Page 1

AS-H40Y - 12kW

AS-H50Y - 15kW

AS-H60Y - 18kW

ALTO

Heat Pump installation manual

F1-F7

Page 2

1

CUSTOMER NAME........................................................................

POOL DEALER..............................................................................

DATE INSTALLED..........................................................................

SERIAL NO.....................................................................................

MODEL...........................................................................................

SAFETY INSTRUCTIONS

Please read this safety instruction carefully before operation.

Heat pump must remain upright at all times.

Do not place objects on to heat pump

Do not disconnect/connect power supply during operation as this may cause serious damage.

Do not insert objects into the air inlet/air outlet grilles.

All electrical connections should be made by a qualified electrician. Do not connect heater to an electrical

supply using a 13 amp plug.

When cleaning the heater unit switch off power supply.

Do not operate electrical switches with wet hands.

Repair or relocation should be carried out by a specialist contractor.

INDEX

Page 4 ............... Installation and Siting

Page 5 ............... Plumbing

Page 9 ............... Electrical Connection & Circuit Diagram

Page 10 ............... Control Panel Functions F1-F7

Page 13 ............. Refrigerant/Flow Meter

Page 14 ............. Control Panel Error Display E1-E4

Page 15 ............. Auto Restart and Defrosting Function

Page 15 ............. FAQ

Page 16 ............. Water Chemistry / Winterising & Start-up Procedure

Page 17 ............. Warranty Policy

Page 18 ............. Heat pump Service & Breakdown

Page 19 ............. Alto Heat Pump Specification

Page 3

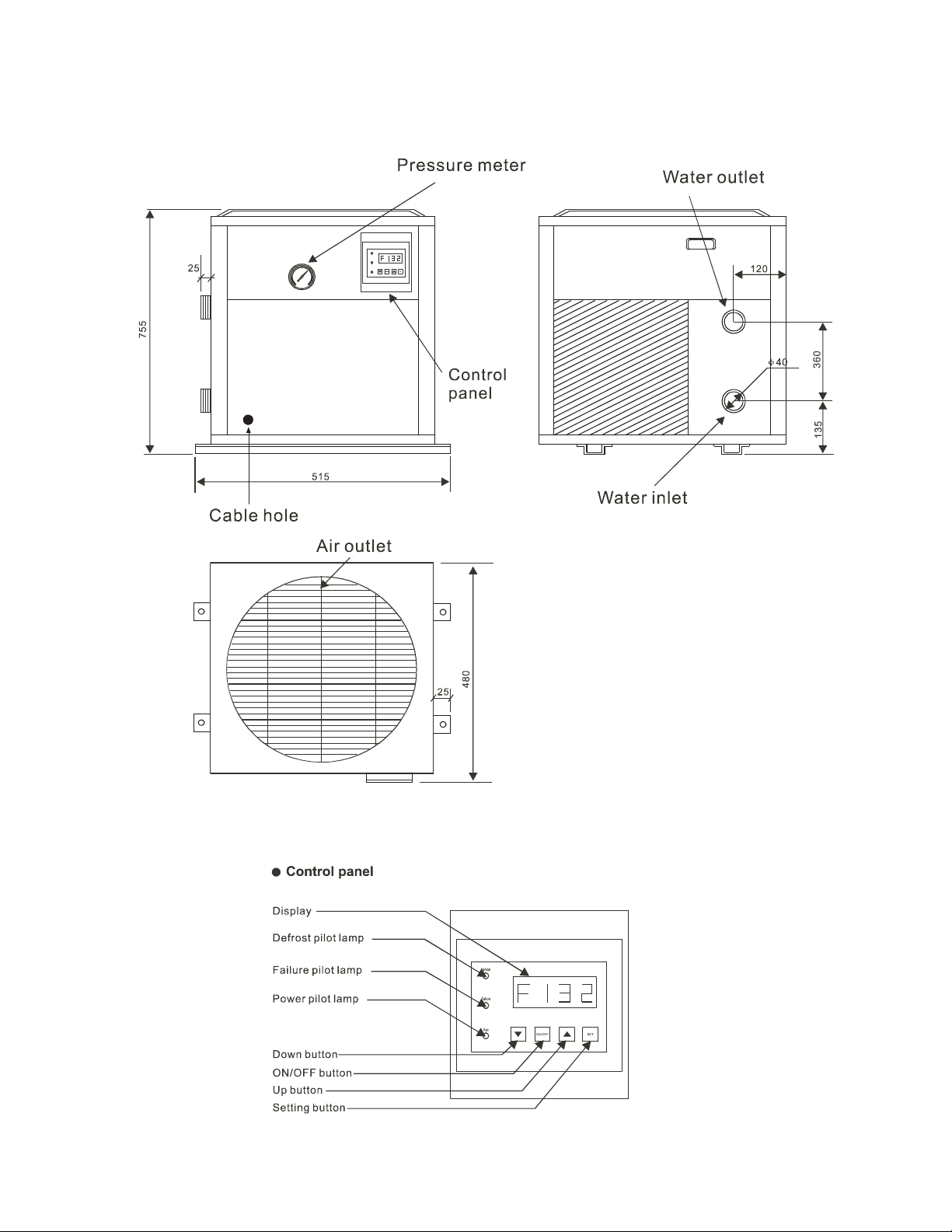

HEAT PUMP- AS-H40Y 12kW

2

Page 4

3

HEAT PUMP- AS-H50Y (15kW) & AS-H60 (18kW)

Page 5

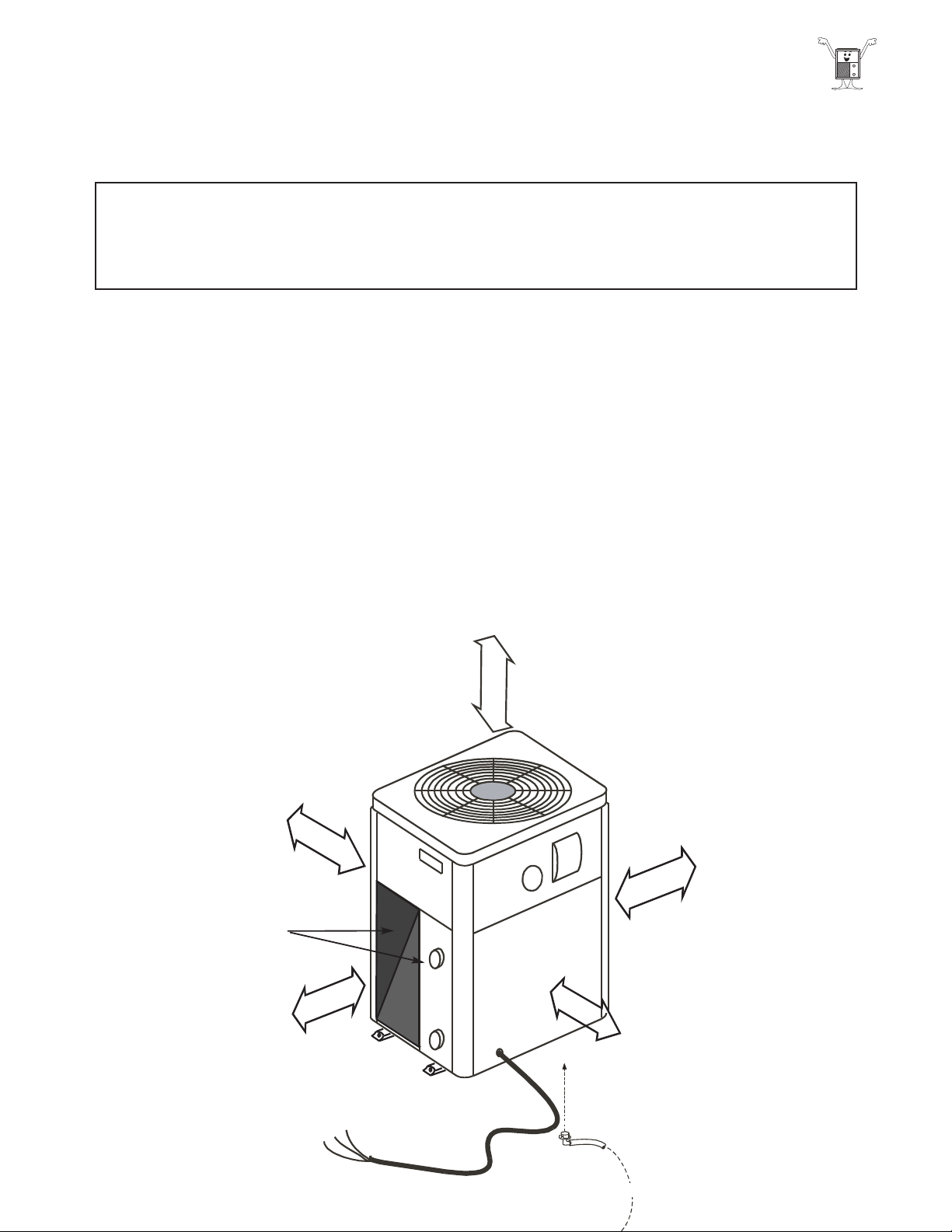

INSTALLATION AND SITING

Prior to installing your heat pump:-

All heat pumps are factory assembled and tested prior to delivery. Please check for any external damage

especially to the evaporator fins, please diagram below. Do not be concerned about minor damage or indentations

to the fins (especially where the fan unit is mounted) as it will not affect performance. If severe damage has

occurred please contact your supplier immediately and do not attempt to install heater unit.

Siting

As the air flow is discharged from the top of the heat pump all units are designed to be installed outside. If unit is to

be installed inside the filtration/plant room adequate ducting and ventilation must be installed. Please contact your

dealer for advice.

Heater unit must be installed using plastic anti vibration pads (provided) on a solid LEVEL foundation i.e.

concrete base or paving slabs. Using the plastic pads reduces vibration noise and prevents corrosion to the base

of the heat pump. DO NOT PLACE ONTO SOFT GROUND I.E. GRASS. Please Note: the heat pump collects

condensation from the evaporator fins and will continually discharge small amounts of condensate (water) out of

the base of the unit via a drain tube. Therefore, it is recommended that the drain tube is directed to an area with

adequate drainage.

Make sure that heat pump remains free of any obstructions, foliage etc. A minimum clearance is required around

heater unit, please see drawing below. Make sure that easy access can be gained to service panel and plumbing

connections. Do not obstruct access panel with plumbing pipework.

Multiple connections- install heat pumps 500mm apart and independently protect each unit by 20amp MCB - see

also page 8, Drw.4 for plumbing detail. Make sure that heat pump grilles are not blocked by loose debris such as

leaves, grass cuttings, garden

furniture etc.

Min. 1000mm

Drain Tube

(optional)

Min. 3500mm

Min. 1000mm

Min. 800mm

Min. 500mm

4

Evaporator Fins

x 3 sides

(protected by a wire

mesh grille)

2.5mm Cable

Power Supply

(prefitted)

IF HEAT PUMP HAS BEEN PLACED ON IT’S SIDE IN TRANSIT THEN HEATER MUST BE LEFT

IN AN UPRIGHT POSITION FOR A MINIMUM PERIOD OF 24HRS PRIOR TO OPERATION

(failing the above may cause damage to the heat pump and invalidate your warranty).

Page 6

5

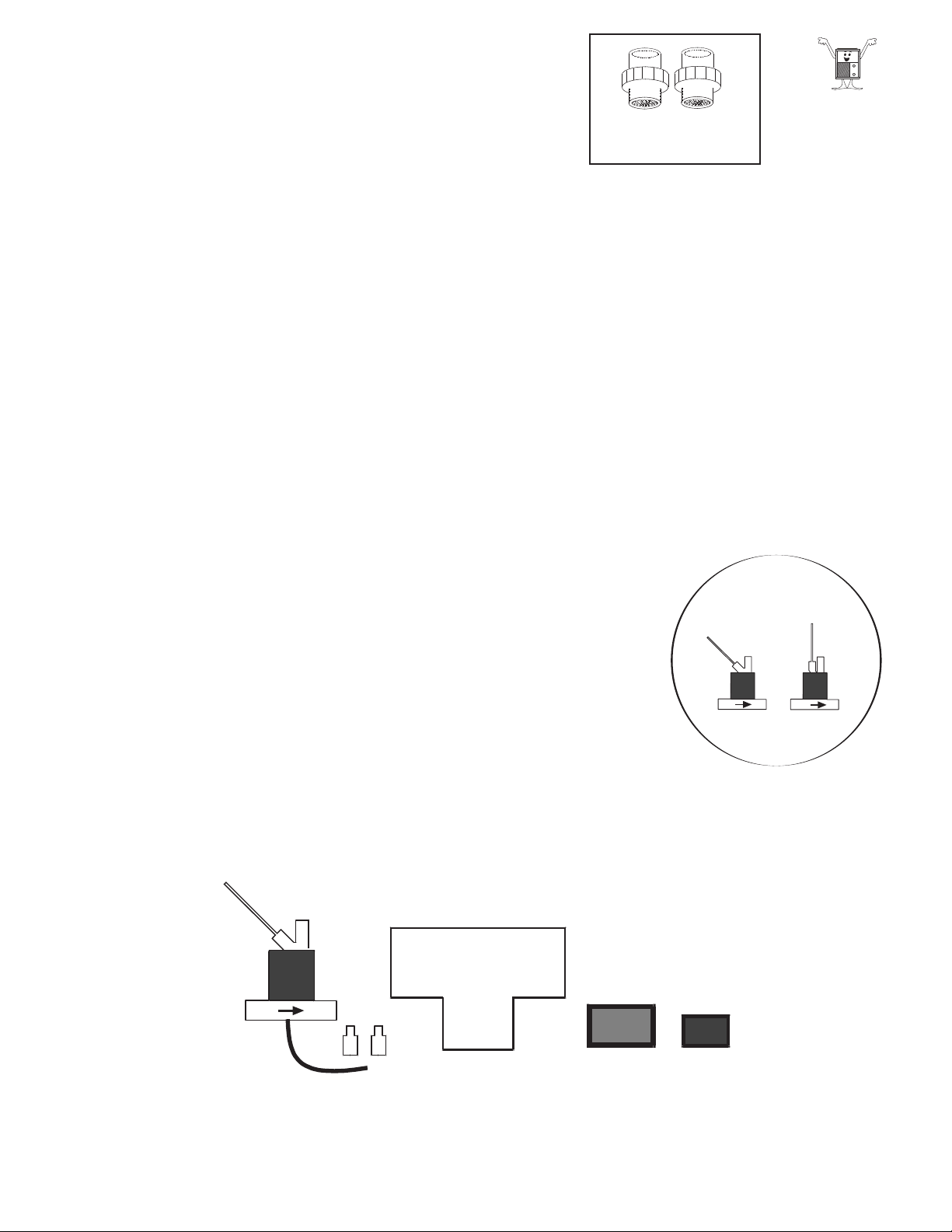

PLUMBING

Alto heat pumps are supplied with 1.5" BSP parallel threads, male. We

strongly recommend a 1.5" female socket union is applied to

inlet/outlets for future draining and servicing of the appliance.

Alto heat pumps must be installed in the return line after the filter. If an

existing heater or back-up heater has been installed then the heat pump

should be installed between the filter and the other heater. If solar

heating has been installed, the heat pump should be installed after the solar heating system. See Drw.2 page7.

If the heat pump is to be installed at a lower level than the pool then isolation valves or non-return valves should be

installed.

Do not route any plumbing lines across heater inlet panels. All plumbing should be adequately supported.

Once all plumbing connections have been completed the filtration should be turned on and the systems tested for

leaks. A refrigerant/flow meter is located next to the control panel. Alto heat pumps will generally take the full flow

of the filtration pump. In some instances if there is too much flow (see page 12 re refrigerant/ flow meter) a by-pass

may be required. If there is insufficient flow an auxiliary booster pump may be required. Please contact your dealer

for advice.

Important - (applicable for stainless steel/copper heat exchangers) Standard unit. If your pool has an automatic

chemical dosing appliance the heat pump should be installed prior to the dosing system. See applicable drawings

(1-4) on pages 7-8.

2 x1.5” Female/Threaded

Socket Unions Required

FLOW SWITCH (Optional)

Alto heat pumps have the option of installing a flow switch. A flow switch will deactivate the heater if there is a loss

of water flow i.e. in the event that the circulation pump deprimes (no flow) the heater

will switch off.

We recommend that the heat pump should be interlock wired with the

circulation pump i.e. heat pump only functions when pool circulation pump is

running. A flow switch (provided) can also be installed as an extra precaution in

the event that there is a loss of water flow (i.e. circulation pump deprimes).

It is our recommendation that the flow switch is installed for added protection

on a pool installation that is below ground. If the heater is to be installed on an

above ground pool, the circulation pump is normally under flooded suction

therefore, heater and filtration pump could be wired together.

In the event that there is no flow ‘E3’ will be displayed on the control panel and

heater will stop functioning.

ELECTRICIAN NOTE - PLEASE CHECK CONTINUITY OF FLOW SWITCH BEFORE INSTALLING.

PLEASE ALSO SEE PAGE 15 - FILTRATION & FAQ

OFF

ON

1 X FLOW SWITCH

1 X CRIMP -ON CONNECTIONS

1 X 1.5”- 0.75” PLN RED. BUSH

1 X 0.75” PLAIN - 0.5” FEMALE THR. RED. BUSH

Page 7

N

L

ON

OFF

CONTACTOR

12

HEATER

Red

Black

OUTLET

FLOW SWITCH

OPERATION

WATER FLOW

FROM PUMP

SOCKET

UNION

TEE

INLET

OFF

ON

Alternative wiring route

SOCKET

UNION

RETURN WATER

FLOW TO POOL

1. Insert reducing bushes (provided) into 1.5” Tee using suitable adhesive.

2. Connect 1.5” Tee to socket union adjacent to Inlet on heat pump. Tee can be installed horizontally or

vertically!

3. Using PTFE tape insert flow switch into Tee making sure that the arrow on the flow switch point

s towards

the heater.

4. Turn off electrical supply to heat pump. Run the wire lead from the flow switch and make connection to No. 1 &

2 on the electric terminal block - see diagram below (wire extension may be required). Note:- you will have to

remove a pre-fitted loop that is already connected to No.1 & 2 see dia. below.

FLOW SWITCH INSTALLATION GUIDE (optional)

ANTI VIBRATION PADS AND DRAIN TUBE

X 4 ANTI VIBRATION PADS (PLASTIC)

Install on underside of heater. It is recommended

that Stainless Steel screws & plugs are used when

securing to floor. Installing anti vibration feet will

also help prevent corrsion to the base of the heat

pump.

1 X DRAIN VALVE (RUBBER) 1 X 2m FLEXIBLE DRAINAGE TUBE

Insert drain valve into drainage hole located on underside of heater and push fit

the drainage tube onto valve (Tip-you will find it much easier to insert drain

valve if it is immersed in hot water or sprayed with silicone spray prior to

fitting). Drain valve installation is optional.

The following parts should be installed prior to connecting pipework. Drain

tube will not fit if vibration pads are not installed on the 12kW model!

IMPORTANT

WHEN INSTALLING FLOW

SWITCH MAKE SURE THAT

ARROW POINTS

TOWARDS THE HEATER

6

Remove ‘pre-fitted loop’

and keep in a safe place

(See FAQ page 15).

Alternative

connection

Page 8

7

Ball

Val v e

BACKWASH

FILTER

FILTER

Pool

Position for optional

Erosion Feeder

Non-Return Valve

Back-Up Heater if

required

Condensate

Water to waste

PUMP

Female/ Threaded

Socket Union

Drw.1 Recommended plumbing layout for a standard heat pump installation.

Drw.2 Recommended plumbing layout when incorporating Solar Heating. If an increased flow rate is

required instal a booster pump as per drw.4 below.

Ball

Valv e

BACKWASH

FILTER

FILTER

Pool

Non-Return Valve

Back-Up Heater if

required

PUMP

Solar Heating

3-Way

Valv e

Install a plumbing bypass for running filtration

& heat pump at night.

Non-Return Valve

Position for optional

Erosion Feeder

Condensate

Water to waste

Female/ Threaded

Socket Union

PLUMBING LAYOUT

Flow Switch

(Optional)

Flow

Switch

(Optional)

Page 9

Ball

Valv e

BACKWASH

FILTER

FILTER

Pool

Non-Return Valve

Back-Up Heater if

required

Condensate

Water to waste

PUMP

Female/ Threaded

Socket Union to be applied

on all inlet/outlets

Position for optional

Erosion Feeder

Ball

Valv e

Ball

Valv e

Condensate

Water to waste

required or

Errosion Feeder

if installed

Drw.4 Recommended plumbing layout when incorporating two heat pump units. IMPORTANT Minimum

flow rate required to use this system is 3000 Litres / 660 Gallons (imperial) per hour.

Ball

Valv e

BACKWASH

FILTER

FILTER

Pool

Position for optional

Erosion Feeder

Non-Return Valve

Back-Up Heater if

required

Condensate

Water to waste

PUMP

Female/ Threaded

Socket Union

Ball

Val ve

BOOSTER PUMP

Solar Heating

3-Way

Val ve

Install a plumbing bypass

for running filtration &

heat pump at night.

Non-Return Valve

Non-Return

Val ve

Drw.3 Recommended plumbing layout when incorporating Solar Heating & Booster Pump

IMPORTANT

Minimum flow rate required to

use this system is 3000 Litres /

660 Gallons (imperial) per hour.

Flow Switch

(Optional)

Flow Switch

(Optional)

Flow Switch

(Optional)

8

Page 10

9

ELECTRICAL CONNECTION & CIRCUIT DIAGRAM

IMPORTANT. It is recommended that all electrical supplies and connections are carried out by a qualified

electrician, in accordance with I.E.E. standards, latest issue, or local codes of practice as applicable.

Also recommended is a protected supply to incorporate fuses or motor type circuit breaker (Type C) to specified

rating (see Data Sheet page 19).

An earth leakage trip (R.C.D) of the current operating type (30mA) is recommended to be fitted to all pool electric's.

Minimum/Maximum Voltage requirements.:

Single phase machines 50Hz 207v 253v

Three phase machines 50Hz 360v 440v

Cycle Frequency 50Hz 47.5Hz 52.5Hz

N.B. This voltage must be available at the heat pump whilst running.

A 40 AMP / 2 Pole Contactor is required to interlock heat pump and circulation pump i.e. heat pump only

functions when pool circulation pump is running. A flow switch (provided & optional - see page 5) can also be

installed as an extra precaution in the event that there is a loss of water flow (i.e. circulation pump deprimes).

NOTE - PLEASE CHECK CONTINUITY OF FLOW SWITCH BEFORE INSTALLING.

High Pressure

Protection

Flow Switch

Transformer

4-Way Valve

Compressor

Relay

Protective

Circuit Breaker

POWER SUPPLY

230V/50HZ

Link

or

Flow Switch

Heat Pump

Main Terminals

Remove Link to

wire flow switch

(see page 6)

L

N

A1

A2

CONTACTOR

40AMP 2 POLE

Contactor required to

interlock heat pump with

circulation pump

L

N

N

L

Control wires

from circulation

pump starter

AS-H40Y (12KW) AS-H50Y (15KW) AS-H60Y (18KW)

SINGLE PHASE (1-N 50HZ)

Page 11

1. When electric supply is connected the ‘Run’ power

light will be on and the display panel will display

the current water temperature. ie.10 H = 10°C.

2. On/OFF button to turn heater on and off.

3. The ‘set’ button is used to set the F1-6 functions

ie.water temperature, defrosting cycle and

defrosting time etc. see pages 11-12

PLEASE READ THE CONTROL

FUNCTIONS CAREFULLY AND MAKE THE

NECESSARY ADJUSTMENTS BEFORE

USING YOUR HEATER

CONTROL PANEL FUNCTIONS

1

3

10 40

H

2

10

Page 12

11

When the ON/OFF buttons is pressed for the first time, the display

panel will display the current water temperature and the desired pool

temperature.

eg. the display may read 10 40 ----- 10 is the current water

temperature 10°C and 40 is the desired water temperature 40°C.

ADJUSTING THE POOL WATER TEMPERATURE

Using the up and down buttons, you can set the swimming pool water

to the desired temperature between +15°C up to + 65°C.

When the SET button is used for the first time, the display panel will

display

F1-this is to set the temperature differential. The

recommended setting is 2°C. To adjust setting YOU MUST PRESS

THE ON/OFF BUTTON FIRST. Then use the UP and DOWN button to

set the differential temperature range between 0 °C ~ 5°. Press on/off

button again to take you back to the normal display. The unit will now

stop working when the swimming pool water temperature reaches the

setting temperature. The unit will automatically restart when the

swimming pool water temperature drops below the setting temperature.

Eg. If current pool water temperature is 20°C, F1 has been set to 02

(heating mode) when the temperature reaches 20°C the heater will stop

and restart when the water temperature is below 18°C.

When the SET button is pressed for the third time, the display panel will

display

F3 - the defrosting time. The recommended setting is 5

minutes. To adjust setting YOU MUST PRESS THE ON/OFF BUTTON

FIRST. Use the UP and DOWN buttons to adjust defrosting time

between 3 to 15 minutes. Press on/off button again to take you back to

the normal display.

When the SET button is pressed twice, the display panel will display

F2- the defrosting cycle. The recommended setting is 30 minutes. To

adjust setting YOU MUST PRESS THE ON/OFF BUTTON FIRST.

Then use the UP and DOWN buttons to adjust defrosting period

between 30 minutes up to 99 minutes. Press on/off button again to take

you back to the normal display. The unit will now start to defrost after

the setting period when the defrosting sensor reaches the frosting

condition.

CONTROL PANEL FUNCTIONS 1-3

NOTE. WHEN PROCESSING FUNCTIONS F1-F5 IF NO ADJUSTMENTS ARE MADE FOR 5 SECONDS

THE DISPLAY WILL REVERT BACK TO THE CURRENT & DESIRED WATER TEMPERATURE AS ABOVE

Page 13

When the SET button is pressed for the fourth time, the display panel will

display:-

F4 : Operation Mode.

F4 C : Cooling Mode.

F4 H : Heating Mode

When the SET button is pressed for the fifth time, the display panel will

display:-

F5 : The defrosting temperature of the evaporator pipe. The

recommended temperature setting for the UK should be set to 0°C

. To adjust

setting YOU MUST PRESS THE ON/OFF BUTTON FIRST. The temperature

can be adjusted using the UP and DOWN buttons between -10°C and 0°C

Press on/off button again to take you back to the normal display.

CONTROL PANEL FUNCTIONS 4-7

When the SET button is pressed for the sixth time, the display panel will

display:-

F6 : EC (Economy) OR ST (Standard) This function is designed for saving

energy.

EC: Heat pump will stop working at an ambient temperature of 5°C and will

automatically restart when the ambient temperature rises above 10°C

Example. When the heat pump is set in Economy mode, the unit will stop working during the

night (when temperature drops below 5°C) and will restart automatically when the

temperature rises throughout the day

.

ST: (

may be shown as 57)

The heat pump will work continuously until the

desired temperatures are reached.

To adjust setting YOU MUST PRESS THE ON/OFF BUTTON FIRST.

When the SET button is pressed for the seventh time, the display panel will

display:- This function is used only in conjunction with a back-up electrical

heater.

F7 : ON/OFF Function. 0= turns off heater. 1= turns on electrical heater.

New

economy

Setting!

12

F7 IS ONLY DISPLAYED IF AN ELECTRIC BACK-UP HEATER HAS BEEN INSTALLED

Page 14

13

RED

area

RED

area

area

RED

area

RED

area

area

RED

area

RED

area

area

After the water heater has been running for more than 24 hrs, it should

be running at full capacity. The PSI reading should be in the region

150 -200. If you want to make the heat pump run more efficiently the

water flow should be adjusted by checking the pressure meter display.

If the meter index is in the green area, the water heater is running in the

most efficient way and you do not need to adjust anything.

If the meter reading is in the red area but you have good water flow

from the circulation pump, it may be as a result of low refrigerant gas

(see below).

In the event that the pressure reading is in the red area

‘A’ (dia.2) it

means there may be insufficient water flow. Prior to any adjustments

make sure your filter is clean by using the ‘backwashing and rinse

procedure (refer to your pool hand book for guidance). Check there are

no obstructions in the suction lines i.e. Main Drain or Skimmer(s).

If you are unable to increase the flow rate, please contact your pool

dealer as you may need to increase the size of the filtration pump or

there is a lack of gas refrigerant. Loss of refrigerant gas is normally

attributed to transit damage or the heater being manhandled incorrectly.

In the unlikely event that there is a refrigerant loss a replacement heater

maybe required.

diagram 1

diagram 3

diagram 2

In the event that the pressure reading is in the red area

‘B’ (dia.3) it

means the water flow is too high. You may need to install a bypass to

decrease the water flow until pressure meter enters the green area.

Please contact you dealer for advice.

POOL WATER AND GAS REFRIGERANT FLOW METER

A

B

Page 15

E1: the water temperature sensor is not working correctly.

E2 : the tube sensor is not working correctly. Please contact your dealer.

E3 : Pool filtration is running but water flow is not sensed. ‘Flow

Switch’ may not be working properly or there is a lack of water

flow. Backwash filter and check suction lines (Skimmer(s) & Main

Drain(s) for obstruction.

E4 : Indicates high water/refrigerant pressure. High limit pressure

switch has activated and turned off power supply.

IF THE HEATER STOPS WORKING ONE OF THE FOUR ERRORS WILL BE DISPLAYED

THE FAILURE LIGHT WILL BE ON AND THE RELEVANT CODE WILL START TO FLASH

CONTROL PANEL FUNCTION - ERROR DISPLAY 1-4

14

PLEASE ALSO SEE PAGE 15 - FILTRATION & FAQ

Page 16

15

AUTO RESTART AND DEFROSTING FUNCTION

AUTO RESTART FUNCTION

The Alto water heat pump has an auto restart function. When the power supply is switched off accidentally, it will

automatically save the operation mode.

When the power supply is restored, the unit will automatically restart after five minutes and operate in the same

working mode.

REVERSE CYCLE DEFROST FUNCTION

When the ambient air temperature is too cold, the evaporator will start to freeze and frost will appear on the

evaporator fins. If this happens the heater will automatically enter a defrosting mode (Reverse Cycle Defrost) and

the defrost light will show in the control panel.

This function will make the unit run as it would if it were a normal cooling unit by heating the outdoor coil using hot

gas to melt any frost / ice. Once the evaporator temperature has reached over 23C or the set defrosting time, the

defrost function is over and reverts back to heating the pool water.

FAQ

The flow switch is faulty, is there a way to bypass the flow switch temporarily?

Yes. Re-insert the ‘pre-fitted loop (see page 6). Heater will need to be turned on and off manually until a

replacement is sent.

How long will it take to heat up my pool?

The answer to this is dependant on a number of factors; the ambient air temperature; heater being sized correctly;

solar cover fitted; plumbing configuration etc. As an indication, at the start of the summer season (May) you should

be able to obtain a water temperature of 24°C / 75°F allowing for approximately one week heat up time. This is

providing that filtration is running 24hrs per day and an average

ambient air temperature of 16°C / 61°F is

achieved.

When I use a heat pump, should I use a pool cover or solar blanket as well?

Yes. Any reduction in pool heat loss directly translates into savings. 82% of all losses are due to convection. Using

a pool cover just at night will save about 40% of the annual heating cost. A thermal pool cover or solar blanket can

significantly reduce pool heating loss. The use of a solar or thermal blanket will also help extend your pool season.

What is the minimum ambient operating temperature?

The Alto Water Heat Pump will actually operate down to an ambient air temperature of 0°C. but with minimal heat

output. Therefore we recommend that the minimum operating temperature should be 5°C. Other conditions such

as wind, shade and physical location will affect the shut-off temperature of the unit.

Will the heat pump require more refrigerant gas?

Unless the Alto Water Heat Pump has a leak in the sealed refrigeration system, the factory charge of Freon should

last for the life of the unit. Freon is very stable and should not degrade or breakdown even under severe operating

conditions. If your unit needs Freon, then it has a leak, and adding Freon will not solve the problem. The leak must

be located and repaired. Fortunately, Freon leaks are very uncommon and usually are due to transit damage.

How Close To Your Pool?

Normally, the pool pump and Heat Pump are installed close together and within 25 feet of the pool. The longer the

distance from the pool, the more heat loss from the piping. Since normally most of the piping is buried, the heat

loss is minimal for runs of up to 50 feet (50 feet to and from the pump = 100 feet total) unless the ground is wet or

the water table is high. A very rough estimate of heat loss per 100 foot is 2500 BTU/hr for every 10° F difference in

temperature between the pool water and ground surrounding the pipe, which translates to about 3% to 5%

increase in run time.

FILTRATION -

BACKWASHING (FILTER) - ONLY APPLICABLE IF FLOW SWITCH HAS NOT BEEN INSTALLED

The Alto water heat pump will continue to run when the filter is being backwashed. Although there is no water flow

through the heat pump it will automatically cut out after a short period of time. Heat pump will automatically restart

when filter is put back to normal operation.

WASTE - ONLY APPLICABLE IF FLOW SWITCH HAS NOT BEEN INSTALLED

If the pool is to be emptied or cleaned through the waste cycle for long periods of time we recommend

that the heat pump is manually turned off until filter is functioning normally..

Page 17

WINTERISING / START-UP procedure - ALL MODELS

WATER CHEMISTRY

The following water quality must be maintained at all times to prevent premature corrosion. It is

recommended that your water balance is checked and balanced by a pool professional. Your warranty

does not cover for damaged caused by poor water chemistry and neglect.

pH: 7.2 -7.6

Total Alkalinity: 80 - 120ppm

Total hardness: Less thab 500ppm

Total Dissolved solids: 1500ppm or lower

Saline Water max: concentration 6%

Chlorine Free Cl: 5ppm Max. Continuous

Cyanuric level 50ppm Max.

Super chlorination Max: 30ppm for 24hrs

Bromine: 8ppm

Baquacil: 25-50ppm

Surface skimmers (above or inground)

Do not use slow dissolving chemical tablets such as chlorine in the skimmer basket(s). This can lead to high

acidic/corrosive pool water affecting the heat exchanger and resulting in a replacement of the whole unit.

Therefore, we recommend that diluted chemicals are fed directly to the pool water or use an automatic dosing

device.

Winterising Procedure

1. Switch off electric supply to heat pump.

2. Turn off circulation pump.

3. Drain water from heat pump by disconnecting pipework to and from heat pump.

Ensure Heat Pump is completely drained.

4. Flush through water circuit in heat pump using clean tap water i.e. a hose into inlet connection - run

for 10 minutes minimum.

5. Drain completely - fit plastic bags secured by elastic bands over water connections.

6. If desired, you can protect from the heater by covering with VENTILATED cover through the winter

season. Do not use plastic sheet as condensation can occur within unit.

NOTE. If the pool has a ‘frost-thermostat’ installed to prevent the pool system from being drained in the

winter months, it is recommended that a plumbing by-pass is installed to prevent unnecessary water flow

through the heater unit.

Start-Up Procedure

1. Remove ventilated cover protection is fitted.

2. Re-connect all plumbing connections to heat pump, filtration etc.

3. Turn on circulation pump and check for leaks.

4. Use control panel to set functions 1-7.

5. Check daily to ensure pool water has the correct pH and the correct chemical balance is being

maintained.

16

Page 18

17

ALTO WARRANTY POLICY

This voluntary policy is supplemental to and in no way affects any statutory rights which the

customer may have.

1 Warranties

1.1 Paramount Pools warrants the Alto Heat Pump for a period of one (1) year from the date installed for both

parts and labour.

1.2 At the end of the first year the following warranties apply as to parts only; labour is excluded from these

warranties:-

1.2.1 The condenser and compressor are warranted for three (3) years;

1.2.2 The stainless steel copper heat exchanger is warranted for three (3) years;

12.3 The titanium heat exchanger is warranted for five (5) years.

2 Exclusions - This warranty does not include the following:-

2.1 The repair of damage due to negligence; abuse or improper installation;

2.1 Incorrect winter de-commissioning;

2.3 Improper operation;

2.4 Improper use of pool chemicals;

2.5 Operation environment;

2.6 Failure to provide reasonable and necessary maintenance;

2.7 Accident or other conditions beyond the normal intended use of the unit;

2.8 Any misuse of the equipment;

2.9 The occurrence of superficial corrosion to the external housing cabinet of the heat pump;

2.10 The furnishings of refrigerant and other expendable material.

3 Conditions for Warranty

The warranty only applies on the following conditions:-

3.1 The customer is to pay for all charges for the Alto Heat Pump in accordance with the original terms of sale.

3.2 All repairs, replacements must be carried out by an authorised service agent appointed by Paramount

Pools.

3.3 This warranty extends only to the original consumer who purchased the Alto Heat Pump.

3.4 The warranty terminates upon the transfer of ownership or if the heat pump is relocated save with the

written permission of Paramount Pools.

3.5 The warranty is only applicable to installations in England, Scotland and Wales.

4 Damages

4.1 Paramount Pools is not liable for any damages of any sort whatsoever, including incidental and

consequential damages.

4.2 Parts returned under the terms of this warranty will be repaired or replaced and return transportation

charges pre-paid within the UK by the best and most economical means

4.3 To the extent permitted by law liability under or in connection with this warranty whether arising in contract

or negligence; breach of statutory duty or otherwise, shall not exceed the value of the contract.

5 Miscellaneous

5.1 This warranty shall be governed by and construed in accordance with the laws of England and Wales and

each party agrees to submit to the jurisdiction of the Courts within England and Wales.

5.2 This warranty is in lieu of all other warranties expressed or implied, written or oral save as prescribed by

statute.

5.3 There are no implied warranties of fitness for a particular purpose that apply to this product.

5.4 Any provisions of this contract which is or may be void or unenforceable shall to the extent of such invalidity

or unenforceability be deemed severable and shall not affect any other provision of this contract.

Page 19

HEAT PUMP SERVICE

An Alto heat pump should give you many years trouble free service. However, to obtain the

maximum efficiency from your heater Alto recommend that your heater is checked and

serviced every 12 months. Service & extended warranty packages are available from a UK Service Agent

(see contact detail below).

HEAT PUMP BREAKDOWN

If you think there is a problem with your heater and are not able to diagnose the fault please contact your

POOL DEALER initially to discuss the symptoms.

BEFORE YOU CALL

To help you prevent unnecessary service call outs, please check the following points:-

· Is there an electric supply to the heater?

· Is there a power cut?

· Have you checked all the house fuses, R.C.D trip?

· Has the electrical supply been disconnected?

· If installed is the time clock correct?

· Have checked you the flow metre?

· Is there enough water flow?

Has the filtration been running for a minimum of twelve hours per day?

· Is there any obstruction in the skimmer?

· Is there any obstruction in the pump basket?

· Is the water at the correct operational level?

· Is the filter pump working?

· Is the filter operating pressure correct?

· Does the filter require backwashing?

· Have you checked the diagnostic control panel?

If the fault can not be diagnosed over the phone then your pool dealer will contact Paramount Pool

Products (UK Importer) who will arrange an appointed UK SERVICE AGENT (Regal Environmental

Systems Ltd) to contact you with a suitable date and time to service the heater unit.

Please have the following information available:-

1. Serial number (located on the aluminum plate placed externally on the heat pump casing) and

the approximate date the unit was installed. (this information should be on the front cover of this

manual)

2. Proof of Installation Date (Bill of sale or original invoice only)

3. Description of the Symptoms.

UK IMPORTER: Paramount Pool Products London Road Hartley Wintney Hook Hants RG27 8HY TEL.

01252 842891 FAX 01252 842388

UK SERVICE AGENT: Regal Environmental Systems Ltd Regal House Upham Street, Upham,

Southampton SO32 1JA TEL01489 860966 FAX 01489 860977

18

Page 20

Model No. AS-H40Y AS-H50Y AS-H60Y

12kW 15kW 18kW

Heating Capacity (Btu) 40000 50000 60000

Cooling Capacity (Btu) 35000 42000 55000

Rated Input (W)

Heating 2540 3185 3790

Cooling 2465 3020 3900

PTC Power (W) -------- -------- -------COP for Heating (w/w) 4.42 4.40 4.44

(at 20 °C ambient air temperature)

Refrigerant R407C R407C R407C

Power Supply

Volt/Phase/Hz 230/1/50 230/1/50 230/1/50

Rated Current (A) -Heating 11.3 14.1 16.8

Cooling 10.9 13.4 17.3

-------- -------- ------

LRA (A) - (Max. Start-up AMPS) 32 36 40

Minimum Flow Rate m3/h (imp.gls) 2.5 (550 gls) 2.5 (550 gls) 2.5 (550 gls)

Maximum Flow Rate m3/h (imp.gls) 10.0 (2200 gls) 13.0 (2850 gls) 18.0 (3975 gls)

Noise Level (whole unit) at 3m <52 <54 <58

System

Compressor type ROTARY ROTARY SCROLL

Electric expansion valve Y Y Y

Features

Electronic Control Panel Y Y Y

Soft Touch Key Pads Y Y Y

LCD Display Y Y Y

Temperature Indicator(°C) 5~45 5~45 5~45

Drain Hose connection Y Y Y

Dimensions WxHxD (mm) 480×755×515 580×715×610 580×715×610

Net Weight (Kg) 65 74 98

Packing Dim. WxHxD (mm) 540×835×540 630×770×710 630×770×710

Gross Weight (Kg) 70 84 110

ALTO

Heat Pumps - SPECIFICATION

USEFUL CONVERSIONS

1,000 British Thermal Units (BTU)

10,000 BTU

1 UK Horsepower

= 0.293 kilowatt/hour

= 1 therm

= 0.7457 kilowatt

Cubic Yards to Cubic Metres

Cubic Metres to Cubic Yards

Cubic Metres to Gallons

Gallons to Cubic Metres

Gallons to Litres

Litres to Gallons

multiply by

multiply by

multiply by

divide by

multiply by

multiply by

0.764555

1.30795

220.717

220.717

4.546

0.22

POOL CAPACITY / VOLUME

To calculate pool capacity measure the

Length ‘L’ - Width ‘W’ - and average water depth ‘D’.

SQUARE OR RECTANGULAR POOLS

CAPACITY = L X W X D X 6.25 gallons (U.K)

ROUND OR OVAL POOLS

CAPACITY = DIA. X DIA. X DEPTH X 4.90 gallons

PUMP CONVERSION

Horse power to Watts x 746

Watts to Horse Power x 0.00134

AREA

Surface area of a Circle 3.14 x Radius(squared)

Perimeter of a circle 3.14 x Dia.

19

CELSIUS FAHRENHEIT

-40 deg. -40 deg.

-17.8 deg. 0 deg.

- 10 deg. 14 deg.

0 deg. 32 deg.

5 deg. 41 deg.

10 deg. 50 deg.

15 deg. 59 deg.

20 deg. 68 deg.

25 deg. 77 deg.

30 deg. 86 deg.

35 deg. 95 deg.

40 deg. 104 deg.

50 deg. 122 deg.

60 deg. 140 deg.

70 deg. 158 deg.

80 deg. 176 deg.

90 deg. 194 deg.

100 deg. 212 deg.

Loading...

Loading...