Page 1

HRX-OM-J049-A

1st edition: Aug. 2006

Rev. A: May. 2007

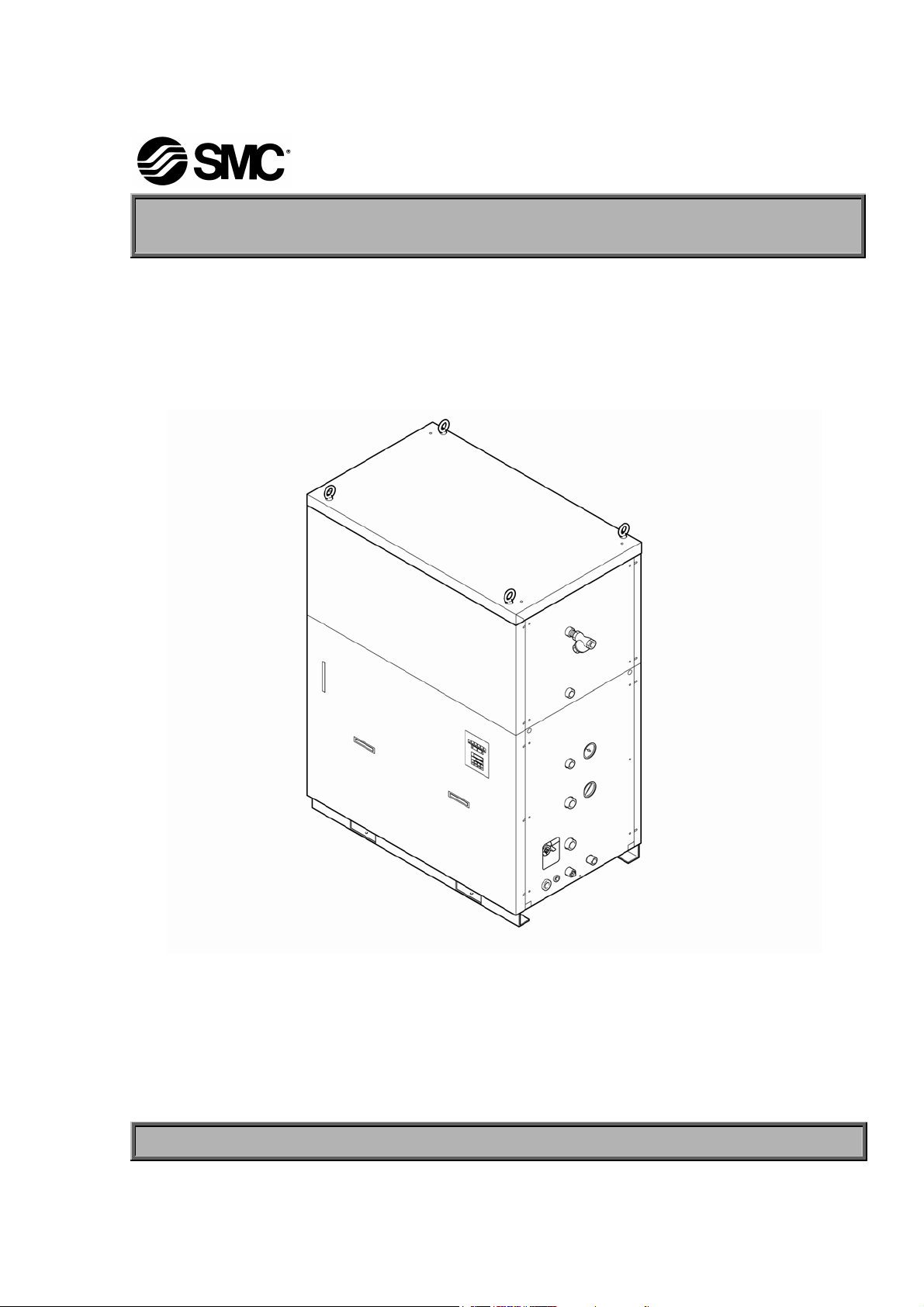

Operation Manual

Water-refrigerated Thermo cooler

HRG010-W

HRG015-W

SMC Corporation

Save This Manual Carefully for Use at Any Time

© 2006 SMC CORPORATION All Rights Reserved

Page 2

To the Customers

Thank you for purchasing our THERMO COOLER HRG Series (hereinafter called “This unit”).

For safety and efficiency, be sure to read and understand this manual thoroughly before performing

operation of this unit.

z All warnings and precautions defined in this manual shall be observed.

z This manual provides instructions for the installation and operation of the unit. Only personnel who

understand basic operation described in this manual are qualified to perform the installation and

operation of the unit.

z Copying, duplicating or transferring any part of or whole contents of this manual without SMC

Corporation’s permission is strictly prohibited.

Note: The contents of this manual are subject to change without notice.

Page 3

HRX-OM-J049-A

Table of Contents

Table of Contents

Chapter 1 Safety Instructions........................................................... 1-1

1.1 Before Using this Unit............................................................................................. 1-1

1.2 Danger, Warning and Caution................................................................................. 1-2

1.2.1 Level of risk ......................................................................................................................... 1-2

1.2.2 Definitions of “Serious injury” and “Minor injury” ................................................................. 1-2

1.2.3 Symbols............................................................................................................................... 1-3

1.3 Hazard Warning Label............................................................................................. 1-4

1.3.1 Classification of risks........................................................................................................... 1-4

1.3.2 Type of hazard warning labels ............................................................................................ 1-5

1.3.3 Location of hazard warning label ........................................................................................ 1-6

1.4 Model label............................................................................................................... 1-6

1.5 Safety Measures...................................................................................................... 1-7

1.5.1 Safety Precautions ..............................................................................................................1-7

1.5.2 Protective equipment........................................................................................................... 1-8

1.6 Emergency Measures.............................................................................................. 1-9

1.7 Disposition of Waste ............................................................................................. 1-10

1.7.1 Recovery of refrigerant and compressor oil ...................................................................... 1-10

1.7.2 Circulating fluid disposal.....................................................................................................1-11

1.7.3 System disposal .................................................................................................................1-11

1.8 Material Safety Data Sheet (MSDS) .......................................................................1-11

Chapter 2 Appearance and Each Section ........................................ 2-1

2.1 Appearance.............................................................................................................. 2-1

2.2 Name of Each Section............................................................................................. 2-2

2.2.1 HRG010-W .......................................................................................................................... 2-2

2.2.2 HRG015-W .......................................................................................................................... 2-3

2.3 Control panel ........................................................................................................... 2-4

Chapter 3 Transport and Installation................................................ 3-1

3.1 Transport.................................................................................................................. 3-1

3.1.1 Transporting with forklift and unit lifting ............................................................................... 3-2

3.1.2 Transporting with caster ...................................................................................................... 3-3

3.2 Installation ............................................................................................................... 3-4

3.2.1 Installation conditions .......................................................................................................... 3-4

3.2.2 Installation location .............................................................................................................. 3-5

3.2.3 Installation location and maintenance work area ................................................................ 3-6

3.2.4 Installation ........................................................................................................................... 3-7

3.2.5 Electrical wiring ................................................................................................................... 3-9

3.2.6 Piping................................................................................................................................. 3-13

HRG010-W HRG015-W

1st edition : Aug. 2006

Rev. A: May. 2007

TOC-1

Page 4

HRX-OM-J049-A

Table of Contents

3.2.7 Supply of circulating fluid................................................................................................... 3-15

3.2.8 Reinstallation of unit ..........................................................................................................3-16

Chapter 4 Startup and Shutdown ..................................................... 4-1

4.1 Pre-check..................................................................................................................4-1

4.1.1 Installation condition ............................................................................................................4-1

4.1.2 Electric wiring.......................................................................................................................4-1

4.1.3 Facility water piping ............................................................................................................. 4-1

4.1.4 Piping for circulating fluid..................................................................................................... 4-1

4.1.5 Supply of circulating fluid.....................................................................................................4-1

4.2 Preparation for startup ............................................................................................ 4-2

4.2.1 Power supply .......................................................................................................................4-2

4.2.2 Setting of circulating fluid temperature ................................................................................4-2

4.2.3 Additional water supply........................................................................................................ 4-3

4.3 Unit Startup and Shutdown ..................................................................................... 4-4

4.3.1 Starting the unit....................................................................................................................4-4

4.3.2 Stopping the unit .................................................................................................................. 4-4

4.4 Check at startup.......................................................................................................4-5

Chapter 5 Error Message and Troubleshooting .............................. 5-1

5.1 Error Message..........................................................................................................5-1

5.2 Troubleshooting.......................................................................................................5-2

5.3 Alarm Reset (Alarm Lamp OFF) ..............................................................................5-3

5.4 Recovery from Power Failure (POWER Lamp ON) ................................................5-6

Chapter 6 Unit Maintenance ............................................................. 6-1

6.1 Control of Water Quality ..........................................................................................6-1

6.2 Inspection and Cleaning..........................................................................................6-2

6.2.1 Daily inspection....................................................................................................................6-3

6.2.2 Quarterly inspection............................................................................................................. 6-4

6.2.3 Biannual inspection.............................................................................................................. 6-4

6.2.4 Check during wintertime ...................................................................................................... 6-5

6.3 Consumables ...........................................................................................................6-6

6.4 Long-term Storage................................................................................................... 6-6

Chapter 7 Documents ....................................................................... 7-1

7.1 Standard Specifications ..........................................................................................7-1

7.2 Optional Specifications ........................................................................................... 7-3

7.3 Outline Dimensions .................................................................................................7-4

7.3.1 HRG010-W, HRG010-W-B, HRG010-W-C, HRG010-W-BC HRG015-W, HRG015-W-B,

HRG015-W-C, HRG015-W-BC............................................................................................ 7-4

7.3.2 HRG010-W-A□, HRG015-W-A□ ....................................................................................... 7-4

7.4 Electric Circuit..........................................................................................................7-5

7.4.1 HRG010-W, HRG015-W...................................................................................................... 7-5

HRG010-W HRG015-W

1st edition : Aug. 2006

TOC-2

Rev. A: May. 2007

Page 5

HRX-OM-J049-A

Table of Contents

7.4.2 HRG010-W-BC, HRG015-W-BC......................................................................................... 7-6

7.5 Flow Chart................................................................................................................ 7-7

7.6 Daily Inspection Sheet............................................................................................ 7-8

HRG010-W HRG015-W

1st edition : Aug. 2006

Rev. A: May. 2007

TOC-3

Page 6

HRX-OM-J049-A

Table of Contents

TOC-4

HRG010-W HRG015-W

1st edition : Aug. 2006

Rev. A: May. 2007

Page 7

Chapter 1 Safety Instructions

Chapter 1 Safety Instructions

Be sure to read and understand all the important precautions in this

manual before operating the unit.

1.1 Before Using this Unit

This chapter describes the safety-related items that users should be aware of upon

z

handling this unit.

This unit is an isothermal fluid circulation system housed in the tank. SMC’s

z

liability under this warranty shall not be available for troubles caused by use for

purposes other than the original intent.

This unit operates under high voltage and contains components that cause a rise

z

in temperature and rotate. All personnel are required to read and understand the

safety-related items in this manual before working with this unit.

HRX-OM-J049-A

This manual is not for comprehensive safety and hygiene education. Such a

z

manual should be provided by a safety training manager.

All personnel who work on or around this unit are to have proper training and

z

education on dangers specific to this unit and safety measures against potential

hazards.

A safety manager is responsible for observing safety standards. Operators and

z

service technicians have individual responsibilies for their safety during

operation of this unit in his/her daily work.

Operators must individually take account of safety and assure a proper working

z

area and working environment.

The relevant personnel must receive proper safety education before working on

z

this unit to prevent dangers. Never conduct work training without giving proper

consideration to safety.

Save this manual at a designated place for reference when necessary.

z

HRG010-W HRG015-W 1.1 Before Using this Unit

1st edition : Aug. 2006

Rev. A: May. 2007

1-1

Page 8

HRX-OM-J049-A

Chapter 1 Safety Instructions

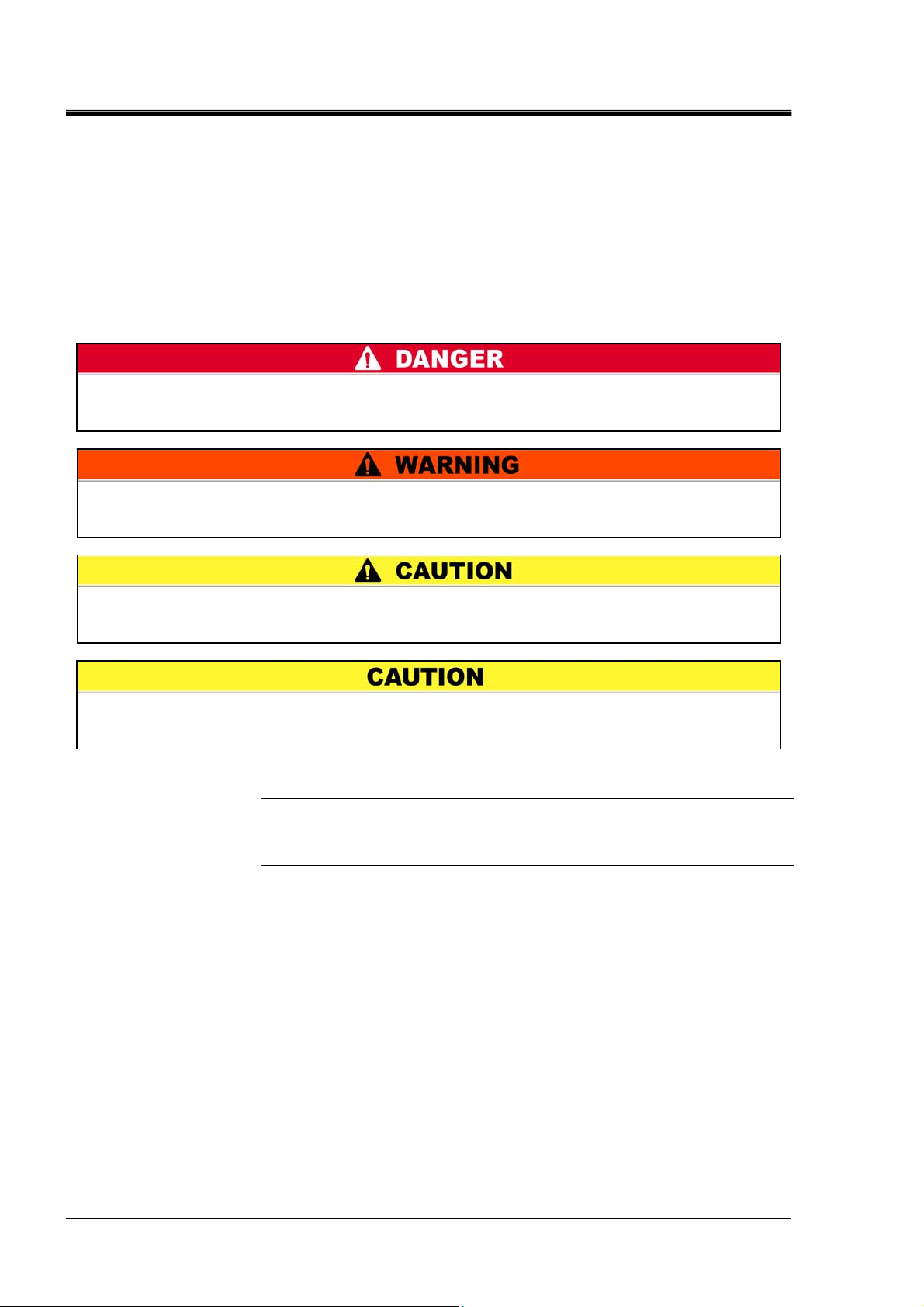

1.2 Danger, Warning and Caution

1.2.1 Level of risk

This unit is designed with the safety of workers and the prevention of system

damage. This manual classifies the risks into the following three categories

according to the level of the hazard: Danger, Warning, and Caution. Read the

statements carefully and thoroughly understand them before operating this unit.

DANGER, WARNING and CAUTION signs are in order according to severity

(DANGER > WARNING > CAUTION). See below for the details.

"DANGER" denotes that there is an imminent hazard which will cause serious

personal injury or death during operation.

"WARNING" denotes that there is a hazard which may cause serious personal injury

or death during operation.

"CAUTION" denotes that there is a hazard which may cause minor personal injury

during operation.

"CAUTION" without an exclamation symbol denotes that there is a hazard which

may cause damage or failure of this unit, facility, or devices.

[Tips]

Tips are provided when there is information personnel are required to be

aware of for system operation and maintenance. If the task carries useful

information, the relevant tips are given as well.

1.2.2 Definitions of “Serious injury” and “Minor injury”

“Serious injury”

This term describes injuries such as loss of eyesight, wound, burns, frostbite, electric

shock, fracture, and toxication that leaves aftereffects which may require prolonged

treatment and hospitalization.

“Minor injury”

This term describes injuries that do not require prolonged treatment or

hospitalization (injuries other than “serious injuries” described above).

1.2 Danger, Warning and Caution HRG010-W HRG015-W

1-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 9

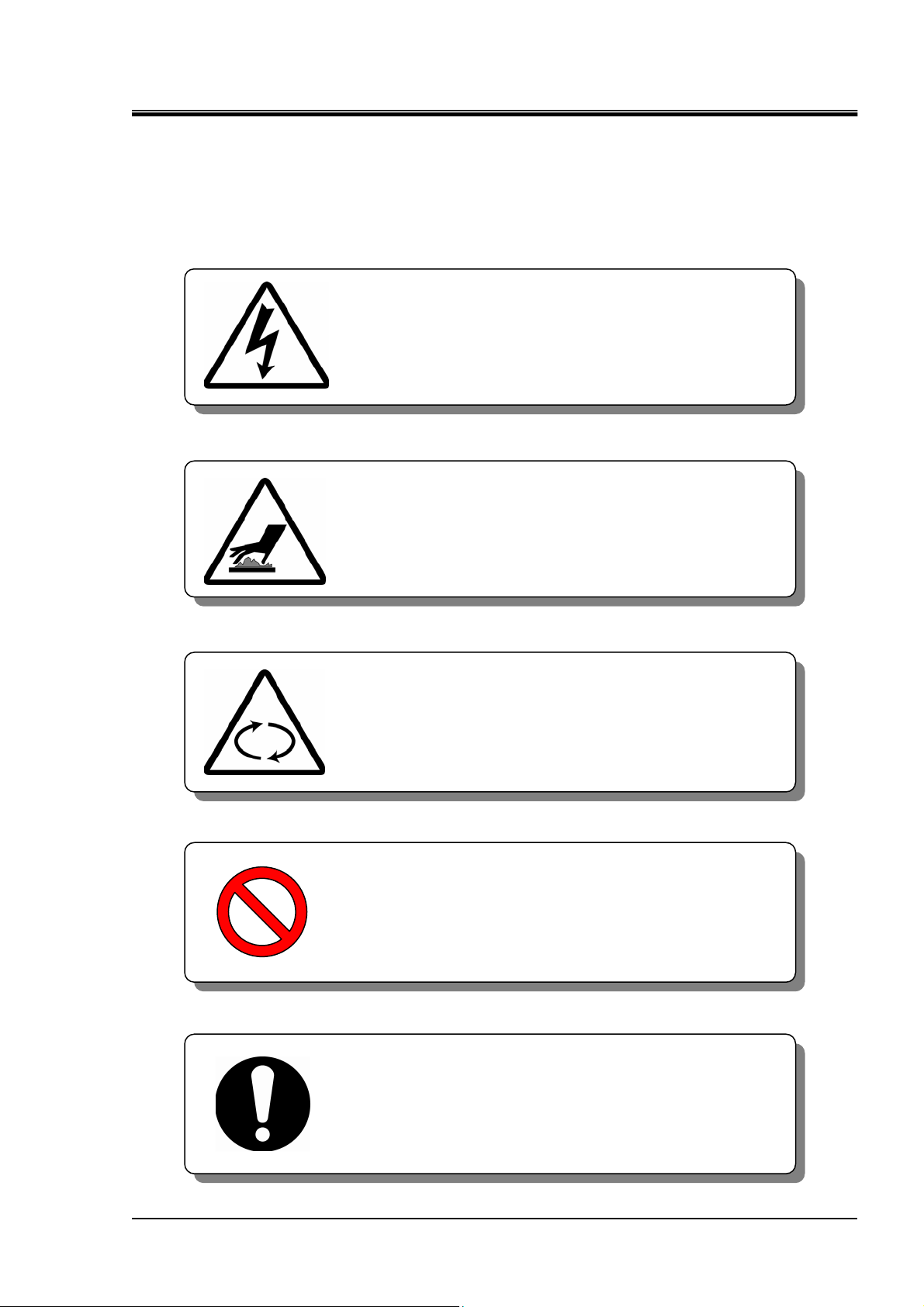

1.2.3 Symbols

This manual provides the following symbols in addition to “Danger”, “Warning”,

and “Caution” to present the warning details in easy-to-understand manner.

Symbol of electrical hazard

This symbol warns you of possible risk of electrical

shock.

Symbol of heat hazard

This symbol warns you of potential burns.

HRX-OM-J049-A

Chapter 1 Safety Instructions

Symbol of rotating shaft hazard

This symbol warns you of possible risk caused by a

rotating object.

Symbol of “Don’ts”

This symbol denotes the items that must not be

attempted.

Symbol of “Dos”

This symbol denotes the “obligation” items which

you must follow in operation of this unit.

HRG010-W HRG015-W 1.2 Danger, Warning and Caution

1st edition : Aug. 2006

Rev. A: May. 2007

1-3

Page 10

HRX-OM-J049-A

p

Chapter 1 Safety Instructions

1.3 Hazard Warning Label

The hazard warning labels indicate where potential hazards are present during unit operation

and maintenance.

The hazard warning labels are in appropriate sizes and colors. They contain symbols in

addition to the descriptions of warnings.

1.3.1 Classification of risks

High voltage hazards

The unit is operated at high voltage and may cause an electrical shock. The

attached label contains the symbol

Only operate the unit with the cover panel attached.

The unit contains the power supply carrying high voltage inside that is

isolated with the cover panel.

Only trained personnel are allowed to work, including unit inspection,

around the power supply.

High temperature hazards

The unit reaches high temperature during operation and may cause burns when

an operator comes in contact. The attached label contains the symbol

There is the presence of the surface in the unit that is at high

temperatures during operation. Potential burns may occur if touched.

Residual heat may cause burns despite the power being turned OFF.

Be sure of the surface reaching room temperature before work.

.

.

Rotating object hazards

The unit includes several parts that rotate during operation and may cause the

operator to get the finger caught in these parts. The attached label contains the

symbol

The unit contains a section which rotates when it is in action. Potential

personal injury may occur if touched. A rotator is structured to come

to a temporary stop and resume rotation.

Avoid

1.3 Hazard Warning Label HRG010-W HRG015-W

1-4

.

erforming work during system operation.

1st edition : Aug. 2006

Rev. A: May. 2007

Page 11

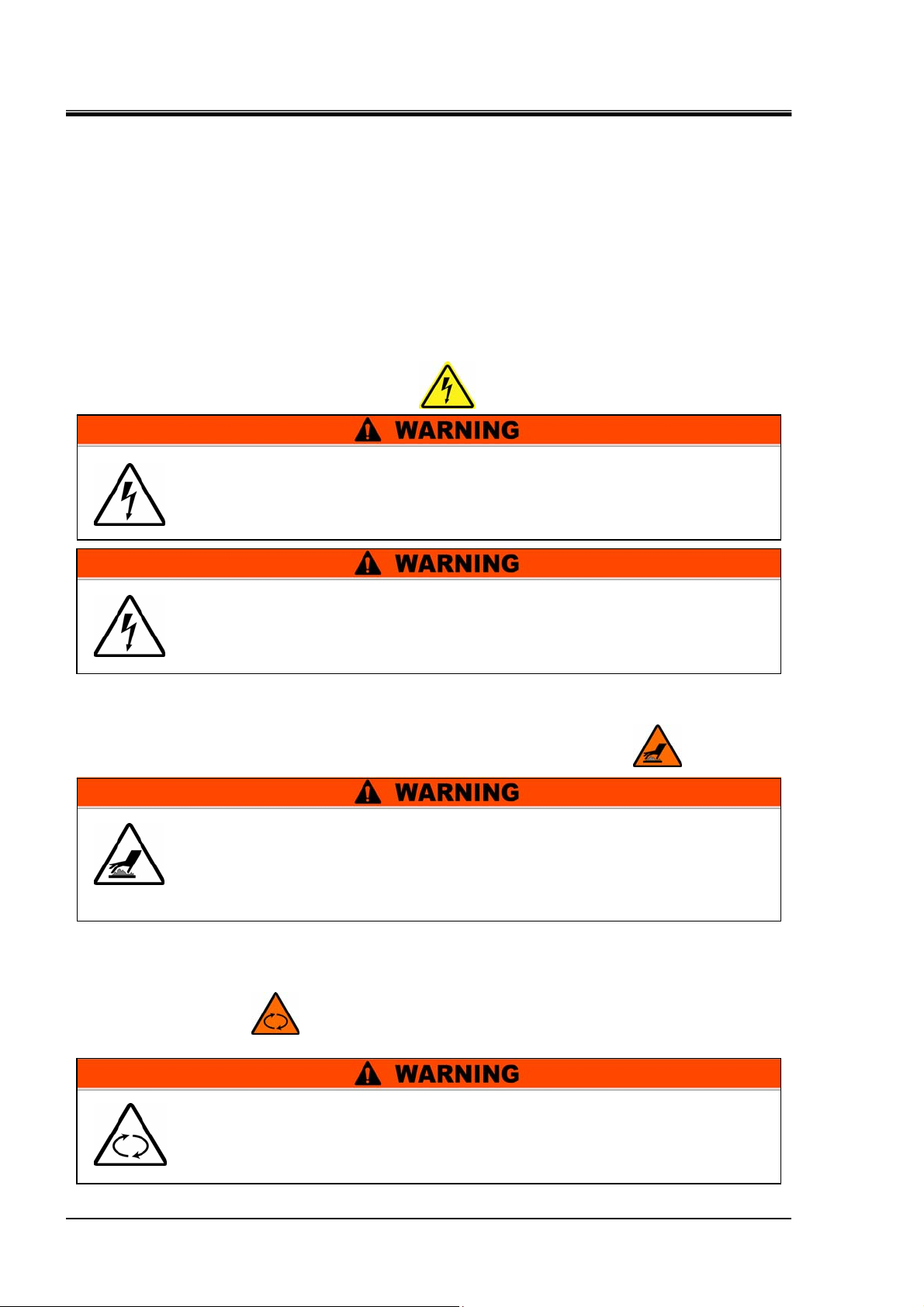

1.3.2 Type of hazard warning labels

Do not remove or deface the warning labels.

Read the contents of the hazard warning labels with care to keep them

in mind.

Warning label on the front panel

HRX-OM-J049-A

Chapter 1 Safety Instructions

Fig. 1-1 Warning Label on the Front Panel

Warning label for high voltage

Fig. 1-2 Warning Label for High Voltage

HRG010-W HRG015-W 1.3 Hazard Warning Label

1st edition : Aug. 2006

Rev. A: May. 2007

1-5

Page 12

HRX-OM-J049-A

Chapter 1 Safety Instructions

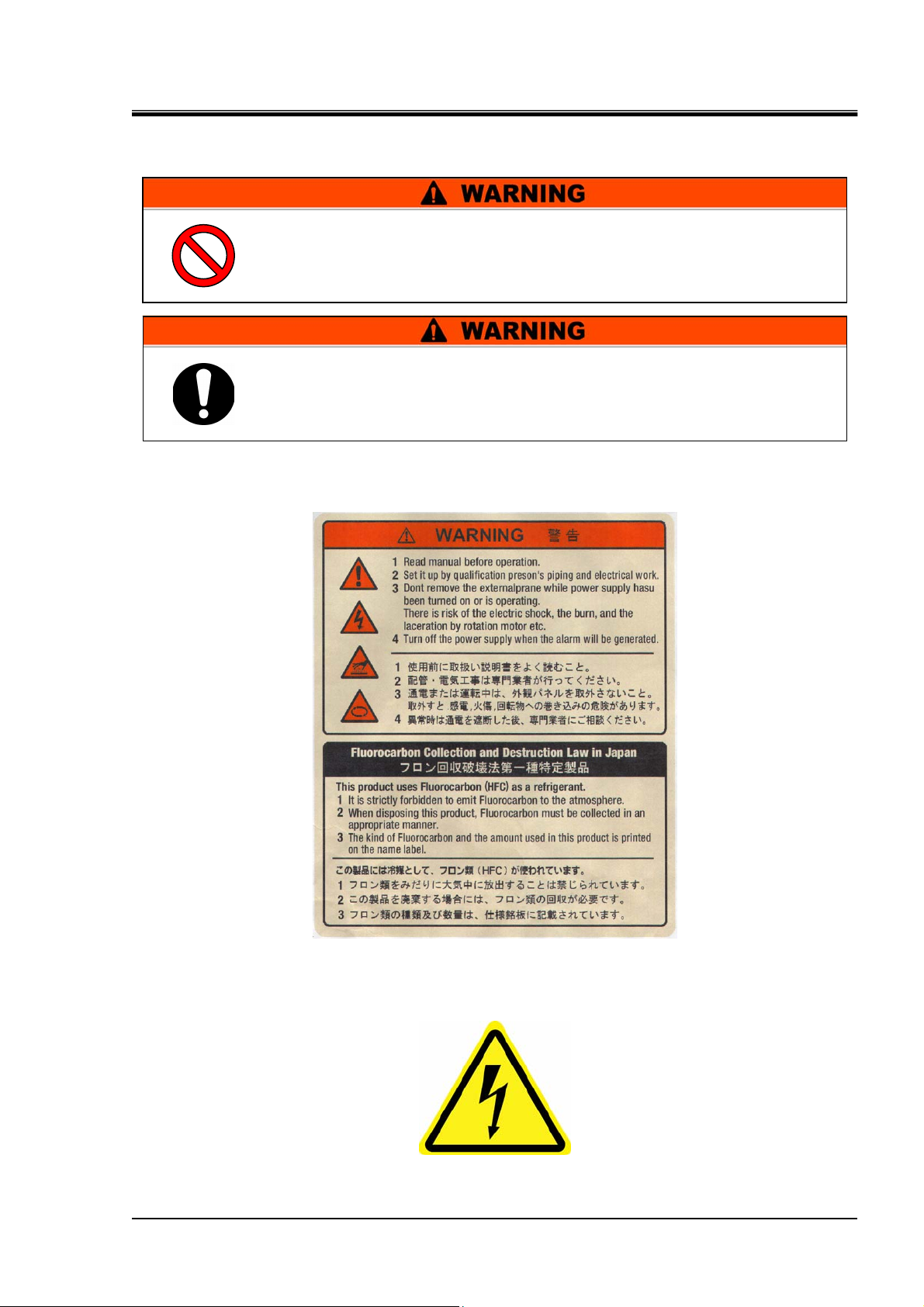

1.3.3 Location of hazard warning label

z Recognize where the hazard warning labels are attached.

z The user is not allowed to reposition the labels. If the label is

replaced due to being peeled off or worn out, keep the previous

position.

Warning label for

Left

high

1.4 Model label

Check the model no. described on the label.

Front

Fig. 1-3 Location of Hazard Warning Label

Warning label on the

front panel

Front

1.4 Model label HRG010-W HRG015-W

1-6

Fig. 1-4 Location of Model Label

1st edition : Aug. 2006

Rev. A: May. 2007

Page 13

1.5 Safety Measures

1.5.1 Safety Precautions

While this system is protected by various safety measures, the following basic safety

precautions should be observed to assure further safe operations.

Follow the following instructions upon operation of this system.

Failure to follow the instructions can lead to personal injury or

hazardous accidents.

Read and understand this manual thoroughly before operation of this system.

z

Before operating the system during maintenance, inform all personnel who are

z

working in the vicinity of the system to alert them of your action.

Use appropriate tools and follow proper procedures.

z

HRX-OM-J049-A

Chapter 1 Safety Instructions

See “1.5.2 Protective equipment”on page 1-8 to wear protective equipment

z

properly.

Refer to your safety manual for emergency evacuation.

z

Use assistance to carry object over 20 kg.

z

Check that all parts and screws are returned to the pre-work conditions at the end

z

of work.

Do not work when intoxicated or feeling ill. Accidents may occur if disregarded.

z

Do not remove a panel unless permitted in this manual.

z

HRG010-W HRG015-W 1.5 Safety Measures

1st edition : Aug. 2006

Rev. A: May. 2007

1-7

Page 14

HRX-OM-J049-A

Chapter 1 Safety Instructions

1.5.2 Protective equipment

This manual defines protective equipment according to work type.

Wear proper protective equipment as shown below, according to work type.

Read and understand the relevant operation manual thoroughly prior

to use of protective equipment.

For system transportation, installation and removal

For handling circulating fluid

For system operation

z Protective footwear z Protective gloves z Hard hat

z Protective footwear z Protective gloves z Protective mask

z Protective apron z Protective goggles

z Protective footwear z Protective gloves

1.5 Safety Measures HRG010-W HRG015-W

1-8

1st edition : Aug. 2006

Rev. A: May. 2007

Page 15

HRX-OM-J049-A

Chapter 1 Safety Instructions

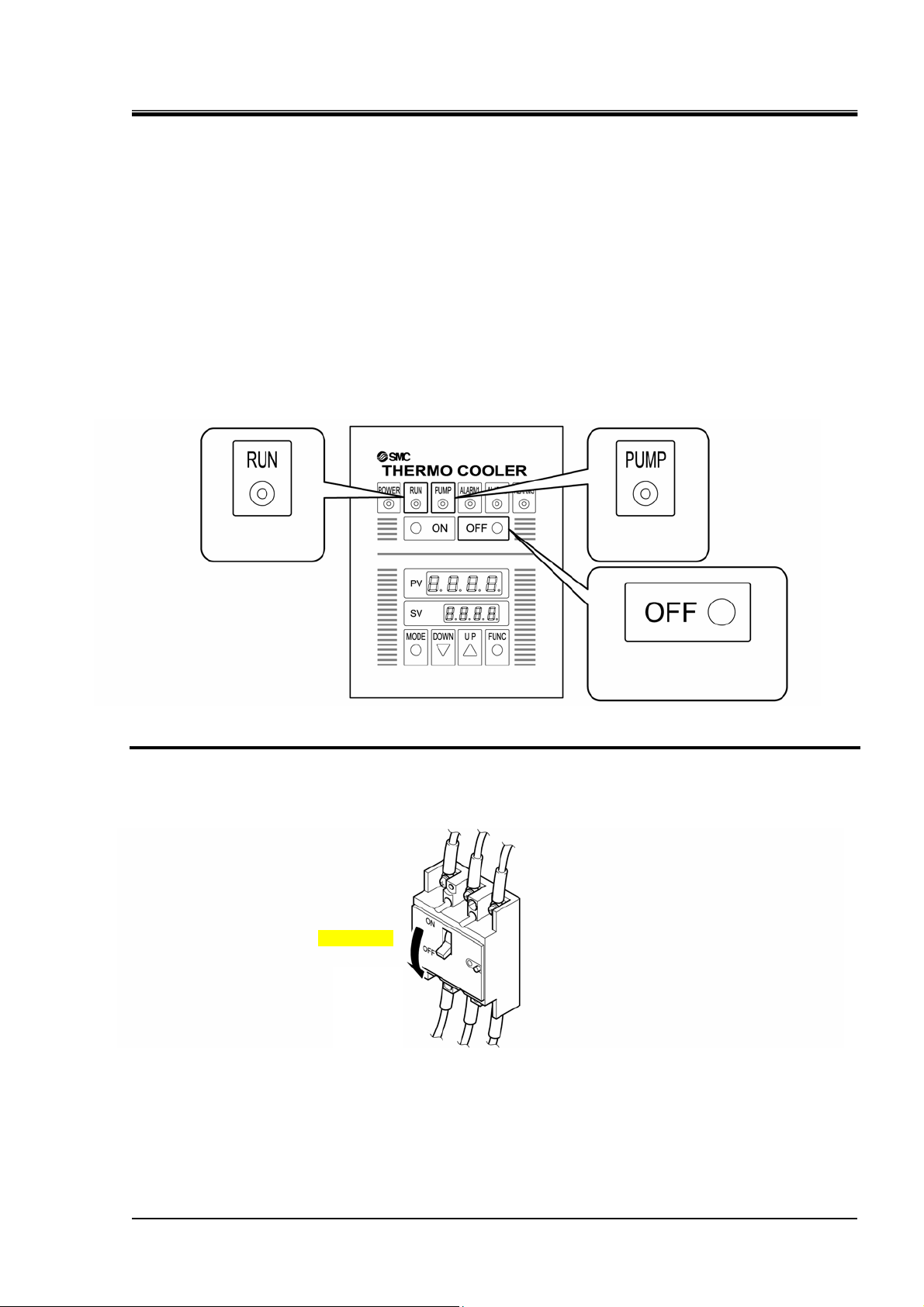

1.6 Emergency Measures

Press the [OFF] switch on the control panel located on the front of the thermo cooler

only if the need to shut off the power arises due to emergency such as natural

disaster, fire, earthquake or personal injury.

With the press of the [OFF] switch, the thermo cooler comes to a stop. The power

supply, however, is designed not to stop, which enables the motor circuit to remain

partially energized.

Make sure to turn off the main power supply (main breaker) before proceeding with

the next task.

1. Press the [OFF] switch on the control panel to bring the thermo cooler to a stop.

[RUN] LED [PUMP] LED

[OFF] LED

Fig. 1-5 Thermo Cooler OFF

2. Always turn off the main breaker (for your power supply equipment).

Switch it off.

前面

Fig. 1-6 Main Power Shutdown (Breaker OFF)

HRG010-W HRG015-W 1.6 Emergency Measures

1st edition : Aug. 2006

Rev. A: May. 2007

1-9

Page 16

HRX-OM-J049-A

Chapter 1 Safety Instructions

1.7 Disposition of Waste

1.7.1 Recovery of refrigerant and compressor oil

The unit belongs to Class 1 in the “Fluorocarbon Recovery and Destruction Law”

and uses freon type refrigerant (HFC) and compressor oil. When these fluids need to

be recovered, read the instructions below and ensure thorough understanding of

them. If you have any questions, contact the local distributor.

Only service personnel or qualified personnel are allowed to open the

panel of the unit.

Do not mix the compressor oil with domestic waste for disposition.

Also, incineration is permitted only at an authorized incinerator.

Comply with municipal ordinances or regulations to dispose of waste.

The release of refrigerant to atmosphere is banned by law. If the

refrigerant needs to be removed, recover it with specific equipment

and request a specialized waste disposal agency for disposal of the

recovered refrigerant. A person must have proper license to perform

refrigerant recovery.

Only personnel with sufficient knowledge and experiences with the

unit and associated equipment are allowed to recover refrigerant and

compressor oil. The person must have proper license to perform

refrigerant recovery.

[Tips]

The type and amount of used freon can be found on the label.

1.7 Disposition of Waste HRG010-W HRG015-W

1-10

1st edition : Aug. 2006

Rev. A: May. 2007

Page 17

1.7.2 Circulating fluid disposal

As to the disposal of a circulating fluid (ethylene glycol solution), consign the

specialized industrial waste disposal agency with the contents detailed.

1.7.3 System disposal

As to the disposal of this system, consign the specialized industrial waste disposal

agency in accordance with law on Waste Disposal and Cleaning.

1.8 Material Safety Data Sheet (MSDS)

Material Safety Data Sheet (MSDS) is supplied separately. Contact the system

supplier if you need the MSDS regarding chemicals used in this system.

For each chemical you purchased, the relevant MSDS is to be obtained under your

responsibility. Keep the MSDS along with this manual in the condition that allows

all personnel to check the contents anytime to gain the understanding of potential

hazards.

HRX-OM-J049-A

Chapter 1 Safety Instructions

HRG010-W HRG015-W 1.8 Material Safety Data Sheet (MSDS)

1st edition : Aug. 2006

Rev. A: May. 2007

1-11

Page 18

HRX-OM-J049-A

Chapter 1 Safety Instructions

1.8 Material Safety Data Sheet (MSDS) HRG010-W HRG015-W

1-12

1st edition : Aug. 2006

Rev. A: May. 2007

Page 19

HRX-OM-J049-A

Chapter 2 Appearance and Each Section

Chapter 2 Appearance and Each Section

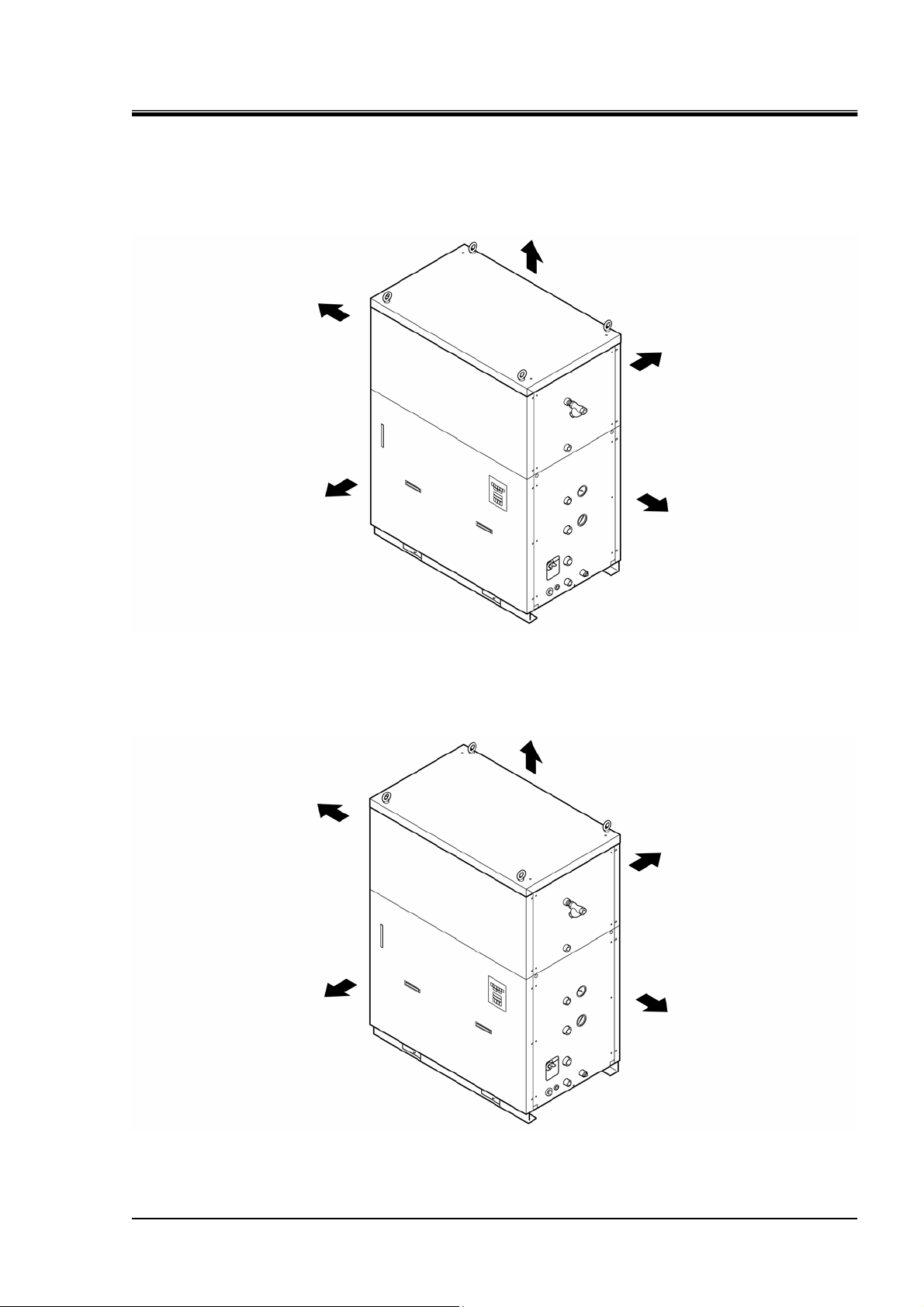

2.1 Appearance

Left

Front

Top

Back

Right

Left

Front

Fig. 2-1 Appearance of HRG010-W

Top

Back

Right

Fig. 2-2 Appearance of HRG015-W

HRG010-W HRG015-W 2.1 Appearance

1st edition : Aug. 2006

Rev. A: May. 2007

2-1

Page 20

HRX-OM-J049-A

Chapter 2 Appearance and Each Section

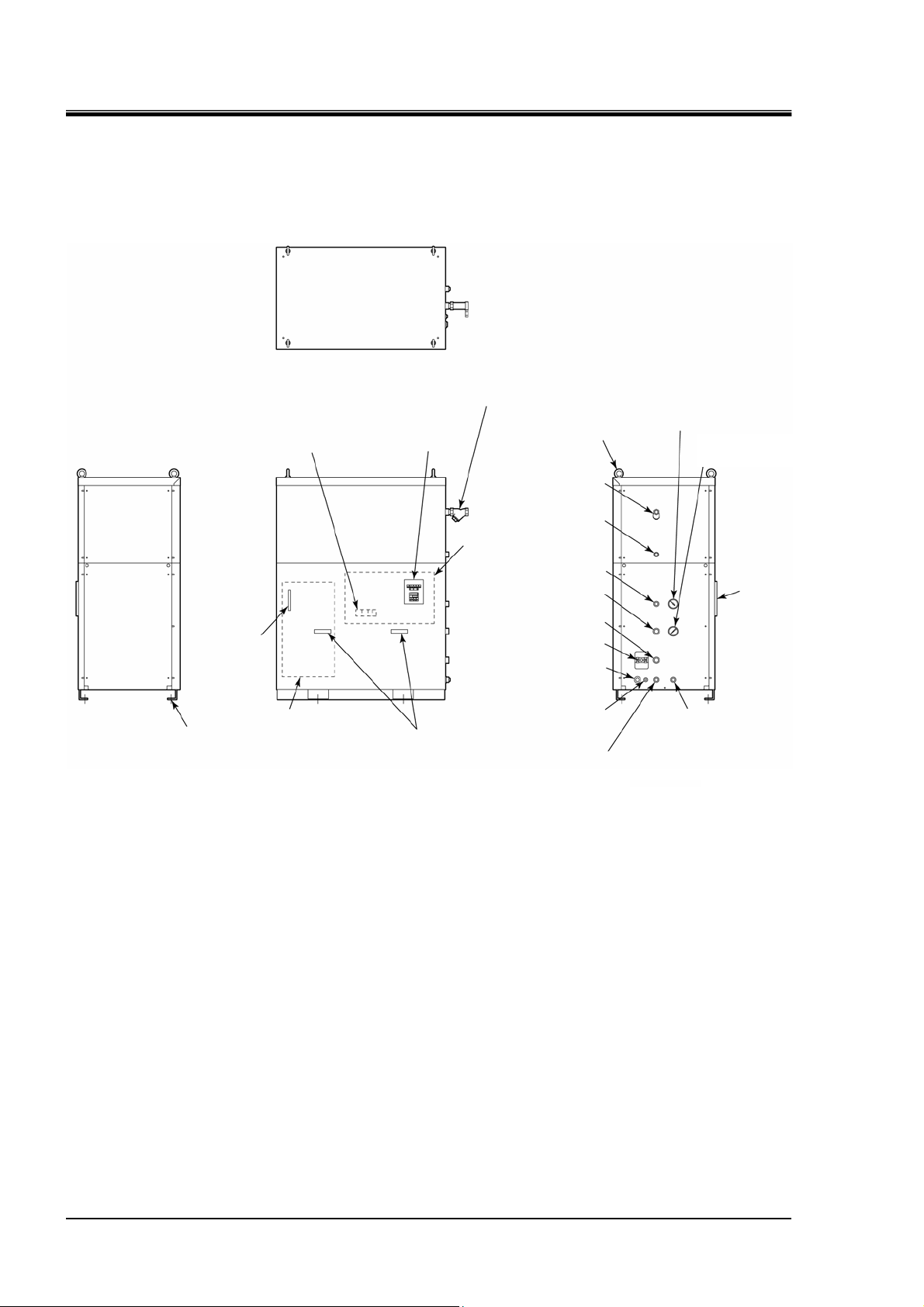

2.2 Name of Each Section

2.2.1 HRG010-W

Left

Level gauge

4-Ø13

(For anchor bolt)

Top

Power/signal connection

terminal block

Tank

Front

Control panel

Circulating fluid OUT Rc3/4

Handle

Y-shaped strainer Rc1/2

(accessory)

Eyebolt M12

Facility water IN Rc1/2

Facility water OUT Rc1/2

Electrical unit

Auto supply port Rc1/2

Circulating fluid RETURN

Rc3/4

Manual relief valve

Power cable access

(Cable Grip)

Signal cable access

(Cable Grip)

Tank drain port Rc1/2

(plugged)

Refrigerant high

pressure gauge

Circulating fluid

pressure gauge

Ventilating hole

Port for overflow Rc1/2

Right

Fig. 2-3 Name of Each Section (HRG010-W)

2.2 Name of Each Section HRG010-W HRG015-W

2-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 21

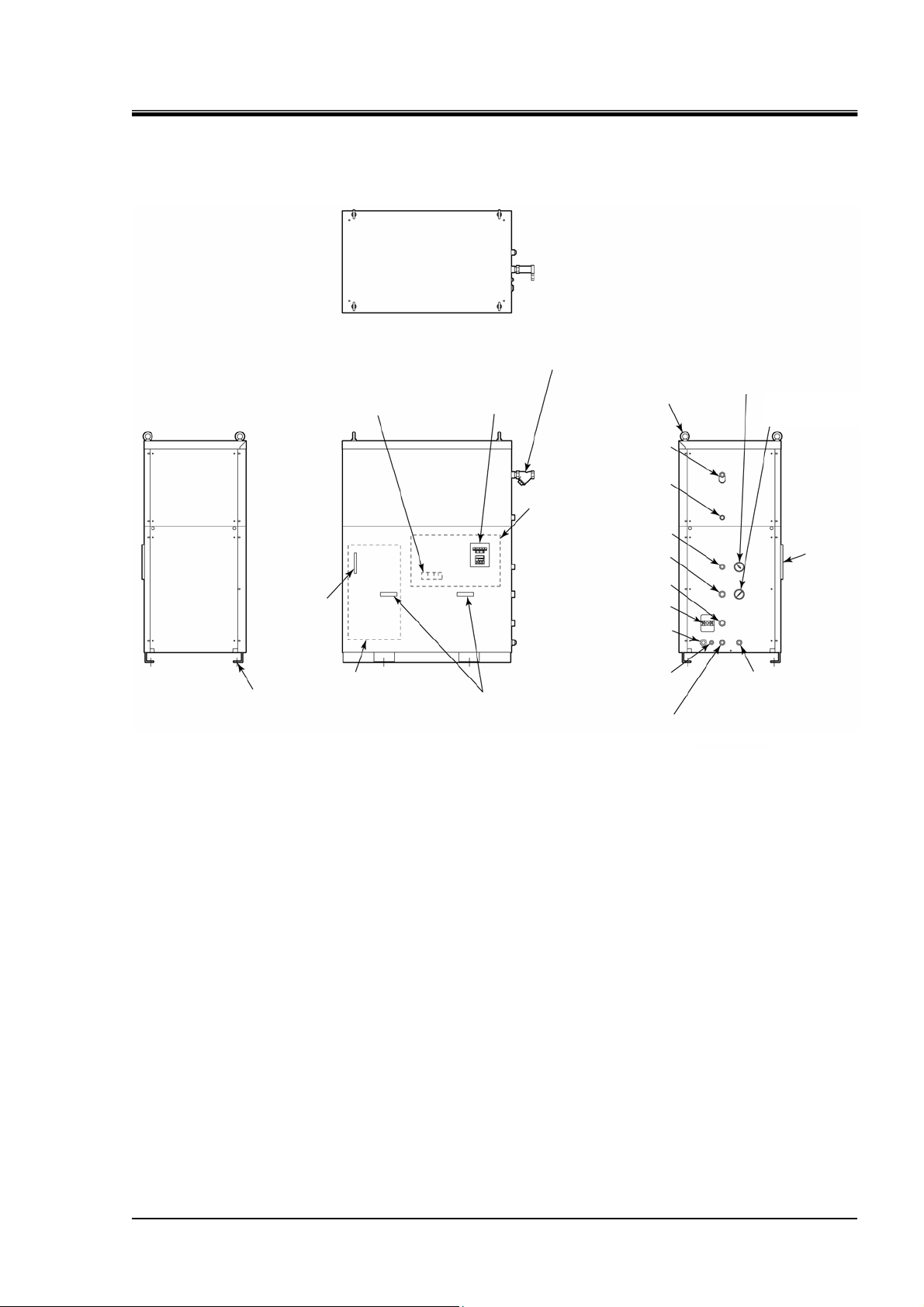

2.2.2 HRG015-W

HRX-OM-J049-A

Chapter 2 Appearance and Each Section

Left

Level gauge

4-Ø13

(For anchor bolt)

Top

Power/signal connection

terminal block

Tank

Front

Y-shaped strainer Rc1/2 (accessory)

Control panel

Facility water IN Rc1/2

Facility water OUT Rc1/2

Electrical unit

Auto supply port Rc1/2

Circulating fluid OUT Rc3/4

Circulating fluid RETURN

Manual relief valve

Power cable access

Signal cable access

Handle

Tank drain port Rc1/2

(plugged)

Eyebolt M12

(Cable Grip)

(Cable Grip)

Refrigerant high

pressure gauge

Circulating fluid

pressure gauge

Ventilating

hole

Rc3/4

Port for overflow Rc1/2

Right

Fig. 2-4 Name of Each Section (HRG015-W)

HRG010-W HRG015-W 2.2 Name of Each Section

1st edition : Aug. 2006

Rev. A: May. 2007

2-3

Page 22

HRX-OM-J049-A

Chapter 2 Appearance and Each Section

2.3 Control panel

The control panel on the system front allows you to perform basic system operation

including temperature adjsutment, system start and stop.

Fig. 2-5 Control Panel

Table 2-1 Control Panel

No. Name Function

1 Digital display, PV / SV

PV Indicates actual temperature of a circulating fluid

SV Indicates set temperature of a circulating fluid

2 [POWER] LED Lights up when the power is supplied.

3 [RUN] LED

4 [PUMP] LED

Lights up when the [ON] switch is pressed.

5 [ALARM 1] LED Lights up when an alarm 1 arises.

6 [ALARM 2] LED Lights up when an alarm 2 arises.

7 [ALARM 3] LED Lights up when an alarm 3 arises.

8 [ON] switch This is used to run the unit.

9 [OFF] switch This is used to stop the unit.

10 [MODE] key This is used to switch the screens between PV and SV.

11 [DOWN] key This is used to decrease set temperature.

12 [UP] key This is used to increase set temperature.

* See “Chapter 5 Error Message and Troubleshooting” for alarms 1 to 3.

2.3 Control panel HRG010-W HRG015-W

2-4

1st edition : Aug. 2006

Rev. A: May. 2007

Page 23

HRX-OM-J049-A

Chapter 3 Transport and Installation

Chapter 3 Transport and Installation

The unit must be handled in correct manner.

Exercise caution to asure personnel safety during the installation,

operation, maintenance, and inspection of the unit.

Only personnel with sufficient knowledge and experiences with the

unit and unit are allowed to transport, install and conduct maintenance

possibly exposed to dangerous situations.

3.1 Transport

The unit is heavy and poses potential danger at transportation. To prevent damage

to the unit, be sure to follow the instructions below when transporting the unit.

If the forklift is used for transporting, ensure that the fork is inserted in

a place as specified in Fig. 3-1 “Forklift Insertion Position and Unit

Lifting”.

z If eyebolts are used for lifting, ensure the unit is held at four points.

z Keep each eyebolt at an angle from Min. 60 degrees with repect to

the postion of the center of gravity when lifting the unit.

Never set the unit on its side.

The refrigerant oil will drain into refrigerant piping from the

compressor, reducing its amount in the compressor. It results in a

compressor failure.

Drain the residual fluid from piping as much as possible to prevent

spill.

If the forklift is used for transporting the unit, be sure to prevent the

fork from contacting the cover panel or pipe connection ports.

HRG010-W HRG015-W 3.1 Transport

1st edition : Aug. 2006

Rev. A: May. 2007

3-1

Page 24

HRX-OM-J049-A

Chapter 3 Transport and Installation

3.1.1 Transporting with forklift and unit lifting

Min. 60°

Forklift insertion side

Lifting position

Min. 60°

Forklift insertion side

Front

Fig. 3-2 Forklift Insertion Position and Unit Lifting

3.1 Transport HRG010-W HRG015-W

3-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 25

Chapter 3 Transport and Installation

3.1.2 Transporting with caster

HRG010-W-A / HRG015-W-A (caster-mounted option)

HRX-OM-J049-A

This unit is heavy, which requires assistance for this work. Exercise

caution and look out for sloped surfaces including ramps.

Do not grab piping or panel handles when transporting the sytem with

the casters.

Potential damage to piping and panels may occur if disregarded.

1. Push the corners of this unit with the adjusters uplifted.

The unit becomes disengaged so that it can be transported with casters.

Turn 360°.

Uplift the adjuster.

Turn 360°.

Caster w/ adjuster

Front

Handle

Pipe port

Fig. 3-3 Caster-mounted Option

HRG010-W HRG015-W 3.1 Transport

1st edition : Aug. 2006

Rev. A: May. 2007

3-3

Page 26

HRX-OM-J049-A

,

Chapter 3 Transport and Installation

3.2 Installation

Do not install the unit in a place possibly exposed to flammable gas.

Ignition may occur if leaked gas is collected around the unit.

This unit is NOT designed for outside use. The unit exposed to

moisture may develop a short circuit which can result in an electrical

shock

Install the unit on a flat and level floor which can support the weight of

the unit. Take measure to prevent the unit from tipping over. Improper

setup may cause water leakage from the unit and personal injury.

Keep ambient temperature of the unit between 5 and 40°C. Unit

operation at below 5°C may lead to failure in the compressor.

Operation at above 40°C will reduce effectiveness of the condenser

and trigger the safety device which brings the unit to a stop.

fire and failure in the unit.

3.2.1 Installation conditions

Do not use or store the unit in the following environments. Potential unit malfunction and

damage may occur if disregarded.

Environment that is exposed to water vapor, salt water or oil mist

z

Environment that is exposed to dust or powdery materials

z

Environment that is exposed to corrosive gas, flammable gas or solvent

z

Environment that is exposed to direct sun light or radiant heat

z

Environment where ambient temperature is out of the specified range between 5°C to 40°C

z

Environment that is subjected to abrupt changes in temprature

z

Environment that is subjected to strong electromagnetic noise (incl. strong electrical field,

z

strong magnetic field, or surge voltage)

Environment that generates static electricity, or condition in which static electricity

z

discharges to the unit

Environment that generates strong high frequencies

z

Environment at high altitudes of over 1000m

z

Condition which allows strong vibrations and impacts to transmit to the unit

z

Condition with external force or load to deform the unit

z

Condition with an insufficient maintenance space as required

z

Condition with no adequate space for ventilation

z

3.2 Installation HRG010-W HRG015-W

3-4

1st edition : Aug. 2006

Rev. A: May. 2007

Page 27

3.2.2 Installation location

Required water sources

Table 3-1 Heat Discharge and Required Quantity of Facility Water (HRG010-W, HRG015-W)

Model

HRG010-W Approx. 16 34

HRG015-W Approx. 23

Outside installation

A water-refrigerated thermo cooler is designed to exhaust heat

through a supply of facility water.

Secure water sources listed below.

Heat discharge

(kW)

HRG010 and HRG015 are IPx3-compliant rainproof systems but not rendered complete

waterproof. Install the system out of direct sunlight as well as direct rain and snow (e.g. under

the eaves).

Chapter 3 Transport and Installation

Facility water temp. range (°C)

5 to 32

(Rated temp.: 25)

HRX-OM-J049-A

Required water

quantity (L/min)

40

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-5

Page 28

HRX-OM-J049-A

Chapter 3 Transport and Installation

3.2.3 Installation location and maintenance work area

Installation with maintenance space is recommended. (See Fig. 3-4)

Ensure an adequate ventilation space for the temperature controller.

Failure to create sufficient space may lead to improper cooling and/or

controller stop.

Access maintenance work area should be required for maintenance.

Min. 800mm

60mm

Min. 800mm

Top

Min. 800mm

Front

Fig. 3-4 Recommended Installation Location

3.2 Installation HRG010-W HRG015-W

3-6

1st edition : Aug. 2006

Rev. A: May. 2007

Page 29

HRX-OM-J049-A

Chapter 3 Transport and Installation

3.2.4 Installation

Preparation of anchor bolts suitable for floor material is your

responsibility.

Prepare M12-anchor bolts (4 pcs.) for installation. See “ 7.3 Outline

Dimensions” for mounting of the anchor bolts.

Keep the unit away from vibration. Install the unit on a flat and stable surface.

z

Refer to “7.3 Outline Dimensions” for the dimensions of the unit.

z

Procedure for Installation

1. The anchor bolts (foundation bolts) are mounted on the level concrete foundation.

Lower this unit, inserting the anchor bolts into the unit.

2. Tighten the hexagonal nut to secure the unit onto the foundation.

3. Make sure of no looseness between the anchor bolts and foundation.

Anchor bolt mounting hole (Ø13)

Base

Hexagonal nut

Anchor bolt

Front

Concrete foundation

Fig. 3-5 Procedure for Installation

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-7

Page 30

HRX-OM-J049-A

Chapter 3 Transport and Installation

HRG010-W-A / HRG015-W-A (caster-mounted option)

As to the HRG010-W-A or HRG015-W-A (caster-mounted option), the

adjusters should be lowered to secure the system after installation.

Caster w/ adjuster Lower the adjusters to secure the system.

Fig. 3-6 HRG010-W-A / HRG015-W-A (Caster-mounted Option)

3.2 Installation HRG010-W HRG015-W

3-8

1st edition : Aug. 2006

Rev. A: May. 2007

Page 31

3.2.5 Electrical wiring

HRX-OM-J049-A

Chapter 3 Transport and Installation

z Do not modify the electrical wiring. Incorrect wiring can cause an

electrical shock and fire. Failure to do so will void any warranty.

z The set value of the safety device must not be changed. Changing

the set value can cause unit failure and fire.

z Only qualified personnel are allowed to install wiring.

z Be sure to disconnect the power for safety. Wiring installation with

the unit energized is strictly prohibitted.

z Use the specified cables. Properly apply strain relief to prevent an

external force from being exerted on the terminals. Poor or loose

connection can cause electrical shock, heat spots, or fire.

z Supply the power to the unit from a reliable power source (without

surge or sag voltage).

z Be sure to use a GFCI breaker to prevent an electrical shock and

burnt compressor motor. The breaker with adequate capacity of

current leakage and load should be selected in accordance with “7.1

Standard Specifications”.

z Ensure that the power supply meets the specification of the unit.

z Always establish a ground for safety.

z Do not connect the ground to a water line, gas pipe or lighting

conductor.

z Do not branch off the wiring to make multiple circuits. Potential hot

spots or fire may occur if disregarded.

Power supply cable and GFCI breaker

Select a cable for power supply and GFCI breaker corresponding to the model no.

provided in the following table.

Table 3-2 Cable for Power Supply and Current Leakage

Item HRG010-W HRG015-W

Power cable

Signal cable

Capacity of GFCI breaker

* Use the breaker with current sensitivity of 30mA at minimum.

Round crimp contact size 8 - 4S 14 - 5S

Y-shaped crimp contact size 1.25Y - 3

Size 4- core 8 mm2 4- core 14 mm2

Size 6- core 0.75 mm2

*

40A 60A

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-9

Page 32

HRX-OM-J049-A

Chapter 3 Transport and Installation

How to conduct wiring

1. Undo the screws (6 pcs.) and take off the front panel.

Screw

Front panel

Front

Fig. 3-7 Removal of Front Panel

Electrical unit

Screw

2. Connect the power supply cable and signal cable as shown in the figure.

Front

Fig. 3-8 Electrical Wiring

Signal cable access

Power cable access

Signal cable Power cable

3.2 Installation HRG010-W HRG015-W

3-10

1st edition : Aug. 2006

Rev. A: May. 2007

Page 33

Electrical wiring diagram

HRX-OM-J049-A

Chapter 3 Transport and Installation

z Prepare cables for the power supplyand signal lines separately .

z Maintain polarities (+, -) of DC24V when connecting the signal cable for

transmitting start/stop command (remote operation).

z Refer to “7.4 Electric Circuit” for the electrical circuit of the unit.

• HRG010-W

ELB/Current leakage breaker

Power supply input

z

User’s preparation

Power supply

cable

Electrical unit

Remote operation signal input

(Remote start upon input of DC+24V)

Remote stop upon input of DC 0V)

Error deteced stop signal output, relay contact

(normally open, closed for error

Contact closed during power-off)

Operation signal output, relay contact

(normally close, opened for error

Contact open during power-off)

Signal cable

FG (Frame ground)

Electrical circuit

Remote operation input circuit

Error detected stop

signal output circuit

Operation signal output circuit

I/O board

Fig. 3-9 Electrical Wiring Diagram (HRG010-W)

• HRG015-W

ELB/Current leakage breaker

Power supply input

Remote operation signal input

(Remote start upon input of DC+24V)

Remote stop upon input of DC 0V)

Error detected stop signal output, relay contact

(normally open, closed for error

Contact closed during Power-off)

Operation signal output, relay contact

(normally close, opened for error

Contact open during power-off)

Fig. 3-10 Electrical Wiring Diagram (HRG015-W)

User’s preparation

Power supply

cable

Signal cable

Electrical unit

Electrical circuit

FG (Frame ground)

Remote operation input circuit

Remote operation input circuit

Operation signal output circuit

I/O board

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-11

Page 34

HRX-OM-J049-A

Chapter 3 Transport and Installation

Procedures for communication cable wiring installation (RS485)

HRG010-W-C / HRG015-W-C (communication feature-laden option)

The communication cables are to adhere to specifications shown below.

Table 3-3 Communication Cable

Item Specifications

Communication cable

Y-shaped crimp contact size 1.25Y-3

Size Shielded twisted-pair wire (0.75mm2)

1. Connect the power cables properly, as shown below.

Front

Fig. 3-11 Communication Cable Wiring

Signal cable access

(communication cable access)

Communication cable

2. Have the converters listed below available. Establish connection with the computer (with a

RS232C terminal).

Table 3-4 Converter (Example)

Item Specifications

RS232C ⇔ RS485 converter

Part number: KS-485

Manufacturer: System Sacom

Connecting connector D-sub 9-pin (male)

Computer ⇔ Converter coupling cable

3.2 Installation HRG010-W HRG015-W

3-12

Part number:AR-305

Manufacturer: Arvel

1st edition : Aug. 2006

Rev. A: May. 2007

Page 35

3.2.6 Piping

HRX-OM-J049-A

Chapter 3 Transport and Installation

Only expert engineers or personnel who have adequate knowledge of

and experiences with piping installation are allowed to install piping.

Potential fluid leakage or stagnant fluid may occur if disregarded.

z Install piping properly. Failure to conduct proper piping installation

z Keep facility water pressure below 0.5MPa.

z Make sure the locations of IN and OUT ports for circulating fluid

z Make sure no entry of dust and foreign materials into the water

z Hold the piping connected port with a pipe wrench when tightening

z Hold the piping connected port with a pipe wrench when tightening

Pipe diameter

Facility water IN Rc1/2 Rc3/4

Facility water OUT Rc1/2 Rc3/4

Auto supply port Rc1/2

Circulating fluid OUT Rc3/4

Circulating fluid RETURN Rc3/4

Port for overflow

Port for drain in tank Rc1/2

may result in the entry of supplied and drained water into the inside

of the building, which may cause the work area and equipment to

get wet.

supply. The reverse connection inhibits proper operation of the unit.

circuit during piping installation.

the pipe. Excessive force will damage the port and cause leaks if

disregarded.

piping.

Pipe

Table 3-5 Pipe diameter

Diameter

HRG010-W HRG015-W

Rc1/2

Recommended

tightening torque

28 to 30N·• m

28 to 30N·• m

28 to 30N·• m

28 to 30N·• m

28 to 30N·• m

28 to 30N·• m

28 to 30N·• m

How to install piping

1. Hold the piping connected port with a specific wrench and tighten the pipe.

[Tips]

Install a valve at the drain port to facilitate the replacing and draining of the circulating fluid from the

tank described in chapter 6 “Unit Maintenance”. (The valve needs to be prepared separately.)

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

Fig. 3-12 Tightening of Pipe

Pipe coupling hole

Sealant

3-13

Page 36

HRX-OM-J049-A

Chapter 3 Transport and Installation

Recommended piping installation

Facility water IN

Facility water OUT

Auto supply port Fluid supply

Facility water

Circulating fluid OUT

Circulating fluid RETURN

Port for overflow

Tank drain port

No. Name

Load device

To the drain port

Fig. 3-13 Recommended Piping Installation

Table 3-6 Recommended Piping Installation

Size

HRG010-W HRG015-W

1 Valve Rc1/2 Rc3/4

2 Y-shaped strainer Rc1/2 Rc3/4

3 Pressure gauge 0 to 1.0 MPa

4 Valve Rc3/4

5 Relieving valve Rc3/4, set from 0 to 0.5 MPa

6 Y-shaped strainer Rc3/4

7 Flow meter Rc3/4, 0 to 100 L/min

[Tips]

Optional accessories listed below are available for the relieving valves shown

in Fig. 3-12 “Recommended Piping Installation”. Separate order for optional

accessories is to be placed upon designing the piping system if used for

piping installation.

Table 3-7 Allied Products

Part No. Name Qty. Note

HRG-BP010 Bypass (relieving valve) piping set 1 set HRG010 optional accessory

HRG-BP015 Bypass (relieving valve) piping set 1 set HRG015 optional accessory

3.2 Installation HRG010-W HRG015-W

3-14

1st edition : Aug. 2006

Rev. A: May. 2007

Page 37

Chapter 3 Transport and Installation

3.2.7 Supply of circulating fluid

1. Open the supply valve laid with pipes.

The fluid supply takes place with the use of the ball tap housed in the tank and stops automatically.

Keep the fluid level in the tank between “HIGH” and “LOW”.

If the circulating fluid is out of the range, the fluid may overflow.

Ensure piping is installed to the overflow outlet and drain pit.

Indicating range

Level gauge

HRX-OM-J049-A

Fig. 3-14 Level Gauge

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-15

Page 38

HRX-OM-J049-A

Chapter 3 Transport and Installation

3.2.8 Reinstallation of unit

If the unit is relocated, only personnel with knowledge of the unit and

associated equipment are allowed to perform unit reinstallation.

Precautions described below must always be followed.

Disconnection of power supply cable

When the unit is transferred to and reinstalled in a different place after operation at

the original place (including trial run), perform transporting and installation of the

unit according to the procedures described below and in Chapter 3.

Be sure to cut off the power supply when disconnecting the power supply cable.

z Only qualified personnel are allowed to install wiring.

z Be sure to cut off the power supply for safety. Wiring with the unit

energized is strictly prohibitted.

3.2 Installation HRG010-W HRG015-W

3-16

1st edition : Aug. 2006

Rev. A: May. 2007

Page 39

Chapter 4 Startup and Shutdown

Chapter 4 Startup and Shutdown

HRX-OM-J049-A

Personnel with adequate knowledge and experiences of this product

and peripheral devices shall be in charge of starting up and shutting

down the unit.

4.1 Pre-check

Check the following items before starting up the unit.

4.1.1 Installation condition

Make sure the unit is installed horizontally.

z

Do not put any heavy object on the unit or apply excess force by piping.

z

4.1.2 Electric wiring

Check that the power cable, ground and I/O signal cables are correctly connected.

4.1.3 Facility water piping

Check the I/O piping of the facility water is installed correctly.

4.1.4 Piping for circulating fluid

Check the I/O piping of the circulating fluid is installed correctly.

4.1.5 Supply of circulating fluid

Check the fluid level is within the specified range shown on the level indicator.

HRG010-W HRG015-W 4.1 Pre-check

1st edition : Aug. 2006

Rev. A: May. 2007

4-1

Page 40

HRX-OM-J049-A

Chapter 4 Startup and Shutdown

4.2 Preparation for startup

4.2.1 Power supply

1. Supply the power.

The following conditions are observed on the control panel upon power-ON.

After 4-sec display of the initial screen on the digital displays PV and SV, temperature and set temperature

z

of the circulating fluid will be displayed..

The [POWER] lamp comes on in 6 sec.

z

[POWER]LED

Digital display PV (circulating fluid temp.)

Fig. 4-1 Power Supply

Digital display SV (set temp.)

4.2.2 Setting of circulating fluid temperature

1. Press the [UP] and [DOWN] keys to set a desired temperature in the digital display SV.

[DOWN]key [UP] key

Note: Circulating fluid setting temp.range is 5 to 35°C.

z

Fig. 4-2 Setting of Circulating Fluid Temperature

Digital display SV (set temp.)

4.2 Preparation for startup HRG010-W HRG015-W

4-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 41

4.2.3 Additional water supply

[TS] switch (pump manual operation switch)

This unit has the [TS] switch (pump manual operation switch) to purge air from the

circulating fluid circuit at initial startup. Remove the front panel, and purge air

according to the procedures given below.

Front

Fig. 4-3 [TS] switch (pump manual operation switch)

HRX-OM-J049-A

Chapter 4 Startup and Shutdown

[TS] switch

(green)

1. Press the [TS] switch for several seconds, monitoring the fluid level gauge.

Air is purged from the pipe, and the fluid level is lowered.

The [ALARM1] lamp comes on (error). The lamp goes out with the press of the [RS] switch after the

z

circulating fluid reaches the range specified on the level indicator.

See “Chapter 5 Error Message and Troubleshooting” for error messages.

z

Front

Fig. 4-4 Location of Reset Switch (Yellow Button)

Control panel

Reset SW [RS]

(yellow button)

2. Supply the circulating fluid again according to section “3.2.7Supply of circulating fluid”.

If leakage occurs due to faultypiping including an opened fitting of eternal piping,

stop manual operation of the pump and fix the leak.

HRG010-W HRG015-W 4.2 Preparation for startup

1st edition : Aug. 2006

Rev. A: May. 2007

4-3

Page 42

HRX-OM-J049-A

Chapter 4 Startup and Shutdown

4.3 Unit Startup and Shutdown

4.3.1 Starting the unit

1. Press the [ON] switch on the control panel.

The unit starts operating and regulates the circulating fluid temperature.

The [RUN] LED and [PUMP] LED on the control panel come on.

[RUN] LED [PUMP] LED

[ON] switch

Fig. 4-5 Starting the Unit

4.3.2 Stopping the unit

1. Press the [OFF] switch on the control panel.

The unit stops.

The [RUN] LED and [PUMP] LED on the control panel go out.

[RUN] LED [PUMP] LED

4.3 Unit Startup and Shutdown HRG010-W HRG015-W

4-4

Fig. 4-6 Stopping the Unit

[OFF] switch

1st edition : Aug. 2006

Rev. A: May. 2007

Page 43

4.4 Check at startup

Check the following items at startup of the unit.

HRX-OM-J049-A

Chapter 4 Startup and Shutdown

When any abnormality is found, press the [OFF] switch immediately to

stop the unit and turn the main power supply off.

Bypass valve

No leak from circulating fluid piping

z

No circulating fluid flowing out of the overflow outlet and tank drain port

z

Circulating fluid pressure within the specified range

z

Normally, the bypass valve is fully opened. If the unit is started up with the valve

fully closed, circulating fluid supply may reach abnormal high pressure depending

on external piping conditions. Be sure to keep the bypass valve fully opened for

initial startup of the unit installed.

Adjust the bypass valve to obtain required pressure and flow rate by checking on

the external pressure gauge and flow meter that can be prepared by customer or

mounted on external piping.

Bypass valve

Right

Fig. 4-7 Bypass Valve

HRG010-W HRG015-W 4.4 Check at startup

1st edition : Aug. 2006

Rev. A: May. 2007

4-5

Page 44

HRX-OM-J049-A

Chapter 4 Startup and Shutdown

Bypass (relieving valve) piping set

[Tips]

Bypass (relieving valve) piping sets listed in table 3-7 “Allied Products” are of

use for the omission of manual bypass valve adjustment.

[Tips]

Relieving valve

The relieving valve automatically opens when the circulating fluid outlet

pressure of the thermo cooler surpasses the set value. The relieving valve is

designed to bypass the circulating fluid that prevents a pressure rise during

fluid flow at low rate.

4.4 Check at startup HRG010-W HRG015-W

4-6

1st edition : Aug. 2006

Rev. A: May. 2007

Page 45

Chapter 5 Error Message and Troubleshooting

Chapter 5 Error Message and

Troubleshooting

5.1 Error Message

This product stops when an error is detected.

Table 5-1 shows the LED conditions (ON/OFF) and signal output in the event of

the error.

or

[POWER] LED [ALARM 2] LED

HRX-OM-J049-A

or

[POWER] LED

or

[ALARM 1] LED

Fig. 5-1 Control Panel

Table 5-1 Error Message

Alarm

Power error - Stopped

Start-up failure - Stopped Greenz

Reverse of pump

and compressor

Tank fluid level

drop

Suspension of

facility water

supply

Pump overload - Stopped Greenz

High temp. of

supplied fluid

Compressor

overload

Setting

range

- Stopped Greenz

Lower limit of

fluid level in

the tank

- Stopped Greenz

40°C and

over

- Stopped Greenz

System

status

Stopped Greenz

Stopped Greenz

POWER RUN ALARM1 ALARM2 ALARM3

LED

(z: Off, {: On)

{ { { { {

{ { { {

{

Redz

{

Redz

{

Redz

{ {

{ {

{ { {

{ {

{ {

{ {

Redz

Redz

{

{

Redz

or

[ALARM 3] LED

Operation

signal

output

Open

contact

Closed

contact

Open

contact

Open

contact

Open

contact

Open

contact

Open

contact

Open

contact

Error stop

signal

output

Closed

contact

Closed

contact

Open

contact

Open

contact

Open

contact

Open

contact

Open

contact

Open

contact

HRG010-W HRG015-W 5.1 Error Message

1st edition : Aug. 2006

Rev. A: May. 2007

5-1

Page 46

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

5.2 Troubleshooting

See “5.3 Alarm Reset” for error recovery.

Table 5-2 Troubleshooting

Error

No power is supplied.

Power error

Start-up

failure

Reverse of

pump and

compressor

Tank fluid

level drop

Suspension of

facility water

supply

Pump

overload

High temp. of

supplied fluid

Compressor

overload

*1) The recovery from an error capable of manual alarm reset takes place with the use of the switch and reset

button after the cause (such as fluid level drop or abnormal temperature) is eliminated.

*2) The recovery from an error capable of automatic alarm reset takes place when the cause (such as fluid level

drop or abnormal temperature) is eliminated after waiting period.

*3) With the tripped detector located, be sure to press the [RESET] button (yellow button) of the system electrical

unit after the elimination of the error cause. The alarm lamp goes out that enables the unit to resume.

Open phase

Overcurrent Request for service. Turn ON the breaker.

Ground fault Request for service. Turn ON the breaker.

Low voltage

Incorrect phase

sequence of power

wiring

Inadequate quantity of

the fulid in the tank, or

drop in the tanked fluid

level

Supplied facility water

falls short of its specified

volume.

Abnormal rise in fluid

supply pressure

Failure in the pump

motor

Abnormal rise in ambient

temperature

Excessive calorific value

of the chiller

Refrigerant leak Request for service.

Compressor error

Failure in the

electromagnetic switch

Other errors in the

refrigerating circuit

Failure in the temp.

controller

Excessive calorific value

of the chiller

Failure in the

compressor motor

Cause Remedies

....... .....................

W.ith the switch in its ON position,

main power. Only

allowed for power wiring.

Supply 3-phase power (R- and

S-phases).Only

allowed for power wiring.

Supply a rated voltage. Only

personnel are allowed for power wiring.

Rewire the power cable for two of three

phases (phase sequence). Only

personnel are allowed for power wiring.

Replenish the circulating fluid (fresh water).

Press the reset button of the high pressure

cutoff switch.

Supply facility water standing at 5 to 32°C.

Press the reset button of the pump

electromagnetic switch (MS1). Adopt a pipe

size suitable for circulating fluid flow, or,

adjust the opening of the manual relief valve.

Request for service.

Improve ambient conditions to provide

ventilation and exhaust heat. Keep the unit

out of direct sunlight and radiant heat.

Reduce a calorific value output from your unit.

Request for service.

Request for service.

Request for service

Request for service.

Press the [RESET] button of the compressor

electromagnetic switch (MS2). Reduce a

calorific value output from your system.

Request for service.

....

qualified personnel are

....

qualified personnel are

....

supply the

Manual reset

qualified

....

qualified

Manual reset

Manual reset

(blue button)

Manual reset

(blue button)

Alarm reset

Detector HRG

-

-

*1)

- -

Manual reset

(yellow

button)

*3)

Manual reset

(yellow

button)

*3)

Manual reset

(yellow

button)

*3)

Manual reset

(yellow

button)

*3)

Manual reset

(yellow

button)

*3)

Auto reset

*2)

(red button)

*1)

*1)

Auto reset

*2)

*1)

5.2 Troubleshooting HRG010-W HRG015-W

5-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 47

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

5.3 Alarm Reset (Alarm Lamp OFF)

Error check

1. Check the alarm number currently activated, and eliminate the error cause (see Table 5-2).

Adjust the unit usage and service condition.

[POWER] LED [ALARM2] LED

[RUN] LED

or

[ALARM1] LED

Fig. 5-2 Alarm Lamps (ON)

[ALARM1] ON ......................... Installation error

[ALARM2] ON ......................... Circulating fluid circuit error

[ALARM3] ON ......................... Refrigerating circuit error

or

or

[ALARM3] LED

HRG010-W HRG015-W 5.3 Alarm Reset (Alarm Lamp OFF)

1st edition : Aug. 2006

Rev. A: May. 2007

5-3

Page 48

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

2. Undo the screws (6 pcs.) to remove the front panel.

Only operate the unit with the cover panel attached.

The unit contains the power supply carrying high voltage inside that is

isolated with the cover panel.

Only trained personnel are allowed to work, including unit inspection,

around the power supply.

There is the presence of the surface in the unit that is at high

temperatures during operation. Potential burns may occur if touched.

Residual heat may cause burns despite the power being turned OFF.

Be sure of the surface reaching room temperature before work.

The unit contains a section which rotates when it is in action. Potential

personal injury may occur if touched. A rotator is structured to come

to a temporary stop and resume rotation.

Avoid performing work during system operation.

Screw

Front panel

Electrical unit

Screw

Front

Fig. 5-3 Removal of Front Panel

5.3 Alarm Reset (Alarm Lamp OFF) HRG010-W HRG015-W

5-4

1st edition : Aug. 2006

Rev. A: May. 2007

Page 49

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

3. Press the Reset switch [RS] (yellow button) on the control panel and make sure that the

alarm lamp goes out.

Front

Fig. 5-4 Location of Reset Switch [RS] (Yellow Button)

Control panel

Reset switch [RS]

(yellow button)

When the alarm lamp goes out by performing steps 1. to 3.

4. Attach the front panel.

5. Implement system startup and shutdown according to “Chapter 4 Startup and Shutdown”.

When the alarm lamp remains on after performing steps 1. to 3.

6. Press the reset button of each detector in the electrical unit.

7. Follow step 3. to press the Reset switch [RS] (yellow button).

The alarm lamp goes out accordingly.

8. Implement system startup and shutdown according to “4.3 Unit Startup and Shutdown”.

Pump overload reset button

(blue button)

Compressor overload reset

button (blue button)

Facility water supply suspension

reset button (red button)

Front

Fig. 5-5 Location of Reset Switch [RS] (Yellow Button)

HRG010-W HRG015-W 5.3 Alarm Reset (Alarm Lamp OFF)

1st edition : Aug. 2006

Rev. A: May. 2007

5-5

Page 50

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

5.4 Recovery from Power Failure (POWER Lamp ON)

Power error check

1. Request an expert engineer to eliminate the cause of a power failure (such as a ground

falut and overcurrent).

[POWER] LED [ALARM2] LED

[RUN] LED

[ALARM1] LED

Fig. 5-6 POWER Lamp (OFF)

[POWER] lamp OFF ............. Power supply error (power failure)

[ALARM3] LED

2. Turn on the main power breaker of your unit, and ensure the [POWER] lamp comes on.

5.4 Recovery from Power Failure (POWER Lamp ON) HRG010-W HRG015-W

5-6

1st edition : Aug. 2006

Rev. A: May. 2007

Page 51

HRX-OM-J049-A

p

Chapter 5 Error Message and Troubleshooting

[HRG010-W-B / HRG015-W-B (earth leakage breaker-mounted option)]

1. Undo the screws (6 pcs.) to remove the front panel.

Only operate the unit with the cover panel attached.

The unit contains the power supply carrying high voltage inside that is

isolated with the cover panel.

Only trained personnel are allowed to work, including unit inspection,

around the power supply.

There is the presence of the surface in the unit that is at high

temperatures during operation. Potential burns may occur if touched.

Residual heat may cause burns despite the power being turned OFF.

Be sure of the surface reaching room temperature before work.

The unit contains a section which rotates when it is in action. Potential

personal injury may occur if touched. A rotator is structured to come

to a temporary stop and resume rotation.

Avoid

erforming work during system operation.

Screw

Front panel

HRG010-W HRG015-W 5.4 Recovery from Power Failure (POWER Lamp ON)

1st edition : Aug. 2006

Rev. A: May. 2007

Electrical unit

Screw

Front

Fig. 5-7 Removal of Front Panel

5-7

Page 52

HRX-OM-J049-A

Chapter 5 Error Message and Troubleshooting

2. Check the earth leakage breaker on the electrical board of the electrical unit.

Earth leakage breaker

Electrical unit

(optional)

Front

Fig. 5-8 Location of Earth Leakage Breaker (Optional)

3. Switch off the earth leakage breaker once.

Switch in the OFF position

Front

Fig. 5-9 Earth Leakage Breaker (OFF)

4. Switch on the earth leakage breaker, and make sure that the [POWER] lamp comes on.

Switch in the ON position

Front

Fig. 5-10 Earth Leakage Breaker (ON)

5.4 Recovery from Power Failure (POWER Lamp ON) HRG010-W HRG015-W

5-8

1st edition : Aug. 2006

Rev. A: May. 2007

Page 53

Chapter 6 Unit Maintenance

6.1 Control of Water Quality

The circulating fluid used in this unit is fresh water (tap water). This

unit may be damaged when unpermitted fluids are used.

Potential fluid leak may occur if disregarded, which results in electric

shock and ground fault.

ONLY use fresh water (tap water) which satisfies water quality

standards as shown in the table below.

Substances

pH (25°C) 6.5 to 8.2 6.0 to 8.0

Electrical conductivity (25°C) (µs/cm) 100

Chloride ion (mgCl-/L) 200 and below 50 and below

Sulfuric acid ion (mgSO

Acid consumption (pH4.8) (mgCaCO3/L) 100 and below 50 and below

Total hardness (mgCaCO3/L) 200 and below 70 and below

Calcium hardness (mgCaCO3/L) 150 and below 50 and below

Standard

Ion silica (mgSiO2/L) 50 and below 30 and below

Iron (mgFe/L) 1.0 and below 0.3 and below

Copper (mgCu/L) 0.3 and below 1.0 and below

Sulfide ion (mgS2-/L) Not detected

Ammonium ion (mgNH

Residual chlorine (mgCl/L) 0.3 and below 0.3 and below

Free carbon dioxide (mgCO2/L) 4.0 and below 4.0 and below

Filtering (μm) 5 and below

Table 6-1 Water quality standards for fresh water (tap water)

Facility water

spec.

(*1)

to 800 100

2-

/L) 200 and below 50 and below

4

+

/L) 1.0 and below 0.1 and below

4

* Refrigeration and Air Conditioning Equipment Water Quality

(*1) Electrical conductivity: Min. 100[μS/cm]

(*2) 0.003 to 0.01 if the unit of M[Ω•cm] is used.

HRX-OM-J049-A

Chapter 6 Unit Maintenance

Circulating fluid spec.

(*1)

to 300

Guideline JRA-GL-02-1994

(*2)

If the periodic inspection finds a nonconforming substance in the

facility water, wash the tank and the cirulating circuit, and replace the

water in the tank. Water will evaporate, and impurities will build up.

Even if no abnormal event occurs, it is recommended to replace the

water in the tank once every three months. Refer to section "6.2

Inspection and Cleaning" for the periodic inspection.

HRG010-W HRG015-W 6.1 Control of Water Quality

1st edition : Aug. 2006

Rev. A: May. 2007

6-1

Page 54

HRX-OM-J049-A

Chapter 6 Unit Maintenance

6.2 Inspection and Cleaning

Do not operate the switches, etc. with wet hands and do not touch any

electrical components such as a power supply plug. It may cause an

electric shock if disregarded.

Keep this unit from water.

Do not wash the unit with water. It may cause an electric shock and fire

if disregarded.

Cut off the power supply of the unit before performing cleaning,

maintenance and inspection. It may cause an electric shock, injury or

burn if disregarded.

Always mount the panel back onto the unit after removing the panel

for inspection or cleaning. Failure to close or re-attach the panel may

cause personal injury or electric shock during unit operation.

6.2 Inspection and Cleaning HRG010-W HRG015-W

6-2

1st edition : Aug. 2006

Rev. A: May. 2007

Page 55

6.2.1 Daily inspection

Perform daily inspection of the items listed in the Table 6-2. If the check finds any

abnormal event, stop system operation and turn off the main power supply.

Request for service promptly.

Table 6-2 Daily Inspection

Inspection item Inspection method

No heavy object is placed on this unit. This unit

Installation

condition

Fluid leak

Water supply

Operation panel

Check of the condition of

unit installation

Check of the piping

connector section

Confirm the reading on the

level indicator

Display check The diplsay assures sharp image and numbers.

Function check The lamp is ON.

should not be subjected to external force.

Temperature and humidity fall within the specified

range.

No leak of facility water and circulating fluid from the

piping connector sections

The fluid level falls within the specified range.

HRX-OM-J049-A

Chapter 6 Unit Maintenance

Circulating fluid

temperature

Circulating fluid

outlet pressure

Refrigerant high

pressure

Operating

condition

Facility water

Confirm the reading on the

LCD screen

Normal temperature should be assured for system

use.

Confirm the reading on the

circulating fluid pressure

Normal pressure should be assured for system use.

gauge

Confirm the reading on the

refrigerant high pressure

Normal flow rate should be assured for system use.

gauge

Operating condition check No abnormal noise, vibration, odor and smoke

Check of facility water

condition

Temperature, flow rate, and pressure fall within the

specified range.

If the above check finds any abnormal event, bring the unit to a halt and turn off

the main breaker. Make sure to perform lockout and tagout before requesting

technical service.

HRG010-W HRG015-W 6.2 Inspection and Cleaning

1st edition : Aug. 2006

Rev. A: May. 2007

6-3

Page 56

HRX-OM-J049-A

Chapter 6 Unit Maintenance

6.2.2 Quarterly inspection

Replacement of circulating fluid

Periodic replacement of circulating fluid (fresh water)

z

Potential algae growth or aqueous corrosion may occur if the old fluid is reused.

Assure a periodic replacement of the fluid according to the situation.

Cleaning of tank

z

Check the circulating fluid in the tank for impurities and foreign matters, and

the tank for slime inside. Assure a periodic cleaning of the tank.

Cleaning of facility water

Water quality standards for faciliry water should fall within specifications.

z

Assure a periodic cleaning of faciliry water equipment and a periodic

z

replacement of faciliry water.

6.2.3 Biannual inspection

Check for leak from the pump mechanical sealing

Remove the panel and check for leak from the pump mechanical sealing. When a

leak is found, it is necessary to replace the mechanical sealing. Contact the local

distributor or SMC’s sales branch.

z Leak from the mechanical sealing

Leakage from the mechanical sealing occurs in structure. Although JIS defines

leakage for 3cc/hr or less (reference value), 0.3cc/hr or more is our leakage

standard suggested for the replacement of the mechanical sealing.

A recommended replacement cycle of the mechanical sealing is 6000 to 8000

hours a year (usually).

6.2 Inspection and Cleaning HRG010-W HRG015-W

6-4

1st edition : Aug. 2006

Rev. A: May. 2007

Page 57

HRX-OM-J049-A

Chapter 6 Unit Maintenance

6.2.4 Check during wintertime

Antifreeze of circulating fluid

This unit is resistant to freezing of the circulating fluid during wintertime and

nighttime.

Ensure the following measures are taken in advance if potential frost damage may

occur in response to changes in the installation and use environments (including

operating period and weather).

1. Leave the power on (the [POWER] lamp remains on, and the [RUN] lamp remains off).

2. Fully open valves laid with pipes on your unit to allow the circulating fluid to flow upon

automatic pump operation.

Antifreeze function (automatic pump operation)

(1) After performing steps 1.and 2., automatic pump operation takes place when the circulating

fluid drops 3°C or below.

(2) The circulating fluid is heated by pump power output.

The pump comes to an automatic stop when the circulating fluid reaches 5°C or higher.

(3) The circulating fluid is allowed to be in the 3- to 5-°C range in temperature that is resistant to

freezing.

z Contact expert engineers.

Complete prevention of freezing the fluid may if the unit is installed

in an intensely cold place.

The above usage conditions require an addition of other antifreezing

unit (such as a commercial tape heater).

HRG010-W HRG015-W 6.2 Inspection and Cleaning

1st edition : Aug. 2006

Rev. A: May. 2007

6-5

Page 58

HRX-OM-J049-A

Chapter 6 Unit Maintenance

6.3 Consumables

Replace the following parts in response to the level of wearing out at inspection.

Table 6-3 Consumables

Part number Part Qty. Remarks

HRG-S0034 Mechanical seal set 1 set Service part for HRG010

HRG-S0035 Mechanical seal set 1 set Service part for HRG015

6.4 Long-term Storage

Follow the procedures below for long-term storage of the unit or for anti-freezing

of the fluid during wintertime.

1. Turn off the main power breaker.

2. Undo the tank drain hole plug to drain the fluid.

3. Remove the top front panel. Open the internal valve (for draining facility water) to drain

facility water. Drain facility water from the overflow outlet completely.

4. Cover the unit with a plastic sheet for storage after draining is completed.

6.3 Consumables HRG010-W HRG015-W

6-6

1st edition : Aug. 2006

Rev. A: May. 2007

Page 59

Chapter 7 Documents

7.1 Standard Specifications

environment

Installation

Operating

Item HRG010-W HRG015-W

Rated ambient temp.

Humidity range 45 to 75%RH (No condensation)

Table 7-1 Standard Specifications (1/2)

HRX-OM-J049-A

Chapter 7 Documents

32°C (5 to 40°C)

Fluid used

Rated capacity of tank 40L 50L

Supply voltage 3-phase AC200(50Hz), AC200 to 220V (60Hz)

Recommended earth

leakage breaker capacity,

Sensitivity current

Rated power consumption 3.2/3.8 - 3.8 kW 4.7/5.8 - 5.8 kW

Rated operating current 12.0/12.5 - 12.5A 18.0/19.0 – 19.0A

Rated consumption

Input

Output

Display

electric energy

Facility water

Start/stop command

Rated temp. / accuracy of

Temp. range of circulating

Rated cooling capacity

Rated heating capacity - (1.1kW of pump motor output only) - (0.75kW of pump motor output only)

Output

signal

Temperature control

Refrigerant high pressure

signal