Page 1

Service Manual

SDG5000 Series

Function/Arbitrary Waveform Generator

2017 SIGLENT TECHNOLOGIES CO., LTD

Page 2

II SDG5000 Service Manual

Page 3

SDG5000 Service Manual I

Guaranty and Declaration

Copyright

SIGLENT TECHNOLOGIES CO., LTD. All Rights Reserved.

Trademark Information

SIGLENT is the registered trademark of SIGLENT TECHNOLOGIES CO., LTD

Declaration

SIGLENT products are protected by patent law in and outside of P.R.C.

SIGLENT reserves the right to modify or change parts of or all the

specifications or pricing policies at company‟s sole decision.

Information in this publication replaces all previously corresponding

material.

Any way of copying, extracting or translating the contents of this manual is

not allowed without the permission of SIGLENT.

SIGLENT will not be responsible for losses caused by either incidental or

consequential in connection with the furnishing, use or performance of this

manual as well as any information contained.

Product Certification

SIGLENT guarantees this product conforms to the national and industrial

standards in china as well as the ISO9001: 2008 standard and the ISO14001:

2004 standard. Other international standard conformance certification is in

progress.

Page 4

II SDG5000 Service Manual

General Safety Summary

Carefully read the following safety precautions to avoid person injury and

prevent damage to the instrument or any products connected to it. To avoid

potential hazards, please use the instrument as specified.

Only qualified technician should perform service procedures

Use Proper Power Line

Use only the special power line of the instrument that approved by local state.

Ground the Instrument

The instrument grounds through the protective terra conductor of the power

line. To avoid electric shock, the ground conductor must be connected to the

earth. Make sure the instrument is grounded correctly before connect its input

or output terminals.

Connect the Signal Wire correctly

The potential of the signal wire is equal to the earth, so do not connect the

signal wire to a high voltage. Do not touch the exposed contacts or

components.

Look Over All Terminals’ Ratings

To avoid fire or electric shock, please look over all ratings and sign instruction

of the instrument. Before connecting the instrument, please read the manual

carefully to gain more information about the ratings.

Do not Operate with Suspected Failures

If you suspect that there is a damage of the instrument, please let a qualified

service personnel check it.

Avoid Circuit or Components Exposed

Do not touch exposed contacts or components when the power is on.

Do not Operate in Wet/Damp conditions

Do not Operate in an Explosive Atmosphere

Keep the Surface of the Instrument Clean and Dry

Page 5

SDG5000 Service Manual III

Safety Terms and Symbols

Terms used on the instrument. Terms may appear on the instrument:

DANGER: Indicates an injury or hazard that may immediately happen.

WARNING: Indicates an injury or hazard that may not immediately happen.

CAUTION: Indicates a potential damage to the instrument or other property

that might occur.

Symbols used on the instrument. Symbols may appear on the instrument:

Hazardous Protective Warning Earth Ground Power

Voltage Earth Ground Switch

Page 6

IV SDG5000 Service Manual

Overview for the Document

The document is for SDG5000 series arbitrary waveform generator, which will

be mostly written as generator for short in the following text. The main contents

described in this manual are:

SDG5000 Series Generator at a glance

This part introduces the main technology characteristics for SDG5000

generator.

The Front Panel at a glance

This part introduces briefly all the buttons and the knob on the front panel.

The Rear Panel at a glance

This part introduces all the ports for easy communication on the rear panel.

Specification

Chapter 1 lists the generator‟s specifications.

Quick Start

Chapter 2 prepares the generator for use and helps you get familiar with a few

of its front-panel features.

Calibration

Chapter 3 provides calibration, verification and adjustment procedures for the

generator.

Assembly Procedures

Chapter 4 provides disassembly procedures for you to get an understanding of

the structure of the generator, thus to install or replace some needed modules,

or troubleshoot faults you encounter while operating it.

Troubleshooting

Chapter 5 provides troubleshooting procedures for the internal main board and

power supply board, as well as the quick guide for general troubles. Before any

operation, you should read the ESD Precautions to avoid personal injuries or

damages to the generator

Maintenance

Chapter 6 provides information on maintenance, daily care and unpacking

inspection of the instrument. The contact information is attached in the end in

case of some unsolvable troubles you encounter.

Page 7

SDG5000 Service Manual V

Convention for the whole Contents

All the description for function and performance in this document are according

to SDG5162 series generator, and apply to generator of the other types. The

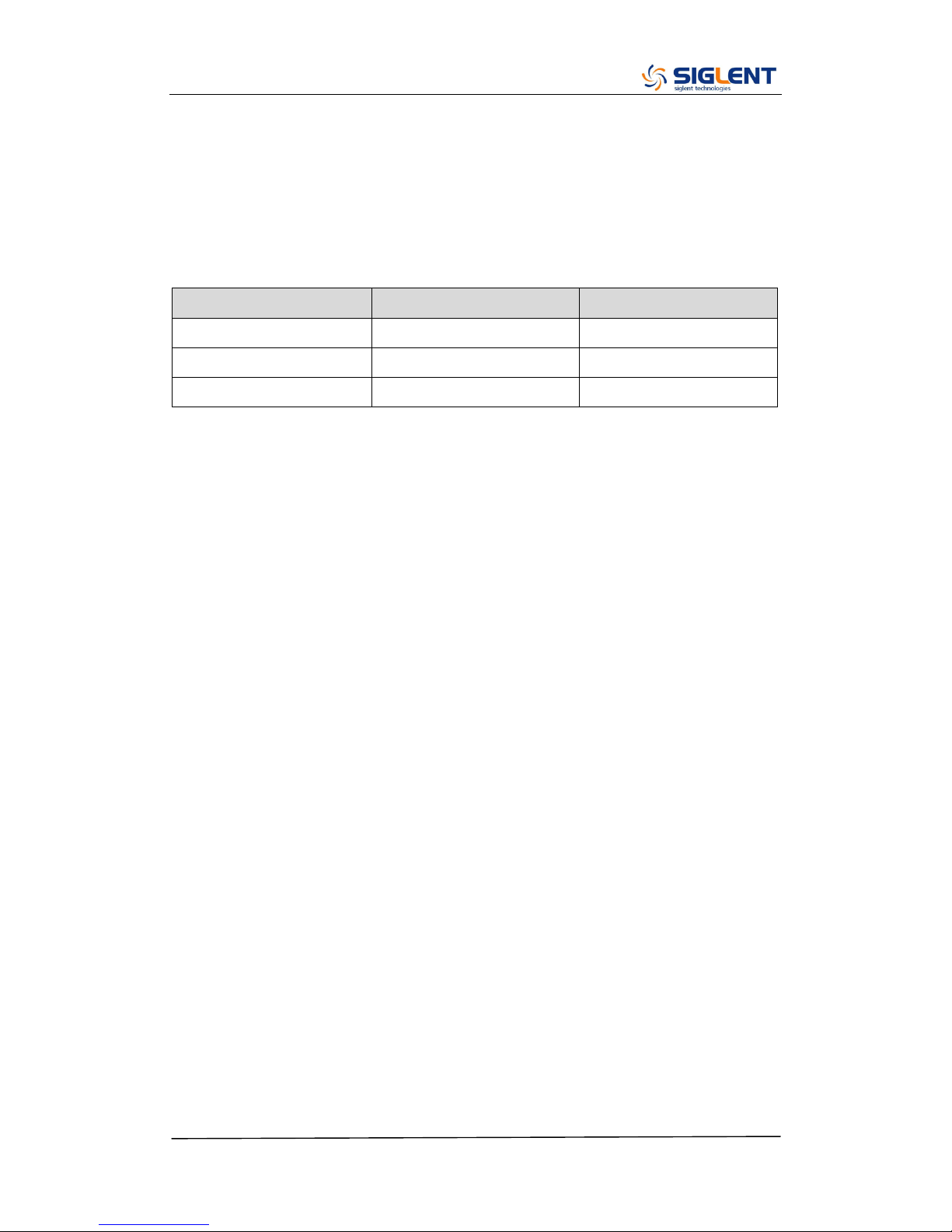

SDS5000 series contains the following types:

Type

Analog Bandwidth

Channel

SDG5082

80 MHz

2

SDG5122

120 MHz

2

SDG5162

160 MHz

2

Page 8

SDG5000_ServiceManual_SM0205

0-E02A

VI

SDG5000 Series at a Glance

SDG5000 Series adopt the direct digital synthesis (DDS) technology, which

can provide stable, high-precision, pure and low distortion signals. Its

combination of excellent system features, easiness in usage and versatile

functions makes this generator a perfect solution for your testing now and in

the future.

Characteristics

Reading the characteristics and specifications given below, you will

understand how SDG5000 can satisfy your requirements.

DDS technology provides precise, stable and low distortional output signal.

4.3inch‟TFT color LCD display.

500MSa/s sampling rate, 14-bit resolution.

Frequency characteristics:

Sine: 1μHz to 160 MHz

Square: 1μHz to 50 MHz

Ramp: 1μHz to 4MHz

Pulse: 1μHz to 40MHz

White Noise: 100MHz bandwidth (-3dB)

Arbitrary: 1μHz to 40MHz

5 standard waveforms: Sine, Square, Ramp, Pulse, Noise.

Self-defined arbitrary waveform.

Multiple modulation function, various modulated waveform: AM, DSB-AM,

FM, PM, ASK, FSK, PWM, Sweep and Burst.

Multiple I/O: external modulation source, external 10 MHz reference input,

external trigger source, waveform output, synchronous signal output.

Support USB storage device. Software updating could also be performed

using USB devices.

Up to 512k sample points of internal waveform depth, which can rebuild or

Page 9

SDG5000_ServiceManual_SM02050-E02A

VII

simulate any complex waveform.

Remote control is realized using the USB cable.

Multiple interfaces: USB host & device. USB-GPIB (IEEE-488) and LAN

(option).

Support the seamless connection with SIGLENT Series Digital

Oscilloscopes; Being able to directly read and rebuild the stored waveform

in the oscilloscopes.

2 languages(English and Chinese)user interface and built-in help system.

Note: All the specifications described in this manual are according to

SDG5162.

Page 10

SDG5000_ServiceManual_SM0205

0-E02A

VIII

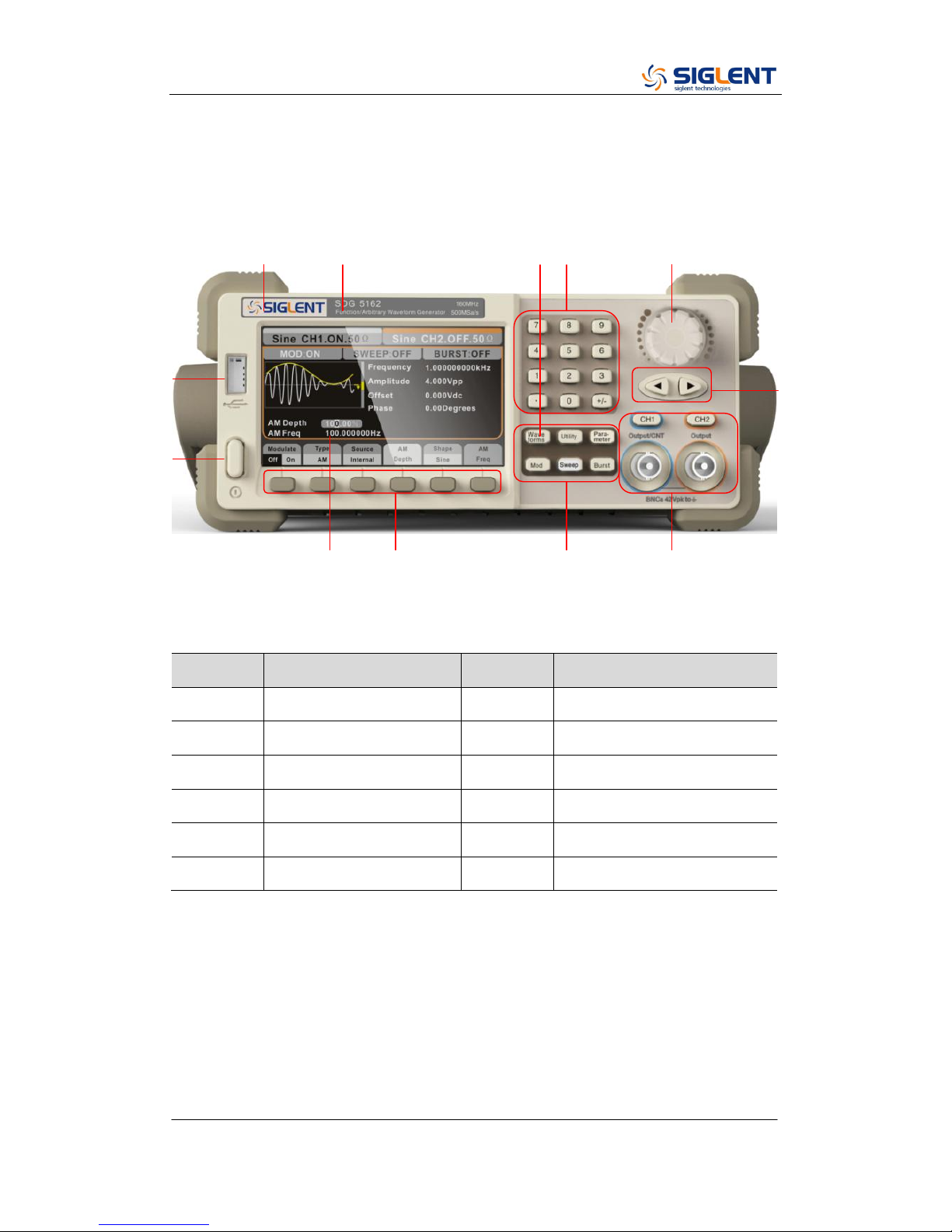

The Front Panel at a Glance

No.

Description

No.

Description

1

Power Switch

7

Universal Knob

2

LCD Display

8

Numeric Keypad

3

Menu Operation

9

Waveform Key

4

Function Keys

10

Type

5

Output Control

11

Logo

6

Direction Keys

12

USB Host

2 3 4 5

11 10 9 8 7

6

1

12

Page 11

SDG5000_ServiceManual_SM02050-E02A

IX

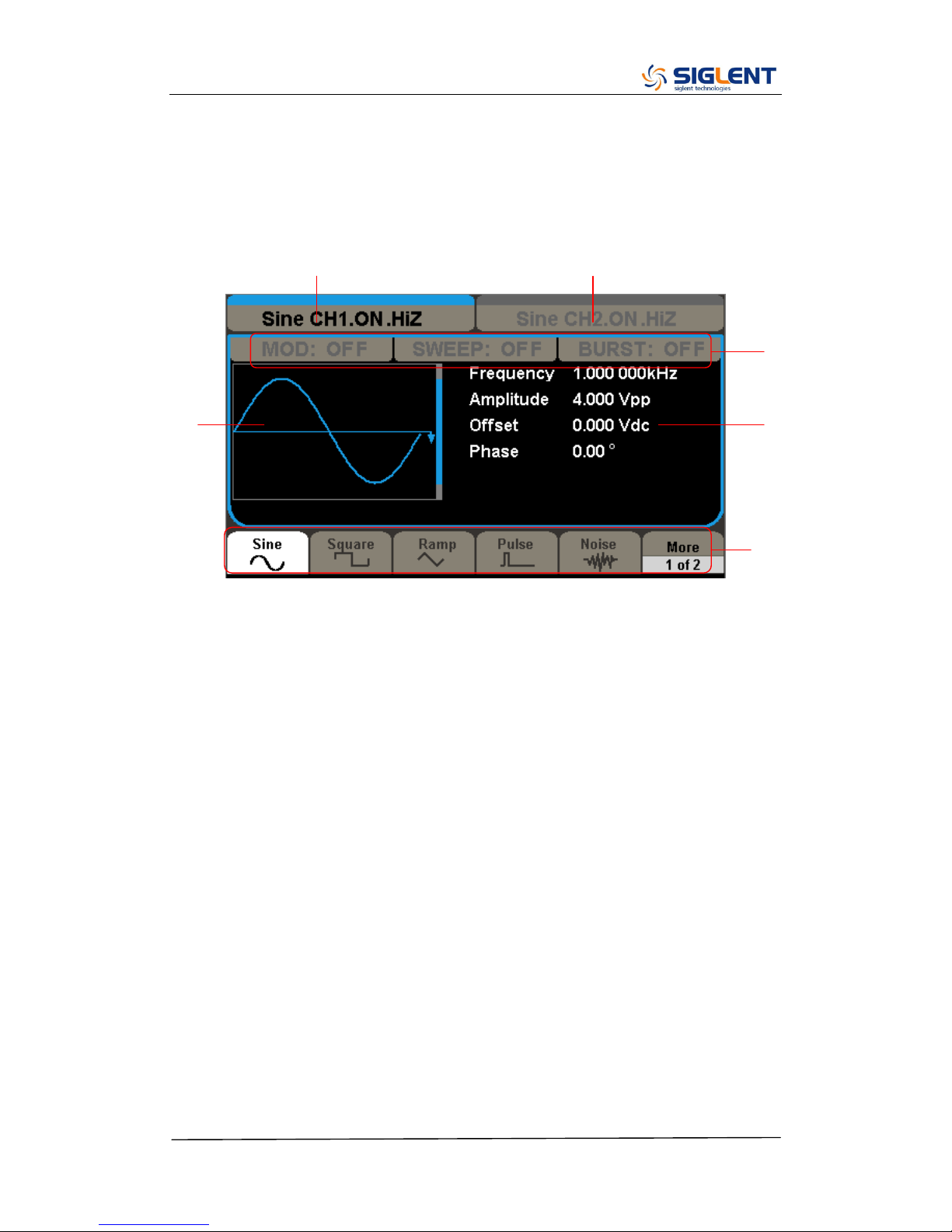

The Front Panel Display at a Glance

Figure1 Display Interface (Sine Wave is the default waveform)

Here are the character definitions in this Service Manual:

The signs for buttons in this manual are the same as the panel buttons. Please

note that, the signs for the functional buttons on the operation panel are

represented by squared words, such as Waveforms, which represents the

transparent functional key with Sine on it on the front panel, while the menu

buttons are represented by brighten words such as Frequency, which means

the frequency option in the Sine menu.

Function

Status

Channel 1 information

Channel 2 information

Waveform

Parameters

Waveform

Display

Waveform type

operational key

Page 12

SDG5000_ServiceManual_SM0205

0-E02A

X

The Rear Panel at a Glance

1. Ext Trig/Gate/FSK/Burst connector

2. 10MHz Output connector

3. USB Device connector

4. Power Socket

5. 10MHz Input connector

6. Sync Output connector

7. Modulation Input connector

WARNING: For protection from electric shock, the grounding power cord must

not be defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

6 5

1 2 3 4

7

Page 13

SDG5000_ServiceManual_SM02050-E02A

XI

Contents

Guaranty and Declaration .......................................................................................................... I

General Safety Summary .......................................................................................................... II

Safety Terms and Symbols ...................................................................................................... III

Overview for the Document ..................................................................................................... IV

SDG5000 Series at a Glance .................................................................................................... VI

The Front Panel at a Glance ................................................................................................. VIII

The Rear Panel at a Glance ...................................................................................................... X

Specification .................................................................................................................................. 1

Specifications ........................................................................................................................ 1

General Specifications ........................................................................................................ 7

Quick Start ..................................................................................................................................... 8

Prepare the Generator for Use .......................................................................................... 9

Adjust the carrying Handle .............................................................................................. 10

Set the Output Frequency ................................................................................................ 11

Set the Output Amplitude ................................................................................................. 13

Set the DC offset ................................................................................................................ 14

Set the Duty Cycle of a Square Wave ........................................................................... 15

Set the Symmetry of a Ramp Wave ............................................................................... 16

Generate a Pulse Waveform ............................................................................................ 17

Generate a Noise Waveform ............................................................................................ 19

Set the DC Voltage ............................................................................................................. 21

Output a Built-In Arbitrary Waveform ........................................................................... 22

Use the Built-In Help System .......................................................................................... 23

Calibration .................................................................................................................................... 24

Calibration Interval ............................................................................................................ 24

Adjustment Recommendations ...................................................................................... 24

Automating Calibration Procedures.............................................................................. 24

Recommended Test Equipment ..................................................................................... 25

Test Considerations ........................................................................................................... 25

Performance Verification Test ......................................................................................... 26

DC Output Verification .............................................................................................. 27

AC Amplitude Verification ........................................................................................ 28

Frequency Response Verification .......................................................................... 29

General Adjustment Procedure ...................................................................................... 31

Scripts for Calibration ............................................................................................... 32

Software Environment .............................................................................................. 32

Warming up .................................................................................................................. 32

Channel Adjustment .................................................................................................. 33

Frequency Response Adjustments ....................................................................... 37

Page 14

SDG5000_ServiceManual_SM0205

0-E02A

XII

Assembly Procedures ............................................................................................................... 38

Security Consideration ..................................................................................................... 38

List of Modules ................................................................................................................... 39

Required Tools .................................................................................................................... 39

Disassembly Procedures ................................................................................................. 39

A view of the whole Instrument ...................................................................................... 40

Removing the Handle ........................................................................................................ 41

Removing the Metal Shell and Rear Cabinet ............................................................... 42

Removing the Front Cabinet ........................................................................................... 43

Removing the Display Module ........................................................................................ 44

Removing the Main Body ................................................................................................. 45

Troubleshooting ......................................................................................................................... 47

ESD Precautions ................................................................................................................ 47

Required Equipment .......................................................................................................... 47

Channel Board Drawing ................................................................................................... 48

Main Board Drawing .......................................................................................................... 49

Check the Power Supply .................................................................................................. 50

Check the Channel Board ................................................................................................ 52

Voltage Checking ........................................................................................................ 52

FPGA Checking ........................................................................................................... 53

Check the Main Board ....................................................................................................... 54

Voltage Checking ........................................................................................................ 54

Mainboard Clock Checking...................................................................................... 54

DSP/CPLD Checking ................................................................................................. 55

Quick Guide for General Failures .................................................................................. 56

Maintenance ................................................................................................................................ 57

Maintain Summary ............................................................................................................. 57

Repackaging for Shipment .............................................................................................. 58

Contact SIGLENT ............................................................................................................... 59

Page 15

SDG5000 Service Manual

1

Specification

These specifications apply to SDG5000 series Arbitrary Waveform Generator.

To verify that an oscilloscope meets specifications, it must first meet the

following conditions:

The generator must have been operating continuously for fifteen minutes

within the specified operating temperature.

You must perform the Self Adjust operation, accessible through the Utility

menu, if the operating temperature changes by more than 5 °C.

The oscilloscope must be within the factory calibration interval of one year.

Specifications

Model

SDG5082

SDG5122

SDG5162

Maximum output frequency

80MHz

120MHz

160MHz

Output channels

2

Sample rate

500MSa/s

Arbitrary waveform length

CH1: 16kpts , CH2: 512kpts

Frequency resolution

1μHz

Vertical resolution

14 bits

Modulation

AM, DSB- AM, FM, PM, FSK, ASK, PWM, Sweep, Burst

Frequency counter

Frequency range:100mHz ~ 200MHz

Standard interface

USB Host & Device

Dimension

W x H x D=261mm x 105mm x 344mm

Page 16

SDG5000 Service Manual

2

Frequency Specification

Model

SDG5082

SDG5122

SDG5162

Waveform

Sine, Square, Ramp, Pulse, Noise, Arbitrary waveform

Sine

1μHz ~ 80MHz

1μHz ~120MHz

1μHz ~ 160MHz

Square

1μHz ~ 30MHz

1μHz ~ 40MHz

1μHz ~ 50MHz

Pulse

1μHz ~ 20MHz

1μHz ~ 30MHz

1μHz ~ 40MHz

Ramp

1μHz ~ 2MHz

1μHz ~ 3MHz

1μHz ~ 4MHz

Gaussian Noise

100MHz (-3dB)

Arbitrary waveform

1μHz ~ 20MHz

1μHz ~ 30MHz

1μHz ~ 40MHz

Resolution

1μHz

Accuracy

within 1 year ±2ppm 0°C ~ 55°C

Square Wave

Rise/Fall time(10% ~ 90%)

6ns

Overshoot

< 3%

Duty

Cycle

1μHz ~ 10 MHz

20% ~ 80%

10 MHz(exclude)~ 40 MHz

40% ~ 60%

40 MHz(exclude)~ 50 MHz

50%

Asymmetric(50% Duty Cycle)

1% of Cycle + 5 ns(typical value)

Jitter (cycle to cycle)

< 100ps(typical value, rms)

Pulse Wave

Period

Maximum: 1000000s Minimum: 25 ns

Pulse width

≥12ns, resolution: 100ps

Rise/Fall time(10% ~ 90%)

6ns ~ 6s, resolution: 100ps

Duty Cycle

0.0001% ~ 99.9999%

Overshoot

< 3%

Jitter (cycle to cycle)

< 100ps(typical value, rms)

Sine Wave Spectrum Purity

Harmonic distortion

DC-1 MHz

<-54dBc

1 MHz - 10 MHz

<-46dBc

10 MHz - 100 MHz

<-36dBc

100 MHz - 160 MHz

<-30dBc

Total harmonic waveform distortion

DC ~ 20 kHz

1Vpp <0.2%

Spurious signal(non-harmonic)

DC ~ 1 MHz

< -70dBc

1 MHz ~ 10 MHz

<-70dBc+6dB/spectrum phase

Phase noise

100kHz Offset, –116dBc / Hz(typical value)

Page 17

SDG5000 Service Manual

3

Ramp Wave

Linearity

< 0.1% of output Peak value

(typical value, 1 kHz, 1Vpp, symmetric 100%)

Symmetry

0% ~ 100%

Arbitrary Waveform

Channel

CH1

CH2

Waveform length

16kpts

512kpts

Vertical resolution

14 bits

14 bits

Sample rate

500MSa/s

500MSa/s

Minimum Rise/Fall time

5ns(typical value)

5ns(typical value)

Jitter(RMS)

2ns(maximum)

2ns(maximum)

Output Characteristics

Channel

CH1

CH2

Amplitude (50Ω )

1mVpp~ 10Vpp(≤40MHz)

1mVpp ~ 10Vpp(≤40MHz)

1mVpp~5Vpp

(40MHz~100MHz)

1mVpp~5Vpp

(40MHz~100MHz)

1mVpp~2.5Vpp

(100MHz~130MHz)

1mVpp~2.5Vpp

(100MHz~130MHz)

1mVpp ~ 1.5Vpp

(130MHz~160MHz)

1mVpp ~ 1.5Vpp

(130MHz~160MHz)

Vertical resolution

(100 kHz sine waveform)

±(0.3dBm+1mVpp)

±(0.3dBm+1mVpp)

Amplitude flatness(based on

100kHz Sine Waveform, 1Vpp)

≤10MHz, ±0.1 dB

≤10MHz, ±0.1 dB

≤60MHz, ±0.2 dB

≤60MHz, ±0.2 dB

≤100MHz, ±0.4 dB

≤100MHz, ±0.4 dB

≤160MHz, ±0.8 dB

≤160MHz, ±0.8 dB

Isolate channel depth

< -80dB

Channel delay

< 1ns

DC

Output characteristic

CH1

CH2

Range(DC)

±5 V(50ohm)

±10 V(high resistance)

±5 V(50ohm)

±10 V(high resistance)

Offset accuracy

±(1%*|setting offset |+1 mV)

±(1%*|setting offset |+1 mV)

Page 18

SDG5000 Service Manual

4

Waveform Output

Channel

CH1/CH2

Impedance

50Ω (typical value)

Protection

short-circuit protection

Isolation

The BNC connectors for channel output, synchronous and modulation input

are isolated to the Re Rack Earth, and the allowable voltage range is ±

42Vpk

AM/DSB-AM Modulation(CH1/CH2)

Carrier

Sine, Square, Ramp, Arbitrary(except DC)

Source

Internal/External

Modulated wave

Sine, Square, Ramp, Noise, Arbitrary

Modulation depth

0% ~ 120%

Modulation frequency

1mHz~50kHz

FM Modulation(CH1/CH2)

Carrier

Sine, Square, Ramp, Arbitrary(except DC)

Source

Internal/External

Modulation waveform

Sine, Square, Ramp, Noise, Arbitrary

Modulation frequency

1mHz ~ 50kHz

PM Modulation(CH1/CH2)

Carrier

Sine, Square, Ramp, Arbitrary(except DC)

Source

Internal/External

Modulation waveform

Sine, Square, Ramp, Noise, Arbitrary

Modulation frequency

1mHz ~ 50kHz

Phase deviation

0 ~ 360°

FSK Modulation(CH1/CH2)

Carrier

Sine, Square, Ramp, Arbitrary(except DC)

Source

Internal/External

Modulation waveform

50% duty square waveform

Key frequency

1mHz ~ 1MHz

ASK Modulation(CH1/CH2)

Carrier

Sine, Square, Ramp, Arbitrary(except DC)

Source

Internal/External

Modulation waveform

50% duty square waveform

Key frequency

1mHz ~ 1MHz

PWM Modulation (CH1/CH2)

Carrier

Pulse

Source

Internal/External

Modulation waveform

Sine, Square, Ramp, Noise, Arbitrary

Modulation frequency

1mHz ~ 50kHz

Sweep(CH1/CH2)

Carrier

Sine, Square, Ramp, Triangle, Arbitrary (except DC)

Page 19

SDG5000 Service Manual

5

Type

linear/logarithmic

Direction

Up/ down

Sweep time

1ms ~ 500s ± 0.1%

Trigger source

Manual, external, internal

Burst(CH1/CH2)

Waveform

Sine, Square, Ramp, Pulse, Noise, Arbitrary (except DC)

Carrier frequency

2mHz ~ 100MHz

Type

Count(1 ~ 1000000 cycles), infinite, Gated

Start/Stop phase

0° ~ 360°

Internal cycle

1μs ~ 1000s ± 1%

Trigger delay

296ns ~ 34s

Gated source

External trigger

Trigger source

Manuel, External or Internal

External Modulation Input

Connector

The rear panel BNC connector, isolated to the Re Rack Earth

Input amplitude

± 4.5Vpk=100% modulation, input impedance >5kΩ

The external input voltage can‟t be over ± 5Vpk, or the instrument will get damaged.

Trigger Input

Connector

The rear panel BNC connector, rack (reference)

Voltage level input

TTL compatible

Slope

Up or down (optional)

Pulse width

> 50 ns

Input impedance

> 5kΩ, DC coupling

Response time

380ns(typical value)

Trigger Output

Connector

The rear panel BNC connector, rack (reference)

Voltage level

TTL compatible

Pulse width

> 60ns(typical value)

Output impedance

50Ω(typical value)

Maximum frequency

1 MHz

SYNC Output

Connector

The rear panel BNC connector, isolated to the Re Rack Earth

Voltage level

TTL compatible

Pulse width

> 50 ns(typical value)

Output impedance

50Ω(typical value)

Maximum frequency

10MHz

Page 20

SDG5000 Service Manual

6

REFCLK Input(10MHz ~ In)

Connector

The rear panel BNC connector, isolated to the Re Rack Earth and all the

other connectors.

Lock range

10MHz ± 50Hz

Signal level

2.3Vpp ~ 3.3Vpp

Lock Time

< 2 s

Input impedance

1KΩ, AC coupling

REFCLK Input(10MHz ~ Out)

Connector

The rear panel BNC connector, rack (reference)

Output frequency

10MHz

Signal level

>1Vpp

Output impedance

50Ω, AC coupling

Frequency Counter

Measurement

Frequency, Period, positive/negative Pulse Width, Duty Cycle

Frequency range

Single Channel: 100mHz ~ 200 MHz

Frequency resolution

6 bits/s

Voltage range and sensitivity(non-modulated signal)

Manual

DC coupling

DC deviation range

±1.5 VDC

100mHz ~ 100 MHz

50mVrms ~ ±2.5V

100 MHz ~ 200 MHz

100mVrms ~ ±2.5V

AC coupling

1 Hz ~ 200 MHz

100mVrms ~ 5Vpp

Pulse Width and Duty

measurement

6Hz ~ 10MHz(80mVrms ~ 5Vpp)

Input adjustment

Input impedance

1 MΩ

Coupling mode

AC/DC

HFR

On/Off

Trigger method

Trigger level range: -3 v ~ 1.8v

Page 21

SDG5000 Service Manual

7

General Specifications

Display

Display type

4.3‟TFT-LCD

Resolution

480×RGB×272

Color

24bit

Contrast(typical value)

500:1

Backlight intensity (typical )

300cd/m2

Power

Voltage

100~240 VACRMS, 45~66 Hz, CATII

100~127 VACRMS, 45~440 Hz, CATII

Power

< 30W

Fuse

1.25A, 250V

Environment

Environmental Temperature

Operation: 0°C ~ 40°C

Non-operation: -20°C ~ 60°C

Cooling method

natural cooling down

Humidity range

Below +35℃: ≤90% relative humidity

+35℃ ~ +40℃: ≤60% relative humidity

Altitude

Operation: < 3,000m

Non-operation: <15,000m

Mechanical

Dimension

Width: 261mm

Height: 105mm

Depth: 344mm

Weight

N.W: 2.8 Kg

IP Protection

IP2X

Calibration Cycle

1 year

Page 22

SDG5000 Service Manual

8

Quick Start

One of the first things you will want to do with your generator is to become

acquainted with the front panel. We have written the exercises in this chapter

to prepare the instrument for use and help you get familiar with some of its

front-panel operations. This chapter is divided into the following sections:

To Prepare the Generator for Use

To Adjust the Carrying Handle

To Set the Output Frequency

To Set the Output Amplitude

To Set a DC Offset Voltage

To Set the Duty Cycle of a Square Wave

To Set the Symmetry of a Ramp Wave

To Configure a Pulse Waveform

To Configure a Noise Waveform

To Select “DC Volts”

To Output a Built-In Arbitrary Waveform

To Use the Built-In Help System

Page 23

SDG5000 Service Manual

9

Prepare the Generator for Use

1. Check the list of accessories

Accessories supplied with the instrument are listed below. If anything is

missing or damaged, please contact your nearest SIGLENT Sales Office.

A Quick Start

A Calibration Certificate

A CD(EasyWave software, Datasheet and User Manual)

A power cord that fits the standard of destination country

A USB cable

2. Connect the power cord and turn on the generator

The instrument runs a short power-on self test, which takes a few seconds.

The generator powers up in the sine wave function at 1 kHz with an amplitude

of 4Vpeak-to-peak (Channel 1). At power-on, the Output connector is disabled.

To enable the Output connector, press the Output key.

If the generator does not turn on, verify that the power cord is firmly connected

to the power socket on the rear panel (the power-line voltage is automatically

sensed at power-on). You should also make sure that the generator is

connected to a power source that is energized.

Then, verify that the generator is turned on.

Note: If the power-on self test fails, the generator may stop with black screen.

For solutions, please contact the nearest SIGLENT sales office or return the

generator to SIGLENT for service.

Page 24

SDG5000 Service Manual

10

Adjust the carrying Handle

To adjust the position, grasp the handle by the sides and pull outward. Then,

rotate the handle to the desired position.

Pull the handle ahead for easy

carrying

Pull the handle down

Page 25

SDG5000 Service Manual

11

Set the Output Frequency

The following steps show you how to change the frequency to 20 KHz.

1. Press the Store/Recall softkey

Press the Store/Recall softkey to enter the parameter set interface. The

waveform parameters including Frequency/Period, Amplitude/HighLevel,

Offset/LowLevel and Phase are for you to modify using the numeric keypad.

2. Press the Frequency/Period softkey

The displayed frequency is either the power-on value or the frequency

previously selected. When you change the function, the same frequency is

used if the current value is valid for the new waveform. If you want to set the

period, press the softkey again to switch to the period parameter

2. Input the desired frequency

Use the digital keypad to input the value directly, enter the value “20”.

Page 26

SDG5000 Service Manual

12

Then press the corresponding softkey to select the desired unit. For example,

press KHz.

Note: You can also enter the desired value using the knob and direction keys.

Page 27

SDG5000 Service Manual

13

Set the Output Amplitude

The following steps show you how to change the amplitude to 8Vpp.

1. Press the Ampl/HLevel softkey

The displayed amplitude is either the power-on value or the amplitude

previously selected. When you change the function, the same amplitude is

used if the current value is valid for the new waveform. If you want to set the

HLevel for the waveform, press the softkey again to switch to the HLevel

parameter.

2. Input the desired amplitude

Use the digital keypad to input the value directly, enter the value “8”.

Then press the corresponding softkey to select the desired unit. For example,

press Vpp.

Note: You can also enter the desired value using the knob and direction keys.

Page 28

SDG5000 Service Manual

14

Set the DC offset

The following steps show you how to change offset to 1Vdc.

1. Press the Offset/LLevel softkey

The displayed offset is either the power-on value or the offset previously

selected. When you change the function, the same offset is used if the current

value is valid for the new waveform. If you want to set the LLevel for the

waveform, press the softkey again to switch to the LLevel parameter.

2. Input the desired offset

Use the digital keypad to input the value directly, enter the value “1”.

Then press the corresponding softkey to select the desired unit. For example,

press Vdc.

Note: You can also enter the desired value using the knob and direction keys.

Page 29

SDG5000 Service Manual

15

Set the Duty Cycle of a Square Wave

At power-on, the default duty cycle for square wave is 50%. You can adjust the

duty cycle from 20% to 80% for output frequencies up to 50 MHz. The following

steps show you how to change the duty cycle to 80%.

1. Select the square wave function

Press Square button and then select the desired output frequency to any value

up to 50 MHz.

2. Press the Duty softkey

Firstly you should press Store/Recall button to enter the parameter setting

interface. The displayed duty is either the power-on value or the percentage

previously selected.

.

3. Input the desired duty

Use digital keypad to input the value directly, enter the value “80”, then press

the corresponding softkey to select the desired unit “%”.

Page 30

SDG5000 Service Manual

16

Set the Symmetry of a Ramp Wave

At power-on, the Symmetry for Ramp wave is 50%. You can adjust the

symmetry from 0% to 100%. The following steps show you how to change the

symmetry to 60%.

1. Select the Ramp wave function

Press Ramp button and then select the desired output frequency to 4MHz.

2. Press the Symmetry softkey

Firstly you should press Store/Recall button to enter the parameter setting

interface. The displayed symmetry is either the power-on value or the

percentage previously selected.

.

3. Input the desired symmetry

Use digital keypad to input the value directly, enter the value “60”, then press

the corresponding softkey to select the desired unit “%”.

Page 31

SDG5000 Service Manual

17

Generate a Pulse Waveform

You can set the generator to output a pulse waveform with variable width, edge

time and delay time. The following steps show you how to generate a 500 µs

pulse waveform with a pulse width of 100 µs, rise time of 8ns and delay time of

50 ns.

1. Select the pulse function

Press the Pulse button to select the pulse function and output a pulse

waveform with the default parameters.

2. Set the Pulse period

Press the Frequency/Period softkey twice and then set the period to 500 µs.

3. Set the Pulse Width

Press the Width/Duty softkey and then set the pulse width to 100 µs. The pulse

width represents the time from the 50% threshold of the rising edge to the 50%

threshold of the next falling edge.

Page 32

SDG5000 Service Manual

18

4. Set the Edge Time

Press the Rise/Fall softkey and then set the rise edge to 8 ns.

5. Set the Pulse Delay

Press the Delay softkey and then set the delay time to 50 ns.

Page 33

SDG5000 Service Manual

19

Generate a Noise Waveform

You can set the generator to output a noise waveform with Stdev and Mean.

The following steps show you how to generate a noise waveform with 500mV

Stdev and 1mV Mean.

1. Select the Noise function

Press the Noise button to select the noise function and output a noise

waveform with the default parameters.

2. Set the Stdev

Press the Stdev softkey and then set the Stdev to 500mV.

Page 34

SDG5000 Service Manual

20

3. Set the Mean

Press the Mean softkey and then set the mean to 1mV.

Page 35

SDG5000 Service Manual

21

Set the DC Voltage

You can set the DC Voltage feature from the Utility Menu, and then set a dc

voltage as an “Offset” value. The following steps show you how to set a dc

voltage with +1Vdc.

1. Select the Store/Recall function

Press the Store/Recall button to enter the parameter setting interface.

2. Set the DC Voltage

Press the DC button to select the DC function and output a DC waveform

with the default parameter.

3. Set the DC Offset

Press the Offset softkey and then set the offset to 1V.

Page 36

SDG5000 Service Manual

22

Output a Built-In Arbitrary Waveform

There are 36 built-in arbitrary waveforms stored in non-volatile memory. The

following steps show you how to output the built-in “exponential fall” waveform

from the front panel.

1. Set the arbitrary waveform function

Press the Arb button to select the arbitrary waveform function. Then

press the Built-In softkey to enter the arbitrary waveform setting interface.

2. Set the Math waveform

Press the Math softkey to display the mathematic waveform as below.

3. Output the exponential fall waveform

Rotate the knob to select the ExpFall waveform and press the Done softkey.

The waveform is output with the present settings unless you change them.

Page 37

SDG5000 Service Manual

23

Use the Built-In Help System

The built-in help system is designed to provide context-sensitive assistance of

some functions. A list of help topics is also available to assist you with several

operations.

1. Read the help information for SDG5000

Press Help button in utility system, you will see a list of help topics as below.

With easy operations on the front panel, you could read any help item you

desired.

2. Press “Cancel” or any function button to exit the help system

Page 38

SDG5000 Service Manual

24

Calibration

This calibration procedure contains performance verification procedure and

adjustment procedure. After receiving a generator, it is recommended to first

confirm that the performance meets the published specifications by following

the performance verification process. If the instrument performance is outside

of the specifications, then perform the appropriate calibration adjustments to

correct the issues.

Calibration Interval

The instrument should be calibrated on a regular interval determined by the

measurement accuracy requirements of your application. A 1-year interval is

adequate for most applications. Accuracy specifications will remain valid only if

performance verification is made at regular calibration intervals. Accuracy

specifications are not valid beyond the1-year calibration interval. SIGLENT

does not recommend extending calibration intervals beyond 2 years for any

application.

Adjustment Recommendations

Specifications are valid only within the period from the last performance

verification. Whatever calibration interval you select, SIGLENT recommends

that re-adjustment should always be performed within the calibration interval.

This is necessary to ensure the accuracy of the performance data measured

during the calibration interval.

Automating Calibration Procedures

The complete verification and adjustment procedures can be automated with

the use of appropriate automated test instrumentation. The complete

instrument configurations specified for each test may be programmed via the

remote interface. Verification data can then be read-back from the instrument

into a test program and compared to the appropriate test limit values.

The instrument can also be adjusted from the remote interface. Remote

adjustment is similar to the local front-panel procedure. A PC can be used to

perform the adjustment by first selecting the required function and range. The

adjustment command is sent to the instrument and then the adjustment is

initiated over the remote interface.

Page 39

SDG5000 Service Manual

25

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not available,

substitute with an instrument of equivalent accuracy.

Instrument

Requirements

Recommended Model

Digital Multimeter(DMM)

DC volts

accuracy: 100ppm

resolution: 100 μV

Agilent 34401A/34461A

Power Meter

Frequency:

10KHz to 50MHz

Agilent U2004A

GPIB cable

GPIB(IEEE488)

Frequency Counter

Accuracy: 0.5ppm

Test Considerations

For optimum performance, all procedures should comply with the following

recommendations:

Updating SDG‟s firmware to the newest version is strongly recommended.

Assure that the ambient temperature is stable and between 18℃ and 28℃.

Ideally, the calibration should be performed at 23℃±1℃.

Assure ambient relative humidity is less than 80%.

Allow a 30 minutes warm-up period before verification or adjustment.

Keep the measurement cables as short as possible, consistent with the

impedance requirements.

Use a 50Ω coaxial cable.

Page 40

SDG5000 Service Manual

26

Performance Verification Test

The performance verification tests are recommended as acceptance tests

when you first receive the instrument. The acceptance test results should be

compared against the specifications given in chapter 1. After acceptance, you

should repeat the performance verification tests at every calibration interval.

If the instrument fails performance verification, adjustment or repair is required.

Page 41

SDG5000 Service Manual

27

DC Output Verification

This test checks if the DC offset listed in the table below are within the

specified range using a DMM.

1. Set the DMM to measure DC voltage. Connect the DMM to the channel 1

output of the generator as shown below.

2. Turn on CH1 and select the DC waveform.

3. Set the instrument to each output value described in the table below, and

measure the output voltage with the DMM. Be sure the generator output

impedance is set to High–Z and the output is enabled.

DC Offset

CH1

CH2

Spec Range

± (1% + 2 mV)

0 mV

-2 mV ~ 2 mV

10 mV

7.9 mV ~ 12.1 mV

100 mV

97 mV ~ 103 mV

1 V

0.988 V ~ 1.012 V

3 V

2.968 V ~ 3.032 V

10 V

9.898 V ~ 10.102 V

-10m V

-12.1 mV ~ -7.9 mV

-100 mV

-103 mV ~ -97 mV

-1 V

-1.012 V ~ -0.988 V

-3 V

-3.032 V ~ -2.968 V

-10 V

-10.102 V ~ -9.898 V

4. Move the BNC cable to CH2 output and perform the same verification as

channel 1.

5. Compare the measured voltage to the spec range shown in the table above.

Page 42

SDG5000 Service Manual

28

AC Amplitude Verification

This test checks the ac amplitude output accuracy at the frequency of 10 kHz

using a DMM.

1. Turn on the generator and choose CH1 as the operating channel. Set the

Load to HiZ under the CH1/CH2 menu.

2. Connect the DMM and generator as shown below.

3. Select Sine waveform of the generator and set the amplitude to the values

listed below in sequence.

Amplitude (V)

CH1 (V)

CH2 (V)

Spec Range (V)

± (1%+1 mV)

11

10.889~11.111

5.6

5.543~5.657

2

1.979~2.021

0.9

0.89~0.91

0.4

0.395~0.405

0.142

0.13958~0.14442

0.064

0.06236~0.06564

0.022

0.02078~0.02322

0.01

0.0089~0.0111

0.004

0.00296~0.00504

4. Move the BNC cable to CH2 output and perform the same verification as

channel 1.

5. Compare the value measured from the DMM to the spec range shown in the

table above.

Page 43

SDG5000 Service Manual

29

Frequency Response Verification

This test checks if the amplitude flatness is within the spec range using a PC

controlled Power Meter. If you do not have a PC controlled Power Meter,

simply ignore the USB connections shown.

1. Turn on the generator and choose CH1 as the operating channel. Set the

Load to 50Ω under the CH1/CH2 menu.

2. Connect the Power Meter, PC and generator as shown below.

3. Select Sine waveform of the generator and set the amplitude to 1 V, and

then step through the frequencies listed below in sequence. Then, set the

amplitude to 2.5V and repeat the frequency steps.

Voltage

1V

Frequency

CH1 (dBm)

CH2 (dBm)

Value

Spec Range

Value

Spec Range

10KHz

V1

3.8833 ~ 4.0744

V2

3.8833 ~ 4.0744

100KHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

1MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

5MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

10MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

20MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

30MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

50MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

80MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

100MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

110 MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

120 MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

160MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

Page 44

SDG5000 Service Manual

30

Voltage

2.5V

Frequency

CH1 (dBm)

CH2 (dBm)

Value

Spec Range

Value

Spec Range

10KHz

V1

11.8474 ~ 12.0281

V2

11.8474 ~ 12.0281

100KHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

1MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

5MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

10MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

20MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

30MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

50MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

80MHz

V1-0.2 ~ V1+0.2

V2-0.2 ~ V2+0.2

100MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

110 MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

120 MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

160MHz

V1-0.8 ~ V1+0.8

V2-0.8 ~ V2+0.8

4. Move the BNC cable to CH2 output and perform the same verification as

channel 1.

5. Compare the value measured from Power Meter to the spec range shown in

the table above.

Page 45

SDG5000 Service Manual

31

General Adjustment Procedure

This chapter explains how to adjust the SDG5000 series generator for

optimum operating performance.

Channel Adjustment which includes three steps: feedback channel

adjustment, channel self adjustment and vertical accuracy calibration.

Feedback channel Adjustment which act as a standard calibration

module, providing the accuracy assurance for Self Adjust.

Channel Self Adjustment which includes internal control channel

adjustment and signal channel adjustment.

Vertical Accuracy Calibration which calibrates the amplitude at low

frequency.

Frequency Response Adjustment which could properly compensate the

amplitude as the frequency increases.

Page 46

SDG5000 Service Manual

32

Scripts for Calibration

SIGLENT provides a free suite for calibrating SDG series products, in which all

scripts are written in Python. Customers can download the package from the

website and just run the scripts to complete the whole calibration process after

some preparation works. For more information, please refer to the instructions

accessible in the provided package.

Download Link:

http://www.siglentamerica.com/prodcut-gjjrj.aspx?id=4705&tid=16&T=2

Software Environment

1. Python

Make sure you have installed Python 2.7 in your computer. The following

modules of Python are required as well: PyVISA, PyQt4 and PyWin32.

2. Microsoft Office

As test reports are saved as „.xls‟, it is necessary that you are working with MS

Office 2003 or higher version.

3. NI VISA

The Python module, PyVISA, is based on the National Instruments VISA I/O

library which can be downloaded from online by searching for PyVISA.

Warming up

Before performing the adjustment procedures, let the generator and other test

equipment warm up for at least 30 minutes in an ambient temperature between

18 °C and 28 °C. Adjustments performed prior to warm-up or outside this

temperature range may result in poor performance.

Page 47

SDG5000 Service Manual

33

Channel Adjustment

The channel adjustment includes three parts: feedback channel adjustment,

channel self adjustment and vertical accuracy calibration.

1. Turn on the generator.

2. Connect the DMM, PC and SDG5000 generator as shown below:

3. Double click and run the script ChannelAdjust.py prepared previously.

Then change the channel connection according to the prompt message.

Note:

If there is a problem in the process of the channel adjustment, you can

separately perform the three parts mentioned above. After the feedback

channel adjustment has been completed, perform a self adjustment. Then

perform the vertical accuracy calibration.

Page 48

SDG5000 Service Manual

34

Feedback Channel Adjustment

The internal feedback channel receives the feedback signal from all the other

channels that are performing self adjustment. This adjustment acts as a

standard test module and must be performed prior to Self Adjust to make sure

it is performed based on a best adjusting accuracy.

1. Connect the DMM, PC and SDG5000 generator as shown below:

2. Double click and run the script FeedbackAdjust.py prepared previously.

The CH1 will be automatically turned on upon running of the script.

Page 49

SDG5000 Service Manual

35

Channel Self Adjustment

1. This adjustment is for internal control channel and signal channel. Through

feedback circuits of the feedback channel and signal channel, this

adjustment helps to obtain the actual working performance for components

from signal channels. After the feedback channel adjustment completed,

disconnect the two BNC cables on channel 1 and channel 2.

2. Select “Self Adjust” to perform the channel Self Adjustment in Test/Cal

system under the Utility menu.

3. Once the “Self Adjust” begins, the generator turns to adjustment interface

and the progress bar displays on the screen. In about 15 seconds it will

reach to 100%, which indicates completing of the self-adjust. You could

press any functional button to exit.

Page 50

SDG5000 Service Manual

36

Vertical Accuracy Calibration

This adjustment aims to calibrate the amplitude at low frequency, using a DMM

with high precision. The SDG5000 begins this portion of the calibration after

the completion of the self adjustment process. It calibrates the Sine wave with

a 10 kHz frequency and selects several amplitudes to calibrate. Compare the

measured amplitude and the standard to obtain a set of compensation values.

1. Connect the DMM, PC and SDG5000 generator as shown below:

2. Double click and run the script VertAccCalib.py prepared previously.

3. Change the channel connection according to the prompt message.

Page 51

SDG5000 Service Manual

37

Frequency Response Adjustments

This adjustment aims to obtain the actual frequency response characteristics

of the signal channel, thus to perform appropriate compensation. Since the

waveform amplitude will decrease as the input frequency increases, it is

essential to compensate for the amplitude to match it to the frequency. This

adjustment should be performed after the channel adjustment.

1. Turn on the generator and connect it to PC using a USB cable.

2. Connecting the USB end of the Power Meter to the USB port of the PC,

upon which the Power Meter indicator light will be brightened. Only after the

indicator light goes out from red, could it be connected to the generator

output.

3. Run the script FrqRespCalib.py prepared previously. In approximately 10

seconds the prompt message will display on the screen to indicate the

operator to connect the Power Meter. After the generator completes the

adjustment for CH1, the prompt message displays on the screen will

prompt the operator to remove the BNC cable to CH2 to start adjustment.

4. After the two channel adjustment completed, please disconnect all

connections.

Page 52

SDG5000 Service Manual

38

Assembly Procedures

This chapter describes how to remove the major modules from the SDG5000

series generator. To install the removed modules or replace new modules,

please follow corresponding operating steps in reverse order.

The following contents are what mainly included in this chapter:

Security Consideration which describes security information needed to

considerate while operating.

List of Module in which the modules to remove are listed.

Required Tool which describes the tools needed to perform the

procedures

Disassembly Procedures which describes in detail how to remove and

install the modules

Security Consideration

Only qualified personnel should perform the disassembly procedures.

Whenever possible, disconnect the power before removing or replacing the

modules. Otherwise, any personal injuries or damages to the components may

occur.

Avoid Electric Shock Hazardous voltages exist on the LCD module and

power supply module. To avoid electrical shock, disconnect the power cord

from the oscilloscope, and then wait at least three minutes for the capacitors in

the oscilloscope to discharge before you begin disassembly.

Preventing ESD Almost all electrical components can be damaged by

electrostatic discharge (ESD) during handling. Component damages can occur

at electrostatic discharge voltages as low as 50 volts. The following guidelines

will help preventing ESD damage when servicing the instrument or any

electronic device.

Disassemble instruments only in a static-free work area.

Use a conductive work area to reduce static charges.

Use a conductive wrist strap to reduce static charge accumulation.

Page 53

SDG5000 Service Manual

39

Minimize handling.

Keep replacement parts in original static-free packaging.

Remove all plastic, foam, vinyl, paper and other static-generating materials

from the immediate work area.

Use only anti-static solder suckers.

List of Modules

The following removable modules are listed in the order of performing

disassembly procedures.

Number of Module

Module

1

Handle

2

Metal Shell and Rear Cabinet

3

Front Cabinet

4

Display Module

5

Main Body

Required Tools

Use these tools to remove or replace the modules in the oscilloscope:

PH2 phillips screwdriver

Disassembly Procedures

This section describes how to remove and install the modules listed above in

the generator in detail. Complete disassembly will be best achieved through

the following operating steps.

Page 54

SDG5000 Service Manual

40

A view of the whole Instrument

The disassembly drawing are shown as below for you to disassemble the

generator in right steps. Before disassembling, please cut the power to avoid

any personal injuries or damages to inside components. Since some modules

of the instrument are sharp, you should also take care while operating to

prevent being scratched.

Table 4-1 A view of the whole instrument

Page 55

SDG5000 Service Manual

41

Removing the Handle

Table 4-2 Removing the handle

Removing steps:

Pull down the handle hard from the two sides of the generator.

To install the handle, please operate as the reverse steps.

Page 56

SDG5000 Service Manual

42

Removing the Metal Shell and Rear Cabinet

Table 4-3 Removing the Metal Shell and Rear Cabinet

Removing steps:

1. Remove the two screws from the rear cabinet of the generator using a PH2

phillips screwdriver.

2. Remove the rear cabinet.

3. Remove the metal shell carefully from the main body to avoid being

scratched.

To install the metal shell and rear cabinet, please operate as the reverse steps.

Rear Cabinet screw

Page 57

SDG5000 Service Manual

43

Removing the Front Cabinet

Table 4-4 Removing the Front Cabinet

Removing steps:

1. Remove the four front cabinet screws using the PH2 screwdriver.

2. Firmly pull up the two screws connected to the main board from the front

panel BNC connectors.

3. Disconnect the display module cable and the USB module cable from the

main board.

4. Separate the front cabinet from the main body of the generator.

To install the front cabinet, please operate as the reverse steps.

Front Cabinet screw

BNC Connector

Page 58

SDG5000 Service Manual

44

Removing the Display Module

Table 4-5 Removing the display module screws

Removing steps:

1. Remove the six screws fixed the keypad circuit board using the PH2 screw

driver.

2. Remove the two screws fixed the USB module using the PH2 screwdriver.

3. Remove the four screws fixed the metallic support using the PH2

screwdriver.

4. Remove the keypad circuit board, silica gel soft keypad, metallic support

and LCD screen from the front cabinet in sequence.

5. Remove the front cabinet universal knob by firmly pull it out.

To install the display module, please operate as the reverse steps.

Keypad Board screw

USB screw

Metallic Support screw

Page 59

SDG5000 Service Manual

45

Removing the Main Body

Table 4-6 Disconnecting all the cables

Table 4-7 Removing all the screws

Page 60

SDG5000 Service Manual

46

Removing steps:

1. Disconnect all cables from the main board and power supply board.

2. Remove all the 20 screws fixed the main board and power supply board

using a the PH2 screwdriver.

3. Separate the main board and power supply board carefully from the main

body of the generator to avoid being scratched by the sharp metal edge.

To install the main body, please operate as the reverse steps.

Page 61

SDG5000 Service Manual

47

Troubleshooting

The internal structure of the generator consists of main board, channel board

and power supply board, and they are linked through cables or connectors.

This chapter explains the main checking procedures for these three boards by

measuring the rated test points on them, thus to help you decide the reason for

the failure you encounter while operating SDG5000 series arbitrary waveform

generator.

ESD Precautions

While performing any internal test of the generator, please refer to the following

precautions to avoid damages to its internal modules or components result

from ESD.

Touch circuit boards by the edges as possible as you can.

Reduce handling of static-sensitive modules when necessary. .

Wear a grounded antistatic wrist strap to insulate the static voltage from

your body while touching these modules.

Operate static-sensitive modules only at static-free areas. Avoid handling

modules in areas that allow anything capable of generating or holding a

static charge.

Required Equipment

The equipment listed in the table are required to troubleshoot the generator.

Table 5-1 Required equipment

Equipment

Critical Specifications

Example

Digital Multimeter

DC Accuracy

±0.015%

SIGLENT SDM3055

Oscilloscope

300MHz Bandwidth

SIGLENT SDS2304X

Page 62

SDG5000 Service Manual

48

Channel Board Drawing

Channel board is a kind of signal conditioning board for output analog signal. It

mainly works on the adjusting of signal parameters such as frequency,

amplitude. Please refer to the following drawing to quickly locate the test points

on the channel board for easy resolution of the failures you encounter.

Page 63

SDG5000 Service Manual

49

Main Board Drawing

Main board is used to control and manage the whole internal system of the

generator. It completes the GUI function, controlling and configuration function

for channel board as well as man-machine interaction. Please refer to the

following drawing to quickly locate the test points on the main board for easy

resolution of the failures you encounter.

Page 64

SDG5000 Service Manual

50

Check the Power Supply

There are two power connectors through which the channel board and main

board can be supplied electricity. For the channel board, there are four voltage

test points on its power connector. For the main board, there is one test point.

Before performing the power supply testing procedure, please make sure that

the generator is grounded correctly through the protective lead of the power

cord. Take care not to touch or even disassemble the power supply module

without any safety precautions, or you may probably suffer from electric shock

or burn. Here are procedures for testing the power supply:

1. Disconnect the power cord of the generator and then check whether the

fuse has been burnt out.

2. Remove metal shell of the generator using a driver, and then disconnect the

power connector connected to the main board.

3. Focus on the Power Connector for channel board, which contains 6 pins

from Pin1 to Pin6. Since two of the six pins are ground wire, you can test the

other four pins that are marked with blue, yellow, red and white to check

whether the voltage value is within the corresponding specified range using

a digital multimeter. The voltage parameters to be tested are listed in table

below:

Table 5-2 Test voltages for the channel board power connector

Voltage value

Pins

Error limit

15.5V

VH+(red)

±5%

-16.5V

VH-(white)

±5%

5.5V

VL+(yellow)

±5%

-6.5V

VL-(blue)

±5%

Table 5-3 Test voltage for the main board power connector

Voltage value

Pins

Error limit

6.5V

VH+(red)

±5%

If each tested voltage value is within the corresponding spec range referring to

the table above, then the power supply works normally. Otherwise, it proves to

be faulted, please return it to the factory to have it repaired or contact

SIGLENT.

Page 65

SDG5000 Service Manual

51

Note: The main power supply provides an input fuse to protect against the

danger of fire in the event of a failure of the power supply circuitry. However,

this fuse will not fail ("open" or "blow") in normal power supply operation except

that a significant overload occurs. Replace the entire main power supply

assembly if the input fuse fails.

Page 66

SDG5000 Service Manual

52

Check the Channel Board

If you want to remove the main board from the metal shelf inside the generator,

you‟d better place it on a clean, insulated mat. In addition, to avoid some chips

or components on the main board being damaged for overheating, it is

essential to cool the main board whenever possible using a fan. Here are

procedures for testing the main board:

1. Several kinds of connectors including Fan Connector, Power Connector and

Keypad Connector are located on the main board. Check if all these

connectors are connected properly.

2. Make sure that the connectors on the channel board are properly connected,

then connect the generator to AC power and turn it on. Check if the voltage

values at all test points are within the spec range using a digital multimeter.

The voltage parameters to be tested are listed in table below:

Voltage Checking

Test the voltage points on the channel board in the table below. If each tested

voltage value is within the corresponding spec range referring to the table

above, then the main board works normally. Otherwise, it proves to be faulted,

please return it to the factory to have it repaired or contact SIGLENT.

Table 5-3 Test voltages of the channel board

Test point

Voltage value

Error limit

+15V

+15V

±5%

-15V

-15V

±5%

-5V

-5V

±5%

+5V

+5V

±5%

VCC3.3V

+3.3V

±5%

VCC5V

+5V

±5%

VCC1.8V

+1.8V

±5%

VCC1.2V

+1.2V

±5%

FAN_12V

+12V

±5%

PLL_3.3V

+3.3V

±5%

Page 67

SDG5000 Service Manual

53

FPGA Checking

To check if the FPGA works normally, please look at the test point marked with

FPGA_LED on the channel board drawing. The LED light twinkles at the

frequency of 1Hz in normal case, if it cannot be lighted or twinkles at incorrect

frequency, then the FPGA may be faulted.

Page 68

SDG5000 Service Manual

54

Check the Main Board

If you want to remove the main board from the metal shelf inside the generator,

you‟d better place it on a clean, insulated mat. In addition, to avoid some chips

or components on the main board being damaged for overheating, it is

essential to cool the main board whenever possible using a fan. Here are

procedures for testing the main board:

1. Several kinds of connectors including Fan Connector, Power Connector and

Keypad Connector are located on the main board. Check if all these

connectors are connected properly.

2. Make sure that the connectors on the main board are properly connected,

then connect the generator to AC power and turn it on. Check if the voltage

values at all test points are within the spec range using a digital multimeter.

The voltage parameters to be tested are listed in table below:

Voltage Checking

Test the voltage points on the main board in the table below. If each tested

voltage value is within the corresponding spec range referring to the table

above, then the main board works normally. Otherwise, it proves to be faulted,

please return it to the factory to have it repaired or contact SIGLENT.

Table 5-4 Test voltages of the main board

Test point

Voltage value

Error limit

+16V

+16V

±5%

3.3V

+3.3V

±5%

VCC5V

+5V

±5%

VCC1.2V

+1.2V

±5%

Mainboard Clock Checking

Mainboard clock is the internal system clock of the generator. To verify if the

clock on the main board works normally, please test the clock frequency listed

below using an oscilloscope.

Test point

Frequency

Stability

Clock_25MHz

25MHz

±50ppm

Page 69

SDG5000 Service Manual

55

DSP/CPLD Checking

DSP and CPLD respectively represent the main control chip and

programmable logic device of the main board. Only when the corresponding

codes loaded successfully, can the two chips work normally.

Look at the DSP_LED/CPLD_LED light on the main board, which indicates the

working state of DSP/CPLD chip. If the light turns on, then the corresponding

codes have been loaded successfully and the chip is in good working state.

Otherwise, there may be failure within it.

Page 70

SDG5000 Service Manual

56

Quick Guide for General Failures

The general hardware failures are described in the following. Reading the

following information can help you quickly handle some easy hardware failures

with more convenience.

1. No start-up after pressing the Power button:

(1) Check if the power cord is correctly connected.

(2) Check if the power button is usable.

(3) Check whether the fuse has been burnt out. If the fuse needs to be

changed, please contact SIGLENT as soon as possible and return the

instrument to the factory to have it repaired by qualified personnel.

(4) Check if the power connector is properly connected to the main board.

(5) If the instrument still does not work normally, please contact SIGLENT.

2. The instrument starts up with a dark screen:

(1) Check if the power connector is properly connected to the main board.

(2) Test if the voltages on the test points marked “-5V” and “LED_ANODE”

are within the spec range.

(3) If the instrument still does not work normally, please contact SIGLENT.

3. No response after pressing any button or abnormal display of the

screen:

(1) Check if the two end of the connector between the keypad circuit board

and the main board is properly connected.

(2) If the instrument still does not work normally, please contact SIGLENT.

Page 71

SDG5000 Service Manual

57

Maintenance

Maintain Summary

SIGLENT warrants that the products it manufactures and sells are free from

defects in materials and workmanship for a period of three years from the date

of shipment from an authorized SIGLENT distributor. If a product or CRT

proves defective within the respective period, SIGLENT will provide repair or

replacement as described in the complete warranty statement.

To arrange for service or obtain a copy of the complete warranty statement,

please contact your nearest SIGLENT sales and service office.

Except that as provided in this summary or the applicable warranty Statement,

SIGLENT makes no warranty of any kind, express or implied, including without

limitation the implied warranties of merchantability and fitness for a particular

purpose. In no case shall SIGLENT be liable for indirect, special or

consequential damages.

Page 72

SDG5000 Service Manual

58

Repackaging for Shipment

If the unit needs to be shipped to SIGLENT for service or repair, be sure to:

1. Attach a tag to the unit identifying the owner and indicating the required

service or repair.

2. Place the unit in its original container with appropriate packaging material

for shipping.

3. Secure the container with strong tape or metal bands.

If the original shipping container is not available, place your unit in a container

which will ensure at least 4 inches of compressible packaging material around

all sides for the instrument. Use static-free packaging materials to avoid

additional damage to your unit.

Page 73

SDG5000 Service Manual

59

Contact SIGLENT

North America

SIGLENT Technologies America, Inc

6557 Cochran Rd Solon, Ohio 44139

Tel: 440-398-5800

Toll Free:877-515-5551

Fax: 440-399-1211

info@siglent.com

www.siglentamerica.com

Headquarters

SIGLENT TECHNOLOGIES CO., LTD.

Blog No.4 & No.5, Antongda Industrial Zone, 3rd Liuxian Road, Bao‟an District, Shenzhen,

518101, China.

Tel:+ 86 755 3661 5186

Fax:+ 86 755 3359 1582

sales@siglent.com

www.siglent.com/ens

Europe

SIGLENT TECHNOLOGIES EUROPE GmbH

Liebigstrasse 2-20, Gebaeude 14, 22113 Hamburg Germany

Tel: +49(0)40-819-95946

Fax: +49(0)40-819-95947

info-eu@siglent.com

www.siglenteu.com

Loading...

Loading...