keep

it in this position.

- First press the front and then the rear

mounting lever (which were flipped

open previously) backwards/down with

your thumb, until they reach the stop

(tension). If this can be done too easily

or only by using considerable force,

then the mounts are set incorrectly. In

either case, have your authorized dealer

correct this to specification.

- Close the two saddle covers of the

locking levers now.

Ensure that the mounting surfaces are

clean and free from oil.

20

5.2 Removing scope

5. Mounting the scope

- Grip rifle at the fore-end with your left

hand and support it on your thigh.

- Flip both covers of the locking levers

open.

- Fist swivel the rear locking lever all the

way to the front/top with your thumb,

until it reaches the stop.

1.

Locking lever pushed forwards (open)

for mounting or removing of scope.

Cover open.

- Grip the centre tube of the scope with

your right hand and keep it in this

position.

- Now swivel the front locking lever all

the way to the front/top with your

thumb, until it reaches the stop.

- Tilt scope to the right and remove it.

A

2.

Locking leverpulled backwards (tighten-

e d ) . This position is reached, when the

front edge of the locking lever (A) stands

at a 90° angle to the barrel axis.

B

3.

Locking leverpulled backwards (tighten-

e d ) .Cover closed. When the locking

lever is in its correct position, the line on

the cover is parallel to the barrel axis (B).

21

6. Care and maintenance

WARNING:

B e f o re perf o rming any

cleaning or maintenance,

make sure the rifle is completely unloaded.

Always make sure you use suitable

materials that are intended for the

purpose of cleaning rifles.

Barrels:

After firing, prior to storing for long

periods and after carrying the rifle, treat

barrels and cartridge chamber with suitable gun oil, particularly when conditions

are damp or wet.

Make sure you thoroughly remove excess

oil from barrels and cartridge chamber

before firing. With a heavy build-up of

cartridge deposits inside the barrel, we

recommend treating these parts with

chemical barrel cleaners.

WARNING:

Make sure you read and adhere to the

instructions and warnings given by the

manufacturer of the cleaning agent.

Metal parts:

Always keep all metal parts of the rifle

clean and lightly oiled.

Stock:

The wooden stocks of all Blaser hunting

rifles have an oil finish. We recommend

regular treatment with a good quality

stock oil or wax.

Gun oil is unsuitable for stock care!

Optics:

Refer to the service instructions of the

manufacturer.

Maintenance:

Take your rifle to your gun dealer for

examination and maintenance before the

hunting season and before hunting trips.

Like your automobile, your rifle is an item

of equipment that needs regular maintenance and inspection.

22

7. Warranty conditions

LIMITED 5 YEAR WARRANTY

BLASER fire a rms are warranted by the

BLASER Jagdwaffen GmbH to be free of

defects in material or workmanship under

normal use and service for a period of 5

years from date of first purchase by a

consumer.

BLASER’s obligation is limited (at BLASER’s

choice) to repairing or replacing at any

of its authorized warranty service stations

any part of a BLASER fire a rm which

BLASER examination discloses to be

defective.

The warranty shall not apply to problems,

malfunctions or defects resulting from accidents, alterations, misuse or bro k e n

stocks. If in the opinion of BLASER gunsmiths or of its authorized warranty service

stations any modifications, changes or additions made outside the BLASER factory

have affected the operation of the weapon

to render it faulty, this warranty shall be

void. This warranty shall also be void if any

part not of BLASER manufacture has been

incorporated into the rifle or if other than

factory loaded ammunition is fired in the

BLASER rifle.

Should you have occasion require warranty service, please contact your local dealer

or the distributor of your country for directions on returning your rifle to an authorized warranty station.

BLASER expressly disclaims any and all implied warranties arising under the UCC or

Common Law, including warranties of fitness for a particular purpose and implied

warranties of merchantability.

BLASER shall not be responsible for any incidental or consequential damages for economic loss or injury or property damage as

a result of any alleged breach of an express

or implied warranty, as a result of negligence, or as a result of any other act or

omission of BLASER. Exclusion or limitation

of consequential or incidental damages are

not allowed in some states so this limitation

or exclusion may not apply to you.

This warranty gives you specific legal rights,

and you may also have other rights which

vary from state to state.

SAVE YOUR RECEIPT AS PROOF OF

PURCHASE.

USA/Canada

SIG Arms Inc.

Corporate Park

Exeter, NH 03833

(603) 772-2303

www.sigarms.com

SIGARMS is a trademark of

SIG Arms Inc.

Manufacturer:

BLASER Jagdwaffen GmbH

Ziegelstadel 1

D-88316 Isny, GERMANY

I M P O RTA N T:

Do not discard.

Keep this manual with

your firearm. Upon change

of ownership, transfer this

manual with the firearm.

18 Industrial Drive, Exeter, NH 03833

SIGARMS Inc.

Ph: (603) 772-2302

Fax: (603) 772-9082

Blaser Jagdwaffen GmbH

D-88316 Isny · GERMANY

OM-K95-USA

Loading...

Loading...