Page 1

Installation

Induction Motors/

Operation

Maintenance

Generators

Horizontal - Medallion

500, 580, 680, 800, 1120 Frames

ODP, WPI, & WPII Enclosures

Types CG, NCG, CGII, NCGII

ANIM-03520-0110

(New Issue)

©2010 Siemens Industry, Inc. All rights reserved.

Page 2

Table of Contents

Page Page

TABLE OF CONTENTS 1 OPERATION 10

SAFETY PROCEDURES 2

INTRODUCTION 3

Warranty 3 Normal Operation 10

Receiving 3 Voltage/Frequency Variation 10

Handling 4 Trouble Shooting 11

Temporary Storage 4

Type Designations 4 Preventive Maintenance 13

Ventilation 4 Inspection 13

INSTALLATION 5

Motor Dimensions 5 Rotor Cleaning 15

Location 5 Stator Cleaning 15

Foundation 5 Insulation Resistance 16

Mounting 5 Drying Insulation 16

Coupling of Sleeve Bearing Motors 5 Bearings 17

External Wiring 6 Bearing Lubrication 20

Changing Direction of Rotation 6 Bearing Replacement 22

Alignment 6

Hot Alignment 7 Identification 25

Vibration 8

Doweling 8

Force Feed Lubrication 8

Typical Motor Control Settings 9

Note - These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation or maintenance. Should further

information be desired or should particular problems arise which are not covered sufficiently for the user’s

purposes, the matter should be referred to the local Siemens Sales Office. The contents of this instruction

manual shall not become part of or modify any prior or existing agreement, commitment or relationship. The

sales contract contains the entire obligation of Siemens. The warranty contained in the contract between the

parties is the sole warranty of Siemens. Any statements contained herein do not create new warranties or modify

the existing warranty.

Siemens machines are built in accordance with the latest applicable revision of the National Electric Code,

Underwriters Laboratories Standards and Procedures, and NEMA (National Electrical Manufacturers Association)

Standards. These publications and this instruction manual should be thoroughly read and understood prior to

beginning any work on this equipment.

The information contained within is intended to assist operating personnel by providing information on the general

characteristics of the purchased equipment. It does not relieve the user of the responsibility of using accepted

engineering practices in the installation, operation and maintenance of this equipment.

Should a conflict arise between the general information in this manual and the contents of the drawings and

supplementary material, the latter shall take precedence.

The illustrations in this book show typical machines. Special features deviate from those pictured.

Initial Start 10

Oil Circulating Systems 10

MAINTENANCE 13

Corrective Maintenance 15

SPARE PARTS 25

MOTOR SERVICE RECORD 33

VIBRATION ANALYSIS SHEET 34

NOTES 35

- 1 -

Page 3

Safety Procedures

This equipment contains hazardous voltages. Death,

serious personal injury or property damage can result

if safety instructions are not followed.

The successful and safe operation of motors and

generators is dependent upon proper handling,

installation, operation and maintenance, as well as

upon proper design and manufacture. Failure to

follow certain fundamental installation and

maintenance requirements may lead to personal injury

and the failure and loss of the motor as well as

damage to other property.

Only qualified personnel should work on or around

this equipment after becoming thoroughly familiar with

all warnings, safety notices and maintenance

procedures contained herein. Only qualified

personnel should be involved in the inspection,

maintenance and repair procedure and all plant safety

procedures must be observed.

Qualified Person: For the purpose of this manual

and product labels, a Qualified person is one who is

familiar with the installation, construction and

operation of the equipment, and the hazards involved.

In addition, he or she has the following qualifications:

a. Is trained and authorized to energize, de-energize,

clear, ground and tag circuits and equipment in

accordance with established safety practices.

b. Is trained in the proper care and use of protective

equipment, such as rubber gloves, hard hat,

safety glasses, face shields, flash clothing, etc., in

accordance with established safety practices.

c. Is trained in rendering first aid.

Danger: For the purpose of this manual and product

labels, Danger indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

Warning: For the purpose of this manual and product

labels, Warning indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

Caution: For the purpose of this manual and product

labels, Caution indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury. It is also used to alert against unsafe

practices.

Motors should be installed and grounded per local and

national codes.

Do not operate this equipment in excess of the values

given on nameplate or contrary to the instructions

contained in this manual. The equipment (or a

prototype) has been factory tested and found

satisfactory for the condition for which it was sold.

Operating in excess of these conditions can cause

stresses and strains beyond design limitations.

Failure to heed this warning may result in equipment

damage and possible personal injury.

DANGER

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working on

this equipment.

NOTE

Squirrel cage induction machines can be driven by

various types of prime movers. These will act as induction

generators. This instruction manual applies to both motors

and induction generators. However, for clarity reasons,

the machine will be referred to as a “motor”.

- 2 -

Page 4

Introduction

DANGER

Hazardous voltage.

Will cause death, serious injury, electrocution

or property damage.

Disconnect all power before working on this

equipment.

These instructions present general recommendations for

installation, operation and maintenance of induction motors

built at the Norwood plant. If additional information is

required, contact Siemens Industry.

Warranty

See your sales contract for warranty coverage.

Documentation of storage maintenance, alignment

and regreasing may be required for certain warranty

considerations.

Receiving

Motors are shipped in first class condition. They have been

inspected and are skidded to prevent damage from ordinary

handling during shipment.

Inspect new motors for shipping invoice. Make the

examination before removing from cars or trucks. If damage

or indication of rough handling is evident, file a claim with

the carrier at once, and notify your Siemens sales

representative.

Remove only the shipping invoice. Do not remove tags

pertaining to lubrication, operation and storage instructions.

Read and follow all instructions to insure that no damage to

motor bearings, (due to condensation) and motor windings

occurs during storage.

Use care in handling. Dropping the motor or otherwise

imposing shock loads can cause unseen and undetected

damage to bearings. This damage such as false brinelling

of the races of anti-friction bearings can result in early

bearing failure.

If supplied, energize space heaters to help prevent

condensation within the motor enclosure.

Motors having sleeve bearings or oil lubricated antifriction

bearings are shipped WITHOUT OIL in the bearing

reservoir. These bearings and journal surfaces are

protected during shipment by a temporary film of rust

inhibiting oil or, when a motor is supplied specifically with

“provisions for oil mist

furnished by the user), the motor is shipped from the factory

with grease in the bearings.

lubrication” (oil supply system

When receiving a motor with sleeve bearings:

1. Remove shaft blocking materials.

2. Visually inspect bearing condition through sight glass

and bearing drain opening.

3. Check for moisture accumulation. Remove any traces

of oxidation before putting the motor into service.

4. Fill bearing reservoirs to normal level with a high grade

industrial lubricating oil. See Maintenance Section of

this instruction book to determine proper oil level.

5. Rotate the shaft a minimum of 10 complete turns by

hand to distribute oil over bearing parts. Make sure the

oil rings in each bearing rotate freely.

When receiving a motor with grease lubricated antifriction bearings:

Motors having grease lubricated antifriction bearings are

shipped with the bearings already lubricated and ready for

operation.

If the elapsed time from the time of shipment to the time in

which the unit is to be started is in excess of three (3)

months, regrease per the lubrication plate mounted on the

motor.

When receiving a motor with oil mist lubricated antifriction bearings:

1. Be sure that the motor is not stored outdoors.

2. Be sure that the oil mist lubrication is connected and

operating before starting the motor.

3. The oil mist lubrication should be in operation within two

weeks after the motor is received from the factory.

When receiving a motor with “provisions for oil mist

lubrication”:

1. Leave the grease in the bearings if the motor is to be

stored.

2. Before operating the motor with oil mist lubrication,

disassemble the motor, and clean the grease from

bearings, end caps, and the bearing housing cavities

with a suitable solvent.

WARNING

Heavy equipment.

Improper handling may cause death, serious injury or property

damage.

Check lifting devices before lifting. Use proper slings, chains

and spreaders.

Note any warning plates on motor and follow instructions on

each plate.

- 3 -

Page 5

Introduction

Handling

Lifting devices are provided for handling only. An

experienced rigger should be used to install motors.

To avoid damage, the use of spreader bars is recommended

on other than single point lifts. Lifting devices are provided to

facilitate handling with shackles and cables. Avoid pounding

or bumping shaft, coupling or bearing parts, as shocks may

damage bearings.

NOTE WEIGHT BEFORE LIFTING. The weight is indicated

on the outline drawing. Apply tension gradually to cables.

Do not jerk or attempt to move the unit suddenly.

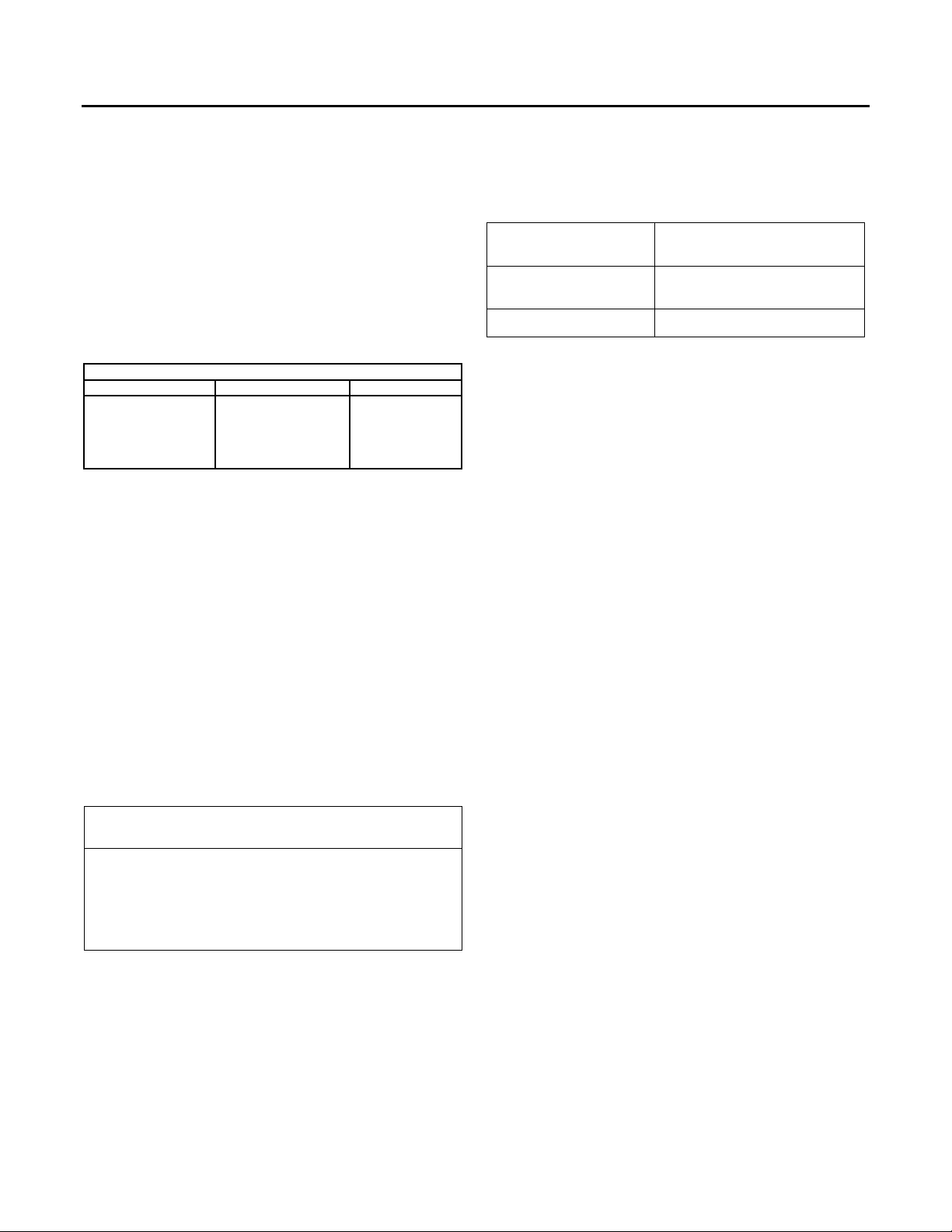

Motor Weights (in pounds)

Frame Size Minimum Maximum

500 2300 5400

580 4300 8400

680 10000 20000

800 15000 31000

1120 26000 37000

Temporary Storage

If the equipment is not to be installed and operated soon after

arrival, store it in a clean, dry, well- ventilated place, free from

vibration and rapid or wide variations in temperature. Rotate

the shaft a minimum of 10 complete turns by hand each

month to coat the bearings with lubricant which will retard

oxidation or corrosion, and prevent possible false brinelling.

If drain plugs are provided in enclosed motors, they must be

removed periodically to drain any water accumulation from

the motor. Consider a unit in storage when:

1. It has been delivered to the job site and is awaiting

installation.

2. It has been installed but operation is delayed over 30

days pending completion of plant construction.

3. There are long (30 day) periods between operating

cycles.

4. The plant (or department) is shut down for 30 days.

NOTE

Storage requirements vary, depending on the length of

storage and the climate. For storage periods of three

months or longer or climate variations, consult Siemens

Storage Recommendations ANIM-03114. Storage

maintenance is to be documented for warranty

information.

Type Designations

The motor type designation consists of a basic letter or

letters indicating the motor enclosure type to which other

letters may be added denoting modifications.

Motor Type Motor Enclosure

CG or NCG

CGII or NCGII Weather Protected Type II

Open Drip Proof or Weather

Protected Type I

Ventilation

Type CG, NCG - 500 Frame

Ventilating air enters through the louvered openings in

bearing housings on both ends of the motor. Non-metallic air

baffles direct air to the rotor fans and through the rotor core.

The air is circulated around the stator coil ends, into the air

gap, and through the vent ducts in the rotor and stator cores.

The air is exhausted out of the motor through the louvered

openings on both sides of the motor. Refer to motor outline

drawing for specific air intake and exhaust locations.

Type CG, – 580, 680, & 800 Frame and

Type CGII, NCGII – 500, 580, 680, & 800 Frame

Ventilating air enters through both sides of the top enclosure.

Non-metallic air baffles direct air to the rotor fans and through

the rotor core. The air is circulated around the stator coil

ends, into the air gap, and through the vent ducts in the rotor

and stator cores. The air is exhausted out of the motor

through the openings on both sides of the motor. Refer to

motor outline drawing for specific air intake and exhaust

locations.

Type CG - 1120 Frame

Ventilating air enters through one end of the top cover. A

single rotor fan pulls the air through the rotor and stator

cores. The air is circulated around the stator coil ends, into

the air gap, and through the vent ducts in the rotor and stator

cores. The air is exhausted out of the motor through the top

cover on both sides of the motor. Refer to motor outline

drawing for specific air intake and exhaust locations.

Type CGII - 1120 Frame

Ventilating air enters through both sides of the top cover. A

single rotor fan pulls the air through the rotor and stator core.

The air is circulated around the stator coil ends, into the air

gap, and through the vent ducts in the rotor and stator cores.

The air is exhausted out of the motor through the openings

on both sides of the motor. Refer to motor outline drawing for

specific air intake and exhaust locations.

- 4 -

Page 6

Installation

Motor Dimensions

For motors built in the frame sizes covered by this

manual, the letter dimensions have the same

definitions as established NEMA standards.

Established dimensions for these frames may be found

on catalog sheets or certified drawings.

CAUTION

Damp Location.

Can cause property damage if equipment is operated

intermittently.

Use space heaters to prevent dampness. Grease

machine fits when unit is reassembled to prevent

corrosion.

Location

Before pouring, locate foundation bolts by use of

template frame and provide secure anchorage (not

rigid). It is recommended that a fabricated steel base

be used between motor feet and foundation. See

certified drawings of motor, base, and driven unit for

exact location of foundation bolts. Allow for grouting

base when pouring. Cast the base footpads level and

in the same plane.

Mounting

Mount the motor base (if used) on foundation or other

support. Shim as required to level. Use laser or spirit

level (check two directions at 90

will be in one plane (base not warped) when base

bolts are tightened. Set motor on the base, install nuts

and tighten.

DO NOT TIGHTEN UNTIL AFTER ALIGNMENT.

o

) to insure motor feet

Select a location for the motor and driven unit that will:

1. Be clean, dry, well ventilated, properly drained, and

provide accessibility for inspection, lubrication and

maintenance. Outdoor installations may require

protection from the elements.

2. Provide adequate space for motor removal without

shifting the driven unit.

3. Permit the motor to safely deliver adequate power.

Temperature rise of a standard motor is based on

operation at an altitude not higher than 3,300 feet

above sea level.

4. Avoid condensation of moisture in bearings and on

windings. Motors should not be stored or operated

in areas subject to rapid temperature changes

unless motors are energized or protected with

space heaters.

Foundation

Concrete (reinforced as required) makes the best

foundation, particularly for large motors and driven

units. In sufficient mass it provides rigid support that

minimizes deflection and vibration. It may be located

on soil, structural steel, or building floors provided the

total weight (motor, driven unit, foundation) does not

exceed the allowable bearing load of the support.

Allowable bearing loads of structural steel and floors

can be obtained from engineering handbooks. Building

codes of local communities give the recommended

allowable bearing loads for different types of soil. For

rough calculation the foundation should be

approximately 2-1/2 times total unit weight.

NOTE

Experience has shown that any base-mounted

assemblies of motor and driven units temporarily aligned

at the factory may twist during shipment. Therefore,

alignment must be checked after mounting.

Realignment is to be documented for warranty

information.

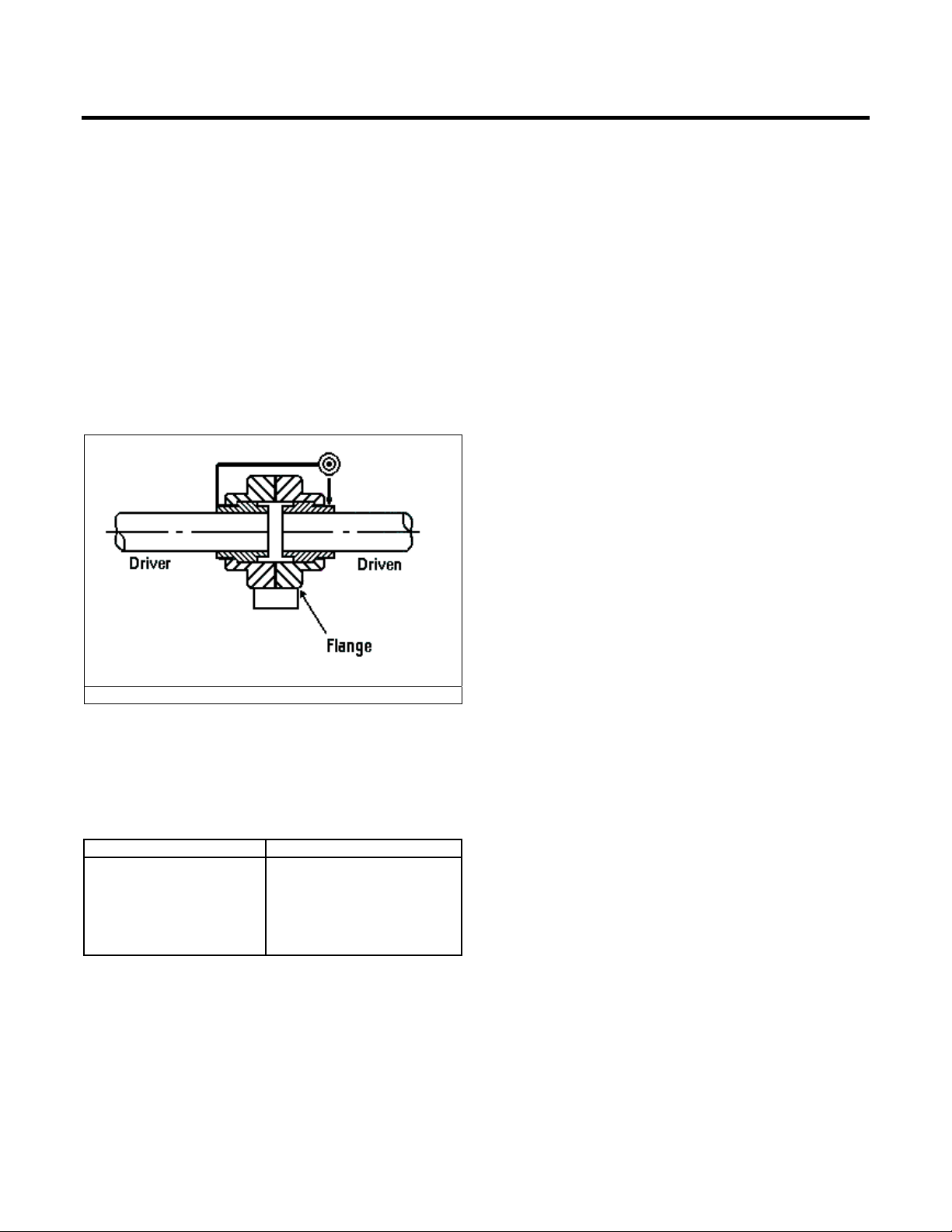

Coupling of Sleeve Bearing Motors

Sleeve bearings cannot withstand externally generated

axial thrust. Antifriction bearings are normally

designed to handle a minimum thrust. As the motor

and driven equipment get hot they may expand

towards each other and with the wrong coupling this

could produce an axial force. Therefore, the selection

of coupling is of extreme importance. If properly

installed, the following types of couplings are

considered to be free from the development of axial

thrust and may be used:

1. Laminated Metal Disk Type

2. Rubber Biscuit Type (Designed for the Speed)

Limited end float models of the following types are

available from several coupling manufacturers and

may be used by selecting the proper end float (See

“End Float – Sleeve Bearings” under Bearing

Replacement)

3. Pin and Bushing Type

4. Gear Type

- 5 -

Page 7

Installation

External Wiring

DANGER

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working on

this equipment.

NOTE

Before running motor, see Initial Start.

Starting and overload control devices must be matched

to motor rating. For safety or convenience they may

need to be installed some distance from the motor.

Follow the control manufacturer’s instructions to make

proper installations and connections. Observe the

following:

1. Connect electrical power supply to conform with

National Electric Code and any local regulations.

Line voltage and wire capacity must match motor

rating stamped on the nameplate.

2. With the driven equipment disconnected,

momentarily energize the motor to check rotation.

3. If motor is three-phase type, reverse rotation (if

required) by interchanging any two of the three

power leads.

Changing Direction of Rotation

Look for rotation plates usually mounted on opposite

drive end of the motor.

CAUTION

Excessive heat.

Motor may overheat if motor cooling fans run in the

wrong direction.

Run motor in direction shown on motor or change fans.

The internal rotor fan direction must be considered if

changing direction of rotation. See the following

Internal Rotor Cooling Fan table to identify which

motors have directional fans.

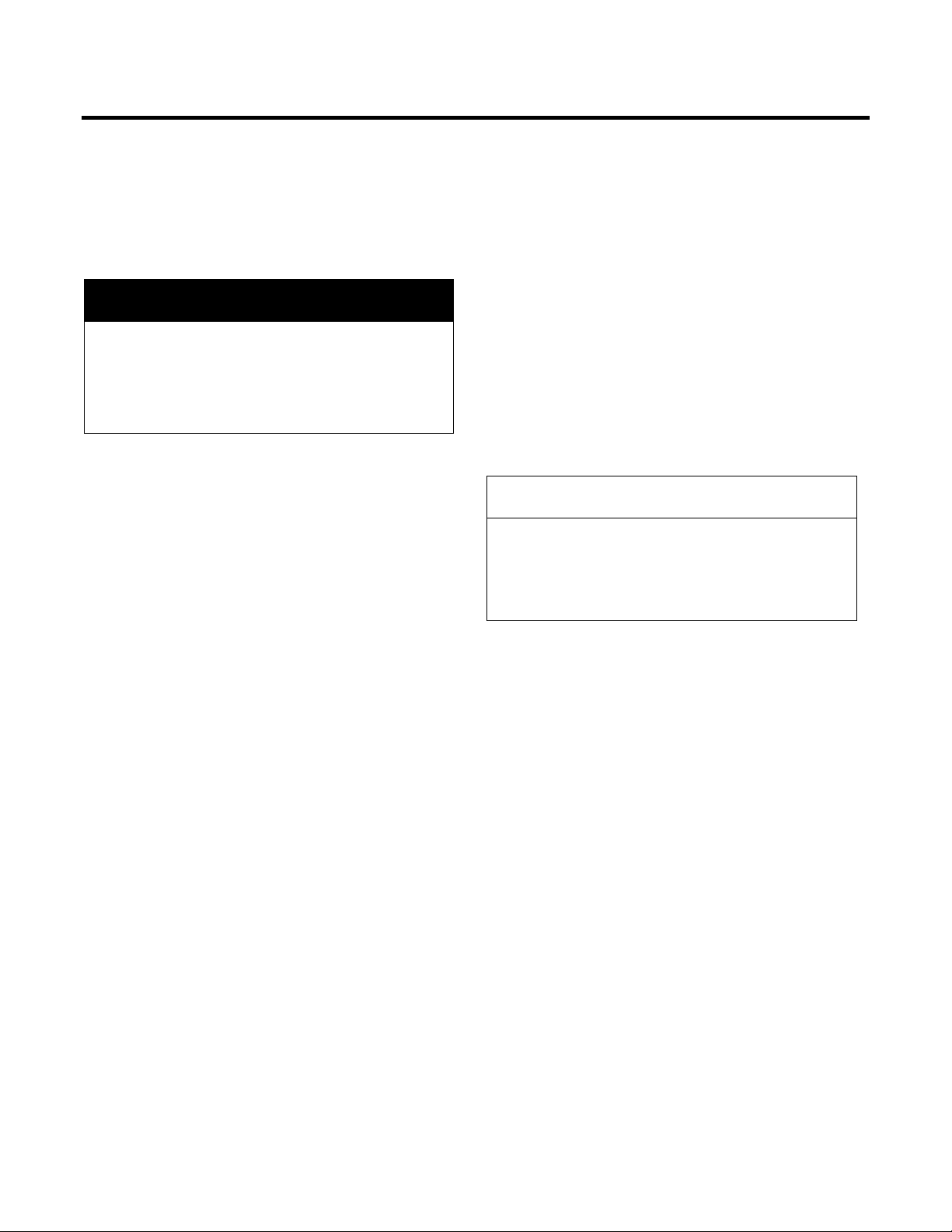

Motor Speed

(No. of poles)

Rotor Material Aluminum Copper Aluminum Copper

500, 580

Frames

680, 800

Frames

1120 Frame N/A N/A N/A 2

1. Inspect rotor to determine whether alternative A or B

below applies;

2. Replace single directional rotor fan with one for the

opposite direction.

3. Fans are bi-directional which allows motor rotation in

either direction without mechanical modification.

4. The single directional rotor fans must be interchanged

end-for-end.

Internal Rotor Cooling Fan

3600 – 3000 RPM

(2 pole)

1 4 3 3

N/A 4 N/A 3

A. If the rotor has integrally cast directional fans,

either rotor machining instructions and

conversion parts can be purchased from the

factory or the rotor core may be removed from

the shaft, switched end-for-end, and

remounted on the shaft.

B. If the rotor has shaft-mounted directional fans,

the fans must be interchanged end-for-end.

1800 RPM & Slower

(4 or more poles)

NOTE

It will be necessary to rebalance the rotor if the fans are

changed.

Alignment

Accurate shaft alignment between motor and driven

equipment is essential. Improper alignment may result

in vibration, bearing overloads and excessive shaft

stresses. Flexible couplings will not compensate for

excessive misalignment.

NOTE

A basic rule is to not have more than five shims in a shim

pack under any one motor foot. Thick shim packs

consisting of many thin shims will cause soft foot,

excessive vibration or twisted frame (motor foot out of

plane).

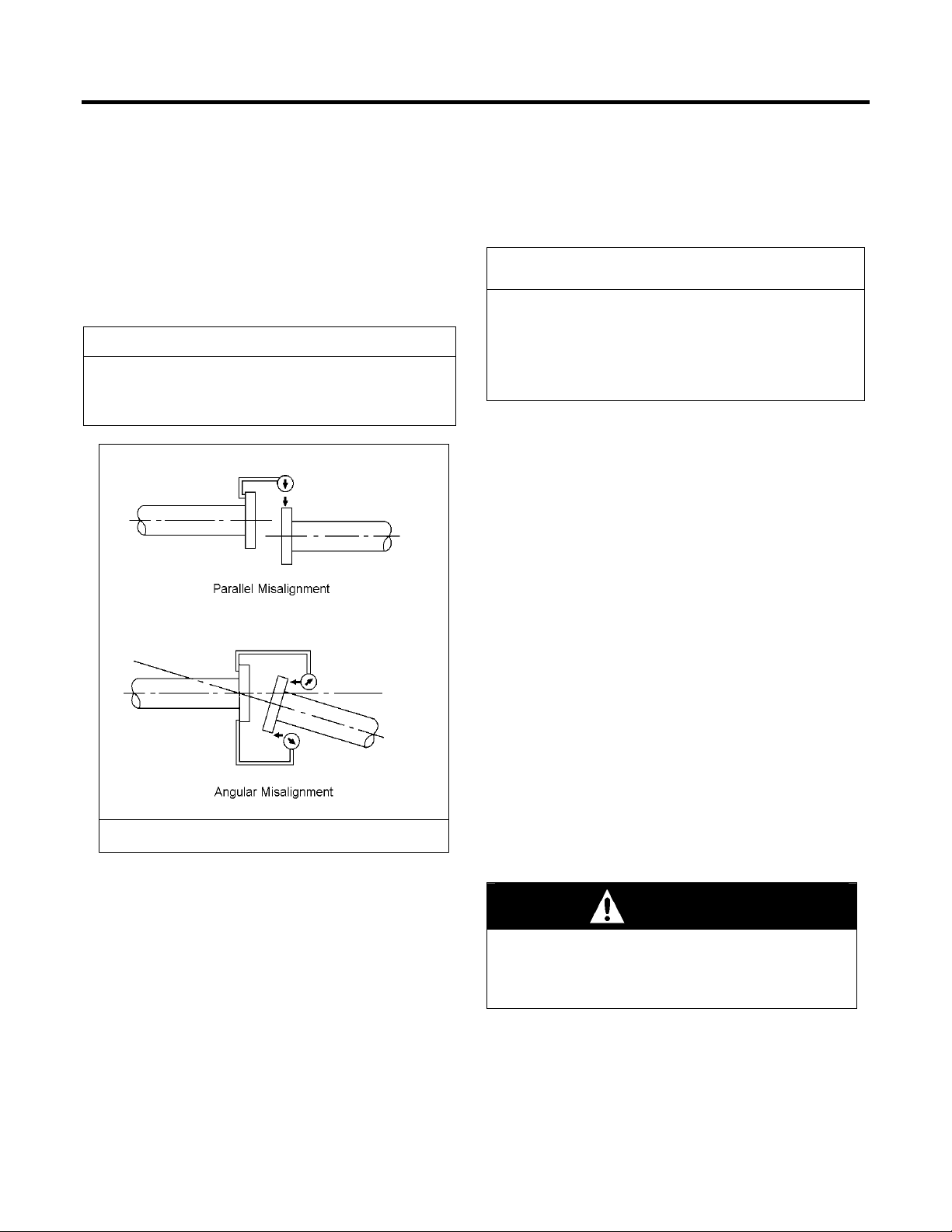

Parallel Alignment

After positioning unit for correct end float, separate the

coupling halves and mount a dial indicator rigidly on

one coupling half with the button on the cylindrical

surface of the other half. Rotate the shafts together,

and take readings at top, bottom and side positions.

Align shaft so difference between top and bottom

readings and the side readings is a maximum of

0.002 inch for a flexible coupling.

- 6 -

Page 8

Installation

Angular Alignment

Hold each shaft at maximum end float. Rotate both

shafts together, and measure between matching points

at the outside diameter of the coupling faces for the

top, bottom and both sides. Use two indicators

because of possible axial shaft movement. Read

difference of variation between them.

Align shafts so that the total indicator variation does

not exceed 0.002 inch. (See Figure 1.)

NOTE

If vibration levels increase cold to hot, alignment should

be checked hot to verify that motor and driven equipment

are properly aligned at operating temperature. Adjust if

necessary.

3. If no change is indicated, retighten the bolt and

repeat the process for each of the remaining three

mounting bolts.

4. If a change is indicated, add shims under motor

foot and retighten until indicator movement is

reduced or eliminated.

NOTE

1. The foot plane is of concern for each unit of rotating

equipment. Check driven equipment if necessary.

2. Base or foundation rigidity can also affect vibration;

check for resonance in supporting structure.

3. Recheck alignment after any change in shims and

document alignment readings for warranty information.

V-Belts

Check belt manufacturer’s recommendations for

maximum speed of sheaves and belts, minimum pitch

diameters, maximum allowable number of belts and

maximum sheave width.

When motor is ordered for V-belt drive, check motor

outline for motor manufacturer’s limits on belt pull,

sheave distance from motor, and sheave diameter.

Use only matched-belt sets. V-grooves must be in line;

sheaves must be parallel and axially aligned. Belts

must enter and leave sheaves with no side bending.

For long bearing life, the belt tension is important;

consult belt manufacturer for proper tension to suit

drive. Protect belts from grease and oil. NEVER use

belt dressing.

Hot Alignment

Figure 1. Diagrams Showing Parallel and

Angular Misalignment

Foot Plane

The proper foot plane exists when adequate shims

have been installed to assure equal pressure on each

foot or corner of motor when the mounting bolts are

loose.

To determine proper foot plane:

1. Mount dial indicator on shaft to be checked so that

contact will rest on either the adjacent shaft or a

bracket from the foundation or base.

2. With mounting bolts tight and indicator set at zero,

release one bolt at the shaft extension end of the

unit and check indicator for a maximum change

of 0.001 inch.

It is possible for the motor shaft height to change

relative to the driven equipment and this should be

compensated for during the alignment procedure.

Heat from driven equipment can also cause horizontal

misalignment.

WARNING

Rotating parts.

Can cause serious injury.

Disconnect and lock out power before working on

equipment.

If motor application is abnormal (high temperature,

extreme vibration, etc.) consult the factory for special

instructions or additional information.

- 7 -

Page 9

Installation

Check for vertical alignment (parallelism) of coupled

drive as follows:

1. Operate unit until normal temperature is reached

(may require several hours).

2. Shut down motor and lock out switch.

3. Mount dial indicator as in Figure 2.

4. Rotate shaft, noting readings at 0°, 90°, 180°, and

270° (both sides, top, and bottom). If within 0.002

inch total indicator reading, or other limit specified

by the factory, unit is satisfactory for operation.

5. If not within limits, add or remove shims as

required to raise or lower motor.

6. If shims are changed for high temperature

operation, repeat alignment procedure to extent

necessary to assure proper alignment. Document

readings for warranty information.

Figure 2. Check of Vertical Alignment

Vibration

Completing Mechanical Installation

After controlling rotor end float and establishing

accurate alignment, it is recommended to drill and

ream the foundation plate and motor feet together for

dowel pins. (See Doweling).

Recheck parallel and angular alignment before bolting

the coupling together. Motor shaft should be level

within 0.03 inch after alignment.

Doweling

Doweling the motor (and driven unit) accomplishes the

following:

1. Restricts movement.

2. Eases realignment if motor is removed from base.

3. Temporarily restrains the motor, should mounting

bolts loosen.

Inserting Dowel Pins

The following procedure is recommended:

a. Check the alignment after the unit has been in

operation approximately one week. Correct as

necessary.

b. Using pre-drilled dowel holes in motor feet as

guides, drill into the mounting base.

c. Ream holes in the feet and base to the proper

diameter for tapered dowel pins. Clean out the

chips.

d. Insert dowel pins.

Force Feed Lubrication

The standard unfiltered housing vibration limits

measured at no load, uncoupled, and with rigid

mounting are as follows based on the requirements of

NEMA MG1-7.8.

Speed Velocity, inches/sec peak

1200 – 3600 RPM 0.120

1000 RPM 0.105

900 RPM 0.096

750 RPM 0.079

720 RPM 0.075

600 RPM 0.063

After alignment is complete and foot mounting bolts are

tight, run motor at no load (or minimum possible).

Check for vibration. If excessive vibration exists and

the alignment is acceptable, check foot plane by

loosening one drive end-mounting bolt at a time as

detailed below. This is to be documented for warranty

information. When resiliently mounted, allowed levels

are 25% higher.

- 8 -

If force feed lubrication is used, flush lubrication lines

thoroughly to make sure the lines are clean before

connecting lines to bearing housings. Be sure that

bearing cavities are filled with oil to the proper level

before starting. See motor outline drawing to

determine proper oil level. Be sure that proper oil

pressure and flow are provided by the supply system.

Verify that the oil drain flow agrees with the factory

requirements. The orientation and size of oil drain

piping supplied with the motor must not be altered. Oil

drain piping should be of the same size or larger from

the motor piping to the oil sump. Piping must slope

downward. Pressure build up in the drain line between

the oil sump and the motor bearing housing can lead to

oil leakage. Document readings for warranty

information.

Page 10

Installation

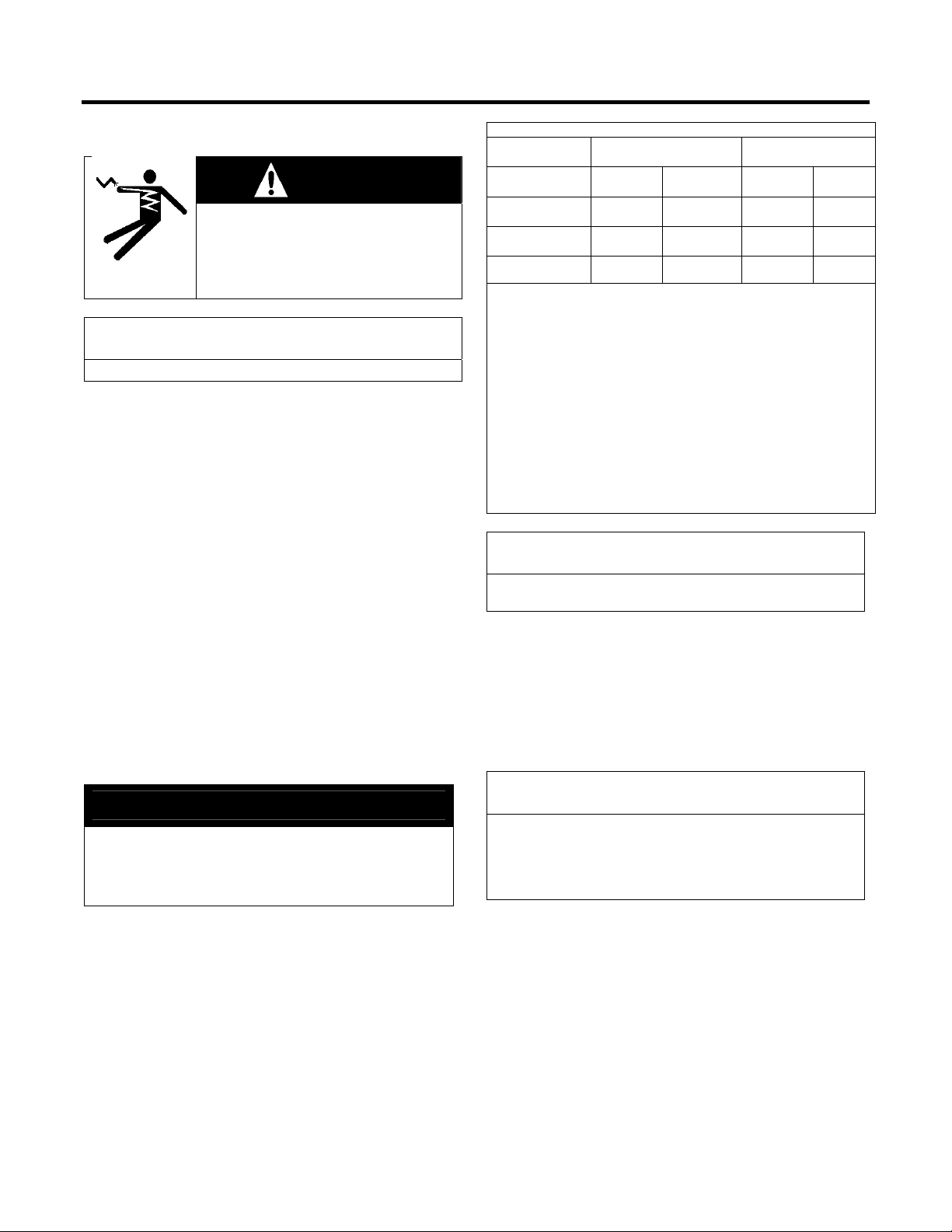

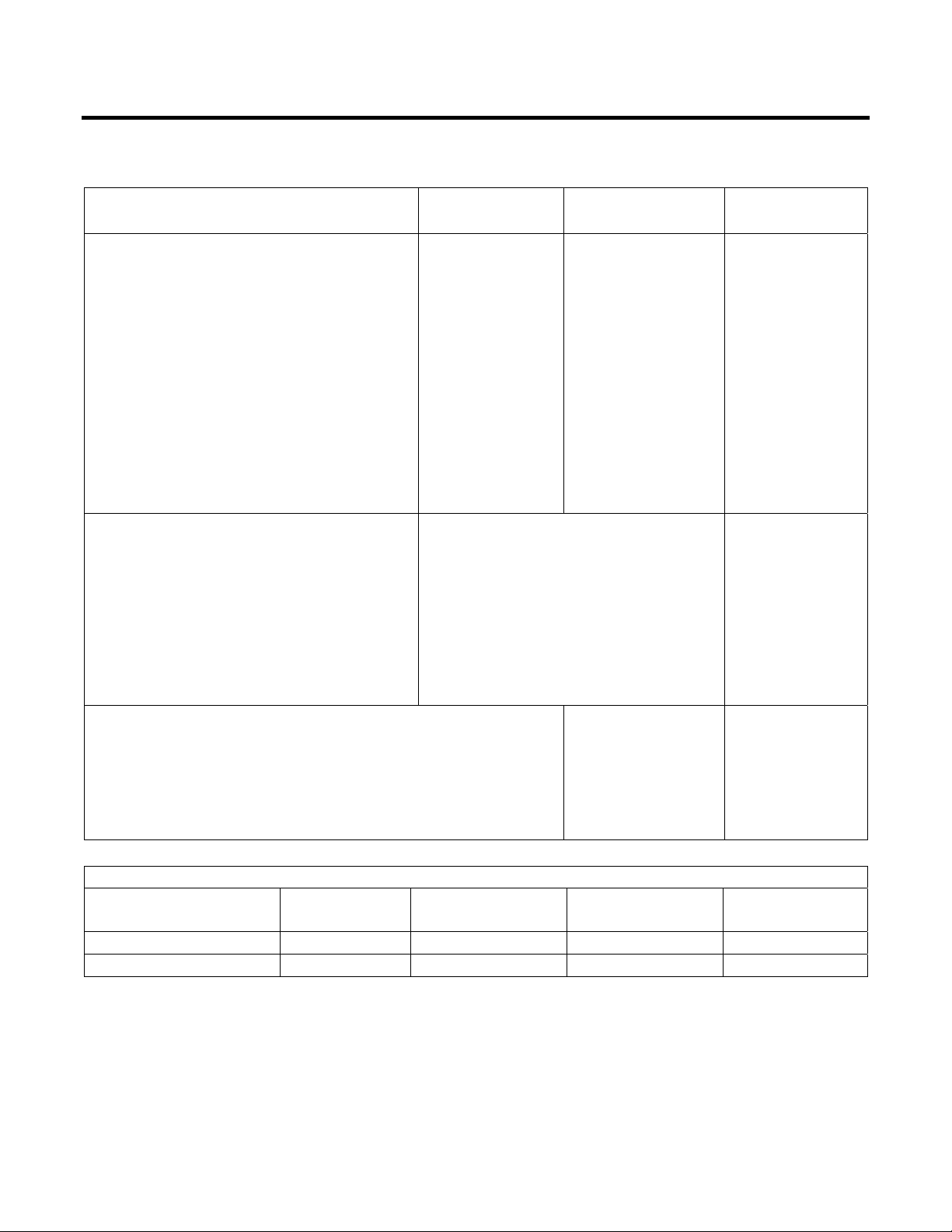

Typical Motor Control Settings

Winding Temperature

• Class B Insulation

• Class F Insulation

Alarm

130°C

155°C

Motor Bearing Temperature

(Thermocouple or RTD’s)

• Sleeve Bearing

• Antifriction Bearing

100°C 105°C

100°C 105°C

(2)

Ground Fault

4 Amps

Primary

Circuit

Instantaneous Overcurrent

• With ½ Cycle Delay

• Without Time Delay

1.8 times Locked Rotor Amps

2.4 times Locked Rotor Amps

Maximum Voltage 110 % of Rated Voltage 10 sec.

Minimum Voltage (the minimum voltage

also applies to starting unless otherwise

specified)

90 % of Rated Voltage 10 sec.

Maximum Frequency Deviation ±5% 10 sec.

Trip

(Shutdown)

155°C

170°C

8 Amps

(2)

Primary

Circuit

Timer Trip

Setting

(1)

(2)

(2)

0.2 sec.

(2)

Maximum of Voltage Plus Frequency Deviation ±10% 10 sec.

Maximum Voltage Unbalance

Maximum Current Unbalance

(3)

1% 15 sec.

(3)

8% 15 sec.

Suggested Vibration Limits

RPM 3600 1800 1200 900 and

Slower

Shaft (mils, pk-to-pk) 3.3 3.7 4.3 5.0

Housing (in./sec.) 0.25 0.25 0.25 0.25

(1)

Maximum time at maximum condition before control device is to operate.

(2)

Increase as necessary to avoid nuisance trips.

(3)

This is the maximum deviation from the average of the three phases.

- 9 -

Page 11

Operation

Initial Start

CAUTION

Do not exceed number of Siemens specified hot and

cold starts per hour.

Will cause overheating.

Allow time between starts to permit stator windings and

rotor cage to cool.

NOTE

If motor has been out of service or in storage for more

than 30 days, consult Siemens Storage

Recommendations ANIM-03114, Preparation for

Service

After installation is completed, but before motor is put

in regular service, make an initial start as follows:

1. Check that motor, starting, and control device

connections agree with wiring diagrams.

2. Check that voltage, phase, and frequency of line

circuit (power supply) agree with motor nameplate.

3. Check motor service record and tags

accompanying motor. Be certain bearings have

been properly lubricated and oil wells are filled.

See motor outline drawing to determine proper oil

level.

4. If possible, remove external load (disconnect drive)

and turn shaft by hand to assure free rotation. This

may have been done during installation procedure;

if so, and conditions have not changed, this check

may not be necessary.

5. If drive is disconnected, run motor at no load long

enough to be certain that no unusual condition

exists. Listen and monitor for excessive noise,

vibration, clicking or pounding and that oil rings are

turning if so equipped. If present, stop motor

immediately. Investigate the cause and correct

before putting motor in service.

6. If drive cannot be disconnected, interrupt the

starting cycle after motor has accelerated to low

speed. Carefully observe for unusual conditions as

motor coasts to a stop. Repeat several times if

necessary. Refer to motor’s Starting Duty

nameplate (if so equipped) or Motor Data Sheet for

recommended number of starts and cooling period

between starts..

7. When checks are satisfactory, operate at lowest

load possible and look for any unusual condition.

Increase load slowly to maximum, checking unit for

satisfactory operation.

Oil Circulating Systems

For motors with oil circulating systems, proceed as

follows before startup;

1. Fill motor reservoirs to normal level (see motor

outline drawing).

2. Follow instructions provided by the oil circulating

system supplier.

3. Put oil circulating system into operation before

starting motor.

Normal Operation

Start the motor in accordance with standard

instructions for the starting equipment used.

Sometimes the load should be reduced to the

minimum, particularly for reduced voltage starting,

and/or high inertia connected loads.

Voltage/Frequency Variation

Motors will operate successfully under the following

conditions of voltage and frequency variation, but not

necessarily in accordance with the standards

established for operating under rated conditions:

1. If the variation in voltage does not exceed

10% above or below rated voltage, with all

phases balanced. Voltage unbalance should not

exceed 1%.

2. If the variation in frequency does not exceed 5%

above or below rated frequency.

3. If the sum of the voltage and frequency variations

does not exceed 10% above or below rated

values provided the frequency variation does not

exceed 5%.

- 10 -

Page 12

Operation

Trouble Shooting

Between regular maintenance inspections, be

alert for signs of motor trouble. Common

symptoms are listed in the following table.

Correct any trouble immediately and AVOID

COSTLY REPAIR AND SHUT DOWN.

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working on

this equipment.

TROUBLE POSSIBLE CAUSES CORRECTION

Motor will not start.

Excessive hum.

Regular clicking. Foreign matter in air gap. Remove foreign matter.

Rapid knocking. Bad anti-friction bearing or dirt in lubricant. Replace bearing, clean grease cavities and

Vibration.

Usually line trouble. Single phasing at

starter.

Under Voltage. Check voltage at motor terminals. Compare to

Excessive Load. Disconnect motor from load to see if it starts

High Voltage. Check input voltage. Check for proper

Unbalanced rotor. Balance rotor.

Excessive wear of sleeve bearings. Replace bearings. Check to determine cause

Misalignment in coupling or feet. Realign motor and driven equipment.

Check power source. DO NOT check with

motor energized! Check overloads, controls

and fuses. Check voltage and compare with

nameplate rating.

nameplate.

without load. Reduce load or replace motor

with unit of greater capacity.

connections.

of wear and replace as necessary. Check

alignment.

renew lubricant.

DANGER

Vibration following motor

repair.

Motor overheating.

(Check with thermocouple

or by resistance method,

do not depend on touch).

Accumulation of dirt on fan. Clean motor.

Vibration in driven machine. Run motor disconnected from driven load and

check for vibration. Eliminate source in driven

equipment.

System natural frequency (resonance). Alter rigidity of base structure.

Rotor out of balance; balance weights of

fans shifted on rotor.

Overload. Measure load and compare with nameplate

Single phase. Check current, all phases.

Dirt in motor. Check flow of air.

Unbalanced voltage. Check voltage, all phases.

Rotor rubbing on stator. Check air gap. Repair motor as necessary.

Balance rotor.

rating. Check for excessive friction in motor or

complete drive. Reduce load or replace motor

with unit of greater capacity.

Check filters, if so equipped.

Clean motor.

- 11 -

Page 13

Operation

Trouble Shooting

TROUBLE POSSIBLE CAUSES CORRECTION

Motor overheating

(continued…)

Fine dust under coupling

having rubber buffers or

pins.

DANGER

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working on

this equipment.

Open stator windings. Disconnect motor from load. Check idle amps

for balance in all three phases. Check stator

resistance in all three phases for balance.

Air Recirculation. Check air intake and exhaust for obstructions.

Check air inlet temperature.

Over voltage/under voltage. Check voltage and compare to rating plate.

Ground. Locate with test lamp or insulation tester and

repair.

Improper electrical connections. Recheck electrical connections.

Heat exchanger tubes blocked. Clean tubes, if so equipped.

Loose heat exchanger tubes. If so equipped, Roll tubes to expand tube

inside diameter using proper expansion tool.

Misalignment. Realign motor and driven equipment.

Inspect coupling.

Bearing overheating.

Oil leakage or excessive

oil usage.

Excessive oil level

fluctuation.

Oil level too high or low (sleeve bearing).

Misalignment. Realign motor and driven equipment.

Excessive tension in belt drive. Reduce tension to point of adequacy.

Excessive end thrust. Reduce thrust. Recheck mounting and

Too much grease (ball or roller bearing). Relieve supply to point set by manufacturer.

Sticking oil ring (sleeve bearing). Clean, repair, or replace. Recheck mounting.

Parts not sealed properly. Seal pipe plugs and connections.

Clogged oil return holes in oil seals. Dismantle and clean oil seals.

High pressure or vacuum in bearing cavity. Measure pressure or vacuum using

Correct oil level. See Maintenance section of

this instruction book to determine proper oil

level.

alignment.

Seal bearing housing split line.

Seal oil seal joint.

manometer (See “Cavity Pressures” under

Bearings).

Check atmospheric vents for obstructions.

Check oil seal gap for uniformity.

- 12 -

Page 14

Maintenance

Preventive Maintenance

Motors are designed to give many years of reliable

service with a minimum of attention. Trouble-free

operation cannot be expected if proper maintenance

is postponed or neglected.

Provide proper maintenance on the equipment.

Follow carefully the instructions contained herein. Be

certain personnel review, understand, and follow

these procedures during periodic maintenance

inspections.

DANGER

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working

on this equipment.

Maintenance should be performed

only by qualified personnel.

CAUTION

Flying dirt, dust or other particles.

May cause eye injury.

Wear safety glasses and dust mask when using

compressed air.

CAUTION

Loose parts or fire.

Can result in product failure or serious property damage.

Maintenance Checklist

1. Verify motor is clean and verify that stator and

rotor ventilation passages are unobstructed.

2. Check for excessive loading or service factor.

3. Verify winding temperature rise not in excess of

rated value.

4. Verify insulation resistance is above

recommended minimum.

5. Verify voltage and frequency variation.

6. Check air gap.

7. Verify that bearing temperatures are within limits

and that lubricant is clean and proper level

maintained.

8. Verify no unusual vibration or noise exists.

9. Check alignment.

10. Check for proper lubrication.

A definite schedule of preventive maintenance

inspections should be established to avoid

breakdown, serious damage and extensive

downtime. The schedule will depend on operating

conditions and experience with similar equipment.

To assure adequate maintenance, and warranty

consideration, it is essential that complete records

be kept for each motor, including description and

rating, maintenance schedule and repairs required

or carried out.

This checklist does not represent an exhaustive

survey of maintenance steps necessary to ensure

safe operation of this equipment. Particular

applications may require further procedures. Should

further information be desired or should particular

problems arise which are not covered sufficiently for

the purchaser’s purposes, the matter should be

referred to the local Siemens Sales Office.

WARNING

Improper maintenance can cause death, serious

injury or property damage.

Use only factory authorized parts for repair of

equipment.

Maintenance should be performed only by qualified

personnel.

Inspection

Each motor should be inspected at regular intervals.

The frequency and thoroughness will depend on the

operating hours, nature of service, and the

environment.

Antifriction Bearing

Access to the motor interior can be gained by

removal of the bearing housing.

1. Remove the bolts holding the inner bearing end

cap to the housing.

2. Remove the bolts holding the bearing housing to

the yoke.

3. Remove the bearing housing by pulling it away

from the face of the yoke. See Air Deflector.

- 13 -

Page 15

Maintenance

Sleeve Bearing – 500, 580, 680, 800 Frames

Access to the motor interior can be gained by

removal of the upper half of the horizontally split

bearing bracket.

1. Remove the parting bolts at the horizontal split.

2. Remove the bolts at the outer circumference of

the upper half of the split-bearing bracket.

3. Pull the upper bracket away from the face of the

frame and remove bracket.

The entire procedure can be done without disturbing

the bearing enclosure or coupling alignment of the

motor to the load. The split-bearing capsule is held

together by bolts.

Sleeve Bearing - 1120 Frames

Access to the motor interior can be gained by

removal of the bearing bracket as follows:

1. Remove the parting bolts at the horizontal split.

2. Carefully remove the top half of the bearing

housing by lifting it straight up and then pull it

away from the lower half.

Air Deflector

Air deflector construction depends on the type and

size of motor. The following conditions will be found

when accessing the motor interior;

1. 500 frame motors have air deflectors that are

retained in the fit between the bearing housing

and the stator yoke. Such air deflectors will be

removed with the bearing housing or can be

easily removed from the stator yoke after

bearing housing removal.

2. 580, 680, 800, or 1120 frame motors have air

deflectors which are mounted with bolts to the

stator yoke.

3. Air deflectors on sleeve bearing motors are

horizontally split.

Cleanliness

The exterior should be kept free of oil, dust, dirt,

water, and chemical. It is particularly important to

keep the air intake and exhaust openings free of

obstructions.

NOTE

If equipment is operated intermittently in very damp

locations, it should be protected by space heaters. To

retard corrosion, grease all machined fits when the

unit is reassembled after a maintenance check.

Loading

Overloading causes overheating and reduces

insulation life. A winding subjected to a 10°C

temperature rise above the maximum limit for its

class may have its insulation life halved.

Underloading a motor is improper as it lowers the

motor power factor and efficiency which results in

higher power cost.

Temperature

Electrical apparatus operating under normal

conditions becomes quite warm. Although some

places may feel hot to the touch, the unit may be

within limits. If checking total temperature by

winding resistance or imbedded detector (RTD), the

total temperature should not exceed the following:

When operating at full load:

Temp. by

Resistance

Temp. by

Embedded

Detector

All HP

1500HP

or less

Over

1500HP

-Under

7000V

Over

1500HP

-Over

7000 V

Class of Insulation System

B F H

120°C

(248°F)

130°C

(266°F)

125°C

(257°F)

120°C

(248°F)

145°C

(293°F)

155°C

(311°F)

150°C

(302°F)

145°C

(293°F)

165°C

(329°F)

180°C

(356°F)

175°C

(347°F)

165°C

(329°F)

When operating at 1.15 service factor load:

Temp. by

Resistance

Temp. by

Embedded

Detector

All HP

1500HP

or less

Over

1500HP

-Under

7000V

Over

1500HP

-Over

7000 V

Class of Insulation System

B F H

130°C

(266°F)

140°C

(284°F)

135°C

(275°F)

130°C

(266°F)

155°C

(311°F)

165°C

(329°F)

160°C

(320°F)

155°C

(311°F)

175°C

(347°F)

190°C

(373°F)

185°C

(365°F)

175°C

(347°F)

These temperatures represent the maximum

temperature for each class of insulation and include

a 40°C ambient temperature. Operation above

these temperatures will result in reduced insulation

life.

- 14 -

Page 16

Maintenance

Vibration

Most problems can be detected when inspected

visually. Check for;

1. Loose or missing parts, such as fan blades, nuts,

bolts, screws, couplings, etc.

2. Accumulation of dirt on fan or rotor.

3. Associated equipment - Disconnect equipment to

determine where the vibration is being generated.

4. Foundation construction - Base, grouting and

associated equipment supporting drives must be

in good condition. Vibration can be amplified by

weak construction. Vibration of base just below

motor feet should not exceed 25% of motor

vibration.

5. History - When was vibration first noted? Was

there a change in loading and/or duty of

equipment? Has ambient vibration changed?

More important than the actual vibration is the

vibration change over a period of time.

Corrective Maintenance

Two factors that require corrective maintenance are

electrical failure or mechanical failure. The first sign

of electrical failure is usually low insulation

resistance. Mechanical failures are usually preceded

by excessive bearing noise or heat.

Low Insulation Resistance

Factors that usually cause low insulation readings

are:

1. Dirty windings (oil, dust, grease, salt, etc.).

2. Excessive moisture.

3. Mechanically damaged insulation.

4. Heat deterioration

Dirty windings can be cleaned and moist windings

dried; however, items 3 and 4 require extensive

repairs by a certified service center.

CAUTION

Flying dirt, dust or other particles.

May cause eye injury.

Wear safety glasses and dust mask when using

compressed air.

Cleaning

Clean the inside and outside of the motor regularly.

Actual conditions existing around the motor dictate

the frequency of cleaning operations. Use the

following procedures as they apply.

1. Wipe off dust, dirt, oil, water, etc., from external

surfaces of the motor. These materials can work

into or be carried into the motor windings and

may cause overheating or insulation breakdown.

2. Remove dirt, dust, or other debris from ventilating

air inlets and exhausts. Do not operate motor

with air passages blocked or restricted.

Rotor Cleaning

Remove rotor. Inspect air vents and remove any

obstructions.

Stator Cleaning

MICLAD™ form wound VPI (vacuum pressure

impregnated) insulated coils may be cleaned with a

quick drying solvent and lint free cloths or steam

cleaned with low-pressure steam, then the entire

stator oven baked at 200°F for 12 hours and then

230°F for 12 hours.

The stator winding insulation resistance should be

measured before and after any cleaning operation.

The windings may be cleaned with a solvent

compatible with the insulation system and oven dried.

Water and detergents with an oven drying cycle may

be used as an alternate on MICLAD™ VPI insulation

systems.

MICLAD™ is a Siemens trademark.

DANGER

Hazardous voltage.

Will cause death, serious injury,

electrocution or property damage.

Disconnect all power before working

on this equipment.

CAUTION

High Voltage.

May damage semi-conductors, small transformers,

voltage regulators, and other devices.

Disconnect from circuit before testing insulation

resistance.

- 15 -

Page 17

Maintenance

Insulation Resistance

Check insulation resistance periodically. Use a hand

cranked or solid state insulation resistance tester and

test with at least 500 volts, but not greater than motor

rated voltage.

For motors with newer insulation systems such as

MICLAD™ VPI, the insulation resistance after one

minute should be greater than 1000 megohms.

(Values in excess of 5000 megohms are common.)

For older motors, the minimum value recommended

in IEEE Standard 43 can be used. The value in

megohms, when corrected to 40°C, is equal to the

motor rated voltage in kilovolts plus 1. For example,

for a motor with a rated voltage of 2300 volts, the limit

value would be:

2.3 + 1 = 3.3 (megohms).

Drying Insulation

If the insulation resistance is less than satisfactory,

and the cause is believed to be excessive moisture in

the windings, dry the windings by applying heat from:

1. A warm air oven.

2. Electric strip heaters.

3. Circulating currents through the coils.

The heat should be applied slowly so the desired

temperature will not be obtained in less than six

hours.

Insulation Drying Temperature*

Class “B” Class “F” Class “H”

200°F 245°F* 275°F*

94°C 118°C 135°C

*Class “F” and “H” insulated units should be baked at 70%

specified temperature (to avoid steam inside winding) for about

six hours, before temperature is raised to drying temperature.

Insulation resistance should be measured before the

heat is applied, and every six to eight hours

thereafter.

NOTE

Insulation resistance will decrease as the motor warms

up; but will begin to increase as the drying process

continues.

A uniform temperature must be maintained in the

motor to obtain constant resistance readings. When

the megger readings remain constant, the drying

process is complete and may be discontinued.

Check for other causes if readings are still low.

Warm Air Oven Drying

1. Remove bearing housings.

2. Remove rotor.

Bake in oven at temperatures specified in Insulation

Drying Temperature table, and follow procedures

described for drying insulation.

Electric Strip Heater Drying

1. Remove bearing housings.

2. Remove rotor.

3. Direct a fan on stator to carry away the moisture.

4. Attach temperature indicators to winding and

apply heat as specified in the Insulation Drying

Temperature table and follow procedures

described for drying insulation.

5. Radiant type heaters are not recommended

because some parts may become scorched

before remote parts reach desired temperature.

Circulating Current Drying

1. Remove bearing housings.

2. Center the rotor in the stator core.

3. Wedge fiber strips into the lower part of the air

gap so rotor does not touch stator core, or

remove rotor.

4. Direct fan on unit to blow away excessive

moisture.

5. Attach temperature indicators to windings. Do not

exceed the drying temperatures in the Insulation

Drying Temperature table.

6. An external source of current can be used to

circulate direct current through the winding of any

type of alternating current motor. A portable low

voltage motor-generator set, such as is used for

welding, is usually suitable.

CAUTION

High temperatures.

May cause damage to insulation.

Avoid hot spots and radiant type heat

- 16 -

Page 18

Maintenance

When this method is used on the stator, the stator

phases may be connected in series or in parallel to

suit the available power supply if both ends of all

phases are accessible. If only three leads are

brought out of the motor, the current may be

circulated between one terminal and the other two

connected together. If this is done, the temperature

of the single lead connection must be checked

frequently, and it is desirable to shift the leads

occasionally. Usually 50 to 100% of full load current

will produce the required temperature. The dc voltage

required for this current will be 0.25 - 5.0% of the

normal voltage per phase, and the corresponding

power will be 0.50 - 3.25% of the rating.

Alternating current can be used on the stators of

squirrel cage induction motors if the rotors are

removed. Alternating current is usually not as easy

to control as required voltage control, and a.c.

requires a higher voltage source, approximately 10 to

30% of the rated winding voltage. In addition, care

must be taken that miscellaneous parts adjacent to

the windings, such as lead studs, core supporting

member, etc., do no overheat due to induced

currents and the lack of normal ventilation.

CAUTION

High temperatures.

May cause damage to insulation.

Avoid hot spots and radiant type heat

Bearings

Long life of bearings is assured by maintaining proper

alignment, belt tension, and lubrication at all times.

Incorrect alignment of solid and flexible couplings can

cause excessive load on bearings, and excessive

vibration and thrust. Misalignment of belt drives can

cause thrust or harmful shaft oscillation. Improper

alignment of gear drives will produce shock loads and

may bend the shaft.

Excessive belt tension often causes overheating and

failure of bearings. Bearings tend to overheat when

pulley centers are too close, pulley diameters are too

small, or belt speed is too high.

Bearing Construction

Two types of bearings are employed in induction

motors. These are;

1. Antifriction bearings.

2. Sleeve bearings.

The type of bearing mounting and supporting

structure will depend upon the type of bearing.

Bearing housing construction will also vary with the

type of bearing. Antifriction bearing motors have one

piece bearing bracket construction. Sleeve bearing

motors have split bearing housings.

Insulated Bearings

One or both bearings may be insulated to prevent

shaft currents from pitting bearing surfaces. The

insulation is located at the joint between the bearing

housing or bracket and the bearing. Insulated

bearings are designated by an instruction plate on

the bearing housing.

Check periodically to be sure the insulation has not

been weakened or destroyed.

The bearing insulation can be checked using an

ohmmeter or circuit test light. For sleeve bearing

motors with one bearing insulated, the shaft must be

raised a few mils at the non-drive end of the motor so

that it is not in contact with the bearing and the shaft

coupling must be parted so that the shaft is not

grounded through the driven equipment. For motors

with both bearings insulated, disconnect bearing

grounding strap before testing for insulation integrity.

Bearing temperature devices must be disconnected

and oil rings must not be in contact with both the

shaft and the bearing.

- 17 -

Page 19

Maintenance

Insulated Bearings

One or both bearings may be insulated to prevent

shaft currents from pitting bearing surfaces. The

insulation is located at the joint between the bearing

housing or bracket and the bearing. Insulated

bearings are designated by an instruction plate on

the bearing housing.

Check periodically to be sure the insulation has not

been weakened or destroyed.

The bearing insulation can be checked using an

ohmmeter or circuit test light. For sleeve bearing

motors with one bearing insulated, the shaft must be

raised a few mils at the non-drive end of the motor so

that it is not in contact with the bearing and the shaft

coupling must be parted so that the shaft is not

grounded through the driven equipment. For motors

with both bearings insulated, disconnect bearing

grounding strap before testing for insulation integrity.

Bearing temperature devices must be disconnected

and oil rings must not be in contact with both the

shaft and the bearing.

Antifriction Bearings

Antifriction bearings are selected to give long service

when they are given proper maintenance. Bearing

failure can be caused by too little or too much

lubrication, contamination, excessive bearing load,

improper installation, alignment, or vibration.

The symptoms of antifriction bearing failure are

excessive vibration, noise, and excessive heat

generation. The races and balls should be

periodically inspected for damage. Any damage

requires replacement of the bearing.

Sleeve Bearings

Check sleeve bearings daily to be sure the oil rings

are turning properly. See motor outline drawing to

determine proper oil level. Add oil through the oil ring

sight glass opening or oil inlet pipe, if so equipped.

Be careful not to overfill.

Drain the oil reservoir by removing pipe plug. Clean

and flush with solvent and refill with fresh filtered oil

every three months to one year, depending on

severity of service. Use a high grade turbine oil

having a viscosity of 300-350 SSU at 100°F for units

of 1800 rpm and lower, and 140-160 SSU at 100°F

for machines above 1800 rpm to 3600 rpm.

In addition, seasonal oil changes are desirable if unit

is subject to wide variations in temperature.

Bearing babbitt temperatures that exceed 90°C

(194°F) or a sudden rise in temperature should be

investigated.

Common causes of hot bearings are:

1. Lack of oil.

2. Incorrect viscosity.

3. Poor quality oil.

4. Inoperative oil ring.

5. Misalignment of couplings or bearings.

6. Insufficient bearing clearance.

7. Oil seal rubbing on shaft.

8. Shaft or bushing rough spots.

9. Plugged oil passages on circulating oil systems.

(Note that circulating oil systems include a filter in

the oil line to strain the oil after it leaves the

pump. Check and clean or replace filter when

necessary.)

10. End thrust on bearing face.

Sleeve bearings are bored to an even dimension and

shaft journals are slightly smaller to obtain running

clearance. Side reliefs are provided to distribute oil

axially and reduce friction. During normal operation,

the shaft is supported on an oil film 0.001 to 0.005

inch thick, depending on speed, load and viscosity.

Unless adverse conditions exist which tend to break

down the oil film, metallic contact occurs only during

starting and stopping. Under normal circumstances,

bearing wear is very small.

Oil Rings

Inspect oil level and oil ring operation frequently. Oil

ring operation can be observed through the oil sight

glass. Oil rings should be perfectly round, free of

burrs or rough edges, turn at a constant speed, and

carry a noticeable amount of oil to the top of the

bearing journal. Failure of the oil ring to turn freely

may be caused by:

1. Ring out of round - rings should be round within

0.062 inch.

2. Fouling on a projection of the bearings, bushing,

or housing.

3. Ring not balanced (heavy side will tend to remain

down).

4. Adhesion to guide slot (trapezoidal section

reduces adhesion).

5. Oil too cold, too viscous, or oil level too high.

6. Shaft not level – oil rings tend to bind.

7. Vibration causing oil ring to bounce and slow

down.

- 18 -

Page 20

Maintenance

At the first sign of oil discoloration or contamination,

replace with new oil. Rapid discoloration is caused by

bearing wear, often from vibration or thrust. Change

oil as required to keep clean.

When assembling the bearing, it is possible to foul

the rings so that they will not turn freely. Check ring

operation by rotating shaft by hand after assembly

Oil Seals

The 680, and 800 frames use fixed labyrinth oil seals.

The oil seals should be centered radially on the shaft

and set so that the radial clearance is uniform on all

sides.

The 500, 580 and 1120 frames use self-centering oil

seals that can accommodate small radial movements

in the shaft. These floating labyrinth seals should be

free to move radially in the bearing housing. A

jammed seal could lead to bearing overheating and

poor vibration due to excessive seal rubbing during

operation.

The primary purposes of the oil seal are:

1. To prevent the entrance of dirt into the bearing

cavity.

2. To retain the oil in the bearing cavity.

3. To provide pressure regulation in the bearing

cavity.

To achieve these purposes it is necessary that a

specific diametrical clearance of oil seal to shaft be

held. The cooling fans of the motor tend to create

suction or pressure in the bearing cavity, which, if

large enough, will push or draw oil mist out along the

shaft. The 500, 580 and 1120 designs are equipped

with a close fitting air seal that serves as a barrier

against excessive pressure or suction inside the

bearing.

Standard oil seal clearances

Frame Diametrical Clearance

500 0.009 to 0.014 inches

580 0.015 to 0.019 inches

680 0.015 to 0.019 inches

800 0.015 to 0.020 inches

1120 0.004 to 0.008 inches

The bearing cavities and oil seals on the 680 and 800

frame designs are vented to the outside air in order to

keep the bearing cavity pressure as close to

atmospheric as possible. For these designs, it is

important that the piping and venting for these oil

seals be kept clean.

NOTE

When a sleeve bearing becomes worn and requires

replacement, the labyrinth oil seal should also be

replaced.

Bearing Clearance Too Large

The clearance between the journal and the bearing

will permit the journal center to be slightly below the

bearing center. With the motor operating, the

presence of the oil film between the journal and the

bearing will cause the shaft to rise slightly.

Too large a bearing clearance or clogged oil return

holes in the bearing will permit excessive oil to seep

out the ends of the bearing. This seepage, combined

with the rotation of the shaft, will create an oil mist

inside the bearing cavity that will tend to leak through

the oil seals. Excessive pressure in a force feed

lubrication system can also cause an oil mist to build

up.

Cavity Pressures

Motors are sensitive to the amount of pressure or

vacuum existing in the bearing cavity. The table

below shows the maximum allowable oil cavity

pressure or vacuum in terms of plus or minus inches

of water:

Frame Drive End

500 ±0.12 ±0.12

580 ±0.12 ±0.12

680 ±0.12 ±0.12

800 ±0.12 ±0.12

1120 ±0.12 ±0.12

For the correction of a high or low reading it is

important that:

1. The parts and joints around the bearing cavity

and oil seals are sealed.

2. Condensation drains, piping, sight gauges and

breathers are functioning properly.

3. Auxiliary equipment extending into close

proximity of the motor bearing housings is

shielded from the oil seals to prevent a transfer of

air from inside to outside the motor. (ex. motor

coupling)

4. All fixed

oil seals are centered properly on the

shaft.

Non-drive

End

- 19 -

Page 21

Maintenance

Sealing Parts

Even though joints may seem to match perfectly,

minute clearances exist through which oil may leak. .

Apply sealant as follows:

1. Surfaces shall be clean of dirt, grease, and oil

sealant. Use a non-oil base solvent if necessary.

2. The mating surfaces should be flat with no nicks

raised above the surface. There should be no

gap when mating surfaces are together.

3a. For 500, 580, and 1120 frames, apply a small

bead of silicone RTV at the bearing housing

parting surfaces. Loctite 518 may be used in

replace of RTV in environments where silicon is

prohibited. Do not apply too much sealant as

excess will be squeezed out and get into

labyrinth seals, bearing, oil cavities, etc. Apply a

uniform, thin layer (about 0.05" thick) of Curil T*

to the floating oil seal surfaces that mate with the

bearing housing. Allow Curil T to cure on the

seals for 15 minutes before insertion into bearing

housing.

3b. For 680 and 800 frames, apply a small bead of

silicone RTV to all mating surfaces of parts where

oil is present, including fixed oil seals and parting

lines.

4. Assemble parts.

*CURIL-T may be ordered through Siemens Customer Service in

Norwood, Ohio. Part number 53-688-487-001 should be used for

ordering purposes.

Bearing Lubrication

Grease Lubricated Antifriction Bearings

NOTE

A common mistake is over-lubrication of bearings.

When grease is added without removing the drain

plug, the excess grease may be forced into and

through the inner bearing cap and thrown on to the

windings. If bearing is over-lubricated, bearing could

run hot, and may lead to failure.

All antifriction bearing motors will have an affixed

plate with lubricating instructions. The instructions on

this plate should be followed to achieve optimum

bearing life and to avoid consequential damage to

rotating parts.

The frequency of relubricating bearings depends on

three factors - speed, type of bearing, and service.

Operating environment or application may dictate

more frequent lubrication.

Relubricate with the type of grease specified on the

lubrication plate mounted on the motor, or a

compatible grease. Mixing of non-compatible

greases can cause bearing failure.

Higher stator temperatures will result in increased

bearing temperatures. Bearing temperatures should

not exceed the limits as stated in Typical Motor

Control Settings. For specific recommendation,

consult factory.

Procedure for relubrication:

1. Stop the motor and lock out the switch.

2. Thoroughly clean the grease inlet fitting or plug.

If the motor has plug, remove plug and clean the

inlet.

3. Remove the drain plug and clean out any

hardened grease.

4. Slowly pump the correct amount of grease into

the grease inlet, per the lubrication plate mounted

on the motor.

5. Start motor and allow to run at least one (1) hour

to expel any excess grease from the drain

opening before re-installing the drain plug.

6. Stop the motor and lock out the switch.

7. Re-install the drain plug.

8. Put the motor back in operation.

The amount of grease for bearings may be calculated

by the following:

G = 0.1 x D x B

Where: G = Amount of grease in fluid ounces

D = Outside diameter of bearing in inches

B = Width of bearing in inches

- 20 -

Page 22

Maintenance

Sleeve Bearings

CAUTION

Maintain proper oil level.

Failure to do so may cause improper lubrication of motor

resulting in damage to the equipment.

Follow lubrication instructions carefully. Avoid adding oil

while unit is running.

Motors with sleeve bearings are shipped without oil.

A rust-inhibiting film is applied at the factory to protect

bearing and journal surfaces during shipment.

Before attempting to operate any sleeve bearing

motor, the following steps must be performed.

1. Visually inspect the bearing condition. Oil ring

inspection ports and drain openings in the

housing are normally provided for this purpose.

2. Check for any accumulation of moisture. If

oxidation is discovered, all traces of it must be

removed before motor is put in service, which will

require disassembly.

3. Flush all oil piping. Fill bearing reservoirs to

normal level. Fill to mark indicated on gauge or

to center of gauge. See the table below for

recommended grades of oil.

4. Rotate shaft several turns by hand to distribute oil

over bearing parts. Make sure oil rings rotate

freely.

Recommended Grades of Turbine Oil

Motor Speed Oil Viscosity at 100°F

3600 or 3000 RPM

1800 & slower

140 - 160 SSU

300 - 350 SSU

ISO

Grade

32

68

NOTE

The oil viscosity at operating temperature is very

important in selecting proper oil and may vary in

different climates.

It is important to maintain the correct oil level, as lack

of lubrication is often the cause of bearing failure.

Inspect oil level and oil ring operation frequently. Oil

ring operation can be observed through the sight

glass mounted at the top of the bearing capsule. Oil

rings should be perfectly round, free of burrs or rough

edges, turn at constant speed and carry a noticeable

amount of oil to the top of the journal. Failure of the

oil ring to turn freely may be caused by:

1. Ring out of round (should be round to 0.062 inch)

2. Fouling on a projection of the bearing bushing.

3. Ring not balanced (heavy side will tend to remain

down).

4. Adhesion to guide slot (trapezoidal section

reduces adhesion).

5. Oil too cold or viscous, or oil level too high.

6. Shaft not level – oil ring tends to bind.

At the first sign of oil discoloration or contamination,

replace with new oil. Rapid discoloration is caused

by bearing wear, often from vibration or thrust.

Change oil as required to keep clean.

Force Feed Lubrication

Oil is metered through an orifice in oil inlet line to

allow the proper amount of lubricating oil to enter the

bearing. Conventional oil rings are also supplied with

the motor to insure temporary bearing lubrication in

the event the force feed oil supply should fail. It is

important to check oil flow frequently. Lack of

lubrication may cause bearing failure.

Checking Sleeve Bearing Clearance

Excessive clearance can cause rapid bearing failure,

and decreased air gap between stator and rotor at

the bottom of the motor. Diametrical sleeve bearing

clearances for the 500, 580, 680, and 800 frame

motors are approximately 2 mils per inch of bearing

diameter. Diametrical sleeve bearing clearances for

the 1120 frame is in the range of 1.5mils per inch of

bearing diameter.

An accurate check of bearing clearance is obtained

with micrometer measurements of the shaft journal

and bearing bore.

- 21 -

Page 23

Maintenance

Bearing Replacement

Antifriction Bearings

For typical antifriction bearing configuration, see

Figure 3.

Replacement bearings may be of a different

manufacturer but must be equal to the originals used in

the motor. When ordering bearings specify as follows:

1. The complete A.F.B.M.A. (Anti-Friction Bearing

Manufacturers’ Association) bearing number from

the motor nameplate.

2. Identifying numerals and manufacturer stamped on

the bearing.

3. Bearing tolerance class, i.e. - A.B.E.C.-1 (Annular

Bearing Engineers’ Committee Tolerance Class

One).

4. Internal radial clearance, i.e. – A.F.B.M.A.-3

(Clearance Class Three).

5. Electric motor quality.

To Replace Antifriction Bearings

1. Remove bolts holding end caps to housings.

2. Remove bolts holding bearing housings to yoke.

3. Remove bearing housings.

4. Remove the bearing with a puller. See Figure 4.

5. Check shaft and housing diameter for proper size

with micrometer.

6. Heat the new bearing in an oven (200°F). While

it is hot, slide the bearing onto shaft – make

certain that the inner race makes a firm even

contact with shaft shoulder. Do not subject

bearing to impact.

7. Let bearing cool - pack bearing caps with the

proper grease.

8. Reassemble end caps and housings.

The amount of grease to be used when repacking a

bearing after cleaning or replacement is shown in the

table below.

Type

Bearing

Deep Groove

Ball

Roller Horizontal 1/3 Full 1/3 Full

Operating

Bearing

(Shaft)

Horizontal 2/3 Full 1/3 Full

*Pack all open bearings full between balls or roller but remove

excess grease on outside of retainers.

Grease Quantity*

(End Caps)

Outer Inner

Figure 3. Ball Bearing Construction

Protect the shaft end with a cap. If bearing is reusable,

make certain the puller applies pressure against the

bearing inner race only. If puller will not hook the bearing

inner race, fabricate a split bushing and install it between

the bearing and the puller hooks.

Figure 4. Removing Bearing with a Puller

- 22 -

Page 24

Maintenance

Sleeve Bearing

When replacing sleeve bearings, it is always desirable

to check the fit (contact pattern) of the bearing to the

shaft. When ordering sleeve bearings, be sure to

provide complete motor nameplate and bearing data. If

bearing is insulated, be sure to replace it with another

insulated bearing.

Whenever a bearing is replaced, cleanliness must be

observed through every step of the operation.

Always inspect the bearing journal surfaces; they must

be smooth and polished. Slight scoring can be

removed with crocus cloth. If the motor shaft has been

seriously scored it must be put between centers and

reground. Journals can be ground 0.001 inch under

size, but they must be round and concentric with shaft

center.

Sleeve Bearing Replacement