Page 1

The Sentry controller is the heart of the Sentry Gas Risk

Management system. It is a microprocessor based system that performs functions including management of the

sensor modules, management of alarm relays and interface with the user via the front panel display , printer output, Modbus digital communication, alarm indicators and

relay outputs.

Sentry system two-way communication between the sensors and the controller results in the capability to perform

one-person calibration and diagnostic checks from the

controller. The user-friendly front panel includes a large

display of the gas concentration and sensor number. V arious scan modes are available to meet the user’s specific

monitoring needs. A separate 2-line alphanumeric display provides more detailed information including sensor

data, error messages and menu prompting for calibration

and set-up.

Sentry

Controller

A series of alarm LEDs instantly inform the user of alarm

status on any of the eight sensors interfaced to the controller. These LEDs are solid for low alarm and flashing for

high alarm. A trouble LED warns that one of 120 diagnostic checks has detected a problem. More information about

the trouble will be displayed on the alphanumeric display .

A calibrate/change LED indicates that calibration or con-

figuration change is being performed on at least one sensor. The remaining sensors will remain on-line providing

continuous protection.

The Sentry keypad, together with the user-friendly menu

on the alphanumeric display , guides the user through setup, calibration and maintenance of the Sentry system.

Sierra Monitor Corp. 1991 T arob Ct., Milpitas, CA 95035, USA, 408-262-661 1, 800-727-4377, F AX: 408-262-9042

Web Site: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

© 2009 by Sierra Monitor Corporation

Page 2

FEATURES AND BENEFITS

Sentry Controller

Gas Risk Management is the key design philosophy behind SENTRY. The user can employ those features that

are most important for a specific application, and, as the

application needs grow or change, the system can be

reconfigured at the keyboard to satisfy expanded requirements.

Menu Prompting

Menu prompting guides the user through system configuration and operation.

Prompting, via the alphanumeric display , keeps the full

range of capabilities at the

operator’s fingertips. When

it is necessary to modify the

system, prompting will enable the change to be handled

quickly and correctly .

USE ARROWS/ENTER

HIGH ALARM = 20

System Security

User identification codes prevent unauthorized users from

changing the configuration and identify those

users who have made

changes. Up to eight

user codes may be as-

USE ARROWS/ENTER

ENTRY CODE = 1234

Diagnostics

An internal self-diagnostic routine makes over 120 checks

of operating parameters to ensure the system is performing properly. System performance measurements and key

reference voltages can be accessed and presented at the

switches automatically to display those sensors in alarm. HIGH-

EST sensor scan will automatically display the sensor recording the highest gas reading - alternately for each gas type. The

user can also SELECT SENSOR displays for a sensor of particu-

lar interest.

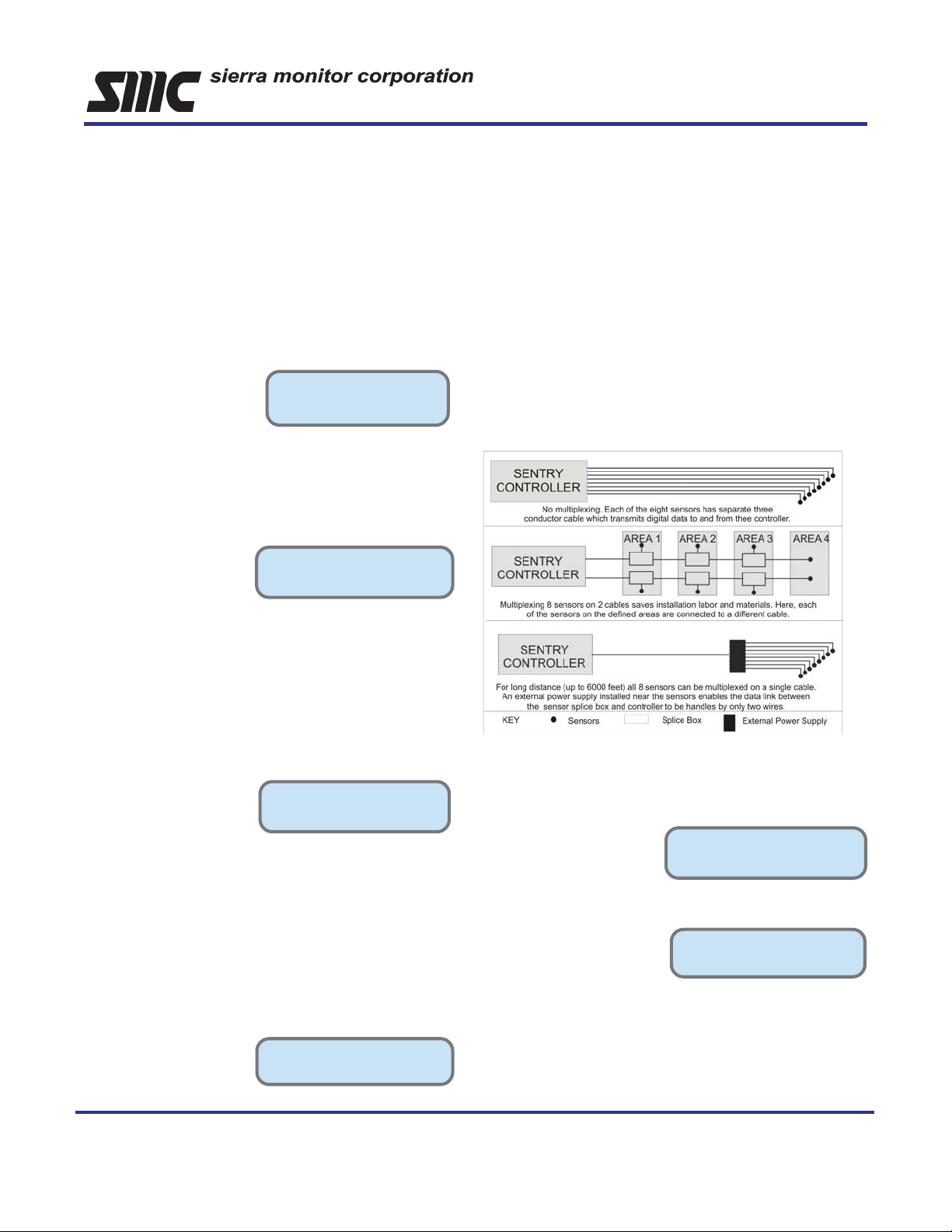

Reduced Installation Costs

Multiplexing of digital signals from the sensors to the controller

on a common cable reduces installation cost. Up to eight sensors can be multiplexed on a single cable. Since each sensor

has a unique address, the controller can communicate with the

sensors in turn. Also, with optional external power supplies to

the sensors, two-wire communication with the controller reduces

the installation costs and increases the distance allowed between the controller and the sensor modules.

A TEST function on the front panel allows testing of the

alarms, system and display. Warning messages on the

alphanumeric display

alert users that a condition

requires attention without

causing a system failure

or interruption.

During calibration Sentry performs a dynamic range check

on every sensor to insure its resolution is sufficient to give

an accurate reading. Sentry avoids false alarms by locking

out sensor alarms during calibration and not allowing excessive amplification of the signal.

COMB. % LEL

FAST ERROR CHECK

Sensor Scan Display

Current sensor gas exposure readings can be viewed continuously in any one of four scan modes. CONTINUOUS

scan displays each sensor in turn.

SAFE scan mode displays

CONDITION SAFE and,

upon an alarm condition,

CONDITION

[SAFE]

Record Keeping made Easy

Reports can be printed via an optional forty-column printer. There

are six types of reports available.

Status Report – a snap–

shot of gas concentrations

and alarm conditions that

can be pre-set to print hourly,

daily, weekly or on demand.

PRESENT CONFIG .:

ST A TUS = 07 DA YS

System Report – lists all

the system parameters including configuration of the software, calibration, printer and

sensor modules.

PRESS ENTER TO:

[SYSTEM REPORT]

Key Event Report – prints when any sensor module read-

ing exceeds a pre-set threshold level, which may or may not be

an alarm level. After the module is above the minimum level,

any change greater than a preset, selectable concentration

change will cause another Key Event Report to print.

Sierra Monitor Corp. 1991 T arob Ct., Milpitas, CA 95035, USA, 408-262-661 1, 800-727-4377, F AX: 408-262-9042

Web Site: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

© 2009 by Sierra Monitor Corporation

Page 3

Sentry Controller

History Report – lists the last time each significant event

has occurred. Includes

system power interruption, history reset, alarm,

concentration and calibration information for

each sensor module.

USE ARROWS/ENTER

PRINT HISTORY : YES

Calibration Report – prints automatically when calibra-

tion is completed.

Diagnostic Report – lists the critical voltage conditions

for each module and can

be selected to print periodically.

H2S PPM

DIAGNOSTIC SCAN

Relay Logic for Customized Response

Standard Relays- the controller has DPDT dry contact

relays for low alarm, high alarm, and trouble. Any one sensor

can activate the appropriate relay.

Individual Relays – If separate relay action is required for

each sensor, then the individual relay option is appropriate.

This option provides individual SPDT dry contact relays for

each alarm level for all sensor modules.

Options to Expand System Flexibility

Battery Back-Up

The battery back-up system provides operating power when

AC power drops below 90 V AC. Includes battery, AC line filter,

two battery charging modes, and a 12 to 24 VDC converter.

Sensor Modules

Sensor modules available for a wide range of gases;

Combustible Gas* Sulfur Dioxide

Oxygen* Nitrogen Dioxide

Hydrogen Sulfide* Hydrogen Chloride

Carbon Monoxide* Hydrogen Cyanide

Chlorine* Ammonia*

Hydrogen Nitric Oxide

Hydrogen Fluoride Methane / Propane

* Refer to IT Series Data Sheet

Analog Input

The analog input modules, 5100-90 and 5100-99 enable the

user to use any sensing device that produces a 4-20 mA DC

signal to communicate with Sentry through an Analog/Digital

signal converter.

Output Expansion Module

The output expansion module provides the same capacity as

the individual Relay Panel, plus it provides 4-20 mA DC outputs proportional to the concentration for each sensor module.

Custom Configuration Relays – the custom configu-

ration relay option permits decision logic before actuating the

relays. Any group of sensors in the same vicinity can actuate

the relay designated for that vicinity (zone).

Software Enhancement Package

The Software Enhancement Package provides the Sentry system with powerful software features by selecting from a menu

of factory set options. These features include:

• MODBUS protocol

Provides the MODBUS protocol software to interface with

a wide variety of third party software. (Other protocols

avalibale)

• Factory Edit Gas Tags and Module Tag

The tags normally selected by the user can be built-in

as default tags

• Enhanced alarm acknowledgment features

Provides high and low alarm acknowledgement and an

emergency alarm (third alarm) feature

Calibration Systems

Calibration gas can be delivered from a central panel through

permanently installed tubing to the sensors. Since Sentry’s

calibration adjustment is performed in software, it is not necessary to make mechanical adjustments at the sensor. Alternatively individual gas delivery lines can be located near the

sensors.

Sierra Monitor Corp. 1991 T arob Ct., Milpitas, CA 95035, USA, 408-262-661 1, 800-727-4377, F AX: 408-262-9042

Web Site: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

© 2009 by Sierra Monitor Corporation

Page 4

MODE

EXPLOSION-PROOF

ACDCT

C

POWER

OR CHANGE

CALIBRATE

S

MODEL

T

T

8

SENTRY

M

INSIDE VIEW

INSTRUMENT RACK

GENERAL SPECIFICATIONS

Sentry Controller

Operating

Power (Standard): 120VAC+10%/-15%, 60 Hz

12 VDC Nom; 10 to 29 VDC

Power (Optional): 220 VAC +10%-15%, 50 Hz

12 VDC Nom; 10 to 29 VDC

Power consumption: 48-Watts nominal

Number of Channels: 2, 4 or 8

Operating Temperature: 320 to 1220 F (00 to 500 C)

0

Storage Temperature: -40

Humidity: 10% to 95% RH

Relays (Standard): Three DPDT 3A, 1 15 V A C

(Ind. Relay Option): 16 SPDT 6A, 115 VAC

(Custom Relay Option): 16 SPDT 6A, 1 15 V AC

(Output Expansion): 16 SPDT 6A, 115 VAC

Analog Outputs: 4-20 mA Current Source

Displays: 4 digit ½” LCD

RS-232 Port: Standard Printer

to 1310 F (-400 to 550 C)

Loop Resistance 800 Ohms Max.

32 character (2x16)

alphanumeric LCD

Option MODBUS

Physical

Dimensions:

Rack Mounted: 7.0” x 4.5” x 12.0” (HxWxD)

17.5 x 1 1.2 x 30.0 cm

NEMA 4X Enclosure: 17.5” x 16.2” x 6.3” (HxWxD)

44.5 x 41.1 x 16.0 cm

NEMA 7 Enclosure: 22.0” x 21.5” x 14.0” (HxWxD)

55.9 x 54.6 x 35.6 cm

Weight:

Rack Mounted: 7.0 pounds (3.2 kg)

NEMA 4X Enclosure: 25.0 pounds (11.3 kg)

NEMA 7 Enclosure 143.0 pounds (65.0 kg)

Approvals: FM Approved, CE Mark

Mounting

Rack Mounted: Shelf for insertion in

Instrument Cabinet

Panel Mounted Panel bracket, bezel

NEMA 4X Enclosure: Wall or vertical surface

NEMA 7 Enclosure: Explosion Proof, Class 1, Div I,

Group C & D

SENSOR LEVEL

TROUBLE

8 88

INFORMAT ION

DISPLAY

ENSOR ALARMS

12345678

FLASH=HI GH SOLID=LOW

ESTMODE

IMEENTERRESET

ilpitas, CA 950 35

ROUBLETROUBL E HIGH HIGH LOW LOW

H N G + - N/C C N/O N/OCN/C N/OCN/C N/OCN/C N/OCN/C N/OCN/C

PSG GSPGSPGSPGSPGSPGSPGSP

HANNEL 1CHANNEL 2CHANNEL 3CHANNEL 4CHANNEL 5CHANNEL 6CHANNEL 7CHANNEL 8

5000

CALIBRATE

OR CHANGE

LEVELSENSOR

POWER

TROUBLE

SENTRY

SENSOR ALARMS

SOLID=LOWFLASH=HIGH

TEST

RESET TIME ENTER

87654321

NEMA 4X NEMA 7

ORDERING INFORMATION

5000-02 Sentry 2-channel Controller*

5000-04 Sentry 4-channel Controller*

5000-08 Sentry 8-channel Controller*

4314-01 Output Expansion Module

5392-00 Individual Relay Panel

5392-01 Custom Configuration Relay Panel

5398-50 Software Enhancement Package

5398-21 Sample Draw System –1 Channel

5398-24 Sample Draw System –4 Channel

5301-XX Printer Packages

5100-02 Sensor Module – Combustible Gas*

5100-03 Sensor Module – Oxygen*

5100-04 Sensor Module – Carbon Monoxide*

5100-05 Sensor Module – Hydrogen Sulfide*

SWITCHES

PRINTER

RACK MOUNT

5100-06Sensor Module – Chlorine*

5100-07Sensor Module – Hydrogen

5100-10Sensor Module – Sulfur Dioxide

5100-12Sensor Module – Nitrogen Dioxide

5100-16Sensor Module – CO (H

5100-19Sensor Module – Nitric Oxide

5100-21Sensor Module – Hydrogen Chloride

5100-22Sensor Module – Hydrogen Cyanide

5100-25Sensor Module – Ammonia*

5100-26Sensor Module – Hydrogen Fluoride

5100-28Sensor Module – Methane*

5100-90Analog/Digital Input Module (8-channel)

5100-99Analog/Digital Input module (1-channel)

* Refer to IT Series Data Sheet

tolerant)

2

Sierra Monitor Corp. 1991 T arob Ct., Milpitas, CA 95035, USA, 408-262-661 1, 800-727-4377, F AX: 408-262-9042

Web Site: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

© 2009 by Sierra Monitor Corporation

Loading...

Loading...