Page 1

MODEL 3100-XX

FLAME DETECTOR

Page 2

Sierra Monitor Corporation

1991 Tarob Court, Milpitas, CA 95035

(408) 262-6611, Toll Free: 800-727-4377

Fax: 408-262-9042

MODEL 3100-XX

Flame Detector

APPLICABILITY & EFFECTIVITY

This manual provides instructions for the following Sierra Monitor products:

Model Description

3100-01 Flame Detector - Standard

3100-02 Flame Detector - Enhanced Relay

3100-03 Flame Detector - Enhanced Relay

3100-04 Flame Detector - Enhanced Relay

3100-05 Flame Detector - Enhanced Relay

3100-06 Flame Detector - Flame Detector - 4-20mA

The instructions are effective for the above models as of March 1, 1997

Applicability & Effectivity

Instruction Manual Part Number: T15007

Rev. C2

Page 3

Instruction Manual

TABLE OF CONTENTS

SECTION PAGE

1. PRODUCT DESCRIPTION 1

2. OPERATION 2

2.1 General 2

2.2 Field-of-View 3

2.3 Range 3

2.4 Environment 3

2.5 Configuration 3

2.6 LED operation 4

2.7 Relay operation 5

3. INST ALLATION 7

3.1 General Precautions 7

3.2 Housing and Conduit 7

3.3 Connection 7

3.4 T esting 8

4. MAINTENANCE 8

4.1 Lens Cleaning 8

5. TROUBLESHOOTING 9

6. SPECIFICATIONS 11

7. W ARRANTY 11

APPENDICES

A. FIGURES

A-1 - Exploded V iew 12

A-2 - Housing Dimensions 12

A-3 - Common Wiring Configurations 13

A-4 - Enhanced Series Wiring Connections 14

B. TABLES 15

B.1 Dip Switch Settings 15

B.2 Connectors 16

B.3 V erify/Aux. Relay Configurations 16

B.4 Fault T able 17

C. WIRING CONNECTIONS 18

INDEX 19

Table of Contents

Page 4

Instruction Manual

1. PRODUCT DESCRIPTION

1.1 Introduction

All versions of the Model 3100 Flame Detector Series utilize Ultraviolet, Infrared and V isible spectrum

to provide continuous and reliable flame detection.

The microprocessor in the Model 3100 is configured with state-of-the-art fire algorithms and continuously analyzes the data from the sensor array

for individual intensity values, change of intensity

values, relationship of intensity values and frequency

signature correlations. Each algorithm is designed

to recognize a different type of flame signature from

the detectors while rejecting common false sources.

When the conditions of any one of the several fire

algorithms are met the Model 3100 declares a fire.

1.2 Fault Diagnostics

The micro-processor is also continuously performing system tests looking for any faults which would

impair its ability to accurately detect a flame and

declare an alarm. The systems being tested include:

input power, sensor circuits, relay circuits, and several other internal systems. The Model 3100 Flame

Detector also performs a through the lens test of

the sensor and lens systems. All faults are recorded

in non-volatile memory and may be retrieved by a

trained technician.

1.3 Configuration

The Model 3100-01 has a Fire Relay and a Fault

Relay which may be connected as normally open or

normally closed contacts. Models 3100-02, -03, 04, and -05 have in addition to the Fire and Faults

relays a Fire Verify system and an Auxiliary Fault

system. The Fire Verify system adds a “field adjustable” level of certainty to the declaration of a

verified fire. The Auxiliary Fault system will activate the Aux. Relay for the Lens Test fault. This

allows a separate indication for the most common

fault (a dirty lens). A technician can know immediately what is wrong and how to fix it (i.e. wipe the

lens) without reading codes, consulting manuals, or

wading through a process of complex diagnostics.

The 3100-06 has an industry standard 4-20 mA output and no relays.

The Model 3100 detector is mounted in a NEMA

4X explosion proof housing, rated for Class I Division 1 & 2 Groups B, C, D, Class II Division 1 & 2

Groups E, F, G, and Class III locations. The electronics are mounted inside an aluminum cup to protect the electronics during installation. All switch

settings and indicators are located on the front of

the Model 3100 detector module allowing field adjustments to be made without removing the detector module from the housing.

Each Model 3100 detector is calibrated and tested

to respond to a 1 square foot Kerosene fire at 80

feet with a Field-of-View of 120°. The Model 3100

detector has four sensitivity settings and six verify

levels.

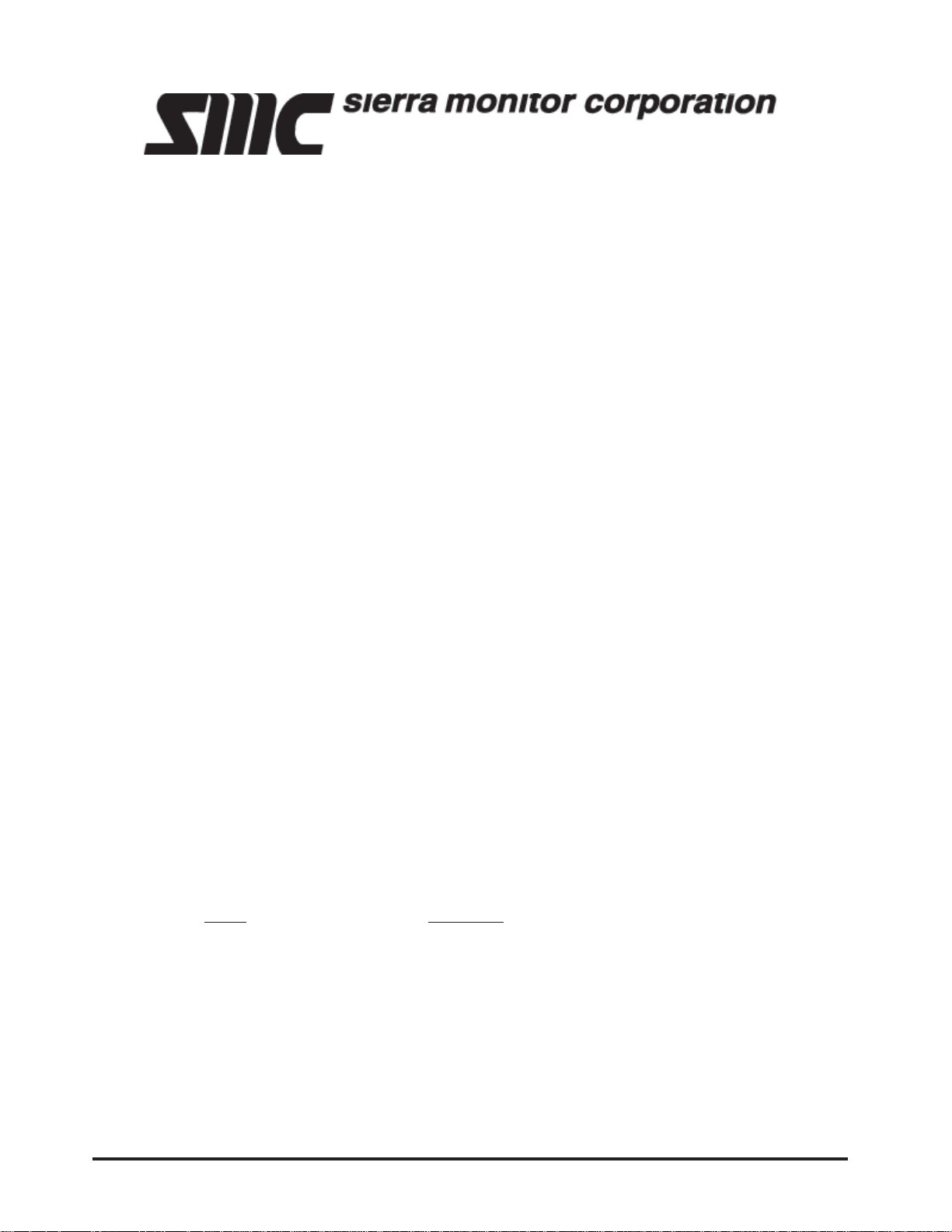

FIGURE 1-1: Model 3100 Series Flame Detector

Model 3100 Series Flame Detector (11/04)

Model

Fire

Rela

y

Fault

Relay

Verify

Relay

Aux.

Relay

3100-01 X X None None

3100-02 X X N/O N/C

3100-03 X X N/C N/O

3100-04 X X N/O N/O

3100-05 X X N/C N/C

3100-06 4-20 mA signal only

Models and Functions

Page: 1

Page 5

Instruction Manual

2. OPERATION

2.1 General

When the Model 3100 Flame Detector is powered

up, the microprocessor checks the configuration

switch settings and configures the detector. The microprocessor then runs a full series of self tests.

After the self test process is complete and all tests

are passed, the detector is ready to detect a fire.

All modes of operation are indicated by two LEDs

located on the front of the detector. Normal Mode

is indicated by a brief flash of the LEDs every 8

seconds. With the device in Normal Mode it is

constantly monitoring the environment and ready

to detect a fire.

When a fire is detected the flame detector will activate the Fire Relay and turn on both LEDs. If the

device is configured for “Latching” Mode the device will remain in Alarm Mode until power is removed. In “Fire Following” Mode the Fire Relay

will reset when the Fire Probability Algorithm determines there is no longer a fire.

The self test system is continuously monitoring the

internal systems. When a fault is detected the Fault

Relay is de-energized. In Fault Mode the LEDs

will flash a code indicating the type of fault. A fault

indication may mean the device is unable to detect

a fire or that a device has become unreliable. (i.e. a

“Voltage Low” fault) For most faults the detector

will return to Normal Mode when the fault condition is corrected.

The Model 3100 Series comes in several versions.

The basic version 3100-01 does not have the Verify

or the Auxiliary Relay systems. The enhanced Models 3100-02, -03, -04 and -05 have the Verify and

Auxiliary Relay systems. These versions represent

the different configurations (Normally Open or

Closed contacts) of the V erify and Auxiliary Relays.

The Auxiliary Relay provides a separate relay output for the Lens Test Fault. The Verify system is

activated when a fire is declared. A V erified Fire is

declared when the conditions of the Verify Fire Algorithm are met. All other functions are the same

as the basic Model 3100-01.

The 3100-06 does not have relay outputs. It uses a

4-20 mA current circuit. The detector's status determines the amount of current flow through the

circuit.

Page: 2

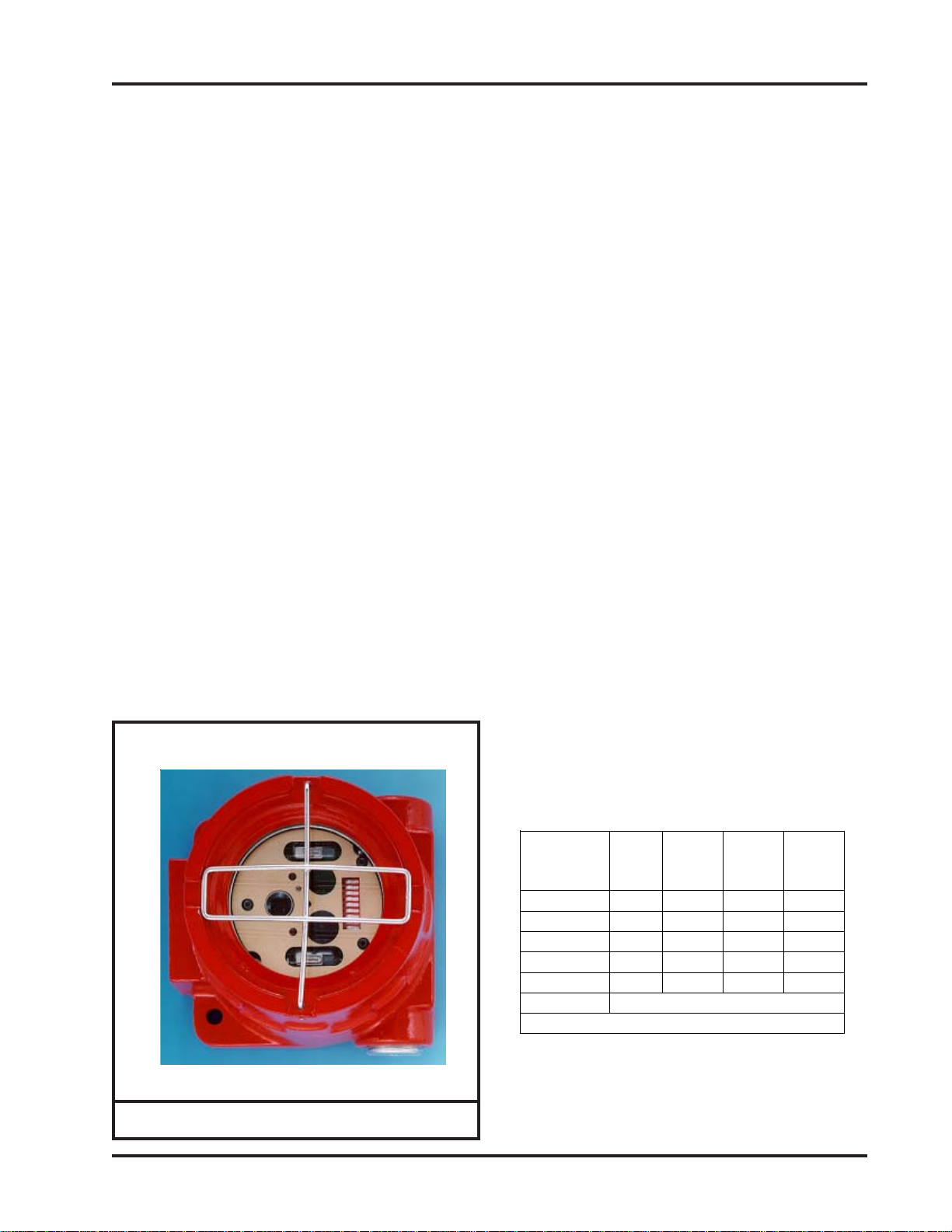

Figure 2-1: Model 3100 Series Field of View

Model 3100 Series Flame Detector (11/04)

Page 6

Instruction Manual

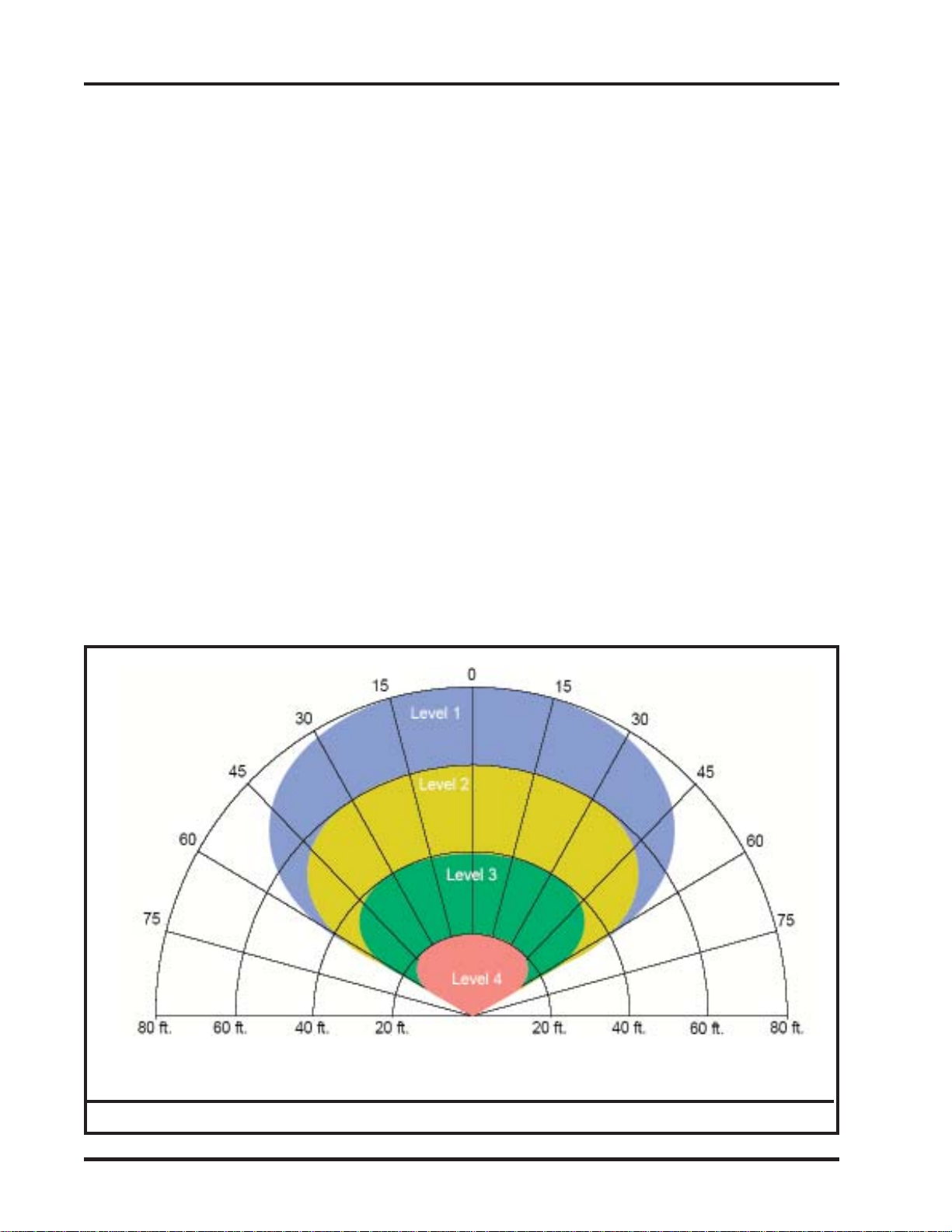

SW1

SW2

SW3

SW4

SW5

SW1 Shown in off position

SW2 Shown in on position

Figure 2-2: Configuration Switches

2.2 Field-of-V iew (See Figure 2-1)

Optical Flame Detectors must be able to “see” the

fire to declare an alarm. Any obstruction between

the detector and the threat area will impair the detectors ability to cover the threat area. An obstruction is anything that is not transparent to the sensor

elements of the detector. UV sensors and some

types of IR sensors cannot see through glass or plastics. The 3100 series of Flame Detectors has a

120° Field of V iew .

When covering a large area the detectors should be

located to provide overlapping fields of view to insure complete coverage.

2.3 Range

The size of fire and type of materials which constitute the threat will affect the detector’s range. Different materials produce different amounts of the

radiant energy used by the detector to “see” the

fire. Also, the range of the detector is a function of

the fire size. Using the square of the distance rule,

if the device will detect a one sq. ft. fire at 60 feet,

to detect a 1/4 size fire (aprox. 6 sq. in.) the devices

must be within 30 feet. The Model 3100 Detector

is optimized to a 1 sq. ft. Kerosene fire at 80 feet

with the sensitivity settings set to maximum sensitivity .

2.4 Environment

All optical flame detectors sense radiant energy at

some frequency or frequencies within their Fieldof-View. Any source which radiates energy at the

same frequency or frequencies used by the detector

SW9

SW8

SW7

SW6

to sense a fire may impact the detector’s ability to

“see” the fire. Care should be taken to minimize

radiant energy sources within the detectors Fieldof-View. Because of the variety of environments

and conditions, a factory trained technician or qualified P.E. should be consulted before deciding on

the location of devices. The Model 3100 Detector

uses an Ultraviolet sensor (180 - 260 nanometers),

an Infrared sensor (.715 - 3.5 microns), and a Visible sensor (480 - 560 nanometers).

2.5 Configuration (See Figure 2-2)

All of the 3100 Series models have field adjustable

configuration switches located on the front face of

the detector. The factory settings are shown in italic

text. The enhanced models have additional configuration options for the Verified Fire.

2.5.1 Sensitivity

All versions have several sensitivity settings

available. The sensitivity settings are 20, 40,

60, and 80 feet. Each setting is optimized to

alarm on a 1 sq. ft. Kerosene fire within 5

seconds. Switches 1 and 2 control the sensitivity. The factory default is 80 feet. (SW1

and SW2 are off.)

Note: Different fuels emit energy at different

rates. For example; a fire involving fuel oil

does not emit energy at the same rate as gasoline. Consequently, the Model 3100 will be

able to respond to a gasoline fire at a little

greater distance than it will to a fuel oil fire.

Similary, a fire involving acetone will be seen

at a greater distance than one involving gaso-

line.

Model 3100 Series Flame Detector (11/04)

Page: 3

Page 7

Instruction Manual

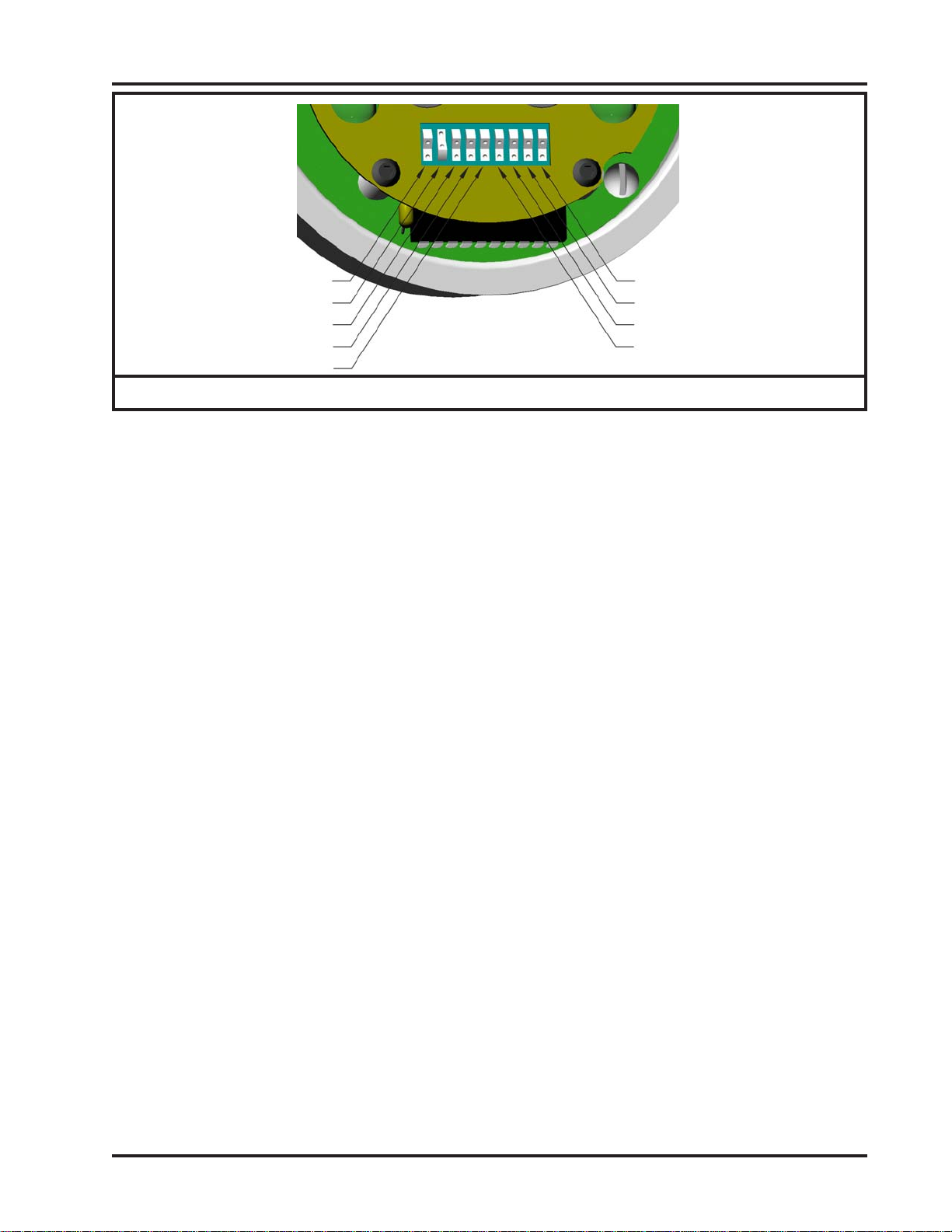

LED 1

(2 locations)

Configuration Switches

Figure 2-3: Model 3100 Series Detector Module (Front)

2.5.2 Verify Control

The Enhanced Model 3100-02, -03, -04, 05 and -06 have the Verified Fire function.

The Verify Control switches allow the user

to select the verify level, disable the verify

function, or make the Verify Relay operate

in parallel with the Fire Relay. The verify

function in enabled when the detector declares an alarm. The verify level sets the

degree of certainty required to declare a verified fire. The lowest level (1) is the lowest

certainty (fastest) and the highest level (6) is

the greatest certainty (slowest) of a fire. The

verify function enables an algorithm which

evaluates the fire signature over time to determine the degree of certainty. When the

degree of certainty exceeds the level set by

the configuration switches a Verified Fire is

declared and the Verify Relay is energized.

Switches 3, 4, and 5 control the verify function. The factory default is verify disabled

and set to level 0. (SW3, SW4 and SW5 are

off.)

2.5.3 Latching Control

The latching controls allow the detector or

individual relay outputs to be set to “Latching” or “Fire Following”. “Latching” causes

the relay to stay energized until power is removed from the detector. “Non-latching” allows the relay to reset (de-energize) when a

flame is not present for a short period of time.

For the detector to be set to "Non-latching"

both Fire Output and Verify Output must be

set to "Non-latching". If either the fire out-

LED 2

Mounting Screw

put or the verify output is set to "Latching"

then the detector will be set to "Latching".

When the detector is set to "Latching" the

LED's will indicate an alarm until the device

is reset regardless of the fire or verify relay

output settings.

The Verify Relay is automatically configured

as “Latching” if the Fire Relay is set to “Latching”. SW6 sets the Fire Relay Output, SW7

sets the Verify Relay Output and SW8 sets

the Detector Mode. To set the detector to

"Non-latching", SW6, SW7 and SW8 must

be set to "Non-latching. The factory defaults

are “Latching” (SW6 and SW7 ar e off.)

2.5.4 Other Configuration Switches

The last configuration switch (SW9) must be

in the off position. The factory default set-

ting is off.

2.6 LED operation (See Figure 2-3)

The status of all versions of the flame detectors can

be determined from the LEDs located behind the

lens on the front of the detector. The LEDs will

flash at intervals or remain on to indicate the detectors status. (Fault Mode, Normal Mode, Alarm

Mode, Verified Fire Mode, and on power up the

Configuration Settings).

2.6.1 Power Up

At power up all versions of the flame detector will begin flashing the LEDs. The LEDs

will flash 8 consecutive patterns which indicates the positions of the configuration

switches. Each pattern indicates the position

Page: 4

Model 3100 Series Flame Detector (11/04)

Page 8

Instruction Manual

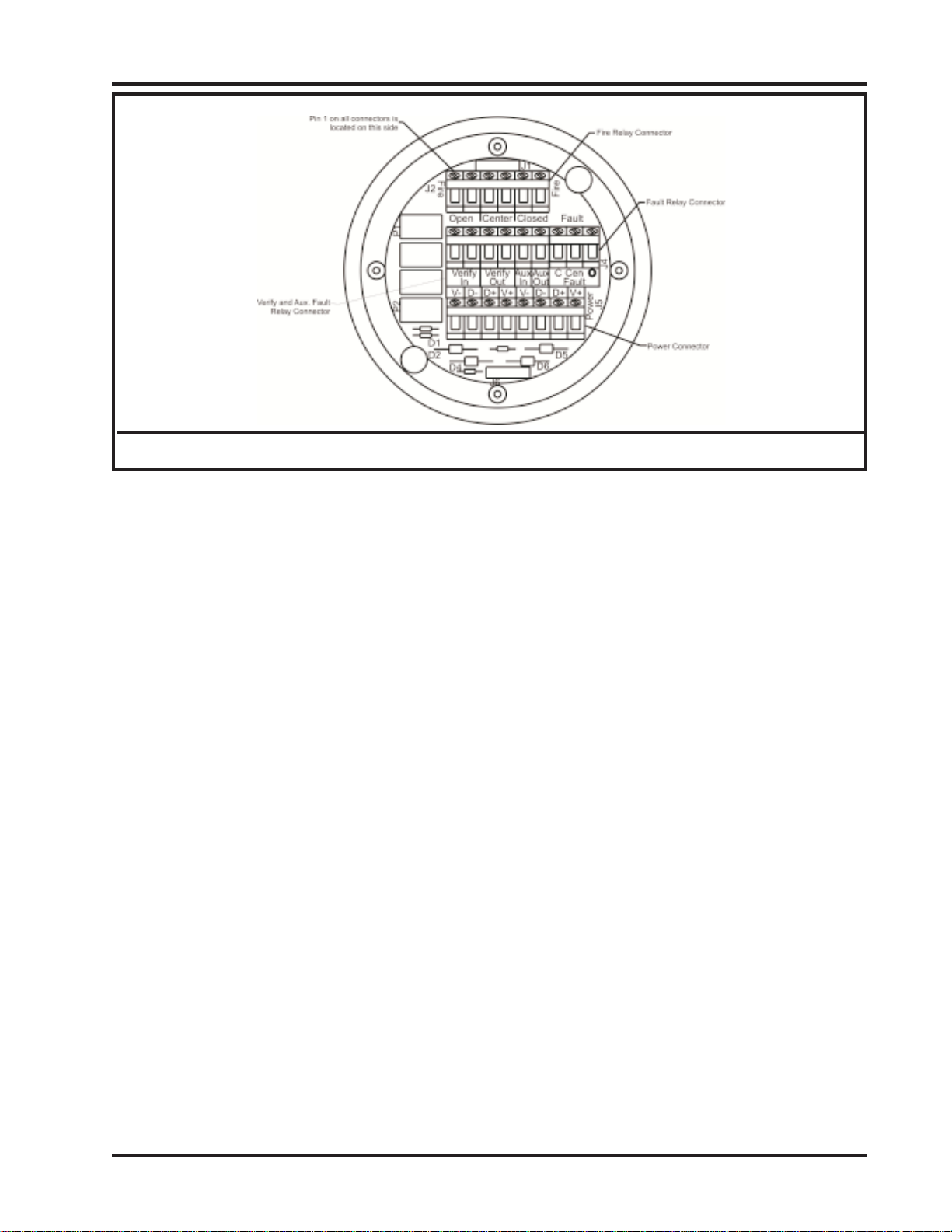

Figure 2-4: Model 3100 Series Detector Module (Back)

(“on” or “off”) of a switch (SW1-SW8).

The first flash pattern indicates the position

of the first switch (SW1), with each consecutive flash indicating the position of the next

switch in order. The flash pattern is as follows: only one LED “on” indicates a switch

in the “off” position, both LEDs “on” indicates a switch in the “on” position. The position of SW9 is not indicated. If SW9 is in

the “on” position the detector will power up

in fault mode.

2.6.2 Normal

In Normal Mode the LEDs will flash briefly

every 8 seconds. Whenever the device is in

any other mode the “flash every 8 seconds”

is suspended until the detector returns to

Normal Mode.

2.6.3 Fire

When any version of the Model 3100 declares a fire, both LEDs will come “on” and

stay “on”. If the detector is set to "Latching"

the LED's will remain "on" and stay "on"

until the detector is powered down. If the

detector is set to "Non-latching" the LED's

will reset to "Normal Mode" when the fire is

no longer being detected. If the Verified Fire

is declared (Verify Fire is only on the Enhanced Models) the LEDs will blink “off”

briefly every second. If the detector is set to

"Latching" the LED's will remain in this state

until the detector is powered down.

2.6.4 Fault

When the detector has power and is in Fault

Mode LED1 (the left LED when facing the

detector with the configuration switches below the LEDs) will be on for 5 seconds while

the LED2 (the right LED) will be off see

Table B.4 on page 12. The LED will turn

"off" and LED 2 will begin flashing 1/2 seconds "on" and 1/2 second "off" a number of

times. The number of times LED2 flashes

indicates the type of fault. This cycle is repeated until the fault is corrected. Only the

highest number fault is indicated. Once a

fault is corrected the next highest level fault

will be indicated until all faults are cured.

Except for fault level 2 and 3, a fire indication will override a fault indication. The detector is disabled if a fault 2 or 3 is indicated.

2.7 Relay operation (See Figure 2-4)

The Model 3100-01 has two relays, the enhanced

Models 3100-02, -03, -04 and -05 have four relays.

The function of the Fire and Fault Relays is the

same on all models. The Verify Relay and Aux.

Relay is only available on the enhanced models. All

relay connections are made at the connectors located on the back of the flame detector module.

2.7.1 Fire Relay

The Fire Relay will energize whenever the

detector declares a fire. Depending on the

configuration setting, the relay will: “Latch-

Model 3100 Series Flame Detector (11/04)

Page: 5

Page 9

Instruction Manual

ing” - remain energized until power is removed, ”Fire Following” - de-energize a short

time after the fire is no longer detected. The

“J2” connector provides connections for both

normally open contacts and normally closed

contacts on the Fire Relay .

2.7.2 Fault Re lay

The Fault Relay is a normally energized relay . It will de-energize when a Fault occurs.

This means the detectors Fault Relay is in

the “Fault” state when the detector has no

power, and remains in the “Fault” state until

the detector is powered up and operating normally. The “J4” connector provides both

normally open contacts and normally closed

contact on the Fault Relay .

2.7.3 Verify Relay

The Verify Relay will energize when a “V erified Fire” is declared. Depending on the configuration the relay will: “Latching” - remain

energized until power is removed, “Fire Following” - de-energize a short time after the

fire is no longer detected. Further, the “Verify

Control” configured to Level 0 will disable

the V erify Relay , and Level 7 causes the Verify

Relay to operate in parallel with the Fire Relay. The connector labeled “Verify In” and

“Verify Out” provides connections for normally open contacts on the 3100-02 and 310004 or normally closed contacts on the 310003 and 3100-05. The configuration of Normally Open or Normally Closed contacts is

fixed and can only be changed by the factory.

3100-02 and 3100-05 models. The configuration of Normally Open or Normally Closed

contacts is fixed and can only be changed by

the factory .

2.7.5 4-20 mA Operation

The 3100-06 uses a 4 to 20 mA current draw

circuit to indicate Fault, Fire, Verify Fire and

Normal Mode. The current draws are as follows:

Fault Mode: 0 mA

Normal Mode: 4 mA

Alarm Mode: 12 mA

V erify Mode: 20 mA

The 4-20 circuit is connected across the J2

connector at contact 6 and 7 where connection 6 is the negative side and connection 7 is

the positive side. Additionally, a jumper between contacts 7 and 8 must be made.

2.7.4 Auxiliary Fault

The Aux. Relay is energized whenever the

detector fails the “Lens Check” test. This

fault indicates the detectors inability to “see”

a fire. Normally , cleaning the lens will clear

this fault. Because a dirty lens is the most

common type of fault, a separate indicator

connected to this relay will simplify maintenance. The connector labeled “Aux In” and

“Aux Out” provides connections for Normally

Open contacts on the 3100-03 and 3100-04

models or Normally Closed contacts on the

Page: 6

Model 3100 Series Flame Detector (11/04)

Page 10

Instruction Manual

3.0 INSTALLATION

3.1 General Precautions

All wiring and installation must be done in accordance with the NFP A 70 and 72 standards and must

comply with any codes specific to the application or

location. Contact the local authority having jurisdiction and the company safety engineer for information on codes which may apply .

3.2 Housing and Conduit

3.2.1 Mounting the Housing

The housing is mounted by using the two

0.3” diameter holes located in ears on the

back of the housing. The two conduit holes

located on the side of the housing are not to

be used for mounting. The detector should

be mounted securely to a flat surface. The

mounting location must be strong enough to

support the detectors 3 lb. weight. Although

the detector is not vibration sensitive the detector should not be exposed to excessive vibration. "(The detector has been tested to

meet the vibration standard set in FM’s Approval Standard Class 3820, Sept. 1979.

(.022" displacement, 10 Hz to 30 Hz sweep

cycled at 2 cpm for 4 hours)"

3.2.2 Installing the Conduit and Wiring

Mount a “Seal Off” at the housing into the

3/4” NPT conduit(s) located on either side

of the housing. Connect the conduit to the

“Seal Off”. If one of the conduit openings is

not used insert a sealing plug into the unused

opening. Run the wires through the conduit,

“Seal Off”, and into the housing. The ends

of the wire should extend several inches (at

least 2” to 4”) beyond the front of the housing base.

3.3 Connection (See Appendix C for information

regarding connection to various systems)

All connections are made on the back of the Model

3100 Flame Detector Module. Remove the housing

cover from the housing base. Loosen the two slotted head captive screws located on the top of the

PC board. Lift the Detector Module out of the

housing base. Strip and connect the wires to the

connectors located on the back of the Detector

Module.

3.3.1 Power

Power for the 3100-01, -02, -03, -04 and 05 flame detector is connected to the J5 connector labeled “Power”. Connect the negative wire to PIN 1. Connect the positive (24

VDC) wire to PIN 4.

Power for the 3100-06 detector connected

to the J2 connector. Connect positive wire

at 4. Connect negative wire at pin 1. Pins 2

and 3 should be left open.

3.3.2 Fire Relay

The Fire Relay has two internal connection

points. Either or both may be used. The

Fire Relay connector, labeled “FIRE”, has

connection points for Normally Open, Normally Closed, and Common. The Normally

Open connections are labeled “Open”, the

Common contacts are labeled “Com”, and

the Normally Closed contacts are labeled

“Closed”.

3.3.3 Verify Relay

The Verify Relay has two internal connection points. Either or both may be used. The

Verify Relay connector is located between

the Power and Fire relay connectors. The

connection points are labeled “V erify In” and

“V erify Out”. The V erify relay is configured

for Normally Open (3100-02 and 3100-04),

or Normally Closed (3100-03 and 3100-05)

operation at the factory .

3.3.4 Fault Re lay

The Fault Relay connector is labeled “Fault”.

The Normally Open connection is labeled

“O”, the Common connection is labeled

“Com”, and the Normally Closed connection is labeled “C”. The Fault Relay is a

normally energized relay. When the detector has no power the Normally Open contact

is closed and the Normally Closed contact is

open.

Model 3100 Series Flame Detector (11/04)

Page: 7

Page 11

Instruction Manual

3.3.5 Auxiliary Relay

The Auxiliary Relay connector is located between the Power and Fire Relay connectors.

The connection points are labeled “Aux In”

and “Aux Out”. The Aux. Relay is configured for Normally Open (3100-03 and 3100-

04), or Normally Closed (3100-02 and 3100-

05) operation at the factory .

3.3.6 4-20 mA Connections

The 4-20 mA connections are connected at

the J2 connections The positive side of the

4-20 mA circuit is connected to Pin 7 and

negative side to Pin 6.

3.4 T esting

The Model 3100 Flame Detector uses ongoing selftest functions which will indicate a fault if any of

the functions fail to pass. If an end to end test is

required, a 1 sq. ft. pan with 1 inch of water and 1/

8 inch of kerosene set at the max. distance set by

the sensitivity settings may also be used. The detector should alarm within 5 seconds of ignition of the

fire.

The Model 3140 Flame Tester is also available. It

simulates a UV/IR flame signature by emitting a

steady state UV signal and modulated IR signal at a

flicker frequency of 5 to 10 Hs.

NOTE: Because of the danger involved with

fire testing all safety precautions

must be observed.

4.0 MAINTENANCE

The self-test functions eliminate the need for most

regular maintenance procedures. If a detector indicates a fault, use the troubleshooting section of this

document to correct the fault. Contact the local

“authority having jurisdiction” or consult the local

codes for any maintenance they may require for the

type of system installed.

4.1 Lens Cleaning

The most common fault is a Lens T est Fault. Regular cleaning of the Lens will eliminate this type of

fault. The frequency will depend on the cleanliness

of the area where the detector is installed and how

the detector is mounted. A detector which is pointed

down should require less cleaning than one that is

pointed up. An area which has lots of oil particulates or dust will require more frequent cleaning than

one that is oil and dust free. The frequency of the

Lens T est Fault will indicate how often cleaning is

necessary . If the device is failing the “Lens test” to

often it may be necessary to install a dust shroud,

realign the detector, or change the detectors mounting location.

To clean the lens: Wipe the lens surface and grill

with a clean lint free cloth. If more extensive cleaning is required use denatured or Isopropyl alcohol

and a clean lint free cloth. Do not use any silica

based solvents. (Most common glass cleaners are

silica based and should not be used to clean the

lens.)

Page: 8

Model 3100 Series Flame Detector (11/04)

Page 12

Instruction Manual

5.0 TROUBLESHOOTING

The flame detector has several built-in self test

mechanisms which verify function and calibration.

The following procedure covers most faults and

problems which may occur during installation or

during the course of normal operation.

5.1 No LED blink or erratic LED blink

With power connected to the detector the LEDs

on the front of the detector module should begin

blinking and blink about every 8 seconds. If they

do not blink or blink in an abnormal fashion.

1. Remove the detector module from the housing.

2. Check voltage at power connector (J5, Pin 1

and Pin 4) Pin 1 should be the connected to

negative, and Pin 4 should be positive. Voltage should be between 15 and 32 volts DC.

3. If Main power is correct and the detector is

not indicating a fault. The detector module

should be returned to the factory .

5.2 Detector Indicates Fault

Use the fault table (Table B.4, page 17) to determine what type of fault is occurring and see appropriate section below to correct. If the corrective actions listed below do not correct the fault,

contact the factory for further diagnostic instructions or instructions on returning the detector for

servicing. (Ref. 2.6.4) or repeat.

5.2.4 Fault T ype 4 - “Voltage Low Fault”

The input voltage is below 15 VDC. Remove the Detector Module from the housing. W ith the detector connected to power,

measure the voltage between Pin 1 and Pin

4 on the Power connector (J5). The voltage should be between 15 - 32 VDC. If the

voltage is out of range check external wiring and power supply . There should not be

more than 1 volt of AC ripple at 24 VDC.

If the measured voltage is in range and there

is no AC ripple, contact the factory for return and service information.

5.2.5 Fault T ype 5 - “Photo Sensor Fault”

One of the Photo Sensors (Visible or IR)

did not pass the internal self test. If both

sensors are clean. The fault may be in the

sensors or the self test circuit. Contact the

factory for further diagnostic information.

5.2.6 Fault T ype 6 - “Relay Fault”

One of the Relay’s coil circuits is open.

There is no corrective action. Contact the

factory for return and service information.

5.2.7 Fault Type 7 - “V oltage High”

The Detector was exposed to an input voltage above 32 Volts. There is no corrective

action. Contact the factory for return and

service information.

5.2.1 Fault T ype 1 - “Lens Test Fault”

Clean lens and grill per section 4.1. Reset

the detector (remove and replace power).

If the fault persists it may indicate a bad

UV tube or UV source tube, factory service is required.

5.2.2 Fault T ype 2 - “Configuration Fault”

Dip Switch SW9 is “ON”. SW9 should be

set to off for normal operation. Change

SW9 to “OFF” and reset detector.

5.2.3 Fault T ype 3 - “Calibration Fault”

Calibration constants have been corrupted.

Factory service is required.

Model 3100 Series Flame Detector (11/04)

5.2.8 Fault T ype 8 - “Temperature Out of

Range”

The internal measured temperature was below -40° C or above 85° C. There is no

corrective action. Contact the factory for

return and service information.

5.3 Device appears to operate normally but will

not alarm to a fire.

When the detector declares an alarm two things

should happen. One, both the LEDs on the front

of the detector should come on. Two, the fire relay should energize. Check the dip switch settings. (SW1, SW2, SW8, and SW9 should be off

SW3 - SW7 have no impact.) Connect an ohm

meter across the Fire relay connections at the “Fire”

connector (Pin 1 and Pin 3 of J2). Run a fire test

per section 3.4.

Page: 9

Page 13

Instruction Manual

1. If the relay closes (0 ohms on the meter) and

the LEDs come “on” the detector is operating

normally. Check external alarm initiating cir cuit wiring.

2. If the relay closes and the LEDs remain off,

or the relay remains open and the LEDs come

on, the detector needs factory service.

3. If the relay remains open and the LEDs remain off, contact the factory for further diagnostic information.

Page: 10

Model 3100 Series Flame Detector (11/04)

Page 14

Instruction Manual

6.0 SPECIFICA TIONS

Sensitivity: 1 ft. sq. Pan fire on axis @ 80 feet within 5 seconds (using standard fuel)

Switch selectable form 20 to 80 feet to a 1 sq. ft. kerosene fire

Field of View: 120 degree cone

Responsivity: UV - 185 to 260 nm, IR - 0.715 to 3.5 microns, Visible - 480 to 560 nm

Input voltage: 15 to 32 volts, typically 24 volts

Current Draw: @24 Volts DC: 72 mA normal mode, 82 mA alarm mode

T emperature Range:

Operating: -40oF to 185oF (-40oC to 85oC)

Storage: -67

LEDs: Display switch settings, fault type, fire and verified fire information

Relays:

Model 3100-01: Fire and Fault Relays

3100-02, -03, -04,

-05 Enhanced Relay

Models:

4-20 mA Outputs

3100-06: 0 mA - Fault, 4 - mA - Normal Mode, 12 mA - Alarm, 20 mA - Verified Fire

Connections: Screw terminals, 14 - 22 AGW wire size

Enclosure: Copper-free Cast Aluminum with epoxy finish, Conduits: T wo 3/4 inch NPT feed-

Hazardous area

classification: NEMA 4X, Explosion Proof

Dimensions: 5.4 x 4.8 x 3.7 inches (13.7 x 12.2 x 9.4 cm)

Weight: 3 lbs (1.3 Kg)

o

F to 230oF(-55oC to 110oC)

120 VAC, 1.0 amp @ 24 VDC resistive, normally open and normally closed contacts,

latching or fire-following modes

Fire, Fault, V erify and Aux Relays

0.5 amp @ 120 VAC, 1.0 amp @ 24 VDC resistive, normally open and normally

closed contacts are available.

through hubs

Class I, Div. 1 and 2, Groups B, C, D, Class II and III, Div. 1 and 2, Groups E, F, G

7.0 LIMITED W ARRANTY

SIERRA MONITOR CORPORATION warrants its

products to be free from defects in workmanship or

material under normal use and service for two years

after date of shipment. SMC will repair or replace without charge any equipment found to be defective during

the warranty period. Final determination of the nature

and responsibility for defective or damaged equipment

will be made by SMC personnel.

All warranties hereunder are contingent upon proper use

in the application for which the product was intended

and do not cover products which have been modified or

repaired without SMC approval or which have been subjected to accident, improper maintenance, installation

or application, or on which original identification marks

have been removed or altered. This Limited Warranty

also will not apply to interconnecting cables or wires,

consumables (ie. calibration gases, batteries, sensors),

Model 3100 Series Flame Detector (11/04)

nor to any damage resulting from battery leakage.

In all cases SMC’s responsibility and liability under this

warranty shall be limited to the cost of the equipment.

The purchaser must obtain shipping instructions for the

prepaid return of any item under this warranty provision and compliance with such instruction shall be a

condition of this warranty .

Except for the express warranty stated above, SMC disclaims all warranties with regard to the products sold

hereunder including all implied warranties of merchantability and fitness and the express warranties stated herein

are in lieu of all obligations or liabilities on the part of

SMC for damages including, but not limited to, consequential damages arising out of/or in connection with

the use or performance of the product.

Page: 11

Page 15

Instruction Manual

APPENDIX A

Figure A-1: Model 3100 Series Exploded View

Page: 12

Figure A-2: Model 3100 Series Dimensions

Model 3100 Series Flame Detector (11/04)

Page 16

Instruction Manual

Figure A-3: Model 3100 Series Common Wiring Connections

Model 3100 Series Flame Detector (11/04)

Page: 13

Page 17

Instruction Manual

Factory jumpers

are used to set

NC or NO

connections

Figure A-4: Model 3100 Series (Enhanced) Wiring Connections

Page: 14

Model 3100 Series Flame Detector (11/04)

Page 18

APPENDIX B

T ABLES

B.1 Dip Switch Settings

B.1.1 Sensitivity

Sensitivity SW1 SW2 Level

20 Foot ON ON 4

40 Foot OFF ON 3

60 Foot ON OFF 2

80 Foot OFF OFF 1

B.1.2 Verify Control (3100-02, -03, -04 and -05 Models only)

Verify Description SW3 SW4 SW5

Level 0 V erify = Fire OFF OFF OFF

Level 1 Min. V erify (shorter) ON OFF OFF

Level 2 Min. V erify (shorter) OFF ON OFF

Level 3 Min. V erify (shorter) ON ON OFF

Level 4 Min. V erify (shorter) OFF OFF ON

Level 5 Min. V erify (shorter) ON OFF ON

Level 6 Max. Verify (longer) OFF ON ON

Level 7 V erify Disabled ON ON ON

Instruction Manual

B.1.3 Fire Output“Latching” Control

Fire Output Description SW6

Latching Alarm until Power down Reset OFF

Following Alarm until no fire (.5 to 10 sec.) O N

B.1.4 Verify Relay “Latching” Control (3100-02, -03, -04 and -05 Models only)

Verify Relay Description SW7

Latching Alarm until Power down Reset OFF

Following Alarm until no fire (.5 to 10 sec.) ON

B.1.5 Detector "Non-Latching" Control

SW6, SW7 and SW8 must be on for the detector to be "Non-Latching".

B.1.6 Factory Use Only

SW8 and SW9 must be in the OFF position for normal operation. They are used for factory

calibration and testing.

Model 3100 Series Flame Detector (11/04)

Page: 15

Page 19

Instruction Manual

B.2 Connectors

B.2.1 Fire Relay Connector

(J2) Fire Relay Description

Pin 1 (Left Most) & Pin 2 Normally Open Side of Relay

Pin 3 & Pin 4 (Middle) Common or Center Side of Relay

Pin 5 & Pin 6 (Right Most) Normally Closed Side of Relay

B.2.2 V erify and Aux. Fault Connector

(J3) V erify/Aux. Description

Pin 1 (Left Most) & Pin 2 Verify Relay Common Side of Relay

Pin 3 & Pin 4 V erify Relay NO or NC Side of Relay

Pin 5 Aux. Fault Relay Common Side of Relay

Pin 6 (Right Most) Aux. Fault Relay NO or NC Side of Relay

B.2.3 Fault Connector

(J4) Fault Relay Description (Normally Energized State)

Pin 1 (Left Most) Normally Closed Side of Relay

Pin 2 (Middle) Common Side of Relay

Pin 3 (Right Most) Normally Open Side of Relay

B.2.4 Power/Communications Connector

(J5) Power/Comm. Description

Pin 1 (Left Most) & Pin 5 Power (DC -)

Pin 2 & Pin 6 Communication RS 485 (-)

Pin 3 & Pin 7 Communication RS 485 (+)

Pin 4 & Pin 8 (Right Most) Power (DC +)

B.2.5 3100-06 Connectors

(J2) Connector Description

Pin 1 (Left Most) Power (DC -)

Pin 2 Communication RS 485 (-)

Pin 3 Communication RS 485 (+)

Pin 4 Power (DC +)

Pin 5 4-20mA Negative

Pin 6 4-20mA Positive

Pin 7 to Pin 8 Jumper (Right Most) Enables 4-20 mA

Page: 16

Model 3100 Series Flame Detector (11/04)

Page 20

Instruction Manual

B.3 V erify/Aux. Relay Configurations

Model # V erify Relay Aux. Relay

3100-02 Open Contacts Closed Contacts

3100-03 Closed Contacts Open Contacts

3100-04 Open Contacts Open Contacts

3100-05 Closed Contact Closed Contacts

B.4 Fault Table

Fault # Fault Label Description

1 Lens T est Fault UV sensors didn’t detect enough UV from the internal UV source.

2 Configuration Fault SW9 is “ON” or a failed program

3 Calibration Fault Device is out of calibration

4 Volt. Low Input Voltage is below 15 VDC

5 Photo. Sensor Fault IR or V isible sensor failed to detect internal test source.

6 Relay Fault Relay coil circuit is open.

7 Volt. High Input Voltage was above 32 VDC

8 Temp. Out of Range Internal device temperature went below -40° C or above 85° C.

B.5 False Alarm S timuli Table

F ALSE ALARM RESPONSE

This table shows the detectors ability to tolerate both modulated and unmodulated false alarm stimuli.

False Alarms Source Distance Unmodulated Modulated

Resistive Electric Heater 1320 W att 6 Feet No Response No Response

Fluorescent Lights (2) 40 W att Bulbs 6 Feet No Response No Response

Halogen Light 500 W att 10 Feet No Response No Response

Incandescent Light 100 W att 6 Feet No Response No Response

Arc W elder 50 Watt 25 Feet No Response No Response

Direct Sunlight 93 million miles No Response No Response

B.6 Fire and False Alarm Stimuli T able

Model 3100 detector response to a fire while exposed to a variety of radiant energy sources.

False Alarms Distance to False Distance Response Time to

Source Alarm Source to Fire Fire

Resistive Electric Heater 1320 W att 6 Feet 6 Feet Less than 5 sec.

Florescent Lights (2) 40 W att Bulbs 6 Feet 6 Feet Less than 5 sec.

Halogen Light 500 W att 10 Feet 6 Feet Less than 5 sec.

Incandescent Light 100 Watt 6 Feet 6 Feet Less than 5 sec.

Arc Welder 50 Watt 25 Feet 6 Feet Less than 5 sec.

Direct Sunlight 93 million miles 6 Feet Less than 5 sec.

Model 3100 Series Flame Detector (11/04)

Page: 17

Page 21

Instruction Manual

B.7 Detector Response to Fuels Table

Fuel Distance Fire Size Response Time

Heptane 80 Feet 1 Square Foot Less than 3 sec.

Silane 50 Feet 18 inch jet Less than 3 sec.

Hydrogen 15 Feet 18 inch jet Less than 5 sec.

Kerosene 75 Feet 1 Square Foot Less than 5 sec.

Page: 18

Model 3100 Series Flame Detector (11/04)

Page 22

APPENDIX C -- WIRING CONNECTIONS

Instruction Manual

Model 3100 Series Flame Detector (11/04)

Page: 19

Page 23

Instruction Manual

Index

A

Alarm

Mode 2, 4

Verified 2

Auxiliary

Relay 1, 2, 5, 6, 7

C

Cleaning 8

Conduit 7, 11

Configuration

Relay Control 4

Sensitivity 3

Switches 3, 4

Verify Control 4

Configuration Switches 5

Connection 7

Connector

Aux. 6, 7

Fault 6, 7

Fire 6, 7

Power 7

Verify 6, 7

Connectors 5, 16

T ype 1 1

D

Detector Module 7

F

Fault 5

Auxiliary 1, 6

Lens Test 1, 8

Relay 1, 2, 6, 7

Field-of-View 1, 3

Fire 5

Relay 1, 2, 4, 6, 7, 16

Testing 8

Verify 1

Fire Following 2, 4, 6

Fire Probability 2

H

Housing 1, 7

L

Latching 2, 4, 6, 15

LEDs 2, 4, 5, 20

Lens 8

Lens Test 1, 2

M

Mode

Alarm 2, 4, 5

Fault 5

Fire Following 2

Latching 2

Normal 2, 4

Verified Fire 4

N

Normal Mode 2, 4, 5

Normally Closed 2, 6, 7

Normally Open 2, 6, 7

P

Power 4, 7, 16, 19

R

Range 3

Relay 5

Aux. 2, 5, 6, 7, 17

Auxiliary 1

Control 4

Fault 1, 2, 6, 7

Fire 1, 2, 4, 6, 7

Fire Following 6

Latching 6

Normally Closed 2

Normally Open 2

Verify 4, 5, 6, 7, 17

S

Seal Off 7

Sensitivity 3

Field-of-View 1

Range 3, 15

Sensor 3

Square of the distance rule 3

Switches

Configuration 3, 4, 15

Sensitivity 3, 15

SW8, SW9 4

Verify Control 4, 15

I

Infrared 3

Page: 20

Model 3100 Series Flame Detector (11/04)

Page 24

T

Testing 8

U

Ultraviolet 3

V

Verified Fire 2, 4, 5, 6

Verify

Control 4

Relay 2, 4, 5, 6, 7, 15

Verify Control 6, 15

Versions 2

Visible 3

W

Wiring 7

Instruction Manual

Model 3100 Series Flame Detector (11/04)

Page: 21

Loading...

Loading...