Page 1

Sierra Radio Systems

Series 200 Control System Owners Manual

Version 1.2

Page 2

Table of Contents

Introduction

Hardware overview

Architecture

Configuring and installing the hardware boards

External connections

Configuring the control system

Introduction

Using DTMF

Using a PC and the CONFIG program

Basic configuration parameters

Radio port configuration

Setting audio levels

Using macros and creating custom commands

Saving the configuration to a file

Downloading configuration to the control system

Terminology and file system

Installing new firmware

Control system operation

Status indication LEDs

Command processor

Unlock codes

Site prefixing

Command reference guide

System-wide Audio Level Setting

Final System Installation Checklist

Appendix

Glossary

Receive qualification, squelch and transmit timing

Telemetry tones and level control

Software architecture and theory of operation

2

Page 3

Introduction

This manual provides all the basic information you need to know to get your control

system installed, configured and on the air quickly. The control system is designed to

work "out of the box" in a standard configuration.

In most installations, all that is required is making the physical connections to power

and the radio equipment and setting a few basic configuration parameters such as call

sign and unlock code (password) and you are on the air.

The control system can be tailored to your particular needs in many ways. This manual

will give you a good overview of many of the parameters that can be changed to tailor

your system to meet your specific needs. Each port can be customized for a particular

behavior including repeaters, RF links, VOIP links, etc. Telemetry, command names,

and many other behaviors can also be customized.

Additional application notes are available on the SRS support web site that provides

detailed information on a variety of special topics.

Basic Checklist

As you read through this document, from time to time you will see a check box. This is

used to get your attention and indicates that this is something you really need to do to

get your control system working. This is part of your “basic check list”. Make sure you

read these notes.

You will also see open check boxes. These are for your to check them off as you go

to make sure you follow all the important steps.

3

Page 4

Architecture Overview

The Series 200 control systems are very modular and scalable. The basic architecture

includes a master CPU board, from 1 to 8 Radio Control Boards (RCBs), and a backplane

to provide the interconnection between boards. Each RCB interfaces with an external

device such as a repeater, RF link, VOIP link, or computer and provides a basic signaling

interface that includes receive audio input, transmit audio output, COR (carrier present),

CTCSS/DCS decode logic input, and PTT (transmit control) output, serial radio control

I/O, and transmitter cooling fan output control.

The RCB can interface with many types of radio and computer equipment without

modification. In some cases, additional signal processing is required. The Series 200 is

designed to allow an additional signal interface board to be added to any of the RCB.

Optional signaling boards include special boards for microwave radio equipment, E&M

signaling, squelch detect, CTCSS tone generation, CTCSS detection, low pass filtering,

high pass filtering, TTL to RS-232 conversion, etc. The optional signaling interface

boards bolt on to the RCB to form a board pair or “module”.

A control system may be as simple as a CPU board, a single RCB and a short backplane.

A fully configured system may occupy an entire 19 inch card rack and contain a CPU,

up to 8 RCBs each with its own special signaling interface board, optional system

interface boards, and a large backplane and power supply board. In any configuration,

the system uses exactly the same CPU and RCB boards so a small system can easily

grow into a large system by simply adding more boards. Additionally, the software that

runs on the smallest configuration is exactly the same as the software for the largest

configuration.

The modular nature of the Series 200 control system make it not only easy to upgrade,

but also very easy to maintain. Boards can be quickly replaced from the front of the card

rack.

Very modular. Very scalable. Easy to maintain.

4

Page 5

System Installation Checklist

Basic Checklist Summary

This is a reminder of the basic steps to get your control system configured and running.

Hardware installation and external connections

Configure all necessary jumpers on each board.

Plug boards into the backplane in the correct slots.

Connect the control system to an external 12 VDC power source.

Connect the CPU’s DB-9 connector to your PC.

Connect each RCB’s DB-9 connector to your external devices: radios (repeater, RF

links, remote base radios), VOIP computers, etc.

Software configuration

Set basic configuration parameters

Call sign

Set radio port configuration

Site prefix

Location ID

Unlock code

Set audio levels

Customize commands

Save the configuration to a file

Download configuration to the control system

5

Page 6

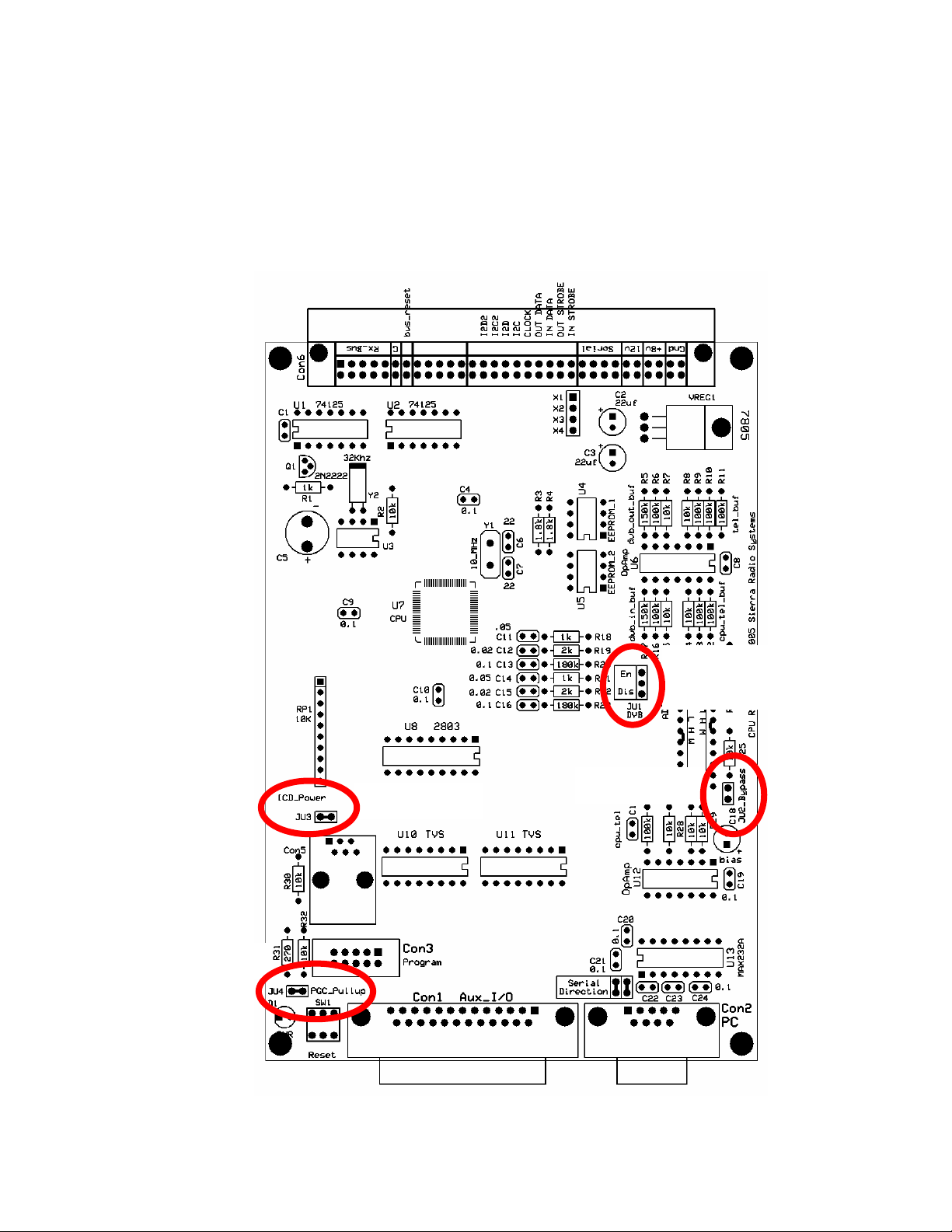

Configuring the CPU Board

Most of the boards in the control system have one or more jumpers that can be set to

configure the board for various special purposes. The default configuration will be used

in most cases. Refer to the SRS Hardware Reference manuals for more details on each

board and the various jumper options.

Here are the default jumper settings for the CPU and RCB boards.

Basic Checklist

Make sure all CPU board jumpers in properly set.

The CPU board executes the main control system functions including routing the audio,

controlling the transmitter PTT lines, command decoding, and command response

telemetry generation. The CPU board also provides a serial RS-232 connection to a PC

for controller configuration, and 24 user defined I/O connections including digital

inputs, analog inputs and buffered digital outputs.

CPU Jumper Settings

JU1 - DVB Jumper

The DVB jumper enables or disables audio from the DVB_bus signal on the backplane.

This signal is audio generated from the optional Digital Voice Board or DVB.

"DIS”

"EN": When using the optional DVB in the system, JU1 MUST be in the enabled or

JU2 - Digital Pot Bypass Jumper

OU

IN:

JU3 - ICD Power

OU

IN: Install if using Con 5, the modular ICD jack for in-circuit programming.

NOTE: When using the ICD jack, you MUST cut the trace on the bottom of board to

enable the ICD power.

In normal operation when not using the DVB, the jumper MUST be in the

disabled or "DIS" position.

"EN" position.

T: Default. Set telemetry level under CPU control. This is the normal state for this

jumper.

Force telemetry pot to mid scale. This overrides the CPU level set for the master

telemetry generator.

T:

Default. For using Con 3, the 10 pin header connector for in-circuit

progamming.

6

Page 7

JU4 - PGC Pullup

IN:

OUT: Remove the jumper when using Con 5, the ICD programming jack.

NOTE: When using the ICD jack, you MUST cut the trace on the bottom of

board.Default CPU Jumper Configuration

Default. Install this jumper for using Con 3, the 10 pin header connector for incircuit programming.

JU3 OUT

JU2 OUT

JU4 IN

All jumpers should be installed in the default positions indicated.

JU1 DVB

Default DIS

7

Page 8

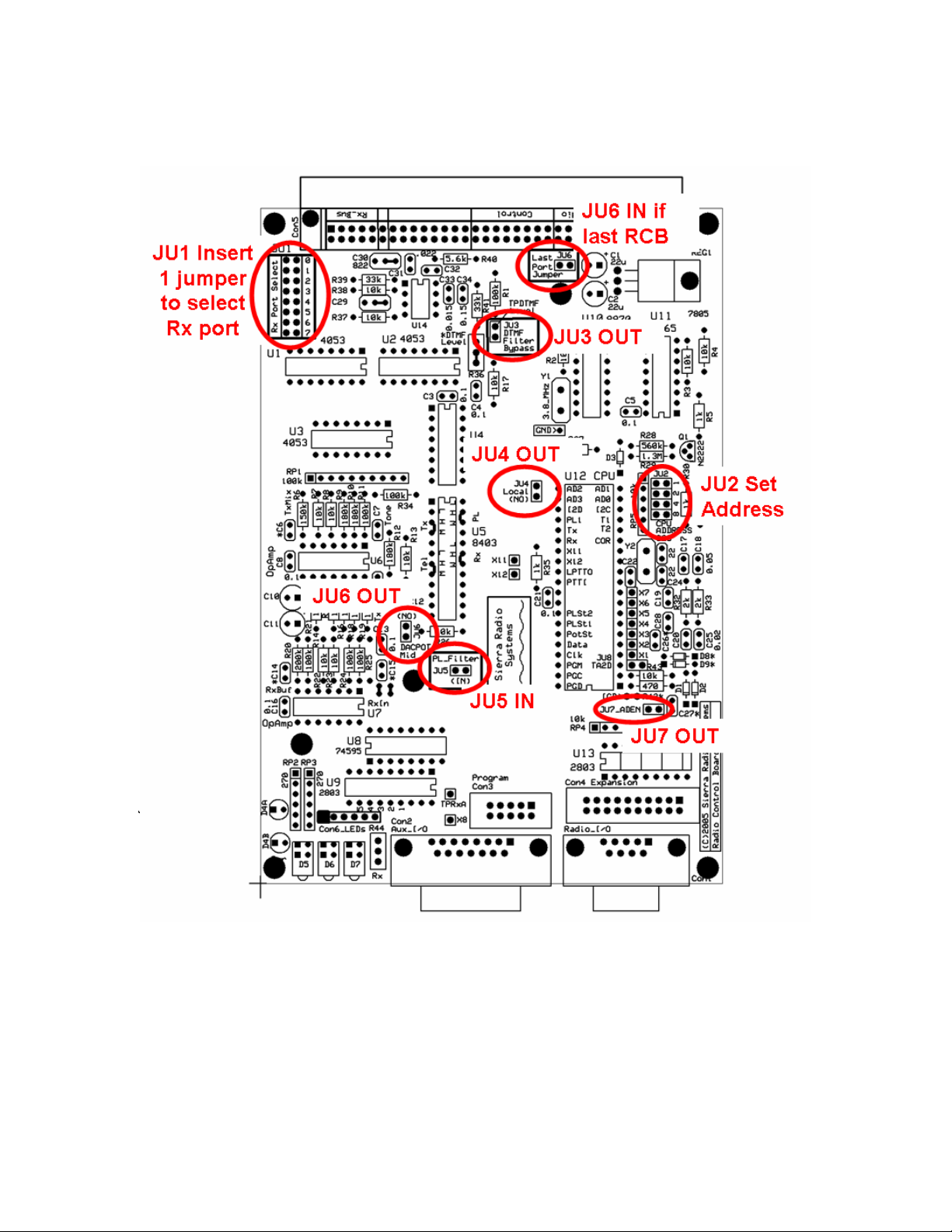

Configuring the Radio Control Board

The radio control board provides the audio interface, level set, audio mixing, local

telemetry (key up and CW ID) generation, serial radio control interface, extra user

programmable open collector outputs. One RCB is required for every radio or VOIP

computer in the system. Each RCB is configured to have one of several "personalities"

including a repeater, RF link, remotely controlled base station, or VOIP computer.

Basic Checklist

Make sure all RCB board jumpers are properly set.

JU1 - RX Port Select

You MUST

to the port you want to assign this board from 0 to 7.

No two boards can have the same rx port select value.

have one (and only one) jumper installed in this block. It must correspond

JU2 - CPU Address

You MUST

should be the same vale as the jumper installed in the Rx Port Select information above.

Jumpers

Port

0 out out out out

1 out out out IN

2 out out IN out

3 out out IN IN

4 out IN out out

5 out IN out IN

6 out IN IN out

7 out IN IN IN

install jumpers in the address header to match the port assignment. This

8 4 2 1

JU 3 - DTMF Filter Bypass

OUT:

IN: Bypass the DTMF filter and dirve the audio directly into the DTMF decoder.

Default. Takes the rx audio through a bandpass filter before it goes to the

DTMF decoder.

JU4 - Local (NO)

OUT: Default

IN: Install the jumper to enable the open collector output of Q2 to drive the "local

COR" input on the local CPU.

8

Page 9

JU5 - PL_Filter (NC)

OUT:

IN:

Remove jumper is using a companion signaling board like the microwave or PL

encode / decode boards.

Default. Install the jumper when opearting the RCB without any signal

conditioning boards.

JU6 - DAC Pot Mid

OUT:

IN: Sets all four digital pots to mid scale.

Default. Allows digital pots to be set by the local CPU.

JU6 – Last Port Jumper (yes, there are two jumpers marked JU6)

OUT:

IN: Insert a jumper in this position if this is the last RCB in the card rack. The Last

JU7 - ADEN

OU

Not used at this time.

Default. Leave the jumper out for all RCB board except the last one.

Port jumper provides a termination on the high speed serial bus and will reduce

noise on the bus.

T: Default.

JU8 - TA2D

OU

T: Default

Not used at this time.

9

Page 10

Default RCB Jumper Configuration

Radio

Note: There are two jumpers labeled “JU6”, the “DAC pot mid” jumper and the “last

port” jumper.

The RCB jumpers should all be set to the defaults. Additionally, each RCB must be

jumpered with the proper addresses set. Each RCB must be assigned one unique address

from 0 to 7.

Jumper block ____ must be set with a single jumper to properly route the Rx

audio to the proper backplane bus signal.

10

Page 11

Hardware Orientation

Power Supply Board

The power supply board provides a power switch and a power LED.

The power switch provides primary power to the CPU, RCB and accessory boards. The

12 VDC from the external power connector is routed to all boards in the card cage and is

not switched.

The power LED indicates that power is being supplied to the rest of the control system.

CPU Board

The CPU board provides a power LED, hardware resest switch, optional I/O connector

(DB25) and the male DB9 RS-232 serial connection to a PC used for computer-based

configuration and control.

To trigger a hardware reset, press the hardware reset button.

Radio Control Board (RCB)

The RCB board provides a power LED, a set of 6 channel status LEDs, a female DB15

auxiliary I/O connector and a female DB9 radio I/O connector.

The channel status LEDs indicate COR (active Rx signal present), PTT (transmitter

active), CTCSS/DCS decode, DTMF decode and two user programmable output bits.

The DB15 auxiliary connector provides many convenient functions including

11

Page 12

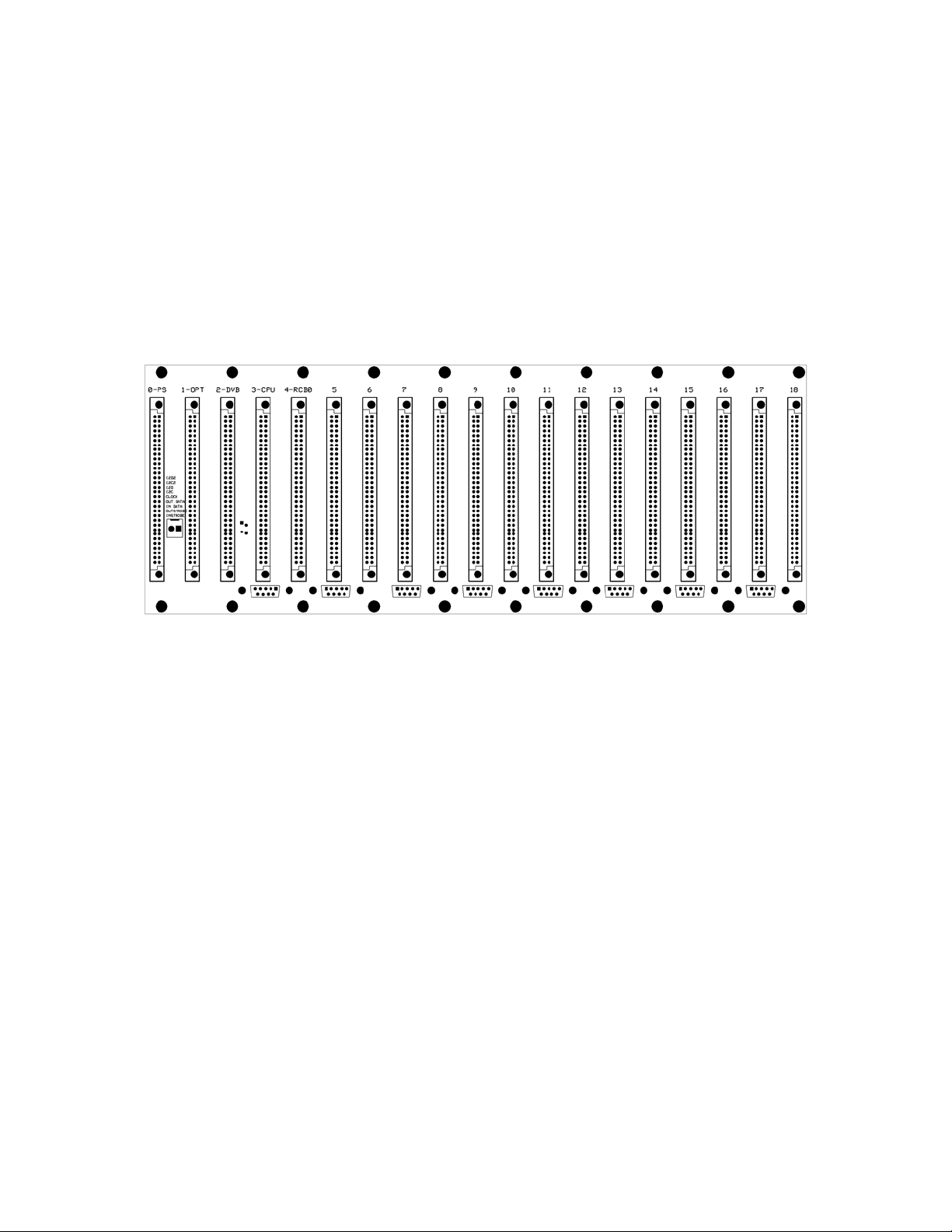

Configuring the Backplane

The system will come configured as ordered. You will need to plug the various boards

into the correct slots in the backplane. If your system is already assembled as desired,

you can skip this section.

The Power Supply, CPU and the first Radio Control Board (RCB) must be placed in

specific slots. After the first RCB, all additional RCBs must be installed next to each

other. There can be no gaps between the CPU and any of the RCBs. When optional

microwave or CTCSS signaling boards are used, these boards are paired with each RCB

and are installed in the slot to the right of the RCB.

The basic control system consists of the card rack with backplane, a power supply board,

CPU board and one Radio Control Board (RCB) for each receiver/transmitter in the

system. All controllers have the first 5 slots assigned as follows…

Slot Assignment

0 Power supply

1 Reserved for future expansion

2 Reserved for future expansion

3 CPU

4 Radio control board - port 0

Radio Control Boards are installed starting in slot 4. Every radio requires a radio control

board. Radio Control Boards must be plugged into the backplane next to each other and

are named port 0 through port 7. There can be NO gaps between boards after port 0.

12

Page 13

A basic 8 port controller will have the following configuration…

Typical 8 port controller

Slot Assignment

0 Power supply

1 Reserved for future expansion

2 Reserved for future expansion

3 CPU

4 Radio control board - port 0

5 Radio control board - port 1

6 Radio control board - port 2

7 Radio control board - port 3

8 Radio control board - port 4

9 Radio control board - port 5

10 Radio control board - port 6

11 Radio control board - port 7

12-18 Empty

Each port is assigned a "personality" which defines the basic behavior of that RCB.

Personalities can be either a repeater, RF link, VOIP link or remotely controlled base

station. The different personalities of a system can be assigned to the ports in any

desired order. The user level and many of the configuration commands refer to specific

ports by a number, often referred to as the link number because most of them will be

links. Configuration of the system is simpler if the number by which a port will be

referred is same as the port number. A typical configuration would have a primary

repeater in port 0, RF links in the next set of ports, VOID links, remote bases and then

any additional repeaters, For example, 2 repeaters, 4 links, and 2 remote bases would be

configured as…

Slot Assignment

0 Power supply

1 Reserved for future expansion

2 Reserved for future expansion

3 CPU

4 Radio control board - port 0 – Repeater 1

5 Radio control board - port 1 – Link 1

6 Radio control board - port 2 – Link 2

7 Radio control board - port 3 – Link 3

8 Radio control board - port 4 – Link 4

9 Radio control board - port 5 – Remote base 1, link 5

10 Radio control board - port 6 – Remote base 2, link 6

11 Radio control board - port 7 – Repeater 2, Radio 7

12-18 Empty

Special Note: There must

is a gap between boards, all ports up to the gap will work fine but all subsequent ports

will not function properly. This breaks the high speed serial control bus which

communicates the state of COR, PL decode, PTT, fan control, user outputs and DTMF

signals to the master CPU.

not be any empty slots between radio control boards. If there

13

Page 14

Using Optional Signaling Boards

If optional signaling boards such as t

boards are used, they are placed in the slot immediately to the right of the radio control

board. A typical 6 port microwave hub would be configured as…

Slot Assignment

0 Power supply

1 Reserved for future expansion

2 Reserved for future expansion

3 CPU

4 Radio control board - port 0 - Microwave radio 1

5 Microwave E&M signaling interface board

6 Radio control board - port 1 - Microwave radio 2

7 Microwave E&M signaling interface board

8 Radio control board - port 2 - Microwave radio 3

9 Microwave E&M signaling interface board

10 Radio control board - port 3 - Microwave radio 4

11 Microwave E&M signaling interface board

12 Radio control board - port 4 - Microwave radio 5

13 Microwave E&M signaling interface board

14 Radio control board - port 5 - Microwave radio 6

15 Microwave E&M signaling interface board

16-18 Empty

he microwave radio board or PL encode / decode

Any combination of Radio Control Boards with or without optional signaling boards

may be used. For example, a site with 1 repeater, 2 microwave radios, 2 narrowband RF

links, one with PL encode/decode, one VOIP interconnect to the internet and one

remote base radio.

Slot Assignment

0 Power supply

1 Reserved for future expansion

2 Reserved for future expansion

3 CPU

4 Radio control board - port 0 - Repeater

5 Radio control board - port 1 - Microwave radio, link 1

6 Microwave E&M signaling interface board

7 Radio control board - port 2 - Microwave radio, link 2

8 Microwave E&M signaling interface board

9 Radio control board - port 3 - RF link 3

10 PL encode / decode signaling interface board for RF link 1

11 Radio control board - port 4 - RF link 4

12 Radio control board - port 5 - VOIP internet interconnect board

13 Radio control board - port 6 - remote base radio

14-18 Empty

14

Page 15

External Connections

Backplane DC Power Connection

Basic Checklist

Make sure you connect the control system to an external 12 VDC power source.

The control system typically uses +12 to +14 VDC and will operate down to10 VDC with

no problems. The external DC power is supplied through a 2 pin connector mounted on

the back of the control system.

The alignment tab is on the top of the connector. As you look at the back of the

backplane, the left pin is +12 VDC in and the right pin is ground.

Make sure the connector is plugged in correctly. The control system is internally fused

on the power supply board just in case something gets shorted out. The fuse value

should be 3 amps.

15

Page 16

CPU Board Connections

The are three types of external connections on the CPU board, the configuration serial

port connector, the general purpose I/O connector and the in-circuit programming

connectors.

Basic Checklist

Make sure you connect the CPU’s DB-9 connector to your PC so you can use the

CONFIG program to configure your control system.

CPU Board Serial Port Connector

This connection is a standard RS-232 ASCII interface between the control system and

your computer. It is used to configure the control system under computer control.

Connector pin outs…

Pin 2 - Rx data in

Pin 3 - Tx data out

Pin 5 - Ground

The configuration serial port is the male DB-9 connector on the front edge of the board.

This connection is not used in normal operation. When using the optional PC-based

configuration software, the PCs serial port is plugged in this connector.

PC Configuration Cable

This cable connects your computer to the main CPU board for upload and downloading

the control systems configuration. The programming cable is a straight through cable.

Connections required are pin 2 to 2, 3 to 3 and 5 to 5. The crossover of txd / rxd is done

on the CPU board. Note that most female to female cable available in computer stores

swap pins 2 and 3, so you may need to make your own cable.

16

Page 17

Con_3 - In-Circuit Progamming Connector

The in-circuit programming connector, Con_3, is used to download new versions of

firmware to the main CPU. This is a 10 pin header connector designed to be used for incircuit programming with an ME Labs in-circuit programmer.

General Purpose I/O Connector

The GPIO connector provides 24 I/O signals that can be used for a variety of purposes.

The signals inlcude 8 TTL level digital inputs with internal logic pullups, 8 open

collector buffered outputs, 8 analog to digital converter inputs and ground.

All 24 I/O signals are protected from over voltage conditions using transient voltage

suppression devices.

Use

Pin

1 Analog input

2 Analog input

3 Analog input

4 Analog input

5 Digital output

6 Digital output

7 Digital output

8 Digital output

9 Digital input

10 Digital input

11 Digital input

12 Digital input

13 Digital input

Digital inputs are pulled up with a 10k resistor and must be either ground or +5 VDC.

Analog inputs must be between 0 and +5V.

Digital outputs are buffered open collector outputs that can sink up to 500 ma.

Pin

Use

14 Analog input

15 Analog input

16 Analog input

17 Analog input

18 Digital output

19 Digital output

20 Digital output

21 Digital output

22 Digital input

23 Digital input

24 Digital input

25 Ground

17

Page 18

Radio Control Board (RCB) Connections

Basic Checklist

Make sure you connect each radio, computer or other external device to the control

system RCBs using the DB9 connector on the front of the RCB.

DB-9 radio connections

The control system has a female DB-9 connector which

is used to connect to an external device including a

repeater, link radio, remote base radio or computer

system. The cable should have a male connector.

This picture is the DB-9 connector as seen on the front of

the control system.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

High impedence Rx audio input from receiver. Input can range from 0 to 2v

peak-to-peak. Anything around 1 v p/p works great. Rx audio may be

unsquelched.

COR ("Carrier Operated Relay"), an active low signal. When the carrier is

present, the COR pin must be pulled to ground.

Ground

PTT ("Push To Talk"), an active low signal. This is an open collector output that

pulls to ground when the controller wants to key the transmitter. The output

can sink a maximum of 250 ma.

Low impedence audio output to the transmitter. Nominal 1v p/p output. Can

be adjusted from 0 to about 4v p/p.

PL decode input active low. Pull this input pin low to indicate the presence of

the proper PL or DPL tone being decoded.

Serial data input. TTL level ASCII input used with serial programmable remote

base radios.

Serial data output. TTL level ASCII input used with serial programmable

remote base radios.

Fan control output. This is an open collector output which is pulled to ground

Pin 9

18

to actuate a relay that will turn on the cooling fan on the transmitter. The output

can sink a maximum of 250 ma.

Page 19

Radio control cable.

The radio co

a 9 pin, shielded cable with all 9 connections wired straight through, with pin 1 to 1, 2 to

2, etc.

In-circuit programming connector

This is a 10

operation. This is the connection where the in-circuit programmer in plugged in when

downloading new versions of firmware to the RCB's local CPU.

RCB Accessory Connector "Aux_IO"

This is a female DB-15 which provid

control, testing and alternate programming connections for the local CPU on the radio

control board.

Typical cable for external device control

8 Open collector user output #2

7 Open collector user output #3

14 Open collector user output #4

6 Open collector user output #5

11 Open collector PTT Output

12 Open collector Tx cooling fan output

13 Ground

ntrol cable connects the control system to the individual radios. The cable is

pin, dual row header connector. This connection is not used in normal

es various optional connections for external device

15 Open collector user output #1

19

Page 20

Microwave Radio Interface Board

This board can be configured to drive a microwave radio that requires balanced audio

and E & M signaling.

Modular jack pin outs

Pin Use

2 Balanced Tx audio out (600 Ohms)

3 PTT "M" signaling

4 Ground

5 Negative voltage input for PTT keying circuit (nomially -24v)

6 COR input, active low

7 Balanced Rx audio input (600 Ohms)

8 Balanced Rx audio input (600 Ohms)

1 Balanced Tx audio out (600 Ohms)

20

Page 21

AS-3 Audio Squelch Board

High impedence Rx audio input from receiver. Input can range from 0 to 2v

Pin 1

peak-to-peak. Anything around 1 v p/p works great. Rx audio may be

unsquelched.

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

COR ("Carrier Operated Relay"), an active low signal. When the carrier is

present, the COR pin must be pulled to ground.

Ground

PTT ("Push To Talk"), an active low signal. This is an open collector output that

pulls to ground when the controller wants to key the transmitter. The output

can sink a maximum of 250 ma.

Low impedence audio output to the transmitter. Nominal 1v p/p output. Can

be adjusted from 0 to about 4v p/p.

PL decode input active low. Pull this input pin low to indicate the presence of

the proper PL or DPL tone being decoded.

Serial data input. TTL level ASCII input used with serial programmable remote

base radios.

Serial data output. TTL level ASCII input used with serial programmable

remote base radios.

Fan control output. This is an open collector output which is pulled to ground

to actuate a relay that will turn on the cooling fan on the transmitter. The output

can sink a maximum of 250 ma.

21

Page 22

Radio I/O – II (RIO-II) Board

22

Page 23

Configuring the Control System

23

Page 24

Control System Configuration Software

Overview

Sierra Radio Systems supplies a software configuration program called “config” that

allows the system administrator to configure the control system through a Windowsbased PC. Config can be used in may different ways to configure a Sierra Radio Systems

control system. Features include a graphic user interface to enter and modify control

system parameters, run files control commands called scripts, reading configuration files

into the program and writing the configuration back out to a file, interactively set audio

levels, and more. The config program can be used “offline” to create and edit a

configuration without a control system. Config uses the serial port on the master CPU

board to transfer information to and from the control system. Config runs on a standard

Windows PC that supports a serial port. A USB to serial adapter can be used is no serial

port is available on the PC.

If you want to a detailed understanding of the config program and data files, skip

forward to section II. If you just want to jump right in and configure your control

system then here we go…

Section I - Setting up a New Configuration

The built in wizard helps you walk through the steps of creating a new configuration.

As you can see from the wizard the steps are…

1. Reset all parameters

2. Customize basic parameters

3. Configure each radio port

4. Set audio levels

5. Set command names and macros

6. Save configuration file

7. Download configuration to the controller

24

Page 25

The steps are simple and in some cases some steps can even be skipped. Here is a

description of what each step does…

1. Reset all parameters

This will set all the configuration parameters in the config program to their normal

default values. Then the configuration file “

default.cfg” will be loaded. This is the

starting point for your new controller configuration.

2. Customize basic parameters

At a minimum, the controller should be personalized with its call sign, site prefix,

location ID and unlock codes. For testing purposes, the defaults are fine but systems

typically need to have their own unique call sign. Also for security reasons, the unlock

code should be changed to something only the site administrator knows. If there are

multiple control systems in a network, the site prefix and location ID should be changed

to something unique to avoid confusion and proper network operation.

25

Page 26

Call signs and location IDs can be up to 20 characters.

The site prefix should be 1, 2 or three unique digits. All site prefix codes are # followed

by the parameter that you enter. If you enter 123, then your prefix will be #123.

Unlock codes should be something that only system administrators know. The

minimum requirement is to specify unlock codes 1 and 2.

3. Configure Each Radio Port

Each port is assigned a personality depending on the type of equipment and desired

behavior. Port types include repeaters, link, VIOP gateways, and remote bases.

Differences between port types

The table below describes the differences in behavior between ports configured as

repeaters, links, irlp nodes, and remote bases. Some of these are just the default

behavior that is created when the port type is defined, and can be changed, either by

port type or by individual port. Others (such as ability to accept commands) are built

into the programmed behavior of the port type.

26

Page 27

Repeater port type

Used for normal repeater operation. Loops repeater receiver audio to transmitter, uses

transmitter carrier delay, mutes all DTMF audio to the transmitter but passes DTMF to

the links, etc.

Link port type

Used for RF or “private” internet VOIP point to point network links. Does not loop

audio, passes all DTMF tones, has no carrier delay unless the signal comes from a

repeater input, etc.

VOIP port type

Used for IRLP, EchoLink and other “public” VOIP systems. Does not loop audio, does

not pass DTMF or any locally generated telemetry, turns off carrier delay by default, etc.

Remote base port type

Used for remotely controlled base stations including Icom, Yaesu, Kenwood serial

programmed radios, BCD and channelized radios. Does not loop audio, does not pass

DTMF or any locally generated telemetry, carrier delay turned off by default, etc

27

Page 28

If the port type is “Remote Base” then the remote base type should be selected for the

controller to generate the correct frequency and mode control data sent to the remote

base radio.

Groups

The control system can support up to 3 independent groups of ports. The default is for

all ports to operate together as group 0. Additional groups can be created by assigning

group #1 or #2 to a port. Each group will act as if its members are the only radios in the

system. All groups must use the same command set and will generate the same type of

telemetry.

Access

This defines the combination of carrier detect (COR) and CTCSS/DCS signaling

required for a valid signal present indication from each receiver.

Enabled

When checked, this makes that specific RCB (radio control board) available to the

system. When unchecked, it is logically disconnected as if the board was pulled from

the card cage.

Default on link

When checked, this port will default to be connected to the other ports in its group when

the system is reset or a site normal command is executed. When unchecked, this port

will be defaulted in the disconnected mode.

28

Page 29

3. Set Audio Levels

Each radio control board has 4 digitally controlled audio level set potentiometers. The

control the receiver and transmitter audio levels, telemetry level generated by the RCB

that is sent only to that specific transmitter and an auxiliary audio input level. The local

telemetry generator per transmitter is used for dial tone, busy signal, function complete,

CW ID and other functions. The auxiliary audio input is typically used for sub-audible

CTCSS and other externally generated signaling tones.

Audio level set dialog box

Use the “radio buttons” to select the specific audio level you want to set. Pick a port on

the left and a level set pot on the top. Then click one of the level adjust buttons on the

right side to change the pot level.

Interactive, real time audio level setting from the computer.

This is an interactive dialog box. Most commands and parameters entered on most

screens are not sent to the control system until the “download configuration to control

system” is performed. In the case of the audio level set screen, as you change audio

level values, they are sent real time to the control system. This allows you to set all

audio levels in the control system while connected to actual radio and test equipment.

This is the equivalent of adjusting up to 36 little audio pots but without having to bring

your little green screwdriver.

Each audio level can be set between 0 and 255. 0 is minimum (“Min”) which shuts off

the audio, 127 is Mid scale and 255 is maximum (“Max”) audio. Audio is adjusted by

29

Page 30

pressing one of the buttons on the right side of the screen. It Up 10 and Down 10 lets

you move quickly across the range of the pot while Up 1 / Down 1 let you fine tune

your levels.

4. Set Command Names and Macros

The control system comes with several dozen built in commands. In the simplest use

mode, all you need to do is select your own personal unlock code and use all the generic

built in commands and everything will work fine. This relies on the unique unlock code

for security, which for most situations may be good enough. It is often desirable to have

some or all of the user commands assigned unique “command names”. This is

accomplished by using the user command macro features of the control system. Up to

250 user macros can be created. A macro can be a simple mapping of a custom

command name to a single built in controller command. For example the built in

command C310 will send the CW ID for the system. If you wanted to have your own

command 123 send a CW ID you would create a macro with the name 123 and the

macro string contents would be C310.

Macros allow you to string several commands together. You can create a command that

will perform multiple actions with a single command name. For example you can create

a command 234 which will execute the internal commands C3311 C3312 C3313 C3304

C351 which will turn on links 1, 2 and 3, turn off link 4 and set the repeater in CTCSS

mode. Macros can even contain other macros.

Special note: If you have any special script files that need to be run to finalize your

configuration, this is the time to do it.

5. Save Configuration File

After you create your configuration, you should save it to a disk file so you can easily

edit or re-download your configuration in the future into the same or another control

system. To generate your configuration file, select File / Save As. You well see a dialog

box like this…

30

Page 31

The dialog box will open with a default file name of “newfile”. It is recommended

that you change the name to something more meaningful, like the name of the radio site

or a version number of your own making. If you enter “bigmountain” for example, you

will create a configuration file named bigmountain.cfg. To create your configuration

file, just press the generate button and in a few seconds you are done.

The newly created configuration file can be read or “loaded” into the config program at

any time, edited or downloaded to your control system.

6. Download configuration to the controller

Now that your configuration file is done, you are ready to download it to your control

system. Select menu Program / Write configuration to controller. The download

dialog box looks like this…

This dialog box will allow you to select which parts of the configuration are to sent to

the control system. You don’t have to send the whole configuration. For example, if

you only changed the callsign you might want to select just the “basic configuration”

selection. Then click “Program Controller”. Only the checked sections of the

configuration will be sent to the controller.

31

Page 32

Once the configuration has been downloaded into the controller, a notice box will

appear to let you know that the configuration download is done.

At this point you are done configuring your control system and have created a reusable

configuration file.

32

Page 33

Terminology and File System

Files

The standard distribution of config comes with a set of support files as follows…

Config_xxx.exe This is the main config program.

*.sll, *.dll, *.tkn These files are part of the config program.

config.env The config program environment file containing PC

installation and configuration data.

default.cfg The default control system configuration file.

scriptxx.scr Script files. These are empty and are modified by the user.

My_reference.htm An html file containing any reference information about

your system such as control codes, site info etc.

SRS Command List.htm This is the list of all built-in commands for the control

system.

Configuration file (*.cfg)

An ascii text file that contains one or more of the configuration parameters for a

particular control system. The configuration file is named yourfilename.cfg where

yourfilename is whatever you like. This file can be hand generated but it is hundreds of

lines long so it is generated by the config program automatically. When you select “file”

then “save as” from the top menu, you have a dialog box that lets you generate a config

date file. Enter the name you want in the config file box. Then, click “apply” then click

“generate”. The config program will generate the complete configuration file for you

based on the current settings you have entered in the various configuration windows.

To load in a saved config file, enter the config file name in the top left field on the main

page and click “load”. You can also click “browse” to look for a file. This will read the

configuration file and load it into all the fields. You can then either edit the

configuration and save it again or download it to the control system.

You can have as many configuration files as you like. Typically one per control system

but you may have various versions depending on what your needs are.

When you look at the contents of the config file, you will see three types of data: a

comment, a configuration switch and configuration data.

33

Page 34

All lines starting with a single quote ’ are comments and are ignored by the config

program.

Switches start with a forward slash / followed by a name such as port_0_type followed

by a space then data. In this example the line assigns the port 1 personality type to be a

1 which means a repeater.

Example:

/port_1_type 1

Note that there are never

one, and only one

space between the switch name and the data, in this case a “1”.

any spaces inside the switch name. Also note there is always

The only exception are a few commands where spaces can be inserted in the data such as

a CW ID string. In this case the switch is on the first line and the string with spaces is on

the next line.

Example:

/cwid_1

DE W1AW

Note the use of the space in the string. This is by far the exception.

Blank lines can be inserted anywhere and will be ignored by the config program.

If a subset of the available parameters are included in the config file, the last

configuration that was loaded will become the default. So if you read in a new config

file with just the call sign of the station, all other parameters that were present in the

system will be used.

When the program initially starts, it will automatically read a default configuration file

called “

default.cfg”. The software is supplied with a generic default.cfg file but

you can modify it and save it off as your own default file.

34

Page 35

Script Files

xxxxxx.scr

The control system accepts commands either from the DTMF decoder or through the

serial port on othe main CPU board. A simple program like HyperTerm can be

connected to the serial port and you can simply type in commands and look at the

results on your screen. Serial port settings are 9600 baud, N81. To make it more

convenient to send several commands to the control system, you can create an ascii text

file called a script file. The script file is simply raw commands that the control system

will understand.

For exampe:

C2011D

C20212345

C000

Which will assign port 0 to be a repeater, port 1,2,3,4,5 to be links and then do a system

resest.

These are called “script” files becauses in addition to the raw command strings the

control system understands, you can insert special commands that the script processor

will interpret and not pass on to the control system. These are either comments or script

processing directives.

Comments start with a single quote ’ just like in a configuration file.

Script processing directives all start with a forward slash / like the switches in the

configuration file.

Script processing directives set the rate at which data is transmitted to the controller,

and various other parameters.

Scripts are executed from the first line to the last. There is no notion of flow control or

other more advanced programming features.

You can load up to 10 of your favorite script files in the main window of the config

program. You can simplly click the edit button to change them or click the run button to

start running them.

Script File Control Directives

‘Comments

Any line that starts with a single quote ‘ is a comment and the rest of the line is ignored by the

config program.

<empty>

Any empty line is ignored by the config program.

/end

Stop processing script file and ignore all lines after /end.

35

Page 36

Script files support the following config.env environmental variables. When these script

directives are encountered, they over ride the default values supplied in the config.env file. See

the section on config.env for details.

/command_delay 500

/digit_delay 20

Script files also support the following config file (xxxxxx.cfg) parameters. See the section on

configuration file parameters for details.

/unlock_code

/prefix

/call_sign

/location_id

Additional script processing directives

/set_audio_all xxx

Sets the value of all Rx, Tx, Telemetry and aux audio digital pots to a value of xxx, where xxx is

between 0 and 255. 0 is no audio and 255 is maximum.

/set_audio_level_port0_rx xxx

/set_audio_level_port0_tx xxx

/set_audio_level_port0_te xxx

/set_audio_level_port0_to xxx

Sets the specific digital pot level to xxx, where the port is “port0” through “port7”. The specific

pot of that port is selected by the last two letters where…

rx is receiver audio level

tx is transmitter audio level

te is the locally generated telemetry audio level

to is the externally generated tone input, for example the PL encode level from an AS-3

audio squelch board.

The level xxx is between 0 and 255. 0 is no audio and 255 is maximum.

/set_audio_level_cpu_0

/set_audio_level_cpu_1

/set_audio_level_cpu_2

/set_audio_level_cpu_3

Sets the specific digital pot on the master CPU board level to xxx. The specific pot of that board is

selected by the last number where…

0 is not used.

1 is audio from the DVB board.

2 is not used.

3 is the master CPU generated telemetry which drives the common telemetry bus that

goes to all transmitters.

/fcg_off

Turns off the function complete generator.

/fcg_on

Turns on the function complete generator.

/wait xxxx

Causes the execution of the script file to stop and wait for xxxx milliseconds.

36

Page 37

Config Program Environment File config.env

Various environment variables are stored in the config.env file. This file is set up once

per installation and does not move with the specific controllers configuration. The

format of the config.env file looks similar to the .cfg and .scr files but always contains a

specific set of parameters. These parameters define which com port is used, the speed,

and other useful or necessary installation specific information.

For example, up to 20 “quick macros” are stored in the config.env file. These are

essentially like a one line “script” where you can put up to 20 of your most commonly

used commands.

The most important thing about the config.env file is to make sure the com port is set

properly. If it is not, when the program starts up you will get a warning saying that it

can not find the serial port. This is the most commonly made mistake in setting up your

environment. Most computers will use com port 1 but you system wmay be different If

you are using a USB to serial adapter you will certainly have to check the hardware

configuration in Windows first then edit the config.env file to make sure they match.

The typical config.env file looks like this…

config.env variable definitions

37

Page 38

‘Comments

Any line that starts with a single quote ‘ is a comment and the rest of the line is ignored by the

config program.

<empty>

Any empty line is ignored by the config program.

/serial_port yes

indicates that the serial port on the computer is active and when the config program is

Yes

launched it should attempt to connect to the control system.

No

will prevent the config program from attempting to communicate with the control system

through the serial port.

/com_port 5

Sets the comp port that the config program should use to communicate with the control system.

/com_speed 9600

Set the serial port’s data rate. Should always be set to 9600

/command_delay 500

The time in milliseconds that the config program will wait between sending commands to the

control system.

/digit_delay 20

The time in milliseconds that the config program will wait between characters when sending

commands to the control system.

/quickmacro_01 809

Up to 20 quick macros can be defined. These are single line command sequences that are

available in the config program. Quick macro 1-4 are found on the main config screen and 1-20

are found on the Quick Macro pull down menu option.

38

Page 39

Installing New Firmware

39

Page 40

Installing New Firmware

To update the firmware on the main CPU or RCB boards, you must use an "in-circuit

programmer". This device provides a connection between your computer and the

control system boards. When installing new firmware, each board must be programmed

individually. The only requirement is that the board must be powered and the in-circuit

programmer must be connected. The in-circuit programmer we recommend is available

from ME Labs and comes in many versions. There are parallel, serial and USB port

versions. The serial version can also be used via RS-232 or through a USB to serial

adapter. They all work fine so you should pick the unit that matches the type of

interface available on your computer.

We prefer the USB version in the plastic enclosure because it provides protection from

shorting out or physical damage.

Here are a few examples of what ME Labs offers…

Option 1 - The EPIC™ Plus Programmer for the parallel port

You must order the following…

EPIC™ Plus Programmer ICSP Board Only (Includes software)

AC adapter

25 pin cable

10 pin header cable

http://www.melabs.com/products/epic.htm#Pricing

Option 2 - The Serial Programmer

You must order the following…

The melabs Serial Programmer ICSP board only

AC adapter

9 pin serial cable

10 pin header cable

http://www.melabs.com/products/serprog.htm

40

Loading...

Loading...