Page 1

Series 820 Instruction Manual Table of Contents

Sierra 820 Series

Top-Trakª Mass Flow Meters

Instruction Manual

Part Number IM-82

Revision C 06-99

5 Harris Court, Building L Monterey, CA 93940

(831) 373-0200 (800) 866-0200 Fax (831) 373-4402

http://www.sierrainstruments.com

Sierra Instruments b.v. Bolstoen 30A 1046 AV Amsterdam The Netherlands

+31(0)20-6145810 Fax +31(0)20-6145815

IM-82-C 0-1

Page 2

Table of Contents Series 820 Instruction Manual

Customer Notice

Sierra Instruments, Inc. is not liable for any damage or personal injury, whatsoever,

resulting from the use of Sierra Instruments standard mass flow meters or controllers for oxygen gas. You are responsible for determining if this mass flow meter or

controller is appropriate for your oxygen application. You are responsible for

cleaning the mass flow meter or controller to the degree required for your oxygen

flow application.

© COPYRIGHT SIERRA INSTRUMENTS 1994

No part of this publication may be copied or distributed, transmitted, transcribed, stored in

a retrieval system, or translated into any human or computer language, in any form or by

any means, electronic, mechanical, manual, or otherwise, or disclosed to third parties

without the express written permission of Sierra Instruments. The information contained in

this manual is subject to change without notice.

TRADEMARKS

Top-Trakª and Cal-Benchª are trademarks of Sierra Instruments, Inc. Other product and

company names listed in this manual are trademarks or trade names of their respective

manufacturers.

All Sierra products are Year 2000 compliant.

0-2 IM-82-C

Page 3

Series 820 Instruction Manual Table of Contents

Table of Contents

Chapter 1 Introduction

Introduction.............................................................1-1

Using this Manual .................................................1-1

Safety Information.................................................1-2

Receipt of System Components..................................1-2

Technical Assistance ..............................................1-2

Top Trak Features......................................................1-3

The 820 Series Flow Sensing Principle .............................1-4

Chapter 2 Installation

Installation Overview ..................................................2-1

Installing the Transducer ..............................................2-2

Compression Fittings .............................................2-2

VCO Fittings .......................................................2-2

VCR Fittings .......................................................2-3

All 1/2-inch Size Connections....................................2-3

Wiring the Transducer.................................................2-4

Standard 0-5 VDC Output Signal Wiring.......................2-5

Optional 4-20 mA Output Signal Wiring........................2-5

Remote Display Installation...........................................2-6

Chapter 3 Operation

Transducer Operation..................................................3-1

Transducer Accuracy..............................................3-1

Referencing the Transducer to Non-Standard Conditions ....3-2

Transducer Over-Ranging ........................................3-2

Zero and Span Adjustments ......................................3-3

Chapter 4 Maintenance and Repair

Transducer Cleaning...................................................4-1

Flow Path Cleaning Model 822/824 .................................4-2

Inlet and Outlet Screens...........................................4-2

Laminar Flow Element............................................4-3

Flow Path Cleaning Model 826/827 .................................4-4

Laminar Flow Element............................................4-4

Flow Path Cleaning Model 822-S/824-S............................4-5

Laminar Flow Element............................................4-5

Sensor Cleaning and Inspection .................................4-8

Transducer Calibration ................................................4-9

Transducer Troubleshooting............ . . . . . . ...................... 4-11

Returning Equipment to the Factory ............................... 4-12

IM-82-C 0-3

Page 4

Table of Contents Series 820 Instruction Manual

Appendix A Conversion Formulas and Gas Tables

Appendix B Production Specifications

List of Figures

1-1. Top-Trak Features (Typical)..................................1-3

1-2. Flow Paths through the Transducer..........................1-4

1-3. Flow Measuring Principle.....................................1-4

2-1. Piping Requirements for 1/2-inch Size Connections.......2-3

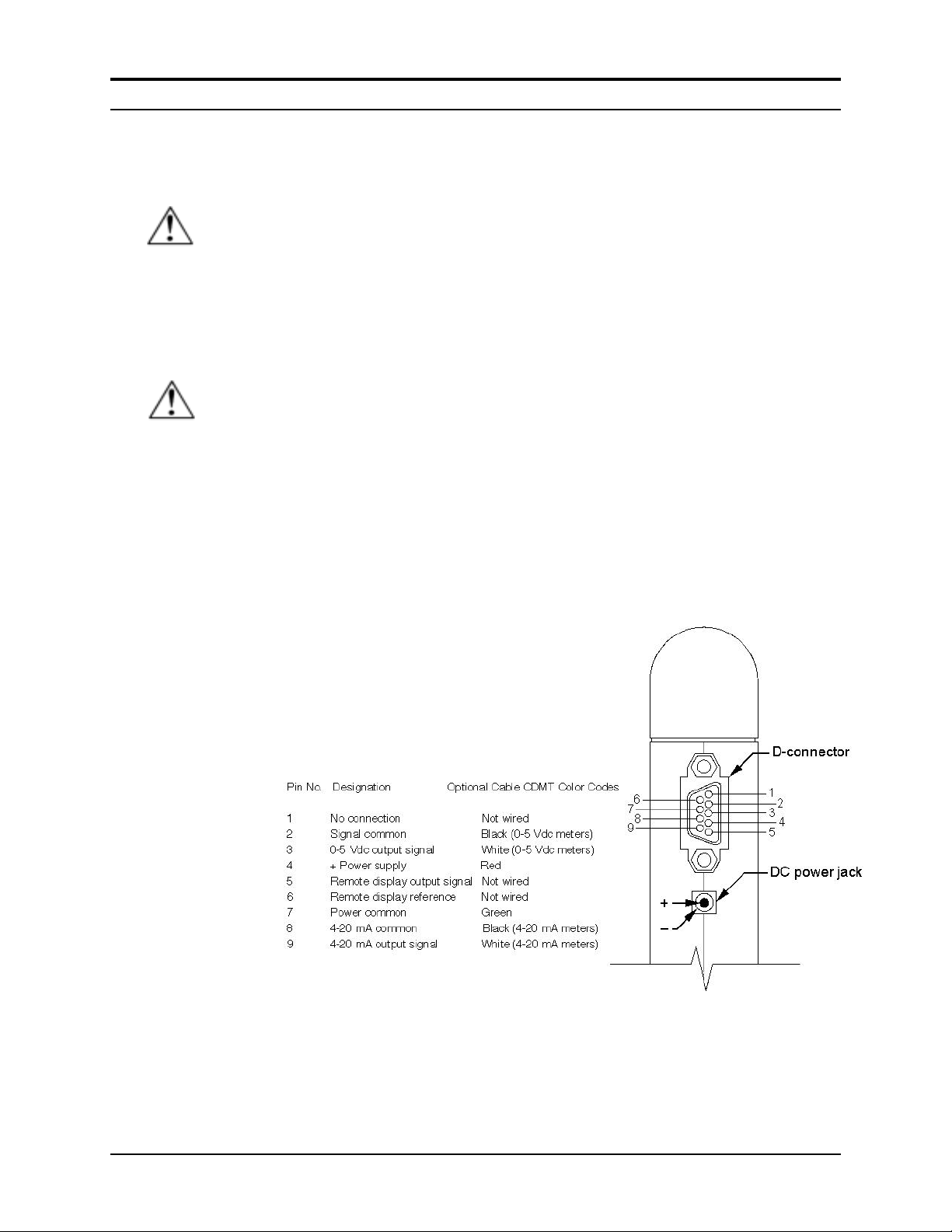

2-2. Transducer D-Connector Pin Assignments .. . . .............2-4

2-3. Standard 0-5 VDC Output Signal Wiring ...................2-5

2-4. Single Transducer Current Loop Connection...............2-5

2-5. Multiple Transducer Current Loop Connections ...........2-6

2-6. Mounting the Remote Display ................................2-6

4-1. Model 822/824 Flow Components.................. . . . . . . . . . 4-2

4-2. Correct LFE Position ..........................................4-3

4-3. Model 826/827 Flow Components.................. . . . . . . . . . 4-4

4-4. Low Flow Transducer LFE Cleaning........................4-5

4-5. Medium Flow Transducer LFE Cleaning ...................4-6

4-6. High Flow Transducer LFE Cleaning .......................4-7

4-7. Printed Circuit Board Component Locations ............. 4-10

0-4 IM-82-C

Page 5

Series 820 Instruction Manual Table of Contents

Cautions

Caution! Only qualified personnel should install the transducer.

Caution! Do not supply +DC power at the D-connector while using a power supply at

the power jack. Both supplies may be damaged.

Caution! Operating a 12 VDC transducer at 24 VDC will cause equipment damage.

Caution! Only qualified personnel should perform transducer service, calibration or

troubleshooting procedures.

Caution! When using toxic or corrosive gases, purge the unit thoroughly with inert

dry gas before disconnecting from the gas line.

Caution! Printed circuit boards are sensitive to electrostatic discharge. To avoid damaging the board, follow these precautions to minimize the risk of damage:

· before handling the assembly, discharge your body by touching a grounded,

metal object

· handle all cards by their edges unless otherwise required

· when possible, use grounded electrostatic discharge wrist straps when handling

sensitive components

IM-82-C 0-5

Page 6

Table of Contents Series 820 Instruction Manual

0-6 IM-82-C

Page 7

Series 820 Instruction Manual Chapter 1 Introduction

Chapter 1 Introduction

This instruction manual covers the installation, operation and maintenance of SierraÕs 820 Series product line including the following

Top-Trakª Models:

· 822 Mass Flow Meter with display (nylon flow body)

· 824 Mass Flow Meter without display (nylon flow body)

· 826 Hi-Flow Meter with display (aluminum flow body)

· 827 Hi-Flow without display (aluminum flow body)

· 822-S Mass Flow Meter with display (stainless steel flow body)

· 824-S Mass Flow Meter without display (stainless steel flow body)

SierraÕs Top-Trak

measurement of gas mass flow. The 820 Series offers a broad range

of sizes and process connections for flexibility and versatility. The

primary standard calibration ensures starting point accuracy and

NIST traceability. The meterÕs 0-5 VDC or 4-20 mA output signal is

provided for recording, data-logging or control. The optional display reads the mass flow rate directly in engineering units or percentage of full scale.

Using This Manual

This manual is organized into four chapters:

· Chapter 1 includes the introduction and theory of operation

· Chapter 2 provides installation and wiring instructions

· Chapter 3 describes transducer operation and features

· Chapter 4 covers maintenance, calibration and troubleshooting

Gas tables and conversion formulas are found in Appendix A.

The product specifications and dimensional drawings are found

in Appendix B.

Throughout this manual, we use the word transducer as a generic

term to represent all models of SierraÕs 820 Series Top-Trak

Mass Flow Meters.

ª

Mass Flow Meters are designed for precise

IM-82-C 1-1

Page 8

Chapter 1 Introduction Series 820 Instruction Manual

Safety Information

Caution and warning statements are used throughout this book to

draw your attention to important information.

Warning! Caution!

This statement appears with information that

is important to protect people and equipment

from damage. Pay very close attention to all

warnings that apply to your application.

This statement appears with information that is

important for protecting your equipment and performance. Read and follow all cautions that apply to your application.

Receipt of System Components

When receiving a Sierra transducer, carefully check the outside

packing carton for damage incurred in shipment. If the carton is

damaged, notify the local carrier and submit a report to the factory or

distributor. Remove the packing slip and check that all ordered components are present and match your specifications (as ordered).

Make sure any spare parts or accessories are not discarded with the

packing material. Do not return any equipment to the factory without

first contacting Sierra Customer Service.

Technical Assistance

If you encounter a problem with your transducer, review the configuration information for each step of the installation, operation and set

up procedures. Verify that your settings and adjustments are consistent with factory recommendations. Refer to Chapter 4, Troubleshooting, for specific information and recommendations.

If the problem persists after following the troubleshooting procedures

outlined in Chapter 4, contact Sierra Instruments by fax or by E-mail

(see inside front cover). For urgent phone support you may call (800)

866-0200 or (831) 373-0200 between 8:00 a.m. and 5:00 p.m. PST.

In Europe contact Sierra Instruments bv at +31 20 6145810. When

contacting Technical Support, make sure to include this information:

· the flow range, serial number, Sierra order number and

model number (all marked on the transducer nameplate)

· the problem you are encountering and any corrective action

taken

· application information (gas, pressure, temperature, pipe and

fitting configuration)

1-2 IM-82-C

Page 9

Series 820 Instruction Manual Chapter 1 Introduction

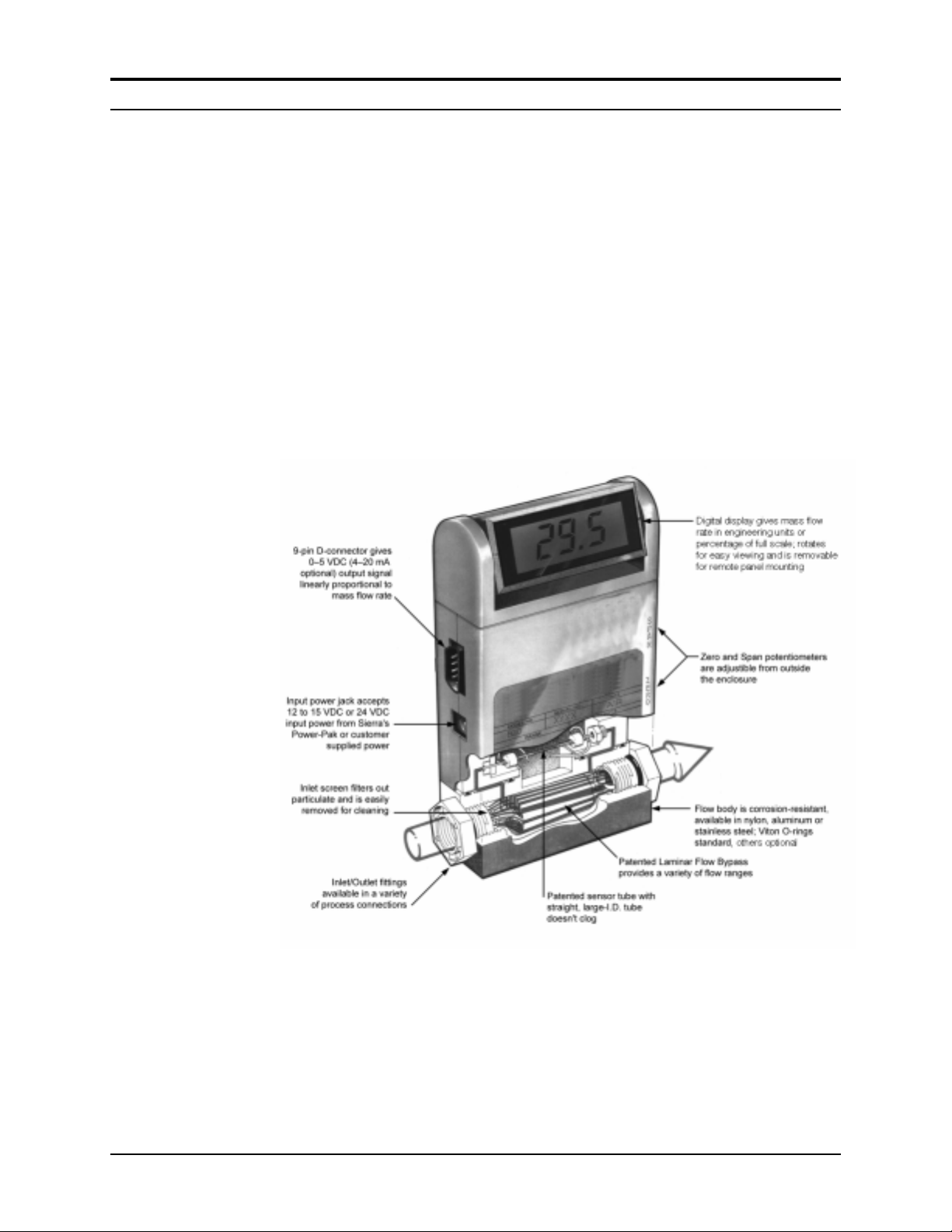

Top-Trak Features

Standard Top-Trak Mass Flow Meters require a 12 to 15 VDC external power source (24 VDC input power optional). The transducerÕs

0 to 5 VDC output signal allows for flow recording, data-logging or

control. A 4 to 20 mA output signal is optionally available. Input

power and output signal connections are made via the 9-pin sub-type

D-connector located on the side of the transducer. An additional input

power jack is located just below the D-connector. (It is important to

connect input power at only one location.)

The transducer shown below is a typical example of a 822 Series

Top-Trak Mass Flow Meter. Other models may vary slightly in their

appearance but are operationally equivalent.

Figure 1-1. Top-Trak Features (Typical)

IM-82-C 1-3

Page 10

Chapter 1 Introduction Series 820 Instruction Manual

The 820 Series Flow Sensing Principle

The operating principle of Top-Trak transducers is based on heat

transfer and the first law of thermodynamics. During operation

process gas enters the instrumentÕs flow body and divides into two

flow paths, one through the sensor tube, the other through the laminar flow element bypass. The laminar flow bypass generates a pressure drop, P1ÐP2, forcing a small fraction of the total flow to pass

through the sensor tube (m1).

Figure 1-2. Flow Paths through the Transducer

Two resistance temperature detector (RTD) coils around the sensor

tube direct a constant amount of heat (H) into the gas stream. In actual operation, the gas mass flow carries heat from the upstream coil

to the downstream coil. The resulting temperature difference (DT) is

detected by the RTD coils and gives the output signal. Since the

molecules of the gas carry away the heat, the output signal is linearly

proportional to gas mass flow.

Figure 1-3. Flow Measuring Principle

1-4 IM-82-C

Page 11

Series 820 Instruction Manual Chapter 2 Installation

Chapter 2 Installation

Installation Overview

To ensure a successful installation, inlet and outlet tubing should be

clean and free from burrs or rims caused by cutting prior to plumbing the transducer into the system. The protective caps covering the

inlet/outlet fittings should not be removed until immediately prior to

installation.

Before installing the transducer, verify the following:

1. Make sure the installation site meets the specific operating pa-

rameters recorded on the transducer’s nameplate. Each trans-

ducer is factory-configured for a specific gas and flow range. If

the operating pressure is more than 50 psi (3.4 bar) away from

the calibration pressure, it is advisable to return the unit to the

factory for re-calibration. (Adjusting zero may be sufficient to

remain within specification.)

2. Do not locate the transducer in areas subject to sudden tempera-

ture changes, moisture, drafts or near equipment radiating sig-

nificant amounts of heat. Make sure to allow adequate space for

cable connectors and wiring.

3. For 1/2-inch size inlet/outlet process connections on models 826

and 827 make sure the location meets the minimum number of

recommended pipe diameters upstream and downstream of the

transducer. A minimum of 5 inches (127 mm) upstream and 2-

1/2 inches (64 mm) downstream is always recommended. (not

necessary for other models)

4. Horizontal mounting is preferable. Vertical mounting is possible

with best results achieved when the factory calibration is specifi-

cally performed for vertical mounting. In vertical positions zero

shift will occur depending on the gas pressure at zero flow.

5. If the gas contains any particulate matter, install an in-line filter

prior to the transducer. Recommended filter size: 15 micron for

flows of 10 sccm to 30 slpm, 30 micron for above 30 slpm.

6. If a potential over-flow condition exists, insert a valve or critical

orifice in the line to limit flow to approximately 25 percent above

the full scale range of the meter.

7. Confirm that the transducer o-ring material is compatible with

the gas to be measured.

8. For remote displays, confirm the supplied cable is of sufficient

length to connect the components.

IM-82-C 2-1

Page 12

Chapter 2 Installation Series 820 Instruction Manual

Caution!

Only qualified

personnel should install

the transducer.

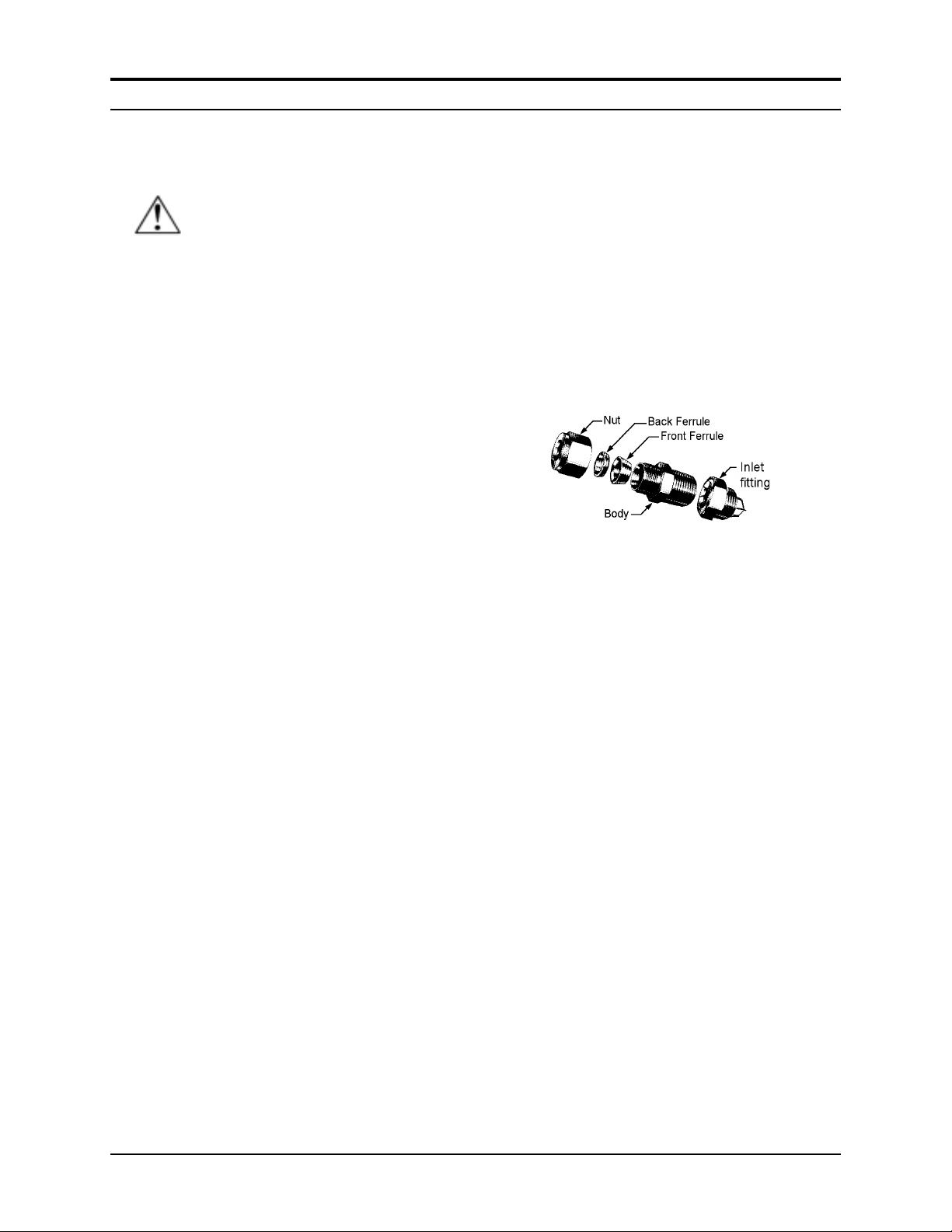

Installing the Transducer

Follow the installation instructions that apply to your transducer’s

process connection. For all 1/2-inch size process connections, observe

the piping recommendations given on page 2-3. Before operation, all

plumbing should be checked carefully for leaks and the transducer

purged with dry nitrogen.

Compression Fittings

1. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

1. Verify the position of the front

and back ferrule. Insert the

tubing into the fitting. Make

sure that the tubing rests

firmly on the shoulder of the

fitting and that the nut is finger

tight. (Do not mix or interchange parts of tube fittings

made by different manufacturers.)

2. Hold the body steady with a backup wrench. For 1/2-

inch size, tighten the nut 1-1/4 turns from finger tight. For 1/8inch, 1/4-inch and 3⁄8-inch sizes, tighten only 3/4 turn from finger tight. Do not over-tighten!

3. Check the system’s entire flow path thoroughly for leaks. (Do

not use liquid leak detectors, instead monitor pressure decay.

Over-exposing the transducer to leak detector fluid may damage

the unit.)

VCO and VCR Fittings

1. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

2. Install new o-rings compatible with the gas to be used. (Do not

mix or interchange parts of tube fittings made by different manufacturers.)

3. Hold the body steady with a backup wrench. Tighten

the nut finger tight and then 1/4 turn tighter with a wrench. Do

not over-tighten!

4. Check the system’s entire flow path thoroughly for leaks. (Do not

use liquid leak detectors, instead monitor pressure decay. Overexposing the transducer to leak detector fluid may damage the unit.)

2-2 IM-82-C

Page 13

Series 820 Instruction Manual Chapter 2 Installation

1/4 Inch Female NPT (standard on nylon flow bodies)

1. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

2. Use a good quality paste pipe thread sealant.

Apply to the pipe threads.

3. Tighten the pipe no more than 1 turn past hand-tight.

Caution! Do not over-tighten,

damage to the instrument may result.

4. Check the system’s entire flow path thoroughly for leaks. (Do not

use liquid leak detectors, instead monitor pressure decay. Over-

exposing the transducer to leak detector fluid may damage the unit.)

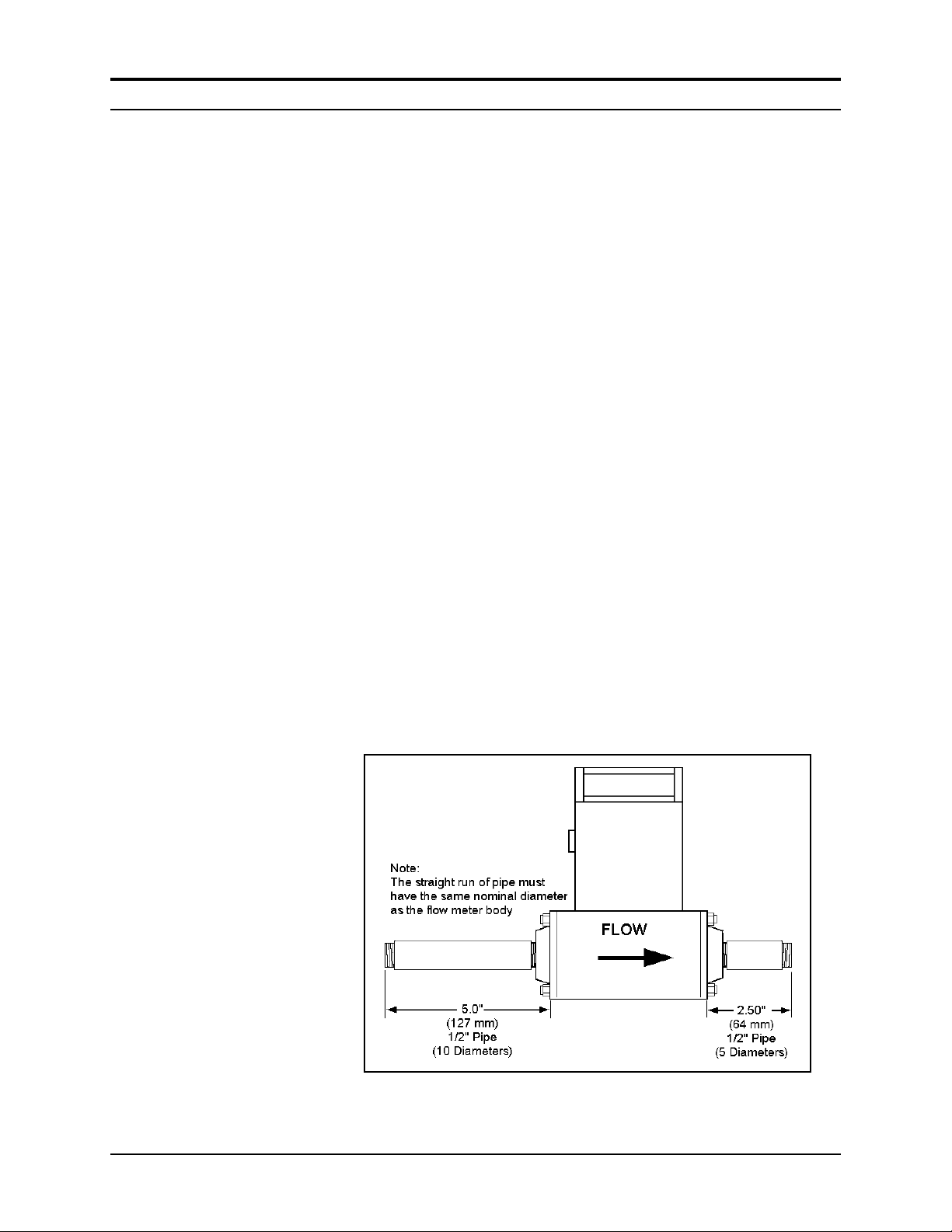

1/2-Inch Size NPT Connections (Models 826,827 only)

1. Install a section of straight pipe at least ten pipe diameters in length

upstream of the transducer. Also, allow at least five pipe diameters

downstream for accurate operation. DO NOT use reducers. If the

preceeding components in the flow path create disturbances extend

the upstream pipe length.

2. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

3. Tighten fittings until leak tight (refer to published standards for

specific recommendations).

4. Check the system’s entire flow path thoroughly for leaks. (Do not

use liquid leak detectors, instead monitor pressure decay. Over-

exposing the transducer to leak detector fluid may damage the unit.)

Figure 2-1.

Piping Requirements for all 1/2-Inch Size Process Connections

IM-82-C 2-3

Page 14

Chapter 2 Installation Series 820 Instruction Manual

Caution!

Do not supply +DC power

at the D-connector while

using a power supply at the

power jack. Both supplies

may be damaged.

Wiring the Transducer

Standard Top-Trak™ transducers require a 12 to 18 VDC power

supply (15 VDC nominal, 100 mA maximum). 24 VDC input power

is optional. Transducers are connected to the power supply through

either the dedicated DC power jack or through the 9-pin D-connector

located on the side of the enclosure. Before powering the unit, check

the transducer’s nameplate to confirm input power:

• PV1 = 12 to 18 VDC

• PV2 = 24 VDC

Note: operating a 24 VDC transducer at 12 to 18 VDC will result in

unreliable operation.

Caution!

Operating a 12 VDC trans-

ducer at 24 VDC will cause

equipment damage.

The transducer’s standard 0 to 5 VDC (4-20 mA optional) output

signal is available through the D-connector. The mating connector is

included with the transducer. Connection details are given on the

following pages.

When the transducer is configured for a remote display, signal connections are made via the 9-pin connector. Input power connections

are not included in the standard interface cable. Remote display

mounting dimensions are given at the end of this chapter.

Figure 2-2. Transducer D-Connector Pin Assignments

2-4 IM-82-C

Page 15

Series 820 Instruction Manual Chapter 2 Installation

Standard 0-5 VDC Output Signal Wiring

The standard 0-5 VDC output signal flows from Pin 3 (0-5 VDC

Out) through the load (1K Ohm minimum) to Pin 7 (Power Common). The figure below is a typical example of input power and

output signal connections.

Figure 2-3. Standard 0-5 VDC Output Signal Wiring

Optional 4-20 mA Output Signal Wiring

The optional 4-20 mA output signal flows from Pin 9 (4-20 mA Out)

through the load (50 to 500 Ohms maximum) to Pin 7 (Power Common). The figure below is a typical example of input power and output signal connections. (Multiple transducer current loop output connections are given on the next page.)

Figure 2-4. Single Transducer Current Loop Connection

IM-82-C 2-5

Page 16

Chapter 2 Installation Series 820 Instruction Manual

Figure 2-5. Multiple Transducer Current Loop Connections

Remote Display Installation

Mount the remote display at a convenient location within reach of the

supplied interface cable. The maximum cable length is 100 feet (30 m).

Figure 2-6. Mounting the Remote Display

2-6 IM-82-C

Page 17

Series 820 Instruction Manual Chapter 3 Operation

Chapter 3 Operation

The output signal of the transducer is either 0-5 VDC (standard) or

4-20 mA (optional). The output signal is linear and proportional to

the gas mass flow rate. For example, for a 0-5 VDC output signal,

5.00 VDC is the output signal for the full scale listed on the transducer’s nameplate, 2.50 VDC is for one-half of full scale, and 0.00

VDC is for zero flow. For a 4-20 mA output signal, 20.00 mA is the

output signal for the full scale, 12.00 mA is for one-half of full

scale, and 4.00 mA is for zero flow.

Transducer Operation

When the transducer is installed and the system has undergone a

complete leak check:

1. Apply power. The output signal will be at a high level for the

first 10 to 20 seconds while the sensor warms up to its normal

operating temperature range. Assuming zero flow, the output

signal will then drop to zero (or 4 mA, depending on output con-

figuration). Allow at least thirty minutes of warm-up time.

2. For first-time start ups, perform an initial zero output check as

described on page 3-3. After checking the initial zero setting, the

transducer is ready to monitor the gas mass flow rate.

Transducer Accuracy

The standard accuracy of Top-Trak is ±1.5% of full scale. The

±1.5% of full scale accuracy means that the 0-5 VDC output signal

is accurate to within ±0.1 VDC. The 4-20 mA output is accurate to

within ±0.4 mA.

For example, the output signal for zero flow can be as much as

+0.1 VDC or +0.4 mA. If the transducer has an output signal at

zero flow, as long as it is within either of these two ranges, it does

not mean it is malfunctioning.

For transducers with a digital display, the accuracy is simply 1.5

times the full scale flow rate stated on the nameplate. For example,

if the full scale is 10 slpm, the digital display will be accurate to

±0.2 slpm. The reading at zero flow may be as much as +0.2 slpm

and still be within the stated accuracy specification.

IM-82-C 3-1

Page 18

Chapter 3 Operation Series 820 Instruction Manual

Referencing the Transducer to Non-Standard Conditions

The gas flow rate output of your transducer is referenced to “standard”

conditions of 21°C (70°F) and 760 mm of mercury (1 atmosphere)

unless otherwise specified on the certificate of calibration. Check the

stated reference conditions of your transducer. If you are comparing

your transducer’s output with another type of flow meter, different

reference conditions could cause a discrepancy between the flow

readings.

For example, the output reading of a Top-Trak will be approximately

7% lower when referenced to 0°C rather than 21°C. To find the flow

rate referenced to other standard conditions or the actual temperature

and pressure conditions in the pipe where your transducer is located,

see Appendix A.

Transducer Over-Ranging

If the flow rate exceeds the full scale value listed on the transducer

nameplate, the output signal and digital display (if so equipped) will

read a higher value. The transducer is not calibrated for over-ranged

flows and will probably be both non-linear and inaccurate. Overrange conditions are indicated by the display and/or output signal

going to a level above the full scale range. When the over-range

condition is removed, it may take several seconds for the transducer

to recover and resume normal operation.

If the supply voltage is only 12 VDC, the over-ranged reading may

exceed the full scale value by 10% maximum. If the supply voltage

is higher, as with the 24 VDC option, then the output can exceed the

full scale by as much as 50%, or more. Digital displays cannot exceed 3-1/2 digits (1999). If the flow rate exceeds 1999, the rightmost digits will blank and only the left-hand “1” will appear on the

display.

3-2 IM-82-C

Page 19

Series 820 Instruction Manual Chapter 3 Operation

Zero and Span Adjustments

The zero and span potentiometers are

accessed through the ports marked on

the side of the transducer. Normally,

span adjustments are not made unless

you are calibrating the transducer. The

span adjustment should not be used

unless you have a known, precise nonzero flow rate that you wish to match.

Before making any zero adjustments,

confirm that the system has reached its

normal operating temperature and pressure and the transducer is mounted in

its final position.

For transducers without the digital display:

1. Power the transducer and allow at least 30 minutes of warm up

time before attempting any adjustments. Set gas flow to zero.

Confirm that no flow exists.

2. Connect a digital multimeter to Pin 3 (0-5 Out) or, Pin 9 (4-20 Out)

and Pin 7 (Power Common). Check the reading. If it does not indi-

cate 0± .05 VDC, (or 4.0± .016mA) adjust the zero potentiometer.

Since the output does not indicate negative numbers, it is neces-

sary to adjust down from a slightly positive reading. Begin by

slowly rotating the zero pot clockwise until a positive reading is

indicated. To complete the zero adjustment, slowly turn the pot

counterclockwise until zero is achieved.

For transducers with the digital display:

1. Power the transducer and allow at least 30 minutes of warm up

time before attempting any adjustments. Set gas flow to zero.

Confirm that no flow exists.

2. Observe the reading on the digital display. If the reading is

greater than 1.5% of full scale, adjust the zero potentiometer.

IM-82-C 3-3

Page 20

Chapter 3 Operation Series 820 Instruction Manual

3-4 IM-82-C

Page 21

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Chapter 4 Maintenance and Repair

Top-Trak™ transducers essentially require no scheduled maintenance

other than periodic flow path cleaning if the gas is dirty. If an in-line

Caution!

It is important that this

transducer be serviced

and/or calibrated by

qualified personnel.

filter is used, the filtering element should be periodically replaced or

ultrasonically cleaned.

Calibration of Sierra Instruments flow meters and controllers requires a calibrating standard of at least equal accuracy and preferably

an order of magnitude better than the transducer, and a skilled factory technician familiar with the Top-Trak. It is recommended that

Top-Trak meters be returned to the factory for annual evaluation and

calibration.

Included in this chapter are general instructions for:

• Transducer Cleaning Instructions..........................page 4-1

• Transducer Calibration......................................page 4-9

• Transducer Troubleshooting..............................page 4-11

• Returning Equipment to the Factory.....................page 4-12

Transducer Cleaning

Due to transducer design variations, separate cleaning instructions

are given in this chapter for each of the following models:

• Model 822/824 with nylon flow body

• Model 826/827 with aluminum flow body

• Model 822-S/824-S with stainless steel flow body

When toxic or corrosive gases are used, the transducer must be

thoroughly purged with inert dry gas before disconnecting from the

gas line. If a transducer used with toxic or corrosive gas is returned

to the factory, the transducer must first be purged clean. A Material

Safety Data Sheet must be enclosed with the unit upon its return.

IM-82-C 4-1

Page 22

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Flow Path Cleaning Model 822/824

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

Figure 4-1. Model 822/824 Flow Components

Inlet and Outlet Screens

1. Remove the transducer from the system.

1. Remove inlet and outlet fittings.

2. Pull out the laminar flow element (LFE) holddowns.

3. Replace or clean the inlet and outlet screens.

4. Re-assemble components. When the transducer is installed in the

system, leak test the connection.

5. To be within the original accuracy, calibrate the transducer (see

page 4-9).

4-2 IM-82-C

Page 23

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Laminar Flow Element

The laminar flow element (LFE) is a precision flow divider which

diverts a preset amount of flow through the sensor tube. The LFE is

made of precision machined 316 stainless steel. The particular LFE

used depends on the gas and flow range of the instrument. To clean

or inspect the LFE:

1. Remove the transducer from the system.

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

1. Remove the inlet and outlet fittings. Pull out the LFE holddowns

and inlet/outlet screens.

2. The LFE has a slightly tapered shape with the larger diameter on

the upstream (inlet) side. To remove, use a blunt object which

does not mar the flow channels to push the LFE from the outlet

side to the inlet side. A 3/8-inch (9 mm) nut driver works well.

3. Clean the LFE using a suitable solvent. Make sure to carefully

clean all active flow channels in the LFE.

4. Re-install the LFE making sure to press it in the correct distance

as shown below.

5. Re-assemble remaining components. When the transducer is in-

stalled in the system, leak test the connection. Re-zero the trans-

ducer (see Chapter 3).

Figure 4-2. Correct LFE Position

IM-82-C 4-3

Page 24

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Flow Path Cleaning Model 826/827

Laminar Flow Element

The laminar flow element (LFE) is a precision flow divider which

diverts a preset amount of flow through the sensor tube. The particular LFE used depends on the gas and flow range of the instrument. To clean or inspect the LFE:

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

1. Remove the transducer from the system.

2. Remove the 6-32 hex nuts and washers. Remove the end caps.

Note the position of the three (3) LFE elements.

3. To remove the LFE, use a blunt object which does not mar the

flow channels to push the LFE from the flow body.

4. Clean the LFE using a suitable solvent. Make sure to carefully

clean all active flow channels in the LFE.

5. Re-install the LFE making sure to position it with both ends

even with the transducer flow body.

6. Re-assemble remaining components. When the transducer is in-

stalled in the system, leak test the connection. Re-zero the transducer (see Chapter 3).

Figure 4-3. Model 826/827 Flow Components

4-4 IM-82-C

Page 25

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Flow Path Cleaning Model 822-S/824-S

Laminar Flow Element

The laminar flow element (LFE) is a precision flow divider which

diverts a preset amount of flow through the sensor tube. The LFE is

made of precision machined 316 stainless steel. The particular LFE

used depends on the gas and flow range of the instrument. Should

the LFE require cleaning or inspection due to deposition, use the appropriate cleaning procedure which is specific to flow body size.

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

Figure 4-4. Low Flow Transducer LFE Cleaning

Low Flow Transducers:

The LFE is accessed by unscrewing the main inlet fitting and removing it from the flow body. The LFE is screwed into the inlet fitting, which has been specially machined for this purpose. To access

the components:

1. Remove the transducer from the system.

1. The inlet filter screen is held in place in the inlet fitting by the

LFE. Disassemble by holding the fitting steady with a wrench

and unscrewing the LFE with a medium flat-tipped screwdriver.

2. Remove the LFE assembly taking care not to bend the inlet

screen. Inspect the sealing O-ring and replace if necessary. In-

spect the inlet screen and replace if corroded or damaged. Light

to medium particulate contamination can be cleaned by back

washing with a suitable solvent. Air dry thoroughly.

3. Inspect the LFE for damage and replace if necessary. Replacement

of the LFE or inlet screen requires transducer re-calibration.

4. Re-assemble components. When the transducer is installed in the

system, leak test the connection. Re-zero the transducer (see

Chapter 3).

IM-82-C 4-5

Page 26

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Figure 4-5. Medium Flow Transducer LFE Cleaning

Medium Flow Transducers:

In the medium flow body, the LFE assembly consists of the honeycomb laminar flow element, inlet screen, 0.63 inch long standoff,

two ranging washers, 2-1⁄4 inch long 4-40 screw and 4-40 nut.

Range changes in the honeycomb element are made with various diameter ranging washers. To access the components:

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

1. Remove the unit from the system.

2. Access the LFE by unscrewing the four 10-32 socket head cap

screws from the inlet side of the flow body and remove the inlet

end cap. (Note the position of the screws, one has a shorter

length.)

3. Remove the LFE assembly taking care not to bend the inlet

screen. Inspect the sealing O-ring and replace if necessary. Inspect the inlet screen and replace if corroded or damaged. Light

to medium particulate contamination can be cleaned by back

washing with a suitable solvent. Air dry thoroughly.

4. Inspect the honeycomb element for damage and replace if neces-

sary. Replacement of the LFE or inlet screen requires transducer

re-calibration.

5. Re-assemble components. When the transducer is installed in the

system, leak test the connection.

6. To be within the original accuracy, calibrate the transducer (see

page 4-9).

4-6 IM-82-C

Page 27

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Figure 4-6. High Flow Transducer LFE Cleaning

High Flow Transducers:

The high flow LFE is similar to the honeycomb element used in the

medium flow body but larger in diameter. The high flow body consists

of four parts: inlet tube, inlet cap, main flow body and end cap. The

inlet tube is only removed to inspect and replace the sealing O-ring

between the inlet tube and inlet cap. To access the components:

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

1. Remove the unit from the system.

2. To remove the inlet screen, remove the four 1⁄4-28 socket head

cap screws on the inlet side of the flow body and separate the

inlet cap from the main flow body.

3. Inspect the inlet screen for damage and corrosion and replace if nec-

essary. Light to medium particulate contamination can be cleaned by

back washing with a suitable solvent. Air dry thoroughly.

4. Inspect the sealing O-ring for damage and replace if necessary.

The inlet screen is mounted with the fine mesh side facing the inlet.

5. To remove the LFE loosen and remove the four threaded rods

holding the end cap to the main flow body. Separate the end cap

from the main flow body and remove the LFE assembly. The LFE

assembly consists of: 6-32 x 31⁄8 inch long screw, a #6 washer,

two ranging washers, honeycomb laminar flow element, LFE,

spacer, inlet filter, and 6-32 nut.

6. Inspect the honeycomb element for damage and replace if neces-

sary. Replacement of the LFE or inlet screen requires transducer

re-calibration.

7. Re-assemble components. When the transducer is installed in the

system, leak test the connection.

8. To be within the original accuracy, calibrate the transducer (see

page 4-9).

IM-82-C 4-7

Page 28

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Sensor Cleaning and Inspection

Due to sensor design variations, the following sensor cleaning instructions are for Model 822-S/824-S only. All other transducer

models must be returned to the factory.

Sensor cleaning is accomplished by simply rodding out the sensor

with the Sensor Cleaning Stylette, part number “CK” available

from Sierra. A 0.028 inch diameter piano wire may also be used.

To access the sensor for inspection or cleaning:

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.

1. Remove the transducer from the system. Remove the two socket

head access port plugs with a 1⁄4-inch Allen wrench. Visually

inspect the sensing ports and sensor.

1. Use a hemostat or tweezers to

push the cleaning wire into the

downstream opening of the

sensor tube. Do not force the

cleaning wire, move it back and

forth–DO NOT TWIST OR

ROTATE.

2. Flush the sensor tube with a

non-residuous solvent compatible with the O-ring material. In cases where solids are deposited

in sensor, units should be returned to factory for complete

cleaning and re-calibration.

3. Blow dry all parts with dry nitrogen and re-assemble. When the

transducer is installed in the system, leak test the connection.

Re-zero the transducer (see Chapter 3).

4-8 IM-82-C

Page 29

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Caution!

It is important that this

transducer be calibrated

only by qualified personnel.

Transducer Calibration

Calibration of Sierra’s flow meters requires a calibration standard of

at least four times the accuracy of the transducer. Sierra’s Cal-Bench

Automated Primary Calibration System is the preferred method of

calibration and is used at the factory for all calibrations from 10 sccm

up to 50 slpm. Most calibrations can be performed with a digital

voltmeter (DVM) or multimeter with 0.25% accuracy and four digits,

dry nitrogen and the K-factor tables included in this manual. Flow

meters require a metering valve for setting a constant flow rate.

The following procedures are offered as guidelines for calibration.

It is always best to return the transducer to the factory for calibration. Calibration checks and minor adjustments to the zero and full

scale are made via the access ports in the enclosure. If the linearity

needs adjustment (when installing a different bypass to change the

range) skip Step 2 and Step 3. If linearity does not need adjustment,

complete only Steps 1 through 3.

Step 1. Warm Up

Plug in the unit to be calibrated and allow at least 30 minutes warm

up time before attempting any adjustments.

Step 2. Zero Adjust

Slide open the zero and span access doors. Connect a DVM or multimeter to the transducer output pins. Adjust the zero potentiometer

for 0.0 volts (4 mA) at zero flow.

Step 3. Check Full Scale

Generate full scale flow using a metering valve in-line with the unit

under test. Compare the indicated flow rate with the flow standard

reading. If they agree to within ±10%, adjust the span potentiometer

for exact agreement. If the readings do not agree within ±10%, attempt to determine the cause of disagreement. Possibilities are:

• leaks in the system or in the transducer

• wrong or improper use of K-factor

• wrong or improper correction for temperature and pressure

• partially clogged or dirty sensor tube

• replacement of components in the flow path do not exactly match

the original parts

This completes transducer calibration. To adjust linearity, continue

with Step 4.

IM-82-C 4-9

Page 30

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Step 4. Adjusting Linearity

First gain access to the printed circuit board inside the enclosure:

1. For units with the digital display, carefully rotate the display un-

til it hits the top plate. Slide the display’s two side panels up and

remove. Move the display aside taking care not to damage the

connecting cable.

2. Remove the two Phillips head screws from the top of the trans-

ducer enclosure. Remove the two Phillips head screws from the

back of the transducer enclosure. Pull the enclosure panels off.

3. Orient the transducer with the component side of the circuit

board facing you. Plug in the transducer and allow to warm up

for at least 30 minutes.

Step 5. Zero Adjust

Connect a DVM to the transducer output pins. Adjust the zero potentiometer for 0.0 volts (4 mA) at zero flow.

Step 6. Calibrate 25%

Use the calibration standard to set a flow rate of 25% of full scale.

Adjust the span potentiometer for 1.25 volts (8 mA) at the output of

the transducer.

Step 7. Calibrate 50%

Increase the flow rate to 50% of full scale. If the output is within

+0.05 V (0.2 mA), no adjustment is necessary. If the output is beyond these limits, install a jumper block at J1 in the appropriate position (see Figure 4-7). Adjust R25 for the proper reading.

Step 8. Calibrate 75% and 100%

Set the flow to 75% of full scale. If the output is outside the limits

set in Step 7, install a jumper block in J2 in the appropriate position.

Adjust R27 for the correct reading. Repeat this procedure for 100%

flow using R29. Repeat Steps 6 through 8 at least one more time.

Figure 4-7. Printed Circuit Board Component Locations

4-10 IM-82-C

Page 31

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

Transducer Troubleshooting

When you suspect that the transducer is not operating correctly,

there are a few simple checks that can be made before taking the unit

out of service:

1. Make certain that there are no leaks in the gas line.

2. Check that all cables are connected and are in good condition.

3. Verify that the power supply is in the correct range and

properly connected to the transducer.

4. Double check connector pin outs when replacing another manu-

facturer’s transducer.

This information is provided to help locate the cause of a transducer

failure. It is not intended to be an all inclusive repair guide. For most

repairs, the unit should be returned to the factory for service.

Problem Possible Cause Solution

No output No power

Inlet filter screen clogged

Clogged sensor

PCB defective

Unit will not zero Gas leak

Application requires high pressure and non-horizontal mounting

PCB defective

Reads full scale

with no flow

Output too high Incorrect calibration or K-factor

Out of calibration

*Model 822-S/824-S see sensor cleaning instructions

Gas leak

Liquid present in system

Defective sensor

Liquid present in system

Defective sensor

Dirty or clogged sensor

Change in composition of gas

Gas leak

LFE dirty

Inlet filter screen clogged

Incorrect inlet conditions

(1/2-inch size models)

PCB defective

Plug in power supply

Clean or replace screen

Return to factory for cleaning*

Return to factory for repair

Find and correct leaks

Re-zero transducer

(see Chapter 3)

Return to factory for repair

Find and correct leaks

Check for liquid in flow path

Return to factory for repair

Correct calibration/k-factor

Check for liquid in flow path

Return to factory for repair

Return to factory for cleaning*

See K-factory tables

Find and correct leaks

Clean LFE

Clean or replace screen

Re-plumb transducer correctly

(See Chapter 2)

Return to factory for repair

IM-82-C 4-11

Page 32

Chapter 4 Maintenance & Repair Series 820 Instruction Manual

Returning Equipment to the Factory

Factory Calibration—All Models

Sierra Instruments maintains a fully-equipped calibration laboratory. All

measuring and test equipment used in the calibration of Sierra transducers

are traceable to NIST Standards. Sierra is ISO-9001 registered and conforms to the requirements of ANSI/NCSL-Z540 and ISO/IEC Guide 25.

Instructions for Returning Your Instrument for Service

The following information will help you return your instrument to Sierra

Instruments' Factory Service Center and will ensure that your order is

processed promptly. Prices may vary depending on the flow range, type

of gas and operating pressure of your unit. To request detailed pricing contact your local Sierra Instruments distributor or contact one of our offices

directly. Our expedite fees are: three-day turnaround 25%, two-day turnaround 40%.

Please follow these easy steps to return your instrument for factory

service:

1. Obtain a Return Materials Authorization Form (RMA) with assigned

number from Sierra Instruments. You may obtain this from the

factory by calling (800) 866 0200 between 8:00 a.m. and 5:00 p.m.

PST Monday through Friday. You may also obtain this number via

e-mail by contacting service@sierrainstruments.com.

2. Once you have obtained an RMA number, complete the form (one

form can be used for multiple units). If you require service beyond

calibration, but do not know which service(s) will be required, describe the symptoms as accurately as possible on the RMA form.

Submit electronically or by fax to (831) 373-2414.

3. Pack your instrument carefully (bubble wrap or molded foam sug-

gested-NOT PEANUTS) and include a copy of the RMA form

(complete with Sierra supplied RMA number) with the unit(s).

4. Ship the unit(s) to the following address:

4-12 IM-82-C

Page 33

Series 820 Instruction Manual Chapter 4 Maintenance & Repair

RETURN ADDRESS:

Sierra Instruments, Inc.

Caution!

Always fully neutralize

any toxic gas trapped in-

side the instrument before

removing it from the gas

line.

CUSTOMER SERVICE AND SUPPORT INFORMATION:

Email Technical Support: service@sierrainstruments.com

Email Sales: sales@sierrainstruments.com

FACTORY USA (recommended):

TOLL FREE: 800-866-0200

European Sales & Service Center:

Attention: Factory Service Center

5 Harris Court, Building L

Monterey, CA 93940 USA

PHONE: 831-373-0200

FAX: 831-373-4402

EMAIL: service@sierrainstruments.com

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Sales & Service Center:

PHONE: + 86 203435 4870

FAX: +86 203435 4872

IMPORTANT SAFETY NOTE ABOUT PURGING

WARNING: When toxic or corrosive gases are used, purge

unit thoroughly with inert dry gas before disconnecting

from the gas line to prevent personnel from being injured

when coming in contact with the instrument.

WARNING: If an instrument used with a toxic or corrosive

gas is returned to the factory, a Material Safety Data Sheet

(MSDS) must be enclosed & attached to the outside of the

box to alert Sierra personnel of the potential hazard. Also,

make sure the inlet & outlet are solidly plugged off.

IM-82-C 4-13

Page 34

Series 820 Instruction Manual Appendix A

Appendix A Conversion Formulas and Gas Tables

Conversion of Flow Rate to Other T and P Conditions

The flow rate of your transducer is referenced to certain ÒstandardÓ

conditions of temperature and pressure. Unless otherwise specified in

your order, these standard conditions are 21°C (70°F) and 760 mm of

mercury (1 atmosphere). If you wish to convert to other ÒstandardÓ

conditions or to find the ÒactualÓ conditions in the pipe where your instrument is installed, use the following relationship:

P

Q2 = Q

P

T

1

2

2

T

1

1

(1)

( )1 = The standard conditions under which your instrument

was calibrated,

= The new standard conditions or the actual temperature

( )

2

and pressure conditions in the pipe,

= The gas mass flow rate referenced to the calibrated standard

Q

1

conditions (sccm or slm),

= The gas mass flow rate referenced to the new standard or

Q

2

actual conditions (sccm or slmÑÒSÓ means Òstandard,Ó

accm or almÑÒAÓ means ÒactualÓ),

P = Absolute pressure (kg/cm

or psia), and

2

T = Absolute temperature (°K or °R) (°K = °C + 273, °R = °F + 460).

Example 1: Changing ÒStandardÓ Conditions

If your transducer has a flow rate reading of 10.00 slm and was calibrated

at standard conditions of 70°F (21°C) and 1 atmosphere (14.7 psia), and if

you wish to convert this reading to standard conditions of 32°F (0°C) and

1 atmosphere, then you would use Equation (1) as follows:

14.7 460 + 32

= (10.0) = 9.28 slm

Q

2

14.7 460 + 70

The flow rate referenced to 0°C will be approximately 7% lower than

when referenced to standard conditions of 21°C.

Example 2: Finding the ÒActualÓ Flow Rate

If the flow rate and calibrated standard conditions are as given in

Example 1 and you wish to find the actual flow rate at 100°F and 30

psig, then you would use Equation (1) as follows:

14.7 460 + 100

= (10.00) = 3.47 slm

Q

2

14.7 + 30 460 + 70

IM-82-C A-1

Page 35

Appendix A Series 820 Instruction Manual

Calculating For a Single Gas

The following tables provide K-factors and thermodynamic properties of gases commonly used with mass flow meters and controllers.

The purpose of these tables is two-fold:

1. Calibrating an ÒactualÓ gas with a reference gas. This is particularly useful if the actual gas is not a common gas or if it is toxic,

flammable, corrosive, etc.

2. Interpreting the reading of a flow meter or flow controller which

has been calibrated with a gas other than the actual gas.

In applying the tables, the following fundamental relationship is used:

Q1/Q2 = K1/K

2

(1)

Where:

Q = The volumetric flow rate of the gas referenced to standard

conditions of 0°C and 760 mm Hg (sccm or slm),

K = The K-factor defined in equation (6),

( ) 1 = Refers to the ÒactualÓ gas, and

( ) 2 = Refers to the ÒreferenceÓ gas.

The K-factor is derived from the first law of thermodynamics applied to the sensor tube, as described in Chapter 1:

¥

mC DT

H =

p

N

(2)

A-2 IM-82-C

Page 36

Series 820 Instruction Manual Appendix A

Where:

H = The constant amount of heat applied to the sensor tube,

¥

m = The mass flow rate of the gas (gm/min)

Cr = The coefficient of specific heat of the gas (Cal/gm);

Cr is given in the Table (at 0°C),

DT = The temperature difference between the downstream and

upstream coils, and

N = A correction factor for the molecular structure of the gas

given by the following table:

Number of Atoms in the Gas Molecule N

Monatomic 1.040

Diatomic 1.000

Triatomic 0.941

Polyatomic 0.880

The mass flow rate, m, can also be written as:

¥

m = Q

¥

(3)

r

Where:

r = The gas mass density at standard conditions (g/l); r is given

in the tables (at 0°C, 760 mm Hg).

Furthermore, the temperature difference, DT, is proportional to the

output voltage, E, of the mass flow meter, or

DT = aE (4)

where:

a = A constant.

If we combine equations (3) and (4), insert them into equation (2),

and solve for Q, we get

Q = (bN/rC

) (5)

p

where:

b = H/aE = a constant if the output voltage is constant.

IM-82-C A-3

Page 37

Appendix A Series 820 Instruction Manual

For our purposes, we want the ratio of the flow rate, Q1, for an actual gas to the flow rate of a reference gas, Q2, which will produce

the same output voltage in a particular mass flow meter or controller.

We get this by combining equations (1) and (5):

Q1/Q2 = K1/K2 = (N1/ r1Cp1)/(N2/r2CP2) (6)

Please note that the constant b cancels out. Equation (6) is the fundamental relationship used in the accompanying tables. For convenience,

the tables give ÒrelativeÓ K-factors, which are the ratios K

1/K2

, instead

of the K-factors themselves. In the tables, the relative K-factor is

K

/KN2 where the reference gas is the commonly used gas, nitrogen

actual

(N2). The remaining columns give Cp and r, enabling you to calculate

K1/K2 directly using Equation (6). In some instances, K1/K2 from the

tables may be different from that which you calculate directly. The value

from the tables is preferred because in many cases it was obtained by

experiment. Sierra calibrates every transducer with primary standards

using the actual gas or a molecular equivalent reference gas. The calibration certificate accompanying the transducer cites the reference gas

used.

Example 1:

A transducer is calibrated for nitrogen (N

), and the flow rate is

2

1000 sccm for a 5.000 VDC output signal. The flow rate for carbon

dioxide at a 5.000 VDC output is:

Q

CO2/QN2

Q

CO2

= K

CO2/K N2

= (0.74/1.000)1000 = 740 sccm

, or

Example 2:

A transducer is calibrated for hydrogen (H

), and the flow rate is

2

100 sccm for a 5.000 VDC output signal. The flow rate for nitrous

oxide (N2O) is found as follows:

Q

N2O/QH2

Q

N2O

= K

N2O/K H2

= (0.71/1.01) 100 = 70.3 sccm

Note that the K-factors relative to nitrogen must be used in each case.

, or

Example 3:

We want a transducer to be calibrated for use with dichlorosilane

(SiH2Cl2) at a 100 sccm full scale flow. We wish to use the preferred reference gas Freon-14 (CF4). What flow of CF4 must we

generate to do the calibration?

Q

SiH2CL2 /QCF4

100/Q

CF4

= 100/0.869 = 115 sccm

Q

CF4

= K

= 0.869

SiH2CL2 /K CF4

A-4 IM-82-C

Page 38

Series 820 Instruction Manual Appendix A

Calculating Dual Gas Mixtures

Equation (6) is used for gas mixtures, but we must calculate N/rC

for the mixture. The equivalent values of r, Cp, and N for a dual

gas mixture are given as follows:

The equivalent gas density is:

¥

r

¥

= ( / ) + ( / )

m

1T

m

r

¥

¥

m

m

2

1

Tr2

Where:

¥

m = m

( )

¥

¥

m

T

= Refers to gas #1, and

1

+ = Total mass flow rate (gm/min),

1

2

( )2 = Refers to gas #2

The equivalent specific heat is:

= F1Cp1 + F2C

C

p

p2

Where:

p

¥

F = ( )/( ) and

F = ( )/( )

m

1

¥

m

2

2

¥

r

m

1r1

T

¥

m

r

T

r

2

The equivalent value of N is:

¥

N = ( / ) N + ( / ) Nm

¥

m

1T1

¥

m

m

2

¥

T2

The equivalency relationships for r, Cp, and N for mixtures of

more than two gases have a form similar to the dual-gas relation-

ship given above.

IMPORTANT NOTE ABOUT K-FACTORS:

Please note that if you have a transducer calibrated for a gas such as

methane and wish to use the K-factors to measure a gas such as air,

that the inaccuracy of the measurement can range from ±5 to 10%.

The use of K-factors is, at best, only a rough

approximation and

should not be used in applications that require a better than ±5 to

10% accuracy.

It should also be noted that certain gases, in similar Òfamilies,Ó will

work exceptionally well with K-factors; however, those instances

are only true when similar thermal properties of the gas are present.

IM-82-C A-5

Page 39

Appendix A Series 820 Instruction Manual

Gas Tables and K-factors

Actual Gas

Symbol

Acetylene C2H

Chemical

2

K-factor

Relative N2Cp(Cal/g)

.58 .4036 1.162

Density

(g/l) @ 0°C

Air 1.00 .240 1.293

Allene (Propadiene) C

3H4

Ammonia NH

3

.43 .352 1.787

.73 .492 .760 NEO

Argon Ar 1.45 .1244 1.782

Arsine AsH

Boron Trichloride BCl

Boron Trifluoride BF

Bromine Br

Boron Tribromide Br

Bromine Pentafluoride BrF

Bromine Trifluoride BrF

Bromotrifloromethane

CBrF

3

3

3

2

3

5

3

3

.67 .1167 3.478

.41 .1279 5.227 KR

.51 .1778 3.025

.81 .0539 7.130

.38 .0647 11.18

.26 .1369 7.803

.38 .1161 6.108

.37 .1113 6.644

(Freon-13 B1)

1,3-Butadiene C4H

Butane C

4H10

1-Butane C4H

2-Butane C

2-Butane

4H8

C4H8 TRANS .291 .374 2.503

Carbon Dioxide CO

Carbon Disulfide CS

6

8

CIS .324 .336 2.503 NEO

2

2

.32 .3514 2.413

.26 .4007 2.593 NEO

.30 .3648 2.503 NEO

.74 .2016 1.964

.60 .1428 3.397

Carbon Monoxide CO 1.00 .2488 1.250

Carbon Tetrachloride CCl

Carbon Tetrafluoride

CF

4

4

.31 .1655 6.860

.42 .1654 3.926

(Freon-14)

Carbonyl Fluoride COF

2

.54 .1710 2.945

Carbonyl Sulfide COS .66 .1651 2.680

Chlorine CL

Chlorine Trifluoride CIF

Chlorodifluoromethane

CHClF

2

3

2

.86 .114 3.163

.40 .1650 4.125

.46 .1544 3.858

(Freon-22)

Chloroform CHCI

Chloropentafluoroethane

C2CIF

3

5

.39 .1309 5.326

.24 .164 6.892

(Freon-115)

Chlorotrifluromethane

CCIF

3

.38 .153 4.660

(Freon-13)

Cyanogen C2N

2

.61 .2613 2.322

Cyanogen Chloride CICN .61 .1739 2.742

Cychlopropane C3H

Deuterium D

Diborane B

2

2H6

Dibromodifluoromethane CBr2F

5

2

.46 .3177 1.877

1.00 .1722 1.799

.44 .508 1.235

.19 .15 9.362

Dibromethane .47 .075 7.76

Dichlorodifluoromethane

CCI

2F2

.35 .1432 5.395

(Freon-12)

Dichlorofluoromethane

CHCl2F .42 .140 4.952

(Freon-21)

Elastomer

O-ring*

* If no O-ring material is specified then O-ring to be used is Viton

A-6 IM-82-C

Page 40

Series 820 Instruction Manual Appendix A

Actual Gas

Symbol

Dichloromethylsilane (CH

Dichlorosilane SiH

Chemical

Dichlorotetrafluoroethane

C

SiCl

3) 2

2Cl2

2Cl2F4

2

K-factor

Relative N2Cp(Cal/g)

.25 .1882 5.758

.40 .150 4.506

.22 .1604 7.626

Density

(g/l) @ 0°C

Elastomer

O-ring*

(Freon-114)

1,1-Difluoroethylene

C

2H2F2

.43 .224 2.857

(Freon-1132A)

Dimethylamine (CH3) 2NH .37 .366 2.011

Dimethyl Ether (CH

2,2-Dimethylpropane C3H

Ethane C

Ethanol C

EthylAcetylene C4H

Ethyl Chloride C

Ethylene C

O .39 .3414 2.055

3) 2

12

2H6

O .39 .3395 2.055

2H6

6

CI .39 .244 2.879

2H5

2H4

.22 .3914 3.219

.50 .4097 1.342

.32 .3513 2.413

.60 .1365 1.251

Ethylene Oxide C2H4O .52 .268 1.965

Fluorine F

Fluoroform (Freon-23) CHF

2

3

.980 .1873 1.695

.50 .176 3.127

Freon-11 CCI3F .33 .1357 6.129

Freon-12 CCI

2F2

Freon-13 CCIF

Freon-13 B1 CFrF

Freon-14 CF

Freon-21 CHCI

4

2

Freon-22 CHCIF

Freon-113

Freon-114 C

CCI2FCCIF

2Cl2F4

Freon-115 C2ClF

Freon-C318 C

Germane GeH

4F6

4

Germanium Tetrachloride GeCL

3

3

F .42 .140 4.952

2

2

5

4

.35 .1432 5.395

.38 .153 4.660

.37 .1113 6.644

.42 .1654 3.926

.46 .1544 3.858

.20 .161 8.360

.22 .160 7.626

.24 .164 6.892

.17 .185 8.397

.57 .1404 3.418

.27 .1071 9.565

Helium He 1.454 1.241 .1786

Hexafluoroethane

C

2F6

.24 .1834 6.157

(Freon-116)

Hexane C6H

Hydrogen H

14

2

.18 .3968 3.845

1.01 3.419 .0899

Hydrogen Bromide HBr 1.000 .0861 3.610

Hydrogen Chloride HCl 1.000 .1912 1.627 KR

Hydrogen Cyanide HC N 1.070 .3171 1.206

Hydrogen Fluoride HF 1.000 .3479 .893 KR

Hydrogen Iodide HI 1.000 .0545 5.707

Hydrogen Selenide H

Se .79 .1025 3.613

2

Hydrogen Sulfide H2S .80 .2397 1.520

Iodine Pentafluoride IF

Isobutane CH(CH

Isobutylene C4H

5

3)3

8

.25 .1108 9.90

.27 .3872 3.593

.29 .3701 2.503

Krypton Kr 1.453 .0593 3.739

Methane CH

4

.72 .5328 .715

Methanol CH3OH .58 .3274 1.429

Methyl Acetylene C

Methyl Bromide CH

3H4

Br .58 .1106 4.236

2

.43 .3547 1.787

Methyl Chloride CH3Cl .1926 2.253

Methyl Fluoride CH

F .68 .3221 1.518

3

* If no O-ring material is specified then O-ring to be used is Viton

IM-82-C A-7

Page 41

Appendix A Series 820 Instruction Manual

Actual Gas

Chemical

Symbol

K-factor

Relative N2Cp(Cal/g)

Density

(g/l) @ 0°C

Elastomer

O-ring*

Methyl Mercaptan CH3SH .52 .2459 2.146

Methyl Trichlorosilane (CH

Molybdenum Hexafluoride MoF

Monoethylamine C

Monomethylamine CH3NH

) SiCl

3

6

2H5NH2

3

.25 .164 6.669

.21 .1373 9.366

.35 .387 2.011

2

.51 .4343 1.386

Neon NE 1.46 .245 .900

Nitric Oxide NO .990 .2328 1.339

Nitrogen N

Nitrogen Dioxide NO

Nitrogen Trifluoride NF

2

2

3

1.000 .2485 1.25

.74 .1933 2.052

.48 .1797 3.168

Nitrosyl Chloride NOCl .61 .1632 2.920

Nitrous Oxide N

Octafluorocyclobutane

O .71 .2088 1.964

2

C

4F6

.17 .185 8.397

(Freon-C318)

Oxygen Difluoride OF

Oxygen O

Ozone O

Pentaborane B

Pentane C

5H9

5HI2

2

2

3

.63 .1917 2.406

1.000 .2193 1.427

.446 .3 2.144

.26 .38 2.816

.21 .398 3.219

Perchloryl Fluoride CIO3F .39 .1514 4.571

Perfluoropropane C

3F8

Phosgene COCl

2

.174 .197 8.388

.44 .1394 4.418

PhosphinePH3 .76 .237 1.517

Phosphorous Oxychloride POCl

Phosphorous Pentafluoride PH

Phosphorous Trichloride PCl

Propane C

Propylene C

3H8

3H6

Silane SiH

Silicon Tetrachloride SiCl

Silicon Tetrafluoride SiF

Sulfur Dioxide So

Sulfur Hexafluoride SF

Sulfuryl Fluoride SO

2F2

3

5

5

4

4

4

2

6

.36 .1324 6.843

.30 .1610 5.620

.30 .1250 6.127

.36 .3885 1.967

.41 .3541 1.877

.60 .3189 1.433

.28 .1270 7.580

.35 .1691 4.643

.69 .1488 2.858

.26 .1592 6.516

.39 .1543 4.562

Teos .090 KR

Tetrafluorahydrazine N

Trichlorofluormethane

CCl

2F4

F .33 .1357 6.129

3

.32 .182 4.64

(Freon-11)

Trichlorisilane SiHCl

1,1,2-Trichloro-1,2,2

CCl2FCClF

3

2

.33 .1380 6.043

.20 .161 8.360

Trifluorethane (Freon-113)

Trisobutyl Aluminum (C

Titanium Tetrachloride TiCl

Trichloro Ethylene C2HCl

Trimethylamine (CH

Tungsten Hexasfuoride WF

Uranium Hexafluoride UF

Vinyl Bromide CH

Vinyl Chloride CH

)Al .061 .508 8.848

4H9

4

3

N .28 .3710 2.639

3)3

6

6

CHBr .46 .1241 4.772

2

CHCl .48 .12054 2.788

2

.27 .120 8.465

.32 .163 5.95

.25 .0810 13.28 KR

.20 .0888 15.70

Xenon Xe 1.44 .0378 5.858

* If no O-ring material is specified then O-ring to be used is Viton

A-8 IM-82-C

Page 42

Series 820 Instruction Manual Appendix B Specifications

Appendix B Product Specifications

Operating Specifications

Gases Most gases; check compatibility with wetted materials; specify when ordering

Mass Flow Rates Models 822/824: 0 to 10 sccm to 0 to 50 slpm;

Gas Pressure Models 822/824:150 psig ( 10 barg) maximum, 20 psig (1.4 barg) optimum

Gas & Ambient Temperature

Leak Integrity Models 822/824, 826/827: 1 X 10-4 atm cc/sec of helium maximum

Pressure Drop Models 822/824:

Models 826/827: 0 to 75 slpm to 0 to 175 slpm;

Models 822-S/824-S: 0 to 10 sccm to 0 to 500 slpm;

flow ranges specified are for an equivalent flow of nitrogen at 760 mm Hg

and 21°C (70°F); other ranges in other units are available (e.g. scfh or

nm3/h)

Models 826/827: 150 psig ( 10 barg) maximum, 20 psig (1.4 barg) optimum

Models 822-S/824-S: 1000 psig (68.9 barg) maximum for low flow bodies only;

500 psig (34 barg) maximum; 20 psig (1.4 barg) optimum

32° to 122°F (0 to 50°C); higher available on special order

Models 822-S/824-S: 5 X 10-9 atm cc/sec of helium maximum

Flow Rate cm of Water mbar in H2O

100 sccm 0.06 0.06 0.024

1 slpm 0.6 0.59 0.236

10 slpm 6.0 5.88 2.36

20 slpm 24.0 23.5 9.45

30 slpm 54.0 53 21.3

40 slpm 96.0 94.7 37.8

50 slpm 130.0 127.4 51.2

Models 826/827: Two inches of mercury maximum at 175 slpm

822/824-S (low).........0.08 psi (0.006 bar or 6 cm of water) differential max;

822/824-S (med).......0.08 psi (0.006 bar or 6 cm of water) differential max;

822/824-S (high)........0.08 psi (6 mbar or 6 cm of water) differential max;

Power Requirements 12 to 18 VDC nominal, 100 mA maximum; 24 VDC optional

Output Signal Linear 0-5 VDC, 1000 Ohms minimum load resistance

Linear 4-20 mA, 30-500 Ohms maximum loop resistance

Display 3.5 digit LCD (0.6 in H); remote mounting option available

15 slpm: 1.5 psi (0.10 bar or 105 cm of water) differential max

100 slpm: 1.5 psi (0.10 bar or 105 cm of water) differential max

300, 400 and 500 slpm: 2 psi (0.14 bar or 140 cm of water)

differential maximum

IM-82-C B-1

Page 43

Appendix B Specifications Series 820 Instruction Manual

Performance Specifications

Accuracy ±1.5% of full scale including linearity over 15 to 25°C and 5 to 60 psia (0.3 to 4 bara)

Repeatability ±0.5% of full scale

Temperature Coefficient 0.08% of full scale per °F (0.15% of full scale per °C), or better

Pressure Coefficient 0.01% of full scale per psi (0.15% of full scale per bar), or better

Response Time 800 ms time constant; six seconds (typical) to within ±2% of final value over 25 to

100% of full scale

Physical Specifications

Wetted Materials 822/824: 10% glass-filled Nylon® 6/6, 316 stainless steel, nickel plating, Viton

o-rings standard, Neoprene® and 4079 Kal-Rez® (or equivalent) o-rings optional

826/827: Anodized aluminum, 316 stainless steel, nickel plating, Viton® o-rings

standard, Neoprene® and 4079 Kal-Rez® (or equivalent) o-rings optional

822-S/824-S: 316 stainless steel, nickel plating, Viton® o-rings standard, Neoprene

and 4079 Kal-Rez® (or equivalent) o-rings optional

®

®

B-2 IM-82-C

Page 44

Series 820 Instruction Manual Appendix B Specificati

ons

IM-82-C B-3

Page 45

Appendix B Specifications Series 820 Instruction Manual

B-4 IM-82-C

Loading...

Loading...