Page 1

SENSORS: SIMPLE TO SMART TO SYSTEMS

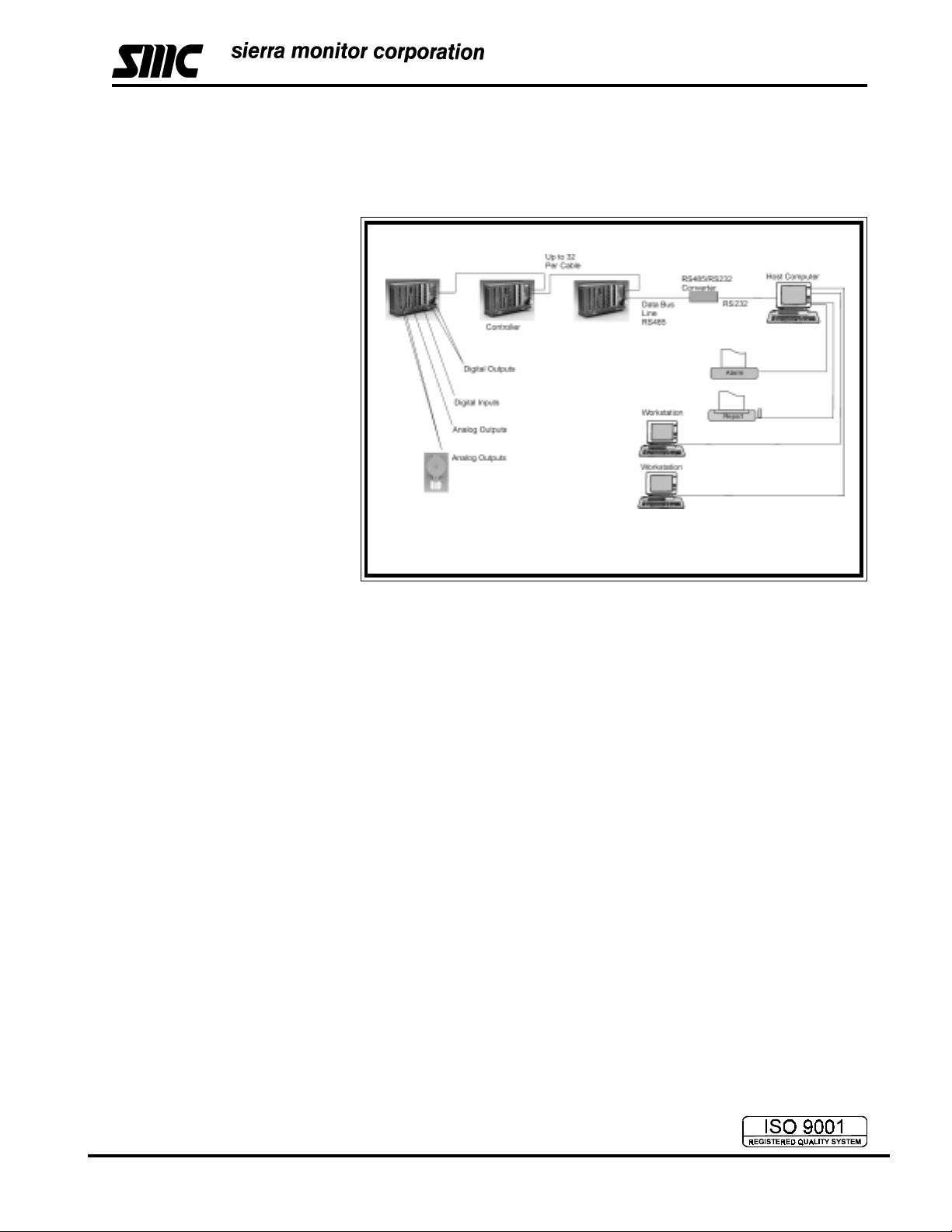

PC-based software plus an

intelligent remote controller

provide the flexibility to

configure sensor system

inputs, outputs, and data

acquisition to a plant’s

specific needs. The result

is greater visibility of plant

operations, allowing better

decisions to be made.

ensors are in our home,

S

transportation, and workplace

affect our safety , environment, and

productivity. You awoke this

morning in a warm room because a

sensor monitored the room

temperature. The car you drove to

work has sensors for temperature,

oxygen emissions, and more. Its

control panels are covered with

lights, gauges, and switches. Yet, conflicting data,

possible burned-out lights, and trying to read too many

gauges, lights and indicators repidly can make your job

difficult and prone to problems.

Sensors are the primary building blocks that provide the

vital function of acquiring data and transmitting it to

human operators. Just as sensors have permitted a

simplified way of flying commercial airlines, sensors

provide the necessary information for efficient and

effective operation of every process and facility .

Sensors must operate under diverse conditions, 24 hours

a day , 365 days a year . Some sensors are designed to

operate in extreme temperatures, pressures, flow, and

corrosive or hazardous conditions. Sensors development

incorporates specific industry needs, including hardened

sensors that are resistant to specific environmental

conditions, miniaturized sensors, disposable sensors,

and sensor systems. Purchasers of sensors must

consider the variables of their specific application. As

an example, purchasers of gas detection sensors must

consider the following when selecting a sensor for their

application: speed of response, measurement range,

accuracy , resolution, interfering gases, operating range

(temperature, humidity, pressure), temperature and

humidity effects, sensor life, ease of calibration,

calibration frequency , and replacement cost.

Figure 1. Typical field-mounted intelligent controller connected to

PC-based DCS.

Technical Reprint TR-004

Simple Sensors

Historically , sensors have been simple devices capable

of monitoring a specific variable. The human operator

reviews the data generated by these simple sensors and

determines what action needs to be taken. Limitations

include:

• All intelligence resides in the sensor controller;

• Communication from sensor to controller is

analog;

• Controllers typically are dedicated to specific

sensor types;

• Multiple sensors require multiple controllers;

• Calibration requires intrusive manual

adjustments of transmitters and a corresponding

adjustment of controllers.

Often, because of these limitations, operating decisions

are based on the input from only a few devices,

concerning a few parameters. Simple sensors generate

data but not information. The operator might be

concerned about data reliability if the sensor was overdue

for calibration, or if the data from a sensor was outside

the norm. The process can end in disaster due to

inaccurate data because of a burned-out bulb or a stuck

needle on a gauge.

Sierra Monitor Corporation 1991 T arob Court Milpitas, CA 95035 USA (408) 262-6611 (800) 727-4377 Fax: (408) 262-9042

Visit our website: www.sierramonitor.com E-mail: sierra@sierramonitor.com

Page 2

Smart Sensors

Smart or intelligent sensors improve the

communication from the sensor to

controller and improve the reliability of

sensor data by better signal processing.

Smart sensors use digital signals rather

than analog signals to transmit to the

controller. Digital signals provide the

opportunity for greater diagnostics and

data checking.

Smart sensor diagnostics involve

continuous checks to identify out-ofbounds system operating criteria. The

sensor accesses operating

characteristics, checks the operating

voltage, and continuously verifies that the

dynamic range of the sensor provides

adequate resolution. Warning messages

from the sensor identify items such as

low sensor sensitivity and low battery .

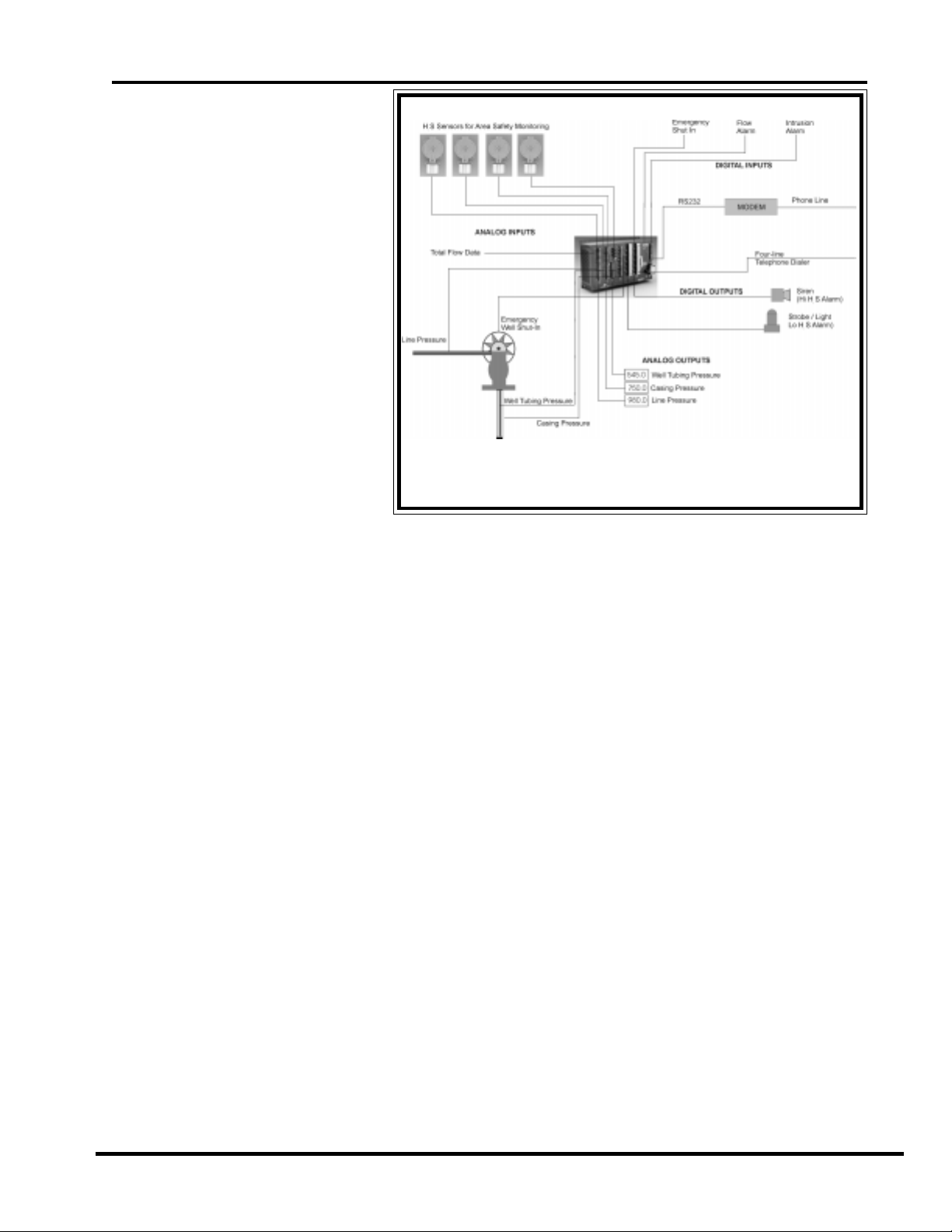

Figure 2. Typical sensor system at a wellhead accepts input from a variety of

sensors concerning safety, environment, process and security; performs

automatic control and alarm functions; and communciations to a central control

facility.

In addition, some smart sensors can deal

with detection of intangible properties

such as softness, freshness, sweetness, or aroma. New

smart sensors in the biological, medical and

pharmaceutical world can detect cholesterol and lipids.

In the industrial sector, smart sensors have enabled the

plant operator to obtain more reliable data.

Sensor Systems

But, more reliable data is still just waiting to be converted

into information. Sensor systems have significantly

improved operator efficiency by effectively and quickly

converting large volumes of data into useful information.

The operator needs input from a variety of sensors and

locations to make knowledgeable decisions. Today’s

more powerful sensor systems have the following

characteristics:

• Accepts input form various sensors (and various

manufactures);

• Provides local display of sensor readings;

• Allows for non-intrusive sensor calibration;

• Provides relays for local alarm action;

• Follows user-defined alarm strategy;

• Accepts feedback signals from final control

elements;

• Has independent battery backup;

• Is a low-cost link to the control room;

• Provides centralized monitoring.

Distributed intelligence is central to proper sensor system

design philosophy. Since the field controllers are

intelligent with the capability to implement alarm logic

and operate independently of the host computer,

interrupted communication with host computer does not

hamper field operation. In addition, sensor systems

provide the user with clear, understandable data that

enables the operator to analyze the situation quickly

and take the required action.

A sensor system not only provides the best features of

local control and centralized monitoring, but also

systemizes the entire monitoring process. The system

provides plant personnel with sufficient, reliable

information to ensure that decisions are made with

maximum knowledge of the current situation. Sensor

systems accept a wide range of sensor inputs, including

those with non-linear signals. The remote controller

conditions to signals, compares with data from various

inputs, and transmits the data to the control room.

Within the I/O controller, the input values are used for

equation processing, alarming, control, event sequencing,

and more. Complex control and logic algorithms and

parameters for each channel can be constructed and

modified by the operator.

Generally, all data from the system is accessible from

the control room via simple twisted pair cabling, telephone

lines, or radio signals. In the control room, the operator

can access data from a variety of sensors. Using PCbased software package combined with an intelligent

remote controller provides the user with the flexibility to

configure sensor system inputs, outputs, and data

acquisition to meet the plant’s specific needs. The result

is greater visibility of plant operations, allowing better

decision to be made.

© 1998 by Sierra Monitor Corporation

Sierra Monitor Corporation 1991 Tarob Court Milpitas, CA 95035 USA (408) 262-6611 (800) 727-4377 Fax: (408) 262-9042

Visit our Web site: www.sierramonitor.com E-Mail: sierra@sierramonitor.com

Loading...

Loading...