Page 1

OPERATION MANUAL

User Software Version 3.1.1A

AMAX 200 is a trademark of Sigma-Amelung GmbH

April 2001 A6846

Page 2

SIGMA DIAGNOSTICS INSTRUMENT WARRANTY

Sigma-Aldrich Co., Inc. ("Sigma"), warrants that instruments it sells to be free from

defects in workmanship and materials during normal use by the original purchaser.

This Warranty shall continue for a period of one year from the date of invoice to the

original purchaser, or until title is transferred from the original purchaser, whichever

occurs first (the "Warranty Period").

If any defects occur during the Warranty Period, contact the Sigma Service Center

immediately, and be prepared to furnish pertinent details concerning the defect, the

model number, and the serial number.

Warranty service is provided 8:30 a.m. through 5:00 p.m., Monday through Friday,

except on Sigma observed holidays. Any service performed at other times, and all

service required to correct defects or malfunctions not covered by this Warranty, will

be billed on a time-and-material basis at Sigma's labor rates then in effect.

This Warranty does not cover defects or malfunctions which: (1) are not reported to

Sigma during the Warranty Period and within one week of occurrence; (2) result from

chemical decomposition or corrosion; (3) are described in the applicable Sigma

Operation Guide; (4) result from maintenance, repair, or modification performed

without Sigma's prior written authorization; or (5) result from misuse, abuse or

accident.

Sigma's liability for all matters arising from the supply, installation, use, repair, and

maintenance of the instrument, whether arising under this Warranty or otherwise,

shall be limited solely to the repair or (at Sigma's sole discretion) replacement of the

instrument or of components thereof. In no event shall Sigma be liable for injuries

sustained by third parties, incidental or consequential damages, or lost profits.

Replaced parts shall become the property of Sigma.

THE FOREGOING IS THE SOLE WARRANTY MADE BY SIGMA REGARDING THE

INSTRUMENT, AND SIGMA SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY

AND OF FITNESS FOR A PARTICULAR PURPOSE.

2001 Sigma-Aldrich Co.

April 2001

Page 3

0

Table of Contents

1 INTRODUCTION .................................................................................................... 1-1

2 ORGANIZATION OF OPERATION MANUAL ............................................................. 2-1

2.1 PICTOGRAMS ..................................................................................................... 2-1

2.2 SECTION DESCRIPTION ..................................................................................... 2-2

3 SPECIFICATIONS.................................................................................................. 3-1

4 FEATURES............................................................................................................ 4-1

4.1 TEST PROGRAMMING ........................................................................................ 4-1

4.2 PROCESSING...................................................................................................... 4-1

4.3 DATA ARCHIVING............................................................................................... 4-1

4.4 MEASUREMENT MODES.................................................................................... 4-1

4.5 CALIBRATION ..................................................................................................... 4-2

4.6 SAMPLE HANDLING ........................................................................................... 4-2

4.7 REAGENT HANDLING......................................................................................... 4-2

4.8 PIPETTING SYSTEM............................................................................................ 4-3

4.9 TEMPERATURE CONTROL ................................................................................. 4-3

4.10 CUVETTE HANDLING ......................................................................................... 4-3

4.11 THROUGH-PUT................................................................................................... 4-3

4.12 QUALITY CONTROL ............................................................................................ 4-4

5 PHYSICAL DESCRIPTION ...................................................................................... 5-1

5.1 OVERVIEW ......................................................................................................... 5-1

5.2 CUVETTE STORAGE CHUTE .............................................................................. 5-1

5.3 INCUBATION RAIL AND PROBE WASH WELL ..................................................... 5-2

5.4 ROBOT ARM ....................................................................................................... 5-2

5.5 MEASURING WELLS........................................................................................... 5-3

5.6 REAGENT AND SAMPLE TRAY............................................................................ 5-3

5.7 SYRINGE ............................................................................................................ 5-4

5.8 BACK VIEW ........................................................................................................ 5-4

6 GENERAL SOFTWARE USE.................................................................................... 6-1

7 POWER ON ........................................................................................................... 7-1

7.1 AMAX 200 .......................................................................................................... 7-1

7.2 PERIPHERAL EQUIPMENT.................................................................................. 7-1

8 TRAFFIC SIGNAL LIGHTS AND STATUS INDICATOR BAR ...................................... 8-1

8.1 TRAFFIC LIGHTS ................................................................................................ 8-1

8.2 STATUS INDICATOR BAR ...................................................................................8-1

8.2.1 Operating Status .................................................................................... 8-1

8.2.2 Reagent Level Monitor ............................................................................ 8-1

8.2.3 Temperature Monitors ............................................................................ 8-2

8.2.4 Lamp Monitor......................................................................................... 8-2

8.2.5 Cuvette Box Monitor............................................................................... 8-2

8.2.6 Cuvette Tray Waste Monitor ................................................................... 8-2

April 2001 TOC 1

Page 4

0

Table of Contents

8.2.7 Fresh Water Input Monitor ..................................................................... 8-2

8.2.8 Waste Water Output Monitor .................................................................. 8-2

8.2.9 Test Group Selection .............................................................................. 8-2

8.2.10 Number of Files in Archive...................................................................... 8-2

8.2.11 File Format Date..................................................................................... 8-2

8.2.12 QC Status Monitor ................................................................................. 8-3

8.2.13 LIS Status Monitor .................................................................................8-3

9 OPERATION - QUICK-START ................................................................................. 9-1

9.1 ENTRY INTO QUICK-START ................................................................................ 9-1

9.2 INTRODUCTION TO QUICK-START DIALOG WINDOW........................................ 9-3

9.3 TEST GROUP SELECTION ..................................................................................9-3

9.4 ORDERING TESTS.............................................................................................. 9-4

9.5 REAGENT TRAY PREPARATION.......................................................................... 9-6

9.6 PRELIMINARY CHECKS ...................................................................................... 9-8

9.7 START PROCESSING .......................................................................................... 9-9

9.8 STOPPING OR ABORTING PROCESSING .......................................................... 9-10

9.9 VIEWING RESULTS .......................................................................................... 9-11

9.10 ADDING NEW SAMPLES................................................................................... 9-11

9.11 REPLENISHING REAGENTS.............................................................................. 9-13

9.12 REPEATING TESTS........................................................................................... 9-13

9.13 ADDING STAT SAMPLES .................................................................................. 9-14

9.13.1 Stat Sample Deletion ............................................................................ 9-15

9.14 PRINTING RESULTS ......................................................................................... 9-16

9.14.1 Routine samples ................................................................................... 9-17

9.14.2 Stat samples......................................................................................... 9-17

9.15 STARTING A NEW SAMPLE TRAY ..................................................................... 9-18

9.16 CHECKING QC RESULTS ................................................................................. 9-18

9.17 OPERATION AND MONITOR FUNCTIONS ......................................................... 9-18

9.17.1 Reagent Overview ................................................................................. 9-19

9.17.2 AMAX200 - Status................................................................................ 9-19

9.17.3 Prime.................................................................................................... 9-20

9.17.4 Wash .................................................................................................... 9-20

9.17.5 Test Groups.......................................................................................... 9-20

9.17.6 Check Reagent ..................................................................................... 9-20

9.17.7 Stop ..................................................................................................... 9-20

9.17.8 Abort .................................................................................................... 9-20

9.18 EXITING QUICK-START .................................................................................... 9-20

ABBREVIATED QUICK-START OPERATING PROCEDURE............................................ 9-22

10 OPERATION - NORMAL ........................................................................................10-1

10.1 REAGENT PREPARATION ................................................................................. 10-1

10.2 FRESH AND WASTE WATER CHECKS.............................................................. 10-3

10.3 CUVETTE PREPARATION.................................................................................. 10-4

10.4 FORMAT

10.5 SAMPLE IDENTIFICATION, POSITIONING AND TEST REQUISITIONING ........... 10-6

10.5.1 Keyboard Addition of New Patients ....................................................... 10-8

DATA FILES ....................................................................................... 10-6

April 2001 TOC 2

Page 5

0

Table of Contents

10.5.2 Keyboard Edit of Old Patients ............................................................. 10-10

10.5.3 Position Samples in Sample Tray........................................................ 10-11

10.6 START PROCESSING ...................................................................................... 10-11

10.6.1 Select Test Group ............................................................................... 10-12

10.6.2 Start................................................................................................... 10-12

10.7 PAUSE, STOP AND ABORT ............................................................................. 10-15

10.7.1 Pause ................................................................................................. 10-15

10.7.2 Stop ................................................................................................... 10-16

10.7.3 Abort .................................................................................................. 10-16

10.8 STAT TESTING................................................................................................ 10-16

10.8.1 Stat Requisitioning ............................................................................. 10-16

10.8.2 Viewing and Printing Stat Results....................................................... 10-17

10.8.3 Emptying Stat Positions and Transferring Sample to Archive.............. 10-17

10.9 OVERVIEW ..................................................................................................... 10-18

10.10 GRAPHIC MODE ............................................................................................. 10-18

10.11 REPEAT TESTING ........................................................................................... 10-18

10.12 PRINTOUT OF RESULTS ................................................................................. 10-19

10.13 EVALUATION OF QC RESULTS....................................................................... 10-20

10.14 PRINTOUT OF PATIENT REPORTS.................................................................. 10-21

10.15 ERRORS DURING PROCESSING: NON-FATAL ................................................ 10-21

10.16 ERRORS DURING PROCESSING: FATAL......................................................... 10-22

10.17 SHUTDOWN.................................................................................................... 10-23

11 MEASUREMENT PRINCIPLES ...............................................................................11-1

11.1 MECHANICAL MEASUREMENT (BALL METHOD) ............................................. 11-1

11.2 OPTICAL MEASUREMENT ................................................................................ 11-3

11.3 KINETIC OPTICAL MEASUREMENT (CHROMOGENIC)...................................... 11-5

12 MENUS OVERVIEW ..............................................................................................12-1

12.1 MAIN MENU...................................................................................................... 12-1

12.2 <ALT>-FUNCTION KEYS ................................................................................... 12-3

12.3 <CTRL-F1>-FUNCTION KEYS............................................................................ 12-5

12.4 DOS PARAMETERS........................................................................................... 12-5

12.5 MENUS OUTLINE ........................................................................................... 12-10

12.6 MENUS FLOWCHARTS ................................................................................... 12-14

13 OVERVIEW MENU ................................................................................................13-1

13.1 AMAX200.......................................................................................................... 13-1

13.2 REAGENT ......................................................................................................... 13-2

13.3 RESULTS .......................................................................................................... 13-3

13.4 SAMPLES.......................................................................................................... 13-4

14 SERVICE MENU ...................................................................................................14-1

14.1 PRIME .............................................................................................................. 14-1

14.2 WASH ............................................................................................................... 14-2

14.3 TRANSFER CUP................................................................................................ 14-2

April 2001 TOC 3

Page 6

0

Table of Contents

14.4 CHECK REAGENT ............................................................................................ 14-3

14.5 LAMP OFF/ON.................................................................................................. 14-3

14.6 CALIBRATE PHOTOMETER .............................................................................. 14-4

14.7 MOVE SYRINGE ............................................................................................... 14-4

14.8 CHECK VOLUMES ............................................................................................ 14-4

14.9 LOCK CHANNELS ............................................................................................. 14-4

14.10 MONITOR ......................................................................................................... 14-6

15 MEASURE MENU..................................................................................................15-1

15.1 TEST GROUPS .................................................................................................. 15-1

15.2 TRAYS .............................................................................................................. 15-2

15.2.1 Show .................................................................................................... 15-4

15.2.2 Delete ................................................................................................... 15-4

15.2.3 Load ..................................................................................................... 15-5

15.2.4 Load Auto............................................................................................. 15-6

15.3 ROBOT RIGHT .................................................................................................. 15-6

15.4 START............................................................................................................... 15-6

15.5 GRAPHIC ........................................................................................................ 15-12

15.6 PAUSE, STOP AND ABORT ............................................................................. 15-14

15.6.1 Pause ................................................................................................. 15-14

15.6.2 Stop ................................................................................................... 15-15

15.6.3 Abort .................................................................................................. 15-15

16 STAT MENU.........................................................................................................16-1

16.1 QUICK-START................................................................................................... 16-1

16.2 STAT POSITION 1 - 8 ........................................................................................ 16-1

16.2.1 Stat Requisitioning ............................................................................... 16-2

16.3 MONITORING AND PRINTING STAT RESULTS.................................................. 16-4

16.4 EMPTYING STAT POSITIONS AND TRANSFERRING DATA TO ARCHIVE........... 16-4

16.5 END.................................................................................................................. 16-5

17 PATIENTS MENU..................................................................................................17-1

17.1 NEW ................................................................................................................. 17-1

17.2 EDIT ................................................................................................................. 17-5

17.3 ADD.................................................................................................................. 17-7

17.4 REPEAT .......................................................................................................... 17-10

17.5 IMPORT .......................................................................................................... 17-12

17.6 EXPORT.......................................................................................................... 17-12

17.7 PATIENT LIST ................................................................................................. 17-13

17.8 RESULT LIST .................................................................................................. 17-13

17.9 RESULTS LIST ON-LINE ................................................................................. 17-15

17.10 REPORT.......................................................................................................... 17-15

18 SYSTEM MENU 1 .................................................................................................18-1

18.1 FORMAT DATA

18.2 SECURITY SYSTEMS: PASSWORD, SIGN ON, OR SET USER PIN ..................... 18-2

18.2.1 Password .............................................................................................. 18-3

FILES ....................................................................................... 18-1

April 2001 TOC 4

Page 7

0

Table of Contents

18.2.2 Sign ON................................................................................................ 18-4

18.2.3 Set User PIN ......................................................................................... 18-4

18.2.3.1 Add an Operator ................................................................... 18-5

18.2.3.2 Signing On ........................................................................... 18-6

18.2.3.3 Delete an Operator ............................................................... 18-7

18.2.3.4 To Edit PIN Information ........................................................ 18-7

18.2.3.5 Forgotten Password .............................................................. 18-8

18.3 DRIVE............................................................................................................... 18-8

18.4 OPTIONS .......................................................................................................... 18-9

18.5 HOST PARAMETERS....................................................................................... 18-11

18.6 LOCATION CODES ......................................................................................... 18-11

18.7 PANELS .......................................................................................................... 18-12

18.8 REPORT FORMAT ........................................................................................... 18-13

18.8.1 To Design the Report Format .............................................................. 18-13

18.8.2 Error Code Definition ......................................................................... 18-14

18.9 VERSION ........................................................................................................ 18-15

19 SYSTEM MENU 2 - PARAMETERS.........................................................................19-1

19.1 TEST GROUPS .................................................................................................. 19-2

19.1.1 To Define or Modify a Test Group ......................................................... 19-3

19.1.2 To Delete a Defined Test Group ............................................................ 19-5

19.2 TESTS............................................................................................................... 19-5

19.2.1 To Define a New Test ............................................................................19-6

19.2.1.1 Description ........................................................................... 19-7

19.2.1.2 Calibration ........................................................................... 19-7

19.2.1.3 Procedure ........................................................................... 19-10

19.2.1.4 Data reduction.................................................................... 19-11

19.2.1.5 Statistics ............................................................................ 19-12

19.2.2 Undo Test Parameter Definition .......................................................... 19-13

19.2.3 Exiting Test Parameter Definition ....................................................... 19-13

19.2.4 Saving Test Parameter Definition ........................................................ 19-13

19.2.5 Copy Test Parameter Definition from One Test to Another .................. 19-14

19.2.6 To Delete a Test from the Test List ...................................................... 19-14

19.2.7 Predilution Mode ................................................................................ 19-14

19.2.8 Derived Fibrinogen ............................................................................. 19-15

19.3 REAGENT LAYOUT ......................................................................................... 19-16

19.3.1 To Define or Modify a Reagent Layout ................................................. 19-17

19.3.2 To Delete a Previously Defined Layout ................................................ 19-18

19.4 REAGENT ....................................................................................................... 19-18

19.4.1 To Define a New Reagent or Modify a Previously Defined Reagent ....... 19-19

19.4.2 To Delete a Reagent ............................................................................ 19-20

19.5 LEVELS .......................................................................................................... 19-20

19.5.1 Diameter ............................................................................................ 19-21

19.5.2 Bottom Levels ..................................................................................... 19-22

19.5.3 Maximum Level .................................................................................. 19-23

19.5.4 Predilution Levels ............................................................................... 19-23

19.6 PUMP.............................................................................................................. 19-24

19.7 MEASURING MODE........................................................................................ 19-25

19.8 TEMPERATURE .............................................................................................. 19-28

April 2001 TOC 5

Page 8

0

Table of Contents

19.9 BACK UP ........................................................................................................ 19-29

19.10 RESTORE ....................................................................................................... 19-29

19.10.1 To Restore a Back Up File................................................................... 19-30

19.10.2 To Activate the Back Up Parameters ................................................... 19-31

20 QUALITY CONTROL MENU ...................................................................................20-1

20.1 QC SETUP ........................................................................................................ 20-4

20.1.1 Westgard Definitions ............................................................................ 20-4

20.1.1.1 Rule...................................................................................... 20-5

20.1.1.2 Enabled ................................................................................ 20-5

20.1.1.3 Alarm ................................................................................... 20-7

20.1.1.4 Option .................................................................................. 20-7

20.1.1.5 Flowchart of Information Transfer......................................... 20-9

20.1.2 Controls ............................................................................................. 20-10

20.1.2.1 Addition of a New Control ................................................... 20-10

20.1.2.2 To Modify a Previously Defined Control ............................... 20-13

20.1.2.3 To Delete a Control ............................................................. 20-15

20.1.2.4 Flowchart of Information Transfer....................................... 20-16

20.2 QC FILES........................................................................................................ 20-17

20.2.1 Create ................................................................................................ 20-17

20.2.1.1 On an Inactive Test............................................................. 20-18

20.2.1.2 On an Active Test ............................................................... 20-19

20.2.1.3 On an Undefined or Partially Defined Test .......................... 20-19

20.2.1.4 Reactivation of Previously Closed Files................................ 20-19

20.2.2 List..................................................................................................... 20-21

20.2.3 Export ................................................................................................ 20-22

20.2.4 Backup............................................................................................... 20-22

20.2.5 Restore ............................................................................................... 20-23

20.2.6 Delete ................................................................................................. 20-24

20.2.7 Flowchart of Information Transfer. ..................................................... 20-25

20.3 QC CHARTS.................................................................................................... 20-26

20.3.1 Thumbnail Charts .............................................................................. 20-27

20.3.2 Zoom Chart ........................................................................................ 20-29

20.3.2.1 Introduction ....................................................................... 20-29

20.3.2.2 Commands ......................................................................... 20-30

20.3.2.3 Mean30/Mean .................................................................... 20-33

20.3.2.4 Comment on a Data Point................................................... 20-33

20.3.2.5 Omit a Data Point. .............................................................. 20-34

20.3.2.6 Append a File...................................................................... 20-35

20.3.2.7 Change the Target Value..................................................... 20-36

20.3.2.8 New File.............................................................................. 20-36

20.3.3 Z-Score Distribution Chart ................................................................. 20-37

20.3.4 Print QC Report .................................................................................. 20-37

20.4 RULE SENSITIVITY SETTINGS........................................................................ 20-39

20.5 VIOLATION EXAMPLES .................................................................................. 20-41

20.6 DISTRIBUTION ............................................................................................... 20-45

20.6.1 Distribution Chart and Report ............................................................ 20-45

20.7 CALIBRATION CURVES .................................................................................. 20-46

20.8 REFERENCES................................................................................................. 20-47

April 2001 TOC 6

Page 9

0

Table of Contents

21 END MENU...........................................................................................................21-1

21.1 REMOVE STAT SAMPLES ................................................................................. 21-1

21.2 HOST STATUS .................................................................................................. 21-1

21.3 PRINTER BUFFER ............................................................................................ 21-2

21.4 DOS SCREEN ................................................................................................... 21-2

22 CALIBRATION......................................................................................................21-1

22.1 AUTOMATIC DILUTION..................................................................................... 22-1

22.2 MANUAL DILUTION .......................................................................................... 22-5

22.3 SINGLE-POINT CALIBRATION........................................................................... 22-6

22.4 DERIVED FIBRINOGEN .................................................................................... 22-6

23 MAINTENANCE ....................................................................................................23-1

23.1 SERVICE OUTLINE ........................................................................................... 23-1

23.2 DAILY MAINTENANCE ...................................................................................... 23-3

23.2.1 Clean Probe Exterior............................................................................. 23-3

23.2.2 Fresh Water Check ............................................................................... 23-3

23.2.3 Waste Fluid Disposal............................................................................ 23-4

23.2.4 System Wash........................................................................................ 23-4

23.2.5 Hydraulic System Leak Check .............................................................. 23-5

23.2.6 Used Cuvette Disposal .......................................................................... 23-5

23.2.7 Cuvette Cassette Disposal Area Check .................................................. 23-5

23.2.8 General Housekeeping.......................................................................... 23-6

23.3 WEEKLY MAINTENANCE .................................................................................. 23-7

23.3.1 Hydraulic System Cleaning................................................................... 23-7

23.3.2 Dust Filter Cleaning ............................................................................. 23-8

23.3.3 Incubation Rail and Wash/Rinse Well Cleaning .................................... 23-8

23.3.3 Coolant Level Check ............................................................................. 23-9

23.4 MONTHLY MAINTENANCE.............................................................................. 23-10

23.4.1 Syringe Cleaning ................................................................................ 23-10

23.4.2 Cleaning of Photometric Measuring Wells ........................................... 23-10

23.5 MISCELLANEOUS UNSCHEDULED MAINTENANCE ....................................... 23-11

23.5.1 Photometer Calibration....................................................................... 23-11

23.5.2 Volume Check .................................................................................... 23-13

23.6 REPLACEMENT PROCEDURES ...................................................................... 23-14

23.6.1 Photometer Lamp ............................................................................... 23-14

23.6.2 Syringe/Plunger Assembly.................................................................. 23-15

23.6.3 Syringe Plunger Tip and O-Ring.......................................................... 23-15

23.6.4 Tubing................................................................................................ 23-16

24 QUALITY ASSURANCE..........................................................................................24-1

24.1 PATIENT SAMPLE ............................................................................................. 24-1

24.2 REAGENTS ....................................................................................................... 24-1

24.3 INSTRUMENT MECHANICS ..............................................................................24-1

24.4 TEST PARAMETERS ......................................................................................... 24-2

24.5 MEASUREMENT ANALYSIS ..............................................................................24-2

24.6 RESULTS .......................................................................................................... 24-2

April 2001 TOC 7

Page 10

0

Table of Contents

25 TROUBLESHOOTING............................................................................................25-1

25.1 NON-FATAL ERRORS........................................................................................ 25-1

25.2 FATAL ERRORS ................................................................................................ 25-1

25.3 GENERAL TROUBLESHOOTING ....................................................................... 25-3

26 INSTALLATION ....................................................................................................26-1

26.1 INSTALLATION.................................................................................................. 26-1

26.2 LOCATION REQUIREMENTS............................................................................. 26-1

26.3 ELECTRICAL REQUIREMENTS AND PRECAUTIONS......................................... 26-1

26.4 REMOVAL OF SHIPPING SAFETY CLAMPS ....................................................... 26-2

26.5 FRESH WATER AND DRAIN CONNECTIONS..................................................... 26-2

26.6 POWER ON ....................................................................................................... 26-2

27 INTERFACE SPECIFICATIONS ..............................................................................27-1

27.1 MODES............................................................................................................. 27-1

27.2 BI-DIRECTIONAL INTERFACE DESCRIPTION ................................................... 27-1

27.3 PROTOCOL ....................................................................................................... 27-3

27.3.1 MASTER to SLAVE ............................................................................... 27-3

27.3.2 SLAVE to MASTER ............................................................................... 27-4

27.4 COMMAND CHARACTERS AND SYMBOLS ....................................................... 27-5

27.5 TIMEOUT.......................................................................................................... 27-5

27.6 REPEAT AFTER <NACK>................................................................................... 27-5

27.7 EXAMPLES (AMAX AS MASTER) ....................................................................... 27-6

27.8 EXAMPLE OF HEADER AND TEST ORDER..................................................... 27-10

April 2001 TOC 8

Page 11

1

Introduction

1 INTRODUCTION

1 INTRODUCTION .................................................................................................... 1-1

April 2001 1-0

Page 12

Page 13

1

Introduction

The AMAX 200 is an automated random access multi-purpose analyzer. The

AMAX 200 may be used as a coagulation analyzer for the detection of fibrin formation

utilizing either mechanical principles (ball method) or photo-optical principles.

Such tests include prothrombin time (PT), activated partial thromboplastin time

(APTT), fibrinogen concentration, thrombin time (TT), functional factor assays and

other clotting tests ending with fibrin formation. In addition, the AMAX 200 may be

used for chromogenic kinetic enzyme analysis (405nm). Such tests include

antithrombin (AT), protein C, protein S, antiplasmin, heparin, plasminogen, PAI-1, tPA

and other assays utilizing an indicator molecule detected at 405 nm. Measurement

may be qualitative or quantitative. When used in conjunction with appropriate

reagents, the sample may be plasma, serum or whole blood.

The AMAX 200 is PC controlled. To provide optimum performance and maximum

versatility, the operating parameters for each test are individually programmed.

Patient samples are identified by the commander PC and registered in a patient file.

With the use of the on-board barcode reader, patient identification is positive. Patient

demographic and result information is archived for subsequent retrieval. Both the

results and the correlated calculations are stored in the patient file. Information may

be transferred to and from a host computer through a bi-directional interface.

The sample storage area is cooled to approximately 15°C. which minimizes sample

deterioration and prevents spontaneous cold activation that may occur at colder

temperatures. Sampling may be from primary tubes or secondary transfer tubes.

Sample and reagent are added using a temperature-controlled probe. All incubation

times are programmable. The programmed volume of reagent is added at the

programmed time. With addition of the start reagent, either the elapsed time or

absorbency is measured.

The measured results are calculated into concentration or activity units with the use of

stored calibration curves.

On-line, real-time statistical analysis and evaluation of QC data assists in determining

if results are valid and patient results may be reported.

Waste disposal is automatic with minimal operator contact with potentially

biohazardous materials.

April 2001 1-1

Page 14

3

Specifications

1 SPECIFICATIONS

3 SPECIFICATIONS.................................................................................................. 3-1

April 2001 3-0

Page 15

Page 16

Specifications

AMAX 200 Dimensions

•

Height 25 inches (64 cm)

•

Width 32¾ inches (83 cm)

•

Depth 28¾ inches (73 cm)

Keyboard

•

Height ca. 1¼ inches (3 cm)

•

Width ca. 11 inches (28 cm)

•

Depth ca. 5¼ inches (13 cm)

Printer

•

Height ca. 10 inches (25 cm)

•

Width ca. 13¾ inches (34 cm)

•

Depth ca. 22 inches (55 cm)

Optional Base Unit Dimensions

•

Height 28¼ inches (71 cm)

•

Width 32¾ inches (82 cm)

•

Depth 27¾ inches (69 cm)

3

Weight

•

AMAX 200 286 pounds (130 kg)

•

Base Unit 165 pounds (75 kg)

Electrical

•

Voltage 90 - 132 VAC; 60 Hz

180 - 265 VAC; 50 Hz

•

Power Consumption 600 VA

•

Fuse Requirements 5A (t) 6.3x32 and 10A (t) 6.3x32

Room Temperature Requirements

•

Maximum Operating Temperature 90°F (32°C)

•

Compensation Required 2047 BT

April 2001 3-1

Page 17

4

Features

4 FEATURES............................................................................................................ 4-1

4.1 TEST PROGRAMMING ........................................................................................ 4-1

4.2 PROCESSING...................................................................................................... 4-1

4.3 DATA ARCHIVING............................................................................................... 4-1

4.4 MEASUREMENT MODES.................................................................................... 4-1

4.5 CALIBRATION ..................................................................................................... 4-2

4.6 SAMPLE HANDLING ........................................................................................... 4-2

4.7 REAGENT HANDLING ......................................................................................... 4-2

4.8 PIPETTING SYSTEM............................................................................................ 4-3

4.9 TEMPERATURE CONTROL ................................................................................. 4-3

4.10 CUVETTE HANDLING ......................................................................................... 4-3

4.11 THROUGH-PUT................................................................................................... 4-3

4.12 QUALITY CONTROL ............................................................................................ 4-4

April 2001 4-0

Page 18

Page 19

Features

4.1 Test Programming

•

Up to 32 tests may be programmed at one time

•

All sample and reagent volumes, incubation times, reagent addition times and

measurement times are programmable to provide maximum flexibility and optimum

test performance

4.2 Processing

•

Random access; multi-tasking

•

Process mechanical, optical and chromogenic tests simultaneously

•

Choice of two operating modes: normal and quick-start

•

Normal mode: up to 12 tests processed simultaneously using multiple screens to

provide for maximum operating flexibility

•

Quick start: up to 8 tests processed simultaneously with all operations performed

using one screen

4.3 Data Archiving

4

•

Up to 1,020 patients may be archived on commander PC hard drive

•

Optional storage of patient data archive on floppy discs

•

Patient demographic, value results and correlating calculation information is stored

in the archive. With graphic mode on, graphic representation of each reaction is

also stored in the archive

4.4 Measurement Modes

•

Photo-optical/chromogenic: 4 channels, 405 nm

•

Mechanical: 4 channels

•

Minimum reaction volume, mechanical: 75 µL

•

Minimum reaction volume, optical/chromogenic: 150 µL

•

Maximum reaction volume, all modes: 600 µL

•

Programmable mechanical impulse mode minimizes break-up of fragile fibrin clots

•

Simultaneous mechanical, photo-optical and chromogenic analysis

•

Real-time graphic reaction display for optical and chromogenic kinetic analyses

•

28 clotting measuring modes; 16 chromogenic measuring modes

•

Monitor available to observe the performance of individual measuring wells

•

Channel locking to remove selected measuring wells from service facilitates

troubleshooting and minimizes downtime by enabling continuation of processing in

the event of isolated channel component failure

April 2001 4-1

Page 20

4

Features

4.5 Calibration

•

1 to 8 calibration curve points

•

Automatic dilution at any desired dilution from 1:1 to approximately 1:14,000

•

Calculation and display of correlation coefficient for each curve

•

Dilution of calibration reference material either automatically or with previously

prepared dilutions

•

Choice of 10 curve calculation types

•

Graphic display of calibration curve for easy visual evaluation

•

Ability to recalculate curve data using multiple curve calculation types

4.6 Sample Handling

Cooled (15 ± 3°C) sample storage area with 60 position continuous-addition sample

•

tray

•

Up to 8 samples at one time may be processed as Stats

•

Up to 17 sample trays with up to 60 samples each may be prepared for processing

(1,020 samples) in a file format period

•

5 µL minimum sample volume

•

Choice of duplicate or single sampling for each test within a test group

•

Automatic sample predilution at any desired dilution from 1:1 to 1:100

•

Automatic dilution to either a higher or lower dilution when result exceeds

calibration curve limits

•

Automatic repeat at a programmable extended time interval for samples failing to

clot within the specified measurement time

•

Integrated bar code scanner provides capability for positive patient ID

•

Optional off-line bar code scanner provides capability for alternative patient ID

entry

4.7 Reagent Handling

•

Cooled (15 ± 3°C) reagent storage area with 24 position reagent tray; 16 used only

for reagent storage, 8 used for either reagent storage or as Stat sample positions

•

3 stir-bar positions

•

Up to 50 reagents may be defined

•

Operator notification of expired reagents

•

Up to 5 reagents may be programmed for each test

•

Up to 12 different reagent tray layouts may be programmed

•

Minimum reagent levels required prior to and during processing are programmable;

reagent levels are continuously monitored and may be refilled with no processing

interruption; audible alarm notifies operator of low reagent volume condition

•

Reagent container dead volume dependent on container size and on the

programmed bottom level sense

•

No tubing; direct probe reagent aspiration results in no reagent waste and minimal

daily maintenance

4-2 April 2001

Page 21

Features

4.8 Pipetting System

•

Samples and reagents are transferred to the reaction cuvette with a temperaturecontrolled probe (37 ± 0.5°C)

•

Liquid level sensor for both sample and reagent

•

Bottom level sensing programmable to any depth for both sample and reagent

positions

•

Cleaning of probe programmable for each reagent

4.9 Temperature Control

•

Reagent/Sample trays: 15 ± 3°C

•

Incubation rail: 37 ± 0.5°C

•

Probe: 37 ± 0.5°C

•

Optical measuring wells: 37 ± 0.5°C

•

Mechanical measuring wells: 37 ± 0.5°C

•

Continuous monitoring and display of temperatures

•

Temperature warning and stop limits are programmable. Audible alarm and

flashing display when temperature is out of the warning limit range. Program stop

if temperature condition is out of the stop limit range and is not corrected within a

specified time period

4

4.10 Cuvette Handling

•

450 on-board cuvette capacity with continuous refill without processing

interruption

•

Automatic disposal of cuvettes through measuring wells at completion of

measurement timing

•

Maximum cuvette utilization

4.11 Through-Put

•

Variable; dependent on test combination, programming and sample conditions

•

Typical through-put:

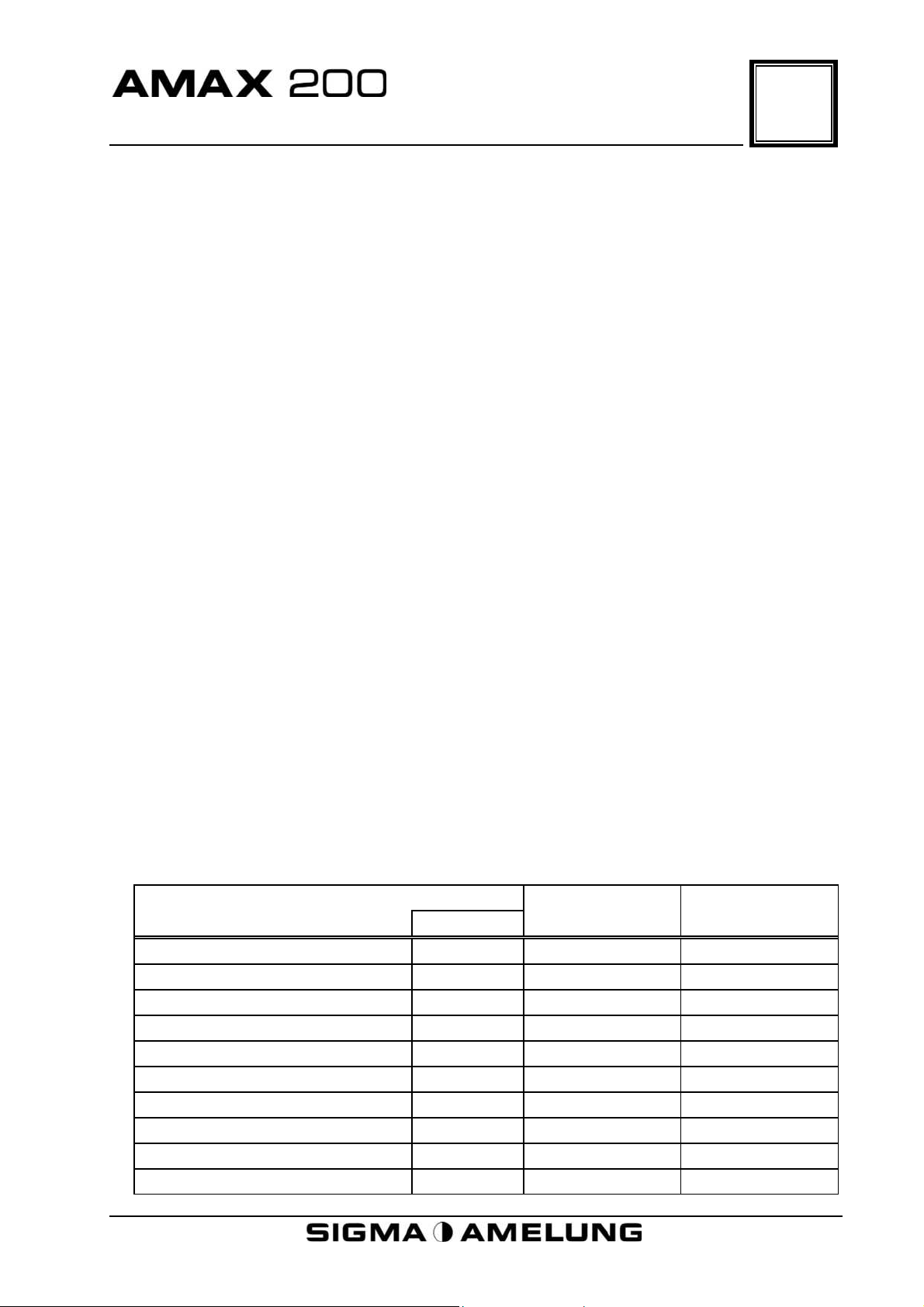

Tests/Hour Single Duplicate

PT-Mechanical (Pipette mode 0) 180 180 90

PT-Mechanical (Pipette mode 2) 240 240 120

PT-Optical (Pipette mode 0) 190 190 95

PT-Optical, Derived Fibrinogen 120 120 60

APTT-Mechanical or Optical 110 110 55

Fibrinogen 115 115 57

AT 80 80 40

Factor Assay 120 120 60

PT-Mechanical/APTT 120 60 30

PT-Mechanical/APTT/AT 90 30 15

Patients/Hour Patients/Hour

April 2001 4-3

Page 22

4

Features

4.12 Quality Control

•

Unlimited number of control files

•

1000 result positions per control level file

•

Levey-Jennings-like graphic representation of up to 1000 results on each control

for each test programmed

•

Zoom chart feature to view specific details including historical rule violations and

operator-entered comments; each data point has associated result, date measured,

time measured, operator logged on when result processed, Westgard rule

evaluation and audit trail for point omission information available

•

Any data point may be omitted after user ID and comment are entered

•

Optional user ID system with four authorization levels available

•

Multiple breakdown (last 30 results, all results, all results up to cursor position) of

statistical data

•

Laboratory defined operator alert conditions with QC error

•

Real-time performance monitor

•

Westgard Rules or other laboratory definable result criteria evaluation

•

Optional processing stop in event of a QC error

•

QC File backup and restore functions available

4-4 April 2001

Page 23

5

Physical Description

1 PH

YSICAL DESCRIPTION

2 PH

YSICAL DESCRIPTION

5 PHYSICAL DESCRIPTION ...................................................................................... 5-1

5.1 OVERVIEW ......................................................................................................... 5-1

5.2 CUVETTE STORAGE CHUTE .............................................................................. 5-1

5.3 INCUBATION RAIL AND PROBE WASH WELL ..................................................... 5-2

5.4 ROBOT ARM ....................................................................................................... 5-2

5.5 MEASURING WELLS........................................................................................... 5-3

5.6 REAGENT AND SAMPLE TRAY............................................................................ 5-3

5.7 SYRINGE ............................................................................................................ 5-4

5.8 BACK VIEW ........................................................................................................ 5-4

April 2001 5-0

Page 24

Page 25

Physical Description

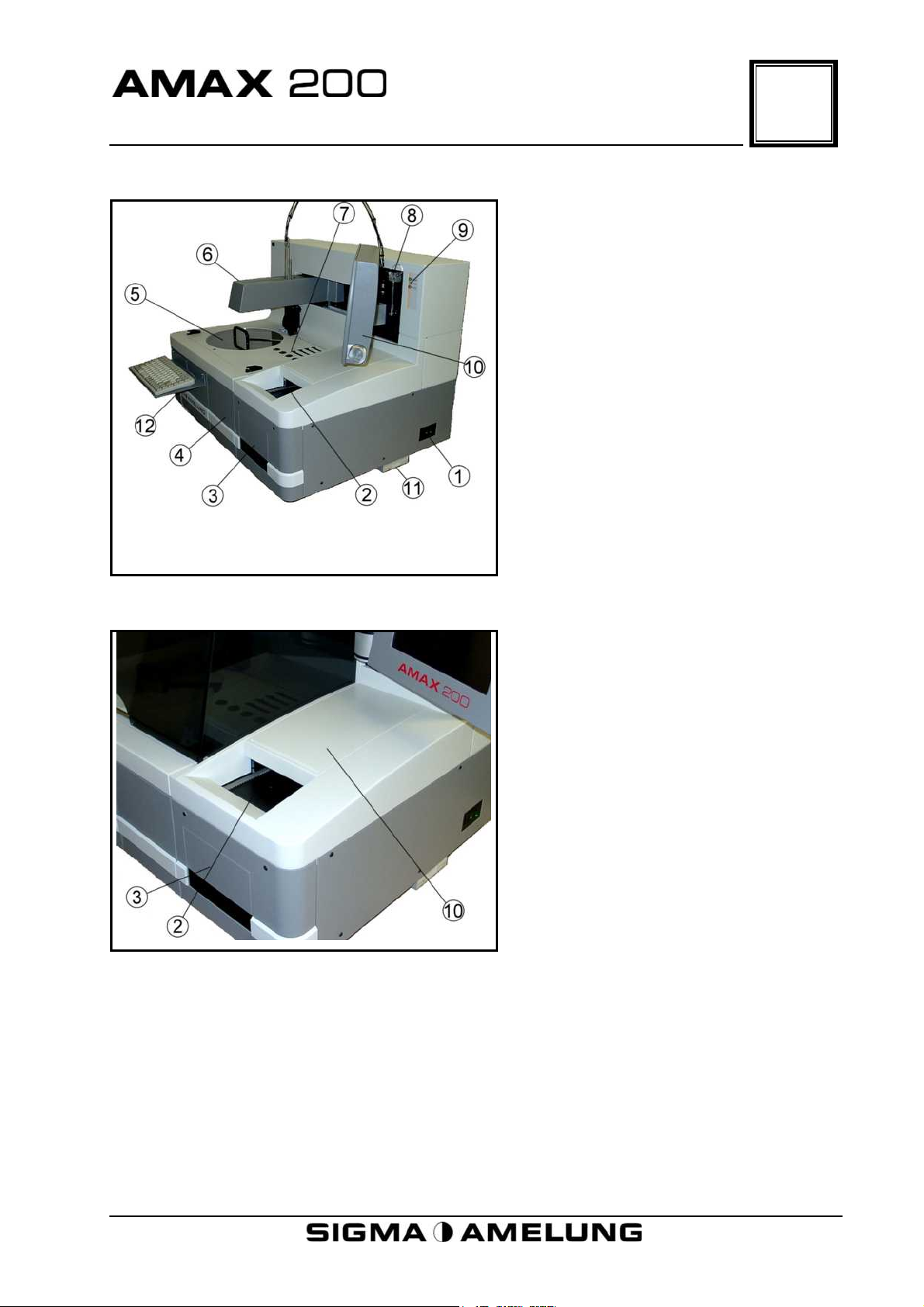

5.1 Overview

1. Power Switch

2. Cuvette Storage Chute

3. Empty Cuvette Box Disposal

Area

4. Cuvette Waste Drawer

5. Reagent/Sample Tray Area

6. Robot Arm

7. Measuring Wells

8. Syringe

9. Status Signal Lamps

10. Monitor

11. Floppy Drive

5

12. Keyboard Tray

5.2 Cuvette Storage Chute

2. Cuvette Chute, Loading Area For

New Cuvette Boxes

3. Empty Cuvette Boxes Disposal

Area

10. Cuvette Storage Chute Cover

April 2001 5-1

Page 26

5

Physical Description

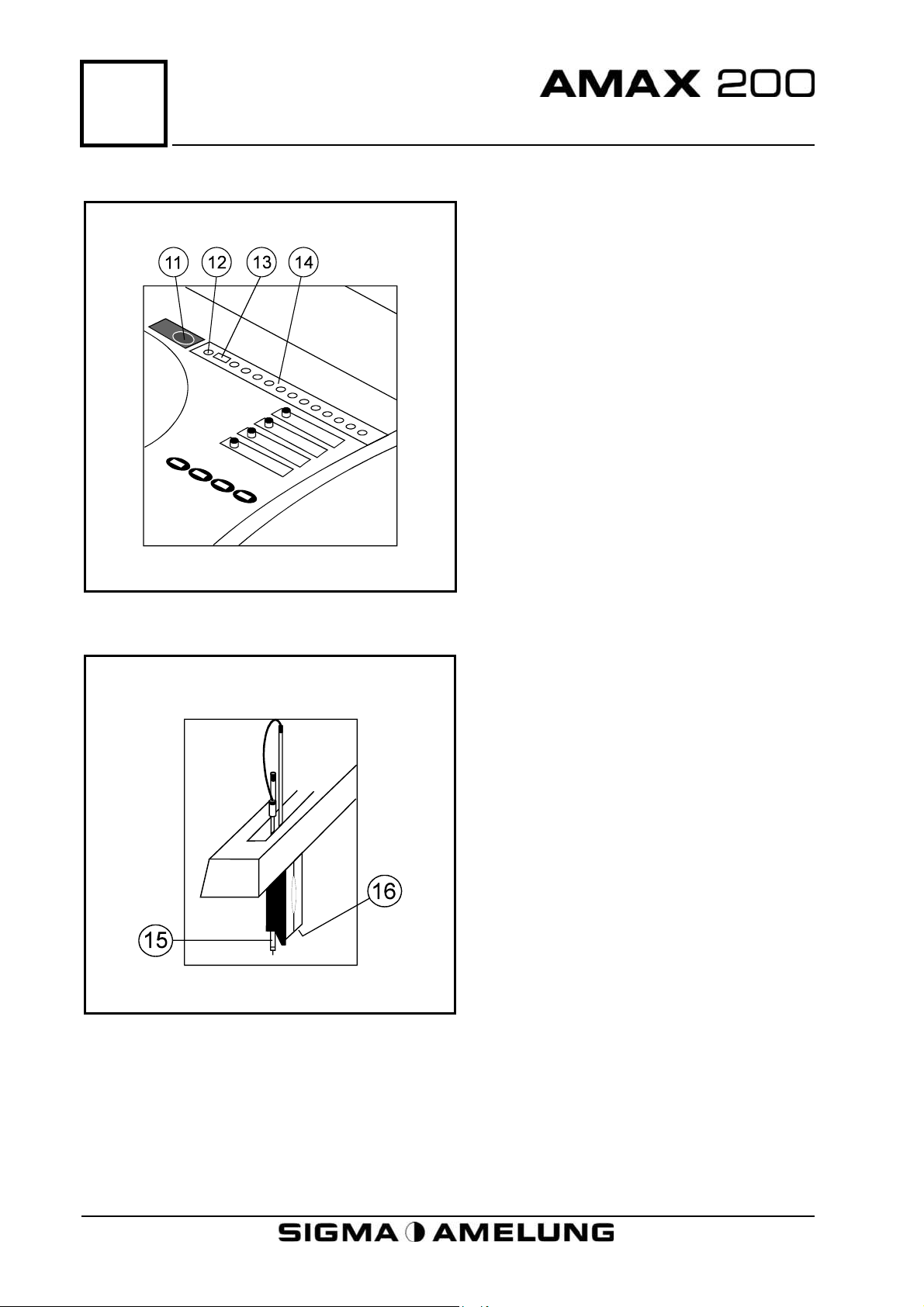

5.3 Incubation Rail and Probe Wash Well

11. Container For Decontaminating

Solution

12. Probe Wash Well

13. Cuvette Transfer Position

14. Incubation Rail

5.4 Robot Arm

15. Temperature Controlled Probe

16. Cuvette Removal and Transfer

Mechanism

5-2 April 2001

Page 27

Physical Description

5.5 Measuring Wells

5.6 Reagent and Sample Tray

5

17. Mechanical Measuring Wells

18. Cover Knob

19. Optical Measuring Wells

20. Cover

21. Sample Tray

22. Reagent Tray

23. Reagent/Sample Tray Well

April 2001 5-3

Page 28

5

Physical Description

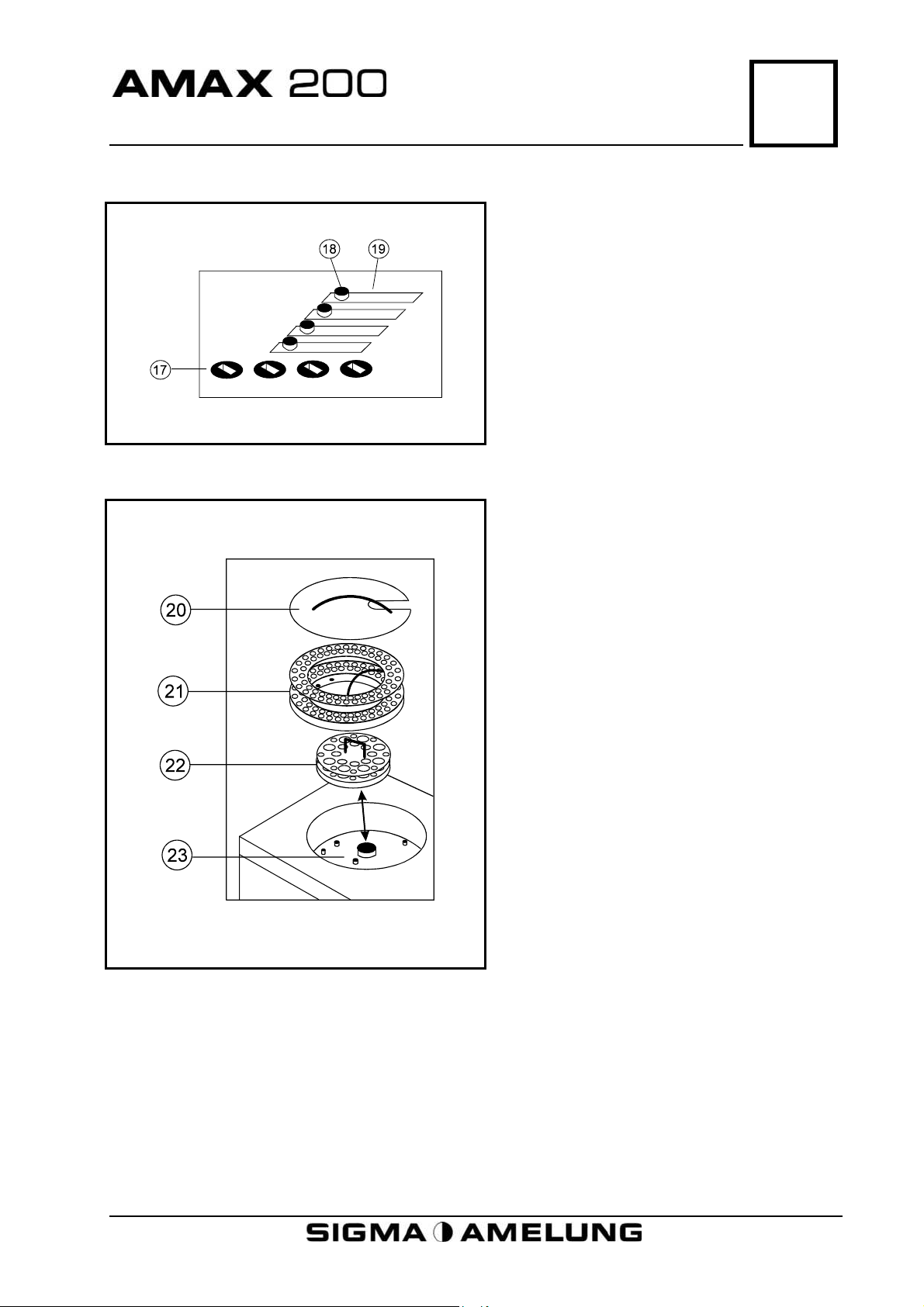

5.7 Syringe

27

28

27. Valve

28. Syringe

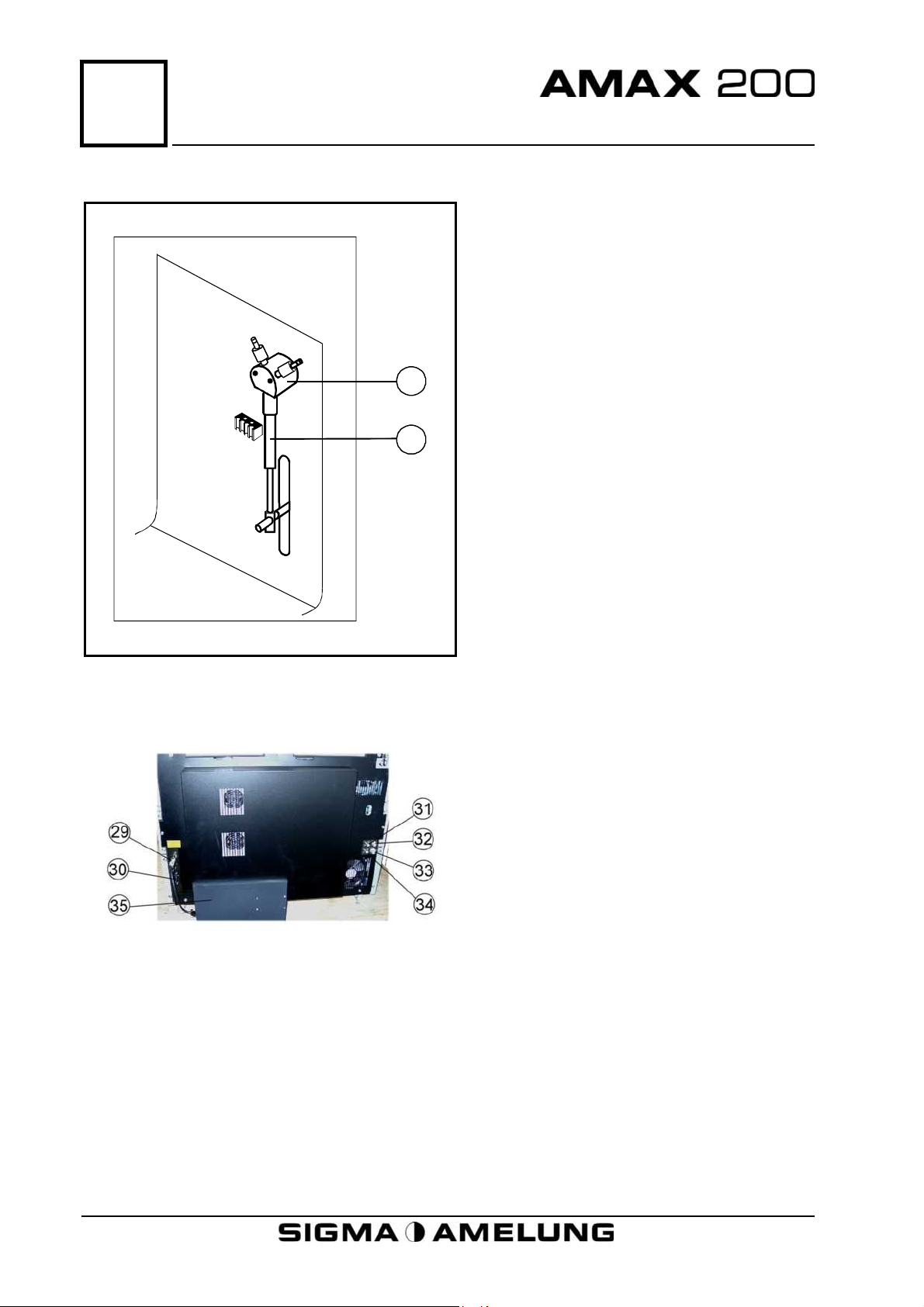

5.8 Back View

29. PC Computer Socket

30. Power Socket

31. Fresh Water Level Sensor

Connector

32. Fresh Water Inlet Connector

33. Drain Outlet

34. Drain Level Sensor Connector

35. Internal PC

5-4 April 2001

Page 29

6

General Software Use

1 GENERAL SOFTWARE USE

6 GENERAL SOFTWARE USE.................................................................................... 6-1

April 2001 6-0

Page 30

Page 31

6

General Software Use

Unless otherwise specified, all user interface instructions and screen descriptions are

for AMAX software version 3.1.1A.

Instructions are presented using conventional software terms. “Type” means use the

keyboard to type in information. “Press” means press the specified key.

Execution actions are in bold and enclosed by < >. For example: When the operator

action required is to press the “Enter” Key, the action is represented as <Enter>.

If simultaneous depression of two keys is required, both keys will be indicated,

separated by a hyphen and enclosed by < >. For example: When the operator action

required is to press both the “Alt” Key and the “F2” Key, the action is represented as

<Alt-F2>.

Menus and submenus may be selected either by moving the <Cursor Keys> to the

desired menu/submenu followed by <Enter> or by pressing the color-coded letter of

the desired menu/submenu.

Move through dialog windows using the <Cursor Keys>. Make appropriate entries

utilizing either the keyboard or <Function Keys>. Help information for the dialog

window appears in the first line at the top of the screen. Active <Function Keys> for

that dialog window are indicated in the second line on the screen. How to exit from the

screen is displayed at the bottom of the dialog window.

Most dialog windows are presented as examples. Because the display of the various

windows is conditional on events, the exact sequencing of window displays may vary.

When the AMAX 200

inactivity. Press any key to return to the menu screen.

When the AMAX 200 is in “Busy” mode, an audible alarm will alert the operator to

situations that may require operator attention or to instrument malfunctions. Pressing

<Alt-F2> will silence the alarm.

is in “Ready” mode, a screen saver will activate after 5 minutes of

April 2001 6-1

Page 32

7

Power On

1 POWER ON

7 POWER ON ........................................................................................................... 7-1

7.1 AMAX 200 .......................................................................................................... 7-1

7.2 PERIPHERAL EQUIPMENT.................................................................................. 7-1

April 2001 7-0

Page 33

Page 34

7

Power On

7.1 AMAX 200

Power up the AMAX 200 by pressing the power supply switch from OFF to ON.

The switch is located on the lower back corner of the right side of the instrument.

The switch lights up green when power to the instrument is ON.

Do not switch OFF and ON rapidly. Wait 10–15

seconds after switching OFF before switching ON.

At power ON, the robot arm and the Reagent/Sample Trays (if positioned in the well)

move to the home position.

7.2 Peripheral Equipment

Two minutes after the AMAX 200 is powered ON, the PC components may be turned

ON. Switch printer, monitor and PC to ON.

WARNING!

The Main Menu of the AMAX 200 Operating Program will be displayed on the monitor

screen.

The PC and other peripheral equipment are considered to be an integral part of the

AMAX 200 and are dedicated to the operation of the system. The addition of any other

software programs (including screen savers) will seriously compromise the operation

and reliability of the AMAX 200.

WARNING!

Under no circumstances should any software other than

that authorized by Sigma-Amelung GmbH be installed

n the PC provided for operation of the AMAX 200.o

April 2001 7-1

Page 35

8

Traffic Signal Lights and Status Indicator Bar

1 US INDICATOR BAR

8. TRAFFIC SIGNAL LIGHTS AND STATUS INDICATOR BAR ...................................... 8-1

8.1 TRAFFIC LIGHTS ................................................................................................ 8-1

8.2 STATUS INDICATOR BAR ...................................................................................8-1

8.2.1 Operating Status .................................................................................... 8-1

8.2.2 Reagent Level Monitor ............................................................................ 8-1

8.2.3 Temperature Monitors ............................................................................ 8-2

8.2.4 Lamp Monitor......................................................................................... 8-2

8.2.5 Cuvette Box Monitor............................................................................... 8-2

8.2.6 Cuvette Tray Waste Monitor ................................................................... 8-2

8.2.7 Fresh Water Input Monitor ..................................................................... 8-2

8.2.8 Waste Water Output Monitor .................................................................. 8-2

8.2.9 Test Group Selection .............................................................................. 8-2

8.2.10 Number of Files in Archive...................................................................... 8-2

8.2.11 File Format Date..................................................................................... 8-2

8.2.12 QC Status Monitor ................................................................................. 8-3

8.2.13 LIS Status Monitor ................................................................................. 8-3

April 2001 8-0

Page 36

Page 37

8

Traffic Signal Lights and Status Indicator Bar

8.1 Traffic Lights

The signal lights are located on the upper right-hand corner of the front panel. The

status of the instrument may be observed from a distance by the following light

patterns:

1. No lighted areas indicate that the instrument is not processing and there are no

error area conditions.

2. Green area lit (Go light) indicates that the instrument is processing and there are

no error conditions.

3. Yellow area lit (Caution light) indicates that a condition requiring operator attention

exists. Condition at this point in time is not of sufficient gravity to stop processing.

Error condition will be displayed in a red field in the status area at the bottom of

the main menu.

4. Red area lit (Stop light) indicates that a serious unrecoverable error condition has

been detected. If processing, the run has been aborted. Follow directions displayed

in red at the top of the monitor screen.

5. Sequential flashing lights indicate that a serious error has occurred and the

instrument is undergoing automatic reset. Processing has stopped.

8.2 Status Indicator Bar

The status of all the critical operating modules is indicated in the “Status Bar” located

across the bottom of the Main Menu screen.

Reagent

Operating

Status

8.2.1 Operating Status

The left-hand side of the status bar at the bottom of the Main Menu screen displays

the operating status. It provides information as to whether the instrument is ready

to operate, is busy, or is waiting for an incubation to end. A black "Ready" is

displayed when no error conditions exist and the instrument is available to begin

processing. A red "Ready" indicates an error condition that needs operator attention

before beginning processing. During processing, the area will be green when there

are no error conditions on the sample currently being processed. The area will be

red when an error condition on the sample has occurred (i.e., duplicate, no sample,

timeout exceeded). The area will revert to green when measuring on the next

sample begins. When "Wait" is displayed, a sample is incubating prior to

measurement and no other tasks are imminent.

Levels

Reagent

Tray

ºC

Incubation

Rail ºC

Probe

ºC

Lamp Status Cuvette

Boxes

Optical

Meas.

ºC

Mech.

Meas.

ºC

Cuvette

Waste

Fresh

Water

Waste

Water

Current Test

Group

Number

of files

in

Archive

File

format

date

QC

Status

LIS

Status

8.2.2 Reagent Level Monitor

Red with flashing “Chk. Reagent” when reagent is below the programmed minimum

volume level. Area is empty when reagent levels are OK or have not been checked.

April 2001 8-1

Page 38

8

Traffic Signal Lights and Status Indicator Bar

8.2.3 Temperature Monitors

The temperatures of five critical areas are constantly monitored. These areas are (1)

Sample/Reagent area; (2) Incubation Rail; (3) Probe; (4) Optical Measuring Wells;

and, (5) Mechanical Measuring Wells. The temperature area will be red with

flashing numbers if the indicated temperature is outside of set limits. When

temperatures are within the set limits, the numbers are displayed in black.

8.2.4 Lamp Monitor

The lamp status monitor indicates whether the lamp is ON or OFF. It will be a red

“Wait” until the operational voltage output is reached. It will be a red field with

flashing “Lamp error” if the lamp is burned out or otherwise inoperable. The area

will be blank if all optical wells have been locked out.

8.2.5 Cuvette Box Monitor

A minimum of two cuvette boxes must always be present. When at least two boxes

are in the cuvette chute, the field will display black “OK”. The field will be red with

flashing “Cups” if fewer than two boxes are present.

8.2.6 Cuvette Tray Waste Monitor

The cuvette boxes fall to the bottom of the chute area and are either removed from

the chute manually or allowed to fall through a disposal opening into a waste

container. When there are no more than two empty boxes in the chute area in front

of the disposal opening, the monitor area will display as black “OK”. When there are

more than two boxes in the disposal area, the area will display as red with flashing

yellow “Tray waste”.

8.2.7 Fresh Water Input Monitor

When the input supply water level is adequate, the area will display as black “OK”.

When input water is below sensor level, the area will display as red with flashing

“Empty”.

8.2.8 Waste Water Output Monitor

When waste water in the output water container is below sensor level, the area will

display as black “OK”. When the waste water is above the sensor level, the area will

display as red with flashing “Full”.

8.2.9 Test Group Selection

Displays the currently selected test group. If no group is currently selected, the

area is blank.

8.2.10 Number of Files in Archive

Displays the number of files stored in the patient archive since the last file format.

8.2.11 File Format Date

Displays the date the patient archive was formatted.

8-2 April 2001

Page 39

Traffic Signal Lights and Status Indicator Bar

8.2.12 QC Status Monitor

When QC evaluation rules are enabled, the results of samples identified as QC

material are monitored as the results are completed. When no rule violation has

occurred, the area will display black “QcOK”. When a rule has been violated, the

area displays as red with flashing “QcErr”.

8.2.13 LIS Status Monitor

Displays the status of the current transmission to the host interface.

Display Description

Lis – black on white Last transmission successful; all OK

Lis – black on red Error in last transmission

Exp – yellow flashing on white Data is being transmitted to host

Exp – yellow flashing on red

Imp – yellow flashing on white Data is being received from host

Imp – yellow flashing on red Data is being received after a previous error

Data is being transmitted after previous

error

8

April 2001 8-3

Page 40

9

Operation – Quick-Start

1 OPERATION – QUICK-START

9 OPERATION - QUICK-START ................................................................................. 9-1

9.1 ENTRY INTO QUICK-START ................................................................................ 9-1

9.2 INTRODUCTION TO QUICK-START DIALOG WINDOW........................................ 9-3

9.3 TEST GROUP SELECTION .................................................................................. 9-3

9.4 ORDERING TESTS.............................................................................................. 9-4

9.5 REAGENT TRAY PREPARATION .......................................................................... 9-6

9.6 PRELIMINARY CHECKS ...................................................................................... 9-8

9.7 START PROCESSING .......................................................................................... 9-9

9.8 STOPPING OR ABORTING PROCESSING .......................................................... 9-10

9.9 VIEWING RESULTS .......................................................................................... 9-11

9.10 ADDING NEW SAMPLES ................................................................................... 9-11

9.11 REPLENISHING REAGENTS.............................................................................. 9-13

9.12 REPEATING TESTS ........................................................................................... 9-13

9.13 ADDING STAT SAMPLES .................................................................................. 9-14

9.13.1 Stat Sample Deletion ............................................................................ 9-15

9.14 PRINTING RESULTS ......................................................................................... 9-16

9.14.1 Routine Samples .................................................................................. 9-17

9.14.2 Stat Samples ........................................................................................ 9-17

9.15 STARTING A NEW SAMPLE TRAY ..................................................................... 9-18

9.16 CHECKING QC RESULTS ................................................................................. 9-18

9.17 OPERATION AND MONITOR FUNCTIONS ......................................................... 9-18

9.17.1 Reagent Overview ................................................................................. 9-19

9.17.2 AMAX 200 - Status ............................................................................... 9-19

9.17.3 Prime.................................................................................................... 9-20

9.17.4 Wash .................................................................................................... 9-20

9.17.5 Test Groups.......................................................................................... 9-20

9.17.6 Check Reagent ..................................................................................... 9-20

9.17.7 Stop ..................................................................................................... 9-20

9.17.8 Abort .................................................................................................... 9-20

9.18 EXITING QUICK-START .................................................................................... 9-20

ABBREVIATED QUICK-START OPERATING PROCEDURE............................................ 9-22

April 2001 9-0

Page 41

Page 42

9

Operation – Quick-Start

The following are prerequisites to operation in the Quick-Start mode:

•

System is powered up (Section 7).

•

All operating parameters have been defined (Sections 18 and 19).

A Quick-Start summary is provided at the end of this section.

9.1 Entry into Quick-Start

“Quick-Start” is an alternative operation mode that has been designed to minimize

operator interaction with multiple screens. Because it is so easy to use this operation

mode, operators with minimal training may utilize it very effectively. It is also very

useful in laboratories with continuous sample arrival.

In order to make operation of the AMAX 200 as simple as possible, the number of

commands needed to operate have been reduced to an absolute minimum. All

operations are carried out using a single dialog window.

Because a single dialog window is used, there are certain limitations when compared

to the normal operating mode.

•

All samples are identified by an ID code. Entry of full patient demographic

information or location is not possible. Either a unique number or name may be

used as the ID code.

•

The integral barcode reader is not used. The barcode number may be entered either

manually with the keyboard or with an off-line barcode reader.

•

The number of tests that may be requested per sample is limited to 8.

•

A maximum of 60 samples may be processed per processing period.

•

The “Quick-Start” dialog window cannot be exited during processing.

Whenever the AMAX 200 is activated, the main menu screen appears:

Overview Service Measure Stat Patients System Q.C. End

Operating

Status

Reagent

Levels

Reagent

Tray

°C

Incubation

Rail °C

Probe

°C

Lamp Status

Optical

Meas.

°C

Mech.

Meas.

°C

Cuvette

Boxes

Cuvette

Waste

Fresh

Water

Waste

Water

Current Test Group QC

Status

Number

of files in

Archive

File

format

date

LIS

Status

The available menus are displayed across the top of the screen.

April 2001 9-1

Page 43

9

Operation – Quick-Start

There are two ways to access the Quick-Start operating mode:

1. Using the <arrow> keys, move the cursor to Stat and press <Enter>; or,

2. Press < t >

The “Stat menu” will open.

Overview Service Measure Stat Patients System Q.C. End

Operating

Status

Reagent

Levels

Reagent

Tray

°C

Incubation

Rail °C

Probe

°C

Quick-Start

Quick-Start

1. Position

2. Position

3. Position

4. Position

Lamp Status

Optical

Meas.

°C

Mech.

Meas.

°C

If there are no Stat positions assigned in

current Test Group reagent layout, only

Quick-Start is displayed.

If Stat positions are assigned in current

Test Group Reagent Layout, the window also

shows the number of assigned Stat

positions (1-8).

Cuvette

Boxes

Cuvette

Waste

Fresh

Water

Waste

Water

Current Test Group

Number

of files in

Archive

File

format

date

QC

Status

LIS

Status

The Stat menu will open with the cursor on “Quick-Start”.

9-2 April 2001

Page 44

9

Operation – Quick-Start

With the cursor on Quick-Start, press <Enter>.

If a Test Group is active, the Quick-Start dialog window opens immediately. If no Test

Group is currently selected, the “Select Test Group” dialog window appears. See

Section 9.3, Step 3 for instructions on selecting a Test Group. If any reagents in the

currently selected Test Group are expired, the “Expired reagent” dialog window will

appear. Replace expired reagent(s) as necessary. After replacing reagents, respond to

“Start run?” with <y><Enter>.

“/”,”*”,”-”,”+”,”R”,<Space> selects, <Shift>-<Enter>, ↓,↑, copies

F1:Display F2:Print F3:Service F8:Panel F9:Process F10:Delete

P. Identification PT-O

1

2

3

4

Sec

PTT-M

Sec

FIB-O

mg/dL

AT%A

5

6

9.2 Introduction to Quick-Start Dialog Window

The keystrokes and function keys used to carry out tasks within Quick-Start are

displayed in the two rows at the top of the screen. The listing serves as a reminder