Page 1

Equipment for Machine Tools

WS 720 A

Single axis controller

User’s Guide Edition 10.93

COM 720 description

Siemens Automation Parts

Page 2

WS 720 A

Single axis controller

Catalogue Index of Manuals

Product brief

Description

SIEMENS

WS 720 A

SIEMENS

WS 720 A

SIEMENS

Index of Manuals

SIEMENS

General Documentation

Planning Manual Hardware

User and Service-Documentation (for details see inside back cover)

Description

PG-Manual

SIEMENS

Additional Documentation

Application Manual

User´s Guide for

OP 720

COM 720

SIEMENS

SIMATIC S5

Single Axis Controller

SIEMENS

WS 720 A

SIEMENS

WS 720 A

SIEMENS

Ausrüstungen für Bearbeitungsmaschinen

WS 720

Einachssteuerung

SIEMENS

WS 720 A

SIEMENS

WS 720 A

Reference Book, Lists

SIEMENS

Electro-Magnetic Guidelines

for WF/WS-Technology

Electro-Magnetic Guidelines

Equipment for Special Machines

Glossary of terms

(available only in German)

(available only in German)

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Equipment for Special Machines

Single Axis Controller

Single Axis Controller

Single Axis Controller

Single Axis Controller

Single Axis Controller

Page 3

Edition October 1993

Equipment for

Machine Tools

WS 720 A

Single axis controller

User’s Guide

for COM 720

Forward

1

Function overview

2

Layout and Installation

3

Working with the software

4

Menu functions

5

Hints when using Windows

6

Appendix

7

Siemens Automation Parts

Page 4

Note

For the sake of clarity this document does not go into all possible situations which may

arise with this product. The document cannot deal with every situation which may arise

during commissioning, operation and maintenance.

If you need special information or have special questions, you should contact your

Siemens representative.

This document is not part of an earlier or existing agreement, promise or right. All

obligations of Siemens are limited to those in the sale contract, which also contains all the

details of the guarantee. The guarantee in the sale contract is not affected by anything in

this document.

BERO, SIMATIC, S I MODRIVE, SINEC, SINUMERIK, STEP are all regi s tered trademarks of Siemens

Aktiengesellschaf t.

The other terms used in this m anual m ay also be trademarks, whose use by third parties may infringe upon t he

rights of the owners of thos e t radem arks

This publication was produced with Microsoft Word 2.0b

Subject to technical changes.

The reproduction, transmission or use of this document or of its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

supplied by patent grant or registration of a utility model or

design, are reserved.

Siemens AG 1993 All Rights Reserved

Page 5

10.99 Appendix

Contents

Page

1 Forward..................................................................................1-1

2 Function overview.................................................................2-1

3 Layout and Installation.........................................................3-1

3.1 Hardware and software overview.............................................................3-1

3.2 Hardware- and Software configuration....................................................3-2

3.3 Installing the COM 720 software.............................................................. 3-2

3.4 Installation of SYSDOK 720..................................................................... 3-2

4 Working with the software....................................................4-1

4.1 Starting display........................................................................................ 4-1

4.2 The machine file ...................................................................................... 4-2

4.3 Selection of data type.............................................................................. 4-3

4.4 Machine data........................................................................................... 4-4

4.5 Part Programs..........................................................................................4-5

4.6 Commissioning display............................................................................4-6

4.7 Transfer ................................................................................................... 4-7

4.8 Technical documentation (SYSDOK 720)................................................4-8

5 Menu functions......................................................................5-1

6 Hints when using Windows..................................................6-1

7 Appendix................................................................................7-1

7.1 Abbreviations...........................................................................................7-1

7.2 Index........................................................................................................ 7-3

Siemens Automation Parts

Page 6

10.99 Forward

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

1 - 1

WS 720 A (BN - COM 720 description)

1 Forward

What information is to be

found in this manual?

This pocket guide describes the installation and use of the COM

720 software. The hardware and software requirements are

specified. Some masks are explained with examples.

For whom is this manual

intended?

The guide is intended for machine design engineers and for

service specialists.

Each group, engineers and specialists must be qualified as

outlined on page 1-2.

What prior knowledge is

needed?

It is assumed that the user of this guide is familiar with general

machine safety guidelines and particular safety requirements of

the country where the machine is to be used.

Familiarity with Windows and with the modules WS721/WS720

are needed to be able to use the COM 720 software.

Finding your way about the

manual?

The manual is divided up into the sections:

ã

Overview

ã

Installation

ã

Operation

The guide is complemented by a function overview, hints to

using Windows, and lists of the functions in the menus and of

the pushbuttons.

Page 7

Forward 10.99

1 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720description)

Definitions and terminology

Qualified personnel

People who are experienced in setting up, optimising and

operating machines and whose qualifications are

commensurate with the an activity, for example:

ã

Training and authorisation to switch power to electrical

circuits and equipment according to the recognised

standards, to earth such equipment and the mark up the

cables on such equipment

ã

Training in the maintenance of safety devices according to

the recognised standards.

ã

First aid training.

Danger

Loss of life, severe personal injurity or substantial damage to

property will result if proper precautions are not taken.

Warning

Loss of life, severe personal injurity or substantial damage to

property can result if proper precautions are not taken.

Caution

Minor personal injurity or property damage can result if proper

precautions are not taken.

☞

This symbol draws attention to important information about the

product or a particular part of the operating instructions.

&

This type of frame contains a reference to another manual.

Siemens Automation Parts

Page 8

10.99 Function overview

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

2 - 1

WS 720 A (BN - COM 720 description)

2 Function overview

Area of application

Ease of programmimg is very important with today’s machines

and COM 720 provides you with an NC editor. Sets of data can

be conveneintly generated, duplicated and modified.

The COM 720 software offers:

−

menu driven Windows operation

−

ability to add comments to programs,

−

Help screen in case of operator errors,

−

info system to offer concise programming tips,

−

print out facility for the WS data,

−

comments window,

−

central data storage,

−

ON or OFF line operation,

−

SYSDOK 720 (WS720 documentation integrated into

software).

Structure

All the data of the WS cards used in a particular SIMATIC S5

system can be grouped together in a machine specific file with

the COM 720 software.

The data structure makes it possible to organise the machine

data, part programs and control configuration. The WS data for

the WS721/WS720 can be stored either on the hard disc of the

PG/PC or on floppy.

COM 720 is also very useful during commissioning, where it can

be used to view status of signals and axis positions.

With the COM 720 software it is possible to see which data files

are present.

Operation

The COM 720 software uses the window structure. The user is

guided by messages into the desired window.

Programming

An NC editor can be used to enter the part programs.

The editor is not only a means of entering the part programs, but

it also carries out a check to see that the entered values are

within tolerance.

Comments can also be inserted with the part program, as an aid

to understanding the program. Each program block can have a

comment line upto 65 characters in length.

Using COM 720 it is also possible to issue the data for MDI

mode. Teach-in is also possible with the COM 720.

Page 9

Function overview 10.99

2 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

Help system

The help system is based on the SYSDOK 720, which is an

integral part of the software. SYSDOK 720 is the Application

Manual of the WS720 not in a book form, but in the software. It

can be called up the screen just like the paper manual can be

opened up.

With few keystrokes you can obtain information relevant to a

given problem, which makes the software very attractive for

newcomers to the WS system. On the one hand there are the

familiar index and contents table of the paper documentation, on

the other there are the electronic search methods for cross

referencing related subjects and other explanations.

There is a key word index to help you in your search. When a

key word is selected, SYSDOK 720 brings up a list of all the

masks which deal with that subject. The selected mask can be

displayed. The work is further facilitated by means of the

electronic book mark and note pad.

SYSDOK 720 is also available as a separate product.

Siemens Automation Parts

Page 10

10.99 Layout and Installation

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

3 - 1

WS 720 A (BN - COM 720 description)

3 Layout and Installation

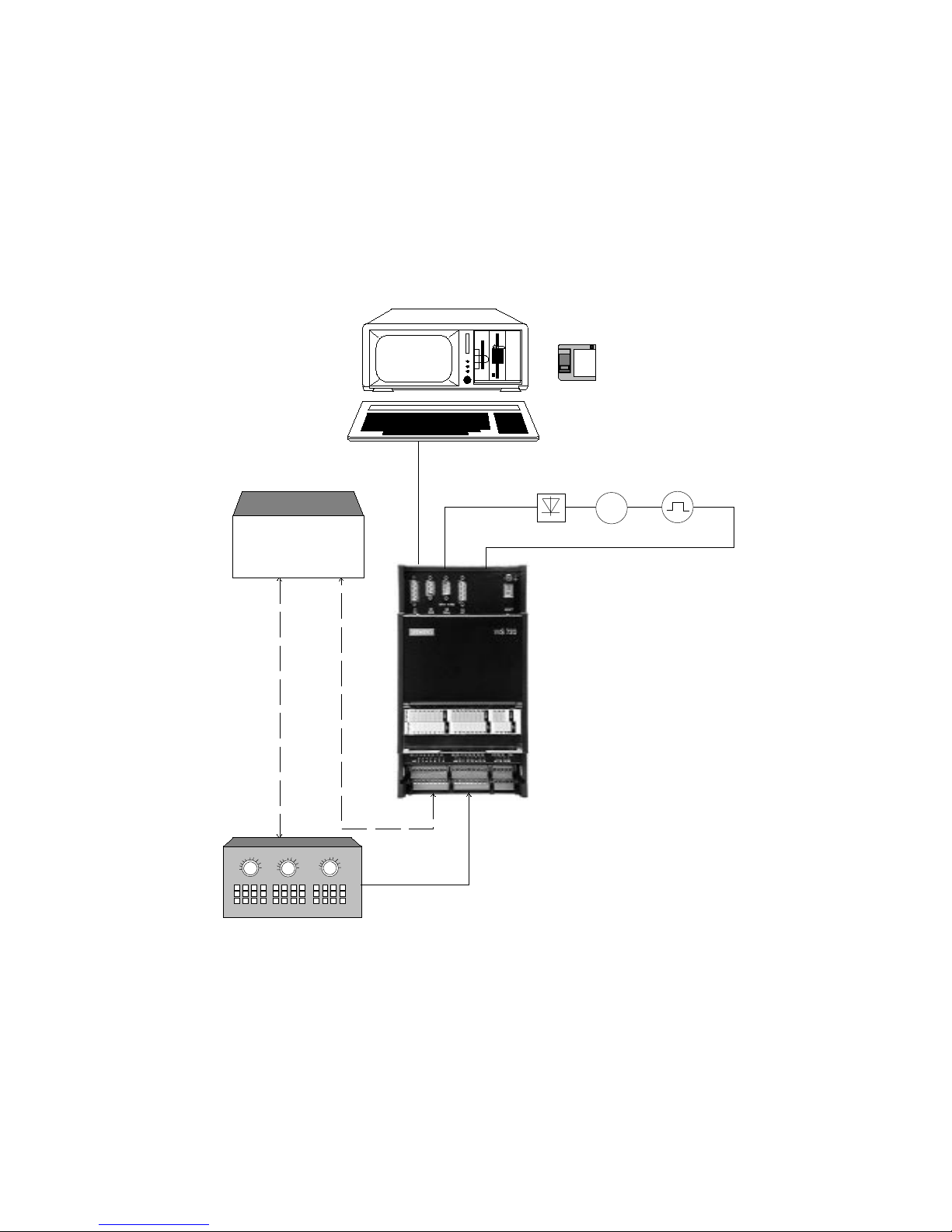

3.1 Hardware and software overview

M

PG 730/PG 750/PG 770/PC

COM 720

additional

possibility

digital

inputs/outputs

Relay

control

or

PLC

Page 11

Layout and Installation 10.99

3 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

3.2 Hardware- and Software configuration

• Hardware configuration

−

Programming units PG 730, PG 750, PG 770 or industrial standard PC with at least Intel

80386 or 80486 processor at least 4MB memory and a hard disc with at least a capacity

of 40MB

−

Appropriate cable from PG/PC to WS 720

−

Single axis controller WS720

−

Printer DR210, DR211, DR230, DR231

• Software configuration

−

MS-DOS 3.3 or higher

−

Microsoft Windows 3.1 or higher

3.3 Installing the COM 720 software

When all hardware and software requirements have been fulfilled, you can load the COM 720

software onto the hard disc of your PG or PC.

•

Find out in which path Windows is installed.

•

Insert the COM 720 disc into the drive and select this drive.

•

Start the installation program with the command INST720.

You will be guided through the installation. If you already have installed the COM 720 software

but wish to re-install, this is no problem. The old settings will be overwritten by the new.

3.4 Installation of SYSDOK 720

The help file

com720at.hlp

contains all the integrated documentation and is installed

automatically with the COM 720 software.

Siemens Automation Parts

Page 12

10.99 Working with the software

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

4 - 1

WS 720 A (BN - COM 720 description)

4 Working with the software

The idea behind the COM 720 software is to have an efficient tool with which to program the

WS720 single axis controller. The convenient operating system facilitates the manipulation of

machine data, part programs and control configurations.

The COM 720 software can be used either ON or OFF line

4.1 Starting display

This following display appears after the COM 720 software has been called up:

Fig. 4.1 Starting display

The field surrounding the is known as a "pushbutton". To proceed further with the

software, either click the "Continue" field with the mouse or press .

Page 13

Working with the software 10.99

4 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

4.2 The machine file

With the open machine file screen it is possible to either retrieve an existing file or open a new

file. The machine file groups all the WS720 specific data together.

Fig. 4.2 Open Machine file

Machine file name

The machine name can have upto 8 alphanumeric characters.

The extension "720" is added automatically.

Path

This displays the current path. The path

(drive):\com720\comanl

is set up automatically when the software is installed.

Already exist

Display (in alphabetical order) and selection of the currently

available machine files. Machine files which are already open

will be shown in square brackets in the in "Drive" box rather than

in the "Already exist" box.

Drive

Selection of the drive and path or of the machine files which are

already open.

Siemens Automation Parts

Page 14

10.99 Working with the software

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

4 - 3

WS 720 A (BN - COM 720 description)

4.3 Selection of data type

At this window the data type is selected, either machine data, part programs or control

configuration.

Fig. 4.3 Selection of dat a type

Title line

Display of the path and of the machine file name.

Data group name

Input field or display of the name of the selected data group. 10

alphanumeric characters are allowed. The list shows all the data

groups which contain the selected data type. "NONAME" will be

shown if no name has yet been issued.

Data branch or type

Selection of the data branch, whereby the possibilities are

machine data, part programs and OFFLINE control

configuration.

Page 15

Working with the software 10.99

4 - 4 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

4.4 Machine data

The machine data editor allows a "fill in the blanks" style of machine data determination. Machine

data which are related are grouped together in their own dialogs.

Fig. 4.4 Processing mac hine data

Title line

Display of machine file, data type and data group name.

MD No.

Selection of the machine datum to be processed.

Process

Call up the input dialog of the currently selected machine datum.

Machine data list

Individual machine data can be selected with the mouse or with

the cursor control. The input dialog for that machine datum can

be selected by pressing or with double click on the mouse.

The COM 720 help is called up by selecting the

in the machine data overview. The

SYSDOK 720 is called up by selecting the "Help" in the Input dialog

Siemens Automation Parts

Page 16

10.99 Working with the software

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

4 - 5

WS 720 A (BN - COM 720 description)

4.5 Part Programs

The part program editor allows a "fill in the blanks" approach to generating a part program. Each

entry is checked to see that it is within the appropriate limits. It is also possible to assign a text to

each program instruction.

Fig. 4.5 Editing part programs

Title line

Display of machine file, data type and data group name.

Editor line

The various data for each instruction can be inserted in the

editor line. The cursor can be moved with either or with the

mouse. The data are accepted into the program with or by

clicking

with the mouse.

Program list

Display of the program instructions (in ascending order). The

editor line is activated by pressing with the cursor on the

desired instruction or by giving the desired instruction a double

click with the mouse. Each field of the instruction is dealt with as

an input dialog in its own right, whereby the input possibilities

and the limits are also displayed.

Page 17

Working with the software 10.99

4 - 6 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

4.6 Commissioning display

The commissioning display offers welcome assistance during commissioning and trouble

shooting.The data in this display are continually updated.

Fig. 4.6 Commissioning dis pl ay

Firmware level

Display of the firmware level of the WS 720

Hardware level

Display of the hardware level of the WS 720

Operating mode

Display of the current operating mode

Selected program number

This field shows the nubmer of the current program when the

mode "Program number select" is active

SS

The current status of the control inputs

RS

The current status of the control outputs

WS status data

Display of the current control and program data, including such

data as following error, loop gain, current velocity, saved value

from block change on the fly, selected override

There are also soft keys for TEACH IN, MDI, velocity values in jog and to display motion fault

messages.

Siemens Automation Parts

Page 18

10.99 Working with the software

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

4 - 7

WS 720 A (BN - COM 720 description)

4.7 Transfer

The transfer dialog is the means whereby machine data and part programs can be moved

between WS and COM 720 software. The details for the source and destination are different

according to whether the dialog is called up from the editor or from the processing branch.

Fig. 4.7 Transfer

Title line

Display of the path and data group name

Direction

Transfer direction

Source/Destination

The source and destination fields are shown according to the

transfer direction

File

The file name for the source or destination

Editor

The editor for source or destination

Module

Which WS module is involved in the transfer

Data group name

Selection of the data to be transferred

Available

Display of the programs available in the WS 720 (only for

transfer of traversing programs)

Activate

The machine data are activated after the transfer from PG/PC

to WS

Command status

Status of the current command

Page 19

Working with the software 10.99

4 - 8 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

4.8 Technical documentation (SYSDOK 720)

The WS720 Application manual is integrated into the software.

SYSDOK 720 has its own order number (6ZB5 440-0TE02-2DA0). This version of

SYSDOK 720 corresponds to the 10.92 Version of the paper Application manual (order number

6ZB5 440-0RT02-0AA0).

Fig. 4.8 SYSDOK 720 example - looking at an error description

Overlays

Overlays are in green and underlined with a broken line. The

overlay will be shown when is pressed or with pressing the

left hand key on the mouse.

Jumps

Jumps are shown in green and underlined with a continuous

line.

&

The help system of Windows has been integrated into

SYSDOK 720. Please refer to your Windows manual for help

and information.

Siemens Automation Parts

Page 20

Menu functions 10.99

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

5 - 1

WS 720 A (BN - COM 720 description)

5 Menu functions

The functions in the menus can be called up from various screens. Each function has various

possibilities in the appropriate drop down menu. Any function which is grey is not available.

This chapter describes the functions currently available.

File Presets Diagnosis Info

Open

After selecting "Open" the dialog box will appear showing the

contents of the machine file

Store and continue

The current data group will be stored without leaving the editor.

Store and change

The current data group will be stored,the editor function is deselected and the system returns to the screen for selection of

"Processing branch".

Store and quit

he current data group will be stored,the editor function is deselected. Furthermore the machine file is closed and the screen

for "Open machine file" is selected.

Copy

−

Copy the selected machine file

−

Copy the selected data group from the current machine file to

another machine file

Delete

−

Delete the current machine file

−

Delete the current data group

Delete WS

−

Delete the part programs stored on the WS module

Transfer

Move the part programs or machine data between the COM 720

software and the WS module.

Activate hardcopy

With this function active, the current screen can be printed out

by pressing

.

Print

Print out of the machine file (in preparation).

Finish

Leaving the COM 720 software whereby all data will be stored

and the machine file will be closed.

Page 21

10.99 Menu functions

5 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

File Presets Diagnosis Info

Online/Offline With this selection it is possible to switch between online and

offline

EPROM Use this feature to store the data into EEPROM or to dowmload

from EEPROM to RAM.

File Presets Diagnosis Info

Commissioning display Use this feature to assist with commissioning or during fault

finding

File Presets Diagnosis Info

Windows Help Help information for Windows

Technical Help Call up for system integrated documentation SYSDOK 720

About COM 720 Information about the COM 720 software

Pushbuttons used

Quit the current menu and return to the previous level.

This is to call up the dialog.

Use this to view the motion fault messages

Use this display to view the velocity levels for jog mode

This pushbutton is used when processing machine data, to show

the limits of the relevant machine data.

Information about the current dialog

Siemens Automation Parts

Page 22

Menu functions 10.99

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

5 - 3

WS 720 A (BN - COM 720 description)

Confirm the question in the dialog box.

To enter a description for the data group.

Delete a movement block in the program list

Use this selection to call up MDI mode from the commissioning

display

Do not do the action described in the dialog box.

The selected machine file will be processed. The next selection

is made in the processing branch.

With "Online" the link is set up to the PLC and shut down again

with "Offline". On- or Off-line is displayed accordingly.

Accept the dialog

Close a machine file

Store the current file.

Use this selection to call up TEACH IN mode from the

commissioning display.

Accept the current data group.

Jump into the next processing level.

Page 23

Siemens Automation Parts

Page 24

10.99 Hints when using Windows

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

6 - 1

WS 720 A (BN - COM 720 description)

6 Hints when using Windows

You’ll need the following Windows commands to work with the COM 720 software:

Function

Tastaturfolge

Activate the menu bar

Confirm

Abort

Change between buttons and In/Output fields

Move within the current menu

;

Open system menu

"Hardcopy/hotkey"

Change the group window

ï

Activate hardcopy

h

To activate a function Press with the underlined letter.

Active functions These are highlighted in the preset colour in the menu.

Inactive functions These functions are in pale grey and cannot be selected.

Activate hardcopy Select in the data menu, an active function is indicated by a check mark.

An Enter always refers to the active window, the active window is highlighted with a differently

coloured frame. The Selection is made with the cursor keys and the Accept with the Enter key or

by positioning the mouse and double clicking the left mouse key.

The colours can be changed with Windows.

&

For further information on Windows, please see your "Windows" manual.

Page 25

Siemens Automation Parts

Page 26

10.99 Appendix

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

7 - 1

WS 720 A (BN - COM 720 description)

7 Appendix

7.1 Abbreviations

A-MF

Strobe signal for M functions

BE

Overtravel

BL

Program running

EFG

Read in enable

EZS

Single move

F

Fault bit

F

Feed rate

FUB

End of function bit

G1

G function in 1st group

G2

G function in 2nd group

M1

M function in 1st group

M2

M function in 2nd group

M3

M function in 3rd group

MD

Machine data

MDI

Manual Data Input

N

Block number

NC

Numerical control

NFB

Follow up mode

PBR

Program running backwards

PC

Personal computer

PEH

Position reached,axis stationary

PG

Programming unit

Q

Output

Q-MF

Acknowledge for M functions

Page 27

Appendix 10.99

7 - 2 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

WS 720 A (BN - COM 720 description)

RFG

Servo enable

RS

Output from WS

RST

Axis reset

RW

Axis moving backwards

RWL

Cancel remaining distance

SA

Block skip

SFG

Start enable

SS

WS inputs

SYN

Axis referenced

SYSDOK

System documentation integrated into software

T-L

Dwell time running

TIP+/-

positive/negative motion or positive/negative voltage output or positive/negative

rotation for rotary axis

VDE

German Electrical Assosiation

VW

Axis moving forwards

W1/W2

Velocity level 1 or 2 or Voltage level 1 or 2

WF

Machine tool module

WS

Machine tool control

X

Position /Dwell time

Siemens Automation Parts

Page 28

10.99 Appendix

Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV02

7 - 3

WS 720 A (BN - COM 720 description)

7.2 Index

A

Abort .................................................. 5-2

Accept................................................ 5-3

Application manual............................. 4-8

Area of application............................. 2-1

C

Close.................................................. 5-3

Command status................................ 4-7

Comments.......................................... 5-3

Commissioning display...................... 4-6; 5-2

Continue............................................. 5-3

D

Data branch or type............................ 4-3

Data group name............................... 4-3; 4-7

Delete................................................. 5-3

Direction............................................. 4-7

E

Editor.................................................. 4-7

Editor line........................................... 4-5

EPROM.............................................. 5-2

F

Firmware level.................................... 4-6

Function overview.............................. 2-1

H

Hardware and software overview....... 3-1

Hardware level................................... 4-6

Hardware- and Software configuration 3-2

Help.................................................... 5-2

Help system ....................................... 2-2

Hints when using Windows................ 6-1

I

Installation of SYSDOK 720............... 3-2

Installing the COM 720 software........ 3-2

J

JOG.................................................... 4-6

Jumps................................................. 4-8

K

Kapitel................................................ 1-1

L

Layout and Installation....................... 3-1

Limits.................................................. 5-2

M

Machine data...................................... 4-4

Machine data list................................ 4-4

MD No................................................ 4-4

MDI..................................................... 4-6; 5-3

Menu functions................................... 5-1

Module............................................... 4-7

motion fault messages....................... 4-6

Move Faults........................................ 5-2

N

No ...................................................... 5-3

O

Offline................................................. 5-2

OK...................................................... 5-3

Online................................................. 5-2; 5-3

Open.................................................. 5-3

Operating mode ................................. 4-6

Operation........................................... 2-1

Overlays............................................. 4-8

P

part program editor............................. 4-5

Part Programs.................................... 4-5

Process.............................................. 5-2

Program list........................................ 4-5

Programming...................................... 2-1

Pushbuttons....................................... 5-2

Q

Qualified personnel............................ 1-2

R

RS...................................................... 4-6

S

Selected program number.................. 4-6

Selection of data type......................... 4-3

SS...................................................... 4-6

Starting display................................... 4-1

Store .................................................. 5-3

Structure............................................. 2-1

SYSDOK 720..................................... 4-8

Page 29

Appendix 10.99

7 - 4 Siemens AG 1993 All Rights Reserved 6ZB5 440-0RV01

WS 720 A (BN - Beschreibung COM 720)

T

TEACH IN .......................................... 4-6; 5-3

Technical documentation................... 4-8

Technical Help ................................... 5-2

The machine file................................. 4-2

Title line..............................................4-3; 4-4; 4-7

Transfer.............................................. 4-7

V

Velocity Levels................................... 5-2

W

Windows Help.................................... 5-2

Working with the software.................. 4-1

WS status data................................... 4-6

Y

Yes..................................................... 5-3

Siemens Automation Parts

Page 30

SIEMENS AG

Suggestions

Corrections

AUT V240

Postfach 4848

For Publication/Manual:

Equipment for Machine Tools

WS 720 A

Single Axis controller

Pocket Guide; COM 720 description

D-90327 Nürnberg

Fed. Rep. of Germany

Order No.: 6ZB5 440-0RV02-0AA1

Edition: October 1993

_

__

From:

Name:

Company/Dept:

Address:

Telephone:

If you find any printing errors when reading this

publication, please let us know, using this form. We also

welcome any suggestions to improve the manual.

Suggestions and/or corrections

Page 31

Areas of Application

Further information about catalogues, manuals and training can be obtained from your local SIEMENS

office. This overview shows which documentation should be used for the various tasks:

Task

Documentation First contact Draft

Design and

Engineering

Installation and

Commissioning

Production

phase

Service

Product brief

Description

Catalogue

Application

Manual

Description of the

Hardware

Electro-Magnetic

Guidelines

Reference Book,

Lists

Description

COM 720

Description

OP 720

Glossary of terms

necessary useful

An overview over area of application and function of all WS/WF modules is given by the catalogue:

Equipment for Machine Tools

WS/WF-Technology • Systems and Components

Catalogue AR 10

This catalogue also contains the order numbers which are required for the planning.

The Trainings-Center offers courses in the positioning area which supply practical as well as theoretical

background. An overview of courses is given by the catalogue:

Information und Training

Courses for Automation Technology

Catalogue IT5

Siemens Automation Parts

Page 32

Types and Purposes of the WS 720 A-Documentation

Product brief

WS 720 A

Order no.: 6ZB5 440-0RL02-0BA0

Target group: Initial contact

(e.g. trade shows)

This colour brochure gives yor

information about:

• Layout

• Operating priciples

• Overall system

• COM 720

A list of the techni c al data of the

WS 720 rounds up the product brief

Description

WS 720 A

Order no.: 6ZB5 440-0RM02-0BA1

Target group: Purchasing,

designers at

machine builder,

plant engineering at

the end customer

This document gives detai l ed

information about:

• Area of application

• Layout

• Operating principles

• Operating

• Programming

• Technical data

• Order details

Description

Electro-magnetic Guidelines

Order no.: 6ZB5 440-0QX02-0BA1

Target group: Machine designers

commissioning and

service people

This document goes into the various

precautions to minimize the effects of

electro magnetic dis turbance:

• General introductions

• Propagation of a disturbance

• EM precautions

• Hook up and installation guidelines

• Static charge precautions

• Further reading

Application Manual

WS 720 A

Order no.: 6ZB5 440-0RT02-0AA0

Target group: Engineers at the

machine builders.

Planners

This document describes the function

and the scope of the features of the

single axis controller.

The functions are described along with

the relevant machine data, i nterface

signals and programming

requirements. Many examples and

practical tips help the engi neer to

apply the information to his practicular

project.

SYSDOK 720

WS 720 A

Order no.: 6ZB5 440-0TE02-2DA0

This electronic documentationSYSDOK assists the

user in his search for

specific information. It

contains the information

of the

Application Manual

SYSDOK runs under

MS-Windows.

Hardware Description

WS 720

Order no.: 6ZB5 440-0RK02-0AA0

Target group: Machine designers

commissioning and

service people

This document gives all t he necessary

information about the hardware:

• Cables and equipment overview

• Cable diagrams and physical

equipment details

• Connection and installation

guidelines

• Technical data

• Peripheral equipment

Reference Book, Lists

WS 720 A

Order no.: 6ZB5 440-0RU02-0BA0

Target group: System integrators,

Service

technicians,

Maintenance

The following information is pres ented

in concise tabular form :

• Signals

• Machine data

• Structure of the part program

• "How to commission" flow chart

• Fault messages

Description OP 720

WS 720 A

Order no.: 6ZB5 440-0QY02-0AA1

Target group: System integrators,

Service technicians,

Software

designerse

This booklet describes how to use the

OP 720, service unit

• Hook up

• Layout

• Menus

• Operator guidance

Description COM 720

WS 720 A

Order no.: 6ZB5 440-0RV02-0AA1

Target group: System integrators

Service technicians,

Software designers

This document describes the features

of the COM 720 software.

• Function overview

• How to install

• How to use

• Menu functions

• Hints about Windows

Page 33

Order No. 6ZB5 440-0RV02-0AA1

Printed in Fed. Rep of Germany

(680) 232/462103 BN 11930.1 (750)

Siemens AG

Automation Group

Automatisierung Systems

for Maschine Tools, Robots

and Special-Purpose Maschines

P.O.Box 4848, D-90327 Nürnberg

Federal Republic of Germany

Siemens Aktiengesellschaft

Siemens AG 1993 All Rights Reserved

Subject to changes without prior notice

Progress

in Automation

Siemens

Siemens Automation Parts

Loading...

Loading...