Page 1

Sigma Holzgas 18-60k

W

Manual and Installation book

of boiler

CHT Heizkessel GmbH

Gartenfelder Strasse 29-37, 13599 Berlin, Tel.:+ 49 30 – 30 64 17 29 Fax: + 49 30 – 30 64 17 27

info@cht-heizkessel.de service@cht-heizkessel.de

wwwwww..cchhtt--hheeiizzkkeesssseell..ddee

IIHHRR PPAARRTTNNEERR FFÜÜRRUUMMWWEELLTTFFRREEUUNNDDLLIICCHHEESS HHEEIIZZEEN

N

Page 2

- 2 -

Manual and Installation book of boiler

Table of contents

1) Short description - 3 -

2) Technical data - 4 -

3) Fuel - 8 -

4) Using and Service - 8 -

5) Control -11-

6) System -14-

7) Parts -17-

8) Boiler installation systems -19-

www.cichewicz.com

With us heating makes economies!

Page 3

- 3 -

1) Short description

1.1) Gasification technology

The wood gas (ger. holzgas) comes in the process of gasifing of the wood. This

is the mixture of flammable gases: the oxide of carbon, hydrogen and methane,

and also incombustible -- nitrogen, the dioxide of carbon, water steam. The

composition of the gas depends on many factors as: from current temperature

in the hearth of the gas generator, the moisture of the loaded fuel and other.

The gasifing of solid fuels is technology counting above 200 years. On the

beginning XIX w. it was used so-called urban gas to the supply of cookers,

street lamp and to industrial aims. It was produced from the carbon then.

Generally -- the artificially formed gas from the gasifing of the solid fuel is called

the generator gas.

Technology this consists in the working on the solid fuel with series of thermochemical reactions, the flammable gas becomes in the result of them. Gasifing

just defines oneself this cycle of conversions. This process holds in the device

called gas-generator.

The type- matter of the wood gas can look as follows:

oxide of the carbon of CO 19%

hydrogen H2 18%

methane CH4 1,25%

dioxide of the carbon 12%

steam water H2O 2,50%

nitrogen N2 the rest

From these exchanged, only three first gases (coloured) are flammable.

Remaining do not burn and make up only unnecessary ballast, in the principle

they thin the gas and reduce its fuel value. From this regard it would be good to

remove them. However nitrogen from the wood gas can’t be removed (the basic

component of air, in which we gasify the wood), then can the water steam

relatively easily humid from the gas in the cooler. The content of the dioxide of

the carbon depends first of all from the temperature in the gas-generator (if

higher, the more CO and less CO2).

Page 4

- 4 -

1.2) Boiler

Boiler of type Westfalia Holzgas on first throw of the uninitiated eye does not

differ from the usual boiler on the wood. It has hearth, loading chamber and

ash-pan. The difference of working is however considerable -- it burns in it not

from the bottom to the top, but inversely. There is the loading chamber at the

top and the transformation of the wood follows in the wood gas in this chamber.

There is the nozzle below the chamber in which burning the wood gas mixed

previously with the air, which flows in from outside, follows. This element is

made from the heat-proof material. There is the ash-pan, in which burning down

the mixture of the wood gas with the air follows, under the nozzle. The boiler on

the wood gas from the back possesses accompanying flue gas to the chimney,

in this place the exchanger of warmth allowing to the heating of water from hot

flue gas is assembled.

The boilers of type Westfalia Holzgas are designed to heating up water in c. h.

installations which computational temperature of supply do not cross 85 °C.

They can be used in c. h. installations of flat, council or productive buildings,

which users require automatic feeding of fuel. Boilers can be assembled both in

modern and conventional heating installations.

Boiler steering has the possibility of pump regulation also loading storage tank.

Boiler of type Westfalia Holzgas utilizes wood in gasification process using

energy contained in wood with efficiency three times higher than traditional

boilers. Smoke and other emissions are cut to a very low level, making our

boilers nature friendly.

All works relating equipments of boiler room, way of installing boiler as

well as his exploitation must be realized compatible with valid norms and

regulations.

2) Technical data

Type Unit

Sigma 20

Sigma 30 Sigma 50

Power Range (Output):

kW

14,9-24

25-32 45-59

Fuel:

Wood (max. humidity 20%, max 50cm long)

Efficiency:

% > 89,90

Boiler Water Volume:

dm3

145 L

165 L 180 L

Max. Working Pressure:

bar 2

Min. Inlet Temp.

o

C 65

Max. Outlet temp.

o

C 85

Flue gases Temperature:

o

C >160

>160 >160

Noise:

dB 52 -65dB (A)

Recommended Chimney

Underpressure

Pa 20-25

CO2 emission

mg/m³ 4800 4820 4950

Page 5

- 5 -

Recommended Chimney's

Intersection

mm 160

160 180

Inlet/Outlet Diameter

“ 1,5

1,5 2

Bottom Outlet Diameter

“ 1/2

1/2 1/2

Weight:

kg

490

540 600

Power Consumption

W

82

82 90

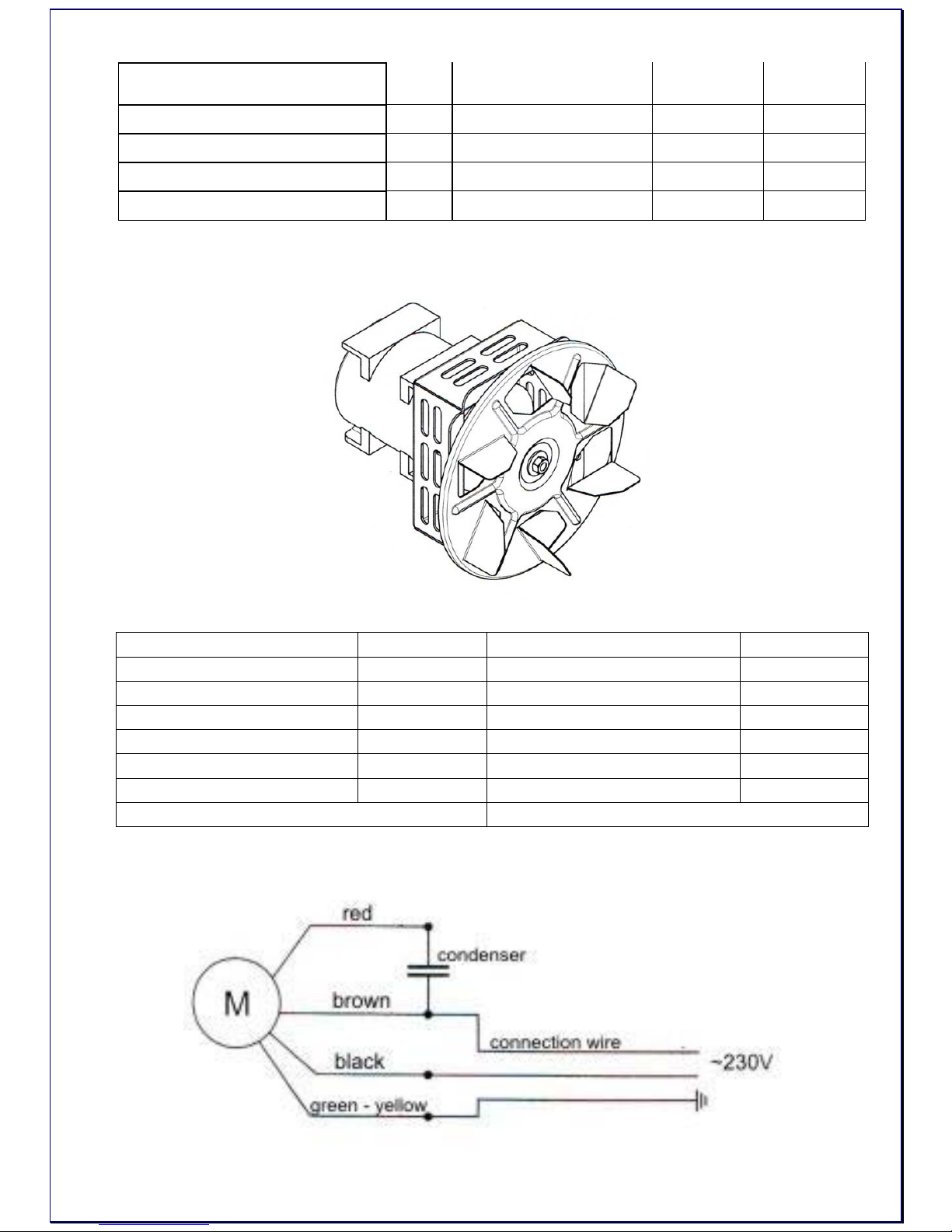

2.1) Outtake Fan WC170

2.1.1) Technical data

Power supply -230V, 50Hz Temp. of surroundings 0=40°C

Power consumption 82W Temp. of fumes do 350°C

Expense of air 38-UM /11 Loudness 65dB

Number of gears 1 Class of tightness IP44

Rotational speed 2400obr/min Class of isolation F

Condenser of the engine 3µF/450V Mass 2,2kg

Kind of the work continuous Supply wire 0,6m

External dimensions 186x174x174mm (lg. x wid. x h.)

2.1.2) Wiring diagram

Page 6

- 6 -

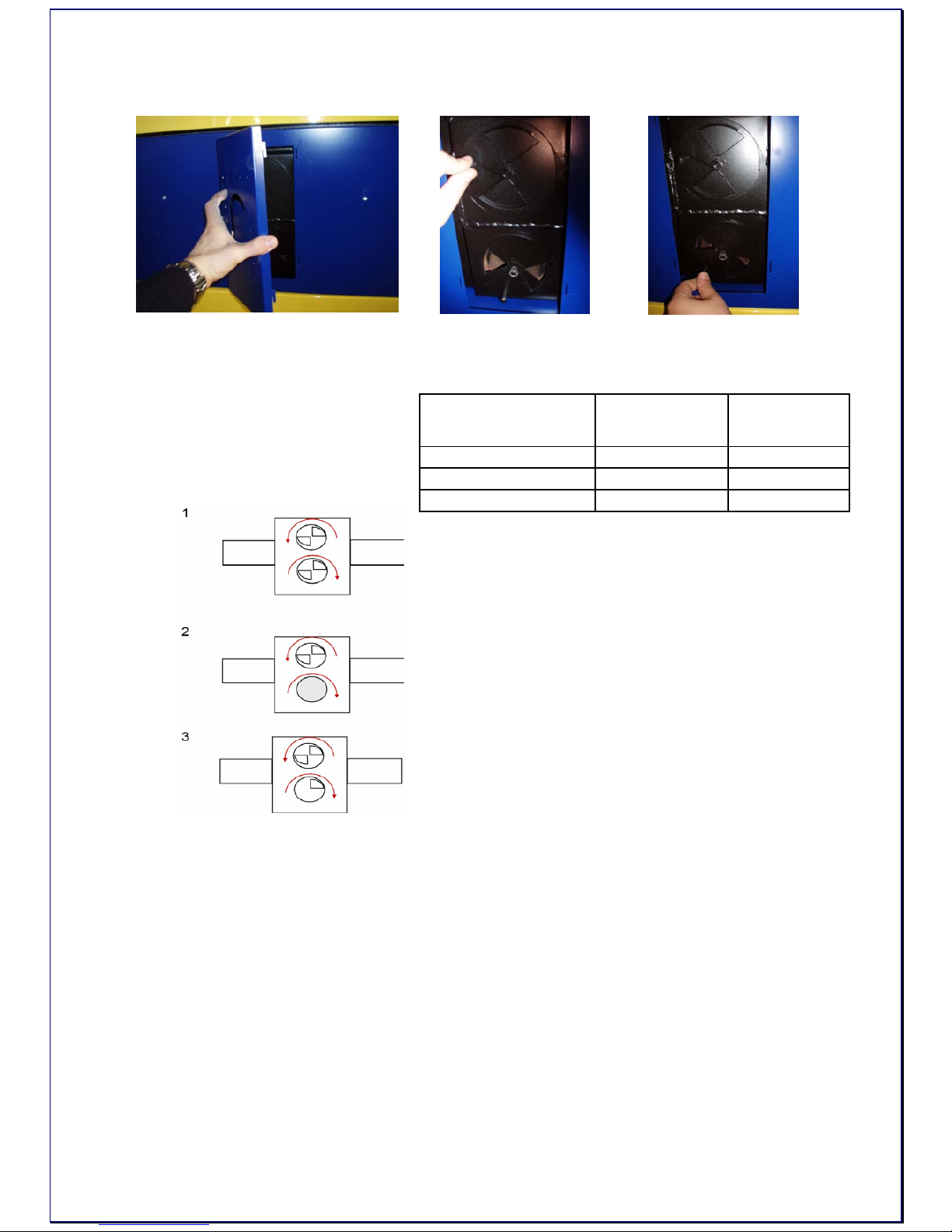

2.1.3) Placing in mounting hole

• Unscrew mounting plate

• Mount fan Wheel, plate and the engine together.

• Screw the plate with mounted fan into the mounting hole.

2.2) Structure of the boiler:

The structure of boiler was worked out on basics of long term researching with

idea about high thermal comfort, exploational and with care about ecology. The

boiler has the three pass structure in shape of vertical and horizontal convective

channels, making the surface of heat exchange. The combustion space is partly

tiled with fire-clay which attends as catalyst of combustion process. The body of

boiler is made from certified steels and welded in cover of argon. Westfalia

Holzgas is equipped in ceramic burner nozzle and ceramic deflectors.

2.3) Special features of Sigma Holzgas:

• Low exploitation cost

• Easy and simple service

• Long wood up to 50cm long

• Efficiency > 90 %

• Fuel loadings - once for 8 -12 hours

• Boiler power modulation 70-100 %

• Small ash quantity

• Electronic controller with

temperature sensor built in

• Nature friendly

• Produced of certify steel

Page 7

- 7 -

2.4) Dimensions of Sigma Holzgas:

mm Sigma 20 Sigma 30 Sigma 50

A

1510

1510

1510

B

725

825

825

C

840

840

960

D

1030

1030

1150

a

1,½"

1,½"

2 “

b

1,½"

1½"

2 “

c

½"

½"

½"

d

ø160

ø160

Ø200

2.5) Schema of Westfalia Holzgas:

Page 8

- 8 -

3) Fuel

9 Wood with humidity up to 25%

9 Chunks dimensions 30-50cm

The wood has to be dry! The efficiency of the boiler falls together with growing

moisture of the wood, settling tartly substances increases and the life of the

boiler drops. Power and proper functioning of the boiler are guaranteed near

maximum moisture the wood to 20%.

The energetic properties of the most popular species of the wood:

Wood type Thermal efficiency per 1 kg

kcal MJ kWh

Spruce 3900 16,25 4,5

Birch 3750 15,50 4,3

Oak 3600 15,10 4,2

Beech 3450 14,40 4,0

4) Using and Service

4.1) Assembly:

1. Fit the ceramic burner nozzle to the boiler via the rectangular hole located

inside of boiler.

2. Mount the ceramic deflectors into their place inside the lower chamber.

1.

2.

4.2) Burning

Put wood-chips or sawdust as base, then put inside little pieces of wood. At the

top put chunks of wood and set the fire with half-open ash doors and full open

shutter.

After firing close fire-doors and turn on work and adjust required temperature on

regulator.

The attemperation is done with help of the mechanical regulator (shutter) of

fireplace and with help of the electronic automatics mastering the work of fan.

Page 9

- 9 -

4.3) Setting air inlets

1.

2. 3.

Upper shutter is responsible for main air inlet.

Lower shutter is responsible for secondary air inlet.

The position of the shutter of

regulating opening in the

front plate of the casing

during exploitation:

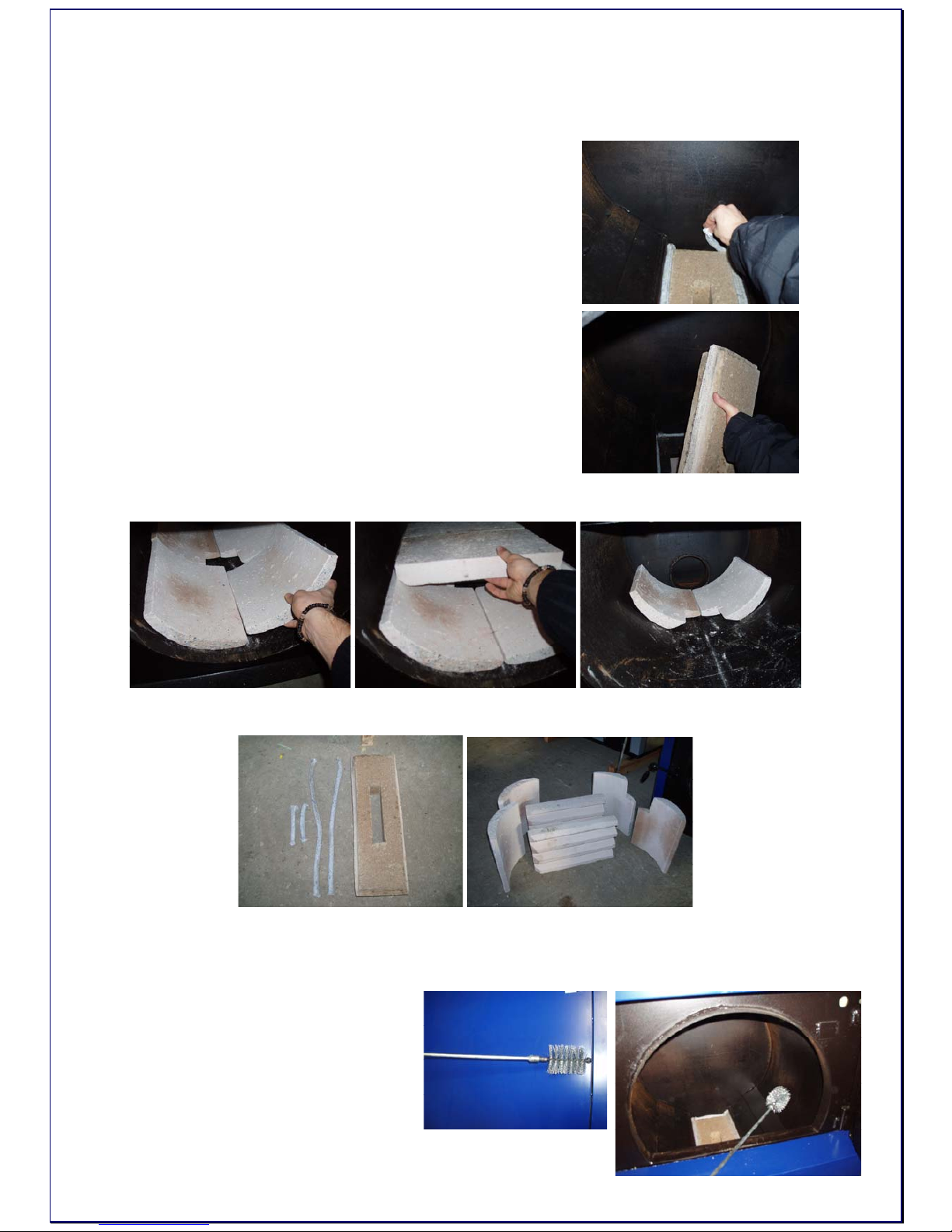

4.4) Cleaning the burner.

When is cooled down completely it is ready for cleaning. Take the burner

nozzle of the assembly hole, remove the deflectors from the lower chamber.

The parts can now be worked with for cleaning.

To ensure best boiler operation, cleaning should be done frequently. This

guarantees the best fuel efficiency. The better the boiler is set up the

longer the intervals between cleaning.

Shutter position Power

Burning time

(in hours)

Max. open Nominal (full) 2

Open on 1/2 70% nominal 3

Closed Minimum 5

Page 10

- 10 -

4.4.1) Clearing the deflectors and burner nozzle…

• Remove the ash and any cinders from the unit.

• Remove any wood left in the unit.

• Remove the tight rope.

• Take out the ceramic nozzle.

• Remove the ceramic deflectors from the lower chamber.

• Brush them gently with soft brush.

• Vacuum the left ash, do not touch the ceramic elements with vacuum head.

4.4.2) clearing the boiler…

The boiler should be emptied

from ash and all of the surfaces

should be brushed in order to

remove soot particles.

Page 11

- 11 -

Pay particular attention to ash in the exhaust deflector

and the flue pipe. The flue pipe does NOT clean itself.

You must do this yourself. An old vacuum cleaner is

the best method.

4.4.3) Clearing the exchanger…

• Upper cleanout

• Lower cleanout

4.4.4) Starting up after cleaning …

Reassemble the burner nozzle and fit deflectors into boiler. Load the boiler

partly and light it normally.

Page 12

- 12 -

5) Controller RK 2001W

5.1) Schematic diagram of work:

ventilator

"H"

speed maximum speed of ventilator "d"

"d"

speed near blowthroughs "E"

work work "P" work "P" work

ventilator

pause pause pause

"c" "c" "c"

T>Ts T<Ts

45 Ts Ts T<31oC

Phaze of

emblazing Automatic work Blanking

Ts -set temperature

6) Using and service

6.1) Fuel

9 pit-coal type 31 and 32 assortment nut O I and O II

9 pea coal Gk

9 coal-fines MI

9 substitutionaly wood (humidity up to 20%)

6.2) Control

6.2.1) Application

RK-2001W controller is a device designed for temperature control of solid fuel

fired boilers. The temperature of the boiler is kept on level set by the user by

controlling the speed of the blow-in fan. The controller constantly monitors the

temperature of water in the boiler, shows it on the display and controls the

central heating pump. To enable more precise temperature control of heated

rooms the controller has been equipped with an input for room thermostat

connection. The controller also enables controlling of the hot water tank pump.

In case of no fuel, the controller has an option to turn on gas or oil boiler

(additional option).

6.2.2) Connection

Before turning on the controller by master switch, connect controller, fan and

the central heating pump power leads to appropriate sockets in the rear of the

Page 13

- 13 -

controller. The temperature sensor should be placed in a measurement hole in

the boiler.

CAUTION! Before plugging in the controller check if the wiring system is properly grounded

and if the terminal screws of the output connector are properly screwed.

CAUTION! A fan and a central heating pump of maximum power of 450W can be connected

to the controller.

CAUTION! As additional option you can connect the UM-1 module to the controller that

allows controlling the additional boiler or the mixing valve and the hot water loading pump. It

is necessary to protect the power supply of these devices with suitable cut-outs.

Outputs of the controller that are not used may remain unconnected.

6.2.3) Operation

After turning the controller on all the elements of the display are lit for a while to

check if they are working properly. The controller, when power appears, returns

to its last state before turning off or power loss.

Front panel of the controller (Pic. 1) consists of:

1-Master switch

2-Display, indicating boiler temperature and parameters

3-Room thermostat indicator

4-Boiler thermostat knob

5-Central heating pump work indicator

6-STOP/choose parameters/erase alarms button

7-START/choose parameters button

8-Start programming /confirm parameters settings button

9-Hot water pump work indicator

Picture 1. Front panel of the RK-2001W controller

Basic operation of the controller is carried out by setting the desired

temperature with boiler thermostat knob, other functions are carried out

according to parameters programmed in service mode. The change in the boiler

temperature setting is shown on the display for a few seconds, e.g. [C 55] and

this value means the temperature of the water in the boiler which the controller

will be trying to achieve. You can also check this value by pressing OK button

Page 14

- 14 -

for a short time. After pressing START button the fan starts to work and the

control process begins. STOP button stops the fan for example to add fuel.

If the controller is not in user or service mode the display shows water

temperature in the boiler and the last character on the display defines the mode

which the controller is currently in:

for example: [50º-] - STOP mode

[50ºC] - WORK mode

[50ºc] - hold up of burning in WORK mode

[50ºU] – heating of hot water in SUMMER mode

[50°u] - hold up of burning in SUMMER mode

[50ºd] – total bacteria control – heating up of hot water

up to 75ºC.

6.2.4) Setting up the user parameters.

Holding OK button enters the user mode and allows reviewing and is indicated

by fast flashing of the room thermostat indicator. You can look through the

parameters with < and > arrow buttons. After choosing the desired parameter

you can switch to the change mode of the parameter by pressing OK button - it

is indicated by the value of the parameter flashing.

Change of the parameter is done by pressing - or + buttons. You can confirm

new settings by pressing OK button and after that the controller allows choosing

another parameter (with < > buttons). If you do not want to change the

parameter value with the < or > button choose [End] and press OK or wait for 1

minute – the controller will exit the user mode and will indicate the temperature

of the water in the boiler

CAUTION: If in the controller the hot water pump is turned off, in the user menu, after

pressing OK, you can only read the set temperature value of the boiler thermostat.

Table 1. Service parameters list

Display Parameter Min Max Step

Factory

default

C 40 Boiler desired temperature L 40 H 90 1˚C L 40

co C

Central heating pump work when “C” (pump

off when “-“)

- C C

cu u

“d” heating up – total bacteria control in hot

water tank

u d u

50˚ Water temperature in hot water tank

End Exit from user mode after pressing OK

(1) Boiler work temperature

The boiler set temperature [C 40] – is the temperature which the controller will

try to achieve in WORK mode.

It is set by direct turning of the knob and is indicated by a short display.

Page 15

- 15 -

(2) Central heating pump work [co C] – WINTER/SUMMER mode

– character “C” indicates that the central heating pump is working. In summer

time the heating can be turned off by choosing the value “-“ with the (-) button

which means turning off the central heating pump.

(3) Total bacteria control in the hot water tank – heating up - the

controller allows to manually launch the total bacteria control process in the

boiler. Choosing the “d” value with (+) button starts the process in which the

boiler is trying to achieve the temperature of 75˚C in the hot water tank. In order

to start the total bacteria control process the boiler should be in WORK mode

(this mode can be turned on by START button). E.g. [70˚d] will appear on the

display. After reaching 75˚C in the hot water tank the controller will return to its

state before choosing this option.

CAUTION: the total bacteria control function can switched on at night when the water from

the hot water tank is not used to prevent the users from burn injury.

(4) Water temperature readout in hot water tank [u50˚] – this

parameter shows the measured temperature value in the hot water tank.

(5) Exit from user mode – choosing the [End] on the display and

pressing OK button causes exit from the parameter setting. Exit from this mode

will also occur if no button is pressed for 1 minute.

6.2.5) Parameter setting – the service mode

Holding OK button for more than 3 seconds enters the service mode where you

can review and change the parameters. It is indicated by slow flashing of the

room thermostat indicator. You can look through parameters with < and > arrow

buttons. After choosing the desired parameter you can enter the parameter

setting mode which is indicated by this value flashing. The change of the value

will occur after pressing – or + button. Pressing OK button will confirm the

changes. After that the controller allows choosing another parameter with < >

buttons. If you do not want to change the parameter value with the < or > button

we choose [End] and pres OK or wait for 1 minute – the controller will exit the

service mode and will start indicating the temperature of the water in the boiler.

Table 2. Service parameters list

Display Parameter Min Max Step

Factory

defaults

∏100

Fan max work power or max power when

∏r 0-10

50 100 10% 100

∏r 1

automatic fan speed control and time of

fan start

--,0 10 1 1

∏n 5 Fan work time --,5 60 1s 5

∏u 6 Fan pause time 1 99 1min 6

P 40 Central heating pup launch temperature 30 70 1˚C 40

Page 16

- 16 -

Ph 2 Central heating pup launch hysteresis 1 10 1˚C 2

Pc 2

Pause time of central heating pump with

30 sec. work periods

--,1 99 1min 2

u 50 Tap hot water desired temperature 30 60 1˚C 50

uh 5 hot water heating hysteresis 1 9 1˚C 5

ur 0

No hot water-0, hot water priority-1, no

hot water priority-2, mixing pump-3

0 2 1 0

L 40 Minimum boiler temperature 30 65 1˚C 40

H 90 Maximum boiler temperature 80 90 1˚C 90

h 5 Boiler temperature hysteresis 1 10 1˚C 5

A 99 Boiler overheating temperature 90 99 1˚C 99

Fd60

Fuel shortage testing time with burning,

increase by 5˚C

1 99 1min 60

Fb30

Fuel shortage testing time in WORK

mode and burning out.

1 99 1min 30

Ar 0

Additional output: 0-FUEL, 1-ALARM, 2-

MIX

0 2 1 0

Prod

Return to factory defaults after pressing

OK

outP

Central heating pump output testing,

press OK - launch

outP out1

out∏ Fan output testing, press OK - launch out∏ out2

outr

Oil boiler launch output testing, press OK

– launch boiler

outr out3

outu

Hot water pump output testing, press OK

- launch

outr out4

End Exit the service mode after pressing OK

In the table above, the first column represents example display indications, in

the next columns there are: parameter description, minimum and maximum

values allowed to set, step of the parameter during the setup. The last column

shows factory defaults to which you can return by choosing [Prod] option.

(1) Fan work parameters

Fan power [Π100] - this value defines power of the fan. When "Πr" parameter is

set to "0-10" this is the maximum power of the fan which can be achieved

during automatic fan control.

Automatic fan speed control [Πr 1] - it is on, when this parameter is set to "0-10"

and causes automatic fan speed decrease when temperature of water in the

boiler reaches desired temperature. If this parameter is set to "-", the fan

automatic smooth speed control is disabled and the fan can work with power set

by "Π" parameter. Setting parameter value in range from 0 to 10 means time in

minutes of the smooth fan speed increase from 40% to value of "Π" - for smooth

boiler start.

Page 17

- 17 -

Fan work time [Πr 1] - time of turning the fan on for a while, to remove

accumulated gases. Setting the parameter to "--" turns this function off. This

function can be active in WORK mode.

Fan pause time [Nu 6] - time between fan work periods

(2) Central heating pump work parameters

Central heating pump launch temperature [P 40] – the value of temperature of

the water in the boiler which causes start of the central heating pump. Central

heating pump works independently from the control process and is launched

additionally in case of boiler overheat.

Central heating pump launch hysteresis [Ph 2]- this parameter defines what

value should the boiler water temperature decrease by, below the launch

temperature, so that the pump turns off.

Repeat launch time of the central heating pump [Pc 2] - in STOP mode or when

room thermostat circuit is open, the central heating pump is launched for 30

seconds to mix water in heating circulation. This parameter defines the repeat

time of launches of the pump.

Setting the parameter to "--" turns this function off.

(3) Preparation of domestic hot water

The controller has additional output allowing to control the hot water tank

loading pump by the UM (UM-1) module.

The hot water temperature [u50] – temperature value which will be kept in the

hot water tank. The heating hysteresis of the hot water heating [uh5] – value

which the temperature in the tank has to decrease by so that the hot water

pump turns on in order to heat up the water in the tank.

Parameter [ur 1] – the [ur 0] value indicates no sensor or hot water pump. The

sensor is not taken into account in testing failures, i.e. it can remain

unconnected and in the user parameter menu there is only the boiler thermostat

set temperature displayed.

[ur 1] value – hot water pump working with priority

[ur 2] value – hot water tank working without priority

[ur 3] value- means controlling of the returning water mixing pump in the boiler

with the launch temperature of [u 50] and hysteresis [uh 5].

(4) Setting of boiler work temperature range

Minimum boiler temperature [L 40] - minimum temperature which can be set

with the boiler thermostat knob.

Maximum boiler temperature [H 90] - maximum temperature which can be set

with the boiler thermostat knob.

Boiler temperature hysteresis [h 5] - this parameter defines what value should

temperature of water in the boiler decrease by, below temperature set with the

thermostat knob, so that the fan turns on.

(5) Protection against boiler overheating

Page 18

- 18 -

Boiler overheating temperature [A 99] - value, exceeding which causes

permanent turn off of the fan to prevent boiler overheating. After the

temperature increases above 80˚C the central heating pump is turned on to cool

down the boiler. Overheating mode is shown by indicating error [E 2] on the

display. It can be turned off by pressing STOP button, but only when

temperature decreases below this temperature.

Fan turn off also occurs in case of damage of the boiler temperature sensor

which is shown on the display with error [E 1].

STB - the controller has additional protection against overheating which is

independent from the processor. In case the temperature increases over 95°C,

the control process is turned off by turning the fan off and launching the central

heating pump. The fan and the pump are turned on to the control process again

when temperature drops below 89°C.

STB circuit enables more precise boiler work control and reduces overheating

possibility.

(6) No fuel

No-fuel testing time during fuel firing start [Fd60] - after switching to WORK

mode, if water temperature does not increase by 5°C in programmed time, the

control process will be turned off and the display will show the message:

[FUEL].

You can return to previous mode by pressing STOP button. No fuel testing time

during fuel firing is finished after the set temperature is achieved.

No-fuel testing time during work mode [Fb30] - in WORK mode, if temperature

of water in the boiler decreases below temperature set with the thermostat, by

hysteresis value, and does not increase by 5°C in the programmed time, the

control process will be turned off and the display will show the message:

[FUEL].

You can cancel the alarm by pressing STOP button.

(7) Additional output

Additional output [Ar 0] – the controller has been equipped with an output that

allows connection of the UM module. When the Ar parameter has the UM

module value “0” it may control the oil or gas boiler – if such boiler exists in the

heating circuit. After switching the controller with the main power switch the

additional boiler is turned off and it turns on again when there is no fuel in the

solid fuel boiler. This function is useful in heating systems where there is a solid

fuel boiler used to cut the heating costs. After erasing the “no fuel” alarm by

pressing STOP button the additional boiler is again turned off and the controller

works again. Setting parameter [Ar] to “1” allows controlling the additional alarm

signaling system with the UM module – which occurs on the controller.

When Ar parameter is set to “2” the UM module allows controlling the mixing

valve servo-motor in the central heating circuit depending on the room

thermostat input. In this case the work of central heating pump depends only on

the boiler temperature.

Page 19

- 19 -

(8) Factory defaults

The controller allows returning to standard settings set by the producer by

choosing [Prod] and pressing OK button. After activating this function, the

controller sets each parameter showed in the table.

(9) Output testing

To make checking the controller work easier, it is possible to test output circuits

which control the fan and the pump, and the additional boiler launching system.

This function is available in service mode, only if the control process is off, i.e.

the controller was in STOP mode before switching to service mode. By

choosing [outP] on the display and pressing OK button you can turn on the

central heating pump for a while, by choosing [outΠ] and pressing OK you can

turn on the fan and by choosing [outr] and pressing OK you can turn the

additional boiler on (if the additional module is connected). Choosing [outu]

allows testing the hot water pump output.

(10) Exiting service mode

By choosing [End] option on the display and pressing OK button you can exit

parameter setting mode.

The controller also exits service mode, when no buttons are pressed for 1

minute.

6.2.6) Additional functions

To improve comfort in heated rooms, the controller has been equipped with an

input that allows connecting any kind of room thermostat with contact output.

When temperature in the room is below desired temperature, the central

heating pump is turned on and the room thermostat indicator is lit.

It means that the boiler should keep temperature set by the room thermostat

knob. After reaching desired temperature in the room, the room thermostat

indicator turns off, the central heating pump is turned off and the boiler switches

to mode in which it keeps burning at minimum temperature.

CAUTION. In case of not having room thermostat in the system, the room thermostat input

contacts must be short-circuited.

6.2.7) Controller failures

The controller is constantly testing if its internal circuits and temperature sensor

are working correctly. After detection of fault, it stops the fan, turns on the

central heating pump and shows proper error message on the display. In case

of failure please turn off the controller, plug the central heating pump to the

power source, ensure appropriate fuel firing in the boiler and contact the

service.

Page 20

- 20 -

When [E 1] error appears on the display, it means fault in the boiler sensor

circuit or temperature below 0°C. [E 2] is displayed if boiler overheats. [E 3]

error means fault and overheating at the same time. Appearing of [E 1] error on

the display after erasing it by pressing STOP button, in spite of temperature

decreasing below 90°C, may mean permanent damage of boiler temperature

sensor (e.g. if the boiler has been overheated above 150°C). In case of

programming the sensor and central heating pump in the service mode the

controller tests the hot water sensor circuit. Appearing of fault [E8] means

damage or lack of hot water sensor.

Picture. 2. RK-2001W connection diagram

Page 21

- 21 -

Picture. 3 UM-1 module connection diagram

6.2.8) Controller removal

In case the removal is necessary proceed as follows:

- turn the master switch off

- disconnect the power of the boiler

- remove the controller from the slot in the boiler

- disconnect all connectors with leads from the controller

6.2.9) Specifications

Voltage: 230V ± 10%, 50Hz

Power consumption: <4VA

Temperature measurement range: 0–99°C ± 1°C

Boiler temperature adjustment range: 30–90°C ± 1°C

Programmed boiler overheating protection: 90 –99°C ± 1°C

Hardware boiler overheating protection (STB): >95°C ± 1°C

Central heating pump launch temperature: 30–70°C ± 1°C

Hot water temperature adjusting range: 30-60°C ± 1°C

Total fan-out: total max 2A/230V

Dimensions (HxWxD): 80x170x100 mm

6.2.10) Notes

Display Parameter User

∏100 Fan max work power or max power when ∏r 0-10

∏r 1 automatic fan speed control and time of fan start

∏n 5 Fan work time

∏u 6 Fan pause time

P 40 Central heating pup launch temperature

Ph 2 Central heating pup launch hysteresis

Pc 2

Pause time of central heating pump with 30 sec. work

periods

u 50 Tap hot water desired temperature

uh 5 hot water heating hysteresis

Page 22

- 22 -

ur 0

No hot water-0, hot water priority-1, no hot water priority-2,

mixing pump-3

L 40 Minimum boiler temperature

H 90 Maximum boiler temperature

h 5 Boiler temperature hysteresis

A 99 Boiler overheating temperature

Fd60 Fuel shortage testing time with burning, increase by 5˚C

Fb30

Fuel shortage testing time in WORK mode and burning

out.

Ar 0 Additional output: 0-FUEL, 1-ALARM, 2-MIX

7) System

7.1) Standards

• Heating System – during installation and operation of the boiler it is very

important to keep safe distance from the inflammable materials. The boiler is

allowed to work only in open type heating systems!

• Electrical installation – the boiler’s power supply is 230V/50Hz

• Chimney – It must be done with respect to current norms and regulations.

Due boiler gasses temperature 90-100 C it is obligatory to put the INOX or

other material tubes into the chimney. Required chimney draught is 0,1 – 0,2

mbar. Installation according to ADJ does entail some testing of the chimney,

which may be carried out by

a sweep

• Important sources of guidance installers: 98/37/EEG; 89/336/EEG;

73/23/EEG; EN 55014-1, 1993 /A1, 1997; EN 55014-1; EN 55014-2 C1

1998; EN 61000-3-2; EN 61000-4-2, -3-4-5-6-11, Level2; EN 50165; EN

50165 C1; EN 60335-1; EN 303-5; EN 12809; EN 13394

7.2) Localization of the boiler:

• Placing on flammable foundation.

• place the boiler on non-flammable and thermal insulating pad which should

protrude not less than 20 mm outside boiler’s dimensions;

• If the boiler is located in the basement it is required to place it on a base

raised not lower than 50 mm over floor’s level. The boiler and the fuel hopper

must stand vertically and can be levelled using the regulating screw in fuel

hopper’s leg.

• The (230V/50Hz) electric socket should be easy to access.

Page 23

- 23 -

7.3) Ventilation:

Accordantly with regulations each

boiler room has to have the ventilation

inlet and outlet in aim of assurance of

correct boilers work and users safety.

Lack of ventilation inlet or it’s stocking

is the most frequent cause of incorrect

work of boiler (the humidity, condense

water, impossibility of higher

temperature obtainment). Ventilation

outlet has instead in task of offtake

from room used air and harmful gases.

In boiler room with chimney with

natural draught it is not it allowed to

use mechanical ventilation.

7.3.1) Ventilation inlet

• The channel of ventilation inlet should have dimension of 50 % area of

chimney intersection, no fewer than 20 x 20 cm

• Channel should be 1m over floor

• In ventilation hole or in channel should be installed device to control of air

flow, however such to forbid decrease of intersection more than to 1/5

• Ventilation duct should be made from incombustible material

7.3.2) Ventilation outlet

• Channel should be made of brick and min. intersection of it should be 25% of

chimney intersection however not smaller than 14 x 14 cm

• Inlets can not have any closing it intersection devices

Page 24

- 24 -

• Spout should be under ceiling of room, led out on roof at least 1,5 m

• Ventilation duct should be made from incombustible material

7.4) Chimney connection:

• Flues should be made in accordance with current regulations.

• To reduce the resistances of flow of flue gases the connection with chimney

should be led in straight line and possible change of direction should be made

with gentle arcs.

• Boilers can be assembled into flues from brick with aligned internal welds

• Combustion duct should begin from floor line

• About 30cm. over floor should be to situated cleanout with tight lock

• Intersection should be

approximate to square with

regard on smaller

resistances of flue gases

flow

• The minimum intersection

of chimney amounts 20 x

20 cm

• The dams of brick between

duct and wall should not be

smaller than 12cm

• Chimney should be led out

over roof

• The location of chimney

outlet depends from the

degree of roof droop and

stages of the flammability.

The roof with angle of

droop to 12º - the chimneys

should stand over roof ridge

0.6m, roof with angle of

droop over 12º - the

chimneys should stand over

roof ridge in case of easily

flammable coverings 0,6m however in case of incombustible or difficultly

flammable covering, the outlet can occur 0,3m over roof ridge.

• Assembly of draught regulator is recommended, which in case of too big

underpressure in chimney opens and suck in the air from the boiler room and

does not pull it through boiler causing the temperature uncontrolled rise.

Interrupter this should be set on required value in dependence from power of

boiler

Page 25

- 25 -

8) Parts

Page 26

- 26 -

No. Part Description Serial Number

01. Left Side Casing F.h.b.l.01

02. Front Casing F.h.p.02

03. Top Casing (Hat) F.h.g.03

04. Door Casing Upper F.h.d.g.04

05. Door Casing Lower F.h.d.d.05

06. Steering Panel F.h.p.s.06

07. Right Side Casing F.h.b.p.07

010. Thermometer F.h.t.010

011. Thermostat F.h.t.011

012. Power Switch WA-12PS F.h.ł.012

013. STB F.h.STB.013

014. Fuse Nest FU max 4A F.h.g.b.014

020. Door Locking F.h.z.d.020

030. Ceramic Deflector Lower Part F.h.c.s.d.030

031. Ceramic Deflector Upper Part F.h.c.s.g.031

032. Ceramic Nozzle F.h.d.s.032

Page 27

- 27 -

9) Boiler installation systems:

¾ Open system

The bottom of the safety tank must be placed:

• In natural circulation systems or with pump on heating water H ≥ 0.3 [m]

over the highest point of the system.

• In systems with pump installed on return water: H ≤ 0.7Hp [m]

Page 28

- 28 -

Page 29

- 29 -

¾ Closed systems

Warning! – To collect boiler in closed system it is important to build in the boiler cooling loop

and then make a right connection:

Page 30

- 30 -

Page 31

- 31 -

Page 32

- 32 -

Loading...

Loading...