SIGLENT SM06035-E01A Service Manual

Service Manual

SDM3055 Series Digital Mulimeter

SM06035-E01A

2016 SIGLENT TECHNOLOGIES CO., LT

SDM3055 Service Manual I

Guaranty and Declaration

Copyright

SIGLENT TECHNOLOGIES CO., LTD All Rights Reserved.

Trademark Information

SIGLENT is the registered trademark of SIGLENT TECHNOLOGIES CO.,

LTD

Declaration

SIGLENT products are protected by patent law in and outside of P.R.C.

SIGLENT reserves the right to modify or change parts of or all the

specifications or pricing policies at company‟s sole decision.

Information in this publication replaces all previously corresponding

material.

Any way of copying, extracting or translating the contents of this manual is

not allowed without the permission of SIGLENT.

SIGLENT will not be responsible for losses caused by either incidental or

consequential in connection with the furnishing, use or performance of this

manual as well as any information contained.

Product Certification

SIGLENT guarantees this product conforms to the national and industrial

standards in china as well as the ISO9001: 2008 standard and the ISO14001:

2004 standard. Other international standard conformance certification is in

progress.

II SDM3055 Service Manual

General Safety Summary

Review the following safety precautions to avoid personal injuries and prevent

damages to this product or any products connected to it. To avoid potential

hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injuries

Use Proper Power Cord. Use only the power cord specified for this product

and approved by local state.

Avoid Electric Shock. To avoid injuries or losses of life, do not connect or

disconnect probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the protective terra

conductor of the power line. To avoid electric shock, the grounding conductor

must be connected to the earth. Make sure the instrument is grounded

correctly before connecting its input or output terminals.

Connect the Probe Properly. Do not connect the probe ground lead to a high

voltage since it has the isobaric electric potential as ground.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markers on the instrument and check your manual for more

information about ratings before connecting.

Use Proper Fuse. Use only the specified fuse.

Do Not Operate Without Covers. Do not operate this instrument with covers

or panels removed.

SDM3055 Service Manual III

Avoid Circuit or Wire Exposed. Do not touch exposed junctions and

components when the unit is powered.

Do Not Operate With Suspected Failures. If you suspect damage occurs to

this instrument, have it inspected by qualified service personnel before

further operation. Any maintenance, adjustment or replacement especially to

the circuits or accessories should be performed by SIGLENT authorized

personnel.

Keep Product Surfaces Clean and Dry.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not

operate the instrument in wet or damp condition.

Do Not Operate in an Explosive Atmosphere. To avoid injuries or fire

hazards, do not operate in an explosive atmosphere.

Safety Terms and Symbols

Terms on the Product. These terms may appear on the product:

DANGER: Indicates an injury or hazard that may immediately happen.

WARNING: Indicates an injury or hazard may be accessible potentially.

CAUTION: Indicates damage to the instrument or other property may occur.

Symbols on the Product. These symbols may appear on the product:

IV SDM3055 Service Manual

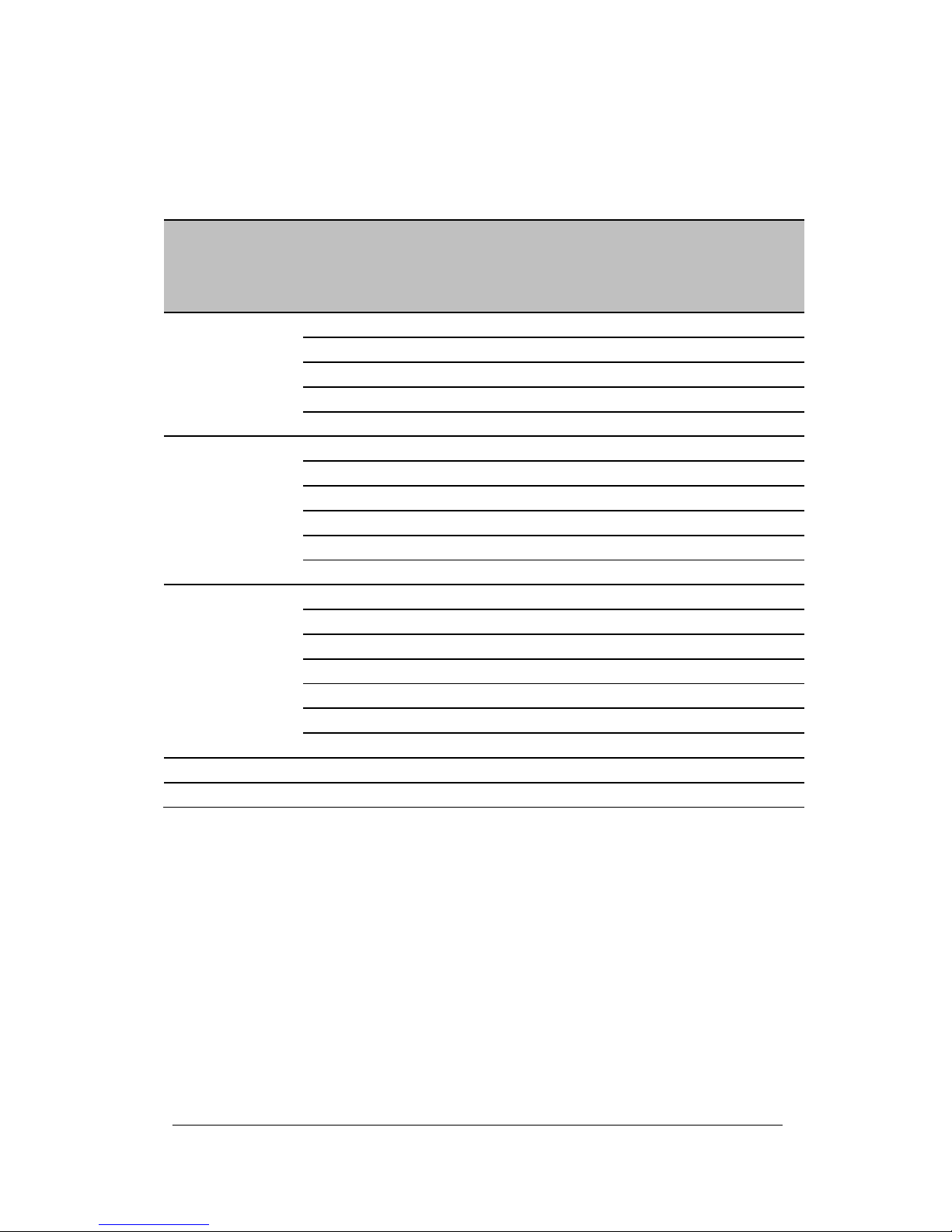

Catalog

Guaranty and Declaration .............................................................................................................. I

General Safety Summary .............................................................................................................. II

General Features and Specifications .......................................................................................... 1

General Features.................................................................................................................... 1

Specifications .......................................................................................................................... 2

Prepare Information ....................................................................................................................... 6

Functional checking ............................................................................................................... 6

Power-on Inspection ...................................................................................................... 6

Default Setup .................................................................................................................. 6

Self Test ........................................................................................................................... 7

Performance Verification ............................................................................................................... 8

Performance verification test items ..................................................................................... 8

Recommended Test Equipment ........................................................................................... 8

Performance verification step ............................................................................................... 8

Test Considerations................................................................................................................ 9

Zero Offset Verification .......................................................................................................... 9

DC Voltage and DC Current Gain Verification ................................................................. 10

Frequency Accuracy Verification ........................................................................................ 11

AC Voltage and AC Current Verification ............................................................................ 12

Capacitance Verification ...................................................................................................... 13

Calibration Adjusting Procedures .............................................................................................. 14

Calibration Adjustment Interval........................................................................................... 14

Calibration is Recommended ............................................................................................. 14

Automating Calibration Procedures ................................................................................... 14

Calibration Adjustment items .............................................................................................. 14

Recommended Test Equipment ......................................................................................... 15

Software Environment ......................................................................................................... 15

Test Considerations.............................................................................................................. 15

Calibration Adjustment step ................................................................................................ 16

Assembly Procedures .................................................................................................................. 17

Security Consideration ........................................................................................................ 17

Required Tools ...................................................................................................................... 17

Disassembly Procedures .................................................................................................... 18

Troubleshooting ............................................................................................................................ 22

ESD Precautions .................................................................................................................. 22

Required Equipments .......................................................................................................... 22

Analog Board Drawing ......................................................................................................... 23

Main Board Drawing ............................................................................................................ 24

Check the Power Supply ..................................................................................................... 25

Check the Analog Board ...................................................................................................... 27

Voltage Checking .......................................................................................................... 27

SDM3055 Service Manual V

Analog board Clock Checking .................................................................................... 28

Check the Main Board ......................................................................................................... 29

Voltage Checking .......................................................................................................... 29

Microprocessor Checking ............................................................................................ 29

Quick Guide for General Failures ...................................................................................... 30

Maintenance .................................................................................................................................. 31

Maintain Summary ............................................................................................................... 31

Repackaging for Shipment .................................................................................................. 31

Contact SIGLENT ......................................................................................................................... 32

SDM3055 Service Manual 1

General Features and Specifications

SDM3055 is a 5½ dual-display instrument designed with 5½ digits readings

resolution and dual-display, especially fitting to the needs of high-precision,

multifunction, and automation measurements. It realized a combination of

basic measurement functions, multiple math functions, and display functions,

etc.

General Features

4.3 inch color TFT-LCD display screen with 480*272 high resolutions

Real 5½ digits readings resolution

Up to 150rdgs/S measurement speed

True-RMS AC Voltage and AC Current measurements

1 Gb Nand Flash size, mass storage configuration files and data files

Built-in cold terminal compensation for thermocouple

Support standard SCPI and control software on PC, compatible with

commands of main stream multimeters

Supports dual-display function, Chinese and English menu

Built-in help system, convenient to acquire information

Support USB Device, USB Host, LAN, and USB-GPIB (only for

SDM3055A) interfaces

Configuration and measured data can be imported or exported via VXI 11,

USBTMC and USB flash drive, which is convenient for users to modify,

view and backup

2 SDM3055 Service Manual

Specifications

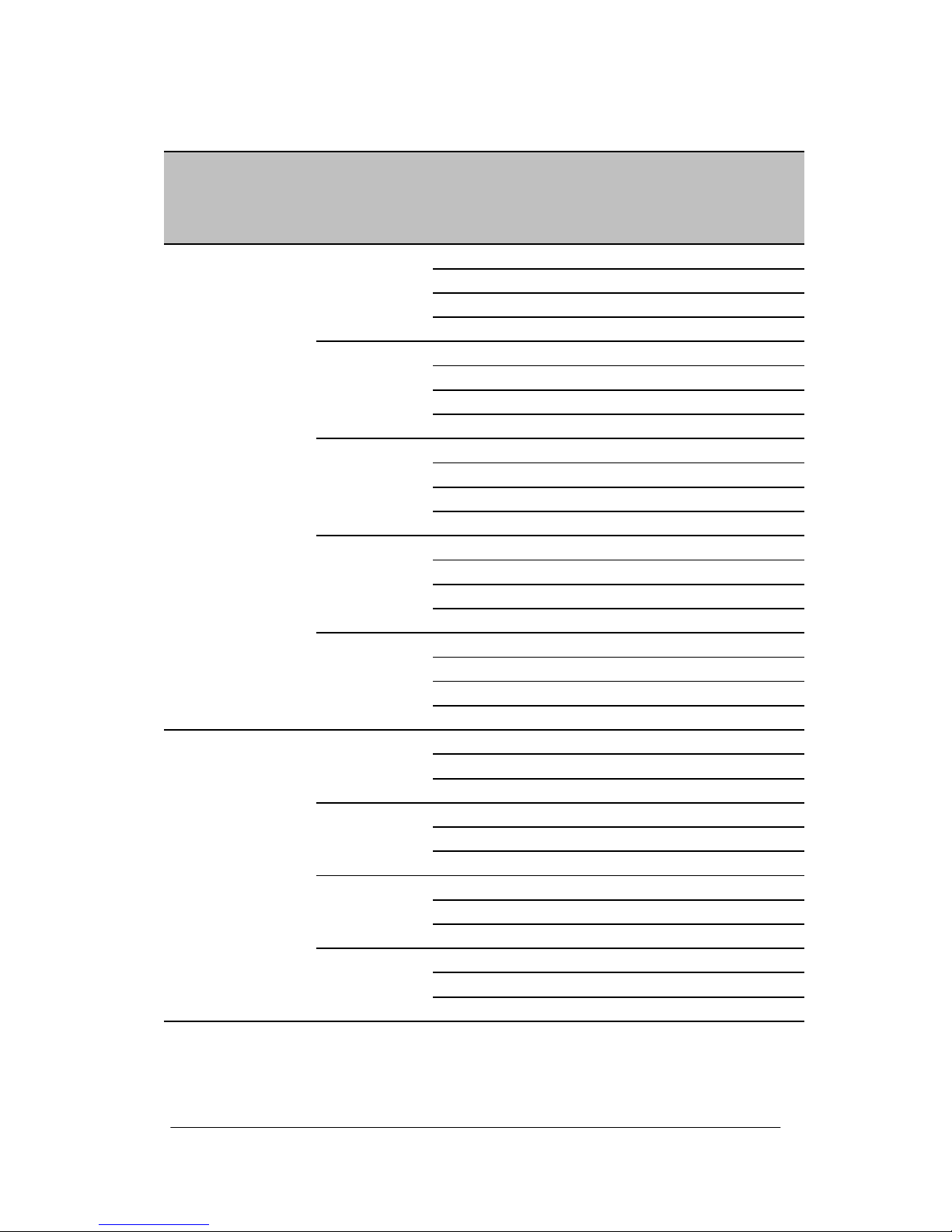

DC Characteristic

Accuracy±(% of Reading + % of Range)

[1]

Function

Range

[2]

Test current or

Load voltage

1 Year

23℃±5℃

Temperature

coefficient

0℃~18℃

28℃~50℃

DC Voltage

200 mV

0.015+ 0.004

0.0015+ 0.0005

2 V

0.015+ 0.003

0.0010+ 0.0005

20 V

0.015+ 0.004

0.0020+ 0.0005

200 V

0.015+ 0.003

0.0015+ 0.0005

1000 V

[4]

0.015+ 0.003

0.0015+ 0.0005

DC Current

200 μA

< 8 mV

0.055+ 0.005

0.003+ 0.001

2 mA

< 80 mV

0.055+ 0.005

0.002+ 0.001

20 mA

< 0.05 V

0.095+ 0.020

0.008+ 0.001

200 mA

< 0.5 V

0.070+ 0.008

0.005+ 0.001

2 A

< 0.1 V

0.170+ 0.020

0.013+ 0.001

10 A

[5]

< 0.3 V

0.250+ 0.010

0.008+ 0.001

Resistance

[3]

200 Ω

1 mA

0.030+ 0.005

0.0030+ 0.0006

2 KΩ

1 mA

0.020+ 0.003

0.0030+ 0.0005

20 KΩ

100 μA

0.020+ 0.003

0.0030+ 0.0005

200 KΩ

10 μA

0.020+ 0.010

0.0030+ 0.0005

2 MΩ

1 μA

0.040+ 0.004

0.0040+ 0.0005

10 MΩ

200 nA

0.250+ 0.003

0.0100+ 0.0005

100 MΩ

200 nA || 10 MΩ

1.75+ 0.004

0.2000+ 0.0005

Diode Test

4.0 V

[6]

1 mA

0.05+ 0.01

0.0050+ 0.0005

Continuity Test

2000 Ω

1 mA

0.05+ 0.01

0.0050+ 0.0005

Remarks:

[1] Specifications are for 0.5 Hour warm-up, “Slow” measurement rate and calibration

temperature 18℃~28℃.

[2] 20% over range on all ranges except for DCV 1000 V, ACV 750 V, DCI 10 A and ACI

10 A.

[3] Specifications are for 4-wire measure or 2-wire measure under “REF” operation. ±0.2Ω

of extra errors will be generated if perform 2-wire measure without “REF” operation.

[4] Plus 0.02 mV of error per 1 V after the first ±500 VDC.

[5] 30 seconds OFF after 30 seconds ON is recommend foe the continuous current that

higher than DC 7 A or AC RMS 7 A.

[6] Accuracy sepcifications are only for voltage measuring at input terminal. The typical

value of current under measure is 1 mA. Voltage drop at diode junction may vary with

current supply.

SDM3055 Service Manual 3

AC Characteristic

Accuracy±(% of Reading + % of Range)

[1]

Function

Range

[2]

Frequency Range

1Year

23℃±5℃

Temperature

coefficient

0℃~18℃

28℃~50℃

True-RMS

AC Voltage

[3]

200 mV

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 KHz

0.2 + 0.05

0.01 + 0.005

20 KHz – 50 KHz

1.0 + 0.05

0.01 + 0.005

50 KHz –100 KHz

3.0 + 0.05

0.05 + 0.010

2 V

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 KHz

0.2 + 0.05

0.01 + 0.005

20 KHz – 50 KHz

1.0 + 0.05

0.01 + 0.005

50 KHz –100 KHz

3.0 + 0.05

0.05 + 0.010

20 V

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 KHz

0.2 + 0.05

0.01 + 0.005

20 KHz – 50 KHz

1.0 + 0.05

0.01 + 0.005

50 KHz –100 KHz

3.0 + 0.05

0.05 + 0.010

200 V

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 KHz

0.2 + 0.05

0.01 + 0.005

20 KHz – 50 KHz

1.0 + 0.05

0.01 + 0.005

50 KHz –100 KHz

3.0 + 0.05

0.05 + 0.010

750 V

20 Hz – 45 Hz

1.5 + 0.10

0.01 + 0.005

45 Hz – 20 KHz

0.2 + 0.05

0.01 + 0.005

20 KHz – 50 KHz

1.0 + 0.05

0.01 + 0.005

50 KHz –100 KHz

3.0 + 0.05

0.05 + 0.010

True-RMS

AC Current

[4]

20 mA

20 Hz – 45 Hz

1.5 + 0.10

0.015 + 0.015

45 Hz – 2 KHz

0.50 + 0.10

0.015 + 0.006

2 KHz – 10 KHz

2.50 + 0.20

0.015 + 0.006

200 mA

20 Hz – 45 Hz

1.5 + 0.10

0.015 + 0.005

45 Hz – 2 KHz

0.50 + 0.10

0.015 + 0.005

2 KHz – 10 KHz

2.50 + 0.20

0.015 + 0.005

2 A

20 Hz – 45 Hz

1.5 + 0.20

0.015 + 0.005

45 Hz – 2 KHz

0.50 + 0.20

0.015 + 0.005

2 KHz – 10 KHz

2.50 + 0.20

0.015 + 0.005

10 A

[5]

20 Hz – 45 Hz

1.5 + 0.15

0.015 + 0.005

45 Hz – 2 KHz

0.50 + 0.15

0.015 + 0.005

2 KHz – 10 KHz

2.50 + 0.20

0.015 + 0.005

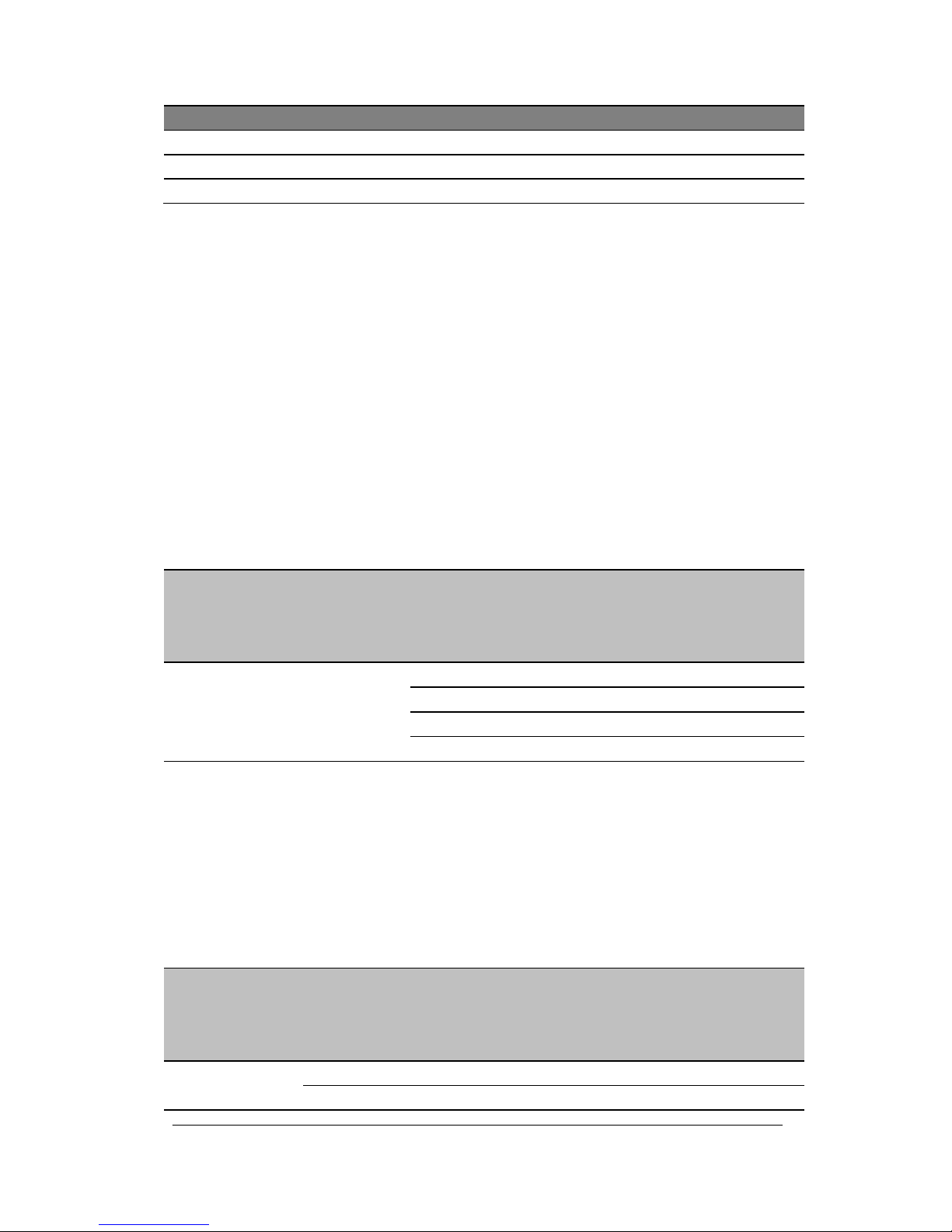

4 SDM3055 Service Manual

Additional wave crest factor error ( not Sine )

[6]

Wave crest coefficient

Error(% Range)

1-2

0.05

2-3

0.2

Remarks:

[1] Specifications are for 0.5 Hour warm-up, “Slow” measurement rate and calibration

temperature 18℃~28℃.

[2] 20% over range on all ranges except for DCV 1000 V, ACV 750 V, DCI 10 A and ACI

10 A.

[3] Specifications are for amplitude of sine wave input > 5% of range. For inputs from 1%

to 5% of range and <50 kHz, add 0.1% of range extra error. For 50 kHz to 100 kHz,

add 0.1% of range extra error.

[4] Specifications are for sine wave input > 5% of range. 0.1% errors wills be added when

the range of input sine wave is 1% to 5% .

[5] 30 seconds OFF after 30 seconds ON is recommend foe the continuous current that

higher than DC 7 A or AC RMS 7 A.

[6] Specifications are for frequency of input < 100Hz

Frequency and Period Characteristic

Accuracy±(% of Reading + % of Range)

[1]

Function

Range

Frequency Range

1 Year

23℃±5℃

Temperature

coefficient

0℃~18℃

28℃~50℃

Frequency

/Period

200 mV to 750 V

[2]

20 Hz – 2 KHz

0.01+0.003

0.002+0.001

2 KHz – 20 KHz

0.01+0.003

0.002+0.001

20 KHz – 200 KHz

0.01+0.003

0.002+0.001

200 KHz –1 MHz

0.01+0.006

0.002+0.002

Remarks:

[1] Specifications are for 0.5 Hour warm-up.

[2]Except for special marks, the AC input voltage is 15% to 120% of range when <100 kHz

and 30% to 120% of range when >100 kHz. 750 V range is limited to 750 Vrms.

Capacitance Characteristic

Accuracy±(% of Reading + % of Range)

[1]

Function

Range

[2]

Max Testing

Current

1 Year

23℃±5℃

Temperature

coefficient

0℃~18℃

28℃~50℃

Capacitance

2 nF

200 nA

3+1.0

0.08+0.002

20 nF

200 nA

1+0.5

0.02+0.001

Loading...

Loading...