Page 1

Model

954 4-Channel MFC Power Supply/Controller

INSTRUCTION MANUAL

954

October

Sierra Instruments, Inc., Headquarters

Sierra Europe, European Headquarters

Sierra Asia, Asia-Pacific Headquarters

Page 2

TABLE OF CONTENTS

PRODUCT DESCRIPTION ------------------------------------------------------------------------------

SPECIFICATIONS -----------------------------------------------------------------------------------------

FRONT PANEL ---------------------------------------------------------------------------------------------

REAR PANEL -----------------------------------------------------------------------------------------------

CONNECTOR PIN DESIGNATIONS

Transducer Connector (J1, J2, J3, J4) ---------------------------------------------------

Analog Output (J5) ----------------------------------------------------------------------------

Alarms (J8) --------------------------------------------------------------------------------------

RS232 (J6) --------------------------------------------------------------------------------------

RS485 (J7, J9) ---------------------------------------------------------------------------------

Model 954 Configuration ------------------------------------------------------------------

STARTUP ----------------------------------------------------------------------------------------------------

MANUAL SETUP

Selecting Display (Flow or Total) ----------------------------------------------------------

Selecting Valve Override (Open, Close or Run) ---------------------------------------

Selecting Setpoint (Control Voltage) -----------------------------------------------------

Selecting Units of Measure and Gas Identifiers --------------------------------------

Selecting Filter (-3dB A/D Converter Filter Frequency ------------------------------

Selecting Input (0-5Vdc, 0-10Vdc or 4-20mA Signal Input -------------------------

Selecting Alarms (High and Low with Hysteresis) ------------------------------------

Selecting Ratio (Master/Slave Operation) ----------------------------------------------

MANUAL CAL/RANGE

Calibrate (Zero Only) -------------------------------------------------------------------------

Calibrate (Range Only) ----------------------------------------------------------------------

Calibrate (Zero & Range) -------------------------------------------------------------------

Range (Changing Range) ------------------------------------------------------------------

Calibrate (Multiplier) --------------------------------------------------------------------------

RS232/485 HOOKUP ------------------------------------------------------------------------------------

RS232/485 COMMANDS

Setting/Reading Setpoint & Flow Alarms -----------------------------------------------

Setting/Reading Alarm Hysteresis, Units of Measure & Gas ID ------------------

Setting/Reading Signal Input & Filter ----------------------------------------------------

Setting/Reading Multiplier ------------------------------------------------------------------

Setting/Blanking/Reading Display --------------------------------------------------------

Resetting Total ---------------------------------------------------------------------------------

Setting/Reading Range Value -------------------------------------------------------------

Enable Master/Slave Channels & Setting Local/Remote Operation -------------

UNITS OF MEASURE TABLE -------------------------------------------------------------------------

GAS IDENTIFICATION TABLE

Gas #1 thru 66 --------------------------------------------------------------------------------

Gas #67 thru 130 -----------------------------------------------------------------------------

Gas #131 thru 180 ---------------------------------------------------------------------------

APPENDIX A, PCA SCHEMATIC DRAWING

1

2

3

4

5

5

6

6

6

6B

7

9

9

10

10

11

11

12

13

14

14

15

15

16

17

18

19

20

21

21

22

22

22

23

24

25

26

Page 3

PRODUCT DESCRIPTION

The Model 954 is a high performance, microprocessor-based 4-channel power

supply/controller designed for use with Mass Flow Controllers (MFC) or Mass Flow Meters

(MFM).

A linear regulator provides a low noise, foldback current limited, thermal overload protected

+15Vdc and -15Vdc power supply for each of the (4) Channels. The Model 954 accepts

user selectable 0-5Vdc, 0-10Vdc or 4-20mA input signals. It also supplies 0-5Vdc, 0-10Vdc

or 4-20mA setpoint signals, for each channel, for flow control in MFCʼs.

The firmware utilizes a Real Time Operating Sytem (RTOS) for real time multitasking

capabilities. This allows continuous monitoring of each channel's flow rates, total flow and

setpoints regardless of the task being performed. A 16-bit multi-channel, high speed,

sigma-delta analog-to-digital converter provides accurate flowrate data. A 32K x 8 battery

backed RAM stores more than 90 Units of Measure and 190 Gas Identifiers selectable by

the user. All pertinent data, required by the microprocessor at power-up to re-initialize the

system, is also stored in the same RAM.

The Model 954 utilizes a 4-line by 20 character back lighted LCD display. A built in

Totalizer, for each channel automatically recognizes the units of measure selected and

adjusts the time base for the integrator accordingly. The user can select either Flow or

Total to be displayed for each channel. When selected, the setpoint signal is displayed and

can be altered via the front panel switches. Override controls for opening or closing the

MFC valves are also available for each channel. Annunciator LED's display the selected

valve override conditions.

Ratio control is user selectable for master/slave operation. Channel 1 is always the master

and any of the other 3 channels may be selected as slaves. This master/slave

arrangement utilizes the actual flow of Channel 1 as the master signal.

Both RS232 and RS485 serial communications are available. All functions selectable from

the front panel switches are also accessible via the RS232/RS485 serial ports. Only one,

either RS232 or RS485, serial port is active at any one time. Selection, including a baud

rate of 9600 or 19.2K, is made via the front panel switches.

Each flow channel has a high and low user programmable alarm. The alarms activate an

opto-isolated open collector transistor output capable of switching 25Vdc @ 10ma.

The unit can be rack mounted using standard half-rack hardware or can be bench mounted

using the retractable stand provided. Input power is selectable, via the rear panel power

selector for 100, 115 or 230 Vac, 50-60 Hz.

PAGE 1

Page 4

SPECIFICATIONS

Signal Input

Number of Channels ----------------------- Signal Type ----------------------------------- Input Resistance

Voltage -------------------------------- Current ---------------------------------

Setpoint Output (Control Signal)

Signal Type ------------------------------------ Accuracy (typ) ---------------------------------

Analog-to-Digital Converter

Inputs ------------------------------------------- Technique ------------------------------------- Resolution ------------------------------------- Speed (max) -----------------------------------

Totalizer (Each Channel)

Technique ------------------------------------- Time Base (Quartz Crystal) -------------- Accuracy (typ) --------------------------------

4

0-5Vdc, 0-10Vdc, 4-20mA , user selectable

>10 Megohm

120 ohms

0-5Vdc, 0-10Vdc, 4-20mA (user selectable)

+/-0.05% FS (Voltage), +/-0.1% FS (Current)

4

Sigma-Delta

16-bit (bi-polar)

100 Hz

Integrated (Riemann Sum) Value

20MHz

+/- 30ppm

Microprocessor

Type -------------------------------------------- Speed ------------------------------------------ Operating System --------------------------- Non-volatile memory ------------------------

Serial Communications

RS232 ------------------------------------------ RS485 ------------------------------------------ Baud Rate --------------------------------------

Transducer Power Supply (Each Channel)

Voltage ----------------------------------------- Current (min) --------------------------------- Current (max) ----------------------------------

Input Power

Voltage ----------------------------------------- Current (typ) ---------------------------------- Fuse ---------------------------------------------

80C31

20MHz

RTOS with multitasking capabilities

32K x 8 Battery backed Ram

Bi-directional (user-slectable)

Full-duplex (user-selectable)

9600 or 19.2K baud (user-selectable)

+/-15Vdc, +/-0.75Vdc

250mA

400MA

100/115/230 Vac, +/-10% (switch selectable)

500 mA

1 amp SLO BLO (Time Delay)

PAGE 2

Page 5

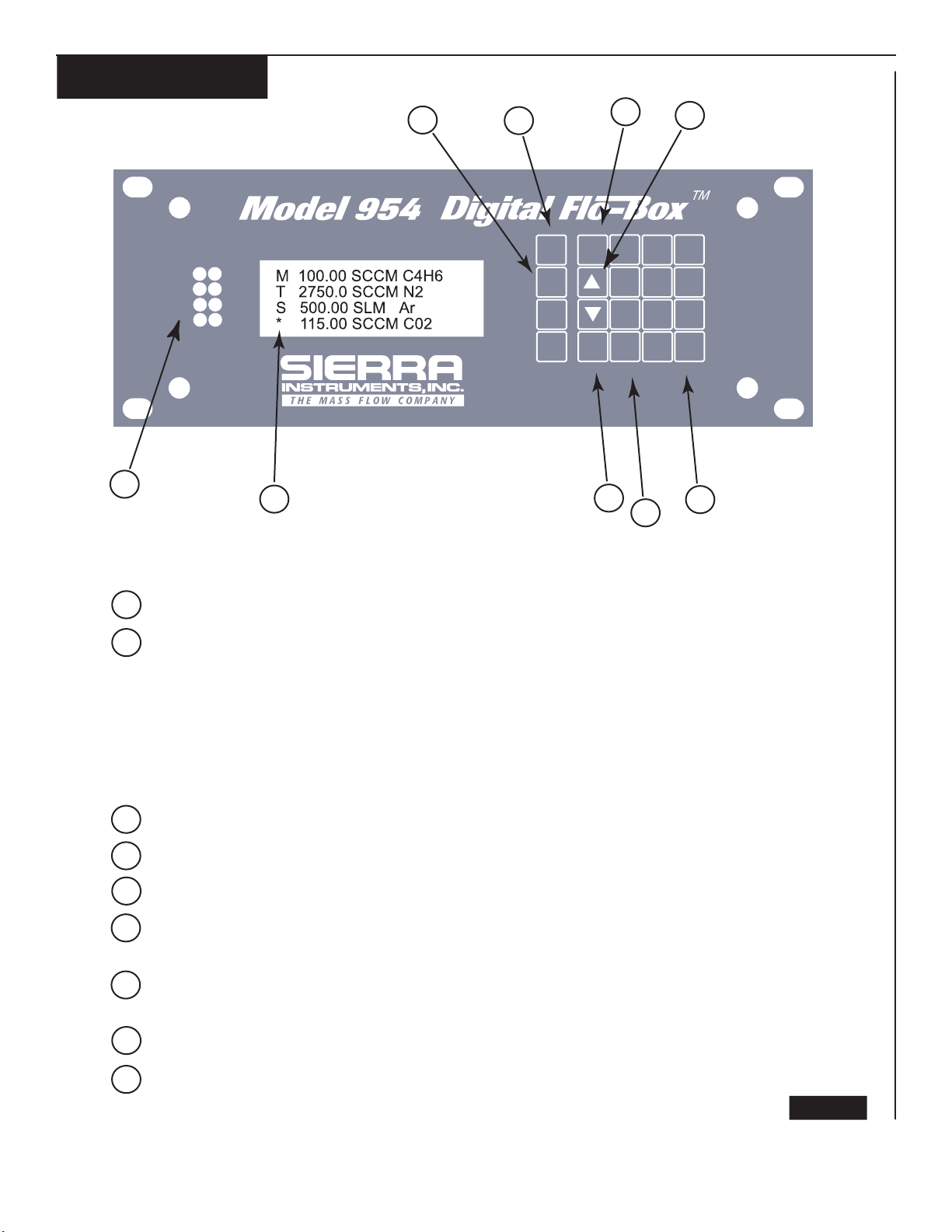

FRONT PANEL

OPEN

CLOSE

CH1

CH2

CH3

CH4

MENU

ESC

8

1

4 5

7

ENTER

6

7

CH

SELECT

PURGE

CLOSE

RUN

2 3

8 9

0

9

6

.

1

2

3

5

4

ANNUNCIATORS: Displays OVERRIDE signal status of each channel. If annunciators are not

illuminated, the Setpoint (Control) voltage is active.

DISPLAY AREA

Column 1: Reserved for displaying (*) Active Channel, (M) Master Channel, (S) Slave Channel or (T) totalizer.

Column 2: Reserved for polarity indicator (minus sign for negative signal, none for positive).

Col's 3 - 8: Actual scaled value of input signal. Displays FLOW or TOTAL in normal display mode. Displays

the Setpoint (Control) value when CH SEL is depressed.

Column 9: Space

Col's 10-14: Units of Measure

Column 15: Space

Col's 16-20: Gas Identifier

ESC: Escape key used to exit MENU sequence without updating current settings.

ENTER: Key used to enter new settings.

KEYPAD: Used to quickly enter new settings.

OVERRIDE: Used with CH SEL to override Setpoint (Control) voltage inputs with valve OPEN or valve

CLOSE signals. RUN disables OPEN or CLOSE selection.

CH SEL: Used to scroll through Channels 1, 2, 3 and 4 to update the selected Channel's

Setpoint (Control) voltage or to send the selected OVERRIDE signal.

MENU: Key used to enter MENU or manual setup sequence.

1

2

3

4

5

6

7

8

SCROLL: Used to scroll MENU selections UP or DOWN

9

PAGE 3

Page 6

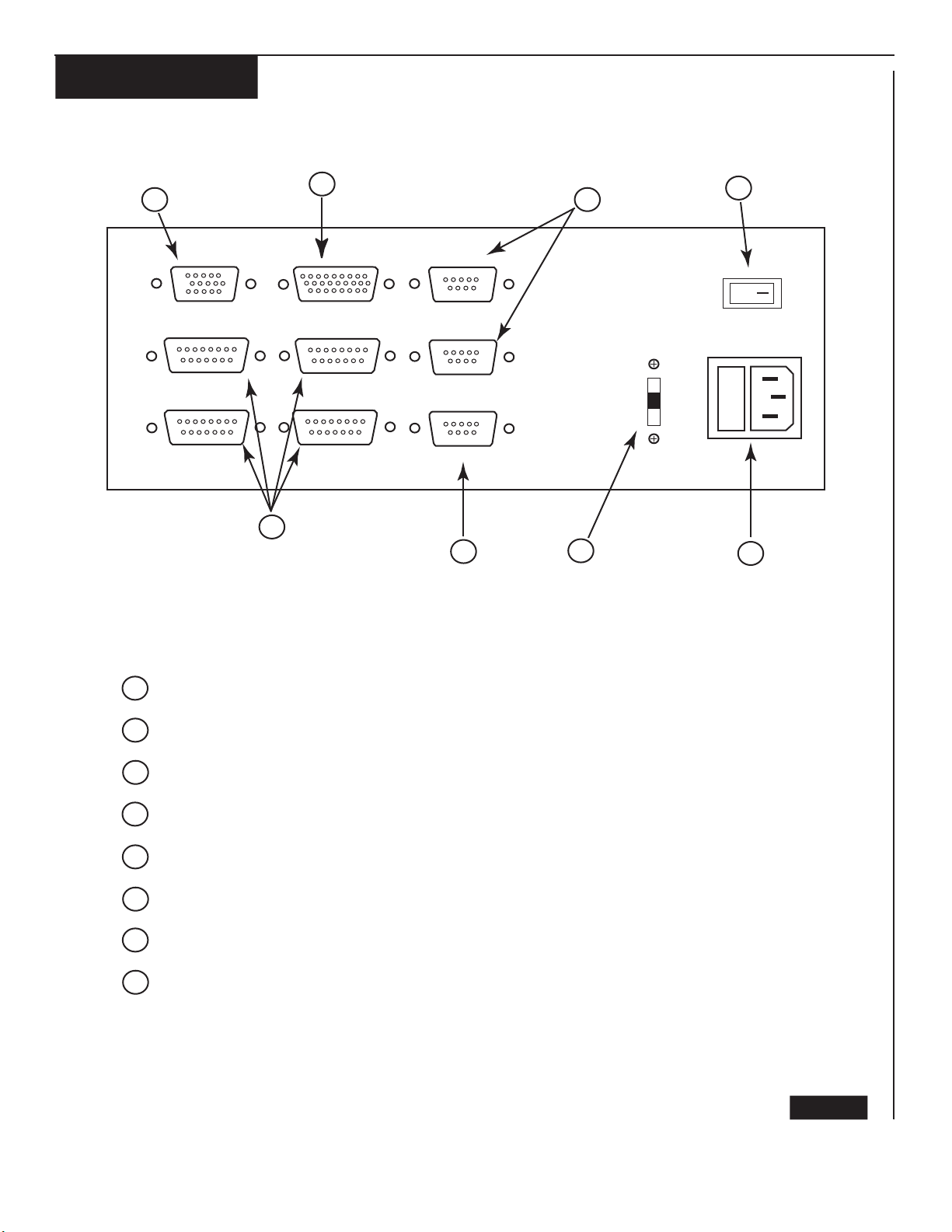

REAR PANEL

5

5

10

15

ANALOG OUT

8

15

CHANNEL 1

8

15

CHANNEL 3

6

7

J5

1

6

11

J1

1

9

J3

1

9

J8

9

18

26

ALARMS

J2

8

15

CHANNEL 2

J4

8

15

CHANNEL 4

1

10

19

1

9

1

9

5

RS485

5

RS485

5

RS232

J9

1

69

J7

1

69

VAC

230

J6

1

69

115

100

8

O

T250 1A

4

3

2

1

POWER INLET WITH FUSE (1 amp TIME DELAY or SLO BLO)

1

2

POWER SELECTOR SWITCH

3

RS232 SERIAL PORT (J6)

TRANSDUCER CONNECTORS (J1, J2, J3, J4)

4

ANALOG OUTPUT (J5)

5

6

ALARMS (J8)

RS-485 SERIAL PORT (J7, J9)

7

POWER ON/OFF SWITCH

8

PAGE 4

Page 7

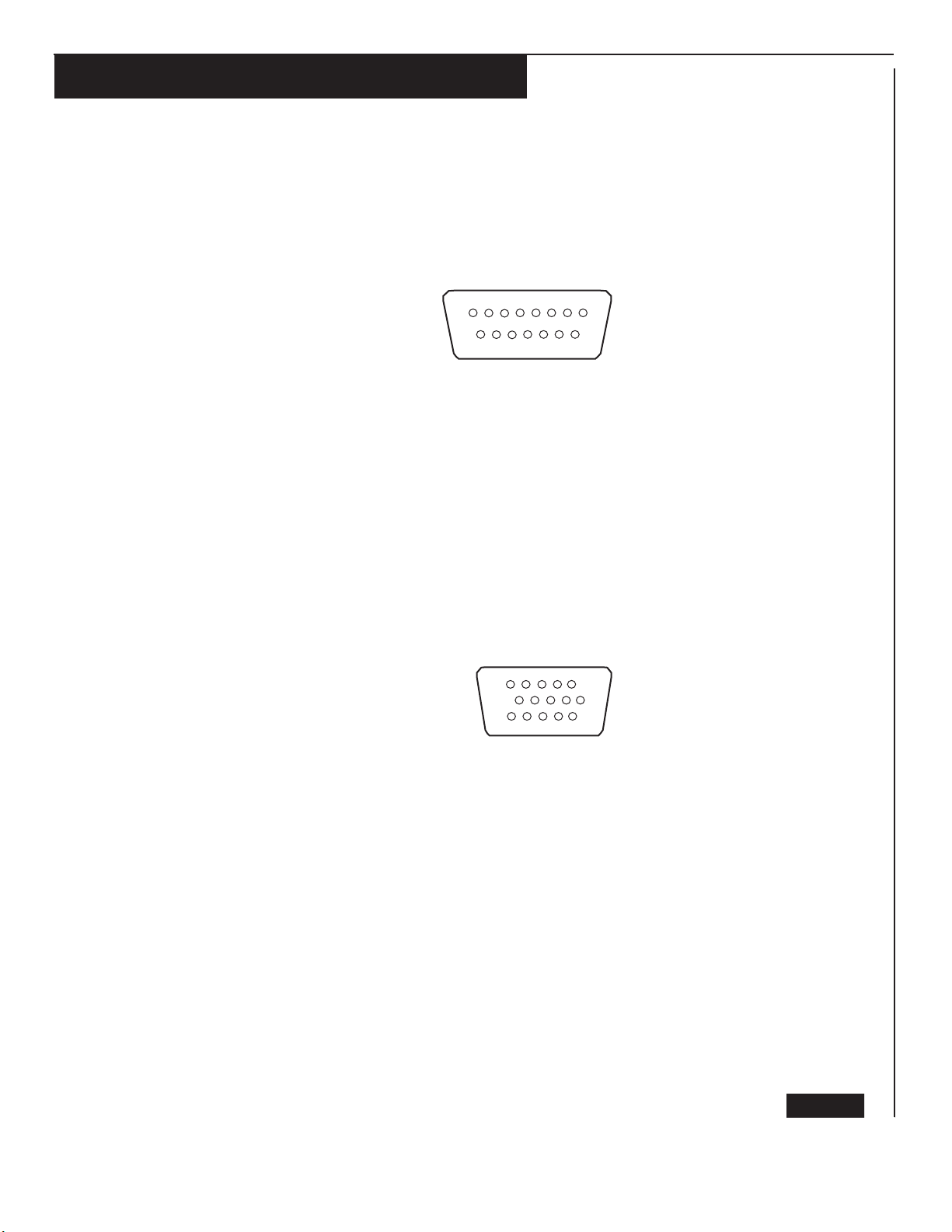

CONNECTOR PIN DESIGNATIONS

TRANSDUCER CONNECTORS (J1, J2, J3, J4)

1 SIGNAL COMMON

2 SIGNAL INPUT

3 GROUND

4 VALVE OPEN

5 GROUND

6 -15Vdc

7 NC

8 SETPOINT SIGNAL

9 GROUND

10 GROUND

11 NC

12 VALVE OFF

13 +15Vdc

14 NC

15 CHASSIS GROUND

8

15

Transducer Connector (Female)

Rear Panel View

1

9

ANALOG OUTPUT (J5)

1 SIGNAL CH 1

2 SIGNAL COMMON CH 1

3 SIGNAL CH2

4 SIGNAL COMMON CH2

5 NC

6 NC

7 NC

8 NC

9 NC

10 NC

11 SIGNAL CH3

12 SIGNAL COMMON CH3

13 SIGNAL CH4

14 SIGNAL COMMON CH4

15 NC

5

10

15

Analog Output Connector (Female)

Rear Panel View

1

6

11

PAGE 5

Page 8

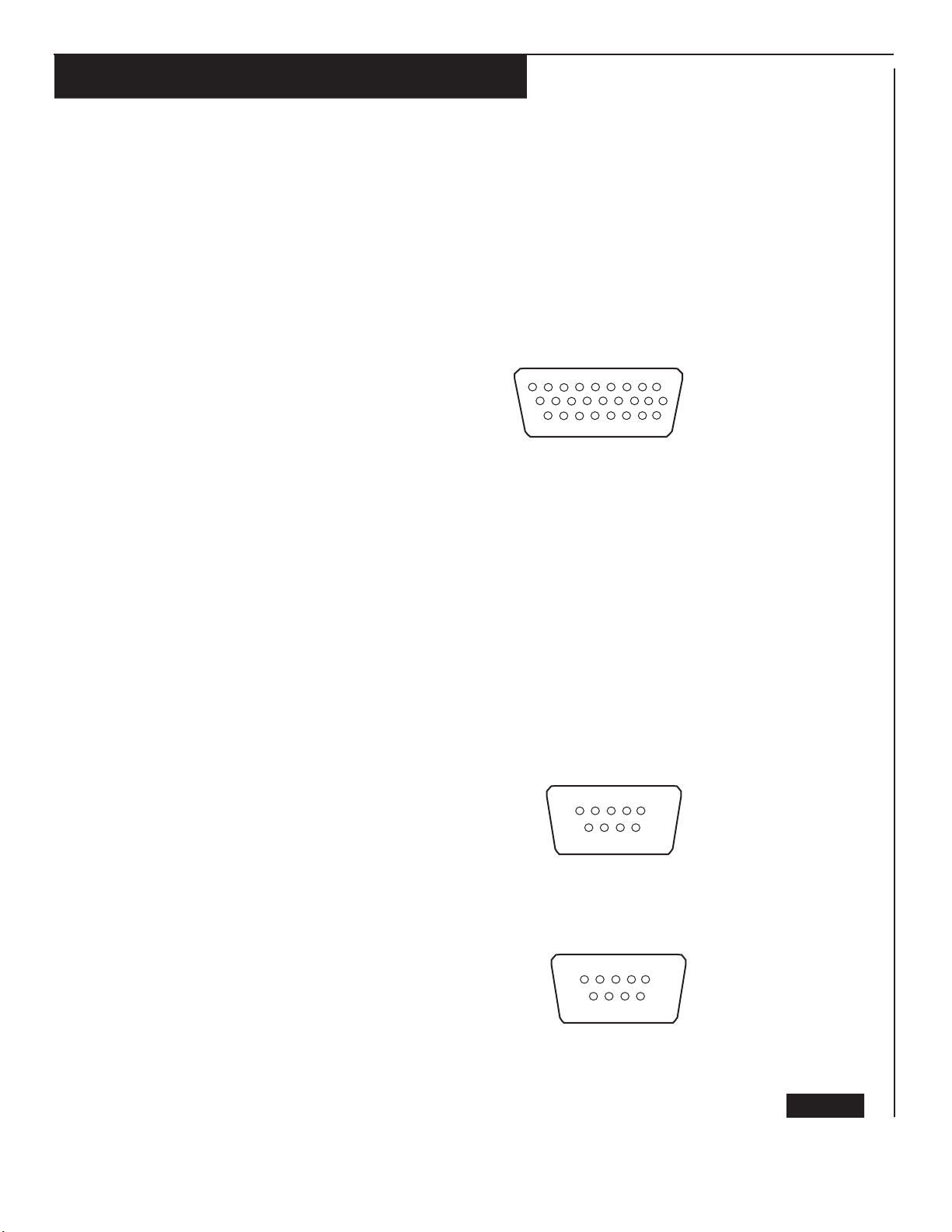

CONNECTOR PIN DESIGNATIONS

ALARMS (J8)

1 CH1 HIGH ALARM

2 CH 1 LOW ALARM

3 CH1 ALARM COMMON

4 CH2 HIGH ALARM

5 CH2 LOW ALARM

6 CH2 ALARM COMMON

7 NC

8 NC

9 NC

10 NC

11 NC

12 NC

13 NC

14 NC

15 NC

16 NC

17 NC

18 NC

19 CH3 HIGH ALARM

20 CH3 LOW ALARM

21 CH3 ALARM COMMON

22 CH4 HIGH ALARM

23 CH4 LOW ALARM

24 CH4 ALARM COMMON

25 NC

26 NC

9

18

26

Alarm Connector (Female)

Rear Panel View

1

10

19

RS232 (J6)

1 NC 6 DSR

2 RXD 7 NC

3 TXD 8 NC

4 DTR 9 NC

5 DIGITAL GROUND

RS485 (J7, J9)

1 NC 6 NC

2 RXD(-) 7 RXD(+)

3 TXD(+) 8 TXD(-)

4 DIGITAL GROUND 9 NC

5 NC

5

RS232 Connector (Female)

Rear Panel View

5

RS485 Connector (Female)

Rear Panel View

1

69

1

69

PAGE 6

Page 9

MODEL 954 CONFIGURATION

As Sierra Instrument supplies mass flow instruments with two different valve circuits (15 Vdc and 30 Vdc),

our Model 954 is designed to accommodate both types. This is accomplished by moving 4 jumpers

(one per channel) on the Model 954 PCA (inside the housing). Please refer to the PCA schematic in

Appendix A for the location of these jumpers. All Model 954 units come factory set for 15 Vdc valve circuit

operation (unless ordered new with a 30 Vdc instrument).

Determining which valve circuit you have inside your Sierra flow instrument.

The following Sierra instruments have 15 Vdc valve circuits:

All Model 830 mass flow meters

All Model 840 mass flow controllers with plastic electronics cover

All Model 840 mass flow controllers with full-scale flow below 1.0 slpm

Model 840L mass flow controllers with metal electronics cover having a plug in the rear of the cover (upper right)

The following Sierra instruments have 30 Vdc valve circuits:

All Model 840M mass flow controllers

Model 840L Mass flow controllers with metal electronics cover having a screw in the rear of the cover (upper right)

The following Sierra instruments should never be used with the Model 954:

Any 840H mass flow controller. Contact Sierra Instruments for information on operating the Model 840H.

Jumper verification and adjustment

Select which one of the Model 954ʼs four channels is to be used with each of your instruments.

With the power disconnected, remove the top 2 large screws on the rear of Model 954. With the screws

removed, carefully slide the top cover to the rear exposing the PCA inside (see Appendix A for PCA

schematic). Locate the jumpers numbered 3 to 10. They are selected as follows:

Jumper position 3 Channel 1 30 Vdc valve

Jumper position 4 Channel 1 15 Vdc valve

Jumper position 5 Channel 2 30 Vdc valve

Jumper position 6 Channel 2 15 Vdc valve

Jumper position 7 Channel 3 30 Vdc valve

Jumper position 8 Channel 3 15 Vdc valve

Jumper position 9 Channel 4 30 Vdc valve

Jumper position 10 Channel 4 15 Vdc valve

Move the jumpers if needed, close the cover, replace the 2 screws.

PAGE 6B

Page 10

START-UP

The Model 954 has a 100 Vac, 115 Vac or 230 Vac, 50/60 Hz power selector switch located at the rear of the

instrument. Please refer to page 4 to locate this switch. Verify the power selector switch is in the proper position

prior to connecting the power cable to the unit. Verify power ON/OFF switch is in the OFF position. Then perform

the following steps.

1. Connect the power cable to the instrument and apply the proper input power. Do not make any other

connections to the instrument.

2. Turn power ON/OFF switch ON.

3. The display will momentarily display the current version of the firmware utilized, If you purchase the model

954 separately, it will show the following

126.72 SCCM #1

126.72 SCCM #2

126.71 SCCM C3H6O

126.72 SCCM C2H3N

If your model 954 was purchased with Sierra MFM or MFC instruments, each channel will be set to the

proper calibration for that unit.

Note: All 4 channels should have the CLOSE annunciators illuminated. The values 126.71 and 126.72

are approximate and is the display for an open signal input . It may not correspond exactly to the

display shown on this unit.

factory default display:

4. Change the Units of Measure and Gas Identifiers as desired. Please refer to page 10. To blank the Units

of Measure select "00" then "ENT". To blank the Gas Identifier select "000" then "ENT". To blank the

entire line, please refer to RS232/485 Commands, Selecting/Blanking/Reading Display on page 21.

5. The Model 954 is factory calibrated at 0.000 and 5.000Vdc to display 0.00 and 100.00 for each channel.

To change the display range, without recalibration, see MANUAL CAL/RANGE, Range(Changing

Range) on page 15. To enter a Gas Correction Factor or Multiplier, refer to MANUAL CAL/RANGE,

Calibrate (Multiplier) on page 16. The factory Multiplier setting is 1.0000.

6. The Model 954 can accept 0-5Vdc, 0-10Vdc or 4-20mA input signals. If either 0-10Vdc or 4-20mA is

required, the instrument needs to be recalibrated. Select the proper signal input for the Transducer to be

used for each channel. Please refer to MANUAL SETUP, Selecting Input on page 11. Do not attempt to

recalibrate the instrument at this time. The factory Input setting is 0-5Vdc.

7. Select Filter to optimize reading stability and conversion speed. The factory Filter setting is 15Hz.

8. Allow 30 minutes warm-up time.

9. Turn power ON/OFF switch OFF.

10 . Connect MFC/MFM #1 to J1 on the Model 954 using the Connector Pin Designation information on

page 5. Connect all ground connections available to the transducer. Example: If the

ground pins, connect all four ground pins shown on J1. All ground pins on J1, J2, J3 and J4 are

common but are routed on separate wires from the connector to a ground plane on the instrument

motherboard.

11

provide +/-15Vdc @ 250-400 mA to each transducer. Do not use a Transducer that requires more than

+/-15Vdc @ 500mA on any channel.

12. Verify the display illuminates and the transducer readings are essentially correct. If the selected signal

input for a channel is 0-5Vdc proceed to Step 13 for that channel. If the selected signal input for a

channel is 0-10Vdc or 4-20mA, that channel needs to be recalibrated. Refer to MANUAL CAL/RANGE,

Calibrate section pages 14 and 15 to recalibrate that channel.

. Connect MFC/MFM #2, 3 and 4 to the instrument. The Power Supply inside The 954 is designed to

MFC/MFM has 4

PAGE 7

Page 11

START-UP

13. To utilize the Setpoint (Control) voltage for MFC's, set the Setpoint voltage for each channel to the

desired setting. Please refer to MANUAL SETUP, Selecting Setpoint (Control Voltage) on page 10.

The factory Setpoint default is 0.0000 for all 4 channels.

The Setpoint voltage, for a 0-5Vdc signal input, is calculated as follows.

Setpoint Voltage = (Setpoint Value/Range Value) * 5.000Vdc

Example: If the Setpoint Value = 120.00 SCCM and the Range Value is 250.00 SCCM,

the Setpoint Voltage = (120.00/250.00)*5.000 = 2.400Vdc.

For a 0-10Vdc signal input

the Setpoint Voltage= (120.00/250.00)*10.000Vdc = 4.800Vdc

For a 4-20mA signal input

the Setpoint Current = (120.00/250.00)*16mA + 4mA = 11.68mA.

14. The Flowrate Alarms are used to monitor the flowrate of the MFC. If the flow rate is not within the

selected HIGH and LOW Alarm values, an opto-isolated open collector output is activated. This output

can be used to illuminate warning lights to alert the user if the Flow Controller's Setpoint (Control)

voltage is not controlling the flow within a desired window. Refer to MANUAL SETUP, Selecting Alarms

on page 12. The factory default is HIGH Alarm set at 75.000, LOW Alarm at 25.000 and HYSTERESIS

at 010 counts.

15. To activate the Setpoint (Control) voltage to the MFC, select RUN for the desired channel. Reference

MANUAL SETUP, Selecting Valve Override (Open, Close or Run) on page 9. The default at power-up

is Valve Close.

16. If the Units of Measure are in flow units, The Model 954 automatically calculates TOTAL flow using a

Riemann Sum Integration method. To display TOTAL or to reset the TOTAL display, refer to

MANUAL/SETUP, Selecting Display (Flow or Total) on page 9. If the Units of Measure are not in flow

units, the TOTAL is not calculated or displayed.

17. The Model 954 has both RS232 and RS485 serial communications ports. Only one port is active at any

one time and is user selectable. The RS232 port has (1) 9-pin D-sub connector, while the RS485 port

has (2) 9-pin D-sub connectors. All Setups described earlier can be performed using the serial

communications ports. Reference RS232/485 Hookup and Commands on pages 17 through 26.

PAGE 8

Page 12

MANUAL SETUP

Selecting Display (Flow or Total)

MENU

--

MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

1

DISPLAY: 1=FLOW

2=TOTAL

-- --

1

--

2

|

|

|

|

|

----

FLOW: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

TOTAL: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

-------------------------------------------- --

RESET TOTAL?

-- --

2

1=NO

2=YES

1

-- --

2

500.0 SCCM Ar

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

500.0 SCCM Ar

T 0000 SCC H2

50.00 SCCM CF4

950.0 SCCM CH4

If Flow is selected, the most significant digit location will be left blank. If Total is selected, a "T" appears in

this location and the Unit of Measure changes accordingly. If the Unit of Measure selected is not a flow

rate unit of measure, Total will not be displayed.

Selecting Valve Overide (Open, Close or Run)

OPEN

CLOSE

CH1 500.0 SCCM Ar

CH2 1000 SCCM H2

CH3 50.00 SCCM CF4

CH4 950.0 SCCM CH4

OPEN

CLOSE

CH1 500.0 SCCM Ar

CH2 1000 SCCM H2

CH3 50.00 SCCM CF4

CH4 950.0 SCCM CH4

OPEN

CLOSE

CH1 500.0 SCCM Ar

CH2 1000 SCCM H2

CH3 50.00 SCCM CF4

CH4 950.0 SCCM CH4

CH SEL

--

* 500.0 SCCM Ar

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

--------------- -----OPEN

|

|

|

|

|

|

|

|

|

------ ------

CLOSE

|

|

|

|

|

|

|

|

|

------ ------

RUN

Channel 1 is shown selected above. An asterisk appears to signify the Channel selected. To select

Channel 2, depress CH SEL switch twice, then select OPEN, CLOSE or RUN. If OPEN is selected,

ground is applied to the appropriate channel connector pin-4. This ground is at the same potential as

pin-9. If CLOSE is selected, ground is applied to pin-12. Both pin-4 and pin-12 are grounded with an

open collector transistor capable of sinking 250mA at 25V. If RUN is selected, no override signals are

sent and the MFC Setpoint control is activated. If the valve override does not appear to function correctly,

you may need to re-configure The Model 954 using the 15/30 VDC jumpers on the PCA. Refer to page 6B

to verify valve circuit configuration of The 954 is correct for your MFM or MFC.

PAGE 9

Page 13

MANUAL SETUP

Selecting Setpoint (Control Voltage)

CH SEL

--

* 575.0 SCCM Ar

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

-- --

CH SEL

500.0 SCCM Ar

*1250.0 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

-- -- -- -- -- -- -- --

1

7

5

0

0

.

ENT

500.0 SCCM Ar

*1575.0 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

The example above shows how the setpoint for Channel 2 is changed. When CH SEL is depressed an

asterisk points to the channel selected. To select Channel 4, depress CH SEL switch 4 times.

The value displayed after the asterisk is the current setpoint value. Typing in a new value overrides the

old value. If ESC is depressed instead of ENT, the old value is retained.

Selecting Units of Measure and Gas Identifiers

MENU

--

MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

2

SETUP:

1=BRIGHTNESS

2=UNITS/GASID

3=FILTER

-- --

2

UNITS: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

-- --

1

UNITS:

1=SCCM

2=SLM

3=%

-- -- --

ENT

1

:

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

4=INPUT

5=ALARM

6=RATIO

:

66=PSI

--------------

--------

GASID:

1=#1

2=#2

3=C3H60

:

191=C8H10

The bold characters shown in the above flow chart indicate the updated Units of Measure and Gas

Identifier selected. Note: When the Units of Measure and Gas Identifiers are selected, ENT must

be depressed before the selection is made. This is because it may require the inputting of more than 1

digit to make the desired selection.

-- -- --

ENT

3

500.0 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

PAGE 10

---------------------------------------

Page 14

MANUAL SETUP

Selecting Filter (-3db A/D Converter Filter Frequency)

MENU

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

2

SETUP:

1=BRIGHTNESS

2=UNITS/GASID

3=FILTER

:

4=INPUT

5=ALARM

6=RATIO

3

-- --

FILTER: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

-- --

1

FILTER: 1=4Hz

2=15Hz

CHANNEL 1 3=30Hz

15Hz 4=100Hz

-- --

1

500.0 SCCM N2

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

The Filter selection sets the output word rate which in turn sets the corner frequency for the sigma-delta A/D

converter. With an output word rate of 15Hz, the filter's corner frequency is typically 12.7Hz. The filters are

optimized to settle to full accuracy every conversion and yield better than 80dB rejection for both 50 and 60Hz

with output word rates at or below 15Hz. The last filter output word rate setting for the selected channel is

displayed for user convenience. Each channel may be set to a different filter output word rate. The factory

default is15Hz for each channel to optimize response time and noise rejection.

Selecting Input (0-5Vdc, 0-10Vdc or 4-20mA Signal Input)

MENU

--

MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

2

SETUP:

1=BRIGHTNESS

2=UNITS/GASID

3=FILTER

:

4=INPUT

5=ALARM

6=RATIO

-- --

4

INPUT: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

-- --

2

ANALOG: 1=0-5V

2=0-10V

CHANNEL 2 3=4-20mA

0-5V

-- --

1

500.0 SCCM N2

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

The Input selection sets the full scale input signal and the full scale setpoint (control) signal for the selected

channel. The selected channel and the input signal setting that was previously selected is displayed during

selection. The factory default is 0-5V for each channel. Any input may be selected for any channel. The

instrument compensates for any incompatibilities even in the Master/Slave configuration.

Example: If the full scale input selected is 0-10V, then the full scale setpoint output is also 0-10V. If the

Master Channel is 0-10V and the Slave Channel is 4-20mA, the instrument compensates for the

incompatibility and sends a 0-10V setpoint signal for the Master and a 4-20mA setpoint signal proportional to

the 0-10V input signal for the Slave.

Note: For most MFC's the full scale input is 0-5V.

PAGE 11

Page 15

MANUAL SETUP

Selecting Alarms (High and Low with Hysteresis)

MENU

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

2

SETUP:

1=BRIGHTNESS

2=UNITS/GASID

3=FILTER

:

4=INPUT

5=ALARM

6=RATIO

5

-- --

ALARM: 1=Chnl 1

2=Chnl 2

3=Chnl 3

4=Chnl 4

----------------------------------------------------------------------------------------------------

ALARMS: 1=HIGH LIMIT

----

----

2=LOW LIMIT

---------

3=HYSTERESIS

4=EXIT

-------------------- -----

-------------- -------

-------- -------

-- ---

4

1

2

3

ALARM:

CHANNEL 1

HIGH LIMIT

--ALARM:

----------------

CHANNEL 1

LOW LIMIT

---------

ALARM:

-----------------------------------

CHANNEL 1

HYSTERESIS 010

75.000

25.000

5

-- -- -- -- -- -- -- --

-- -- -- -- -- -- -- --

1

----------------------- -- -- -- --

0

0

-- -------

1

.

0

.

0

0

-------------------------------

0

0 ENT

0

0 ENT

0

1

ENT

------------------

----------------------------------------------------

500.0 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

--------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------

-----------------------------------------------------------------------------

Each channel has a HIGH and LOW alarm to monitor the flow rate signal. If the flow rate is higher than

the HIGH alarm or less than the LOW alarm, an optically isolated open collector output is turned

on. This alarm may be used as a warning that the flow rate is not within the limits set by

the setpoint (control) signal. A programmable HYSTERESIS of 1 to 999 counts provide a

deadband for the alarms. To exit the alarm setup a

"4" to exit must be selected.

In the above example, the HIGH alarm limit was changed from 75.000 to 50.000, the LOW alarm limit

from 25.000 to 10.000 and HYSTERESIS from 010 to 001. The factory default is 75.000, 25.000 and

010 for the HIGH, LOW and HYSTERESIS settings, respectively.

PAGE 12

Page 16

MANUAL SETUP

Selecting Ratio (Master/Slave Operation)

MENU

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

2

SETUP:

1=BRIGHTNESS

2=UNITS/GASID

3=FILTER

:

4=INPUT

5=ALARM

6=RATIO

-- --

6

RATIO:

1=DISABLE MASTER

2=ENABLE MASTER

3=EXIT

------ -------

-- -----

--------------------------------------------------------------------------------------------------------

SLAVE A:

----

1=DISABLED

---------

2=CHAN 2

3=EXIT

---------------- ---

------------ ----

--- ---

3

1

2

SLAVE B:

1=DISABLED

2=CHAN 3

3=EXIT

SLAVE B:

-- 1=DISABLED

--------------------------------

2=CHAN 3

3=EXIT

-------- -----

-- -------

2

-------- -----

--- -------

2

SLAVE C:

1

1=DISABLED

2=CHAN 4

3=EXIT

SLAVE C:

-- 1=DISABLED

------------

2=CHAN 4

3=EXIT

SLAVE C:

1

1=DISABLED

2=CHAN 4

3=EXIT

1

500.0 SCCM C3H60

1000 SCCM H2

2

50.00 SCCM CF4

950.0 SCCM CH4

--------------------------

--- ---

1

--- ---

1

--- ---

1

-- --

2

500.0 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

M 500.0 SCCM C3H60

1000 SCCM H2

S 50.00 SCCM CF4

950.0 SCCM CH4

M 500.0 SCCM C3H60

S 1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

M 500.0 SCCM C3H60

--S 1000 SCCM H2

------------

50.00 SCCM CF4

S 950.0 SCCM CH4

---

SLAVE C:

1=DISABLED

------------------------------

2=CHAN 4

3=EXIT

----------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------

M 500.0 SCCM C3H60

--- ---

1

S 1000 SCCM H2

S 50.00 SCCM CF4

-- --

2

950.0 SCCM CH4

M 500.0 SCCM C3H60

--S 1000 SCCM H2

------------

S 50.00 SCCM CF4

S 950.0 SCCM CH4

500.0 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

PAGE 13

Page 17

MANUAL CAL/RANGE

Calibrate (Zero only)

MENU

SCREEN 1

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

3

CAL/RANGE

1=CALIBRATE

2=RANGE

SCREEN 2

-- --

1

SCREEN 3

CALIBRATE: 1=Chnl1

2=Chnl2

3=Chnl3

4=Chnl4

-- ---

1

-------------------------------------------------------------------------------------------------------

---------------

----

------------

SCREEN 4

CALIBRATE:

1=ZERO ONLY

2=ZERO & RANGE

3=RANGE ONLY

:

4=MULTIPLIER

-- --

1

ZERO:

CHANNEL 1

SIGNAL

ENTER TO ACCEPT

SCREEN 5

9

--- ----

ENT

SCREEN 6

0.0 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

The "Zero only" sequence shown above is used to zero the MFC. Verify the input signal is at or

close to zero prior to performing this sequence. In SCREEN 5, the data shown after "SIGNAL" is the raw

analog-to-digital data corresponding to the input signal applied. This data is live and will change as the

input signal is changed. It should be close to zero, unless the MFC is being zeroed at a point other than

zero. If ENT is depressed during SCREEN 5, the value present at the input will be zeroed on the display,

as shown in SCREEN 6. If ESC is entered, the previous zeroed value applies.

Calibrate (Range only)

MENU

SCREEN 1

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

3

CAL/RANGE

1=CALIBRATE

2=RANGE

SCREEN 2

-- --

1

SCREEN 3

CALIBRATE: 1=Chnl1

2=Chnl2

3=Chnl3

4=Chnl4

-- ---

1

SCREEN 4

CALIBRATE:

1=ZERO ONLY

2=ZERO & RANGE

3=RANGE ONLY

:

4=MULTIPLIER

-- --

3

-------

----

------------

SCREEN 5

RANGE VALUE:

CHANNEL 1

VALUE 100.00

ENTER TO ACCEPT

1

5

-- -- -- -- -- -- -- --

Entering 0150.0 instead of 150.00

will result in a full scale display

of 150.0 instead of 150.00

.0

0

0

ENT

SCREEN 6

RANGE VALUE:

CHANNEL 1

SIGNAL

ENTER TO ACCEPT

25963

-- --

ENT

SCREEN 7

150.00 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

-------------------

The Range only sequence is used to calibrate the full scale reading of the MFC. Apply a full scale input

signal, typically 5Vdc to the signal input prior to performing this sequence. At SCREEN 5, the user has 2

alternatives. The first is to accept the display RANGE value shown by depressing ENT. The second is to

enter a new RANGE value, as shown above, prior to completing the RANGE sequence. The Signal

displayed on SCREEN 6 is the live, un-scaled analog-to-digital converter data, and will change as the

input changes. The value present when ENT is depressed will be used in the full scale calibration

calculations. If ESC is entered instead of ENT, the previous calibration applies. NOTE: DO NOT USE

THE RANGE ONLY SEQUENCE TO CHANGE RANGES. USE SELECTION 2 SHOWN IN SCREEN 2.

PAGE 14

Page 18

MANUAL CAL/RANGE

Calibrate (Zero & Range)

MENU

SCREEN 1

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

3

CAL/RANGE

1=CALIBRATE

2=RANGE

SCREEN 2

-- --

1

SCREEN 3

CALIBRATE: 1=Chnl1

2=Chnl2

3=Chnl3

4=Chnl4

-- ---

1

-------------------------------------------------------------------------------------------------------

----------------

SCREEN 4

CALIBRATE:

----

1=ZERO ONLY

-----------

2=ZERO & RANGE

3=RANGE ONLY

:

4=MULTIPLIER

-- 2 --

1

SCREEN 5

ZERO:

CHANNEL 1

VALUE

ENTER TO ACCEPT

9

-- --

ENT

SCREEN 6

RANGE VALUE:

CHANNEL 1

VALUE 100.00

ENTER TO ACCEPT

1

5

-- -- -- -- -- -- -- --

.0

0

0

ENT

---------

---------------------

SCREEN 7

RANGE VALUE:

----

CHANNEL 1

-----------

SIGNAL

ENTER TO ACCEPT

25963

-- --

ENT

SCREEN 8

150.00 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

The Zero & Range calibration allows both zero and full scale calibrations to be performed in the same

sequence. The input signal needs to be changed from a zero to a full scale value during the calibration

sequence. The same rules apply as previously mentioned in the Zero only and Range only procedures.

Range (Changing Range)

SCREEN 2

CAL/RANGE

1=CALIBRATE

2=RANGE

-- --

2

MENU

SCREEN 1

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

3

-------------------------------------------------------------------------------------------------------

SCREEN 4

----

-----------

RANGE VALUE:

CHANNEL 1

VALUE

ENTER TO ACCEPT

100.00

1

5

-- -- -- -- -- -- -- --

.0

0

0

ENT

SCREEN 3

RANGE: 1=Chnl1

2=Chnl2

3=Chnl3

4=Chnl4

SCREEN 5

150.00 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

-- ---

1

----------------

The Range sequence is not a calibration sequence. Changing the Range value simply replaces the

Range value used during the previous full scale calibration. The analog-to-digital converter data used

during the previous full scale calibration is still valid. Ranging is a simple way to change ranges when

changing MFC's. It assumes the full scale output voltage of the new MFC is the same as the previous

MFC.

PAGE 15

Page 19

MANUAL CAL/RANGE

Calibrate (Multiplier)

MENU

SCREEN 1

-MENU: 1=DISPLAY

2=SETUP

3=CAL/RANGE

4=COMM

-- --

3

CAL/RANGE

1=CALIBRATE

2=RANGE

SCREEN 2

-- --

1

SCREEN 3

CALIBRATE: 1=Chnl1

2=Chnl2

3=Chnl3

4=Chnl4

-- ---

1

-------------------------------------------------------------------------------------------------------

----------------

SCREEN 4

CALIBRATE:

----

1=ZERO ONLY

-----------

2=ZERO & RANGE

3=RANGE ONLY

:

4=MULTIPLIER

-- --

4

SCREEN 5

MULTIPLIER

CHANNEL 1

FACTOR 1.0000

1

.

0

5

-- -- -- -- -- -- -- --

0

0

ENT

SCREEN 6

105.00 SCCM C3H60

1000 SCCM H2

50.00 SCCM CF4

950.0 SCCM CH4

Entering a MULTIPLIER value changes the display by that multiplier factor. All data values are multiplied

by the MULTIPLIER prior to display. The MULTIPLIER is sometimes referred to as a GAS

CORRECTION factor when used with MFC's. If the MFC is calibrated with nitrogen and

another gas is used with the MFC, a GAS CORRECTION factor can be entered to recalibrate

the MFC to the gas used.

PAGE 16

Page 20

RS232/485 HOOKUP

BI-DIRECTIONAL RS-232 CONNECTION

PC1

COM1/COM2

TXD ---------------------------- RXD --------------------------- GND -----------------------------

IC-232

J6-3

2

5

KDT-4000

RXD

TXD

DIGITAL GND

IC-232

RS232/485 data is transmitted at 9600 or 19.2K baud (user-selectable)

in the following format:

One Start Bit

Eight Data Bits in ASCII Format

No Parity Bit

One Stop Bit

Note: All commands and queries are case sensitive and require an upper

case character.

Reading Display

RS232 Query:

C1 Response: "CH1<>sddd.dd<>eeeee<>xxxxx<>z

where: <>= blank (ASCII 20)

s= polarity sign (blank for +, ASCII 2E for -)

ddd.dd= data in ASCII format with decimal in

displayed position.

eeeee= unit of measure

xxxxx= gas id

z= carriage return (ASCII 0D)

C5 Response: "CH1<>sddd.dd<>eeeee<>xxxxx<>z

CH2<>sddd.dd<>eeeee<>xxxxx<>z

CH3<>sddd.dd<>eeeee<>xxxxx<>z

CH4<>sddd.dd<>eeeee<>xxxxx<>z"

MULTIDROP/4-WIRE FULL DUPLEX

RS-485 CONNECTION

PC1

COM1/COM2

TXD(+) ----------------------------TXD(-) ----------------------------RXD(+) ----------------------------RXD(-) -----------------------------

IC-485

PC2

COM1/COM2

TXD(+) ----------------------------TXD(-) ----------------------------RXD(+) ----------------------------RXD(-) -----------------------------

IC-485

--------------------- RXD(+)

------------------ RXD(-)

---------------- TXD(+)

-------------- TXD(-)

--------------------- RXD(+)

------------------ RXD(-)

---------------- TXD(+)

------------- TXD(-)

--------------------- RXD(+)

------------------ RXD(-)

---------------- TXD(+)

------------- TXD(-)

:

:

:

--------------------- RXD(+)

------------------ RXD(-)

---------------- TXD(+)

------------- TXD(-)

:

:

:::

:

:

------------ -----------------------------------------------------------------------------------------------------

---------------- -------------------------------------------------------------------------------------------------

-------------------- --------------------------------------------------------------------------------------------

------------------------ ----------------------------------------------------------------------------------------

RXD(+)

RXD(-)

TXD(+)

TXD(-)

J7-7

2

3

8

J9-7

2

3

8

J7-7

2

3

8

J9-7

2

3

8

J7-7

2

3

8

J9-7

2

3

8

KDT-4000 #01

RXD(+)

RXD(-)

TXD(+)

TXD(-)

IC-485

KDT-4000 #02

IC-485

KDT-4000 #nn

IC-485

RS485 Query:

*aaC1 Response: "CH1<>sddd.dd<>eeeee<>xxxxx<>z

*aaC5 Response: "CH1<>sddd.dd<>eeeee<>xxxxx<>z

CH2<>sddd.dd<>eeeee<>xxxxx<>z

CH3<>sddd.dd<>eeeee<>xxxxx<>z

CH4<>sddd.dd<>eeeee<>xxxxx<>z"

where: aa= KDT-4000 address

Reference: Checking/Changing RS485 Address on pg 19.

Note: nn=32 maximum (drivers and receivers)

PAGE 17

Page 21

RS232/485 COMMANDS

Checking Model 954 RS485 Address Setting

RS485 Query:

*00X Response: "MULTIDROP ADDRESS: 01"

Note: All Model 954's will respond to * 0 0 X. To prevent bus

contention, connect only 1 Model 954 to the RS485

port for this check.

Setting Setpoint (Control) Voltage

RS232 Command:

SP1<dd.ddd> Set CH1 Setpoint to dd.ddd

SP2<dd.ddd> Set CH2 Setpoint to dd.ddd

SP3<dd.ddd> Set CH3 Setpoint to dd.ddd

SP4<dd.ddd> Set CH4 Setpoint to dd.ddd

Example: Send S P 1 1 0 0 . 0 0

CH1 Setpoint (Control) Voltage setting will be

100.00.

Note: < > must contain 5 digits and 1 decimal point.

<ddddd.> is a valid entry. Setpoint is always positive.

RS485 Command:

*aaSP1<dd.ddd> Set CH1 Setpoint at Address 01 to dd.ddd

*aaSP2<dd.ddd> Set CH2 Setpoint at Address 01 to dd.ddd

*aaSP3<dd.ddd> Set CH3 Setpoint at Address 01 to dd.ddd

*aaSP4<dd.ddd> Set CH4 Setpoint at Address 01 to dd.ddd

Example: Send * 0 1 S P 2 2 5 0 0 . 0

Model 954 with Address 01 will have CH2 Setpoint

(Control) Voltage set to 2500.0

Changing Model 954 RS485 Address Setting

RS485 Command:

*00x<aa> Set 954 Address to aa

Example: Send * 0 0 x 2 2

Model 954 will respond with a "spade" character

to

acknowledge receipt of this command and

change its Address to "22"

Reading Setpoint (Control) Voltage

RS232 Query:

SP1 Response: "SP1ddd.dd"

SP2 Response: "SP2ddd.dd"

SP3 Response: "SP3ddd.dd"

SP4 Response: "SP4ddd.dd"

RS485 Query:

*aaSP1 Response: "SP1ddd.dd"

*aaSP2 Response: "SP2ddd.dd"

*aaSP3 Response: "SP3ddd.dd"

*aaSP4 Response: "SP4ddd.dd"

Setting Alarms

RS232 Command:

A1H<dd.ddd> Set CH1 High Alarm to dd.ddd

A2L<dd.ddd> Set CH1 Low Alarm to dd.ddd

A2H<dd.ddd> Set CH2 High Alarm to dd.ddd

A2L<dd.ddd> Set CH2 Low Alarm to dd.ddd

A3H<dd.ddd> Set CH3 High Alarm to dd.ddd

A3L<dd.ddd> Set CH3 Low Alarm to dd.ddd

A4H<dd.ddd> Set CH4 High Alarm to dd.ddd

A4L<dd.ddd> Set CH4 Low Alarm to dd.ddd

Example: Send A 4 L 3 5 . 0 0 0

CH4 Low Alarm Setpoint will be 35.000

RS485 Command:

*aaA1H<dd.ddd> Set CH1 High Alarm at Address 02 to dd.ddd

*aaA1L<dd.ddd> Set CH1 Low Alarm at Address 02 to dd.ddd

*aaA2H<dd.ddd> Set CH2 High Alarm at Address 02 to dd.ddd

*aaA2L<dd.ddd> Set CH2 Low Alarm at Address 02 to dd.ddd

*aaA3H<dd.ddd> Set CH3 High Alarm at Address 02 to dd.ddd

*aaA3L<dd.ddd> Set CH3 Low Alarm at Address 02 to dd.ddd

Example: Send *02A3H500.00

Model 954 with Address 02 will have CH3 High

Alarm set to 500.00

Reading Alarms

RS232 Query:

A1H Response: A1H ddd.dd

A1L Response: A1L ddd.dd

A2H Response: A2H ddd.dd

A2L Response: A2L ddd.dd

A3H Response: A3H ddd.dd

A3L Response: A3L ddd.dd

A4H Response: A4H ddd.dd

A4L Response: A4lL ddd.dd

RS485 Query:

*aaA1H Response: A1H ddd.dd

*aaA1L Response: A1H ddd.dd

*aaA2H Response: A2H ddd.dd

*aaA2L Response: A2L ddd.dd

*aaA3H Response: A3H ddd.dd

*aaA3L Response: A3L ddd.dd

*aaA4H Response: A4H ddd.dd

*aaA4L Response: A4L ddd.dd

PAGE 18

Page 22

RS232/485 COMMANDS

Setting Alarm Hysteresis

RS232 Command:

HY1<ddd> Set CH1 Alarm Hysteresis to ddd

HY2<ddd> Set CH2 Alarm Hysteresis to ddd

HY3<ddd> Set CH3 Alarm Hysteresis to ddd

HY4<ddd> Set CH4 Alarm Hysteresis to ddd

where 000<ddd<250

Example: Send HY1010

CH1 Alarm Hysteresis set to 10 counts.

RS485 Command:

*aaHY1<ddd> Set CH1 Hysteresis at Address aa to ddd

*aaHY2<ddd> Set CH2 Hysteresis at Address aa to ddd

*aaHY3<ddd> Set CH3 Hysteresis at Address aa to ddd

*aaHY4<ddd> Set CH4 Hysteresis at Address aa to ddd

Example: Send * 0 1 HY3100

Model 954 with Address 01 will have CH3 Alarm

Hysteresis set to 100

Setting Units of Measure

RS232 Command:

UM1<dd> Set CH1 Unit of Measure to selection dd

UM2<dd> Set CH2 Unit of Measure to selection dd

UM3<dd> Set CH3 Unit of Measure to selection dd

UM4<dd> Set CH4 Unit of Measure to selection dd

Reference Units of Measure Table on pg 14 for selection

Example: Send UM101

CH1 Unit of Measure will be SCCM

RS485 Command:

*aaUM1<dd> Set CH1 Unit of Measure at Address 02 to

selection dd

*aaUM2<dd> Set CH1 Unit of Measure at Address 02 to

selection dd

*aaUM3<dd> Set CH3 Unit of Measure at Address 02 to

selection dd

*aaUM4<dd> Set CH2 Unit of Measure at Address 02 to

selection dd

Example: Send *03UM366

Model 954 with Address 02 will have CH3 Unit of

Measure set to PSI

Reading Alarm Hysteresis

RS232 Query:

HY1 Response: HY1ddd

HY2 Response: HY2ddd

HY3 Response: HY3ddd

HY4 Response: HY4ddd

Example: Send IN3 Response: IN3

RS485 Query:

*aaHY1 Response: HY1ddd

*aaHY2 Response: HY2ddd

*aaHY3 Response: HY3ddd

*aaHY4 Response: HY4ddd

Reading Units of Measure

RS232 Query:

UM1 Response: UM1dd

UM2 Response: UM2dd

UM3 Response: UM3dd

UM4 Response: UM4dd

Example: Send UM1

Response: UM11 if CH1 Unit of Measure was

SCCM

RS485 Query:

*aaUM1 Response: UM1dd

*aaUM2 Response: UM2dd

*aaUM3 Response: UM3dd

*aaUM4 Response: UM4dd

Setting Gas Idenfifier

RS232 Command:

GS1<ddd> Set CH1 Gas Identifier to selection dd

GS2<ddd> Set CH2 Gas Identifier to selection dd

GS3<ddd> Set CH3 Gas Identifier to selection dd

GS4<ddd> Set CH4 Gas Identifier to selection dd

Reference Gas Identifier Table on pgs 15, 16 and 17 for

selection

Example: Send GS1050

CH1 Gas Identifier will be C2H6O

Reading Gas Identifier

RS232 Query:

GS1 Response: GS1ddd

GS2 Response: GS2ddd

GS3 Response: GS3ddd

GS4 Response: GS4ddd

Example: Send GS3

Response: GS3050 if CH1 Gas Identifier was

C2H60

PAGE 19

Page 23

RS232/485 COMMANDS

Setting Signal Input

RS232 Command:

IN1<d> Set CH1 Signal Input to selection d

IN2<d> Set CH2 Signal Input to selection d

IN3<d> Set CH3 Signal Input to selection d

IN4<d> Set CH4 Signal Input to selection d

where d=1 Signal Input = 0-5V

d=2 Signal Input = 0-10V

d=3 Signal Input = 4-20mA

Example: Send IN33

CH3 Signal Input selection is 4-20mA. This also

sets CH3 Setpoint (Control) signal to 4-20mA.

RS485 Command:

*aaIN1<d> Set CH1 Signal Input at Address aa to selection d

*aaIN2<d> Set CH2 Signal Input at Address aa to selection d

*aaIN3<ddd> Set CH3 Signal Input at Address aa to selection d

*aaIN4<ddd> Set CH4 Signal Input at Address aa to selection d

Example: Send *01IN31

Model 954

with Address 01 will have CH3 Signal

Input set for 0-5V.

Setting Filter

RS232 Command:

FL1<d> Set CH1 Filter selection to d

FL2<d> Set CH2 Filter selection to d

FL3<d> Set CH3 Filter selection to d

FL4<d> Set CH4 Filter selection to d

Where d=1 Filter = 4Hz

d=2 Filter = 15Hz

d=3 Filter = 30Hz

d=4 Filter =100Hz

Example: Send FL12

CH1 Filter f(-3dB) will be 15Hz

RS485 Command:

*aaFL1<d> Set CH1 Filter at Address aa to selection d

*aaFL2<d> Set CH1 Filter at Address aa to selection d

*aaFL3<d> Set CH3 Filter at Address aa to selection d

*aaFL4<d> Set CH2 Filter at Address aa to selection d

Example: Send *03FL13

Model 954 with Address 03 will have CH1 Filter

selection set for 30Hz.

Reading Signal Input Selection

RS232 Query:

IN1 Response: IN1<>d<>zzzzz

IN2 Response: IN2<>d<>zzzzz

IN3 Response: IN3<>d<>zzzzz

IN4 Response: IN4<>d<>zzzzz

Where zzzzz = 0-5V for d=1

zzzzz = 0-10V for d=2

zzzzz = 4-20mA for d=3

Example: Send IN3 Response: IN3 3 4-20mA

RS485 Query:

*aaIN1 Response: IN1<>d<>zzzzz

*aaIN2 Response: IN2<>d<>zzzzz

*aaIN3 Response: IN3<>d<>zzzzz

*aaIN4 Response: IN4<>d<>zzzzz

Example: Send *10IN2 Response: IN2 1 0-5V

Reading Filter

RS232 Query:

FL1 Response: FL1<>d<>zzzzz

FL2 Response: FL2<>d<>zzzzz

FL3 Response: FL3<>d<>zzzzz

FL4 Response: FL4<>d<>zzzzz

Where zzzzz = 4Hz for d=1

zzzzz = 15Hz for d=2

zzzzz = 30Hz for d=3

zzzzz = 100Hz for d=4

Example: Send FL1

Response: FL1 2 15Hz if CH1 Filter selection

was 2.

RS485 Query:

*aaFL1 Response: FL<>1<>zzzzz

*aaFL2 Response: FL<>2<>zzzzz

*aaFL3 Response: FL<>3<>zzzzz

*aaFL4 Response: FL4<>4<>zzzzz

PAGE 20

Page 24

RS232/485 COMMANDS

Setting Multiplier

RS232 Command:

ML1<d.dddd> Set CH1 Multiplier to d.dddd

ML2<d.dddd> Set CH2 Multiplier to d.dddd

ML3<d.dddd> Set CH3 Multiplier to d.dddd

ML4<d.dddd> Set CH4 Multiplier to d.dddd

Example: Send ML31.1375

CH3 Multiplier=1.1375

RS485 Command:

*aaML1<d.dddd> Set CH1 Multiplier at Address aa to d.dddd

*aaML2<d.dddd> Set CH2 Multiplier at Address aa to d.dddd

*aaIN3<d.dddd> Set CH3 Multiplier at Address aa to d.dddd

*aaIN4<d.dddd> Set CH4 Multiplier at Address aa to d.dddd

Example: Send *05ML31.0000

Model 954 with Address 05 will have CH3

Multiplier set to 1.0000.

Setting/Blanking Display (Flow or Total)

RS232 Command:

D1<d> Set CH1 Display to selection d

D2<d> Set CH2 Display to selection d

D3<d> Set CH3 Display to selection d

D4<d> Set CH4 Display to selection d

Where d=1 sets Display for TOTAL

d=2 sets Display for FLOW

d=3 blanks Display for selected Channel

Example: Send D11

CH1 Display shows TOTAL

RS485 Command:

*aaD1d Set CH1 Display at Address aa to selection d

*aaD2d Set CH2 Display at Address aa to selection d

*aaD3d Set CH3 Display at Address aa to selection d

*aaD4d Set CH4 Display at Address aa to selection d

Example: Send *03D12

Model 954 with Address 03 will display FLOW on

CH1

Reading Multiplier

RS232 Query:

ML1 Response: ML1<><>d.dddd

ML2 Response: ML2<><>d.dddd

ML3 Response: ML3<><>d.dddd

ML4 Response: ML4<><>d.dddd

Example: Send ML3 Response: ML3 1.1375

RS485 Query:

*aaML1 Response: ML1<><>d.dddd

*aaML2 Response: ML2<><>d.dddd

*aaML3 Response: ML3<><>d.dddd

*aaML4 Response: ML4<><>d.dddd

Reading Display (Selection)

RS232 Query:

D1 Response: D1d

D2 Response: D2d

D3 Response: D3d

D4 Response: D4d

Example: Send D1

RS485 Query:

Response: D12 indicates d=2 for FLOW on CH1

*aaD1 Response: D1d

*aaD2 Response: D2d

*aaD3 Response: D3d

*aaD4 Response: D4d

PAGE 21

Page 25

RS232/485 COMMANDS

Resetting Total

RS232 Command:

T1R Reset CH1 Total to zero

T2R Reset CH2 Total to zero

T3R Reset CH3 Total to zero

T4R Reset CH4 Total to zero

Example: Send T3R

CH3 Total reset to zero

RS485 Command:

*aaT1R Reset CH1 Total at Address aa to zero

*aaT2R Reset CH2 Total at Address aa to zero

*aaIT3R Reset CH3 Total at Address aa to zero

*aaIT4R Reset CH4 Total at Address aa to zero

Example: Send *01T1R

Model 954 with Address 01 CH1 Total reset to zero

Setting Range Value

RS232 Command:

SN1<d.dddd> Set CH1 Range value to d.dddd

SN2<d.dddd> Set CH2 Range value to d.dddd

SN3<d.dddd> Set CH3 Range value to d.dddd

SN4<d.dddd> Set CH4 Range value to d.dddd

Example: Send SN1150.00

CH1 Range value set to 150.00

RS485 Command:

*aaSN1<d.dddd> Set CH1 Range value at Address aa to d.dddd

*aaSN2 <d.dddd> Set CH2 Range value at Address aa to d.dddd

*aaSN3 <d.dddd> Set CH3 Range value at Address aa to d.dddd

*aaSN4 <d.dddd> Set CH4 Range value at Address aa to d.dddd

Example: Send *03SN35000.0

Model 954 with Address 03 will have CH3 Range

value set to 5000.0.

Enable Master Channel (CH1)

RS232 Command:

R11 Enable Master Channel (CH1)

R12 Disable Master Channel (CH1)

Note: Master Channel must be enabled before

enabling Slave Channel(s)

Setting Local or Remote Operation

RS232 Command:

RE1 Local Operation (Front Panel Enabled)

RE2 Remote Operation (Front Panel Disabled)

RS485 Command:

*aaRE1 Local Operation (Front Panel Enabled)

*aaRE2 Remote Operation (Front Panel Disabled)

Reading Range Value

RS232 Query:

SN1 Response: SN1d.dddd

SN2 Response: SN2d.dddd

SN3 Response: SN3d.dddd

SN4 Response: SN4d.dddd

Example: Send SN1

Response: SN1150.00

RS485 Query:

*aaSN1 Response: SN1d.dddd

*aaSN2 Response: SN2d.dddd

*aaSN3 Response: SN3d.dddd

*aaSN4 Response: SN4d.dddd

Enable Slave Channels (CH2, CH3 and CH4)

RS232 Command:

R21 Enable Slave A (CH2)

R22 Disable Slave A (CH2)

R31 Enable Slave B (CH3)

R32 Disable Slave B (DH3)

R41 Enable Slave C (CH4)

R42 Disable Slave C (CH4)

RS485 Command;

*aaR21 Enable Slave A (CH2)

*aaR22 Disable Slave A (CH2)

*aa R31 Enable Slave B (CH3)

*aaR32 Disable Slave B (CH3)

*aaR41 Enable Slave C (CH4)

*aa R42 Disable Slave C (CH4)

PAGE 22

Page 26

UNITS OF MEASURE TABLE

# Description Abbrev Total

1 Standard Cubic Centimeters per Minute SCCM SCC

2 Standard Liters per Minute SLM SL

3 Percent % NA

4 Volts V NA

5 Millivolts MV NA

6 Counts CNT NA

7 Normal Liters per Minute NLM NL

8 Standard Liters per Second SLS SL

9 Normal Liters per Second NLS NL

10 Standard Liters per Hour SLH SL

11 Normal Liters per Hour NLH NL

12 Standard Milliliters per Minute SMLM SML

13 Normal Milliliters per Minute NMLM NML

14 Standard Milliliters per Second SMLS SML

15 Normal Mililiters per Second NMLS NML

16 Standard Milliliters per Hour SMLH SML

17 Normal Milliliters per Hour NMLH NML

18 Normal Cubic Centimeters per Minute NCCM NCC

19 Standard Cubic Centimeters per Second SCCS SCC

20 Normal Cubic Centimeters per Second NCCS NCC

21 Standard Cubic Centimeters per Hour SCCH SCC

22 Normal Cubic Centimeters per Hour NCCH NCC

23 Standard Cubic Feet per Minute SCFM SCF

24 Normal Cubic Feet per Minute NCFM NCF

25 Standard Cubic Feet per Second SCFS SCF

26 Normal Cubic Feet per Second NCFS NCF

27 Standard Cubic Feet per Hour SCFH SCF

28 Normal Cubic Feet per Hour NCFH NCF

29 Standard Cubic Meters per Minute SCMM SCM

30 Normal Cubic Meters per Minute NCMM NCM

31 Standard Cubic Meters per Second SCMS SCM

32 Normal Cubic Meters per Second NCMS NCM

33 Standard Cubic Meters per Hour SCMH SCM

34 Normal Cubic Meters per Hour NCMH NCM

35 Standard Cubic Meters per Hour SCMH SCM

36 Normal Cubic Inches per Minute NCIM NCI

37 Standard Cubic Inches per Second SCIS SCI

38 Normal Cubic Inches per Second NCIS NCI

39 Standard Cubic Inches per Hour SCIH SCI

40 Normal Cubic Incher per Hour NCIH NCI

41 Pounds per Minute LBM LB

42 Pounds per Second LBS LB

43 Pounds per Hour LBH LB

44 Kilograms per Minute KgM Kg

45 Kilograms per Second KgS Kg

46 Kilograms per Hour KgH Kg

47 Grams per Minute GRM GR

48 Grams per Second GRS GR

49 Grams per Hour GRH GR

50 Moles per Minute MolM Mol

51 Moles per Second MolS Mol

52 Moles per Hour MolH Mol

53 Kilomoles per Minute KMolM KMol

54 Kilomoles per Second KMolS KMol

55 Kilomoles per Hour KMolH KMol

56 Watts W NA

57 Bits per Second BPS BP

58 Seconds S NA

59 Minutes M NA

60 Hours H NA

61 Watt*Hours WH W

62 Torr TORR NA

63 Bar BAR NA

64 Pascals Pa NA

65 Inches of Water inH20 NA

66 Pounds per Square Inch PSI NA

PAGE 23

Page 27

GAS IDENTIFICATION TABLE

# GAS GAS ID DISPLAY

1 Acetic Acid C2H4F2 #1

2 Acetic Acid, Anhydride C4H603 #2

3 Acetone C3H60 C3H60

4 Acetonitryl C2H3N C2H3N

5 Acetylene C2H2 C2H2

6 Air Air Air

7 Allene C3H4 C3H4

8 Ammonia NH3 NH3

9 Argon Ar Ar

10 Arsine AsH3 AsH3

11 Benzene C6H6 C6H6

12 Boron Trichloride BCl3 BCl3

13 Boron Triflouride BF3 BF3

14 Bromine Br2 Br2

15 Bromochlorodifluoromethane CBrClF2 #15

16 Bromodifluoromethane CHBrF2 #16

17 Bromotrifluormethane CBrF3 CBrF3

18 Butane C4H10 C4H10

19 Butanol C4H10O C4H10O

20 Butene C4H8 C4H8

21 Carbon Dioxide CO2 CO2

22 Carbon Disulfide CS2 CS2

23 Carbon Monoxide CO CO

24 Carbon Tetrachloride CCl4 CCl4

25 Carbonyl Sulfide COS COS

26 Chlorine Cl2 Cl2

27 Chlorine Trifluoride ClF3 ClF3

28 Chlorobenzene C6H5Cl #28

29 Chlorodifluoroethane C2H3ClF2 #29

30 Chloroform CHCl3 CHCl3

31 Chloropentafluoroethane C2ClF5 #31

32 Chloropropane C3H7Cl #32

33 Cisbutene C4H8 C4H8

34 Cyanogen C2N2 C2N2

35 Cyanogen Chloride ClCN ClCN

36 Cyclobutane C4H8 C4H8

37 Cyclopropane C3H6 C3H6

38 Deuterium H22 H22

39 Diborane B2H6 B2H6

40 Dibromodifluoromethane CBr2F2 #40

41 R21 CHCl2F R21

42 Dichloromethane CH2Cl2 #42

43 Dichloropropane C3H6Cl2 #43

44 Dichlorosilane H2SiCl2 #44

45 Diethyl Amine C4H11N #45

46 Diethyl Ether C4H10O #46

47 Diethyl Sulfide C4H10S #47

48 Difluoroethylene C2H2F2 #48

49 Dimethylamine C2H7N C2H7N

50 Dimethyl Ether C2H6O C2H6O

51 Dimethyl Sulfide C2H6S C2H6S

52 Divinyl C4H6 C4H6

53 Ethane C2H6 C2H6

54 Ethane, 1-chloro-1,1,2,2-tetraflouro- C2HClF4 #54

55 Ethane, 1-chloro-1,2,2,2-tetrafluoro- C2HClF4 #55

56 Ethanol C2H6O C2H6O

57 Ethylacetylene C4H6 C4H6

58 Ethyl Amine C2H7N C2H7N

59 Ethylbenzene C8H10 C8H10

60 Ethyl Bromide C2H5Br #60

61 Ethyl Chloride C2H5Cl #61

62 Ethyl Fluoride C2H5F C2H5F

63 Ethylene C2H4 C2H4

64 Ethylene Dibromide C2H4Br2 #64

65 Ethylene Dichloride C2H4Cl2 #65

66 Ethylene Oxide C2H4O C2H4O

PAGE 24

Page 28

GAS IDENTIFICATION TABLE

# GAS GAS ID DISPLAY

67 Ethyleneimine C2H4N C2H4N

68 Ethylidene Dichloride C2H4Cl2 #68

69 Ethyl Mercaptan C2H6S C2H6S

70 Fluorine F2 F2

71 Formaldehyde CH2O CH2O

72 Freon 11 CCl3F CCl3F

73 Freon 12 CCl2F2 #73

74 Freon 13 CClF3 CClF3

75 Freon 14 CF4 CF4

76 Freon 22 CHClF2 #76

77 Freon 23 CHF3 CHF3

78 Freon 114 C2Cl2F4 #78

79 Furan C4H4O C4H4O

80 Helium He He

81 Heptafluoropropane C3HF7 C3HF7

82 HMDS C6H19NSi2 HMDS

83 Hexamethyldisiloxane C6H18OSi2 #83

84 Hexane C6H14 C6H14

85 Hexafluorobenzene C6F6 C6F6

86 Hexene C6H12 C6H12

87 Hydrazine N2H4 N2H4

88 Hydrogen H2 H2

89 Hydrogen Bromide HBr HBr

90 Hydrogen Chloride HCl HCl

91 Hydrogen Cyanide CHN CHN

92 Hydrogen Fluoride HF HF

93 Hydrogen Iodide HI HI

94 Hydrogen Selenide H2Se H2Se

95 Hydrogen Sulfide H2S H2S

96 Isobutane C4H10 C4H10

97 Isobutanol C4H10O #97

98 Isobutene C4H8 C4H8

99 Isopentane C5H12 C5H12

100 Isopropyl Alcohol C3H8O C3H8O

101 Isoxazole C3H3NO #101

102 Ketene C2H2O C2H2O

103 Krypton Kr Kr

104 Methane CH4O CH4O

105 Methanol CH4O CH4O

106 Methyl Acetate C3H6O2 #106

107 Methyl Acetylene C3H4 C3H4

108 Methylamine CH5N CH5N

109 Methyl Bromide CH3Br CH3Br

110 Methyl Chloride CH3Cl CH3Cl

111 Methylcyclohexane C7H14 C7H14

112 Methyl Ethyl Amine C3H9N C3H9N

113 Methyl Ethyl Ether C3H8O C3H8O

114 Methyl Ethyl Sulfide C3H8S C3H8S

115 Methyl Fluoride CH3F CH3F

116 Methyl Formate C2H4O2 #116

117 Methyl Iodide CH3I CH3I

118 Methyl Mercaptan CH4S CH4S

119 Methylpentene C6H12 C6H12

120 Methyl Vinyl Ether C3H6O C3H6O

121 Neon Ne Ne

122 Nitric Oxide NO NO

123 Nitrogen N2 N2

124 Nitrogen Dioxide NO2 NO2

125 Nitrogen Tetroxide N2O4 N2O4

126 Nitrogen Trifluoride NF3 NF3

127 Nitromethane CH3NO2 #127

128 Nitrosyl Chloride NOCl NOCl

129 Nitrous Oxide N2O N2O

130 n-Pentane C5H12 C5H12

PAGE 25

Page 29

GAS IDENTIFICATION TABLE

# GAS GAS ID DISPLAY

131 Octane C8H18 C8H18

132 Oxygen O2 O2

133 Oxygen Difluoride F2O F2O

134 Ozone O3 O3

135 Pentaborane B5H9 B5H9

136 Pentane C5H12 C5H12

137 Perchloryl Fluoride ClFO3 CLFO3

138 Perfluorocyclobutane C4F8 C4F8

139 R116 C2F6 C2F6

140 Perfluoropropane C3F8 C3F8

141 Phenol C6H6O C6H6O

142 Phosgene COCl2 COCl2

143 Phosphine PH3 PH3

144 Phosphorus Trifluoride PF3 PF3

145 Propane C3H8 C3H8

146 Propyl Alcohol C3H8O C3H8O

147 Propyl Amine C3H9N C3H9N

148 Propylene C3H6 C3H6

149 Pyradine C5H5N C5H5N

150 R32 CH2F2 CH2F2

151 R123 C2HCl2F3 R123

152 R123A C2HCl2F3 R123A

153 R125 C2HF5 C2HF5

154 R134 C2H2F4 R134

155 R134A C2H2F4 R134A

156 R143 C2H3F3 R143

157 R143A C2H3F3 R143A

158 R152A C2H4F2 R152A

159 R218 C3F8 C3F8

160 R1416 C2H3Cl2F R1416

161 Radon Rn Rn

162 Sec-butanol C4H10O #162

163 Silane SiH4 SiH4

164 Silicone Tetrafluoride SiF4 SiF4

165 Sulfur Dioxide SO2 SO2

166 Sulfur Hexafluoride SF6 SF6

167 Sulfur Tetrafluoride SF4 SF4

168 Sulfur Trifluoride SF3 SF3

169 Sulfur Trioxide SO3 SO3

170 Tetrachloroethylene C2Cl4 #170

171 Tetrafluoroethylene C2F4 C2F4

172 Tetrahydrofuran C4H8O C4H8O

173 Tert-butanol C4H10O #173

174 Thiophene C4H4S C4H4S

175 Toluene C7H8 C7H8

176 Transbutene C4H8 C4H8

177 Trichloroethane C2H3Cl3 #177

178 Trichloroethylene C2HCl4 #178

179 R113 C2Cl3F3 R113

180 Triethylamine C6H15N #180

181 Trimethyl Amine C3H9N C3H9N

182 Tungsten Hexafluoride WF6 WF6

183 Uranium Hexafluoride UF6 UF6

184 Vinyl Bromide C2H3Br #184

185 Vinyl Chloride C2H3Cl #185

186 Vinyl Fluoride C2H3F C2H3F

187 Water Vapor H2O H2O

188 Xenon Xe Xe

189 Xylene, m- C8H10 C8H10

190 Xylene, 0- C8H10 C8H10

191 Xylene, p- C8H10 C8H10

PAGE 26

Page 30

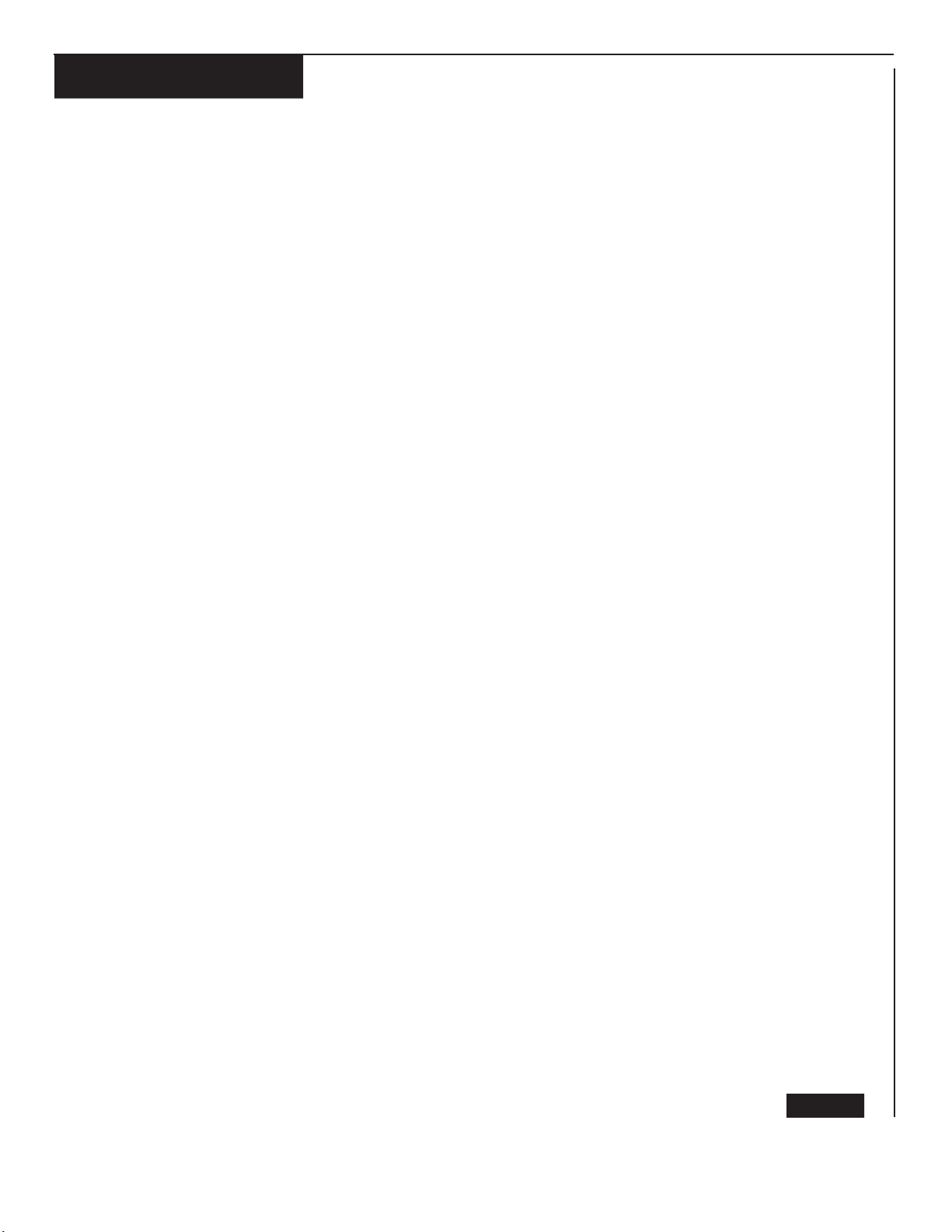

per channel

Appendix A

Model 954

Internal Circuit Assembly Board

Page 31

Display Assembly

Appendix A

Model 954

Zero Adj

10V Range

(CH4)

FS Adj

10V Range

(CH4)

20mA Adj

(CH4)

4mA Adj

(CH4)

Input Offset Adj

for 4-20mA Signal

Zero Adj

10V Range

(CH3)

R32

R12

R5

20mA Adj

(CH3)

R76

4mA Adj

(CH3)

FS Adj

10V Range

(CH3)

R8

R75

4mA Adj

(CH2)

R83

Zero Adj

10V Range

(CH2)

R31

R11

FS Adj

10V Range

(CH2)

20mA Adj

(CH2)

R74

Zero Adj

10V Range

(CH1)

R30

R10

FS Adj

10V Range

R7

Reference

Voltage Adj

(5.000V)

(CH2)

20mA Adj

(CH1)

4mA Adj

(CH1)

FRONT

R29

R9

R6

U67U67

R73

R126

C84C84

C85C85

C86C86

C87C87

C88C88

Adjustment Potentiometer Locations

Loading...

Loading...