Page 1

Pellet Heater Repair Manual

Please familiarize yourself with entire manual before attempting a repair or

adjustment of the heaters.

MODEL EF 3800 PELLET HEATER

MODEL EF 5000 PELLET HEATER

MODEL EF3801PELLET HEATER

Sierra Products Inc., 5061 Brooks St., Montclair, CA 91763

MODEL EFI 4000 PELLET INSERT

P/N 140154 R1 1/05 rb

Page 2

Table of Contents

1. Introduction & Service Philosophy....................p. 3

2. Tools & Service Kit...........................................p. 4

3. Warranty & Return Parts Policy........................p. 5

4. Sample Claim Form..........................................p. 6

5. Service Calls.....................................................p. 7

6. Trouble Shooting Flow Charts..........................p. 8

7. Electric Schematic...................................p. 19 - 20

8. Component Replacement...............................p. 21

9. Illustrations.................................................p. 24 - 25

2

Page 3

1. INTRODUCTION & SERVICE PHILOSOPHY

Following is a comprehensive service manual which will assist both dealer or service personnel in maintaining and servicing

the Easyfire Pellet Stoves.

Before getting into the specifics of service we would like to give an overview of our service philosophy and what we expect of

dealers when they take on the Easyfire line.

To become a pellet stove dealer means, by definition, that you will be making a commitment to service. This is an appliance,

not another wood stove. If you are not prepared to enter into the appliance repair and service business then you should not

even consider becoming a pellet stove dealer. Pellet stoves for the most part are wonderful heaters that will, with proper

maintenance, provide years of clean, trouble free burning and quality heat. The simple fact is they have many moving parts,

unlike a wood stove, and these parts require lubrication and maintenance. Because the pellet technology is new the user

must be educated and trained as to the proper use and maintenance from season to season to avoid performance problems.

For these reasons we require our dealers to set up a service department that is dedicated to keeping the customer happy with

a care free unit. The user must be made aware of his or her responsibilities and what is required to keep the unit working at

peak performance. The service department and personnel should adhere to the following guidelines:

1. Service personnel should possess a high degree of mechanical aptitude, good common sense coupled with an

analytical mind. The ability to read and use electrical schematics, listen to customer complaints politely and determine what

might be causing the difficulty. The customer needs to feel confident that the service person will be able to detect system

malfunctions accurately, analyze problems and solve them.

2. When entering the customer's hom e the service person should be neat and clean in appearance, have the necessary

tools and parts required to attend to the problem and share with the custom er an explanation of charges and the customer's

responsibilities in regards to future maintenance. T his m ust be done in such a m anner that there is no misunderstanding or ill

feeling.

3. Remember, it is the service person who represents your business when in the customer's home. A good impression by

the service person creates a good impression of your business. The work is expected to be neat and professionally done.

4. When a customer calls for service they should be greeted with a friendly calming voice, assuring them that the problem

will be given prompt attention. It is important to get and give accurate, relevant information. The following is an information

guideline:

a. Customer nam e, address and phone number.

b. Serial number of the stove.

c. What the customer thinks is wrong.

d. When did the problem start.

e. When was the unit last serviced?

f. When and where was the stove purchased?

g. Who installed the unit and when?

Note: At this point the problem can usually be dealt with by phone (90% of pellet stove problems are lack of cleaning).

5. If you need to schedule a service call remember the following:

Prioritize calls so that "no heat" calls are taken care of first. Do minor calls next but don't put them off or you will only have an

angry, upset customer who will cause a lot of grief for you and your business. Stick to your schedule. If you tell a customer

you will be there tomorrow at 2:00 p.m . Be there at 2:00 p.m. or call well in advance to let them know, their tim e is valuable

too. If a part is needed and you don't have it, tell them, and order one as soon as you get back to the store. Give honest

responses, not creative excuses.

6. Once on the job the service person must use a systematic approach and think in terms of cause and effect. After some

experience with the stove you should be able to look at the fire, flame pattern, sounds and smells and detect problems

3

Page 4

immediately. To obtain this degree of expertise you must acquaint yourself with every component and stove function. Never

guess!

TOOLS & SERVICE KIT

The tools and equipment needed for servicing the Easyfire Pellet Stove are as follows:

a. Good shop vacuum with blower capabilities.

b. Set of socket drivers which must include 11/32, 1/2 & 7/16 sockets or nut drivers.

c. Phillips and plastic coated slot screw drivers

d. Flashlight

e. Extension cord with ground

f. Allen wrench set (long handle)

g. Wire stripper and cutter

h. Electrical continuity tester with light or LED

i. Fully charged 12V Gel Cell Battery at least 30amp

j. Assorted crimp connectors with crimp tool

The Easyfire Service Kit which includes:

a. Fan Motor, Feed Motor

b. Main Circuit Board

c. Switch Board (control board and knob)

d. One each T-1 and T-2 Sensor

e. Three (3) each fuses, (1A, SB) for rear panel AC Line

and 5mm fuse (6.3A, SB) for main board 12V line.

f. Digital read out volt multi meter

h. One each bridge rectifier

4

Page 5

EasyFire™ Pellet Heater

Warranty Replacement Program

EASYFIRE LIMITED LIFE TIME, THREE, ONE YEAR WARRANTY

Sierra Products, Inc.(SPI) warrants to the original consumer that this stove will be free of defective materials and workmanship

for a period as listed below from the date of purchase. This warranty does not extend to any parts damaged through abuse,

accident, or neglect or warpage due to overfiring; nor does it apply if the stove has been repaired or modified without SPI’s written

authorization. If the stove proves to be defective in material or workmanship within the warranty period, SPI will, at no charge,

repair or replace (at its option) any defective parts, if the purchaser ships the parts or the stove, freight prepaid, to SPI or the

nearest authorized service center. SPI may require the consumer to supply reasonable proof of the stoves purchase date.

WARRANTY SCHEDULE: OUTER BODY - LIMITED LIFETIME, FIREBOX COMPONENTS - THREE YEARS,

ELECTRIC COMPONENTS - ONE YEAR.

This warranty is in lieu of any other express warranty. Any implied warranties, including but not limited to any

implied warranty of merchantability or fitness for a particular purpose shall not extend beyond one year from the date

of purchase.

The purchaser's sale and exclusive remedy shall be for the repair or replacement of defective parts, as provided for in this

warranty. No other remedy (including but not limited to incidental or consequential damages for lost profits, lost sales, injury to

person or property, or other incidental or consequential loss) shall be available to the purchaser.

Some states do not allow limitations on how long an implied warranty lasts and some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitations or exclusions may not apply to you.

SPI’s warranty obligation and the purchaser's rights under it can be altered only by a subsequent written agreement between SPI

and the purchaser.

The remedies provided in this warranty are void unless the attached warranty registration card is received by SPI within 30 days

from the date of purchase.

If you have a warranty claim or questions about the performance of your stove, you are requested to contact your dealer. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARRANTY W ORK:

All warranty work must be authorized by the factory in advance of the repair and an authorization number assigned. A

warranty claim form must be completed and signed by both the repair person and the customer. All claims must be submitted

to your distributor, if you are buying products through a distributor. In the event a unit has to be replaced, the warranty claim

form must be affixed to the unit with a description of the defect. Only the factory can authorize a heater return!

Any replacement parts required may be obtained from Sierra Products and will require a Purchase Order. Parts will be

invoiced to the dealer account and credit will be issue upon return to Sierra. All returned parts must be accom panied by a

warranty claim form. If you have a warranty claim for installing the part, use the same claim form and authorization number.

Please note... No credit will be issued until a warranty form with an authorization number is received along with the

defective part.

AUTHORIZED WARRANTY PAYMENT:

Sierra Products will credit the distributor/dealer account the sum of sixty five dollars ($65.00) per occurrence and forty cents

($.40) per mile, maximum one hundred miles round trip.

5

Page 6

EasyFire™ Pellet Heater

Warranty Claim Form

Customer Information: Unit Information:

Name:_________________________________ RMA Number ____________

Address:_______________________________ Model Number ___________

City/State/Zip:___________________________ Serial Number _____________

Phone:________________________________ Date of Purchase _________

Dealer Information:

Name:_______________________________ Date:__________________

Address:_____________________________ Mileage:________________

City/State/Zip:________________ Serviceman_________________

Describe Defect: _____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

Describe Repair: _____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

Customer Verification:

I verify that the above repairs were made to my EasyFire Heater and that I am the original owner of the

above model.

Customer Signature:________________________________________

Service Person Verification:

I verify that the above repairs were made to the above EasyFire Heater.

Service Person Signature:_______________________________________

Distributor Authorization:_______________________________________

Sierra Products Inc. 5061 Brooks St. Montclair, CA 91763

6

P/N 140154 10/07

Page 7

SERVICE CALLS

The objective when making a service call is to get the customer up and running as quickly as possible. For this reason the

best method of attack is to find the problem quickly and isolate the faulty component and swap it out with the good component

in your dealer service kit. The defective module or part can then be repaired to returned to the factory away from the

customer's home.

With this objective in mind the EasyFire troubleshooting can be divided into six (6) general categories:

1. The fan and feed motors.

2. The main circuit board.

3. The switch (control knob) circuit board.

4. The temperature sensors T-1 and T-2.

5. The AC power line com ponents, i.e.,

6. The wiring harness and connectors thereto.

These six (6) areas represent the areas where problem s might occur. They are listed in the order of highest probability,

based on their history and level of complexity. The design of the electronics has been done with reliability as the highest

priority, and the components which are under the most electrical or thermal stress are very conservatively rated.

The main board has been listed second due to the large number of parts, which increases its chances of failure on a

statistical basis. In practice, however, it should be the most reliable due to the rigorous test procedure each board goes

through before being installed on the stoves. Because of this mechanical items such as the m otors should be suspect first.

Remember, ninety per cent (90%) of pellet stove failures are due to improper m aintenance by the end user! Check the stove

for cleanliness and routine maintenance before doing any mechanical service work.

Following is a list of complaints and/or service problems which represent at least ninety five (95% per cent of possible service

calls:

1. Stove not running at all.

2. Feed motor runs, but no fan.

3. Fan motor runs, but no feed.

4. Stove runs, but shuts down about 10 minutes after start up.

5. Stove runs, but keeps shutting down with over-temp (red)

LED coming on.

6. Stove runs, but heat output remains at the LOW level, even

when switch is on HIGH.

7. Stove does not run on battery or battery does not charge.

8. Stove runs on FAN position but when switched to LOW, MEDIUM

or HIGH shuts off immediately.

9. Stove seems to be running very HIGH or CLEAN mode at all

times.

10. Fan speed seems normal for each position, but feed rate

seems excessive even on LOW.

Following is a trouble shooting Flow Chart for each of the problems outlined above. If you follow the flow chart carefully each

of the problem s can be solved quickly and easily.

7

Page 8

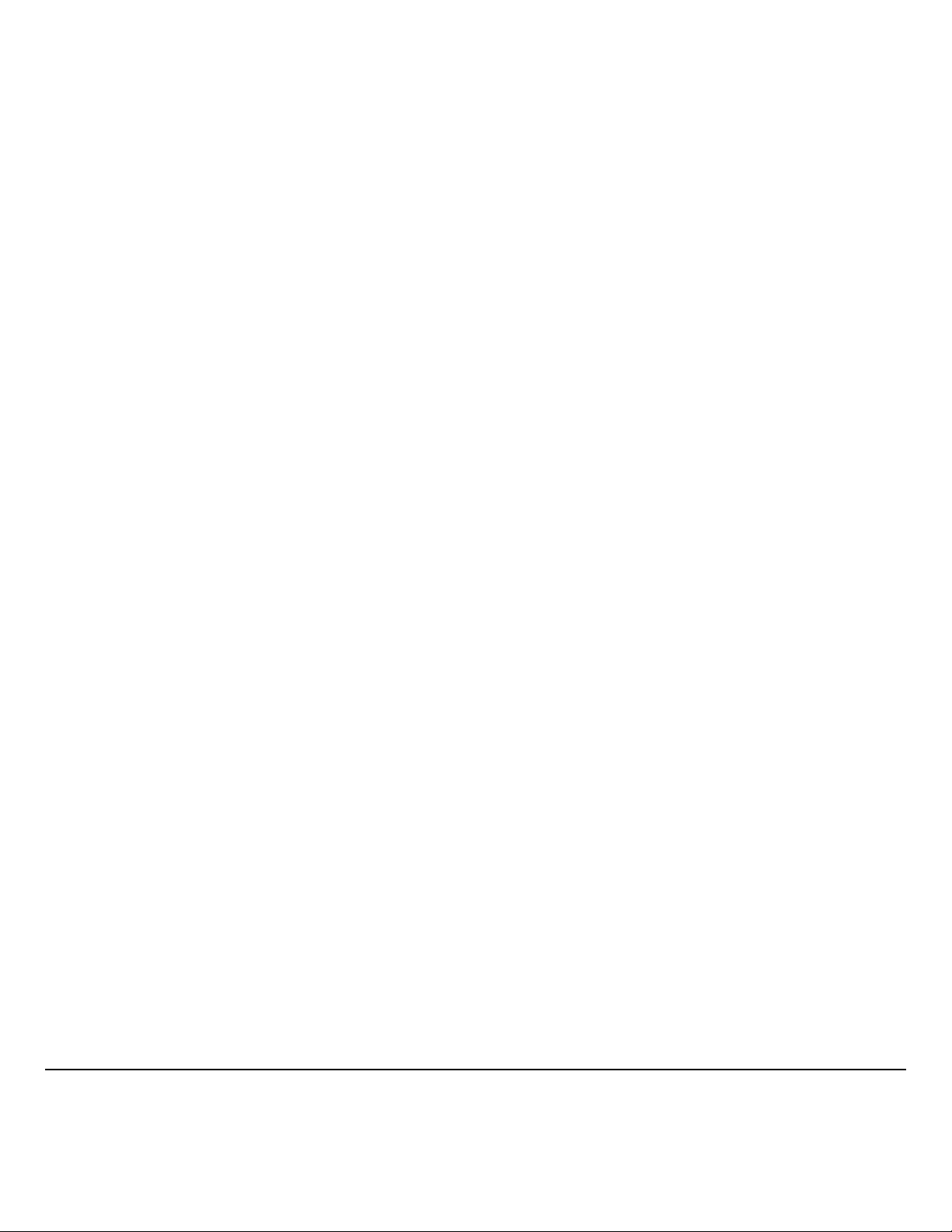

Trouble Shooting Flow Chart #1 - Stove not running at all.

8

Page 9

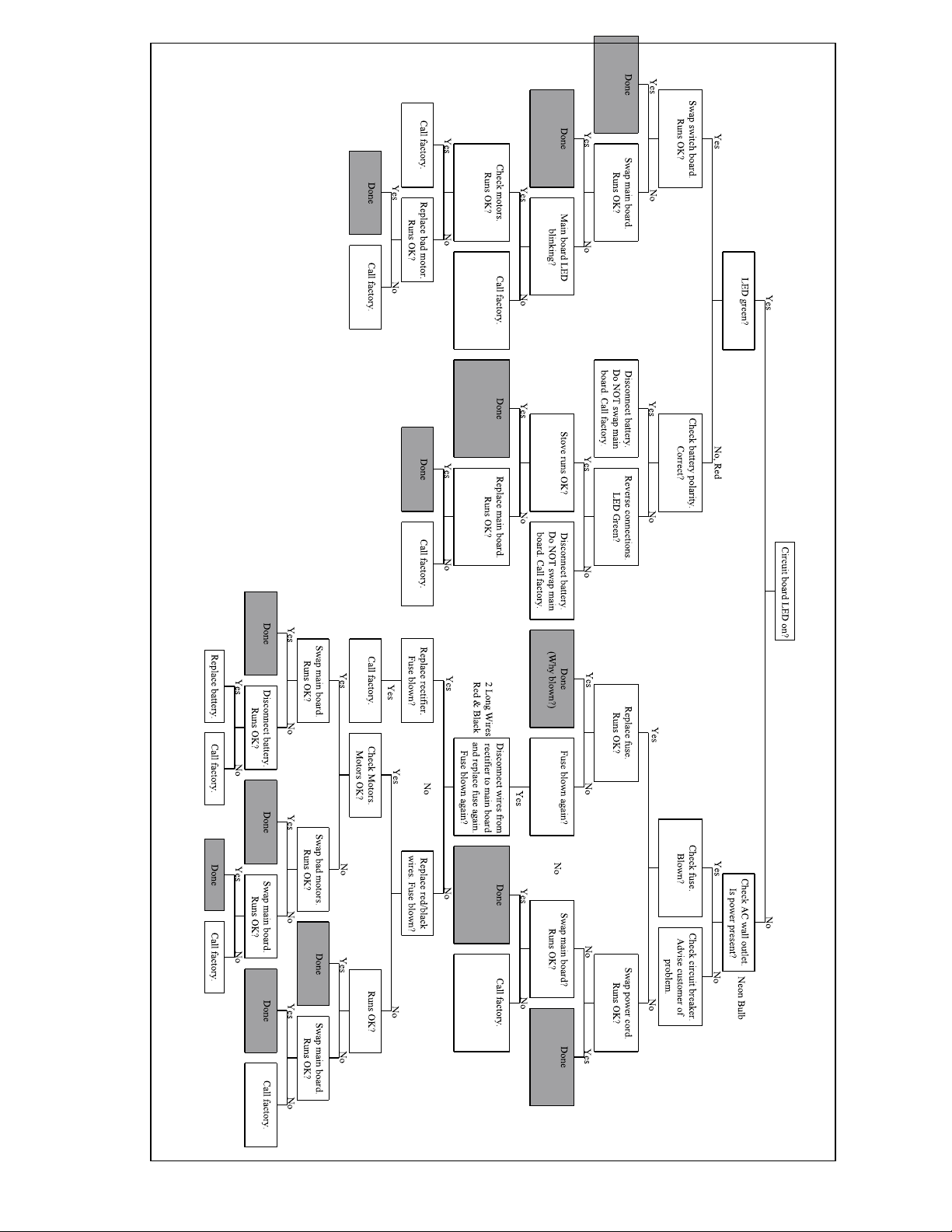

Trouble Shooting Flow Chart #2 - Feed motor runs, but no fan.

Trouble Shooting Flow Chart #3 - Fan motor runs, but no feed.

9

Page 10

Trouble Shooting Flow Chart #4 - Stove runs, but shuts down in 10 minutes (Make sure stove is hot

enough - 140°F).

Trouble Shooting Flow Chart #5 - Stove runs, but shuts

down randomly with over-temp LED On.

Steady Red = High Temp

Blinking Red = Blocked Flue

1 0

Page 11

Trouble Shooting Flow Chart #6 - Stove runs, heat output stays Low, even on High setting.

Trouble Shooting Flow Chart #7 - Stove will not run on battery or charge battery.

1 1

Page 12

Trouble Shooting Flow Chart #8 - Stove runs in fan only mode, but when turned to L ow , Med, or High, it shuts off

immediately.

Trouble Shooting Flow Chart #9 - Fan always very high, all

modes except off.

Trouble Shooting Flow Chart #10 - Feed always very high, all

modes except off.

1 2

Page 13

Trouble Shooting Flow Chart #11 - Stove runs fine and then

shuts off for no apparent reason.

Check the feed “trim” button and adjust to higher

(clockwise) setting. If the feed is too low, the stove

will cool down and when it reaches a lower

temperature will shut down automatically. This can

be corrected by adjusting the feed setting to a

higher setting.

Trouble Shooting Flow Chart #12 - Fan speed erratic

(Surges)

Feed System exploded view

1 3

Page 14

2005 and newer control switch assem bly

Pre 2005 control sw itch assembly

1 4

Page 15

EasyFire B Model Pellet Heater Quick Troubleshoot and Technical Guide

SPI’s EasyFire pellet heaters are designed to operate as a seasonal zone heater burning 1/4" wood pellet fuel. Utilizing a

12VDC control and drive system allows for extended battery operation when AC power fails. The following outlines the

general operating parameters and trouble shooting encountered during installation and seasonal operation. Basic

operation is controlled combustion of wood pellets metered by the feed drive system into a burn pot and a

combustion/convection fan motor providing separate air for combustion and heat exchange. T his process is controlled by a

digital main controller which monitors all function through two sensors and incoming outgoing operating voltages.

Additionally, starting functions are provided by an industrial style cartridge heater located in the burn pot and both internal

and optional thermostat.

Standard operation: With both 120VAC and 12VDC battery power attached and a functional pellet flue system the heater

is designed to operate continuously during the heating season. On a daily bases the heater requires fuel to be added to the

storage hopper and depending on the fuel quality, burn pot area cleaned. Starting and operating sequences are controlled

by an operating software program contained on a EPRO M m emory chip. Fuel rate is controlled by m ode setting and trim

position (standard trim knob setting is 9:00 and is located on control panel next to operation buttons). Normal start up and

operation summary follows:

Condition - Heater is cold, power connected, button to “OFF” position. Hopper door closed (safety switch closed). External

therm ostat jum ped (factory standard) or optional thermostat closed to call for heat.

1) Select a run button (Low, Medium, High) and press. The LED light will shift from OFF to run button.

A) Feed motor starts initial fuel shot (approx. 40 seconds) and ignitor ON. Ignitor will begin to start heating

and pass 300 degrees in 30 seconds.

B) Fan motor starts in 60 seconds @ 3 volts providing combustion and convection air. Feed will cycle OFF

completing the start up fuel shot. Smoke will be visible normally visible through the door glass with in 2

minutes.

C) Feed will cycle ON for short periods during the start cycle add small amounts of fuel. H eater continue in

START UP mode until temperature rise is confirmed by sensors or for a total of 10 minutes.

If temperature does not increase by 15C during this STARTUP phase the heater will begin the SHUTDOWN (for

further information read SHUTDOW N in several paragraphs).

2) RUN mode begins when temperature rise is achieved (normally within 5-7 minutes).

A) Fan increases based on run button selected. Feed pulses increase based on temperature and TRIM

setting. Feed trim adjustm ent allows for a lower or higher average fuel delivery.

Initial flam e is high based on a cool heater and fuel shots provided for start up. As operating tem perature is

reached the feed pulse will decrease and flame will drop.

B) Feed rate will vary up and down as the heater adjusts for operating temperature. Temperature measured

at T-2 sensor mounted on fan housing manifold.

C) Heater will continue to operate as long as fuel, thermostat setting, and operating button remains.

Condition - Shutting down operating heater. Selecting the OFF button or external thermostat no longer calls for heat.

A) Feed m otor immediately stops. No fuel is added to the burn pot and the coals remaining began the burn

out.

B) Fan is reduced to shut off voltage of 5 volts and maintained until sensor T-2 records a 20C reduction of

temperature or 20 minutes time elapses.

Other related operating parameters

Three basic functions are constantly monitored during operation including flue drafting, operating temperatures, and AC

power input. Blocked flue will cause an unsafe condition and will cause the unit to shut down with a steady RED fault

indication noted on the control panel. Continued high temperature may cause a unsafe condition. The heater will stop the

feed during high temperatures to allow the heater to cool. A flashing RED will indicate high operating temperature. AC

power outage will stop external thermostat function if the optional battery is connected allowing the heater to run

continuously while AC is out.

Common operating problems:

(Refer to installation manual and repair manual for additional information regarding specific component replacement and

testing).

1 5

Page 16

Basic tools required for troubleshooting - Multi Volt/Ohm Meter, standard and phillips screw drivers, standard jewelers

screw driver (fan speed adjustments on main control board).

No power - Power is provided by both AC and DC supplies. There are two replaceable fuses located near the power

connections. They are identified as Main (1 amp) and Ignitor (5 amp). If AC power is present to the main control system a

LED will be lit on the O FF button. If DC power is present a GR EEN LED will be lit on the control panel.

Quick Testing -

1) Check AC power with volt meter at wall socket - 115VAC.

2) Check DC power at battery - 12VDC.

3) Remove fuses and check continuity with OHM meter. Blown fuses can be cause by voltage spikes (lightning,

power company). If fuse is found blown, replace only once and retest. If the fuse blows again further

troubleshooting is required before further fuse replacem ent.

Start up:

No fuel - Fuel located in the hopper is feed by a auger from the hopper bottom up to the shoot which directs the pellets into

the burn pot. The feed motor is controlled by the main control system and on models EF3801B, 5001B, and 5001U-B a

hopper safety switch (EF4001-B auger can not be accessed from the hopper door). The switch will disable the feed system

if the hopper lid is open. The switch is located on the upper right hopper vertical panel and is accessed through a sm all

panel. Fuels is only feed in Low to High operating modes and requires “priming” auger. If hopper is out of fuel, cycle from

OFF to LOW several times to allow pellets to feed into burn pot.

Quick Testing -

1) Confirm hopper lid is sitting on the switch arm and the arm is closing. With hopper lid open, push the switch arm down

and listen for click noting switch closure. With heater cold, and lid open, push switch arm down, push Low and the feed

motor should start to turn.

2) Confirm feed motor is not jammed by emptying hopper and verifying a foreign object has not be caught. Remove top

cover from feed tube from inside hopper if there is any question. If the feed motor is mechanically jammed, the control

system has a built in circuit breaker. The breaker will require a reset by cycling from OFF to LOW . Do not recycle more

than three times so the circuit does not become damaged by overheating.

3) Pellets Jamm ed in feed shoot (above burn pot). Remove all jammed pellets and clean shoot with scraper.

Ignitor does not heat up - The ignitor has a separate 120VAC circuit which includes a fuse, relay, and ignitor. This circuit is

activated by the main control board via a 12VDC wire harness lead. W hen the m ain control call for start the 12VDC circuit

is closed sending 12VDC to the relay. As the relay closes, the 120VAC circuit is completed and the ignitor begins to heat.

As noted in prior section, if 120VAC power is not available the heater will still start the fan and feed if 12VDC is connected

allowing a manual start with starter and m atch light.

Quick Testing -

1) Inoperative ignitor most likely have a blown fuse. Remove the 5 am p ignitor fuse and test with OHM meter.

Replace if blown. As noted before if fuse blows again then further testing is required.

2) Testing ignitor requires access to the relay located near the main board assembly. Access is through the lower

right pedestal for the 3801/5001, junction box on the 4001 insert, and lower right cabinet for the 5001U. Remove

the power to the unit. Unplug the ignitor lead from the relay and the neutral circuit. Using the OHM meter check for

continuity between the two leads. If the circuit is open the ignitor has failed. If the circuit is complete check one

lead and then ground the other lead to the ignitor base. If circuit is com plete ignitor has failed. A grounded circuit

will cause the fuse to blow.

3) If ignitor check out, remove the harness leads to the relay and using the volt meter set to 20VDC, confirm 12VDC

when the power is reapplied a run button is pushed. If 12VDC is found then the relay has failed.

Heater starts then burns out - The start up is controlled by the control system and best results are from a cold start. If a

warm heater is immediately restarted it may not be able to confirm the required temperature increase as the heater

temperature is already warm and the temperature is actually falling during the initial start up. Allow the heater to cool and

shut down before restarting.

Trim settings - W ill not change the first portion of the start up however will effect the initial run mode. If the trim is fully

counter clockwise (Lowest) the heater may run low on fuel, most likely if the operating conditions are warm. High or Max

1 6

Page 17

trim settings may cause the opposite problem as the heater feeds to much fuel and allows the HIGH TEMP control stop

the feed to cool the stove. Best starting trim setting is the mid point or 9:00 o-clock.

High temp starts will also occur if the burn pot has additional fuel prior to start up. This additional fuel which is then added

too as the start cycle begins pushes the temperatures up as the heater starts. This is considered an temperature

overshoot as the tem perature climbs quickly.

Heater will not start when run button is pushed - Check external therm ostat jumper or rem ote thermostat as the unit will

not attempt a start unless this circuit is closed.

Run mode Troubleshooting:

Once the heater reaches the run mode it will continue operation by using the coals in the burn pot to light the pellets

continuing to fall. If the coal bed burns down at some point the pellets may not light and then the heater will shut down.

This is normally confirmed by finding the burn pot with unburned fuel and shut off. This can also happen if the hopper runs

low on fuel or the fuel bridges (hangs on the hopper sides).

Run mode problem generally are either operational or limits exceeded - Blocked Flue (loss of flue draft) or High

Temperature is exceeded. Blocked flue indication is a solid RED LED on the control panel and requires a recycle of the

heater to clear. This is for the operators protection as a blocked flue could cause a dangerous condition. Block flue most

likely is not fully blocked and will occur if the flue pipe is subject to high wind conditions or is blocked by ash. If this

happens during initial installation a corrective action to the flue system will be required. Check the installation manual for

flue recommendations.

Operational problems are generally related to ash build up in the burn pot or the heat exchange system and can be correct

by cleaning.

Over Feeding - Over feeding is a common problem and is related to a lack of combustion air rather than to much fuel. If

the heater is clean and seems to feed more fuel adjust the trim down to slow the feed rate. If the heater has been operated

for sometime since the last cleaning then shutting it down and cleaning will solve the over feed. Check the door for proper

adjustment as a partially closed door will cause reduced combustion air. Operating the heater for an extended time with an

open door will cause a shut down with RED LED and require a restart.

Immediate RED LED when a run m ode is selected indicates a failed sensor (generally a T-1). Replacement of sensors are

accomplished by removing the rear access panel and normally requires removing the flue pipe. Review repair manual for

additional information.

Shutdown:

Shut down is the simplest mode as the feed is stopped and the fan continues to operate until the heater is cool. If the fan

continues to run after it is fully cold then the T-2 sensor and the main control did not register the required temperature

reduction. Unplug the heater to reset and run again. If problem persists then the T-2 sensor or the control system will

require com ponent replacement.

Battery Operation Troubleshooting -

Battery operation requires a fully charge 12VDC battery capable of sustained 2 amp/hr. loads while maintaining a minimum

of 11.2 VDC. This voltage is required for proper system operation. Most battery operation problems can be traced to a

battery in pour condition.

Quick Testing

Remove battery from heater and charge overnight with automotive type battery charger. Test battery with automotive load

tester. Replace if required. Testing connections from terminals on rear of heater back to the harness. If all connects are

secure a main control board will be required.

Additional detailed inform ation is contained in the installation and repair manuals. Please refer to these for in depth

troubleshooting guides and harness replacem ent.

1 7

Page 18

Component Adjustments and Replacement:

Main Control Board - Main control board is located in the lower right pedestal (3801/5001) or lower right rear - 4001 insert

and right switch plate for the 5001U. The control board is held in place with several phillips screws.

Fan speed adjustments are accomplished by turning the LOW and HIGH fan pots on the lower right corner. These

adjustments are made in the corresponding run mode. Factory settings are based on fan voltage as read across the motor

terminals 6.8VDC LOW, and 9.0VDC HIGH.

A GREEN LED light flashes on the control board to confirm AC or DC power is present.

Switch Board - Switch board is attached to access panel with several phillips screws. Harness plugs into bottom of switch.

Sensors - Access for sensors is through the rear panels. Both the T-1 and T-2 sensors are the same sensor type mounted

differently. T-1 is mounted on the exhaust side of the combustion fan housing. It is held in place with a tie wrap. T-1 sensor

allows for cabinet air to drawn through the high temp plastic holder. When door is open or flue blocks the flow reverses. T2 sensor is attach to a aluminum block and attached to the manifold. Wire harness connections should be secure and not

pulled tight.

Additional information is available on line@ www.sierraproductsinc.net/pages/customer_service

Technical Customer Service - 909-399-3355x29

Red Light Fault Indications:

W hen the Hi-Temp/Flue indicator light com es on (red lite beneath control knob) it m eans a fault has been detected in

either the flue system, over temperature, or fan/feed motor.

Slow Flash Red Light - Indicates a blocked flue. Check flue and clean out for built up ash deposits.

Solid Red Light - Indicates an over temperature. Check the air intake at rear of unit. Turn the feed trim down 25% to

reduce fuel rate.

Fast Flash Red Light - Requires unit to be unplugged to reset. Indicates a feed motor jam or fan motor fault. Fan motor

test would require running unit on “fan and clean” only to determine if red light indication is repeated. If not, feed system is

jammed and requires the hopper access cover to be removed and jammed material to be removed

1 8

Page 19

1 9

Page 20

2 0

Page 21

EF AutoLite Igniter

Replacement Instruction

Please read this entire instruction before attempting repair.

WARNING - ELECTRIC SHOCK POTENTIAL.

All repairs must be accomplished with the

115VAC and 12 DC power disconnected from

heater.

Figure 1 Insert Connection Panel

Basic start up operation is as follows (with thermostat

jumped):

1) From “Off” press operating button (Low). DC controller

energizes the 115VAC relay completing the igniter high

voltage connection. Igniter temperature imm ediately

rises from room temperature.

2) Combustion fan starts at 1 minute along with feed motor

for 1 ½ minutes providing start up fuel.

3) Pellets start to ignite approx. 3 to 4 minutes. Feed motor

starts at 4 m inutes to provide additional start up fuel.

4) At 7 minutes unit should have flame in burn pot. If no

temperature rise is noted by T-1 (sensor) at 20 minutes

heater starts shut down process.

TROUBLESHOOTING IGNITER SYSTEM

The igniter system incorporates a cartridge style high

wattage 115VAC igniter located at the bottom of the pellet

burn pot. This system is continuously cooled by incoming

combustion air and provides years of general service.

However, for the igniter to work properly the burner pot must

be cleaned as required to allow the pellets to fall onto the

igniter. Generally, this is accomplished during normal

cleaning which would include removing the burn pot and

brushing the ash from the pot and igniter. Removing the

screen from below the ignitor and brushing all ash from the

burn pot holder will also aid in the starting process.

Check the igniter rod surface for disintegration or obvious

damage. If any white ceramic material is showing through

the SS protective cover the igniter should be replaced.

Figure 2 Stove Connection Panel

GENERAL INFORMATION

Your EASYFIRE Pellet Heater is equipped with the Autolite

Automatic ignition and operating system.

The AutoLite system is integrated into the heater to allow for

automatic start up using a heating element located in the

burn pot. This element starts the initial fire required to burn

the wood pellets. The system operates on 115VAC power

supplied through a separate fuse for seven minutes during

the initial heater start up. After the seven minute period the

AutoLite system is deactivated and the heater operates

based on the EasyFire digital control system requirements.

If the house AC power should quit, the AutoLite system will

not be available. however, with the optional battery attached

the heater can be manually lit.

Once the burn pot is cleaned and the igniter inspected the

remaining system checks are electrical. A simple check of

the system may be accomplished on a cold heater by

placing a gloved hand on the igniter rod and pressing one of

the operating button (Low). The igniter will start to get hot

immediately (2 minute temperature 500°F). If not

temperature rise is noted then continue with electrical

trouble shooting.

Autolite Wiring Diagram

2 1

Page 22

ELECTRICAL TROUBLE SHOOTING

WARNING: Only a trained technician should attempt to

repair a pellet heater electrical system.

Note: All tests should be accom plished w ith the unit

thermostat by-passed.

Remove both AC and DC power from unit. The igniter

system is protected with a 5 amp fuse located on the back

or side of the heater (Figure 1). The igniter is switched “Off”

and “On” by the control system via a relay located in the

lower right pedestal in front of the control board

(EF3801/5001) or in lower left rear of the unit accessed

from the back (EF4001). Wiring on all igniter systems are

the same. The following test steps will require a multi-meter

with AC/DC volt and ohm functions:

a. Unplug heater from wall outlet and 12VDC power!

b. Remove 5 amp fuse holder cap and fuse by pressing

in and turning counter clockwise. Test fuse with ohm

meter to confirm is not “open”. If fuse is open go to

Testing Igniter “d”. If fuse is good continue.

c. Check 115VAC power wire connection to relay and

neutral wire connection to igniter terminal. This can

be accom plished with the ohm meter. If wire is

disconnected or open replace.

d. Disconnect igniter leads from relay and neutral. Test

continuity with ohm meter between leads. If open

igniter is defective. If continuity exists then check for

internal grounding by checking each lead to the

shielded conduit of the igniter leads. If continuity

exists to ground then igniter is defective. If meter

reads open on both leads to ground then igniter

should produce heat when properly connected to

115VAC.

e. W ith igniter disconnected from relay, attach volt

meter (set meter to 200VAC) leads to relay 115VAC

out terminal and igniter neutral. Reapply 115VAC

power. Press operating button low. Relay should

imm ediately engage applying 115VAC to meter. If

meter has 115VAC then replace igniter as it should

be activated. If no AC power outputted from relay.

Continue to next test.

f. Disconnect DC control wires from harness to relay.

Attach volt meter (set meter to 20VDC) leads to

harness terminals. Reapply 115VAC power. Press

operating button low. Control system should

imm ediately engage applying 12VDC to meter. If

meter has 12VDC then replace relay as it should be

activated. If relay does not engage, exchange control

board and/or main switch board.

REPLACEMENT PARTS:

ITEM

NO.

1 120120 12VDC RELAY

2 120117 CARTRIDGE HEATER

3 120118 AUTOLITE CONTROL SWITCH

4a 202163 BURN POT SCREEN 5001

4b 202164 BURN POT SCREEN 3801/4001

5a 300501 BURN POT 5001-AUTOLITE

5b 300500 BURN POT 3801/4001-AUTOLITE

6 110510 5 AMP FUSE MDL5 (NOT SHOWN)

Customer Service & Replacement Parts

Replacement parts are available from your local dealer or

on-line @ www.sierraproductsinc.net . or call or write:

Customer Service

Sierra Products, Inc.

5061 Brooks St. Ste. B,

Montclair, CA 91763

Phone 1-909-399-3355

Fax 1-909-399-3357

www.sierraproductsinc.net

PART

NO.

DESC RIP TION

Sierra Products, Inc. 5061 Brooks St. Ste. B, Montclair, CA 91763

2 2

P/N 140804 10/07

Page 23

Sierra Products, Inc. 5061 Brooks St. Ste. B, Montclair, CA 91763

2 3

P/N 140804 10/07

Page 24

Pre 2004 Pellet Stove Wiring Detail

Sierra Products, Inc. 5061 Brooks St. Ste. B, Montclair, CA 91763

2 4

P/N 140804 10/07

Page 25

2005 HARNESS WIRING DETAIL

Sierra Products, Inc. 5061 Brooks St. Ste. B, Montclair, CA 91763

2 5

P/N 140804 10/07

Page 26

Figure 1

EF3801/4001 V1 Feed System

Service or Repair Instruction

OVERVIEW

The EasyFire feed system consists of four main components, feed

motor and mounting plate, feed auger shaft, feed disk, and feed disk

bushing (Figure 1). These components are designed to provide

thousands of hours of service and rarely require service or

replacem ent. O peration of feed system is controlled by the main

control board based on the stoves temperature and heat setting. Unlike

other pellet stoves, the system operates by increasing and decreasing

the speed of the auger and disk. Pellets are pushed forward toward the

disk and as the disk rotates clockwise (from front of stove) allows the

pellets to be feed into the shoot. Three feed disk sizes are available

with the standard = 1, medium = 2, and large = 3. #3 feed disks are for

large or long pellets only. If overfeeding or under-feeding is a problem

and adjusting the feed trim will not compensate, changing the feed disk

is advised.

Removing and Replacing the Feed Assem bly: The feed assem bly

and gear motor is accessed by removing the rear inspection panel for

both the heater and insert. Remove the four or six #8 screws

attaching the inspection cover and rem ove cover. Remove all pellets

from hopper and feed disk area inside unit. Locate feed motor and

unplug wire harness connections (note location of red banded wire on

motor to assure proper rotation of motor). Remove wing nuts (or #10

nuts on some units) attaching feed motor bracket to rear of feed shoot.

Gently remove feed assembly by pulling toward the rear of unit. The

feed shaft maybe removed by loosening the allen screws holding the

shaft coupler. Remove the two #8 phillips screws holding the feed

motor bracket to the gear motor. Reverse process to install feed

motor assembly.

Bushing replacement: Disk bushing may be replaced by removing 2#8 retaining screws and carefully prying with a large flat blade screw

driver from inside hopper (Figure 2). To re-install bushing clean area

with thinner or alcohol and apply a sm all am ount of red lock-tight to bushing. Align with plate and carefully pry back with

screw driver. Straighten bushing and install retaining screws.

Shaft or Disk Replacem ent: The feed disk and shaft depth are set

at the factory to allow the feed disk to ride fully in the feed disk

bushing. When replacing either component, make sure the installed

disk ride toward the rear of the disk (Figure 3) and does not extend

to far forward. If the disk is set to far forward it may jamb causing

the shaft to bend or break. Assemble the new components onto the

motor drive loosely then install into stove. Carefully position disk and

mark or tighten disk onto shaft. Rem ove disk and motor assembly

from stove and tighten with 1/8" allen wrench.

NOTE: WHEN ASSEMBLING THE SHAFT AND COUPLER,

ALWAYS USE A SMALL AMOUNT OF LOCK TIGHT (RED) ON

ALLEN SET SCREWS. AFTER THE ASSEMBLY HAS BEEN

INSTALLED THE FEED DISK MUST RIDE IN THE CENTER OF

THE FEED BUSHING.

2 6

Figure 3

5061 Brooks St. Montclair, CA 91763

800-527-4790 Fax 1-909-399-3357

www.sierraproductsinc.com

P/N EF3801 4001 Sensor replacment 4/04

Page 27

EF3801/4001 T-1/T-2 Sensor

Replacement Instruction

OVERVIEW

First production 2005 stoves Serial #3384 to #3420 require precautionary replacement of both T-1 and T-2 sensors. The

sensors located in the stove body sense the operating temperatures and overall parameters of the stove. The T-1 sensor

provides blocked flue and operating sensing while the T-2 sensor provides start up, shut down, and over temp. sensing.

The first 26 units have a sensor assembly attached in such a way that may cause the stove to act erratically. As a

precaution we are requiring replacement of the sensors and offering a repair credit. Please contact customer service @

800-527-4790x29 for further inform ation.

T-1 and T-2 Sensor Replacement:

Rem oval from 3801 and 4001 Insert: The T-1 and T-2 sensors maybe accessed by removing the inspection covers on

back of the unit. The T-1 sensor is installed into to the right side of the combustion housing just above the exhaust tube.

Unplug the harness connector to the sensor. Using a wrench, unscrew the brass fitting and sensor holder from the

exhaust pipe. The T-2 sensor is located right of the com bustion housing attached on the lower portion of the m anifold.

Unplug the harness connector the sensor. Rem ove the #10 nut attaching the sensor holder and rem ove the sensor.

Reverse process to install new sensor fitting and holder. Reinstall the rear panel and confirm standard operation.

5061 Brooks St. Montclair, CA 91763

909-399-3355 Fax 1-909-399-3357

www.sierraproductsinc.com

2 7

Page 28

REMOVAL AND REPLACEMENT OF COMPONENTS

WARNING: RISK OF ELECTRIC SHOCK! REMOVE ALL POWER CORDS FROM UNIT BEFORE ATTEMPTING ANY

SERVICE.

1. Circuit Board: The circuit board is located on the lower right hand side of the heater or insert (facing

from the front fig.1 - pg. 21).

Removal from Heater: Remove the two #8 phillips screws securing the panel to the pedestal side. Open the panel

by lifting up and out. Lay panel flat and remove two #8 phillips screws securing the control board stand-offs to the panel.

Gently remove board from 44 pin connector by firmly holding panel and pulling board toward you. Rem ove #8 nuts

attaching stands to the board and rem ove stands (these nuts are located on the lower right and left corners of the board).

Reverse the process to install new control board.

Rem oval from Insert: Remove the two #8 phillips screws securing the control cover from the hopper side.

Remove the two #8 phillips screws attaching the control board the stand-offs (these screws are located at the lower right

and left corners of the board). Gently remove board from 44 pin connector by pulling down on the board. Reverse the

process to install a new control board.

2. Fan Motor: The fan motor is located directly under the combustion fan housing. Access is provided through

the rear inspection covers on both the heater and insert. Remove the #8 screws attaching the covers. Rem ove the wire

harness leads to the motor noting there position both red and black. Next remove the plastic convection fan blade by

carefully pushing against the fan hub. Rem ove the four #10 nuts holding the fan m otor base plate to the housing. Carefully

pry the base plate breaking the factory silicon seal. Remove motor from unit. Using a long allen wrench loosen the allen

set screws holding the combustion fan blades on the motor shaft. Remove the two #10 nuts holding the motor mount tho

the fan plate. Remove the two #8 phillips screws holding the motor mount to the motor. Reverse the process to replace fan

motor assembly.

NOTE: WHEN INSTALLING THE COMBUSTION FAN BLADES ON THE MOTOR SHAFT, USE LOCK TIGHT (RED)

ON THE ALLEN SET SCREWS. THE PROPER POSITION OF THE BLADES IS THE OUTER BLADE POSITIONED AT

THE END OF THE SHAFT AND THE SECOND BLADE TIGHT TO THE BACK OF THE FIRST. WHEN ASSEMBLING

THE FAN MOTOR PLATE BACK INTO THE UNIT, USE HIGH TEMPERATURE SILICONE SEAL ON CLEANED

MATING SURFACES.

Fan motor brushes maybe replaced by carefully removing the plastic screw caps on each side of the motor and replacing

with factory replacements.

3. Control Switch: The control switch is located on the right side of both the heater and insert. In both units

remove the two #8 phillips screws holding the cover. Using a small blade standard screw driver carefully loosen the set

screw on the control knob. Next remove the 9/16 nut attached to the switch shaft. Remove the switch and unplug the

harness connector. Reverse procedure to install new

switch.

4. Transformer and Rectifier: The transformer and rectifier are located inside the cabinet on both the heater and

insert. Remove the inspection cover on the rear and locate the transform er. Rem ove the two #6 phillips screws and nuts.

Remove the wires noting the positions. Remove the transformer. The rectifier maybe removed by unplugging the wires

from the harness and transformer (note the position of the red and black harness wires). Remove the #6 phillips screw

and nut. Remove the rectifier. Reverse the procedure to install new parts.

5061 Brooks St. Montclair, CA 91763

909-399-3355 Fax 1-909-399-3357

www.sierraproductsinc.com

2 8

Page 29

5061 Brooks St. Montclair, CA 91763

909-399-3355 Fax 1-909-399-3357

www.sierraproductsinc.com

2 9

Page 30

5061 Brooks St. Montclair, CA 91763

909-399-3355 Fax 1-909-399-3357

www.sierraproductsinc.com

3 0

Loading...

Loading...