Page 1

MODEL 4105 SERIES

GAS SENSOR MODULE

WITH DIGITAL DISPLAY AND

NON-INTRUSIVE CALIBRATION

4-20 mA

Page 2

Sierra Monitor Corporation

1991 Tarob Court, Milpitas, CA 95035

(408) 262-6611 (800) 727-4377

Fax: (408) 262-9042

E-Mail: sierra@sierramonitor.com

MODEL 4105 SERIES

GAS SENSOR MODULE

WITH DIGITAL DISPLAY AND

NON-INTRUSIVE CALIBRATION

4-20 mA

APPLICABILITY & EFFECTIVITY

This manual provides instructions for the following Sierra Monitor products:

Model Description

4105-02 Combustible Gas Sensor Module with Non-Intrusive Calibration

4105-03 Oxygen Gas Sensor Module with Non-Intrusive Calibration

4105-04 Carbon Monioxide Gas Sensor Module with Non-Intrusive Calibration

4105-05 Hydrogen Sulfide Gas Sensor Module with Non-Intrusive Calibration

4105-06 Chlorine Gas Sensor Module with Non-Intrusive Calibration

4105-07 Hydrogen Gas Sensor Module with Non-Intrusive Calibration

4105-10 Sulfur Dioxide GasSensor Module with Non-Intrusive Calibration

4105-12 Nitrogen Dioxide Gas Sensor Module with Non-Intrusive Calibration

4105-21 Hydrogen Chloride Gas Sensor Module with Non-Intrusive Calibration

4105-22 Hydrogen Cyanide Gas Sensor Module with Non-Intrusive Calibration

4105-25 Ammonia Gas Sensor Module with Non-Intrusive Calibration

4105-26 Hydrogen Flouride Gas Sensor Module with Non-Intrusive Calibration

The instructions are effective for the above models as of April 1, 1998

Instruction Manual Part Number: T13008

Rev. E1

Page 3

TABLE OF CONTENTS

SECTION PAGE

1. PRODUCT DESCRIPTION 1

1.1 Introduction 1

1.2 Application 1

1.3 Configuration 1

1.3.1 Electronics 1

1.3.2 Sensor 1

2. CAUTIONS WARNINGS & RECOMMENDATIONS 2

2.1 Introduction 2

2.2 Wiring 2

2.3 Sensor Modules - General 2

2.4 Preventative Maintenance 2

3. QUICK START 3

3.1 Overview 3

3.2 Wiring 3

3.3 Module Installation 3

3.4 Wiring Connection 3

3.5 Transmitter Installation 3

3.6 Start-up & Operation 3

4. OPERATION 4

4.1 Introduction 4

4.2 Signal Value 4

5. CALIBRATION 5

5.1 Frequency of Calibration 5

5.2 Calibration Process 5

5.3 Equipment Required 5

5.4 Calibration Procedure 5

5.5 Fault Supervision 5

6. SERVICE 6

6.1 Sensor Module Configuration 6

6.2 Enclosure Replacement 6

6.3 Transmitter Replacement 6

6.4 Sensor Replacement 6

7. INSTALLATION 8

7.1 Sensor Locations 8

7.2 Sensor Mounting 8

7.3 Explosion Proof Installation 8

7.4 Power Supply 8

8. SPECIFICATIONS 10

9. REPLACEMENT PARTS 13

10. WARRANTY 13

11. APPENDICES 14

Page 4

1. PRODUCT DESCRIPTION

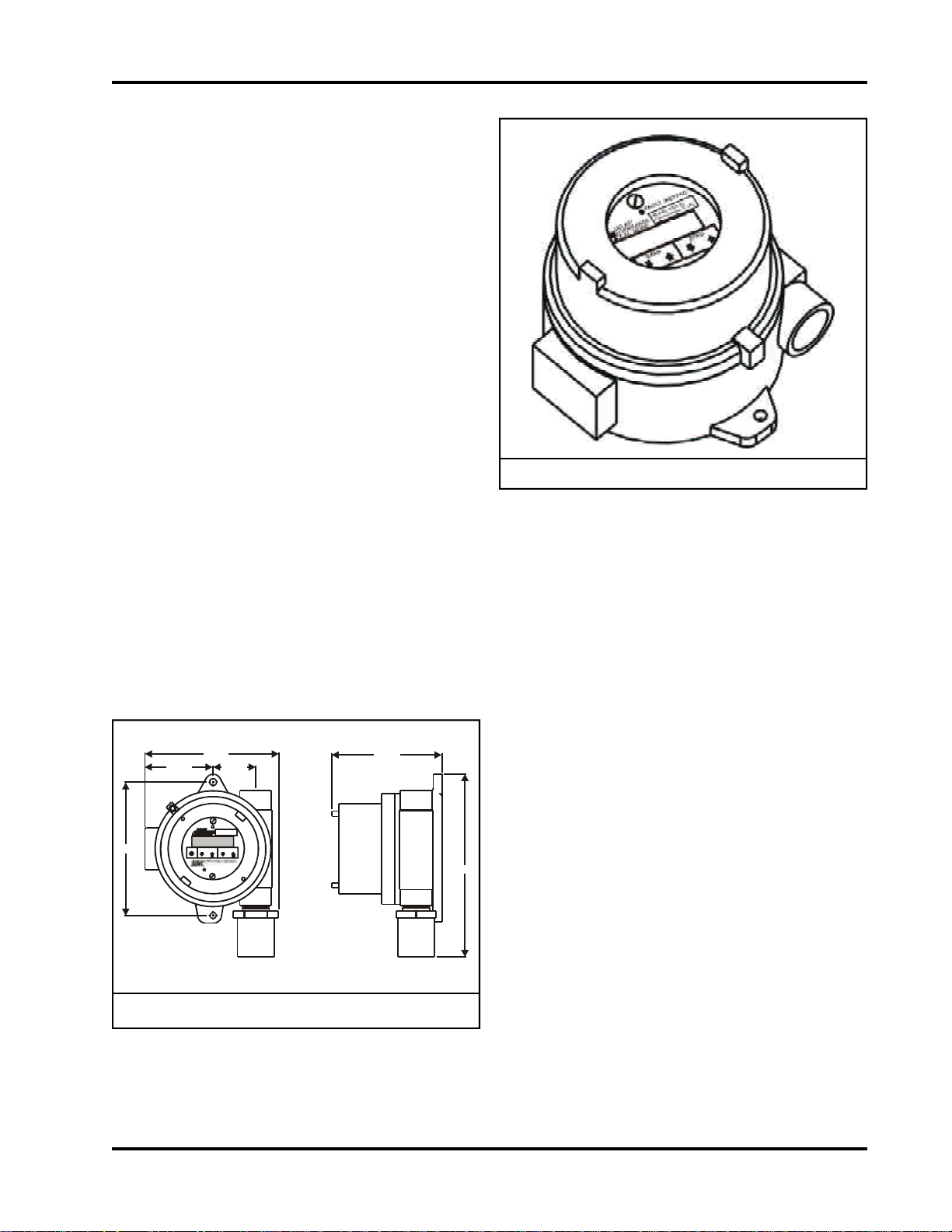

5.42"

2.81"

1.75"

4.50"

7.25"

1.1 Introduction

Model 4105 Series Gas Sensor module features nonintrusive calibration, 4-20 mA output signal and local

continuous display of the gas concentration in ppm

(toxics), % LEL (Combustibles), or % vol (Oxygen). It

is designed for use with industry standard control instruments.

This manual provides instructions for 4105 series gas

sensor modules that utilize common packaging and

transmitter electronics with different sensors for detection of various gases. The full model number of

the gas sensor module includes a suffix, 4105-XX,

where “XX” is a number that identifies a gas type.

1.2 Application

The Model 4105-XX Gas sensor is intended for use in

ambient monitoring applications. It is designed for

fixed installation and for continuous operation.

Instruction Manual

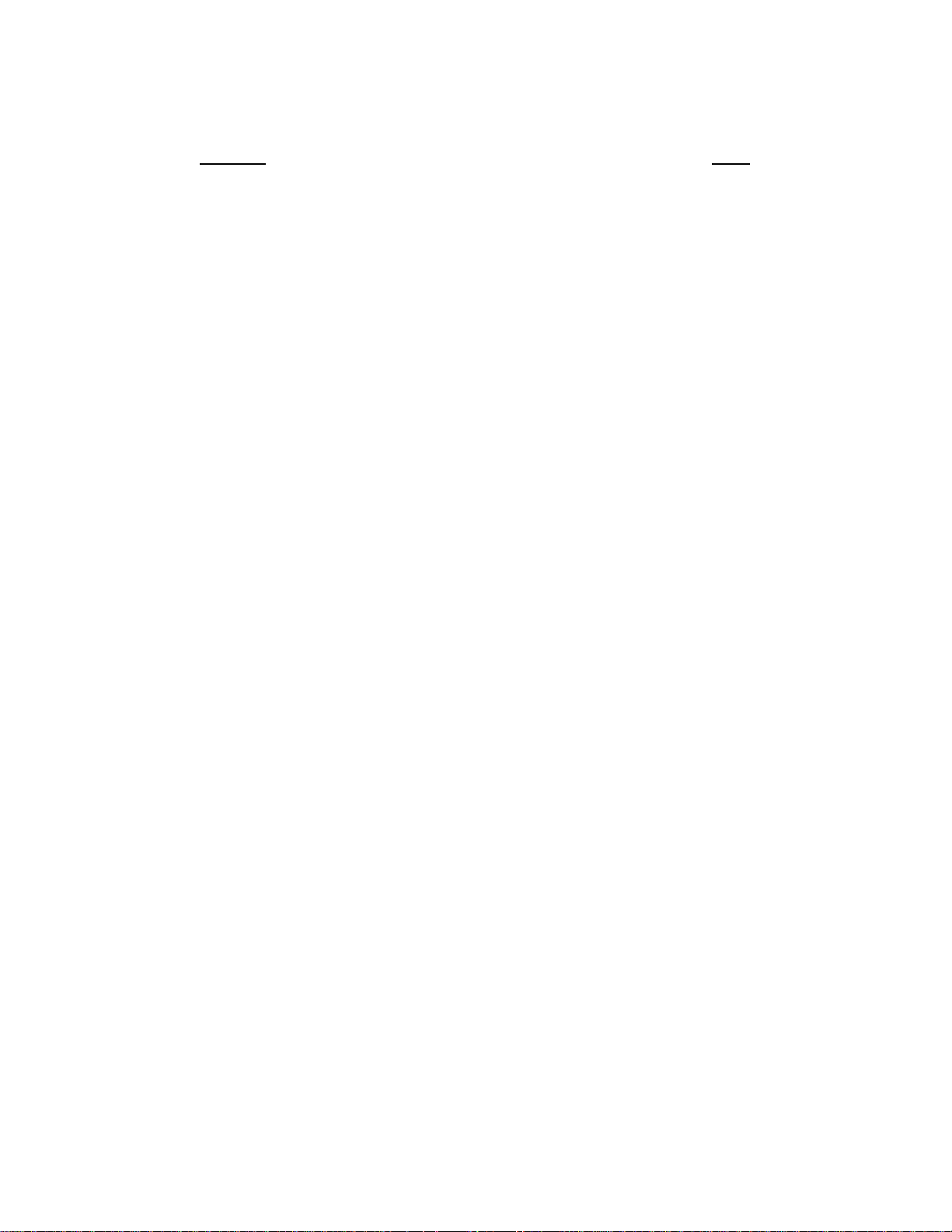

Figure 1.1 Model 4105 Gas Sensor Module

Optional fittings and adapters can be supplied by Sierra Monitor to provide continuous sample delivery

to the sensor module.

1.3 Configuration

The gas monitor is comprised of a NEMA-7/4 enclosure which contains the transmitter electronics and a

gas sensor which is installed in one of the two 3/4"

conduit hubs.

FAULT /KEYPAD

MODEL 4105-02

Combustibles

% LEL

5.50"

Unity SPAN ZERO

Ph. 408-262-6611

Milpitas, CA

CAL

1.3.1 Electronics

When installed, the transmitter electronics will be connected to a power supply and control device via three

wire cable.

The electronics provide a 4-20 mA current loop which

is proportional to the full sensitivity of the sensor.

Integral features include:

- L.C.D. readout of ppm of gas concentration.

- Magnetic switches for non-intrusive calibration.

- Visual indicators for fault condition.

- Electrical fault (0 mA) to controller.

The transmitter electronics assembly includes a

printed circuit assembly and a cover plate which contains the L.C.D. readout and magnetic switches for

calibration.

1.3.2 Sensor

The gas sensor cell is enclosed in a threaded housing

and is plugged into a signal card located in the enclosure. This configuration allows for easy field replacement of the sensor cell.

Figure 1.2 Outline View - Gas Sensor Module

Model 4105 Gas Sensor Module (12/02)

Combustible: The gas sensor is a catalytic bead type.

Toxics & Oxygen: The gas sensor is an Electro Chemi-

cal type.

Page: 1

Page 5

Instruction Manual

2. CAUTIONS WARNINGS &

RECOMMENDATIONS

2.1 INTRODUCTION

Although the sensor module is designed and constructed for installation and operation in industrial

applications including “hostile” environments, caution should be taken to insure that the installation is

in compliance with this instruction manual and that

certain procedures and conditions are avoided.

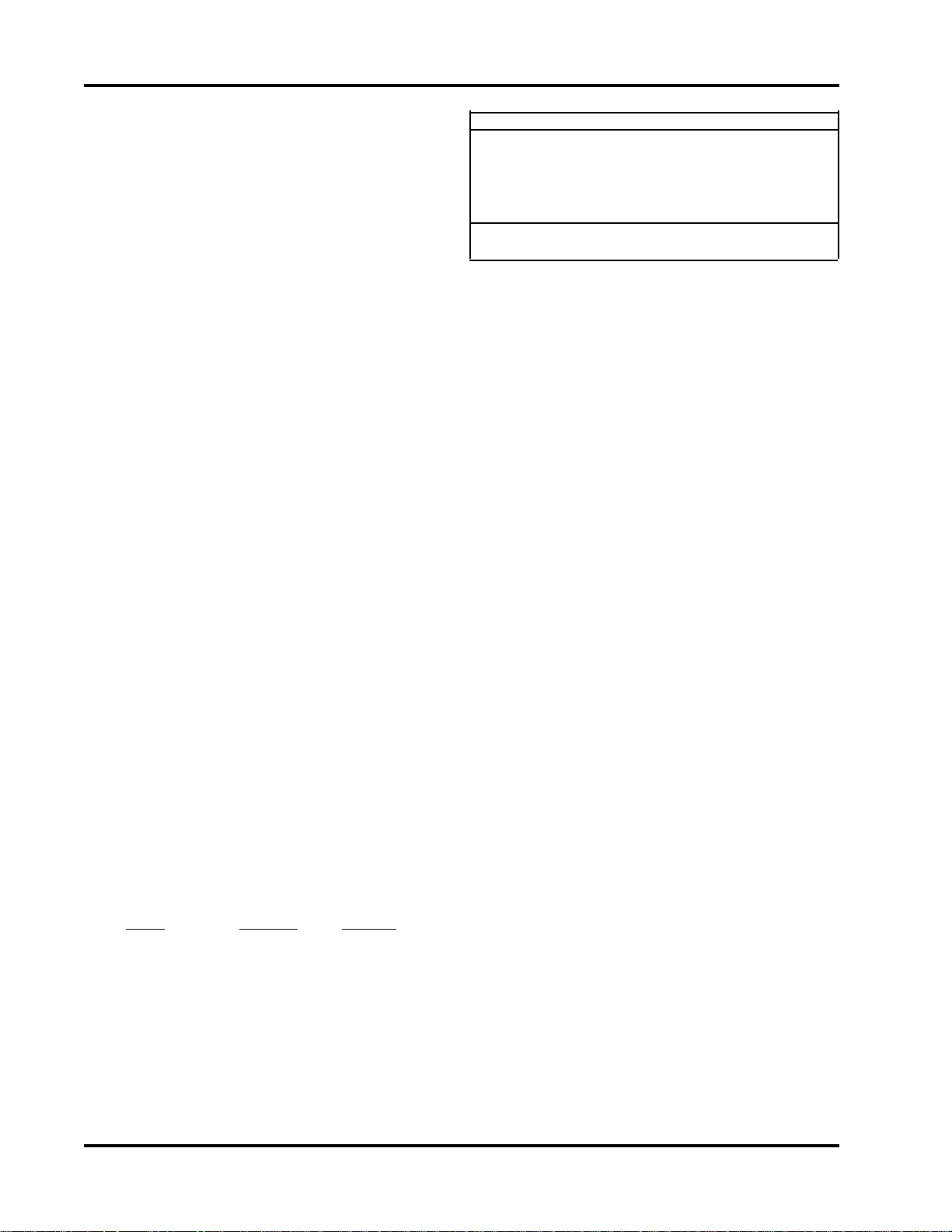

READ AND UNDERSTAND THIS INSTRUCTION

MANUAL BEFORE OPERATING OR SERVICING

THIS EQUIPMENT.

Wire Gauge Maximum Length

20 AWG 2,000 Ft.

18 AWG 3,000 Ft.

16 AWG 4,000 Ft.

14 AWG 6,500 Ft.

12 AWG 9,000 Ft.

Table 2.1

Recommended Wire/Cable Gauge

NOTE: Temperature rating of cable wire insulation

must be above 75oC (85oC or greater rated wiring is

recommended). If cable runs through higher temperature environments, it should be specified for that environment.

2.2 WIRING

Electro magnetic and radio frequency interference to

the analog communication between the sensor and

the controller may occur. The manufacturer recommends that extra caution be taken where the installation is near any sources of these interferences:

Avoid running sensor cable close to high power

cables, radio transmission lines, or cables subject to

pulses of high current. Avoid running cables near

large electric motors or generators.

Use shielded cable in any location which may be expected to be electrically noisy or where cable is expected to be in close contact with AC wiring. The

shield should be connected to the controller common, one side only.

The wiring should be run in either a cable tray or

conduit as required by applicable code and area classification. Control wiring should not be installed in a

cable tray or conduit with higher voltage and AC circuits. See Table 2.1 for recommended wire gauge.

Wiring connections at the gas sensor module are as

follows:

Wire# Function Terminal

1 Power PWR

2 Signal SIG OUT

3 Ground GND

Connect an earth ground to the ground screw provided in the base of the gas sensor module enclosure.

All splices must be via either a lug and terminal system or soldered. Improperly spliced cable can result

in corrosion, resistance changes and system errors.

2.3 SENSOR MODULES - GENERAL

Sensors should be facing down. Avoid installing sensor modules where they will be unnecessarily exposed

to wind, dust, water (esp. direct hose down), shock,

or vibration. Observe temperature range limitations.

Sensors may be adversely affected by prolonged exposure to certain materials. Loss of sensitivity, or

corrosion, may be gradual if such materials are present

in low concentrations. These materials include: Halides (compounds containing chlorine, fluorine, bromine, or iodine), silicones, acid vapors, caustic liquids or vapors.

Sensor modules must not be painted. Paint may contain compounds which will contaminate the sensor.

Paint will also cause clogging of the sintered metal

cup and will cause difficulties during attachment of

the calibration fitiing. The module should be tagged

“DO NOT PAINT”.

When sensors are replaced the thread on the sensor

housing must be lubricated with an antizieze com-

pound non-silicone based to avoid metal to metal

binding which will damage the housing threads.

2.4 PREVENTATIVE MAINTENANCE

DUST AND DIRT CONTROL: When calibration is

performed the controller and sensors should be

checked visually to determine if dust or dirt build up

needs to be removed. This cleaning should be done

with dry instruments such as compressed air, cloth

wipes or wisk broom.

WIRING OR CABLE CONDITIONS: Any wiring or

cables which are not in conduit should be checked

once a year for damage to insulation or corrosion

of splice or terminal points.

Page: 2

Model 4105 Gas Sensor Module (12/02)

Page 6

3. QUICK START

MODEL 4105-05

3.1 Overview

The gas sensor module has been supplied factory calibrated and ready for immediate installation and operation. An installer familiar with installation and operation of gas detection products can use this section to

begin immediate use of the monitor.

3.2 Wiring

Provide three conductor wiring from the power supply/control device to the sensor module location. See

section 2.2 for wiring specifications.

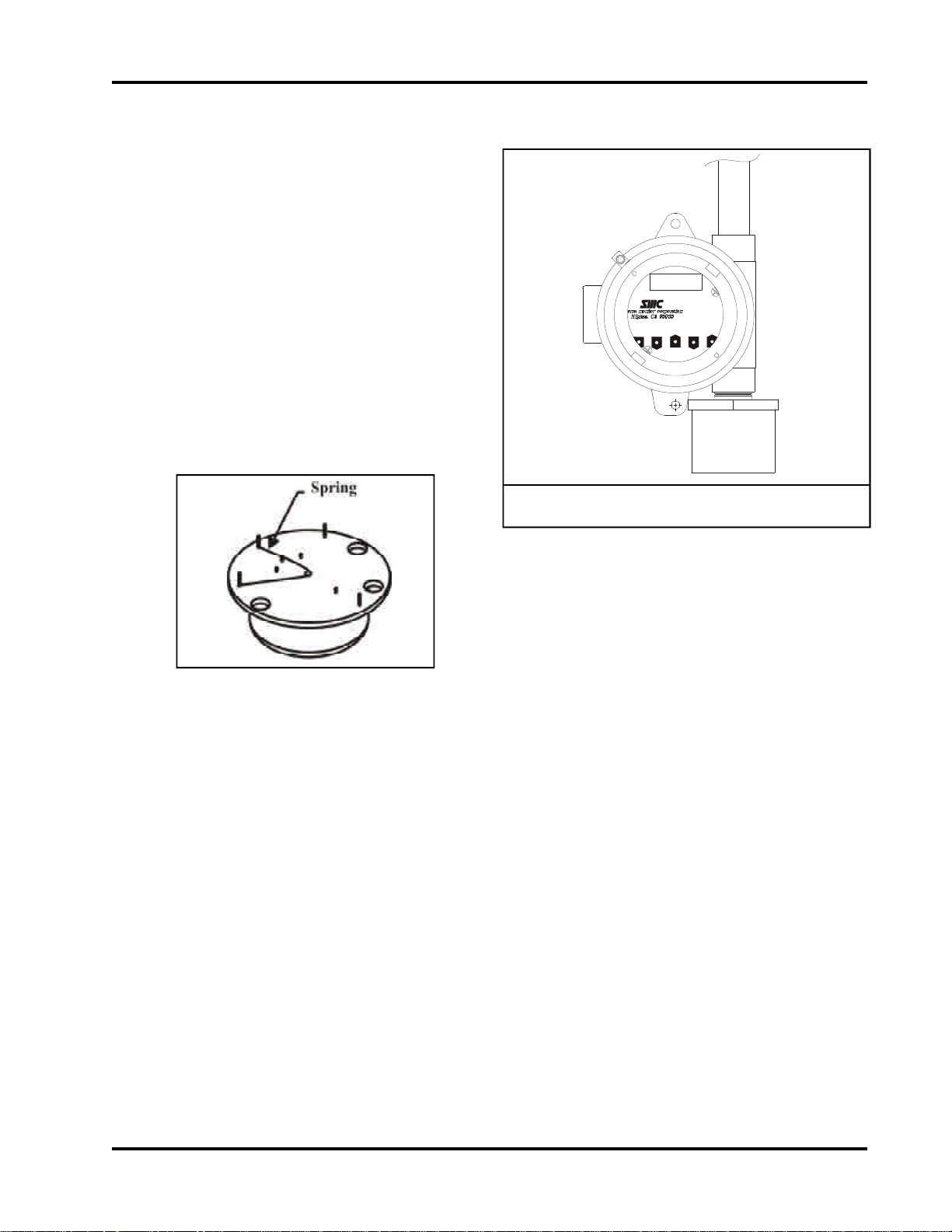

3.3 Module Installation

Remove spring on electromechanical sensor prior to

installation. See Figure below.

Instruction Manual

PPM

HS PPM

2

GAS MONITOR

Unity

Typical Vertical Mounting on Conduit

FAULT

ZEROSPAN

Figure 3.1

The module can either be installed on the end of a

3/4" conduit, or attached to a vertical surface using

the mounting flange on the enclosure.

WARNING:

- The installation must meet any hazardous environment codes for electrical equipment.

- The sensor module enclosure mounting must be

far enough from any vertical surface to allow removal and replacement of the sensor assembly

which is threaded into the second 3/4" conduit

hub.

3.4 Wiring Connection

To gain access to the I/O PCB for wiring or mounting

purposes, loosen the two captive thumb screws in the

4105-XX front panel and remove the PANEL/CPU PCB

assembly as far as is allowed by the ribbon cable.

Terminal positions on the I/O printed circuit assembly

are labeled PWR (power), OUTSIG (signal), GND (TB2).

Make the corresponding connections to the control

device/power supply.

The sensor harness should remain connected to the

I/O assembly at “TB1”.

3.5 Transmitter Installation

To install the front panel assembly, align the two thumb

screws with their mating stand-offs and firmly hand

tighten. Be sure the front panel is centered in the

4105-XX housing opening.

WARNING:

- If the sensor transmitter is installed in a classified hazardous area, replace the threaded cover

prior to providing power.

3.6 Start-up & Operation

To begin operation of the sensor module provide 21-30

VDC from a regulated power supply.

Model 4105 Gas Sensor Module (12/02)

Page: 3

Page 7

Instruction Manual

FAULT /KEYPAD

Milpitas, CA

Ph. 408-262-6611

FAULT /KEYPAD

Milpitas, CA

Ph. 408-262-6611

4. OPERATION

4.1 Introduction

Under normal conditions the sensor module does not

require operator or technician intervention. The following are conditions under which the module requires

attention:

- Routine periodic calibration.

- Calibration after a high gas alarm.

- Sensor replacement on a planned schedule or

when a sensor failure occurs.

- Periodic cleaning as necessary.

- Unanticipated maintenance.

4.2 Signal Value

During normal operation the current loop of the sensor module and the controller will be between 4 mA

indicating no presence of gas, and 20 mA indicating

that the full scale concentration of gas is present. The

signal value is proportional to the concentration of

gas present.

Page: 4

MODEL 4105-02

Combustibles

Unity SPAN ZERO

CAL

% LEL

Figure 4.1

Transmitter Cover Plate

Unity

MODEL 4105-05

HS2PPM

SPAN ZERO

CAL

Model 4105 Gas Sensor Module (12/02)

Page 8

5. CALIBRATION

5.1 Frequency of Calibration

Instruction Manual

The manufacturer recommends that the gas sensor

module be calibrated every ninety days.

5.2 Calibration Process

The output signal of the gas sensor module is calibrated using a span mixture containing a known concentration of the gas of interest. The concentration

of the span gas must be within the full scale of the

sensor module and should be either 50% of the full

scale, or approximately equal to the lowest alarm level.

Calibration requires application of the span gas to the

sensor and adjustment of the “SPAN” magnetic switch

making the module signal output and display equivalent to the concentration of sample gas. The 4-20 mA

output is held at 1.5 mA while activated for calibration

to prevent alarms being tripped by calibration gas

application.

5.3 Equipment Required

The following tools and equipment will be required

for calibration:

- Magnetic tool

- Gas Sensor Calibrator, Model 1260-XX

or Model 1200-26 or permeation tube

- Calibration Gas

- Disbursing Calibration Adapter (Model 5358-

01)

5.4 Calibration Procedure

Routine calibrations are easily performed using the

magnetic tool provided with each sensor.

Briefly hold the magnet tool close to the small dot

located on the lower edge of the front panel. The

arrow on the upper left side of the LED will illuminate

and the 4-20 mA output is locked at 1.5 mA, indicating

that the sensor module is ready for calibration. Simply expose the sensor to a ZERO gas and observe the

L.C.D. readout. In normal situations, simply exposing

the sensor to an atmosphere free of the gas of interest

is satisfactory. If it does not return to the correct

ZERO reading, a ZERO adjustment is required. Hold

the magnet close to the UP ZERO or DOWN ZERO

indicators and adjust the reading to the correct ZERO

reading.

Connect the calibration adapter and expose the sensor to an appropriate SPAN gas using a span mixture

containing a known concentration of the gas of interest at a minimum flow rate of 300 cc/minute. (Use permeation tube for 4105-25) Allow 3-5 minutes before

making any adjustments.

If the L.C.D. does not display the correct SPAN value,

a SPAN adjustment is required. With the arrow still

flashing, hold the magnet close to the UP SPAN or

DOWN-SPAN indicators and adjust the reading to the

correct SPAN value. (The 4-20 mA out is automatically adjusted.)

The monitor is now calibrated. Deactivate calibration

by holding the magnet close to the small dot again.

This releases the 1.5 mA lock.

5.5 Fault Identification

A Fault condition is detected if the sensor output drifts

far enough negative to cause the 4-20 mA output to

reach 1.5 mA (±15% of full scale) or the sensor failure.

The sensor module demonstrates that a fault condition exists by illuminating the RED LED on the front

panel and by holding the 4-20 mA output at 0 mA.

These conditions will exist until the fault is corrected.

Model Gas Min. Flow Rate

(cc/min)

4105-02 CH

4105-03 O

4

2

100

100

4105-04 CO 150

4105-05 H2S 300

4105-06 Cl

4105-07 H

4105-10 SO

4105-12 NO

2

2

2

2

300

300

300

300

4105-21 HCl 300

4105-22 HCN

4105-25** NH

*

3

300

400

4105-26 HF 500

*Note: SO2 may be used instead of HCN to

calibrate: 10ppm SO2 = 16 ppm HCN

*Note: H2S may be used instead of HCl to

calibrate: 10 ppm H2S = 20 ppm HCl

** Note: Use permeation tube for 4105-25

Model 4105 Gas Sensor Module (12/02)

Table 4.1

Calibration Span Gas Flow Rates

Page: 5

Page 9

Instruction Manual

6. SERVICE

6.1 Sensor Module Configuration

The gas sensor module is comprised of the following

sub assemblies:

4105-XX Gas Sensor Module

-SPM25002 Transmitter Assembly

-SPT25013 Combustible Gas Sensor

Module Transmitter Assembly

-SPM25003 Oxygen and Toxic Gas Sensor

Module Transmitter Assemby

(must specify gas type)

-4205-XX Sensor Assembly

[Where "xx" is the suffix to the gas sensor

module number (Table 6.1)]

There is no field servicable components below

the sub assembly level.

Warning: Prior to removal of the transmitter assembly, remove system power at

the controller or other power source.

Model Gas Module

4105-02 Combustible

4105-03 Oxygen

4105-04 CO

4105-05 H2S

4105-06 Cl

4105-07 H

4105-10 SO

4105-12 NO

2

2

2

2

4105-21 HCl

4105-22 HCN

4105-25 NH

3

4105-26 HF

Table 6.1

Model Numbers

6.3 Transmitter Replacement

The transmitter assembly should be replaced when it

is determined that it is unreliable, noisy or cannot be

adjusted for calibration. This may occur due to age,

corrosion or failed components.

To replace the transmitter assembly:

1. Remove the cover of the main enclosure.

2. Remove the front panel by loosening the two captive thumb screws in the 4105-XX front panel and

remove the PANEL/CPU PCB assembly as far as is

allowed the by the ribbon cable.

3. Unscrew the sensor harness from the transmitter

(TB1).

4. Remove the three wires from the P,S,G terminals

(TB2).

5. Remove the I/O PCB.

6. Reverse the preceding steps to install the new

transmitter.

7. Restore power and allow a minimum of 30 minutes

for stabilization before re-calibration.

6.4 Sensor Replacement

The sensor should be replaced when it is determined

that:

- It is no longer possible to obtain correct Zero and

Span values at the test points or at the controller.

- The sensor output signal is noisy, causing erroneous gas level readings.

To replace the sensor:

1. Remove the gas sensor module enclosure lid.

2. Remove the front panel by loosening the two captive thumb screws in the 4105-XX front panel and

remove the PANEL/CPU PCB assembly as far as is

allowed the by the ribbon cable.

3. Unscrew the sensor wires from the transmitter..

6.2 Enclosure Replacement

The enclosure should be replaced if the lid threads or

conduit threads have been damaged, or if the enclosure has corroded sufficiently that it no longer meets

the required NEMA classification.

To replace the enclosure follow the transmitter and

sensor assembly removal instructions, remove the

damaged enclosure from it’s conduit or wall mounting, install a new enclosure and continue the transmitter and sensor assembly replacement instructions.

Page: 6

4. Unscrew the old sensor assembly from the enclosure conduit hub. Remove the sensor assembly

with its harness.

5. Reverse the preceding steps to install the sensor

assembly.

Model 4105 Gas Sensor Module (12/02)

Page 10

6.4a.Combustibles

Instruction Manual

1. Verify the voltage across A to R equals 2 volt. If

not, adjust volts potentiometer R11

2. Verify the voltage from GND (TB2) to VOUT

equals 0.4 volts. If not adjust BAL potentiometer (R2)

3. Verify that the voltage at VOUT is equal to the

voltage desired.

• The VOUT test point on the I/O PCB has a range

of 0.4-2 volts for 0-100% of the measurement

range. Therefore, 0%=0.4 volts, 25%=0.8,

50%=1.2 volts, 75%=1.6 volts, 100%=2 volts.

• Selecting the jumper at JP1 assigns one of four

different sensitivity ranges to the module. The

JP1 positions are labeled 1, 2, 3 & 4. JP1 jumper

set the coarse up scale SPAN values by affecting the gain of the analog circuit. JP1 is set

correctly if an application of 50% of full scale

reads between 1.0 & 1.4 volts on VOUT. Finetuning of these setting is done later by adjusting the 4105-02 magnetic control.

JP1 gain values are as follows:

JP1 with jumper in position 1 = GAIN = 51

JP1 with jumper in position 2 = GAIN = 26

JP1 with jumper in position 3 = GAIN = 12.5

JP1 with jumper in position 4 = GAIN = 7

JP1 with no jumper = GAIN = 1

• The 4105-XX has 4 fixed ranges of sensitivity,

which are selectable via JP1.

• The JP1 positions are labeled 1, 2, 3 & 4.

• JP1 jumper set the coarse up scale SPAN values

by affecting the gain of the analog circuit.

• JP1 is set correctly if a 50% of full-scale gas

read between 1.0 & 1.4 volts on VOUT.

• Fine-tuning of these settings is done later by

adjusting the 4105-XX via magnetic control.

• Select the jumper at JP1 as required. JP1 gain

values are as follows:

JP1 with jumper in position 1 = GAIN = 5.5

JP1 with jumper in position 2 = GAIN = 4

JP1 with jumper in position 3 = GAIN = 2.3

JP1 with jumper in position 4 = GAIN = 1.5

JP1 with no jumper = GAIN = 1

• More than one jumper may be installed to allow

additional gain value. Multiple jumper are additive in relation of the gain value. For example, if

a gain of 6.5 is needed, jumper should be placed

in positions 2 and 3 to provide a gain of 6.3.

Note: Allow the new sensor to stabilize for a minimum of 30 minutes and then calibrate using the

procedure in Section 5.

• More than one jumper may be installed to allow

additional gain value. Multiple jumper are additive in relation of the gain value. For example, if

a gain of 20 is needed, jumper should be placed

in positions 3 and 4 to provide a gain of 20.

6.4b LEL Sensor Fault Supervision

The typical failure mode of catalytic bead sensors

is the reference or active beads open circuit. In

rare cases a short circuit may develop. The 410502 is equipped with fault detection circuitry that

detects either condition. A FAULT is also signaled

if the output drifts below -10% of full scale. The

4105-02 signals a FAULT condition exists by overwriting the LCD with a FLt message, flashing the

red LED on the front panel and clamping the 420mA output at 0mA. These conditions remain until

the FAULT is corrected.

6.4c Electrochemical (Oxygen and Toxics)

Verify that the voltage VOUT is equal to the voltage as desired.

• The VOUT test point on the I/O PCB has a range

of 0.4-2 volts for 0-100% of the measurement

range.

6.4d Missing Electromechanical Sensor Fault Supervision

Many electromechanical sensor housings allow for

easy replacement of defective sensors by making the

sensors 'plug in'. A problem is that if the sensor is

removed, many transmitters continure to display the

safe reading of 0 PPM. The 4105-XX is equipped with

fault detection circuitry that detects a missing sensor.

Within several minutes of removing an EC sensor, the

4105-XX will signal a FAULT condition. A FAULT is

also detected if the sensor output drifts below -10%

of full scale. the Model 4105-XX demonstrates a

FAULT condition exists by overwriting the LCD reading with FLt, illuminating the red LED on the front

panel and by clamping the 4-20mA output at 0mA.

These conditions exist until the FAULT is corrected.

Model 4105 Gas Sensor Module (12/02)

Page: 7

Page 11

Instruction Manual

7. INSTALLATION

7.1 Sensor Locations

Select locations for each of the sensors based on the

following:

- Consider the density of the gas to determine

height of sensor above floor or ground level.

- Sensors should be placed close to the potential

source of gas.

- Sensors should be placed in areas accessible for

calibration.

- Sensors must be pointed down and the conduit

should include an inverse trap to reduce moisture (condensation) from accumulating in the electronics enclosure. See Figure 7.1.

7.2 Sensor Mounting

Where possible sensor modules should be installed

with the sensor facing vertically down. The lid of the

sensor module should face out for easy access.

Sensors may be mounted directly onto the end of a

vertical conduit, or bracketed to a vertical surface using the two mounting flanges. Insure that the body of

the enclosure is at least 1" from the wall so that the

sensor assembly can be rotated for removal and replacement. See Figure 6.1 for installation configurations.

7.3 Explosion Proof Installation

Where area classification requires explosion proof

(NEMA-7) installation a sealing fitting will be required

immediately above the gas sensor module enclosure.

7.4 Power Supply

The power supplied by the controlling device or an

external power supply must meet the following specifications:

Voltage: 21-30 VDC

Current: 180 mA (Combustibles)

40 mA (Oxygen & Toxics)

Page: 8

Figure 7.1

Gas Sensor Module Installation

Model 4105 Gas Sensor Module (12/02)

Page 12

Instruction Manual

ELECTROCHEMICAL SENSORS

T B 2

P 1

R I B B O N C A B L E

T O C P U A S S Y .

U 2

1 3 2 4

R 2

J P 1

U 5

U 4

Combustible

V O U T

U 1

V O U T

P 1

R I B B O N C A B L E

T O C P U A S S Y .

U 2 U 7

R A C

T B 1

Sensor Pwr./Sig.

V O L T S B A L

U 3

R 1 1

Black

Brown

1 3 2 4

J P 1

Red

U 4

V O U T

ST-46A/EC I/O PCB FOR

P 1

R I B B O N C A B L E

T O C P U A S S Y .

U 2 U 7

1 3 2 4

J P 1

U 5

U 1

J P 2

R 1 9

S C R

T B 1 T B 2

Sensor Pwr./Sig.

B A

U 1

J P 2

U 5

Toxics

Short R&C

Black

Red

R 1 9

S C R

T B 1 T B 2

Sensor Pwr./Sig.

B A

Black

Red

White

Model 4105 Gas Sensor Module (12/02)

U 4

ST-46A/EC I/O PCB FOR

Oxygen

Figure 7.2

Wiring Diagram

Page: 9

Page 13

Instruction Manual

8. SPECIFICATIONS

Model 4105-02 4105-03 4105-04 4105-05 4105-06 4105-07 4105-10

Gas Comb. O

2

Sensor Type Catalytic E.C. E.C. E.C E.C. E.C. E.C.

Units %LEL % Vol ppm ppm ppm ppm ppm

Range 0-100 0-25% 0-1000 0-100 0-10 0-1000 0-100

Resolution 3% F.S. 0.1% F.S. 1 0.1 0.1 2 0.5

Response Time Note 1 10 sec. 25 sec. 30 sec. 60 sec. 30 sec. 20 sec.

to 90% of signal

Sensor Life

2

3 Yrs 2 yrs 2 yrs 2 yrs 2 yrs 2 yrs 2 yrs

Operating Range

Temperature 14 to 158oF 19 to 122oF 14 to 122oF 14 to 122oF 14 to 122oF 14 to 122oF 14 to 122oF

-10 to 75oC -7 to 50oC -10 to 50oC -10 to 50oC -10 to 50oC -10 to 50oC -10 to 50oC

Relative Humidity 10-95% 5-99% 15-90% 15-90% 15-90% 10-90% 15-90%

Pressure 10% 10% 10% 10% 10% 10% 10%

Electrical Data

Input Voltage DC 19-30VDC at less than 100 mA

Output-Normal 4-20 mA DC linear

Output-Trouble 0 mA

CO H2S Cl

2

H

2

SO

2

Construction

Dimensions H: 7.6", D: 4.6", W: 4.2" (19.3 x 11.7 x 10.7 cm)

Weight (Module) 5.0 lb. (2.2 kg)

Mounting 3/4" NPT

Housing Explosion proof

(NEMA 7) / NEMA 4X Enclosure (Div. I, Class 1, Groups B, C, D)

Notes: 1. Step to 50% LEL within 10 sec, recovery to 10% LEL within 30 sec.

2. Sensor life is for use at standard temperature and pressure with occasional

exposure to the gas of interest

Page: 10

Model 4105 Gas Sensor Module (12/02)

Page 14

8. SPECIFICATIONS (Continued)

Instruction Manual

Model 4105-12 4105-21 4105-22 4105-2534105-26

Gas NO

2

HCL HCN NH

3

HF

Sensor Type E.C. E.C. E.C. E.C. E.C.

Units ppm ppm ppm ppm ppm

Range 0-20 0-20 0-20 0-50 0-10

Resolution 0.2 0.5 0.1 0.1 0.5

Response Time 35 sec. 150 sec 70 sec. 45 sec. 30 sec.

to 90% of signal

Sensor Life

2

2 yrs 2 yrs 2 yrs N/A N/A

Operating Range

Temperature 14 to 122oF 14 to 122oF 14 to 122oF 14 to 113oF 14 to 113oF

-10 to 50oC -10 to 50oC -10 to 50oC -10 to 45oC -10 to 45oC

Relative Humidity 15-90% 15-90% 15-90% 20-90% 20-90%

Pressure 10% 10% 10% 10% 10%

Electrical Data

Input Voltage DC 19-30 VDC at less than 100 mA

Output-Normal 4-20 mA DC linear

Output-Trouble 0 mA

3

Construction

Dimensions H: 7.6", D: 4.6", W: 4.2" (19.3 x 11.7 x 10.7 cm)

Weight (Module) 5.0 lb. (2.2 kg)

Mounting 3/4" NPT

Housing Explosion proof

(NEMA 7) / NEMA 4X Enclosure (Div. I, Class 1, Groups B, C, D)

Notes: 2. Sensor life is for use at standard temperature and pressure with occasional exposure to the gas of interest

3. Diffusion via membrane. Dimensions are H: 10.2", D: 6.0", W: 6.0" (25.9 x 15.2x 15.2 cm)

Model 4105 Gas Sensor Module (12/02)

Page: 11

Page 15

Instruction Manual

8. SPECIFICATIONS (Cont.)

Cross Sensitivities (toxic sensors)

Model Gas Reading from 100 ppm of interfering gas

Number Type CO H2S Cl

2

4105-04 CO 100 315 -15 <40 50 -55 30 2 40 <50

4105-05 H2S <0.5 100 -20 <0.1 <15 -15 0 0 0 0

4105-06 Cl

4105-07 H

2

4105-10 SO

4105-12 NO

2

2

0 <-10 100 0 0 105 0 0 0 0

<1 <20 0 100 3 0 35 3 35 85

<1 0 -40 0 100 -100 0 0 15 0

0 -20 90 0 0 100 0 0 -3 0

2

4105-21 HCl 0 75 -10 0 35 -2 0 100 -8 0

4105-22 HCN <0.5 -50 0 160 -190 -5 30 100 <1

4105-25 NH

0 0 0 - 40 0 0 - - -

3

4105-26 HF 0 0 9 0 9 5 - 6 - -

H

2

SO

NO

2

NO HCl HCN C2H

2

4

Page: 12

Model 4105 Gas Sensor Module (12/02)

Page 16

9. REPLACEMENT PARTS

4205-02 Sensor Assembly, Combustible, Non-Intrusive

4205-03 Sensor Assembly, 4-20 mA O2, Non-Intrusive

4207-04 Sensor Assembly, 4-20 mA CO, Non-Intrusive

4205-05 Sensor Assembly, 4-20 mA H2S, Non-Intrusive

4205-06 Sensor Assembly, 4-20 mA Cl2, Non-Intrusive

4207-07 Sensor Assembly, 4-20 mA H

4207-10 Sensor Assembly, 4-20 mA SO2, Non-Intrusive

4207-12 Sensor Assembly, 4-20 mA NO2, Non-Intrusive

4207-21 Sensor Assembly, 4-20 mA HCl, Non-Intrusive

4207-22 Sensor Assembly, 4-20 mA HCN, Non-Intrusive

4207-25 Sensor Assembly, 4-20 mA NH3, Non-Intrusive

4207-26 Sensor Assembly, 4-20 mA HF, Non-Intrusive

5311-00 Rainshield

Non-Intrusive

2,

Instruction Manual

10. LIMITED WARRANTY

SIERRA MONITOR CORPORATION warrants its products

to be free from defects in workmanship or material under

normal use and service for two years after date of shipment.

SMC will repair or replace without charge any equipment

found to be defective during the warranty period. Final

determination of the nature and responsibility for defective

or damaged equipment will be made by SMC personnel.

All warranties hereunder are contingent upon proper use in

the application for which the product was intended and do

not cover products which have been modified or repaired

without SMC approval or which have been subjected to

accident, improper maintenance, installation or application,

or on which original identification marks have been removed

or altered. This Limited Warranty also will not apply to

interconnecting cables or wires, consumables (ie. calibration gases, batteries, sensors), nor to any damage resulting

from battery leakage.

In all cases SMC’s responsibility and liability under this

warranty shall be limited to the cost of the equipment. The

purchaser must obtain shipping instructions for the prepaid

return of any item under this warranty provision and compliance with such instruction shall be a condition of this warranty.

Except for the express warranty stated above, SMC disclaims

all warranties with regard to the products sold hereunder

including all implied warranties of merchantability and fitness and the express warranties stated herein are in lieu of

all obligations or liabilities on the part of SMC for damages

including, but not limited to, consequential damages arising

out of/or in connection with the use or performance of the

product.

Model 4105 Gas Sensor Module (12/02)

Page: 13

Page 17

Instruction Manual

Appendix A: Unity Gain Mode

The Unity magnetic control is available during CAL

MODE to allow the ZERO and SPAN adjustments to be

centered within their range. This is similar to setting a

potentiometer so the wiper terminal is exactly halfway

between the clockwise and counterclockwise terminals.

this is identified as the UNITY GAIN mode. In UNITY

GAIN the ZERO controls have a ± 15% of full scale

adjustment range. For example, in UNITY GAIN, if the

sensor's ZERO output has drifted so high that it reads

15% with ZERO gas applied, the DOWN ZERO magnetic

control could still bring the 4105-XX reading to ZERO.

However, it will be at the end of its adjustment range. If

the ZERO adjustment required is greater than ±10% of

full scale, a BALANCE adjustment should be performed

as described in Appendix A.

In UNITY GAIN the SPAN controls have a .5 to 2 adjustment range. For example, in UNITY GAIN, if a sensor's

output sensitivity has been reduced to the point where

50% SPAN gas provides only a 25% reading, the UP

SPAN magnetic control could still calibrate the reading

to the proper value of 50%. However, it will be at the end

of its adjustment range.

Appendix B: L.C.D. Readout Calibration Procedure

The 3 1/2 digit LCD meter span and decimal points

may be configured for full scale ranges such as 1100, 0-25, 0-10.0, 0-1000 and many others. Zero percent of full-scale readings, or those corresponding

to 4mA, are always assumed to equal a reading of 0.

Holding the magnet over the CAL key for at least 5

seconds enters the LCD METER SPAN SETUP

MODE. After this, the current setting for 100% full

scale is displayed and may be modified using the UP/

DOWN SPAN keys. This sets the LCD reading displayed when the 4-20mA output equals 30mA. Decimal points are added with the UNITY key.

Appendix C: End of Sensor Life Indication

Old sensors near the end of their service life require

higher gain settings. M4105-XX "END OF SENSOR

LIFE" (ESL) feature may be used to indicate condition. A span trip point may be entered that when exceeded, causes the LCD to flash and ESL reading for

2-seconds each 10 seconds. Holding the magnet to

the UNITY key for at least 5 seconds brings the LCD

a span value set-point reading for setting when the

ESL indication trips. CAL MODE GAIN adjustments

range between .5 and 2 and the ESL set-point is adjustable between 1.5 and 2.01 with 2.01 turning the

ESL feature off. The current span setting may be

viewed on the LCD during NORMAL MODE by

touching the DOWN SPAN key.

Page: 14

Model 4105 Gas Sensor Module (12/02)

Page 18

Instruction Manual

Appendix C: Combustible Gas Scaling Factors (Table 1)

Where possible, calibration gas should be the same as the gas to be detected. If this is not possible then a scaling factor

should be used to determine the “equivalent value” of the calibration gas in terms of the gas to be detected. (Note:

Concentration of calibration gas must be less than the factor number listed on Table 1).

The formula for calibration is as follows:

Display = (Cal gas) / Factor

where: Display = the span gas applied

Cal gas is the percent methane used for calibration.

Factor is a number that corresponds to the gas to be measured. (see Table 1)

Example: The application is for measurement of Propane and Methane is the calibration gas.

The factor for Propane (from Table 1) is 55.

For the example, calibration gas is Methane at 40% LEL.

Display = 40% LEL Methane / 55 = 0.73

Display = Adjust span until LCD reads 73.

Model 4105 Gas Sensor Module (12/02)

Page: 15

Page 19

Instruction Manual

COMBUSTIBLE GAS SCALING FACTORS

For combustible gas monitoring, a calibration standard of Methane or Propane my be used in conjunction with scaling

factors to cause alarm function in %LEL scale of another gas as follows:

GAS METHANE PROPANE

FACTOR FACTOR

Acetaldehyde 60 109

Acetic Acid 54 98

Acetic Anhydride 46 83

Acetone 52 94

Acetylene 57 103

Alkyl Alcohol 51 92

Ammonia 126 229

n-Amyl Alcohol 33 59

Aniline 39 71

Benzene 41 74

Biphenyl 25 45

1,3-Butadiene 56 101

n-Butane 58 106

iso-Butane 52 94

Butene-1 45 82

cis-Butene-2 48 88

trans-Butene-2 51 92

n-Butyl Alcohol 34 62

iso-Butyl Alcohol 53 96

tert-Butyl-Alcohol 74 134

n-Butyl Benzene 31 57

iso-Butyl Benzene 32 58

n-Butyric Acid 38 69

Carbon Disulfide 18 32

Carbon Monoxide 75 137

Carbon Oxysulphide 93 169

Chlorobenzene 34 62

Cyanogen 89 162

Cyclohexane 41 74

Cyclopropane 62 113

n-Decane 33 59

Diethylamine 49 88

Dimethylamine 58 105

2,3-Dimethylpentane 40 72

2,3-Dimethylpropane 40 72

Dimethylsulphide 43 79

1,4-Dioxane 45 81

Epichlorohydrin 45 82

Ethane 68 123

Ethyl Acetate 51 93

Ethyl Alcohol 73 132

Ethylamine 53 95

Ethyl Benzene 36 65

Ethyl Bromide 91 165

Ethyl Chloride 57 103

Ethylcyclopentane 40 72

Ethylene 71 128

Ethylenedichloride 66 120

Ethyleneoxide 52 94

GAS METHANE PROPANE

FACTOR FACTOR

Diethyl Ether 46 84

Dimethoxyethane 42 75

Dimethyl Ether 63 113

Dimethylformamide 46 83

Ethyl Formate 44 80

Ethylmercaptan 56 102

n-Heptane 39 70

n-Hexane 37 67

Hydrazine 45 82

Hydrogencyanide 48 86

Hydrogen 77 139

Hydrogen Sulfide 41 74

Methane 100 181

Methyl Actetate 50 90

Methyl Alcohol 86 156

Methylamine 77 140

Methyl Bromide 90 162

Methyl Chloride 102 186

Methylcyclohexane 44 80

Methylenedichloride 93 168

Methylethylether 44 80

Methylethylketone 41 75

Methyl Formate 67 121

Methylmercaptan 61 110

Methylpropionate 51 93

Methyl n-propylketone 40 73

Napthalene 34 62

Nitromethane 34 62

n-Nonane 31 57

n-Octane 37 68

n-Pentane 46 83

i-Pentane 46 84

Propane 55 100

n-Propyl Alcohol 47 85

n-Propylamine 48 88

n-Propylchloride 50 90

Propylene 52 93

Propyleneoxide 46 83

iso-Propylether 44 79

Propyne 42 75

Toluene 40 73

Triethylamine 40 72

Trimethylamine 48 88

Vinylethylether 42 76

o-Xylene 36 65

m-Xylene 39 71

p-Xylene 39 71

JP-4 (Jet Fuel) 41 73

NOTES:

1. Scaling factors are not FMRC approved.

2. Base data source: EEV sensor specification catalog. (EEV claims some data is the result of specific tests,

other data is empirically derived.)

3. Display = Cal Gas / Factor = % LEL

=> must be less than 1

TABLE 1

COMBUSTIBLE GAS SCALING FACTORS

Page: 16

Model 4105 Gas Sensor Module (12/02)

Loading...

Loading...