Siemens Worm Gearbox S 5 BA 2012 Operating Instructions Manual

MOTOX Worm Gearbox S

BA 2012

Operating Instructions · 03/2013

MOTOX

Answers for industry.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

BA 2012

MOTOX

Worm Gearbox S

BA 2012

Operating Instructions

General information and

_________________

safety notes

_________________

Technical description

Incoming goods, transport,

_________________

and storage

_________________

Installation

_________________

Commissioning

_________________

Operation

Faults, causes, and

_________________

remedies

_________________

Service and maintenance

_________________

Disposal

_________________

Technical data

_________________

Spare parts

Declaration of Incorporation,

_________________

Declaration of Conformity

1

2

3

4

5

6

7

8

9

10

11

12

03/2013

70000004024300

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

70000004024300

Ⓟ 05/2013 Technical data subject to change

Copyright © Siemens AG 2013.

All rights reserved

Table of contents

1 General information and safety notes ........................................................................................................ 5

1.1 General information .......................................................................................................................5

1.2

1.3

1.4

1.5

2

Technical description............................................................................................................................... 11

2.1

2.2

2.3

2.4

3

Incoming goods, transport, and storage................................................................................................... 13

3.1

3.2

3.3

4

Installation ............................................................................................................................................... 17

4.1

4.2

4.3

Copyright........................................................................................................................................7

Intended use ..................................................................................................................................7

Obligations of the user ...................................................................................................................8

Particular types of hazards ..........................................................................................................10

General description......................................................................................................................11

Cooling.........................................................................................................................................11

Rating plate..................................................................................................................................11

Surface treatment ........................................................................................................................12

Incoming goods............................................................................................................................13

Transport......................................................................................................................................14

Storage.........................................................................................................................................15

Unpacking ....................................................................................................................................17

General information on installation ..............................................................................................17

Tightening torque for fastening bolts on the gearbox ..................................................................19

4.4

4.5

4.6

4.7

4.8

4.9

4.9.1

4.9.2

4.9.3

4.10

4.11

5

Commissioning ........................................................................................................................................ 31

6

Operation................................................................................................................................................. 33

BA 2012

Operating Instructions, 03/2013, 70000004024300

Gearbox with foot mounting.........................................................................................................20

Gearboxes in foot or flange version.............................................................................................20

Gearbox with C-type housing flange............................................................................................21

Mounting the input or output element on the gearbox .................................................................22

Removing and installing the protection cover..............................................................................24

Installing and removing the shaft-mounted gearbox....................................................................25

General information on installing the shaft-mounted gearbox.....................................................25

Installing the hollow shaft with parallel key..................................................................................26

Removing the hollow shaft with parallel key................................................................................27

Torque arms with shaft-mounted gearboxes ...............................................................................29

Mounting the motor ......................................................................................................................30

3

Table of contents

7 Faults, causes, and remedies.................................................................................................................. 35

8 Service and maintenance ........................................................................................................................ 37

8.1

8.2

8.3

8.4

9

Disposal................................................................................................................................................... 41

10

Technical data ......................................................................................................................................... 43

10.1

10.2

10.3

11

Spare parts.............................................................................................................................................. 47

12

Declaration of Incorporation, Declaration of Conformity........................................................................... 49

12.1

12.2

General notes about maintenance.............................................................................................. 37

Check gearbox for leaks ............................................................................................................. 38

Cleaning the gearbox or geared motor ....................................................................................... 39

Checking tightness of fastening bolts ......................................................................................... 40

General technical data ................................................................................................................ 43

Weight ......................................................................................................................................... 45

Types of construction .................................................................................................................. 46

Declaration of Incorporation........................................................................................................ 49

EC Declaration of Conformity...................................................................................................... 50

BA 2012

4 Operating Instructions, 03/2013, 70000004024300

General information and safety notes

1.1 General information

ATEX version gearboxes

Instructions and measures that apply in particular to ATEX version gearboxes.

Note

Siemen

observance of these operating instructions.

These operating instructions are part of the gearbox delivery. Store the operating instructions

near the gearbox.

These operating instructions apply to the standard version of the MOTOX worm gearbox S in

sizes 08, 18, and 28.

s AG does not accept any liability for damage and failures that result from the non-

1

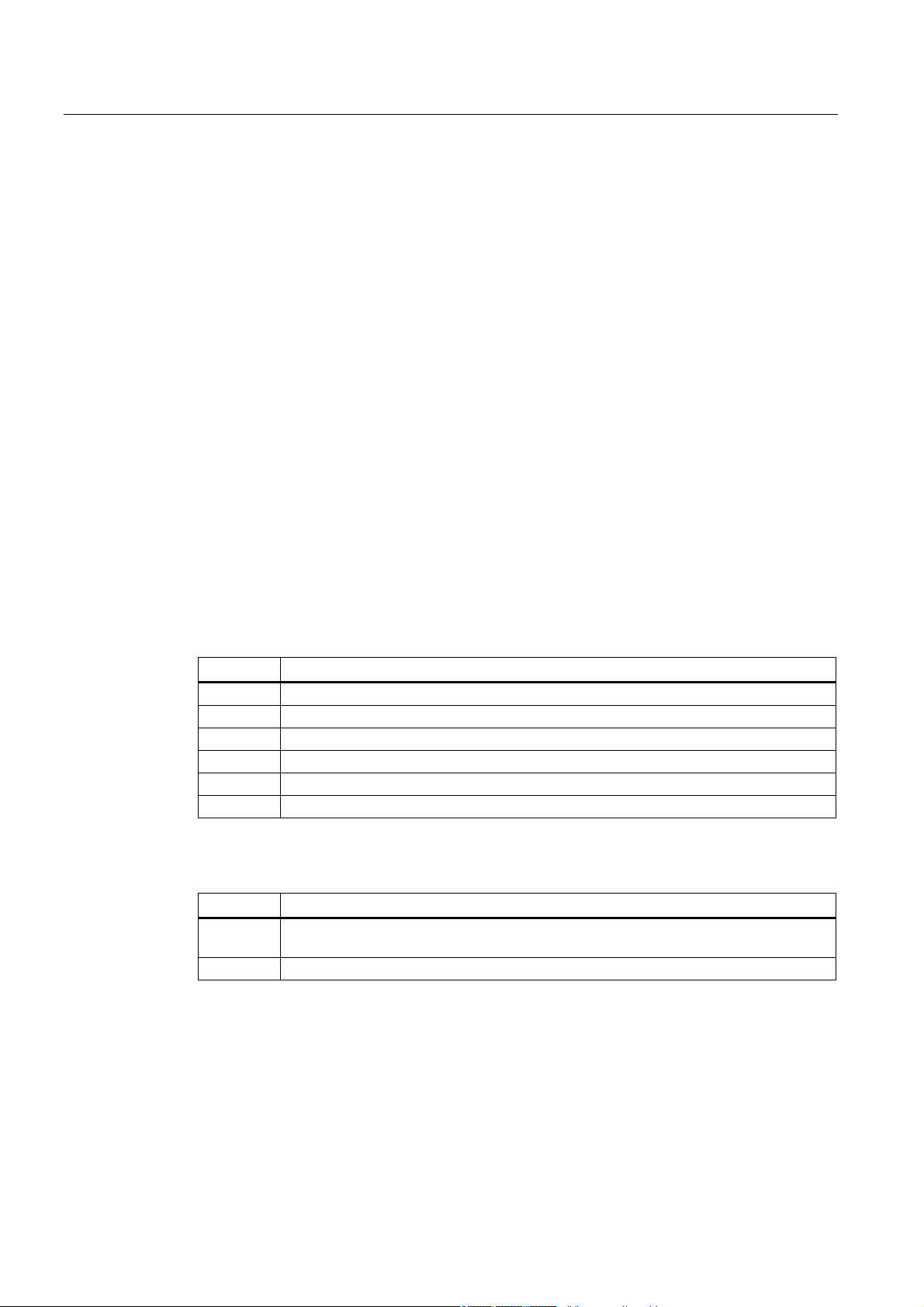

Table 1- 1 Order number code

MOTOX gearbox

Worm gearbox S 2 K J 1 7

Note

In addition to these o

documentation apply to special gearbox designs and the associated supplementary

equipment.

Please refer to the other operating instructions supplied with the product.

perating instructions, special contractual agreements and technical

Structure of the order number position

1 2 3 4 5

BA 2012

Operating Instructions, 03/2013, 70000004024300

5

General information and safety notes

1.1 General information

The gearboxes described here correspond to the state of the art at the time these operating

instructions were printed.

Siemens AG reserves the right to change individual components and accessory parts in the

interest of further development. The changes serve to improve the performance and safety.

The significant features are retained.

If you have any technical questions, please contact Technical Support.

Europe - Germany

Phone: +49 (0) 911 895 7222

Fax: +49 (0) 911 895 7223

America - USA

Phone: +1 42 32 62 25 22

Asia - China

Phone: +86 10 64 75 75 75

E-Mail: support.automation@siemens.com

Internet German: http://www.siemens.de/automation/support-request

Internet English: http://www.siemens.com/automation/support-request

Applicable operating instructions

Table 1- 2 MOTOX gearbox operating instructions

Title Product

BA 2010 MOTOX Gearbox

BA 2011 MOTOX Worm Gearbox SC

BA 2012 MOTOX Worm Gearbox S

BA 2019 MOTOX Input Units

BA 2510 MOTOX Optional Add-on Units

BA 2515 MOTOX Gearbox for Monorail Conveyors

Table 1- 3 Motor operating instructions

Title Product

BA 2310 Three-phase and Single-phase Alternating Current Motors and Brake Motors with

Accessories

BA 2320 LA / LG and LAI / LGI Motors

BA 2012

6 Operating Instructions, 03/2013, 70000004024300

General information and safety notes

1.2 Copyright

1.2 Copyright

The copyright to these operating instructions is held by Siemens AG.

These operating instructions must not be wholly or partly reproduced for competitive

purposes, used in any unauthorized way or made available to third parties without

agreement of Siemens AG.

1.3 Intended use

ATEX version gearboxes

The ATEX gearbox meets the requirements of the Explosion Protection

Directive 94/9/EC.

In the case of ATEX version gearboxes, please observe instructions marked with

this symbol.

The MOTOX worm gearboxes described in these operating instructions have been designed

for stationary use in general machine engineering applications.

Unless otherwise agreed, the gearboxes have been designed for use in machinery and

plants in industrial environments.

The gearboxes have been built using state-of-the-art technology and are shipped in an

operationally reliable condition. Changes made by users could affect this operational

reliability and are forbidden.

Note

The performanc

e data assumes an ambient temperature of -20 °C to +40 °C and an

installation altitude of up to 5 000 m above sea level.

In the case of other ambient temperatures and installation altitudes, please contact Technical

Support.

The gearboxes are designed only for the area of application described in Section Technical

data (Page 43).

Do not op

erate the gearboxes outside the specified performance limits.

Any different operating conditions require new contractual agreements.

Do not climb on the gearbox. Do not place any objects on the gearbox.

BA 2012

Operating Instructions, 03/2013, 70000004024300

7

General information and safety notes

1.4 Obligations of the user

1.4 Obligations of the user

The operator must ensure that all persons assigned to work on the gearbox have read and

understood these operating instructions and that they follow them in all points in order to:

● Eliminate the risk to life and limb of users and other persons.

● Ensure the operational safety of the gearbox.

● Avoid disruptions and environmental damage through incorrect use.

Note the following safety information:

Shut down the geared motors and disconnect the power before you carry out any work on

them.

Make sure that the drive unit cannot be turned on accidentally, e.g. lock the key-operated

switch. Place a warning notice at the drive connection point which clearly indicates that work

is in progress on the geared motor.

Carry out all work with great care and with due regard to "safety".

For all work, observe the relevant regulations for work safety and environment protection.

Read the instructions on the rating plates attached to the geared motor. The rating plates

must be kept free from paint and dirt at all times. Replace any missing rating plates.

In the event of changes during operation, switch off the drive unit immediately.

Take appropriate protective measures to prevent accidental contact with rotating drive parts,

such as couplings, gear wheels or belt drives.

Take appropriate measures to prevent accidental contact with parts and equipment that heat

up to over +70 °C during operation.

When removing protective equipment, keep fasteners in a safe place. Re-attach removed

protective equipment before commissioning.

Collect and dispose of used oil in accordance with regulations. Remove oil spillages

immediately with an oil-binding agent in compliance with environmental requirements.

BA 2012

8 Operating Instructions, 03/2013, 70000004024300

General information and safety notes

1.4 Obligations of the user

Do not carry out any welding work on the gearbox. Do not use the gearbox as a grounding

point for welding operations.

Carry out equipotential bonding in accordance with applicable regulations and directives by

electrotechnology specialists.

Do not use high-pressure cleaning equipment or sharp-edged tools to clean the gearbox.

Observe the permissible tightening torque of the fastening bolts.

Replace damaged bolts with new bolts of the same type and strength class.

Siemens AG accepts the warranty only for original spare parts.

The manufacturer who installs the geared motors in a plant must include the regulations

contained in the operating instructions in its own operating instructions.

BA 2012

Operating Instructions, 03/2013, 70000004024300

9

General information and safety notes

1.5 Particular types of hazards

1.5 Particular types of hazards

WARNING

Extreme surface temperatures

Hot surfaces over +55 °C pose a burn risk.

Cold surfaces below 0 °C pose a risk of damage due to freezing.

Do not touch the gearbox without protection.

WARNING

Hot, escaping oil

Before starting any work wait until the oil has cooled down to below +30 °C.

WARNING

Poisonous vapors when working with solvents

Avoid breathing in vapors when working with solvents.

Ensure adequate ventilation.

WARNING

Risk of explosion when working with solvents

Ensure adequate ventilation.

Do not smoke!

WARNING

Risk of eye injury

Rotating parts can throw off small foreign particles such as sand or dust.

Wear protective eyewear!

In addition to the prescribed personal protection gear, also wear suitable protective gloves

and safety glasses.

BA 2012

10 Operating Instructions, 03/2013, 70000004024300

Technical description

2.1 General description

The gearbox is supplied with one transmission stage.

The gearbox housing is made from die-cast aluminum.

The worm shaft is hardened and ground. The gear is manufactured from high-quality bronze.

All shafts are mounted in roller bearings.

The gearbox is lubricated for life with high-quality synthetic oil.

Radial shaft sealing rings are used in the standard version. At higher ambient temperatures

over +40 °C to +80 °C, shaft sealing rings of temperature-resistant material are used, subject

to contractual agreement.

2.2 Cooling

NOTICE

High housing temperature

2

Dust deposits prevent heat radiation and cause high housing temperatures.

Keep the gearbox free from dirt and dust, etc.

The gearbox does not normally require additional cooling. The generously dimensioned

housing surface is sufficient for dissipating heat losses where there is free convection. If the

housing temperature exceeds a value of +80 °C, please contact Technical Support.

2.3 Rating plate

The rating plate on the gearbox or geared motor is of coated aluminum foil. It is covered with

a special masking film which ensures permanent resistance to UV radiation and media of all

kinds, such as oils, greases, salt water and cleaning agents.

BA 2012

Operating Instructions, 03/2013, 70000004024300

11

Technical description

2.4 Surface treatment

The adhesive and the material ensure firm adhesion and long-term legibility within the

operating temperature range from -40 °C to +155 °C.

The edges of the rating plate are paint-finished to match the color of the gearbox or motor to

which it is affixed.

In special cases, riveted or bolted metal plates are used.

2.4 Surface treatment

Standard-version gearboxes are not painted at the factory. If necessary, they can be painted

with any kind of commercially available paint.

ATEX version gearboxes

As standard, the gearbox is not painted. The gearbox is optionally delivered

complete with primer and paint finish.

ATEX version gearboxes

When applying conductive paint, the operating company must ensure that the

paint remains in a perfect state. The paint finish must be checked at intervals of

approximately 2 - 3 years.

ATEX version gearboxes

An excessively high electrostatic charge must be avoided.

Ensure that highly active mechanisms that cause the paint finish to generate a

charge are avoided.

Highly active mechanisms that can generate charges:

fast airflow

with a high dust content directed past the gearbox

sudden escape of compressed gases containing particulates

harsh abrasi

ve processes (not referring to manual cleaning / wiping with

cleaning rags).

NOTICE

Sealing lips must not come into contact with paint

Cover the shaft sealing rings.

BA 2012

12 Operating Instructions, 03/2013, 70000004024300

Incoming goods, transport, and storage

3.1 Incoming goods

NOTICE

Transport damage impairs the correct function of the gearbox

Never commission a faulty gearbox or geared motor.

Note

Do not open

Note

ck that the technical specifications are in accordance with the purchase order.

Che

Inspect the delivery immediately on arrival for completeness and any transport damage.

Notify the freight company of any damage caused during transport immediately (this is the

only way to have damage rectified free of charge). Siemens AG will not accept any claims

relating to items missing from the delivery and which are submitted at a later date.

or damage parts of the packaging that preserve the product.

3

The gearbox or geared motor is delivered in a fully assembled condition. Additional items are

sometimes delivered packaged separately.

The products supplied are listed in the dispatch papers.

BA 2012

Operating Instructions, 03/2013, 70000004024300

13

Incoming goods, transport, and storage

3.2 Transport

3.2 Transport

NOTICE

Damage caused by force

Transport the gearbox or geared motor carefully. Avoid knocks.

Before putting the drive into operation, remove any transport fixtures and keep them safe or

render them ineffective. For further transports reuse or reactivate them again.

Different forms of packaging may be used, depending on the size of the gearbox or geared

motor and the method of transport. Notwithstanding contractual agreements to the contrary,

the packaging complies with HPE Packaging Guidelines (Bundesverband Holzpackmittel

Paletten Exportverpackungen e.V., the German Federal Association for wooden packaging

means, pallets, and export packaging).

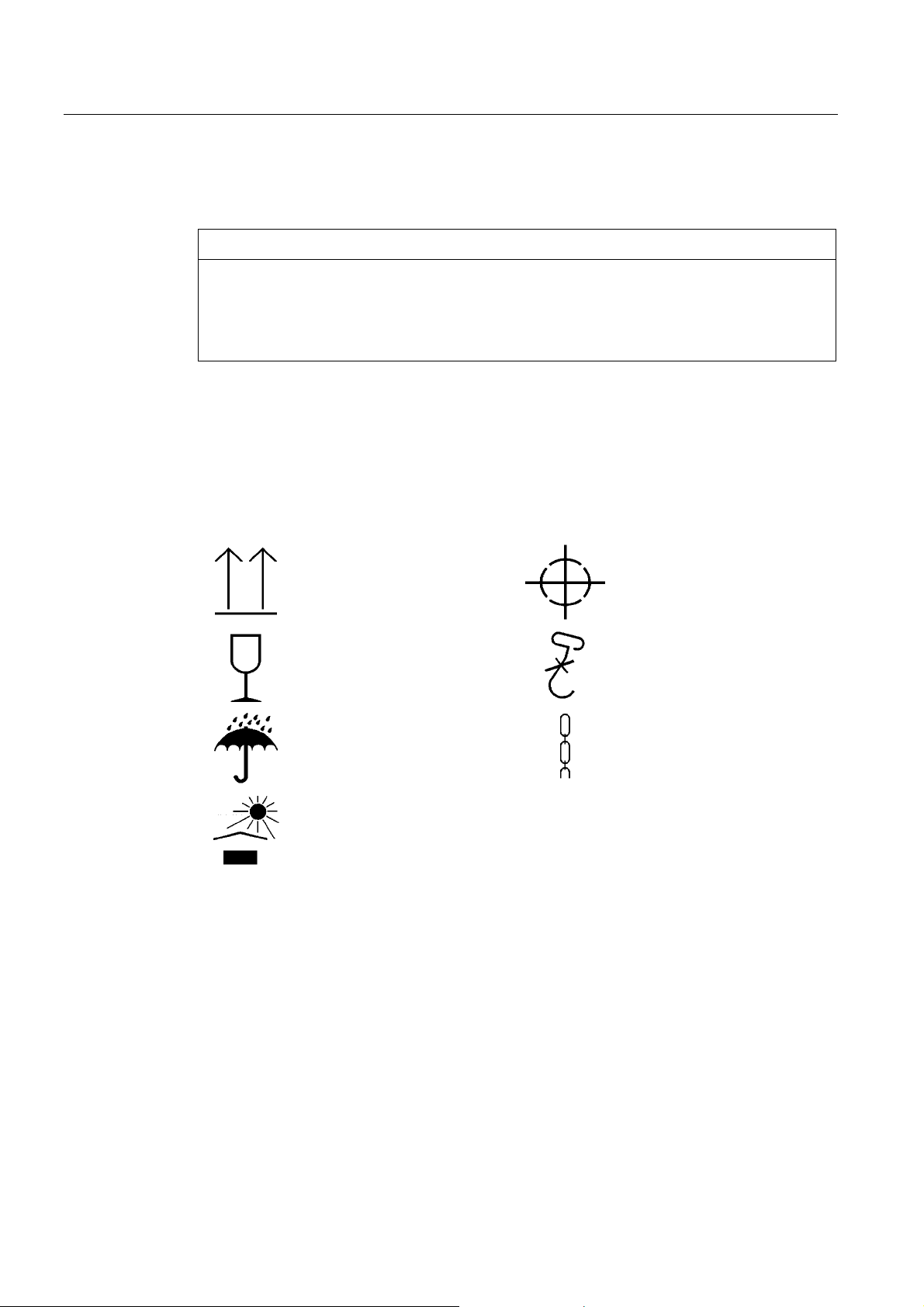

Note the symbols which appear on the packing. These have the following meanings:

This way up

Center of gravity

Fragile

Keep dry

Do not use hand hook

Attach here

Keep cool

BA 2012

14 Operating Instructions, 03/2013, 70000004024300

Incoming goods, transport, and storage

3.3 Storage

3.3 Storage

WARNING

Danger of serious injuries caused by falling objects

Danger of damage to the gearbox when stacked

Do not stack gearboxes or geared motors on each other.

NOTICE

Failure of the external protection

Mechanical damage, chemical damage and thermal damage, such as scratches, acids,

alkalis, sparks, welding beads and heat cause corrosion.

Do not damage the paint finish.

Unless contractually agreed otherwise, the guarantee period for the standard preservative

lasts 6 months from the date of delivery.

In the case of storage in transit over 6 months, special arrangements must be made for

preservation. Please contact Technical Support.

Store the gearbox or geared motor in dry, dust-free rooms that are maintained at a constant

temperature.

The storage location must be vibration- and shock-free.

The free shaft ends, sealing elements and flange surfaces must have a protective coating.

BA 2012

Operating Instructions, 03/2013, 70000004024300

15

Loading...

Loading...