SIGLENT SDS2000X Service Manual

Service Manual

SDS2000X Series Digital Oscilloscope

2017 SIGLENTTECHNOLOGIES CO., LTD

SIGLENT

SDS1000X+ Service Manual I

Guaranty and Declaration

Copyright

SIGLENT TECHNOLOGIES CO., LTD All Rights Reserved.

Trademark Information

SIGLENT is the registered trademark of SIGLENT TECHNOLOGIES CO.,

LTD

Declaration

SIGLENT products are protected by patent law in and outside of P.R.C.

SIGLENT reserves the right to modify or change parts of or all the

specifications or pricing policies at company‟s sole decision.

Information in this publication replaces all previously corresponding

material.

Any method of copying, extracting or translating the contents of this

manual is not allowed without the permission of SIGLENT.

SIGLENT will not be responsible for losses caused by either incidental or

consequential reasons in connection with the furnishing, use or

performance of this manual as well as any information contained.

Product Certification

SIGLENT guarantees this product conforms to the national and industrial

standards in China as well as the ISO9001: 2008 standard and the

ISO14001: 2004 standard. Other international standard conformance

certification is in progress.

SIGLENT

II SDS2000X Service Manual

General Safety Summary

Review the following safety precautions to avoid personal injuries and

prevent damages to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injuries

Use Proper Power Cord. Use only the power cord specified for this product

and approved by your local governing agencies.

Avoid Electric Shock. To avoid injuries or potential loss of life, do not

connect or disconnect probes or test leads while they are connected to a

voltage source.

Ground the Product. This product is grounded through the protective

ground conductor of the power line. To avoid electric shock, the grounding

conductor must be connected to the earth ground. Make sure the instrument

is grounded correctly before connecting its input or output terminals.

Connect the Probe Properly. Do not connect the probe ground lead to a

high voltage since it has the isobaric electric potential as ground.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the instrument and check your manual for more

information about ratings before connecting.

Use Proper Fuse. Use only the specified fuse.

Do Not Operate Without Covers. Do not operate this instrument with

covers or panels removed.

SIGLENT

SDS2000X Service Manual III

Avoid Circuit or Wire Exposed. Do not touch exposed junctions and

components when the unit is powered.

Do Not Operate With Suspected Problems. If you suspect damage has

occurred to this instrument, have it inspected by qualified service personnel

before further operation. Any maintenance, adjustment or replacement,

especially to the circuits or accessories should be performed by SIGLENT

authorized personnel.

Keep Product Surfaces Clean and Dry.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not

operate the instrument in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injuries or fire

hazards, do not operate in an explosive atmosphere.

Safety Terms and Symbols

Terms on the Product. These terms may appear on the product:

DANGER: Indicates an injury or hazard that may immediately happen.

WARNING: Indicates an injury or hazard may be potentially accessible.

CAUTION: Indicates damage to the instrument or other property may occur.

Symbols on the Product. These symbols may appear on the product:

SIGLENT

SDS2000X Service Manual 1

Contents

Guaranty and Declaration ................................................................................................................. I

General Safety Summary ................................................................................................................. II

General Features ............................................................................................................................... 3

General Features ....................................................................................................................... 3

Prepare Information .......................................................................................................................... 6

Functional checking .................................................................................................................. 6

Power-on Inspection .......................................................................................................... 6

Probe Compensation ......................................................................................................... 8

Auto Setup ......................................................................................................................... 9

Self Calibration ............................................................................................................... 10

Interface Test ........................................................................................................................... 12

USB Host Test ................................................................................................................. 12

USB Device Test ............................................................................................................. 13

LAN Port Test ................................................................................................................. 14

Pass/Fail out Test ............................................................................................................. 16

Performance Test ............................................................................................................................ 18

To Verify DC Gain Accuracy .................................................................................................. 23

To Verify Offset Accuracy ....................................................................................................... 25

To Verify Time Base Accuracy ................................................................................................ 27

To Verify Trigger Delay .......................................................................................................... 28

To Verify Ext Trigger Delay .................................................................................................... 29

To Verify Ext Trigger Level .................................................................................................... 30

To Verify Noise Floor .............................................................................................................. 31

To Verify Bandwidth ............................................................................................................... 32

To Verify Bandwidth Limit ..................................................................................................... 34

To Verify Trigger Sensitivity ................................................................................................... 35

To Verify Input Impedance ...................................................................................................... 37

To Verify AWG ........................................................................................................................ 38

Adjusting Procedures ...................................................................................................................... 40

Warming Up ............................................................................................................................ 40

Self Calibration ....................................................................................................................... 40

Required Equipment ............................................................................................................... 40

Software Installation ............................................................................................................... 41

Adjusting Steps ....................................................................................................................... 41

Assembly Procedures ...................................................................................................................... 44

Security Considerations .......................................................................................................... 44

List of Modules ....................................................................................................................... 44

Required Tools ........................................................................................................................ 45

Disassembly Procedures.......................................................................................................... 46

Removing the Front-Panel Knobs ................................................................................... 46

Removing the Rear Panel ................................................................................................ 47

Removing the Rear Metal Cover ..................................................................................... 49

Removing the Front Panel ............................................................................................... 50

Removing the LCD, Channel Board and Keyboard ........................................................ 51

Removing the Main Board .............................................................................................. 52

Troubleshooting Hardware Failures ........................................................................................ 54

ESD Precautions.............................................................................................................. 54

Required Equipment........................................................................................................ 54

Main Board Drawing....................................................................................................... 55

Troubleshooting Flowchart ............................................................................................. 56

Check the Power Supply ................................................................................................. 58

Check the Main Board .................................................................................................... 59

Check the Display Module .............................................................................................. 60

SIGLENT

2 SDS2000X Service Manual

Handling General Hardware Failures .............................................................................. 61

Contact SIGLENT........................................................................................................................... 62

SIGLENT

SDS2000X Service Manual 3

General Features

General Features

SIGLENT‟s SDS2000X series Super Phosphor Oscilloscopes are available in

bandwidths of 70 MHz, 100 MHz, 200 MHz and 300 MHz, utilize a maximum

sample rate of 2 GSa/s and a maximum record length of 140 Mpts. The most

commonly used functions can be accessed with its user-friendly one-button

design.

The SDS2000X series employs a new generation of SPO technology. It

employs an innovative digital trigger system with high sensitivity and low jitter.

The maximum waveform capture rate is 140,000 wfm/s (normal mode) and up

to 500,000 wfm/s (sequence mode). It also employs not only the

more-common 256-level intensity grading display function but also a powerful

color temperature display mode. The SDS2000X‟s trigger system supports

multiple powerful triggering modes including serial bus triggering. History

waveform recording and sequence acquisition allow for extended waveform

records to be captured, stored, and analyzed. An impressive array of

measurement and math capabilities, options for a built-in 25 MHz arbitrary

waveform generator, 16 digital channels (MSO), as well as serial decoding are

also features of the SDS2000X.

Table 1 General features

Model

Bandwidth

Sampling Rate

Memory Depth

Channel

SDS2072X

70 MHz

2 GS/s

140 Mpts

2

SDS2074X

70 MHz

2 GS/s

140 Mpts

4

SDS2102X

100 MHz

2 GS/s

140 Mpts

2

SDS2104X

100 MHz

2 GS/s

140 Mpts

4

SDS2202X

200 MHz

2 GS/s

140 Mpts

2

SIGLENT

4 SDS2000X Service Manual

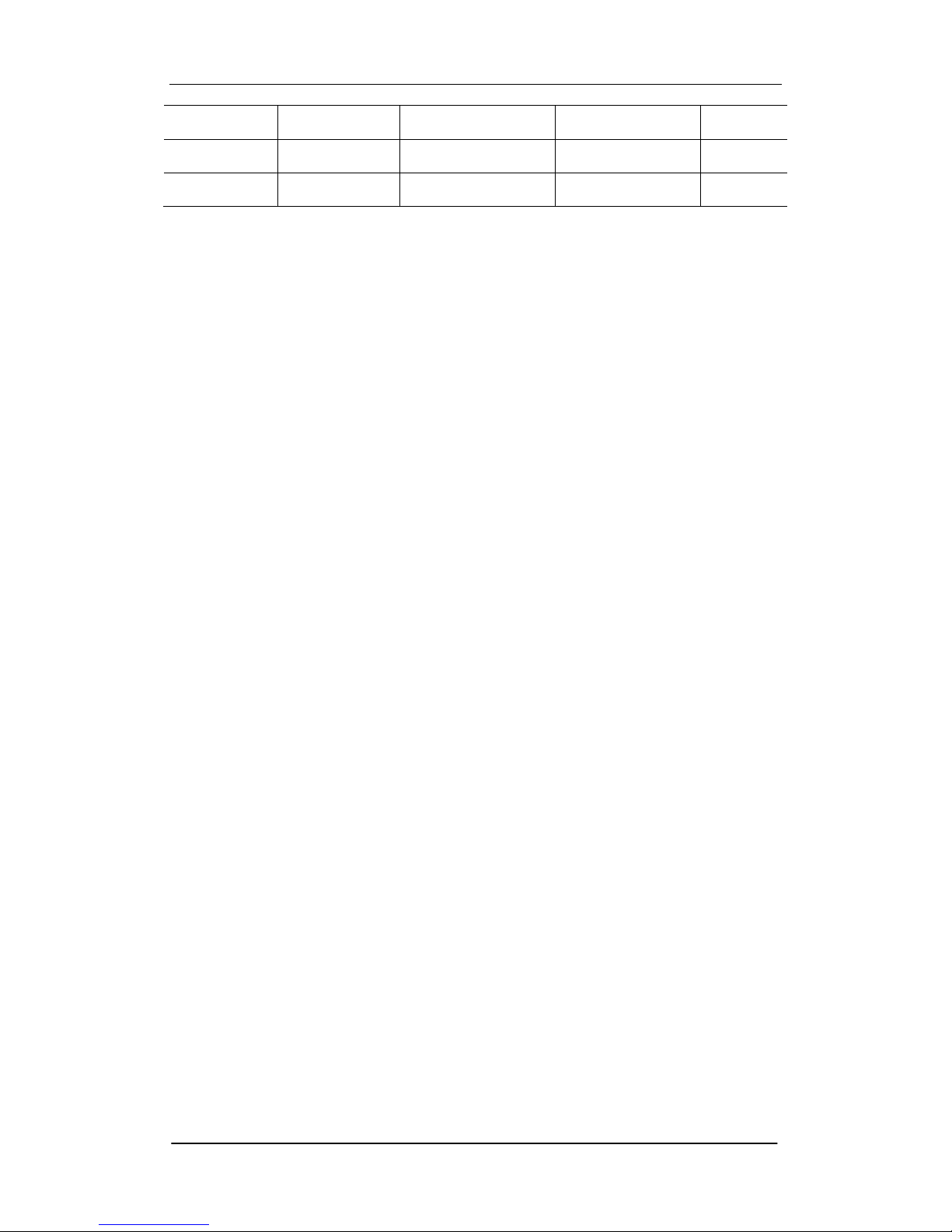

SDS2204X

200 MHz

2 GS/s

140 Mpts

4

SDS2302X

300 MHz

2 GS/s

140 Mpts

2

SDS2304X

300 MHz

2 GS/s

140 Mpts

4

70 MHz, 100 MHz, 200 MHz, 300 MHz models

Real-time sampling rate up to 2 GSa/s

New generation of SPO technology

Waveform capture rate up to 140,000 wfm/s (normal mode), and 500,000 wfm/s

(sequence mode)

Supports 256-level intensity grading and color temperature display

Record length up to 140 Mpts

Digital trigger system

Intelligent trigger: Edge, Slope, Pulse, Window, Runt, Interval, Dropout,

Pattern and Video (HDTV supported)

Serial bus triggering and decode, supports protocols IIC, SPI, UART,

RS232, CAN, LIN

Low background noise, supports 1 mV / div to 10 V / div voltage scales

10 types of one-button shortcuts; supports Auto Setup, Default Setup,

Cursor, Measure, Roll, History, Persist, Clear Sweep, Zoom and Print

Segmented acquisition (Sequence) mode. Divides the maximum record

length into multiple segments (up to 80,000), according to trigger

conditions set by the user - with a very small dead time segment - to

capture the qualifying event

History waveform record (History) function. The maximum recorded

waveform length is 80,000 frames

37 automatic measurement functions. Supports Statistics calculations,

Gating measurement, Math measurement, History measurement, Ref

measurement

Waveform math function (FFT, addition, subtraction, multiplication, division,

integration, differentiation, square root)

High Speed hardware-based Pass/ Fail function

25 MHz DDS arbitrary waveform generator - built-in 10 waveform functions

(Optional)

SIGLENT

SDS2000X Service Manual 5

Large 8 inch TFT-LCD display with 800 * 480 resolution. Multiple interfaces,

including USB Host, USB Device (USBTMC), LAN (VXI-11), Pass / Fail,

Trigger Out

Supports SCPI remote control commands

Supports Multi-language display and embedded online help

SIGLENT

6 SDS2000X Service Manual

Prepare Information

Before initiating performance verification or any adjustments, it is

recommended the user follow these procedures. The following topics are

discussed in this chapter.

How to perform functional checks

How to operate four standard interface tests

How to use self-calibration routine

How to recall factory Default settings

For more detailed information about oscilloscope operation, please refer to the

Quick Start Guide.

Functional checking

The functional checking details three types of checks used to determine if the

oscilloscope is operating properly.

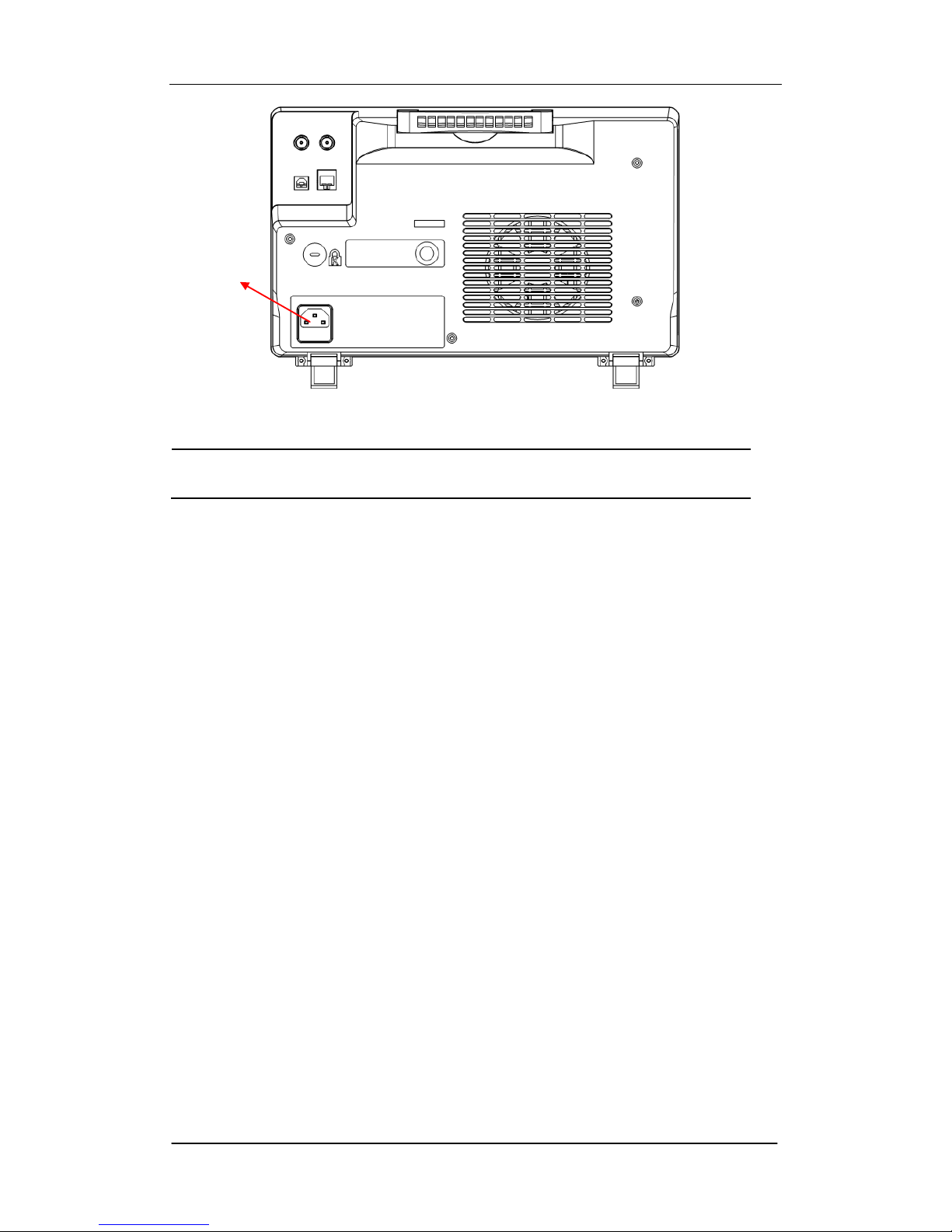

Power-on Inspection

The normal operating voltage for the SDS2000X series digital oscilloscope is in

range of 100-240 VRMS ,50 Hz/ 60 Hz/ 440Hz. Connect the power cord to the

socket on the rear panel of the oscilloscope.

SIGLENT

SDS2000X Service Manual 7

Figure 1 Connect power cord

Note: To avoid electric shock, make sure that the instrument is

correctly grounded to the earth before connecting AC power.

Press the power-on button located at the lower left corner of the front panel

and note that several oscilloscope keys will be lighted for about 6 seconds

simultaneously, until the boot screen appears. The oscilloscope will then begin

to perform its power-on tests automatically, after which the DEFAULT SETUP

button can be pressed in order to recall the factory default settings.

The socket

SIGLENT

8 SDS2000X Service Manual

Probe Compensation

It is necessary to compensate the probe at first use so as to properly match the

probe to the oscilloscope‟s input channel. Non-compensated or poorly

compensated probes may cause measurement inaccuracies or errors. The

probe compensation steps are as follows:

1. Set the attenuation switch on the probe to 10X.

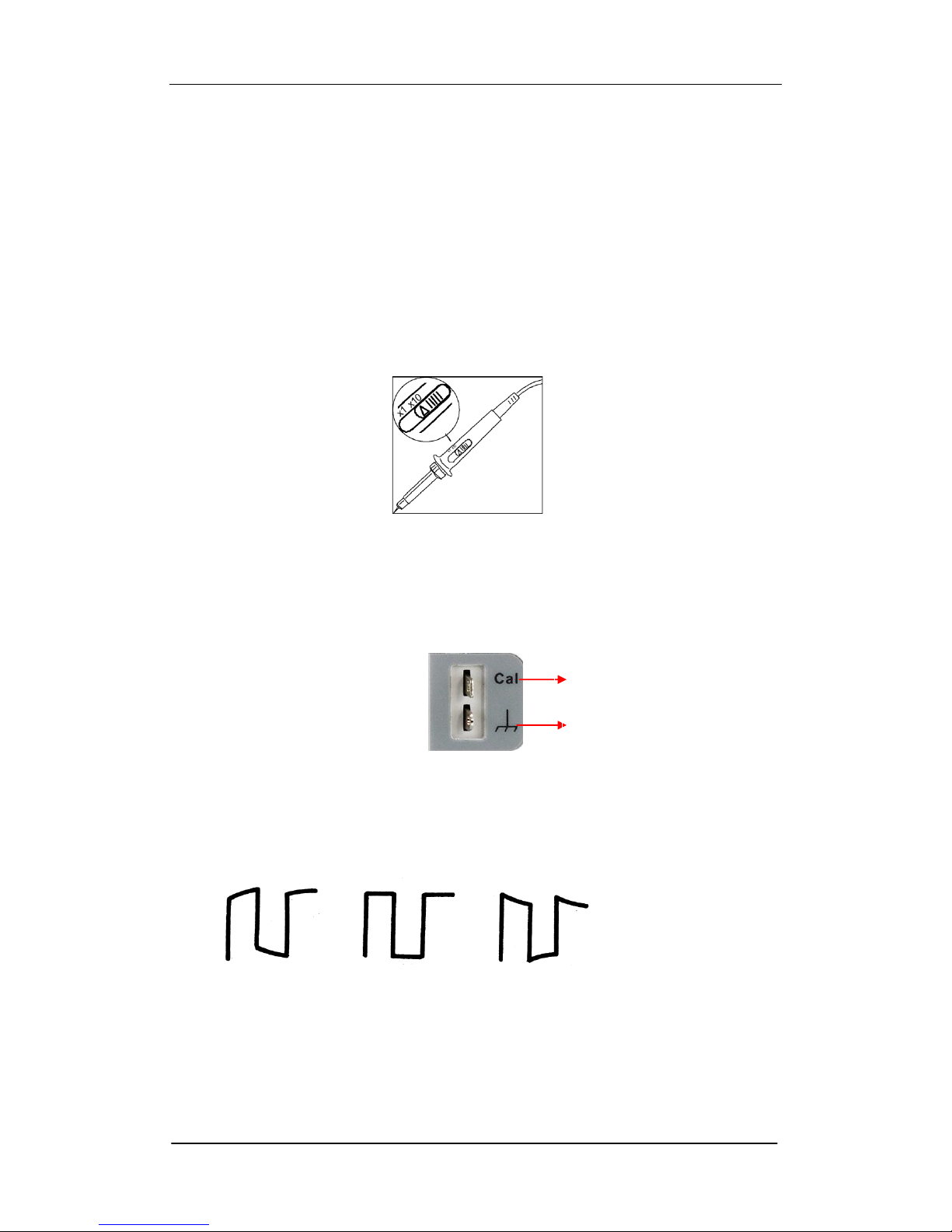

Figure 2 Set the attenuation switch

2. Connect the alligator clip of the probe to the Ground Terminal on the front

panel, and then use the probe to connect CH1 BNC input connector to the

Compensation Signal Output Terminal.

3. Press AUTO Setup.

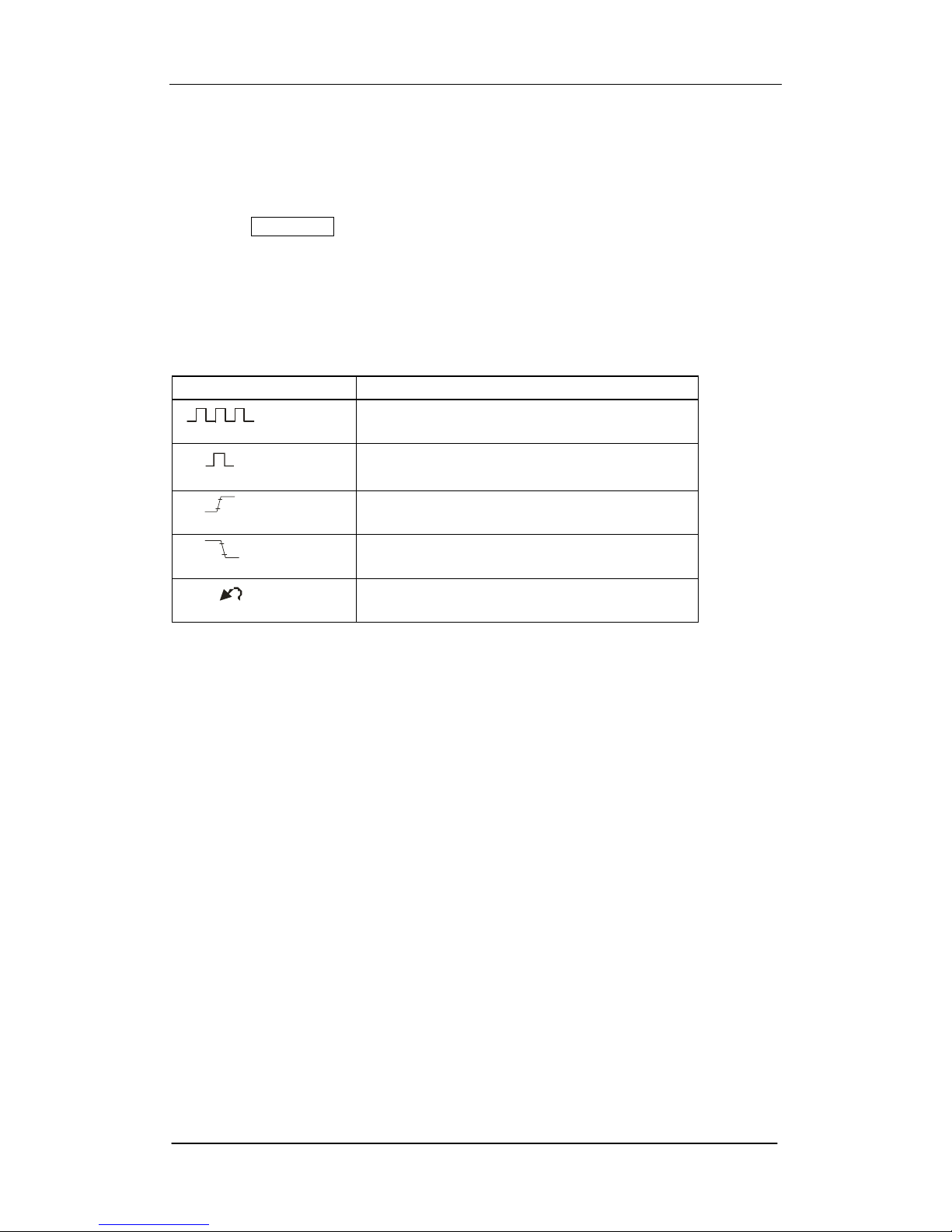

4.Observe waveform on the screen. The displaying should be a square

waveform as shown in the figure below:

Under Compensated Over

Compensated Correctly Compensated

5. If the waveform does not show as “compensated correctly”, use a

nonmetallic screwdriver to adjust the low-frequency compensation

adjustment hole on the probe until the waveform displays correctly.

Ground Terminal

Compensation Terminal

SIGLENT

SDS2000X Service Manual 9

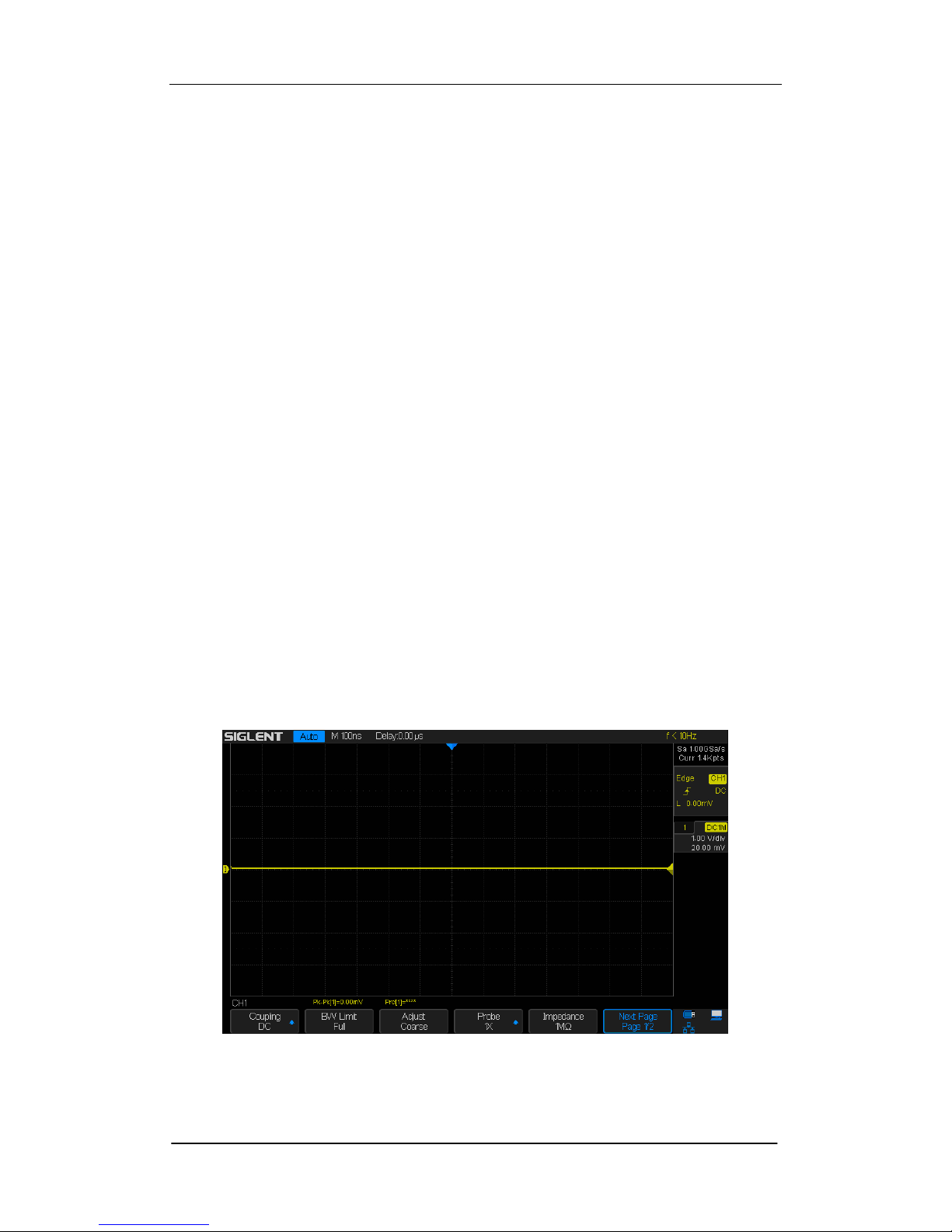

Auto Setup

Press the Auto Setup key to enable the waveform auto setting function. The

oscilloscope will automatically adjust the horizontal time base, vertical scale

and trigger mode according to the input signal to obtain an optimum waveform

display.

Table 2 Auto setting menu

Option

Introduction

(Multi-cycle sine)

Display several waveform cycles

(Single-cycle sine)

Display single waveform cycles

(Rising edge)

Display the rising edge of waveform

(Falling edge)

Display the falling edge of waveform

(Undo Setup)

Recall the previous setup of oscilloscope

The input signal frequency must be higher than 20 Hz, with the amplitude

greater than 8 mV.

Select the channel with the lowest frequency when several channels are

connected to signals.

SIGLENT

10 SDS2000X Service Manual

Self Calibration

The self-calibration routine can quickly adjust the oscilloscope to perform at

the optimum state in order to achieve the maximum accuracy. Self-calibration

can be performed at any time, especially when a change in the ambient

temperature of 5℃ or more has occurred. Make certain that the oscilloscope

has been warmed up or operated for more than 30 minutes before performing

the self-calibration.

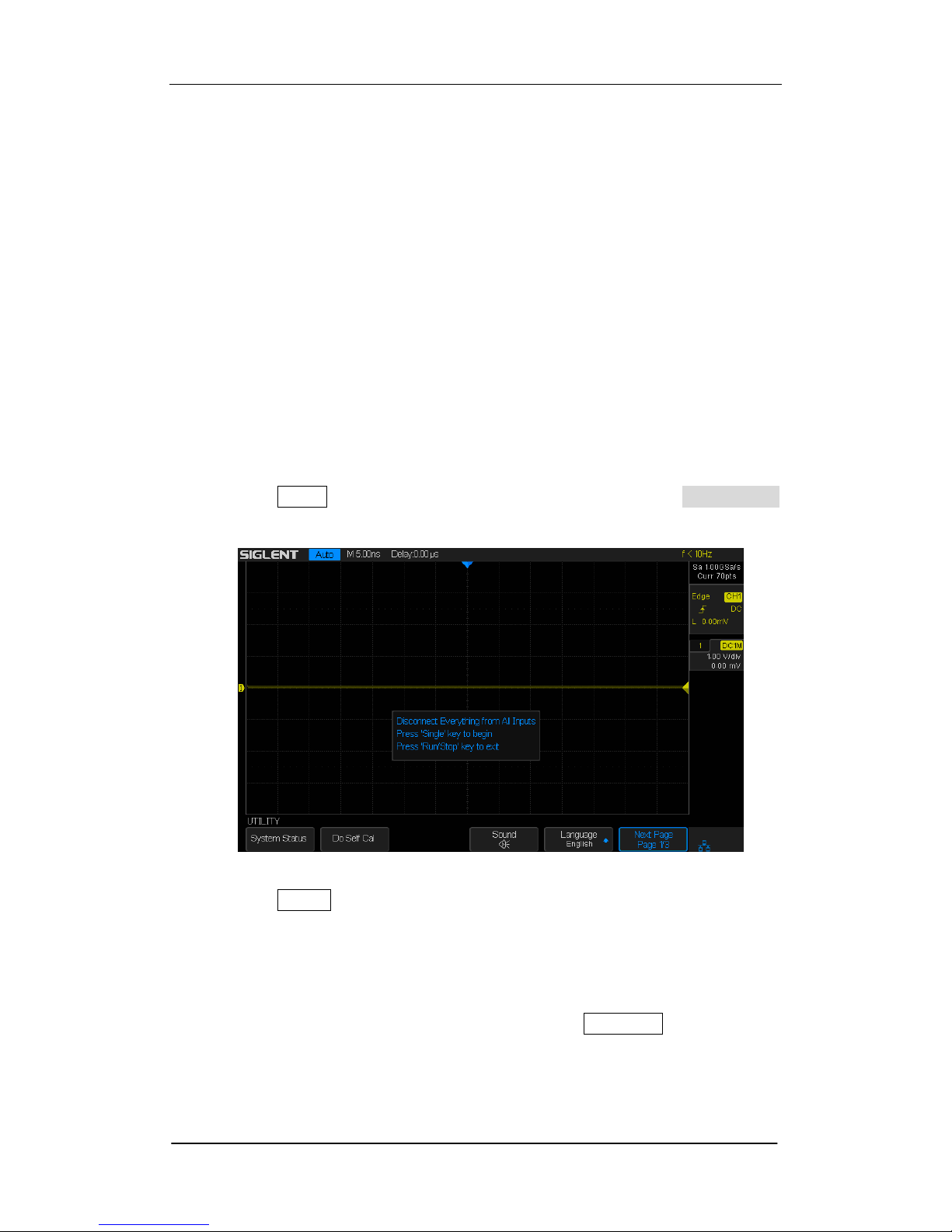

Use the following steps to perform self calibration:

1. Disconnect all leads from all input channels.

2. Press the Utility button on the front panel, and then press the Do Self Cal

softkey. The oscilloscope will display the message box as shown below:

Figure2-3 Calibration Interface

3. Press the Single button on the front panel to perform the self calibration

program. During the calibration, most of the oscilloscope‟s keys are

disabled.

4. When the self calibration process is completed, the following message will

appear: “Press Run/Stop key to exit”. Press the Run/Stop button on the

front panel to exit the calibration interface.

Note: Under normal conditions the self-calibration procedure will take

SIGLENT

SDS2000X Service Manual 11

approximately 20 seconds. If it does not complete within this period of time or it

stops on one of the calibration settings, then there may be a problem with the

instrument.

SIGLENT

12 SDS2000X Service Manual

Interface Test

The SDS2000X series oscilloscope is designed with four standard interfaces:

USB Host, USB Device, LAN and Pass/Fail. Connecting to other instruments

via these interfaces enables the oscilloscope to achieve additional capabilities.

In order to ensure the oscilloscope is operating properly it is recommended

that the user first test the interfaces.

USB Host Test

To test whether the USB Host interface is operating correctly.

Tools:

● A U disk

Steps:

1. Insert a U disk (flash drive) into the USB Host interface on the front panel of

the oscilloscope.

2. A message prompt “USB Flash Drive Plug In!”,appears on the screen, and

an icon will be shown in the lower right corner of the screen which confirms

the U disk has been successfully recognized.

Figure 3 USB drive in interface

SIGLENT

SDS2000X Service Manual 13

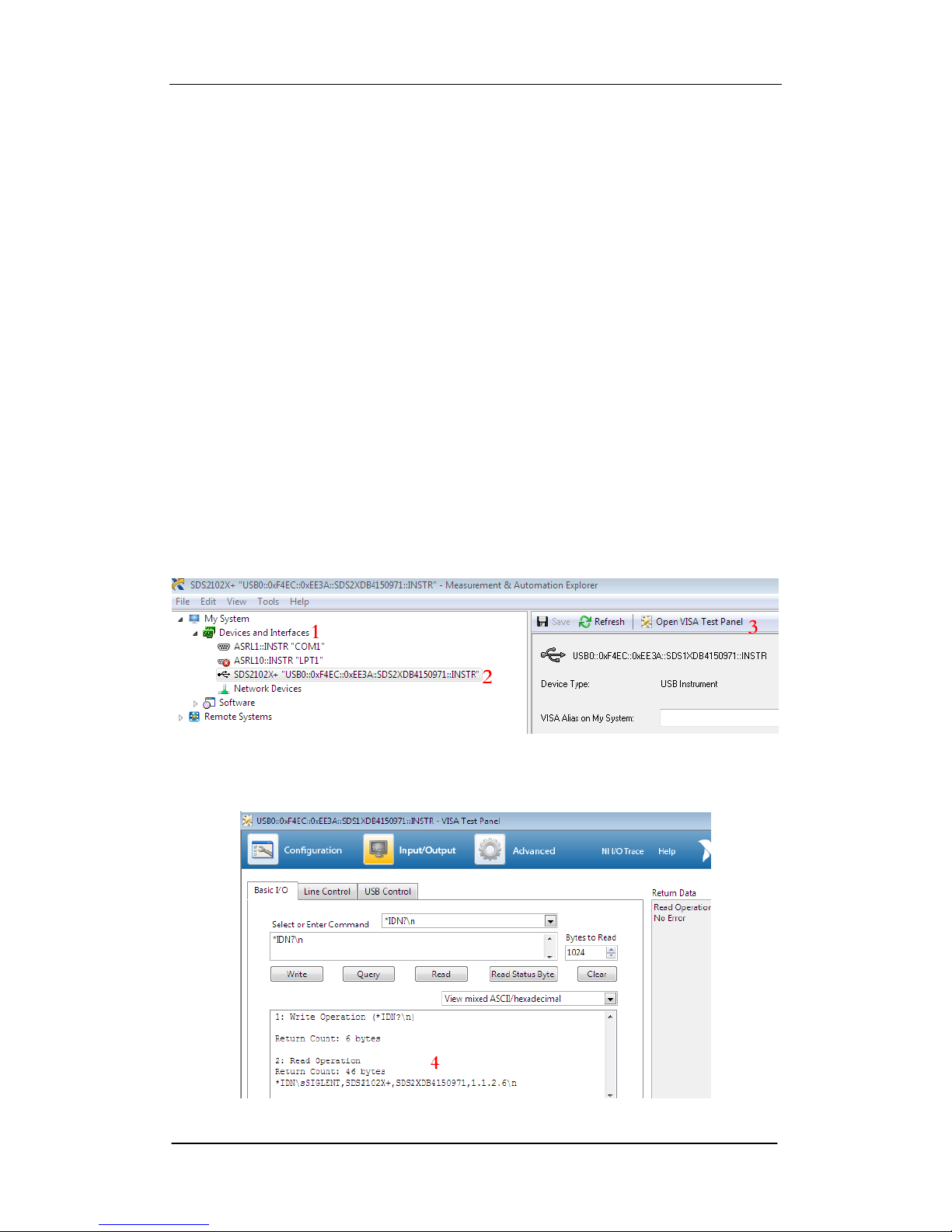

USB Device Test

To test if the USB Device interface operating correctly.

Tools:

● A computer with USB interface

● A standard USB cable (Type AB)

● NI Max software

Steps:

1. Set up NI Max software in a computer and Install the driver step by step

following the instructions.

2. Connect the oscilloscope to the computer using an USB cable.

3. Run NI Max software. Click “Device and Interface” at the upper left corner of

the NI software interface and immediately the “USBTMC” device symbol is

displayed.

4. Click “Open VISA Test Panel” option button, and then the following Interface

will appear. Next, click the “Input/Output” option button and click the “Query”

option button in order to view the Read operation information.

SIGLENT

14 SDS2000X Service Manual

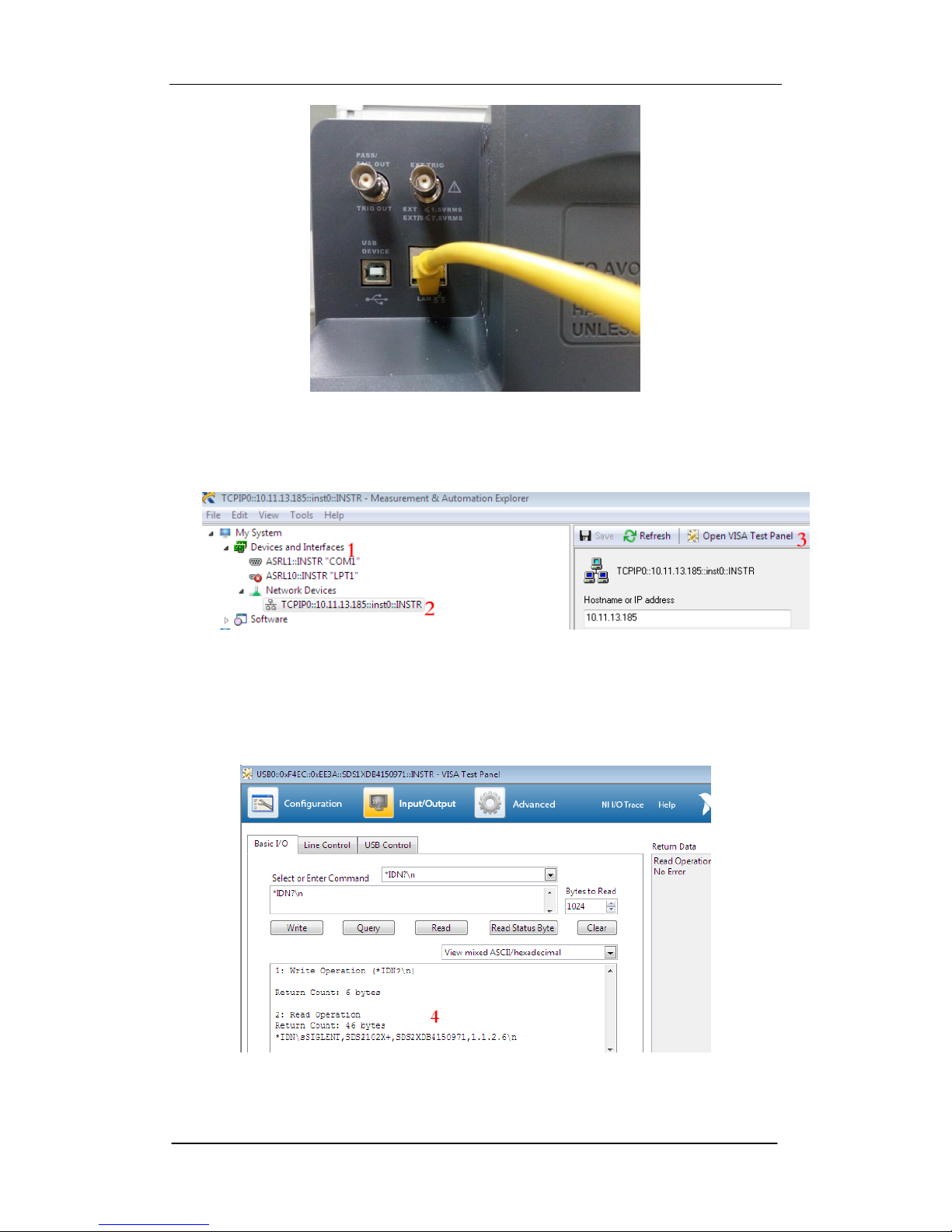

LAN Port Test

Use to test if the LAN interface operates correctly when connected with NI Visa

software.

Tools:

● A computer with LAN interface

● A standard LAN cable

●NI Max software

Steps:

1. Set up NI Max software in a computer and install the driver using the

following instructions.

2. Press Utility Page2/3 I/O LAN, input usable IP Address

and Subnet Mask.

Figure 4 IP Setting interface

3. Connect the oscilloscope to the computer using a LAN cable via the LAN

interface ports.

SIGLENT

SDS2000X Service Manual 15

Figure 5 LAN interface

4. Run NI Max software. Click “Device and Interface” at the upper left corner of

the NI software interface and select the “LAN” device symbol.

5. Click “Open VISA Test Panel” option button, which then displays the

following interface (below). Then click the “Input/Output” option button and

click the “Query” option button;. The Read operation information will be

displayed.

Loading...

Loading...