SIGLENT SDS1000D Service Manual

Service Manual

Service Manual

SDS1000D Digital Storage Oscilloscope

June 2011

SIGLENT Technologies Co., Ltd.

Service Manual

Declaration

Copyright © SIGLENT Technologies Co.,Ltd. All rights reserved.

Contents in this Manual are not allowed to copy, extract and translate before being

allowed by SIGLENT Company.

Service Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this product or

any products connected to it. To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

1. To Avoid Fire or Personal Injury

●

●●

● Use Proper Power Cord. Use only the power cord specified for this product and certified

for the country of use.

●

●●

● Connect and Disconnect Properly. Do not connect or disconnect probes or test leads while

they are connected to a voltage source.

●

●●

● Ground the Product. This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the product, ensure

that the product is properly grounded.

●

●●

● Connect the Probe Properly. The probe ground lead is at ground potential. Do not connect

the ground lead to an elevated voltage.

●

●●

● Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and

marking on the product. Consult the product manual for further ratings information before

making connections to the product.

●

●●

● Do Not Operate Without Covers. Do not operate this product without covers or panels

removed.

●

●●

● Use Proper Fuse. Use only the fuse type and rating specified for this product.

Service Manual

●

●●

● Avoid Exposed Circuitry. Do not touch exposed connections and components when power is

present.

●

●●

● Do Not Operate With Suspected Failures. If you suspect there is damage to this product,

have it inspected by qualified service personnel.

●

●●

● Do Not Operate in Wet/Damp Conditions.

●

●●

● Do Not Operate in an Explosive Atmosphere.

●

●●

● Keep Product Surfaces Clean and Dry.

Power Line Conducted Emission Limits (Class B)

Measuring standard: EN61326:1998+A1, 2002+A2, 2003

2. Safety Terms and Symbols

Terms used on the Product. These terms may appear on the product:

DANGER: Indicates an injury hazard immediately accessible as you read the marking.

WARNING: Indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION: Indicates a hazard to property including the product.

Symbols used on the Product. These symbols may appear on the product:

Service Manual

Document Summarize

Chapter 1 Specifications

List the specifications and general specifications of SDS1000D series digital oscilloscope.

Chapter 2 Prepare for Use

Introduce the preparatory work should be done before using the oscilloscope.

Chapter 3 Performance Test

Introduce how to execute the performance test to understand current performance status of the

oscilloscope.

Chapter 4 Calibration

Introduce how to calibrate the oscilloscope.

Chapter 5 Disassembly and Assembly

Introduce how to disassemble and assemble the oscilloscope to understand its structure.

Chapter 6 Trouble

List the troubles may appear during measuring and the solutions.

Chapter 7 Replaceable Parts

List the replaceable parts for user’s repair or exchange.

Service Manual

Catalogue

Document Summarize.......................................................................................................................6

Chapter 1 Specifications...................................................................................................................8

Specifications............................................................................................................................8

Generic Specifications............................................................................................................12

Chapter 2 Prepare for Use...............................................................................................................13

General Inspecting..................................................................................................................14

Power-On Inspection...............................................................................................................15

Probe Compensation...............................................................................................................16

Auto Setup ..............................................................................................................................17

Chapter 3 Performance Test............................................................................................................19

Interface Test...........................................................................................................................20

USB Host Test................................................................................................................20

USB Device Test.............................................................................................................21

RS-232 Test.....................................................................................................................22

Pass/Fail Test...................................................................................................................24

Specification Test....................................................................................................................25

Test DC Gain Accuracy...................................................................................................25

Test Bandwidth................................................................................................................26

Test Trigger Sensitivity...................................................................................................27

Test Noise........................................................................................................................27

Chapter 4 Calibration......................................................................................................................28

Self Calibration.......................................................................................................................28

Chapter 5 Disassembly and Assembly............................................................................................30

Notice......................................................................................................................................31

Disassemble and Assemble On-off and Knobs.......................................................................32

Disassemble and Assemble Back Rind...................................................................................33

Disassemble and Assemble Back Cover Board.......................................................................34

Disassemble and Assemble Top Cover Board.........................................................................35

Disassemble and Assemble Fan..............................................................................................36

Disassemble and Assemble power board................................................................................37

Disassemble and Assemble Metal Shelf .................................................................................38

Disassemble and Assemble Main board..................................................................................39

Disassemble and Assemble LCD............................................................................................40

Disassemble and Assemble Keyboard ....................................................................................41

Chapter 6 Prompting Messages and Troubleshooting.....................................................................42

Prompting messages:...............................................................................................................42

Troubleshooting......................................................................................................................44

Chapter 7 Updating Parts................................................................................................................45

Service Manual

Chapter 1 Specifications

All specifications apply to 10X probe and SDS1000D Digital Storage Oscilloscopes. To verify

that the oscilloscope meets specifications, the oscilloscope must first meet the following

conditions:

●

The oscilloscope must have been operating continuously for thirty minutes within the

specified operating temperature.

●

You must perform the Do Self Cal operation, accessible through the Utility menu, if the

operating temperature changes by more than 5° C.

●

The oscilloscope must be within the factory calibration interval

①①①①

.

All specifications are guaranteed unless noted “typical”.

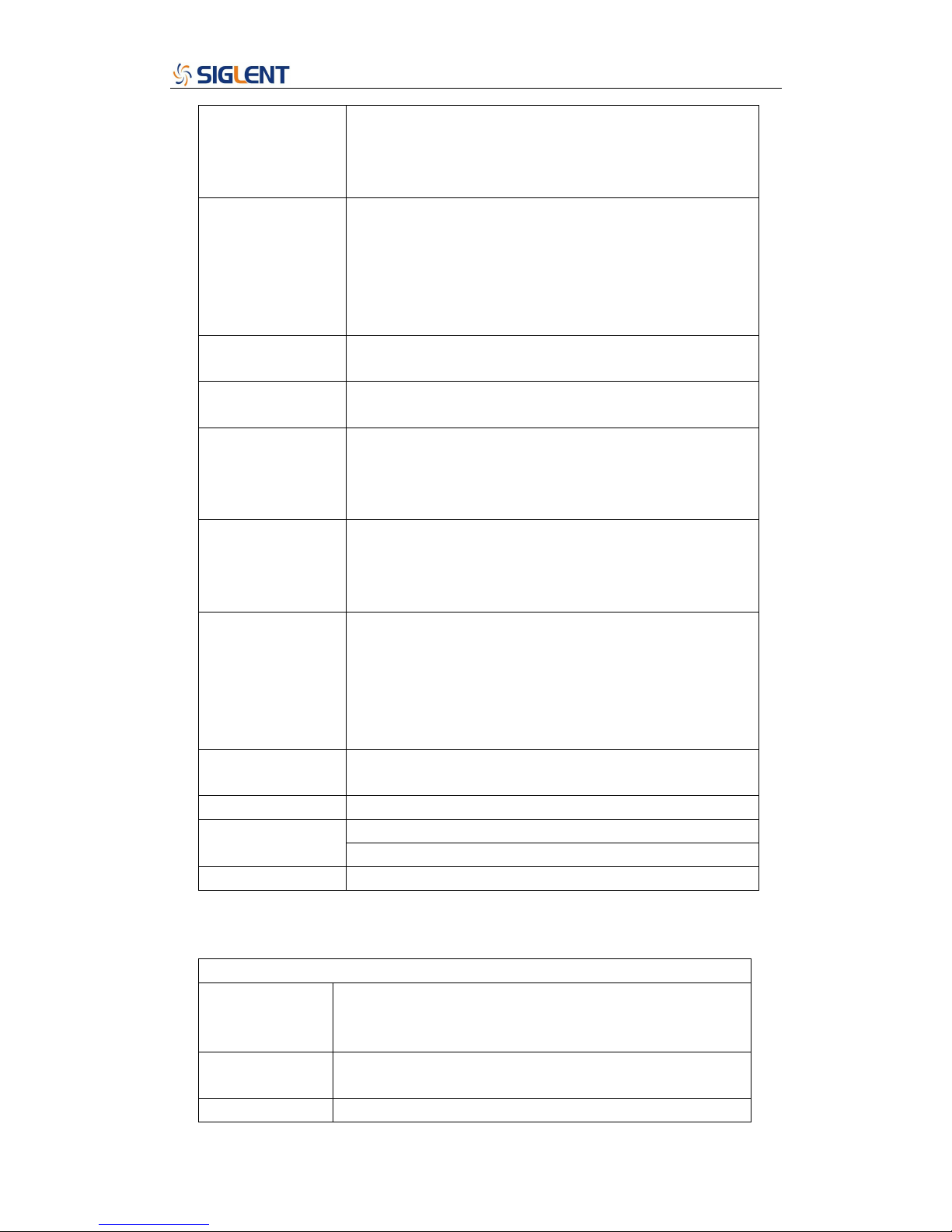

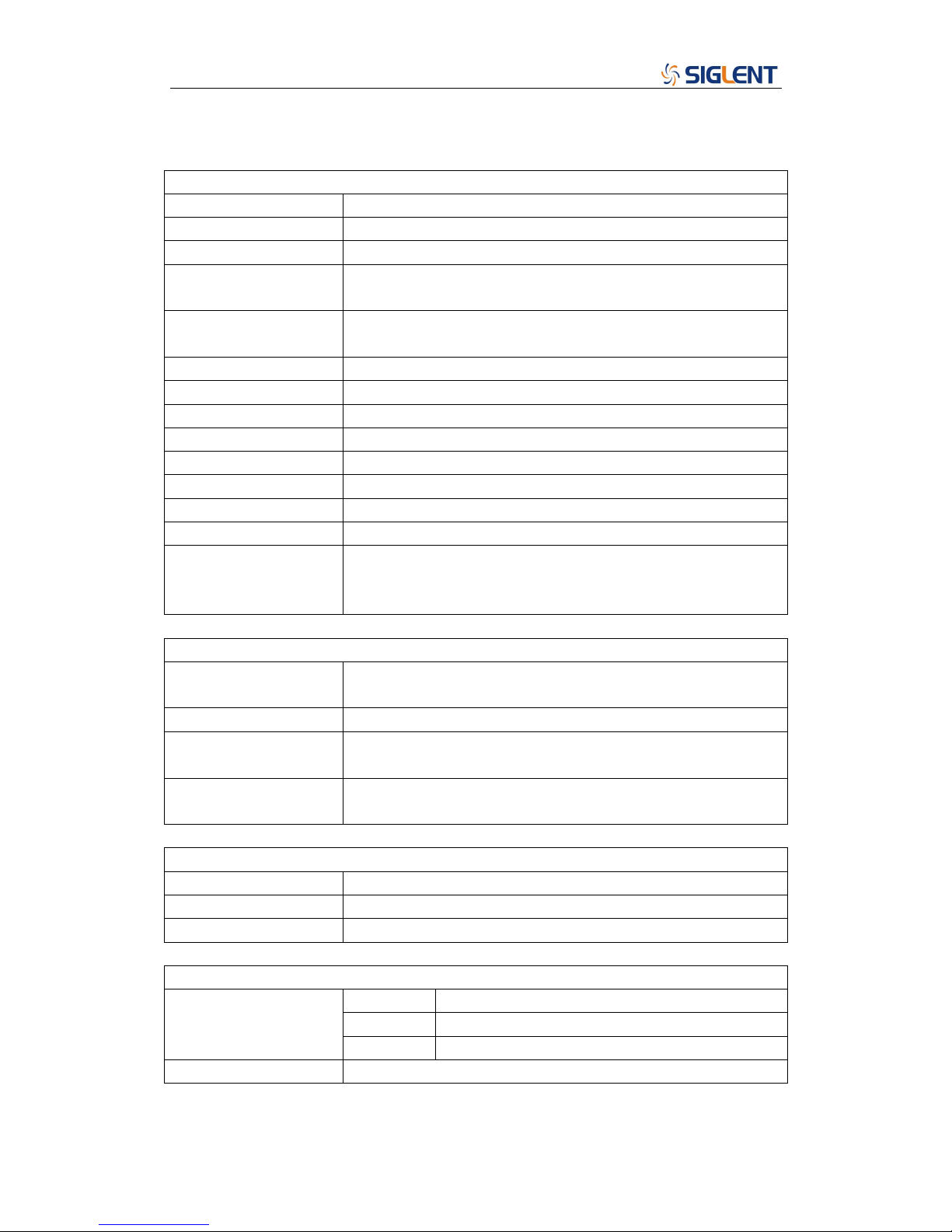

Specifications

Inputs

Input Coupling AC, DC, GND

Input Impedance 1MΩ±2% || 16Pf±3Pf

Maximum input voltage

400V (DC+AC PK-PK,1MΩ input impedance),CAT

I,CAT II

Probe attenuator

1X、10X

Probe attenuator Factors

Set

1X、5X、10X、50X、100X、500X、1000X

Vertical System

Vertical Sensitivity

2mV/div - 10V/div(1-2-5 order)

Channel voltage

offset range

2mV-200mV: ±800mV

206mV-10V: ±40V

Vertical Resolution 8 bit

Channels 2

Analog

Bandwidth

200MHz(SDS1202D)

150MHz(SDS1152D)

Service Manual

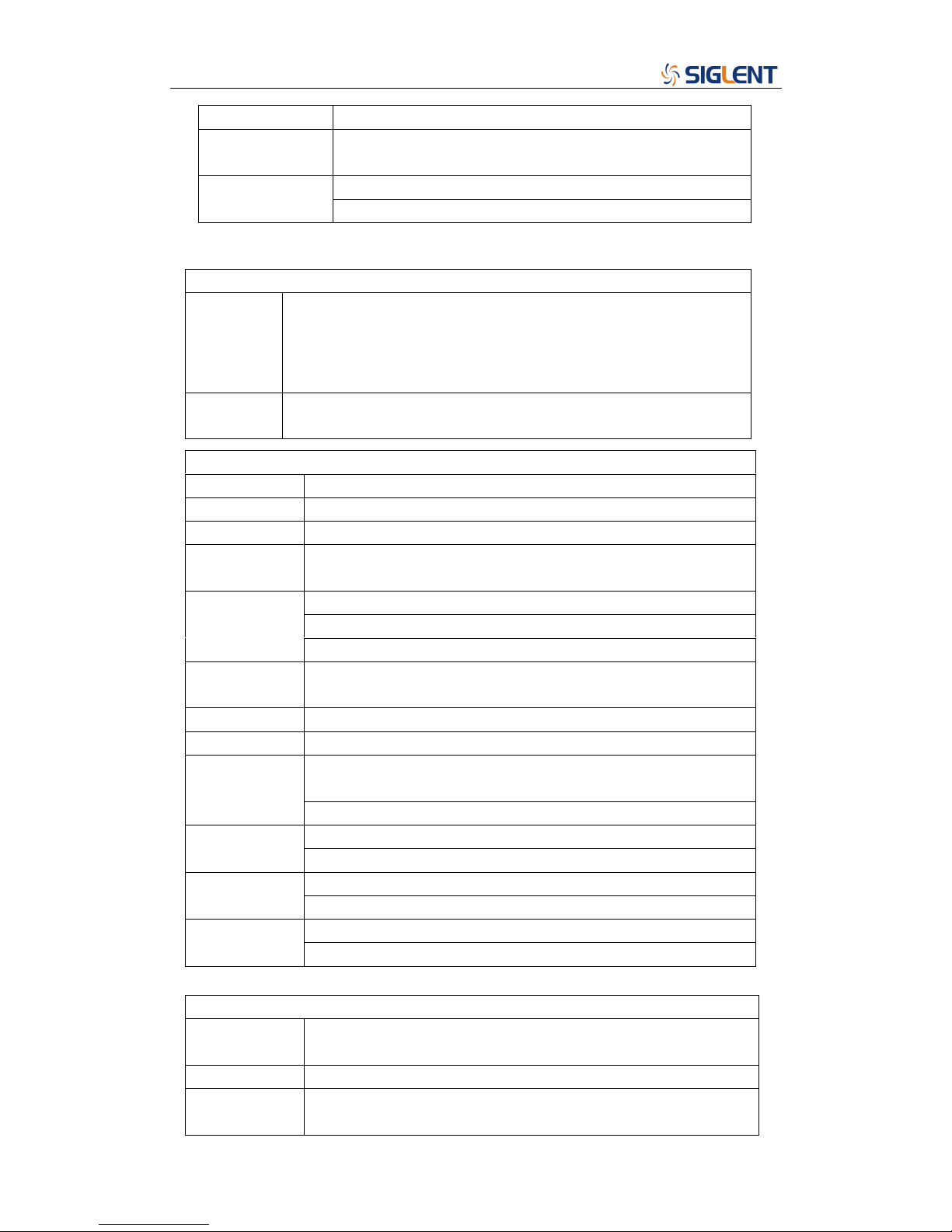

Horizontal System

Real Time

Sampling

Rate

Single Channel:500MSa/s,Double Channel: 250MSa/s

Equivalent

Sampling Rate

50GSa/s

Measure Display MAIN, WINDOW, WINDOW ZOOM, ROLL, X-Y

100MHz(SDS1102D)

60MHz(SDS1062D)

40MHz(SDS1042D)

25MHz(SDS1022D)

Single-shot

Bandwidth

200MHz(SDS1202D)

150MHz(SDS1152D)

100MHz(SDS1102D)

60MHz(SDS1062D)

40MHz(SDS1042D)

25MHz(SDS1022D)

Lower frequency

limit (AC -3dB)

≤10Hz(at input BNC)

DC Gain Accuracy

<±3.0%: 5mv/div to 10V/div in Fixed Gain Ranges

<±4.0%:typical for 2mv/div and Variable Gain Ranges

DC Measurement

Accuracy:

All Gain settings≤

100mv/div

±[3%X(reading+offset)1% of offset +0.2div+2mv]

DC Measurement

Accuracy:

All Gain settings>

100mv/div

±[3%X(reading+offset)1% of offset +0.2div+100mv]

Rise time

<1.7ns (SDS1202D)

<2.3ns (SDS1152D)

<3.5ns (SDS1102D)

<5.8ns (SDS1062D)

<8.8ns (SDS1042D)

<14ns (SDS1022D)

Vertical input

coupling

AC, DC, GND

Math operation +, -, *, /, FFT

Window mode: Hanning, Hamming, Blackman, Rectangular FFT

Sampling points: 1024

Bandwidth limited 20MHz (-3dB)(SDS1022D doesn’t have this function )

Service Manual

Modes

Time base

Accuracy

±50ppm measured over 1ms interval

2.5nS/DIV - 50S/DIV Horizontal Scan

Range

Roll: 100mS/DIV ~50S/DIV (1-2.5-5 order)

Measure System

Auto

Measure

(32 Types)

Vpp, Vmax, Vmin, Vamp, Vtop, Vbase, Vavg, Mean,Crms, Vrms,

ROVShoot, FOVShoot, RPREShoot, FPREShoot, Rise time, Fall time,

Freq, Period,+ Wid,-Wid, +Dut, -Dut, BWid, Phase, FRR, FRF,

FFR, FFF, LRR, LRF, LFR, LFF

Cursor

Measure

Manual mode, Track mode and Auto mode

Trigger System

Trigger Types Edge, Pulse Width, Video, Slope, Alternative

Trigger Source

CH1、CH2、EXT、EXT/5、AC Line

Trigger Modes Auto, Normal, Single

Trigger

Coupling

AC, DC, LF rej, HF rej

CH1,CH2: ±6divisions from center of screen

EXT: ±1.2V

Trigger Level

Range

EXT/5: ±6V

Trigger

Displacement

Pre-trigger:(Memory depth/(2*sampling)),

Delay Trigger: 260DIV

Holdoff range 100ns – 1.5s

Edge Trigger Edge type: Rising, Falling, Rising and Falling

Trigger Modes: ( > , < , = )Positive Pulse Width, ( > , < ,

=)Negative Pulse Width

Pulse Width

Trigger

Pulse Width Range: 20ns – 10s

Support signal Formats: PAL/SECAM, NTSC Video Trigger

Trigger condition : odd field, even field, all lines, line Num

(>,<, =) Positive slope, (>,<, =) Negative slope

Slope Trigger

Time: 20ns-10s

CH1 trigger type: Edge, Pulse, Video, Slope Alternative

Trigger

CH2 trigger type: Edge, Pulse, Video, Slope

X-Y Mode

X-pole Input /

Y-Pole Input

Channel 1 (CH1) / Channel 2 (CH2)

Phase Error ±3 degrees

Sample

Frequency

XY mode has a breakthrough that trade oscilloscopes restrict sampling

rate at 1MSa/s and supports 5KSa/s~200MSa/s ,(1-2.5-5 order)

Service Manual

Hard Ware Frequency Counter

Reading resolution 6 Bytes

Range DC Couple, 10Hz to MAX Bandwidth

Signal Types Satisfying all Trigger signals(Except Pulse width trigger and

Video Trigger)

Control Panel Function

Auto Set

Auto adjusting the Vertical, Horizontal system and Trigger

Position

Save/Recall Support 2 Group referenced Waveforms,20 Group setups,20

Group captured Waveforms internal Storage/Recall function

and USB flash driver storage function.

Service Manual

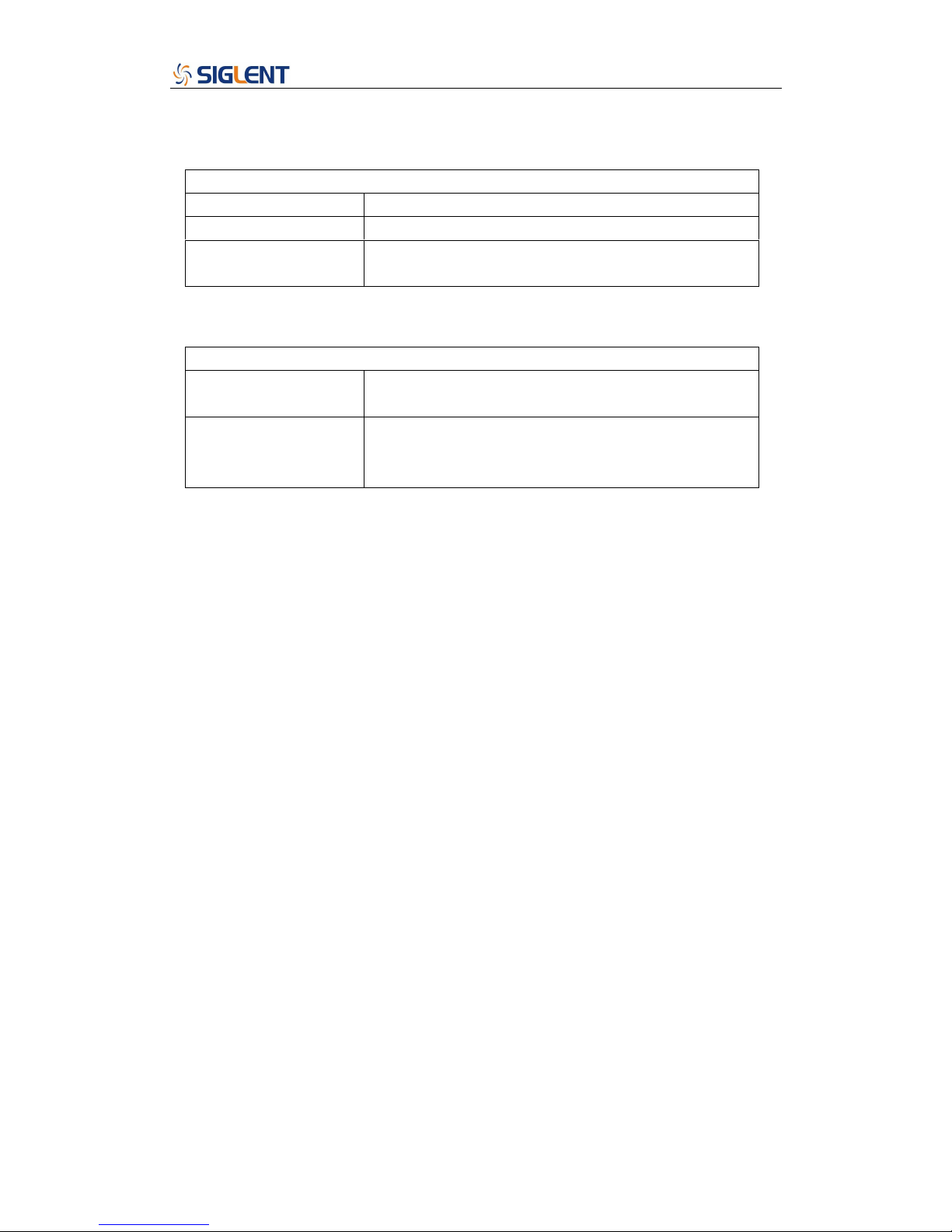

Generic Specifications

Display System

Display Mode Color TFT 5.7in.(145mm)diagonal Liquid Crystal Display

Resolution 320 horizontal by 234 vertical pixels

Display Color 64K color

Display Contrast

(Typical state)

150:1

Backlight Intensity

(Typical state)

300nit

Wave display range 8 x 12 div

Wave Display Mode Point, Vector

Persist Off, 1 sec, 2 sec, 5 sec, Infinite

Menu Display 2 sec, 5 sec, 10 sec, 20 sec, Infinite

Screen-Saver Off,1min,2min,5min,10min,15min,30min,1hour,2hour,5hour

Skin Classical, Modern, Tradition, Succinct

waveform interpolation Sin(x)/x

Color model Normal , Invert

Language Simplified Chinese, Traditional Chinese, English, Arabic, French,

German, Russian, Spanish, Portuguese

Japanese, Korean, Italian

Environments

Temperature Operating:10 to +℃ 40℃

Not operating: -20 to +℃ 60℃

Cooling The fan forces it cold.

Humidity Operating: 85%RH, 40℃, 24 hours

Not operating: 85%RH, 65℃, 24 hours

Height Operating: 3000m

Not operating: 15,266m

Power Supply

Input Voltage 100-240 VAC, CAT II, Auto selection

Frequency Scope 45Hz to 440Hz

Power 50VA Max

Mechanical

length 305mm

Width 133mm

Dimension

Height 154mm

Weight 2.3 kg

Service Manual

Chapter 2 Prepare for Use

This chapter includes the following contents:

● General Inspecting

● Power-On Inspecting

● Connect the Probe

● Probe Compensation

● Auto Setting

Service Manual

General Inspecting

After receiving a new SDS1000D series oscilloscope, please inspect the instrument as follows:

1....Inspect the shipping container for damage.

Keep the damaged shipping container or cushioning material until the contents of the shipment

have been checked for completeness and the instrument has been checked mechanically and

electrically.

2....Inspect the whole instrument.

In case there is any mechanical damage or defect, or the instrument does not operate properly

or fails performance tests, notify the SIGLENT Sales Representative.

If the shipping container is damaged, or the cushioning materials show signs of stress, notify

the carrier as well as the SIGLENT Sales Department. Keep the shipping materials for

carrier’s inspection.

3....Check the accessories.

Accessories supplied with the instrument are listed below. If the contents are incomplete or

damaged, notify the SIGLENT Sales Representative.

Standard Accessories:

● Two pieces 1:1,(10:1) Passive Probes

● An User Manual

● A Certification

● A Guaranty Card

● An CD(including EasyScope3.0 computer software system)

● A Power Cord that fits the standard of destination country

● An USB Cable

Service Manual

Power-On Inspection

Normal operating voltage for DS1000CA series digital oscilloscope is the range of 100-240VRMS

with the frequency from 45Hz to 440Hz. Connect one terminal of the power cord to the socket in

left side of the oscilloscope and the other to the power source.

Picture 2-1 Connect power line

Press the button on top of oscilloscope, some keys on the front panel will be lighted for about 6

seconds until the normal display appears. And then you can operate the oscilloscope.

After power-on, the oscilloscope performs the self test automatically. After the test, press the

“DEFAULT/SETUP” button, then recall the Factory settings.

Picture 2-2 Power-On Inspecting

Loading...

Loading...