Page 1

Quick-Installation Instructions for 820-Series Meters

1. If equipped with a black nylon flow body, DO NOT OVERTIGHTEN your fittings or

pipes when installing them into the hexed-portions of the flow body. Use two wraps of Teflon

tape on each of your fittings, hold the plastic hexagonal nuts with a wrench, and tighten your

fittings no more than one (1) turn past hand tight.

2. On models 826 and 827, consult the Operator’s Manual, Chapter 2, for recommended

upstream and downstream straight-run piping requirements.

3. NEVER TEST FOR LEAKS WITH LIQUID LEAK DETECTOR. If liquid seeps into the

electronics or the hidden sensor compartment below them, the instrument may be damaged.

Use a pressure-decay test instead.

4. Install an upstream in-line particulate or moisture filter if the gas contains any

particulate matter or liquid. (15-micron particulate filter for flows up to 30 slpm is

recommended, 30 micron for flows above 30 slpm).

5. Mount for a horizontal gas-flow. This is preferable unless the factory calibration

was specifically performed for a vertical flow. Consult your Calibration Certificate. (Horizontal

flow is assumed unless vertical flow upward or downward is specified).

6. Apply the gas listed on the label to the inlet at the recommended inlet (not maximum)

pressure as listed on the Calibration Certificate. Obtain this pressure by blocking off the flow

downstream.

7. On units equipped and calibrated for a 4-20 mA output signal, DO NOT APPLY

POWER TO THE OUTPUT SIGNAL LOOP. This is NOT a loop-powered device. Damage will

occur.

8. Before applying input power to the meter, check the model number for the

following codes: “PV1” models require 12-15 VDC, while “PV2” models require 24 VDC.

Applying the incorrect voltage may damage the instrument or give incorrect zero or flow

readings.

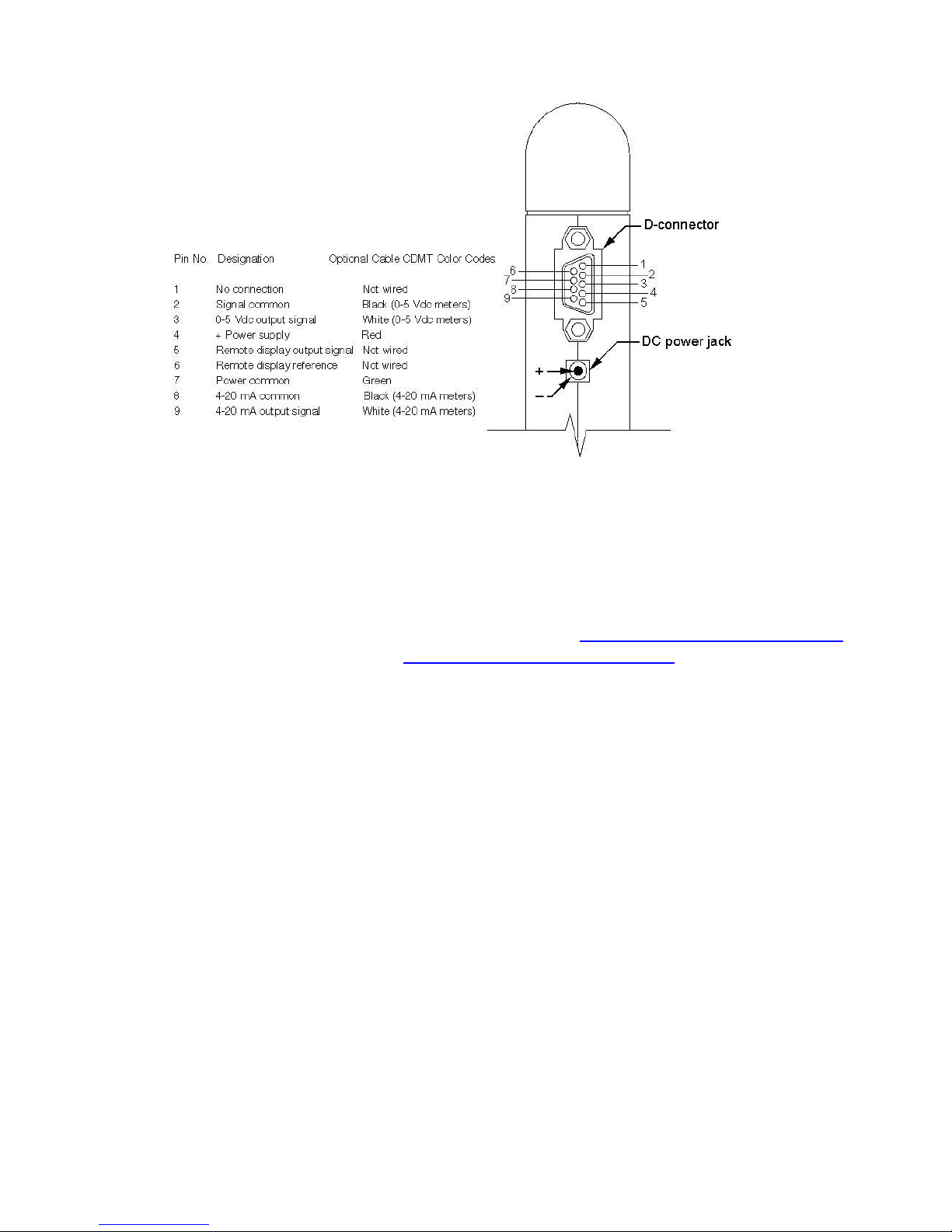

9. Wire the instrument per the diagram on the back of this card, or the Operator’s

Manual, Chapter 3.

10. Apply power, allow a 15-minute warm-up period, and verify or adjust the zero setting.

This adjustment can be made by sliding the door open on the side of the instrument, inserting

a small screwdriver, and turning the potentiometer. On models without displays, monitor the

output signal and always adjust DOWN from a positive output, stopping at 4.05 mA (V4

instruments) or 15 mV (V1 instruments). (See the Operator’s Manual, Chapter 3)

11. An annual factory evaluation and calibration is recommended.

Email Technical Support: Service@sierrainstruments.com

Website Self Service: www.sierrainstruments.com (Click “Sales & Service” Button)

Phone Technical Support:

SIERRA FACTORY: 800-866-0200 OR 831-373-0200 SIERRA EUROPE: + 31 72 5071

400

Page 2

47-0395 B

Limited Warranty Policy- Register Online

All Sierra products are warranted to be free from defects in material and workmanship and will be repaired or

replaced at no charge to Buyer, provided return or rejection of product is made within a reasonable period but no

longer than one (1) year for calibration and non-calibration defects, from date of delivery. To assure warranty

service, customers must register their products online on Sierra’s website. Online registration of all of your

Sierra products is required for our warranty process. Register now at www.sierrainstruments.com/register.

Learn more about Sierra’s warranty policy at www.sierrainstruments.com/warranty.

Loading...

Loading...